Page 1

H

OME

SPECIFICATIONS 6.1

OVERALL GEAR RATIOS

Overall gear ratios indicate the number of engine revolutions

required to drive the rear wheel one revolution.

Gear

All Models

1 10.11

2 6.96

3 4.95

4 3.86

5 3.15

CHAINS AND BELTS

Primary Chain Adjustments

Free Play

COLD Engine

Inches Millimeters

5/8-7/8 inch 15.9-22.2 mm

SPROCKETS

Number of Teeth

Sprocket

Engine 25

Clutch 36

Tr ansmission 32

Rear wheel 70

All Models

CLUTCH

Clutch

Ty pe Wet-multiple disc

Clutch lever free play

Clutch screw adjustment

Description

1/16-1/8 in.

1.6-3.2 mm

loosen 1/2-1 turn after

lightly seating

HOT Engine

3/8-5/8 inch 9.5-15.9 mm

Primary Chaincase Lubricant

Ounces Milliliters

Amount

32 946

Quart Gallon

Part Number

99887-84 99886-84

Rear Belt Adjustment

Deflection

On Jiffy Stand Without

Rider or Luggage

10 psi (69 kPa)

in Rear Shocks

Motorcycle Upright

With Rear Wheel

in the Air

Inches Millimeters

1/4 - 5/16

at 10 lbs force

3/16 - 1/4

at 10 lbs force

6.4 - 7.9

at 4.5 kg force

4.8 - 6.4

at 4.5 kg force

TORQUE VALUES

Item

Primary chain tensioner

shoe nut

Te nsioner shoe adjuster

plate screws

Primary chain inspection

cover screws

Clutch adjuster screw

locknut

Clutch inspection cover

screws

Clutch diaphragm spring

retainer to clutch hub bolts

Rear axle cone nut 95-105 ft-lbs 129-142 Nm

Rear swingarm pivot

shaft locknut

Rear swingarm bracket

bolts

ft/in-lbs Nm

21-29 ft-lbs 29-39 Nm

12-14 ft-lbs 16-19 Nm

84-108

in-lbs

72-120

in-lbs

84-108

in-lbs

90-110

in-lbs

40-45 ft-lbs 54-61 Nm

34-42 ft-lbs

10-12 Nm

8-14 Nm

10-12 Nm

10-12 Nm

46-57 Nm

Continued ...

2004 Touring: Drive 6-1

Page 2

H

OME

TORQUE VALUES (CONT.’D)

Item

Shock bottom

mounting bolt

Exhaust pipe TORCA

clamps

Heat shield worm drive

clamp screws

Tr ansmission mainshaft

sprocket nut

Mainshaft sprocket nut

lockplate socket head

screws

Rear wheel sprocket bolts 55-65 ft-lbs 75-88 Nm

Primary chaincase to

crankcase and transmission

Front and rear starter

mounting screws

Starter jackshaft bolt 60-80

Engine compensating

sprocket nut

Clutch hub mainshaft nut 70-80 ft-lbs 95-108 Nm

Primary chaincase cover

allen head socket screws

Primary chaincase drain

plug

Passenger footboard

socket screws

Shifter lever

socket screws

1/4”

5/16”

ft/in-lbs Nm

35-40 ft-lbs 47-54 Nm

45-60 ft-lbs 61-81 Nm

20-40

in-lbs

60 ft-lbs, then

35° to 45°

90-110

in-lbs

18-21 ft-lbs 24-28 Nm

13-20 ft-lbs 18-27 Nm

in-lbs

150-165 ft-lbs 203-224 Nm

84-108

in-lbs

36-60

in-lbs

15-18 ft-lbs 20-24 Nm

90-110

in-lbs

18-22 ft-lbs 24-30 Nm

2.3-4.5 Nm

81 Nm, then

35° to 45°

10-12 Nm

6.8-9.0 Nm

9-12 Nm

4.1-6.8 Nm

10.2-12.4 Nm

6-2 2004 Touring: Drive

Page 3

H

CAUTION

f1840x6x

Primary

Chain

Retaining

Ring

Adjuster Shoe

Narrow End Forward

Top Center Nut

OME

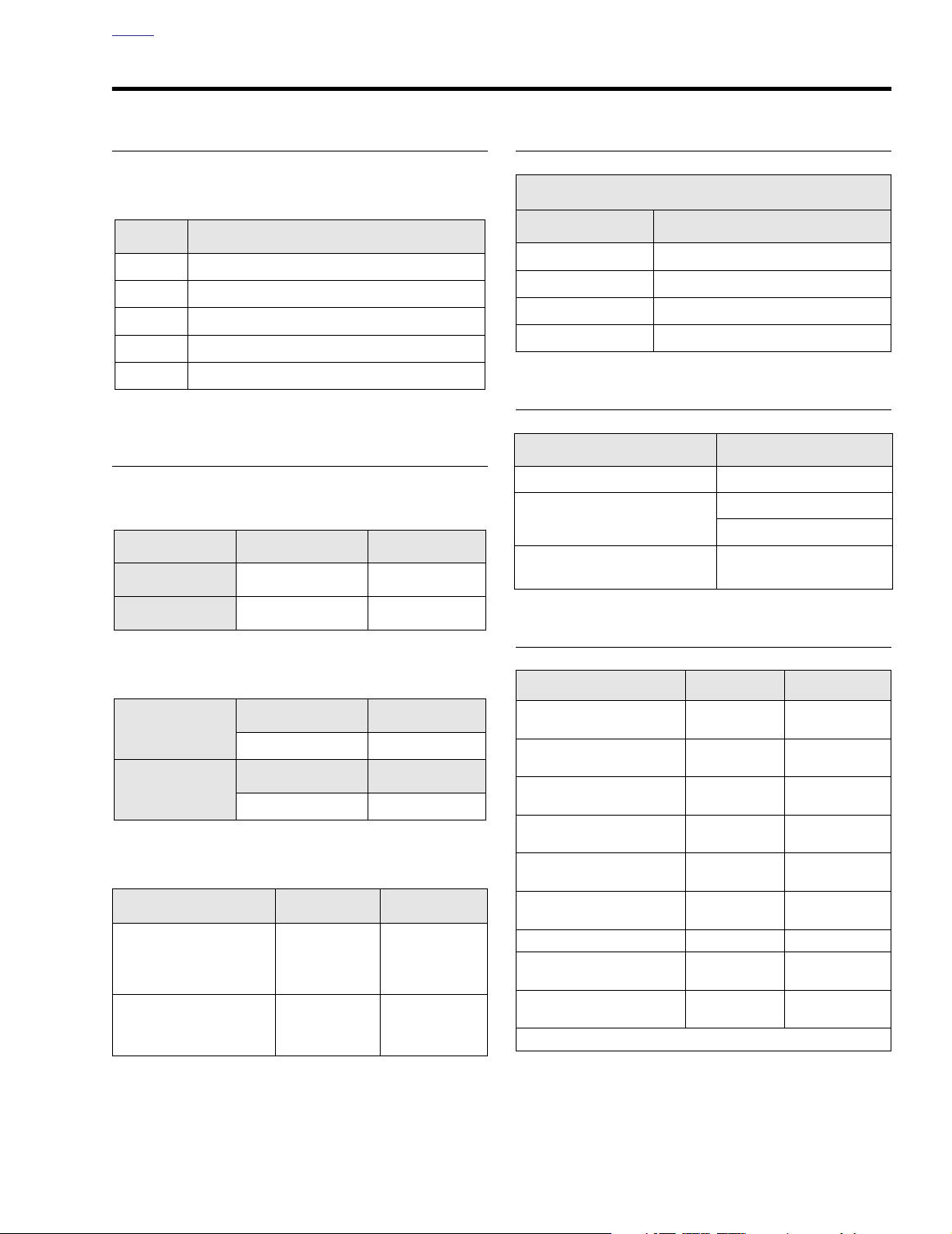

PRIMARY CHAIN AND SPROCKETS 6.2

PRIMARY CHAIN ADJUSTMENT

At the 1000 mile (1600 km) service interval, and at every

5000 mile (8000 km) service interval thereafter, inspect the

primary chain tension. Proceed as follows:

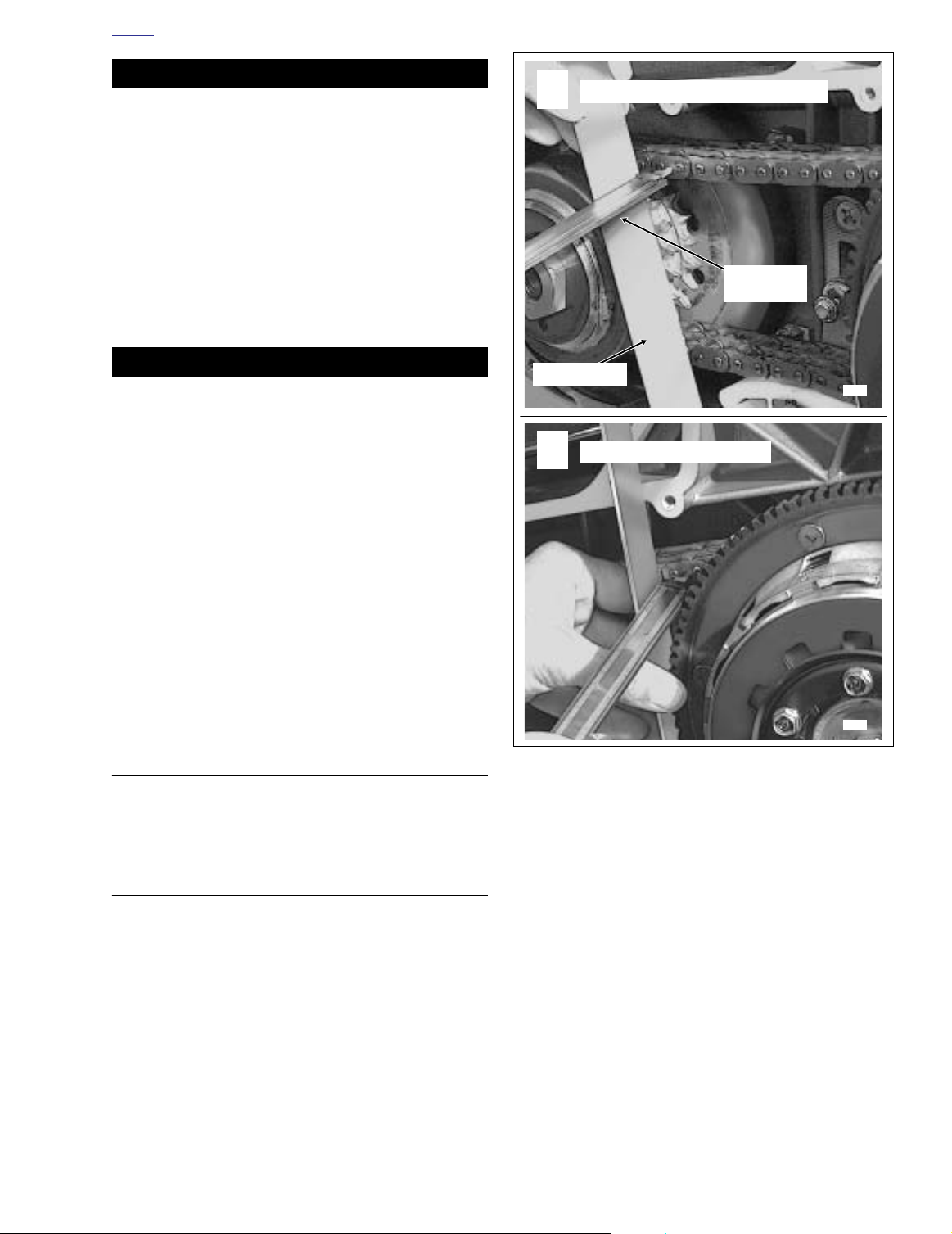

1. See Figure 6-1. Using a T27 TORX drive head, remove

four screws to free the primary chain inspection cover

from the primary chaincase cover.

2. Check the primary chain tension. Push on the upper

strand to verify that it has free up and down movement

midway between the engine compensating sprocket

(front) and the clutch sprocket (rear).

3. Measure the free play to be sure that it falls within the

ranges specified for a hot or cold engine:

Table 6-1. Primary Chain Adjustment

(Free Play)

COLD ENGINE

HOT ENGINE

Inches Millimeters

5/8-7/8 inch 15.9-22.2 mm

3/8-5/8 inch 9.5-15.9 mm

4. If the chain is too tight or too loose, then adjust as follows:

a. Locate the chain tensioner assembly and loosen the

top center nut a maximum of two turns. See Figure

6-2.

b. Raise or lower the chain tensioner assembly as

necessary to obtain the specified free play.

f1210x6x

1

4

Inspection

Primary

Chain

Cover

1

32

Clutch

43

Inspection

Cover

5

2

Figure 6-1. Primary Chaincase Cover

Figure 6-2. Chain Tensioner Assembly

NOTE

As chains stretch and wear, they run tighter at one spot than

another. Always adjust the free play at the tightest spot in the

chain. Replace the primary chain if it is worn to the point

where it cannot be properly adjusted.

Always keep the primary chain properly adjusted. Allowing the chain to run too tight or too loose will result in

excessive chain and sprocket wear.

c. Tighten the top center nut of the chain tensioner

assembly to 21-29 ft-lbs (29-39 Nm).

5. Align holes in

new

gasket with holes in the primary

chaincase cover. Using a T27 TORX drive head, install

four screws to secure primary chain inspection cover to

primary chaincase cover. Alternately tighten screws to

84-108

in-lbs

(10-12 Nm) in a crosswise pattern. See

Figure 6-1.

