Page 1

HOM

E

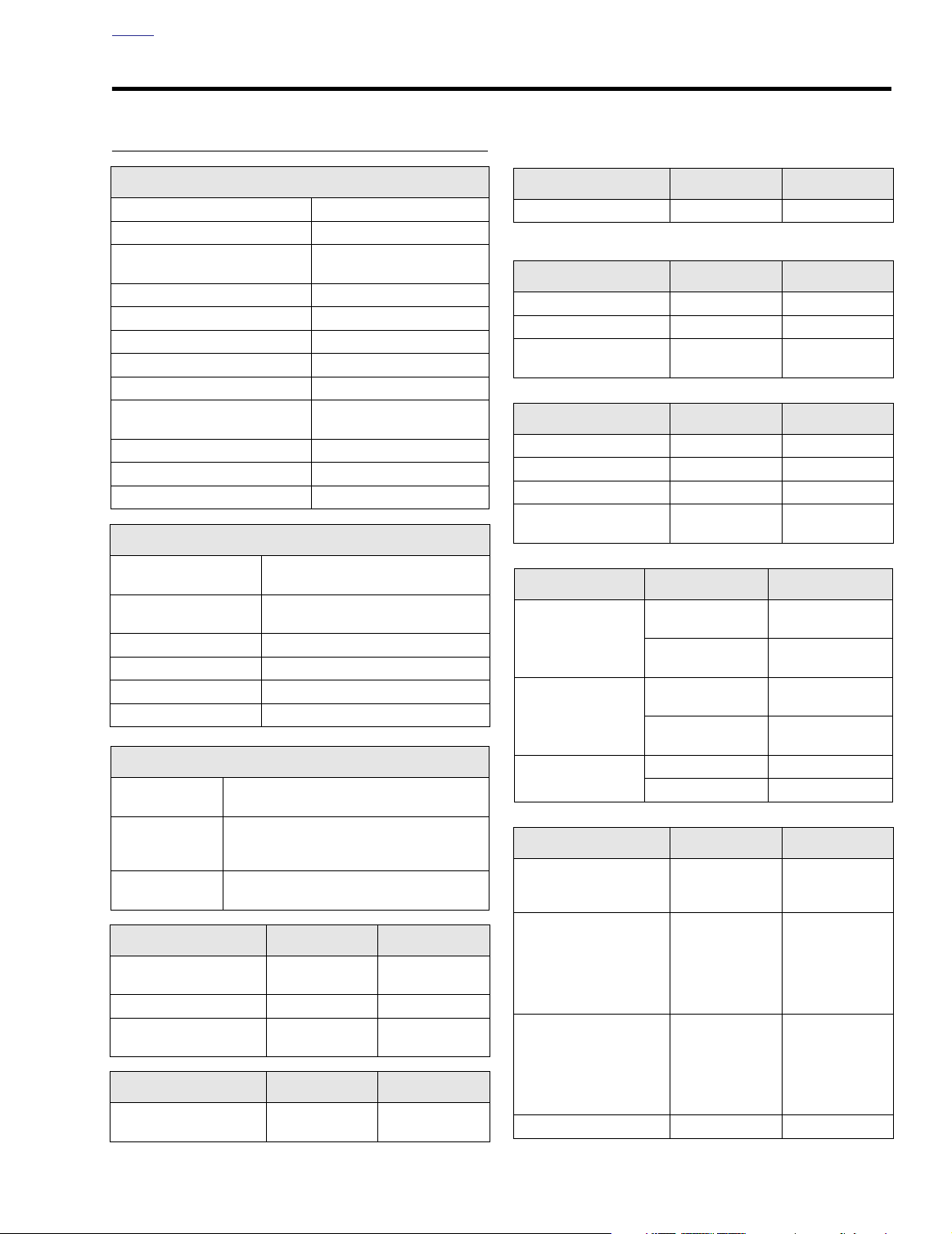

SPECIFICATIONS 3.1

MANUFACTURING TOLERANCES

General

Number of cylinders 2

Ty pe 4-cycle, 45˚V2, air-cooled

To rque

Bore 3.75 in. (95.25 mm)

Stroke 4.00 in. (101.6 mm)

Piston displacement (approx.) 88 cu. in. (1450 cc)

Compression ratio 9.0:1

Combustion chamber 5.187 cu. in. (85 cc) bathtub

Cam system

Max. sustained engine speed 5500 rpm

Idle speed 1000 rpm +/- 50

Weight 165 lbs (74.8 kg)

85 ft-lbs (115.2 Nm) @ 3000

rpm, chrome dual exhaust

Tw in cams, chain driven with

spring loaded tensioners

Ignition System

Ty pe

Ignition timing:

1050 rpm (Hot Idle)

Spark plug size 12 mm

Spark plug type Harley-Davidson 6R12

Spark plug gap 0.038-0.043 in. (0.97-1.09 mm)

Spark plug torque 12-18 ft-lbs (16-24 Nm)

Sequential, non waste spark,

MAP-N control

o

20o-30

Oiling System

Pump

Pressure

Filtration

Rocker Arm

Shaft fit in bushing

(loose)

End clearance 0.003-0.013 0.08-0.33

Bushing fit in rocker arm

(tight)

Rocker Arm Shaft

Shaft fit in rocker arm

support plate (loose)

Tw in gerotor, dual scavenge, crank mounted

and driven, internal oil pump, dry sump

30-38 psi (207-262 kN/m2) at

2000 rpm and normal operating temperature

of 230o F (110o C)

10 micron media,

filtered between pump and engine

IN. MM

0.0005-0.0020 0.013-0.051

0.002-0.004 0.051-0.102

IN. MM

0.0007-0.0022 0.018-0.056

Hydraulic Lifter

Fit in crankcase (loose) 0.0008-0.0020 0.02-0.05

Cylinder Head

Valve guide in head (tight) 0.0020-0.0033 0.051-0.084

Valve seat in head (tight) 0.003-0.0045 0.076-0.114

Head gasket surface

(flatness)

Valve

Fit in guide: exhaust 0.0015-0.0033 0.038-0.084

Fit in guide: intake 0.0008-0.0026 0.020-0.066

Seat width 0.040-0.062 1.02-1.58

Stem protrusion from

cylinder head boss

Valve Spring

Closed

Open

Free length

@ 1.751-1.848 in.

@ 44.45-46.9 mm

@ 1.282-1.378 in.

@ 32.6-35.0 mm

2.105-2.177 in. 1.926-1.996 in.

53.47-55.3 mm 48.9-50.7 mm

Piston

Fit in cylinder:

Early Style Piston

Late Style Piston

Ring end gap:

To p compression ring

2nd compression ring

Oil control ring

Ring side clearance:

To p compression ring

2nd compression ring

Oil control ring

Piston pin fit (loose) 0.0002-0.0005 0.005- 0.013

IN. MM

IN. MM

0-0.006 0-0.0152

IN. MM

1.990-2.024 50.55-51.41

Outer Inner

72-92 lbs

33-42 kg

183-207 lbs

83-94 kg

38-49 lbs

@ 1.577-1.683 in.

17-22 kg

@ 40.1-42.8 mm

98-112 lbs

@ 1.107-1.213 in.

44-51 kg

@ 28.1-30.8 mm

IN. MM

0.0006-0.0017

0.0014-0.0025

0.010-0.020

0.014-0.024

0.010-0.050

0.0012-0.0037

0.0012-0.0037

0.0031-0.0091

0.015-0.043

0.036-0.064

0.25-0.51

0.36-0.61

0.25-1.27

0.030-0.094

0.030-0.094

0.079-0.23

2004 Touring: Engine 3-1

Page 2

HOM

E

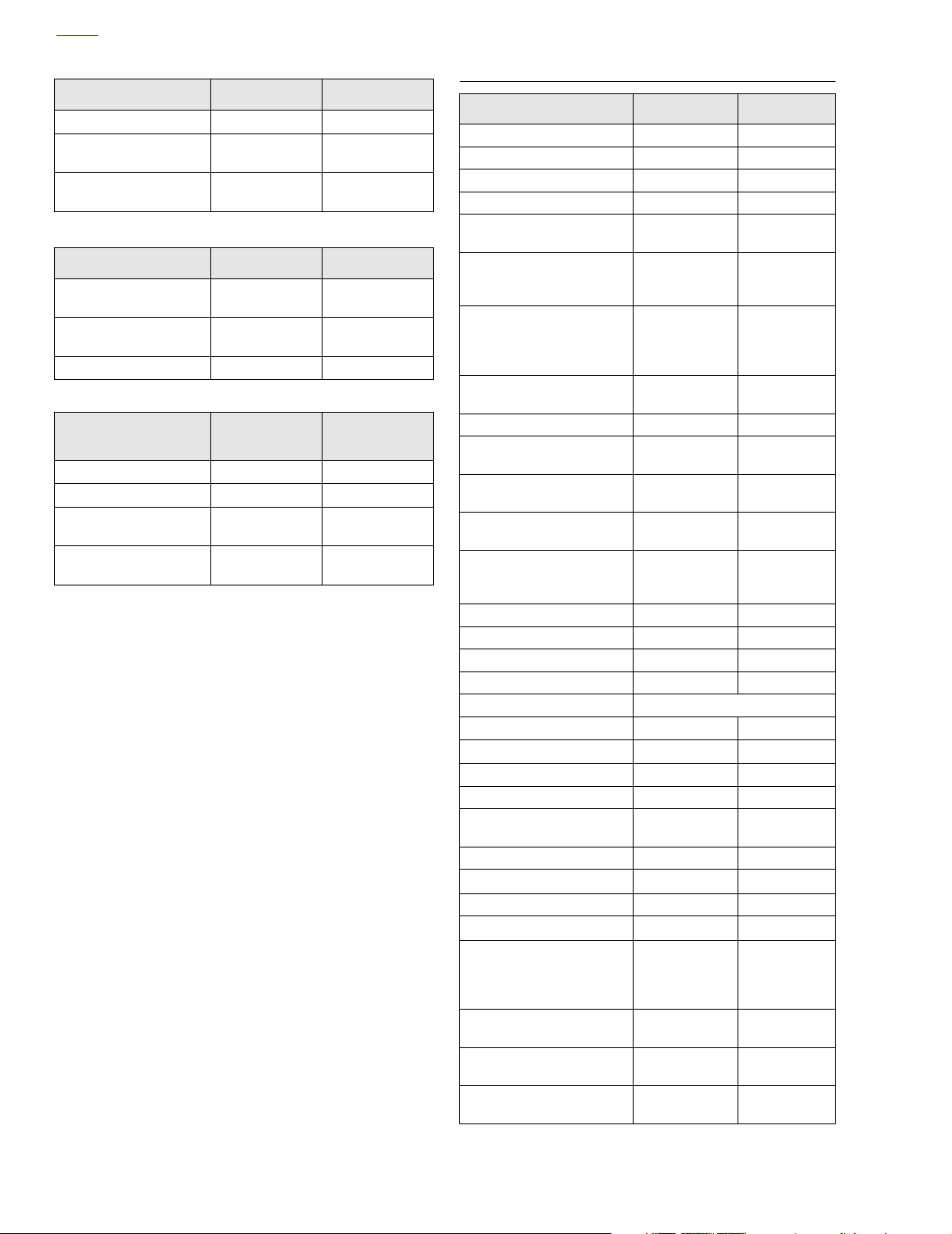

MANUFACTURING TOLERANCES (CONT.)

