Page 1

H

f1368a8x

Set/Resume

Switch

0

30

50

40

110

120

60

70

80

90

100

0

20

30

70

80

40

50

60

10

MPH

H

A

R

L

E

Y

-

D

A

V

I

D

S

O

N

C

E

R

T

I

F

I

E

D

RPM

x100

H

A

R

L

E

Y

-

D

A

V

I

D

S

O

N

f2160x8x

Cruise Enabled/Engaged Lamp

Tachometer

OME

CRUISE CONTROL (FLHRC, FLTR, FLHTCU) 8.30

GENERAL

The Cruise Control system provides automatic vehicle speed

control. The electronics and stepper motor are contained in a

control module mounted under the left side cover. The stepper motor actuates the cruise control cable through a gear

train and ribbon reel.

SYSTEM OPERATION

To engage and disengage the cruise control system, proceed

as follows:

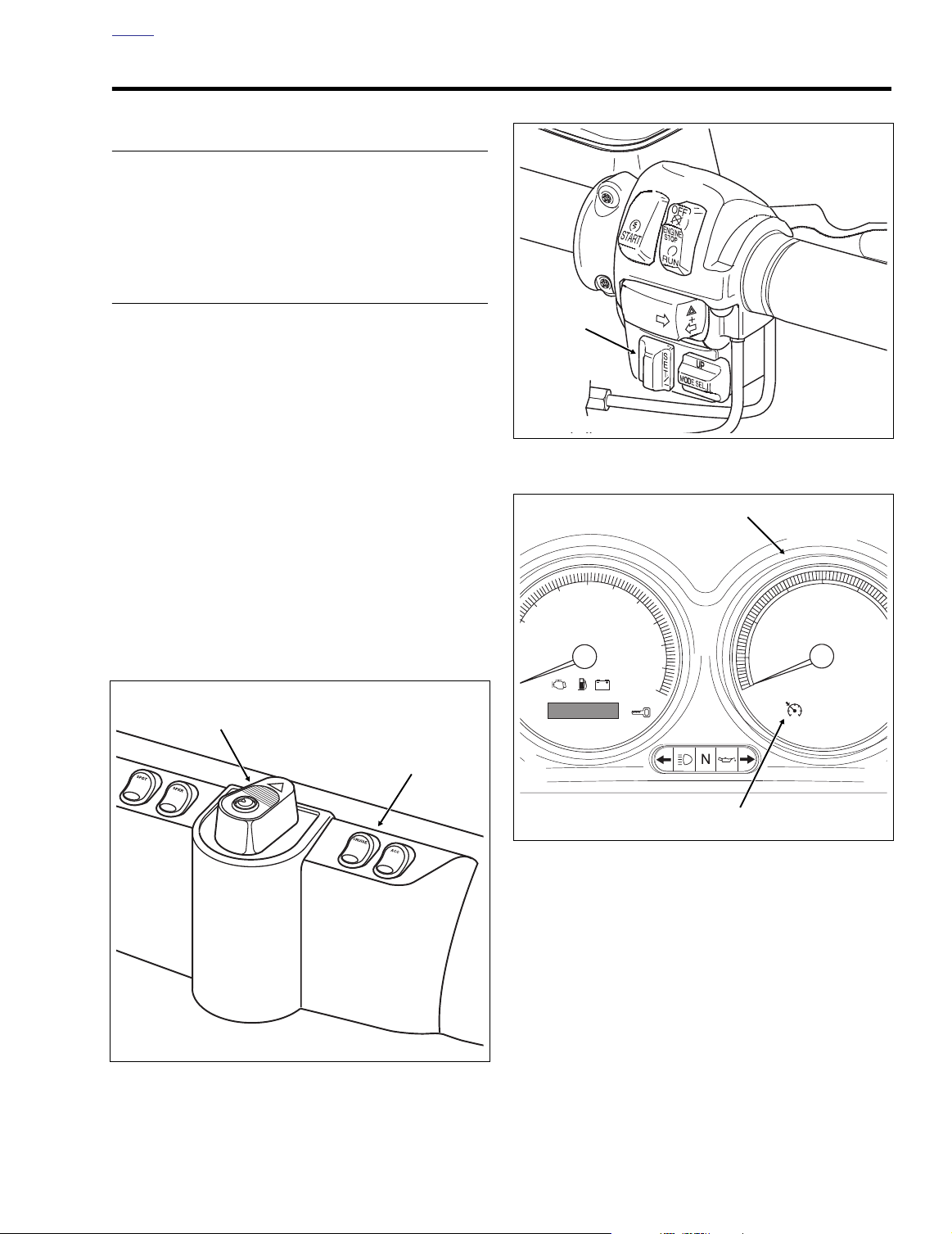

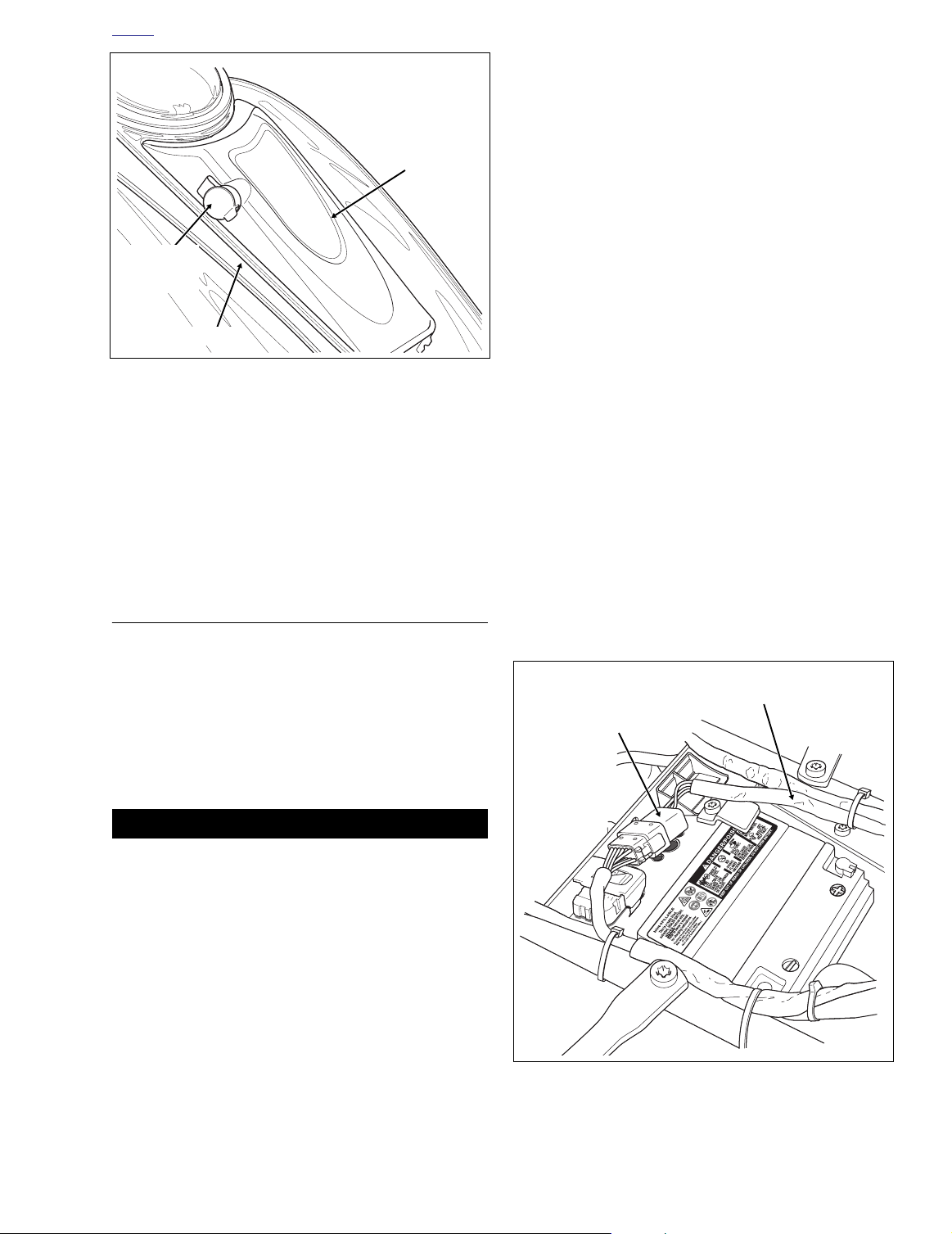

1. While riding in fourth or fifth gear, turn the Cruise ON/

OFF Switch to the ON position. See Figure 8-123. The

switch is located on the fairing cap of FLHTCU models,

the instrument nacelle of FLTR models, and the left handlebar lower switch housing on FLHRC models. The

Cruise Enabled/Engaged lamp in the tachometer face

(speedometer on FLHRC models) turns red to indicate

that the system is activated. See Figure 8-125. A red

lamp in the switch on both FLHTCU and FLTR models

also indicates this condition to the rider.

2. Power (12 vdc) is supplied to the cruise control module

through a 15 amp fuse located in the fuse block mounted

under the left side cover.

3. With the motorcycle traveling at the desired “cruise”

speed (30 mph/48 km/h to 85 mph/137 km/h), momentarily push the Cruise SET/RESUME switch to SET. See

Figure 8-124.

