Page 1

f1240x2x

0

10

30

20

50

40

110

120

60

70

80

90

100

0

20

30

40

50

10

MPH

H

A

R

L

E

Y

-

D

A

V

I

D

S

O

N

C

E

R

T

I

F

I

E

D

RPM

x100

H

A

R

L

E

Y

-

D

A

V

I

D

S

O

N

f2160x8x

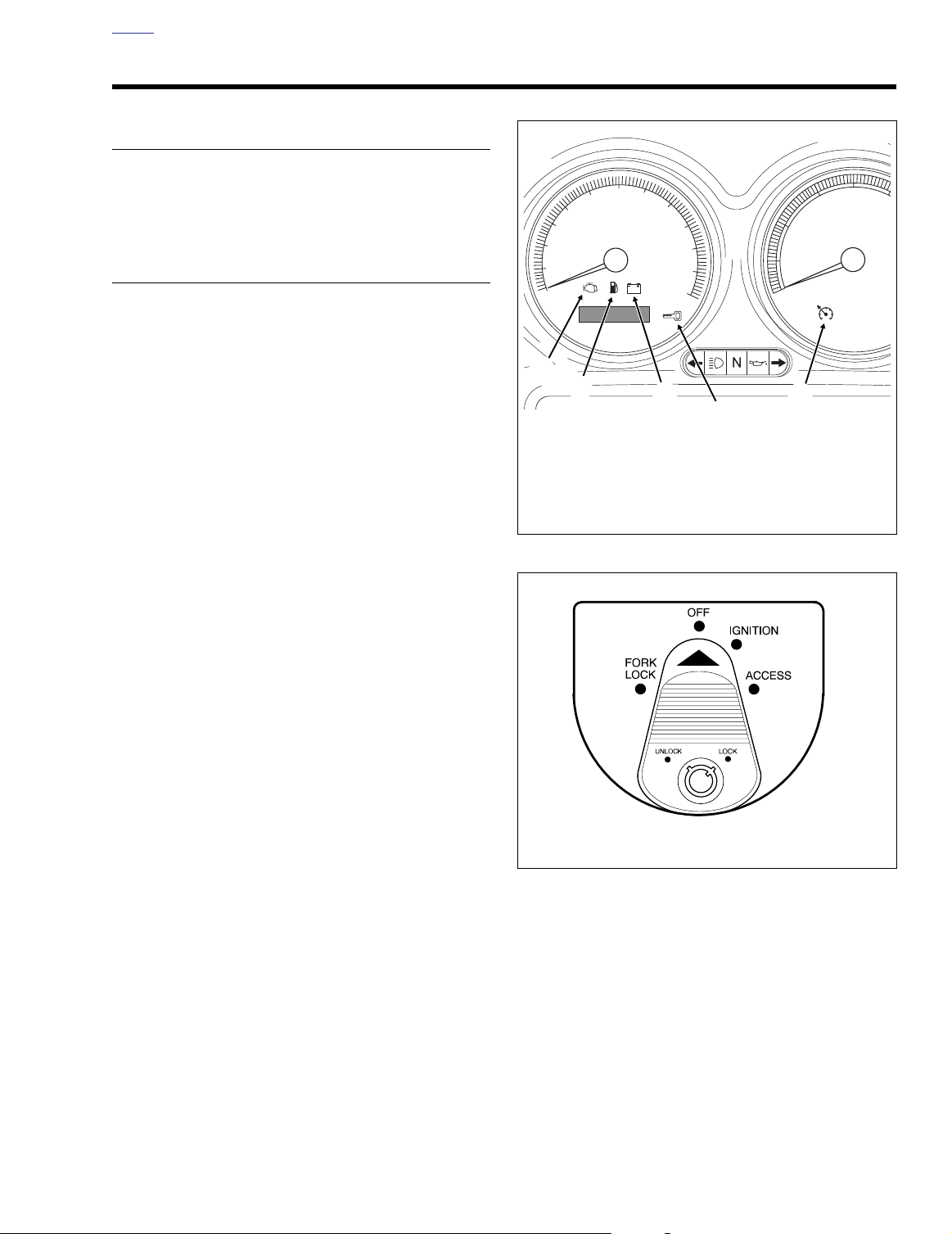

Check Engine Lamp

2

HOME

2004 CHECKING FOR DIAGNOSTIC TROUBLE CODES 2.1

CHECK ENGINE LAMP

To diagnose electronic control module (ECM) or ignition control module (ICM) system problems, start by observing the

behavior of the check engine lamp.

NOTES

See Figure 2-2. “Key ON” means that the ignition key is

●

turned to ON and the engine stop switch is set to RUN

(although the engine is

When the ignition switch is turned ON, the check engine

●

lamp will illuminate for approximately four seconds and

then turn off.

●

If the check engine lamp is not illuminated at Key ON.

See 2.2 INITIAL DIAGNOSTIC CHECK: SPEEDOME-

TER.

If the check engine lamp comes on late (after 20 sec-

●

onds). See 2.2 INITIAL DIAGNOSTIC CHECK: SPEED-

OMETER.

If the check engine lamp fails to turn OFF after the initial

●

four second period. See 2.2 INITIAL DIAGNOSTIC

CHECK: SPEEDOMETER.

not

running).

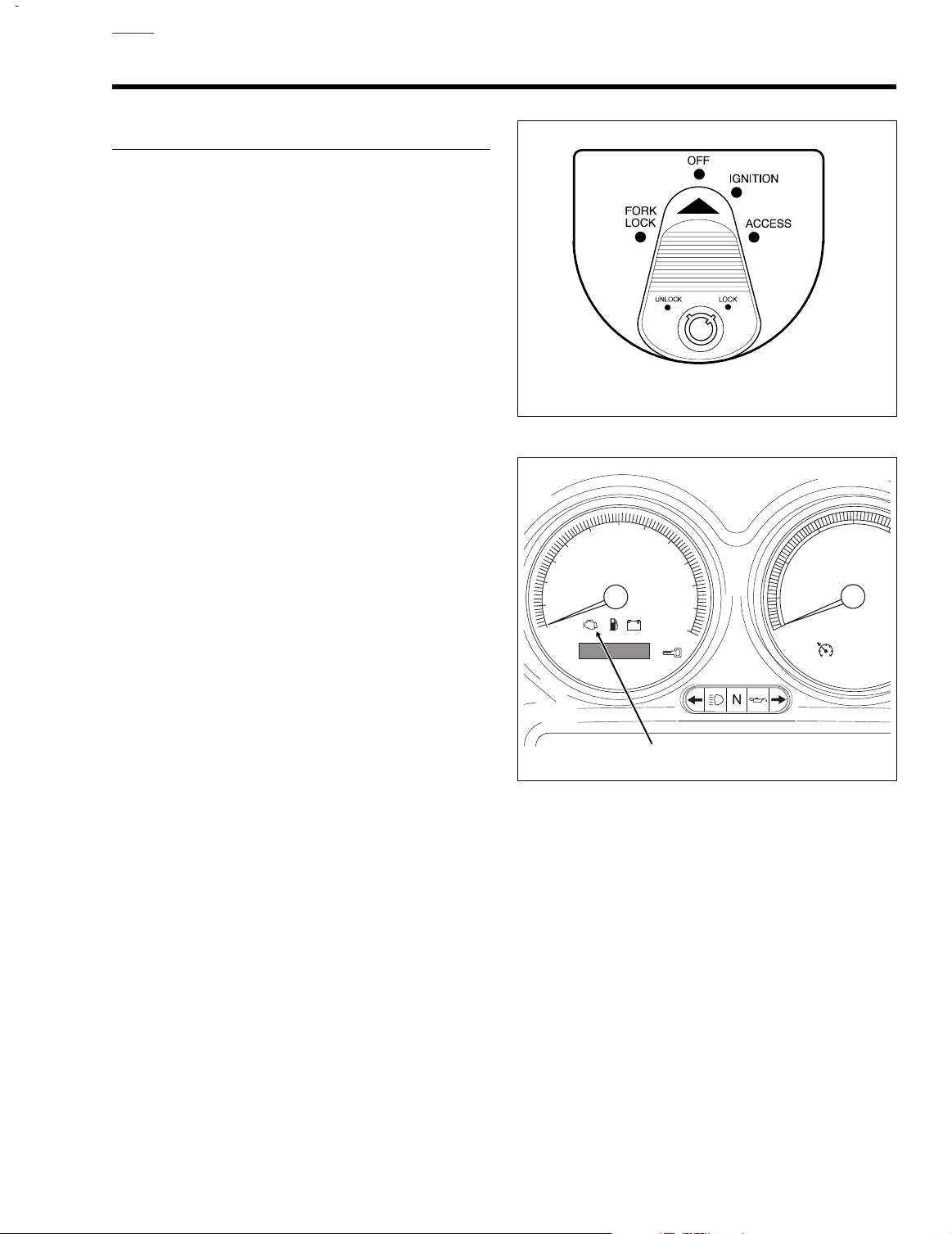

Figure 2-2. Ignition Switch (FLTR, FLHT/C/U)

1. See Figure 2-3. After lamp turns off after being illuminated for the first four second period, one of three situations may occur.

a. The lamp remains off. This indicates there are no

current fault conditions or stored diagnostic trouble

codes (DTC) currently detected by the ignition control module (ICM) or electronic control module

(ECM).

b. The lamp stays off for only four seconds and then

comes back on for an eight second period. This indicates an diagnostic trouble code is stored, but no

current diagnostic trouble code exists.

c. If the lamp remains on beyond the eight second

Figure 2-1. Speedometer

period, then a current diagnostic trouble code exists.

2. See CODE TYPES which follows for a complete descrip-

tion of diagnostic trouble code formats.

NOTES

Some diagnostic trouble codes can only be fully diagnosed

during actuation. For example, a problem with the ignition coil

will be considered a current fault even after the problem is

corrected, since the ECM/ICM will not know of its resolution

until after the coil is exercised by vehicle start sequence. In

this manner, there may sometimes be a false indication of the

current diagnostic trouble code.

2004 Touring: Instruments 2-1

Page 2

HOME

SECURITY LAMP

To diagnose TSM/TSSM system problems, start by observing

the behavior of the security lamp.

NOTES

●

To provide an indication of TSM/TSSM diagnostic trouble

codes, the security lamp is enabled on all models.

See Figure 2-2. “Key ON” means that the ignition key is

●

turned to ON and the engine stop switch is set to RUN

(although the engine is

●

When the ignition switch is turned ON, the check engine

lamp will illuminate for approximately four seconds and

then turn off.

If the check engine lamp is not illuminated at Key ON,

●

see 2.2 INITIAL DIAGNOSTIC CHECK: SPEEDOME-

TER.

●

If the check engine lamp comes on late (after 20 seconds), see 2.2 INITIAL DIAGNOSTIC CHECK: SPEED-

OMETER.

If the check engine lamp fails to turn OFF after the initial

●

four second period, see 2.2 INITIAL DIAGNOSTIC

CHECK: SPEEDOMETER.

not

running).

1. See Figure 2-3. After lamp turns off after being illumi-

nated for the first four second period, one of three situations may occur.

a. The lamp remains off. This indicates there are no

current fault conditions or stored diagnostic trouble

codes currently detected by the ignition control module (ICM) or electronic control module (ECM).

b. The lamp stays off for only four seconds and then

comes back on for an eight second period. This indicates an diagnostic trouble code is stored, but no

current diagnostic trouble code exists.

c. If the lamp remains on beyond the eight second

period, then a current diagnostic trouble code exists.

2. See CODE TYPES which follows for a complete description of diagnostic trouble code formats.

NOTE

Some diagnostic trouble codes can only be fully diagnosed

during actuation. For example, a problem with the turn signals

will be considered a current fault even after the problem is

corrected, since the TSM/TSSM will not know of its resolution

until after the turn signals are activated. In this manner, there

may sometimes be a false indication of a diagnostic trouble

code.

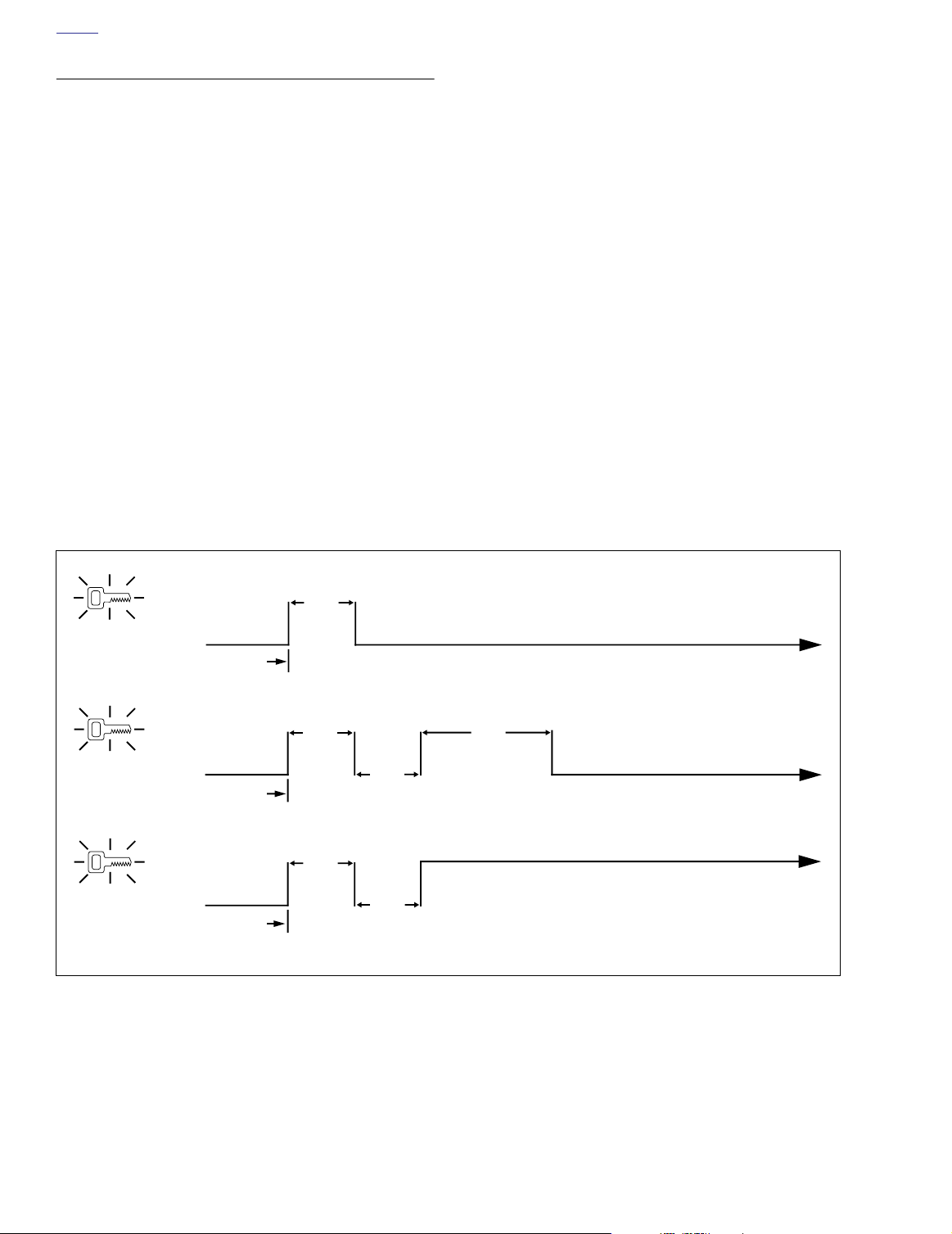

ON

OFF

ON

OFF

ON

OFF

A

Key ON

B

Key ON

C

Key ON

4 Sec.

Lamp OFF: No Current or Historic DTCs

Lamp ON 8 Seconds:

Only Historic DTCs Exist

4 Sec.

4 Sec.

4 Sec.

4 Sec.

Figure 2-3. Check Engine and Security Lamp Operation

8 Sec.

Lamp Remains ON: Current DTC *

Historic DTCs May Also Exist

*

Lamp OFF

2-2 2004 Touring: Instruments

Page 3

HOME

CODE TYPES

There are two types of diagnostic trouble codes (DTCs): current and historic. If a diagnostic trouble code is stored, it can

be read using speedometer self diagnostics. See 2.3

SPEEDOMETER SELF DIAGNOSTICS.