ADJUSTER SHOE REPLACEMENT

If the nylon adjuster shoe is worn or damaged, replace as follows:

1. Remove the primary chaincase cover. See Section 6.5

PRIMARY CHAINCASE, REMOVAL, steps 1-8.

2004 Touring: Drive 6-3

Page 4

H

OME

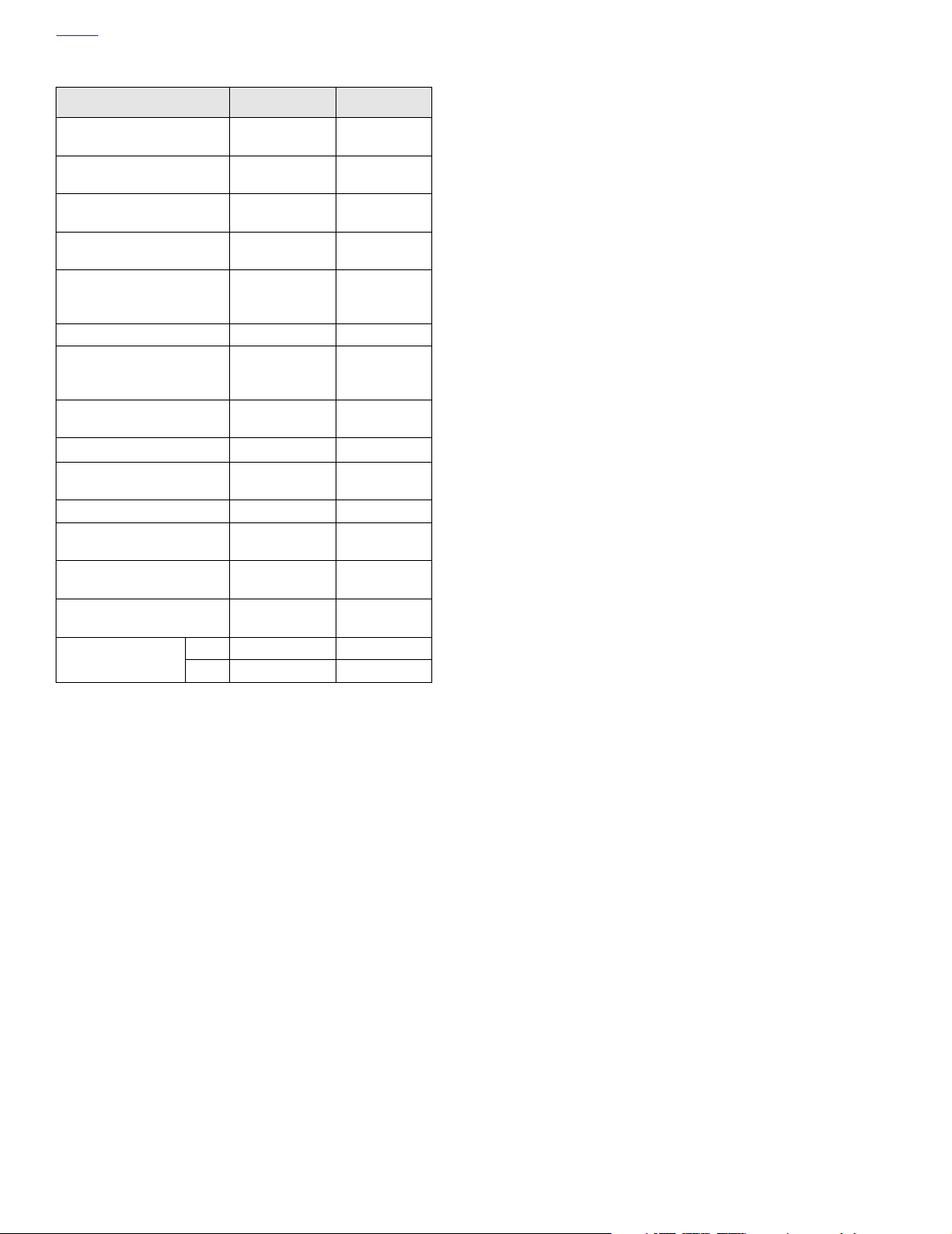

f1096dxd

1

2

1. Sprocket Nut

2. Sprocket Cover

3. Sliding Cam

4. Compensating Sprocket

5. Shaft Extension

EXPLODED VIEW

2

1

3

6. Alternator Rotor SpacerLow Output Rotor Only

0.020 inch (0.508 mm)

4

4

3

5

5

7. Alternator Rotor

8. Sprocket Shaft Spacer

9. Engine Sprocket Shaft

NOTE

Alternator stator, oil seal and left

crankcase not shown.

6

CROSS SECTIONAL VIEW

7

Figure 6-3. Engine Compensating Sprocket Components

2. Loosen top center nut from captured bolt of chain tensioner assembly. See Figure 6-2.

6-4 2004 Touring: Drive

9

8

6

3. Lower the chain tensioner assembly until the adjuster

shoe just contacts the inner primary housing.

Page 5

H

7947

B

Measure at Clutch Sprocket

A

7949

Dial Vernier

Caliper

Straightedge

Measure at Compensating Sprocket

OME

1WARNING1WARNING

Always wear proper eye protection when removing retaining rings. Use the correct retaining ring pliers. Verify

that the tips of the pliers are not damaged or excessively

worn. Slippage may propel the ring with enough force to

cause eye injury.

4. Remove retaining ring from nub and pull adjuster shoe

from chain tensioner. Discard adjuster shoe and retaining ring.

5. Slide

new

adjuster shoe onto chain tensioner. Be sure

that the narrow end of the shoe is at the front, the wider

end at the rear.

1WARNING1WARNING

Always wear proper eye protection when installing retaining rings. Use the correct retaining ring pliers. Verify

that the tips of the pliers are not damaged or excessively

worn. Slippage may propel the ring with enough force to

cause eye injury.

6. To lock position of adjuster shoe, install

ring onto nub of chain tensioner. Verify that retaining ring

is fully seated in the groove.

7. Raise or lower the chain tensioner assembly as necessary to obtain the specified free play. See PRIMARY

CHAIN ADJUSTMENT, steps 2-4.

8. Tighten the top center nut of the chain tensioner assembly to 21-29 ft-lbs (29-39 Nm).

9. Install the primary chaincase cover. See Section 6.5

PRIMARY CHAINCASE, INSTALLATION, steps 20-31.

new

retaining

DISASSEMBLY

See Section 6.5 PRIMARY CHAINCASE, REMOVAL, steps

1-16.

CLEANING AND INSPECTION

1. Periodically inspect the primary chain for cracked, broken or badly worn links. Replace as necessary.

2. Inspect compensating sprocket components for damage

or wear. Replace parts as necessary.

3. Inspect clutch sprocket for damage or wear. If broken or

damaged teeth are found, the clutch shell and sprocket

assembly must be replaced.

Figure 6-4. Check Sprocket Alignment

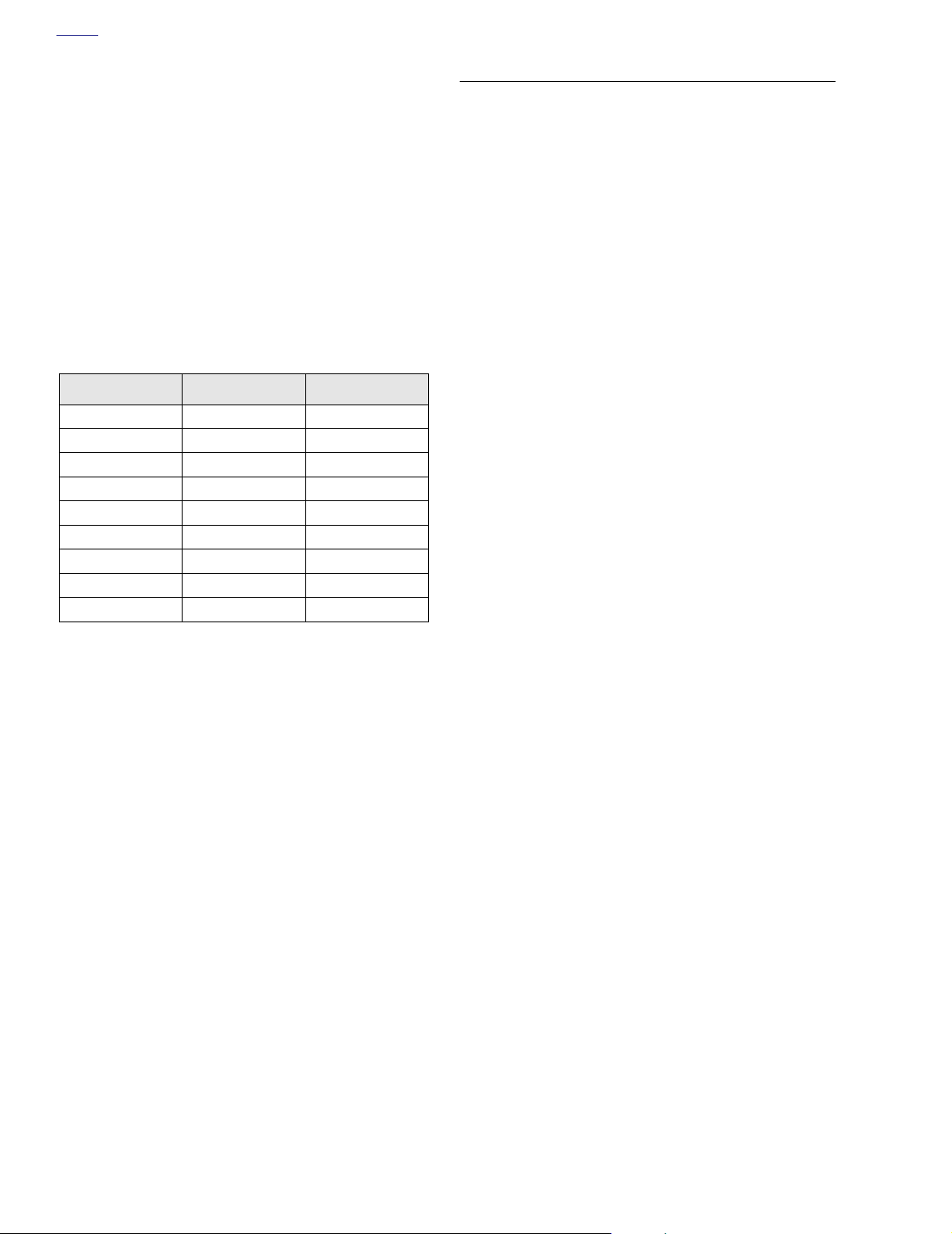

Sprocket Alignment (Figure 6-3, 6-4)

The engine compensating sprocket is aligned with the clutch

sprocket by a spacer installed between the alternator rotor

and shaft extension (low output rotor only). Reinstall the

same thickness spacer removed or determine the correct

spacer size as follows:

1. With the primary chaincase cover removed, verify that

the primary chain tension is properly adjusted. See PRI-

MARY CHAIN ADJUSTMENT in this section.

2. At both the engine compensating sprocket and clutch

sprocket sides, push the primary chain inward as far as it

will go.

2004 Touring: Drive 6-5

Page 6

H

OME

3. Place a straightedge vertically across the flanges (cover

gasket surface) near the engine compensating sprocket.

4. Using a dial vernier caliper, measure the distance from

the straightedge to the chain link sideplate. Measure as

close to the engine compensating sprocket as possible

and record the measurement. See A of Figure 6-4.

5. Repeat the measurement on the clutch sprocket side.

See B of Figure 6-4.

For proper primary chain alignment, the difference

between the two measurements must not exceed 0.030

inch (0.76 mm). If the measurement is not within specification, install the appropriate variable thickness spacer

on the engine sprocket shaft between the alternator rotor

and shaft extension. See the adjacent table for the various spacer thicknesses.

Table 6-2. Alternator Rotor Spacers

Inches

0.010 0.25 35850-84

0.020 0.51 35851-84

0.030 0.76 35852-84

0.060 1.52 24032-70

0.090 2.29 24033-70

0.120 3.05 24034-70

0.150 3.81 24035-70

0.180 4.57 24036-70

0.210 5.33 24037-70

Millimeters Part Number

ASSEMBLY

See Section 6.5 PRIMARY CHAINCASE, INSTALLATION,

steps 8-31.

