Page 1

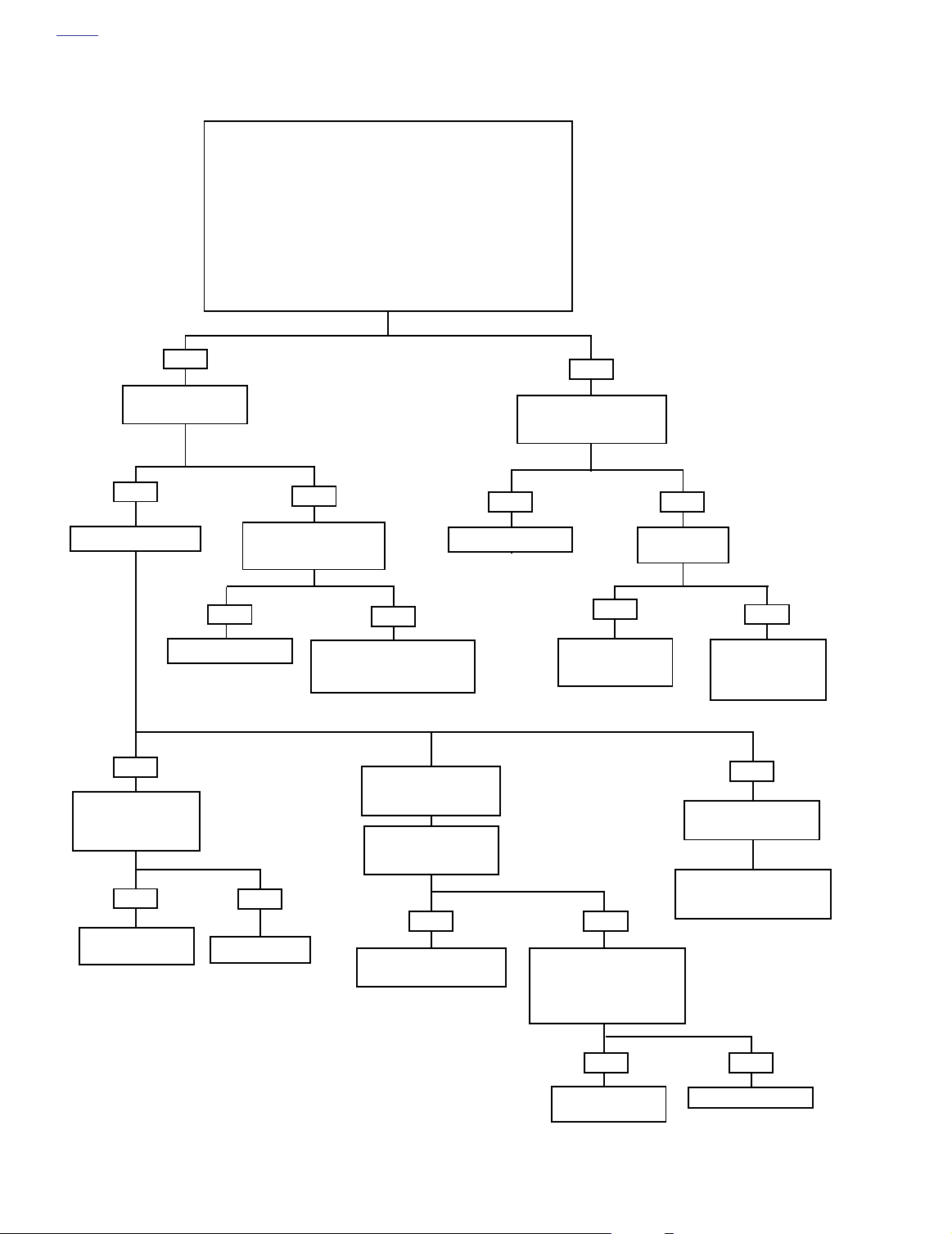

HOME

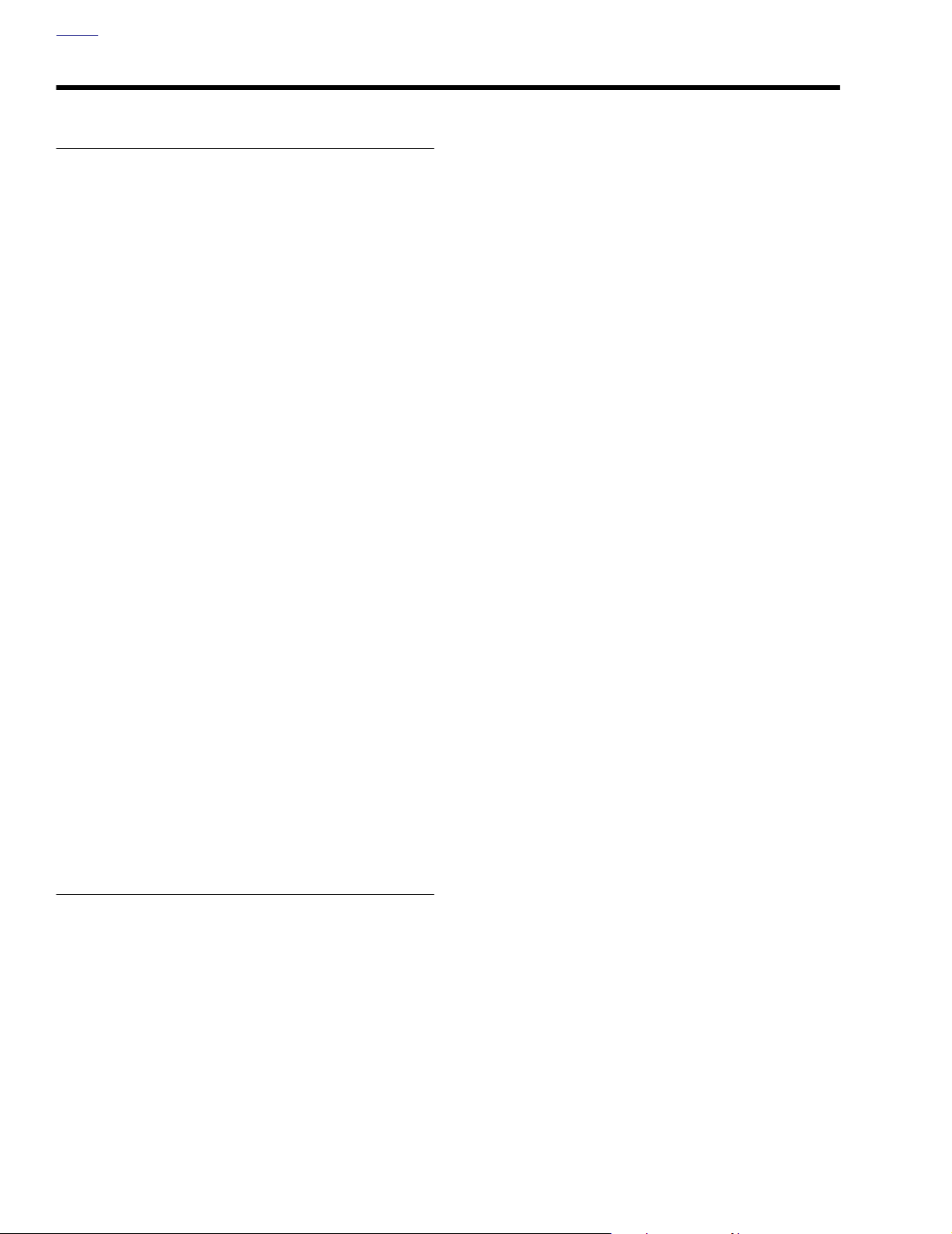

Spare

ECM Power

f2223x9x

EFI System

Relay

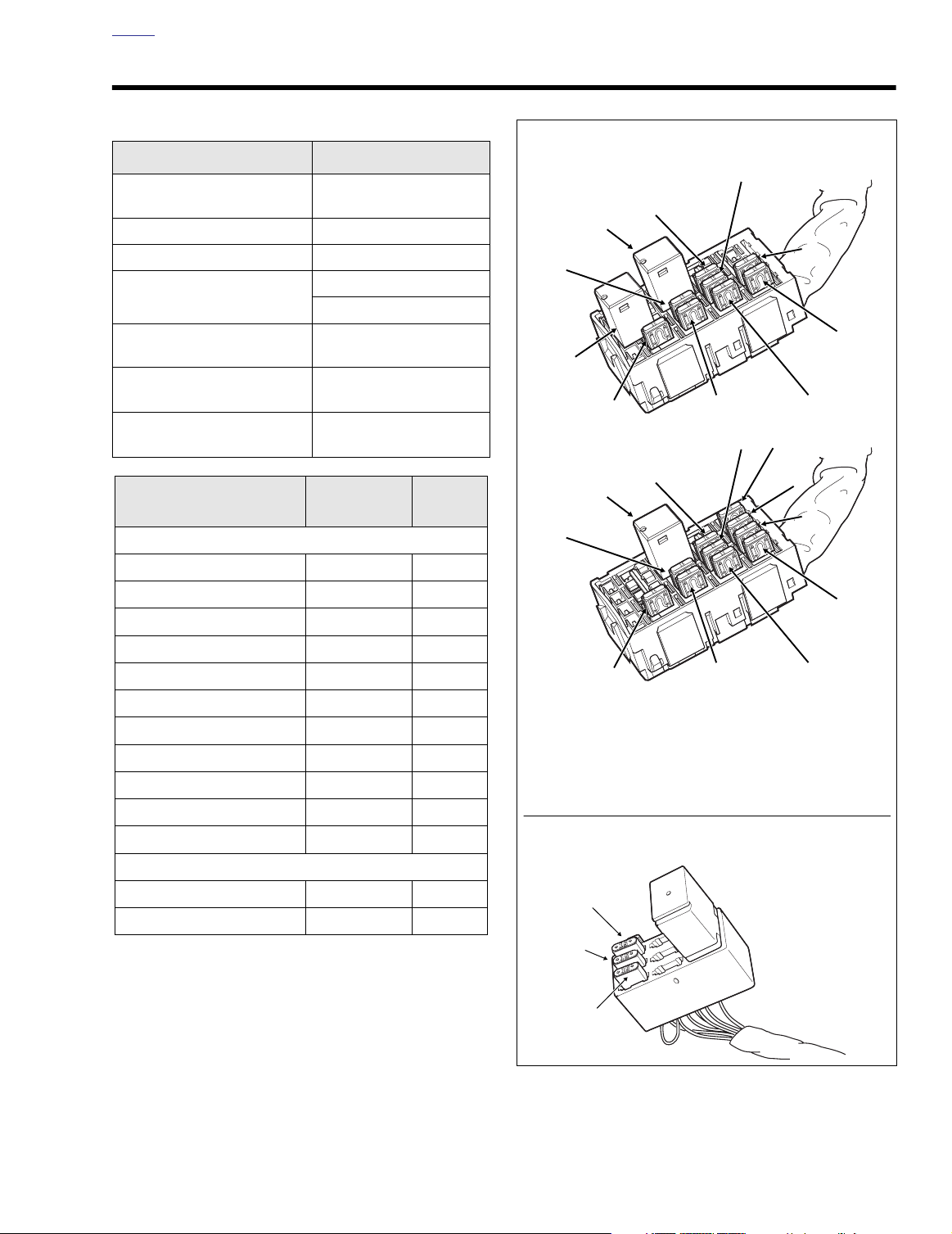

System Fuse Block (Under Left Side Cover)

EFI Fuse Block (Under Right Side Cover)

11

10

9

1

8

5

4

3

2

FLHR/C/S

11

10

9

1

8

7

6

5

4

3

2

FLTR, FLHT/C/U

1. Headlamp

2. Ignition

3. Lighting

4. Instruments

5. Brakes/Cruise

6. Radio Memory

7. Radio Power

8. Accessory

9. Battery

10. Brake Light Relay

11. P&A

12. Starter Relay

12

f2210x8x

f2204x8x

Fuel Pump

SPECIFICATIONS 5.1

IGNITION

Spark timing advance

Idle speed 990 ± 50 RPM

Spark plug size 12 mm

Spark plug gap

Spark plug type

Ignition coil primary

resistance

Ignition coil secondary

resistance

System Fuses

Maxi-Fuse 40 Orange

Headlamp 15 Blue

Ignition 15 Blue

Lighting 15 Blue

Instruments 15 Blue

Brakes/Cruise 15 Blue

Radio Memory 15 Blue

Radio Power 10 Red

Accessory 15 Blue

Battery 15 Blue

P & A 15 Blue

EFI Fuses

Fuel Pump 15 Blue

ECM Power 15 Blue

Circuit

DATA

0°-45° BTDC (range)

12° BTDC@1000 RPM

0.038-0.043 in

0.97-1.09 mm

Harley-Davidson

No. 6R12 (no substitute)

0.3-0.5 ohms

2500-3500 ohms

Rating

(Amperes)

Color

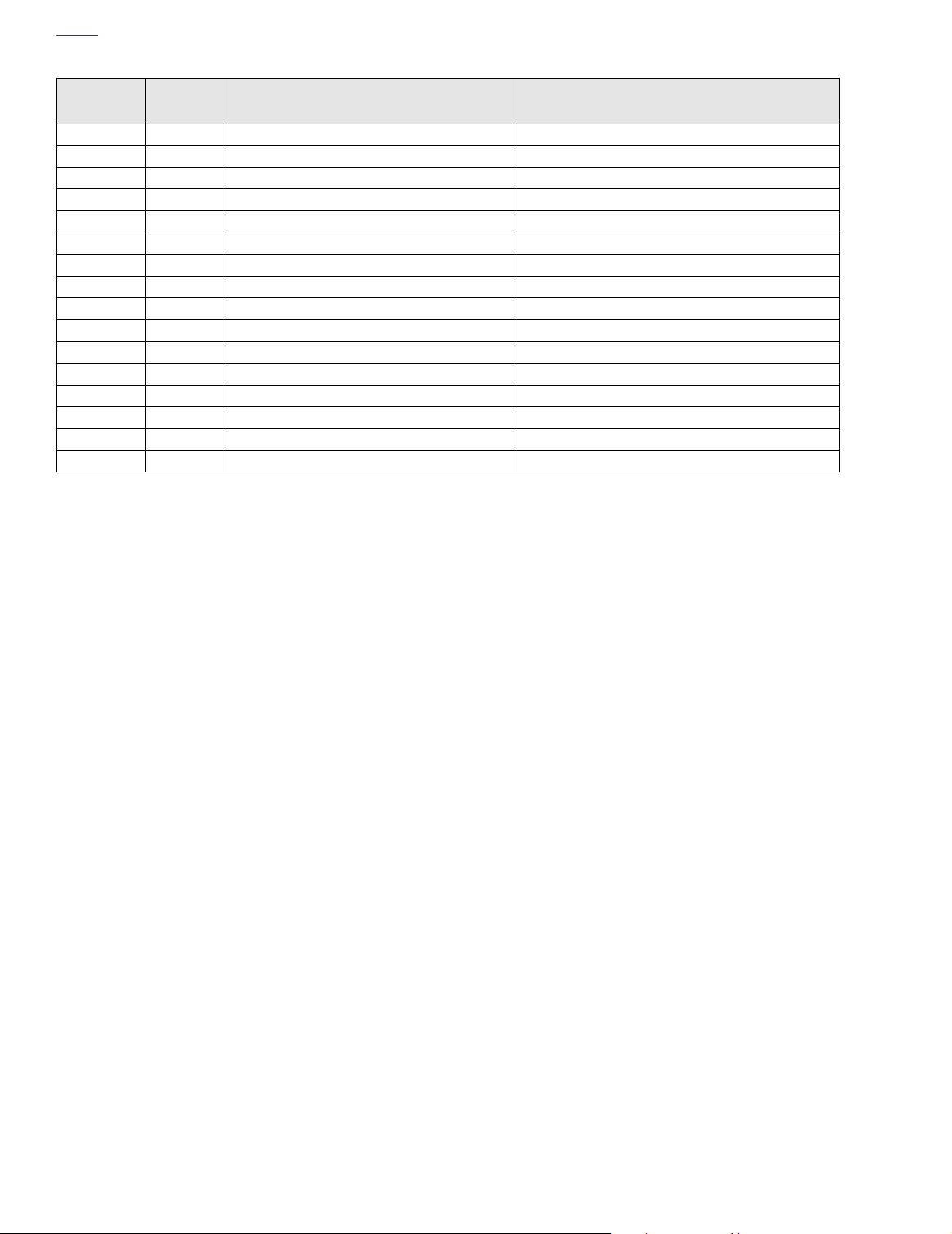

Figure 5-1. Fuse Locations

2004 Touring: Engine Management (EFI) 5-1

Page 2

HOME

NOTES

5-2 2004 Touring: Engine Management (EFI)