Connecting Rod

Piston pin fit (loose) 0.0007-0.0012 0.018-0.030

Side play between

flywheels

Connecting rod to

crankpin (loose)

Flywheel

Runout

(flywheels at rim)

Runout

(shaft at flywheel)

End play 0.003-0.010 0.076-0.254

Crankshaft/Sprocket

Shaft Bearings

Bearing fit (loose) 0.0002-0.0015 0.005-0.038

Crankshaft runout 0.0-0.003 0.0-0.076

Bearing fit in

crankcase (tight)

Bearing inner race on

crankshaft (tight)

IN. MM

0.005-0.015 0.13-0.38

0.0004-0.0017 0.0102-0.0432

IN. MM

0.000-0.010 0.000-0.254

0.000-0.002 0.000-0.051

IN. MM

0.0038-0.0054 0.097-0.137

0.0004-0.0014 0.010-0.036

TORQUE VALUES

Item

Breather assembly bolts 90-120

Cam cover screws 125-155

Cam cover plate screws 20-30

Cam support plate screws 90-120

Bearing retainer plate

screws

Crank sprocket flange bolt

Primary cam sprocket

flange bolt

Crank position sensor

screw

Piston jet screws 25-35

Tr ansmission housing to

crankcase bolts

Crankcase to front engine

mounting bracket bolts

Crankcase bolts

Cylinder head bolts

Cylinder studs 10-20 ft-lbs 14-27 Nm

Engine oil drain plug 14-21 ft-lbs 19-28 Nm

Lifter cover screws 90-120

Oil pan screws 84-108

Oil filter 1/2-3/4 turn after gasket contact

Oil filter mount 12-16 ft-lbs 16-22 Nm

Crankcase oil fittings/plugs

Oil hose cover screws 84-108

Oil pressure switch/sender 96-120

Rocker arm support

plate bolts

Rocker cover bolts 15-18 ft-lbs 20-24 Nm

Rocker housing bolts

Spark plugs 12-18 ft-lbs 16-24 Nm

Stator screws

Upper engine mounting

bracket:

To cylinder heads

To top stabilizer link

Engine temperature

sensor

Intake flange adapter

screws

Exhaust flange adapter

nuts

ft/in-lbs NM

in-lbs

10-14 Nm

in-lbs

14-18 Nm

in-lbs

2.3-3.4 Nm

in-lbs

10-14 Nm

20-30

in-lbs

2-3 Nm

15 ft-lbs,

loosen one full

turn, 24 ft-lbs

15 ft-lbs,

loosen one full

turn, 34 ft-lbs

90-120

in-lbs

in-lbs

15 ft-lbs,

30-35 ft-lbs

33-38 ft-lbs 45-52 Nm

10 ft-lbs,

15-19 ft-lbs

120-144

in-lbs

15-17 ft-lbs

o

+ 90

turn

in-lbs

in-lbs

120-168

in-lbs

in-lbs

in-lbs

18-22 ft-lbs 24-30 Nm

120-168

in-lbs

55-75

in-lbs

35-40 ft-lbs

18-22 ft-lbs

120-180

in-lbs

96-144

in-lbs

100-120

in-lbs

20.3 Nm,

loosen one full

turn, 32.5 Nm

20.3 Nm,

loosen one

full turn, 46.1

Nm

10.2-13.6 Nm

2.8-4.0 Nm

20 Nm,

41-48 Nm

14 Nm,

20-26 Nm

,

13.6-16.3 Nm,

20.3-23.1 Nm

+ 90o turn

10-14 Nm

9-12 Nm

13.6-18.9 Nm

10-12 Nm

11-14 Nm

13.6-18.9 Nm

6.2-8.5 Nm

48-54 Nm

24-30 Nm

13.6-20.3 Nm

10.9-16.3 Nm

11.3-13.6 Nm

3-2 2004 Touring: Engine

Page 3

HOM

E

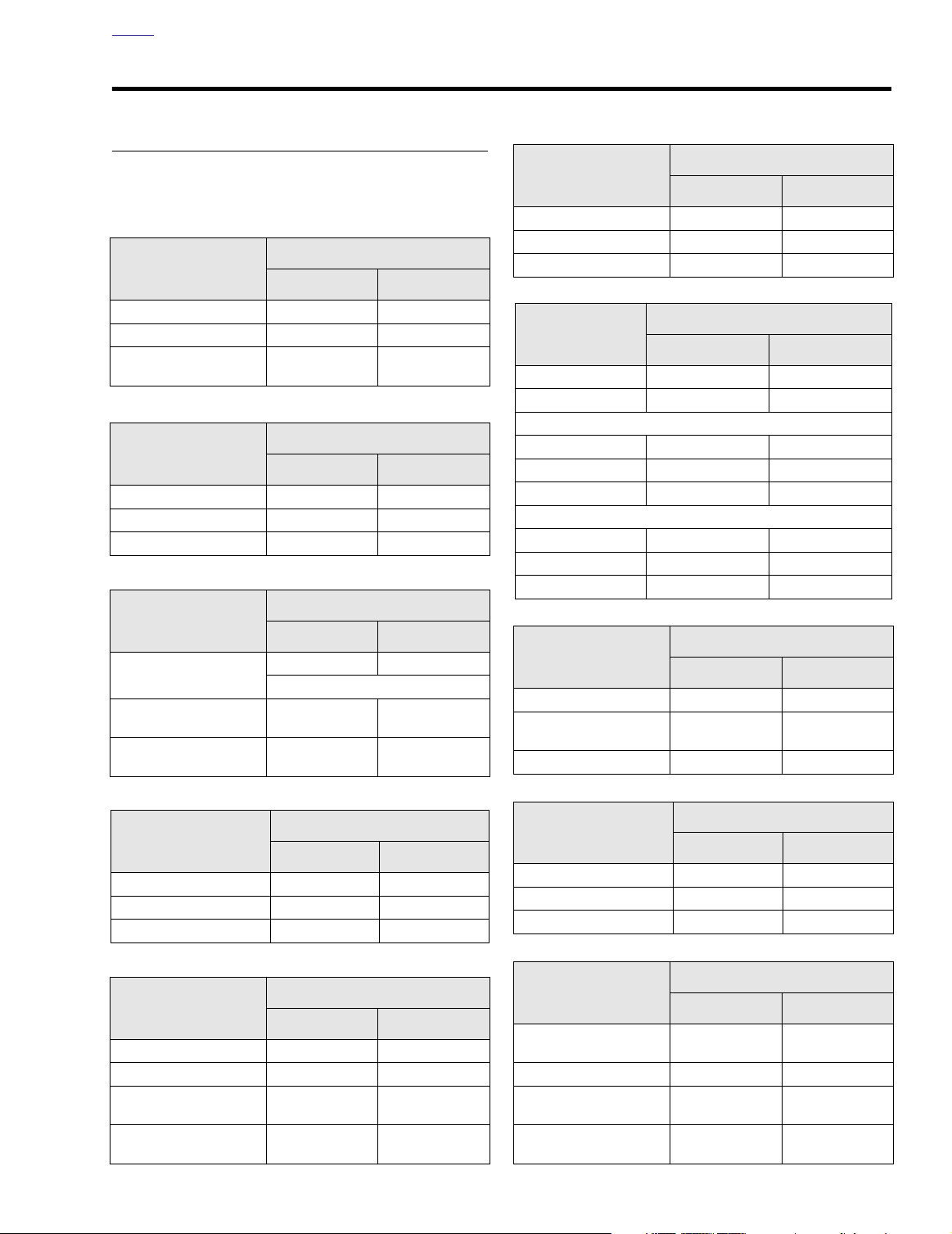

SERVICE WEAR LIMITS 3.2

GENERAL

REPLACE IF

IN. MM

REPLACE IF

IN. MM

REPLACE IF

IN. MM

Wear limits can be used as a guide when deciding whether to

reuse engine parts. Replace used parts whenever the following wear limits are exceeded.

Rocker Arm/

Rocker Arm Shaft

Shaft fit in bushing (loose) More than 0.0035 More than 0.089

End clearance More than 0.025 More than 0.635

Shaft fit in rocker arm

support plate (loose)

More than 0.0035 More than 0.089

REPLACE IF

IN. MM

REPLACE IF

Hydraulic Lifter

IN. MM

Fit in crankcase More than 0.003 More than 0.08

Roller fit More than 0.0015 More than 0.038

Roller end clearance More than 0.015 More than 0.38

REPLACE IF

Cam Support Plate

IN. MM

Cam chain

tensioner shoe wear

Crankshaft bushing fit

in cam support plate

Crankshaft bushing

maximum ID

More than 0.090 More than 2.29

1/2 thickness of shoe

Less than 0.0008 Less than 0.0203

More than 0.8545 More than 21.704

Cylinder Bore

Standard More than 3.752 More than 95.301

0.005 in. oversize More than 3.757 More than 95.428

0.010 in. oversize More than 3.762 More than 95.555

Piston

Fit in cylinder (loose) More than 0.003 More than 0.076

Piston pin fit (loose) More than 0.0008 More than 0.020

Ring end gap

To p compression More than 0.030 More than 0.76

2nd compression More than 0.034 More than 0.86

Oil control ring rails More than 0.050 More than 1.27

Ring side clearance

To p compression More than 0.0045 More than 0.11

2nd compression More than 0.0045 More than 0.11

Oil control ring rails More than 0.010 More than 0.25

Connecting Rod

Piston pin fit (loose) More than 0.002 More than 0.051

Side play between

flywheels

Fit on crankpin (loose) More than 0.002 More than 0.051

More than 0.020 More than 0.508

Cylinder Head

REPLACE IF

IN. MM

Valve guide in head (tight) Less than 0.002 Less than 0.051

Valve seat in head (tight) Less than 0.002 Less than 0.051

Head warpage More than 0.006 More than 0.152

REPLACE IF

Cylinder

IN. MM

Ta per More than 0.002 More than 0.051

Out of round More than 0.002 More than 0.051

Warpage of gasket or

O-ring surfaces: top

Warpage of gasket or

O-ring surfaces: base

More than 0.006 More than 0.152

More than 0.004 More than 0.102

Flywheel

REPLACE IF

IN. MM

Runout (flywheels at rim) More than 0.015 More than 0.381

Runout (shaft at flywheel) More than 0.003 More than 0.076

End play More than 0.010 More than 0.254

Crankshaft/Sprocket

Shaft Bearings

Bearing to shaft

clearance

Shaft runout More than 0.003 More than 0.076

Bearing fit in

crankcase (tight)

Bearing inner race

on shaft (tight)

More than 0.0015 More than 0.038

Less than 0.0038 Less than 0.097

Less than 0.0004 Less than 0.010

REPLACE IF

IN. MM

2004 Touring: Engine 3-3

Page 4

HOM

E

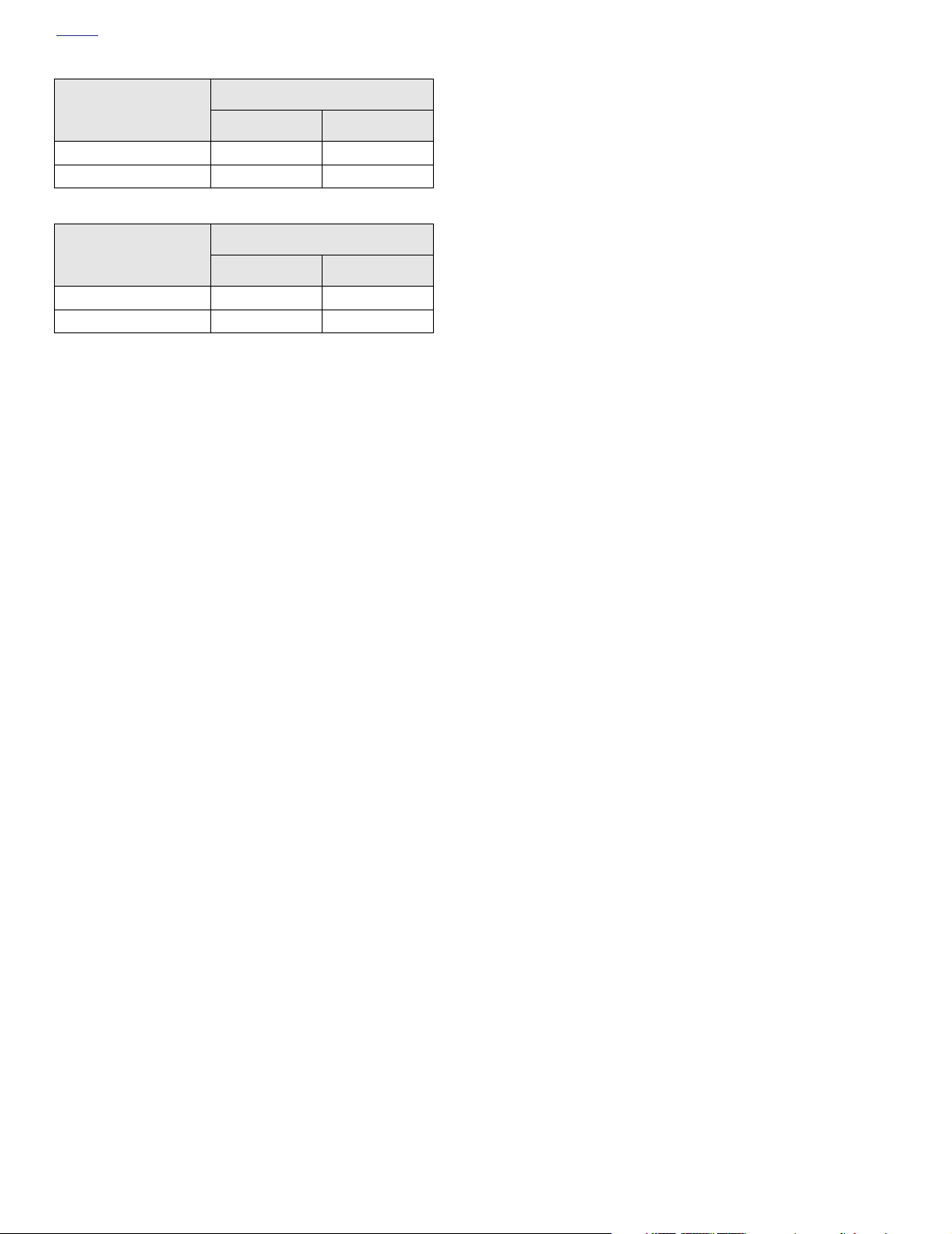

SERVICE WEAR LIMITS (CONT.)

