Page 1

5

HOME

SPECIFICATIONS 5.1

STARTER

Item

Free (no load) speed 3000 rpm (min.) @ 11.5 V

Free (no load) current 90 amp (max.) @ 11.5V

Stall torque 8.0 ft-lbs (10.8 Nm) @ 2.4 V

Specification

SERVICE WEAR LIMITS

Item

Brush length minimum 0.433 11

Commutator diameter

minimum

IN. MM

1.141 29

TORQUE VALUES

Item

Thru-bolts 39-65

End cover mounting

bracket

End cover center screw 90-110

Battery cable terminal

bolts

Starter front and rear

mounting screws

Oil filler spout allen head

socket screws

Starter jackshaft bolt

Solenoid terminal nut 70-90

ft/in-lbs Nm

in-lbs

50-60

in-lbs

in-lbs

60-96

in-lbs

13-20 ft-lbs 18-27 Nm

84-108

in-lbs

60-80

in-lbs

in-lbs

4.4-7.3 Nm

5.6-6.8 Nm

10.2-12.4 Nm

6.8-10.9 Nm

9.5-12.2 Nm

6.8-9.0 Nm

7.9-10.2 Nm

2004 Touring: Starter 5-1

Page 2

HOME

STARTER SYSTEM 5.2

GENERAL

The starter is made up of an armature, field winding assembly, solenoid, drive assembly, idler gear, and drive housing.

The starter motor torque is increased through gear reduction.

The gear reduction consists of the drive pinion on the armature, an idler gear, and a clutch gear in the drive housing. The

idler gear is supported by rollers and the clutch gear is part of

the overrunning clutch/drive assembly.

The overrunning clutch is the part which engages and drives

the clutch ring gear. It also prevents the starter from overrunning. The field windings are connected in series with the

armature through brushes and commutator segments.

The starter relay is a non-repairable part and must be

replaced if it malfunctions.

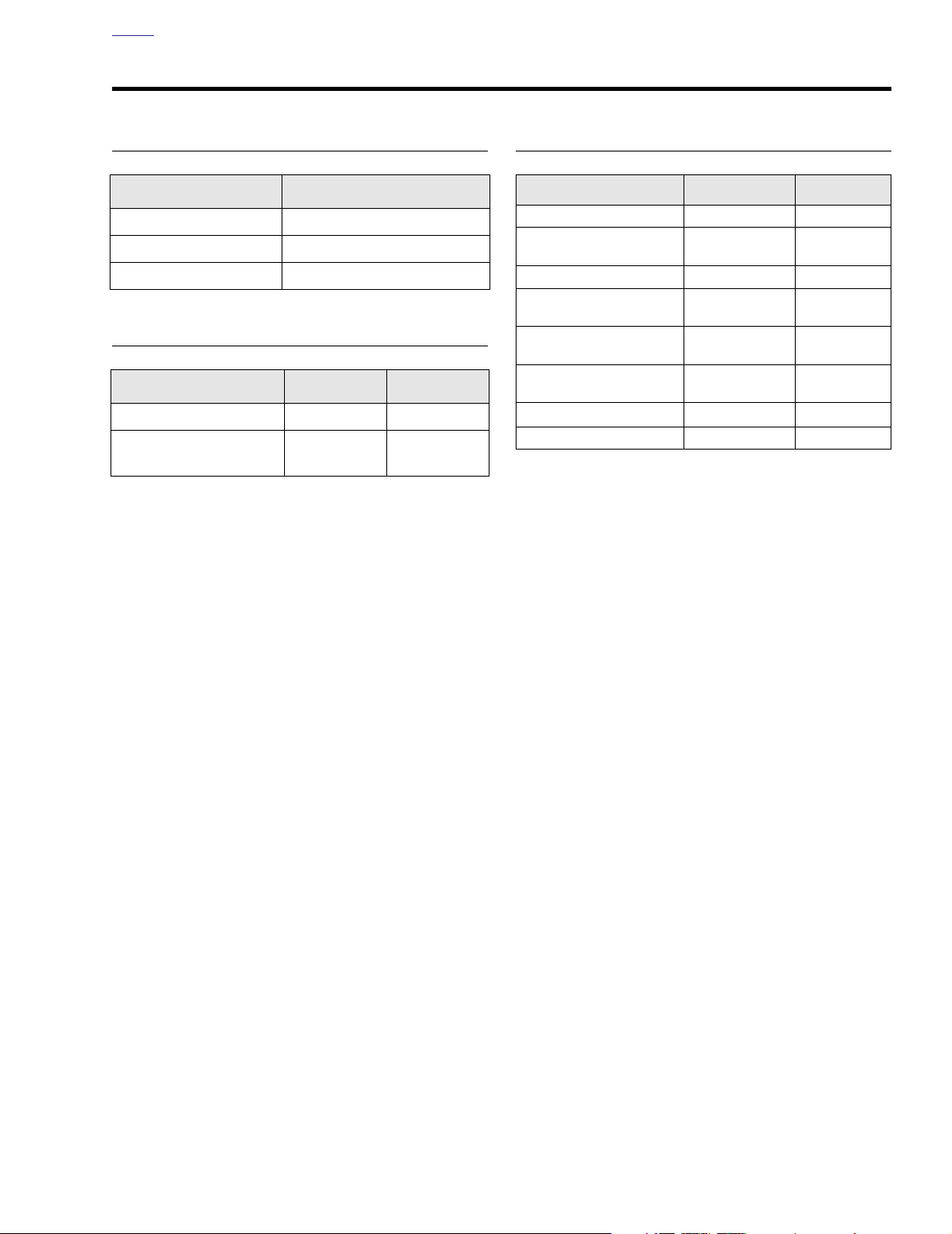

Operation (Figure 5-1)