Page 3

HOME

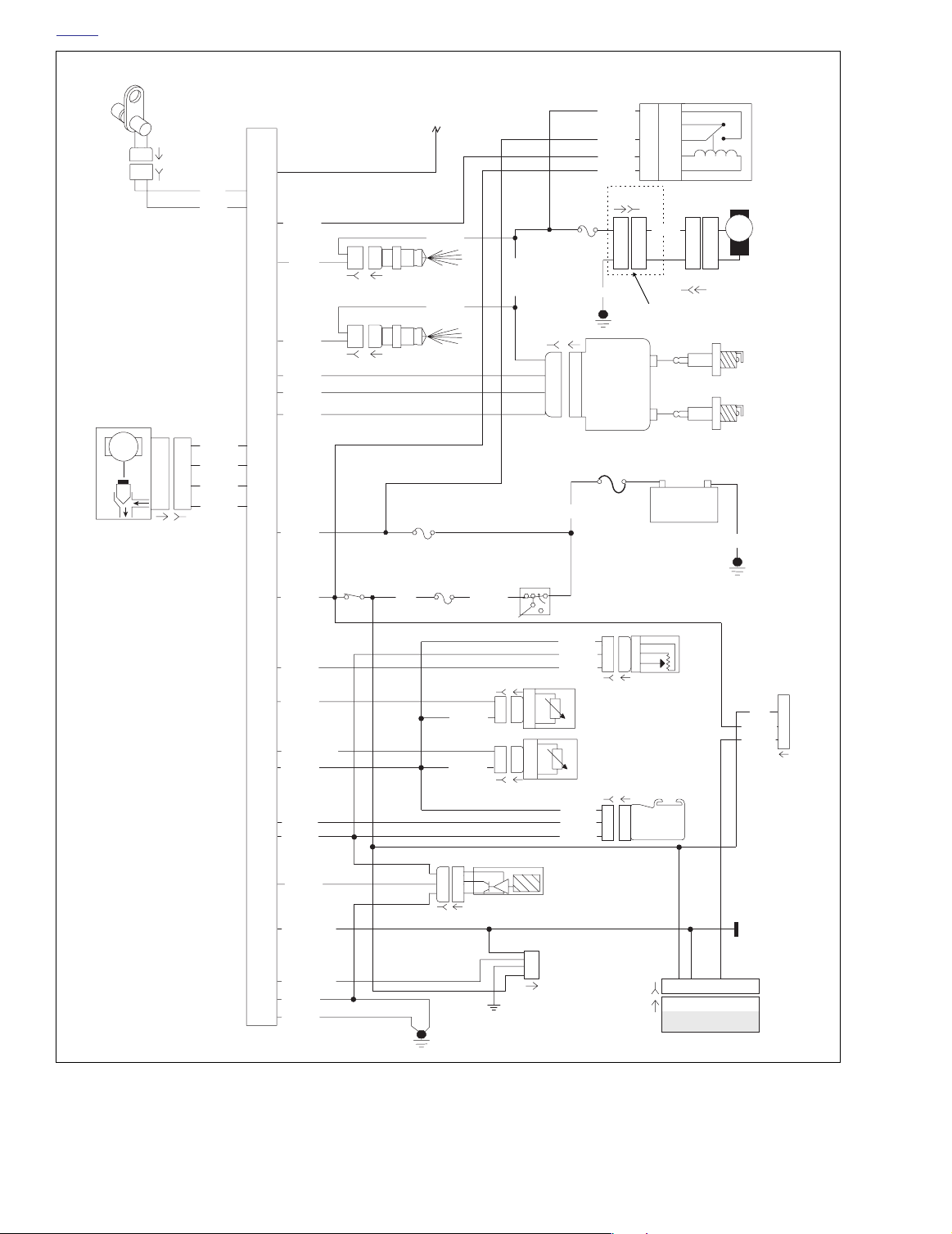

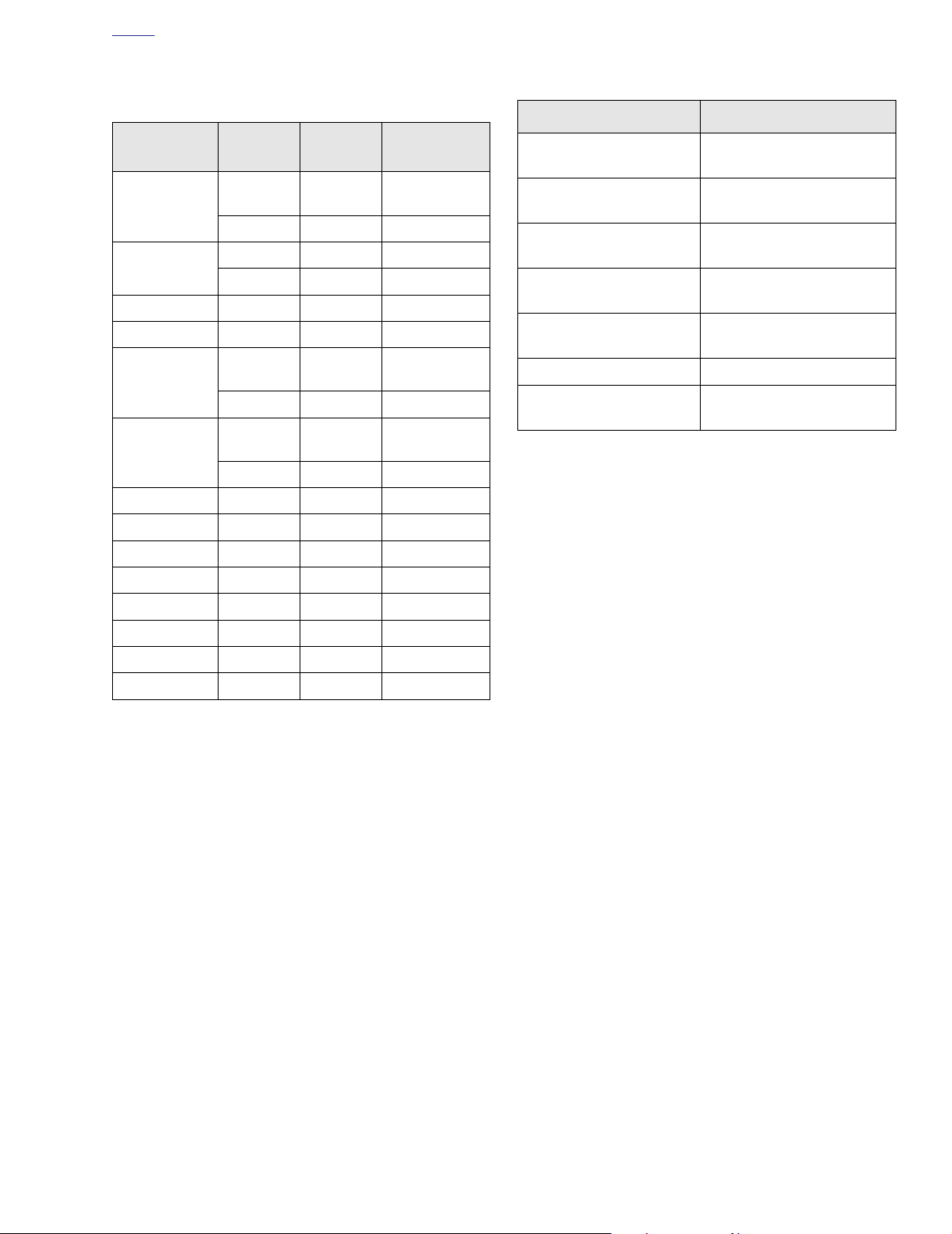

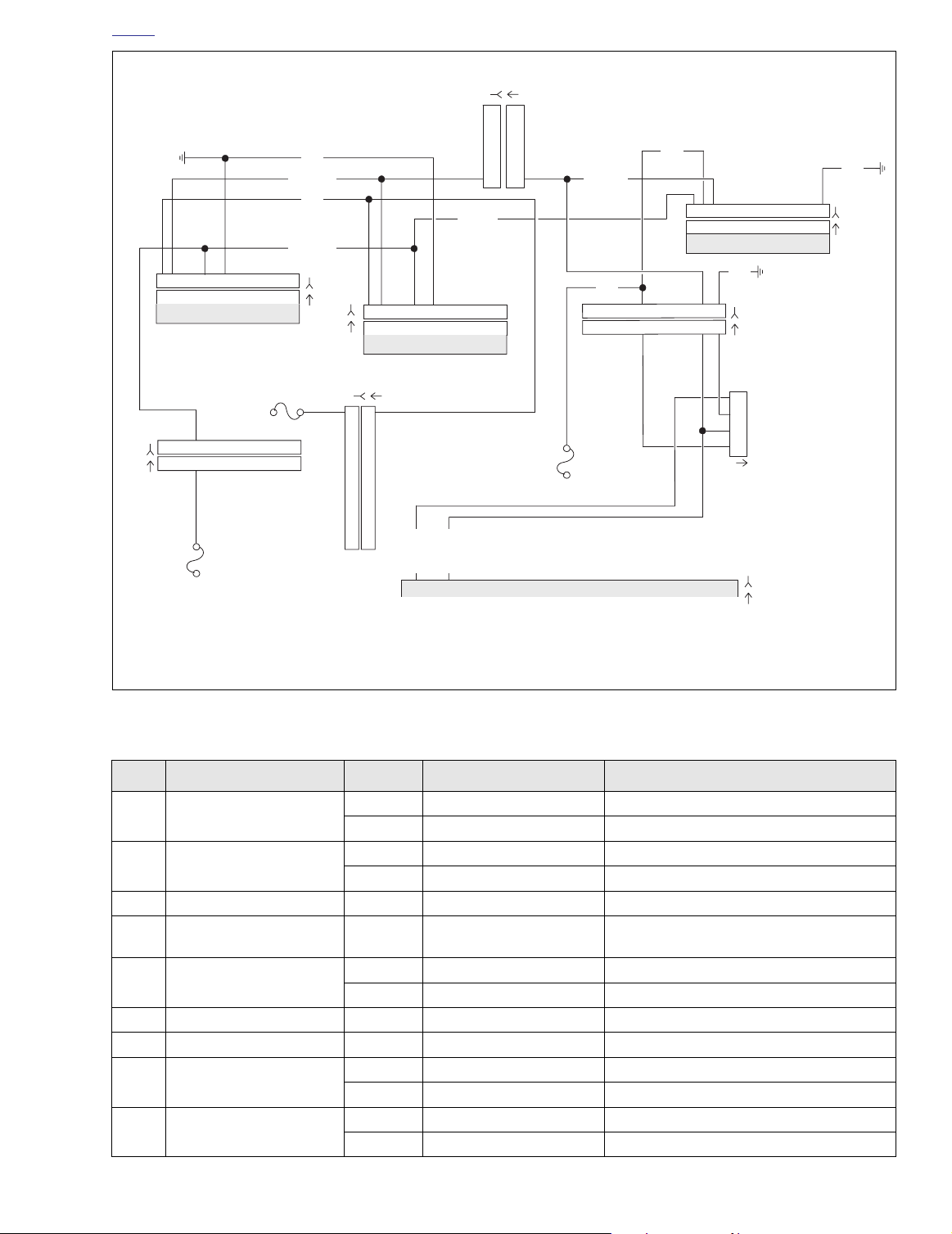

EFI SYSTEM 5.2

GENERAL

The engine management system consists of the following

components:

Electronic control module (ECM).

●

●

Crank position sensor (CKP).

●

Manifold absolute pressure sensor (MAP).

Intake air temperature sensor (IAT).

●

●

Engine temperature sensor (ET).

Idle air control (IAC).

●

●

Throttle position sensor (TP).

●

Vehicle speed sensor (VSS).

Tu rn signal module (TSM) or optional, factory-installed

●

turn signal security module (TSSM). This includes an

integrated bank angle sensor (BAS).

Ignition coil.

●

The ECM is mounted under the electrical caddie cover (left

side of vehicle). It computes the spark advance for proper

ignition timing based on sensor inputs (from CKP, MAP and

TP sensor) and regulates the low-voltage circuits between

battery and ignition coil.

The bank angle sensor is within the TSM/TSSM. If the vehicle

lean angle exceeds 45 degrees for one second, the fuel

pump is shut off. Once the sensor is tripped, the motorcycle

must be uprighted, turned off and then on again before the

engine can be restarted. This is communicated across the

data bus.

Front and rear coils fire each spark plug independently (one

cylinder at a time - no wasted spark). The coil also has an

extra terminal to monitor current on the coil secondary circuit.

This is used for knock detection and combustion diagnostics.

The ignition system gives a spark near top dead center for

starting. At RPM and loads above this, the system gives a

spark advance that varies between 0° and 50°.

The IAT, ET and TP sensors are used to provide information

to the ECM to fine tune spark and fuel delivery. The VSS is

used as an input for idle speed control.

TROUBLESHOOTING

See the diagnostic charts that follow for troubleshooting information.

The ECM contains all of the solid state components used in

the ignition system. The dwell time for the ignition coil is also

calculated in the microprocessor and is dependent upon battery voltage. The programmed dwell is an added feature to

give adequate spark at all speeds. (The ECM has added protection against transient voltages, continuous reverse voltage

protection, and damage due to jump starts.) The ECM is fully

enclosed to protect it from vibration, dust, water or oil. This

unit is a non-repairable item. If it fails, it must be replaced.

The crank position sensor (CKP) is located in the front left

side of the crankcase. The CKP generates an AC signal

which is sent to the ECM where it is used to reference engine

position (TDC) and speed. It functions by taking readings off

the 30 teeth on the left side flywheel (two teeth are missing to

establish a reference point).

The MAP sensor is located on top of the intake manifold. The

MAP sensor monitors the intake manifold pressure (vacuum)

and sends the information to the ECM where the module

adjusts the spark and fuel timing advance curve for optimum

performance.

2004 Touring: Engine Management (EFI) 5-3

Page 4

HOME

[79A]

[79B]

Intake air

control

12

12

[87A]

CKP

System relay

Ion sense

A

A

B

B

C

C

D

D

Constant

[87B]

Switch power

R

BK

Inj. F

Inj. R

Coil R

Coil F

BE/GN

BN/R

BK/PK

BK/O

power

[78]

30

12

21

19

27

11

29

35

36

18

17

31

13

[62B]

To Ta chometer

(FLHR/C/S Optional)

Y/GN

BE/GY

IQCPR

87

87A

30 85 86

System

relay

GN/O

15 Amp

fuel pump

fuse

W/BK

[13A] [13B]

123

123

O/GY

123

123

Fuel

pump

3

GN/O

4

AB

AB

Y/GN

W/Y

[141B][141A]

All Except

FLHR/C/S

GN/GY

GY/BE

[84B] [84A]

AB

AB

[85B] [85A]

Y/GN

Y/GN

[83B] [83A]

AB CD

BK

AB CD

Coil

Y/BE

BE/O

40 Amp

Maxi fuse

Battery

–+

BK

BE/GY

W/BK

Engine

stop

switch

15 Amp

ECM fuse

15 Amp

IGN fuse

GY R/BK

R

Ignition switch

Vehicle speed sensor

f2208g8x

TP sensor

ET sensor

IAT sensor

5v sensor gnd.

MAP sensor

5v sensor pwr.

Serial data

Flash pin

Power gnd.

Power gnd.

