Page 1

HOME

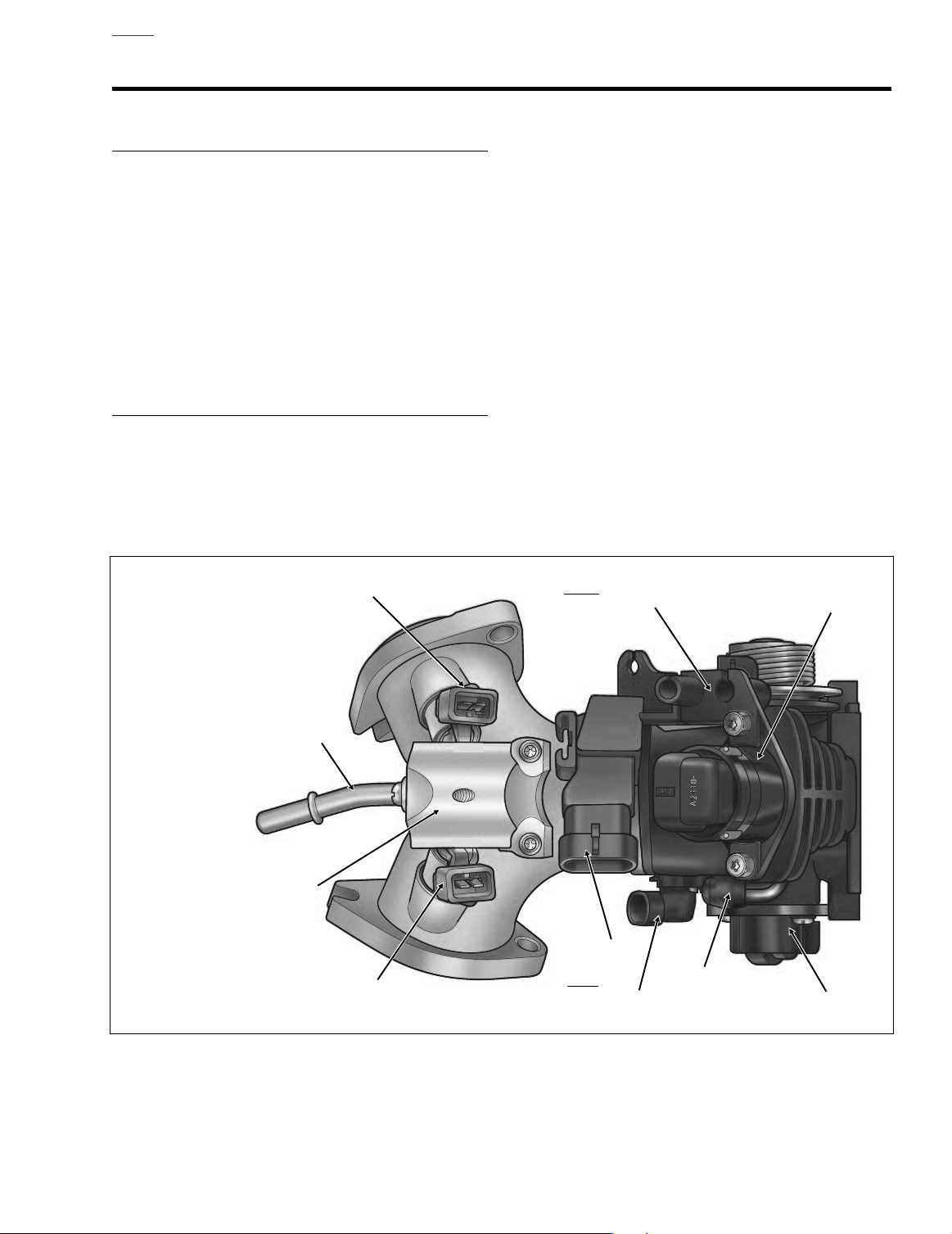

INDUCTION MODULE ASSEMBLY 9.5

GENERAL

See Figure 9-23. The Induction Module Assembly consists of

the following components:

●

Induction Module

Fuel Supply Line

●

Fuel Rail/Fuel Supply Tube

●

●

Fuel Injectors

●

Intake Air Temperature Sensor

Throttle Position Sensor

●

Manifold Absolute Pressure Sensor

●

●

Idle Air Control

INDUCTION MODULE

REMOVAL

1. Partially remove fuel tank. See Section 9.4 FUEL TANK

(FUEL INJECTED), PA RTIAL REMOVAL, either FLHT/

C/U/I, FLTRI or FLHR/C/S/I.