When the starter switch is pushed, the starter relay is activated and battery current flows into the pull-in winding and

the hold-in winding, to ground.

The magnetic forces of the pull-in and hold-in windings in the

solenoid, pull the plunger and cause it to shift to the left, so

that the pinion gear is engaged with the clutch ring gear. At

the same time, the main solenoid contacts are closed and

battery current flows directly through the field windings to the

armature and to ground. Simultaneously, the pull-in winding

is opened.

The current continues flowing through the hold-in winding,

keeping the main solenoid contacts closed. At this point the

starter begins to crank the engine.

After the engine has started, the pinion gear turns freely on

the pinion shaft through the action of the overrunning clutch

which prevents the armature overrunning by the rotation of

the clutch ring gear.

When the starter switch is released, the current of the hold-in

winding is fed through the main solenoid contacts and the

direction of the current in the pull-in winding is reversed. The

solenoid plunger is returned to its original position by the

return spring, disengaging the pinion gear from the clutch

ring gear.

5-2 2004 Touring: Starter

Page 3

HOME

Pinion

gear

Idler gear

STARTER AT MOMENT STARTER SWITCH IS CLOSED

Field winding

Plunger

Armature

Brush

Ball

bearing

Main

contacts

Clutch

ring gear

Pinion

gear

Overrunning

Idler gear

clutch

Field winding

Hold-In

winding

STARTER DURING CRANKING

Pull-In

winding

Start

circuit. See

wiring

diagram.

Battery

Armature

Brush

Ball

bearing

Plunger

Main

contacts

Clutch

ring gear

Overrunning

clutch

Figure 5-1. Starter Operation

Hold-in

winding

Pull-In

winding

Start circuit.

