Page 1

4

HOME

BULB CHART 8.1

GENERAL

The chart below gives the bulb requirements for FLHTP and

FLHP police model motorcycles.

For Cycle Signal Lamp replacement bulbs, phone Whelen

Engineering at (203) 526-9504.

NOTE

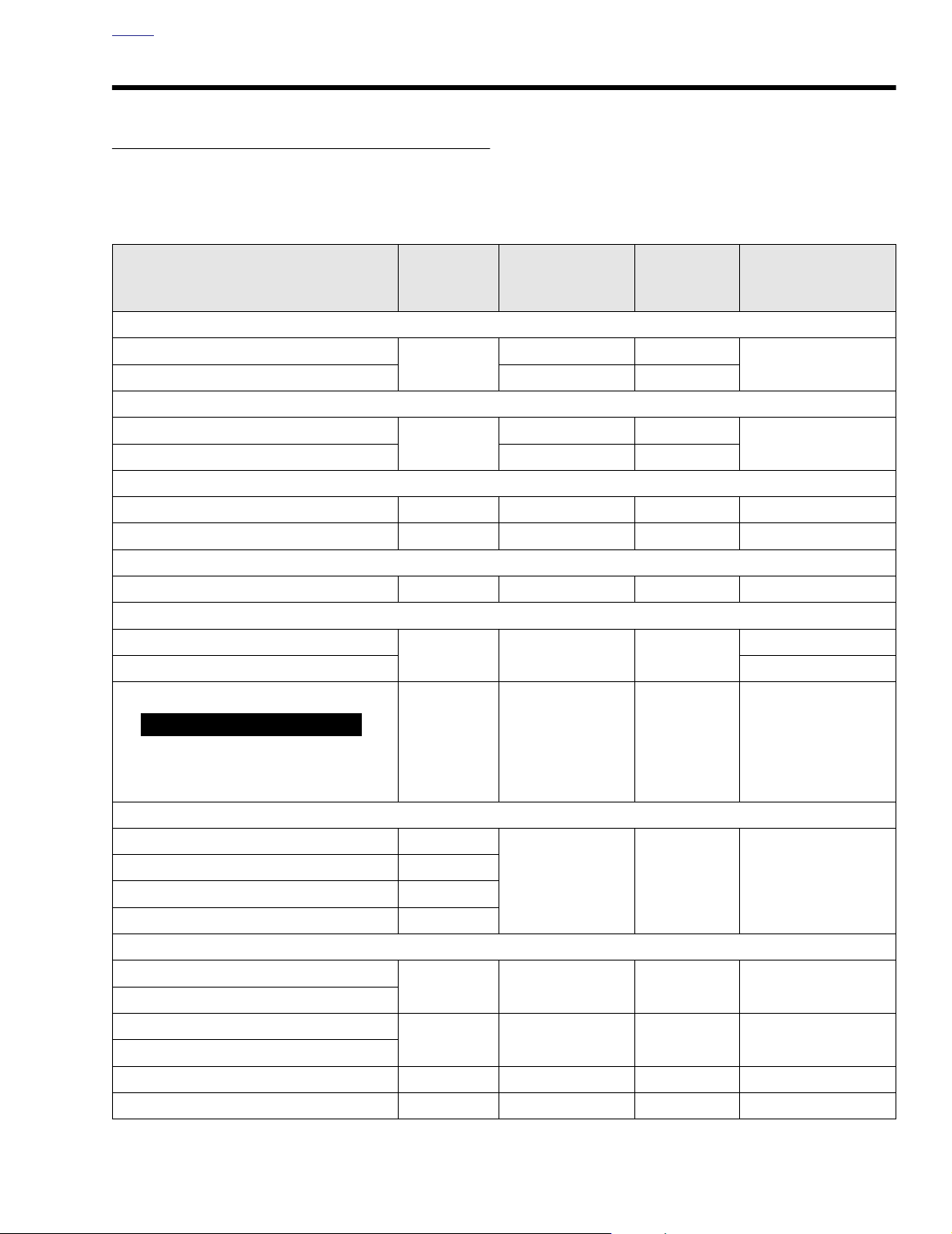

Table 8-1. Bulb Chart FLHTP/FLHP

LAMP DESCRIPTION

(ALL LAMPS 12V)

Head Lamp

Low Beam

HIgh Beam 5.00 60

Tail/Stop Lamp

Ta il Lamp

Stop Lamp 2.10 24

Turn Signal Lamp

Front / Running 2 2.25 / 0.59 27/7 68168-89

Rear 2 2.25 27 68572-64B

Rear Fender Tip Lamp

Rear Fender Tip Bulb 2 0.33 3.7 53439-79

Pursuit Lamp

Left (Red)

Right (Blue) 68728-64

Rear Strobe, if provided

NUMBER OF

BULBS

(REQUIRED)

1

1

12.530

CURRENT DRAW

(AMPERAGE)

4.58 55

0.59 6

WATTAGE

HARLEY-DAVIDSON

PA RT NUMBER

68329-03

68167-88

68727-64A

1

WARNING

As a high voltage source, rear strobe must

be off at least 10 minutes before servicing.

Inadequate safety precautions may result

in death or serious injury. (00097a)

Instrument Panel Lamps-FLHTP

High Beam Indicator 1

Oil Pressure Indicator 1

Neutral Indicator 1

Tu rn Signal Indicator 2

Gauge Lamps-FLHTP

Speedometer

Ta c hometer

Voltmeter

Fuel Gauge

Engine** N/A N/A N/A N/A

Pursuit 1 0.08 1.1 68642-96

**

LED illuminated. LED’s are

**

**

not

repairable. Assembly must be replaced if LED fails.

N/A N/A N/A N/A

1 0.24 3.4 67445-00

N/A 20 67598-88

0.15 2.1 68024-94

2004 FLT Police: Electrical 8-1

Page 2

HOME

Table 8-1. Bulb Chart FLHTP/FLHP

LAMP DESCRIPTION

(ALL LAMPS 12V)

Instrument/Gauge Lamps-FLHP Indicator Module (with LED’s)

High Beam Indicator

Oil Pressure Indicator

Neutral Indicator

Tu rn Signal Indicator

Fuel Gauge

Speedometer**

Odometer**

Engine**

Pursuit**

**

LED illuminated. LED’s are

**

not

repairable. Assembly must be replaced if LED fails.

NUMBER OF

BULBS

(REQUIRED)

N/A 0.05 N/A 68113-99

N/A N/A N/A N/A

CURRENT DRAW

(AMPERAGE)

WATTAGE

HARLEY-DAVIDSON

PA RT NUMBER

8-2 2004 FLT Police: Electrical

Page 3

HOME

CAUTION

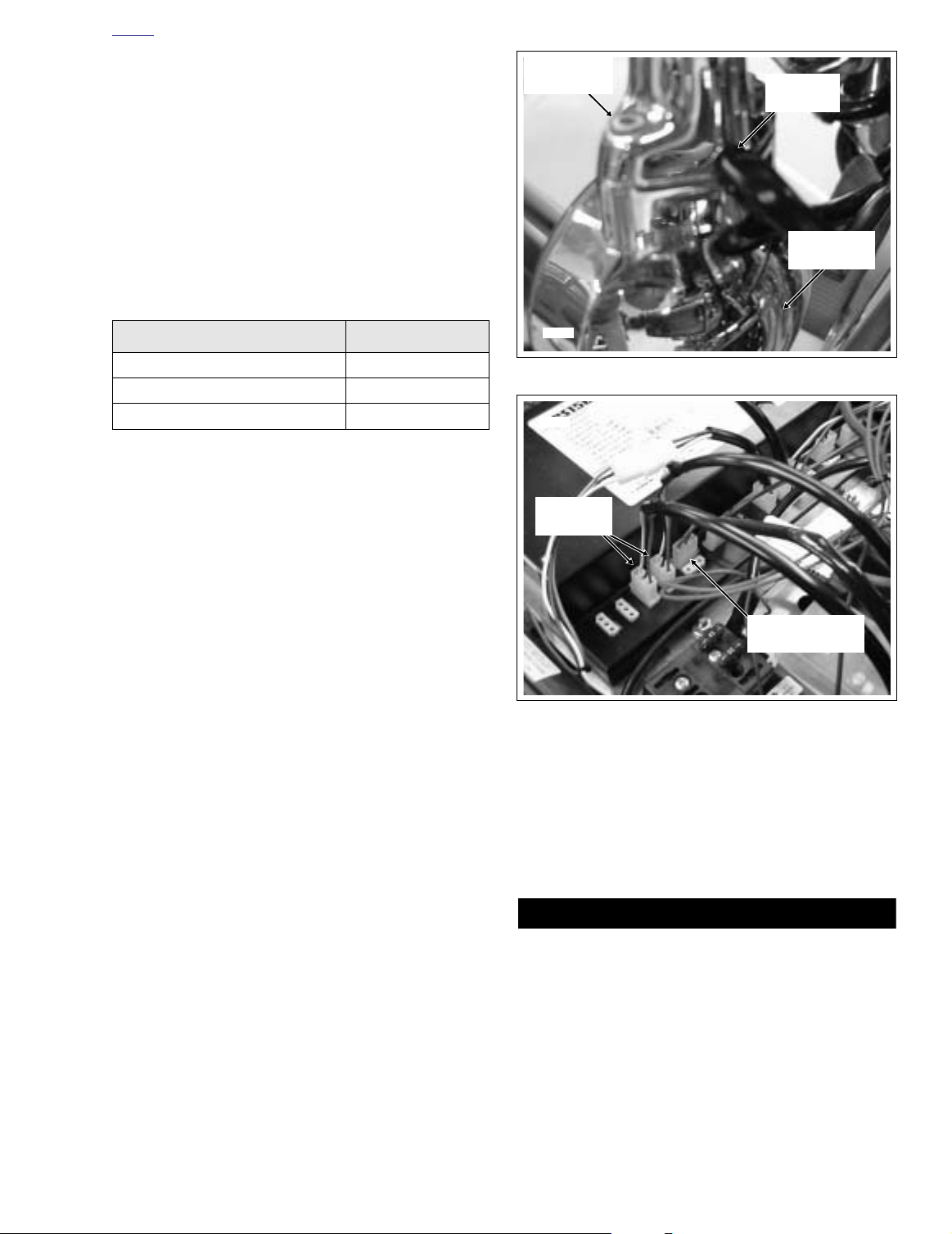

System Fuse Block (Under Left Side Cover)

11

10

9

1

8

5

4

3

2

FLHP/E

11

10

9

1

8

7

6

5

4

3

2

FLHTP

1. Headlamp

2. Ignition

3. Lighting

4. Instruments

5. Brakes/Pursuit

6. Radio Memory

7. Siren

8. Accessory

9. Battery

10. Brake Light Relay

11. P&A

12. Starter Relay

12

f2283x8x

f2204x8x

7

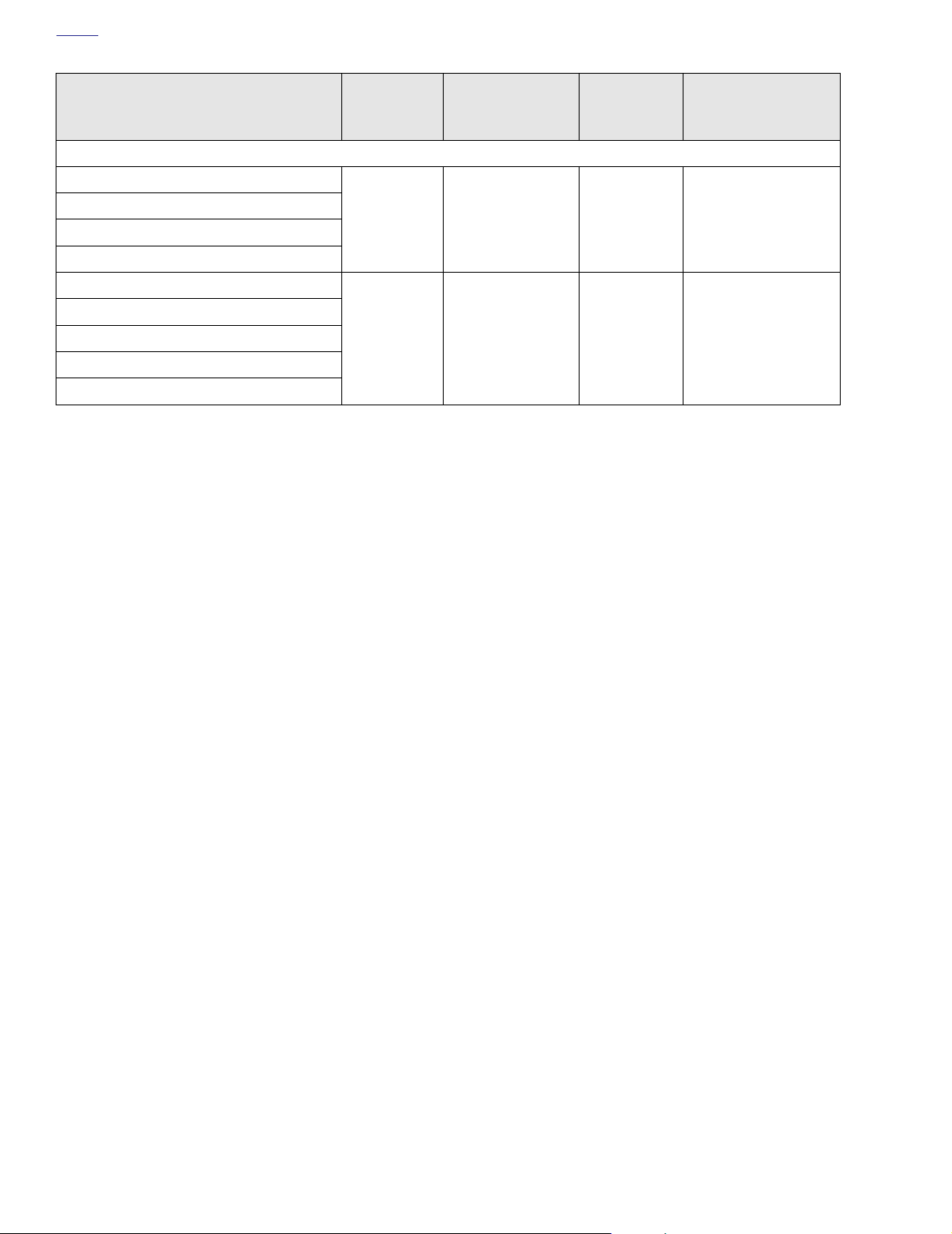

SYSTEM FUSES/RELAYS 8.2

GENERAL

Fuses are provided to protect electrical components. To

inspect or replace the fuses, carefully follow the procedures

below. If an electrical fault occurs after replacement of a fuse,

see your Harley-Davidson dealer for service.