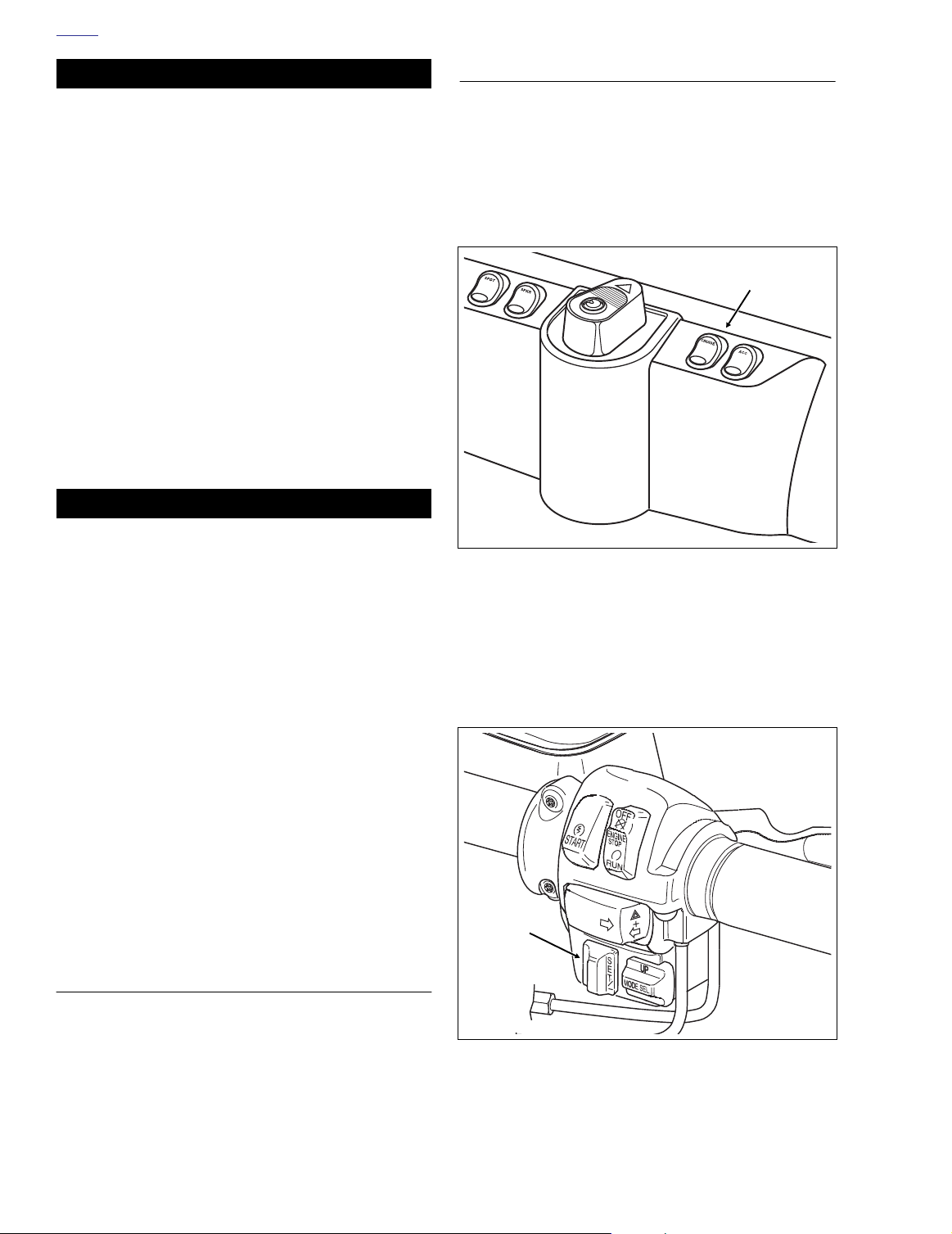

Figure 8-124. Right Handlebar Switch Assembly

(FLTR, FLHTCU)

Ignition/Light

Key Switch

Cruise ON/OFF

Switch

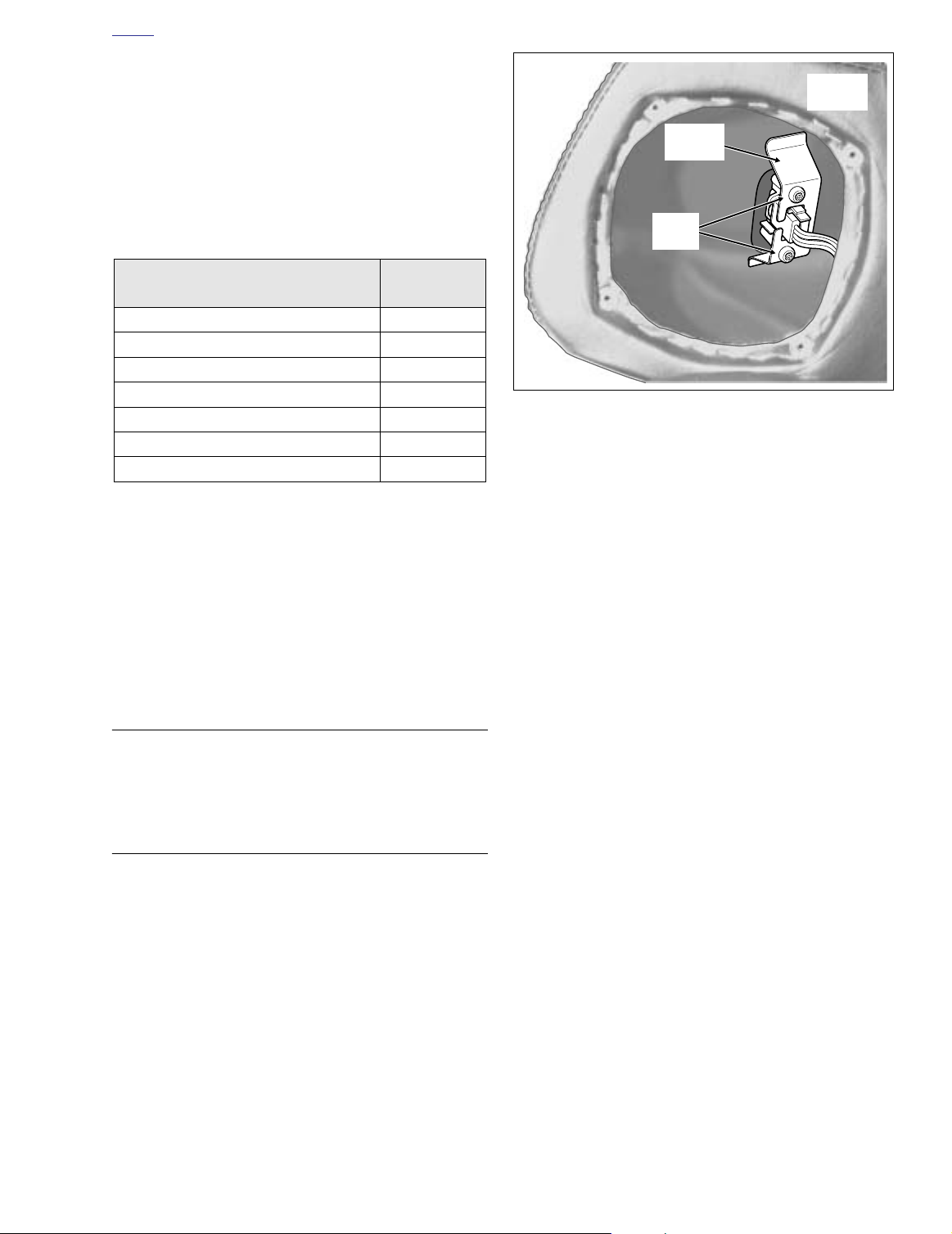

Figure 8-125. Instrument Panel (FLHTCU)

The cruise control module “reads” the vehicle speed

sensor (VSS) output to establish the desired vehicle

speed. The module then sends a signal to the stepper

motor which drives the ribbon reel to take up the slack in

the cruise cable. The Cruise Enabled/Engaged lamp in

the tachometer face (speedometer on FLHRC models)

turns from red to green to indicate that the cruising

speed is locked in. See Figure 8-125.

4. The cruise control module monitors both the engine

RPM and the VSS output speed signal. The module signals the stepper motor to open or close the throttle to

keep the speedometer output speed signal constant.