A

BK/W

GY/V

24

PK/Y

6

LT GN/Y

7

26

BK/W

V/W

25

R/W

14

W/GN

33

LT GN/V

5

1

LT GN/R

BK

10

28

BK

[65B] [65A]

A

B

C

BK/W

BK/W

A

B

C

[90B] [90A]

21

21

A

A

B

B

[89B] [89A]

[91A]

3

1

2

4

R/W

GY/V

BK/W

V/W

R/W

Vehicle

speed

sensor

Data link

connector

AB

B

C

C

[88B] [88A]

ET sensor

IAT sensor

[80B] [80A]

AB

AB

C

C

[30B]

[30A]

MAP

sensor

TP

sensor

3

2

3

2

hand controls

GY

W/BK

W/BN

To speedometer

and tachometer

7

7

To right

3

4

5

[22A]

TSM/

TSSM

Figure 5-2. EFI System Circuit - Simplified

5-4 2004 Touring: Engine Management (EFI)

Page 5

HOME

0

10

30

20

50

40

110

120

60

70

80

90

100

0

20

30

40

50

10

MPH

H

A

R

L

E

Y

-

D

A

V

I

D

S

O

N

C

E

R

T

I

F

I

E

D

RPM

x100

H

A

R

L

E

Y

-

D

A

V

I

D

S

O

N

f2160x8x

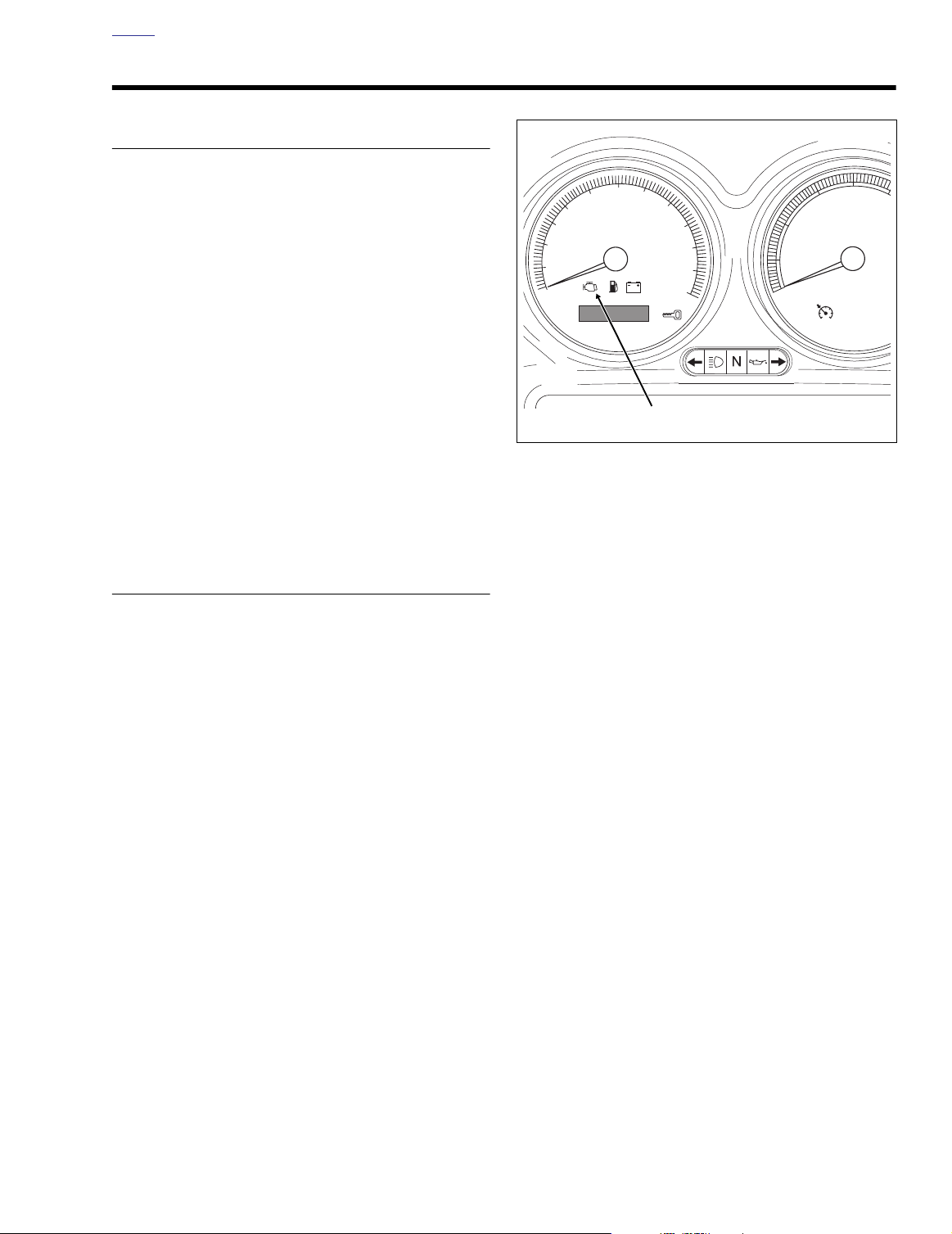

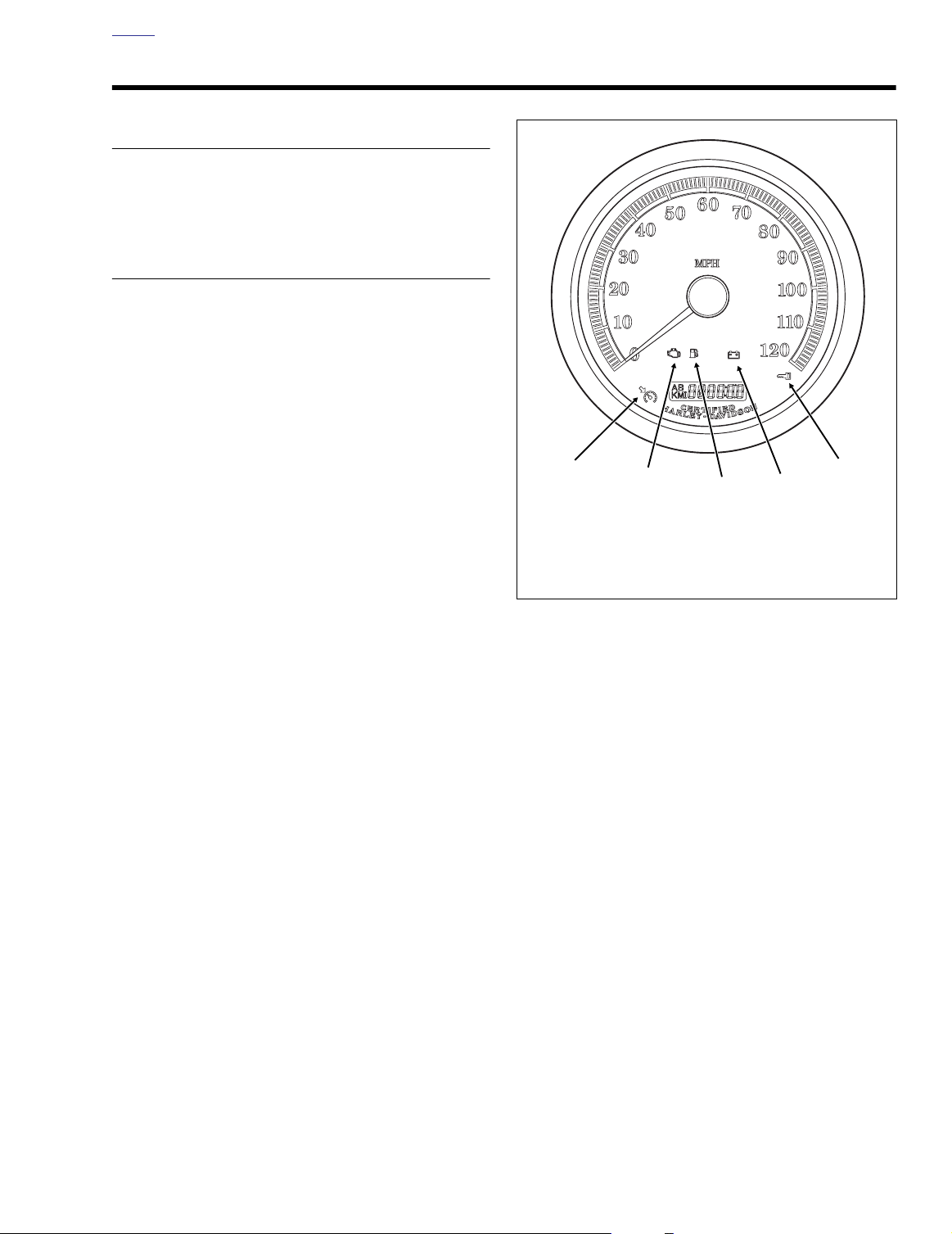

Check Engine Lamp

EFI DIAGNOSTIC INTRODUCTION 5.3

SYSTEM PROBLEMS

All system problems fall into at least one of three general categories.

No Start

The engine cranks over freely, but will not start. This does not

include situations where the engine will not crank, such as a

security disabled starter, dead battery, etc. This condition

assumes that all obvious checks (fuel in tank, etc.) have been

made.

Poor Performance

The engine starts but there are performance problems. These

problems may include poor fuel economy, rough idle, engine

misfire, engine hesitation, severe spark knock, etc.

Check Engine Lamp

See Figure 5-3. The check engine lamp indicates the ECM

has determined a fault condition exists. There may also be

starting or performance problems.

RESOLVING PROBLEMS

To resolve system problems, five basic steps are involved. In

order of occurrence, they are:

1. Check for diagnostic trouble codes by using speedometer self diagnostics. See 5.4 CHECKING FOR DIAG-

NOSTIC TROUBLE CODES: EFI.

2. Retrieve diagnostic trouble codes by using speedometer

self diagnostics. See 5.6 SPEEDOMETER SELF DIAG-

NOSTICS.

3. Diagnose system problems. This involves using special

tools and the diagnostic flow charts in this section.

4. Correct problems through the replacement and/or repair

of the affected components.

5. After repairs are performed, the work must be validated.

This involves clearing the trouble codes and confirming

proper vehicle operation as indicated by the lack of trouble codes.

Figure 5-3. Speedometer

2004 Touring: Engine Management (EFI) 5-5

Page 6

HOME

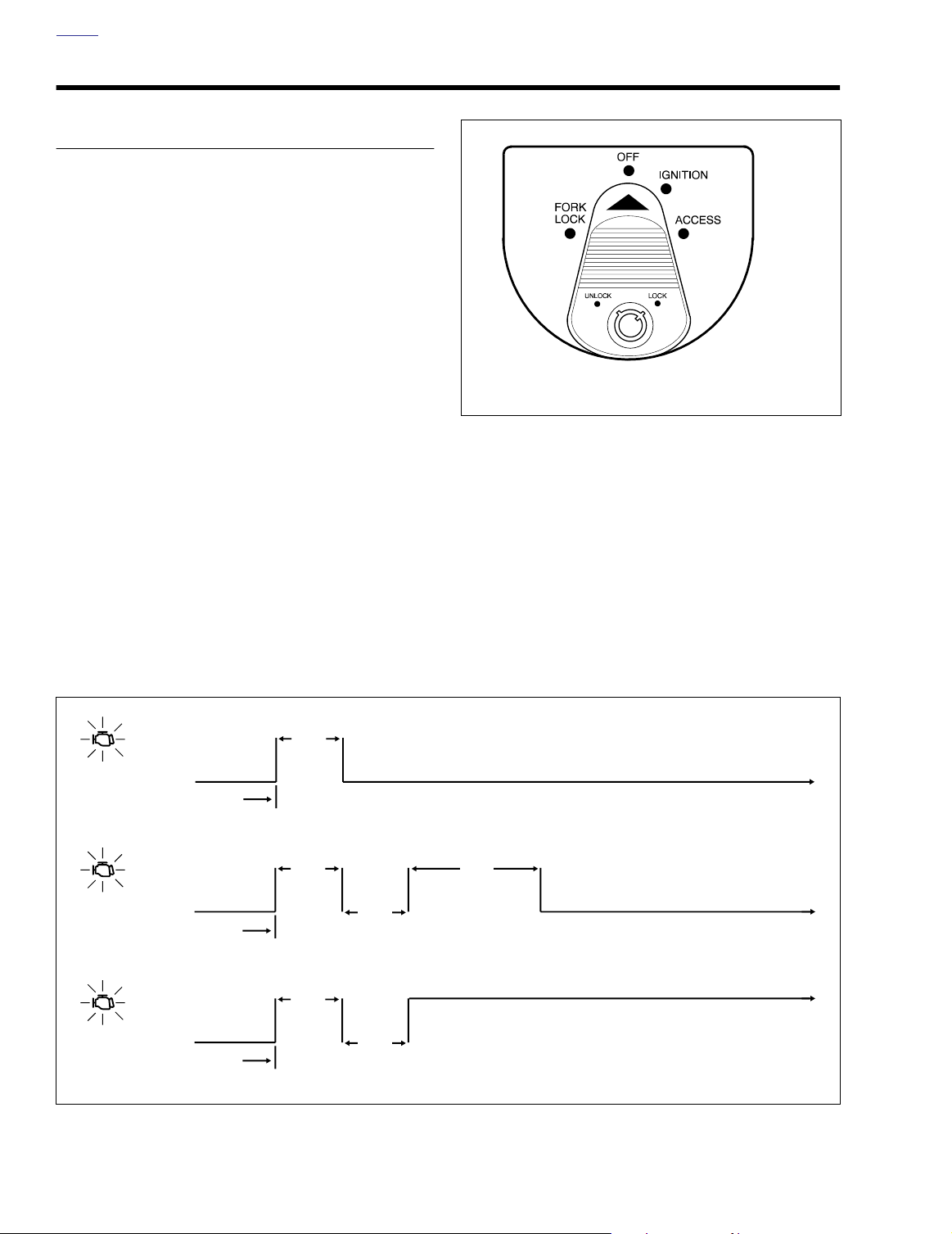

CHECKING FOR DIAGNOSTIC TROUBLE CODES: EFI 5.4

CHECK ENGINE LAMP

To diagnose system problems, start by observing the behavior of the check engine lamp.

NOTES

See Figure 5-4. “Key ON” means that the ignition key is

●

turned to IGN and the engine stop switch is set to RUN

(although the engine is

When the ignition key is turned ON, the check engine

●

lamp will illuminate for approximately four seconds and

then turn off.

●

If the check engine lamp is not illuminated at Key ON or if

it fails to turn OFF after the initial four second period,

then the speedometer may need to be replaced. See 5.5

INITIAL DIAGNOSTIC CHECK: EFI.

not

running).

f1240x2x

Figure 5-4. Ignition Switch (FLTR, FLHT/C/U)

1. When the lamp turns off after being illuminated for the

first four second period, it will:

a. Remain off if there are no fault conditions or trouble

codes currently detected by the ignition control module. See A of Figure 5-5.

b. Come back on for an 8 second period if only historic

codes exist. See B of Figure 5-5.

c. Come back on, and remain on, if a current trouble

code exists. See C of Figure 5-5.

ON

4 Sec.

A

OFF

Key On

Lamp ON 8 Seconds:

Only Historic Trouble Codes Exist

ON

4 Sec.

B

OFF

Key On

4 Sec.

2. See CODE TYPES which follows for a complete descrip-

tion of trouble code formats.

NOTE

Some trouble codes can only be fully diagnosed during actuation. For example, a problem with the ignition coil will be

considered a current fault even after the problem is corrected,

since the ECM will not know of its resolution until after the coil

is exercised by vehicle start sequence. In this manner, there

may sometimes be a false indication of the current trouble

code.

Lamp OFF: No Current or Historic Trouble Codes

8 Sec.

Lamp OFF

ON

4 Sec.

C

OFF

Key On

Figure 5-5. Check Engine Lamp Operation

5-6 2004 Touring: Engine Management (EFI)

4 Sec.

Lamp Remains ON: Current Trouble Code *

Historic Trouble Codes May Also Exist

*

Page 7

HOME

CODE TYPES

There are two types of diagnostic trouble codes (DTCs): current and historic. If a diagnostic trouble code is stored, it can

be read using speedometer self diagnostics. See 5.6

SPEEDOMETER SELF DIAGNOSTICS.

All diagnostic trouble codes reside in the memory of the

ECM/ICM, TSM/TSSM, speedometer or tachometer until the

code is cleared by use of the speedometer self diagnostics.

See 5.6 SPEEDOMETER SELF DIAGNOSTICS.

A historic diagnostic trouble code is also cleared after a total

of 50 trips has elapsed. A trip consists of a start and run

cycle. After the 50 trip retention period, the diagnostic trouble

code is automatically erased from memory providing that no

subsequent faults of the same type are detected in that

period.

Current

Current trouble codes are those which occur during the

present ignition cycle. See the appropriate flow charts for

solutions.

Historic

If a particular problem happens to resolve itself, the active

status problem is dropped and it becomes a historic code

rather current code.

Historic codes are stored for a length of time to assist in the

diagnosis of intermittent faults. See Figure 5-5. The check

engine lamp will come back on for 8 seconds to indicate the

existence of only historic codes.

It is important to note that historic codes may also be present

whenever the system indicates the existence of a current

code. See MULTIPLE DIAGNOSTIC TROUBLE CODES if

multiple trouble codes are found.

Diagnostic charts are designed for use with current trouble

codes and as a result they frequently suggest part replacement. When diagnosing a historic code the charts can be

helpful but should not lead to part replacement without verification the part is faulty.

RETRIEVING DIAGNOSTIC TROUBLE CODES

The engine management system provides two levels of diagnostics.

The most sophisticated mode uses a computer based

●

diagnostic package called the DIGITAL TECHNICIAN

(Part No. HD-44750).

The second mode requires using the speedometer self

●

diagnostics. Speedometer, tachometer (if equipped),

TSM/TSSM and ECM codes can be accessed and

cleared. See 5.6 SPEEDOMETER SELF DIAGNOSTICS

for more information.

MULTIPLE DIAGNOSTIC TROUBLE CODES

While it is possible for more than one fault to occur and set

more than one trouble code, there are several conditions

which may result in

The MAP and TP and vehicle speed sensors are con-

●

nected to the same reference line (+5V Vref). If the reference line goes to ground or open, multiple codes will be

set (DTC P0107, P0122 and P0501).

Serial data codes (DTC U1300, U1301, U1016, U1064,

●

U1097 and U1255) may be accompanied by other

codes.

resolving the other codes.