6-6 2004 Touring: Drive

Page 7

H

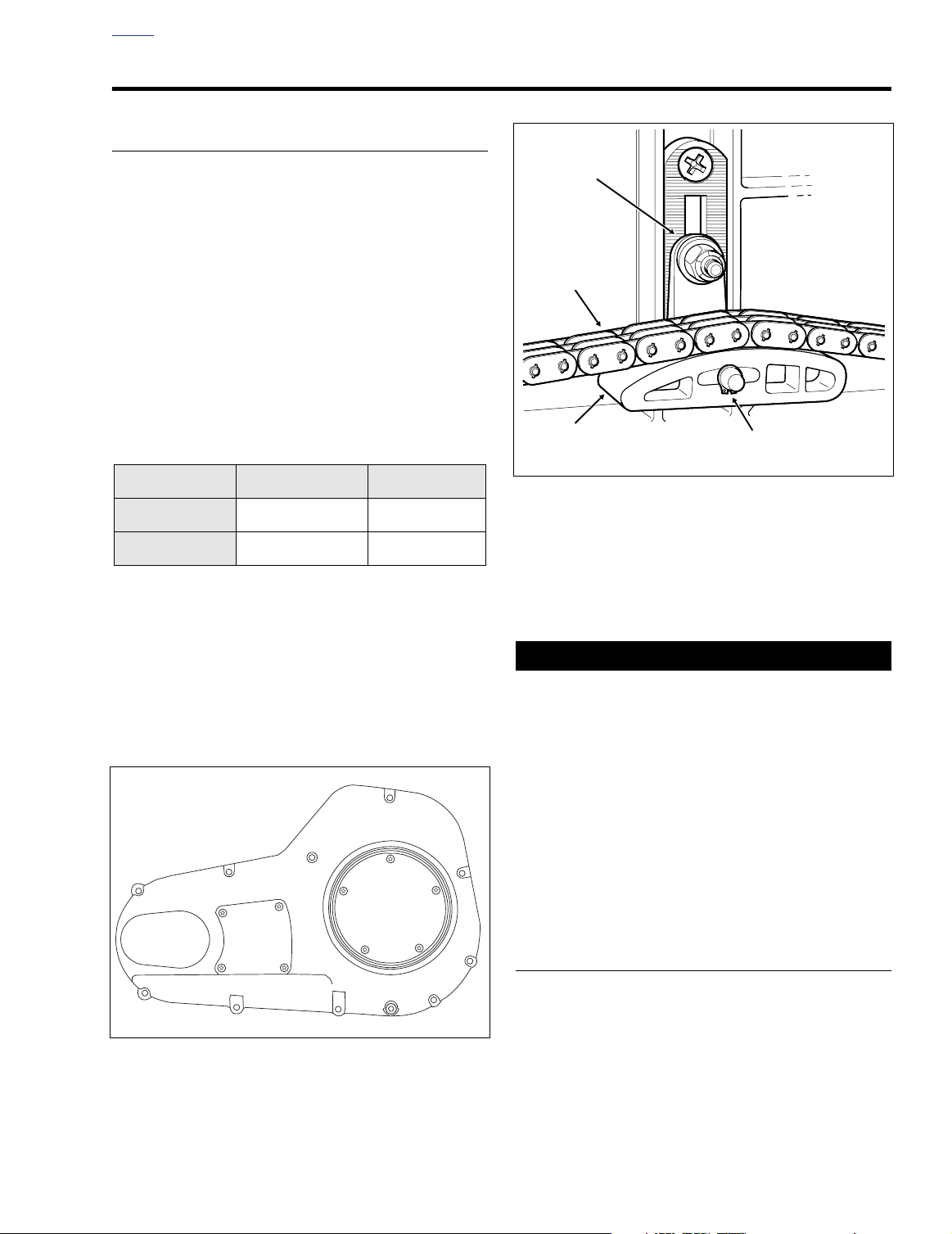

f1440x6x

Rubber

Boot

Jam

Nut

Cable

Adjuster

Cable

End

f1421x6x

Clutch

Cable

Clutch Lever

Bracket

Ferrule

Adjust for 1/16-1/8 inch

(1.6-3.2 mm) gap

between ferrule

and bracket

OME

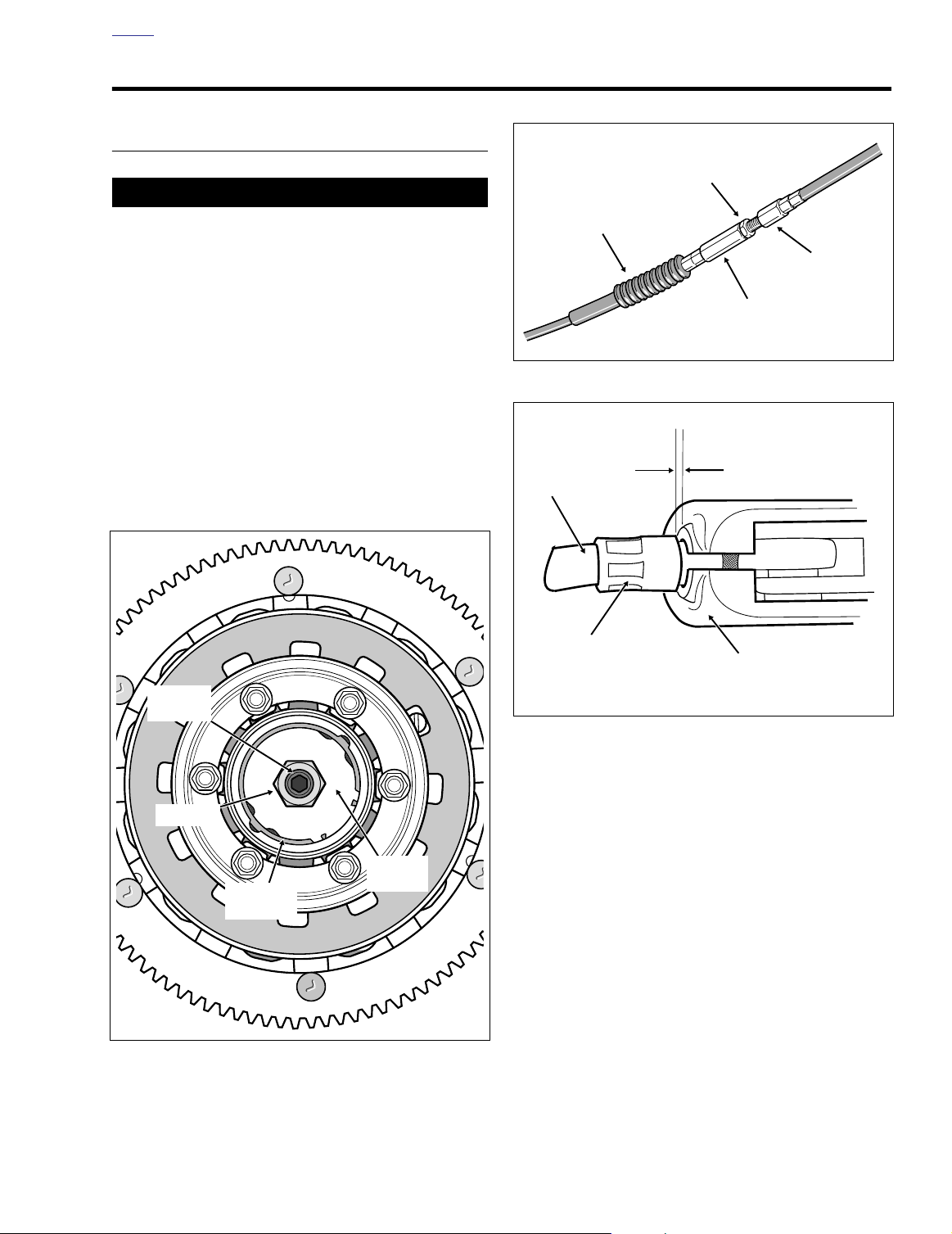

CLUTCH 6.3

ADJUSTMENT

CAUTION

Perform the clutch adjustment with the motorcycle at

room temperature. The clearance at the adjuster screw

will increase as the power train temperature increases. If

adjuster screw is adjusted while the powertrain is hot,

clearance at push rod bearing could be insufficient with

power train cold and clutch slippage could occur.

Adjust the clutch at the 1000 mile (1600 km) service interval,

and at every 5000 mile (8000 km) service interval thereafter.

NOTE

Also perform adjustment procedure whenever any clutch

components are replaced. Then repeat adjustment after first

500 miles (800 km) of use.

1. Stand motorcycle upright and level.

Figure 6-6. Clutch Cable Adjuster Mechanism

Adjuster

Screw

Locknut

Retaining

Ring

Figure 6-5. Clutch Adjustment

Release

Plate

f1509b6x

Figure 6-7. Adjust Clutch Free Play

2. Using a T27 TORX drive head, remove five screws (with

captive washers) to free clutch inspection cover from primary chaincase cover.

3. See Figure 6-6. Slide rubber boot off cable adjuster.

Holding cable adjuster with 1/2 inch wrench, loosen jam

nut using a 9/16 inch wrench. Back jam nut away from

cable adjuster. Move adjuster toward jam nut to introduce a large amount of free play at hand lever.

4. See Figure 6-5. Loosen locknut on clutch adjuster screw.

To take up all free play in push rods, turn screw inward

(clockwise) until lightly seated.

5. Back out adjuster screw 1/2 to 1 turn. While holding

adjuster screw with an allen wrench, tighten locknut to

72-120

in-lbs

(8-14 Nm).

6. Squeeze clutch lever to maximum limit three times to set

ball and ramp release mechanism.

2004 Touring: Drive 6-7

Page 8

H

OME

7. Turn cable adjuster away from jam nut until slack is eliminated at hand lever. Pull clutch cable ferrule away from

clutch lever bracket to check free play. Turn cable

adjuster as necessary to obtain 1/16 to 1/8 inch (1.6-3.2

mm) free play between end of cable ferrule and clutch

lever bracket, as shown in Figure 6-7.

8. Hold adjuster with 1/2 inch wrench. Using 9/16 inch

wrench, tighten jam nut against cable adjuster. Cover

cable adjuster mechanism with rubber boot.

9. Remove quad ring from groove in primary chaincase

cover. Wipe all lubricant from the quad ring and inspect

for cuts, tears or signs of deterioration. Replace as necessary.

10. Swab all lubricant from the quad ring groove. Install

quad ring in primary chaincase cover with the nubs contacting the ring groove walls.

NOTE

If lubricant is not thoroughly removed from both the quad ring

and groove, compression of the ring during installation of the

clutch inspection cover can cause lubricant to be squeezed

to the outboard side of the ring groove, resulting in some

temporary weepage around the inspection cover.

11. Using a T27 TORX drive head, install five screws (with

captive washers) to secure clutch inspection cover to the

primary chaincase cover. Alternately tighten screws to

84-108

in-lbs

(10-12 Nm) in the pattern shown in Figure

6-1.

REMOVAL/INSTALLATION

To remove the clutch without disassembly, see Section 6.5

PRIMARY CHAINCASE, REMOVAL, steps 1-16.

For installation instructions, see Section 6.5 PRIMARY

CHAINCASE, INSTALLATION, steps 8-31.

NOTE

If only the clutch pack is to be disassembled, see PA RT IAL

DISASSEMBLY below, a procedure that can be performed on

the motorcycle without removing the clutch shell or hub.

For complete disassembly of the clutch, which includes

clutch pack disassembly and bearing replacement, see

COMPLETE DISASSEMBLY.

PARTIAL DISASSEMBLY

CLUTCH PACK ONLY

1. Remove the primary chaincase cover. See Section 6.5

PRIMARY CHAINCASE, REMOVAL, steps 1-8.

2. Remove six bolts to release diaphragm spring retainer

from clutch hub. See Figure 6-9.

3. Remove diaphragm spring retainer, diaphragm spring

and pressure plate from clutch hub.

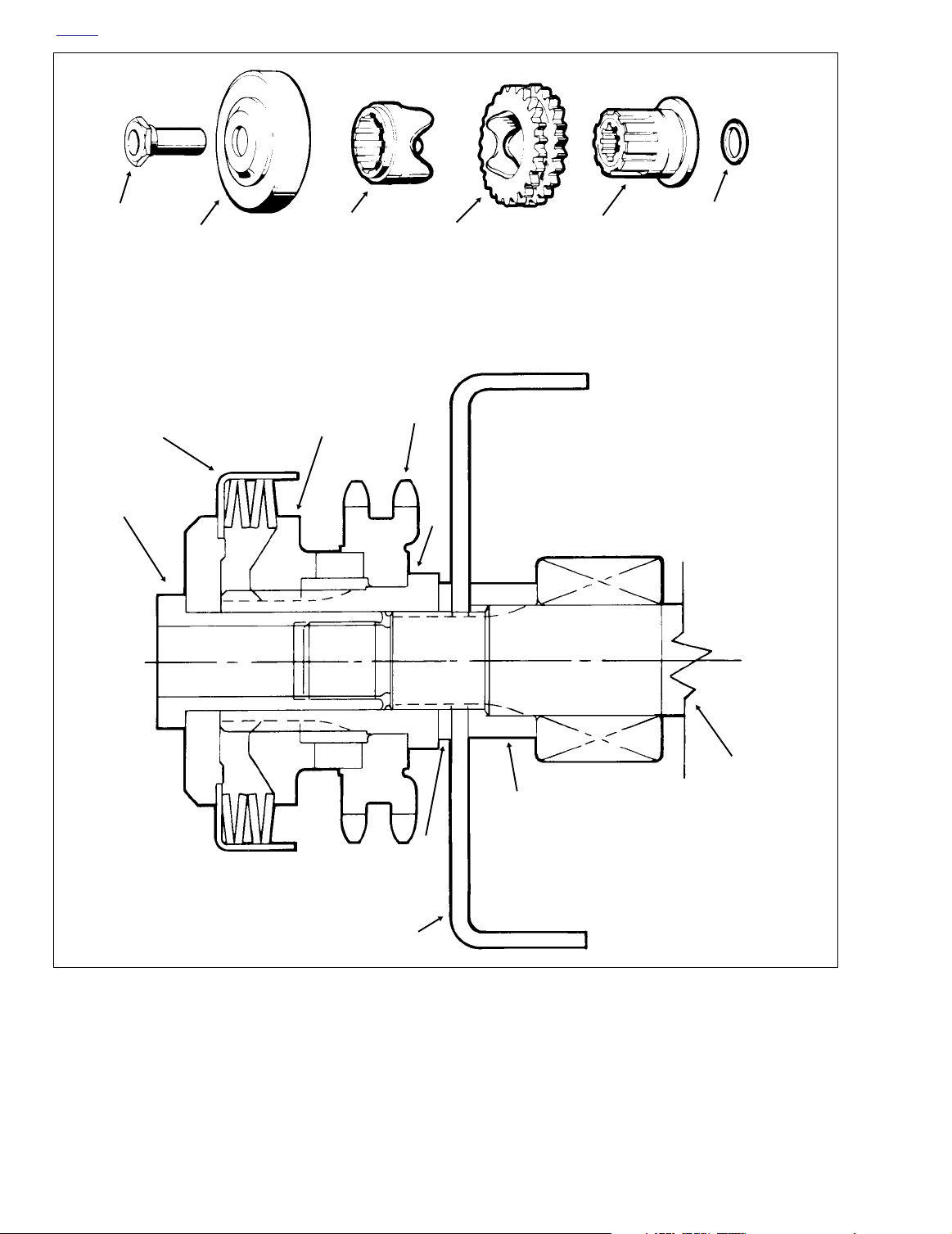

f1523x6x

Clutch

Shell

Damper

Spring Seat

Figure 6-8. Clutch Pack Stack-Up (Cut-Away View)

4. Remove friction plates, steel plates, damper spring and

damper spring seat from clutch hub.

