Page 1

HOME

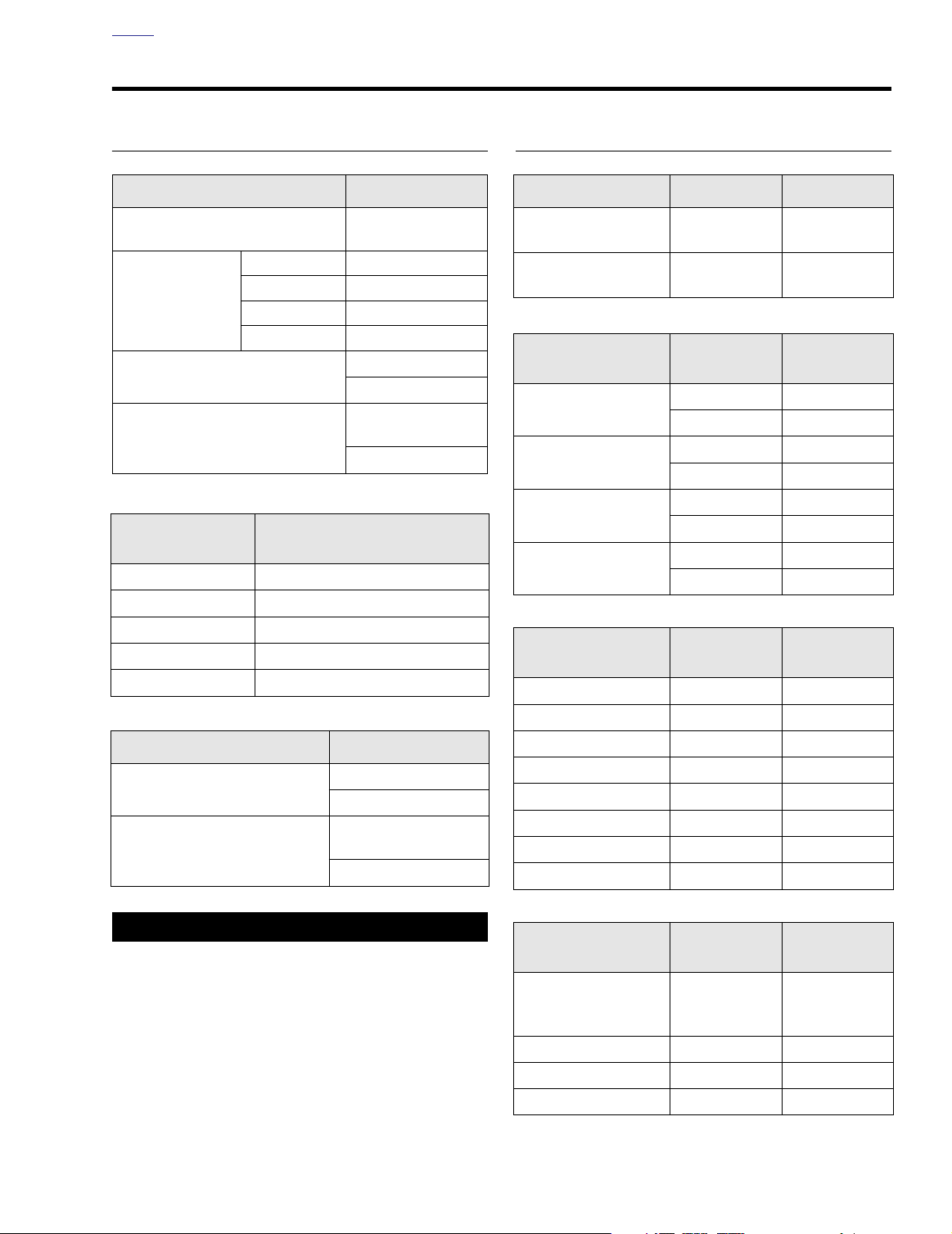

SPECIFICATIONS 7.1

TRANSMISSION DATA

TRANSMISSION

Ty p e

Quart Part No. 99892-84

Semi-synthetic

transmission

lubricant

Capacity (dry)

Capacity (wet)

GEAR

First 3.21

Second 2.21

Third 1.57

Fourth 1.23

Fifth 1.00

ENGINE OIL

Capacity (dry)

Capacity (wet)

Case of Quarts Part No. 98853-96

Gallon Part No. 99891-84

Case of Gallons Part No. 98852-96

Internal Gear Ratios

(Domestic, HDI and Swiss)

DATA

5-speed forward -

constant mesh

24 oz.

710 ml

Approximately

20-24 oz.

590-710 ml

DATA

4 quarts

3.8 liters

Approximately

3-1/2 quarts

3.3 liters

SERVICE WEAR LIMITS

SHIFTER FORKS

Shifter fork to cam

groove end play

Shifter fork to gear

groove end play

SHIFTER DOG

GEARS

2nd-5th

2nd-3rd

1st-4th

1st-3rd

MAINSHAFT

TOLERANCE

Mainshaft runout 0.000-0.003 0.000-0.08

Mainshaft end play none none

1st gear clearance 0.0000-0.0080 0.000-0.203

2nd gear clearance 0.0000-0.0800 0.000-2.032

3rd gear end play 0.0050-0.0420 0.127-1.067

3rd gear clearance 0.0003-0.0019 0.008-0.048

4th gear end play 0.0050-0.0310 0.127-0.787

4th gear clearance 0.0003-0.0019 0.008-0.048

IN. MM

0.0017-0.0019 0.043-0.048

0.0010-0.0110 0.025-0.279

MINIMUM

CLEARANCE

0.035 in. 0.139 in.

0.89 mm 3.53 mm

0.035 in. 0.164 in.

0.89 mm 4.17 mm

0.035 in. 0.152 in.

0.89 mm 3.86 mm

0.035 in. 0.157 in.

0.89 mm 3.99 mm

IN. MM

MAXIMUM

CLEARANCE

CAUTION

A bent jiffy stand, modified suspension or uneven parking area can cause dipstick to indicate a false low oil

condition.

NOTE

Since a sidecar equipped motorcycle is fixed in an upright

position, the actual full engine oil level is about 1/2 inch (12.7

mm) above the FULL mark on the dipstick.

MAIN DRIVE

GEAR (5TH)

Bearing fit in

transmission case

(loose)

Fit on mainshaft 0.0001-0.0009 0.0025-0.023

End play none none

Fit in side door (tight) 0.0014-0.0001 0.036-0.0025

2004 Touring: Transmission 7-1

IN. MM

0.0003-0.0017 0.008-0.043

Page 2

HOME

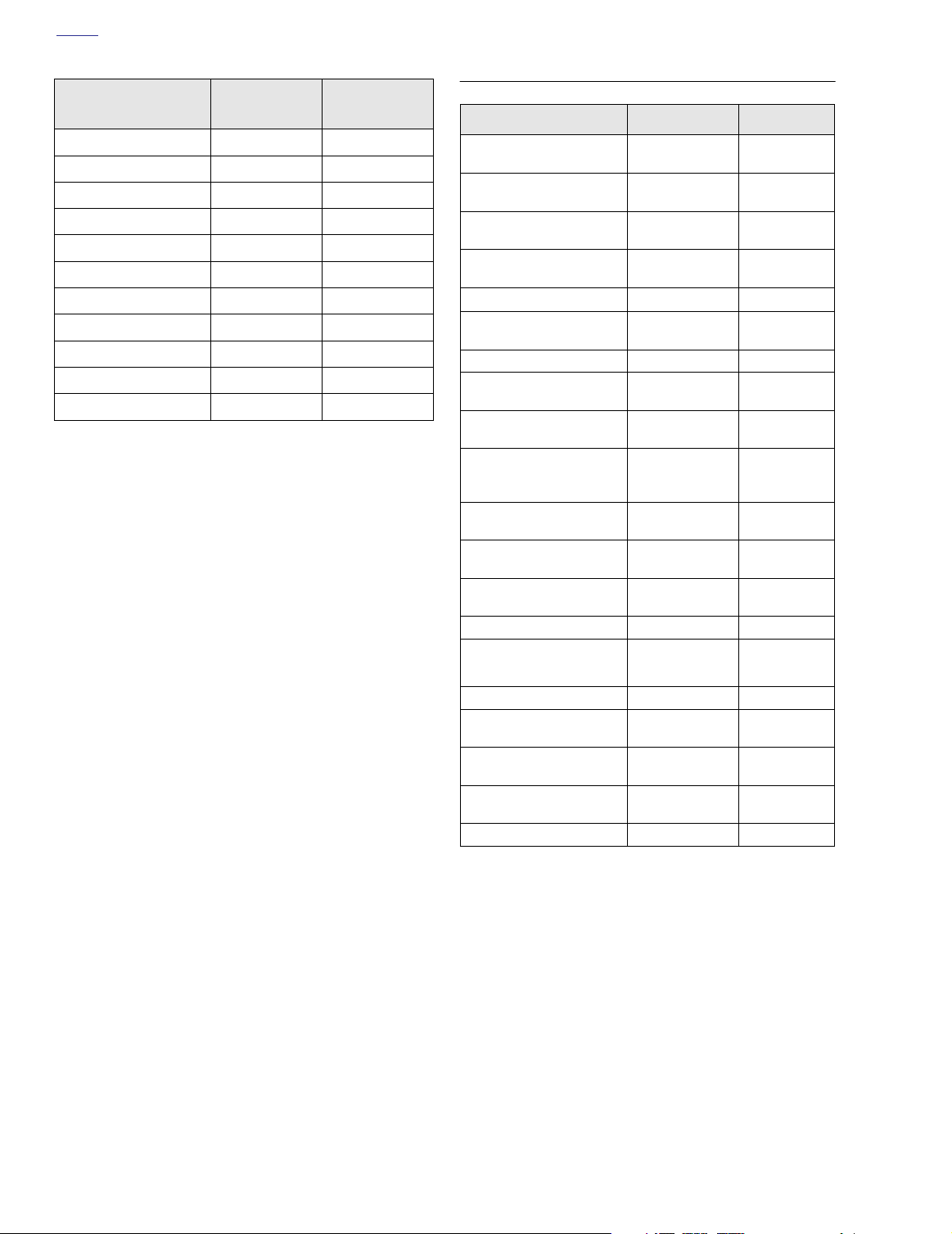

SERVICE WEAR LIMITS (CONT.’D)