Refer to Ta bl e 5-5. This table gives most ECM DTCs a priority

ranking.

one

fault setting

Always

correct the serial data codes before

multiple

trouble codes:

2004 Touring: Engine Management (EFI) 5-7

Page 8

HOME

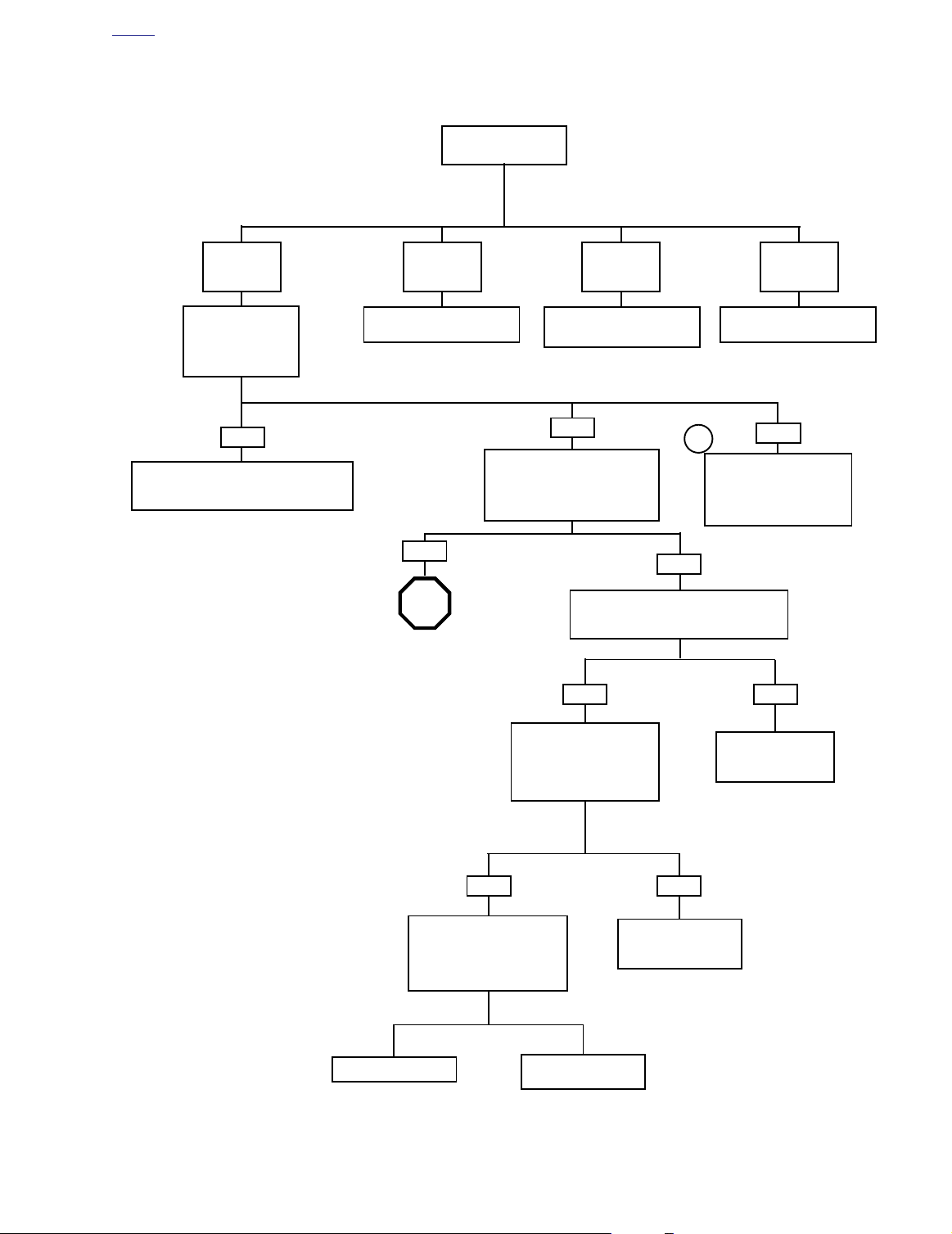

INITIAL DIAGNOSTIC CHECK: EFI 5.5

GENERAL

To locate faulty circuits or other system problems, follow the

diagnostic flow charts in this section. For a systematic

approach, always begin with INITIAL DIAGNOSTICS which

follows. Read the general information and then work your way

through the flow chart box by box.

Diagnostic Notes

If a numbered circle appears adjacent to a flow chart box,

then more information is offered in the diagnostic notes. Many

diagnostic notes contain supplemental information, descriptions of various diagnostic tools or references to other parts

of the manual where information on the location and removal

of components may be obtained.

Circuit Diagram/Wire Harness Connector Table

When working through a flow chart, refer to the illustrations,

the associated circuit diagram and the wire harness connector table as necessary. The wire harness connector table for

each circuit diagram identifies the connector number, description, type and general location.

In order to perform most diagnostic routines, a Breakout Box

and a DVOM are required. See 5.7 BREAKOUT BOX: EFI.

To perform the circuit checks with any degree of efficiency, a

familiarity with the various wire connectors is also necessary.

Reprogramming ECM

Diagnostic charts frequently suggest ECM replacement. In

the event an electronic control module (ECM) needs to be

replaced, it must be reprogrammed using a computer based

diagnostic package called DIGITAL TECHNICIAN (Part No.

HD-44750). See your dealer. Password learn procedure must

also be performed. See 3.24 PASSWORD LEARN.

Diagnostic Tips

If speedometer reads “No Rsp” (no response) while in

●

diagnostic mode, check data bus for an open or short to

ground between data connector [91A] Terminal 3 and

ECM, TSM/TSSM, tachometer (if equipped) or speedometer. For more information on speedometer diagnostic

mode see 5.6 SPEEDOMETER SELF DIAGNOSTICS.

●

Check for an open diagnostic test terminal between data

Te rminal 3 and ECM Terminal 5. With ignition key turned

ON, transmit data should be typically 0.6-0.8 volts. The

range of acceptable voltage is greater than 0 and less

than 7.0 volts.

●

If speedometer reads “BUS er” (serial data bus error),

refer to flow charts in 5.12 STARTS, THEN STALLS.

Diagnostic Notes

The reference numbers below correlate with the circled numbers on the diagnostic check flow charts. See page 5-15.

1. Compare engine behavior to symptoms tables.

a. Starts hard. Refer to Ta bl e 5-2.

b. Hesitates, stumbles, surges, misfires and/or slug-

gish performance. Refer to Ta ble 5-3.

c. Engine exhaust emits black smoke or fouls plugs.

Refer to Ta ble 5-4.

2. Connect BREAKOUT BOX (Part No. HD-43682) to

speedometer using HD-46601 adapters.

All EFI diagnostic codes are listed on page 5-11 in Ta ble 5-5.

Other Codes

See 3.9 INITIAL DIAGNOSTIC CHECK: TSM/TSSM for any

codes related to the turn signal module (TSM) or turn signal

security module (TSSM).

See 2.2 INITIAL DIAGNOSTIC CHECK: SPEEDOMETER for

any codes related to the speedometer or tachometer.

INITIAL DIAGNOSTICS

General Information

The diagnostic check (see page 5-15) is an organized

approach to identifying a problem caused by an electronic

control system malfunction.

5-8 2004 Touring: Engine Management (EFI)

Page 9

HOME

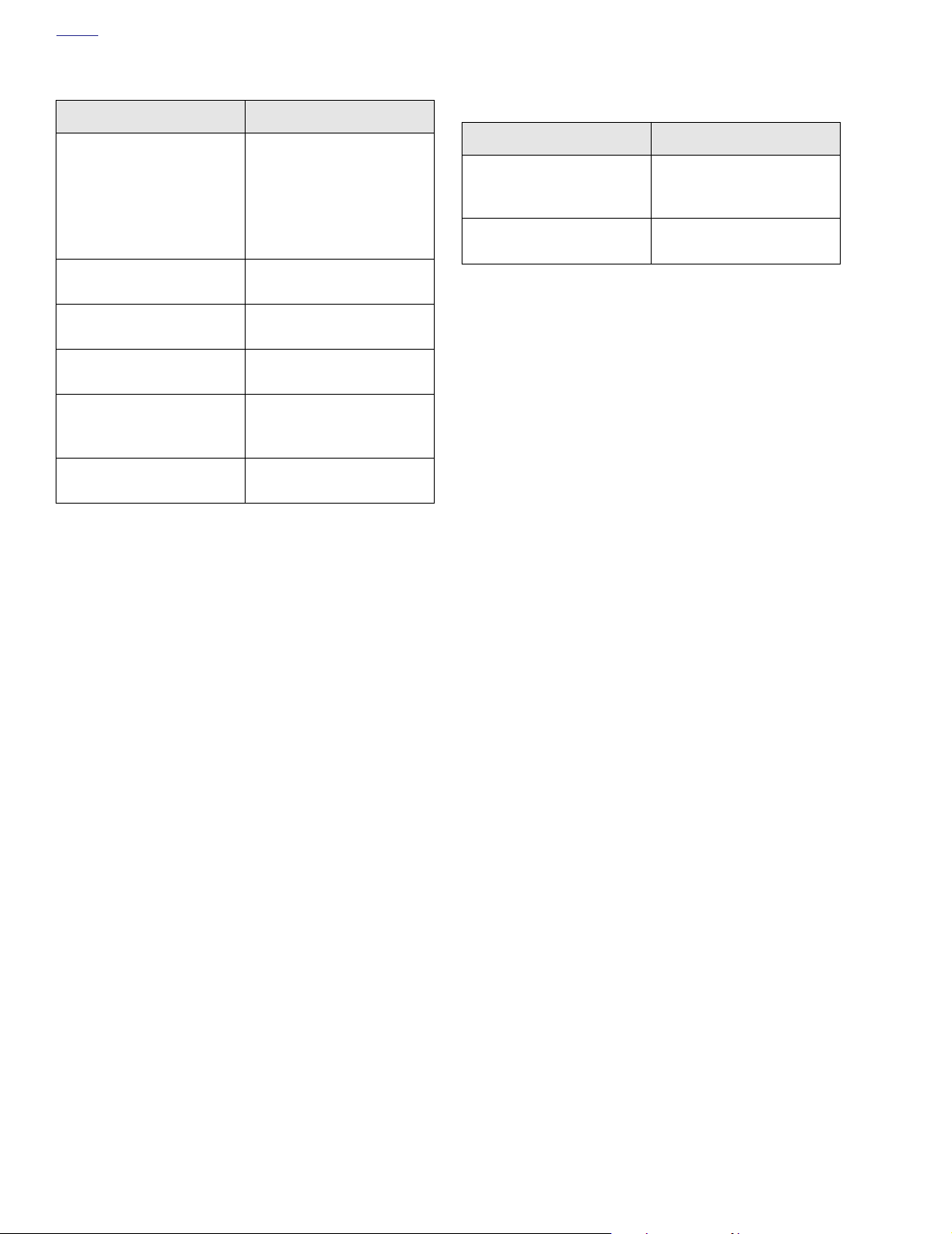

Table 5-1. Typical Scan Values for

Engine Data

ITEM

MAP sensor

TP sensor

IAC pintle 0 155 30-45 steps

RPM 800 5600 990

ET sensor

IAT sensor

INJ PW front 0 50 mS 2-4 mSec

INJ PW rear 0 50 mS 2-4 mSec

Advance front 0 45° 10-15°

Advance rear 0 45° 10-15°

VSS 0 120 0 MPH

Battery voltage 10 15 14.5 volts

ENG RUN off Run Run

Idle RPM 800 1250 990

MIN.

VALUE

10 kPa 104 kPa

0 volts 5.1 volts

0100 0%

0.2 volts 4.5 volts 0.2-1.0 volts

3° F

(-16° C)

0.0 volts 5.0 volts 0.5-3.23 volts

3° F

(-16° C)

0.0 volts 5.0 volts 2.0-3.5 volts

MAX.

VALUE

464° F

(240° C)

248° F

(120° C)

HOT

IDLE

10.3-13.3 in. Hg

35-45 kPa

230-300° F

(110-150° C)

104-140° F

(40-60° C)

Table 5-2. Engine Starts Hard

SYMPTOM

Battery discharged

Spark plugs

Spark plug wires

Ignition coil

Valve sticking

Water or dirt in fuel system Drain and refill with fresh fuel.

Loss of battery power to

ECM terminal 31*

* Codes will not clear (although they appear to).

See charging system troubleshooting in this section.

5.17 MISFIRE AT IDLE OR

UNDER LOAD.

5.17 MISFIRE AT IDLE OR

UNDER LOAD.

5.17 MISFIRE AT IDLE OR

UNDER LOAD.

See Section 3 in the Touring

Service Manual.

5.11 NO ECM POWER

SOLUTION

NOTE

Hot idle specifications are with stock exhaust, the engine

operating at 990 RPM and an engine temperature of approximately 260° F (127° C). Idle settings may be changed with

the idle set procedure. See the Touring Service Manual.

2004 Touring: Engine Management (EFI) 5-9

Page 10

HOME

Table 5-3. Engine Performance Problems

SYMPTOM

Manifold leak

NOTE- When manifold leak

is large enough, IAC will

close to 0 and code P0505

will set

MAP sensor plugged or not

operating properly

Water or dirt in fuel system

Spark plugs

Throttle plate not opening

fully

Low fuel pressure

See 5.9 INTAKE LEAK

TEST.

A low IAC count may also

indicate an air leak.

5.19 DTC P0107, P0108.

Drain and refill with fresh

fuel.

5.17 MISFIRE AT IDLE OR

UNDER LOAD.

See throttle cable adjustment in the Touring Service

Manual.

5.15 FUEL PRESSURE

TEST.

SOLUTION

Table 5-4. Engine Exhaust Emits

Black Smoke or Fouls Plugs

SYMPTOM

See AIR CLEANER FILTER

Clogged air filter

MAP sensor plugged or not

operating properly

in the Touring Service Manual.

5.19 DTC P0107, P0108.

SOLUTION

5-10 2004 Touring: Engine Management (EFI)