The engine RPM is monitored to detect engine

f2031x8x

Figure 8-123. Fairing Cap (FLHTCU)

2004 Touring: Electrical 8-99

Page 2

H

OME

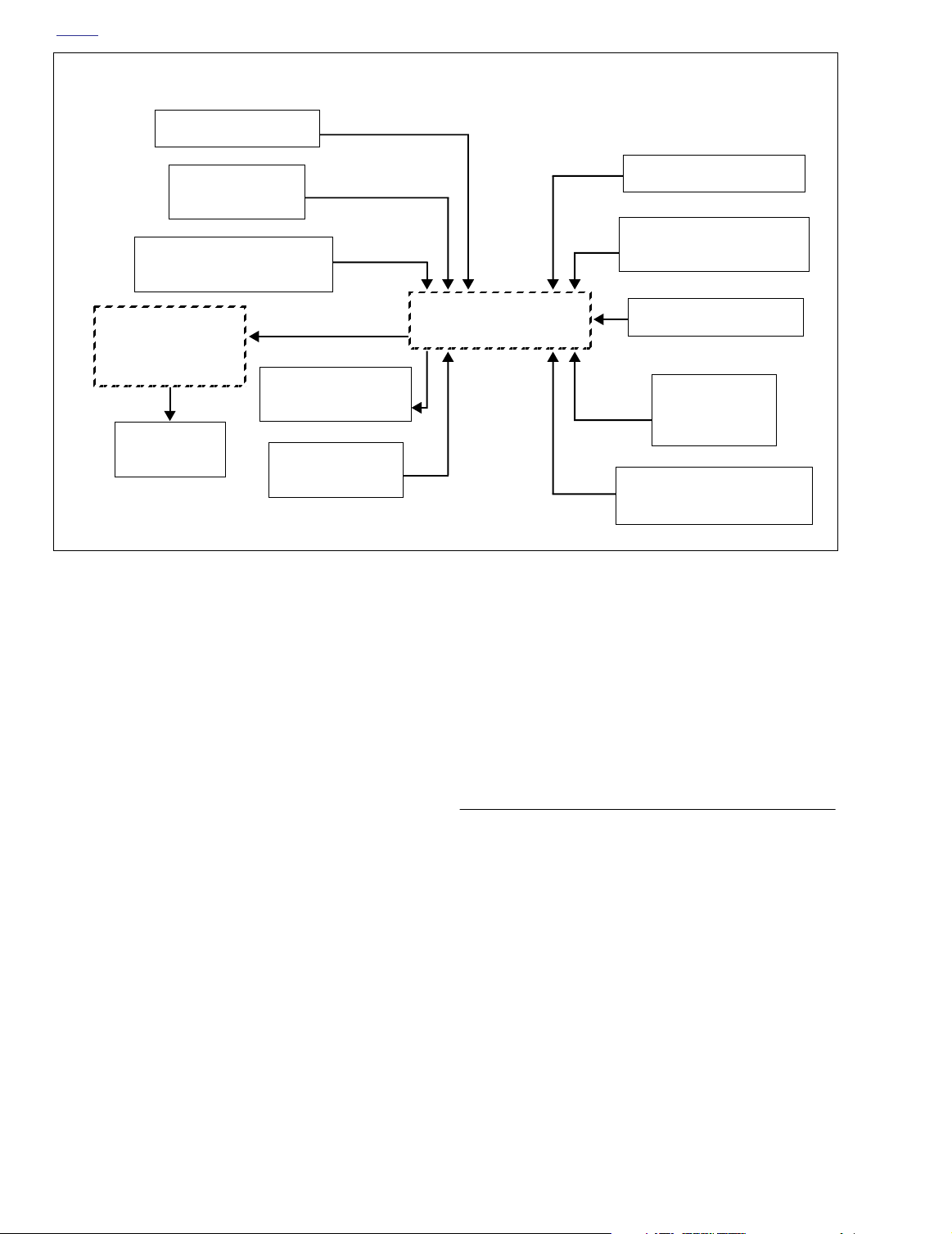

DISENGAGE SEQUENCEENGAGE SEQUENCE

CRUISE SWITCH ON

SET/RESUME

SWITCH TO SET

READS VSS

OUTPUT SPEED SIGNAL

STEPPER MOTOR

GEAR TRAIN

& RIBBON REEL

CRUISE ENGAGED

LAMP

THROTTLE

ACTUATION

*Tachometer receives signal from ignition coil on

carbureted models, and from ECM on EFI models.

overspeed, a condition which automatically causes

cruise disengagement.

5. The cruise control automatically disengages (stepper

motor drives cruise cable to the full-out position) whenever the cruise control module receives one of the following inputs:

a. Front or rear brake is applied.

b. Throttle is “rolled back” or closed, thereby actuating

idle cable roll-off (disengage) switch.

c. Motorcycle clutch is disengaged (module senses

too great an increase in RPM).

d. Cruise ON/OFF Switch placed in the OFF position.

The switch is located on the fairing cap of FLHTCU

models, the instrument nacelle of FLTR models, and

the left handlebar lower switch housing on FLHRC

models. The green Cruise Enabled/Engaged lamp

in the tachometer face (speedometer on FLHRC

models) is extinguished to indicate that the system

is deactivated. The red lamp in the fairing cap switch

of FLHTCU models and the instrument nacelle

switch of FLTR models is also extinguished.

e. Handlebar mounted Engine Stop Switch placed in

the OFF position. (This removes tachometer input

signal which results in module disengagement.)

ENGINE RPM

MONITORED*

Figure 8-126. Cruise System Diagram

FRONT/REAR BRAKE

IDLE CABLE ROLL-OFF

(DISENGAGE) SWITCH

CRUISE

MODULE

f. Handlebar mounted Cruise SET/RESUME switch is

pushed to SET and held in that position until vehicle

speed drops below 30 mph (48 km/h).

If the vehicle speed is above 30 mph (48 km/h) when the

Cruise SET/RESUME Switch is released, then the cruise

system automatically re-engages.

CRUISE SWITCH OFF

HANDLEBAR

ENGINE STOP

SWITCH OFF

CLUTCH DISENGAGE

(ENGINE RPM)

NOTE

CABLE ADJUSTMENT

NOTE

Always adjust the cables in the sequence presented below,

that is, throttle and then idle cable. The cruise cable only

requires adjustment if the cruise module or cruise cable are

removed or replaced, and then it must be adjusted last using

the CABLE LASH INITIALIZATION routine on the next page.

THROTTLE CABLE

1. With handlebar in straight ahead position, idle cable

adjusted to full slack and throttle control grip turned to

wide open throttle (WOT), adjust pull open cable to

obtain full throttle opening at carburetor/induction module.

8-100 2004 Touring: Electrical

Page 3

H

OME

2. Twist throttle grip to full closed position. Check that idle

stop-screw is touching idle stop with handlebar in

straight ahead position, and while turning handlebar

from “lock-to-lock”.

NOTE

If idle stop-screw is not touching idle stop, adjust (loosen)

pull-open cable just enough so that contact is made through

full lock-to-lock handlebar movement. Also check that cruise

cable has slack and is not opening throttle. Loosen cruise

cable if required.

3. Rotate throttle grip to WOT and release. Throttle must

return to idle position freely. If it does not, check for

incorrect cable routing, damaged cables or binding in the

throttle grip.

IDLE CABLE

1. Remove left side saddlebag. See Section 2.25 SAD-

DLEBAG, REMOVAL.

2. Gently pull side cover from frame downtubes (no tools

required).

3. Lift the locking latch and remove the cruise module connector [17]. With idle cable still adjusted to full slack position, connect ohmmeter to violet/yellow and orange/

violet leads on connector [17A].

4. Ohmmeter must indicate infinity (switch contacts open).

If ohmmeter indicates continuity, the roll-off switch may

be shorted and entire cable must be replaced.

5. With handlebar in straight ahead position, adjust idle

cable until approximately 0.06 inch (1.5 mm) of freeplay

exists at the outside diameter (OD) of the throttle grip.

6. With light force, rotate the throttle grip toward the closed

position. The ohmmeter must indicate continuity. If it

does not, decrease freeplay at throttle grip by adjusting

the idle cable to obtain continuity while maintaining

some freeplay at the throttle grip.

7. While holding the throttle grip (with light force) in the

closed position, turn handlebar from “lock-to-lock”. Ohmmeter must indicate continuity throughout handlebar

movement.

8. With handlebar in straight ahead position, rotate throttle

grip to WOT and release. Throttle must return to idle

position freely.

9. Repeat step 8 with handlebar at full left and right positions. If throttle does not return to idle position freely,

loosen idle cable slightly and repeat steps 6-9.

10. Install cruise module connector [17] and engage locking

latch.

11. Align barbed studs in side cover with grommets in frame

downtubes and push firmly into place (no tools

required).

12. Install left side saddlebag. See Section 2.25 SADDLE-

BAG, INSTALLATION.

CABLE LASH INITIALIZATION

With the elimination of the mechanical cruise cable adjuster,

the tolerance stack-ups are intended to result in a cable that

is too long. The extra cable length is then taken up upon execution of the Cable Lash Initialization routine. During the routine, the system calculates the number of “motor steps” the

cable is pulled before the throttle plates are moved (a maximum of 200 motor steps equivalent to 1.2 inches or 31 mm).

This information is then stored in permanent memory.

NOTE

Perform the initialization routine whenever the cruise module,

cruise cable or throttle body are removed or replaced. For

best results, be sure the engine is at normal operating temperature and throttle and idle cables are correctly adjusted

and operational.