5. See CLEANING AND INSPECTION in this section.

Damper

Spring

Clutch

Hub

Steel Plate

Narrow

Friction Plate

ASSEMBLY

CLUTCH PACK ONLY

1. Submerge and soak all friction and steel plates in PRIMARY CHAINCASE LUBRICANT for at least five minutes.

2. Install the narrow friction plate on the clutch hub engaging tabs on plate with slots in clutch shell.

3. Install damper spring seat on clutch hub so that it seats

inboard of narrow friction plate.

4. Install damper spring on clutch hub with the concave

side up (facing opposite damper spring seat). See Fig-

ure 6-8.

5. Install a steel plate and then a friction plate on the clutch

hub. Install seven remaining sets in the same manner,

alternating between steel plates and friction plates.

6. Install pressure plate on clutch hub aligning holes in

plate with threaded bosses on hub.

7. Seat diaphragm spring in recess of pressure plate with

the concave side down.

8. Align holes in diaphragm spring retainer with threaded

bosses on clutch hub. Tabs on spring retainer contact

flats on inboard side of bosses.

9. Install six bolts to secure diaphragm spring retainer to

clutch hub. Alternately tighten bolts to 90-110

(10.2-12.4 Nm).

10. Install the primary chaincase cover. See Section 6.5

PRIMARY CHAINCASE, INSTALLATION, steps 20-31.

in-lbs

6-8 2004 Touring: Drive

Page 9

H

OME

5

6

f1514x6x

4

2

3

7

8

1

9

10

11

12

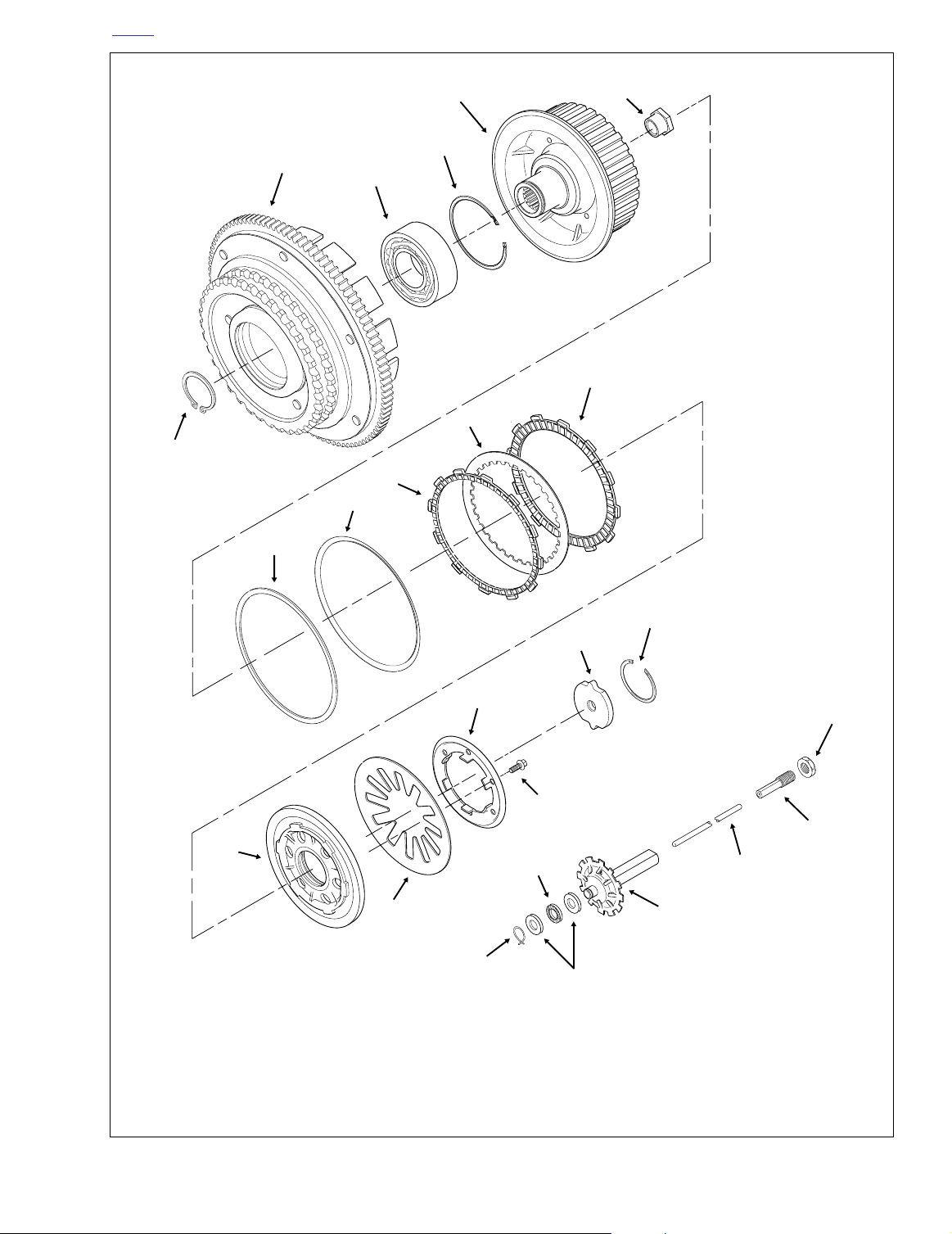

1. Retaining Ring

2. Clutch Shell

3. Bearing

4. Retaining Ring

5. Clutch Hub

6. Mainshaft Nut

7. Friction Plate (9)

8. Steel Plate (8)

9. Narrow Friction Plate

14

13

24

10. Damper Spring

11. Damper Spring Seat

12. Pressure Plate

13. Diaphragm Spring

14. Diaphragm Spring Retainer

15. Bolt (6)

16. Release Plate

16

15

23

22

17. Retaining Ring

18. Locknut

19. Adjuster Screw

20. Push Rod

21. Oil Slinger

17

18

19

20

21

22. Thrust Washer (2)

23. Throw Out Bearing

24. Retaining Ring

Figure 6-9. Clutch Assembly

2004 Touring: Drive 6-9

Page 10

H

OME

CLEANING AND INSPECTION

1. Wash all parts in cleaning solvent, except for friction

plates and bearing, if removed. Blow dry with compressed air.

Remove retaining ring from clutch hub.

2. Check

friction plates

●

Wipe all lubricant from the friction plates. Measure

as follows:

the thickness of each plate with a dial caliper or

micrometer. If the thickness of any plate is less than

0.143 inch (3.62 mm), discard the friction plates and

replace with an entirely new set.

Look for worn or damaged fiber surface material

●

(both sides).

NOTE

Replace all nine friction plates with an entirely new set if any

individual plate shows evidence of wear or damage.

3. Check

steel plates

Discard any plate that is grooved or bluish in color.

●

as follows:

Blue plates are likely warped or distorted.

●

Check each plate for distortion. Lay the plate on a

precision flat surface. Insert a feeler gauge between

the plate and the flat surface in several places.

Replace any steel plate that is warped more than

0.006 inch (0.15 mm).

4. See Figure 6-9. Holding the clutch hub, rotate the clutch

shell to check bearing for smoothness. Replace the

bearing if it runs rough or binds.

f1519x6x

Press clutch hub from bearing.

5. Check the primary chain sprocket and the starter ring

gear on the clutch shell. Replace the clutch shell if either

sprocket or ring gear are badly worn or damaged.

6. Check the slots that mate with the clutch plates on both

the clutch shell and hub. Replace shell or hub if slots are

worn or damaged.

7. Check the diaphragm spring and diaphragm spring

retainer for cracks or bent tabs. Obtain a new diaphragm

spring or diaphragm spring retainer if either condition

exists.

COMPLETE DISASSEMBLY

CLUTCH PACK AND BEARING

1. Remove clutch assembly from the motorcycle. See Section 6.5 PRIMARY CHAINCASE, REMOVAL, steps 1-16.

2. Remove six bolts to release diaphragm spring retainer

from clutch hub. See Figure 6-9.

3. Remove diaphragm spring retainer, diaphragm spring

and pressure plate from clutch hub.

f1522x6x

Figure 6-10. Remove Clutch Hub from Clutch Shell

4. Remove friction plates, steel plates, damper spring and

damper spring seat from clutch hub.

CAUTION

To avoid possible bearing damage, do not disassemble

the clutch shell and hub assembly unless the bearing,

hub or shell require replacement. Replace the bearing if

disassembled.

6-10 2004 Touring: Drive

Page 11

H

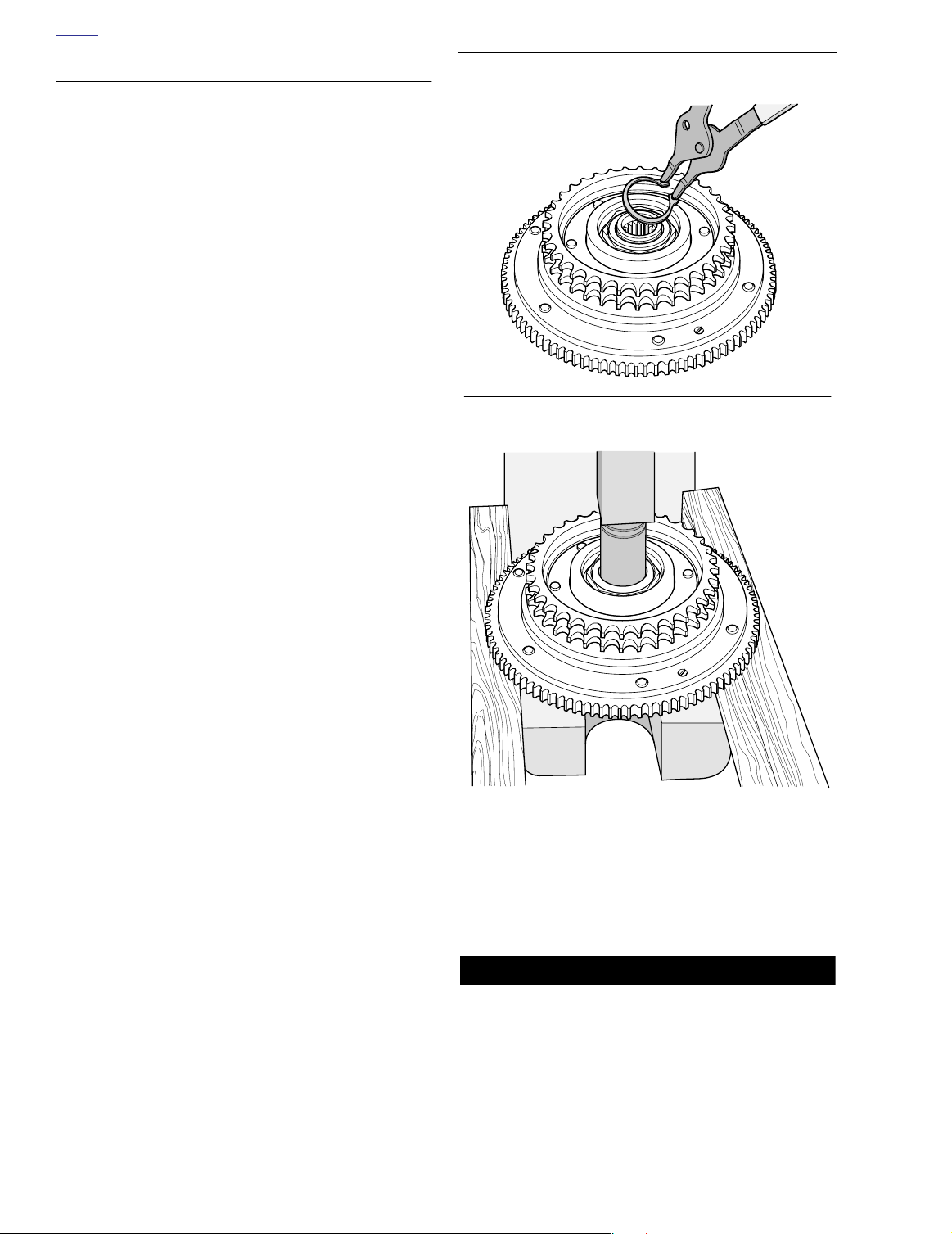

1WARNING1WARNING

OME

Remove retaining ring from clutch shell.