All diagnostic trouble codes reside in the memory of the

ECM/ICM, TSM/TSSM, speedometer or tachometer until the

code is cleared by use of the speedometer self diagnostics.

See 2.3 SPEEDOMETER SELF DIAGNOSTICS.

A historic diagnostic trouble code is also cleared after a total

of 50 trips has elapsed. A trip consists of a start and run

cycle. After the 50 trip retention period, the diagnostic trouble

code is automatically erased from memory providing that no

subsequent faults of the same type are detected in that

period.

Current

Current diagnostic trouble codes are those which presently

disrupt motorcycle operation. See the appropriate flow charts

for solutions.

Historic

Historic diagnostic trouble codes can only be identified as historic using a computer based diagnostic package called DIGITAL TECHNICIAN (Part No. HD-44750), when historic

diagnostic codes are present.

If a particular problem happens to resolve itself, the active

status problem is dropped and it becomes a historic fault

rather current fault.

Historic diagnostic trouble codes are stored for a length of

time to assist in the diagnosis of intermittent faults.

It is important to note that historic diagnostic trouble codes

may also be present whenever the system indicates the existence of a current fault. See MULTIPLE DIAGNOSTIC TROU-

BLE CODES if multiple diagnostic trouble codes are found.

RETRIEVING DIAGNOSTIC TROUBLE CODES

The engine management system provides two levels of diagnostics.

●

The most sophisticated mode employs a computer

based diagnostic package called DIGITAL TECHNICIAN

(Part No. HD-44750).

●

The second mode requires using the speedometer self

diagnostics. Speedometer, tachometer (if equipped),

TSM/TSSM and ECM diagnostic trouble codes can be

accessed and cleared. See 2.3 SPEEDOMETER SELF

DIAGNOSTICS.

MULTIPLE DIAGNOSTIC TROUBLE CODES

While it is possible for more than one fault to occur and set

more than one diagnostic trouble code, there are several conditions which may result in

tic trouble codes:

Serial data diagnostic trouble codes (DTC U1016, U1064,

U1097, U1255, U1300 and U1301) may be accompanied by

other codes.

codes before resolving the other codes.

For proper resolution to multiple diagnostic trouble codes

refer to diagnostic trouble code priority chart page 2-6,Ta b le

2-2.

Always

one

fault setting

correct the serial data diagnostic trouble

multiple

diagnos-

Diagnostic charts are designed for use with current diagnostic trouble codes and as a result they frequently suggest wire

repair or part replacement.

2004 Touring: Instruments 2-3

Page 4

HOME

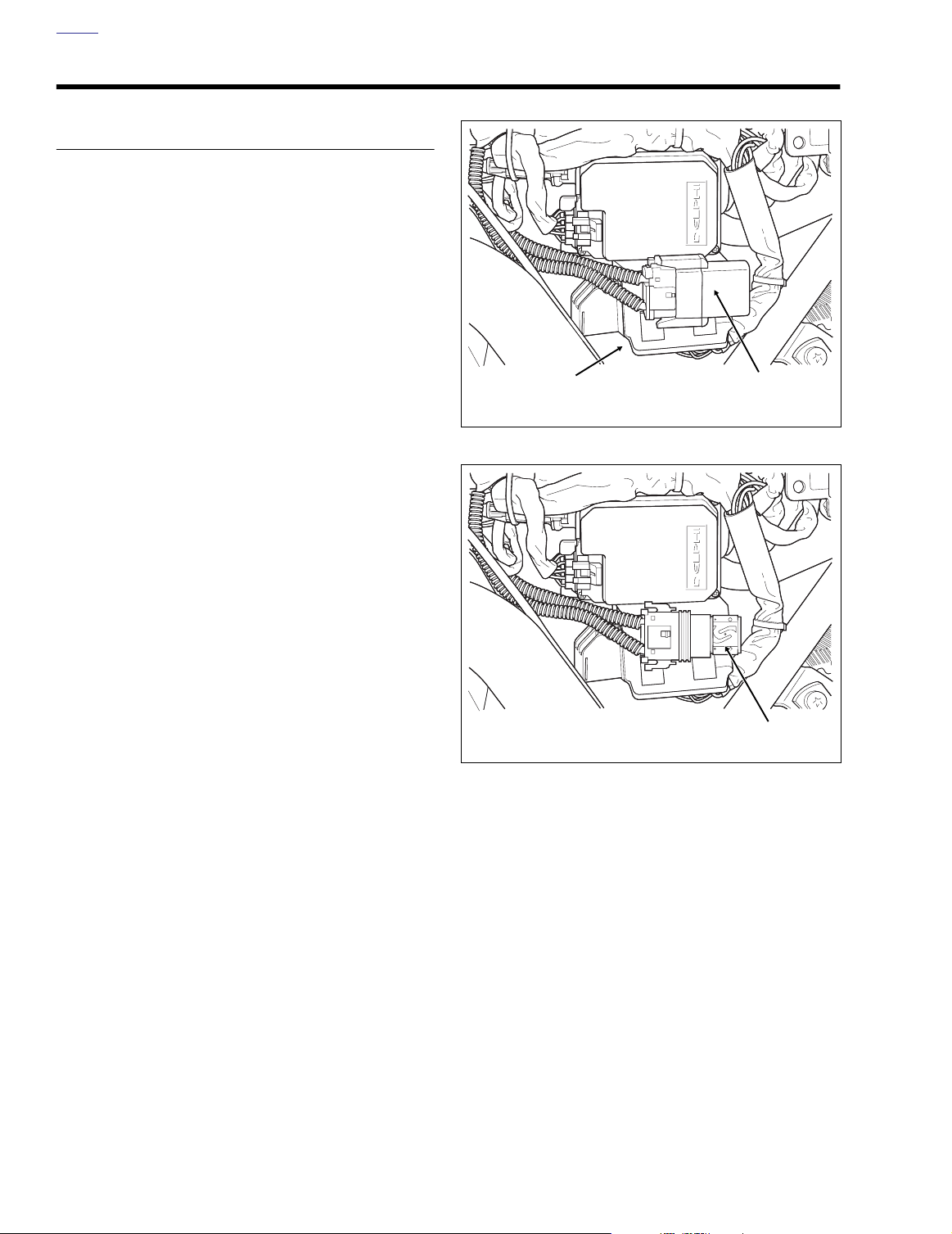

INITIAL DIAGNOSTIC CHECK: SPEEDOMETER 2.2

GENERAL

●

Constant power is supplied to the speedometer through

terminal 5 of connector [39]. The speedometer turns on

when power is applied to terminal 1 of connector [39].

The speedometer goes through an initialization

sequence every time power is removed and re-applied to

terminal 6. The visible part of this sequence is the check

engine lamp (in “run” mode), security lamp (models with

security only), backlighting, odometer and fuel level (EFI

only). Upon key ON, the check engine lamp and security

lamp will illuminate for 4 seconds and then (if parameters

are normal) go out.

●

To locate faulty circuits or other system problems, follow

the diagnostic flow charts and tests in this section. For a

systematic approach, always begin with INITIAL DIAG-

NOSTICS which follows. Read the general information

and then work your way through the flow chart box by

box.

●

Loss of power on any of the four power inputs will

change speedometer behavior. Refer to Ta bl e 2-1.

Speedometer Function Chart-Loss Of Input.

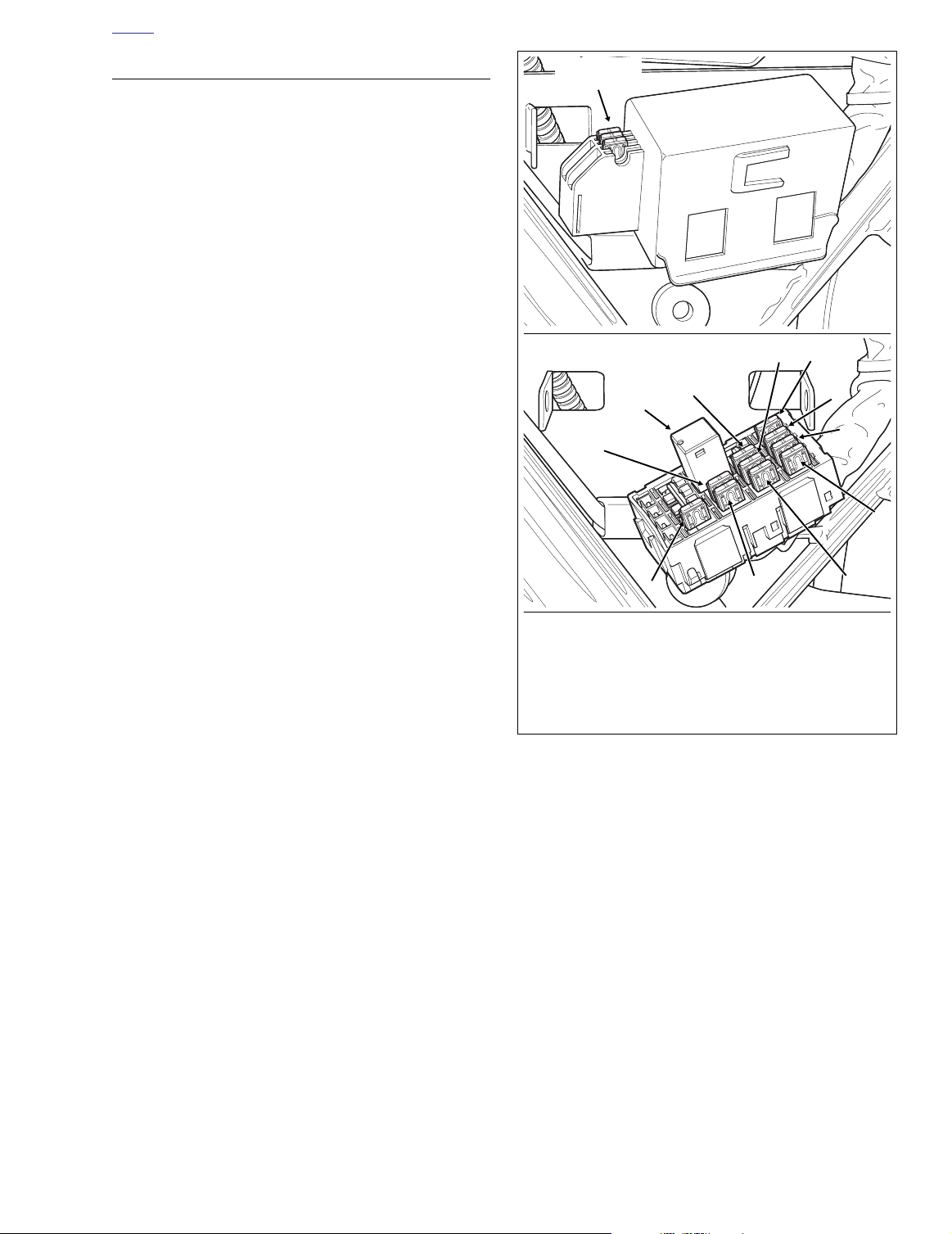

f2206x8x

Fuse

Block

Figure 2-4. Remove Left Side Cover

Maxi-Fuse

Cover

Diagnostic Notes

If a numbered circle appears adjacent to a flow chart box,

then more information is offered in the diagnostic notes. Many

diagnostic notes contain supplemental information, descriptions of various diagnostic tools or references to other parts

of the manual where information on the location and removal

of components may be obtained.

Circuit Diagram/Wire Harness Connector Table

When working through a flow chart, refer to the illustrations,

the associated circuit diagram and the wire harness connector table as necessary. The wire harness connector table for

each circuit diagram identifies the connector number, description, type and general location.

In order to perform most diagnostic routines, a Breakout Box

and a digital volt/ohm meter (DVOM) are required. See 2.5

BREAKOUT BOX: SPEEDOMETER.

To perform the circuit checks with any degree of efficiency, a

familiarity with the various wire connectors is also necessary.

f2207x8x

Maxi-Fuse

Figure 2-5. Remove Maxi-Fuse Cover

2-4 2004 Touring: Instruments

Page 5

HOME

1. Headlamp

2. Ignition

3. Lighting

4. Instruments

5. Brakes/Cruise

6. Radio Memory

7. Radio Power

8. Accessory

9. Battery

10. Brake Light Relay

11. P&A

Fuse Block

Cover

Spare Fuse

Holder

f2209x8x

f2203x8x

11

10

9

1

8

7

6

5

4

3

2

INITIAL DIAGNOSTICS

Diagnostic Tips

If Speedometer reads “BUS Er” with the ignition key

●

turned ON (engine stop switch at RUN with the engine

off), check data bus for an open or short to ground.

between data link connector [91A] terminal 3 and ICM

connector [10B] terminal 12 (carbureted models), ECM

connector [78B] terminal 5 (EFI models), TSSM connector [30B] terminal 3, Speedometer connector [39B] terminal 2 or tachometer (if equipped) connector [108B]

terminal 2.

Check for an open data test terminal between data link

●

connector [91A] terminal 3 and TSM/TSSM connector

[30B] terminal 3. With ignition key turned ON, serial data

bus voltage should be typically 0.6-0.8 volts. The range

of acceptable voltage is greater than 0 and less than 7.0

volts.

To identify intermittents, wiggle instrument and/or vehicle

●

harness while performing steps in the Diagnostic Check

charts.

Diagnostic Notes

The reference numbers below correlate with the circled numbers on the diagnostic check flow charts. See page 2-11.

1. Connect BREAKOUT BOX (Part No. HD-42682) and

INSTRUMENT HARNESS ADAPTERS (Part No. HD-

46601) between wire harness and speedometer.

All Speedometer diagnostic trouble codes are listed on page

2-6 in Ta bl e 2-2.

Other Codes

See 3.9 INITIAL DIAGNOSTIC CHECK: TSM/TSSM for any

diagnostic trouble codes related to the turn signal module

(TSM) or turn signal security module (TSSM).

See 4.4 INITIAL DIAGNOSTIC CHECK: ICM for any diagnos-

tic trouble codes related to the ignition control module (ICM).

See 5.5 INITIAL DIAGNOSTIC CHECK: EFI for any diagnostic trouble codes related to the electronic control module

(ECM).