SYSTEM FUSES

Removal

1. Verify that the Ignition/Light Key Switch is turned to the

OFF position.

2. Remove left side saddlebag.

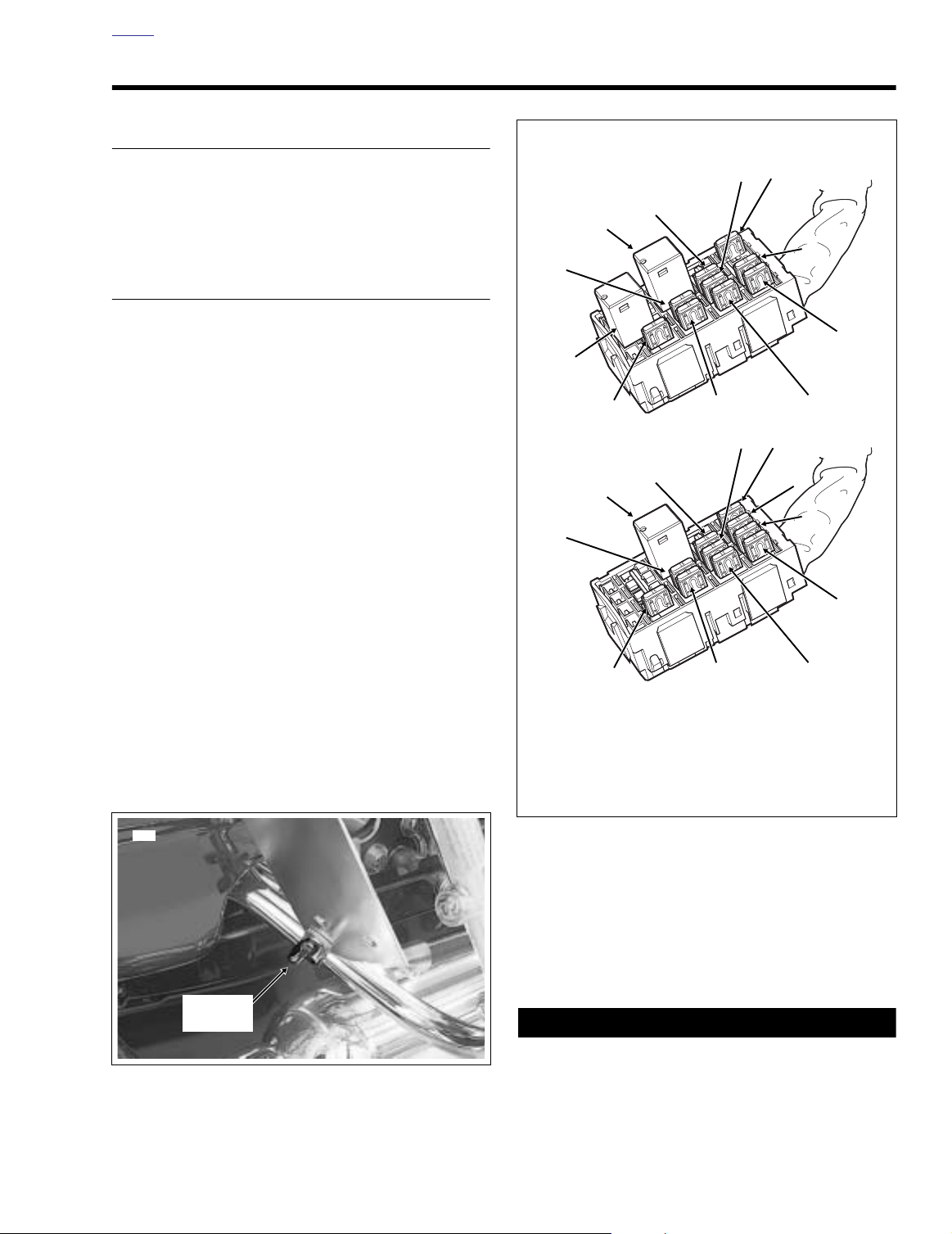

3. Remove wing nut style bolt to release bottom of siren

amplifier mounting bracket from clamp on saddlebag

guard. Rotate bracket upward to gain complete access to

side cover area. Loosen top bolt, if necessary. See Fig-

ure 8-1.

4. Gently pull side cover from frame downtubes (no tools

required). Exercise caution to avoid scratching side cover

on amplifier mounting bracket.

5. Depress latches on maxi-fuse holder and then slide

cover rearward to disengage tongue from groove in fuse

block cover.

6. Pull fuse block from tabs on mounting bracket. Tabs on

bracket fit into slots on each side of fuse block cover.

The fuse block cover also serves as the spare fuse holder.

One spare 10 amp and 15 amp fuse are provided.

NOTE

7. Remove the fuse block cover. Raise lipped side slightly

to disengage slots from tabs on fuse block.

8243

Wing Nut

Style Bolt

Figure 8-1. Siren Amplifier Mounting Bracket

Figure 8-2. Fuse Locations

8. Remove fuse from fuse block and inspect the element.

See Figure 8-2. Replace fuse if element is burned or broken. Automotive type ATO fuses are used.

NOTE

The fuse block cover also serves as the spare fuse holder.

One spare 10 amp and 15 amp fuse are provided.

Always use replacement fuses that are of the correct

type and value. Use of incorrect fuses can result in damage to the electrical system. See Tab le 8-2. (00222a)

2004 FLT Police: Electrical 8-3

Page 4

HOME

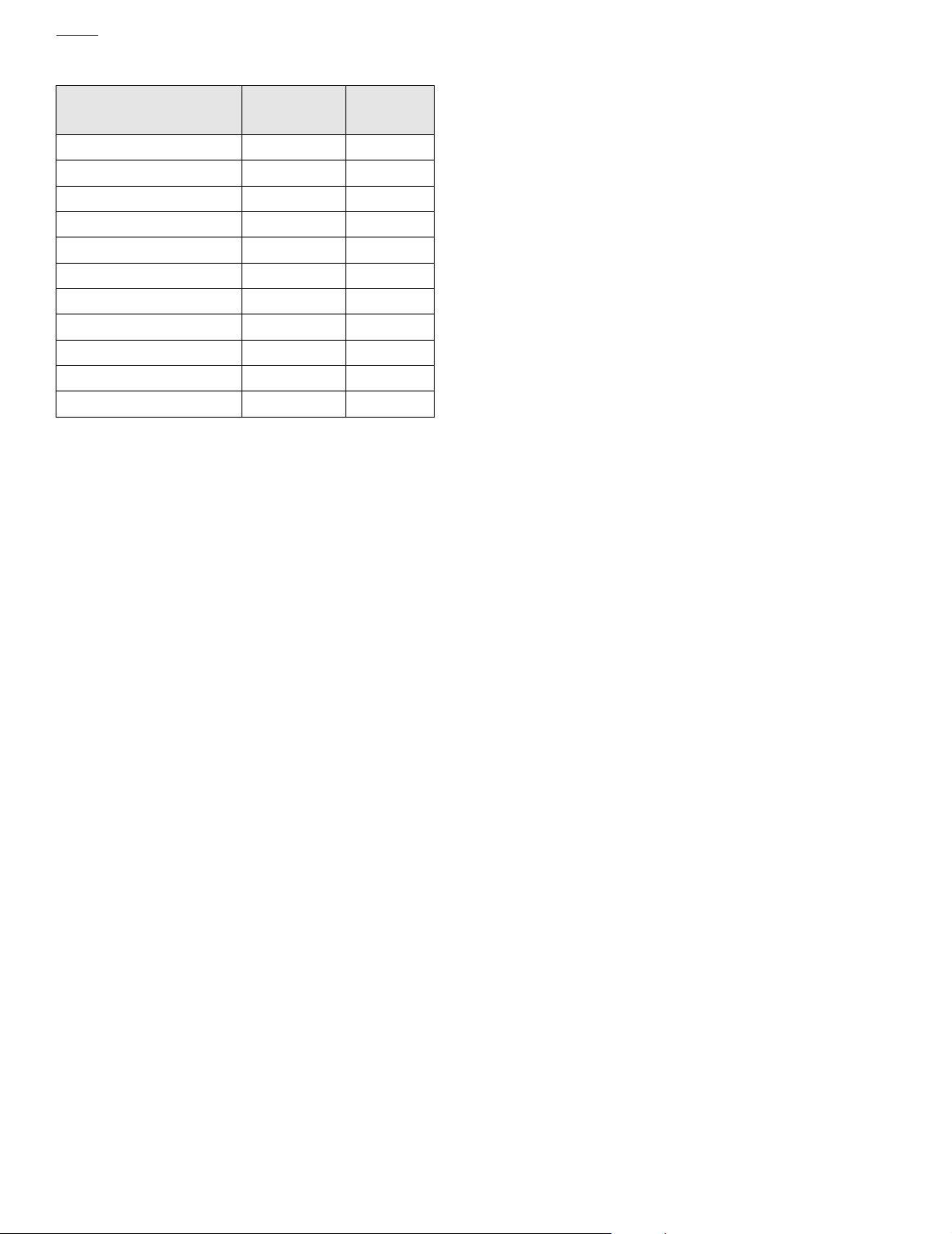

Table 8-2. FLHTP/FLHP System Fuses

CIRCUIT

Maxi-Fuse 40 Orange

Headlamp 15 Blue

Ignition 15 Blue

Lighting 15 Blue

Instruments 15 Blue

Brakes/Pursuit 15 Blue

Radio Memory 15 Blue

Siren 10 Red

Accessory 15 Blue

Battery 15 Blue

P & A 15 Blue

RATING

(AMPERES)

COLOR

Installation

1. Install fuse in fuse block.

2. Slide cover over fuse block until slots fully engage tabs

on block.

3. Slide fuse block into position on mounting bracket. Tabs

on bracket fit into slots on each side of fuse block cover.

4. Slide maxi-fuse cover forward to engage tongue in

groove of fuse block cover and then insert maxi-fuse

holder into cover until latches engage.

5. Align barbed studs in side cover with grommets in frame

downtubes and push firmly into place (no tools required).

6. Rotate siren amplifier mounting bracket downward.

Install wing nut style bolt to secure bracket to clamp on

saddlebag guard. Tighten top bolt, if loosened.

7. Install left side saddlebag.

8-4 2004 FLT Police: Electrical

Page 5

HOME

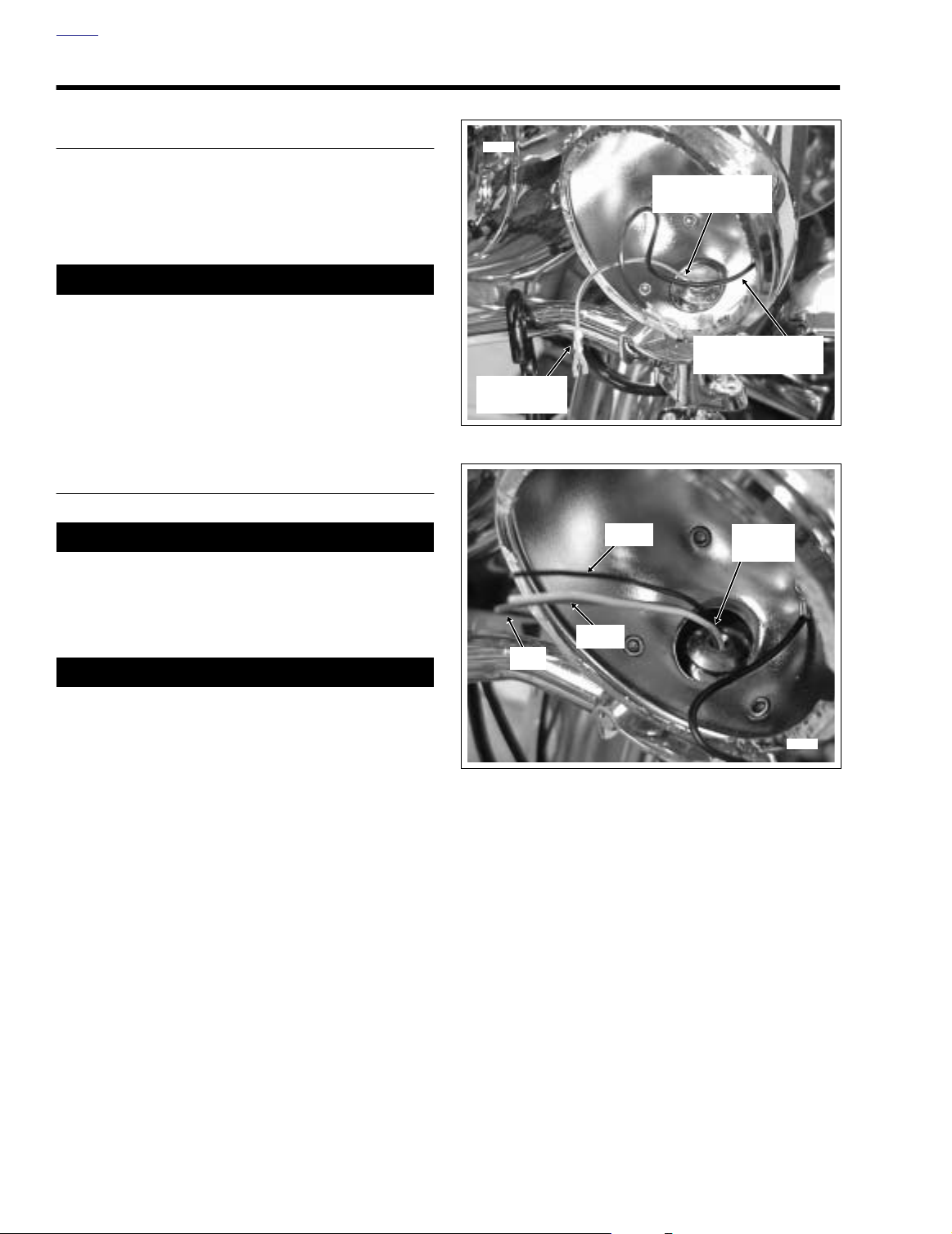

i04382

Chrome

Ring

Phillips

Screw

i04383

Torx

Screws

Torx

Screws

STROBE HEADLAMP 8.3

GENERAL

This Strobe Headlamp Kit is designed for installation on both

FLHP and FLHTP model motorcycles.