Press bearing from clutch shell.

f1521x6x

6. Supporting clutch shell in same orientation, use arbor

press and a suitable press plug to press hub from bearing in clutch shell. See lower frame of Figure 6-10.

7. Turn clutch shell over so that the sprocket side is down.

Remove retaining ring from groove in clutch shell bore.

See upper frame of Figure 6-11.

8. Turn clutch shell over so that sprocket side is up. Using

arbor press and a suitable press plug, press on inner

race to remove bearing from clutch shell bore. See lower

frame of Figure 6-11.

9. See CLEANING AND INSPECTION in this section.

ASSEMBLY

CLUTCH PACK AND BEARING

1. Orient clutch shell in arbor press with sprocket side

down. Be sure to support clutch shell bore on sprocket

side. Using a suitable press plug, press against outer

race until bearing contacts shoulder in clutch shell bore.

Always wear proper eye protection when installing retaining rings. Use the correct retaining ring pliers. Verify

that the tips of the pliers are not damaged or excessively

worn. Slippage may propel the ring with enough force to

cause eye injury.

f1520x6x

Figure 6-11. Remove Bearing from Clutch Shell

1WARNING1WARNING

Always wear proper eye protection when removing retaining rings. Use the correct retaining ring pliers. Verify

that the tips of the pliers are not damaged or excessively

worn. Slippage may propel the ring with enough force to

cause eye injury.

5. With the sprocket side up, remove retaining ring from

clutch hub groove. See upper frame of Figure 6-10.

NOTE

Note that one side of the retaining ring is beveled. Always

install the ring with the beveled side opposite the bearing.

2. Install retaining ring in groove of clutch shell bore, so

that the flat side of the ring is in towards the bearing, the

beveled side out.

3. Center hub in bearing. Be sure that bearing inner race is

supported with sleeve on sprocket side. Press hub into

bearing until hub shoulder contacts bearing inner race.

4. Turn assembly over so that the sprocket side is up.

Install retaining ring in groove of clutch hub.

5. Place clutch assembly on bench oriented with the

sprocket side down.

6. Submerge and soak all friction and steel plates in PRIMARY CHAINCASE LUBRICANT for at least five minutes.

7. Install the narrow friction plate on the clutch hub engaging tabs on plate with slots in clutch shell. See Figure 6-

12.

8. Install damper spring seat on clutch hub so that it seats

inboard of narrow friction plate.

9. Install damper spring on clutch hub with the concave

side up (facing opposite damper spring seat). See Fig-

ure 6-8.

2004 Touring: Drive 6-11

Page 12

H

OME

Narrow Plate

f1513x6x

Regular Plate

Figure 6-12. Friction Plates

10. Install a steel plate and then a friction plate on the clutch

hub. Install seven remaining sets in the same manner,

alternating between steel plates and friction plates.

11. Install pressure plate on clutch hub aligning holes in

plate with threaded bosses on hub.

12. Seat diaphragm spring in recess of pressure plate with

the concave side down.

13. Align holes in diaphragm spring retainer with threaded

bosses on clutch hub. Tabs on spring retainer contact

flats on inboard side of bosses.

14. Install six bolts to secure diaphragm spring retainer to

clutch hub. Alternately tighten bolts to 90-110

in-lbs

(10.2-12.4 Nm).

15. Install clutch assembly on motorcycle. See Section 6.5

PRIMARY CHAINCASE, INSTALLATION, steps 8-31.

6-12 2004 Touring: Drive

Page 13

H

10 lbs. (4.5 kg)

of Force

f1652x6x

See Table 6-3.

Rear Wheel

Sprocket

Transmission

Sprocket

OME

SECONDARY DRIVE BELT AND SPROCKETS 6.4

ADJUSTMENT

1. Remove left side saddlebag. See Section 2.25 SAD-

DLEBAG, REMOVAL.

2. Check deflection at the loosest spot in the belt with the

transmission in neutral and the motorcycle cold. Use

BELT TENSION GAUGE (HD-35381A), or install narro

saddle (HD-35381-3) on existing gauge, and apply 10

lbs. (4.5 kg) of force at the midpoint of the bottom belt

strand. See Figure 6-13. Belt deflection should be as follows:

Table 6-3. Belt Deflection

w

Orientation

Inches Millimeters

On Jiffy Stand

Without Rider or Luggage

10 psi (69 kPa) in Rear Shocks

Motorcycle Upright

With Rear Wheel in the Air

1/4 - 5/16 6.4 - 7.9

3/16 - 1/4 4.8 - 6.4

If belt deflection is within specification, install left side

saddlebag. If adjustment is necessary, proceed to step

3.

3. Remove right side saddlebag. See Section 2.25 SAD-

DLEBAG, REMOVAL.

4. Remove right side muffler as follows:

a. Open worm drive clamps to remove heat shield

from rear header pipe in front of muffler.

Increase

Belt

Deflection

Reduce

Belt

Deflection

Figure 6-13. Check and Adjust Belt Deflection

b. Using a bungee cord, tie the muffler to the lower

saddlebag support rail.

c. Loosen TORCA clamp between rear header pipe

and muffer.

d. Remove two bolts (with lockwashers) to detach muf-

fler from the lower saddlebag support rail.

e. Remove bungee cord to release muffler from lower

saddlebag support rail.

5. Standing on right side of motorcycle, remove E-clip from

groove at end of axle. Loosen cone nut, and then snug

to 15-20 ft-lbs (20-27 Nm). See Figure 6-14.

RIGHT SIDELEFT SIDE

Cone

Nut

Weld

Nub

Weld

Nub

Weld

Nut

8398

E-Clip

8407

Figure 6-14. Move Rear Wheel Forward Until Adjuster Cams Just Contact Weld Nubs

2004 Touring: Drive 6-13

Adjuster

Cam

Page 14

H

OME

6. If belt is too tight, move to step 7 to increase belt deflection. If belt is too loose, reduce belt deflection as

described below:

a. Rotate weld nut on left side of axle in a clockwise

direction.

b. Check belt deflection. Apply 10 lbs. (4.5 kg) of force

at the midpoint of the bottom belt strand. Belt

deflection should be within the range specified in

Ta bl e 6-3.

c. If belt is still too loose, repeat steps 6(a) through

6(b). If belt is now too tight, move to step 7.

7. If belt is too tight, increase belt deflection as follows:

a. Using a hydraulic center stand, raise motorcycle so

that the rear wheel is off the ground.

b. Rotate weld nut on left side of axle in a counter-

clockwise direction.

c. Push wheel forward slightly so that adjuster cam

just contacts weld nub on both sides of rear swingarm. See Figure 6-14.

d. Check belt deflection. Apply 10 lbs. (4.5 kg) of force

at the midpoint of the bottom belt strand. Belt

deflection should be within the range specified in

Ta bl e 6-3.

e. If belt is still too tight, repeat steps 7(b) through 7(d).

If belt is now too loose, move to step 6.

CAUTION

Verify that the exhaust pipes do not contact the vehicle

frame or any mounted components. Contact will cancel

the effect of the rubber isolation mounts and transmit

vibration to the rider via the vehicle frame.

d. Verify that exhaust pipes are in alignment and do

not contact the motorcycle frame or mounted components.

e. Tighten the TORCA clamp to 45-60 ft-lbs (61-81

Nm).

f. Open worm drive clamps and install heat shield on

rear header pipe. Position clamp so that screw is on

the outboard side in the most accessible position.

CAUTION

Verify that the heat shields do not contact the vehicle

frame or any mounted components. Contact will cancel

the effect of the rubber isolation mounts and transmit

vibration to the rider via the vehicle frame.

g. Remove bungee cord from muffler.

12. Install saddlebags. See Section 2.25 SADDLEBAG,

INSTALLATION.

8.

Holding

right side to 95-105 ft-lbs (128.8-142.4 Nm).

If the axle moves during tightening of the cone nut, then the

the belt deflection procedure must be restarted.

9. Recheck belt deflection to verify that it is still within specification.

If the belt deflection is not within specification, loosen

cone nut and then snug to 15-20 ft-lbs (20-27 Nm)

before returning to step 6.

10. With the flat side out, install

side of axle.

11. Install right side muffler as follows:

TORCA muffler clamps have eliminated the need for silicone

or graphite tape during assembly. To ensure sealing integrity

of muffler clamps and prevent the possibility of leakage, Harley-Davidson recommends that TORCA clamp assemblies be

discarded and replaced each time they are removed.

a. Slide

b. Using a bungee cord, tie muffler to lower saddlebag

c. Tighten the two bolts (with lockwashers) to fasten

weld nut on left side of axle, tighten cone nut on

NOTE

new

E-clip in groove on right

NOTE

new

TORCA clamp onto free end of rear

header pipe.

support rail. Install muffler on rear header pipe.

Place TORCA clamp into position between rear

header pipe and muffler.

the muffler to the lower saddlebag support rail.

CLEANING AND INSPECTION

1. Use a spray solution of soap and water to clean belt.

Avoid immersion. Wipe the belt down or blow dry.

Although the belt's urethane compound is resistant to

most solvents, these should only be used on a limited

basis, and then must always be followed by a soap and

water wash.

2. Inspect the edges of the belt for cuts or unusual wear

patterns. While some beveling of the outside edge is

common, and by itself is not usually harmful, it is an indication of sprocket misalignment.

3. Inspect the outside ribbed surface of the belt for signs of

stone puncture. Since it is not always easy to observe

this type of damage, look closely.

4. On the inside of the belt, inspect the roots of the belt

teeth to see if the tensile cords are exposed. See upper

frame of Figure 6-15. The tensile cords are covered by a

layer of nylon facing and another layer of polyethylene.

Once these layers are worn through, the tensile cords

become visible. Visible tensile cords are an indication

that the transmission sprocket tooth tip diameter is

severely worn. Furthermore, belt failure is imminent,

since the tooth tips will continue to scratch away at the

tensile cords until the belt is completely worn through.

NOTE

During initial operation, the thin coating of polyethylene will

wear off as it is burnished into the belt fabric. This is a normal

condition and not an indication of belt wear.

6-14 2004 Touring: Drive

Page 15

H

CAUTION

OME

DRIVE BELT/TRANSMISSION SPROCKET WEAR

Look for

Drive Belt

Tensile Cords

Worn Tooth

Profile

Cracks Here

High-Pressure

Contact Here

5. Look for signs of cracking at the base of the belt teeth

where contact may be made with the “corners” of worn

transmission sprocket teeth. See upper frame of Figure

6-15. Replace the belt if cracking is evident.

Sliding

NOTE

If the belt is replaced for reasons other than stone damage,

the transmission and/or rear wheel sprockets also should be

replaced. Use of worn or damaged sprockets will severely

affect belt service life.

6. For common types of belt wear and damage, see lower

frame of Figure 6-15.

REPLACEMENT

DRIVE BELT WEAR

Internal Tooth Crack

(Hairline)

OK to Run, But Monitor

Missing Teeth

Replace Belt

Fuzzy Edge Cord

(Not Serious)

OK to Run, But Monitor

Transmission

Sprocket

Pack Man Cracks

Replace Belt

Chipping

(Not Serious)

OK to Run, But Monitor

Hook Wear

Replace Belt

f1632x6x

f1651x6x

Removal

1. Remove rear wheel and rear swingarm. See Section

2.20 REAR SWINGARM, REMOVAL.

2. Remove the primary chaincase assembly. See Section

6.5 PRIMARY CHAINCASE, REMOVAL.

3. Remove the old belt from the transmission sprocket.

Installation

Handle the drive belt with care. Never bend belt forward

into a loop smaller than five inches (127 mm) diameter.

Never bend belt into a reverse loop smaller than ten

inches (254 mm) diameter. Over bending will weaken belt

and result in premature failure. Always install belt in the

same direction of rotation as when it was removed. For

other handling tips, see Figure 6-16.

1. Install the

2. Install the primary chaincase assembly. See Section 6.5

PRIMARY CHAINCASE, INSTALLATION.

3. Install rear swingarm and rear wheel. Adjust belt deflection. See Section 2.20 REAR SWINGARM, INSTALLA-

TION.

new

belt on the transmission sprocket.

Cross-Sectional View

Stone Damage

Replace Belt

if Damage on Edge

Bevel Wear

(Outboard Edge Only)

OK to Run, But Monitor

Figure 6-15. Drive Belt/Transmission Sprocket Wear

TRANSMISSION SPROCKET

Removal

1. Remove rear wheel. See Section 2.4 REAR WHEEL,

REMOVAL.

2. Remove the primary chaincase assembly. See Section

6.5 PRIMARY CHAINCASE, REMOVAL.

2004 Touring: Drive 6-15

Page 16

H

OME

Forward bend must not be less than 5 in. (127 mm). Reverse bend must not be less than 10 in. (254 mm).

Minimum Diameter

Do not twist. Do not crimp, pinch or kink.

AB

Minimum Diameter

CD

CAUTION

Mishandling drive belt will result in premature failure.

For maximum strength, integrity and longevity, avoid

over bending (A and B), twisting (C), crimping, pinching or kinking (D), and prying (E).

Figure 6-16. Proper Drive Belt Handling

3. See Figure 6-17. Remove the two socket screws and

lockplate to free the sprocket nut.

NOTE

The transmission sprocket nut has left handed threads. Turn

the nut clockwise to remove from the main drive gear.

4. Remove the sprocket nut. Use an air impact wrench for

best results.