Figure 2-6. Fuse Block (FLTR, FLHTC/U)

2004 Touring: Instruments 2-5

Page 6

HOME

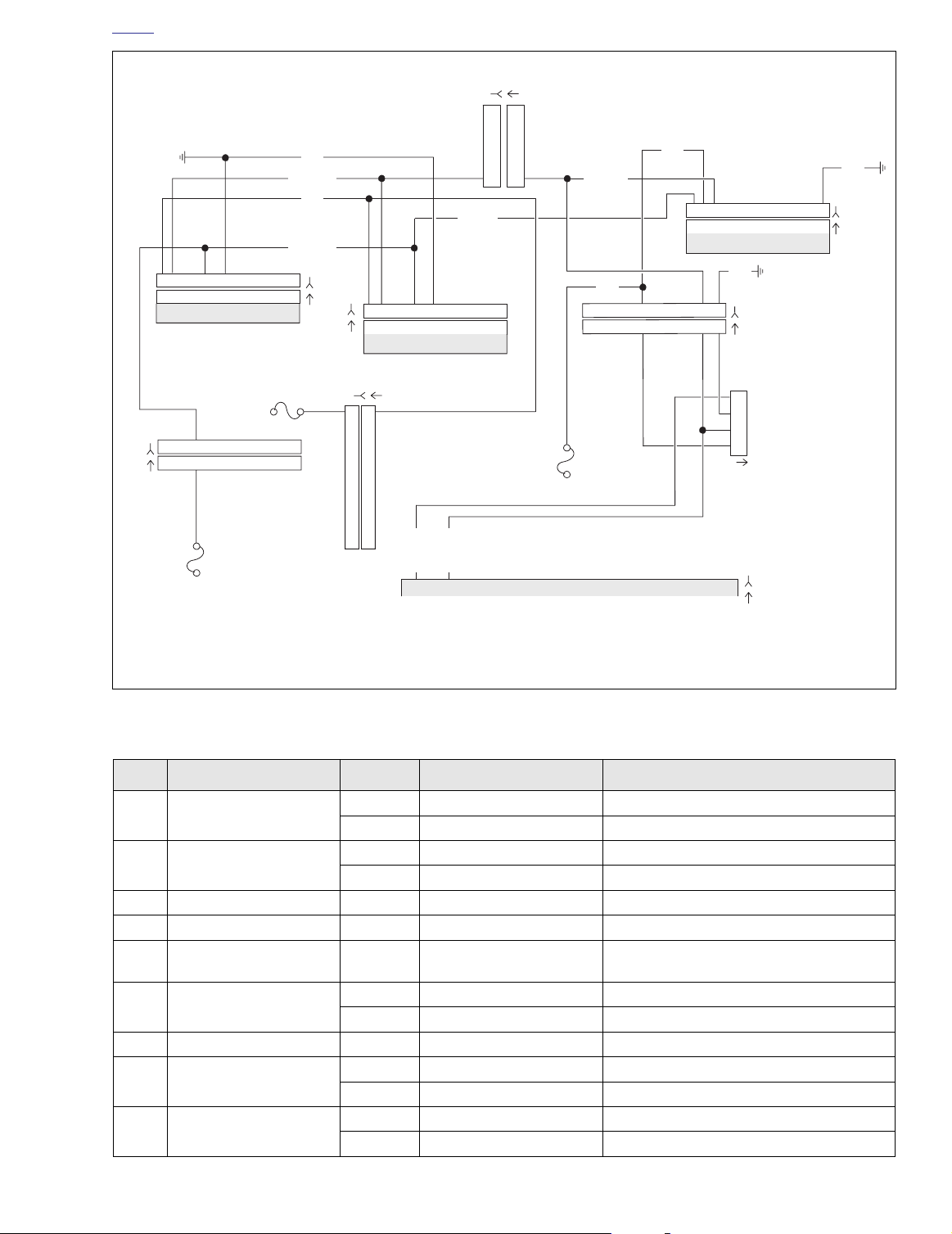

Table 2-1. Speedometer Function Chart-Loss Of Input

Terminal 5

(Constant)

●

Security lamp

glows dimly during 4-second

bulb check

Terminal 1 (IGN) Terminal 6 (ACC) Terminal 7 (GRD)

●

Will not “wow”

●

Tu rn signals still functional

Speedometer will indicate

●

vehicle speed (zero)

Ta chometer unaffected

●

●

Security lamp still functional

●

Check engine lamp and

●

Speedometer will

be non-functional

in accessory and

ignition modes

Security lamp still

●

performs 4-second bulb check in

ignition mode

●

Speedometer completely non-functional

●

Diagnostics absent

Terminal 8 and 11

(Reset Switch)

●

No reset switch

function

●

Will not “wow”

battery lamp non-functional

●

Diagnostics absent

Table 2-2. Speedometer/Tachometer Diagnostic Trouble Codes (DTC) Priority Chart

DTC

“BUS Er” 1 Serial data bus shorted low/open/high

U1300 2 Serial data bus shorted low

U1301 3 Serial data bus shorted open/high

U1016 4 Loss of ECM serial data 2.13 DTC U1016 Speedometer/tachometer

U1064 5 Loss of TSM/TSSM serial data 2.14 DTC U1064, U1255 Speedometer/tachometer

U1255 6

B1007 7 Ignition line overvoltage 2.11 DTC B1006, B1007 Speedometer/tachometer

B1006 8 Accessory line overvoltage 2.11 DTC B1006, B1007 Speedometer/tachometer

B1008 9 Reset switch closed 2.12 DTC B1008 Speedometer

B1004 10 Fuel level sending unit low 2.10 DTC B1004, B1005 Speedometer

B1005 11 Fuel level sending unit high/open 2.10 DTC B1004, B1005 Speedometer

PRIORITY FAULT CONDITION SOLUTION MODULE

Missing response from other module

(TSM/TSSM and/or ICM/ECM) at startup

2.15 DTC U1300, U1301

or “BUS ER”

2.15 DTC U1300, U1301

or “BUS ER”

2.15 DTC U1300, U1301

or “BUS ER”

2.14 DTC U1064, U1255 Speedometer/tachometer

Speedometer/tachometer

Speedometer/tachometer

Speedometer/tachometer

2-6 2004 Touring: Instruments

Page 7

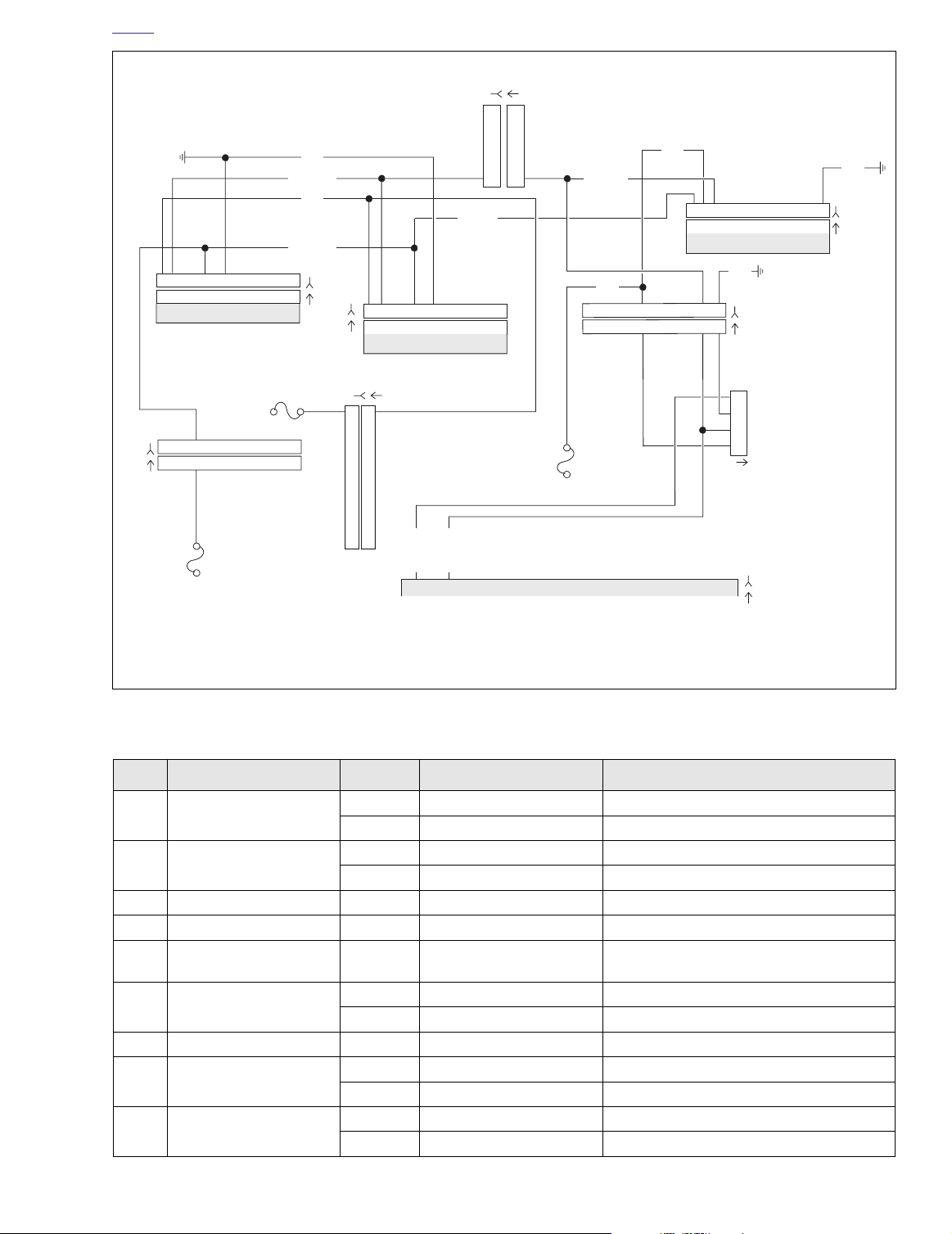

HOME

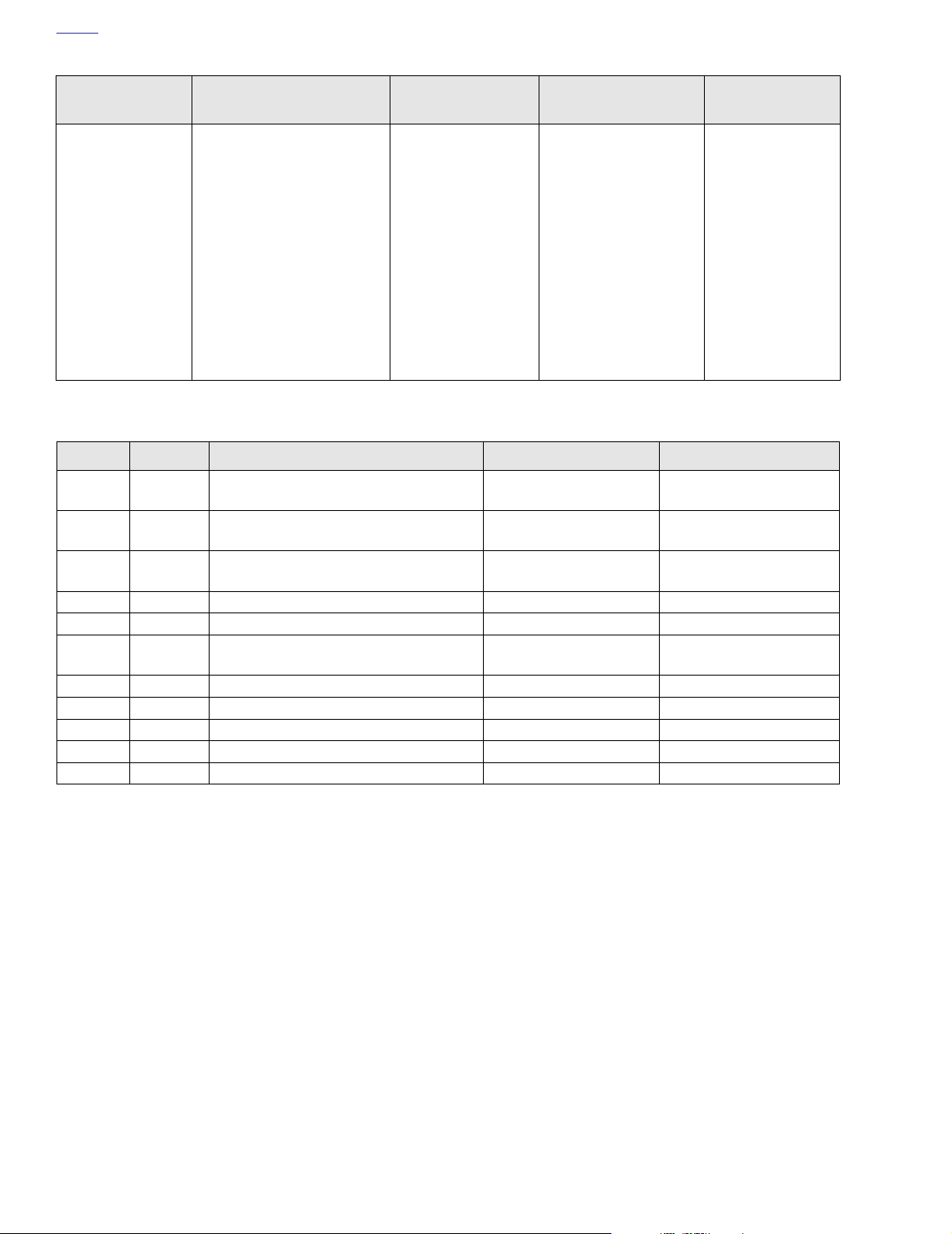

Ignition Control Module

Data Link

TSM/TSSM

LtGN/V

15A

Ignition

Fuse

GY

[8B]

[8A]

[91A]

LtGN/V

BK

LtGN/V

[39B]

[39A]

[10B]

[10A]

Speedometer

O

BK

Serial data

[108B]

[108A]

Tachometer

BN/GY

[156B] [156A]

[30B]

[30A]

15A

Accessory

Fuse

[1B] [1A]

Main to Interconnect

Harness

Ignition

Harness

Main to Interconnect

Harness

f2208z8x

15A

Battery

Fuse

[2A]

[2B]

Main to Interconnect

Harness

BK

GY

BN/GY

321654987121110

321654987121110

321654987121110

321654987121110

6

6

5

5

4

4

3

3

2

2

1

1

321654987121110

321654987121110

121110

987

65

4

32

1

1

6

5

4

32

121110

987

NO. DESCRIPTION TYPE LOCATION

[1] Main to Interconnect Harness 12-Place Deutsch (Black) Inner Fairing - Right Radio Support Bracket

[2] Main to Interconnect Harness 12-Place Deutsch (Gray) Inner Fairing - Right Fairing Support Brace

[8] Ignition Harness 12-Place Deutsch Under Right Side Cover

[10] Ignition Control Module 12-Place Deutsch Under Right Side Cover

[30] Turn Signal/Security Module 12-Place Deutsch

[39] Speedometer 12-Place Packard Inner Fairing (Back of Speedometer)

[91] Data Link 4-Place Deutsch Under Right Side Cover

[108] Tachometer 12-Place Packard Inner Fairing (Back of Tachometer)

[156] Main to Interconnect Harness 6-Place Deutsch Inner Fairing - Right Fairing Support Brace

321654987121110

321654987121110

123

123

6

6

101112 78945

101112 78945

Figure 2-7. Diagnostic Check: FLHT/C (Carbureted)

Table 2-3. Wire Harness Connectors in Figure 2-7.