To set the correct cable lash, proceed as follows:

a. Push the Cruise Switch on the right handlebar to

RESUME and hold

b. Tu rn the Cruise ON/OFF switch to ON.

c. Turn the Ignition/Light Key Switch to IGNITION.

d. Start the engine. The green Cruise Enabled/

Engaged lamp in the tachometer face (speedometer

on FLHRC models) will illuminate. Wait 3 seconds

for the lamp to go off.

e. Release the Cruise Switch from the RESUME posi-

tion.

f. Push the Cruise Switch to RESUME and hold

Cruise will pull in cable until change in RPM is

detected. The number of motor steps required to rev

the engine is stored in memory.

g. After engine revs and Cruise Enabled/Engaged

lamp is extinguished, release the Cruise Switch

from the RESUME position.

h. Turn the Ignition/Light Key Switch to OFF.

.

THROTTLE/IDLE CABLES

NOTE

While the same throttle cable is used on all Touring models,

the idle cable of “cruise” models is provided with a cruise rolloff (disengage) switch.

REMOVAL

1. See Section 2.21 THROTTLE CABLES (NON-CRUISE),

REMOVAL, THROTTLE SIDE.

2. Remove the air cleaner and backplate. See Section 4.5

AIR CLEANER, REMOVAL.

3. Raise fuel tank to access cables in area of frame back-

bone. For carbureted models, see Section 4.7 FUEL

TANK (CARBURETED), PA RTIAL REMOVAL, FLHT/C,

or FLHR/S. For fuel injected models, see Section 9.4

FUEL TANK (FUEL INJECTED), PARTIAL REMOVAL,

FLHT/C/U/I, FLTRI, or FLHR/C/S/I.

.

2004 Touring: Electrical 8-101

Page 4

H

OME

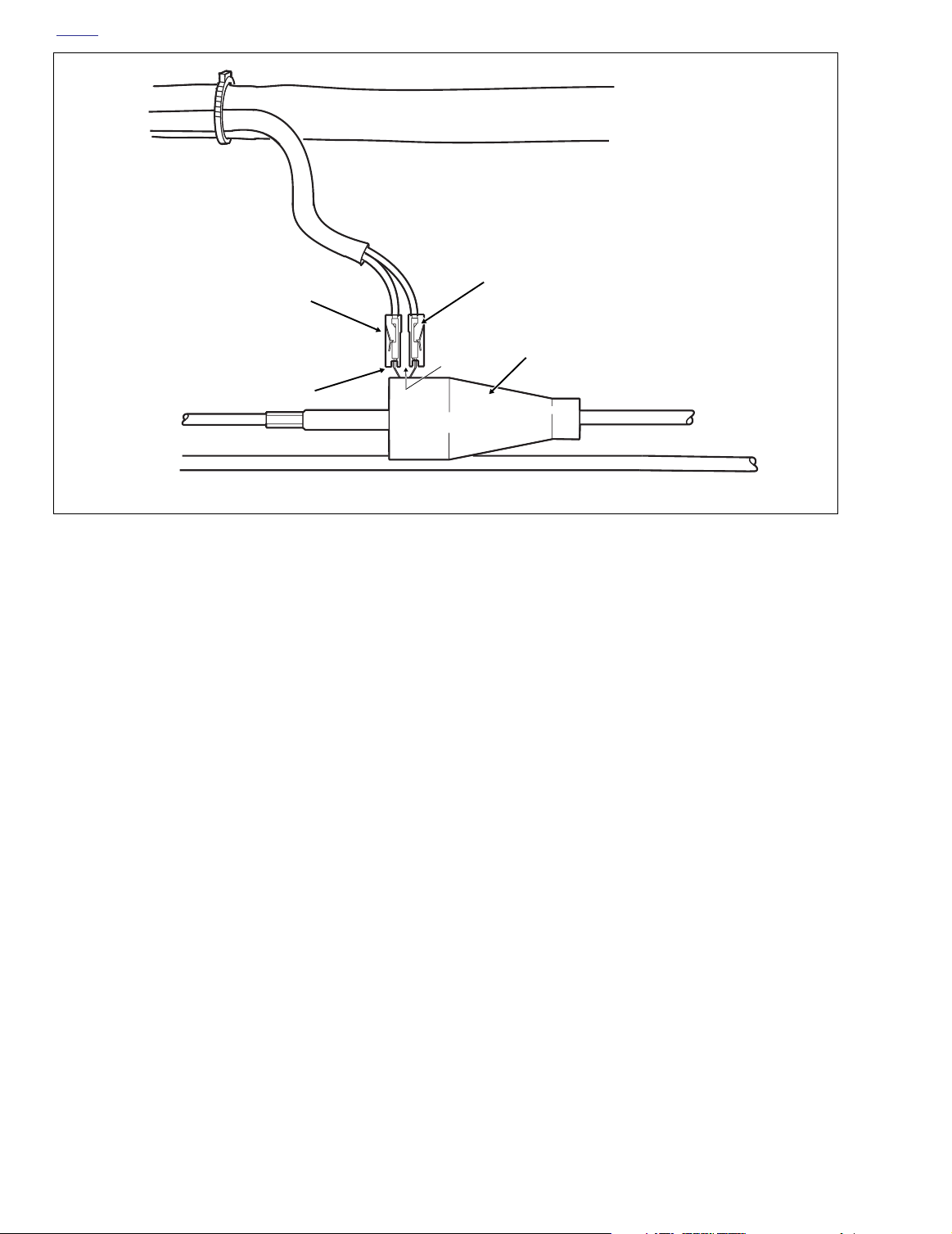

Insulator

Switch Spade

Contact

Female Spade

External

Step

Main

Harness

Terminal

Cruise Control

Roll-Off Switch

(Under Boot)