Breather Assembly

REPLACE IF

IN. MM

Breather cover warpage More than 0.005 More than 0.13

Breather baffle warpage More than 0.005 More than 0.13

Valve Stem to

Guide Clearance

Intake More than 0.0035 More than 0.089

Exhaust More than 0.0040 More than 0.102

REPLACE IF

IN. MM

3-4 2004 Touring: Engine

Page 5

HOM

CAUTION

E

GENERAL INFORMATION 3.3

FUEL

Use a good quality leaded or unleaded gasoline (91 pump

octane or higher). Octane rating is usually posted on the

pump.

CAUTION

Using gasolines with alcohol additives (such as methanol) can cause rubber components within the fuel system to fail or result in engine damage.

GASOLINE/ALCOHOL BLENDS

Harley-Davidson motorcycles were designed to give the best

performance using unleaded gasoline. Some fuel suppliers

sell gasoline/alcohol blends as a fuel. The type and amount

of alcohol added to the fuel is important.

●

DO NOT USE GASOLINES CONTAINING METHANOL.

Using gasoline/methanol blends will result in starting

and driveablility deterioration and damage to critical fuel

system components.

●

ETHANOL is a mixture of 10% ethanol (Grain alcohol)

and 90% unleaded gasoline. Gasoline/ethanol blends

can be used in your motorcycle if the ethanol content

does not exceed 10%.

REFORMULATED OR OXYGENATED GASOLINES

●

(RFG): “Reformulated gasoline” is a term used to

describe gasoline blends that are specifically designed

to burn cleaner than other types of gasoline. Your motorcycle will run normally using this type of gas.

Yo u may find that some gasoline blends adversely affect the

starting, driveability or fuel efficiency of your bike. If you

experience one or more of these problems, we recommend

you try a different brand of gasoline or gasoline with a higher

octane rating.

LUBRICATION

CHECKING ENGINE OIL LEVEL

Oil level cannot be accurately measured on a cold

engine. For preride inspection, with motorcycle leaning

on jiffy stand on level ground, oil should register on dipstick between arrows when engine is cold. Do NOT add

oil to bring the level to the FULL mark on a COLD

1. Perform engine oil level

a. With the vehicle resting on the jiffy stand on level

ground, wipe off the dipstick and insert it back into

the oil pan with the plug pushed completely into the

fill spout.

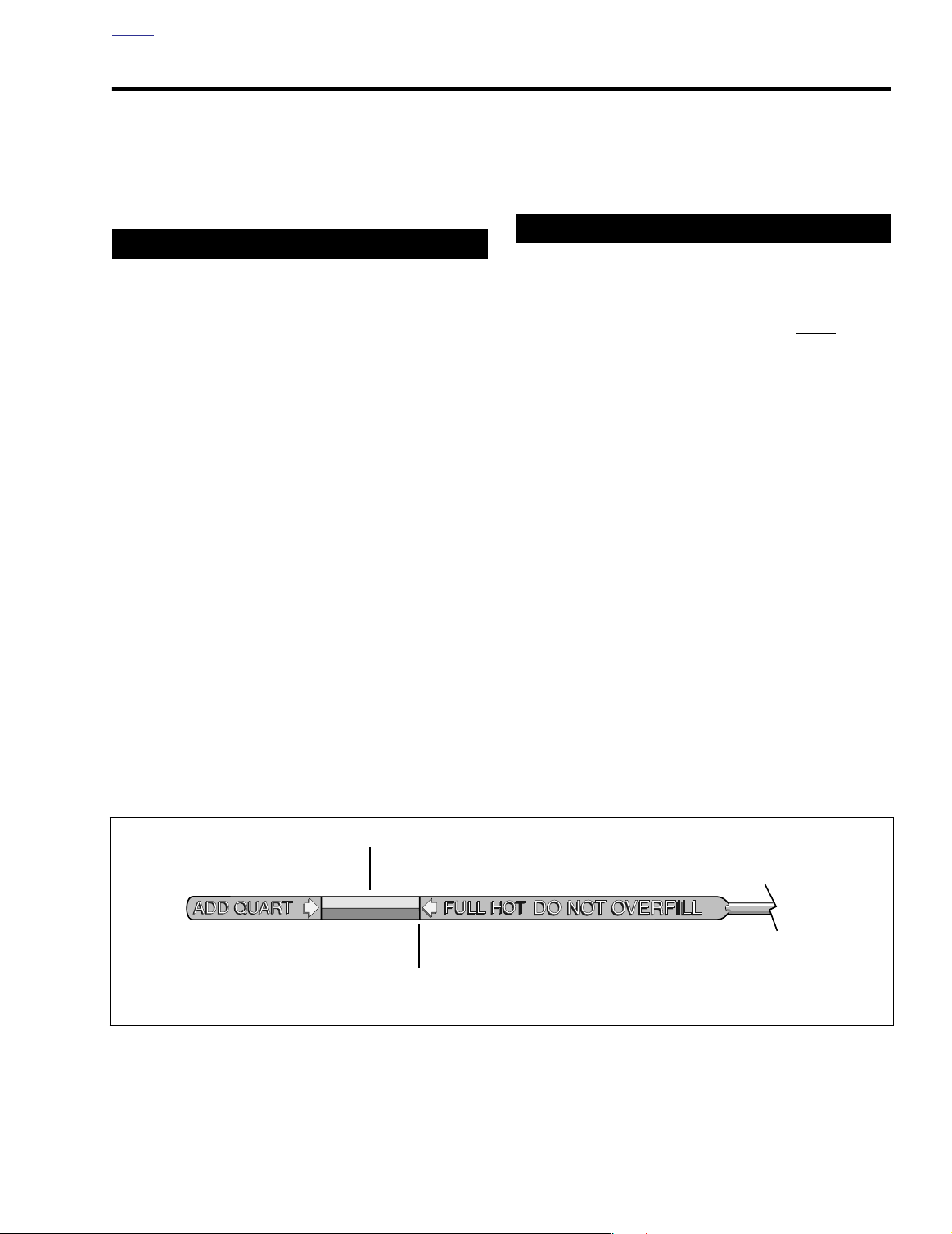

b. Remove the dipstick and note the level of the oil. Oil

level should register between the two arrows on the

dipstick. See Figure 3-1. If oil level is at or below the

lower arrow, add only enough oil to bring the level

between the two arrows on the dipstick.

2. Perform engine oil level

a. Ride vehicle until engine is at normal operating tem-

perature.

b. With the vehicle resting on the jiffy stand on level

ground, allow engine to idle for 1-2 minutes. Turn

engine off.

c. Wipe off the dipstick and insert it back into the oil

pan with the plug pushed completely into the fill

spout.

d. Remove the dipstick and note the level of the oil.

Add only enough oil to bring the level to the FULL

mark on the dipstick. See Figure 3-1. Do not overfill.

COLD CHECK

HOT CHECK

as follows:

as follows:

engine.

COLD CHECK

HOT CHECK

f1254b3x

Figure 3-1. Engine Oil Dipstick

2004 Touring: Engine 3-5

Page 6

HOM

E

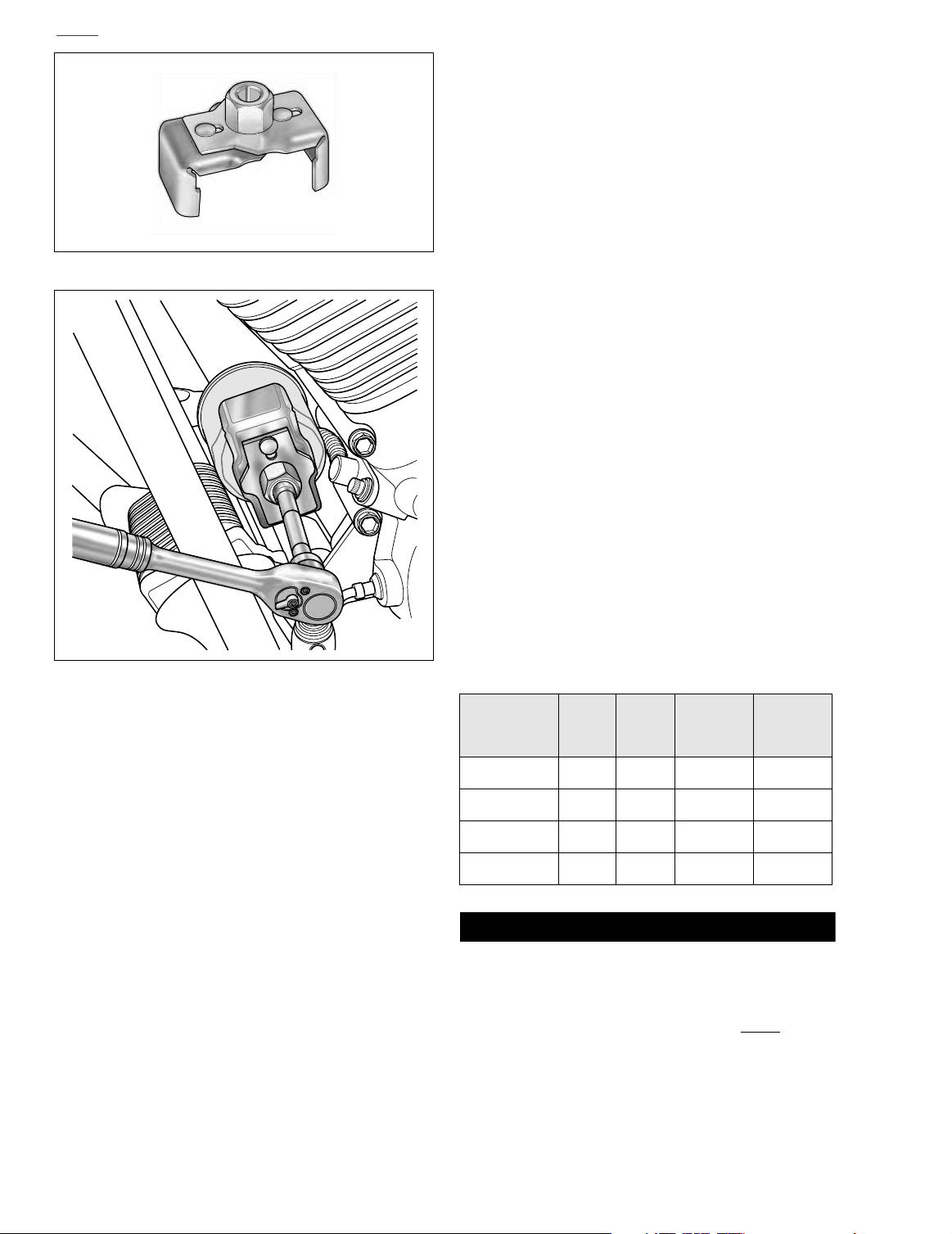

Figure 3-2. Oil Filter Wrench (Part No. HD-42311)

f1641x3x

5. Remove the oil filter as follows:

a. Obtain the OIL FILTER WRENCH (HD-42311). The

tool allows easy removal of the oil filter without risk

of damage to the crankshaft position sensor or

cable.

b. Place the jaws of the wrench over the oil filter with

the tool oriented vertically. See Figure 3-3.

c. Using a 3/8 inch drive with a 4 inch extension, turn

wrench in a counterclockwise direction. Do not use

with air tools.

NOTE

Use OIL FILTER WRENCH (HD-44067) if HD-42311 is not

available.

6. Clean the oil filter mount flange of any old gasket material.

7. Lubricate gasket with clean engine oil and install

new

oil

filter on filter mount. Hand tighten oil filter 1/2-3/4 turn

after gasket first contacts filter mounting surface. Do

NOT

use OIL FILTER WRENCH for oil filter installation.