NOTE

The Strobe Headlamp Kit as well as replacement Strobe

Lamps (Part Number 68692-02) are available at your HarleyDavidson Dealer.

INSTALLATION

1WARNING1WARNING

To protect against shock and accidental start-up of vehicle, disconnect the negative battery cable before proceeding. Inadequate safety precautions could result in

death or serious injury. (00048a)

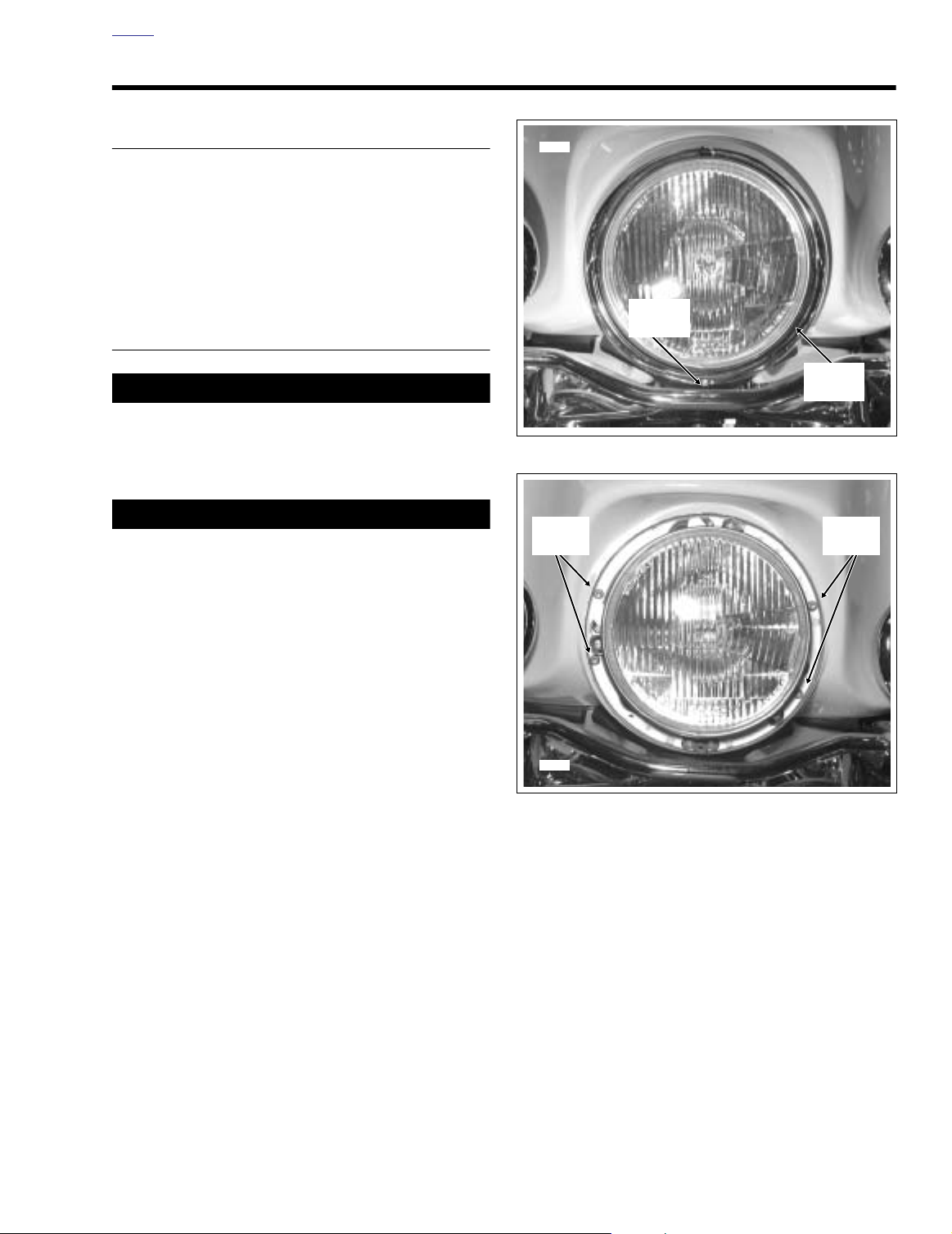

Figure 8-3. Remove Headlamp Door (FLHTP)

1WARNING1WARNING

Always disconnect the negative battery cable first. If the

positive cable should contact ground with the negative

cable installed, the resulting sparks may cause a battery

explosion which could result in death or serious injury.

(00049a)

1. Disconnect battery cables, negative cable first.

2. See Figure 8-3. Remove the Phillips screw at the bottom

of the headlamp door (chrome ring). Remove the headlamp door.

3.

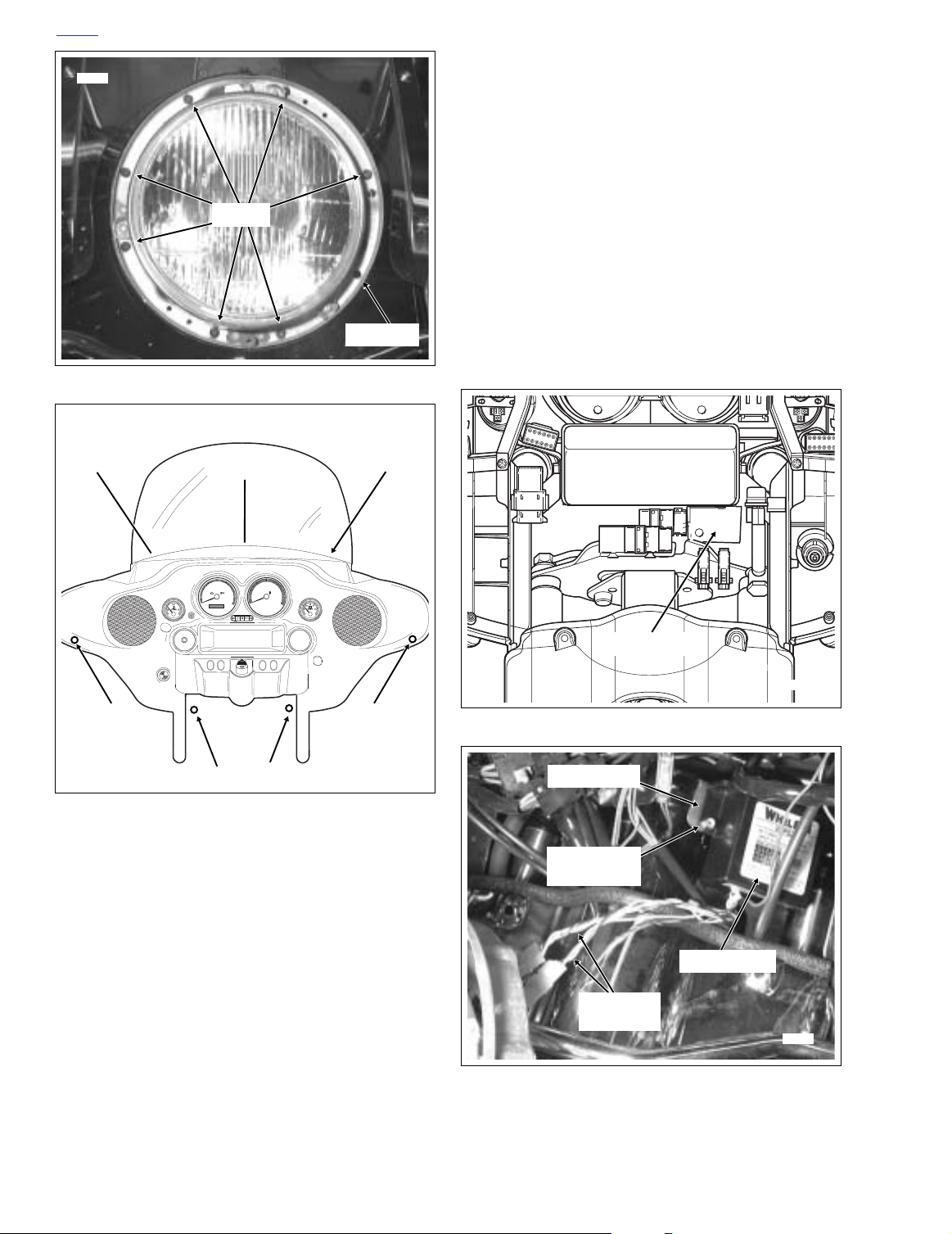

FLHTP:

Remove the four Torx screws to free the head-

lamp housing from the fairing. See Figure 8-4.

FLHP:

Remove the seven Phillips screws to free the

headlamp housing from the headlamp nacelle. See Fig-

ure 8-5.

4. Squeeze the two external tabs (if present) to remove the

wire connector at the back of the headlamp bulb.

Remove the headlamp housing assembly from the vehicle.

5.

FLHP:

Move to step 16.

FLHTP:

Proceed as follows:

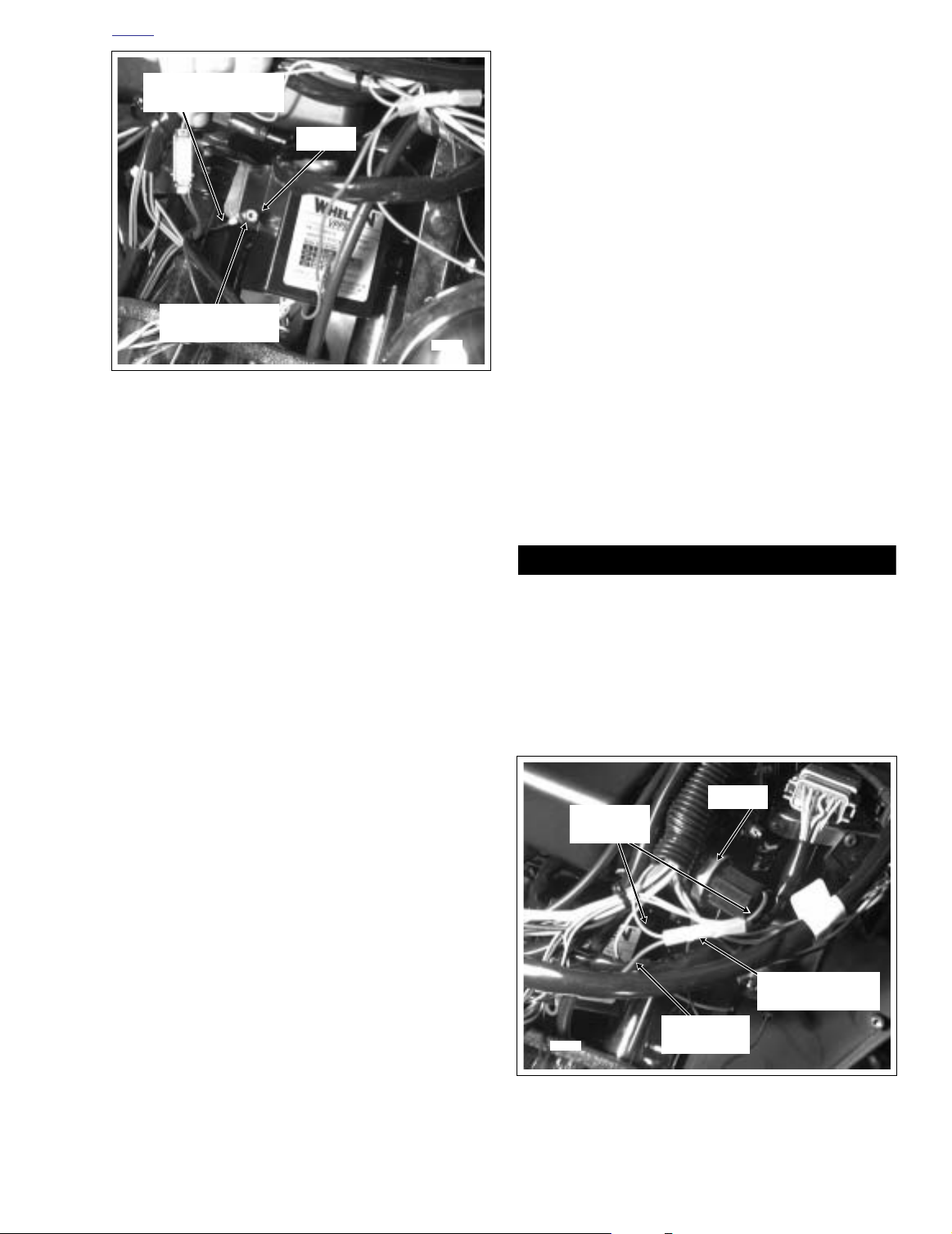

a. See Figure 8-6. Standing at the front of the vehicle,

use a T27 TORX drive head to remove the three

outer fairing screws (1, 2 and 3) and flat washers

just below the windshield.

b. Moving to the inner fairing side, use a T27 TORX

drive head to remove the two fairing screws (4 and

7) just above the wind deflectors on the left and right

side.

Figure 8-4. Headlamp Housing Mount (FLHTP)

c. Turn the handlebar to the right and remove the outer

fairing screw (5) reaching in below the left side of the

fairing cap. Turn the handlebar to the left and

remove the fairing screw (6) below the right side of

the fairing cap.

d. Remove the windshield and lift the fairing off the

motorcycle.