Idle Cable

f2037x8x

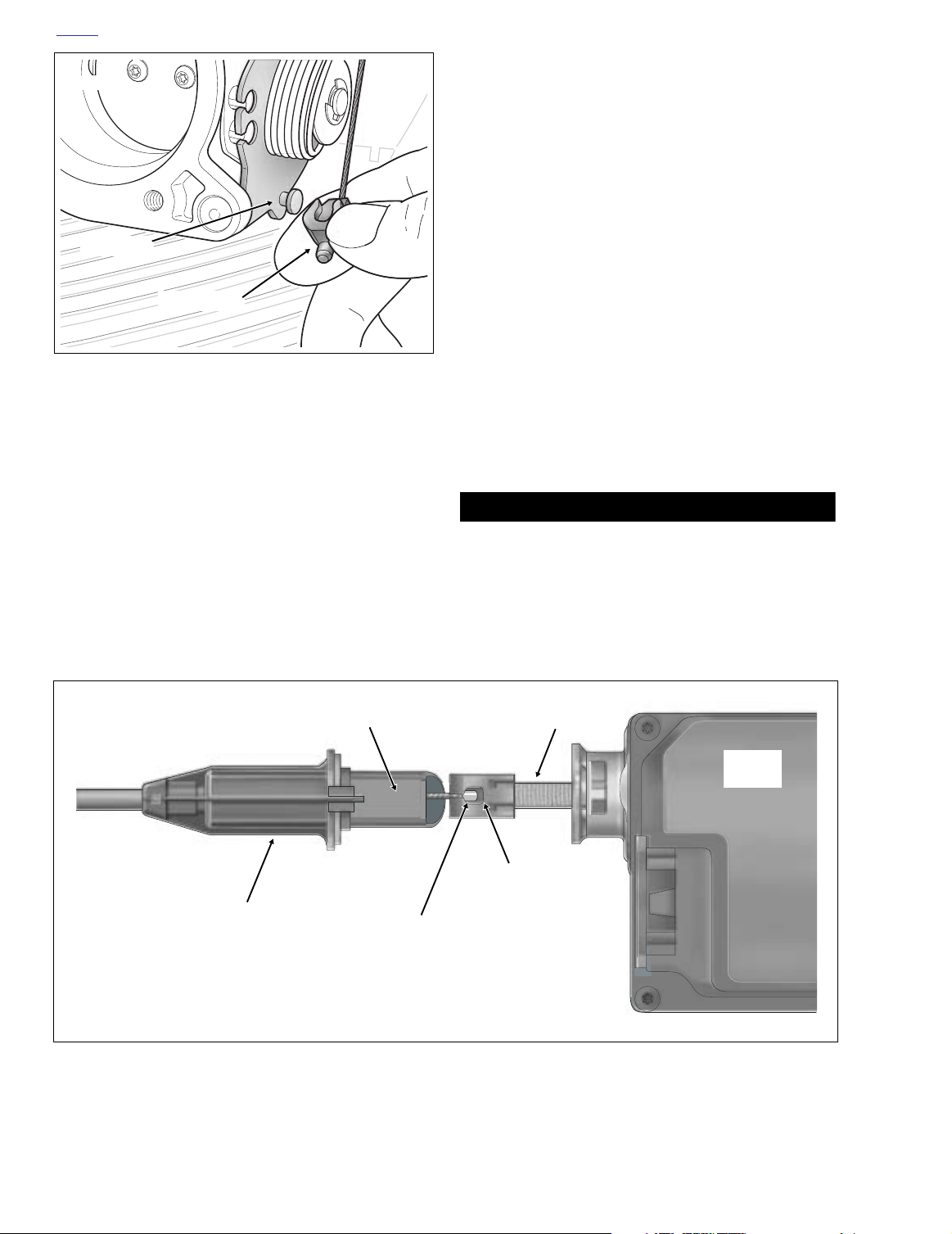

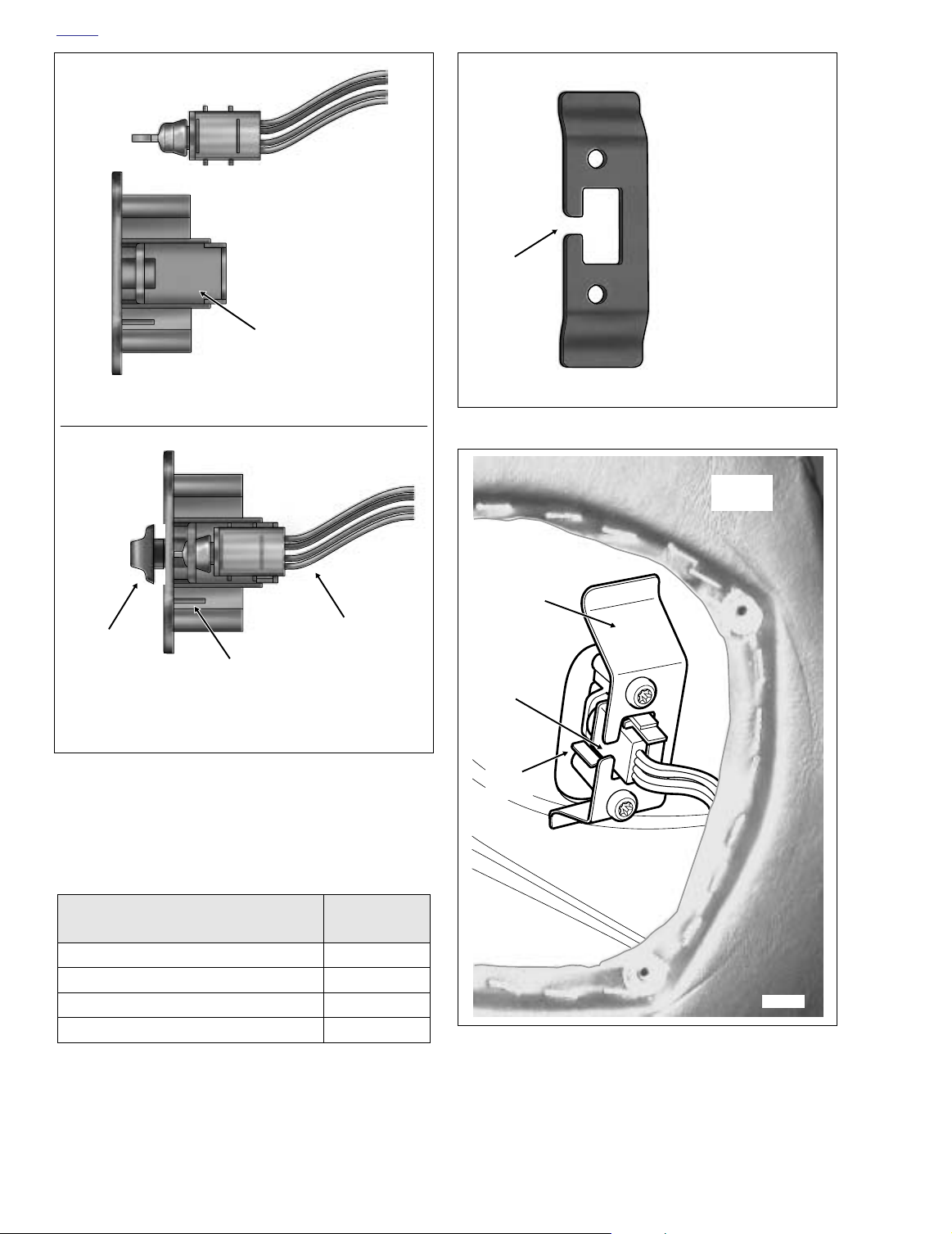

Figure 8-127. Throttle/Idle Cable Configuration (Right Side View)

4. Locate the cruise control roll-off switch plumbed into the

idle cable on the right side of the vehicle. See Figure 8-

127. Push rubber boot on switch forward to access

spade type wire terminals.

5. Remove both female spade type terminals from spade

contacts on cruise control roll-off switch.

6.

Carbureted:

Using a needle nose pliers, carefully pull

idle cable barrel from upper inboard hole in throttle

wheel. Pull throttle cable barrel from remaining hole.

Release idle and throttle cables from guides in throttle

cable bracket.

Induction Module:

Using a needle nose pliers, carefully

pull idle cable barrel from upper hole in throttle wheel.

Pull throttle cable barrel from lower hole. Using slots,

release idle and throttle cables from guides in throttle

cable bracket.

7. Free cables from J-clamp riveted to right side of frame

backbone.

8. If present, remove screw (with flat washer) to release Jclamp from wellnut in right side of steering head.

Remove J-clamp from cables.

INSTALLATION

1. See Section 2.21 THROTTLE CABLES (NON-CRUISE),

INSTALLATION, THROTTLE SIDE.

Throttle Cable

2. Route the throttle and idle cables as follows:

FLHTCU:

Route the cables downward following the

brake line to the inner fairing. Pass the cables through

the inner fairing grommet and then loop them toward the

rear along the right side of the steering head.

FLHRC:

Route the cables downward following the right

handlebar to the handlebar clamp shroud. Pass the

cables through the opening in the shroud and then loop

them toward the rear along the right side of the steering

head. Capture cables in J-clamp and then start screw

(with flat washer) to fasten J-clamp to wellnut in right

side of steering head. Tighten screw to 9-18

in-lbs

(1.0-

2.0 Nm).

3. Route the throttle and idle cables rearward along the

right side of the frame backbone. After passing through

J-clamp riveted to frame backbone, route cables downward to carburetor/induction module.

4. Use a pliers to straighten spade contacts of cruise rolloff switch if bowed or bent back. The contacts must be

parallel and line up perpendicular to the idle cable.

5. Separate the cruise roll-off switch wires up to the point

where they enter the wire harness conduit. Now route

the leads straight down.

6. Orient the idle cable so that the spade contacts are at

the top.

8-102 2004 Touring: Electrical

Page 5

H

OME

7. Slide the insulators onto the switch spade contacts

(polarity is not a factor). For maximum insertion, be sure

that the external step on the insulators face each other.

See Figure 8-127.

8. Fit the rubber boot over the cruise control roll-off switch.

An oval cut in the boot accommodates the switch spade

terminal connections.

9. Position the throttle cable below the idle cable.

10.

Carbureted:

shorter cable guide in throttle cable bracket. Drawing

throttle cable downward, fit barrel end into lower outboard hole in throttle wheel. Install sleeve and spring on

idle cable housing into longer cable guide inserting barrel end into upper inboard hole in throttle wheel.

Induction Module:

ing into shorter cable guide at top of throttle cable

bracket. Drawing throttle cable downward, fit barrel end

into lower hole in throttle wheel. Install sleeve and spring

on idle cable housing into longer cable guide at bottom

of throttle cable bracket inserting barrel end into upper

hole in throttle wheel.

11. Verify that cables are fully seated in channel of throttle

wheel, and using cable adjusters at handlebar, tighten

Install sleeve on throttle cable housing into

Install sleeve on throttle cable hous-

cables as necessary to keep barrel ends from dislodging. Verify operation by turning throttle grip and observing cable action.

12. Install fuel tank. For carbureted models, see Section 4.7

FUEL TANK (CARBURETED), INSTALLATION (AFTER

PA RTIAL REMOVAL), FLHT/C, or FLHR/S. For fuel

injected models, see Section 9.4 FUEL TANK (FUEL

INJECTED), INSTALLATION (AFTER PARTIAL

REMOVAL), FLHT/C/U/I, FLTRI, or FLHR/C/S/I.

13. Install backplate and air cleaner assembly. See Section

4.5 AIR CLEANER, INSTALLATION.

14. Adjust the throttle and idle cables. Be sure to use the

cable adjustment procedure for Ultra models. See

CABLE ADJUSTMENT, in this section.