NOTE

Use of the Premium 10 micron synthetic media oil filter is

highly recommended, Part No. 63798-99 (Chrome) or 6373199 (Black).

Figure 3-3. Remove Engine Oil Filter

CHANGING ENGINE OIL AND FILTER

NOTE

At the 1000 mile (1600 km) service interval, and at every

5000 mile (8000 km) service interval thereafter, change the

engine oil and engine oil filter. If motorcycle is ridden hard,

under dusty conditions or in cold weather, change engine oil

and filter more often.

1. Ride vehicle until engine is at normal operating temperature.

2. Locate oil filler plug/dipstick on right side of vehicle at top

of transmission case. To remove the oil filler plug, pull

steadily while moving plug back and forth.

3. Locate oil drain plug at front left side of the oil pan.

Remove the oil drain plug and allow oil to drain completely.

4. Inspect the oil drain plug O-ring for cuts, tears or signs of

deterioration. Replace as necessary.

8. Install engine oil drain plug with O-ring. Tighten plug to

14-21 ft-lbs (19-28 Nm).

9. With vehicle resting on jiffy stand, add 3-1/2 quarts (3.3

liters) engine oil as specified in Ta bl e 3-1. Use the proper

grade of oil for the lowest temperature expected before

the next oil change.

Table 3-1. Recommended Engine Oils

Harley-Davidson

Type

HD Multi-grade

HD Multi-grade

HD Regular Heavy

HD Extra Heavy

Viscosity

SAE

10W40

SAE

20W50

SAE

SAE

Harley-

Davidson

Rating

HD 360

HD 360

HD 360

50

HD 360

60

CAUTION

Oil level cannot be accurately measured on a cold

engine. For preride inspection, with motorcycle leaning

on jiffy stand on level ground, oil should register on dipstick between arrows when engine is cold. Do NOT add

oil to bring the level to the FULL mark on a COLD

10. Perform engine oil level

COLD CHECK

Lowest

Ambient

Temperature

Below 40˚F

(4˚C)

Above 40˚F

(4˚C)

Above 60˚F

(16˚C)

Above 80˚F

(27˚C)

as follows:

Cold Weather

Starts Below

50˚F (10˚C)

Excellent

Good

Poor

Poor

engine.

3-6 2004 Touring: Engine

Page 7

HOM

CAUTION

E

a. With the vehicle resting on the jiffy stand on level

ground, wipe off the dipstick and insert it back into

the oil pan with the plug pushed completely into the

fill spout.

b. Remove the dipstick and note the level of the oil. Oil

level should register between the two arrows on the

dipstick. See Figure 3-1. If oil level is at or below the

lower arrow, add only enough oil to bring the level

between the two arrows on the dipstick.

11. Perform engine oil level

a. Ride vehicle until engine is at normal operating tem-

perature.

b. With the vehicle resting on the jiffy stand on level

ground, allow engine to idle for 1-2 minutes. Turn

engine off.

c. Wipe off the dipstick and insert it back into the oil

pan with the plug pushed completely into the fill

spout.

d. Remove the dipstick and note the level of the oil.

Add only enough oil to bring the level to the FULL

mark on the dipstick. See Figure 3-1. Do not overfill.

12. Start engine and carefully check for oil leaks around

drain plug and oil filter.

HOT CHECK

as follows:

WINTER LUBRICATION

Combustion in an engine produces water vapor. During starting and warm-up in cold weather, especially in freezing temperatures, the vapor condenses to water before the

crankcase is hot enough to exhaust it through the breather

system. If the engine is run long enough for the crankcase to

become thoroughly heated, the water returns to vapor and is

then exhausted.

An engine used for only short trips, and seldom allowed to

thoroughly warm up, accumulates increasing amounts of

water in the oil pan. Water mixed with oil forms a sludge that

causes accelerated engine wear. In freezing temperatures,

the water becomes slush or ice, which may clog oil lines and

result in engine failure.

Always change the engine oil more often in winter. If the

engine is used for short runs, change the oil even more frequently. The farther below freezing the temperature drops the

more often the oil should be changed.

OIL PRESSURE INDICATOR LAMP

The

red

OIL PRESSURE indicator lamp illuminates to indicate improper circulation of the engine oil. The lamp illuminates when the ignition is first turned on (before the engine is

started), but should be extinguished once the engine is running.

Check the engine oil level if the oil pressure indicator

lamp remains illuminated. If the oil level is normal, stop

the engine immediately. Do not ride the vehicle until the

probem is located and corrected.

If the indicator lamp is not extinguished, it may be the result

of a low oil level or diluted oil supply. In freezing weather, the

oil feed and return lines can clog with ice or sludge. A defect

in the lamp wiring, faulty oil pressure switch/sender, damaged oil pump, plugged oil filter element, incorrect oil viscosity, broken or weak spring in the oil pressure relief valve and/

or damaged or incorrectly installed O-rings in the engine may

also cause the indicator lamp to remain on.

To troubleshoot the problem, always check the engine oil

level first. If the oil level is OK, determine if oil returns to the

pan from the oil return hose. If oil does not return, shut off the

engine until the problem is located and corrected.

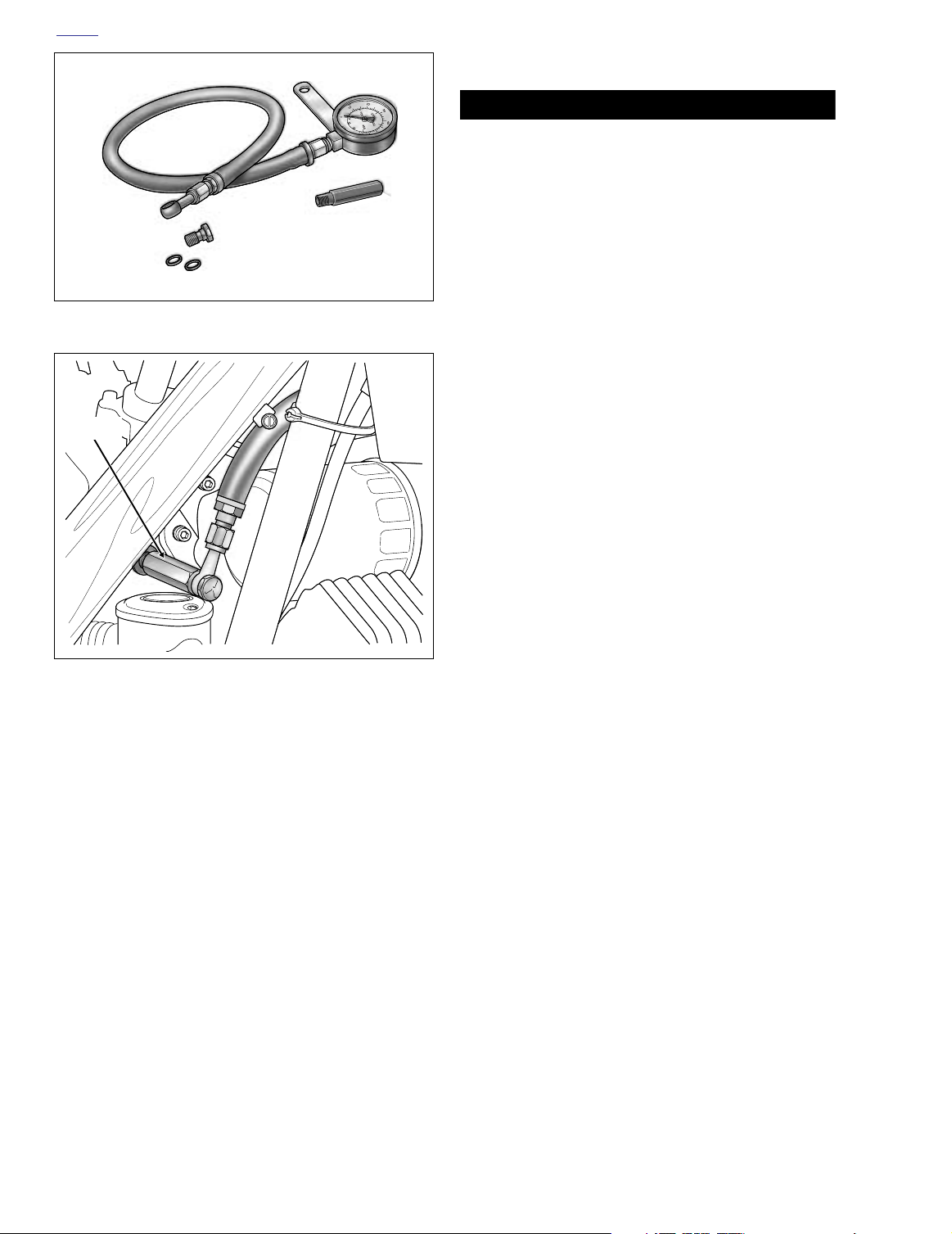

To check the engine oil pressure, proceed as follows:

1. Verify engine oil level. See CHECKING ENGINE OIL

LEVEL in this section.

2. Locate the oil pressure switch/sender at the front right

side of the crankcase.

3. On FLHR/C/S models, pull elbow from post of oil pressure switch. On FLHT/C/U and FLTR models, pull external latch outward and use rocking motion to remove

Packard connector from oil pressure sender.

4. On FLHR/C/S models, use a 15/16 inch Open End Crow

Foot (Snap-On FC30B) to remove oil pressure switch

from crankcase. On FLHT/C/U and FLTR models, use 11/16 inch Open End Crow Foot (Snap-On FC34A) to

remove oil pressure sender.

5. Start OIL PRESSURE GAUGE ADAPTER (HD-96921-

110) into crankcase bore. Using a 5/8 inch open end

wrench, turn adapter until snug. See Figure 3-4.

6. Moving to left side of vehicle, route banjo fitting and hose

of OIL PRESSURE GAUGE (HD-96921-52B) over

shifter lever and oil filter to right side of engine. See Fig-

ure 3-5.

7. Slide washer on banjo bolt and insert through banjo fitting on gauge. Install second washer on bolt and thread

into adapter until snug.

8. Run vehicle or simulate road running until engine is at

normal operating temperature, approximately 230

(110o C.). Gauge reading will not be accurate if engine is

not completely warmed.

9. Verify that oil pressure is 30-38 psi (207-262 kN/m2) at

2000 rpm.

10. Remove banjo bolt (and washers) from adapter. Remove

gauge from vehicle and then remove adapter from

crankcase.

o

F.

2004 Touring: Engine 3-7

Page 8

HOM

E

ENGINE OIL FLOW

Gauge

Banjo

Bolt

Washers

Figure 3-4. Oil Pressure Gauge

(Part No. HD-96921-52B)

Adapter

Figure 3-5. Install Adapter and Oil Pressure Gauge

NOTE

If reusing oil pressure switch/sender, apply Loctite Pipe Sealant with Teflon 565 to threads.

11. Start oil pressure switch/sender into crankcase bore.

12. On FLHR/C/S models, use a 15/16 inch Open End Crow

Foot (Snap-On FC30B) to tighten oil pressure switch to

96-120

models, use 1-1/16 inch Open End Crow Foot (Snap-On

FC34A) to tighten oil pressure sender to same torque.

13. On FLHR/C/S models, install elbow on post of oil pressure switch. On FLHT/C/U and FLTR models, install

Packard connector to oil pressure sender.

If wire socket terminal requires replacement, see APPENDIX

B.5 SEALED BUTT SPLICE CONNECTORS.

14. Test oil pressure switch/sender for proper operation.

in-lbs

(11-14 Nm). On FLHT/C/U and FLTR

NOTE

Adapter

Part No. HD-96921-110

f1646x3x

Oil

Filter

CAUTION

The oiling system is carefully designed for optimum efficiency. All oil holes and passageways are specially

sized. Exercise caution to avoid enlarging oil holes during cleaning. Any modification of the oiling system will

adversely affect oil pressure or cooling and lubrication

efficiency.