See wiring

diagram

Battery

2004 Touring: Starter 5-3

Page 4

HOME

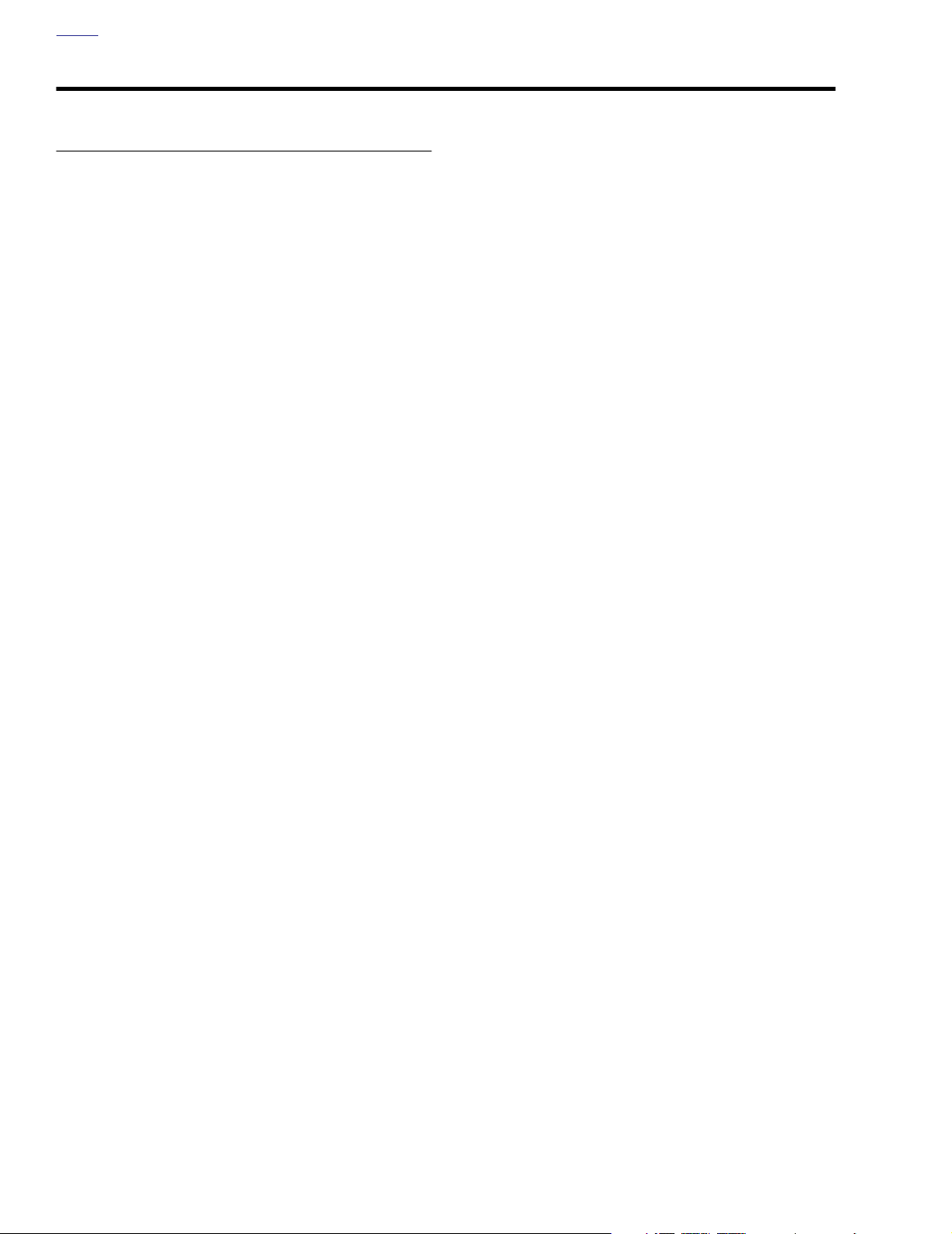

STARTER RELAY 5.3

REMOVAL

FLHR/C/S

FLHR/C/S

1. Remove left side saddlebag. See Section 2.25 SAD-

DLEBAG, REMOVAL.

2. Gently pull side cover from frame downtubes (no tools

required).

3. Depress latches on maxi-fuse holder and then slide

cover rearward to disengage tongue from groove in fuse

block cover.

4. Pull fuse block from tabs on mounting panel. Tabs on

panel fit into slots on each side of fuse block cover.

NOTE

The fuse block cover also serves as the spare fuse holder.

One spare 10 amp and 15 amp fuse are provided.

5. Remove the fuse block cover. Raise lipped side slightly

to disengage slots from tabs on fuse block.

6. Pull relay from slots in fuse block. See upper frame of

Figure 5-2.

Brake Light

Relay [124]

Starter

Relay [123]

Check the wire tags for positive

identification of relays. Starter

relay can be positively identified

by heavy gauge Green wire.

NOTE

Starter

Relay [123]

f2210x8x

FLTR, FLHT/C/U

Ignition Keyswitch

Relay [126]

FLTR, FLHT/C/U

1. Remove seat. See Section 2.24 SEAT, REMOVAL.

2. Locate the starter relay installed in cavity of frame crossmember at rear of battery box. See lower frame of Fig-

ure 5-2.

3. Place a finger on the rubber molding to hold it in position, and using a needle nose pliers, carefully pull on tab

to release starter relay. Since the position of the relays

may be reversed, starter relay can be positively identified by heavy gauge Green wire.

4. Remove harness connector from bottom of relay.

INSTALLATION

FLHR/C/S

1. Install

7. Slide cover over fuse block until slots fully engage tabs

8. Slide fuse block into position on mounting panel. Tabs on

new

relay in fuse block.

on block.

panel fit into slots on each side of fuse block cover.

f2192x8x

Figure 5-2. Locate Starter Relay

9. Slide maxi-fuse cover forward to engage tongue in

groove of fuse block cover and then insert maxi-fuse

holder into cover until latches engage.

10. Align barbed studs in side cover with grommets in frame

downtubes and push firmly into place (no tools

required).

5-4 2004 Touring: Starter

Page 5

HOME

11. Install left side saddlebag. See Section 2.25 SADDLE-

BAG, INSTALLATION.

FLTR, FLHT/C/U

1. Install harness connector at bottom of

2. Place a finger on the molding to hold it in position and

push on relay until seated in cavity of frame crossmember.

3. Install seat. See Section 2.24 SEAT, INSTALLATION.

new

relay.

2004 Touring: Starter 5-5

Page 6

f2268x8x

Frame

Cross Member

Frame Hole

Cruise Cable

Routing Only

Main Power

To Maxi-Fuse

Negative

Battery Cable

Positive

Battery Cable

HOME

STARTER 5.4

REMOVAL

1. Remove seat. See Section 2.24 SEAT, REMOVAL.

1WARNING1WARNING

To protect against shock and accidental start-up of vehicle, disconnect the negative battery cable before proceeding. Inadequate safety precautions could result in

death or serious injury.

2. Unthread bolt and remove battery negative cable (black)

from battery negative (-) terminal.

3. Remove the primary chaincase cover. See Section 6.5

PRIMARY CHAINCASE, REMOVAL, steps 3-8.

4. Bend tab on lockplate away from head of jackshaft bolt.

5. Holding pinion gear to prevent rotation, remove the jackshaft bolt with lockplate and thrust washer.

6. From right side of motorcycle, remove starter front

mounting screw with lockwasher. Remove rear mounting

screw with lockwasher (and battery negative cable ring

terminal). Remove Keps nut from stud of bracket tab and

remove exhaust support bracket.