COUNTERSHAFT

TOLERANCE

Countershaft runout 0.000-0.003 0.00-0.08

Countershaft end play none none

1st gear clearance 0.0003-0.0019 0.008-0.048

1st gear end play 0.0050-0.0039 0.127-0.099

2nd gear clearance 0.0003-0.0019 0.008-0.048

2nd gear end play 0.0050-0.0440 0.127-1.118

3rd gear clearance 0.0000-0.0080 0.000-0.203

4th gear clearance 0.0000-0.0080 0.000-0.203

4th gear end play 0.0050-0.0390 0.127-0.991

5th gear clearance 0.0000-0.0080 0.000-0.203

5th gear end play 0.0050-0.0040 0.127-0.102

IN. MM

TORQUE VALUES

Item

Shifter linkage rod

locknuts

Detent arm pivot screw

to right support block

Shifter cam support

block screws

Tr an smission top cover

socket head screws

Neutral switch

Clutch release cover

socket head screws

Clutch cable fitting 36-60

Tr an smission lubricant

drain plug

Tr ansmission filler

plug/dipstick

Tr an smission side door

5/16 inch screws

1/4 inch screws

Mainshaft/countershaft

locknuts

Tr an smission mainshaft

sprocket nut

Tr ansmission sprocket

nut lockplate screws

Oil pan bolts 84-108

Tr ansmission-to-engine

mounting bolts

Oil hose cover 84-108

Rear swingarm

bracket bolts

Rear swingarm

pivot shaft locknut

Shifter lever to shifter

shaft socket head screw

Engine oil drain plug 14-21 ft-lbs 19-28 Nm

ft/in-lbs Nm

80-120

in-lbs

84-108

in-lbs

84-108

in-lbs

84-108

in-lbs

120-180

120-144

in-lbs

in-lbs

in-lbs

14-21 ft-lbs 19-28 Nm

25-75

in-lbs

13-16 ft-lbs

84-108

in-lbs

45-55 ft-lbs 61-75 Nm

60 ft-lbs, then

35° to 45°

90-110

in-lbs

in-lbs

15 ft-lbs,

then

30-35 ft-lbs

in-lbs

34-42 ft-lbs 46-57 Nm

40-45 ft-lbs 54-61 Nm

18-22 ft-lbs 24-30 Nm

9.0-13.6 Nm

9.5-12.2 Nm

9-12 Nm

9-12 Nm

13.6-20.3 Nm

13.6-16.3 Nm

4-7 Nm

2.8-8.5 Nm

18-22 Nm

9-12 Nm

81 Nm, then

35° to 45°

10.2-12.4 Nm

9-12 Nm

20.3 Nm,

40.7-47.5 Nm

10-12 Nm

then

7-2 2004 Touring: Transmission

Page 3

HOME

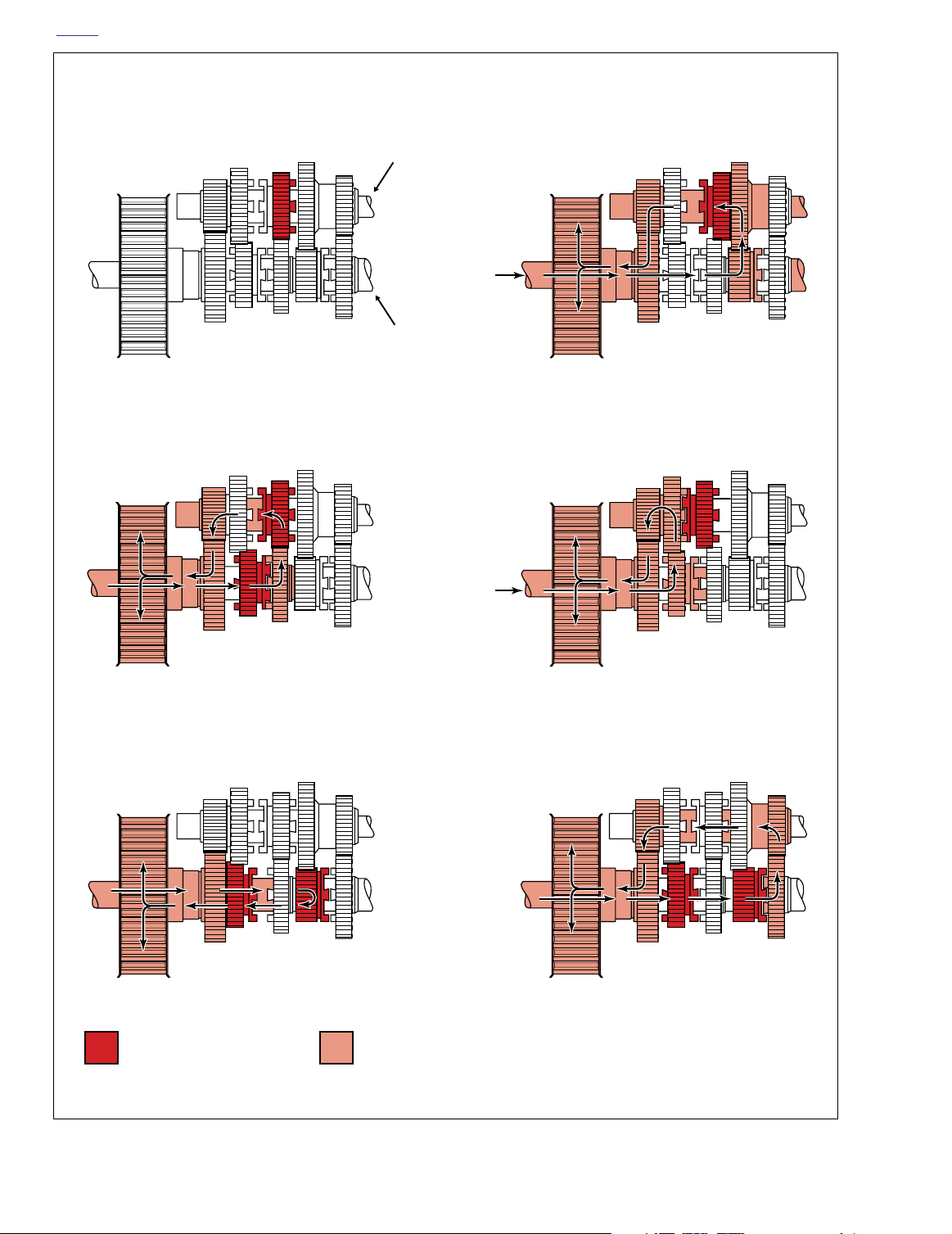

TRANSMISSION POWER FLOW 7.2

GENERAL

See Figure 7-1. The 5-speed transmission consists of two

parallel shafts supporting five gears each. The longer, or

mainshaft, also supports the clutch and serves as the input

shaft. The shorter shaft is called the countershaft.

Each gear on the mainshaft is in constant mesh with a corresponding gear on the countershaft. Each of these five pairs

of gears makes up a different speed in the transmission.

The transmission gears are divided into two types, gears that

are splined and rotate with the shaft, and freewheeling gears

that ride on bearings and spin freely on the shaft. A splined

gear always meshes with a freewheeling gear. Also, three of

the splined gears are able to slide sideways on the shaft.

These sliding gears are used to change transmission

speeds. The projections (or dogs) on the sides of the sliding

gears, engage dogs on adjacent freewheeling gears, transmitting power through the transmission.

Gear shifting is accomplished by three forks which fit into

grooves machined into the hubs of the three sliding gears.

The position of the shifter forks is controlled by a drumshaped shifter cam located on the top of the transmission.

Neutral

Power is introduced to the transmission through the clutch. In

neutral, with the clutch engaged, the mainshaft 1st and 2nd

gears are rotating, but no power is transferred to the countershaft since countershaft 1st and 2nd are freewheeling gears.

4th Gear

The shift into fourth is made when mainshaft 2nd is disengaged from mainshaft 3rd and mainshaft 1st engages mainshaft 4th, locking it to the mainshaft.

5th Gear

The shift from fourth to fifth gear occurs when mainshaft 1st

is shifted out of mainshaft 4th, and mainshaft 2nd is shifted

directly into the main drive gear. Mainshaft 2nd lock the main

drive gear to the mainshaft resulting in a direct one-to-one

drive ratio from the clutch to the sprocket.

1st Gear

When the transmission is shifted into first gear, countershaft

3rd, which rotates with the countershaft, engages countershaft 1st, which has been spinning freely on the countershaft

driven by mainshaft 1st.

Now countershaft 3rd is no longer freewheeling, but locked to

the countershaft causing the countershaft and countershaft

5th to turn. Countershaft 5th transmits the power to the main

drive gear and the sprocket.

2nd Gear

Second gear is engaged when countershaft 3rd is shifted out

of countershaft 1st and engages countershaft 2nd. This locks

countershaft 2nd to the countershaft to complete the power

flow as shown.

3rd Gear

Tw o shifter forks are used to make the shift from second to

third. One fork moves countershaft 3rd out of countershaft

2nd to its neutral position, while another fork engages mainshaft 2nd with mainshaft 3rd. This locks mainshaft 3rd to the

mainshaft to complete the power flow as shown.