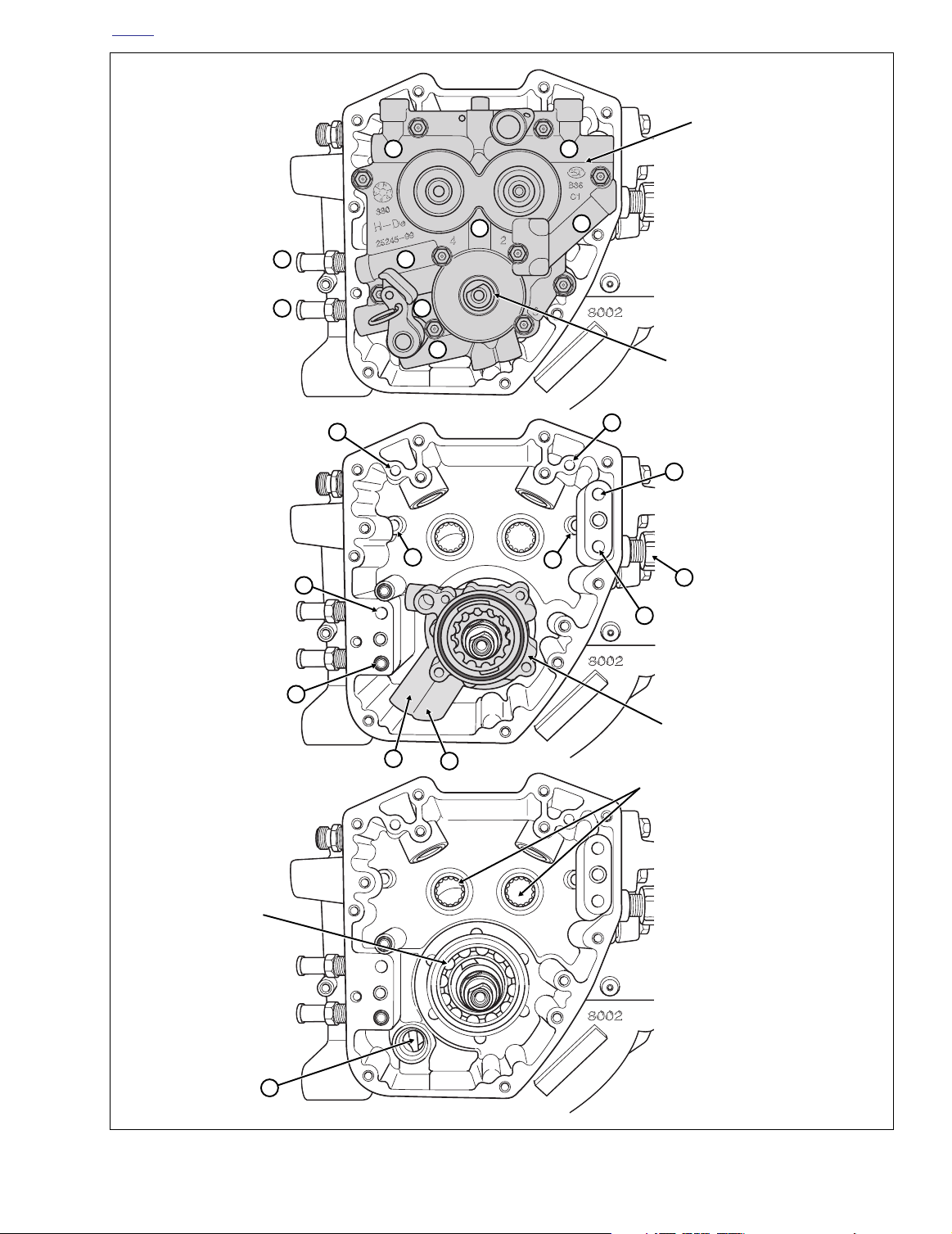

Oil Feed (Figures 3-6, 3-7)

Oil flows from the oil pan through a passageway at the front

of the transmission housing into a flexible hose clamped to

the lower fitting (A1) at the rear right side of the crankcase.

Running through a passageway in the crankcase, the oil exits

a hole in the crankcase flange (B2) and enters a hole on the

inboard side of the cam support plate. Passing through a

channel in the cam support plate (A3), the oil enters the feed

side of the oil pump. See OIL PUMP OPERATION. The feed

gerotors of the pump direct the flow up a second channel in

the cam support plate (A4).

A drilling in this channel connects to a pressure relief valve

mounted in the bypass port of the cam support plate (A5).

When the oil pressure exceeds the setting of the valve spring

(35 psi), the orifice opens to bypass excess oil back to the

feed side of the pump (A3).

Oil not returned to the feed side exits a hole on the inboard

side of the cam support plate and passes through a hole in

the crankcase flange (B6). Flowing through a passageway in

the crankcase, where a reading is taken by the oil pressure

sender (B7), the oil exits the lower hole in the oil filter mount

(D8).

After circulating through the oil filter, the flow of oil is directed

back into the crankcase through the upper hole in the oil filter

mount (D9). Exiting a passageway in the crankcase through

a hole in the crankcase flange (B10), the flow of oil reenters

the cam support plate.

Filtered oil is then routed to the top and bottom ends of the

engine, as described below.

Top End (Figures 3-6, 3-7)

Oil passes through a channel in the cam support plate exiting

the inboard side through two holes near the top (A11, A12).

Entering two holes in the crankcase flange (B13, B14), one

leading to the front cylinder and the other to the rear, the oil

travels through passageways in the crankcase to the hydraulic lifter bores (D15).

Exiting a hole in each lifter bore (E16), the oil flows around

the lifter and enters a hole at the side of the lifter body. As the

chamber inside the lifter body is filled, the push rod socket

rises to achieve the no-lash fit of the valve train components.

The flow of oil then exits a hole centered in the lifter socket

and runs up the hollow push rods.

3-8 2004 Touring: Engine

Page 9

HOM

E

f1581b3x

A

B

Cam Support Plate

12 11

26

38

1

36

3

5

4

Crankshaft

Bushing

14

24

37

23

13

10

7

C

Crankshaft

Bearing

6

2

f1573b3x

Oil Pump

35

25

Cam Needle Bearings

34

f1580b3x

Figure 3-6. Engine Oil Flow - Cam Support Plate/Right Crankcase Half

2004 Touring: Engine 3-9

Page 10

HOM

E

NOTE

Note that there is one additional hole drilled into the inside

lifter bores- while the oblong hole circulates oil around the

lifter body as described, the round hole (E17) feeds oil to the

piston jets in the flywheel compartment.

Exiting holes at the top of the hollow push rods, oil enters a

hole at the bottom of the intake and exhaust rocker arms.

Lubricating the rocker arm bushings, oil flows down the

rocker arm shafts and exits a pin hole in the outboard side of

each rocker arm housing (F18) where it sprays the valve

springs and the top of the valve stem.

Oil runs down to the low side of the rocker housing and

enters the exhaust valve spring pocket where a drain hole

(G19) leads to a passageway in the cylinder head casting.

Oil exits the bottom of the cylinder head and passes through

a ring dowel (H20) on the “down side” of the cylinder flange.

The oil runs through a vertical passageway in the cylinder,

passes through a second ring dowel on the “down side” of

the cylinder deck (I21) and enters the left crankcase half.

Flowing through a horizontal passageway in the left crankcase half (J22), oil runs through a third ring dowel (K23) to

the right crankcase half where it travels through another passageway before emptying into the cam compartment (B23,

B24).

Oil collecting in the cam compartment is picked up by one of

two scavenge lobes on the oil pump (B25).

Bottom End (Figures 3-6, 3-7, 3-8)

Oil travels down the center passage of the cam support plate

(A26) and sprays out through pin holes on each side of the

casting to lubricate both the primary and secondary cam

chains. Oil also passes through a hole in the crankshaft

bushing where the flow enters a drilling in the crankshaft

(L27).

Oil runs down the center of the crankshaft and then up a

cross drilling into the right side of the flywheel. The flow exits

a drilling in the crank pin bore, enters the crank pin and then

sprays out through three holes to lubricate the lower rod

bearing set.

The oil splash and mist created by the action of the flywheel

lubricates the crankshaft bearing and the camshaft needle

bearings in the right crankcase half. This same action serves

to lubricate the sprocket shaft bearing in the left crankcase

half (M28).

Since the oil mist also lubricates the cylinder walls, three

holes on each side of the piston (in the area of the third ring

land) evacuate excess oil scraped from the walls on the piston downstroke.

The piston jets (N29), which receive a supply of oil from the

intake lifter bores, spray the underside of the piston for cooling of the piston crown and skirt area. A check valve in each

jet opens only when the oil pressure reaches 12-15 psi, at

which point the engine is operating above idle speed. At idle

speeds (9-12 psi), the valve remains closed to prevent over

oiling and to ensure proper system operating pressure.

Oil spray from each piston jet also enters a hole at the bottom

of each pin boss (O30) for lubrication of the piston pin.

Another hole at the top of the connecting rod (D31) allows a

portion of the oil to reach the upper rod bushing.

Surplus oil falls back to the bottom of the flywheel compartment where it collects in the sump area (P32). Oil in the

sump is drawn to the cam compartment through an internal

channel (P33, C34) that connects with the second scavenge

lobe of the oil pump (B35).

Oil Return (Figures 3-6, 3-8)

The “dual kidney” designation given to the oil pump refers to

its two scavenging functions, whereby it simultaneously

draws oil from both the cam and flywheel compartments.

Oil sucked up by the scavenge lobes passes through the

scavenge gerotors of the oil pump and is directed through a

return channel in the cam support plate (A36). See OIL

PUMP OPERATION.

Exiting a hole on the inboard side of the cam support plate,

the oil enters a hole in the crankcase flange (B37).

The oil flows through a passageway in the crankcase and

exits the upper fitting at the rear right side of the crankcase

(A38). Passing through a flexible hose connection, the flow of

oil runs through a passageway at the front of the transmission housing (Q39) before emptying into the oil pan at the

front of the baffle (R40).

The oil flows to the rear of the oil pan along each side of the

baffle. Spring tension holds the unit tight against the bottom

of the pan to prevent oil from entering or escaping around the

perimeter of the baffle. At the back of the oil pan, the oil

enters the open side of the baffle where it is redirected forward. The baffle plates slow the circulation of the oil through

the pan to enhance cooling.

Oil pickup occurs in the front compartment of the baffle

where a passageway in the casting (S41) directs the flow

upward. Passing through a second passageway in the transmission housing (Q42), the flow of oil enters the flexible hose

connection (A1) to repeat the circuit.

Also note that a third flexible hose clamped to a fitting behind

the rear lifter cover connects the cam compartment with the

oil filler spout. This crankcase breather connection provides

the pressure balance necessary for oil circulation.

Oil Pump Operation

The oil pump consists of a housing containing two gerotor

gear sets, one feed and the other scavenge. Driven by the

crankshaft, the feed gerotor set distributes oil to the engine,

while the scavenge gerotor set draws oil from the cam and

flywheel compartments and returns it to the oil pan.

3-10 2004 Touring: Engine

Page 11

HOM

E

D

15

31

9

8

H

20

E

F

17

16

18

I

J

21

22

G

19

K

23

Figure 3-7. Engine Oil Flow - Top End

2004 Touring: Engine 3-11

Page 12

HOM

E

L

M

P

27

32

33

Q

28

42

39

N

O

R

40

29

30

S

41

3-12 2004 Touring: Engine

Figure 3-8. Engine Oil Flow - Bottom End

Page 13

f1562x3x

B

A

C

Inner

Gerotor

Outer

Gerotor

Seal

Oil In

Seal

Oil Out

HOM

E

Each gerotor gear set has two parts, an inner and outer gerotor. The inner and outer gerotors have fixed centers that are

slightly offset to one another. Also, the inner gerotor has one

less tooth.

As the crankshaft rotates, the cavity between the inner and

outer gerotors on the inlet side of the pump increases in volume. This creates a vacuum causing oil to be drawn in. The

cavity continues to increase until the volume is equivalent to

that of the missing tooth on the inner gerotor. Also note that

the inlet and outlet sides of the pump are sealed by the tips

and lobes of the inner and outer gerotors. See A of Figure 3-

9.

Continued rotation moves the pocket of oil to the outlet side

of the pump. In this area, the cavity decreases in volume as

the gerotor teeth mesh causing the oil to be squeezed out the

discharge port. As the cavity on the outlet side is emptied, a

second seal formed by the tips and lobes of the inner and

outer gerotors prevents oil on the outlet side (high pressure)

from being transferred to the inlet side (low pressure). See B

of Figure 3-9.

In operation, the gerotors provide a continuous flow of oil.

See C of Figure 3-9.

Breather Operation

NOTE

The crankcase breather system relieves crankcase pressure

produced by the downstroke of the pistons and allows crankcase vapors vacated from each cylinder to be directed into

the air filter element. Through effective recirculation of crankcase vapors, the system serves to eliminate the pollutants

normally discharged from the crankcase.