7. Pull back rubber boot and remove flange nut from starter

post. Remove main power and battery positive cable

ring terminals from starter post. See Figure 5-3.

8. Depress external latch and pull solenoid connector from

top of starter housing.

9. Locate oil filler plug/dipstick on right side of motorcycle

at top of transmission case. To remove the oil filler plug,

pull steadily while moving plug back and forth.

10. Remove the starter from the right side of the motorcycle,

carefully sliding it through the space between the

exhaust pipe and side cover.

NOTE

If necessary, remove allen screw and decorative chrome

cover to facilitate starter removal.

11. Remove the coupling from the starter motor output shaft,

if necessary.

12. Before disassembly, perform tests on the assembled

starter. See DISASSEMBLY, TESTING AND REPAIR in

this section.

INSTALLATION

1. Inspect the retaining ring within the output shaft coupling

for damage or distortion. Replace as necessary. With the

counterbore on the outboard side, install the coupling on

the starter motor output shaft, if removed.

Figure 5-3. Battery Cable Routing (Right Side View)

2. From right side of motorcycle, tilt starter and work into its

installed position. Starter output shaft coupling must

remain on shaft and mate to starter jackshaft. See Section 5.6 STARTER JACKSHAFT, if necessary.

3. Install oil filler plug/dipstick at top of transmission case

on right side of motorcycle.

4. Install slot of exhaust support bracket onto stud of

bracket tab aligning other holes with those in starter

flange. Start Keps nut on stud.

5. Engaging hole in exhaust support bracket, install starter

front mounting screw with lockwasher. Install rear

mounting screw with lockwasher (and battery negative

cable ring terminal) in the same manner.

6. Alternately tighten starter front and rear mounting

screws to 13-20 ft-lbs (18-27 Nm). Tighten Keps nut on

stud of bracket tab.

7. Install battery positive and main power cable ring terminals onto starter post. Install flange nut and tighten to

70-90

in-lbs

(7.9-10.2 Nm). Pull down rubber boot over

terminal connections on starter post. See Figure 5-3.

8. Snap solenoid connector to terminal at top of starter

housing.

NOTE

If removed, install allen screw to fasten decorative chrome

cover to starter.