1. Fuel Injector (Front)

2. Throttle Cable Bracket

3. Idle Air Control

4. Throttle Position Sensor

5. Purge Tube Fitting

(California Models Only)

6. Intake Air Temperature Sensor

7. Manifold Absolute Pressure

Sensor

8. Fuel Injector (Rear)

9. Fuel Rail

10. Fuel Supply Tube

10

1

2. Remove air cleaner and backplate. See Section 4.5 AIR

CLEANER, REMOVAL.

3. Pull purge tube from fitting at top of induction module

(California models only). See Figure 9-23.

4. Using a needle nose pliers, carefully pull idle cable barrel from upper hole in throttle wheel. Pull throttle cable

barrel from lower hole. Using slots, release idle and

throttle cables from guides in throttle cable bracket.

5. On cruise control equipped models, remove E-clip from

sleeve at end of cruise cable housing. Using slot,

remove cable housing from cable guide in throttle cable

bracket. Push the plastic end fitting on the cruise cable

to the outboard side to release from wheel pin. See Fig-

ure 9-24.

6. Remove idle air control and manifold absolute pressure

sensor connectors. Pull external latch(es) outward and

use rocking motion to separate pin and socket halves.

7. Depress wire form to remove electrical connectors from

front and rear fuel injectors.

8. Remove throttle position sensor and intake air temperature sensor connectors.

Front

2

3

f2162x9x

9

7

8

Figure 9-23. Induction Module Assembly

Rear

6

5

4

2004 Touring: Fuel Injection 9-27

Page 2

HOME

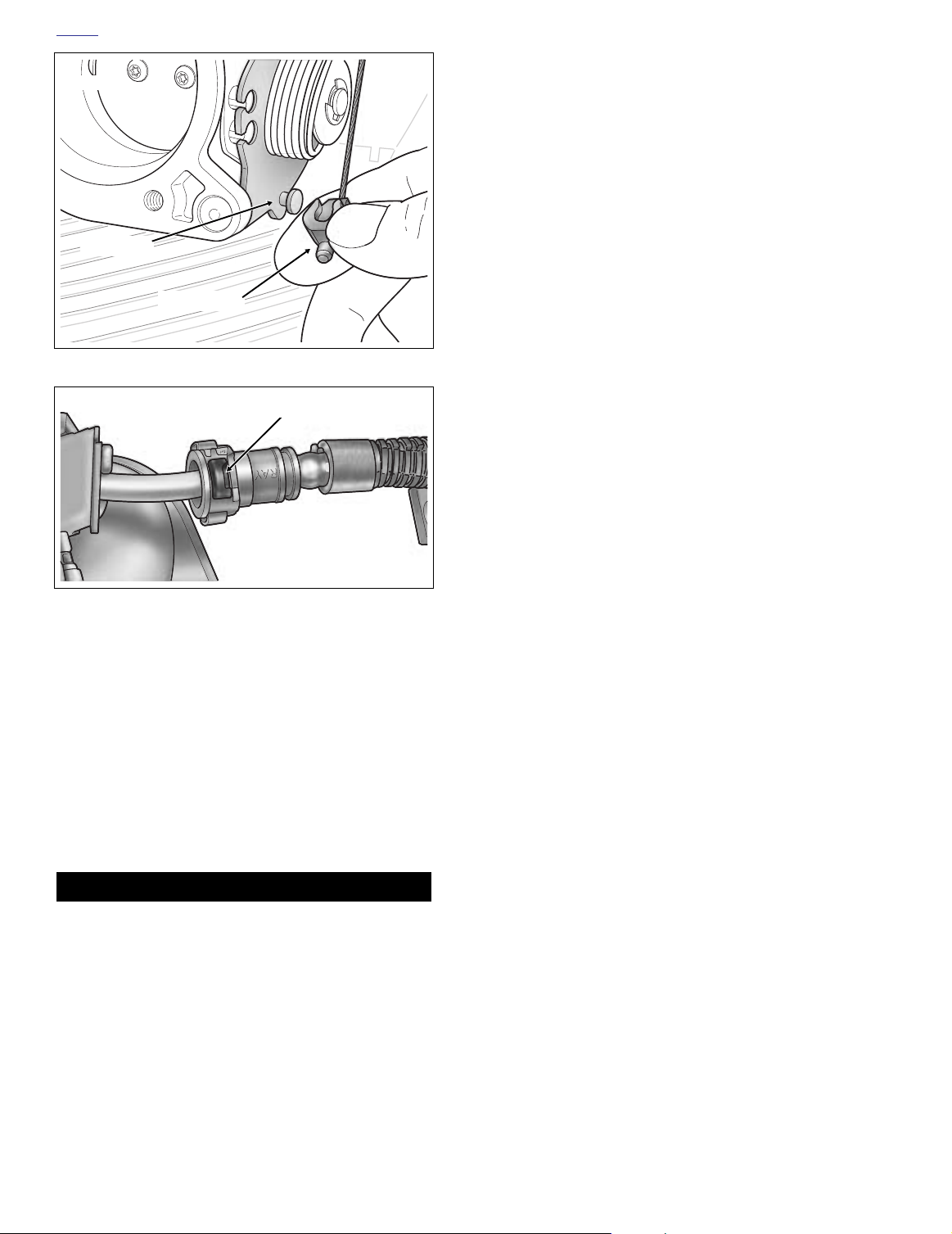

f1965x8x

Wheel Pin

End Fitting

Figure 9-24. Remove End Fitting From Wheel Pin

Button

f1922x9x

Figure 9-25. Remove Fuel Supply Line From Supply Tube

9. Remove right side allen head socket screws from front

and rear cylinder head flange adapters. For best results,

use a long 1/4 inch ball allen head socket with end driver

4 inches long.

10. Moving to opposite side of vehicle, just loosen left side

allen head socket screws from flange adapters. Slots in

flanges make removal of left side screws unnecessary.

To better access bolts, loosen acorn nut and swing horn

assembly out of the way.

11. Slide induction module out from right side of vehicle.

Use caution around horn bracket to prevent damage to

fuel line.

1WARNING1WARNING

A small amount of gasoline will drain from the fuel supply line when disconnected from the supply tube. Thoroughly wipe up any spilled fuel immediately. Dispose of

rags in a suitable manner. Gasoline is extremely flammable and highly explosive. Inadequate safety precautions

could result in death or serious injury.

12. Depress button on inboard side of fuel supply line and