Page 11

HOME

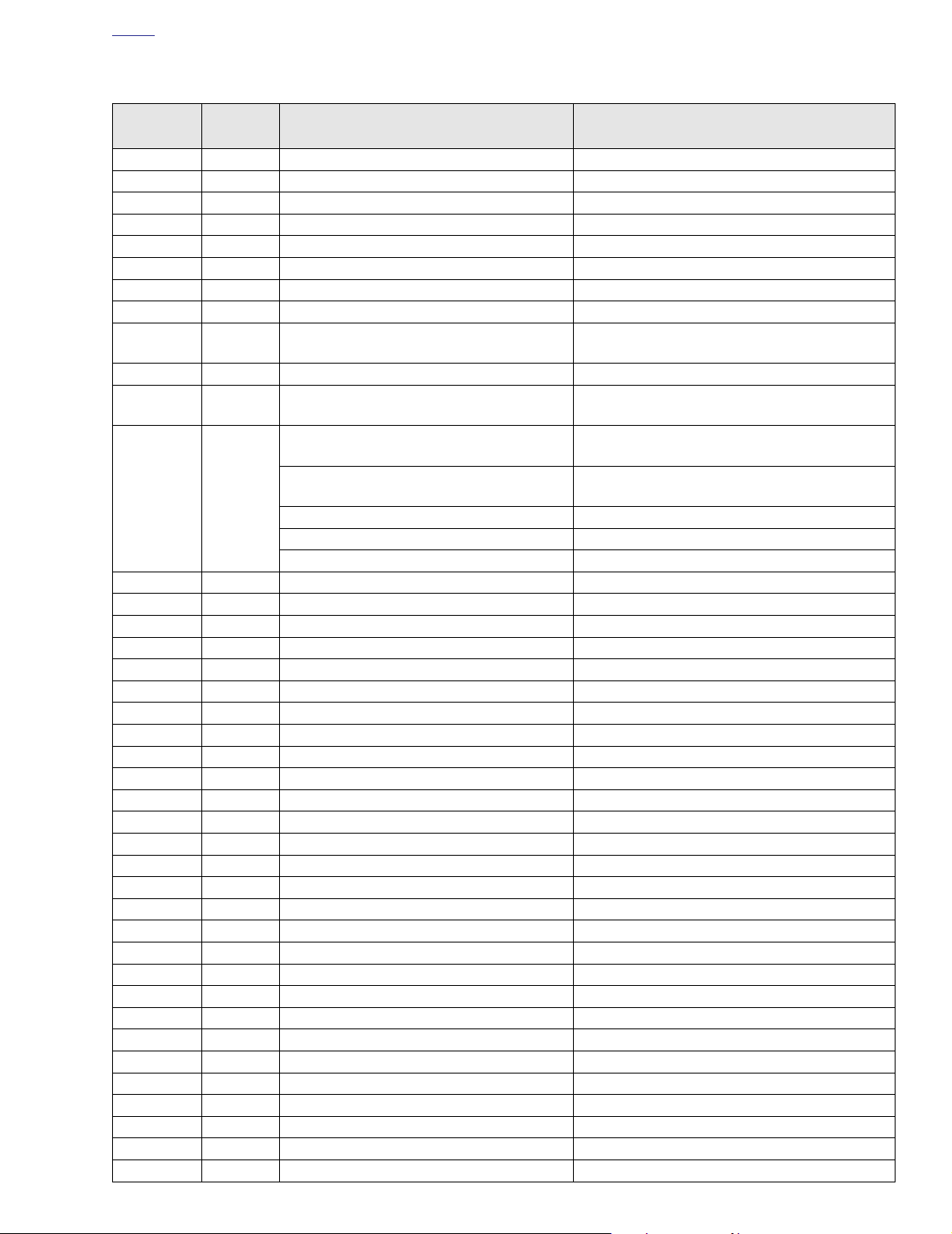

Table 5-5. EFI Diagnostic Trouble Codes (DTC) and Fault Conditions

PRIORITY

RANKING

1 P0605 ECM flash error 5.27 DTC P0603, P0605

2 P0603 ECM EEPROM error 5.27 DTC P0603, P0605

3“BUS Er” Serial data bus shorted low/open/high 5.12 STARTS, THEN STALLS

4U1300 ECM serial data low 5.12 STARTS, THEN STALLS

5U1301 ECM serial data open/high 5.12 STARTS, THEN STALLS

6U1300 TSSM serial data low 5.12 STARTS, THEN STALLS

7U1301 TSSM serial data open/high 5.12 STARTS, THEN STALLS

8U1300 Speedometer/tachometer serial data low 5.12 STARTS, THEN STALLS

9U1301

10 U1064 Loss of TSM/TSSM serial data at ECM 5.30 DTC U1064, U1255

11 U1064

12 U1016

13 U1097 Loss of speedometer serial data at TSSM 5.31 DTC U1097, U1255

14 U1255 Missing response at TSSM 3.21 DTC U1016, U1255

15 U1255 Missing response at speedometer 5.31 DTC U1097, U1255

16 P1003 System relay contacts open 5.14 SYSTEM RELAY CHECK

17 P1002 System relay coil high/shorted 5.14 SYSTEM RELAY CHECK

18 P1001 System relay coil open/low 5.14 SYSTEM RELAY CHECK

19 P1004 System relay contacts closed 5.14 SYSTEM RELAY CHECK

20 P1009 Incorrect password 5.28 DTC P1009, P1010

21 P1010 Missing password (starts then stalls) 5.28 DTC P1009, P1010

22 P0373 CKP sensor intermittent 5.24 DTC P0373, P0374

23 P0374 CKP sensor synch error 5.24 DTC P0373, P0374

24 P0122 TP sensor open/low 5.22 DTC P0122, P0123

25 P0123 TP sensor high 5.22 DTC P0122, P0123

26 P0107 MAP sensor open/low 5.19 DTC P0107, P0108

27 P0108 MAP sensor high 5.19 DTC P0107, P0108

28 P0117 ET sensor voltage low 5.21 DTC P0117, P0118

29 P0118 ET sensor open/high 5.21 DTC P0117, P0118

30 P0112 IAT sensor voltage low 5.20 DTC P0112, P0113

31 P0113 IAT sensor open/high 5.20 DTC P0112, P0113

32 P1351 Front ignition coil open/low 5.29 DTC P1351, P1352, P1354, P1355

33 P1354 Rear ignition coil open/low 5.29 DTC P1351, P1352, P1354, P1355

34 P1352 Front ignition coil high/shorted 5.29 DTC P1351, P1352, P1354, P1355

35 P1355 Rear ignition coil high/shorted 5.29 DTC P1351, P1352, P1354, P1355

36 P1357 Front cylinder combustion intermittent 5.18 COMBUSTION ABSENT/INTERMITTENT

37 P1358 Rear cylinder combustion intermittent 5.18 COMBUSTION ABSENT/INTERMITTENT

38 P0261 Front injector open/low 5.23 DTC P0261, P0262, P0263, P0264

39 P0263 Rear injector open/low 5.23 DTC P0261, P0262, P0263, P0264

40 P0262 Front injector high 5.23 DTC P0261, P0262, P0263, P0264

DTC NO. FAULT CONDITION SOLUTION

Speedometer/tachometer serial data open/

high

Loss of TSM/TSSM serial data at speedometer

Loss of all ECM serial data (state of health) at

TSSM

Loss of all ECM serial data (state of health) at

speedometer

Loss of vehicle speed 3.21 DTC U1016, U1255

Loss of vehicle inhibit motion 3.21 DTC U1016, U1255

Loss of powertrain security status 3.21 DTC U1016, U1255

5.12 STARTS, THEN STALLS

5.30 DTC U1064, U1255

3.21 DTC U1016, U1255

3.21 DTC U1016, U1255

2004 Touring: Engine Management (EFI) 5-11

Page 12

HOME

Table 5-5. EFI Diagnostic Trouble Codes (DTC) and Fault Conditions

PRIORITY

RANKING

41 P0264 Rear injector high 5.23 DTC P0261, P0262, P0263, P0264

42 P0562 Battery voltage low 5.26 DTC P0562, P0563

43 P0563 Battery voltage high 5.26 DTC P0562, P0563

44 P0501 VSS sensor low 5.25 DTC P0501, P0502

45 P0502 VSS sensor high 5.25 DTC P0501, P0502

46 P1356 Rear cylinder no combustion 5.18 COMBUSTION ABSENT/INTERMITTENT

47 P1353 Front cylinder no combustion 5.18 COMBUSTION ABSENT/INTERMITTENT

48 P0505 Loss of idle speed control 5.16 IDLE AIR CONTROL

49 B1135 Accelerometer fault 3.19 DTC B1135

51 B1134 Starter output high 3.18 DTC B1134

52 B1121 Left turn output fault 3.15 TURN SIGNAL ERRORS

53 B1122 Right turn output fault 3.15 TURN SIGNAL ERRORS

54 B0563 Battery voltage high 3.16 DTC B0563

55 B1131 Alarm output low 3.17 DTC B1131, B1132

56 B1132 Alarm output high 3.17 DTC B1131, B1132

57 B1141 Ignition switch open/low 3.15 TURN SIGNAL ERRORS

DTC NO. FAULT CONDITION SOLUTION

5-12 2004 Touring: Engine Management (EFI)

Page 13

HOME

f2208u8x

321654987121110

321654987121110

Speedometer

BK

LtGN/V

O

BN/GY

[39B]

[108B]

[108A]

[39A]

321654987121110

321654987121110

Tachometer

[156B] [156A]

6

6

5

5

4

4

3

3

2

2

1

1

BN/GY

Main to Interconnect

Harness

LtGN/V

GY

65

4

32

1

1

65

4

32

GY

987

987

321654987121110

321654987121110

TSM/TSSM

BK

[8B]

121110

121110

[8A]

Harness

BK

[30B]

[30A]

EFI

[1B] [1A]

123

123

Main to Interconnect

Harness

6

6

15A

Ignition

Fuse

1

2

3

4

Data Link

[91A]

[2B]

[2A]

15A

Accessory

Fuse

321654987121110

321654987121110

Main to Interconnect

Harness

101112 78945

101112 78945

LtGN/V

15A

Battery

Fuse

LtGN/R

51

Flash pin

ECM

Serial data

[78B]

[78A]

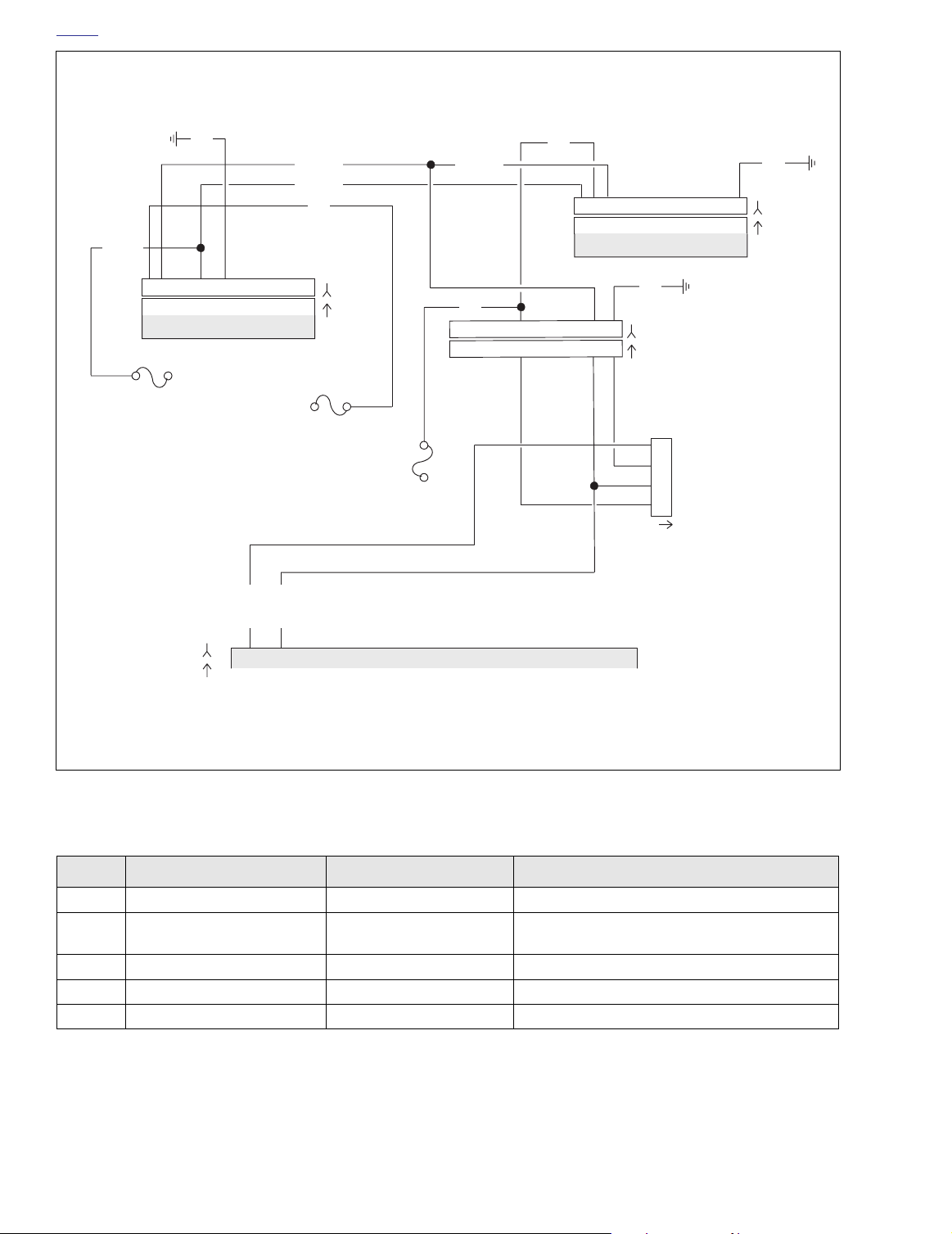

Figure 5-6. Diagnostic Check (FLTR, FLHT/C/U)

Table 5-6. Wire Harness Connectors in Figure 5-6.

NO.

[1]

[2]

[8] Main to EFI Harness All 12-Place Deutsch (Gray) Under Right Side Cover

[30]

[39] Speedometer

[78] Electronic Control Module All 36-Place Packard Under Right Side Cover

[91] Data Link All 4-Place Deutsch Under Right Side Cover

[108] Tachometer

[156]

DESCRIPTION MODEL TYPE LOCATION

Main to Interconnect

Harness

Main to Interconnect

Harness

Tu rn Signal/Security

Module

FLHT/C 12-Place Deutsch (Black) Inner Fairing - Right Radio Support Bracket

FLTR 12-Place Deutsch (Black) Inner Fairing - Below Radio (Left Side)

FLHT/C 12-Place Deutsch (Gray) Inner Fairing - Right Fairing Support Brace

FLTR 12-Place Deutsch (Gray) Inner Fairing - Below Radio (Left Side)

All 12-Place Deutsch

Cavity in Crossmember at Rear of

Battery Box (Under Seat)

FLHT/C 12-Place Packard Inner Fairing (Back of Speedometer)

FLTR 12-Place Packard Under Bezel (Back of Speedometer)

FLHT/C 12-Place Packard Inner Fairing (Back of Tachometer)

FLTR 12-Place Packard Under Bezel (Back of Tachometer)

Main to Interconnect

Harness

FLHT/C 6-Place Deutsch Inner Fairing - Right Fairing Support Brace

FLTR 6-Place Deutsch Inner Fairing - Front of Right Fairing Bracket

2004 Touring: Engine Management (EFI) 5-13

Page 14

HOME

f2208t8x

BN/GY

321654987121110

321654987121110

Speedometer

15A

Battery

Fuse

BK

15A

Accessory

Fuse

LtGN/V

BN/GY

O

[39B]

[39A]

15A

Ignition

Fuse

LtGN/V

GY

3

21

321

GY

BK

321654987121110

321654987121110

[30B]

[30A]

TSM/TSSM

BK

98

7

65

4

98

7

65

4

121110

[8B]

121110

[8A]

EFI

Harness

1

2

3

4

Data Link

[91A]

LtGN/V

LtGN/R

[78B]

[78A]

1

Flash pin

5

Serial data

ECM

Figure 5-7. Diagnostic Check (FLHR/C/S)

Table 5-7. Wire Harness Connectors in Figure 5-7.

NO.

[8] Main to EFI Harness 12-Place Deutsch Under Right Side Cover

[30] Turn Signal/Security Module 12-Place Deutsch

[39] Speedometer 12-Place Packard Under Console (Back of Speedometer)

[78] Electronic Control Module 36-Place Packard Under Right Side Cover

[91] Data Link 4-Place Deutsch Under Right Side Cover

DESCRIPTION TYPE LOCATION

Cavity in Crossmember at Rear of

Battery Box (Under Seat)

5-14 2004 Touring: Engine Management (EFI)

Page 15

HOME

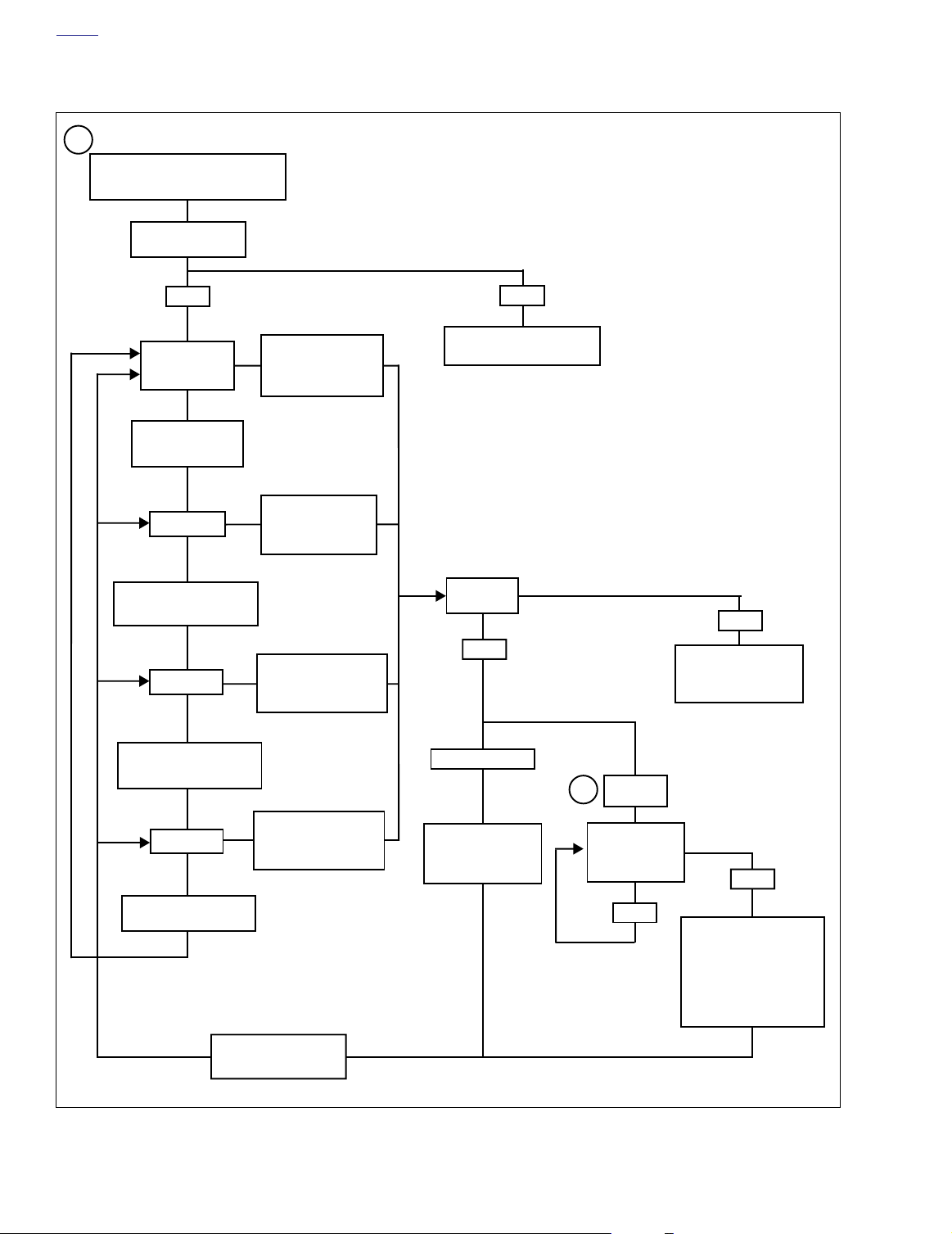

Diagnostic Check (Part 1 of 2)

Does engine

start?

YES.

Starts and

runs.

Check for trouble

codes. See 5.6

SPEEDOMETER

SELF DIAGNOSTICS

Codes found?

YES

Refer to applicable trouble code priority chart.

All diagnostic codes are listed on page 5-11

in Table 5-5. Codes are listed by priority.