2004 Touring: Starter 5-6

Page 7

HOME

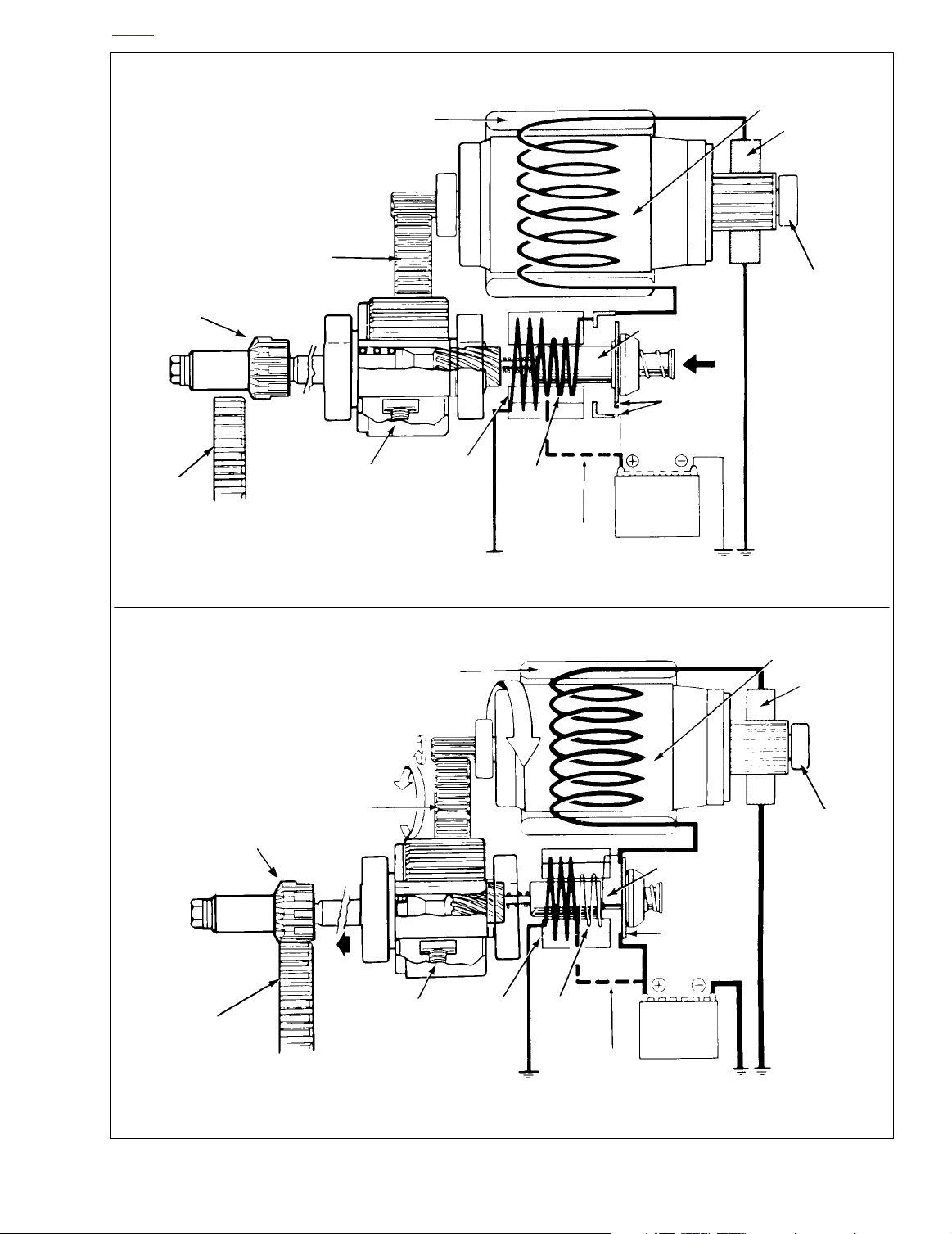

1. Field wire

2. Thru-bolt (2)

3. Field coil

4. End cap

5. End cap screw (2)

6. Brush spring (4)

7. Brushes

8. Brush holder

9. Armature

10. Armature bearings

11. Drive housing mounting screw (2)

12. Lockwasher (2)

13. Drive housing

14. Solenoid housing

9

14

10

21

22

15. Drive assembly/overrunning clutch

16. Idler gear

17. Idler gear bearing & cage

18. O-ring

19. Spring

20. Shaft

21. Return spring

22. Ball

23. O-ring (2)

23

7

6

3

23

10

16

4

5

2

7

8

1

17

12

11

Figure 5-4. Starter

NOTE

If removed, install allen screw to fasten decorative chrome

cover to starter.

9. Slide lockplate and

bolt, if removed. Insert bolt into jackshaft bore.

10. Insert key on lockplate through slot in thrust washer and

into keyway on jackshaft. Thread the jackshaft bolt into

the starter shaft making sure that the lockplate key

remains in the keyway.

new

thrust washer onto jackshaft

20

19

15

18

13

11. Holding pinion gear to prevent rotation, tighten jackshaft

bolt to 60-80

against flat of bolt head to secure.

12. Install the primary chaincase cover. See Section 6.5

PRIMARY CHAINCASE, INSTALLATION, steps 20-31.

13. Insert bolt through battery negative cable (black) into

threaded hole of battery negative (-) terminal. Tighten

bolt to 60-96

14. Install seat. See Section 2.24 SEAT, INSTALLATION.

in-lbs

(6.8-9.0 Nm). Bend tab on lockplate

in-lbs

(6.8-10.9 Nm).

f1107axx

2004 Touring: Starter 5-7

Page 8

HOME

DISASSEMBLY, TESTING AND REPAIR

1. See Figures 5-4 and 5-5. Disconnect field wire (1).

3497

Figure 5-5. Remove Thru-Bolts

2. See Figures 5-4 and 5-6. Remove thru-bolts (2).

Remove field coil (3) and end cap (4).

3. See Figures 5-7 and 5-8. Remove the end cap screws

and cap.

3500

Figure 5-7. Remove End Cap Screws and O-Rings

3501

3498

3499

Figure 5-8. Remove End Cap

4. See Figures 5-4 and 5-9. Disengage brush springs (6)

and pull field coil brushes (7) out of brush holders (8).

3502

Figure 5-6. Remove Field Coil and Cap

5-8 2004 Touring: Starter

Figure 5-9. Remove Brush Holder

Page 9

HOME

CAUTION

2231

Commutator

Starting groove in mica

with 3 cornered file

Mica

Segments

Wrong way

Mica must not be left

with a thin edge next to

segments.

Figure 5-10. Undercutting the Mica Separators

5. Check the brush length. Brushes less than 0.433 inch

(11 mm) long should be replaced.

NOTE

Replace brushes in sets of four only.

●

Field coil and brush holder brushes are attached to field

●

coil and brush holder. To replace brushes, replace field

coil and brush holder.

6. See Figure 5-4. Remove armature (9).

7. Place armature in lathe or truing stand and check runout

of commutator. Commutators with more than 0.015 in.

(0.38 mm) of runout should be replaced or machined on

a lathe. Commutators should be replaced when diameter is less than 1.141 in. (29.98 mm).

Commutator

Undercutting mica with piece

of hacksaw blade

Mica

Right way

Mica must be cut away

clean between segments.

Do not use sandpaper or emery cloth on commutator.

The abrasive grit may remain on commutator segments

and could cause excessive brush wear.

10. See Figure 5-11. Check for SHORTED ARMATURE with

a growler. Place armature on growler. Hold a thin steel

strip (hacksaw blade) against armature core and slowly

turn armature. A shorted armature will cause the steel

strip to vibrate and be attracted to the core. Shorted

armatures should be replaced.