remove from supply tube. See Figure 9-25.

13. Remove seals from flange adapters. Discard seals.

Remove flange adapters from outlet ports of induction

module.

14. If it should become necessary to split the induction module, that is, separate the throttle body from the intake

manifold, proceed as follows:

a. Remove top and bottom T20 TORX screws to sepa-

rate intake manifold and throttle body flanges.

b. Remove O-ring from counterbore of throttle body

flange. Discard O-ring.

INSTALLATION

1. If induction module was split, assemble the intake manifold and throttle body as follows:

a. Apply a thin coat of clean engine oil to

Install O-ring in counterbore of throttle body flange.

Mate intake manifold and throttle body flanges.

b. Apply Loctite Wicking Threadlocker 290 (green) to

threads of two T20 TORX screws. Install screws and

alternately tighten to 27-33

Allow approximately 3-6 hours to elapse for compound to cure.

2. Slide fuel supply line onto tube at top of induction module. A slight tug will verify that the line is locked in place.

3. Orientate the induction module as shown in Figure 9-23.

With the counterbore facing outward, slide cylinder head

flange adapters onto outlet ports of induction module.

The flange adapters are not interchangeable. Look next

to the slotted bolt hole for a stamp that indicates F(ront)

and R(ear) cylinder.

4. Place a

eled side in against the counterbore.

5. Standing on right side of engine, slide induction module

toward installed position so that open-ended slots on

flange adapters begin to engage allen head socket

screws loosely installed on left side. Use caution around

horn bracket to prevent damage to fuel line.

6. Install sleeve on throttle cable housing into shorter cable

guide at top of throttle cable bracket. Drawing throttle

cable downward, fit barrel end into lower hole in throttle

wheel. Install sleeve and spring on idle cable housing

into longer cable guide at bottom of throttle cable bracket

inserting barrel end into upper hole in throttle wheel.

7. On cruise control equipped models, slide groove in

cruise cable end fitting over cap of wheel pin. Push on

end fitting until it snaps in place. Using slot, slip cruise

cable housing into cable guide in throttle cable bracket.

Install

ing.

8. Align fixed holes in flange adapters with those in cylinder

heads and start allen head socket screws. For best

results, use a long 1/4 inch ball allen head socket with

end driver 4 inches long.

new

seal in each flange adapter with the bev-

new

E-clip on sleeve at end of cruise cable hous-

in-lbs

new

O-ring.