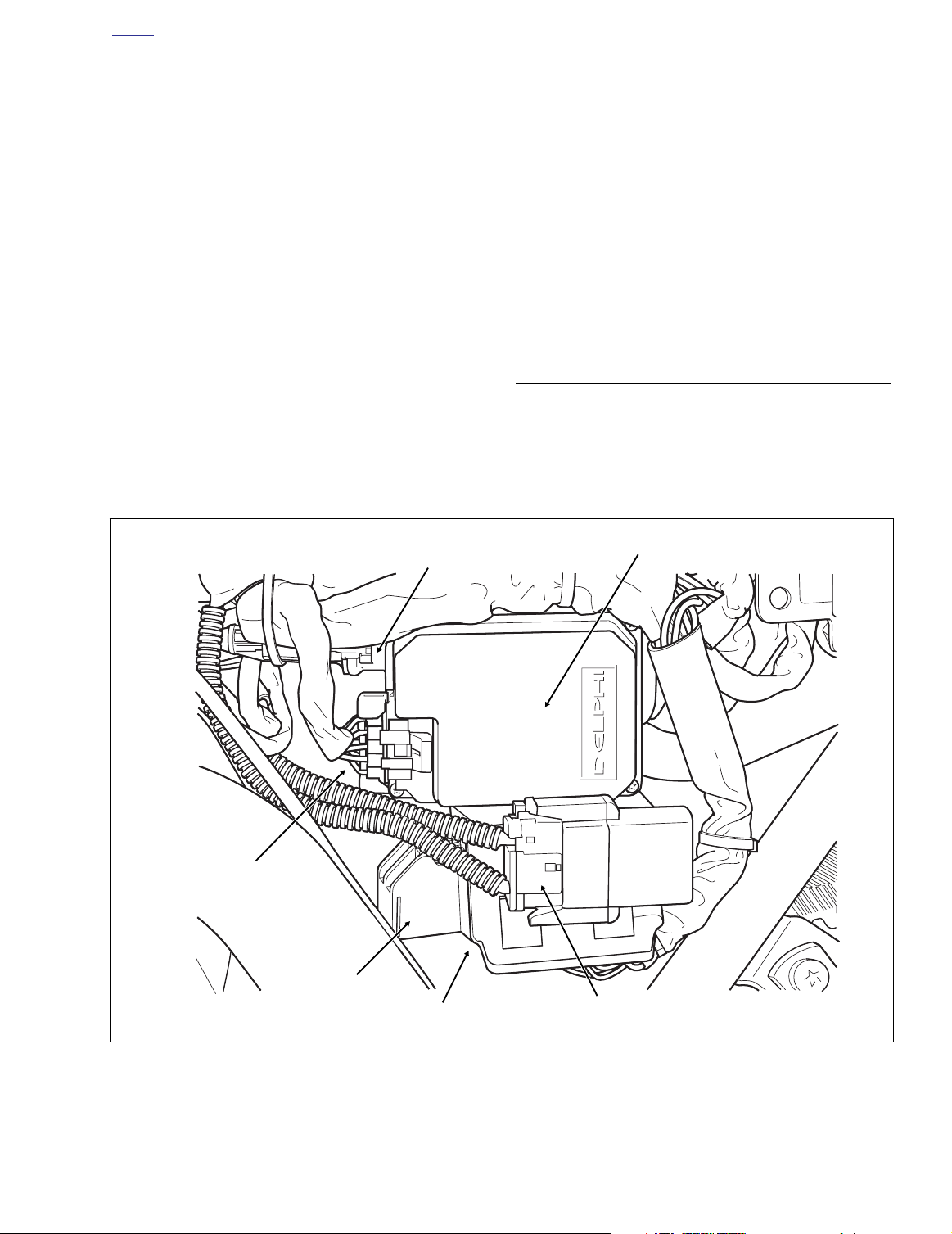

CRUISE CABLE

REMOVAL

1. Remove the air cleaner and backplate. See Section 4.5

AIR CLEANER, REMOVAL.