2004 Touring: Transmission 7-3

Page 4

HOME

Neutral 1st Gear

4

Countershaft

Mainshaft

In

2

5

Out

2

5

1

3

3rd Gear 2nd Gear

In

52

Out

3

1

4

5

In

2

1

3

3

4

1

4

5th Gear 4th Gear

In

52

3

Sliding Member Power Flow

7-4 2004 Touring: Transmission

Out

1

4

Figure 7-1. Transmission Power Flow Schematic

Out

52

In

3

1

4

Page 5

HOME

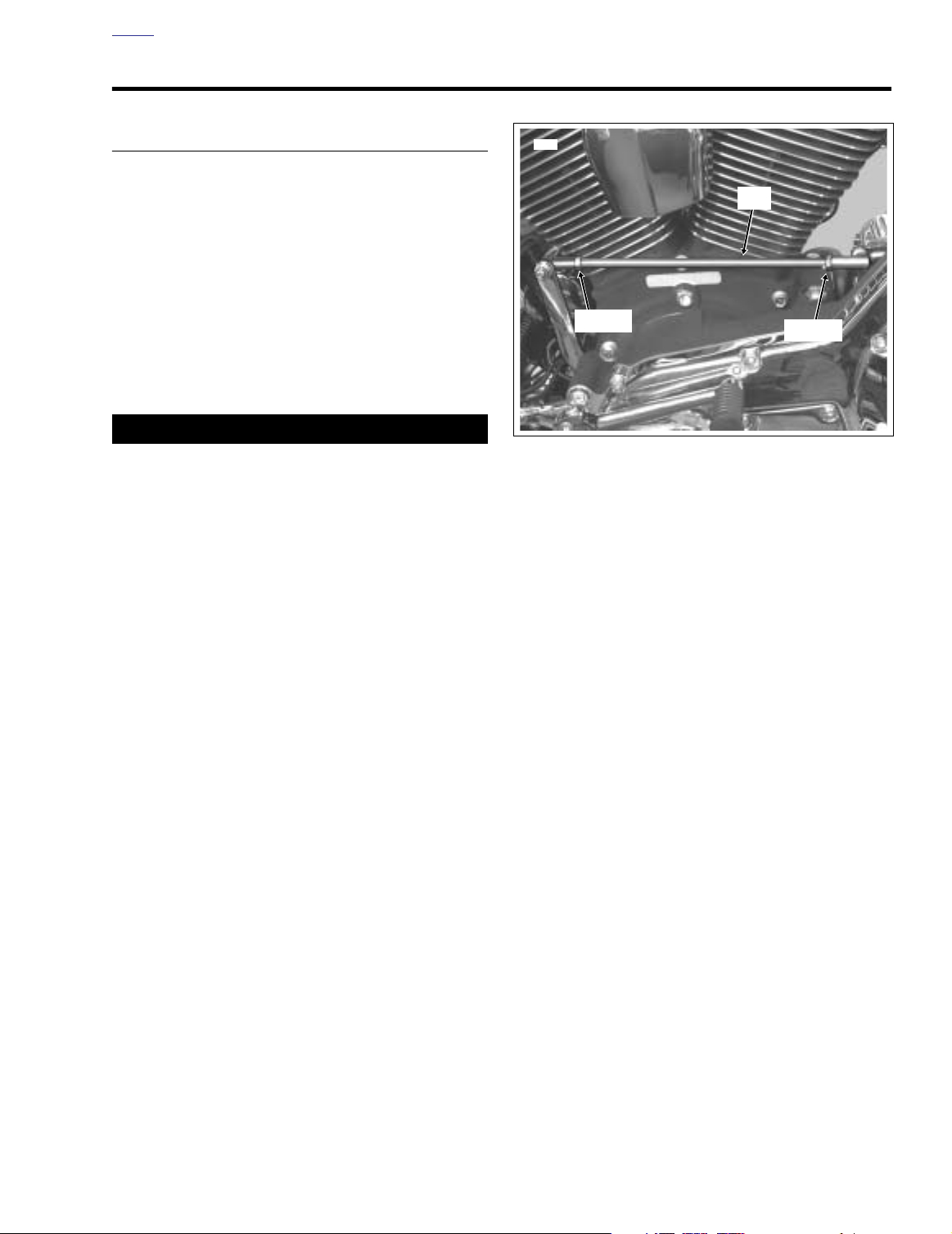

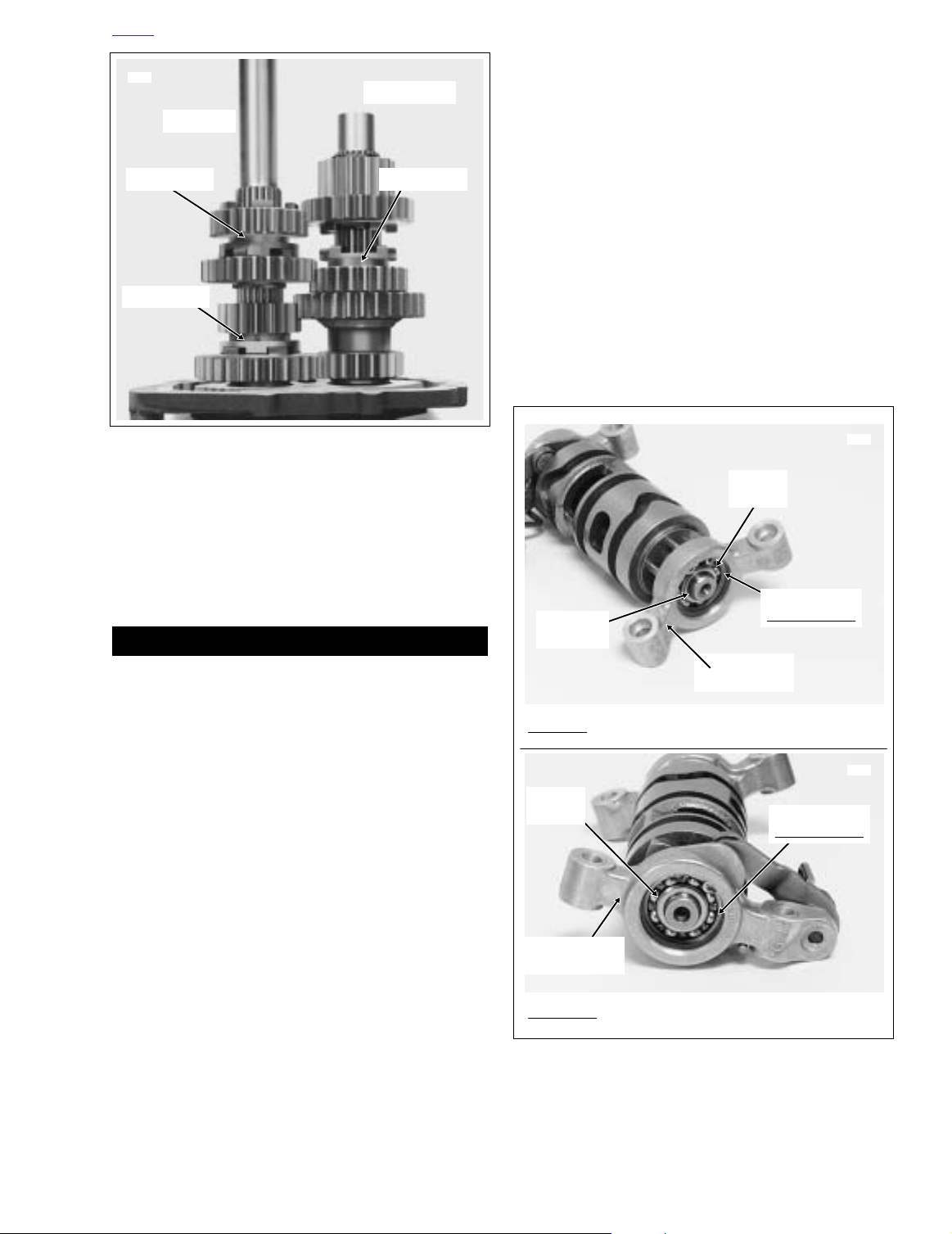

8471

Locknut

Locknut

Rod

SHIFTER LINKAGE 7.3

ADJUSTMENT

If operating problems exist, check the shifter linkage for wear,

interference or adjustment. If adjustment is necessary, see

SHIFTER LINKAGE below. If problems persist, see the

checks under Section 1.1 TROUBLESHOOTING, TRANS-

MISSION, along with the repair procedures in this section.

Shifter Linkage

The shifter linkage is set at the factory and should not need

adjustment under normal circumstances. However, if full

engagement or full lever travel is not achieved, adjust the

linkage rod as follows:

CAUTION

To ensure proper gear engagement and avoid possible

damage to transmission, the shifter lever should not

contact the footboard when shifting. A minimum clearance of 3/8 inch (9.5 mm) between shifter lever and footboard must be maintained to accommodate engine

movement when running.

1. Remove locknut, lockwasher and flat washer to free front

end of shifter rod from shifter lever. See Figure 7-2.

2. Loosen locknuts and adjust rod as necessary.

3. Install flat washer, lockwasher and locknut to fasten front

4. Tighten locknuts to 80-120

Figure 7-2. Shifter Linkage Adjustment

end of shifter rod to shifter lever.

in-lbs

(9.0-13.6 Nm).

2004 Touring: Transmission 7-5

Page 6

HOME

SHIFTER CAM ASSEMBLY/SHIFTER FORKS 7.4

DISASSEMBLY

1. Remove maxi-fuse. See Section 8.3 SYSTEM FUSES,

MAXI-FUSE, REMOVAL.

2. Remove the exhaust system in two sections. See Section 3.7 REMOVING ENGINE FROM CHASSIS, steps 3-

9.

3. Remove the magnetic drain plug at the bottom right side

of the oil pan and drain the transmission lubricant into a

suitable container. Remove the fill plug/dipstick.

4. Using fingers and flat tip screwdriver, remove two elbow

connectors from neutral switch studs. Using 7/8 inch box

end wrench, remove neutral switch and O-ring from

transmission top cover. Remove preformed vent hose

from the top cover fitting, if necessary.

5. Remove the five socket head screws from the transmission top cover. Remove the top cover from the transmission case. Remove and discard the cover gasket.

f1889b7x

CAUTION

Pulling shifter cam assembly from dowels allows left

support block to rotate freely, which can cause screws

and washers to drop into transmission case if left

loosely installed.

6. See Figure 7-3. Remove the four hex head screws (with

flat washers) to free the right and left shifter cam support

blocks. Raise shifter pawl and lift shifter cam assembly

from dowels on deck of transmission case.

7. See CLEANING AND INSPECTION, steps 2 and 3, on

the next page. If necessary, disassemble shifter cam

assembly as follows:

1WARNING1WARNING

Always wear proper eye protection when removing retaining rings. Use the correct retaining ring pliers. Verify

that the tips of the pliers are not damaged or excessively

worn. Slippage may propel the ring with enough force to

cause eye injury.

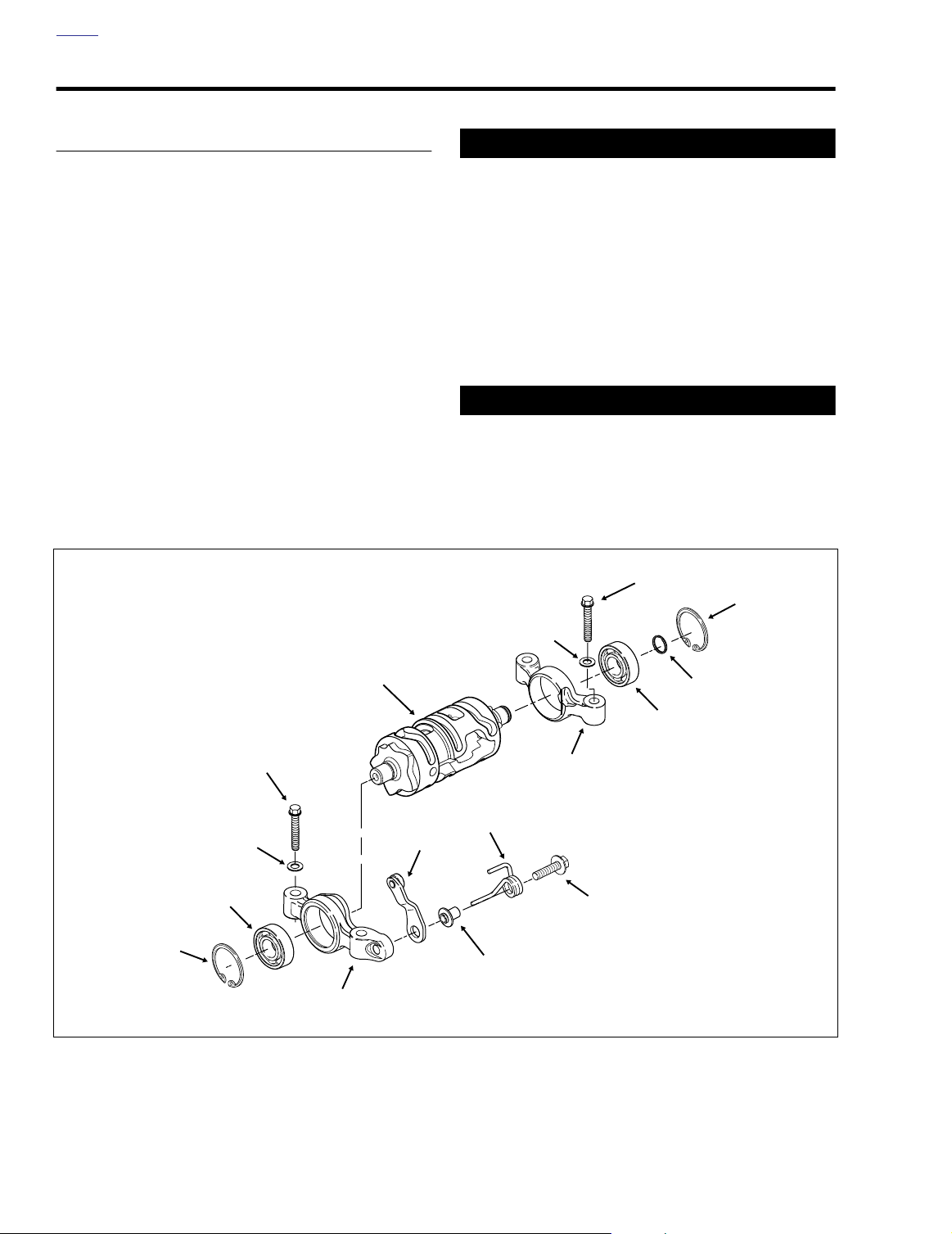

Flat

Washer

Hex Head

Screw

Retaining

Ring

Retaining

Ring

Washer

Roller

Bearing

Hex Head

Screw

Flat

Shifter Cam

Right

Support Block

Figure 7-3. Shifter Cam Assembly

Detent

Arm

Spiral

Lock Ring

Roller

Bearing

Left

Support Block

Spring

Pivot

Screw

Spring

Sleeve

7-6 2004 Touring: Transmission

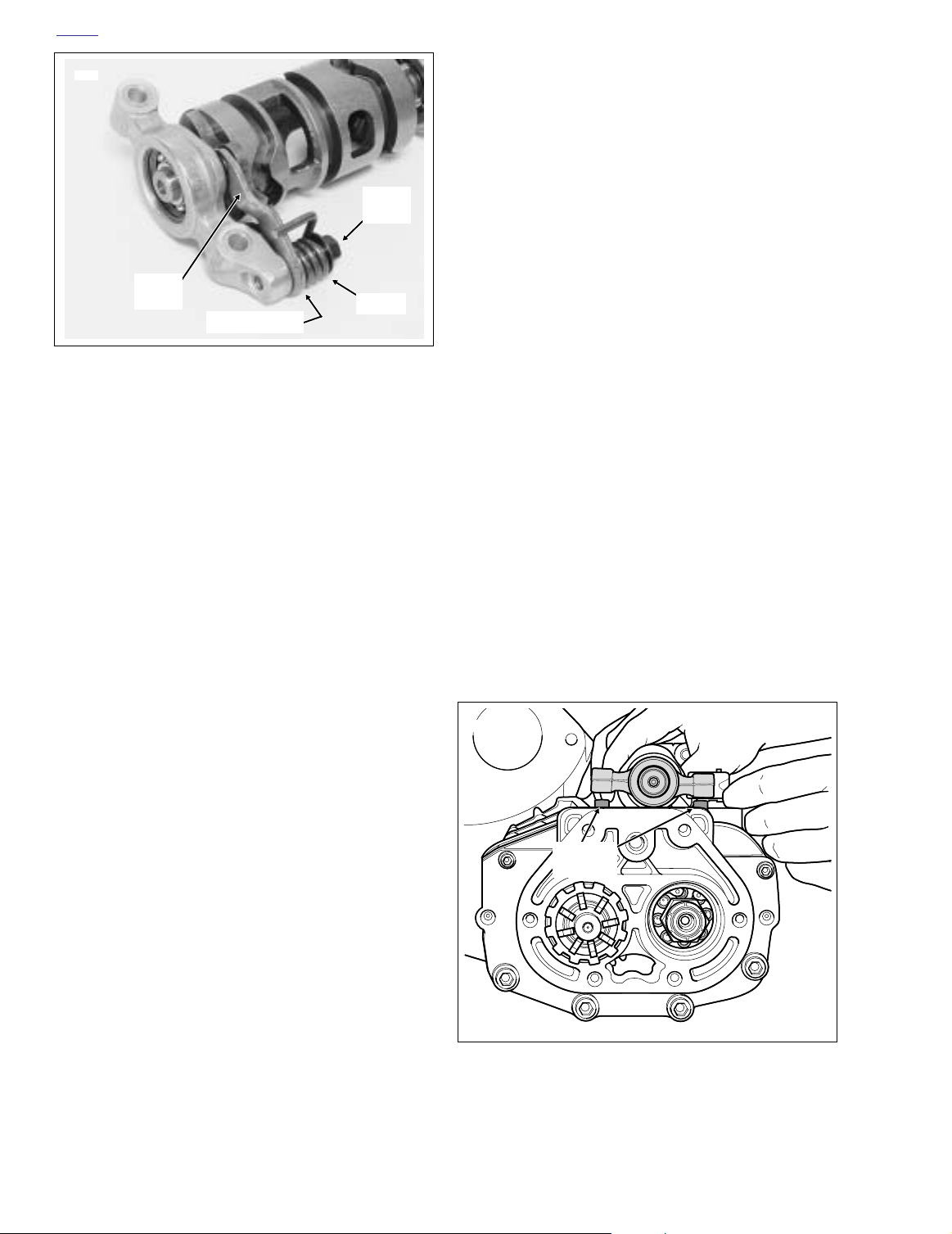

Page 7

HOME

1WARNING1WARNING

f1892x7x

Fork

Shaft

Inner

Ramp

Retaining

Ring

Cable

Fitting

12. Remove the fork shaft from the hole on the right side of

the transmission case. See Figure 7-5. Remove the

shifter forks from the mainshaft and countershaft gear

grooves.