(3.1-3.7 Nm).

9-28 2004 Touring: Fuel Injection

Page 3

HOME

1WARNING1WARNING

1WARNING1WARNING

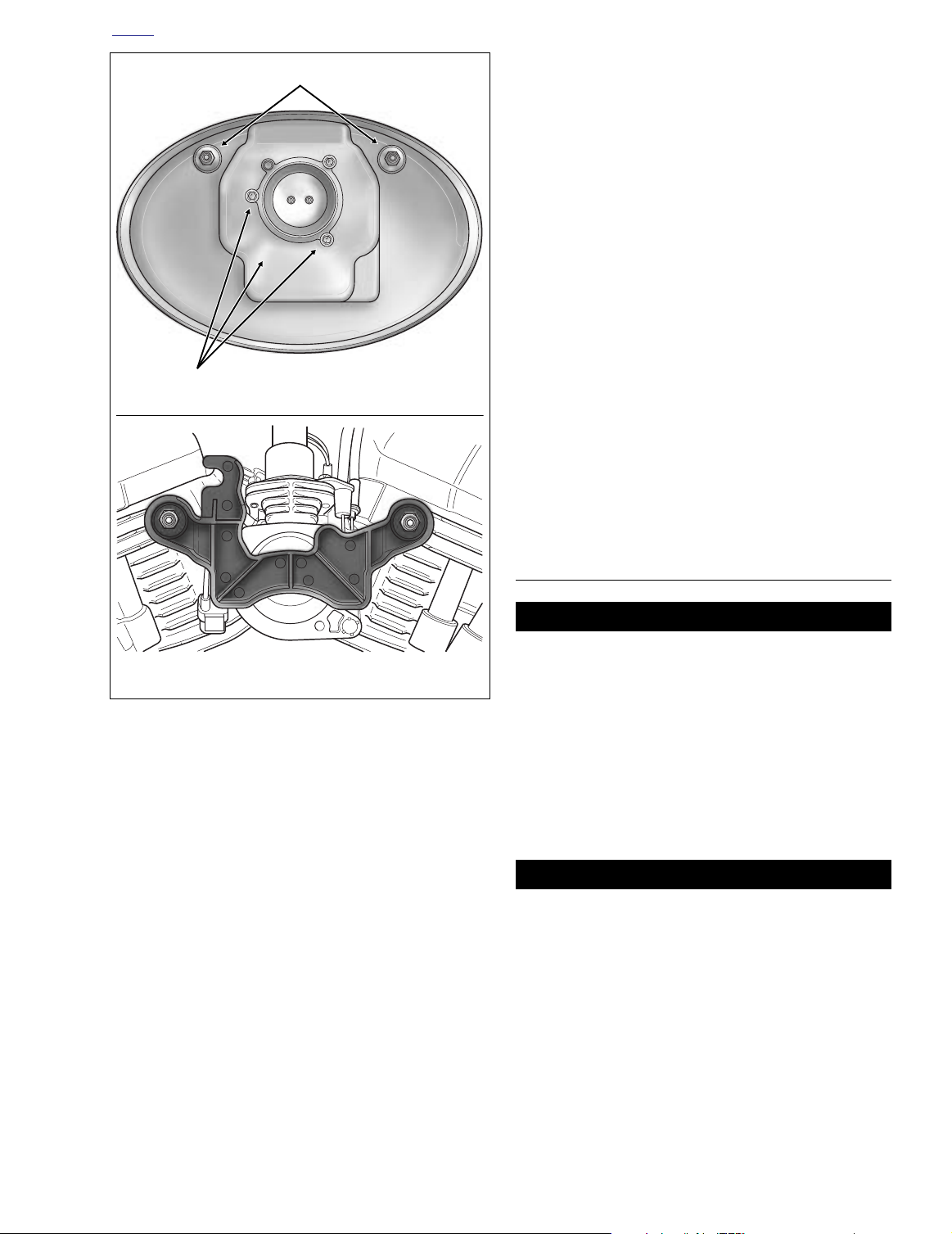

f1966x9x

T27 TORX

f2079x9x

Screws

Breather Bolts

Backplate

11. Remove breather bolts and T27 TORX screws to remove

backplate, if installed.

12. Tighten allen head socket screws in fixed holes of flange

adapters to 96-144

13. Remove breather bolts to remove alignment bracket, if

installed.