As each piston pushes downward on its power and intake

stroke, displaced air in the flywheel compartment is vented

through the crankshaft bearing into the cam compartment

and then up the push rod covers into the rocker housing.

Air rushes under the rocker arm support plate, which is elevated slightly, and passes through an opening at the bottom

of the plate to enter the breather baffle compartment.

In the baffle compartment, the flow of air passes upward

through the oil filter gauze, where the oil is removed from the

air. Two pin holes in the rocker arm support plate act as drain

holes to rid the baffle compartment of the oil separated from

the air.

Passing through the oil filter gauze, the flow of air passes

through the umbrella valve into the breather compartment.

The flaps of the umbrella valve only allow air to be vented

one way, rising to allow the passage of air, but then falling

back into place to seal the vent holes as the flow of air stops.

In the breather compartment, the flow of air reverses direction passing downward through holes aligned in the breather

baffle, rocker arm support plate and rocker housing. Exiting

the rocker housing, the air enters a passageway cast into the

top of the cylinder head. Proper orientation of the rocker

housing gasket is critical for effective sealing of this passageway.

Figure 3-9. Gerotor Operation

Flowing through the cylinder head passageway, the air

passes through a drilling in the air cleaner backplate bolt and

then through a breather tube into the air filter element.

NOTE

Air cleaner mounting without installation of the breather

tubes allows crankcase vapors to be vented into the atmosphere in violation of legal emissions standards.

2004 Touring: Engine 3-13

Page 14

HOM

E

HOW TO USE THIS SECTION 3.4

GENERAL

Three basic levels of service are presented in this section:

top end overhaul, bottom end overhaul and subassembly service and repair. The manner in which these instructions are

used depends upon the level of disassembly required.

Top End Overhaul

If servicing only cylinder head components, pistons, cylinders

and/or upper rod bushings, see Section 3.5 STRIPPING

MOTORCYCLE FOR SERVICE, and then proceed to Section

3.9 TOP END OVERHAUL, DISASSEMBLY. During top end

disassembly, the engine may be left in the chassis for service.

NOTE

If the engine is to be removed from the chassis, see Section

3.7 REMOVING ENGINE FROM CHASSIS in lieu of Section

3.5 STRIPPING MOTORCYCLE FOR SERVICE.

In the top end disassembly instructions, references are made

to Section 3.11 SUBASSEMBLY SERVICE AND REPAIR for

service of all top end subassemblies.

To rebuild the engine after a top end overhaul is complete,

perform the steps under Section 3.9 TOP END OVERHAUL,

ASSEMBLY, immediately following the disassembly instruc-

tions. Then, refer to Section 3.6 ASSEMBLING MOTORCY-

CLE AFTER STRIPPING to complete the project.

NOTE

For clarity, all artwork in this section shows the engine

removed from the chassis for service.

Bottom End Overhaul

Bottom end service may require either partial or complete

disassembly of the engine. Servicing components in the cam

compartment requires only partial disassembly, while servicing those in the flywheel compartment requires complete disassembly. An easy rule to remember is that any time the

crankcase halves must be split, complete disassembly needs

to occur. The cam compartment can be accessed through

removal of the cam cover making complete engine disassembly unnecessary.

During bottom end service that requires complete disassembly, the engine must be removed from the chassis and placed

in an engine stand. To begin, see Section 3.7 REMOVING

ENGINE FROM CHASSIS.

After the motorcycle has been stripped and the engine

removed, follow all of the steps under Section 3.9 TOP END

OVERHAUL, DISASSEMBLY. When finished, continue with

disassembly of the bottom half by performing those steps

listed under Section 3.10 BOTTOM END OVERHAUL, DIS-

ASSEMBLY.

Engine in Chassis Engine Removed

Top End Overhaul,

Service and Repair-

Top End Overhaul,

Motorcycle After

Engine in Chassis Engine Removed

Compartment.

Motorcycle for

Top End Overhaul,

Service and Repair-

Top End Overhaul,

Motorcycle After

TOP END SERVICE

Stripping

Motorcycle for

Service.

Disassembly.

Subassembly

To p End.

Assembly.

Assembling

Stripping.

BOTTOM END SERVICE

Cam

Stripping

Service.

Disassembly,

Steps 1-11.

Bottom End

Overhaul,

Disassembly,

Steps 1-14.

Subassembly

Bottom End.

Bottom End

Overhaul,

Assembly,

Steps 6-25.

Assembly,

Steps 29-39.

Assembling

Stripping.

Flywheel Compartment

Removing Engine

From Chassis.

Top End Overhaul,

Disassembly.

Subassembly

Service and Repair-

To p End.

Top End Overhaul,

Assembly.

Installing Engine

In Chassis.

or Complete Engine

Overhaul.

Removing Engine

From Chassis.

To p End Overhaul,

Disassembly.

Bottom End

Overhaul,

Disassembly.

Subassembly

Service and Repair-

To p End.

Subassembly

Service and Repair-

Bottom End.

Bottom End

Overhaul,

Assembly.

To p End Overhaul,

Assembly.

Installing Engine

In Chassis.

3-14 2004 Touring: Engine

Figure 3-10. Top/Bottom End Service

Page 15

HOM

E

As with the top end disassembly instructions, references are

made to Section 3.11 SUBASSEMBLY SERVICE AND

REPAIR for service of bottom end subassemblies.

Since it is standard practice to inspect and clean all oil passages when the engine is completely disassembled, a

detailed explanation of the engine oil circuit is presented

under Section 3.3 GENERAL INFORMATION, ENGINE OIL

FLOW.

To rebuild the engine after a bottom end overhaul is complete, perform the steps under Section 3.10 BOTTOM END

OVERHAUL, ASSEMBLY, and then proceed to Section 3.9

TOP END OVERHAUL, ASSEMBLY, to rebuild the upper

end.

Once the engine is assembled, refer to Section 3.8 INSTALL-

ING ENGINE IN CHASSIS to complete the project.

The flow charts on the preceding page show how the same

subsections are used for various levels of service.

Subassembly Service and Repair

Finally, if the task entails servicing of only one particular subassembly, then move directly to Section 3.11 SUBASSEM-

BLY SERVICE AND REPAIR for all service instructions.

For example, if just installing new cams, then refer to Section

3.11 SUBASSEMBLY SERVICE AND REPAIR, CAM SUPPORT PLATE.

The steps under Section 3.9 TOP END OVERHAUL and Sec-

tion 3.10 BOTTOM END OVERHAUL that need to be fol-

lowed for the removal and installation of the cam support

plate are given.

Furthermore, detailed instructions for disassembling, cleaning, inspecting, replacing and assembling cam support plate

components are provided.

2004 Touring: Engine 3-15

Page 16

HOM

E

STRIPPING MOTORCYCLE FOR SERVICE 3.5

PROCEDURE

NOTE

If performing top end service (or both cam compartment and

top end), follow steps 1-21. If servicing cam compartment

components only, perform steps 1-12.

1. Drain and remove fuel tank. Proceed as follows:

Carbureted:

RETED), COMPLETE REMOVAL, FLHT/C, or FLHR/S.

Fuel Injected:

INJECTED), COMPLETE REMOVAL, FLHT/C/U/I,

FLTRI, or FLHR/C/S/I.

2. Remove left side saddlebag. See Section 2.25 SAD-

DLEBAG, REMOVAL.

3. Gently pull left side cover from frame downtubes (no

tools required).

4. On Ultra models, hold locknut at bottom of left fairing

lower, and using a T40 TORX drive head, turn inside

screw to free assembly from engine guard clamp. Discard rubber washer.

5. Repeat steps 2-4 to remove saddlebag, side cover and

fairing lower on right side of vehicle.

6. Remove the air cleaner and backplate. See Section 4.5

AIR CLEANER, REMOVAL.

7. Remove two allen head socket screws (with lockwashers

and flat washers) to release right side front footboard

brackets from frame weldment. For best results,

approach from left side of vehicle using a 3/8 inch ball

allen with extension.

8. Remove exhaust system in two sections as follows:

a. Open two worm drive clamps to release heat shield

over rear header pipe to crossover pipe connection

(above starter).

b. Loosen TORCA clamp between rear header pipe

and crossover pipe. Remove Keps nut and pull

bracket tab and stud from slots in TORCA clamp

and exhaust support bracket.

c. Spray PB Blaster or other suitable penetrating oil in

and around joint between rear header pipe and

crossover pipe.

d. Moving to left side of vehicle, remove two bolts (with

lockwashers) to detach left side muffler from the

lower saddlebag support rail.

See Section 4.7 FUEL TANK (CARBU-

See Section 9.4 FUEL TANK (FUEL

e. Pull and twist on crossover pipe to remove left side

exhaust from vehicle. For best results, be sure to

allow sufficient time for the penetrating oil to work.

f. Remove TORCA clamp assembly from crossover

pipe and discard.

NOTE

To ensure sealing integrity of TORCA clamps and prevent the

possibility of leakage, Harley-Davidson recommends that

TORCA assemblies be discarded and replaced each time

they are removed.

g. Moving to right side of vehicle, open two worm drive

clamps and release heat shield from front header

pipe. Using an impact wrench with long 1/2 inch

swivel socket, remove two exhaust flange nuts to

release front header pipe from studs of front cylinder head. Slide exhaust flange down header pipe to

improve clearance around exhaust port.

h. Open two worm drive clamps and release heat

shield from rear header pipe. Remove two exhaust

flange nuts to release rear header pipe from studs

of rear cylinder head.

i. Open two worm drive clamps to release heat shield

over front header pipe to rear header pipe connection (outboard of transmission side door).

j. Remove bolt (with flat washer and locknut) from

transmission exhaust bracket clamp on front header

pipe. Use a channel lock to open clamp and then

remove from header pipe and transmission exhaust

bracket.

k. Remove two bolts (with lockwashers) to detach right

side muffler from the lower saddlebag support rail.

l. Depressing rear brake pedal, remove right side

exhaust from vehicle.

m. Remove and discard gaskets from front and rear

exhaust ports.

9. Moving to left side of vehicle, pull boots on spark plug

cables to release from spark plug and ignition coil towers. Release cables from three cable clips at bottom of

frame backbone.

10. Remove spark plugs.

11. Pull external latch outward and use rocking motion to

remove electrical connector from left side of ignition coil.

12. Pull sides of ignition coil bracket outward to remove from

bosses of front fuel tank mount.

13. Remove connections to carburetor or induction module.

Proceed as follows:

3-16 2004 Touring: Engine

Page 17

HOM

E

Carbureted:

a. Standing on left side of vehicle, remove electrical

connector from manifold absolute pressure (MAP)

sensor at top of intake manifold.

b. Locate the fuel enrichener knob under the left side

of the fuel tank, and loosen hex nut at backside of

mounting bracket. Slide cable assembly free of slot

in mounting bracket.

Fuel Injected:

a. Standing on right side of vehicle, remove idle air

control and manifold absolute pressure sensor connectors. Pull external latch(es) outward and use

rocking motion to separate pin and socket halves.

b. Depress wire form to remove electrical connectors

from front and rear fuel injectors.

c. Remove throttle position sensor and intake air tem-

perature sensor connectors.

d. Moving to left side of vehicle, pull back boot to

reveal engine temperature sensor at back of front

cylinder. Pull external latch outward and remove

connector. Cut cable strap to release conduit from

horn bracket.

e. Tuck free ends of EFI wire harness under main wire

harness on frame backbone to keep conduit and

connectors out of the way.

a. Remove right side allen head socket screws from

front and rear cylinder head flange adapters. For

best results, use a long 1/4 inch ball allen head

socket with end driver 4 inches long.

b. Moving to opposite side of vehicle, just loosen left

side allen head socket screws from flange adapters.

Slots in flanges make removal of left side screws

unnecessary.

c. Remove intake manifold/carburetor or induction

module from right side of vehicle.

18. Standing on left side of vehicle, remove two hex head

bolts (with flat washers) to release top engine mounting

bracket from cylinder heads.

19. Leaving ground wire ring terminal in place, detach

socket terminal of yellow lead from spade contact at

back of horn. Release wire conduit from J-clamp.

20. Moving to right side of vehicle, turn hex head bolt to

release stabilizer link from frame weldment.

21. Remove horn, top engine mounting bracket and stabilizer link as an assembly.

14. Remove idle and throttle control cables as follows:

Carbureted:

idle cable barrel from upper inboard hole in throttle

wheel. Pull throttle cable barrel from remaining hole.

Release idle and throttle cables from guides in throttle

cable bracket.

Fuel Injected:

idle cable barrel from upper hole in throttle wheel. Pull

throttle cable barrel from lower hole. Using slots, release

idle and throttle cables from guides in throttle cable

bracket.