13. To replace the transmission gears or side door bearings,

see Section 7.6 MAINSHAFT/COUNTERSHAFT. To

replace the main drive gear, see Section 7.7 MAIN

DRIVE GEAR.

CLEANING AND INSPECTION

f1896x7x

a. Retract detent arm and slide right support block off

b. Moving to opposite side, remove spiral lock ring

c. Slide left support block off end of shifter cam.

8. Slide rubber boot off clutch cable adjuster. Holding cable

adjuster with 1/2 inch wrench, loosen jam nut using 9/16

inch wrench. Back jam nut away from cable adjuster.

Move adjuster toward jam nut to introduce a large

amount of free play at hand lever.

Coupling

Figure 7-4. Clutch Release Cover Assembly

end of shifter cam. Remove pivot screw to release

detent arm, spring sleeve and spring. Remove and

discard retaining ring. Press against inner race of

roller bearing to remove from support block. Discard

roller bearing.

from groove at left end of shifter cam. Using a small

knife, push on end of spiral lock ring working tip of

blade under edge of ring. Raise end of ring until free

of ring groove. Work around circumference of ring to

alternately pull spirals from ring groove. Discard

ring.

Remove and discard retaining ring. Press against

inner race of roller bearing to remove from support

block. Discard roller bearing.

Clutch Cable

Compressed air can pierce the skin and cause injury.

Never use your hand to check for leaks or to determine

air flow rates. Wear safety glasses to shield your eyes

from flying dirt and debris. Failure to comply could result

in death or serious injury.

1. Clean all parts with solvent (except left and right support

blocks if roller bearings installed). Blow dry with low

pressure compressed air.

2. Inspect roller bearings. Verify that bearings rotate freely

without sticking.

3. Inspect the shifter cam for cracks or wear. Inspect the

ends for grooves or pitting. Install

whenever the shifter cam is replaced.

4. Check the shifter fork shaft. Replace if bent or damaged.

5. Using a small carpenter’s square, verify that the shifter

fork shafts are square. If a fork does not rest directly on

the square, then it is bent and must be replaced. See

Figure 7-6.

new

roller bearings

9. Remove six socket head screws to free clutch release

cover from transmission side door. Remove and discard

gasket.

10. Remove retaining ring and lift inner ramp out of clutch

release cover. Turn the inner ramp over so that ball sockets are facing outboard. Remove hook of ramp from button on coupling. Remove coupling from clutch cable end.

See Figure 7-4.

11. Unscrew the cable fitting from the clutch release cover.

Remove clutch cable and fitting.

Figure 7-5. Remove Fork Shaft/Shifter Forks

(Right Side View)

2004 Touring: Transmission 7-7

Page 8

HOME

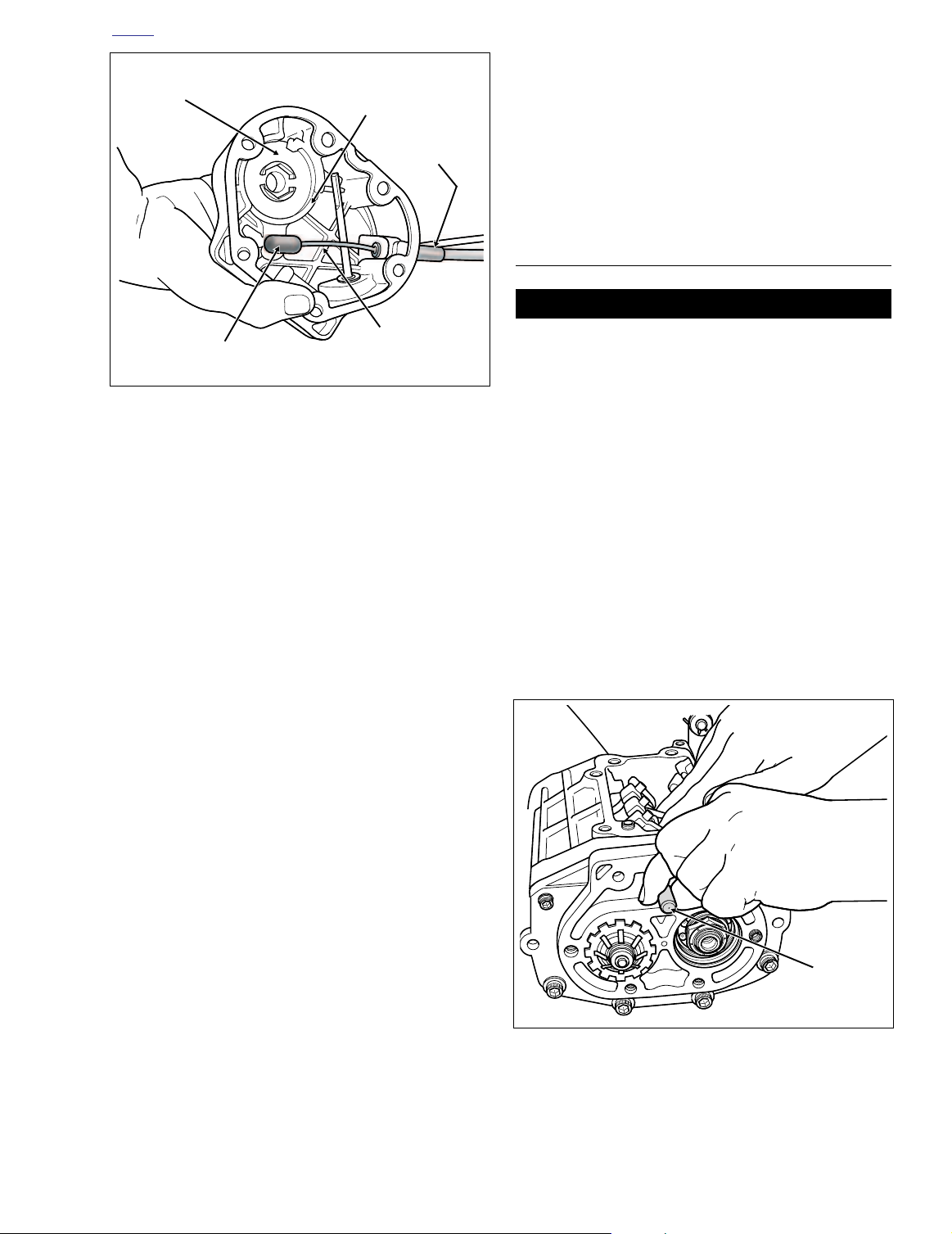

f1888x7x

Carpenter’s

Square

Shifter

Fork

Fork Shaft

Figure 7-6. Check Shifter Forks for Squareness

ASSEMBLY

1. See upper frame of Figure 7-8. Find the shifter fork with

the centered pin. Holding the fork so that the pin is positioned at the rear of the transmission case, install the

fork in the countershaft gear fork groove. See Figure 7-9.

2. Slide the two outer forks into the mainshaft gear fork

grooves so that the pins are positioned on the inside (offset outboard). After installation, the pins of all three forks

should be in alignment.

SHIFTER FORKS

Centered

Shifter

Shaft

Offset

Outboard

Pin

Mainshaft

7976

1

2

3

Right

Side

Left

Side

0.165 in. (4.19 mm)

Minimum

(2 places on each fork)

1. 4th gear shifter fork

2. 1st and 2nd gear shifter fork

3. 3rd and 5th gear shifter fork

f1100bxx

Figure 7-7. Shifter Fork Identification

6. Inspect the shifter forks for wear. With a micrometer or

dial caliper, measure the width of the forks where they

contact the gear fork grooves. Replace any fork that

measures less than 0.165 inch (4.19 mm). See Figure 7-

7.

7. Inspect the neutral switch. Depress plunger and observe

the action. Plunger should spring back without binding.

Switch is non-repairable and must be replaced if defective. See ASSEMBLY, step 11.

Countershaft

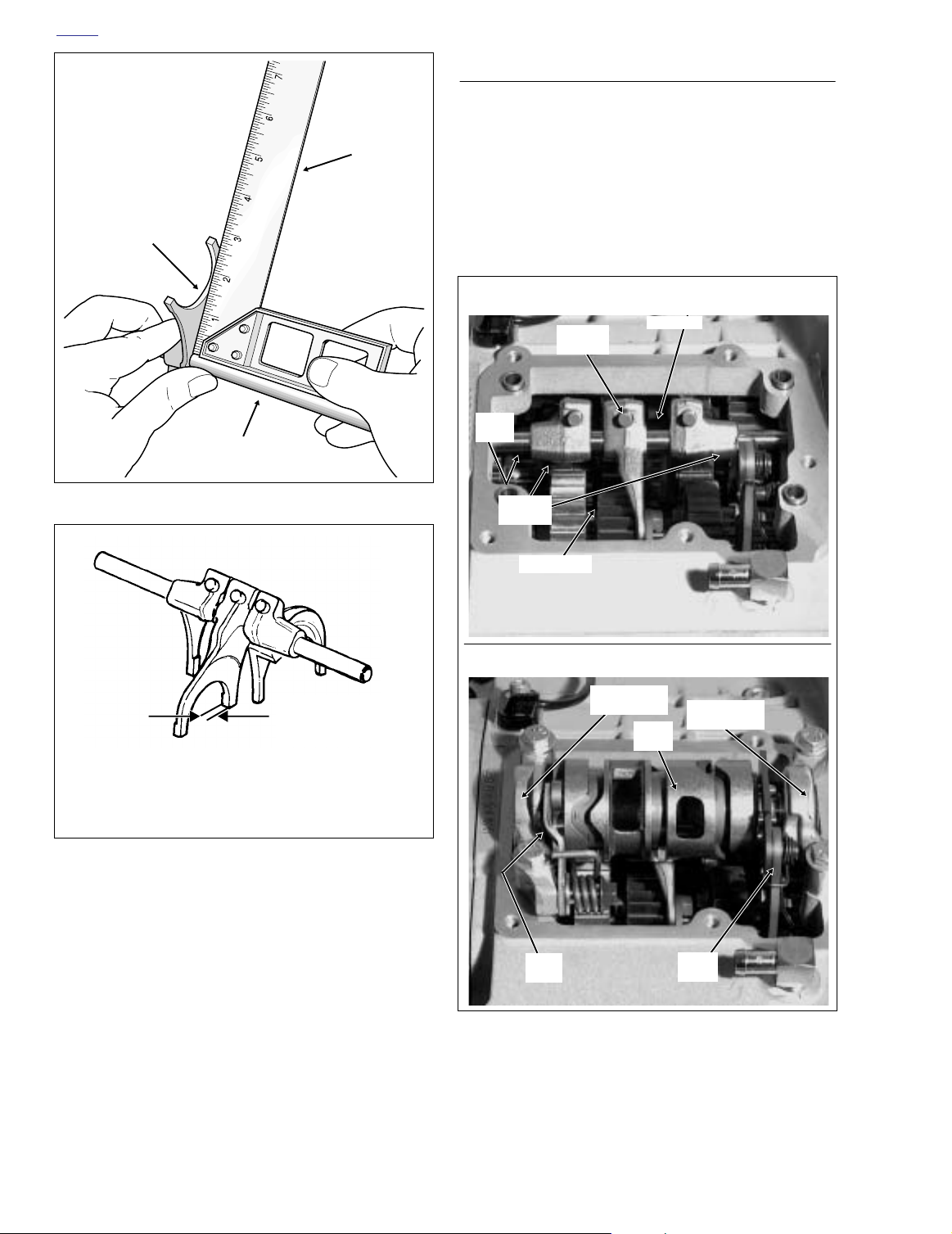

SHIFTER CAM ASSEMBLY

Right

Detent

Arm

Support Block

Shifter

Cam

Left

Support Block

Shifter

Pawl

Figure 7-8. Install Shifter Forks/Shifter Cam

7975

7-8 2004 Touring: Transmission

Page 9

HOME

7410

7411

Left Side

Right Side

Roller

Bearing

Spiral

Lock Ring

Retaining Ring

Beveled Side Out

Left

Support Block

Roller

Bearing

Retaining Ring

Beveled Side Out

Right

Support Block

8256

Countershaft

Mainshaft

Fork Groove

Fork Groove

Fork Groove

Figure 7-9. Shifter Fork Groove Locations

3. Insert the fork shaft into the hole on the right side of the

transmission case. Slide the shaft through the shifter

forks and into the drilling on the left side of the case. See

Figure 7-5.

c. Place right support block under ram of arbor press.