6. Install the power supply as follows:

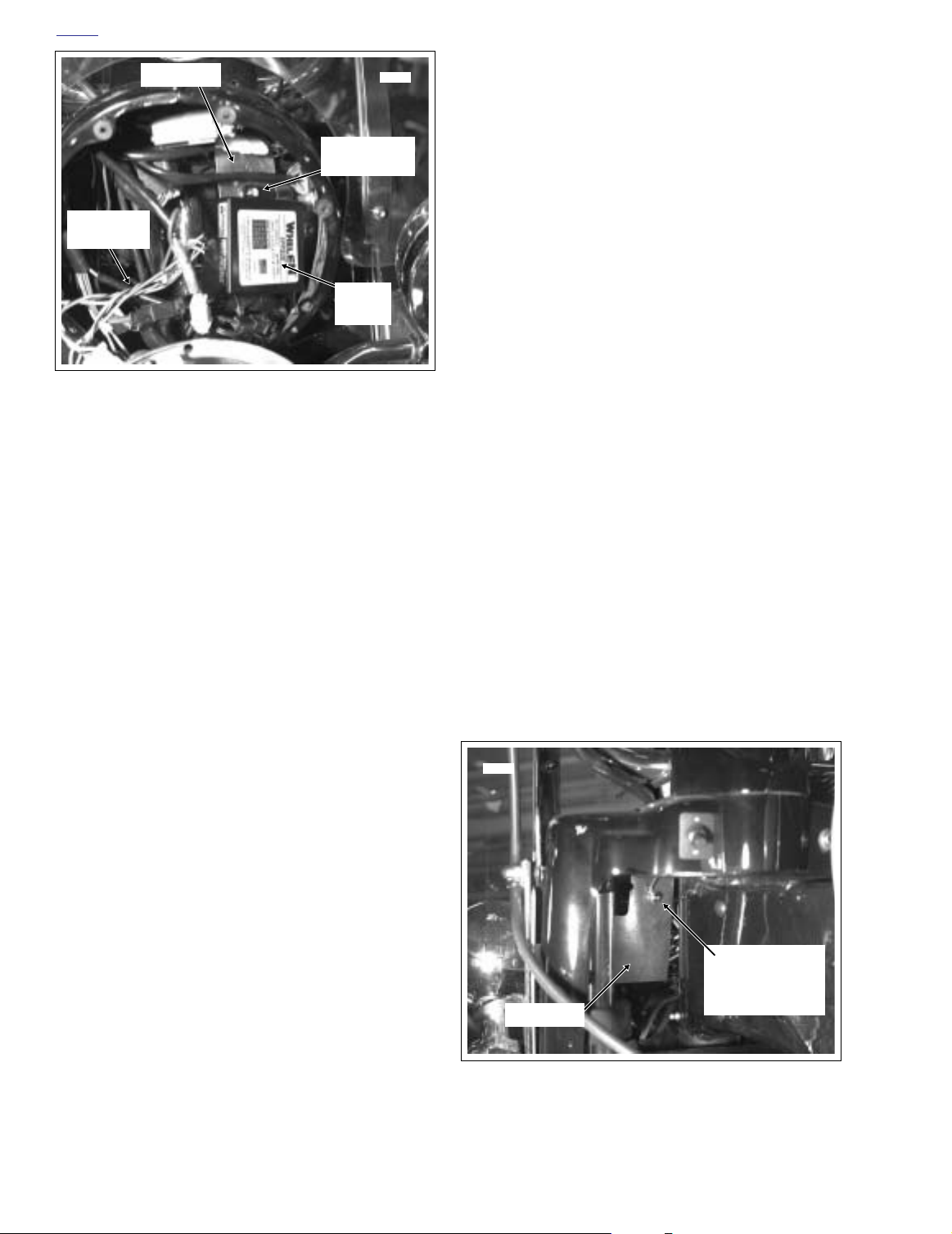

a. See Figure 8-7. Locate the metal plate on which the

power supply will be mounted. Remove the black

plastic wire retainer (Christmas Tree) from the hole

in the metal plate.

2004 FLT Police: Electrical 8-5

Page 6

HOME

i04384

Screws

Figure 8-5. Headlamp Housing Mount (FLHP)

Not Used

c. Moving to the inner fairing side, reach in under the

fairing cap and slide the screw through the holes in

the metal plate and power supply. Returning to the

front, loosely install lockwasher and locknut.

d. Carefully pull out the two strobe harnesses, the red

(power) wire and the black (ground) wire, so that it is

free of the power supply and other wiring.

7. Obtain ring terminal from kit. Strip 3/8 inch (9.5 mm)

insulation from end of black (ground) wire exiting power

supply. Using a wire crimpers, install and crimp ring terminal to wire.

8. See Figure 8-9. While holding the power supply and

mounting screw in position, remove the locknut and lockwasher loosely installed. Install black (ground) wire ring

terminal onto screw and reinstall lockwasher and locknut.

Tighten locknut securely.

1

2

40

60

50

70

30

50

80

40

90

30

20

100

10

MPH

0

120

C

E

D

R

E

I

T

F

I

H

N

A

R

O

S

L

D

E

I

Y

V

-

D

A

60

20

70

10

110

x100

RPM

0

80

H

N

A

R

O

S

L

D

E

I

Y

V

-

D

A

UNLOCK

4

6

5

3

7

f1755d8x

Figure 8-6. Remove Outer Fairing (FLHTP)

NOTE

When installing the power supply, note that it is not an exact

fit. It may be necessary to manipulate the power supply into

various positions to obtain the optimal alignment and position. Also note that the hole in the metal plate is slightly larger

than the hole in the power supply mount. While the overall fit

may appear less than perfect, the power supply will be secure

once the hardware is fully tightened.

b. See Figure 8-8. Obtain the power supply (with wir-

ing), screw, lockwasher and locknut from kit. Position the power supply, so that the mounting hole on

the left side is aligned with the hole in the metal

plate.

Storage Box

Metal Plate

i04390

Figure 8-7. Locate Metal Mounting Plate (FLHTP)

Metal Plate

Locknut and

Lockwasher

Power Supply

Strobe

Harnesses

i04391

Figure 8-8. Mount Strobe Power Supply (FLHTP)

8-6 2004 FLT Police: Electrical

Page 7

HOME

1WARNING1WARNING

i04393

Flasher

Red (Power)

Wire

Sealed Butt

Splice Connector

Gray/Black

Wire

Ground Wire

From Power Supply

Locknut

d. Moving to the inner fairing side, use a T27 TORX

drive head to start the two fairing screws (4 and 7)

just above the wind deflectors on both the left and

right side.

e. Turn the handlebar to the left and reaching in below

the fairing cap, start the right side fairing screw (6).

Tu rn the handlebar to the right and start the fairing

screw (5) on the left side.

f. Alternately tighten the four fairing screws on the

inner fairing side to 20-30

in-lbs

(2.7-3.4 Nm).

g. Moving to the front of the vehicle, tighten the outer

fairing screws below the windshield to 25-30

in-lbs

(2.8-3.4 Nm).

Ring Terminal

and Lockwasher

i04392

Figure 8-9. Install Ground Wire Ring Terminal

9. Route the red (power) wire upward toward the right side

of the plastic storage box and proceed as follows:

NOTE

The flasher is cable strapped to the fairing on the right side of

the storage box.

a. Locate the flasher and remove the three-place con-

nector. Cut the gray/black wire at a point about 4-5

inches (101.6-127.0 mm) from the connector.

b. Strip 3/8 inch (9.5 mm) of insulation from both ends

of gray/black wire. Strip 3/8 inch (9.5 mm) of insulation from red (power) wire from power supply.

c. Obtain the sealed butt splice connector from the kit.

Butt splice the red (power) wire to the gray/black

wire. See Section B.5 SEALED BUTT SPLICE

CONNECTORS in the 2004 Touring Models Service

Manual (Part No. 99483-04). See Figure 8-10.

11. Obtain the new strobe headlamp assembly from the kit.

Reaching in through the headlamp opening of the fairing,

retrieve the two headlamp strobe harnesses. Mate the

harnesses to the connectors at the back of the headlamp.

12. See Figure 8-4. Align holes in new headlamp assembly

with those in fairing (headlamp door bracket at bottom).

Install the four TORX screws.

13. See Figure 8-3. Fit the square-shaped portion of the

headlamp door spring into the slot at the top of the headlamp housing and then snap the headlamp door (chrome

ring) into place. Install the Phillips screw at the bottom of

the headlamp door.

Always connect the positive battery cable first. If the positive cable should contact ground with the negative cable

installed, the resulting sparks may cause a battery explosion which could result in death or serious injury.

(00068a)

14. Install battery cables, positive cable first.

15. Test strobe headlamp for proper operation.

d. Connect the three-place connector to the flasher

and carefully tuck the wiring in and around the existing wiring.

e. Obtain cable strap from kit and fix location of wiring.

Be sure wiring is positioned so that it will not be

pinched or kinked when outer fairing is installed.

10. Install outer fairing as follows:

a. Place the outer fairing on the motorcycle.

b. Place the windshield in position on the inner fairing

aligning the slots with the threaded inserts.

c. See Figure 8-6. Using a T27 TORX drive head, start

the three outer fairing screws (1, 2 and 3) and flat

washers just below the windshield.

Figure 8-10. Flasher and Flasher Connector

2004 FLT Police: Electrical 8-7

Page 8

HOME

Strobe

Harnesses

Metal Plate

i04394

Locknut and

Lockwasher

f. See Figure 8-12. While holding the power supply,

remove the locknut. Remove screw and lockwasher

allowing power supply to seat inside the nacelle.

Route black (ground) wire to the rear of the metal

plate. Install ring terminal and lockwasher on screw.

Slide the screw through the metal plate and power

supply and install locknut. Tighten locknut securely.

g. Locate the white two-place connector inside the

headlamp nacelle (pursuit switch) and carefully pull

both connector and wiring free. Cut the gray/purple

wire at a point about 2-3 inches from the connector.

Power

Supply

Figure 8-11. Mount Strobe Power Supply (FLHP)

16.

FLHP:

Install the power supply as follows:

NOTE

When installing the power supply, note that it is not an exact

fit. It may be necessary to manipulate the power supply into

various positions to obtain the optimal alignment and position. Also note that the hole in the metal plate is slightly larger

than the hole in the power supply mount. While the overall fit

may appear less than perfect, the power supply will be secure

once the hardware is fully tightened.

a. See Figure 8-11. Locate the metal plate on which

the power supply will be mounted. Remove the black

plastic wire retainer (Christmas Tree) from the hole

in the plate.

b. Obtain the power supply (with wiring), screw, lock-

washer and locknut from kit. Install lockwasher on

screw. Position the power supply, so that the upper

mounting hole is aligned with the hole in the metal

plate.

h. Strip 3/8 inch of insulation from both ends of gray/

purple wire. Strip 3/8 inch of insulation from red

(power) wire from power supply.

i. Obtain the sealed butt splice connector from the kit.

Butt splice the red (power) wire to the gray/purple

wire. See Section B.5 SEALED BUTT SPLICE

CONNECTORS in the 2004 Touring Models Service

Manual (Part No. 99483-04).

j. Carefully tuck the wiring in and around the existing

wiring. Obtain cable strap from kit and fix location of

wiring. Be sure wiring is positioned so that it will not

be pinched or kinked when headlamp housing is

installed.

17. See Figure 8-13. Obtain the new strobe headlamp

assembly from the kit. Reaching into the headlamp

nacelle, retrieve the two headlamp strobe harnesses.

Mate the harnesses to the connectors at the back of the

headlamp.

18. Align holes in headlamp housing with those in headlamp

nacelle (headlamp door bracket at bottom). Install the

seven Phillips screws.

i04395

c. Moving to the rear of the handlebars, reach in under

the headlamp nacelle and slide the screw through

the holes in the metal plate and power supply.

Returning to the front of the motorcycle, loosely

install locknut.

d. Carefully pull out the two strobe harnesses, the red

(power) wire and the black (ground) wire, so that it is

free of the power supply and other wiring.

e. Obtain ring terminal from kit. Strip 3/8 inch insulation

from end of black (ground) wire exiting power supply.

Using a wire crimpers, install and crimp ring terminal

to end of wire.

8-8 2004 FLT Police: Electrical

Ground Wire

Ring Terminal

Metal Plate

and Lockwasher

Figure 8-12. Install Ground Wire Ring Terminal

Screw with

Page 9

HOME

1WARNING1WARNING

Strobe

Harness

Connectors

Headlamp

Assembly

i04396

Figure 8-13. Install Strobe Harness to Headlamp

19. Fit the square-shaped portion of the headlamp door

spring into the slot at the top of the headlamp housing

and then snap the headlamp door (chrome ring) into

place. Install the Phillips screw at the bottom of the headlamp door. See Figure 8-3.

Always connect the positive battery cable first. If the positive cable should contact ground with the negative cable

installed, the resulting sparks may cause a battery explosion which could result in death or serious injury.

(00068a)

20. Install battery cables, positive cable first.

21. Test strobe headlamp for proper operation.

2004 FLT Police: Electrical 8-9

Page 10

HOME

STROBE KIT (PAR-36) 8.4

GENERAL

The Strobe Kit Par-36 (Part No. 69172-01) is designed for

installation on both FLHP and FLHTP model motorcycles

when equipped with the H-D Police Tour-Pak, and is available

from your Harley-Davidson Dealer.

1WARNING1WARNING

The rider’s safety depends on the correct installation of

this kit. If the following installation procedures are not

within your capabilities, or if you do not have the correct

tools, have your Harley-Davidson dealer perform this

installation. Failure to do the installation correctly could

result in death or serious injury.

INSTALLATION

1WARNING1WARNING

To protect against shock and accidental start-up of vehicle, disconnect the negative battery cable before proceeding. Inadequate safety precautions could result in

death or serious injury. (00048a)

1WARNING1WARNING

i03977

Cut Terminal

From Wire

Figure 8-14. Modify Existing Wiring

Red

White

Push Wire Down

Black

Through Stem

Tuck Ground Wire

Back Into Bucket

Harness

Wires

Always disconnect the negative battery cable first. If the

positive cable should contact ground with the negative

cable installed, the resulting sparks may cause a battery

explosion which could result in death or serious injury.

(00049a)

1. Disconnect battery cables, negative battery cable first.

2. Remove fuel tank. See Section 9.4 FUEL TANK (FUEL

INJECTED) in the 2004 Touring Models Service Manual

(Part No. 99483-04).

3. Remove two socket head screws to free the left turn signal assembly from the mounting bracket.

4. Remove Phillips screw to release chrome ring from

bucket of passing/pursuit lamp. Carefully pull the sealed

beam unit out of the bucket.

5. Disconnect the wire terminals from the sealed beam unit.

6. See Figure 8-14. Locate the passing/pursuit lamp power

wire (gray/black) and cut the terminal off.

i03978

Figure 8-15. Route Harness Wiring into Lamp Bucket

7. Push the wire down through the mounting bracket stem

while carefully pulling it out the opposite side. Cut the

wire where it exits the conduit. Tape the end of the wire

and tuck inside conduit.

NOTE

Tu ck the black (ground) wire with terminal into the lamp

bucket so it is out of the way.

8. Obtain one of the strobe harnesses from kit and locate

the open end (3 wires, no connector).

9. Starting inside Tour-Pak, push the open end of the harness through the right side straight fitting at the bottom of

the Tour-Pak. Route harness along frame tube, under

fuel tank and along existing turn signal lamp conduit up

to front of motorcycle.

8-10 2004 FLT Police: Electrical

Page 11

HOME

1WARNING1WARNING

i03979

Recessed

Area

Socket Head

Screw

Turn Signal

Assembly

i03980

Power Supply

Control Harness

Strobe

Harnesses

10. See Figure 8-15. Push the three harness wires up

through the mounting bracket stem and into the lamp

bucket following the route used to remove the original

power wire.