14. Install electrical connectors on fuel injectors.

15. Install manifold absolute pressure sensor and idle air

control connectors.

16. Install intake air temperature sensor and throttle position

sensor connectors.

17. Connect purge tube to fitting at top of induction module

(California models only). See Figure 9-23.

18. Install fuel tank. See Section 9.4 FUEL TANK (FUEL

INJECTED), INSTALLATION (AFTER PARTIAL

REMOVAL), FLHT/C/U/I, FLTRI or FLHR/C/S/I.

19. Turn the Ignition/Light Key Switch to ON and then back

to OFF to reset idle air control to park position.

20. Install backplate and air cleaner. See Section 4.5 AIR

CLEANER, INSTALLATION.

21. Check throttle and idle control cable adjustment. Check

cruise cable adjustment.

in-lbs

(10.9-16.3 Nm).

Bracket

Figure 9-26. Install Backplate or Bracket

9. Use the air cleaner backplate or INDUCTION SYSTEM

ALIGNMENT BRACKET (P&A Part No. 40054-01) to

properly locate induction module. Proceed as follows:

a.

Backplate

plate to front and rear cylinder heads. Install three

T27 TORX screws to secure backplate to face of

induction module. See upper frame of Figure 9-26.

b.

Alignment bracket

into holes in face of induction module, install two

breather bolts to fasten bracket to front and rear cylinder heads. See lower frame of Figure 9-26.

10. Tighten allen head socket screw in fixed holes of flange

adapters until snug. Moving to left side of engine, tighten

screws in slotted holes to 96-144

If moved, swing horn assembly back into position and

tighten acorn nut.

: Install two breather bolts to fasten back-

: Fitting pins on inboard side

in-lbs

(10.9-16.3 Nm).

FUEL SUPPLY LINE

The gasoline in the fuel supply line downstream of the

fuel pump is under high pressure (58 psi). To avoid an

uncontrolled discharge or spray of gasoline, always

purge the system of high pressure gas before the fuel

supply line is disconnected. Inadequate safety precautions could result in death or serious injury.

REMOVAL

1. Partially remove fuel tank. See Section 9.4 FUEL TANK

(FUEL INJECTED), PARTIAL REMOVAL, FLHT/C/U/I,

FLTRI or FLHR/C/S/I.

A small amount of gasoline will drain from the fuel supply line when disconnected from the fuel tank. Thoroughly wipe up any spilled fuel immediately. Dispose of

rags in a suitable manner. Gasoline is extremely flammable and highly explosive. Inadequate safety precautions

could result in death or serious injury.

NOTE

Check valve in the fuel tank fitting impedes any further fuel

seepage once external fuel line has drained.

2004 Touring: Fuel Injection 9-29

Page 4

HOME

Button

f1922x9x

Figure 9-27. Remove Fuel Supply Line From Supply Tube

2. Pull up on chrome sleeve of quick-connect fitting on left

side of fuel tank and pull down on fuel supply line to disconnect. See Figure 9-24.

3. Raise fuel tank approximately 2 inches. Move the fuel

tank crossover hose to the rear of the ignition coil, so

that the tank can be raised an additional 2-3 inches.

Move fuel tank straight back slightly and rest on frame

backbone.

4. Obtain several 1 x 2 inch wooden blocks. Raise the front

and rear of the fuel tank off the frame backbone by placing blocks in the recess centered at the bottom of the

tank.

FUEL RAIL/FUEL SUPPLY TUBE

REMOVAL

1. See INDUCTION MODULE, REMOVAL, in this section.

2. Depress button on inboard side of fuel supply line and

remove from fuel supply tube. See Figure 9-27.

3. Using a T20 TORX drive head, remove screw to release

fuel supply tube clamp. See Figure 9-28.

4. Gently pull fuel supply tube from fuel rail. Remove sealing washer from end of fuel supply tube. Remove O-ring

from fuel rail bore. Discard sealing washer and O-ring.

Fuel Supply

Tube Clamp

1WARNING1WARNING

A small amount of gasoline will drain from the fuel supply line when disconnected from the supply tube at the

top of the induction module. Thoroughly wipe up any

spilled fuel immediately. Dispose of rags in a suitable

manner. Gasoline is extremely flammable and highly

explosive. Inadequate safety precautions could result in

death or serious injury.

5. Depress button on inboard side of fuel supply line and

remove from supply tube. See Figure 9-27.