Center

new

roller bearing over bore with the lettered side up. Using a suitable driver, press against

outer race until bearing makes firm contact with the

counterbore. Install

new

retaining ring with the flat

side in against the bearing (beveled side out). See

lower frame of Figure 7-10.

d. Hold spring so that ends are pointing to the right.

Insert long end of spring sleeve into right side of

spring. Insert pivot screw into left side of spring

sleeve. With roller facing screw head, slide detent

arm onto short end of spring sleeve positioning arm

between spring ends. Start pivot screw into

threaded hole in right support block positioning support block between spring ends. Tighten pivot screw

to 84-108

in-lbs

(9.5-12.2 Nm). Retract detent arm

and slide right support block onto end of shifter

cam. See Figure 7-11.

4. Check the sliding movement of the forks and gears. All

parts should move freely without binding.

1WARNING1WARNING

Always wear proper eye protection when installing retaining rings. Use the correct retaining ring pliers. Verify

that the tips of the pliers are not damaged or excessively

worn. Slippage may propel the ring with enough force to

cause eye injury.

5. If disassembled, assemble shifter cam assembly as follows:

a. Place left support block under ram of arbor press.

Center

tered side up. Using a suitable driver, press against

outer race until bearing makes firm contact with the

counterbore. Install

new

roller bearing over bore with the let-

new

retaining ring with the flat

side in against the bearing (beveled side out). See

upper frame of Figure 7-10.

b. Place left support block onto end of shifter cam.

Start bottom end of

new

spiral lock ring into ring

groove. Alternately work around circumference of

ring feeding each spiral into the ring groove a section at a time. When complete, verify that spiral lock

ring is fully seated in the groove.

Figure 7-10. Shifter Cam Assembly

2004 Touring: Transmission 7-9

Page 10

HOME

7411

Pivot

Screw

Detent

Arm

Spring

Spring Sleeve

Figure 7-11. Shifter Cam Assembly

6. To ensure proper location, verify that four locating dowels are in place on the deck of the transmission case.

7. Raise the shifter cam pawl and place the shifter cam

assembly over the locating dowels. See Figure 7-12.

While aligning the holes in the support blocks with the

dowels on the deck of the transmission case, slide the

shifter forks as necessary so that the fork pins engage

the channels in the shifter cam. See lower frame of Fig-

ure 7-8.

8. Hand start the hex head screws (with flat washers) to

fasten the right and left support blocks to the transmission case. Alternately tighten the four support block

screws to 84-108

in-lbs

(9-12 Nm) in a crosswise pat-

tern.

NOTE

Check the gear engagement and clearance in every gear to

make sure assembly and alignment is correct.

9. Obtain a

new

top cover gasket and align the holes with

those in the transmission case. Align the holes in the top

cover with those in the gasket. Install the five socket

head screws and tighten to 84-108

in-lbs

(9-12 Nm).

The long screw is installed in the center hole on the left

side of the top cover.

10. Install preformed vent hose to top cover fitting, if removed.

b. Lubricate O-ring with clean transmission oil.

c. Using 7/8 inch box end wrench, install neutral

switch with O-ring in the transmission top cover.

Tighten to 120-180

in-lbs

(13.6-20.3 Nm).

d. Install the two elbow connectors on neutral switch

studs.

NOTE

The neutral switch is not polarity sensitive, so the elbow connectors can be attached to either stud.

12. See Figure 7-4. Install clutch cable fitting into clutch

release cover. Do not tighten at this time.

NOTE

Replace cable fitting O-ring if damaged or deformed.

13. Hold clutch cable coupling with button facing outboard.

Place cable end in recess of coupling. With ball sockets

facing outboard, place hook of inner ramp on button of

coupling. Holding inner ramp and coupling together, turn

the assembly over. Place inner ramp (ball socket side

down) over balls in outer ramp sockets. Install the retaining ring so that the opening is above and to the right of

the outer ramp tang slot in the clutch release cover.

14. Verify that the two locating dowels are in place on the

transmission side door. Hang a

new

gasket on the dow-

els.

15. Holding clutch release cover in position against transmission side door, install six socket head screws. Alternately tighten screws to 120-144

in-lbs

(13.6-16.3 Nm)

in the sequence shown in Figure 7-13.

16. Tighten clutch cable fitting to 36-60

f1891x7x

in-lbs

(4-7 Nm).

Locating

Dowels

NOTE

Whenever the transmission top cover is removed, be sure to

install neutral switch after top cover installation to ensure

proper switch engagement.

11. Install the neutral switch in the transmission top cover as

follows:

a. Roll the vehicle back and forth to verify that the

transmission is in NEUTRAL.

7-10 2004 Touring: Transmission

Figure 7-12. Place Support Blocks on Locating Dowels

Page 11

HOME

f1893x7x

1

3

5

6

4

2

Figure 7-13. Clutch Release Cover Torque Sequence

17.Check the O-ring on the transmission lubricant drain plug

for tears, cuts or general deterioration. Replace as necessary.

CAUTION

19. Fill the transmission with 20-24 oz. (590-710 ml) of transmission lubricant or until the lubricant level on the dipstick

of the filler plug is at the F(ULL) mark with the motorcycle

in a level, upright position and the filler plug resting on the

threads.

Use only Harley-Davidson SEMI-SYNTHETIC TRANSMISSION LUBRICANT: Part No.’s 99892-84 (quart),

98853-96 (case of quarts), 99891-84 (gallon), or 9885296 (case of gallons).

20. Install the transmission filler plug/dipstick in the clutch

release cover. Tighten the plug to 25-75

in-lbs

(2.8-8.5

Nm).

21. Adjust the clutch cable. See Section 6.3 CLUTCH,

ADJUSTMENT.

22. Install the exhaust system. See Section 3.8 INSTALL-

ING ENGINE IN CHASSIS, steps 46-52.

23. Install maxi-fuse. See Section 8.3 SYSTEM FUSES,

MAXI-FUSE, INSTALLATION.

Do not overtighten filler or drain plugs. Overtightening

plugs may cause leaks.

18. Install the transmission lubricant drain plug and tighten

to 14-21 ft-lbs (19-28 Nm).

2004 Touring: Transmission 7-11

Page 12

HOME

CLUTCH RELEASE COVER 7.5

REMOVAL/DISASSEMBLY

1. Remove maxi-fuse. See Section 8.3 SYSTEM FUSES,

MAXI-FUSE, REMOVAL.

2. Remove the exhaust system in two sections. See Section 3.7 REMOVING ENGINE FROM CHASSIS, steps 3-

9.

3. Remove the magnetic drain plug at the bottom right side

of the oil pan and drain the transmission lubricant into a

suitable container. Remove the filler plug/dipstick.

4. Remove six socket head screws to free clutch release

cover from transmission side door. Depress clutch lever

to break the cover seal, and then remove and discard

gasket.

5. Slide rubber boot off clutch cable adjuster. Holding cable

adjuster with 1/2 inch wrench, loosen jam nut using 9/16

inch wrench. Back jam nut away from cable adjuster.

Move adjuster toward jam nut to introduce a large

amount of free play at hand lever.

1WARNING1WARNING

Always wear proper eye protection when removing retaining rings. Use the correct retaining ring pliers. Verify

that the tips of the pliers are not damaged or excessively

worn. Slippage may propel the ring with enough force to

cause eye injury.

6. Remove retaining ring securing ball and ramp mechanism to clutch release cover.

7. See Figure 7-14. Lift inner ramp out of clutch release

cover. Turn the inner ramp over so that ball sockets are

facing outboard. Remove hook of ramp from button on

coupling. Remove coupling from clutch cable end.

8. Remove balls from outer ramp sockets. Remove outer

ramp from clutch release cover.

9. Unscrew the cable fitting from the clutch release cover.

Remove clutch cable and fitting.

CLEANING AND INSPECTION

1. Wash the ball and ramp components in cleaning solvent.

2. Inspect the three balls and the ball socket surfaces on

both the inner and outer ramps for wear, pitting, surface

breakdown and other damage.

3. Check fit of the inner ramp hub in the outer ramp.

Replace both parts if excessive wear is noted.

4. Inspect the inner/outer ramp retaining ring for damage or

distortion.

7960

Ramp

Connector

Button

Coupling

Cable

End

Recess

Figure 7-14. Clutch Release Cover Assembly

5. See Figure 7-14. Check the recess in the clutch release

cover casting where the inner and outer ramps are

retained. There should be no wear/lips worn into the

bore that would catch the ramps and cock them, causing

improper clutch adjustment.

6. Check clutch cable for damage and frayed or worn ends.

Check cable fitting O-ring for cuts, tears or signs of deterioration.

Balls

Inner

Ramp

Clutch

Release

Cover

Tang

Slot

Ball

Socket

Outer

Ramp

Tang

ASSEMBLY/INSTALLATION

1. Install clutch cable fitting into clutch release cover. Do

not tighten cable fitting at this time.

NOTE

Replace cable fitting O-ring if damaged or deformed.

7-12 2004 Touring: Transmission

Page 13

HOME

CAUTION

8496

Clutch

Release

Cover

Filler

Plug

7957

Clutch

Release

Cover

Coupling

Outer

Ramp

Ball

Socket

Ball in

Socket

Tang

Balls

Inner

Ramp

Figure 7-15. Install Outer Ramp and Balls

8. Holding clutch release cover in position, install six socket

head screws. Tighten screws to 120-144

in-lbs

(13.6-

16.3 Nm) in the sequence shown in Figure 7-13.

9. Tighten clutch cable fitting to 36-60

in-lbs

(4-7 Nm).

10. Check the O-ring on the transmission lubricant drain plug

for tears, cuts or general deterioration. Replace as necessary. Install the transmission lubricant drain plug and

tighten to 14-21 ft-lbs (19-28 Nm).

Do not overtighten filler or drain plugs. Overtightening

plugs may cause leaks.

11. Remove the filler plug from the clutch release cover, if

installed. See Figure 7-16. Check the O-ring for tears,

cuts or general deterioration. Replace as necessary.

See Figure 7-17.

12. Fill the transmission with 20-24 oz. (590-710 ml) of

transmission lubricant or until the lubricant level on the

dipstick of the filler plug is at the F(ULL) mark with the

motorcycle in a level, upright position and the filler plug

resting on the threads.

2. See Figure 7-15. Place outer ramp in clutch release

cover recess with tang in cover slot.

3. Apply a multi-purpose grease to the balls and outer

ramp sockets. Place a ball in each of three outer ramp

sockets.

4. Hold coupling with button facing outboard. Place cable

end in recess of coupling. With ball sockets facing outboard, place hook of inner ramp on button of couplng.

Holding inner ramp and coupling together, turn the

assembly over.

5. Place inner ramp (ball socket side down) over balls in

outer ramp sockets.

1WARNING1WARNING

Always wear proper eye protection when installing retaining rings. Use the correct retaining ring pliers. Verify

that the tips of the pliers are not damaged or excessively

worn. Slippage may propel the ring with enough force to

cause eye injury.

6. Install the retaining ring so that the opening is above and

to the right of the outer ramp tang slot in the clutch

release cover.

7. Verify that the two locating dowels are in place on the

transmission side door. Hang a

els.

new

gasket on the dow-

Use only Harley-Davidson SEMI-SYNTHETIC TRANSMISSION LUBRICANT: Part No.’s 99892-84 (quart),

98853-96 (case of quarts), 99891-84 (gallon), or 9885296 (case of gallons).

13. Install the transmission filler plug/dipstick in the clutch

release cover. Tighten the plug to 25-75

in-lbs

(2.8-8.5

Nm).

14. Adjust the clutch cable. See Section 6.3 CLUTCH,

ADJUSTMENT.

Figure 7-16. Transmission Case (Right Side)

2004 Touring: Transmission 7-13

Page 14

HOME

OMF50

O-Ring

Figure 7-17. Transmission Lubricant Filler Plug/Dipstick

15. Install the exhaust system. See Section 3.8 INSTALL-

ING ENGINE IN CHASSIS, steps 46-52.

16. Install maxi-fuse. See Section 8.3 SYSTEM FUSES,

MAXI-FUSE, INSTALLATION.