11. Obtain three socket terminals and one 3-place socket

housing from kit.

12. Install sockets on wires. See Section B.2 AMP MULTILOCK ELECTRICAL CONNECTORS in the 2004 Touring Models Service Manual (Part No. 99483-04).

13. Taking note of the numbers stamped on the socket housing, install the terminals into their respective chambers.

Table 8-3. Terminal Location

TERMINAL WIRE COLOR CHAMBER

Red 1

Black 2

White 3

NOTE

The red Par-36 Strobe is typically installed on the left side of

the motorcycle, while the blue strobe is installed on the right.

14. Obtain the red Par-36 strobe lamp from kit and mate the

harness connector with the left side strobe connector.

15. Position the strobe within the lamp bucket and reinstall

the chrome ring using Phillips screw. Tighten securely.

16. See Figure 8-16. Make sure conduit rests in the recess

of the clamp area as shown. Install the left turn signal

assembly to the mounting bracket using two socket head

screws. Tighten screws securely.

17. Using the blue Par-36 strobe, perform steps 3-16 on the

right side of the motorcycle.

18. Route the left and right strobe harnesses under the fuel

tank then toward the rear of the motorcycle following the

same paths as the conduit for the left and right turn signal lamps. Continue along the frame tubes and then back

into the opening in the Tour-Pak.

19. Obtain three cable straps from kit and secure the strobe

harness to the frame (or turn signal lamp conduit) at suitable locations. Repeat step for the other harness.

Figure 8-16. Install Turn Signal to Mounting Bracket

Figure 8-17. Connect Strobes to Power Supply Outlets

21. Obtain the power supply control harness and Instruction

Sheet J02192 from kit. Install harness following instructions. Connect control harness to power supply.

22. Install fuel tank. See Section 9.4 FUEL TANK (FUEL

INJECTED) in the 2004 Touring Models Service Manual

(Part No. 99483-04).

20. See Figure 8-17. Connect the strobe harness connectors

to the power supply as shown.

NOTE

Depending on which of the four outlets are chosen, the flash

pattern can be set so lamps flash alternately or simultaneously. You may want to experiment with the various outlets

until the desired flash pattern is obtained.

Always connect the positive battery cable first. If the positive cable should contact ground with the negative cable

installed, the resulting sparks may cause a battery explosion which could result in death or serious injury.

(00068a)

23. Install battery cables, positive cable first.

24. Close Tour-Pak and test strobe lights for proper operation.

2004 FLT Police: Electrical 8-11

Page 12

HOME

POLE LAMP 8.5

GENERAL

6105

Harley-Davidson police model motorcycles are shipped from

the factory with the brackets necessary to mount a police pole

lamp.

INSTALLATION

1. Rotate knurled rings to remove from pole lamp.

2. Cut all but approximately 14 inches (356 mm) of wire off

pole lamp.

3. Crimp terminals on wires and install in pin side of 2-place

Deutsch connector. See Section B.1 DEUTSCH ELECTRICAL CONNECTORS, in the 2004 Touring Models

Service Manual (Part No. 99483-04).

NOTE

The black wire must go to the black and the green/red wire

must go to the red. The lamp will not work if wires are not

matched correctly.

4. Slide pole through grommet in luggage rack. Spray glass

cleaner on pole to lubricate surfaces, if necessary.

5. Install knurled ring at bottom of pole with the beveled

side up. See Figure 8-18.

6. Insert pole through lower bracket and install second

knurled ring with the beveled side down.

7. Alternately tighten knurled rings to lock position of pole.

8. Mate pin and socket halves of 2-place Deutsch connector. Secure connector and conduit to saddlebag guard

and saddlebag support bracket using

See Figure 8-19.

new

cable straps.

Knurled Ring

(Bevel Up)

6106

Lower

Bracket

Knurled Ring

(Bevel Down)

Figure 8-18. Install Pole Lamp

Connector

8-12 2004 FLT Police: Electrical

Cable

Strap

Figure 8-19. Install Cable Straps

Page 13

HOME

SIREN AND PUBLIC ADDRESS SYSTEM 8.6

GENERAL

The siren and public address (PA) system consists of: amplifier, speaker, microphone, microphone jack, siren, horn/siren

switches and connecting wiring.

The Whelen 100 watt siren amplifier, WS-320, (Part No.

91156- 93) uses a waterproof connector.

Table 8-4. Troubleshooting

PROBLEM

Siren and PA not

operational.

Siren and PA not

operational.

Connector not properly installed. Be sure connector is properly oriented and screw is tight.

Faulty amplifier or speaker. Substitute a known good amplifier and check system func-

CAUSE SOLUTION

TROUBLESHOOTING

If siren and/or PA system are inoperative, refer to the troubleshooting chart below.

Apply wheel bearing grease to connector pins and sockets

to reduce corrosion.

tion. If system is still inoperative, substitute a known good

speaker and check for system operation.

NOTE

If neither an amplifier nor speaker is available, see Section

8.8 SPEAKER, TROUBLESHOOTING in this manual. If

speaker checks “good”, continue at Section 8.7 VOLTAGE

CHECKS, RESISTANCE AND CONTINUITY CHECKS.

Siren functions, PA

not operational.

PA gain control not properly

adjusted.

Inoperative microphone.

Microphone jack or connecting

leads do not provide good electrical connection.

Wrong microphone.

See Section 8.10 SIREN AMPLIFIER, GAIN ADJUST-

MENT.

Substitute a known good microphone. If known good microphone is not available, see Section 8.11 MICROPHONE

AND JACK.

See Section 8.11 MICROPHONE AND JACK.

Some Whelen microphones are electrically different and

cannot be interchanged.

NOTE

Microphones used with WS-320 amplifiers should be

marked 010245648-00.

2004 FLT Police: Electrical 8-13

Page 14

HOME

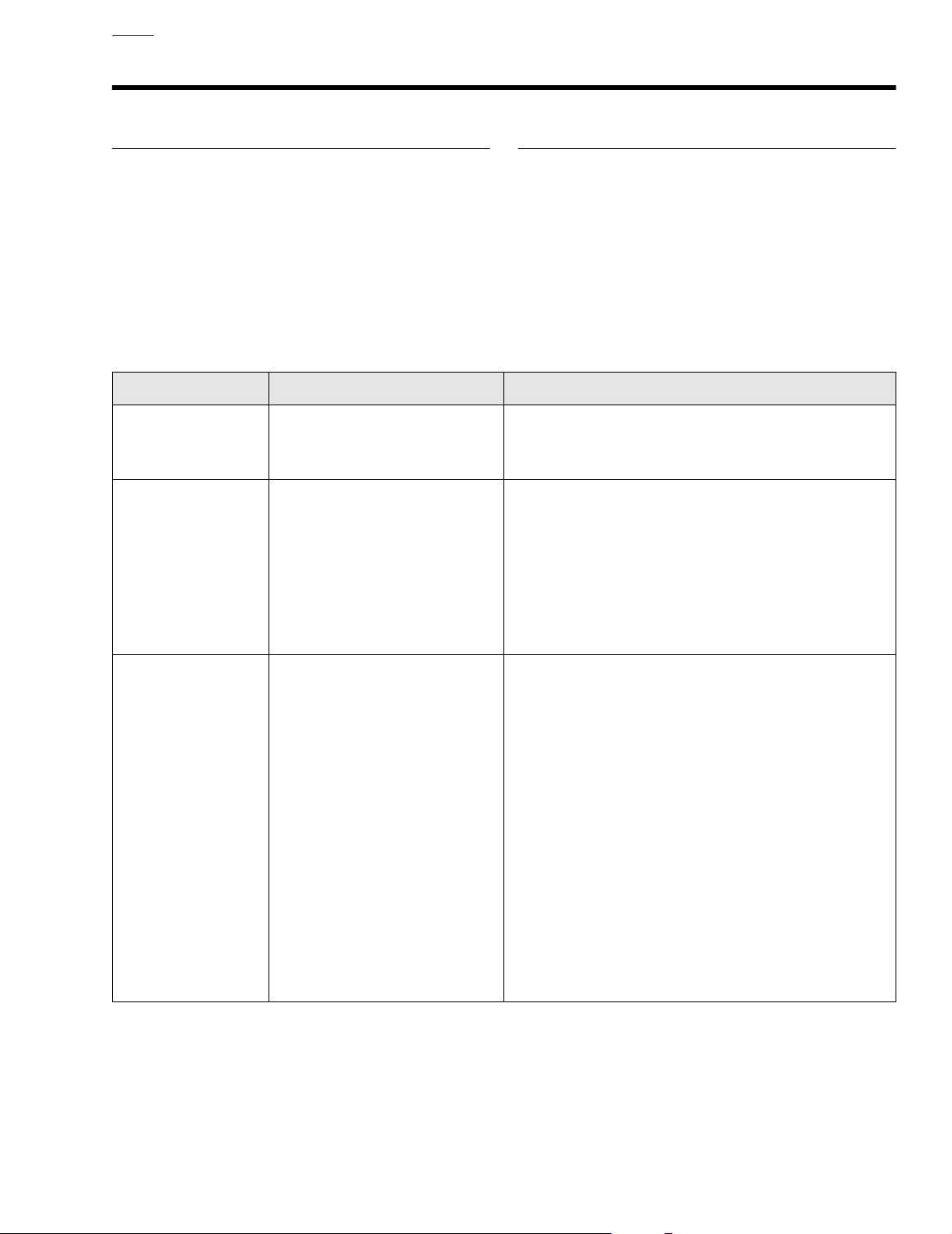

VOLTAGE CHECKS 8.7

ALL MODELS

See Figure 8-20, Table 8-5, and the appropriate wiring diagram in Section 8.15 WIRING DIAGRAMS. Measure the voltages at the motorcycle siren harness connector (pins 1C, 2F,

and 1F) as listed in Ta bl e 8-5. The Ignition/Light Key Switch

must at IGNITION while checking voltages. Connect common

or negative lead of voltmeter to a good ground. If voltages

specified in Table 8-4 are not present, refer to applicable wiring diagram to diagnose the problem.

p0011a8x

To Motorcycle Harness

Pin Description

1A Ground (-) to motorcycle

3A Speaker (+)

12 Vdc supply to amplifier.

1C

Present when ignition is on.

3C Speaker (-)

Air horn enabled - 12 Vdc is present when

1D

connected to horn circuit and button is

pushed. See Section 8.12 AIR HORN.

2D Push-to-talk (mic)

1E Mic (-)

Yelp, 12 Vdc is present when siren/horn

1F

switch is ON.

Wail, 12 Vdc is present when siren switch

2F

is ON.

3F Mic (+)

Table 8-5. Voltage Checks at

Motorcycle Siren Harness

Switch

Ignition ON 12 Vdc

Siren OFF

Siren/Horn ON

Siren ON

Siren/Horn OFF

Siren/Horn ON

Siren ON

Switch

Position

VOLTAGE MEASURED AT

1C 2F 1F

Do Not

Measure

Do Not

Measure

Do Not

Measure

PINS

Do Not

Measure

0 Vdc 12 Vdc

12 Vdc 0 Vdc

12 Vdc 12 Vdc

Do Not

Measure

Figure 8-20. Pin Connector

8-14 2004 FLT Police: Electrical

Page 15

HOME

RESISTANCE AND CONTINUITY CHECKS

See Figure 8-20 and Table 8-6 below. Perform checks with

both battery cables removed.

Table 8-6. Resistance/Continuity Checks (Battery Cables Disconnected)

OHMMETER PROBE

LOCATION (PINS)

3A & 3C 6-10 Ohms Speaker coil voice and leads from pin connector to speaker.

3F & 1E Infinity Verifies microphone circuit is not shorted.

Press and hold PTT switch

with probes on pins 2D & 1E.

OHMETER COMPONENT AND WIRE BEING CHECKED

Verifies PTT switch is functioning and two microphone leads from

connector have continuity.

0-1 Ohms

For microphone jack connections, see Figure 8-28. To c heck third

lead, place one probe on pin 3F and the other probe on tip terminal of

microphone jack.

CAUTION

Do not connect ohmmeter probes to a “live” circuit or

ohmmeter will be damaged.

If ohmmeter readings in Table 8-5 are not obtained, refer to

Section 8.15 WIRING DIAGRAMS and diagnose the problem

using the appropriate schematic.

Common probe to ground,

other probe to pin 1A.

0-1 Ohms Checks amplifier to motorcycle ground.

2004 FLT Police: Electrical 8-15

Page 16

HOME

SPEAKER 8.8

TROUBLESHOOTING

If speaker is inoperative, check voice coil impedance as follows:

1. Disconnect speaker leads and measure impedance by

connecting ohmmeter leads to speaker leads.

2. Measured resistance must be 6-10 ohms.

3. Replace speaker if resistance is not within specification.

NOTE

A binding voice coil or torn speaker cone could also cause

speaker to be inoperative. To check for these conditions, connect speaker to shop stereo. If speaker works, it’s functional.

Connector

Bolt

Screw

4579p

REMOVAL

1. Cut two cable straps to release 2-place Deutsch connector and cable from top rail of right side engine guard. Disconnect pin and socket halves. See Figure 8-21.

2. Reaching into speaker horn, remove flange locknuts, flat

washers and rubber washers from top and side bolts.

Pull bolts from speaker horn and mounting bracket.

Remove flat washers and rubber washers between horn

and mounting bracket.

3. Remove bolt to release back of speaker from mounting

bracket.

INSTALLATION

1. Position speaker in mounting bracket aligning holes in

speaker with those in bracket.

2. Loosely install bolt to fasten mounting bracket to back of

speaker. See Figure 8-21.

3. Position rubber washers and flat washers between holes

in horn and mounting bracket, rubber washers against

horn.

NOTE

Be sure the speaker voice coil drain hole is facing down to

provide good drainage. Hole is located 180° from “Made in

USA” logo. See Figure 8-22.

4. Slide bolts through mounting bracket, flat washers, rubber washers and horn. Reaching into speaker horn,

install rubber washers, flat washers and flange locknuts

on bolts.

5. Alternately tighten all fasteners. Rubber washers should

deform slightly when flange locknuts are properly tightened.

Figure 8-21. Speaker (Rear View)

4578p

Drain

Hole

Figure 8-22. Speaker (Bottom View)

6. Mate pin and socket halves of 2-place Deutsch connector. Install two

cable to top rail of right side engine guard.

Use of a high pressure washer on or near speaker can

result in damage.