Cleaning and Inspection

1. Using a non-volatile cleaning solvent, thoroughly clean

the transmission sprocket of all grease and dirt.

2. Carefully inspect the sprocket for cracks or other damage.

Do not pry.

3. Inspect the sprocket for heavy pitting, which indicates a

high degree of abrasive wear.

4. Look for “sharp” corners at the top of each sprocket

tooth, particularly where the flank joins the top radius. A

smooth transition should exist between the flank and

radius. While worn teeth will appear to have an edge

across the face width of the tooth, heavily worn teeth will

have a flat across the top. If the flat is 1/8 inch (3 mm)

wide or more, replace the transmission sprocket and

drive belt. See upper frame of Figure 6-15.

E

Installation

1. Install the transmission sprocket (with belt) on the main

drive gear.

6-16 2004 Touring: Drive

Page 17

H

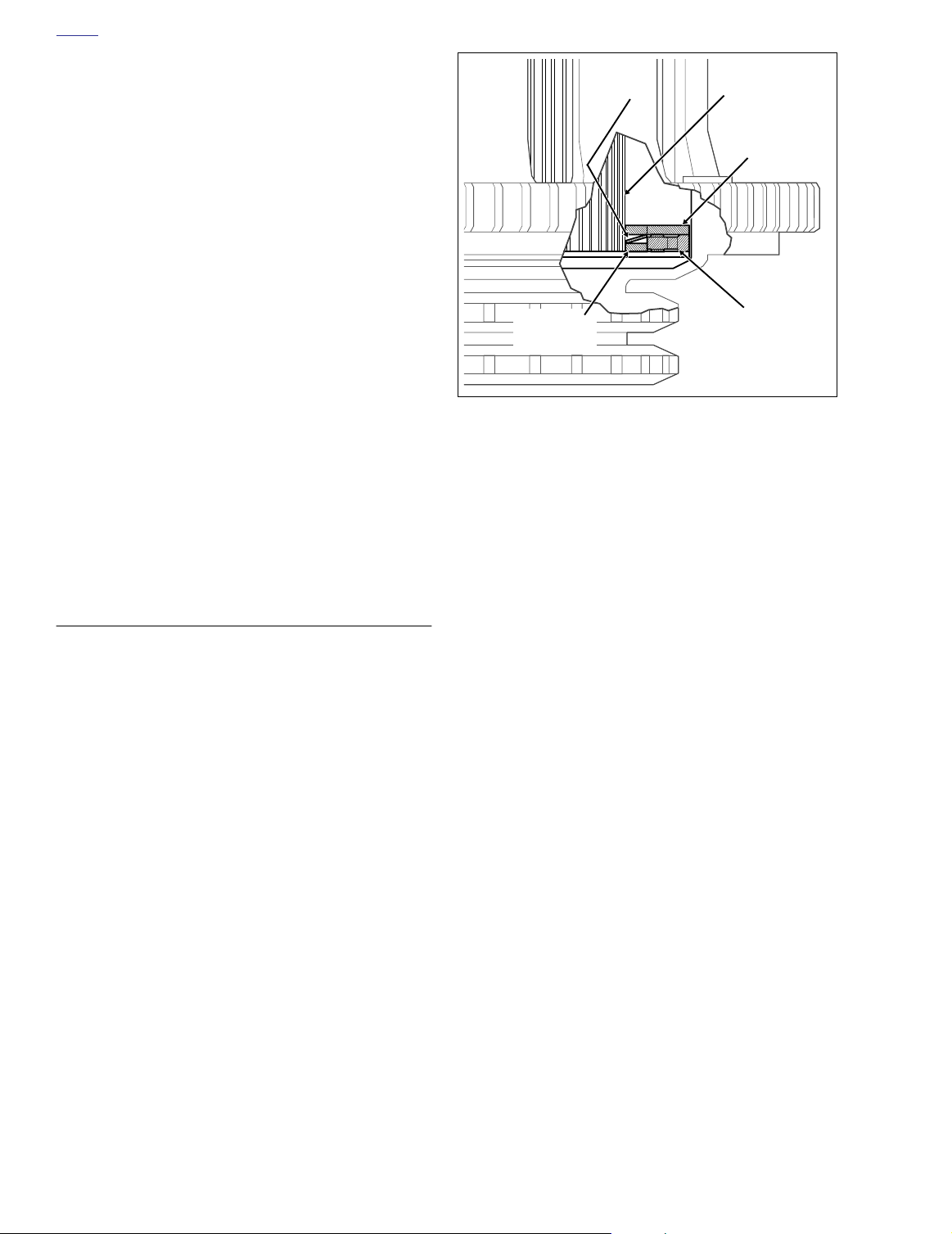

f1855x7x

f1856x7x

Sprocket

Locking Tool

Transmission

Sprocket

Sprocket

Locking Tool

Sprocket

Nut

Pivot Shaft

OME

Main Drive

Gear

Mainshaft

Oil Seal

Spacer

Sleeve

Lockplate

Sprocket

Nut

Quad Seal

Transmission

Sprocket

f1172a6x

Lubricate

Contact Surfaces

Socket

Screw

Figure 6-17. Transmission Sprocket Components

2. To install the sprocket nut, follow the appropriate procedure based on whether a new or used nut is being

installed.

CAUTION

Exercise caution to avoid getting oil on the threads of

the sprocket nut or the integrity of the lock patch may be

compromised.

New sprocket nut:

smear a small quantity of clean

engine oil on the inside face of both the sprocket nut and

the sprocket. Limit the application to where the surfaces

of the two parts contact each other. Install the sprocket

nut until finger tight.

NOTE

The transmission sprocket nut has left handed threads. Turn

the nut counterclockwise to install.

Used sprocket nut:

apply Loctite High Strength Threadlocker 262 (red) to the threads of the sprocket nut. Also

smear a small quantity of Loctite or clean engine oil on

the inside face of both the sprocket nut and the sprocket.

Limit the application to where the surfaces of the two

parts contact each other. Install the sprocket nut until finger tight.

3. Lock transmission sprocket with the FINAL DRIVE

SPROCKET LOCKING TOOL (Part No. HD-41184). See

Figure 6-18.

Insert handle of tool below pivot shaft inboard of bottom

frame tube and attach to sprocket. Snug thumbscrew to

lock position of tool on sprocket. See Figure 6-19.

4. Install pilot of MAINSHAFT LOCKNUT WRENCH (Part

No. HD-94660-37B) on threaded end of mainshaft. See

Figure 6-20. Slide sleeve of locknut wrench over pilot

and onto sprocket nut. Tighten sprocket nut to 60 ft-lbs

(81 Nm). As the nut is tightened the handle of the

sprocket locking tool rises to contact the pivot shaft,

thereby preventing sprocket/mainshaft rotation. See Fig-

ure 6-21.

Figure 6-18. Final Drive Sprocket Locking Tool

(Part No. HD-41184)

Figure 6-19. Install Final Drive Sprocket Locking Tool

5. Scribe a straight line on the transmission sprocket nut

continuing the line over onto the transmission sprocket

as shown in Figure 6-22. Tighten the transmission

sprocket nut an additional 35° to 40°.

2004 Touring: Drive 6-17

Page 18

H

OME

Wrench

7. If holes in lockplate do not align with those in sprocket,

tighten sprocket nut as necessary (up to the 45° maximum) until sprocket and lockplate holes are in alignment. See Figure 6-22.

CAUTION

Figure 6-20. Mainshaft Locknut Wrench/Pilot

(Part No. HD-94660-37B )

Sprocket

Nut

Pilot

Mainshaft

Locknut

Wrench

Pilot

f1857x7x

f1858x7x

Maximum allowable tightening of sprocket nut is 45° of

counterclockwise rotation after a torque of 60 ft-lbs (81

Nm). Do not loosen sprocket nut to align holes or nut will

be under tightened.

8. Insert two socket head screws through lockplate into

sprocket holes. Tighten screws to 90-110

in-lbs

(10-12

Nm).

NOTE

The socket head screws have a thread locking compound

that allows them to be reused up to three times. The fourth

time the screws are removed, replace with

new

screws (H-D

Part No. 3594).

9. Install primary chaincase assembly. See Section 6.5

PRIMARY CHAINCASE, INSTALLATION.

10. Install rear wheel and adjust belt deflection. See Section

2.4 REAR WHEEL, INSTALLATION.

REAR WHEEL SPROCKET

Removal

1. Remove rear wheel. See Section 2.4 REAR WHEEL,

REMOVAL.

2. Remove five bolts with flat washers securing sprocket to

hub.

Torque

Wrench

Figure 6-21. Install Mainshaft Locknut Pilot/Wrench

and Torque Sprocket Nut

6. Install lockplate over nut so that two diagonally opposite

holes align with two tapped holes in sprocket. To find the

best fit, lockplate can be rotated to a number of positions

and can be placed with either side facing sprocket.

6-18 2004 Touring: Drive

Sprocket Nut

Transmission

Sprocket

Scribe Line

on Nut and Sprocket

Figure 6-22. Tighten/Secure Sprocket Nut

f1977x6x

45°

35°

Page 19

H

OME

Cleaning and Inspection

1. Using a non-volatile cleaning solvent, thoroughly clean

the rear wheel sprocket of all grease and dirt.

2. Carefully inspect the sprocket for cracks or other damage.

3. Inspect each sprocket tooth for large chrome chips having sharp edges. Look for gouges caused by contact

with a hard object. If large enough, both of these conditions will leave a corresponding pattern in the belt face

and are cause for rear sprocket replacement.

4. Without obvious damage, rear wheel sprocket replacement may be a subjective decision based on general

appearance. Using medium pressure, drag a scribe or

the sharp point of a knife blade across the root of a

groove. Even though the plating is lightest in the root

area, a knife point should not penetrate the chrome. If

the blade slides across the chrome plating without digging in, then the chrome is still good. On the other hand,

if you can feel the scribe digging in and it leaves a visible

mark, then the chrome plating has worn off and the bare

aluminum is being cut. Loss of chrome is cause for rear

sprocket replacement.

Installation

1. Apply two drops of Loctite High Strength Threadlocker

271 (red) to threads of each of five sprocket bolts.

Secure sprocket to hub using bolts with flat washers

(and locknuts on laced wheels). Tighten bolts to

55-65 ft-lbs (75-88 Nm).

2. Install rear wheel and adjust belt deflection. See Section

2.4 REAR WHEEL, INSTALLATION.

2004 Touring: Drive 6-19

Page 20

H

OME

PRIMARY CHAINCASE 6.5

GENERAL

The primary chaincase is a sealed housing containing the

primary chain, clutch, engine compensating sprocket, chain

tensioner assembly, alternator and starter drive mechanism.

LUBRICATION

At the 1000 mile (1600 km) service interval, and at every

5000 mile (8000 km) service interval thereafter, change the

primary chaincase lubricant as follows:

1. Using a T27 TORX drive head, remove five screws (with

captive washers) to free clutch inspection cover from primary chaincase cover.

2. Remove magnetic drain plug at bottom of primary chaincase cover. Drain lubricant into suitable container. See

Figure 6-23.

3. Clean drain plug. If plug has accumulated a lot of debris,

inspect the condition of chaincase components.

4. Inspect drain plug O-ring for cuts, tears or signs of deterioration. Replace as necessary.

5. Install drain plug back into primary chaincase cover.

Tighten plug to 36-60

6. Pour 32 ounces (946 ml) of Harley-Davidson PRIMARY

CHAINCASE LUBRICANT through the clutch inspection

cover opening, Part No. 99887-84 (quart) or Part No.

99886-84 (gallon). See Figure 6-24.

f1210x6x

4

Primary

Chain

Inspection

Cover

in-lbs

1

32

(4.1-6.8 Nm).

1

Clutch

43

Inspection

Cover

2

5

Primary

Chaincase Cover

Lubricant

f1508b6x

Figure 6-24. Fill Primary Chaincase With Lubricant

CAUTION

Do not overfill the primary chaincase with lubricant.

Overfilling may cause rough clutch engagement, incomplete disengagement, clutch drag and/or difficulty in

finding neutral at engine idle.

7. Remove quad ring from groove in primary chaincase

cover. Wipe all lubricant from the quad ring and inspect

for cuts, tears or signs of deterioration. Replace as necessary.

8. Swab all lubricant from the quad ring groove. Install

quad ring in primary chaincase cover with the nubs contacting the ring groove walls.

NOTE

If lubricant is not thoroughly removed from both the quad ring

and groove, compression of the ring during installation of the

clutch inspection cover can cause lubricant to be squeezed

to the outboard side of the ring groove, resulting in some

temporary weepage around the inspection cover.

9. Using a T27 TORX drive head, install five screws (with

captive washers) to secure clutch inspection cover to the

primary chaincase cover. Alternately tighten screws to

84-108

in-lbs

(10-12 Nm) in the pattern shown in Figure

6-23.

Figure 6-23. Primary Chaincase Cover

6-20 2004 Touring: Drive

Drain Plug

REMOVAL

1. Remove seat. See Section 2.24 SEAT, REMOVAL.

Page 21

H

1WARNING1WARNING

OME

f1840x6x

Top Center Nut

Primary

Chain

Adjuster

Shoe

Figure 6-25. Chain Tensioner Assembly

1WARNING1WARNING

To protect against shock and accidental start-up of vehicle, disconnect the negative battery cable before proceeding. Inadequate safety precautions could result in

death or serious injury.

2. Unthread bolt and remove battery negative cable (black)

from battery negative (-) terminal.

3. Standing on left side of motorcycle, remove magnetic

drain plug at bottom of primary chaincase cover. Drain

lubricant into suitable container.