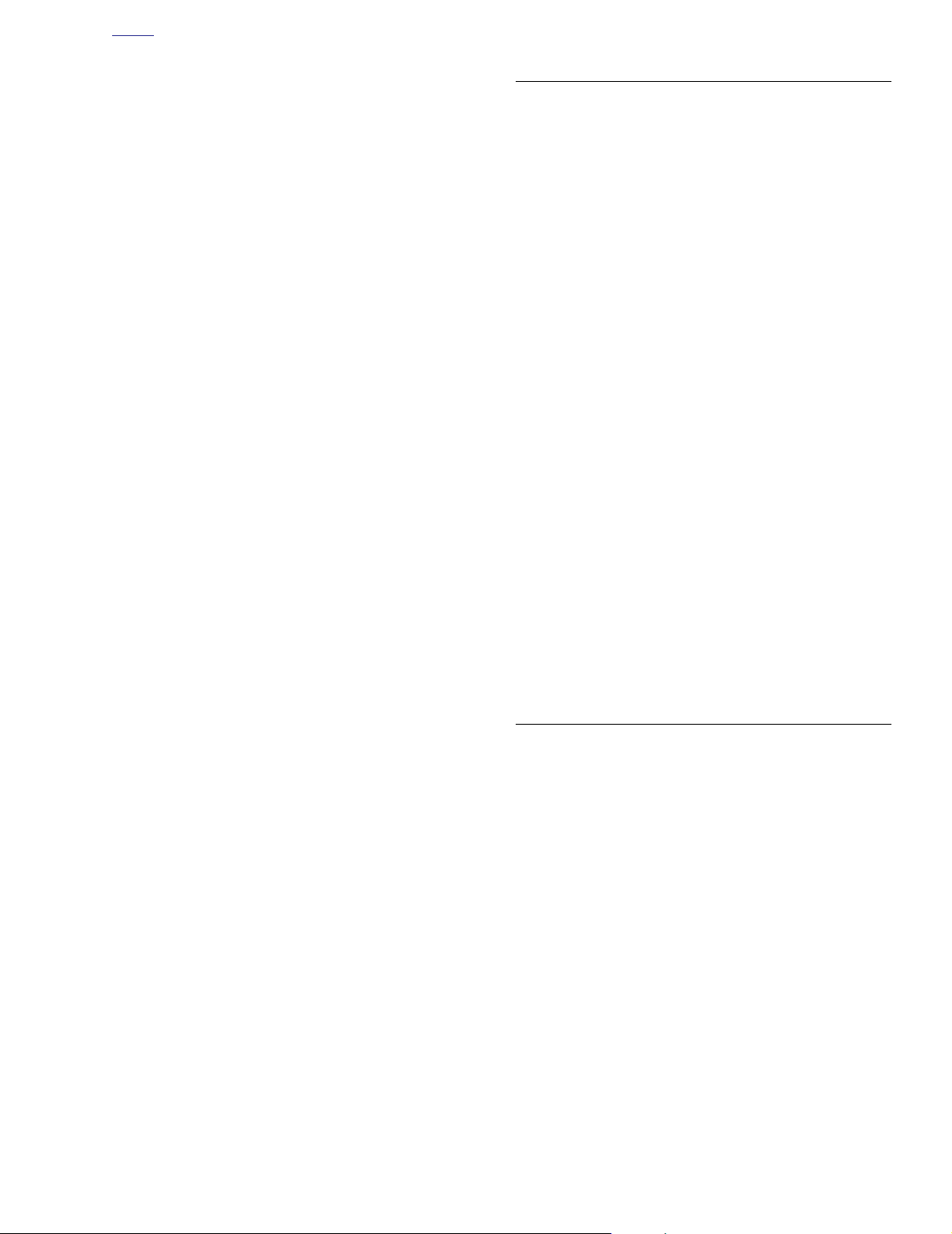

f2206x8x

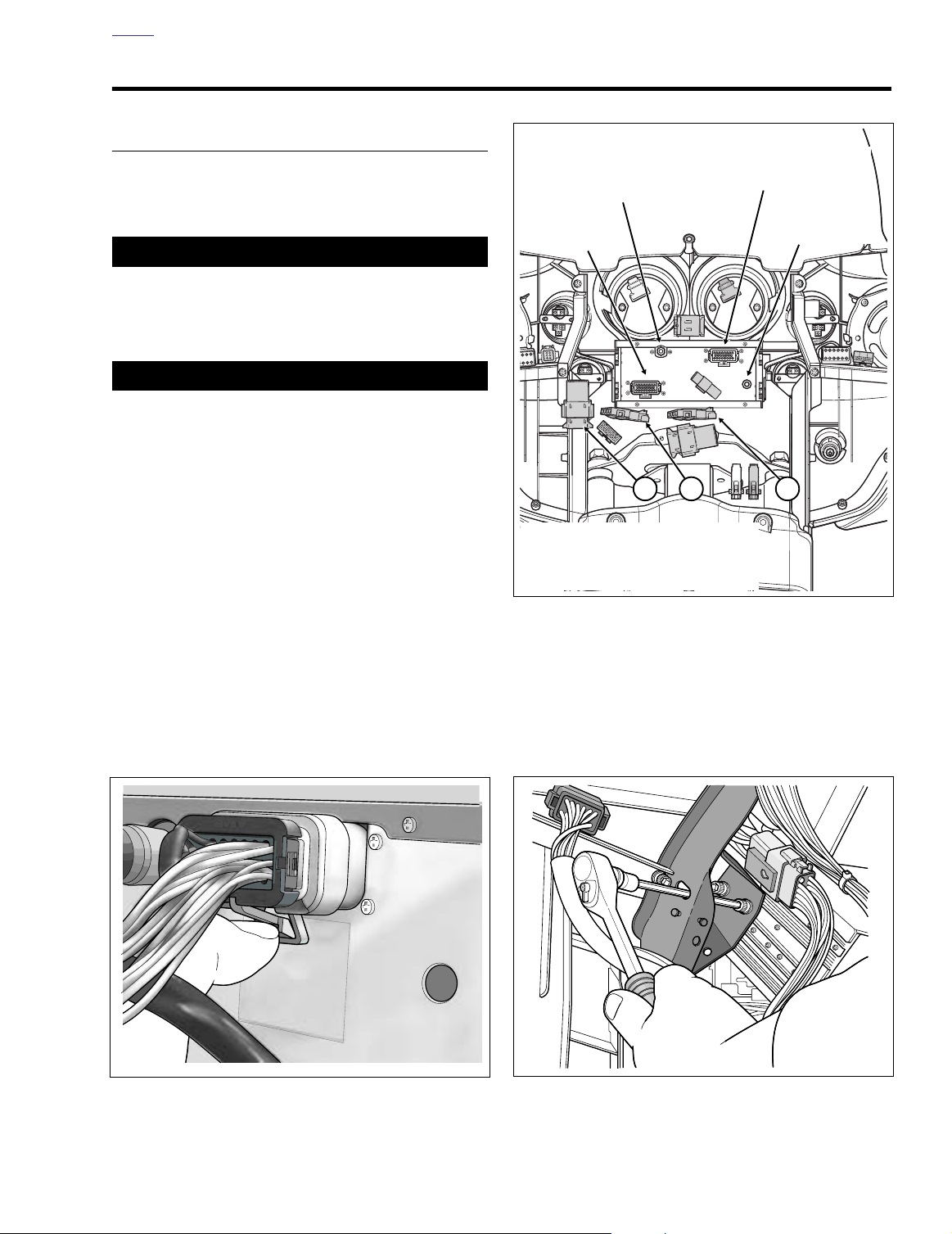

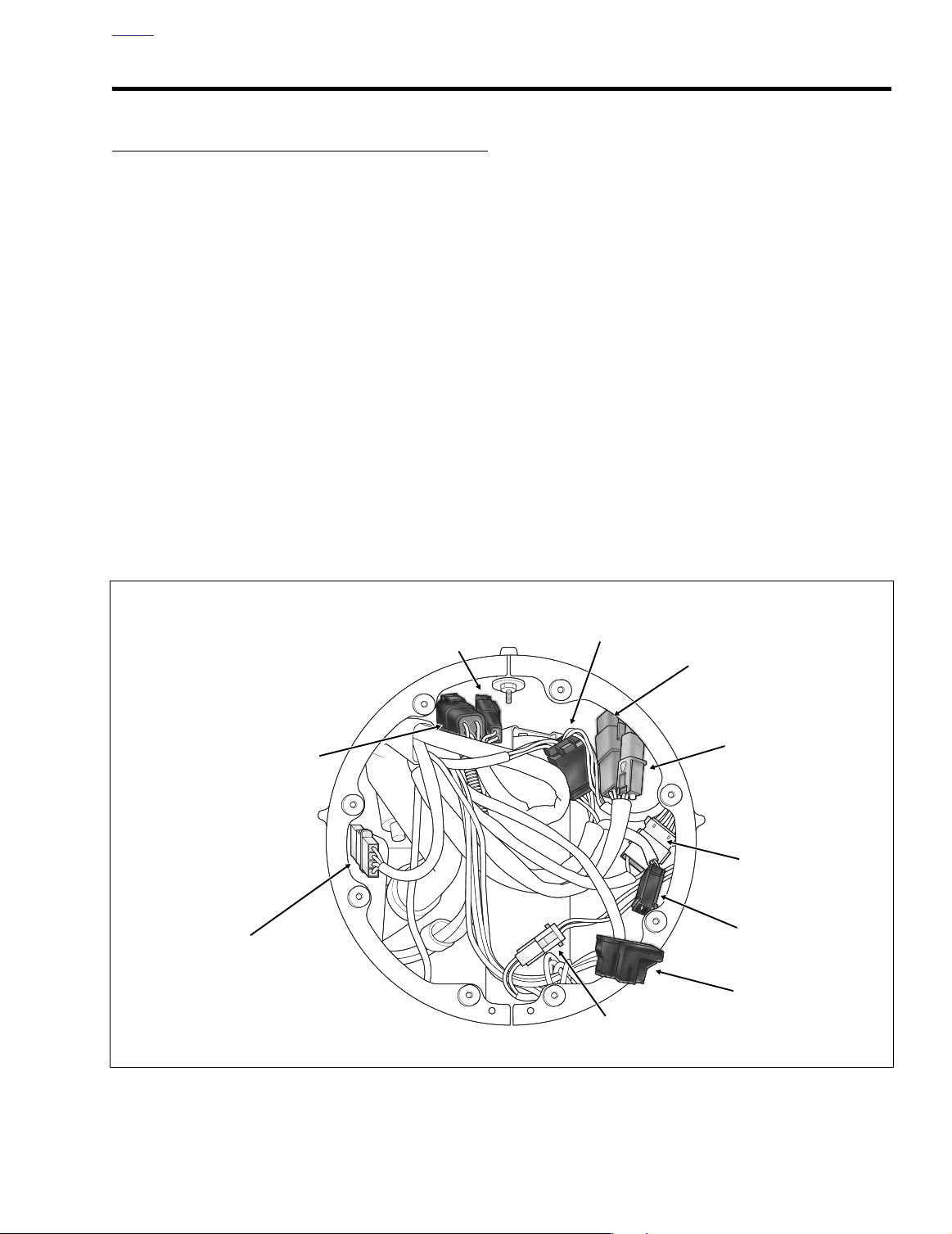

Cruise Module

Connector [17]

Spare Fuse

Holder

Cruise Cable

Connector

Fuse Block

Cruise Module

Maxi-Fuse

Holder

Figure 8-128. Cruise Control Module (Under Left Side Cover)

2004 Touring: Electrical 8-103

Page 6

H

OME

f1965x8x

7. Pull the cable out of the connector and remove the cable

end bead from the ribbon end eyelet. See Figure 8-130.

8. Pull anchored cable clip from hole in frame crossmember. See Figure 8-131.

9. Carefully pull cruise cable from beneath fuel tank drawing it out through hole in frame crossmember.

INSTALLATION

Wheel Pin

End Fitting

Figure 8-129. Remove End Fitting From Wheel Pin

2. Remove E-clip from sleeve at end of cruise cable housing. Discard E-clip. Using slot, remove cruise cable

housing from cable guide in throttle cable bracket.

3. Push the plastic end fitting on the cruise cable to the outboard side to release from wheel pin. See Figure 8-129.

4. Remove left side saddlebag. See Section 2.25 SAD-

DLEBAG, REMOVAL.

5. Gently pull side cover from frame downtubes (no tools

required).

6. Rotate cruise cable connector in a counterclockwise

direction to detach from cruise module. See Figure 8-

128.

Flat

1. Draw the cruise cable forward along the left side of the

frame backbone, and then route the cable toward the

right side of the vehicle in front of the top engine stabilizer bracket.

2. Slide groove in cruise cable end fitting over cap of wheel

pin. Push on end fitting until it snaps in place. See Figure

8-129.

3. Using slot, slip cruise cable housing into cable guide in

throttle cable bracket. At bottom of bracket, install

new

E-clip on sleeve at end of cruise cable housing.

4. Feed cruise cable and connector through hole in frame

crossmember. See Figure 8-131.

CAUTION

Be sure that the ribbon is not twisted. A twisted ribbon

may adversely affect performance or even prevent cruise

operation.

5. With the hole in the ribbon end eyelet and the flat on the

cable connector housing facing outboard, fit cable end

bead into ribbon end eyelet. See Figure 8-130.

Ribbon

Cruise Cable

Connector

f1549x8x

Figure 8-130. Remove Cable End Bead From Ribbon End Eyelet

8-104 2004 Touring: Electrical

Cruise

Module

Ribbon End

Eyelet

Cable End

Bead

Page 7

H

1WARNING1WARNING

f2004x8x

Mounting

Holes

OME

f1548x8x

Cruise

Cable

Cable Clip

Hole

Figure 8-131. Cruise Cable Routing (Left Side)

6. Verify that bead, eyelet and ribbon are lined up correctly.

If necessary, remove plastic end fitting from wheel pin

and gently pull on end fitting to remove cable slack.

Reinstall end fitting, if removed.

7. Insert cruise cable connector into cruise module and

rotate in a clockwise direction until tabs on connector

fully engage grooves or detentes in cruise module housing.

8. Capture cruise cable in cable clip and anchor in hole of

frame crossmember. See Figure 8-131.

9. Adjust the throttle and idle cables. See CABLE ADJUST-

MENT, in this section.

10. Install backplate and air cleaner assembly. See Section

4.5 AIR CLEANER, INSTALLATION.

11. Align barbed studs in side cover with grommets in frame

downtubes and push firmly into place (no tools

required).

12. Install left side saddlebag. See Section 2.25 SADDLE-

BAG, INSTALLATION.

13. Perform the CABLE LASH INITIALIZATION routine des-

cribed in this section.

Always disconnect the negative battery cable first. If the

positive cable should contact ground with the negative

cable installed, the resulting sparks may cause a battery

explosion which could result in death or serious injury.

4. Unthread bolt and remove battery negative cable (black)

from battery negative (-) terminal.

5. Unthread bolt and remove battery positive cable (red)

from battery positive (+) terminal.

6. Using a T40 TORX drive head, loosen bolt to move lip of

hold-down clamp off edge of battery. Remove battery

from battery box.

7. Lift the locking latch and remove the cruise module connector [17]. See Figure 8-128.

8. Rotate cruise cable connector in a counterclockwise

direction to detach from cruise module.

9. From inside battery box, remove three flange bolts.

Carefully pull cruise module away from side of battery

box exercising caution to avoid losing grommets.

INSTALLATION

1. Install grommets into holes on left side of battery box

with the larger OD on the outboard side. See Figure 8-

132.