YES.

Starts, then

stalls.

See 5.12 STARTS, THEN

STALLS.

YES

STOP

Go to Diagnostic

Check (Part 2 of 2).

NO.

Cranks, but

will not start.

See 5.10 ENGINE CRANKS,

BUT WILL NOT START.

NO

Unable to enter diagnostic mode.

With ignition switch OFF, press and

release odometer reset switch.

Does odometer display appear with

display backlighting?

Check for continuity to ground on terminal 7

of speedometer. Wiggle harness during con-

tinuity check. Continuity present?

YES NO

See 1.2 STARTING SYSTEM

1

No codes displayed. For

symptoms that may not set

diagnostic trouble codes,

refer to table 5-2, Table 5-3

and Table 5-4.

NO

NO.

Engine will not

crank.

DIAGNOSIS.

NO

Check continuity (with ignition

switch OFF) between terminals

8 and 11 on breakout box. Con-

tinuity present when speedome-

ter reset switch is depressed?

Replace speedometer.

Check for battery voltage at

terminal 5 of speedometer

while wiggling harness. Bat-

tery voltage continuously

YES

Replace speedometer

reset switch.

Locate and repair open

between terminal 7

present?

NO

Locate and repair open

between terminal 5 and

battery fuse.

and ground.

2004 Touring: Engine Management (EFI) 5-15

Page 16

HOME

Diagnostic Check (Part 2 of 2)

YES

Turn key to ACC. Is

backlight present?

YES

Is problem intermittent?

Perform “wow” test. See 5.6 SPEEDOMETER SELF DIAGNOSTICS.

1) backlight should illuminate

2) needle should sweep its full range of motion

3) LED’s that should illuminate:

• check engine

• battery

• security (all models)

4) LED’s that may illuminate:

• low fuel (EFI models)

• cruise (even though not cruise equipped)

Continued from Diagnostic Check (Part 1 of 2).

The following features should be functional

Are all features functional?

NO

Check for battery voltage at

breakout box terminal 6.

Battery voltage present?

YES

Replace speedometer.

NO

Check for battery voltage at

terminal 1 of breakout box.

Battery voltage present?

NO

Is instrument

fuse blown?

Replace speedometer.

YES

Repeat Diagnostic

Check while wiggling

harnesses. Intermittent

present?

YES

Locate and repair

intermittent.

YES

NO

No trouble found.

NO

Locate and repair open on O/W

wire between terminal 6 of connector [39] and accessory fuse.

Intermittent vehicle speed

Remove and inspect vehi-

cle speed sensor. Debris

Remove debris. Reinstall

YES

indication.

present?

YES

vehicle speed sensor.

YES

Locate and repair

source of fault.

Replace fuse.

NO

Check for damaged wiring/

loose connection between

vehicle speed sensor and

ECM. Is wiring damage/loose

connection present?

YES

NO

Locate and repair

open between terminal

1 of connector [39]

and instrument fuse.

NO

Tachometer Inoperative

(no engine speed).

See Test 2.4 (Part 1 of 2)

under 2.4 SPEEDOMETER/

TACHOMETER.

NO

5-16 2004 Touring: Engine Management (EFI)

Locate and repair

source of fault.

Replace Speedometer.

Page 17

HOME

d0715x8x

1

1. Cruise On/Engaged

2. Check Engine

3. Low Fuel

4. Battery

5. Security

2

3

4

5

SPEEDOMETER SELF DIAGNOSTICS 5.6

GENERAL

The speedometer is capable of displaying and clearing

speedometer, tachometer, TSM/TSSM, and ICM/ECM trouble

codes (diagnostic mode).

DIAGNOSTICS

Diagnostic Tips

●

For a quick check of speedometer function, a “wow” test

can be performed. See Figure 5-8. Press and hold

odometer reset switch then turn ignition switch ON.

Release reset switch. Background lighting should illuminate, speedometer needle should sweep its full range of

motion, and indicator lamps [battery, security, low fuel

(EFI models) check engine and cruise] should illuminate.

Some lamps may illuminate even though they do not

apply to the vehicle. For example, the cruise lamp may

illuminate even though the motorcycle may not be

equipped with cruise control.

●

If instrument module fails “wow” test, check for battery,

ground, ignition, speedometer reset switch and accessory to speedometer. If any feature in the speedometer is

non-functional, see 2.2 INITIAL DIAGNOSTIC CHECK:

SPEEDOMETER.

Diagnostic Notes

Use of speedometer self diagnostics assumes that DIGITAL

TECHNICIAN (Part No. HD-44750) is

The reference numbers below correlate with the circled numbers in the Speedometer Self Diagnostics (chart)

1. To exit diagnostic mode, turn ignition switch OFF.

2. To clear DTCs for selected module, press speedometer

reset switch for more than 5 seconds when code is displayed. This procedure will clear all codes for selected

module.

not

available.

Figure 5-8. Speedometer (FLHR/C/S)

2004 Touring: Engine Management (EFI) 5-17

Page 18

HOME

Speedometer Self Diagnostics (chart)

1

While holding odometer reset switch in,

turn ignition switch to IGN. Make sure

Run/Stop switch is in RUN position.

Release reset switch.

Does “diag” appear?

YES

”P” flashing.

To choose TSM/

TSSM, press and

release reset switch.

”S” flashing.

To choose Speedometer,

press and release reset

switch.

”SP” flashing.

To choose Tachometer,

press and release reset

switch.

”T” flashing.

To choose ECM, press

and release reset switch.

To display DTCs for the

ECM, press and hold

reset switch for more

than 5 seconds.

To display DTCs for

TSM/TSSM, press and

hold reset switch for

more than 5 seconds.

To display DTCs for

speedometer, press and

hold reset switch for more

than 5 seconds.

To display DTCs for

tachometer, press and

hold reset switch for more

than 5 seconds.

NO

See 2.2 INITIAL DIAGNOSTIC

CHECK: SPEEDOMETER.

Device

response?

YES

“none” displayed.

Press and release

reset switch. Part num-

ber of module will be

displayed.

DTC

2

displayed.

Press and release

reset switch.

Are more DTCs

displayed?

YES

NO

“no rsp” displayed.*

Tachometer malfunction.

2.4 SPEEDOMETER/

See

TACHOMETER.

* Models not equipped

with a tachometer will

display “no rsp” normally.

NO

“end” displayed.

To clear all DTCs for

selected module hold reset

switch for more than 5 seconds. If DTCs are not to be

cleared, Press and release

reset switch. Part number of

module will be displayed.

Press and release reset

switch again to continue to

next module.

Figure 5-9. Speedometer Self Diagnostics

5-18 2004 Touring: Engine Management (EFI)

Page 19

HOME

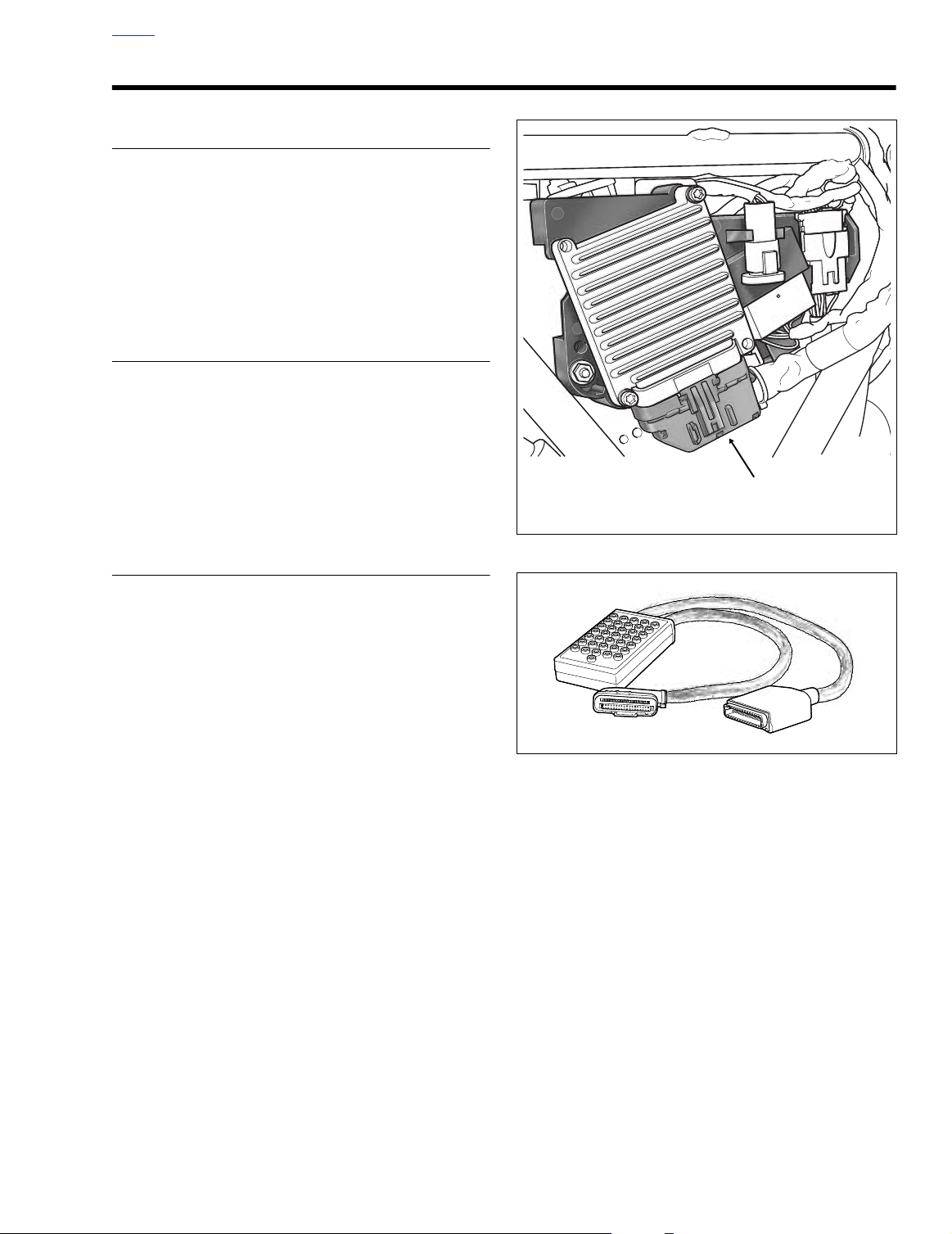

f1917x9x

Electronic Control

Module Connector [78]

BREAKOUT BOX: EFI 5.7

GENERAL

The BREAKOUT BOX (Part No. HD-43876) splices into the

main harness. Used in conjunction with a DVOM, it allows circuit diagnosis of wiring harness and connections without having to probe with sharp objects.

NOTE

See wiring diagrams for ECM terminal functions.

INSTALLATION

1. Remove right saddlebag and side cover. See Figure 5-

10.

2. Depress latch and remove connector [78B] to release

EFI harness from ECM.

3. Install connectors on Breakout Box to ECM and EFI harness connectors.

REMOVAL

1. Separate connectors to remove Breakout Box between

ECM and EFI harness.

2. Install connector [78B] to connect EFI harness to ECM.

3. Install right side cover and saddlebag.

Figure 5-10. Electrical Bracket (Under Right Side Cover)

Figure 5-11. Breakout Box (Part No. HD-43876)

2004 Touring: Engine Management (EFI) 5-19

Page 20

HOME

WIGGLE TEST 5.8

GENERAL

The wiggle test indicates the presence of intermittents in a

wiring harness.

PROCEDURE

1. See Figure 5-12. Connect DVOM (Part No. HD-39978) to

wiring harness between the suspect connections. When

diagnosing ECM connections, use a BREAKOUT BOX

(Part No. HD-43876) to simplify the procedure. See 5.7

BREAKOUT BOX: EFI.

2. Set DVOM to read voltage changes.

3. Start motorcycle engine and run at idle.

4. Shake or wiggle harness to detect intermittents. If intermittents are present, radical voltage changes will register

on the DVOM.

hd39978

Figure 5-12. Fluke 78 Multimeter (DVOM)

(Part No. HD-39978)

5-20 2004 Touring: Engine Management (EFI)

Page 21

HOME

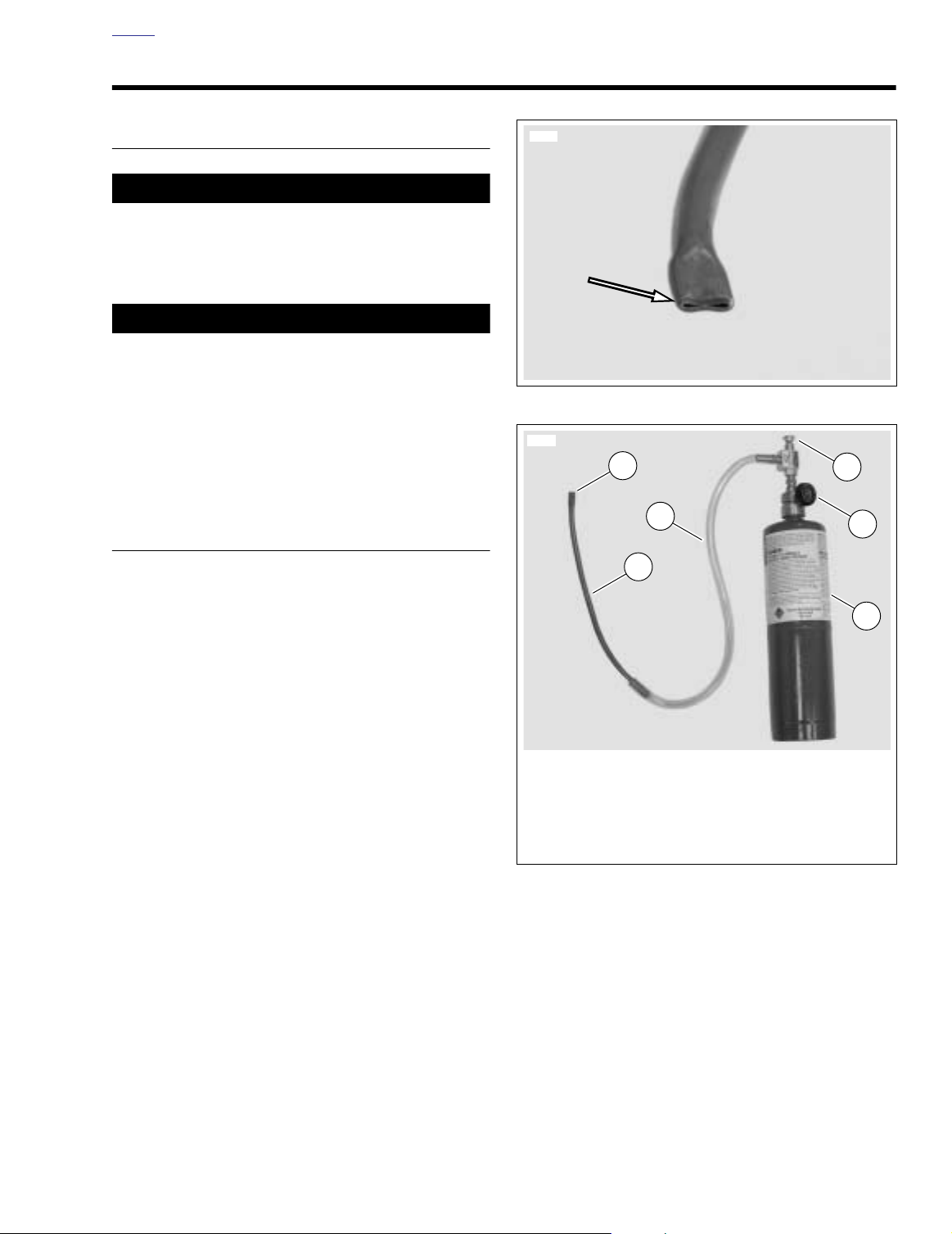

9648

9649

1. Nozzle

2. Copper tube

3. Hose

4. Valve

5. Knob

6. Propane bottle

1

2

3

5

6

4

INTAKE LEAK TEST 5.9

GENERAL

1DANGER

Propane is an extremely flammable liquid and vapor.

Vapor may cause flash fire. Keep away from heat, sparks

and flame. Keep container closed. Use only with adequate ventilation.

1WARNING1WARNING

Read all directions and warnings on propane bottle. Failure to follow all directions and warnings on bottle could

result in death or serious injury.

●

To prevent false readings, keep airbox cover installed

when performing test.

Do not direct propane into air cleaner, false readings will

●

result.

Figure 5-13. Nozzle

LEAK TESTER

Parts List

●

Standard 14 oz. propane cylinder.

Snap-on YA7148 Propane Enrichment Kit.

●

12 in. (304 mm) long-1/4 in. (6 mm) diameter copper tub-

●

ing.

Tester Assembly

1. Cut rubber hose from kit to 18 in. (457 mm) in length.

2. See Figure 5-13. Flatten one end of copper tube to form

a nozzle.

3. Insert round side of copper tube into end of tubing.

Figure 5-14. Leak Tester

2004 Touring: Engine Management (EFI) 5-21

Page 22

HOME

INTAKE LEAK TESTING

1. Start engine.

2. Warm engine to operating temperature.

3. See Figure 5-14. Turn knob (5) counterclockwise to open

propane bottle (6).