NOTE

If drain plug has accumulated a lot of debris, inspect the condition of chaincase components.

4. Remove socket screw with lockwasher to remove passenger footboard from rear swingarm bracket.

5. Remove socket screw (with lockwasher and flat washer)

to release front footboard forward bracket from frame

weldment. For best results, approach from opposite side

using a 3/8 inch ball allen with extension. To free front

footboard rear bracket from frame weldment and jiffy

stand bracket, remove lower hex bolt (with lockwasher)

and upper hex bolt (with lockwasher and locknut).

6. Remove locknut, lockwasher and flat washer to free

shifter rod from front inboard shifter lever.

7. Remove socket head screws and pull both toe and heel

shifter levers from shifter shaft. Remove rubber spacer. If

preferable, remove socket head screw to release front

inboard shifter lever instead, and then pull shifter shaft/

lever assembly from primary chaincase bore. When pulling any lever from splined shaft, always mark splines on

both shaft and lever to assist in assembly.

8. Remove ten allen head socket screws (with captive

washers) from primary chaincase cover. Remove primary chaincase cover from motorcycle.

9. Loosen top center nut from captured bolt of chain tensioner assembly. See Figure 6-25. Lower the chain tensioner assembly as required, so that the adjuster shoe

rests flat on casting of primary chaincase.

Always wear proper eye protection when removing retaining rings. Use the correct retaining ring pliers. Verify

that the tips of the pliers are not damaged or excessively

worn. Slippage may propel the ring with enough force to

cause eye injury.

10. Remove retaining ring and pull release plate (with locknut and adjuster screw) from clutch hub. See Figure 6-

26.

11. Obtain the PRIMARY DRIVE LOCKING TOOL (HD-

41214). See Figure 6-27.

With the flat side against the upper strand of the primary

chain, insert stepped side of tool into teeth of engine

compensating sprocket. Using a breaker bar and 1-1/2

inch socket, turn the sprocket nut in a counterclockwise

direction. Once the stepped area of the tool is drawn into

the sprocket, rotation of the primary drive is stopped.

Continue turning sprocket nut until loose. See Figure 6-

28.

Adjuster

Screw

Locknut

Release

Retaining

Ring

Figure 6-26. Clutch Hub Release Plate Assembly

Plate

f1509b6x

2004 Touring: Drive 6-21

Page 22

H

OME

NOTE

If too much loctite, or perhaps the wrong loctite, was used to

install the engine compensating sprocket nut, it may be very

difficult to remove. In these cases, break down loctite using

heat from a small propane torch. Apply heat evenly around

nut head in a circular motion, but not for so long as to turn nut

blue. Do not direct heat at chain tensioner assembly and

other components or damage will result. If unable to loosen

sprocket nut with breaker bar after applying heat, use air

impact wrench as the last alternative.

1WARNING1WARNING

Use extreme caution when operating propane torch.

Read the manufacturers instructions carefully before

use. Do not direct open flame or heat toward any fuel

system component. Extreme heat can cause fuel ignition

and explosion. Inadequate safety precautions could

result in death or serious injury.

12. Reverse the position of the primary drive locking tool.

With the flat side against the upper strand of the primary

chain, insert stepped side of tool into teeth of clutch

sprocket. Using a breaker bar and 1-3/16 inch socket,

turn the clutch hub mainshaft nut in a cloc

until loose. See Figure 6-30.

Do not place the tool on the

lower strand of the primary

chain. Rotation of either the compensating sprocket nut or clutch

hub nut causes tool to exert

enough force to break or shatter

the nylon adjuster shoe.

Figure 6-27. Primary Drive Locking Tool

(Part No. HD-41214)

kwise direction

CAUTION

Alternator Rotor Spacer

Low Output Rotor Only - 0.020 In.

f1208axx

Compensating

Sprocket

Sprocket

Cover

Shaft

Extension

Sliding

Cam

Compensating

Sprocket Nut

Figure 6-29. Engine Compensating Sprocket Assembly

NOTE

Clutch hub mainshaft nut has left handed threads.

13. Remove the primary drive locking tool. Remove the

clutch hub mainshaft nut and engine compensating

sprocket nut.

14. Remove sprocket cover and sliding cam. See Figure 6-

29.

15. Remove clutch, primary chain, compensating sprocket

and shaft extension as a single assembly. See Figure 6-

31.

16. Remove the alternator rotor spacer from the engine

sprocket shaft, if present.

NOTE

The alternator rotor spacer is only present on those vehicles

with the 38 amp low output rotor.

7859

Primary Drive

Locking Tool

Breaker

Bar

Figure 6-28. Place Primary Drive Locking Tool

and Loosen Compensating Sprocket Nut

6-22 2004 Touring: Drive

7856

Primary Drive

Locking Tool

Breaker

Bar

Figure 6-30. Place Primary Drive Locking Tool

and Loosen Clutch Hub Mainshaft Nut

Page 23

H

1WARNING1WARNING

CAUTION

1WARNING1WARNING

OME

Compensating

Sprocket

7943

coatings into the steel backing). Replace the lip seal.

See STARTER JACKSHAFT BUSHING AND LIP SEAL

- PRIMARY CHAINCASE in this section.

4. Check the shifter bracket bushings in the primary chaincase. Replace the bushings if necessary. See SHIFTER

BRACKET BUSHINGS in this section.

Primary

Chain

Shaft

Extension

Figure 6-31. Remove Clutch Assembly, Primary Chain,

Compensating Sprocket and Shaft Extension

17. Bend tab on lockplate away from head of jackshaft bolt.

Holding pinion gear to prevent rotation, remove the jackshaft bolt with lockplate and thrust washer. Carefully pull

jackshaft assembly from primary chaincase bore.

18. From right side of motorcycle, remove starter front

mounting screw with lockwasher. Remove rear mounting

screw with lockwasher, but do not disconnect chassis

ground cable ring terminal.

19. Returning to left side of motorcycle, remove two bolts

(with flat washers) from outside edge of primary chaincase.

20. Using a chisel and hammer, bend tabs on lockplates

away from heads of 5 inside bolts. Remove bolts (with

lockplates) to free primary chaincase from crankcase

and transmission housings. Remove primary chaincase

from motorcycle.

21. Remove O-ring from crankcase lip and discard.

Clutch

Assembly

INSPECTION AND REPAIR

1. Inspect the primary chaincase for cracks or other damage. Replace as necessary.

2. Check the mainshaft bearing. Bearing must rotate freely

without drag. Replace the bearing if necessary. Replace

the lip seal. See MAINSHAFT BEARING AND LIP SEAL

on this page.

NOTE

Also check the bearing inner race on the mainshaft. Replace

the race if scored or excessively worn. See MAINSHAFT

BEARING INNER RACE in this section.

3. Check the starter jackshaft bushing in the primary chain-

case. Check the jackshaft bushing in the primary chaincase cover. Replace the bushings if they are damaged

or excessively worn (i.e., through the teflon and copper

DISASSEMBLY

MAINSHAFT BEARING AND LIP SEAL

REMOVAL

Always wear proper eye protection when removing retaining rings. Use the correct retaining ring pliers. Verify

that the tips of the pliers are not damaged or excessively

worn. Slippage may propel the ring with enough force to

cause eye injury.

1. Remove retaining ring from groove on clutch side of primary chaincase. Turn the chaincase over to transmission side.

2. Pull lip seal from bearing bore on transmission side of

primary chaincase. Use a seal remover or rolling head

pry bar for best results. Remove retaining ring from

groove on same side of chaincase.

Failure to provide proper support will cause the casting

to crack or break around the outside diameter of the

boss. Any damage to the casting requires replacement

of the primary chaincase.

3. Place primary chaincase in arbor press with the transmission side up. Be sure to properly support boss on

clutch side to avoid damage to casting.

4. Center bearing under ram, and using a suitable driver,

carefully press out bearing applying pressure to the

outer race.

INSTALLATION

1. Inspect the bearing bore to verify that it is clean and

smooth.

Always wear proper eye protection when installing retaining rings. Use the correct retaining ring pliers. Verify

that the tips of the pliers are not damaged or excessively

worn. Slippage may propel the ring with enough force to

cause eye injury.

2004 Touring: Drive 6-23

Page 24

H

OME

f1216x6x

Figure 6-32. Mainshaft Bearing Inner Race Remover

(Part No. HD-34902B)

f1217x7x

Bearing

Inner Race

Mainshaft

Plug

Bridge

4. Place primary chaincase in arbor press with the clutch

side up. Be sure to properly support boss on transmission side to avoid damage to casting.

5. Place bearing over bore with the lettered side up. Center

bearing under ram, and using a suitable driver, apply

pressure to the outer race until bearing makes contact

with the installed retaining ring.

6. Install second retaining ring to lock position of bearing in

bore on clutch side of chaincase. Verify that retaining

ring is fully seated in the groove.

7. Turn chaincase over, so that the transmission side is up.

With the open (lip garter spring) side facing the bearing,

press fit a new lip seal into the bore until it makes contact with the installed retaining ring. Be sure to support

bearing outer race on clutch side during the press procedure. Verify that seal is square in the bore and completely seated around its circumference.

8. Lubricate the bearing and lip seal with multi-purpose

grease or clean H-D 20W50 engine oil.

MAINSHAFT BEARING INNER RACE

NOTE

The bearing inner race must be properly positioned on the

mainshaft to align with the bearing outer race in the primary

chaincase. To remove and install the bearing inner race, use

the combination MAINSHAFT BEARING INNER RACE

REMOVER/INSTALLER, Part No. HD-34902B. See Figure 632 and Figure 6-34.

Puller

Plate

Long

Bolt

Flat

Washer

Forcing

Screw

Figure 6-33. Pull Mainshaft Bearing Inner Race

2. Install retaining ring in groove on transmission side of

primary chaincase. Verify that the retaining ring is fully

seated in the groove.

3. Apply a thin film of clean H-D 20W50 engine oil to bearing bore and O.D. of new bearing.

CAUTION

Failure to provide proper support will cause the casting

to crack or break around the outside diameter of the

boss. Any damage to the casting requires replacement

of the primary chaincase.

REMOVAL

1. Install small flat washers on two long bolts of puller tool.

Slide one bolt into channel on each side of bridge so that

washer is between bridge and bolt head. Thread bolts

into stamped side of U-shaped puller plate an equal

number of turns.

2. Sparingly apply graphite lubricant to threads of forcing

screw to ensure smooth operation. Thread forcing screw

into center hole of bridge.

3. Position U-shaped puller plate between bearing inner

race and sprocket nut. See Figure 6-33.

4. Install mainshaft plug into end of transmission mainshaft. Thread the forcing screw into the bridge until the

steel ball at the end of the screw seats in the cavity of

the mainshaft plug. Verify that the tool assembly is

square so that the bearing is not cocked during removal.

5. Continue turning the forcing screw until the bearing inner

race is pulled free of the mainshaft.

INSTALLATION

1. See Figure 6-35. Chamfered edge first, slide the bearing

inner race onto the transmission mainshaft.

2. Thread extension shaft onto end of mainshaft.

6-24 2004 Touring: Drive

Page 25

H

OME

f1215x6x

Figure 6-34. Mainshaft Bearing Inner Race Installer

(Part No. HD-34902B)

Install Inner Race

and Extension Shaft

Extension

Shaft

Wrench

Flat

NOTE

Extension shaft has left handed threads, so turn counterclockwise to install.

3. See Figure 6-35. Slide installer tube over extension shaft

until it contacts bearing inner race. Sparingly apply

graphite lubricant to threads of extension shaft to ensure

smooth operation.

4. Place both large flat washers over threaded portion of

extension shaft until they contact installer tube. Install

large hex nut onto extension shaft.

5. With a wrench on flats at threaded end of extension

shaft, hold shaft stationary while turning hex nut in a

clockwise direction. In this manner, press race onto shaft

so inside edge is 0.100 in. (2.54 mm) from main drive

gear.

6. Lubricate the race with multi-purpose grease or clean

engine oil.

STARTER JACKSHAFT BUSHING AND LIP SEAL - PRIMARY CHAINCASE

REMOVAL

1. Remove bushing from jackshaft bore of primary chain-

case. For best results, use a bushing/bearing puller with

expandable collet and slide hammer.

2. Remove lip seal from bore.

Bearing

Inner Race

Install Tube, Flat Washers

and Hex Nut

Flat

Washers

Installer

Tube

f1218x7x

Figure 6-35. Press Bearing Inner Race onto Mainshaft

Hex

Nut

INSTALLATION

1. Inspect the bushing bore to verify that it is clean and

smooth. Place primary chaincase in arbor press with the

clutch side up. Support forward part of case so that it lies

flat on transmission mounting flanges.

2. With the open (lip garter spring) side facing up, press fit

a new lip seal into the jackshaft bore until it makes solid

contact with the shoulder on the transmission side. Verify

that the seal is square in the bore and completely seated

around its circumference.

3. See Figure 6-36. Press new bushing into bore. Bushing

must be flush with boss or at a depth not exceeding

0.010 in. (0.76 mm).

4. Lubricate the bushing and seal lip with multi-purpose

grease or clean engine oil.

STARTER JACKSHAFT BUSHING PRIMARY CHAINCASE COVER

REMOVAL

1. Remove bushing from jackshaft bore of primary chain-

case cover. For best results, use a bushing/bearing

puller with expandable collet and slide hammer.

2. Inspect the bushing bore to verify that it is clean and

smooth.