7-14 2004 Touring: Transmission

Page 15

HOME

1WARNING1WARNING

7969

Mainshaft

Locknut

Fork

Shaft

Countershaft

Locknut

7970

Side

Door

Rear

Indent

MAINSHAFT/COUNTERSHAFT 7.6

NOTE

Check the eight digit number stamped on the transmission

case just above the side door. If the third digit is “9,” then the

transmission was built for Japan only. If the digit is “0,” then it

was built for all countries except Japan. If servicing a Japanese transmission, follow the steps under REMOVAL below

and then see Appendix D.1 JAPANESE MAINSHAFT/COUN-

TERSHAFT for disassembly and assembly instructions.

REMOVAL

1. Remove the exhaust system in two sections. See Section 3.7 REMOVING ENGINE FROM CHASSIS, steps 3-

9.

2. Remove the shifter cam and shifter fork assemblies. See

Section 7.4 SHIFTER CAM ASSEMBLY/SHIFTER

FORKS, DISASSEMBLY.

3. Remove the primary chaincase cover. Remove clutch

assembly, primary chain, and compensating sprocket

components. Remove the starter jackshaft assembly

and primary chaincase. See Section 6.5 PRIMARY

CHAINCASE, REMOVAL.

4. Remove oil filler spout and starter. See Section 5.4

STARTER, REMOVAL, steps 6-12.

5. Remove the bearing inner race from the transmission

mainshaft. See Section 6.5 PRIMARY CHAINCASE,

MAINSHAFT BEARING INNER RACE, REMOVAL.

6. Remove the oil slinger assembly (with two-piece push

rod and clutch release bearing components).

7. Lock the transmission. This can be accomplished by

manually engaging the shifter dogs of any two gears

(mainshaft or countershaft) with the shifter dogs of an

adjacent gear and then turning the mainshaft counterclockwise.

8. Remove the locknut from both the mainshaft and countershaft. Use an air impact wrench for best results. See

Figure 7-18. Remove the spacer from each shaft.

9. Remove the six socket head screws (bottom four with

flat washers) to free both the side door and transmission

exhaust bracket from the transmission case. Pull the

side door, mainshaft and countershaft from the transmission case as a single assembly. Remove and discard the

door gasket. See Figure 7-19.

DO NOT USE A HAMMER TO REMOVE THE SIDE DOOR.

If the side door sticks or binds on the locating dowels, gently

pry open using the indents at each side of the door. See Fig-

ure 7-19.

10. To remove the main drive gear, refer to Section 7.7 MAIN

DRIVE GEAR, REMOVAL, steps 6-11.

NOTE

Figure 7-18. Remove Mainshaft/Countershaft Locknuts

Figure 7-19. Remove Transmission Side Door

DISASSEMBLY

Always wear proper eye protection when removing retaining rings. Use the correct retaining ring pliers. Verify

that the tips of the pliers are not damaged or excessively

worn. Slippage may propel the ring with enough force to

cause eye injury.

2004 Touring: Transmission 7-15

Page 16

HOME

3559

Figure 7-20. Note Gear Location During Disassembly

NOTE

Use the TRANSMISSION SHAFT RETAINING RING PLIERS, Part No. J-5586, to remove all mainshaft and countershaft retaining rings. Note each gear and its location as it is

removed. See Figure 7-20.

1. Position the assembly on a bench with the side door

down, mainshaft on the left hand side.

2. See A in Figure 7-21. Working from the end of the countershaft toward the side door, remove the retaining ring

from the countershaft.

3. Remove the countershaft 5th gear.

4. Remove the countershaft 2nd gear and thrust washer.

5. See B in Figure 7-21. Gently pull apart the split cage

bearing and remove.

6. Remove the retaining ring and the countershaft 3rd gear.

7. See C in Figure 7-21. Moving to the mainshaft, remove

the mainshaft 2nd gear.

8. See D in Figure 7-21. Remove the upper retaining ring

and thrust washer.

NOTE

For best results, move the lower retaining ring toward the

side door. The mainshaft 3rd gear will move down the shaft

for easy access to the upper retaining ring.

9. Remove the mainshaft 3rd gear.

10. Remove the thrust washer and lower retaining ring.

11. See E in Figure 7-21. Gently pull apart the split cage

bearing and remove.

12. Leave both the mainshaft and countershaft 1st gears

and the mainshaft and countershaft 4th gears on their

respective shafts.

CAUTION

Supporting the gears is necessary to provide support for

the side door bearing inner races. Failure to support the

gears will result in bearing damage.

13. Support the countershaft 1st gear and press out the

countershaft.

14. Remove the mainshaft 1st gear.

15. Support the mainshaft 4th gear and press out the mainshaft.

16. Remove the spacer from the mainshaft. Remove the

mainshaft 4th gear, thrust washer and retaining ring.

Remove the split cage bearing from the mainshaft race.

17. Remove the spacer from the countershaft. Remove the

countershaft 4th gear and the countershaft 1st gear.

Remove the thrust washer and retaining ring. Gently pull

apart the split cage bearing and remove.

CLEANING AND INSPECTION

1. Clean all parts in cleaning solvent and blow dry with

compressed air.

2. Check gear teeth for damage. Replace the gears if they

are pitted, scored, rounded, cracked or chipped.

3. Inspect the engaging dogs on the gears. Replace the

gears if the dogs are rounded, battered or chipped.

4. Inspect the side door bearings. Bearings must rotate

freely without drag. Replace the bearings if pitted or

grooved. Proceed as follows:

a. Remove the retaining rings and press the bearings

out of the side door.

CAUTION

To avoid side door damage, use a flat plate for support

when pressing in new bearings.

b. When installing new bearings, always press on the

bearing OD marked with the number stamp. The

number stamp must face toward the outside surface

of the side door. Use a flat plate to support the

inboard side of the side door at the bearing bores.

NOTE

Note that one side of the retaining rings are beveled. Always

install the ring with the beveled side opposite the bearing.

Side doors using the beveled retaining rings are marked with

a “drill-point” hole between the bearing bores. See Figure 7-

23.

c. Install

new

retaining rings with the flat side in

towards the bearing, the beveled side out.

7-16 2004 Touring: Transmission

Page 17

HOME

AB

Retaining Ring

Countershaft 5th

Countershaft 2nd

Thrust Washer

CD

Split Cage

Bearing Race

Mainshaft 2nd

Retaining Ring

Thrust Washer

Mainshaft 3rd

Split Cage

Bearing

Retaining Ring

Countershaft 3rd

E

Split Cage

Bearing Race

Mainshaft 1st

Mainshaft 4th

Thrust Washer

Retaining Ring

Countershaft 1st

Countershaft 4th

NOTE

Leave the mainshaft and countershaft

1st and 4th gears installed until the

shafts are pressed from the side door.

Figure 7-21. Mainshaft/Countershaft Disassembly

2004 Touring: Transmission 7-17

Page 18

HOME

ASSEMBLY

1WARNING1WARNING

Always wear proper eye protection when installing retaining rings. Use the correct retaining ring pliers. Verify

that the tips of the pliers are not damaged or excessively

worn. Slippage may propel the ring with enough force to

cause eye injury.

1WARNING1WARNING

Always use new retaining rings when assembling the

mainshaft and countershaft. Reusing retaining rings can

cause the transmission to become “locked” during vehicle operation, a situation which could result in death or

serious injury.

NOTE

Use the TRANSMISSION SHAFT RETAINING RING PLIERS, Part No. J-5586, to install all mainshaft and countershaft retaining rings.

8255

1. Install a

side door end of the mainshaft. Slide the thrust washer

onto the side door end of the mainshaft until it contacts

the retaining ring. Lightly coat the split cage bearing with

oil and install in the mainshaft race next to the thrust

washer.

2. See Figure 7-22. Install mainshaft 4th gear over the split

cage bearing with the shifter dogs up. From the opposite

end of the shaft, slide on the mainshaft 1st gear with the

shifter fork groove facing the side door end of the shaft.

3. Install a

side door end of the countershaft. Slide the thrust

washer onto the side door end of the countershaft until it

contacts the retaining ring. Lightly coat the split caged

bearing with oil and install in the countershaft race next

to the thrust washer.

4. See Figure 7-22. Install countershaft 1st gear over the

split caged bearing with the taper on the ID facing down

(flat side up). From the same end of the shaft, slide on

the countershaft 4th gear so that the sleeve contacts the

taper of the countershaft 1st gear.

new

retaining ring in the groove closest to the

new

retaining ring in the groove closest to the

Retaining Ring

Groove

Mainshaft 1st

Shifter Fork Groove

Mainshaft 4th

MAINSHAFT COUNTERSHAFT

Retaining Ring

Groove

Split Cage

Bearing Race

Taper

Countershaft 1st

Sleeve

Countershaft 4th

Shifter Dogs

Figure 7-22. Install Mainshaft and Countershaft 1st and 4th Gears

7-18 2004 Touring: Transmission

Page 19

HOME

7969

Retaining

Ring

Drill Point

Bearing

Locknut

5. See Figure 7-25. Slide the spacers onto the shafts with

the tapered side facing the side door end. Note that the

mainshaft spacer has a shoulder while the countershaft

spacer does not.

CAUTION

Failure to support the inner races while pressing shafts

through the side door bearings will result in bearing

damage.

6. Place the side door in an arbor press. Support the inner

bearing races with a suitable socket. Starting with the

mainshaft, press the shafts into the bearings. With the

shafts properly pressed into the side door, the spacers

will have no end play. Be sure to install the mainshaft to

the left of the fork shaft hole (when viewing the side door

from the top).

7. Install a spacer and locknut on the threaded end of each

shaft and tighten the nuts until finger tight. See Figure 7-

23. Final tightening is performed under INSTALLATION,

steps 4 and 5.

Figure 7-23. Side Door Bearings

8256

Retaining Ring

Thrust Washer

Thrust Washer

Retaining Ring

Retaining Ring

Thrust Washer

Mainshaft 2nd

Mainshaft 3rd

Split Cage Bearing

Mainshaft 1st

Mainshaft 4th

Split Cage Bearing

MAINSHAFT

COUNTERSHAFT

Countershaft 5th

Countershaft 2nd

Split Cage Bearing

Countershaft 3rd

Countershaft 4th

Retaining Ring

Thrust Washer

Retaining Ring

Retaining Ring

Thrust Washer

Countershaft 1st

Split Cage Bearing

Figure 7-24. Completed Side Door Assembly

2004 Touring: Transmission 7-19

Page 20

HOME

f1103axx

1. Side door

2. Gasket

3. Mainshaft spacer

4. Countershaft spacer

5. Mainshaft

6. Countershaft

7. Spacer (2)

8. Locknut (2)

9. Bearings, one-piece

split cage (4)

10. Mainshaft 4th gear

11. Thrust washer (5)

12. Retaining ring (6)

13. Mainshaft 1st gear

14. Countershaft 4th gear

15. Retaining ring

16. Countershaft 1st gear

17. Countershaft 3rd gear

18. Mainshaft 3rd gear

19. Countershaft 2nd gear

20. Thrust washer (2)

21. Countershaft 5th gear

22. Mainshaft 2nd gear

23. Push rod

24. Push rod – left side

25. Clutch release bearing

9

9

20

25

5

12

11

18

22

20

24

15

8

10

3

11

12

23

11

7

12

13

1

2

4

16

14

11

9

12

9

6

19

21

12

17

12

11

Figure 7-25. Side Door, Mainshaft and Countershaft Assembly (Exploded View)

8. See Figure 7-24. Install countershaft 3rd gear with the

shifter fork groove facing opposite the side door.

9. Install a

mainshaft 1st gear. Slide a thrust washer down the

mainshaft until it contacts the retaining ring. Lightly coat

a split caged bearing with oil and install in the mainshaft

race next to the thrust washer. Place mainshaft 3rd gear

over the bearing. Install a second thrust washer and a

new

10. Install a

tershaft 3rd gear. Slide a thrust washer down the countershaft until it contacts the retaining ring. Lightly coat a

split caged bearing with oil and install in the countershaft

race next to the thrust washer. Install the countershaft

2nd gear over the bearing with the shifter dogs facing

the side door end of the shaft.

7-20 2004 Touring: Transmission

new

retaining ring in the groove just above the

retaining ring above the gear

new

retaining ring in the groove above the coun-

11. Slide the countershaft 5th gear down the countershaft

until it contacts the countershaft 2nd gear. Install a

retaining ring in the groove above the countershaft 5th

gear.

12. Install the mainshaft 2nd gear on the shaft with the

shifter fork groove towards the side door.

The final assembly appears as shown in Figure 7-24.

NOTE

Install the main drive gear, if removed. See Section 7.7 MAIN

DRIVE GEAR, INSTALLATION.

new

Page 21

HOME

L = 5/16 Inch S = 1/4 Inch

S

L

7969

4

1

5

L

6

L

2

S

3

L

Figure 7-26. Side Door Screw Size and Torque Sequence

INSTALLATION

1. Verify that the two locating dowels are in place on the

right side of the transmission case. Hang a

on the dowels. Install the assembled side door in the

transmission case. See Figure 7-19.