If speaker center cone is removed to make installation easier,

apply 2-3 drops of Loctite 242 (blue) on center cone screw

and then tighten until snug.

new

cable straps to secure connector and

CAUTION

NOTE

8-16 2004 FLT Police: Electrical

Page 17

HOME

HANDLEBAR SWITCHES 8.9

HORN/SIREN YELP SWITCH

NOTE

Consult the 2004 Touring Models Service Manual (Part No.

99483-04) for assembly/disassembly instructions and general

repair procedures.

Removal

1. See LEFT SIDE HANDLEBAR SWITCHES, DISASSEMBLY, page 8-70 of the 2004 Touring Models Service Manual (Part No. 99483-04).

2. From inside the switch housing, carefully cut cable strap

to free conduit from the turn signal switch bracket.

3. Remove the Phillips screw (with lockwasher) to release

the turn signal switch bracket. Remove the switch

assembly from the housing.

4. Remove the two T8 TORX screws and the Phillips screw

(with lockwasher) to release the lower bracket. Carefully

lift out the bracket so as not to disturb the spring-loaded

ramp on the inboard side of the housing.

5. Carefully remove the keycap disengaging slot from hook

on ramp.

6. While holding down the ramp, pull both switches from the

housing.

7. Cut the wires from the old switches as follows:

●

Ye llow/Black wire: 1-1/4 inches (32 mm)

Orange/White wires: 1-7/8 inches (48 mm)

●

●

Brown/Black wire: 1-1/2 inches (38 mm)

NOTE

Replacement Horn/Siren Yelp Switch wires are cut to length

and partially stripped (Yellow/Black wire: 3-3/4 inches (95

mm); Orange/White wires: 3-1/2 inches (89 mm); Brown/

Black wire: 3-3/8 inches (86 mm).

8. See GENERAL REPAIR PROCEDURES, page 8-78 of

the 2004 Touring Models Service Manual (Part No.

99483-04).

NOTE

If the ramp and spring mechanism becomes loose, install as

follows: Using the blade of a small screwdriver, compress

spring and place in wider portion of channel at bottom of

ramp. Verify that spring is evenly compressed and is not

cocked or skewed. Push spring so that it bottoms in channel.

With tab side of ramp facing inboard and hook end on switch

side of casting, install ramp so that narrow channels engage

pins cast into housing.

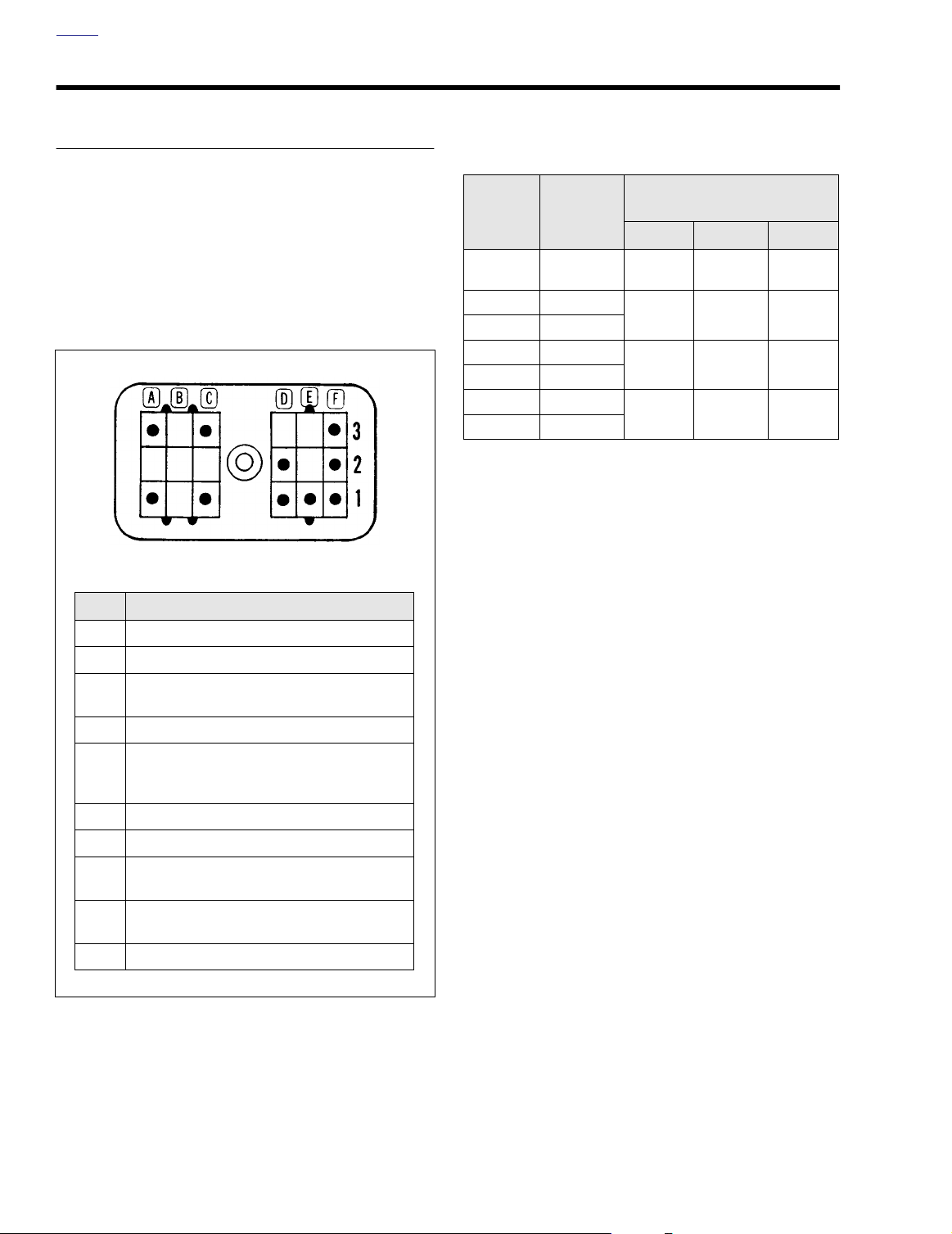

Right Handlebar Switch Housings

Upper Switch Housing:

● Engine Start Switch

● Engine Stop Switch: Off/Run

Lower Switch Housing:

● Tu rn-Right Signal Switch

● Front Stoplight Switch

● Pole and Pursuit Lamp Switch:

Off/Aux(iliary)/Purs(uit)

f1236a2x

f1237a2x

Left Handlebar Switch Housings

Upper Switch Housing:

● Siren Switch: On/Off

● Light Switch: Hi(gh) and Lo(w) Beam

Lower Switch Housing:

● Tu rn-Left Signal Switch

● Horn/Siren Yelp Switch

● Clutch/Starter Interlock Switch

Figure 8-23. Police Handlebar Switch Assemblies

2004 FLT Police: Electrical 8-17

Page 18

HOME

Installation

1. Install the switches in the housing with contacts facing

tabs on ramp. For best results, install one switch at a

time. Ribs cast in lower housing hold switches in position.

The Horn switch with the Yellow/Black lead (pivot point

towards rider) is installed at the bottom, while the Siren

Ye lp switch with the Brown/Black lead (pivot point

towards the front) is at the top. Route switch wires in

channel on the outboard side of the ribbed area.

2. Install the keycap engaging slot with hook on ramp.

3. Install lower bracket sliding pin through keycap and

engaging hole in lower casting.

4. Slide T8 TORX screws through holes in lower bracket

and switches and thread into lower casting until snug.

5. Install Phillips screw (with lockwasher), to secure lower

bracket to threaded boss in housing. Verify operation of

Horn and Siren Yelp switches to ensure that both are

spring returned.

6. Install Clutch Interlock Switch in bore of lower switch

housing, if loose.

7. Insert tapered end of

hole in turn signal switch bracket and then feed back

through using the adjacent hole. Reserve the oblong

hole for the bracket screw.

Be sure that all splices are positioned above the turn signal

switch bracket.

8. Place the turn signal switch assembly into the housing

aligning the oblong hole in the bracket with the lower

bracket weld nut. Be sure that bracket is fully seated.

Ta bs on each side are captured in slots cast into switch

housing.

9. Install Phillips screw (with lockwasher) to secure bracket

inside housing.

new

7 inch cable strap into round

NOTE

from end of conduit. Cut any excess cable strap material.

If necessary, bend angular arm of bracket downward to

firmly secure Clutch Interlock Switch in installed position.

14. See LEFT SIDE HANDLEBAR SWITCHES, ASSEMBLY,

page 8-80 of the 2004 Touring Models Service Manual

(Part No. 99483-04).

CLUTCH INTERLOCK SWITCH

NOTE

All Police models have a Clutch Interlock Switch that prevents

the motorcycle from starting (even in Neutral) if the clutch

lever is not pulled in.

Removal

1. See LEFT SIDE HANDLEBAR SWITCHES, DISASSEMBLY, page 8-70 of the 2004 Touring Models Service Manual (Part No. 99483-04).

2. From inside the switch housing, carefully cut cable strap

to free conduit from the turn signal switch bracket.

3. Remove the Phillips screw (with lockwasher) to release

the turn signal switch bracket. Remove the switch

assembly from the housing.

4. Remove the Clutch Interlock Switch from the housing.

5. Cut wires 1/4 inch (6 mm) from old switch. Discard switch

assembly.

NOTE

Replacement Clutch Interlock Switch wires are cut to length

(looking at backside, left side switch wire is 2-1/4 inches (57

mm), right side is 2-3/4 inches (70 mm) and partially stripped.

6. See GENERAL REPAIR PROCEDURES, page 8-78 of

the 2004 Touring Models Service Manual (Part No.

99483-04).

CAUTION

If routed incorrectly, wires may be pinched by casting or

handlebar resulting in switch failure.

10. Loop switch wires so that spliced lengths are positioned

directly over bracket screw.

11. Capturing conduit about 1/4 inch (6 mm) from end,

securely tighten cable strap to draw conduit to bracket.

Remove any excess cable strap material.

12. On opposite side, install second 7 inch cable strap capturing conduit and wire splices. Securely tighten cable

strap to draw splices to conduit. Remove any excess

cable strap material.

13. Route wire bundle to upper switch housing below and

then forward of the main wire harness positioning conduit

in channel next to angular arm of bracket. Secure bundle

to arm placing

8-18 2004 FLT Police: Electrical

new

cable strap 1/4 inch (6 mm)

Installation

1. Install Clutch Interlock Switch in bore of lower switch

housing.

2. Insert tapered end of

hole in turn signal switch bracket and then feed back

through using the adjacent hole. Reserve the oblong

hole for the bracket screw.

Be sure that all splices are positioned above the turn signal

switch bracket.

3. Place the turn signal switch assembly into the housing

aligning the oblong hole in the bracket with the lower

bracket weld nut. Be sure that bracket is fully seated.

Tabs on each side are captured in slots cast into switch

housing.

new

7 inch cable strap into round

NOTE

Page 19

HOME

Clutch Interlock

Switch

p0040a8x

Figure 8-24. Lower Switch Housing

4. Install Phillips screw (with lockwasher) to secure bracket

inside housing.

CAUTION

If routed incorrectly, wires may be pinched by casting or

handlebar resulting in switch failure.

5. Loop switch wires so that spliced lengths are positioned

directly over bracket screw.

6. Capturing conduit about 1/4 inch (6 mm) from end,

securely tighten cable strap to draw conduit to bracket.

Remove any excess cable strap material.

7. On opposite side, install second 7 inch cable strap capturing conduit and wire splices. Securely tighten cable

strap to draw splices to conduit. Remove any excess

cable strap material.

8. Route wire bundle to upper switch housing below and

then forward of the main wire harness positioning conduit

in channel next to angular arm of bracket. Secure bundle

to arm placing

of conduit. Cut any excess cable strap material. If necessary, bend angular arm of bracket downward to firmly

secure Clutch Interlock Switch in installed position.

new

cable strap 1/4 inch (6 mm) from end

PURSUIT/AUXILIARY SWITCH

Removal

1. See RIGHT SIDE HANDLEBAR SWITCHES, DISASSEMBLY, page 8-70 of the 2004 Touring Models Service

Manual (Part No. 99483-04).

2. From inside the switch housing, carefully cut cable strap

to free conduit from the turn signal switch bracket.

3. Remove the Phillips screw (with lockwasher) to release

the turn signal switch bracket. Remove the switch

assembly from the housing.

4. Remove the two T8 TORX screws and the Phillips screw

(with lockwasher) to release the lower bracket. Remove

the bracket from the housing.

5. Pull both switches from the housing.

6. Cut the wires from the old switches as follows:

Gray/Black wire: 1-1/2 inches (38 mm)

●

●

Orange/Violet wires: 1-7/8 inches (48 mm)

Green/Red wire: 1-1/4 inches (32 mm)

●

NOTE

Replacement Pursuit/Auxiliary Switch wires are cut to length

and partially stripped (Gray/Black wire: 2 inches (51 mm);

Orange/Violet wires: 1-7/8 inches

1-3/4 inches (45 mm).

7. See GENERAL REPAIR PROCEDURES, page 8-78 of

the 2004 Touring Models Service Manual (Part No.

99483-04).

8. Move keycap to the OFF position. Install the switches in

the housing with contacts facing the recessed area on

the ramp. Ribs cast in lower housing hold switches in

position.

The Auxiliary switch with the Gray/Black lead is installed

at the bottom, while the Pursuit switch with the Green/

Red lead is at the top. Route switch wires into corner

space outside of the ribbed area.

If the keycap and ramp mechanism requires replacement,

install as follows: Slide ramp upward to remove from keycap

shaft. Remove keycap from switch housing. Install spring into

hole on inboard side of

spring. Use a small amount of grease to hold ball in place.

Install keycap so that ball engages detente in switch housing.

Slide ramp over keycap shaft so that tongues on ramp

engage grooves in keycap shaft.

new

Installation

(48 mm)

NOTE

keycap. Position ball on end of

; Green/Red wire:

9. See LEFT SIDE HANDLEBAR SWITCHES, ASSEMBLY,

page 8-80 of the 2004 Touring Models Service Manual

(Part No. 99483-04).

1. Install lower bracket with the weld nut side down.

2. Slide the T8 TORX screws through holes in lower bracket

and switches and thread into lower casting until snug.

2004 FLT Police: Electrical 8-19

Page 20

HOME

3. Install Phillips screw (with lockwasher), to secure lower

bracket to threaded boss in housing. Work Auxiliary and

Pursuit switches to ensure smooth operation.