15. Free idle and throttle control cables from J-clamp fastened to right side of frame backbone. Move cables up

and out of the way.

16. If equipped with cruise control, remove E-clip from

sleeve at end of cruise cable housing. Using slot,

remove cable housing from cable guide in throttle cable

bracket. Push the plastic end fitting on the cruise cable

to the outboard side to release from wheel pin. Move

cable up and out of the way.

17. Remove intake manifold/carburetor or induction module.

Proceed as follows:

Using a needle nose pliers, carefully pull

Using a needle nose pliers, carefully pull

2004 Touring: Engine 3-17

Page 18

HOM

E

ASSEMBLING MOTORCYCLE AFTER STRIPPING 3.6

PROCEDURE

NOTE

If top end service was performed (or both cam compartment

and top end), follow steps 1-19. If only cam compartment

components were serviced, perform steps 8-18.

1. Install intake manifold/carburetor or induction module.

Proceed as follows:

a. With the counterbore facing outward, slide cylinder

head flange adapters onto outlet ports of intake

manifold/induction module. The flange adapters are

not interchangeable. Look next to the slotted bolt

hole for a stamp that indicates F(ront) and R(ear)

cylinder.

b. Place a

beveled side in against the counterbore.

c. Standing on right side of engine, slide intake mani-

fold/induction module toward installed position so

that open-ended slots on flange adapters begin to

engage allen head socket screws loosely installed

on left side.

d. Align fixed holes in flange adapters with those in

cylinder heads and start allen head socket screws.

For best results, use a long 1/4 inch ball allen head

socket with end driver 4 inches long.

e. Use the air cleaner backplate or INDUCTION SYS-

TEM ALIGNMENT BRACKET (P&A Part No.

40054-01) to properly locate carburetor/induction

module. Proceed as follows:

Backplate

plate to front and rear cylinder heads. Install three

T27 TORX screws to secure backplate to face of

carburetor/induction module.

Alignment bracket

into holes in face of carburetor/induction module,

install two breather bolts to fasten bracket to front

and rear cylinder heads.

f. Tighten allen head socket screw in fixed holes of

flange adapters until snug. Moving to left side of

engine, tighten screws in slotted holes to 96-144

lbs

g. Remove breather bolts and T27 TORX screws to

remove backplate, if installed.

h. Tighten allen head socket screws in fixed holes of

flange adapters to 96-144

i. Remove breather bolts to remove alignment

bracket, if installed.

new

seal in each flange adapter with the

: Install two breather bolts to fasten back-

: Fitting pins on inboard side

(10.9-16.3 Nm).

in-lbs

(10.9-16.3 Nm).

in-

2. Install horn, top engine mounting bracket and stabilizer

link as an assembly. Proceed as follows:

a. Moving to right side of vehicle, turn hex head bolt to

secure stabilizer link to frame weldment. Tighten

bolt to 18-22 ft-lbs (24-30 Nm).

b. Attach socket terminal of yellow lead to spade con-

tact at back of horn. Capture wire conduit in Jclamp.

c. Standing on left side of vehicle, install two hex head

bolts (with flat washers) to secure top engine

mounting bracket to front and rear cylinder heads.

Alternately tighten bolts to 35-40 ft-lbs (48-54 Nm).

3. If equipped with cruise control, slide groove in cruise

cable end fitting over cap of wheel pin. Push on end fitting until it snaps in place. Using slot, slip cruise cable

housing into cable guide in throttle cable bracket. Install

new

E-clip on sleeve at end of cruise cable housing.

4. Route idle and throttle control cables through J-clamp

fastened to right side of frame backbone.

5. Install idle and throttle control cables as follows:

Carbureted:

shorter cable guide in throttle cable bracket. Drawing

throttle cable downward, fit barrel end into lower outboard hole in throttle wheel. Install sleeve and spring on

idle cable housing into longer cable guide inserting barrel end into upper inboard hole in throttle wheel.

Induction Module:

ing into shorter cable guide at top of throttle cable

bracket. Drawing throttle cable downward, fit barrel end

into lower hole in throttle wheel. Install sleeve and spring

on idle cable housing into longer cable guide at bottom

of throttle cable bracket inserting barrel end into upper

hole in throttle wheel.

6. Adjust cables as necessary to keep barrel ends from dislodging. Verify that cables are seated in channel of throttle wheel. Verify operation by turning throttle grip and

observing cable action.

7. Install connections to carburetor or induction module.

Standing on left side of vehicle, proceed as follows:

Install sleeve on throttle cable housing into

Install sleeve on throttle cable hous-

Carbureted:

a. Moving to left side of vehicle, install electrical con-

nector to manifold absolute pressure (MAP) sensor

at top of intake manifold.

b. Slide threaded portion of enrichener cable into slot

of mounting bracket. Flat on threads must face rear

of vehicle for script on enrichener knob to be right

side up. With the external tooth lockwasher and hex

nut positioned on the inboard side of the mounting

bracket, tighten hex nut to 20-35

Nm).

in-lbs

(2.3-4.0

3-18 2004 Touring: Engine

Page 19

HOM

CAUTION

E

Fuel Injected:

a. Install electrical connectors on fuel injectors.

b. Install manifold absolute pressure sensor and idle

air control connectors.

c. Install intake air temperature sensor and throttle

position sensor connectors.

d. Moving to left side of vehicle, install connector to

engine temperature sensor at back of front cylinder.

Pull boot over sensor to keep out dirt and debris.

Install

new

cable strap to secure connector conduit

to horn bracket.

8. Install exhaust system as follows:

a. Install

b. Place right side exhaust into position on vehicle and

c. Start two bolts (with lockwashers) to secure right

d. Start two exhaust flange nuts to secure rear header

e. Engaging transmission exhaust bracket, capture

To ensure sealing integrity of TORCA clamps and prevent the

possibility of leakage, Harley-Davidson recommends that

TORCA assemblies be discarded and replaced each time

they are removed.

f. Moving to left side of vehicle, slide

g. Twist and push left side exhaust onto crossover

h. Start two bolts (with lockwashers) to secure left side

i. Returning to left side of vehicle, position TORCA

Verify that the exhaust pipes do not contact the vehicle

frame or any mounted components. Contact will cancel

the effect of the rubber isolation mounts and transmit

vibration to the rider via the vehicle frame.

j. Tighten the exhaust system as follows:

new

gaskets in both the front and rear cylin-

der head exhaust ports (with the tapered side out).

start two exhaust flange nuts to secure front header

pipe to studs of front cylinder head.

side muffler to the lower saddlebag support rail.

pipe to studs of rear cylinder head.

front header pipe in transmission exhaust bracket

clamp. Use a channel lock to close clamp, if necessary. Finger tighten clamp bolt (with flat washer and

locknut).

NOTE

new

TORCA

clamp assembly onto crossover pipe.

pipe.

muffler to the lower saddlebag support rail.

clamp between rear header pipe and crossover

pipe. Fit bracket tab into slot of TORCA clamp

engaging stud in slot of exhaust support bracket.

Start Keps nut on stud.

CAUTION

Using a long 1/2 inch swivel socket, tighten the top

●

nut of the front cylinder head exhaust flange to 9-18

in-lbs

(1-2 Nm). Tighten the bottom nut to 100-120

in-lbs

(11.3-13.6 Nm). Final tighten the top nut to

100-120

●

Tighten the bottom nut of the rear cylinder head

exhaust flange to 9-18

top nut to 100-120

tighten the bottom nut to 100-120

in-lbs

(11.3-13.6 Nm).

in-lbs

(1-2 Nm). Tighten the

in-lbs

(11.3-13.6 Nm). Final

in-lbs

(11.3-13.6

Nm).

●

Tighten the transmission exhaust bracket clamp bolt

to 60-96

●

Tighten the two bolts (with lockwashers) to fasten

in-lbs

(6.8-10.8 Nm).

the right side muffler to the lower saddlebag support

rail.

Tighten the two bolts (with lockwashers) to fasten

●

the left side muffler to the lower saddlebag support

rail.

Verify that all exhaust pipes are in alignment and do

●

not contact the vehicle frame or mounted components.

Tighten the TORCA clamp between the rear header

●

pipe and crossover pipe to 45-60 ft-lbs (61-81 Nm).

●

Tighten Keps nut securing bracket tab to exhaust

support bracket.

Verify that the heat shields do not contact the vehicle

frame or any mounted components. Contact will cancel

the effect of the rubber isolation mounts and transmit

vibration to the rider via the vehicle frame.

NOTE

Position worm drive clamps so that screws are on the outboard side in the most accessible position.

k. Open worm drive clamps and install heat shields as

follows:

Over front header pipe (below exhaust port).

●

●

Over rear header pipe (below exhaust port).

Over front header pipe to rear header pipe connec-

●

tion (outboard of transmission side door).

Over rear header pipe to crossover pipe connection

●

(above starter).

l. Position each worm drive clamp so that screw is on

the outboard side in the most accessible position

and then tighten to 20-40

in-lbs

(2.3-4.5 Nm).

9. Insert two allen head socket screws (with lockwashers

and flat washers) through frame weldment into right side

front footboard brackets. For best results, approach from

left side of vehicle using a 3/8 inch ball allen with extension.

10. Install the backplate and air cleaner. See Section 4.5

AIR CLEANER, INSTALLATION.

2004 Touring: Engine 3-19

Page 20

HOM

E

11. On Ultra models, place fairing lower into position on right

side of vehicle. Holding T40 TORX screw inside fairing

lower, install

attach fairing bottom to engine guard. Do not tighten

locknut.

12. Align barbed studs in right side cover with grommets in

frame downtubes and push firmly into place (no tools

required).

13. Install right side saddlebag. See Section 2.25 SADDLE-

BAG, INSTALLATION.

14. Repeat steps 11-13 to install side cover, saddlebag and

fairing lower on left side of vehicle.

15. Install spark plugs in front and rear cylinder heads.

Install the plugs finger tight and then tighten to 12-18 ftlbs (16-24 Nm).

16. Install ignition coil and spark plug cables as follows:

a. With the coil towers facing rear of vehicle, hold igni-

tion coil and bracket at bottom of frame backbone.

Pull sides of bracket outward and install on bosses

of front fuel tank mount. See Figure 3-11.

b. Install electrical connector on left side of ignition

coil.

c. Install spark plug cable to front cylinder onto left

side coil tower. Verify that spark plug cable is captured in double-sided cable clip at bottom left side of

frame backbone. Install

damaged or missing.

d. Install spark plug cable to rear cylinder onto right

side coil tower. Verify that spark plug cable is captured in two single-sided cable clips at bottom left

side of frame backbone. Install

studs if damaged or missing.

new

rubber washer, clamp and locknut to

new

cable clip on T-stud if

new

cable clips on T-

17. Install the fuel tank. Proceed as follows:

Carbureted:

RETED), INSTALLATION (AFTER COMPLETE

REMOVAL), FLHT/C, or FLHR/S.

Fuel Injected:

INJECTED), INSTALLATION (AFTER COMPLETE

REMOVAL), FLHT/C/U/I, FLTRI, or FLHR/C/S/I.

18. On Ultra models, hold locknut at bottom of fairing lower,

and using a T40 TORX drive head, turn inside screw to

fasten assembly to engine guard clamp. Tighten screw

to 90-100

site side of vehicle.

19. Adjust idle and throttle control cables as follows:

Non-Cruise:

(NON-CRUISE), ADJUSTMENT.

Cruise Equipped:

TROL (FLHRC, FLTR, FLHTCU), CABLE ADJUSTMENT.

See Section 4.7 FUEL TANK (CARBU-

See Section 9.4 FUEL TANK (FUEL

in-lbs

(10.2-11.3 Nm). Repeat step on oppo-

See Section 2.21 THROTTLE CABLES

See Section 8.30 CRUISE CON-

3-20 2004 Touring: Engine

Page 21

HOM

E

REMOVING ENGINE FROM CHASSIS 3.7

PROCEDURE

1. Drain and remove fuel tank. Proceed as follows:

Carbureted:

RETED), COMPLETE REMOVAL, FLHT/C, or FLHR/S.

Fuel Injected:

INJECTED), COMPLETE REMOVAL, FLHT/C/U/I,

FLTRI, or FLHR/C/S/I.

2. Remove the primary chaincase. See Section 6.5 PRI-

MARY CHAINCASE, REMOVAL, steps 2-18.

3. Remove left side saddlebag. See Section 2.25 SAD-

DLEBAG, REMOVAL.