1DANGER

Propane is an extremely flammable liquid and vapor.

Vapor may cause flash fire. Keep away from heat, sparks

and flame. Keep container closed. Use only with adequate ventilation.

NOTE

Do not direct propane stream toward front of engine. If propane enters air cleaner, a false reading will be obtained.

4. See Figure 5-15. Aim nozzle toward possible sources of

leak such as fuel injectors and intake tract.

5. See Figure 5-14. Push valve (4) to release propane.

To ne of engine will change when propane enters source

of leak.

10054

Figure 5-15. Checking for Leaks

5-22 2004 Touring: Engine Management (EFI)

Page 23

HOME

d0273x8x

7863

ENGINE CRANKS, BUT WILL NOT START 5.10

GENERAL

If the starter will not crank the engine, the problem is not EFI

related. Refer to SECTION 1-STARTING & CHARGING or

SECTION 3-TSM & TSSM.

DIAGNOSTICS

Diagnostic Notes

The reference numbers below correlate with the circled numbers on the Test 5.10 flow charts.

1. Check for trouble codes. See RETRIEVING DIAGNOS-

TIC TROUBLE CODES under 5.4 CHECKING FOR

DIAGNOSTIC TROUBLE CODES: EFI.

2. Check the condition of the battery. Perform a voltage test

and recharge if below 12.60V. Check battery connections

and perform load test. Replace the battery if necessary.

See BATTERY in the Touring Service Manual.

3. Connect BREAKOUT BOX (Part No. HD-43876). See 5.7

BREAKOUT BOX: EFI.

4. Remove spark plug cable from spark plug.

a. Visually check condition of plug.

b. See Figure 5-16. Attach cable to SPARK TESTER

(Part No. HD-26792). Clip tester to cylinder head

bolt.

c. While cranking engine, look for spark. Repeat pro-

cedure on other spark plug cables.

NOTE

Engine will not spark with both spark plugs removed. When

checking for spark, use SPARK TESTER (Part No. HD-

26792) with both plugs installed.

Diagnostic Tips

Figure 5-16. Spark Tester

Figure 5-17. Ignition Coil Circuit Test

5. Use HARNESS CONNECTOR TEST KIT (Part No. HD-

41404), gray pin probe and patch cord.

6. Typically, when IAC is not functioning, the engine will not

start unless throttle is opened and the engine will stall

when throttle is closed.

7. See Figure 5-17. Plug IGNITION COIL CIRCUIT TEST

ADAPTER (Part No. HD-44687) and FUEL INJECTOR

TEST LAMP (Part No. HD-34730-2C) into Breakout Box

Te r minals 13 and 11. Start engine. If lamp flashes, no

problem is found. Repeat for Breakout Box Terminals 13

and 29.

8. Use HARNESS CONNECTOR TEST KIT (Part No. HD-

41404), brown socket probe and patch cord.

Check TP sensor value with DVOM. If TP sensor is equal to or

greater than 3.8 volts, system is in “clear flood” mode and

engine will not start. While spark is present, fuel is shut off.

Problem can be mechanical, such as throttle cables stuck.

2004 Touring: Engine Management (EFI) 5-23

Page 24

HOME

Intake air

control

[79A]

[79B]

12

12

[87A]

CKP

System relay

Ion sense

Coil R

Coil F

A

A

B

B

C

C

D

D

Constant

[87B]

Switch power

R

BK

Inj. F

Inj. R

BE/GN

BN/R

BK/PK

BK/O

power

[78]

30

12

21

19

27

11

29

35

36

18

17

31

13

[62B]

To Ta chometer

(FLHR/C/S Optional)

Y/GN

BE/GY

IQCPR

87

87A

30 85 86

System

relay

GN/O

15 Amp

fuel pump

fuse

W/BK

[13A] [13B]

123

123

O/GY

123

123

Fuel

pump

3

GN/O

4

AB

AB

Y/GN

W/Y

[141B][141A]

All Except

FLHR/C/S

GN/GY

GY/BE

[84B] [84A]

AB

AB

[85B] [85A]

Y/GN

Y/GN

[83B] [83A]

AB CD

BK

AB CD

Coil

Y/BE

BE/O

40 Amp

Maxi fuse

Battery

–+

BK

BE/GY

W/BK

Engine

stop

switch

15 Amp

ECM fuse

15 Amp

IGN fuse

GY R/BK

R

Ignition switch

Vehicle speed sensor

f2208g8x

TP sensor

ET sensor

IAT sensor

5v sensor gnd.

MAP sensor

5v sensor pwr.

Serial data

Flash pin

Power gnd.

Power gnd.

A

BK/W

GY/V

24

PK/Y

6

LT GN/Y

7

26

BK/W

V/W

25

R/W

14

W/GN

33

LT GN/V

5

1

LT GN/R

BK

10

28

BK

[65B] [65A]

B

C

A

BK/W

BK/W

A

B

C

[90B] [90A]

21

21

A

A

B

B

[89B] [89A]

[91A]

3

1

2

4

R/W

GY/V

BK/W

V/W

R/W

Vehicle

speed

sensor

Data link

connector

AB

B

C

C

[88B] [88A]

ET sensor

IAT sensor

[80B] [80A]

AB

AB

C

C

[30B]

[30A]

MAP

sensor

TP

sensor

3

2

3

2

hand controls

GY

W/BK

W/BN

To speedometer

and tachometer

7

7

To right

3

4

5

[22A]

TSM/

TSSM

Figure 5-18. EFI System Circuit - Simplified

5-24 2004 Touring: Engine Management (EFI)

Page 25

HOME

Table 5-8. Wire Harness Connectors in Figure 5-18.

NO.

[22]

[30] Turn Signal/Security Module All 12 - Place Deutsch

[65] Vehicle Speed Sensor All 3 - Place Deutsch

[78] Electronic Control Module All 36-Place Packard Under Right Side Cover

[79] Crankshaft Position Sensor All 2 - Place Mini-Deutsch Bottom of Voltage Regulator

[80]

[83] Ignition Coil All 4 - Place Packard Below Fuel Tank (Left Side)

[84] Front Injector All 2 - Place Packard Below Fuel Tank (Left Side)

[85] Rear Injector All 2 - Place Packard Below Fuel Tank (Left Side)

[87] Idle Air Control All 4 - Place Packard Below Fuel Tank (Right Side)

[88] Throttle Position Sensor All 3 - Place Packard Below Fuel Tank (Right Side)

[89] Intake Air Temperature Sensor All 2 - Place Packard Below Fuel Tank (Right Side)

[90] Engine Temperature Sensor All 2 - Place Packard Back of Front Cylinder (Left Side)

[91] Data Link All 4 - Place Deutsch Under Right Side Cover

DESCRIPTION MODEL TYPE LOCATION

Right Handlebar Switch

Controls

Manifold Absolute Pressure

Sensor

FLHT/C/U

FLTR

FLHR/C/S 6 - Place Deutsch

All 3 - Place Packard Top of Induction Module

12-Place Deutsch

(Black)

12-Place Deutsch

(Black)

Inner Fairing - Fork Stem Nut Lock Plate

Inner Fairing - Right Side of Radio Bracket

Inside Headlamp Nacelle - Fork Stem

Nut Lock Plate (Right Side)

Cavity in Crossmember at Rear of

Battery Box (Under Seat)

Under Right Side Cover

(Behind Electrical Bracket)

(Left Side)

2004 Touring: Engine Management (EFI) 5-25

Page 26

HOME

Test 5.10 (Part 1 of 4)

ENGINE CRANKS, BUT WILL NOT START

Fresh fuel in tank?

Refer to IGNITION COIL in the Tour-

ing Service Manual for proper coil ter-

connected to proper coil terminals?

NOTE

minal location.

Spark plug wires firmly

Check for trouble

1

codes.

Codes found?

Refer to Table 5-5.

Start with

the lowest ranking

code.

YES

YES

NO

NO

2

Add fuel /connect

Is TSM/TSSM mounted in

proper orientation?

Check battery connections

and voltage. Is voltage

above 12.60?

Does battery pass

spark plugs.

YES

YES

load test?

NO

Install TSM/TSSM properly.

NO

Was battery allowed to dis-

charge? Was battery drawn

down by starting problem?

Recharge battery.

Turn ignition key ON and engine stop

switch to RUN. Did fuel pump run for 2

seconds and check engine lamp illumi-

YES

Connect breakout box to ECM [78]. Measure

3

voltage to breakout box with DVOM at terminal

13 (+) and terminal 4 (-). Crank engine for

greater than 2 seconds to insure proper system

operation. 6-12 volts present continuously?

YES

STOP

Go to Test 5.10

(Part 2 of 4).

5-26 2004 Touring: Engine Management (EFI)

YES

nate for 4 seconds?

NO

No pump,

light OK.

See

5.13 FUEL SYSTEM

ELECTRICAL TEST.

NO

Go to bold asterisk in

Test 5.10 (Part 4 of 4).

NO

Replace battery.

NO

No light or pump

See 5.11 NO ECM POWER.

Page 27

HOME

Test 5.10 (Part 2 of 4)

ENGINE CRANKS, BUT WILL NOT START

Install fuel pressure gauge (Part No. HD-41182).

cranking engine (for more than 2 seconds to

ensure proper system operation), verify that

fuel pressure rises to 55-62 PSI (380-427 kPa).

Continued from Test 5.10 (Part 1 of 4).

See 5.15 FUEL PRESSURE TEST. While

Adequate fuel pressure present?

NOYES

Check spark plug condition, replace if fouled.

Reinstall spark plugs before checking spark.

Check spark at both plugs while cranking.

4

6

Spark present?

YES

Ver ify connector is securely attached

to each injector. If so, disconnect fuel

injector connector and attach fuel

injector test lamp (HD-34730-2C).

Crank engine. Does lamp flash?

YES

Monitor IAC pintle for 10 seconds

after turning ignition OFF. Does pin-

tle extend and then retract during

10 second key OFF

reset procedure?

YES

Check for plugged fuel

injectors. Injectors

plugged?

NO

Correct problems with

fuel injectors. See 5.23

DTC P0261, P0262,

P0263, P0264.

NO

See 5.16 IDLE

AIR CONTROL.

NO

Check battery voltage at

Terminal A (+) of coil connector

[83B] using DVOM. Battery

voltage present for 2 seconds

5

after key ON?

YES

STOP

Go to Test 5.10

(Part 3 of 4).

Incorrect pressure. See 5.15

FUEL PRESSURE TEST.

NO

Open in Y/GN wire

between splice for fuel

pump wire and ignition

coil. Repair open

YES

Replace plugged

injector(s).

NO

Check engine compression.

Clear codes using speedometer self diagnostics.

See 5.6 SPEEDOMETER SELF DIAGNOSTICS.

Confirm proper operation with no check engine

lamp.

2004 Touring: Engine Management (EFI) 5-27

Page 28

HOME

Test 5.10 (Part 3 of 4)

ENGINE CRANKS, BUT WILL NOT START

YES

Check coil connections.

Connections OK?

YES

Test spark plug cable resis-

tance. See 5.17 MISFIRE AT

IDLE OR UNDER LOAD.

Resistance OK?

YES

Replace

coil.

7

Continued from Test 5.10 (Part 2 of 4).

Perform coil circuit test. Does lamp flash?

NO

Repair.

NO

Replace spark

plug cables.

NO

Disconnect ECM connector [78]. Inspect

for damaged terminals, terminals backed

out or corroded. Terminal problems

YES

Repair terminal

damage.

YES

present?

Reconnect. Problem

STOP

NO

still exist?

NO

Problem

fixed.

Clear codes using speedometer self diagnostics.

See 5.6 SPEEDOMETER SELF DIAGNOSTICS.

Confirm proper operation with no check engine

lamp.

Go to Test 5.10

(Part 4 of 4).

5-28 2004 Touring: Engine Management (EFI)

Page 29

HOME

Test 5.10 (Part 4 of 4)

ENGINE CRANKS, BUT WILL NOT START

Continued from Test 5.10 (Part 3 of 4).

Check connectors for moisture and cor-

rosion. Check wires for chafing. Connect DVOM to ECM terminals 12 and

30 on Breakout Box and set it for AC

volts. Crank engine. Does DVOM read

1 VAC minimum?

Reprogram and

learn password.

At some point in the flow chart you

may be instructed to jump directly

to a the box with the bold asterisk.

Disregard the asterisk (but not the

instruction box) if your normal progression through the chart brings

you to this location.

YES NO

Check for continuity between

terminal 30 on Breakout Box

and Terminal 1 of connector

[79B].

Continuity present?

YES

YES

Replace ECM.

NO

Disconnect CKP connector

[79]. Check connectors for

moisture and corrosion. Check

wires for chafing. Is connector

or wire damage present?

YES NO

Repair damage.

NO

Connect DVOM to Terminals

8

engine. Does DVOM read 1

1 and 2 of [79A]. Crank

VAC minimum?

YES

With meter still connected,

check for resistance.

Is resistance 600-1200 ohms?

NO

Locate and repair open on

BK wire between Terminal 2 of

connector [79B] and terminal

12 on Breakout Box.

Locate and repair open on

R wire between Terminal 1 of

connector [79B] and terminal

30 on Breakout Box.

Loosen sensor at crankcase.

Check for contamination or

damage. Tighten sensor.

Clear codes using speedometer self diagnostics.

See 5.6 SPEEDOMETER SELF DIAGNOSTICS.

Confirm proper operation with no check engine

lamp.

Replace crank position sensor.

2004 Touring: Engine Management (EFI) 5-29

Page 30

HOME

NO ECM POWER 5.11

GENERAL

No Spark/No Check Engine Lamp at Key ON

Constant power is supplied to the ECM through terminal 31.

The ECM turns on when power is applied to terminal 13 of

connector [78]. The ECM goes through an initialization

sequence every time power is removed and re-applied to terminal 13. The only visible part of this sequence is the check

engine lamp. Upon starting, the check engine lamp will illuminate for 4 seconds and then (if parameters are normal) go

out.

If battery power is absent at ECM terminal 31:

DTCs cannot be cleared. Tool will show them as cleared

●

but will be present next time ignition key is cycled.

ECM cannot be re-flashed.

●

Vehicle will start but IAC pintle will not reset at key OFF.

●

Eventually pintle will be out of position causing performance problems.

NOTE

The key ON sequence also activates the idle air control

motor. If power from terminal 31 is disrupted (blown fuse,

etc.) always turn the key OFF wait 10 seconds then turn the

key ON to reset the motor to the default position.

System Fuse Block (Under Left Side Cover)

FLHR/C/S

10

9

8

5

11

12

f2210x8x

1

FLTR, FLHT/C/U

10

9

2

7

8

6

5

11

4

3

4

DIAGNOSTICS

Diagnostic Notes

The reference numbers below correlate with the circled numbers on the Test 5.11 flow charts.

1. Connect BREAKOUT BOX (Part No. HD-43876). See 5.7

BREAKOUT BOX: EFI.

NOTE

Adapters are not used on FLTR and FLHT/C/U models.

2. Connect BREAKOUT BOX (Part No. HD-42682)

between connectors [22A] and [22B] using Adapters

(HD-42962) on FLHR/C/S models.

f2204x8x

1. Headlamp

2. Ignition

3. Lighting

4. Instruments

5. Brakes/Cruise

6. Radio Memory

EFI Fuse Block (Under Right Side Cover)

Fuel Pump

ECM Power

1

Spare

Figure 5-19. Fuse Locations

2

7. Radio Power

8. Accessory

9. Battery

10. Brake Light Relay

11. P&A

12. Starter Relay

EFI System

Relay

3

f2223x9x

5-30 2004 Touring: Engine Management (EFI)

Page 31

HOME

[78A] [78B]

31

13

ECM

BE/GY

W/BK

12 11 10 9 8 7 6 5 4 3 2 1

[8A]

[8B]

15 Amp

ECM Fuse

R/BK

DCB

R

A

40 Amp

Maxi Fuse

[33A]

[33B]

f2208f8x

–+

Battery

BK

15 Amp

Ignition Fuse

Ignition

Switch

10

28

12 11 10 9 8 7 6 5 4 3 2 1

12 11 10 9 8 7 6 5 4 3 2 1

BK

BK

BK

GY

Engine Stop

Switch

[1A]

[1B]

[22A]

[22B]

Figure 5-20. ECM Power Circuit (FLTR, FLHT/C/U)

Table 5-9. Wire Harness Connectors in Figure 5-20.

NO.