4. See Figure 8-25. Insert tapered end of

new

7 inch cable

strap into round hole in turn signal switch bracket and

then feed back through using the adjacent hole. Reserve

the oblong hole for the bracket screw.

NOTE

Be sure that all splices are positioned above the turn signal

switch bracket.

5. Place the turn signal switch assembly into the housing

aligning the oblong hole in the bracket with the lower

bracket weld nut. Be sure that bracket is fully seated.

Ta bs on each side are captured in slots cast into switch

housing.

6. Install Phillips screw (with lockwasher) to secure turn signal switch bracket inside housing.

7 Inch

Cable Strap

Bracket

Right Turn

Signal Switch

CAUTION

If routed incorrectly, wires may be pinched by casting or

handlebar resulting in switch failure.

7. Loop switch wires so that spliced lengths are positioned

directly over bracket screw.

8. Capturing conduit about 1/4 inch (6 mm) from end,

securely tighten cable strap to draw conduit to bracket.

Remove any excess cable strap material.

9. On opposite side, install second 7 inch cable strap capturing conduit and wire splices. Securely tighten cable

strap to draw splices to conduit. Remove any excess

cable strap material.

f1294x2x

Figure 8-25. Insert Cable Strap in Switch Bracket

10. Route wire bundle to upper switch housing in channel

next to angular arm of bracket. Secure bundle to arm

placing

new

cable strap 1/4 inch (6 mm) from end of conduit. Cut any excess cable strap material. If necessary,

bend angular arm of bracket downward to firmly secure

Front Stoplight Switch in installed position.

11. See RIGHT SIDE HANDLEBAR SWITCHES, ASSEMBLY, page 8-80 of the 2004 Touring Models Service Manual (Part No. 99483-04).

8-20 2004 FLT Police: Electrical

Page 21

HOME

4577p

4575p

Adjustment Screw

(Under Access Hole Screw)

SIREN AMPLIFIER 8.10

AMPLIFIER

Part No. /Description

91156-93 Whelen 100 Watt (WS-320) Siren Amplifier

REMOVAL

See Figure 8-26. The Whelen amplifiers are mounted to the

mounting bracket in front of the left saddlebag with screws

and washers.

1. Pull back rubber boot.

2. Loosen connector screw and disconnect connector.

3. Remove mounting screws.

INSTALLATION

1. Position amplifier as shown in Figure 8-26.

2. Install mounting screws and tighten to 6 ft-lbs (8 Nm).

3. Plug in the connector and tighten connector screw.

4. Install rubber boot.

GAIN ADJUSTMENT

NOTE

The Public Address (PA) amplifier gain is set at the manufacturer and normally does not require adjustment. If it has feedback, low volume or distortion, adjust the gain as follows:

1. Remove access screw to expose the internal adjusting

screw. See Figure 8-27.

2. Press Push-To-Talk switch on microphone, speak into

microphone in normal manner and while speaking, carefully turn internal adjusting screw, with a proper size

screwdriver, to obtain maximum distortion free output.

3. Replace access screw.

Figure 8-26. Whelen Amplifier Mounting

Figure 8-27. PA Gain Adjustment Screw

2004 FLT Police: Electrical 8-21

Page 22

HOME

MICROPHONE AND JACK 8.11

MICROPHONE

Troubleshooting

1. To verify that Push-To-Talk (PTT) switch is functioning

properly, connect probes of ohmmeter to tip and ring of

microphone plug. See Figure 8-28.

2. With PTT switch off (not depressed) there must be no

continuity.

3. Depress PTT switch. Ohmmeter must read 0-1 ohm.

Replace microphone if there is no continuity.

REMOVAL

1. FLHTP: Remove outer fairing. See OUTER FAIRING/

WINDSHIELD, REMOVAL, page 2-120 of the 2004 Touring Models Service Manual (Part No. 99483-04).

FLHP: Remove headlamp assembly. See HEADLAMP

ASSEMBLY, REMOVAL, page 8-25 of the 2004 Touring

Models Service Manual (Part No. 99483-04).

2. Remove nut and washer to release microphone jack.

3. Unsolder leads from jack terminals.

INSTALLATION

1. Solder leads to jack terminals as shown in Figure 8-28.

2. Install microphone jack and secure with washer and nut.

3. FLHTP: Install outer fairing. See OUTER FAIRING/

WINDSHIELD, INSTALLATION, page 2-120 of the 2004

Touring Models Service Manual (Part No. 99483-04).

FLHP: Install headlamp assembly. See HEADLAMP

ASSEMBLY, INSTALLATION, page 8-25 of the 2004

Touring Models Service Manual (Part No. 99483-04).

p0013a8x

4

3

5

R

W

BE

To Pin Connector

2

1

Microphone Jack

6

Microphone Plug

1. Sleeve

2. Ring

3. Tip

Microphone Plug

Microphone Jack

4. Ring

5. Sleeve

6. Tip

8-22 2004 FLT Police: Electrical

Figure 8-28. Microphone and Jack Connections

Page 23

HOME

AIR HORN 8.12

ENABLING AIR HORN

1. FLHTP: Remove outer fairing. See OUTER FAIRING/

WINDSHIELD, REMOVAL, page 2-120 of the 2004 Touring Models Service Manual (Part No. 99483-04).

FLHP: Remove headlamp assembly. See HEADLAMP

ASSEMBLY, REMOVAL, page 8-25 of the 2004 Touring

Models Service Manual (Part No. 99483-04).

2. Locate the gray 12-place Deutsch connector for the left

side handlebar switch controls [24]. See Figure 8-29 for

FLHTP models, Figure 8-30 for FLHP models.

3. Remove the secondary lock from the socket half of the

connector and proceed as follows:

a. Pull seal pin from cavity 11.

b. Remove Y/BK wire from cavity 6.

c. Install Y/BK wire in cavity 11. See Figure 8-31.

d. Push seal pin into cavity 6.

NOTE

For instructions on properly removing and installing wire terminals, see APPENDIX B.1, DEUTSCH ELECTRICAL CONNECTORS, REMOVING/INSTALLING SOCKETS, page B-1

of the 2004 Touring Models Service Manual (Part No. 99483-

04).

4. Place a rag in the speaker cone to reduce volume. Turn

the Ignition/Light Key Switch to IGNITION and test operation of air horn.

Left Handlebar Controls [24]

(Gray)

p0118x8x

Figure 8-30. Headlamp Nacelle (FLHP)

MOVE Y/BK WIRE TO CAVITY

11 IF USING WHELEN SIREN

AMPLIFIER & AIR HORN

FUNCTION IS DESIRED

p0042c8x

Left Handlebar Controls [24]

(Gray)

[24B]

(GRAY)

1

O/W

2

Y

3

BE

4

W

W/V

Y/BK

BK/R

BK/R

PK/BK

TN/BK

Y/BK

FROM

5

MAIN

6

HARNESS

7

[24A]

8

9

10

11

12

CLUTCH

LOCKOUT SWITCH

SIREN OFF/RUN

SWITCH

HEADLAMP HI/LO

SWITCH

LEFT

DIRECTIONAL

SWITCH

HORN/SIREN

SWITCH

Figure 8-31. Enabling the Air Horn (All Models)

5. FLHTP: Install outer fairing. See OUTER FAIRING/

WINDSHIELD, INSTALLATION, page 2-120 of the 2004

p0058x8x

Touring Models Service Manual (Part No. 99483-04).

FLHP: Install headlamp assembly. See HEADLAMP

Figure 8-29. Inner Fairing (FLHTP)

ASSEMBLY, INSTALLATION, page 8-25 of the 2004

Touring Models Service Manual (Part No. 99483-04).

2004 FLT Police: Electrical 8-23

Page 24

HOME

TOUR-PAK 8.13

GENERAL

i03730

The Tour-Pak Kit (White- Part No. 53238-01; Black- Part No.

53239-01) is designed for installation on both FLHP and

FLHTP model motorcycles and is available from your HarleyDavidson Dealer.

1WARNING1WARNING

The rider’s safety depends on the correct installation of

this kit. If the following installation procedures are not

within your capabilities, or if you do not have the correct

tools, have your Harley-Davidson dealer perform this

installation. Failure to do the installation correctly could

result in death or serious injury.

Phillips Screws

with Washers

Luggage

Rack Spacer

Hex Head

Screws

INSTALLATION

1. See Figure 8-32. Remove the five hex head cap screws

and two smaller Phillips screws (with washers) securing

existing radio tray to mounting rail. Leave the two rectangular license plate spacers and set aside three remaining spacers. Discard screws and washers, but save nuts

for installation later. Discard radio tray.

2. See Figure 8-33. Carefully remove Tour-Pak assembly

and hardware from shipping container. Open Tour-Pak.

Remove the three nuts securing the power supply

mounting plate to the bottom of the Tour-Pak. Save for

reinstallation.

3. Note connector locations for reinstallation and disconnect the strobe head connectors from the power supply.

4. See Figure 8-34. Set power supply aside temporarily.

Raise and position (lean) the mounting plate up against

the front side of Tour-Pak to provide access to the TourPak permanent mounting holes. If necessary, use a

cable strap to hold plate in place. Temporarily set TourPak assembly aside.

Figure 8-32. Remove Radio Tray and Hardware

Strobe Head

Connectors

Nut

Nut

Figure 8-33. Remove Plate Securing Power Supply

i03732

i03731

Nut

8-24 2004 FLT Police: Electrical

Power Supply

Mounting Plate

Leaning Toward

Front of Tour-Pak

Figure 8-34. Provide Room For Mounting Tour-Pak

Page 25

HOME

i03733

Trim Panel

Nuts

Seat Pin

Cut Cable

Straps

Securing

Pole Lamp

Harness

i03734

Tour-Pak Mounting

Bolts (with Washers)

Washers

and Nuts

License Plate

Bracket Spacer

Luggage

Rack Spacer

i03735

i03736

Spacer

Mounting

Block

Washer

and Nut

5. See Figure 8-35. Remove the quick release seat pin clip

from the seat pin and pivot the seat forward as far as

possible. It may be necessary to tie or brace seat in the

full forward position.

6. Remove the two nuts and washers securing the trim

panel assembly to the fender and remove panel. Save

hardware and panel for reinstallation.

1WARNING1WARNING

To protect against shock and accidental start-up of vehicle, disconnect the negative battery cable before proceeding. Inadequate safety precautions could result in

death or serious injury. (00048a)

1WARNING1WARNING

Always disconnect the negative battery cable first. If the

positive cable should contact ground with the negative

cable installed, the resulting sparks may cause a battery

explosion which could result in death or serious injury.

(00049a)

7. Disconnect battery cables, negative battery cable first.

Figure 8-35. Remove Trim Panel

8. Cut the two cable straps securing the pole lamp harness

to the support rail. Discard cable straps. Route pole lamp

harness away from Tour-Pak mounting area.

9. See upper frame of Figure 8-36. Return to the Tour-Pak.

Using parts from kit, pre-install four long hex head bolts

with washers from inside bottom of Tour-Pak at four permanent mounting holes.

10. Raise the Tour-Pak up and position onto rack with four

mounting bolts aligned with four holes in support rail (two

on each side).

See lower frame of Figure 8-36. Make sure the two

license plate bracket spacers remain in position and

bolts can pass through them. Obtain the two rectangular

luggage rack spacers and four nuts saved from step 2.

Obtain four new washers from kit and loosely install

washers and nuts to secure Tour-Pak to support rail.

11. Obtain rear mounting block (with1 hole), hex head bolt

and two flat washers from kit. Also obtain rectangular

spacer and nut saved from step 1.

12. See Figure 8-37. Install washer to bolt and position bolt

above hole at rear center Tour-Pak above rear block

mounting position.

13. Orient rear mounting block (with hole running vertical)

and position between recessed area of Tour-Pak (near

center) and rail support. Install bolt through Tour-Pak,

rear block and rail, then loosely Install spacer followed by

washer and nut.

Figure 8-36. Install Tour-Pak Mounting Hardware

Figure 8-37. Install Tour-Pak Mounting Block

2004 FLT Police: Electrical 8-25

Page 26

HOME

14. Obtain the remaining mounting block (with 2 holes), two

long Phillips and two flat washers from kit.

15. See Figure 8-38. Install flat washers to Phillips screws

and position screws above two holes near front center of

To ur-Pak above front mounting block position.

16. Position block (with holes running vertical) between TourPak and air tank mounting bracket. Install screws

through Tour-Pak and mounting block and thread into air

tank mounting bracket. Tighten screws to 22 in-lbs (2.5

Nm).

17. Return to mounting hardware installed in Steps 9

through 15 and alternately tighten to 60-84 in-lbs (6.8-

9.5 Nm).

18. See Figure 8-39. Reposition power supply onto mounting

plate and reinstall the three nuts removed in step 3 to

provide access for mounting Tour-Pak. Obtain two more

nuts from kit and install to remaining mounting plate

studs. Tighten nuts to 80 in-lbs (9.0 Nm).

19. Reconnect the strobe head (male to female) connectors

disconnected in step 4.

Front

Air Tank

Mounting

Mounting

Block

Bracket

i03737

Figure 8-38. Install Tour-Pak Front Mounting Block

i03738

Nut

NOTE

When performing the next few steps, install battery mounting

bracket, battery strap and battery only. Do NOT connect battery terminals at this time.

20. See Figure 8-40. Loosely assemble battery mounting

bracket with bolt, washers and nut obtained from kit.

21. Orient and position battery behind mounting bracket as

shown. Loosely install battery strap using two bolts, four

washers and two nuts from kit.

22. Make sure battery is centered and mounting bracket is

positioned properly. While pushing mounting bracket forward, tighten bracket hardware to 120-144 in-lbs (13.6-

16.3 Nm). Return to battery strap hardware and tighten

to 120-144 in-lbs (13.6-16.3 Nm).

Nut

Nut

Strobe

Connectors

Nut

Figure 8-39. Install Power Supply Mounting Plate and

Reconnect Strobe Heads

Battery

Battery

Strap

i03739

Mounting

Bracket

Nut

Nut

8-26 2004 FLT Police: Electrical

Washer

Washer

Figure 8-40. Install Battery Mounting Bracket and Battery

Page 27

HOME

i03739

Positive

Cable

Negative

Cable

i03741

2-Pin

Connector

Control

Harness

PNA

Accessory

Connector

i03742

Maxi-Fuse

Positive Cable

Radius to Prevent

Terminal Kinking

Pole Lamp

Harness

Connector

23. See Figure 8-41. Locate positive and negative battery

cables in Tour-Pak. Make sure cables are not touching

each other or anything metal in the Tour-Pak.