8. Check depth of mica on commutator. If undercut is less

than 0.008 in. (0.20 mm), use an undercutting machine

to undercut the mica to 1/32 in. (0.79 mm) deep. The

slots should then be cleaned to remove any dirt or copper dust.

9. See Figure 5-10. If an undercutting machine is not available, undercutting can be done satisfactorily using a thin

hacksaw blade. After undercutting, lightly sand the

armature with crocus cloth to remove any burrs.

Figure 5-11. Shorted Armature Test Using Growler

2004 Touring: Starter 5-9

Page 10

HOME

11. See Figure 5-12. Check for a GROUNDED ARMATURE

with an ohmmeter or continuity tester. Touch one probe

to any commutator segment, and the other probe to the

armature core. There should be no continuity (infinite

ohms). If there is any continuity the armature is

grounded and should be replaced.

Figure 5-12. Grounded Armature Test

13. See Figure 5-14. Check for GROUNDED FIELD WINDING with an ohmmeter or continuity tester. Touch one

probe to the frame, and the other probe to each of the

brushes attached to the field winding. There should be

no continuity (infinite ohms). If there is any continuity at

either brush, the field winding(s) are grounded and the

field frame should be replaced.

Figure 5-14. Grounded Field Test

12. See Figure 5-13. Check for OPEN ARMATURE with an

ohmmeter or continuity tester. Check for continuity

between all commutator segments. There should be

continuity (0 ohms) at all test points. No continuity at any

test point indicates armature is open and should be

replaced.

Figure 5-13. Armature Open Test

14. See Figure 5-15. Check for OPEN FIELD WINDING with

an ohmmeter or continuity tester. Touch one probe to the

field wire, and the other probe to each of the brushes

attached to the field coils. There should be continuity. If

there is no continuity at either brush, the field winding(s)

are open and the field frame should be replaced.

Figure 5-15. Open Field Test

5-10 2004 Touring: Starter

Page 11

HOME

f1540a5x

3506

15. See Figure 5-16. Te st BRUSH HOLDER INSULATION

with an ohmmeter or continuity tester. Touch one probe

to holder plate and the other probe to each of the positive (insulated) brush holders. There should be no continuity (infinite ohms). If there is continuity at either brush

holder, the brush holder assembly should be replaced.

To uch one probe to the non-insulated brush holders and

the other probe to the holder plate. If you measure any

resistance, the brush holder must be replaced.

f1541x5x

Figure 5-16. Brush Holder Insulation Test

16. Check armature bearings (10) and replace if necessary.

See Figure 5-4.

NOTE

Spring (21) and ball (22) are loose in shaft gear end. See

Figure 5-4.

Figure 5-18. Drive Housing Assembly

Figure 5-19. Clutch Assembly

17. See Figures 5-4, 5-17 and 5-18. Remove the two drive

housing mounting screws (11) and washers (12).

Remove drive housing (13) from solenoid housing (14).

18. See Figures 5-4 and 5-19. Remove drive (15), idler gear

(16) and idler gear bearing (17) from drive housing (13).

O-ring (18) is in groove in drive housing.

f1557x5x

19. Remove spring (19) and shaft (20).

Figure 5-17. Remove Drive Housing

2004 Touring: Starter 5-11

Page 12

HOME

ASSEMBLY

1. See Figure 5-4. Replace O-rings (18, 23).

CAUTION

Do not use solvents to clean drive assembly/over-running clutch (15). It is lubricated and sealed. If you use a

solvent to clean it, the lubricant will be washed out and

the clutch will fail.

2. Clean, inspect and lubricate drive assembly components. Lubricate parts with high temperature grease

such as LUBRIPLATE 110.

3. When installing drive assembly components, open end

of idler bearing cage (17) faces toward solenoid.

4. When installing drive housing (13) to solenoid housing

(14) use new O-ring (18). Be sure to install return spring

(21) and ball (22).

5. Lubricate armature bearings (10) with high temperature

grease such as LUBRIPLATE 110. Install armature (9)

and field coil (3) to solenoid housing (14).

6. Replace brush springs (6), if necessary. Install brushes

(7) and brush holder (8).

7. Install end cap (4) with screws (5).

8. Install thru-bolts (2).

9. Connect field wire (1) to solenoid terminal. Tighten solenoid terminal nut to 70-90

in-lbs

(7.9-10.2 Nm).

5-12 2004 Touring: Starter

Page 13

HOME

STARTER SOLENOID 5.5

GENERAL

The starter solenoid is a switch designed to open and close

the starting circuit electromagnetically. The switch consists of

contacts and a winding around a hollow cylinder containing a

movable plunger. When the winding is energized by the battery, the magnetism produced pulls the plunger into the coil.

The plunger moves against two main switch contacts, closing

the circuit.

DISASSEMBLY

1. See Figure 5-20. Remove screws and washers. Clip

comes off with screw.

Solenoid

Housing

Plunger

2. Remove cover and gasket. Discard gasket.

3. Plunger can now be removed from solenoid housing.

ASSEMBLY

1. Replace wire connection hardware as necessary.

2. Apply a light coat of Lubriplate® 110 to plunger shaft.

Install plunger in solenoid housing.