INSTALLATION

1. Slide fuel supply line onto tube at top of induction module. A slight tug will verify that the line is locked in place.

See Figure 9-27.

2. Pull up on chrome sleeve of quick-connect fitting on left

side of tank and insert neck of fuel supply line fitting.

While pushing up on bottom of fuel supply line fitting,

pull down on chrome sleeve until it “clicks” into the

locked position. Tug on fuel supply line to be sure that it

will not come free.

3. Install fuel tank. See Section 9.4 FUEL TANK (FUEL

INJECTED), INSTALLATION (AFTER PARTIAL

REMOVAL), FLHT/C/U/I, FLTRI, or FLHR/C/S/I.

9407

Figure 9-28. Remove Fuel Supply Tube Clamp

T20 TORX

Screws

Fuel Rail

8495

Figure 9-29. Remove Fuel Rail

9-30 2004 Touring: Fuel Injection

Page 5

HOME

Electrical

Connector

O-Ring

f1934x9x

Sealing

O-Ring

Figure 9-30. Install Fuel Supply Tube

5. Using a T20 TORX drive head, remove two screws to

release fuel rail from induction module. See Figure 9-29.

6. Pull fuel rail with attached fuel injectors from induction

module. To overcome the resistance of the bottom Oring on both fuel injectors, gently rock assembly back

and forth while pulling.

7. Pull fuel injectors from fuel rail. To overcome the resistance of the top O-ring, gently rock each fuel injector

while pulling.

8. Remove O-rings from fuel injectors. Discard O-rings.

See Figure 9-31.

Washer

f1935x9x

FUEL INJECTORS

REMOVAL

1. See INDUCTION MODULE, REMOVAL, in this section.

2. Depress button on inboard side of fuel supply line and

remove from fuel supply tube. See Figure 9-27.

3. Using a T20 TORX drive head, remove screw to release

fuel supply tube clamp. See Figure 9-28.

4. Using a T20 TORX drive head, remove two screws to

release fuel rail from induction module. See Figure 9-29.

5. Pull fuel rail with attached fuel injectors from induction

module. To overcome the resistance of the bottom Oring on both fuel injectors, gently rock assembly back

and forth while pulling.

6. Pull fuel injectors from fuel rail. To overcome the resistance of the top O-ring, gently rock each fuel injector

while pulling.

7. Remove O-rings from fuel injectors. Discard O-rings.

See Figure 9-31.

INSTALLATION

INSTALLATION

1. Apply a thin coat of clean engine oil to

rings. Install O-rings on fuel injectors. See Figure 9-31.

2. With the electrical connector topside, push fuel injectors

into induction module bores. Rotate fuel injectors, so

that the electrical connectors are on the outboard side.

3. Push fuel rail over fuel injectors until fuel rail flange contacts boss on induction module.

4. Using a T20 TORX drive head, install two screws to fas-

ten fuel rail to induction module. Alternately tighten

screws to 27-33

5. Note the collar on each end of the fuel supply tube. Slide

a

new

sealing washer down the shorter neck until it contacts the collar. Slide a

contacts the sealing washer. See Figure 9-30. Push tube

into fuel rail bore until collar is flush with casting.

6. Align hole in fuel supply tube clamp with hole in fuel rail.

Using a T20 TORX drive head, install screw and tighten

to 27-33

fuel supply tube so that it angles downward.

7. See INDUCTION MODULE, INSTALLATION, in this sec-

tion.

in-lbs

(3.0-3.7 Nm). See Figure 9-29.

new

o-ring down the tube until it

in-lbs

(3.0-3.7 Nm). See Figure 9-28. Rotate

new

injector O-

1. Apply a thin coat of clean engine oil to

rings. Install O-rings on fuel injectors. See Figure 9-31.

2. With the electrical connector topside, push fuel injectors

into induction module bores. Rotate fuel injectors, so

that the electrical connectors are on the outboard side.

3. Push fuel rail over fuel injectors until fuel rail flange contacts boss on induction module.

4. Using a T20 TORX drive head, install two screws to fasten fuel rail to induction module. Alternately tighten

screws to 27-33

in-lbs

(3.0-3.7 Nm). See Figure 9-29.

Figure 9-31. Fuel Injector

new

injector O-

2004 Touring: Fuel Injection 9-31

Page 6

HOME

5. Align hole in fuel supply tube clamp with hole in fuel rail.

Using a T20 TORX drive head, install screw and tighten

to 27-33

fuel supply tube so that it angles downward.