2. Install the four 5/16 inch screws (with flat washers) to

fasten transmission exhaust bracket and bottom of side

door to the transmission case. Install the two 1/4 inch

screws to fasten the top of the side door to the transmission case. Alternately tighten six screws until snug.

3. Resetting the torque wrench as necessary, tighten the

four 5/16 inch screws to 13-16 ft-lbs (18-22 Nm) and the

two 1/4 inch screws to 84-108

in-lbs

sequence shown in Figure 7-26.

4. Lock the transmission. This can be accomplished by

manually engaging the shifter dogs of any two gears

(mainshaft or countershaft) with the shifter dogs of an

adjacent gear and then turning the mainshaft locknut

counterclockwise.

new

gasket

(9-12 Nm) in the

5. With the transmission locked, tighten the mainshaft and

countershaft locknuts to 45-55 ft-lbs (61-75 Nm). See

Figure 7-23.

6. Install the oil slinger assembly (with two-piece push rod

and clutch release bearing components).

7. Install shifter cam and fork assemblies. See Section 7.4

SHIFTER CAM ASSEMBLY/SHIFTER FORKS,

ASSEMBLY.

8. Install the bearing inner race on the transmission mainshaft. See Section 6.5 PRIMARY CHAINCASE, MAIN-

SHAFT BEARING INNER RACE, INSTALLATION.

9. Install the starter and oil filler spout. See Section 5.4

STARTER, INSTALLATION, steps 1-3 and 5-7.

10. Install the primary chaincase and starter jackshaft

assembly. Install the clutch assembly, primary chain, and

compensating sprocket components. Install the primary

chaincase cover. See Section 6.5 PRIMARY CHAIN-

CASE, INSTALLATION.

11. Install the exhaust system. See Section 3.8 INSTALL-

ING ENGINE IN CHASSIS, steps 46-52.

2004 Touring: Transmission 7-21

Page 22

HOME

MAIN DRIVE GEAR 7.7

REMOVAL

NOTE

Leave the transmission case in the frame unless the case

itself requires replacement. For illustration purposes, some

photographs may show the case removed.

1. Remove the exhaust system in two sections. See Section 3.7 REMOVING ENGINE FROM CHASSIS, steps 3-

9.

2. Remove the shifter cam and shifter fork assemblies. See

Section 7.4 SHIFTER CAM ASSEMBLY/SHIFTER

FORKS, DISASSEMBLY.

3. Remove the primary chaincase cover. Remove the

clutch assembly, primary chain, and compensating

sprocket components. Remove the starter jackshaft

assembly and primary chaincase. See Section 6.5 PRI-

MARY CHAINCASE, REMOVAL.

4. Remove oil filler spout and starter. See Section 5.4

STARTER, REMOVAL, steps 6-12.

5. Remove the bearing inner race from the transmission

mainshaft. See Section 6.5 PRIMARY CHAINCASE,

MAINSHAFT BEARING INNER RACE, REMOVAL.

6. See Figure 7-27. Remove the six socket head screws

(bottom four with flat washers) to free both the side door

and transmission exhaust bracket from the transmission

case. Pull the side door, mainshaft and countershaft

from the transmission case as a single assembly.

Remove and discard the door gasket.

7970

Rear

Indent

Figure 7-27. Remove Transmission Side Door

Side

Door

1WARNING1WARNING

Always wear proper eye protection when removing retaining rings. Use the correct retaining ring pliers. Verify

that the tips of the pliers are not damaged or excessively

worn. Slippage may propel the ring with enough force to

cause eye injury.

NOTE

DO NOT USE A HAMMER TO REMOVE THE SIDE DOOR.

If the side door sticks or binds on the locating dowels, gently

pry open using the indents at each side of the door. See Fig-

ure 7-27.

7. Remove the two socket screws and lockplate to free the

sprocket nut. Remove the sprocket nut. Use an air

impact wrench for best results.

NOTE

The transmission sprocket nut has left handed threads. Turn

the nut clockwise to remove from the main drive gear.

8. Moving to rear wheel, remove E-clip and loosen hex nut

on right side of axle. Moving to left side, turn adjuster

cam in a counterclockwise direction until belt tension is

relieved. Remove the belt from the transmission

sprocket.

9. Remove the transmission sprocket, spacer sleeve, mainshaft oil seal and quad seal.

10. Remove the retaining ring from the roller bearing bore.

11. Pull the main drive gear using HD-35316B, MAIN DRIVE

GEAR REMOVER AND INSTALLER. See instructions

provided with the tool.

12. Using a block of wood and a hammer, remove the roller

bearing from the transmission case. Discard the bearing.

NOTE

Always replace the main drive gear bearing when the main

drive gear is removed. The bearing will be damaged during

the removal procedure.

CLEANING AND INSPECTION

1. Clean all parts in solvent except the transmission case

and needle bearings. Blow dry with compressed air.

7-22 2004 Touring: Transmission

Page 23

HOME

8254

0.080 In. Step

Oil Seal

8253

Inner

Needle

Bearing

0.080 In. Step

Needle

Ram

Bearing

Installer

Outer

0.315 In. Step

Needle

Bearing

Main Drive

Gear

Figure 7-28. Press Clutch Side Needle Bearing into

Main Drive Gear

CAUTION

shown in Figure 7-28. The tool will bottom on the gear

when the correct depth is obtained.

3. Turn over tool and press on oil seal using the 0.080 inch

step (garter spring side toward main drive gear). See

Figure 7-29.

NOTE

An alternative method is provided which allows the oil seal to

be pressed into place after installation of the main drive gear.

For detailed information, see Section 7.7 MAIN DRIVE

GEAR, INSTALLATION, step 14.

4. See Figure 7-30. Tur n over the main drive gear in the

arbor press. Using the step a second time (0.080 inch

step), press in inner (transmission side) needle bearing.

8252

The transmission case and needle bearings must not be

cleaned. Normal cleaning methods will wash dirt or other

contaminants into the bearing case (behind the needles)

and lead to bearing failure.

2. When replacing seals, lightly coat outside diameter of

seal with Loctite RETAINING COMPOUND No. 609.

3. Inspect the main drive gear for pitting and wear. Replace

if necessary.

4. Replace the sprocket if the teeth are rounded or damaged.

5. Inspect the needle bearings on the inside of the main

drive gear. If the mainshaft race surface appears pitted

or grooved, replace the needle bearings.

Needle Bearing Replacement

NOTE

If the main drive gear needle bearings and/or oil seal need to

be replaced, proceed as follows.

1. Remove old oil seal and needle bearings.

NOTE

To install the main drive gear needle bearings and seal, use

the INNER/OUTER MAIN DRIVE GEAR NEEDLE BEARING

and SEAL INSTALLER, Part No. HD- 37842A.

Figure 7-29. Press Oil Seal on Main Drive Gear

2. Install outer (clutch side) needle bearing using an arbor

press and the 0.315 inch step end of tool HD-37842A as

Figure 7-30. Press Transmission Side Needle

Bearing into Main Drive Gear

2004 Touring: Transmission 7-23

Page 24

HOME

Figure 7-31. Main Drive Gear Large Oil Seal Installer

(Part No. HD-41496)

f2273x7x

Transmission

Case

Right Side View

Main Drive

Gear

f1172a6x

Mainshaft

Oil Seal

Spacer

Sleeve

Lockplate

Sprocket

Nut

Quad Seal

Figure 7-33. Final Drive Sprocket Locking Tool

(Part No. HD-41184)

Transmission

Sprocket

Sprocket

Locking Tool

Pivot Shaft

f1855x7x

f1856x7x

Transmission

Sprocket

Lubricate

Contact Surfaces

Socket

Screw

Figure 7-32. Install Transmission Sprocket Components

INSTALLATION

1. Install new main drive gear bearing using the MAIN

DRIVE GEAR REMOVER/INSTALLER (Part No. HD35316B). To prevent damage, always apply force to the

bearing outer race during installation. Install a new

retaining ring with the beveled side out and the 90°

opening facing the rear. See inset of Figure 7-32. Install

the main drive gear in the transmission case using the

special tool.

2. Verify that the two locating dowels are in place on the

right side of the transmission case. Hang a new gasket

on the dowels. Inserting the mainshaft through the main

Sprocket

Nut

Sprocket

Locking Tool

Figure 7-34. Install Final Drive Sprocket Locking Tool

drive gear, place the side door against the case. Tighten

the 5/16 inch mounting screws to 13-16 ft-lbs (18-22

Nm). Tighten the 1/4 inch screw to 84-108 in-lbs (9-12

Nm).

7-24 2004 Touring: Transmission

Page 25

HOME

Wrench

Pilot

f1857x7x

f1858x7x

Sprocket

Nut

Pilot

Torque

Wrench

Mainshaft

Locknut

Wrench

3. With the garter spring side out (toward the transmission

case), place a new seal on lip of MAIN DRIVE GEAR

LARGE OIL SEAL INSTALLER (Part No. HD-41496).

See Figure 7-31. Slide the tool over the mainshaft so

that it is positioned squarely over the bearing bore in the

transmission housing. Hand press the seal into the bore;

a rubber mallet may be used to lightly tap the driver, if

necessary. Install the quad seal. See Figure 7-32.

4. Apply a small amount of the appropriate H-D transmission lubricant to outside diameter of spacer sleeve.

5. Install spacer sleeve on the main drive gear with chamfer facing inboard. Install the transmission sprocket.

Install the belt on the sprocket as the sprocket is

installed on the main drive gear.

6. Install the sprocket nut. The procedure is based on

whether a new or used nut is being installed.

CAUTION

Exercise caution to avoid getting oil on the threads of

the sprocket nut or the integrity of the lock patch may be

compromised.

New sprocket nut: smear a small quantity of clean

engine oil on the inside face of both the sprocket nut and

the sprocket. Limit the application to where the surfaces

of the two parts contact each other. Install the sprocket

nut until finger tight.

Figure 7-35. Mainshaft Locknut Wrench/Pilot

(Part No. HD-94660-37B )

NOTE

The transmission sprocket nut has left handed threads. Turn

the nut counterclockwise to install on the main drive gear.

Used sprocket nut: apply Loctite 262 (red) to the

threads of the sprocket nut. Also smear a small quantity

of Loctite or clean engine oil on the inside face of both

the sprocket nut and the sprocket. Limit the application

to where the surfaces of the two parts contact each

other. Install the sprocket nut until finger tight.

7. Lock transmission sprocket with FINAL DRIVE

SPROCKET LOCKING TOOL, Part No. HD-41184. See

Figure 7-33. Insert handle of tool below pivot shaft

inboard of bottom frame tube and attach to sprocket.

Snug thumbscrew to lock position of tool on sprocket.

See Figure 7-34.

8. Install pilot of MAINSHAFT LOCKNUT WRENCH (Part

No. HD-94660-37B) on threaded end of mainshaft. See

Figure 7-35. Slide sleeve of locknut wrench over pilot

and onto sprocket nut. Tighten sprocket nut to 60 ft-lbs

(81 Nm). As the nut is tightened the handle of the

sprocket locking tool rises to contact the pivot shaft,

thereby preventing sprocket/mainshaft rotation. See Fig-

ure 7-36.

9. Scribe a straight line on the transmission sprocket nut

continuing the line over onto the transmission sprocket

as shown in Figure 7-37. Tighten the transmission

sprocket nut an additional 35° to 40°.

Figure 7-36. Install Mainshaft Locknut Pilot/Wrench

and Torque Sprocket Nut

10. Install lockplate over nut so that two diagonally opposite

holes align with two tapped holes in sprocket. To find the

best fit, lockplate can be rotated to a number of positions

and can be placed with either side facing sprocket.

2004 Touring: Transmission 7-25

Page 26

HOME

Sprocket Nut

f1977x6x

45°

35°

Transmission

Sprocket

Scribe Line

on Nut and Sprocket

Figure 7-37. Tighten/Secure Sprocket Nut

11. If holes in lockplate do not align with those in sprocket,

tighten sprocket nut as necessary (up to the 45° maximum) until sprocket and lockplate holes are in alignment. See Figure 7-37.

CAUTION

Maximum allowable tightening of sprocket nut is 45° of

counterclockwise rotation after a torque of 60 ft-lbs (81

Nm). Do not loosen sprocket nut when attempting to

align holes.

12. Insert two socket head screws through lockplate into

sprocket holes. Tighten screws to 90-110 in-lbs.

NOTE

The socket head screws have a thread locking compound

that allows them to be reused up to three times. The fourth

time the screws are removed, replace with new screws (H-D

Part No. 3594).