3. Install

Gasket

new

gasket. Place cover in position and install

screws, washers and clip.

Cover

Clip

Screw and

Washer

5-13 2004 Touring: Starter

CAUTION

Do not tighten the inside nut without

removing other items shown. Movement

will cause damage to the contact.

Figure 5-20. Starter Solenoid

f1079axx

Page 14

HOME

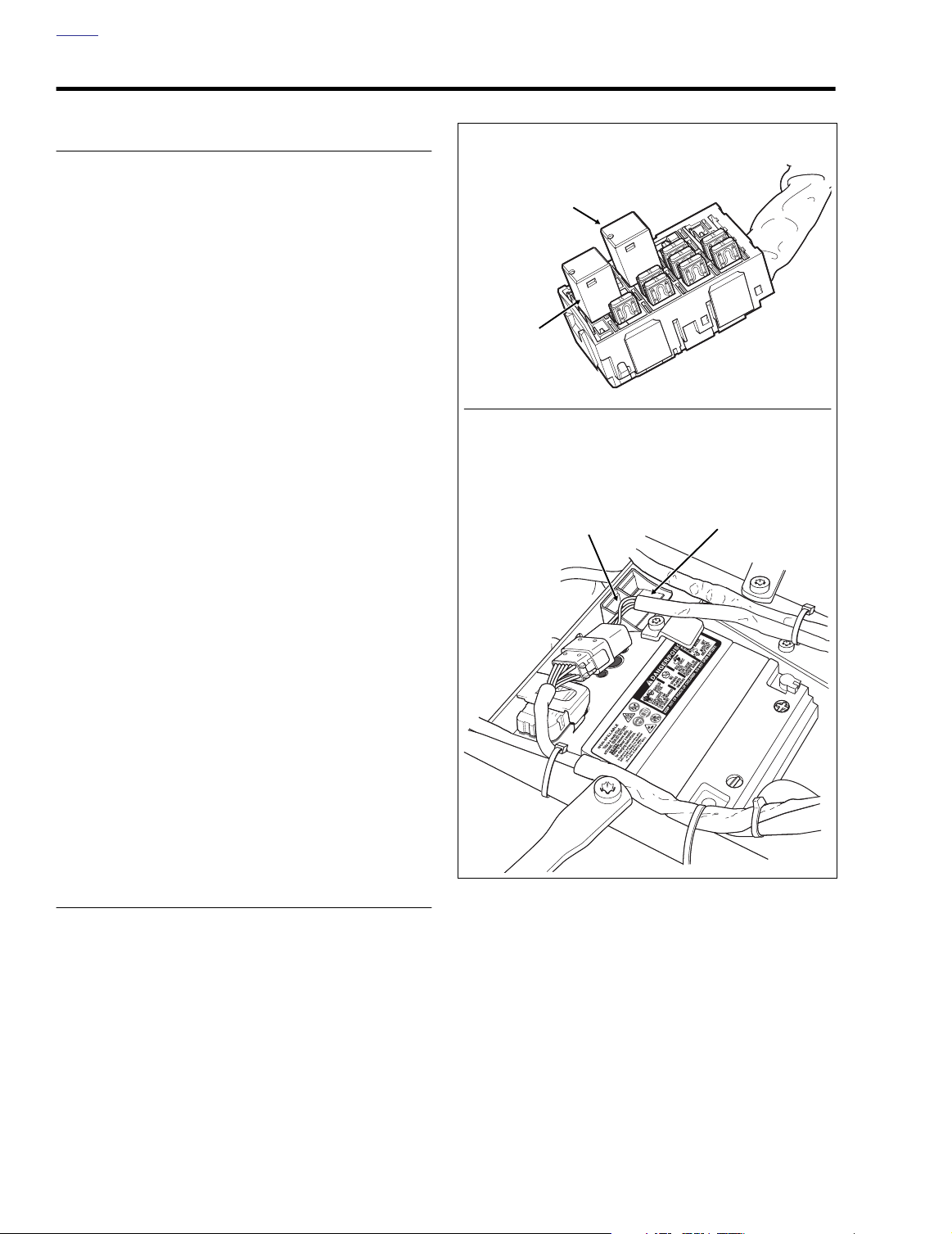

7945

Starter

Jackshaft

Assembly

STARTER JACKSHAFT 5.6

REMOVAL/DISASSEMBLY

1. Remove seat. See Section 2.24 SEAT, REMOVAL.

1WARNING1WARNING

To protect against shock and accidental start-up of vehicle, disconnect the negative battery cable before proceeding. Inadequate safety precautions could result in

death or serious injury.

2. Unthread bolt and remove battery negative cable (black)

from battery negative (-) terminal.

3. See Figure 5-21. Remove the primary chaincase cover.

Remove the clutch assembly, primary chain and compensating sprocket components as a single assembly.

See Section 6.5 PRIMARY CHAINCASE, REMOVAL,

steps 3-15.