6. See INDUCTION MODULE, INSTALLATION, in this sec-

tion.

in-lbs

(3.0-3.7 Nm). See Figure 9-28. Rotate

INTAKE AIR TEMPERATURE SENSOR

8495

REMOVAL

1. Remove maxi-fuse. See Section 8.3 SYSTEM FUSES,

MAXI-FUSE, REMOVAL.

2. Remove air cleaner and backplate. See Section 4.5 AIR

CLEANER, REMOVAL.

3. Disconnect the intake air temperature sensor connector.

See Figure 9-32. Pull external latches outward and use

a rocking motion to separate pin and socket halves.

4. Using a T10 TORX drive head, remove two screws to

release intake air temperature sensor from induction

module. See Figure 9-32.

5. Remove and discard gasket.

INSTALLATION

1. Place

2. Insert sensor into induction module with electrical con-

3. Using a T10 TORX drive head, install two screws to

4. Install the intake air temperature sensor connector.

5. Install backplate and air cleaner. See Section 4.5 AIR

6. Install maxi-fuse. See Section 8.3 SYSTEM FUSES,

new

gasket on flange of intake air temperature

sensor.

nector facing toward the left side of the vehicle. See Fig-

ure 9-32.

secure intake air temperature sensor to induction module. Alternately tighten screws to 12

See Figure 9-32.

CLEANER, INSTALLATION.

MAXI-FUSE, INSTALLATION.

in-lbs

(1.4 Nm).

Intake Air

Temperature

Sensor

Figure 9-32. Induction Module (Rear View)

f1936x9x

Figure 9-33. Intake Air Temperature Sensor

3. Disconnect the throttle position sensor connector. See

Figure 9-32. Pull external latch outward and use a rock-

ing motion to separate pin and socket halves.

4. Using a T20 TORX drive head, remove two screws to

release sensor from induction module. See Figure 9-32.

Throttle

Position

Sensor

Thermistor

Gasket

INSTALLATION

THROTTLE POSITION SENSOR

REMOVAL

1. Remove maxi-fuse. See Section 8.3 SYSTEM FUSES,

MAXI-FUSE, REMOVAL.

2. Remove air cleaner and backplate. See Section 4.5 AIR

CLEANER, REMOVAL.

9-32 2004 Touring: Fuel Injection

1. With electrical connector facing down, fit pocket of throttle position sensor over throttle shaft.

2. Align holes in flange of throttle position sensor with holes

in induction module. It may be necessary to turn the sensor slightly to align holes.

3. Using a T20 TORX drive head, install two screws to

secure throttle position sensor to induction module.

Alternately tighten screws to 27-33

See Figure 9-32.

in-lbs

(3.0-3.7 Nm).

Page 7

HOME

8315

Throttle Cable

Bracket

T20 TORX

Screws

f1701x9x

Rubber

Seal

Electrical

Connector

Pressure Port

4. Using the throttle lever mechanism, open and close the

throttle plates to check for proper operation. Be sure that

the mechanism operates smoothly without binding or

sticking.

5. Install the throttle position sensor connector.

6. Install backplate and air cleaner. See Section 4.5 AIR

CLEANER, INSTALLATION.

7. Install maxi-fuse. See Section 8.3 SYSTEM FUSES,

MAXI-FUSE, INSTALLATION.

MANIFOLD ABSOLUTE PRESSURE SENSOR

REMOVAL

1WARNING1WARNING

The screw securing the throttle cable bracket and idle air

control flange to the induction module has a loctite

patch that may make it very difficult to remove. Since a

heat gun may be needed to break down the loctite,

remove induction module from vehicle, so that heat is

not applied close to fuel tank. Gasoline is extremely

flammable and highly explosive. Inadequate safety precautions could result in death or serious injury.

1. See INDUCTION MODULE, REMOVAL, in this section.

CAUTION

The idle air control screw has a loctite patch that may

make it very difficult to remove. If necessary, use a heat

gun to break down the loctite. Apply heat evenly around

screw head in a circular motion. Do not direct heat at idle

air control and other components or damage can occur.

2. Using a T20 TORX drive head, remove two screws to

release throttle cable bracket from induction module.

See Figure 9-34. Discard idle air control flange screw.

3. Pull pressure port from hole in induction module. See

Figure 9-35.

Figure 9-34. Remove Screws to Release Bracket

Figure 9-35. Manifold Absolute Pressure Sensor

3. Align hole in throttle cable bracket with hole at side of

induction module. Start screw into induction module.