2004 Touring: Drive 6-25

Page 26

H

OME

f1212a6x

Primary

Chaincase

Press Bushing Flush

With Boss or to a

Maximum Depth of

0.010 In. (0.25 mm)

Bushing

Lip Seal

Press Lip Seal

Transmission

Against Shoulder

Side

Figure 6-36. Install Jackshaft Seal and Bushing in

Primary Chaincase

INSTALLATION

1. Using a T27 TORX drive head, remove five screws (with

captive washers) to free clutch inspection cover from primary chaincase cover.

SHIFTER BRACKET BUSHINGS

REMOVAL

1. Remove spacer and shifter shaft assembly from shifter

bracket bore of primary chaincase.

2. Using an arbor press, press bushings from bore. Inspect

the bushing bore to verify that it is clean and smooth.

INSTALLATION

1. Place primary chaincase in arbor press.

2. Press new bushing into each end of bore. Installed

bushings must be flush to 0.010 inch (0.76 mm) above

outer edge of bore.

3. Install shifter shaft in shifter bracket bore. Install spacer

on shifter shaft.

4. Assemble primary chaincase. See Section 6.5 PRI-

MARY CHAINCASE, INSTALLATION, on the next page.

2. Place primary chaincase cover in arbor press. Support

forward part of case so that it lies flat around the clutch

inspection cover bore.

3. Press new bushing into bore. Bushing must be flush with

boss or at a depth not exceeding 0.010 in. (0.76 mm).

4. Lubricate the bushing with multi-purpose grease or

clean engine oil.

6-26 2004 Touring: Drive

Page 27

H

CAUTION

OME

11

17

14

7

1. Magnetic drain plug and O-ring

2. Primary chaincase cover

3. Bolt (3), 5/16-18 x 3 in.

4. Hole

5. Lockplate (5)

6. Bolt (4), 5/16-18 x 1-3/4 in.

7. Primary chaincase

8. Lip seal

9. Retaining ring (2)

10. Bearing, mainshaft

11. Lip seal

12. Bushing

13. Bushing

14. Bushing (2)

14

25

5

6

18

12

5

3

3

4

5

25

19

6

19

15. Primary chain inspection cover

16. Quad ring

17. O-ring

18. Dowel pin (2)

19. Gasket

20. Screw, cover (5)

22

8

13

9

10

9

2

21

16

1

15

21. Screw, cover (5)

22. Gasket

23. Screw (4)

24. Screw (5)

25. Washer (2)

26. Clutch inspection cover

f1048x6x

20

26

24

23

Figure 6-37. Primary Chaincase Assembly

INSTALLATION

1. Install new O-ring on lip of crankcase.

CAUTION

Failure to apply silicone sealer to the bolts and bolt

holes on the inboard side of the primary chaincase may

result in oil leakage after assembly.

2. On the crankcase/transmission side of the primary

chaincase, apply RTV silicone sealer to the following

areas:

● Around the two rear primary chaincase to crank-

case bolt holes. See B in left frame of Figure 6-38.

● Around the three primary chaincase to transmission

bolt holes. See right frame of Figure 6-38.

Also apply the silicone sealer to the threads of the five

fasteners installed in these holes.

The mainshaft splines may damage the sealing surface

of the lip seal if the protector sleeve is not used.

3. Place the seal protector sleeve (from the MAIN DRIVE

GEAR SEAL INSTALLER, HD-41405) over the mainshaft splines. Lightly lubricate the sleeve with clean

engine oil.

4. Place the primary chaincase into position against the

crankcase and transmission housings. Remove the seal

protector sleeve from the mainshaft.

5. See A in left frame of Figure 6-38. Start two forward

bolts (1-3/4 inches with flat washers) to fasten outside

edge of primary chaincase to front of crankcase.

2004 Touring: Drive 6-27

Page 28

H

OME

Start four 1-3/4 inch bolts to engine. Start three 3 inch bolts to transmission.

7948

3

2

With Lockplate

A

With Flat Washer

With Lockplate

B

4

1

Figure 6-38. Primary Chaincase Screw Size and Torque Sequence

See B in left frame of Figure 6-38. From within the primary chaincase, start two forward bolts (1-3/4 inches

with lockplates) to fasten primary chaincase to rear of

crankcase.

See right frame of Figure 6-38. From within the primary

chaincase, start three rearward bolts (3 inches with lockplates) to fasten primary chaincase to front and rear of

transmission.

Tighten the seven bolts to 18-21 ft-lbs (24-28 Nm) in the

numerical sequence shown in Figure 6-38.

Bend one tab on each lockplate against the flat of the

bolt head to secure.

6. On right side of motorcycle, install the front starter

mounting screw with lockwasher. Install rear mounting

screw and lockwasher (with chassis ground cable ring

terminal). Alternately tighten front and rear starter

mounting screws to 13-20 ft-lbs (18-27 Nm).

With Lockplate

7

5

6

7946

8. Install alternator rotor spacer on engine sprocket shaft, if

present. See Figure 6-29.

NOTE

The alternator rotor spacer is only present on those vehicles

with the 38 amp low output rotor.

9. Install the clutch, primary chain, compensating sprocket

and shaft extension as a single assembly. See Figure 6-

31. Start clutch assembly on the mainshaft, while plac-

ing the shaft extension on the engine sprocket shaft. The

clutch hub and shaft extension are splined, so a slight

rotation of the chain drive will aid in lining up the splines.

10. Place sliding cam over shaft extension. Slide sprocket

cover over sliding cam. See Figure 6-29.

11. Apply two drops of Loctite High Strength Threadlocker

262 (red) to the threads of the engine compensating

sprocket nut. Install nut and hand tighten in a clockwise

direction.

7. Returning to left side of motorcycle, gently insert jackshaft assembly into primary chaincase so that splined

end of shaft engages coupling on starter output shaft.

Insert key on lockplate through slot in thrust washer and

into keyway on jackshaft. Thread the jackshaft bolt into

the starter shaft making sure that the lockplate key

remains in the keyway. Holding pinion gear to prevent

rotation, tighten jackshaft bolt to 60-80 in-lbs (6.8-9.0

Nm). Bend tab on lockplate against flat of bolt head to

secure.

6-28 2004 Touring: Drive

12. Apply two drops of Loctite High Strength Threadlocker

262 (red) to the threads of the clutch hub mainshaft nut.

Install nut and hand tighten in a counter

clockwise

direction.

NOTE

Clutch hub mainshaft nut has left handed threads.

13. Obtain the PRIMARY DRIVE LOCKING TOOL (HD-

41214). See Figure 6-39.

Page 29

H

1WARNING1WARNING

7858

Primary Drive

Locking Tool

Torque

Wrench

OME

With the flat side against the upper strand of the primary

chain, insert stepped side of tool into teeth of clutch

sprocket. Verify that adjuster shoe of chain tensioner

assembly rests fl

at on casting of primary chaincase, and

then using a torque wrench and 1-1/2 inch socket,

tighten sprocket nut to 150-165 ft-lbs (203-224 Nm). See

Figure 6-40.

NOTE

Once the stepped area of the tool is drawn into the sprocket,

rotation of the primary drive is stopped.

14. Reverse the position of the primary drive locking tool.

With the flat side against the upper strand of the primary

chain, insert stepped side of tool into teeth of engine

compensating sprocket. Using a torque wrench and 1-3/

16 inch socket, tighten clutch hub mainshaft nut to 70-80

ft-lbs (95-108 Nm). See Figure 6-41.

15. Remove the primary drive locking tool.

16. Install release plate (with locknut and adjuster screw)

into clutch hub bore. The word “OUT” is stamped on the

release plate to indicate the outboard side.

CAUTION

Do not place the tool on the

lower strand of the primary

chain. Rotation of either the compensating sprocket nut or clutch

hub nut causes tool to exert

enough force to break or shatter

the nylon adjuster shoe.

Figure 6-39. Primary Drive Locking Tool

(Part No. HD-41214)

Always wear proper eye protection when installing retaining rings. Use the correct retaining ring pliers. Verify

that the tips of the pliers are not damaged or excessively

worn. Slippage may propel the ring with enough force to

cause eye injury.

17. Install retaining ring in clutch hub bore to lock release

plate in position. Verify that the retaining ring is completely seated in the groove.

18. Adjust clutch. See Section 6.3 CLUTCH, ADJUST-

MENT, steps 3-8.

19. Adjust primary chain tension. See Section 6.2 PRIMARY

CHAIN AND SPROCKETS, PRIMARY CHAIN ADJUSTMENT, steps 2-4.

20. Remove old gasket from flange of primary chaincase

and discard. Thoroughly clean gasket surface. Hang

new gasket on dowels.

21. Start ten allen head socket screws (five long, five short)

with flat washers to install primary chaincase cover.

Tighten screws to 84-108 in-lbs (9-12 Nm) in the numer-

ical sequence shown in Figure 6-42.

22. Clean magnetic drain plug and inspect O-ring for cuts,

tears or signs of deterioration. Replace O-ring as necessary. Install drain plug back into primary chaincase cover

and tighten to 36-60 in-lbs (4.1-6.8 Nm).

23. Using a T27 TORX drive head, remove five screws (with

captive washers) to free clutch inspection cover from primary chaincase cover, if installed.

Primary Drive

Locking Tool

Torque

Wrench

Figure 6-40. Place Primary Drive Locking Tool

and Torque Compensating Sprocket Nut

7857

Figure 6-41. Place Primary Drive Locking Tool

and Torque Clutch Hub Mainshaft Nut

2004 Touring: Drive 6-29

Page 30

H

OME

S = Short Screw, 1-1/4 In.

f1210x6x

L = Long Screw, 1-1/2 In.

S

L

2

S

6

S

4

Primary

Chain

Inspection

Cover

8

Clutch

Inspection

Cover

L

10

9

5

3

S

S

Figure 6-42. Primary Chaincase Cover Torque Sequence

and Screw Size

Primary

Chaincase Cover

Drain

1

Plug

L

L

7

L

CAUTION

Do not overfill the primary chaincase with lubricant.

Overfilling may cause rough clutch engagement, incomplete disengagement, clutch drag and/or difficulty in

finding neutral at engine idle.

25. Remove quad ring from groove in primary chaincase

cover. Wipe all lubricant from the quad ring and inspect

for cuts, tears or signs of deterioration. Replace as necessary.

26. Swab all lubricant from the quad ring groove. Install

quad ring in primary chaincase cover with the nubs contacting the ring groove walls.

NOTE

If lubricant is not thoroughly removed from both the quad ring

and groove, compression of the ring during installation of the

clutch inspection cover can cause lubricant to be squeezed

to the outboard side of the ring groove, resulting in some

temporary weepage around the inspection cover.

27. Using a T27 TORX drive head, install five screws (with

captive washers) to secure clutch inspection cover to the

primary chaincase cover. Alternately tighten screws to

84-108 in-lbs (10-12 Nm) in the pattern shown in Figure

6-44.

28. If installing toe and heel shifter levers, perform steps

28(a) thru 28(d). If just installing front inboard shifter

lever, perform steps 28(c) and 28(d).

Lubricant

f1508b6x

Figure 6-43. Fill Primary Chaincase With Lubricant

24. Pour 32 ounces (946 ml) of Harley-Davidson PRIMARY

CHAINCASE LUBRICANT through the clutch inspection

cover opening, Part No. 99887-84 (quart) or Part No.

99886-84 (gallon). See Figure 6-43.

a. Install rubber spacer onto end of shifter shaft.

f1210x6x

1

43

2

Figure 6-44. Clutch Inspection Cover Torque Sequence

5

6-30 2004 Touring: Drive

Page 31

H

OME

b. Set the shifter levers down, so that the Harley-

Davidson script on the rubber peg is topside. Now

look at the socket head screw hole. If the hole is

countersunk at the bottom, then it is the inboard

shifter lever (toe). If the hole is countersunk at the

top, it is the outboard shifter lever (heel).

c. Install lever(s) onto splined shaft taking note to align

marks placed on splines during disassembly.

d. Install socket head screw(s) to fasten lever(s) to

shaft. Tighten 1/4 inch screws to 90-110 in-lbs

(10.2-12.4 Nm) or 5/16 inch screws to 18-22 ft-lbs

(24-30 Nm).

29. Install flat washer, lockwasher and locknut to fasten

shifter rod to front inboard shifter lever.

30. Install socket screw with lockwasher to fasten passenger

footboard to rear swingarm bracket. Tighten screw to 1518 ft-lbs (20-24 Nm). Repeat step on opposite side of

motorcycle.

31. Install left side footboard and bracket assembly as follows:

a. Insert socket screw (with lockwasher and flat

washer) through frame weldment into front footboard forward bracket. For best results, approach

from opposite side of motorcycle using a 3/8 inch

ball allen with extension.

b. At front footboard rear bracket, slide upper hex bolt

through frame weldment, jiffy stand bracket and

footboard bracket thru hole. Install lockwasher and

locknut. Slide lower hex bolt through frame weldment and jiffy stand bracket into threaded hole of

footboard bracket.

c. Tighten front bracket socket screw to 30-35 ft-lbs

(41-48 Nm).

d. Alternately tighten rear bracket hex bolts to 15-20 ft-

lbs (20-27 Nm).

32. Insert bolt through battery negative cable (black) into

threaded hole of battery negative (-) terminal. Tighten

bolt to 60-96 in-lbs (6.8-10.9 Nm).

33. Install seat. See Section 2.24 SEAT, INSTALLATION.

2004 Touring: Drive 6-31

Page 32

H

OME

NOTES

6-32 2004 Touring: Drive

Loading...

Loading...