NOTE

If only the jackshaft bolt, thrust washer, lockplate, pinion gear

and/or spring require servicing, then the primary chain and

clutch assembly may be left in place.

Figure 5-21. Primary Chaincase

f1211c5x

Jackshaft

Bolt

Key

Lockplate

Coupling

Spring

Slot

Retaining

Ring

Pinion

Gear

Thrust

Tab

Washer

Figure 5-22. Starter Jackshaft Assembly

Retaining

Keyway

Jackshaft

Primary

Cover Bushing

Ring

Output

Shaft

Coupling

Counterbore

Primary Chaincase

Bushing

2004 Touring: Starter 5-14

Page 15

HOME

4. Bend tab on lockplate away from head of jackshaft bolt.

See Figure 5-22.

5. Holding pinion gear to prevent rotation, remove the jack-

shaft bolt with lockplate and thrust washer.

6. Carefully pull jackshaft assembly from the primary chain-

case bore.

7. Remove the pinion gear from the jackshaft.

8. Remove the coupling from the jackshaft. Remove the

spring from the coupling.

CAUTION

Do not force the output shaft coupling through the oil

seal in the primary chaincase or the resulting damage

will require seal replacement.

9. From right side of motorcycle, remove starter front

mounting screw with lockwasher. Remove rear mounting

screw with lockwasher (and battery negative cable ring

terminal). Remove Keps nut from stud of bracket tab and

remove exhaust support bracket.

10. Pull back rubber boot and remove flange nut from starter

post. Remove main power and battery positive cable

ring terminals from starter post.

11. Depress external latch and pull solenoid connector from

top of starter housing.

12. Locate oil filler plug/dipstick at top of transmission case.

To remove the oil filler plug, pull steadily while moving

plug back and forth.

13. Remove the starter from the right side of the motorcycle,

carefully sliding it through the space between the

exhaust pipe and side cover.

NOTE

If necessary, remove allen screw and decorative chrome

cover to facilitate starter removal.

14. Remove the coupling from the starter motor output shaft.

ASSEMBLY/INSTALLATION

NOTE

To replace the jackshaft bushings and/or seals in the primary

chaincase or primary chaincase cover, see Section 6.5 PRI-

MARY CHAINCASE, DISASSEMBLY.

1. Inspect the retaining ring within the output shaft coupling

for damage or distortion. Replace as necessary. With the

counterbore on the outboard side, install the coupling on

the starter motor output shaft, if removed.

2. From right side of motorcycle, tilt starter and work into its

installed position. Starter output shaft coupling must

remain on shaft and mate to starter jackshaft.

3. Install oil filler plug/dipstick at top of transmission case.

4. Install slot of exhaust support bracket onto stud of

bracket tab aligning other holes with those in starter

flange. Start Keps nut on stud.

5. Engaging hole in exhaust support bracket, install starter

front mounting screw with lockwasher. Install rear

mounting screw with lockwasher (and battery negative

cable ring terminal) in the same manner.

6. Alternately tighten starter front and rear mounting

screws to 13-20 ft-lbs (18-27 Nm). Tighten Keps nut on

stud of bracket tab.

7. Install battery positive and main power cable ring terminals onto starter post. Install flange nut and tighten to

70-90

in-lbs

(7.9-10.2 Nm). Pull down rubber boot over

terminal connections on starter post.

8. Snap solenoid connector to terminal at top of starter

housing.

NOTE

If removed, install allen screw to fasten decorative chrome

cover to starter.

9. Inspect the retaining ring within the coupling for damage

or distortion. Replace as necessary.

10. Insert narrow end of jackshaft into shallow side of coupling until gear face contacts installed retaining ring.

(Look at position of retaining ring within coupling to

determine shallow side.)

11. Slide spring over narrow end of jackshaft until it contacts

retaining ring.

12. Slide pinion gear over narrow end of jackshaft until it

contacts spring.

13. Slide lockplate and

bolt, if removed. Insert bolt into jackshaft bore.

14. Gently insert jackshaft assembly into primary chaincase

so that splined end of shaft engages coupling on starter

output shaft.

15. Insert key on lockplate through slot in thrust washer and

into keyway on jackshaft. Thread the jackshaft bolt into

the starter shaft making sure that the lockplate key

remains in the keyway.

16. Holding pinion gear to prevent rotation, tighten jackshaft

bolt to 60-80

against flat of bolt head to secure.

17. Install the clutch, primary chain, and compensating

sprocket components. Install the primary chaincase

cover. See Section 6.5 PRIMARY CHAINCASE,

INSTALLATION, steps 9-31.

18. Insert bolt through battery negative cable (black) into

threaded hole of battery negative (-) terminal. Tighten

bolt to 60-96

19. Install seat. See Section 2.24 SEAT, INSTALLATION.

new

thrust washer onto jackshaft

in-lbs

(6.8-9.0 Nm). Bend tab on lockplate

in-lbs

(6.8-10.9 Nm).

2004 Touring: Starter 5-15

Page 16

HOME

NOTES

5-16 2004 Touring: Starter

Loading...

Loading...