24. See Figure 8-42. Route control harness (from Tour-Pak)

along left upper frame tube to PNA accessory connector

in space immediately in front of motorcycle battery.

25. Connect control harness to PNA accessory connector.

26. Locate the two-pin connector originally routed to pole

lamp and connect to the two-pin connecter coming from

To ur-Pak.

NOTE

Prior to installing positive battery terminal to battery post,

locate insulated end of positive battery cable (directly after

maxi-fuse) and bend a 90 degree radius into the cable as

shown. This will keep the terminal from kinking when installing terminal to battery post.

1WARNING1WARNING

Always connect the positive battery cable first. If the positive cable should contact ground with the negative cable

installed, the resulting sparks may cause a battery explosion which could result in death or serious injury.

(00068a)

Figure 8-41. Positive and Negative

Tour-Pak Battery Cables

27. See Figure 8-43. Route the positive battery cable with

Maxi-fuse as shown and loosely install positive battery

terminal over existing terminal to battery positive post.

Tu ck the Maxi-Fuse along with the pole lamp harness

down into the space between the battery and the left

upper frame tube as shown. Tighten terminal to 30 in-lbs

(3.4 Nm).

28. Route the negative battery cable around the front of the

battery and install terminal over existing terminal to negative battery post. Tighten terminal to 30 in-lbs (3.4 Nm).

Figure 8-42. Install Tour-Pak Harness and

2-Pin Connectors

Figure 8-43. Install Tour-Pak Battery Cables

to Motorcycle

2004 FLT Police: Electrical 8-27

Page 28

HOME

29. See Figure 8-44. Install cable strap to secure Tour-Pak

Harness to mounting rail.

30. See Figure 8-45. Reinstall trim panel to fender using nuts

and washers saved from step 7.

31. Reinstall trim panel cover to protect battery and wiring.

32. Pivot seat downward and lower until it engages seat pin

completely. Install quick release seat pin clip to fully

secure seat.

1WARNING1WARNING

After installing seat, pull upward on front of seat to be

sure it is locked in position. If seat is loose, it could shift

position during vehicle operation and startle the rider,

causing loss of control and death or serious injury.

(00070a)

1WARNING1WARNING

i03743

Tour-Pak

Harness

Figure 8-44. Secure Tour-Pak Harness to Mounting Rail

Cable

Strap

Always connect the positive battery cable first. If the positive cable should contact ground with the negative cable

installed, the resulting sparks may cause a battery explosion which could result in death or serious injury.

(00068a)

33. See Figure 8-46. Return to Tour-Pak and locate positive

and negative battery cables. Route positive battery terminal to battery and install terminal to battery post.

Tighten terminal to 30 in-lbs (3.4 Nm).

34. Route negative battery terminal to negative battery post

and install terminal. Tighten terminal to 30 in-lbs (3.4

Nm).

35. Close Tour-Pak and test strobe lights for proper operation.

Trim Panel

i03744

Figure 8-45. Reinstall Trim Panel

Negative Post

and Terminal

Positive Post

and Terminal

8-28 2004 FLT Police: Electrical

i03740

Figure 8-46. Install Tour-Pak Battery Terminals

Page 29

HOME

ELECTRICAL CONNECTOR LOCATIONS 8.14

Table 8-7. FLHTP Wire Harness Connectors

No. Description Type Location Fig.

Left Handlebar Controls-

[24]

Air Horn Option

[57] Siren/PA Speaker 2 - Place Deutsch Top Rail of Engine Guard (Right Side) -

[59] Rear Pole Lamp 2 - Place Deutsch Under Luggage Rack (Left Side) -

[69] Pursuit Flasher Relay Connector Inner Fairing - Inboard of Left Fairing Bracket 8-47

[70] Siren Amplifier Harness 12 -Place Deutsch Inner Fairing - Left Fairing Support Brace 8-47

[72] Siren Amplifier 18 - Place Packard Top Rail of Saddlebag Guard (Left Side) -

[73] Pursuit Lamps 2 - Place Multilock (White) Inner Fairing - Next to Top Fork Bracket 8-47

[108] Tachometer 6 - Place Packard Inner Fairing - Back of Tachometer 8-47

1. Tachometer [108]

2. Left Handlebar Controls [24]

3. Siren Amplifier Harness [70]

4. Pursuit Flasher [69]

5. Pursuit Lamps [73] (White)

12 - Place Deutsch (Gray) Inner Fairing - Left Fairing Support Brace 8-47

3

1

2

p0058x8x

4

5

Figure 8-47. Inner Fairing (FLHTP)

2004 FLT Police: Electrical 8-29

Page 30

HOME

Table 8-8. FLHP Wire Harness Connectors

No. Description Type Location Fig.

[24]

Left Handlebar Controls

Air Horn Option

12 - Place Deutsch (Gray) Inside Headlamp Nacelle 8-48

[57] Siren/PA Speaker 2 - Place Deutsch Top Rail of Engine Guard (Right Side) -

[59] Rear Pole Lamp 2 - Place Deutsch Under Luggage Rack (Left Side) -

[69] Pursuit Flasher Relay Connector Under Left Side Cover -

[72] Siren Amplifier 18 - Place Packard Top Rail of Saddlebag Guard (Left Side) -

[73] Pursuit Lamps 2 - Place Multilock (White) Inside Headlamp Nacelle 8-48

[108] Tachometer 3 - Place Deutsch Inside Headlamp Nacelle 8-48

p0118x8x

Left Handlebar Controls [24] (Gray)

Air Horn Option

Pursuit Lamps [73]

8-30 2004 FLT Police: Electrical

Tachometer [108]

Figure 8-48. Headlamp Nacelle (FLHP)

Page 31

HOME

WIRING DIAGRAMS 8.15

SUBJECT PAGE NO.

FLHTP

Main Harness . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-33

Interconnect Harness . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-34

Electronic Fuel Injection (EFI) Harness . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-35

Ignition Switch . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-36

Tail Lamp, Pursuit Lamps, Directional Lamps and Fender Tip Lamps . . . . . . . . . . . . . 8-36

Starting and Charging . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-37

Handlebar Controls, Speedometer, Tachometer and Indicator Lamps . . . . . . . . . . . . 8-38

Siren Amplifier and Strobe Harness . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-39

Optional Strobe System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-44

FLHP, FLHPE

Main Harness . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-40

Electronic Fuel Injection (EFI) Harness . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-41

Starting and Charging . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-42

Handlebar Controls, Indicator Lamps, Tail Lamp, Pursuit Lamps,

Directional Lamps, Accessory/Spot Switch, Speedometer and Tachometer . . . . . . . . 8-43

Siren Amplifier and Strobe Harness . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-39

Optional Strobe System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-44

NOTE

Harness Part No.’s may be included on some wiring diagrams. Use these numbers for

reference only. ALWAYS REFER TO THE 2004 FLT POLICE MODELS PARTS CATALOG

(Part No. 99545-04) WHEN ORDERING WIRING HARNESSES.

2004 FLT Police: Electrical 8-31

Page 32

HOME

NOTES

8-32 2004 FLT Police: Electrical

Page 33

HOME

TSM/TSSM

VSS/SERIAL DATA LINK

SECURITY INDICATOR

LEFT TURN FEED

RIGHT TURN FEED

RIGHT TURN SW INPUT

LEFT TURN SW INPUT

START RELAY CONTROL

IGNITION ENABLE

ALARM SIGNAL

TURN SIGNAL/

TURN SIGNAL SECURITY

MODULE

TO

IGNITION/EFI

HARNESS

[8A]

(GY)

TO

INTERCONNECT

HARNESS

[1A]

(BK)

TO

INTERCONNECT

HARNESS

[2A]

(GY)

TO

INTERCONNECT

HARNESS

[15A]

OIL

PRESSURE

SENDER

[139A]

BATTERY

IGNITION

GROUND

[30A]

12

BK

11

LGN/V

10

CRANK POSITION

9

8

7

6

GY

5

W/GN

4

3

BE/O

W/BK

2

BN/GY

1

12

11

10

9

8

7

6

5

4

3

2

1

12

11

10

9

8

7

6

5

4

3

2

1

D

C

B

A

SENSOR

BK

R

[79A]

D C B A

BK

R

[8B]

O/GY

GN/R

W/V

W/BN

O/BE

BN

V

W/BK

O/W

O/R

GY

O/V

O

[1B]

[2B]

[15B]

R

BK

W/GN

TN

GN/Y

BN/GN

O

Y/BK

Y/W

BN/GY

BE

BK/R

R/BE

BK

BK/GN

BE

R/O

[139B]

1

2

3

4

5

6

7

8

9

10

11

12

2

1

BN/GN

GN/Y

BN/GY

GY

LGN/V

BN/V

V

BN

W/BN

W/V

TN/GN

LGN/BN

BK

(GY)

2

1

[79B]

THROTTLE

ROLL-OFF

SWITCH

[75A]

[75B]

[30B]

Y/V

[75C]

[75D]

O/V

FUEL

PUMP

FUEL PUMP

ASSEMBLY

IN TANK

AT TOP OF TANK

70369-02

FUEL TANK

HARNESS

HORN

[122 ]

Y/BK

BK

[13B]

[13A]

[131]

TN

BK

[141A]

123

12

3

BK

Y/W

O/GY

123

3

12

BK

Y/W

O/GY

NEUTRAL

SWITCH

EFI

[141B]

BK

RH GND

STUD

- FRAME GROUND -

LH GND

STUD

(BK)

[12B]

TOUR-PAK

R/BE

O/W

REAR

STOPLIGHT

SWITCH

[121]

BK

BE

R/Y

321

[12A]

TO INTERCONNECT

BN/V

[156B]

(GY)

BK

BE/BK

OPTIONAL

SECURITY

SIREN

[142A]

POWER

SIGNAL

GROUND

A B C

BKBK/GN

BN/GY

LGN/BN

BK

[142B]

MAIN POWER

AT S TARTER

V/Y

BK

ABCDEFGHJ

W/BE

R/GN

LGN/V

[156A]

12

3456

ON/OFF

SET/COAST

RESUME/ACCEL

GROUND

THROTTLE ROLL-OFF

CRUISE CONTROL MODULE

[5B]

R

O/V

W/GN

GN/R

R/BE

BE/O

K

IGNITION

SET LAMP

BRAKE SIGNAL

SPEED SIGNAL

ENGINE SPEED

40A

MAXI-FUSE

A B

R

R

[17B]

[17A]

VOLTAGE

REGULATOR

[77A]

R

O/V

R/Y

R/BE

BK

O

BE

BE

GY

O/V

O/W

O/R

BN/GY

O/BE

4E

3F

3E

4F

1B 1A

1D 1C

1H 1G

1F 1E

4D 4C

2B

2D 2C

2F 2E

3B 3A

R/O

3D 3C

4B 4A

[7A]

12345678

CONNECTOR

[64B]

3

5

2

1

INSTRUMENTS - 15A

LIGHTS - 15A

HEADLAMP - 15A

IGNITION - 15A

IGN - 2A MAX

P&A

BRAKE/PURSUIT - 15A

ACCESSORIES - 15A

P& A - 15A

RADIO MEM - 15A

BATTERY - 15A

SIREN - 10A

BK

BK

BN

O/W

R/Y

V

TO REAR

LIGHTING

[7B]

B+

BE

[160B]

R

BK

BRAKE

RELAY

2A

TO

IGNITION

SWITCH

[33B]

A

BCD

R/GY

R

R/BK

R/BK

R/BK

R/GY

R

O/GN

KEYSWITCH IGN RELAY

[33A]

R/BK

BK

O

R/Y

O/R

[4A]

(BK - LOCATED UNDER

85

8630

BK

R/BK

START RELAY

8630 87A

85

TN/GN

BK/R

START

SOLENOID

4

3

ACCESSORY

2

CONNECTOR

1

87A

R

O/GN

R/GY

[126A]

[126B]

R/BK

[123A]

[123B]

GN

[128B]

SEAT)

f2227o8x

2004 FLHTP, DOMESTIC and INTERNATIONAL Models,

Main Harness

8-33

Page 34

HOME

TO

RIGHT-HAND

CONTROLS

[22B]

PURSUIT

FLASHER

TO MAIN HARNESS

[2B]

[2A]

Y/W

345

BE

BN/GY

2

1

BK/R

(GY)

R/BE

10

11

9

X

P

L

(BK)

[22A]

1

O/W

2

R/BE

3

4

5

6

7

8

9

10

11

12

G/Y

W/BK

W/BN

BK/R

O/V

GY/BK

GN/R

GY/V

GY/BN

GY/BK

12

[69B] [69A]

BK

678

/Y

N

O/R

TN

G

Y/BK

TO MAIN HARNESS

1011

12

9

O/PK

W/BN

W/V

BN

[1B]

V

W/BK

O/W

O/R

FUEL

12345678

[1A]

(BK)

/V

/Y

O

O

G

[116A] [116B]

+

1

O

1

2

S

[117A]

3

2

[117B]

O

BK

Y/W

VOLTMETER

[110A] [110B]

+

BK

O

1

2

S

[111A]

3

1

2

[111B]

BK

O

BK

TO

LEFT-HAND

CONTROLS

[24B]

TO

INDICATOR

LAMPS

[21B]

HEADLAMP

[38]

GND

10

11

12

10

(GY)

[24A]

1

2

3

4

5

6

7

8

9

[21A]

1

2

3

4

5

6

7

8

9

LO-BEAM

HI-BEAM

O/W

Y

BE

W

W/V

Y/BK

BK/R

BK/R

PK/BK

TN/BK

Y/PK

BN

GN/Y

W

V

BK

O

TN

O

BK

BK

(BK)

BK

(BK)

[70A]

[15A]

(BK)

1

2

3

4

5

6

AMPLIFER

7

HARNESS

8

9

10

11

12

A

B

HARNESS

C

D

TO

SIREN

[70B]

TO MAIN

[15B]

O/PK

TN/BK

PK/BK

Y/PK

GN/R

BK

BK

BE

BK

O/W

BK

CIGAR LIGHTER

BK

Y

W

(BK)

[31A]

BK

123456

TURN SIGNALS

BE

BN

FRONT

V

BK

BE

GY/BN

12

PURSUIT

LAMPS

(WE)

GY/V

[73A]

[32A]

BE

12

FENDER

TIP LIGHT

(BK)

[156B]

LGN/V

1234

MAIN

HARNESS

(GY)

(BK)

[39B] [108B]

1

O

LGN/V

34

2

IGNITION

DATABUS