See Figure 9-34.

4. Align hole at top of throttle cable bracket with thru hole in

flange of idle air control. Start

patch into induction module.

new

screw with loctite

INSTALLATION

1. If reusing sensor, inspect rubber seal on pressure port

for cuts, tears or signs of deterioration. Replace as necessary. See Figure 9-35.

2. With the electrical connector facing toward the rear of

the induction module (side opposite throttle cable

bracket), insert pressure port into hole in induction module.

5. Using a T20 TORX drive head, tighten screw at side of

throttle cable bracket to 27-33

6. Tighten flange screw of idle air control to 25

Nm).

7. Move free end of throttle return spring into slot in throttle

cable bracket. See Figure 9-34.

8. See INDUCTION MODULE, INSTALLATION, in this sec-

tion.

2004 Touring: Fuel Injection 9-33

in-lbs

(3.0-3.7 Nm).

in-lbs

(2.8

Page 8

HOME

IDLE AIR CONTROL

REMOVAL

1WARNING1WARNING

The screws securing the idle air control flange to the

induction module have a loctite patch that may make

them very difficult to remove. Since a heat gun may be

needed to break down the loctite, remove induction

module from vehicle, so that heat is not applied close to

fuel tank. Gasoline is extremely flammable and highly

explosive. Inadequate safety precautions could result in

death or serious injury.

1. See INDUCTION MODULE, REMOVAL, in this section.

CAUTION

The idle air control screws have a loctite patch that may

make them very difficult to remove. If necessary, use a

heat gun to break down the loctite. Apply heat evenly

around screw head in a circular motion. Do not direct

heat at idle air control and other components or damage

can occur.

2. Using a T20 TORX drive head, remove two screws to

release throttle cable bracket from induction module.

See Figure 9-34. Discard flange screw of idle air control.

3. Remove remaining screw to release flange of idle air

control from top of induction module. Discard screw.

4. Pull idle air control from bore of induction module.

5. Remove O-ring from body of idle air control. Discard Oring. See Figure 9-37.

Idle Air

Control

Figure 9-36. Induction Module (Rear View)

f1938x9x

O-Ring

Figure 9-37. Idle Air Control

8495

INSTALLATION

1. Apply a thin coat of clean engine oil to

Install O-ring on counterbore of induction module flange.

2. With the electrical connector facing the left side of the

induction module (intake manifold side), install idle air

control into bore.

3. Align hole in throttle cable bracket with hole at side of

induction module. Start screw into induction module.

See Figure 9-34.

4. Align hole at top of throttle cable bracket with thru hole in

flange of idle air control. Start

patch into induction module.

5. Install remaining screw into flange of idle air control.

Again, use

6. Using a T20 TORX drive head, tighten screw at side of

throttle cable bracket to 27-33

9-34 2004 Touring: Fuel Injection

new

screw with loctite patch.

new

in-lbs

new

O-ring.

screw with loctite

(3.0-3.7 Nm).

7. Alternately tighten flange screws of idle air control to 25

in-lbs

(2.8 Nm).

8. Move free end of throttle return spring into slot in throttle

cable bracket.

9. See INDUCTION MODULE, INSTALLATION, in this sec-

tion.

Page 9

HOME

1. Throttle Position Sensor

2. T20 TORX Screw- 14mm (3)

3. T10 TORX Screw (2)

4. Intake Air Temperature Sensor

5. Gasket

6. O-Ring

7. Idle Air Control

8. T20 TORX/Hex Screw (2)

9. Throttle Cable Bracket

10. Fuel Injector

11. T20 TORX Screw- 17mm (5)

12. Fuel Rail

13. Fuel Supply Tube Clamp

14. Fuel Supply Tube

15. Sealing Washer

16. O-Ring

17. Manifold Absolute

Pressure Sensor

18. Rubber Seal

19. Socket Head Screw (4)

20. Flange Adapter (2)

3

4

2

6

5

21. Adapter Seal (2)

22. Intake Manifold

23. O-Ring

24. Throttle Body

10

8

7

11

13

14

11

15

16

10

12

9

2

17

18

19

20

1

f2161x9x

22

23

11

19

24

Figure 9-38. Induction Module Assembly

21

2004 Touring: Fuel Injection 9-35

Page 10

HOME

NOTES

9-36 2004 Touring: Fuel Injection

Loading...

Loading...