Seal Protector

Sleeve

Driver

Figure 7-38. Main Drive Gear Seal Installer

(Part No. HD-41405 )

f1853x7x

Oil Seal

Seal Protector

Sleeve

Figure 7-39. Slide Protector Sleeve/Oil Seal on Mainshaft

f1854x7x

Seal

Driver

13. Adjust the belt tension and complete installation of rear

wheel. See Section 6.4 SECONDARY DRIVE BELT

AND SPROCKETS, ADJUSTMENT, steps 6-10.

14. If the main drive gear oil seal was not installed with the

needle bearings (or if a faulty seal is discovered with the

main drive gear installed in the transmission case), an

alternative method is provided using the MAIN DRIVE

GEAR SEAL INSTALLER, HD-41405. See Figure 7-38.

NOTE

If a serviceable seal is already installed, proceed to step 15.

To install the oil seal with the main drive gear in the

transmission case, proceed as follows:

a. Verify that the garter spring is in place on the lip of

the oil seal.

7-26 2004 Touring: Transmission

Figure 7-40. Install Oil Seal Using Driver

b. Place the seal protector sleeve over the end of the

mainshaft. Lightly lubricate the protector sleeve and

seal ID with clean transmission oil.

c. Squarely seat the oil seal on the seal protector

sleeve with the garter spring facing the transmission

case. See Figure 7-39.

Page 27

HOME

d. Using the seal driver, hand press the seal onto the

mainshaft. A rubber mallet may be used to lightly

tap the driver, if necessary.

15. Install the bearing inner race on the transmission mainshaft. See Section 6.5 PRIMARY CHAINCASE, MAIN-

SHAFT BEARING INNER RACE, INSTALLATION.

16. Install shifter cam and fork assemblies. See Section 7.4

SHIFTER CAM ASSEMBLY/SHIFTER FORKS,

ASSEMBLY.

17. Install the starter and oil filler spout. See Section 5.4

STARTER, INSTALLATION, steps 1-3 and 5-7.

18. Install the primary chaincase and starter jackshaft

assembly. Install the clutch assembly, primary chain, and

compensating sprocket components. Install the primary

chaincase cover. See Section 6.5 PRIMARY CHAIN-

CASE, INSTALLATION.

19. Install the exhaust system. See Section 3.8 INSTALL-

ING ENGINE IN CHASSIS, steps 46-52.

Countershaft Needle Bearing Replacement

1. Find a suitable bearing driver 1-1/4 inch (31.75 mm) in

diameter.

2. From the outside of the transmission case place the needle bearing open end first next to the bearing bore. Hold

the driver squarely against the closed end of the bearing

and tap the bearing into place. The bearing is properly

positioned when it is driven inward flush with the outside

surface of the case or to a maximum depth of 0.030 inch

(0.76 mm).

3. Lubricate the bearing with TransLube.

2004 Touring: Transmission 7-27

Page 28

HOME

TRANSMISSION CASE/OIL PAN 7.8

GENERAL

The transmission case and oil pan can be removed as an

assembly if the transmission case must be replaced.

If necessary, the oil pan can be removed without removing

the transmission case. Once the rear wheel is removed, the

oil pan can be slid out from the rear.

f2267x7x

12

9

11

10

6

5

8

7

4

2

5

5

1

3

24

17

6

REMOVAL

Transmission Case and Oil Pan

1. See Figure 7-41. Remove both the engine oil and transmission lubricant drain plugs from the oil pan. Drain the

fluids into suitable containers.

2. Remove the mainshaft and countershaft assemblies.

See Section 7.6 MAINSHAFT/COUNTERSHAFT,

REMOVAL.

13

14

15

16

18

19

20

1. Screw

2. Screw

3. Oil hose cover

4. Oil hose (2)

5. Hose clamp (6)

6. Straight fitting (3)

7. Crankcase

breather hose

8. Screw (4)

9. Oil filler cap/dipstick

10. Oil filler spout

11. Filler spout gasket

12. Transmission

housing

13. Dowel pin

14. Bolt (4)

15. Washer (4)

16. Ring dowel

17. Baffle spring

18. Serpentine baffle

19. Oil pan gasket

20. Oil pan

21. O-ring (2)

22. Magnetic plug (2)

23. Pipe plug

24. Screw (12)

7-28 2004 Touring: Transmission

Transmission

Drain Plug

Figure 7-41. Transmission Case and Oil Pan

21

22

23

22

21

Engine Oil

Drain Plug

Page 29

HOME

8

6

2

3

9

11

5

1

4

10

12

7

f1677x3x

RIGHT

SIDE

LEFT

SIDE

Transmission

Drain Plug

Engine Oil

Drain Plug

7968

Centering

Screw

Washer

Retaining

Ring

Splined

Shifter Shaft

Figure 7-42. Shifter Pawl Centering Screw

Shifter

Lever Spring

Shifter

Pawl

Slot

7. Using a side cutters, cut and remove clamps on transmission side of oil supply and return hoses. Pull hoses

from fittings on transmission housing.

8. Cut and remove clamp on transmission side of crankcase breather hose. Pull hose from fitting on oil filler

spout.

9. Remove four bolts (with flat washers) to free front of

transmission from rear of crankcase. Loosen and

remove bolts in a crosswise pattern. Move transmission

rearward until two ring dowels in lower flange are free of

crankcase.

NOTE

If the main drive gear was not removed from the transmission

case, then it may be removed at this time. See Section 7.7

MAIN DRIVE GEAR, REMOVAL.

10. Remove the transmission case from the right side of the

vehicle.

NOTE

If removal is difficult, remove the twelve socket head bolts to

separate the oil pan from the transmission case. For best

results, use a long 3/16 inch ball hex socket driver. Holes in

the lower frame crossmember allow access to bolts which

would not otherwise be accessible.

Splined

Centering

Spring

Shifter Shaft

Perform the following procedure if only the oil pan must be

removed.

7967

Figure 7-43. Shifter Pawl Assembly

1. See Figure 7-44. Remove both the engine oil and transmission lubricant drain plugs from the oil pan. Drain the

fluids into suitable containers.

3. Remove rear wheel and rear swingarm. See Section

2.20 REAR SWINGARM, REMOVAL.

NOTE

The main drive gear and bearing may be removed with the

transmission case in the frame. See Section 7.7 MAIN

DRIVE GEAR, REMOVAL.

4. Remove the socket screw from the shifter lever. Remove

the lever from the splined end of the shifter shaft. Mark

splines on shaft and lever as they are removed to assist

in assembly. See Figure 7-42.

5. Using a T50 TORX drive head, turn the centering screw

out until it clears the centering spring slot of the shifter

pawl assembly. Remove the retaining ring and flat

washer from the splined end of the shifter shaft. See Fig-

ure 7-43. Push on end of shaft to free shifter pawl

assembly from transmission case.

6. Remove two allen head socket screws to release oil

hose cover. See Figure 7-41.

Figure 7-44. Oil Pan Torque Sequence

NOTE

Oil Pan Only

2004 Touring: Transmission 7-29

Page 30

HOME

2. Install lifting strap around frame backbone, and using

overhead jack, support vehicle from the top.

3. Remove rear wheel. See Section 2.4 REAR WHEEL,

REMOVAL.

4. With a long 3/16 inch ball hex socket driver (Snap-On

stock number FABL6 or equal), remove the twelve

socket head bolts from the bottom of the oil pan.

NOTE

Holes in the frame crossmember allow access to bolts which

would not otherwise be accessible.

CAUTION

Remove the engine oil dipstick before attempting to

slide the oil pan rearward. Contact with the oil pan will

result in damage to the dipstick.

5. Slide oil pan rearward and remove from underside of

transmission.

CLEANING AND INSPECTION

1. Clean all parts in solvent except the transmission case

and needle bearings. Blow dry with compressed air.

CAUTION

The transmission case and needle bearings must not be

cleaned. Normal cleaning methods will wash dirt or other

contaminants into the bearing case (behind the needles)

and lead to bearing failure.

2. Inspect the shifter pawl and centering spring for wear.

Replace lever assembly if pawl ends are damaged.

Replace centering spring if elongated.

3. Inspect the shifter lever spring. Replace the spring if it

fails to hold the pawl on the cam pins.

4. Thoroughly clean the oil pan with solvent, if removed.

5. Inspect the hoses for nicks, cuts or general deterioration.

Replace as necessary. Used compressed air to verify

that hoses and fittings are unobstructed.

INSTALLATION

Oil Pan Only

NOTE

The following procedure describes installation of the oil pan

with the transmission case mounted in the motorcycle frame.

Follow the applicable steps to install the oil pan with the

transmission case removed from the motorcycle frame.

1. Coat gasket surface of oil pan with a thin coat of HYLO-

MAR® gasket sealer.

2. Place gasket on oil pan and allow sealer to dry until

tacky.

3. It is normal for the baffle springs to hold the oil pan away

from transmission housing. Use a long screwdriver to

compress the springs as the pan enters the housing.

Exercise caution to avoid cocking or distorting the

springs.

4. Position oil pan under transmission and install the twelve

oil pan bolts, but only tighten about two turns after initial

thread engagement.

CAUTION

Inspect the oil pan gasket to ensure that gasket is properly positioned. If gasket was moved out of position,

remove bolts and repeat step 3 to ensure that gasket is

properly positioned.

5. Tighten the oil pan bolts to 84-108 in-lbs (9-12 Nm) following the numerical sequence shown in Figure 7-44.

6. Install rear wheel. See Section 2.4 REAR WHEEL,

INSTALLATION.

7. Remove lifting strap to release frame backbone from

overhead jack.

Transmission Case and Oil Pan

NOTE

If the main drive gear was assembled prior to mounting of the

transmission, place belt on transmission sprocket as transmission is placed in position.

1. From right side of vehicle, place the transmission case

(with oil pan) in the motorcycle frame. Move transmission forward until two ring dowels in lower flange fully

engage holes in crankcase. Support the engine and

transmission, so that they do not sag at their mating surfaces.

2. Install the transmission-to-engine mounting bolts as follows:

a. Using a crosswise pattern, hand tighten

(with flat washers) to secure transmission housing

to rear of crankcase.

b. Alternately tighten the four bolts to 15 ft-lbs (20.3

Nm) in the same crosswise pattern.

NOTE

For best results, use Open End Crowfoot (Snap-On FC018)

on upper left and upper right transmission housing to

crankcase bolts.

c. Repeating the pattern again, final tighten the four

bolts to 30-35 ft-lbs (40.7-47.5 Nm).

3. Slide new clamps onto free ends of oil supply and return

hoses. See Figure 7-41. Install hoses onto transmission

fittings. Crimp clamps using the Hose Clamp Pliers (HD-

41137).

four bolts

7-30 2004 Touring: Transmission

Page 31

HOME

f1894x7x

Figure 7-45. Shifter Pawl Assembly

4. Slide new clamp onto free end of crankcase breather

hose. Install hose onto fitting of oil filler spout. Crimp

clamp using HOSE CLAMP PLIERS (HD-97087-65B).

10. Install the primary chaincase and starter jackshaft

assembly. Install clutch assembly, primary chain, and

compensating sprocket components. Install the primary

chaincase cover. See Section 6.5 PRIMARY CHAIN-

CASE, INSTALLATION.

11. Install rear swingarm and rear wheel. Adjust belt tension. See Section 2.20 REAR SWINGARM, INSTALLA-

TION.

12. Install engine oil drain plug and tighten to 14-21 ft-lbs

(19-28 Nm).

13. Add engine oil. See Section 3.3 GENERAL INFORMA-

TION, CHANGING ENGINE OIL AND FILTER, steps 9-

12.

5. Install two allen head socket screws (with captive washers) to secure oil hose cover to transmission and engine

housings. Longer screw goes to engine housing. Alternately tighten screws to 84-108 in-lbs (10-12 Nm).

6. Slide splined end of shifter shaft through sleeved bore

until it protrudes from left side of case. Install flat washer

and retaining ring on splined end of shaft. Hold the

shifter pawl assembly inside the transmission case so

that the centering spring slot is aligned with the centering screw. Using a T50 TORX drive head, tighten centering screw until snug. See Figure 7-45.

7. Install the shifter lever onto the splined end of the shifter

shaft taking note to align marks placed on splines during

disassembly. Install socket head screw and tighten to

18-22 ft-lbs (24-30 Nm). Make sure screw registers in

slot of shifter lever.

8. Install the mainshaft and countershaft assemblies. See

Section 7.6 MAINSHAFT/COUNTERSHAFT, INSTAL-

LATION.

9. Install belt on transmission sprocket.

2004 Touring: Transmission 7-31

Page 32

HOME

NOTES

7-32 2004 Touring: Transmission

Loading...

Loading...