4. Gently pull left side cover from frame downtubes (no

tools required).

5. On Ultra models, hold locknut at bottom of left fairing

lower, and using a T40 TORX drive head, turn inside

screw to free assembly from engine guard clamp. Discard rubber washer.

6. Repeat steps 3-5 to remove saddlebag, side cover and

fairing lower on right side of vehicle.

7. Remove the air cleaner and backplate. See Section 4.5

AIR CLEANER, REMOVAL.

8. Remove two allen head socket screws (with lockwashers

and flat washers) to release right side front footboard

brackets from frame weldment. For best results,

approach from left side of vehicle using a 3/8 inch ball

allen with extension.

9. Remove exhaust system in two sections as follows:

a. Open two worm drive clamps to release heat shield

over rear header pipe to crossover pipe connection

(above starter).

b. Loosen TORCA clamp between rear header pipe

and crossover pipe. Remove Keps nut and pull

bracket tab and stud from slots in TORCA clamp

and exhaust support bracket.

c. Spray PB Blaster or other suitable penetrating oil in

and around joint between rear header pipe and

crossover pipe.

d. Moving to left side of vehicle, remove two bolts (with

lockwashers) to detach left side muffler from the

lower saddlebag support rail.

e. Pull and twist on crossover pipe to remove left side

exhaust from vehicle. For best results, be sure to

allow sufficient time for the penetrating oil to work.

f. Remove TORCA clamp assembly from crossover

pipe and discard.

See Section 4.7 FUEL TANK (CARBU-

See Section 9.4 FUEL TANK (FUEL

NOTE

To ensure sealing integrity of TORCA clamps and prevent the

possibility of leakage, Harley-Davidson recommends that

TORCA assemblies be discarded and replaced each time

they are removed.

g. Moving to right side of vehicle, open two worm drive

clamps and release heat shield from front header

pipe. Using an impact wrench with long 1/2 inch

swivel socket, remove two exhaust flange nuts to

release front header pipe from studs of front cylinder head. Slide exhaust flange down header pipe to

improve clearance around exhaust port.

h. Open two worm drive clamps and release heat

shield from rear header pipe. Remove two exhaust

flange nuts to release rear header pipe from studs

of rear cylinder head.

i. Open two worm drive clamps to release heat shield

over front header pipe to rear header pipe connection (outboard of transmission side door).

j. Remove bolt (with flat washer and locknut) from

transmission exhaust bracket clamp on front header

pipe. Use a channel lock to open clamp and then

remove from header pipe and transmission exhaust

bracket.

k. Remove two bolts (with lockwashers) to detach right

side muffler from the lower saddlebag support rail.

l. Depressing rear brake pedal, remove right side

exhaust from vehicle.

m. Remove and discard gaskets from front and rear

exhaust ports.

10. Remove connections to carburetor or induction module.

Proceed as follows:

Carbureted:

a. Moving to left side of vehicle, pull external latch out-

ward and use rocking motion to remove electrical

connector from manifold absolute pressure (MAP)

sensor at top of intake manifold.

b. Locate the fuel enrichener knob under the left side

of the fuel tank, and loosen hex nut at backside of

mounting bracket. Slide cable assembly free of slot

in mounting bracket.

Fuel Injected:

a. Standing on right side of vehicle, remove idle air

control and manifold absolute pressure sensor connectors. Pull external latch(es) outward and use

rocking motion to separate pin and socket halves.

b. Depress wire form to remove electrical connectors

from front and rear fuel injectors.

2004 Touring: Engine 3-21

Page 22

HOM

E

8316

Figure 3-11. Remove Ignition Coil Bracket From Vehicle

c. Remove throttle position sensor and intake air tem-

perature sensor connectors.

d. Moving to left side of vehicle, pull back boot to

reveal engine temperature sensor at back of front

cylinder. Pull external latch outward and remove

connector. Cut cable strap to release conduit from

horn bracket.

e. Tu ck free ends of EFI wire harness under main wire

harness on frame backbone to keep conduit and

connectors out of the way.

11. Remove idle and throttle control cables as follows:

Carbureted:

Using a needle nose pliers, carefully pull

idle cable barrel from upper inboard hole in throttle

wheel. Pull throttle cable barrel from remaining hole.

Release idle and throttle cables from guides in throttle

cable bracket.

Fuel Injected:

Using a needle nose pliers, carefully pull

idle cable barrel from upper hole in throttle wheel. Pull

throttle cable barrel from lower hole. Using slots, release

idle and throttle cables from guides in throttle cable

bracket.

12. Free idle and throttle control cables from J-clamp fastened to right side of frame backbone. Move cables up

and out of the way.

13. If equipped with cruise control, remove E-clip from

sleeve at end of cruise cable housing. Using slot,

remove cable housing from cable guide in throttle cable

bracket. Push the plastic end fitting on the cruise cable

to the outboard side to release from wheel pin. Move

cable up and out of the way.

14. Moving to left side of vehicle, pull boots on spark plug

cables to release from spark plug and ignition coil towers. Release cables from three cable clips at bottom of

frame backbone.

15. Remove spark plugs.

16. Pull external latch outward and use rocking motion to

remove electrical connector from left side of ignition coil.

17. Pull sides of ignition coil bracket outward to remove from

bosses of front fuel tank mount. See Figure 3-11.

18. Moving to right side of vehicle, remove two allen head

socket screws to release oil hose cover.

19. Using a side cutters, cut and remove clamps on engine

side of oil hoses. Pull hoses from crankcase fittings.

20. Cut and remove clamp on breather hose behind rear

lifter cover. Pull hose from crankcase fitting and tuck

behind transmisson to engine flange to keep out of the

way.

21. Remove the voltage regulator. See Section 8.9 VOLT-

AGE REGULATOR, REMOVAL.

22. To release stator cable conduit, remove P-clip from left

side stud on lower frame crossmember. Remove P-clip

from cable conduit. Draw stator connector and cable

conduit to rear of engine stabilizer link and then up to

area in front of primary chaincase.

23. Depress tangs inside socket housing and back out sockets through wire end of connector. Proceed as follows:

a. Looking into the socket housing, take note of the

cavity on each side of the terminal.

b. Gently insert pick (Snap-On TT600-3) into the cavity

about 1/4 inch (6.4 mm) or until it stops, and pivot

the side of the pick toward the terminal body.

Repeat step on other cavity. See Figure 3-12.

c. Gently tug on cable to pull terminal from chamber. If

terminal is still locked, one or both tangs are not

fully depressed. Repeat steps 24(b) and 24(c) as

necessary.

d. Repeat procedure to release second terminal.

f1911x8x

Pick

Figure 3-12. Remove Socket Terminals

From Stator/Voltage Regulator Connector

3-22 2004 Touring: Engine

Page 23

HOM

1CAUTION

E

24. Remove conduit from stator cables. For best results, pull

one cable and socket terminal through conduit at a time.

Ta pe cables to crankcase so that they are out of the way

and will not be pinched or cut during engine removal.

25. Remove crankshaft position sensor and oil pressure

switch/sender as follows:

a. Locate crankshaft position sensor connector [79], 2-

place Mini-Deutsch, next to oil filter mount. Depress

button on socket terminal side and pull apart pin

and socket halves.

b. Remove allen head socket screw to free crank posi-

tion sensor mount from crankcase. Pull sensor from

bore. Remove O-ring from groove on sensor body.

Discard O-ring.

Figure 3-13. Engine/Transmission Bench Stand

(Part No. HD-42310)

c. Locate the oil pressure switch/sender at the front

right side of the crankcase. On FLHR/C/S models,

pull elbow from post of oil pressure switch. On

FLHT/C/U and FLTR models, pull external latch outward and use rocking motion to remove Packard

connector from oil pressure sender.

d. On FLHR/C/S models, use a 15/16 inch Open End

Crow Foot (Snap-On FC30B) to remove oil pressure

switch from crankcase. On FLHT/C/U and FLTR

models, use 1-1/16 inch Open End Crow Foot

(Snap-On FC34A) to remove oil pressure sender.

26. Coil main harness conduit and allow to hang below

lower frame tube at front of vehicle. If harness is not

moved out of the way, it may be damaged during engine

removal.

27. Place jack under oil pan at rear of vehicle. Using a block

of wood to distribute pressure across the length of the

casting, raise the jack until firm contact is made with the

bottom of the oil pan.

28. Standing on left side of vehicle, remove two hex head

bolts (with flat washers) to release top engine mounting

bracket from cylinder heads.

29. Remove elbow terminals from spade contacts at back of

horn. Release wire harness conduit from J-clamp.

30. Moving to right side of vehicle, turn hex head bolt to

release stabilizer link from frame weldment.

35. Cover lower frame tubes (both left and right side) with

foam padding or bubble pack. Split loom conduit or a half

shell of PVC tubing will also produce good results. Protection is necessary to prevent nicks or paint damage to

left frame tube and chafing, cutting or kinking of the

brake line, wire cables and conduit at the top of the right

frame tube.

36. Cover rocker covers of front and rear cylinders with foam

padding or bubble pack.

The engine weighs approximately 165 pounds (74.8 kg).

Use a suitable lifting device, if necessary. Exercise caution to avoid personal injury.

37. Move engine forward far enough to clear two ring dowels

in lower flange of transmission housing. Raise engine

and remove from right side of vehicle. Exercise caution

to avoid contact with rear brake master cylinder reservoir

and brake line, wire cables and conduit at top of lower

frame tube.

38. Using the TWIN CAM 88 CRADLE (HD-42310-2), install

engine in BENCH STAND (HD-42310) or ROLLING

STAND (HD-43646A). See Figure 3-13.

39. Remove intake manifold/carburetor or induction module.

Proceed as follows:

31. Remove horn, top engine mounting bracket and stabilizer link as an assembly.

32. Remove four bolts (with flat washers) to free rear of

crankcase from transmission housing. Loosen and

remove bolts in a crosswise pattern.

33. Remove two bolts (with flat washers) to free front of

crankcase from front engine mounting bracket.

34. Wrap rear master cylinder reservoir with foam padding

or bubble pack.

a. Remove right side allen head socket screws from

front and rear cylinder head flange adapters. For

best results, use a long 1/4 inch ball allen head

socket with end driver 4 inches long.

b. Moving to opposite side of vehicle, just loosen left

side allen head socket screws from flange adapters.

Slots in flanges make removal of left side screws

unnecessary.

c. Remove intake manifold/carburetor or induction

module from right side of vehicle.

2004 Touring: Engine 3-23

Page 24

HOM

E

40. Remove the rotor as follows:

1CAUTION

The high-output rotor is used on fuel injected vehicles,

FLHR/C/S/I excepted. Since the high-output rotor contains magnets that are considerably more powerful than

those used on low-output rotors, the ROTOR REMOVER/

INSTALLER and SHAFT PROTECTOR SLEEVE (HD-

41771) must be used to prevent parts damage and possible hand injury during removal and installation.

High Output Rotor - 45 Amp

a. Verify that threads of engine sprocket shaft are

clean, especially of old Loctite material. Thread the

Shaft Protector Sleeve onto the shaft.

b. Tu rn thumbscrews of Rotor Remover/Installer into

threaded holes in rotor face.

c. Rotate handle of forcing screw in a clockwise direc-

tion to remove rotor from shaft.

Low Output Rotor - 38 Amp

CAUTION

Do not strike or drop rotor. Damage to magnet adhesive

may result in rotor failure.

a. Fabricate wire hooks or use the ends of two allen

wrenches to carefully pull rotor at holes in rotor

face.

b. Pull rotor from stator. Magnets in rotor cause some

resistance during removal.

41. Remove stator as follows:

a. Using a T27 TORX drive head, remove four screws

to free stator from crankcase. Discard screws.

b. Using point of awl, carefully lift capped rib on grom-

met away from crankcase and then insert into bore

between grommet and casting. See Figure 3-14. Tilt

awl slightly squirting isopropyl alcohol or glass

cleaner into opening. Repeat this step at one or two

other locations around grommet.

c. While pushing on capped rib from outside of crank-

case, draw grommet through bore by pulling on

cable stop with needle nose pliers. Rock grommet

back and forth to facilitate removal, if necessary.

Exercise caution to avoid damaging ribs on grommet if stator is to be reused.

42. Remove the oil filter as follows:

a. Obtain the OIL FILTER WRENCH (HD-42311). The

tool allows easy removal of the oil filter without risk

of damage to the crankshaft position sensor or

cable.

b. Place the jaws of the wrench over the oil filter with

the tool oriented vertically.

Capped

Rib