Cavity in Crossmember at Rear of Battery Box

1

2

3

4

12

12

(Under Seat)

2004 Touring: Instruments 2-7

Page 8

HOME

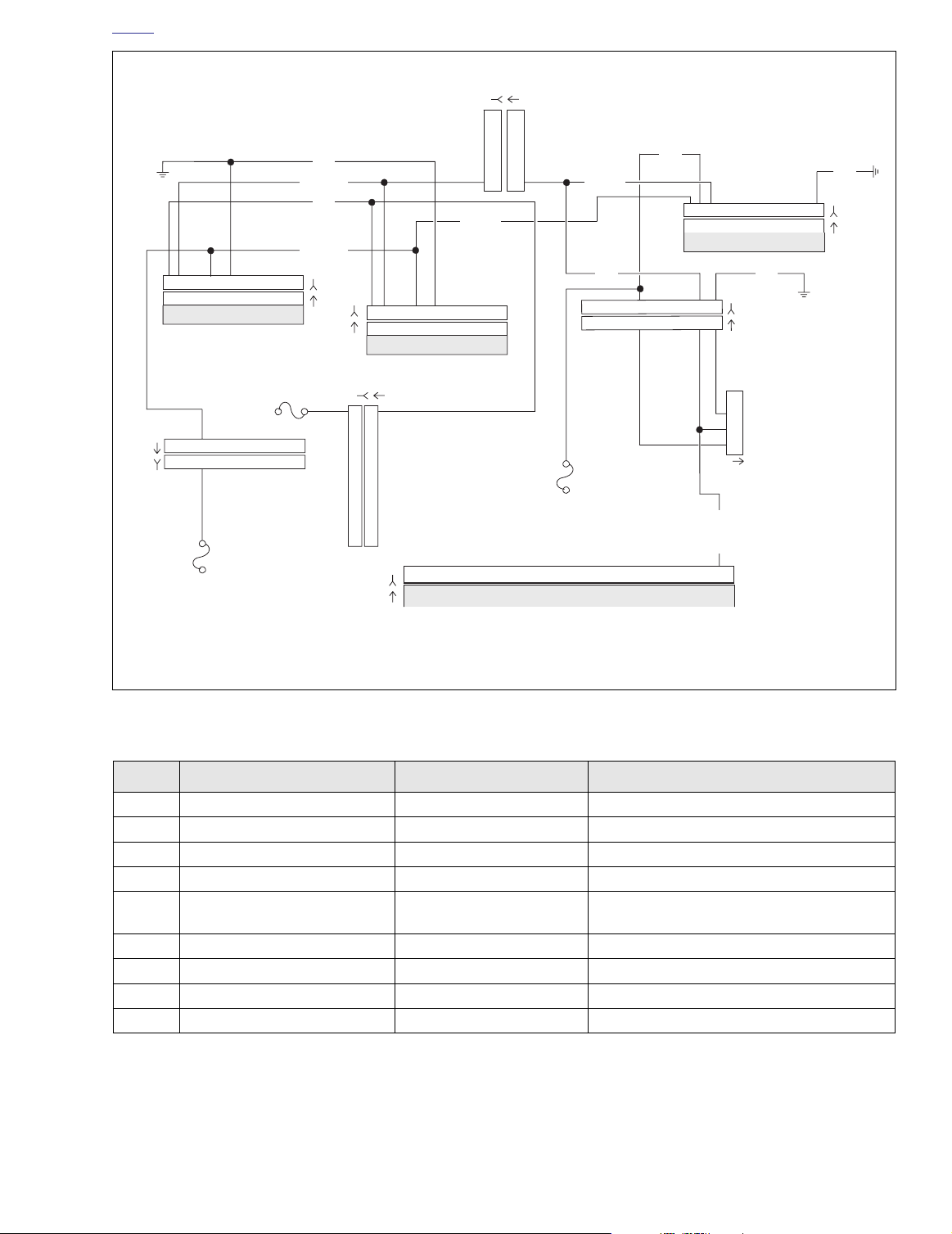

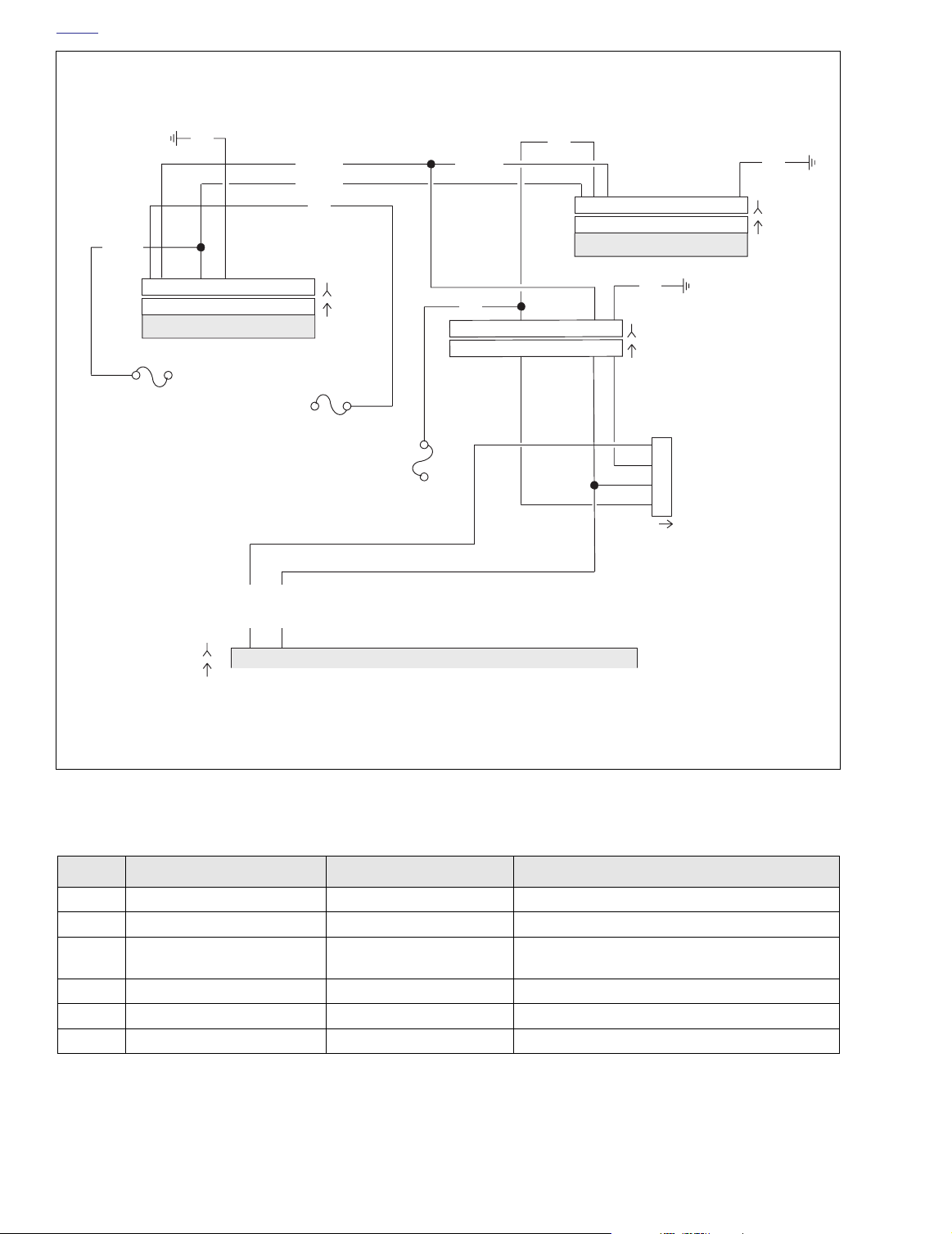

f2208y8x

BN/GY

BK

321654987121110

321654987121110

15A

Battery

Fuse

Speedometer

LtGN/V

BN/GY

O

15A

Accessory

Fuse

[39B]

[39A]

15A

Ignition

Fuse

LtGN/V

GY

21

21

GY

BK

321654987121110

321654987121110

[30B]

[30A]

TSM/TSSM

BK

[8B]

[8A]

[91A]

Ignition

Harness

1

2

3

4

Data Link

987

6

54

3

98

7

654

3

121110

121110

LtGN/V

[10B]

[10A]

Ignition Control Module

12

12

Serial data

Figure 2-8. Diagnostic Check: FLHR/S (Carbureted)

Table 2-4. Wire Harness Connectors in Figure 2-8.

NO.

[8] Ignition Harness 12-Place Deutsch Under Right Side Cover

[10] Ignition Control Module 12-Place Deutsch Under Right Side Cover

[30] Turn Signal/Security Module 12-Place Deutsch

[39] Speedometer 12-Place Packard Under Console (Back of Speedometer)

[91] Data Link 4-Place Deutsch Under Right Side Cover

DESCRIPTION TYPE LOCATION

Cavity in Crossmember at Rear of

Battery Box (Under Seat)

2-8 2004 Touring: Instruments

Page 9

HOME

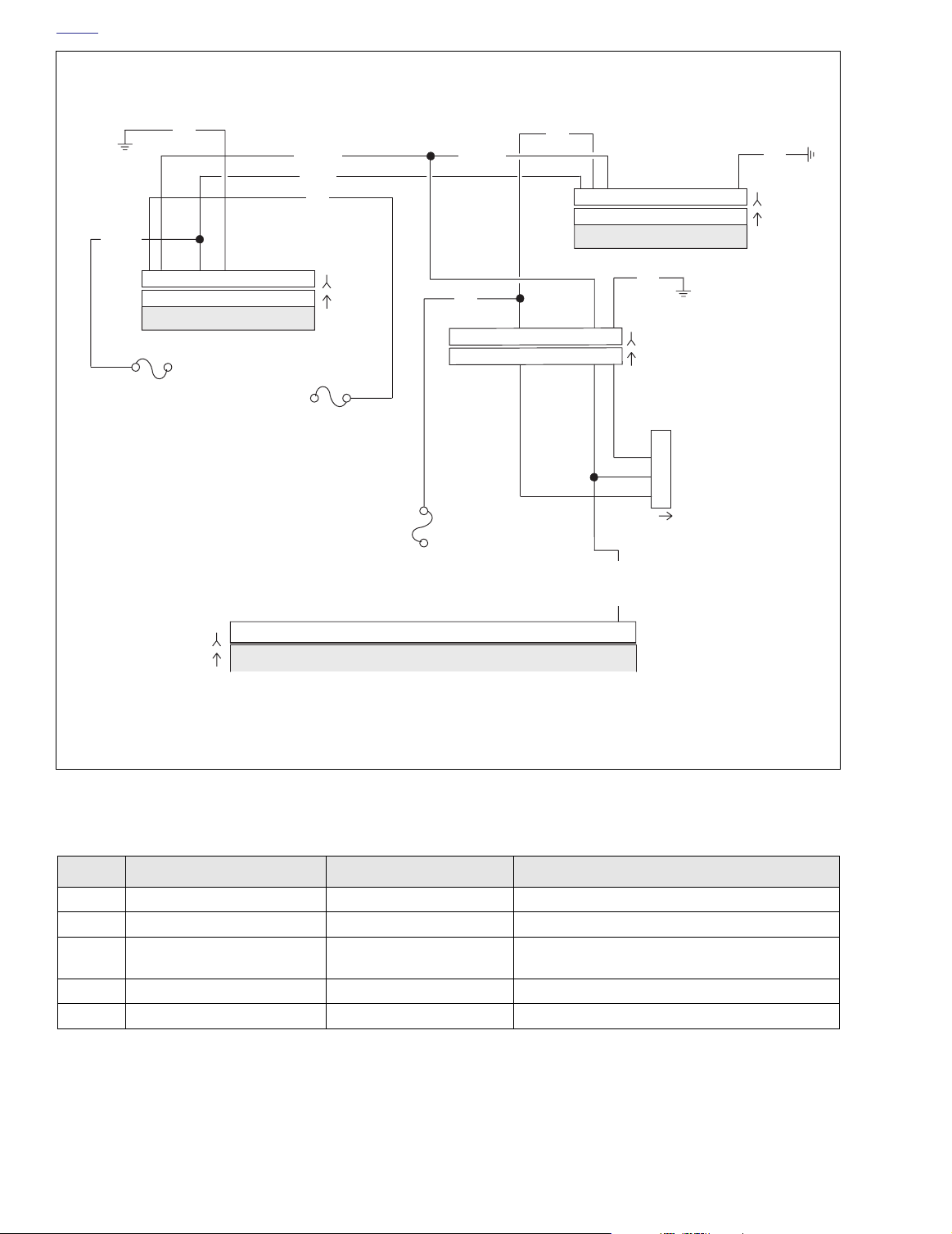

ECM

Data Link

TSM/TSSM

LtGN/V

15A

Ignition

Fuse

GY

[8B]

[8A]

[91A]

LtGN/V

BK

LtGN/V

[39B]

[39A]

[78B]

[78A]

Speedometer

O

BK

Serial data

[108B]

[108A]

Tachometer

BN/GY

[156B] [156A]

[30B]

[30A]

15A

Accessory

Fuse

[1B] [1A]

Main to Interconnect

Harness

Ignition

Harness

Main to Interconnect

Harness

f2208u8x

15A

Battery

Fuse

[2B]

[2A]

Main to Interconnect

Harness

LtGN/R

BK

BN/GY

GY

Flash pin

321654987121110

321654987121110

321654987121110

321654987121110

6

6

5

5

4

4

3

3

2

2

1

1

321654987121110

321654987121110

121110

987

65

4

32

1

1

65

4

32

121110

987

NO.

[1]

[2]

[8] Ignition Harness All 12-Place Deutsch Under Right Side Cover

[10] Ignition Control Module All 12-Place Deutsch Under Right Side Cover

[30]

[39] Speedometer

[91] Data Link All 4-Place Deutsch Under Right Side Cover

[108] Tachometer

[156]

123

123

321654987121110

321654987121110

6

6

101112 78945

101112 78945

51

DESCRIPTION MODEL TYPE LOCATION

Main to Interconnect

Harness

Main to Interconnect

Harness

Figure 2-9. Diagnostic Check: FLTR, FLHT/C/U (Fuel Injected)

Table 2-5. Wire Harness Connectors in Figure 2-9.

FLHT/C 12-Place Deutsch (Black) Inner Fairing - Right Radio Support Bracket

FLTR 12-Place Deutsch (Black) Inner Fairing - Below Radio (Left Side)

FLHT/C 12-Place Deutsch (Gray) Inner Fairing - Right Fairing Support Brace

FLTR 12-Place Deutsch (Gray) Inner Fairing - Below Radio (Left Side)

Tu rn Signal/Security

Module

All 12-Place Deutsch

FLHT/C 12-Place Packard Inner Fairing (Back of Speedometer)

FLTR 12-Place Packard Under Bezel (Back of Speedometer)

Cavity in Crossmember at Rear of

Battery Box (Under Seat)

FLHT/C 12-Place Packard Inner Fairing (Back of Tachometer)

FLTR 12-Place Packard Under Bezel (Back of Tachometer)

Main to Interconnect

Harness

FLHT/C 6-Place Deutsch Inner Fairing - Right Fairing Support Brace

FLTR 6-Place Deutsch Inner Fairing - Front of Right Fairing Bracket

2004 Touring: Instruments 2-9

1

2

3

4

Page 10

HOME

f2208t8x

BN/GY

321654987121110

321654987121110

Speedometer

15A

Battery

Fuse

BK

15A

Accessory

Fuse

LtGN/V

BN/GY

O

[39B]

[39A]

15A

Ignition

Fuse

LtGN/V

GY

3

21

321

GY

BK

321654987121110

321654987121110

[30B]

[30A]

TSM/TSSM

BK

98

7

65

4

98

7

65

4

121110

[8B]

Ignition

[8A]

Harness

121110

1

2

3

4

Data Link

[91A]

LtGN/V

LtGN/R

[78B]

[78A]

1

Flash pin

5

Serial data

ECM

Figure 2-10. Diagnostic Check: FLHR/C/S (Fuel Injected)

Table 2-6. Wire Harness Connectors in Figure 2-10.

NO.