[1] Main to Interconnect Harness 12-Place Deutsch (Black) Inner Fairing (Right Fairing Bracket)

[8] Main to EFI Harness 12-Place Deutsch (Gray) Under Right Side Cover

[22] Right Handlebar Switches 12-Place Deutsch (Black) Inner Fairing (Right Fairing Support Brace)

[33] Ignition/Light Key Switch 4-Place Packard

[78] ECM 36-Place Packard Under Right Side Cover

DESCRIPTION TYPE LOCATION

Inner Fairing

(Front of Top Fork Bracket -Below Radio)

2004 Touring: Engine Management (EFI) 5-31

Page 32

HOME

[78A] [78B]

31

13

ECM

BE/GY

W/BK

12 11 10 9 8 7 6 5 4 3 2 1

[8A]

[8B]

15 Amp

ECM Fuse

R/BK

IB

R

A

40 Amp

Maxi Fuse

[33A]

[33B]

f2208e8x

–+

Battery

BK

15 Amp

Ignition Fuse

Ignition

Switch

10

28

12-Place on FLHP

12 11 10 9 8 7 6 5 4 3 2 1

BK

BK

BK

GY

Engine Stop

Switch

[22A]

[22B]

Figure 5-21. ECM Power Circuit (FLHR/C/S)

Table 5-10. Wire Harness Connectors in Figure 5-21.

NO. DESCRIPTION TYPE LOCATION

[8] Main to EFI Harness 12-Place Deutsch (Gray) Under Right Side Cover

[22] Right Handlebar Switches 6-Place Deutsch (Black) Inside Headlamp Nacelle

[33] Ignition/Light Key Switch 3-Place Packard Under Console

[78] ECM 36-Place Packard Under Right Side Cover

5-32 2004 Touring: Engine Management (EFI)

Page 33

HOME

Test 5.11 (Part 1 of 2)

NO ECM POWER

Check ECM and ignition fuse.

Are fuses OK?

YES

Disconnect ECM connector [78]. Inspect

for damaged terminals, terminals backed

out or corrosion. Terminal problems

With ignition ON, probe ECM Terminal 13 on

1

Breakout Box with a circuit test lamp con-

nected to ground. Does test lamp illuminate?

connected to ground. Does test

present?

YES

Repair terminal

damage.

YES

YES

Probe ECM Terminal 31 on

Breakout Box with test lamp

lamp illuminate?

NO

STOP

Go to Test 5.11

(Part 2 of 2).

NO

Reconnect. Problem

still exist?

NO

Problem

fixed.

NO

Locate and repair short

to ground. Replace 15

amp fuse.

YES

Probe ECM Terminal 10 and

28 on Breakout Box with test

lamp connected to +12V (bat-

tery positive terminal). Does

test lamp illuminate?

YES

Replace ECM.

Reprogram and learn

password.

NO

Repair open in

BK wire between

connector [78B] and

ground 1.

NO

Probe red wire terminal in

15 amp ECM fuse holder

with test lamp connected

to ground. Does test lamp

illuminate?

YES

Repair open in BE/GY

wire between fuse

holder and ECM con-

nector [78].

NO

Repair open in

red wire between 40

amp maxi fuse and 15

amp fuse holder.

2004 Touring: Engine Management (EFI) 5-33

Page 34

HOME

Test 5.11 (Part 2 of 2)

NO ECM POWER

Continued from Test 5.11 (Part 1 of 2).

2

Measure voltage at terminal 3 (BK) of

breakout box. Battery voltage present?

Clear codes using speedometer self diagnostics.

See 5.6 SPEEDOMETER SELF DIAGNOSTICS.

Confirm proper operation with no check engine

lamp.

YES

With ignition ON, Measure

voltage at terminal A (BK).

Battery voltage present?

YES

Repair open circuit on W/BK wire

between ECM and connector [22A].

NO

Repair open (GY) wire between

connector [22] and fuse.

NO

Repair/Replace engine stop

switch or wiring.

5-34 2004 Touring: Engine Management (EFI)

Page 35

HOME

f1917x9x

Data Link

Connector [91]

STARTS, THEN STALLS 5.12

GENERAL

Diagnostic Trouble Codes U1300, U1301 or “BUS Er”

See Figure 5-22. The typical serial data voltage range is 0

volts (inactive) to 7 volts (active). Due to the short pulse, voltages will be much lower on a DVOM. In analog mode, a

DVOM reading serial data will show continuous voltage when

active, typically 0.6-0.8 volts. The range for acceptable operations is greater than 0 and less than 7.0 volts.

NOTE

Problems in the fuel system or idle air control system may

also create this symptom.

Table 5-11. Code Description

DTC DESCRIPTION

U1300 Serial data low

U1301 Serial data open/high

DIAGNOSTICS

Diagnostic Tips

● If serial data is shorted, these codes will automatically

trip the check engine light.

● DTCs P1009 and P1010 may accompany DTCs U1300

and U1301.

Diagnostic Notes

The reference numbers below correlate with the circled numbers on the Test 5.12 flow charts.

1. Check for trouble codes. See RETRIEVING DIAGNOS-

TIC TROUBLE CODES under 5.4 CHECKING FOR

DIAGNOSTIC TROUBLE CODES: EFI.

2. Use HARNESS CONNECTOR TEST KIT (Part No. HD-

41404), black socket probes and patch cord.

Figure 5-22. Electrical Bracket (Under Right Side Cover)

2004 Touring: Engine Management (EFI) 5-35

Page 36

HOME

f2208u8x

321654987121110

321654987121110

Speedometer

BK

LtGN/V

O

BN/GY

[39B]

[39A]

[108B]

[108A]

BN/GY

321654987121110

321654987121110

Tachometer

[156B] [156A]

6

6

5

5

4

4

3

3

2

2

1

1

Main to Interconnect

Harness

LtGN/V

GY

65

4

32

1

1

65

4

32

GY

987

987

321654987121110

321654987121110

TSM/TSSM

BK

[8B]

121110

121110

[8A]

Harness

BK

[30B]

[30A]

EFI

[1B] [1A]

123

123

Main to Interconnect

Harness

6

6

15A

Ignition

Fuse

1

2

3

4

Data Link

[91A]

[2B]

[2A]

15A

Accessory

Fuse

321654987121110

321654987121110

Main to Interconnect

Harness

101112 78945

101112 78945

LtGN/V

15A

Battery

Fuse

LtGN/R

51

Flash pin

ECM

Serial data

[78B]

[78A]

Figure 5-23. Serial Data Circuit (FLTR, FLHT/C/U)

Table 5-12. Wire Harness Connectors in Figure 5-23.

NO. DESCRIPTION MODEL TYPE LOCATION

Main to Interconnect

[1]

Harness

Main to Interconnect

[2]

Harness

[8] Main to EFI Harness All 12-Place Deutsch Under Right Side Cover

Tu rn Signal/Security

[30]

Module

[39] Speedometer

[78] Electronic Control Module All 36-Place Packard Under Right Side Cover

[91] Data Link All 4-Place Deutsch Under Right Side Cover

[108] Tachometer

[156]

Main to Interconnect

Harness

FLHT/C 12-Place Deutsch (Black) Inner Fairing - Right Radio Support Bracket

FLTR 12-Place Deutsch (Black) Inner Fairing - Below Radio (Left Side)

FLHT/C 12-Place Deutsch (Gray) Inner Fairing - Right Fairing Support Brace

FLTR 12-Place Deutsch (Gray) Inner Fairing - Below Radio (Left Side)

All 12-Place Deutsch

Cavity in Crossmember at Rear of

Battery Box (Under Seat)

FLHT/C 12-Place Packard Inner Fairing (Back of Speedometer)

FLTR 12-Place Packard Under Bezel (Back of Speedometer)

FLHT/C 12-Place Packard Inner Fairing (Back of Tachometer)

FLTR 12-Place Packard Under Bezel (Back of Tachometer)

FLHT/C 6-Place Deutsch Inner Fairing - Right Fairing Support Brace

FLTR 6-Place Deutsch Inner Fairing - Front of Right Fairing Bracket

5-36 2004 Touring: Engine Management (EFI)

Page 37

HOME

f2208t8x

BN/GY

321654987121110

321654987121110

Speedometer

15A

Battery

Fuse

BK

15A

Accessory

Fuse

LtGN/V

BN/GY

O

[39B]

[39A]

15A

Ignition

Fuse

LtGN/V

GY

3

21

321

GY

BK

321654987121110

321654987121110

[30B]

[30A]

TSM/TSSM

BK

98

7

65

4

98

7

65

4

121110

[8B]

EFI

[8A]

Harness

121110

1

2

3

4

Data Link

[91A]

LtGN/V

LtGN/R

[78B]

[78A]

1

Flash pin

5

Serial data

ECM

Figure 5-24. Serial Data Circuit (FLHR/C/S)

Table 5-13. Wire Harness Connectors in Figure 5-24.

NO. DESCRIPTION TYPE LOCATION

[8] Main to EFI Harness 12-Place Deutsch Under Right Side Cover

[30] Turn Signal/Security Module 12-Place Deutsch

[39] Speedometer 12-Place Packard Under Console (Back of Speedometer)

[78] Electronic Control Module 36-Place Packard Under Right Side Cover

[91] Data Link 4-Place Deutsch Under Right Side Cover

Cavity in Crossmember at Rear of

Battery Box (Under Seat)

2004 Touring: Engine Management (EFI) 5-37

Page 38

HOME

Test 5.12 (Part 1 of 2)

STARTS, THEN STALLS: DTC U1300, U1301 or

“BUS Er”

Fresh gasoline

in tank?

NOYES

YES.

DTC P1009,

P1010 found. See

5.28 DTC P1009,

P1010.

YES.

U1300 or U1301

codes found.

STOP

Go to Test 5.12

(Part 2 of 2).

YES

Tap lightly on fuel injectors.

Problem still exist?

Check for trouble codes using.5.6

SPEEDOMETER SELF DIAG-

1

NOSTICS. Codes found?

NO.

No codes

found.

Will engine start with throttle

opened partially and stall when

throttle closed?

YES. NO.

See 5.16 IDLE AIR

CONTROL.

Add gasoline.

YES.

BUS Er present.

speedometer will not

communicate with other

modules.

STOP

Check fuel pressure while

cranking engine. See 5.15

FUEL PRESSURE TEST. Is

fuel pressure OK?

NO

Fuel pressure problem. See

flow chart under 5.15 FUEL

PRESSURE TEST.

Go to Test 5.12

(Part 2 of 2).

YES

Replace fuel injectors.

Problem still exist?

YES NO

Replace ECM.

Reprogram and learn

password.

5-38 2004 Touring: Engine Management (EFI)

NO

System

OK.

System

OK.

Clear codes using speedometer self diagnostics.

See 5.6 SPEEDOMETER SELF DIAGNOSTICS.

Confirm proper operation with no check engine

lamp.

Page 39

HOME

Test 5.12 (Part 2 of 2)

STARTS, THEN STALLS: DTC U1300, U1301 or

“BUS Er”

Continued from Test 5.12 (Part 1 of 2)

Set run/stop switch to RUN. Turn ignition key ON.

Is BUS Er present?

YES

Tu rn ignition key OFF.

Disconnect ECM at connector

[78]. Turn ignition key ON.

Is BUS Er present?

Tu rn ignition key OFF.

Disconnect TSM/TSSM at connector

[30]. Turn ignition key ON.

Is BUS Er present?

YES

Is vehicle equipped

with a tachometer?

NO YES

Tu rn ignition key OFF. Disconnect tachometer

at connector [108]. Turn ignition key ON.

Is BUS Er present?

2

NOYES

Replace ECM.

Reprogram and perform

password learn.

NO

Replace TSM/TSSM. Per-

form password learn.

NO

Tu rn ignition key OFF. While wiggling

harness, check for continuity to ground at

terminal 3 of connector [91A].

Is continuity to ground present at any time?

YES

Locate and repair

intermittent short

to ground.

YES

Locate and repair

intermittent short

to voltage.

NO

Tu rn ignition switch ON.

While wiggling harness,

check for voltage at terminal

3 of connector [91A].

Is voltage present at

any time?

NO

No problem

found.

YES

Tu rn ignition key OFF. Disconnect

speedometer at connector [39].

Check for continuity to ground at

2

terminal 3 of connector [91A].

Is continuity to ground present?

YES

Locate and repair short

to ground.

Clear codes using speedometer self diagnostics.

See 5.6 SPEEDOMETER SELF DIAGNOSTICS.

Confirm proper operation with no check engine

lamp.

NO

Replace tachometer.

NO

Tu rn ignition switch ON.

Check for voltage at terminal

3 of connector [91A].

Is voltage present?

YES

Locate and repair short

to voltage.

2004 Touring: Engine Management (EFI) 5-39

NO

Replace

speedometer.

Page 40

HOME

FUEL SYSTEM ELECTRICAL TEST 5.13

GENERAL

With ignition switch turned to IGNITION and the engine stop

switch at RUN, the ECM will energize the system relay to

complete the circuit to the in-tank fuel pump. It will remain on

as long as the engine is cranking or running, and the ECM is

receiving ignition reference pulses from the CKP. If there are

no reference pulses, the ECM will de-energize the system

relay within 2 seconds after ignition is ON or engine has

stalled, or immediately after the ignition is shut OFF.

The fuel pump delivers fuel to the injectors. The pressure regulator is where the system pressure is controlled. Excess fuel

flow is bypassed into the fuel tank through the pressure regulator. When the engine is stopped, the pump can be turned on

by applying battery voltage and ground to the fuel pump connector [141A]. The fuel pump connector is located on the canopy at the top of the fuel tank. Improper fuel system pressure

may contribute to one or all of the following symptoms.

● Engine cranks, but won’t run.

● Engine cuts out (may feel like ignition problems).

● Hesitation, loss of power and poor fuel economy.

NOTE

After turning ignition OFF, you must wait 10 seconds before

turning the ignition back ON to get the fuel pump to reprime.

This time out period is necessary for the ECM and IAC to

reset.

f1924x8x

Fuel Tank

Fuel Tank Harness

Connector [13]

Not Present on FLHR/C/S

Figure 5-25. Fuel Pump/Fuel Level Sender Connector

(FLTR, FLHT/C/U)

EFI System Relay

Spare

DIAGNOSTICS

Diagnostic Notes

The reference numbers below correlate with the circled numbers on the Test 5.15 flow charts.

1. Turns on fuel pump if wiring is OK. If pump runs, problem

is in basic fuel delivery.

2. Use HARNESS CONNECTOR TEST KIT (Part No. HD-

41404), brown pin probe and patch cord.

3. Connect BREAKOUT BOX (Part No. HD-43876). See

Section 5.7 BREAKOUT BOX: EFI.

4. Use HARNESS CONNECTOR TEST KIT (Part No. HD-

41404), purple pin probe and patch cord.

Fuel

Pump

f2223x9x

ECM Power

Figure 5-26. EFI Fuse Block

5-40 2004 Touring: Engine Management (EFI)

Page 41

HOME

Idle air

control

System relay

Inj. F

Inj. R

[87B][87A]

BE/GN

A

A

B

B

BN/R

BK/PK

C

C

D

BK/O

D

Constant power

Switch power

[78]

4

21

19

35

36

18

17

31

13

GN/O

W/Y

GN/GY

BE/GY

W/BK

AB

AB

[84B] [84A]

AB

AB

[85B] [85A]

Engine

stop

switch

Y/GN

Y/GN

15 Amp

ECM fuse

15 Amp

IGN fuse

GY R/BK

fuel pump

Y/GN

15 Amp

fuse

BK

40 Amp

Maxi Fuse

R

Ignition switch

Y/GN

BE/GY

GN/O

W/BK

[13A] [13B]

123

87

IQCPR

87A

30 85 86

123

O/GY

[141B][141A]

All Except

FLHR/C/S

Battery

[62B]

123

123

–+

BK

System

relay

Fuel

pump

MAIN FUSE BLOCK COVER

Power gnd.

Power gnd.

10A

15A

15A

SPARE FUSES

HEADLAMPS

F

H

BRAKE

RELAY

15A

15A

J

10

28

BK

BK

15A

G

MAIN FUSE BLOCK

E

BRAKE

RELAY

P&A

IGN

15A

15A

15A

P&A

IGN

RADIO PWR

BATTERY

RADIO MEM

ACCESS.

CRUISE/BRK

INSTRUMENTS

LIGHTS

D

B

4

10A

3

15A

2

15A

1

15A

A

C

f2208d8x

Figure 5-27. Fuel Pump Circuit

Table 5-14. Wire Harness Connectors in Figure 5-27.

NO. DESCRIPTION TYPE LOCATION

[13] Fuel Tank Harness 3-Place Multilock Behind Fuel Tank (Under Seat)

[78] ECM 36-Place Packard Under Right Side Cover

[141] Fuel Pump/Fuel Level Sender 3-Place Mini-Deutsch Top of Canopy (Under Console)

2004 Touring: Engine Management (EFI) 5-41

Page 42

HOME

Test 5.13 (Part 1 of 4)

FUEL SYSTEM ELECTRICAL TEST

Is ECM fuse OK?

YES

Repair as

necessary.

YES

Is fuel pump fuse OK?

YES

Check for 12 volts at terminals 1 (+) and 3 (-) of fuel

1

pump connector [141B] during first 2-3 seconds

2

between connector Pin 1 of [141A] and

after key ON.

Voltage present?

YES

Check for corroded

connections or loose

connectors between fuel pump

and pump connector [141B].

Poor connections?

NO

With key OFF, check for open

pump circuit. Connect ohmmeter

Pin 3 of connector [141A].

Continuity present?

NO

STOP

NO

STOP

NO

Check for continuity to

ground on [141B] terminal 3.

Continuity present?

YES

Go to 5.11 NO