[8] Ignition Harness 12-Place Deutsch Under Right Side Cover

[10] Ignition Control Module 12-Place Deutsch Under Right Side Cover

[30] Turn Signal/Security Module 12-Place Deutsch

[39] Speedometer 12-Place Mini-Deutsch Under Console (Back of Speedometer)

[78] Electronic Control Module 36-Place Packard Under Right Side Cover

[91] Data Link 4-Place Deutsch Under Right Side Cover

DESCRIPTION TYPE LOCATION

Cavity in Crossmember at Rear of

Battery Box (Under Seat)

2-10 2004 Touring: Instruments

Page 11

HOME

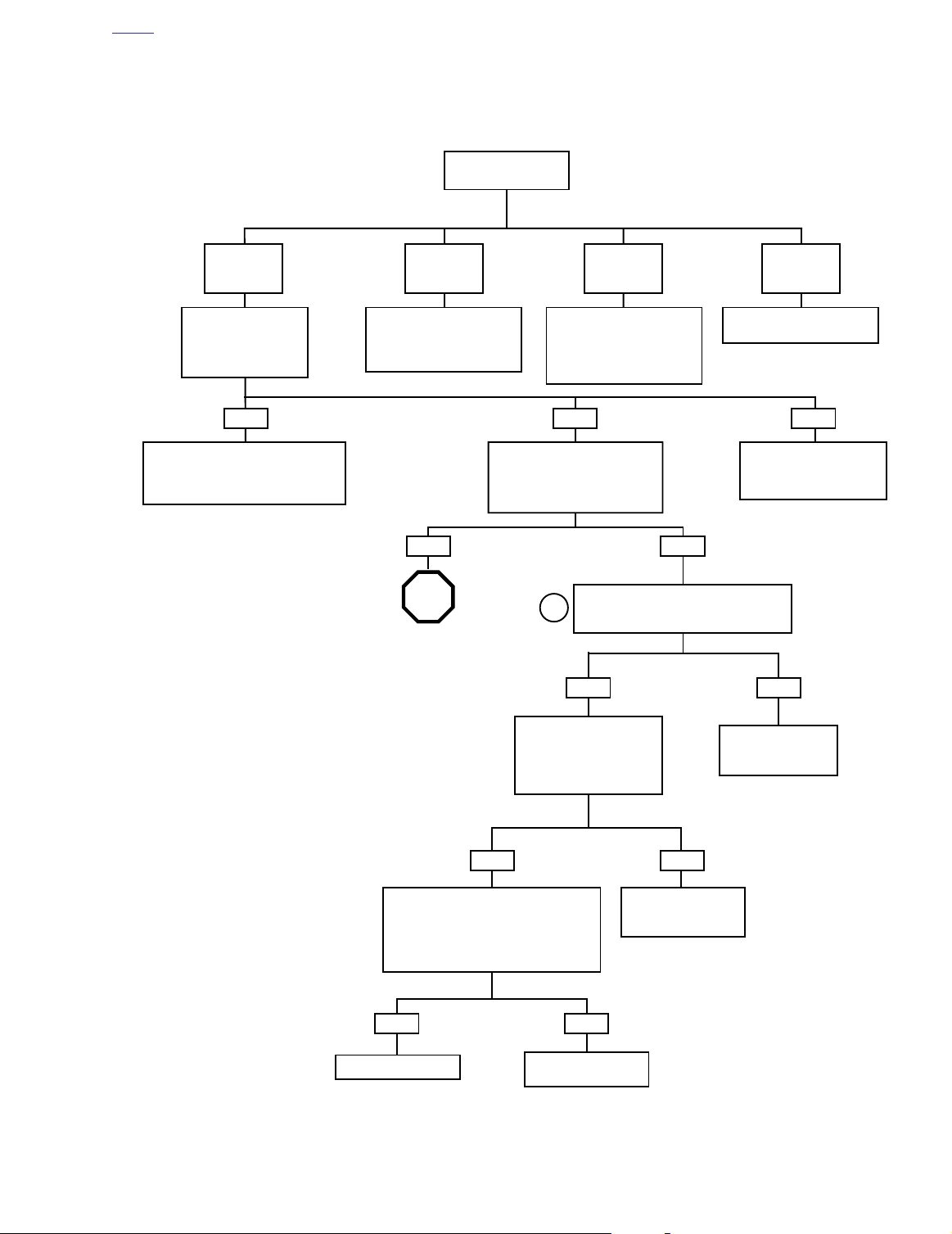

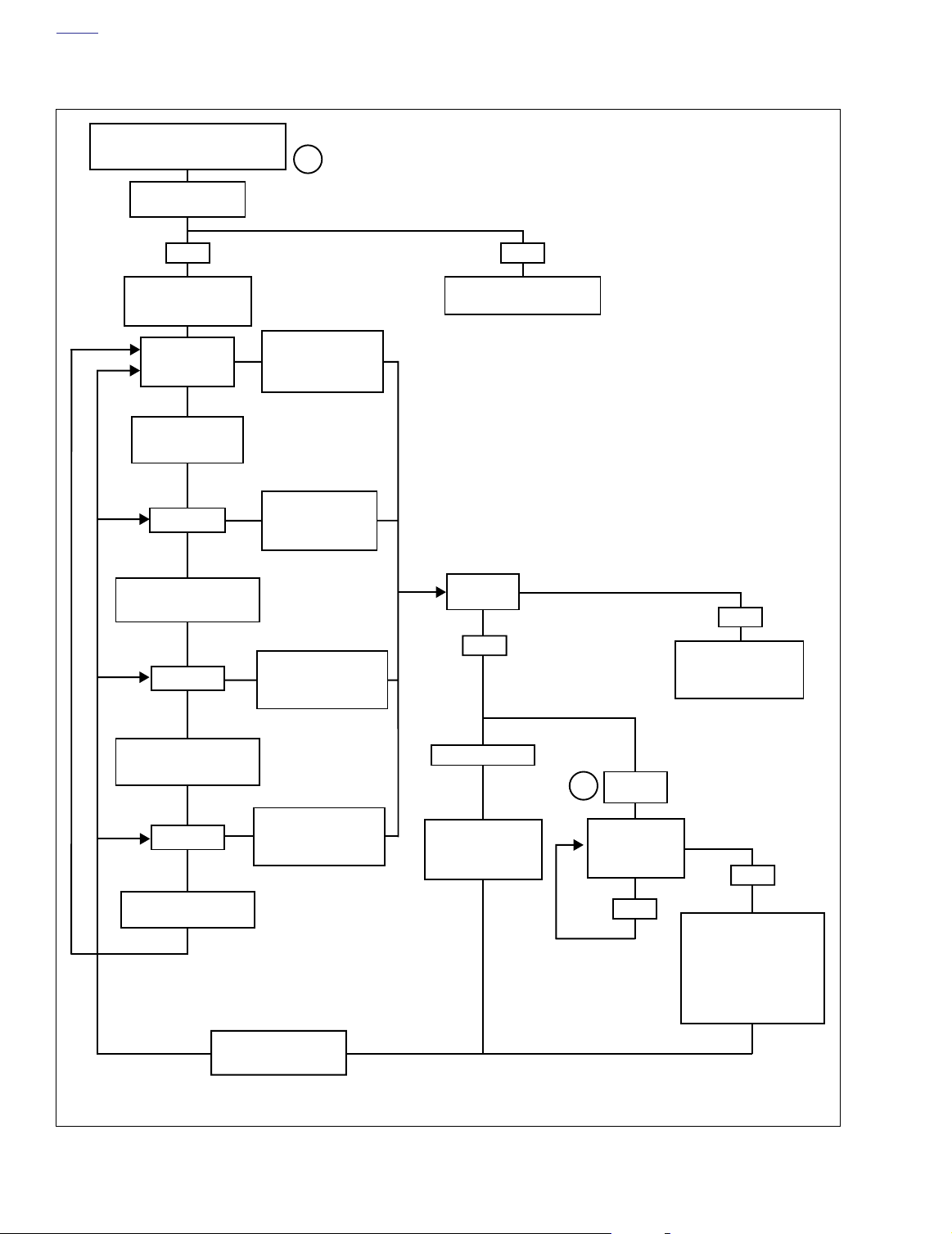

Diagnostic Check (Part 1 of 2)

Does engine

start?

YES.

Starts and

runs.

Check for diagnostic

trouble codes. See 2.3

SPEEDOMETER SELF

DIAGNOSTICS

Codes found?

YES

Refer to applicable diagnostic trouble

code priority chart. All diagnostic codes

are listed on page 2-6 in Table 2-2.

Codes are listed by priority.

YES.

Starts, then

stalls.

For carbureted models, see

4.10 STARTS, THEN STALLS.

For EFI models, see 5.12

STARTS, THEN STALLS.

Unable to enter diagnostic mode.

With ignition switch OFF, press and

release odometer reset switch.

Does odometer display appear with

YES

STOP

Go to Diagnostic

Check (Part 2 of 2).

NO.

Cranks, but

will not start.

For carbureted models, see 4.9

ENGINE CRANKS, BUT WILL

NOT START. For EFI models,

see 5.10 ENGINE CRANKS,

BUT WILL NOT START.

NO

display backlighting?

Check for continuity to ground on terminal 7

of speedometer. Wiggle harness during con-

1

Check for battery voltage at

terminal 5 of speedometer

while wiggling harness. Bat-

tery voltage continuously

tinuity check. Continuity present?

YES NO

present?

NO

Locate and repair open

NO.

Engine will not

crank.

See 1.2 STARTING SYSTEM

DIAGNOSIS.

NO

No codes displayed. For

symptoms that may not set

diagnostic trouble codes,

refer to Table 2-1.

between terminal 7

and ground.

YES NO

With connector [39] disconnected from

speedometer, check continuity (with ignition

switch OFF) between terminals 8 and 11 on

Breakout Box. Continuity present when

speedometer reset switch is depressed and

Replace speedometer.

infinity when released?

Locate and repair open

between terminal 5 and

NOYES

Replace speedometer

reset switch.

battery fuse.

2004 Touring: Instruments 2-11

Page 12

HOME

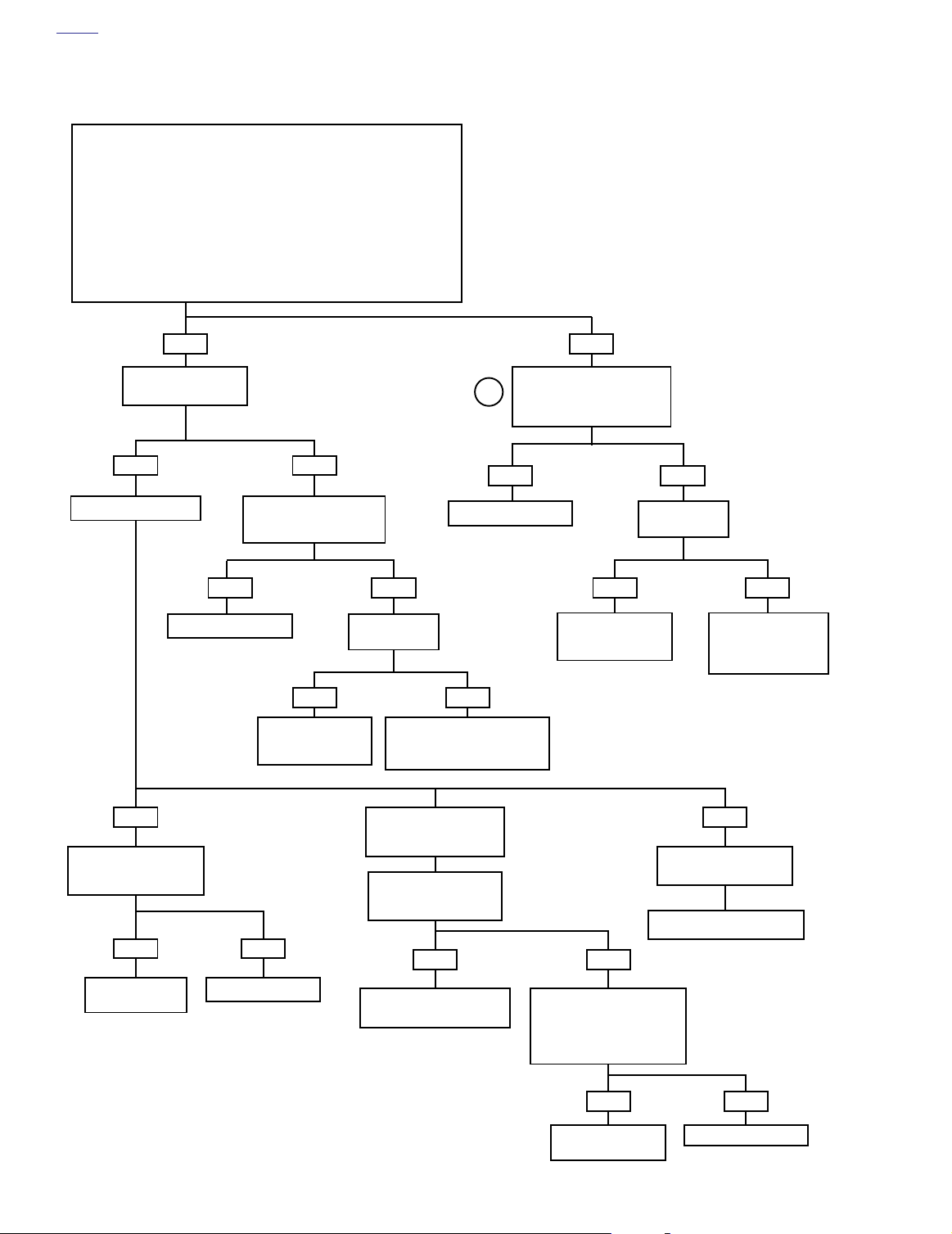

Diagnostic Check (Part 2 of 2)

Perform “wow” test. See 2.3 SPEEDOMETER SELF DIAGNOSTICS.

1) backlight should illuminate

2) needle should sweep its full range of motion

3) LED’s that should illuminate:

• check engine

• battery

• security (all models)

4) LED’s that may illuminate:

• low fuel (EFI models)

• cruise (although not cruise equipped on some models)

Is problem intermittent?

Continued from Diagnostic Check (Part 1 of 2).

The following features should be functional

Are all features functional?

YES

Turn key to ACC. Is

backlight present?

YES

Check for battery voltage at

breakout box terminal 6.

Battery voltage present?

YES

NO

NO

NO

With ignition switch turned to

IGN, check for battery voltage

1

at terminal 1 of Breakout Box.

Battery voltage present?

YES NO

Replace Speedometer.

Is instrument

fuse blown?

YES NO

Replace speedometer.

YES

Repeat Diagnostic Check

while wiggling harnesses.

Intermittent present?

YES NO

Locate and repair

intermittent.

Locate and repair

source of fault.

Replace fuse.

No trouble found.

YES

Is accessory fuse

blown?

Locate and repair open on O/W

wire between termin al 6 of con-

nector [39] and accessory fuse.

Intermittent vehicle speed

Remove and inspect vehi-

YES

indication.

cle speed sensor. Debris

present?

YES

Remove debris. Reinstall

vehicle speed sensor.

NO

Locate and repair

source of fault.

Replace fuse.

Tachometer Inoperative

See Test 2.4 (Part 1 of 2).

NO

Check for damaged wiring/

loose connection between

vehicle speed sensor and ICM/

ECM. Is wiring damage/loose

connection present?

Locate and repair open

between terminal 1 of

connector [39] and

instrument fuse.

NO

(no engine speed).

2-12 2004 Touring: Instruments

YES NO

source of fault.

Replace Speedometer.Locate and repair

Page 13

HOME

0

10

30

20

50

40

110

120

60

70

80

90

100

0

20

30

40

50

10

MPH

H

A

R

L

E

Y

-

D

A

V

I

D

S

O

N

C

E

R

T

I

F

I

E

D

RPM

x100

H

A

R

L

E

Y

-

D

A

V

I

D

S

O

N

f2160x8x

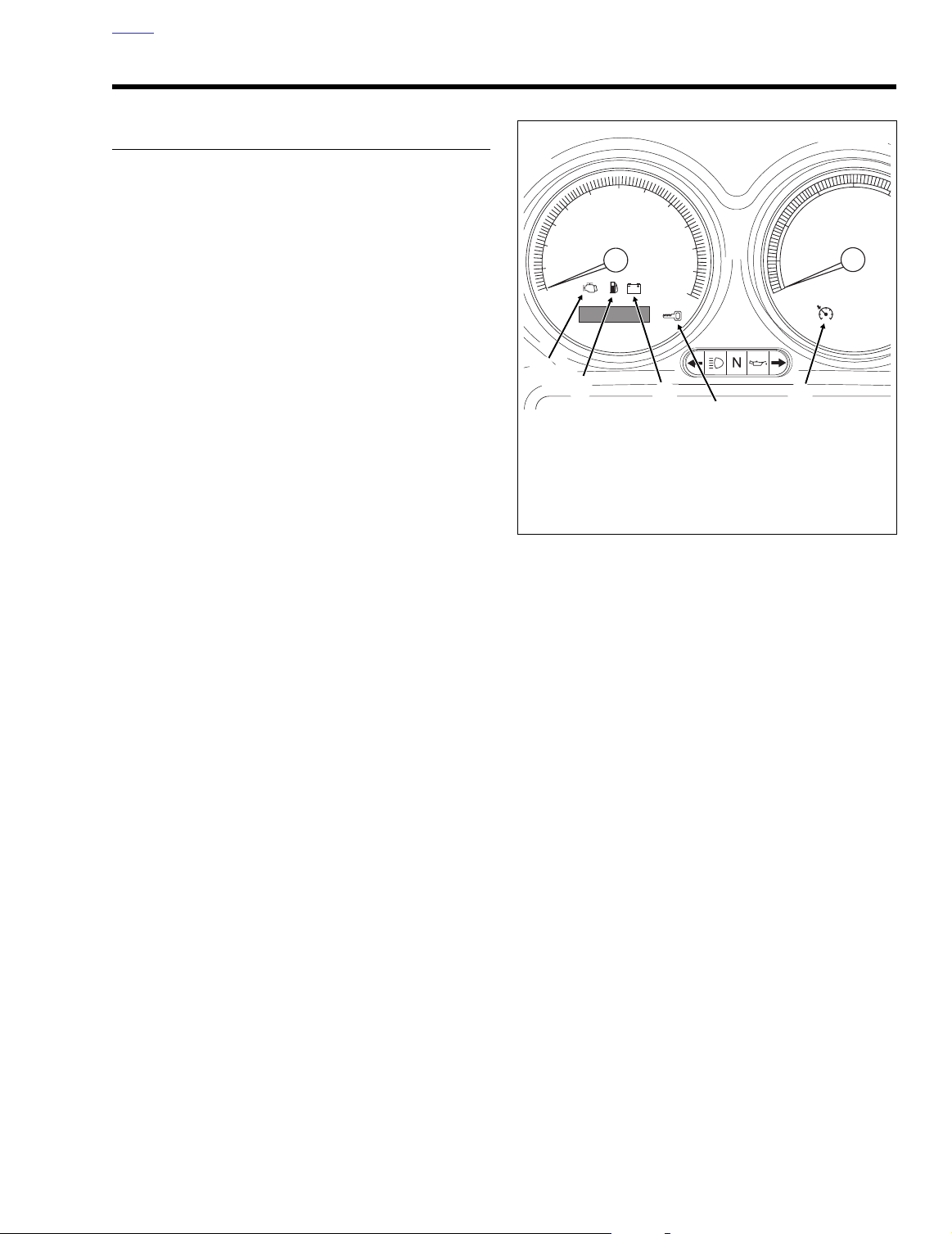

1. Check Engine

2. Low Fuel

3. Battery

4. Security

5. Cruise (Where Applicable)

1

2

3

4

5

f1240x2x

SPEEDOMETER SELF DIAGNOSTICS 2.3

GENERAL

The speedometer is capable of displaying and clearing

speedometer, tachometer, TSM/TSSM, and ICM/ECM diagnostic trouble codes (diagnostic mode).

DIAGNOSTICS

Diagnostic Tips

● For a quick check of speedometer function, a “wow” test

can be performed. Press and hold odometer reset switch

then turn ignition switch ON. Release reset switch. Background lighting should illuminate, speedometer needle

should sweep its full range of motion, and indicator

lamps [battery, security, low fuel (EFI models) check

engine and cruise should illuminate. Some lamps may

illuminate even though they do not apply to the vehicle.

For example, the cruise lamp may illuminate although

this feature does not apply to some models.

● If instrument module fails “wow” test, check for battery,

ground, ignition, speedometer reset switch and accessory to speedometer. If any feature in the speedometer is

non-functional, see 2.2 INITIAL DIAGNOSTIC CHECK:

SPEEDOMETER.

Diagnostic Notes

Use of speedometer self diagnostics assumes that DIGITAL

TECHNICIAN (Part No. HD-44750) is not available.

The reference numbers below correlate with the circled numbers in the Speedometer Self Diagnostics (chart)

1. To exit diagnostic mode, turn ignition switch OFF.

2. To clear diagnostic trouble codes (DTCs) for selected

module, press speedometer reset switch for more than 5

seconds when code is displayed. This procedure will

clear all diagnostic trouble codes for selected module.

Figure 2-11. Icons

Figure 2-12. Ignition Switch (FLTR, FLHT/C/U)

2004 Touring: Instruments 2-13

Page 14

HOME

Speedometer Self Diagnostics (chart)

While holding odometer reset switch in,

turn ignition switch to IGN. Make sure

Run/Stop switch is in RUN position.

Release reset switch.

Does “diag” appear?

YES NO

1

Press and release reset

switch.

“PSSPT” appears.

”P” flashing.

To choose TSM/

TSSM, press and

release reset switch.

”S” flashing.

To choose Speedometer,

press and release reset

switch.

”SP” flashing.

To choose Tachometer,

press and release reset

switch.

”T” flashing.

To choose ICM, press and

release reset switch.

To display DTCs for the

ECM/ICM, press and

hold reset switch for

more than 5 seconds.

To display DTCs for

TSM/TSSM, press and

hold reset switch for

more than 5 seconds.

To display DTCs for

speedometer, press and

hold reset switch for more

than 5 seconds.

To display DTCs for

tachometer, press and

hold reset switch for more

than 5 seconds.

See 2.2 INITIAL DIAGNOSTIC

CHECK: SPEEDOMETER.

Device

response?

YES

“none” displayed.

Press and release

reset switch. Part num-

ber of module will be

displayed.

DTC

2

displayed.

Press and release

reset switch.

Are more DTCs

displayed?

YES

NO

“no rsp” displayed.*

Tachometer malfunction.

2.4 SPEEDOMETER/

See

TACHOMETER.

* Models not equipped

with a tachometer will

display “no rsp” normally.

NO

“end” displayed.

To clear all DTCs for

selected module hold reset

switch for more than 5 seconds. If DTCs are not to be

cleared, Press and release

reset switch. Part number of

module will be displayed.

Press and release reset

switch again to continue to

next module.

2-14 2004 Touring: Instruments

Figure 2-13. Speedometer Self Diagnostics

Page 15

HOME

0

10

30

20

50

40

110

120

60

70

80

90

100

0

20

30

40

50

10

MPH

H

A

R

L

E

Y

-

D

A

V

I

D

S

O

N

C

E

R

T

I

F

I

E

D

RPM

x100

H

A

R

L

E

Y

-

D

A

V

I

D

S

O

N

f2160x8x

1. Check Engine

2. Low Fuel

3. Battery

4. Security

5. Cruise (Where Applicable)

1

2

3

4

5

SPEEDOMETER/TACHOMETER 2.4

GENERAL

NOTE

Some icons may illuminate during “wow” test though the icon

has no functionality on that vehicle.

The speedometer consists of a speedometer display and several icons. The icons include: check engine, security, battery,

and low fuel (EFI only).

Reset Switch

See Figure 2-14. Pressing the odometer reset switch pro-

vides the following capabilities:

● Change the odometer display between mileage, trip A

and trip B values (press and immediately release).

● Reset an individual trip odometer (press and hold 2-3

seconds).

● Gain access to the diagnostic mode, clear diagnostic

trouble codes and exit diagnostic mode. See 2.3

SPEEDOMETER SELF DIAGNOSTICS.

● Display odometer while key is OFF. Press and hold reset

switch while key is OFF and odometer mileage will be

displayed.

● On models with dual scale speedometers, toggle

between miles/kilometers on odometer and trip odometer display. To toggle display, turn key ON. Press and

hold reset switch while odometer is displayed. Release

switch when change is noted. (If reset switch is held

while trip odometer is displayed, trip odometer will reset.)

Figure 2-14. Icons (FLHT/C/U)

2004 Touring: Instruments 2-15

Page 16

HOME

SPEEDOMETER THEORY OF OPERATION

The speedometer consists of a vehicle speed sensor, ICM/

ECM, odometer reset switch and the speedometer. The vehicle speed sensor is mounted on the right side of transmission

case below the starter. The sensor circuitry is that of a HallEffect sensor that is triggered by the gear teeth of 4th gear on

the transmission mainshaft.

The output from the sensor is a series of pulses that are interpreted by ICM/ECM circuitry, converted into serial data inside

the ICM/ECM then sent to the speedometer to control the

position of the speedometer needle and the liquid crystal

(LCD) odometer display. The vehicle speed serial data is also

transmitted to the TSM/TSSM for turn signal cancellation.

The odometer mileage is permanently stored and will not be

lost when electrical power is turned off or disconnected. The

odometer reset switch allows switching between the odometer, trip odometer A and trip odometer B displays.

To zero the trip odometer, have the desired trip odometer display visible, press and keep the reset switch depressed. The

trip odometer mileage will be displayed for 2-3 seconds and

then the trip mileage will return to zero miles.

TACHOMETER THEORY OF OPERATION

The tachometer receives serial data from the ICM/ECM. The

tachometer interprets the serial data and converts it into

tachometer needle movement.

DIAGNOSTICS

Diagnostic Notes

The reference numbers below correlate with circled numbers

on the tachometer diagnostic flow chart.

1. If problems are intermittent, wiggle harness while performing tests.

2. Connect BREAKOUT BOX (Part No. HD-42682) and

INSTRUMENT HARNESS ADAPTERS (Part No. HD-

46601) between wire harness and tachometer.

3. Use HARNESS CONNECTOR TEST KIT (Part No. HD-

41404), black pin probe and patch cord.

The odometer can display six numbers to indicate a maximum of 999999 miles/kilometers. The trip odometers can display six numbers with a tenth of a mile accuracy for a

maximum of 99999.9 miles/kilometers.

Job/Time Code Values

Dealership technicians filing warranty claims should use the

job/time code values in Digital Technician.

2-16 2004 Touring: Instruments

Page 17

HOME

Test 2.4 (Part 1 of 2)

TACHOMETER INOPERATIVE

Perform “wow” test. See 2.3 SPEEDOMETER SELF

The following features should be functional

1) backlight should illuminate

2) needle should sweep its full range of motion

3) LED’s may illuminate:

cruise (although not cruise equipped on some

models)

pursuit (although may not be a police vehicle)

DIAGNOSTICS.

Are all features functional?

YES

Is problem intermittent?

YES

Repeat Diagnostic

Check while wiggling

harnesses.

NO

No trouble found.

NO

Check for battery voltage at terminal 1

of breakout box. Is battery voltage

present?

Is instrument

YES NO

NO

fuse blown?

Check for continuity between

breakout box terminal 2 and

terminal 7 of connector [20].

YES

STOP

Go to Test 2.4 (Part

2 of 2).

YES

Is continuity present?

Locate and repair open

Locate and repair

NO

on LGN/V wire.

source of fault.

Replace fuse.

Locate and repair

open in orange wire

between terminal 1 of

connector [108] and

instrument fuse.

2004 Touring: Instruments 2-17

Page 18

HOME

Test 2.4 (Part 2 of 2)

TACHOMETER INOPERATIVE

Continued from Test 2.4 (Part 1 of 2).

Check for continuity to ground on breakout box

terminal 7. Wiggle harness during continuity

check. Is continuity present?

Check for battery voltage at

Is battery voltage present?

YES

Replace tachometer.

Check for battery voltage

at breakout box terminal 5

while wiggling harness.

continuously present?

YES

breakout box terminal 6.

Locate and repair open on O/W

wire between terminal 6 of con-

nector [108] and accessory fuse.

YES

Is battery voltage

NO

NO

Locate and repair open

on BN/GY wire between

terminal 5 of connector

[108] and battery fuse.

NO

Locate and repair open

on BK wire between ter-

minal 7 of connector

[108] and ground.

2-18 2004 Touring: Instruments

Page 19

HOME

10086

f2001x8x

f1998x9x

BREAKOUT BOX: SPEEDOMETER 2.5

GENERAL

The BREAKOUT BOX (Part No. HD-42682) and INSTRUMENT HARNESS ADAPTERS (Part No. HD-46601) connect

to speedometer connector [39]. Used in conjunction with a

DVOM, it allows circuit diagnosis of wiring harness and connections without having to probe with sharp objects

NOTE

See wiring diagrams for speedometer terminal functions.

INSTALLATION

1. See Figure 2-16. Bend back the external latches slightly

and remove connector [39B].

2. Connect Instrument Harness Adapters to connectors

[39A] and [39B].

3. Attach connectors from Breakout Box to Instrument Harness Adapters.

Figure 2-16. Speedometer Connector [39]

REMOVAL

1. Detach connectors from Breakout Box to Instrument Harness Adapters.

2. See Figure 2-15. Detach Instrument Harness Adapters

from connectors [39A] and [39B].

3. Install connector [39B] to speedometer.

Figure 2-17. Breakout Box (Part No. HD-42682)

Figure 2-15. Instrument Harness Adapters

(Part No. HD-46601)

2004 Touring: Instruments 2-19

Page 20

HOME

SPEEDOMETER PERFORMANCE CHECK 2.6

GENERAL

See Figure 2-18. Use the SPEEDOMETER TESTER (Part

No. HD-41354) for speedometer diagnostics. These diagnostics may include:

● Checking speedometer operation.

● Te sting speedometer needle sweeping action.

The tester generates a simulated vehicle speed sensor signal

which is sent to the ICM/ECM. The ICM/ECM interprets the

signal then sends a message to the speedometer. This signal

aids in determining whether speedometer replacement is

necessary.

● Verifies serial data message to speedometer.

NOTES

● Use the following procedures in conjunction with the

manual supplied with the speedometer tester.

● Te st results may be inaccurate if tester battery is low.

TESTING

NOTE

The SPEEDOMETER TESTER (Part No. HD-41354) cannot

be used to verify the calibration of a speedometer and it will

not verify the speedometer’s function to support legal proceedings. It’s purpose is to verify speedometer function when

performing service diagnosis or repair. It can also assist in

determining if speedometer replacement is necessary.

hd41354

Figure 2-18. Speedometer Tester (HD-41354)

Speedometer Operation Test

1. See Figure 2-19. Disconnect the 3-place vehicle speed

sensor connector [65] under right side cover (behind

electrical bracket). Attach speedometer tester connector.

2. Place speedometer tester power switch in the ON position. Place signal switch in the OUT position.

3. Turn vehicle ignition switch ON and Run/Off switch to

Run.

4. When speedometer tester displays “P_ _ _ _1”:

a. Press 1 and ENTER on the tester keypad.

b. Enter a frequency from Ta ble 2-7. Note that different

markets use different frequencies.

c. Verify that speedometer display reads the corre-

sponding speed. To change the test frequency,

press CLEAR to cancel and enter the new frequency. Press ENTER to begin and reverify.

NOTE

The speedometer should be accurate within -0 to +4 MPH (0

to +6.5 KPH).

Table 2-7. Speedometer Test Frequency in Hertz (All Models Except Police)

MARKET 20 MPH 40 MPH 60 MPH 80 MPH 30 KPH 60 KPH 100 KPH 130 KPH

DOMESTIC 442 885 1327 1770 - - - -

CANADA ----41382513751788

HDI ----41382513751788

GREAT BRITAIN 442 885 1327 1770 413 825 1375 1788

JAPAN ----44889614931941

Table 2-8. Speedometer Test Frequency in Hertz (Police)

MARKET 20 MPH 40 MPH 60 MPH 80 MPH 30 KPH 60 KPH 100 KPH 130 KPH

DOMESTIC 462 924 1386 1848 ----

CANADA ----43186114351866

HDI ----43186114351866

GREAT BRITAIN 462 924 1386 1848 431 861 1435 1866

JAPAN ----43186114351866

2-20 2004 Touring: Instruments

Page 21

HOME

Deutsch Socket

Housings

Deutsch Pin

Housing

f1437a8x

Tester Connector

Speedometer Sensor

Connector [65]

5087

See Figure 2-20. Fabricate a test harness using the following

parts. This harness can also be used to test the tachometer.

● Tw o Deutsch 3-place socket housings (Part No. 72113-

94BK) and six socket terminals (Part No. 72191-94).

● Deutsch 3-place pin housing (Part No. 72103-94BK) and

three pin terminals (Part No. 72190-94).

● Six lengths of 18 gauge wire, each 6.0 in. (15 cm) long.

Before attempting the actual vehicle speed sensor check, two

system checks must be made. Install the test harness at the

speedometer sensor connector.

● Te st for voltage to sensor by checking for 8-12 volts on

red wire in connector [65B].

● Then check for continuity to ground on black wire in con-

nector [65B].

Figure 2-19. Mate Sensor and Tester Connectors

Speedometer Needle Sweep Test

The tester’s sweep function moves the speedometer needle

through the full range of movement. This allows for testing the

smoothness of operation and checking for hesitancy or a

stuck needle.

1. See Figure 2-19. Disconnect vehicle speed sensor connector. Attach speedometer tester connector to speedometer sensor connector.

2. Place speedometer tester power switch in the ON position. Place signal switch in the OUT position.

3. Turn vehicle ignition switch ON.

4. Begin test by pressing 0 on the tester keypad and then

pressing ENTER. The tester will scan for two seconds,

then the tester will put out a 1 Hz signal.

5. Select a test range.

a. Press 2 to select LO range (1-20 Hz).

b. Press 5 to select CEN range (21-999 Hz).

c. Press 8 to select HI range (1000-20,000 Hz).

6. After selecting a range, use the corresponding arrow

keys to accelerate through the range. As you move

through the speed range, check for smooth needle

movement.

a. If testing LO range, press 1 or 3.

b. If testing CEN range, press 4 or 6.

c. If testing HI range, press 7 or 9.

1. Raise rear wheel off floor.

2. Install the test harness between the vehicle speed sensor connectors.

3. Place speedometer tester power switch in the ON position. Place signal switch in the IN position.

4. Plug the speedometer tester into the test harness. Turn

vehicle ignition switch ON.

5. Press ENTER on the tester keypad.

6. Rapidly rotate rear wheel of motorcycle.

a. If reading on speedometer tester changes as wheel

is rotated, speedometer sensor is OK.

b. If reading does not change on carbureted models,

see 4.18 DTC P0501, P0502. If reading does not

change on EFI models, see 5.25 DTC P0501,

P0502.

Vehicle Speed Sensor Test

If the speedometer is inoperative, but backlighting and odometer work, the vehicle speed sensor may not be working.

Figure 2-20. Test Harness

2004 Touring: Instruments 2-21

Page 22

HOME

FUEL GAUGE OPERATION 2.7

THEORY OF OPERATION

With ignition switch ON, the fuel gauge is connected to +12

volts. Current flows through the gauge and variable resistor in

the fuel gauge sending unit to ground. The sending unit float

controls the amount of resistance in the variable resistor.

Inoperative gauges may be caused by three circumstances.

● Sender or fuel gauge not grounded.

● Malfunction in sender or fuel gauge.

● Broken or disconnected wire from ignition switch to fuel

gauge.

Use the FUEL GAUGE AND SENDER TEST to test suspect

components.

FUEL GAUGE AND SENDER TEST

NOTE

Always refer to the applicable wiring diagram (at the rear of

this manual) when troubleshooting instruments or gauges.

1. Remove gauge. Ground Y/W wire of fuel gauge sender

located at bottom of gauge. Turn ignition switch ON.

a. Fuel gauge must indicate FULL. If gauge indicated

FULL, gauge is functioning correctly. Proceed to

step 2.

2. Set MULTI-METER (Part No. HD-35500) to RXI scale to

measure the resistance of the sending unit. Place one

probe on Y/W and the other probe on a good ground.

FLHT/C/U, FLTR:

If fuel tank is full, the reading should be 7-14 ohms. An

empty tank should have a 74-95 ohm resistance. A half

full tank will be approximately 30-38 ohms.

FLHR/C/S:

If fuel tank is full, the reading should be 27-40 ohms. An

empty tank should have a 240-264 ohm resistance. A

half full tank will be approximately 97-118 ohms.

ALL MODELS:

If a very high resistance or infinity is indicated on the

meter, the sender may be “open” or not grounded. Check

that sender and fuel tank are grounded by placing one

probe of Multi-Meter on sender flange and the other

probe on crankcase. Meter must indicate one ohm or

less. Replace sender if one ohm or less was present. If a

higher resistance is present, check for poor connection

on ground wire.

3. Check voltage to O/W (+) and BK (-) wire of fuel gauge

connector [117] if gauge did not indicate FULL.

a. Correct reading is equivalent to battery voltage.

b. If battery voltage is not present check for broken or

disconnected wire. Replace gauge if wiring problem

is not found.

b. If gauge did not indicate FULL, proceed to step 3.

2-22 2004 Touring: Instruments

Page 23

HOME

N

f1346x2x

Rubber

Boot

Bulb

Housing

Paddle

Lense

Indicator Lamp

Connector [21]

INDICATOR LAMPS: FLTR, FLHT/C/U 2.8

GENERAL

See Figure 2-21. All models except FLHR/C/S are equipped

with incandescent indicator lamps which may be replaced

individually. See the Touring Models Service Manual for lamp

replacement procedure. See DIAGNOSTICS which follows

for troubleshooting procedures.

Table 2-9. Indicator Lamp Connector [20]

TERMINAL

3Brown Right Turn

4 White High Beam

5Violet Left Turn

6Orange Neutral/Oil Pressure Power

8Tan Neutral Lamp To Switch

9Green/Yellow Oil Pressure Lamp To Switch

12 Black

WIRE

COLOR

FUNCTION

Tur n S i gnal/High Beam

Ground

Table 2-10. Indicator Lamp Wiring

INDICATOR LAMP CONNECTION

Oil pressure Ground Through Switch

Neutral Ground Through Switch

High beam 12 VDC When Active

Right/left turn 12 VDC When Active

Figure 2-21. Indicator Lamp Assembly

(FLTR, FLHT/C/U)

Job/Time Code Values

Dealership technicians filing warranty claims should use the

job/time code values printed in bold text underneath the

appropriate repair.

Diagnostic Notes

The reference number below correlates with the circled number on the Diagnostics flow charts on the next page.

1. Connect BREAKOUT BOX (Part No. HD-42682) (black)

between wire harness connector [20A] and instruments

connector [20B].

2004 Touring: Instruments 2-23

Page 24

HOME

DIAGNOSTICS

Oil Pressure or Neutral Indicator Will Not Function

Turn on ignition switch. Check for

1

12 VDC at Breakout Box terminal 6.

Turn off ignition switch.

Was 12 VDC present?

YES

Check for continuity to

ground at Breakout Box

terminal 8 (neutral) and

terminal 9 (oil pressure).

Is continuity present?

YES

Replace indicator lamp.

5191

Check each terminal for continuity

to ground through switch.

NO

Check for blown fuses

or locate open.

5048

NO

Is continuity present?

YES

Repair open in GN/Y

wire (oil pressure) or

TN wire (neutral).

5048

High Beam or R/L Turn Signal Indicator Will Not Function

NO

Replace oil

pressure switch.

5161 5157

NO

Replace neutral

switch.

1

Breakout Box terminal 5 (left turn), terminal 3

Check for ground at

Breakout Box terminal 12.

Is ground present?

YES

Check for 12 VDC when circuit is active:

(right turn) or terminal 4 (high beam).

Is voltage present?

YES

Replace indicator lamp.

2-24 2004 Touring: Instruments

5191

NO

Locate and repair

open in circuit.

5048

NO

Locate and repair

open in circuit.

5048

Page 25

HOME

f2095x8x

Paddles

INDICATOR LAMPS: FLHR/C/S 2.9

GENERAL

FLHR/C/S models are equipped with Light Emitting Diode

(LED) indicators. The indicator lamp assembly is not serviceable. If one LED is bad, the entire assembly must be

replaced.

See DIAGNOSTICS which follows for troubleshooting proce-

dures.

Table 2-11. Indicator Lamp Connector [21]

TERMINAL WIRE COLOR FUNCTION

1Violet Left Turn

2 White High Beam

3Green/yellow Oil Pressure

4BrownRight Turn

5Tan Neutral

6Orange Neutral/Oil Pressure

7BlackLeft Turn/high Beam

8 Not used N/A

Figure 2-22. Release Paddles to Free

Indicator Lights Assembly (FLHR/C/S)

Table 2-12. LED Assembly Wiring

INDICATOR LAMP CONNECTION

Oil pressure Ground Through Switch

Neutral Ground Through Switch

High beam 12 VDC When Active

Right/left turn 12 VDC When Active

Job/Time Code Values

Dealership technicians filing warranty claims should use the

job/time code values printed in bold text underneath the

appropriate repair.

2004 Touring: Instruments 2-25

Page 26

HOME

DIAGNOSTICS

Oil Pressure or Neutral Indicator Will Not Function

Check for 12 VDC at terminal 6

of connector [21A].

Is 12 VDC present?

YES

Check for continuity to

ground on connector [21] at

terminal 5 (neutral) and ter-

minal 3 (oil pressure). Is

continuity present?

YES

Replace indicator

lamp assembly.

5191

Check each terminal for continuity

to ground through switch.

NO

Check for blown

fuses or find open.

5048

NO

Is continuity present?

YES

Repair open in GN/Y

wire (oil pressure) or

TN wire (neutral).

pressure switch.

5048

High Beam or R/L Turn Signal Indicator Will Not Function

NO

Replace oil

NO

Replace neutral

switch.

5161 5157

Check for ground at terminal 2

of connector [21A].

Is ground present?

YES

Check for 12 VDC when circuit is

active. Use terminal 1 (left turn), ter-

minal 4 (right turn) and terminal 2

(high beam). Voltage present?

YES

Replace indicator

lamp assembly.

5191 5048

2-26 2004 Touring: Instruments

NO

Locate and repair

open in circuit.

5048

NO

Locate and repair

open in circuit.

Page 27

HOME

10086

f2001x8x

f1998x9x

DTC B1004, B1005 2.10

GENERAL

The fuel level is monitored by the speedometer pin 9 of connector [39] (Y/W).

● If the voltage on pin 9 of connector [39] exceeds the

lower limit for greater than or equall to 15 seconds a DTC

B1004 will set.

● If the voltage on pin 9 of connector [39] exceeds the

upper limit (or is open) for greater than or equall to 15

seconds a DTC B1005 will set.

Table 2-13. Code Description

DTC DESCRIPTION

B1004 Fuel level sending unit low.

B1005 Fuel level sending unit high/open.

DIAGNOSTICS

Diagnostic Tips

If fuel gauge is performing erratically (possible false diagnostic trouble codes), inspect for unobstructed movement of

sending unit arm. Repair or align as necessary.

Diagnostic Notes

The reference numbers below correlate with the circled numbers on the 2.10 flow chart.

1. Use HARNESS CONNECTOR TEST KIT (Part No. HD-

41404), brown pin probe and patch cord.

2. Connect BREAKOUT BOX (Part No. HD-42682) and

INSTRUMENT HARNESS ADAPTERS (Part No. HD-

46601) between wire harness and speedometer.

Figure 2-24. Speedometer Connector [39]

Figure 2-25. Breakout Box (Part No. HD-42682)

Figure 2-23. Instrument Harness Adapters

(Part No. HD-46601)

2004 Touring: Instruments 2-27

Page 28

HOME

f2208s8x

To accessory fuse

To battery fuse

To Instrument

fuse

[39B]

[39A]

BN/GY

GY

BK

O/W

1

6

2

5

6

1

5

2

Speedometer

Fuel Level

Sender

To Fuel Gauge

BK

Y/W

[141A]

3

1

2

[141B]

3

1

2

Y/W

LGN/V

5 5

9

7

7

9

1

1

Y/W

FLTR, FLHT/C/U Only

BK

3

2

2

[13B]

[13A]

3

[2B][2A]

Lt GN/R

Lt GN/V

BK

GY

1

2

3

4

Connector

Data Link

12V

[78B]

[78A]

LGN/R

15

LGN/V

ECM

Figure 2-26. Fuel Sender Circuit

Table 2-14. Wire Harness Connectors in Figure 2-26.

NO. DESCRIPTION MODEL TYPE LOCATION

[91A]

[2] Main to Interconnect Harness

FLHT/C 12-Place Deutsch (Gray)

FLTR 12-Place Deutsch (Gray) Inner Fairing - Below Radio (Left Side)

[13] Fuel Tank Harness

[39] Speedometer

FLHT/C 3-Place Multilock Behind Fuel Tank (Under Seat)

FLTR 3-Place Multilock Behind Fuel Tank (Under Seat)

FLHT/C 12-Place Packard Inner Fairing (Back of Speedometer)

FLTR 12-Place Packard Under Bezel (Back of Speedometer)

[78] Electronic Control Module All 36-Place Packard Under Right Side Cover

[91] Data Link All 4-Place Deutsch Under Right Side Cover

[141] Fuel Level Sender

FLHT/C 3-Place Mini-Deutsch Top of Canopy (Under Console)

FLTR 3-Place Mini-Deutsch Top of Canopy (Under Console)

Inner Fairing - Right Fairing Support

Brace

2-28 2004 Touring: Instruments

Page 29

HOME

Test 2.10: DTC 1004

FUEL LEVEL SENDING UNIT

Disconnect speedometer con-

nector [39]. Check continuity

between terminal 2 of connec-

tor [141B] and ground.

Continuity present?

YES NO

Locate and repair short to

ground.

Clear codes using speedometer self diagnostics.

See 2.3 SPEEDOMETER SELF DIAGNOSTICS.

Confirm proper operation with no check engine

lamp.

Repair/replace fuel level

sending unit.

2004 Touring: Instruments 2-29

Page 30

HOME

Test 2.10: DTC B1005

FUEL LEVEL SENDING UNIT

Disconnect Speedometer connector [39].

1

Measure voltage on terminal 2 of connector

[141B] (Y/W). Should be 0 volts. Is it?

Check continuity between terminal

2 of connector [141B] (Y/W) and

1

breakout box terminal 11 (BK).

2

Check continuity to ground on ter-

1

minal 3 of connector [141B] (BK).

Is continuity present?

YES

Repair/replace fuel level

sending unit.

YES

Continuity present?

YES

Locate and repair open on BK

NO

wire (ground circuit).

NO

Locate and repair short

to voltage.

NO

Locate and repair open

on Y/W wire.

2-30 2004 Touring: Instruments

Clear diagnostic trouble codes using speedometer

self diagnostics. See 2.3 SPEEDOMETER SELF

DIAGNOSTICS. Confirm proper operation with no

check engine lamp.

Page 31

HOME

DTC B1006, B1007 2.11

GENERAL

Accessory Or Ignition Line Overvoltage

Ignition and accessory voltage is constantly monitored by the

speedometer (terminal 1-ignition and terminal 6-accessory).

If the battery voltage fails to meet normal operating parameters, a diagnostic trouble code is set.

● DTC B1006 is displayed when accessory line voltage is

greater than 16.0 volts for longer than 5 seconds.

● DTC B1007 is displayed when ignition line voltage is

greater than 16.0 volts for longer than 5 seconds.

NOTE

ICM/ECM or TSM/TSSM may also set a battery voltage diagnostic trouble codes.

Table 2-15. Code Description

DTC DESCRIPTION

B1006 Accessory line overvoltage

B1007 Ignition line overvoltage

2004 Touring: Instruments 2-31

Page 32

HOME

Test 2.11

ACCESSORY OR IGNITION LINE OVERVOLTAGE:

DTC B1006/B1007

Is battery charger connected?

YES NO

Disconnect battery charger. Clear codes.

Sometimes battery charger may cause

overvoltage condition which will set codes.

Start vehicle. Run at 3000

RPM for 5 seconds. Does

YES

Diagnose charging system.

See Charging System.

NOTE

code reset?

NO

System normal.

Diagnose charging system.

See Charging System.

Clear codes using speedometer self diagnostics.

See 2.3 SPEEDOMETER SELF DIAGNOSTICS.

Confirm proper operation with no check engine

lamp.

2-32 2004 Touring: Instruments

Page 33

HOME

DTC B1008 2.12

GENERAL

Reset Switch Closed

DTC B1008 will be set if switch terminals are in a constant

shorted state.

Table 2-16. Code Description

DTC DESCRIPTION

B1008 Reset switch closed

DIAGNOSTICS

Diagnostic Notes

The reference numbers below correlate with the circled numbers on the 2.12 flow chart.

1. Connect BREAKOUT BOX (Part No. HD-42682) and

INSTRUMENT HARNESS ADAPTERS (Part No. HD-

46601) between wire harness and speedometer, lea

speedometer disconnected.

ving

2004 Touring: Instruments 2-33

Page 34

HOME

d0723x2x

Speedometer

[39B][39A]

10

11

12

1

2

3

4

5

6

7

8

BK

9

BK

Reset

Switch

Figure 2-27. Reset Switch Circuit

Table 2-17. Wire Harness Connectors in Figure 2-27.

NO. DESCRIPTION MODEL TYPE LOCATION

[39] Speedometer

FLHT/C 12-Place Packard Inner Fairing (Back of Speedometer)

FLTR 12-Place Packard Under Bezel (Back of Speedometer)

2-34 2004 Touring: Instruments

Page 35

HOME

Test 2.12

RESET SWITCH CLOSED: DTC B1008

Remove reset switch rubber boot.

Clear codes using 2.3 SPEEDOM-

ETER SELF DIAGNOSTICS.

Codes still present?

With speedometer disconnected, measure

1

resistance between terminals 8 and 11

(black) on Breakout Box. Resistance should

be less than 1 ohm with switch depressed

and infinity ohms when released. Is it?

YES

Replace speedometer.

YES

NO

Replace switch.

NO

Replace boot.

Clear codes using speedometer self diagnostics.

See 2.3 SPEEDOMETER SELF DIAGNOSTICS.

Confirm proper operation with no check engine

lamp.

2004 Touring: Instruments 2-35

Page 36

HOME

DTC U1016 2.13

GENERAL

Loss of ICM/ECM Serial Data

The serial data connector provides a means for the ignition

control module (ICM) or electronic control module (ECM),

TSM/TSSM and speedometer to communicate their current

status. When all operating parameters on the serial data bus

are within specifications, a state of health message is sent

between the components. A DTC U1016 indicates that the

ICM/ECM is not capable of sending this state of health message.

Table 2-18. Code Description

DTC DESCRIPTION

Loss of all ICM/ECM serial data

(state of health)

U1016

Loss of vehicle speed

Loss of vehicle inhibit motion

Loss of powertrain security status

Carbureted

f1917x9x

Ignition Control Module

Connector [10]

f2191x8x

DIAGNOSTICS

Diagnostic Notes

The reference numbers below correlate with the circled numbers on the Test 2.13 flow chart.

1. Connect BREAKOUT BOX (Part No. HD-42682) (gray)

between TSM/TSSM connector [30A] and wire harness

connector [30B]. See 3.11 BREAKOUT BOX: TSM/

TSSM.

6924

4

3

1. Terminal 1: flash pin-EFI models (Lt GN/R)

2. Terminal 2: ground (BK)

3. Terminal 3: serial data (Lt GN/V)

4. Terminal 4: power (GY)

5. Protective cap

1

5

2

Fuel Injected

Figure 2-29. Electrical Bracket (Under Right Side Cover)

2. Connect BREAKOUT BOX (Part No. HD-42682) (black)

between ICM connector [10A] and wiring harness connector [10B]. See 4.6 BREAKOUT BOX: ICM

3. Connect BREAKOUT BOX (Part No. HD-43876)

between wire harness and ICM/ECM. See 5.7 BREAK-

OUT BOX: EFI.

Electronic Control

Module Connector [78]

Figure 2-28. Data Link Connector

2-36 2004 Touring: Instruments

Page 37

HOME

Ignition Control Module

Data Link

TSM/TSSM

LtGN/V

15A

Ignition

Fuse

GY

[8B]

[8A]

[91A]

LtGN/V

BK

LtGN/V

[39B]

[39A]

[10B]

[10A]

Speedometer

O

BK

Serial data

[108B]

[108A]

Tachometer

BN/GY

[156B] [156A]

[30B]

[30A]

15A

Accessory

Fuse

[1B] [1A]

Main to Interconnect

Harness

Ignition

Harness

Main to Interconnect

Harness

f2208z8x

15A

Battery

Fuse

[2A]

[2B]

Main to Interconnect

Harness

BK

GY

BN/GY

321654987121110

321654987121110

321654987121110

321654987121110

6

6

5

5

4

4

3

3

2

2

1

1

321654987121110

321654987121110

121110

987

65

4

32

1

1

6

5

4

32

121110

987

NO. DESCRIPTION TYPE LOCATION

[1] Main to Interconnect Harness 12-Place Deutsch (Black) Inner Fairing - Right Radio Support Bracket

[2] Main to Interconnect Harness 12-Place Deutsch (Gray) Inner Fairing - Right Fairing Support Brace

[8] Ignition Harness 12-Place Deutsch Under Right Side Cover

[10] Ignition Control Module 12-Place Deutsch Under Right Side Cover

[30] Turn Signal/Security Module 12-Place Deutsch

[39] Speedometer 12-Place Packard Inner Fairing (Back of Speedometer)

[91] Data Link 4-Place Deutsch Under Right Side Cover

[108] Tachometer 12-Place Packard Inner Fairing (Back of Tachometer)

[156] Main to Interconnect Harness 6-Place Deutsch Inner Fairing - Right Fairing Support Brace

321654987121110

321654987121110

123

123

6

6

101112 78945

101112 78945

Figure 2-30. Serial Data Circuit: FLHT/C (Carbureted)

Table 2-19. Wire Harness Connectors in Figure 2-30.

Cavity in Crossmember at Rear of

Battery Box (Under Seat)

1

2

3

4

12

12

2004 Touring: Instruments 2-37

Page 38

HOME

f2208y8x

BN/GY

BK

321654987121110

321654987121110

15A

Battery

Fuse

Speedometer

LtGN/V

BN/GY

O

15A

Accessory

Fuse

[39B]

[39A]

15A

Ignition

Fuse

LtGN/V

GY

21

21

GY

BK

321654987121110

321654987121110

[30B]

[30A]

TSM/TSSM

BK

[8B]

[8A]

[91A]

Ignition

Harness

1

2

3

4

Data Link

987

6

54

3

98

7

654

3

121110

121110

LtGN/V

[10B]

[10A]

Ignition Control Module

12

12

Serial data

Figure 2-31. Serial Data Circuit: FLHR/S (Carbureted)

Table 2-20. Wire Harness Connectors in Figure 2-31.

NO. DESCRIPTION TYPE LOCATION

[8] Ignition Harness 12-Place Deutsch Under Right Side Cover

[10] Ignition Control Module 12-Place Deutsch Under Right Side Cover

[30] Turn Signal/Security Module 12-Place Deutsch

[39] Speedometer 12-Place Packard Under Console (Back of Speedometer)

[91] Data Link 4-Place Deutsch Under Right Side Cover

Cavity in Crossmember at Rear of

Battery Box (Under Seat)

2-38 2004 Touring: Instruments

Page 39

HOME

ECM

Data Link

TSM/TSSM

LtGN/V

15A

Ignition

Fuse

GY

[8B]

[8A]

[91A]

LtGN/V

BK

LtGN/V

[39B]

[39A]

[78B]

[78A]

Speedometer

O

BK

Serial data

[108B]

[108A]

Tachometer

BN/GY

[156B] [156A]

[30B]

[30A]

15A

Accessory

Fuse

[1B] [1A]

Main to Interconnect

Harness

Ignition

Harness

Main to Interconnect

Harness

f2208u8x

15A

Battery

Fuse

[2B]

[2A]

Main to Interconnect

Harness

LtGN/R

BK

BN/GY

GY

Flash pin

321654987121110

321654987121110

321654987121110

321654987121110

6

6

5

5

4

4

3

3

2

2

1

1

321654987121110

321654987121110

121110

987

65

4

32

1

1

65

4

32

121110

987

NO. DESCRIPTION MODEL TYPE LOCATION

[1]

[2]

[8] Ignition Harness All 12-Place Deutsch Under Right Side Cover

[10] Ignition Control Module All 12-Place Deutsch Under Right Side Cover

[30]

[39] Speedometer

[91] Data Link All 4-Place Deutsch Under Right Side Cover

[108] Tachometer

[156]

321654987121110

321654987121110

Main to Interconnect

Harness

Main to Interconnect

Harness

Table 2-21. Wire Harness Connectors in Figure 2-32.

Tu rn Signal/Security

Module

Main to Interconnect

Harness

123

123

6

6

101112 78945

101112 78945

51

Figure 2-32. Serial Data Circuit: FLTR, FLHT/C/U (Fuel Injected)

FLHT/C 12-Place Deutsch (Black) Inner Fairing - Right Radio Support Bracket

FLTR 12-Place Deutsch (Black) Inner Fairing - Below Radio (Left Side)

FLHT/C 12-Place Deutsch (Gray) Inner Fairing - Right Fairing Support Brace

FLTR 12-Place Deutsch (Gray) Inner Fairing - Below Radio (Left Side)

All 12-Place Deutsch

FLHT/C 12-Place Packard Inner Fairing (Back of Speedometer)

FLTR 12-Place Packard Under Bezel (Back of Speedometer)

Cavity in Crossmember at Rear of

Battery Box (Under Seat)

FLHT/C 12-Place Packard Inner Fairing (Back of Tachometer)

FLTR 12-Place Packard Under Bezel (Back of Tachometer)

FLHT/C 6-Place Deutsch Inner Fairing - Right Fairing Support Brace

FLTR 6-Place Deutsch Inner Fairing - Front of Right Fairing Bracket

2004 Touring: Instruments 2-39

1

2

3

4

Page 40

HOME

f2208t8x

BN/GY

321654987121110

321654987121110

Speedometer

15A

Battery

Fuse

BK

15A

Accessory

Fuse

LtGN/V

BN/GY

O

[39B]

[39A]

15A

Ignition

Fuse

LtGN/V

GY

3

21

321

GY

BK

321654987121110

321654987121110

[30B]

[30A]

TSM/TSSM

BK

98

7

65

4

98

7

65

4

121110

[8B]

Ignition

[8A]

Harness

121110

1

2

3

4

Data Link

[91A]

LtGN/V

LtGN/R

[78B]

[78A]

1

Flash pin

5

Serial data

ECM

Figure 2-33. Serial Data Circuit: FLHR/C/S (Fuel Injected)

Table 2-22. Wire Harness Connectors in Figure 2-33.

NO. DESCRIPTION TYPE LOCATION

[8] Ignition Harness 12-Place Deutsch Under Right Side Cover

[10] Ignition Control Module 12-Place Deutsch Under Right Side Cover

[30] Turn Signal/Security Module 12-Place Deutsch

[39] Speedometer 12-Place Mini-Deutsch Under Console (Back of Speedometer)

[78] Electronic Control Module 36-Place Packard Under Right Side Cover

[91] Data Link 4-Place Deutsch Under Right Side Cover

Cavity in Crossmember at Rear of

Battery Box (Under Seat)

2-40 2004 Touring: Instruments

Page 41

HOME

Test 2.13

LOSS OF ICM/ECM SERIAL DATA: DTC U1016

Can you read ECM/ICM hardware P/N?

See 2.3 SPEEDOMETER SELF DIAGNOSTICS.

Install Breakout Box on TSM/TSSM.

1

CARBURETED

2

MODELS

While wiggling harness, check

continuity between breakout box

terminal 3 (gray) and breakout

box terminal 12 (black).

Continuity present?

YES

EFI MODELS

3

While wiggling harness, check conti-

nuity between terminal 3 (gray) of

TSM/TSSM breakout box and termi-

nal 5 of ECM Breakout Box.

Continuity present?

1

CARBURETED

2

MODELS

Check continuity between

breakout box terminal 3

(gray) and breakout box

terminal 12 (black).

Continuity present?

YES

Replace ICM.

Reprogram and learn

password.

NO or “No Rsp”

Install Breakout Box on TSM/TSSM

3

Check continuity between termi-

Check continuity between termi-

nal 2 (black) of speedometer

nal 3 (gray) of TSM/TSSM break-

Breakout Box and terminal 5 of

out box and terminal 5 of ECM

ECM Breakout Box.

breakout box.

Continuity present?

Continuity present?

NO

Repair open on

LtGN/V wire.

Reprogram and learn

EFI MODELS

YES

Replace ECM.

password.

YES

Clear codes. Test ride.

Does DTC U1016

return?

YES

Replace ICM.

Reprogram and learn

password.

NO

Repair intermittent

on LtGN/V wire.

NO

No trouble found.

YES

Clear codes. Test ride. Did DTC

U1016 return?

YES NO

Replace ECM.

Reprogram and learn

password.

No trouble found.

Clear codes using speedometer self diagnostics.

See 2.3 SPEEDOMETER SELF DIAGNOSTICS.

Confirm proper operation with no check engine

lamp.

2004 Touring: Instruments 2-41

Page 42

HOME

DTC U1064, U1255 2.14

GENERAL

Loss of TSM/TSSM Serial Data

The serial data connector provides a means for the ignition

control module (ICM) or electronic control module (ECM),

TSM/TSSM and speedometer to communicate their current

status. When all operating parameters on the serial data bus

are within specifications, a state of health message is sent

between the components. A DTC U1064 indicates that the

TSM/TSSM is not receiving this state of health message.

Table 2-23. Code Description

DTC DESCRIPTION

U1064 Loss of TSM/TSSM serial data

U1255 Serial data error/missing message

DIAGNOSTICS

Diagnostic Notes

The reference numbers below correlate with the circled numbers on the Test 2.14 flow chart.

1. Connect BREAKOUT BOX (Part No. HD-42682) as follows:

a. Mate black socket housing on Breakout Box with

speedometer connector [39] using SPEEDOMETER

HARNESS ADAPTER (Part No. HD-46601).

b. Mate black pin housing on Breakout Box with speed-

ometer harness connector [39B] using SPEEDOMETER HARNESS ADAPTER (Part No. HD-46601).

c. Mate gray socket housing on Breakout Box with

TSM/TSSM connector [30A].

d. Mate gray pin housing on Breakout Box with har-

ness connector [30B].

Spring

Clip

Turn Signal/Security

Module

Figure 2-34. Frame Crossmember (Under Seat)

6924

4

1

3

2

1. Terminal 1: flash pin-EFI models (Lt GN/R)

2. Terminal 2: ground (BK)

3. Terminal 3: serial data (Lt GN/V)

4. Terminal 4: power (GY)

5. Protective cap

Figure 2-35. Data Link Connector

f2013x8x

5

2-42 2004 Touring: Instruments

Page 43

HOME

Ignition Control Module

Data Link

TSM/TSSM

LtGN/V

15A

Ignition

Fuse

GY

[8B]

[8A]

[91A]

LtGN/V

BK

LtGN/V

[39B]

[39A]

[10B]

[10A]

Speedometer

O

BK

Serial data

[108B]

[108A]

Tachometer

BN/GY

[156B] [156A]

[30B]

[30A]

15A

Accessory

Fuse

[1B] [1A]

Main to Interconnect

Harness

Ignition

Harness

Main to Interconnect

Harness

f2208z8x

15A

Battery

Fuse

[2A]

[2B]

Main to Interconnect

Harness

BK

GY

BN/GY

321654987121110

321654987121110

321654987121110

321654987121110

6

6

5

5

4

4

3

3

2

2

1

1

321654987121110

321654987121110

121110

987

65

4

32

1

1

6

5

4

32

121110

987

NO. DESCRIPTION TYPE LOCATION

[1] Main to Interconnect Harness 12-Place Deutsch (Black) Inner Fairing - Right Radio Support Bracket

[2] Main to Interconnect Harness 12-Place Deutsch (Gray) Inner Fairing - Right Fairing Support Brace

[8] Ignition Harness 12-Place Deutsch Under Right Side Cover

[10] Ignition Control Module 12-Place Deutsch Under Right Side Cover

[30] Turn Signal/Security Module 12-Place Deutsch

[39] Speedometer 12-Place Packard Inner Fairing (Back of Speedometer)