2. Align threaded holes on inboard side of cruise module

with holes in grommets and install flange bolts from

inside battery box.

3. Alternately tighten flange bolts to 60-96

Nm). Install cruise module connector [17] and engage

locking latch.

in-lbs

(6.8-10.9

CRUISE CONTROL MODULE

REMOVAL

1. Remove the air cleaner and backplate. See Section 4.5

AIR CLEANER, REMOVAL.

2. Push the plastic end fitting on the cruise cable to the outboard side to release from wheel pin. See Figure 8-129.

3. Remove seat. See Section 2.24 SEAT, REMOVAL.

Figure 8-132. Battery Box (Right Side View)

2004 Touring: Electrical 8-105

Page 8

H

OME

CAUTION

Be sure that the ribbon is not twisted. A twisted ribbon

may adversely affect performance or even prevent cruise

operation.

4. With the hole in the ribbon end eyelet and the flat on the

cable connector housing facing outboard, fit cable end

bead into ribbon end eyelet. See Figure 8-130.

5. Verify that bead, eyelet and ribbon are lined up correctly.

If necessary, remove plastic end fitting from wheel pin

and gently pull on end fitting to remove cable slack.

6. Insert cruise cable connector into cruise module and

rotate in a clockwise direction until tabs on connector

fully engage grooves or detentes in cruise module housing.

7. Install the cruise module connector [17] until locking

latch engages. See Figure 8-128.

8. Place battery in battery box, terminal side forward.

Rotate hold-down clamp so that lip (with rubber pad)

rests on edge of battery and tighten clamp bolt.

1WARNING1WARNING

Always connect the positive battery cable first. If the

positive cable should contact ground with the negative

cable installed, the resulting sparks may cause a battery

explosion which could result in death or serious injury.

CRUISE CONTROL SWITCHES

FAIRING CAP

See Figure 8-133. For instructions on replacement of the

CRUISE ON/OFF SWITCH, see Section 8.19 FAIRING

CAP SWITCHES (FLHTC/U), Section 8.20 INSTRUMENT NACELLE SWITCHES (FLTR), or Section 8.21

HANDLEBAR SWITCHES (FLHRC).

Cruise ON/OFF

Switch

f2031x8x

Figure 8-133. Fairing Cap (FLHTCU)

9. Insert bolt through battery positive cable (red) into

threaded hole of battery positive (+) terminal. Tighten

bolt to 60-96

10. Insert bolt through battery negative cable (black) into

threaded hole of battery negative (-) terminal. Tighten

bolt to 60-96

11. Install seat. See Section 2.24 SEAT, INSTALLATION.

12. Slide groove in cruise cable end fitting over cap of wheel

pin. Push on end fitting until it snaps in place. See Figure

8-129.

13. Install backplate and air cleaner assembly. See Section

4.5 AIR CLEANER, INSTALLATION.

14. Perform the CABLE LASH INITIALIZATION routine des-

cribed in this section.

in-lbs

in-lbs

(6.8-10.9 Nm).

(6.8-10.9 Nm).

AUDIO HARNESS

For instructions on replacement of the audio harness,

see Section 8.32 WIRING HARNESSES AND CABLES,

AUDIO HARNESS (FLHTCU).

HANDLEBAR

See Figure 8-134. For instructions on replacement of the

handlebar mounted CRUISE SET/RESUME switch, see

Section 8.21 HANDLEBAR SWITCHES, SWITCH

REPAIR/REPLACEMENT.

f1368a8x

Set/Resume

Switch

Figure 8-134. Right Handlebar Switch Assembly

(FLTR, FLHTCU)

8-106 2004 Touring: Electrical

Page 9

H

f2238x8x

Radio Antenna

Cable [51]

Radio [27]

Black

CB Antenna

Cable [50]

Ultra Only

Radio [28]

Gray

Ultra Only

1. Main to Interconnect [1]

2. Main to Interconnect [15]

3. Ignition/Light Key Switch [33]

1 2 3

f1559x8x

OME

PREMIUM SOUND SYSTEM (FLHTC/U, FLTR) 8.31

RADIO (FLHTC/U)

REMOVAL

1. Remove seat. See Section 2.24 SEAT, REMOVAL.

1WARNING1WARNING

To protect against shock and accidental start-up of vehicle, disconnect the negative battery cable before proceeding. Inadequate safety precautions could result in

death or serious injury.

CAUTION

To prevent possible damage to the sound system,

always verify that the Ignition/Light Key Switch is in the

OFF position before disconnecting the battery negative

cable from the battery terminal.

2. Verify that the Ignition/Light Key Switch is in the OFF

position. Unthread bolt and remove battery negative

cable (black) from battery negative (-) terminal.

3. Remove the outer fairing. See Section 2.29 UPPER

FAIRING/WINDSHIELD (FLHT/C/U), OUTER FAIRING/

WINDSHIELD, REMOVAL.

NOTE

To separate pin and socket halves of Radio connectors [27]

and [28], use thumbnail to pull down external latch before

pulling socket from pin side. See Figure 8-135.

4. See Figure 8-136. Separate pin and socket halves of the

following connectors:

a. Radio connector [27], 23-place Amp (black).

f1555x8x

Figure 8-136. Radio Connections - FLHTCU

b. Radio antenna cable connector [51].

c. Radio connector [28], 23-place Amp (gray).

models only.

d. CB antenna cable connector [50]. Rotate knurled

nut counterclockwise until free.

Ultra models only.

Ultra

Figure 8-135. Pull Down Latch to Free Radio Connector

Figure 8-137. Release Carrier from Fairing Brackets

2004 Touring: Electrical 8-107

Page 10

H

OME

5. Move the following connectors from their fixed locations:

a. Main to interconnect harness connector [1], 12-

place Deutsch (black); T-stud at front of right fairing

bracket.

b. Main to interconnect harness connector [15], 4-

place Packard (black); anchor in hole at bottom of

radio (right side).

c. Ignition/light key switch connector [33], 4-place

Packard; anchor in hole at bottom of radio (center).

6. Using a long shank ball end socket (Snap-on® FABL6E),

remove four screws to release radio from left and right

radio support brackets. Use oblong holes in fairing

brackets to access screws. See Figure 8-137.

7. Pull radio forward to remove. If radio nose seal gets

caught on radio support brackets, rock up and down until

free.

INSTALLATION

1. Position radio between radio support brackets and push

into approximate position. If radio nose seal gets caught

on radio support brackets, rock up and down while pushing. If necessary, spray nose seal with contact cleaner

and repeat step.

2. Before pushing radio into cut of inner fairing, verify that

nose seal is not distorted, compressed or pinched.

3. Align threaded inserts in radio sides with oblong holes in

left and right radio support brackets. Starting with the

rear screws, install four socket screws to fasten radio to

brackets. Tighten screws to 35-45

4. See Figure 8-136. Mate pin and socket halves of the following connectors:

a. Radio connector [27], 23-place Amp (black).

b. Radio antenna cable connector [51].

c. Radio connector [28], 23-place Amp (gray).

models only.

d. CB antenna cable connector [50]. Insert pin and

rotate knurled nut clockwise until tight.

only.

5. Return the following connectors to their fixed locations:

a. Main to interconnect harness connector [1], 12-

place Deutsch (black); T-stud at front of right fairing

bracket.

b. Main to interconnect harness connector [15], 4-

place Packard (black); anchor in hole at bottom of

radio (right side).

c. Ignition/light key switch connector [33], 4-place

Packard; anchor in hole at bottom of radio (center).

in-lbs

(4.0-5.1 Nm).

Ultra

Ultra models

6. Install outer fairing. See Section 2.29 UPPER FAIRING/

WINDSHIELD (FLHT/C/U), OUTER FAIRING/WINDSHIELD, INSTALLATION.

CAUTION

To prevent possible damage to the sound system,

always verify that the Ignition/Light Key Switch is in the

OFF position before connecting the battery negative

cable to the battery terminal.

7. Verify that the Ignition/Light Key Switch is in the OFF

position. Insert bolt through battery negative cable

(black) into threaded hole of battery negative (-) terminal. Tighten bolt to 60-96

8. Install seat. See Section 2.24 SEAT, INSTALLATION.

in-lbs

(6.8-10.9 Nm).

FRONT FAIRING SPEAKERS

REMOVAL

1. Remove the outer fairing. See Section 2.29 UPPER

FAIRING/WINDSHIELD (FLHT/C/U), OUTER FAIRING/

WINDSHIELD, REMOVAL.

2. Carefully pull the socket terminals from the speaker

spade contacts.

3. Using a T25 TORX drive head, remove three screws to

release the speaker adapter assembly from the inner

fairing.

4. Carefully pull speaker from adapter.

INSTALLATION

1. With the speaker spade contacts at the top of the

adapter, the top being the side with the widest edge,

snap speaker into adapter using finger pressure.

2. If speaker grille is loose, apply 3M-847 adhesive (HD

Part No. 99618-60) to outer edge of adapter ring. Install

grille on adhesive.

3. With the widest edge of adapter at the top, align holes in

speaker adapter assembly with those in inner fairing.

4. Install two long screws to secure top of speaker adapter

assembly to inner fairing. Capturing fairing support

brace, install short screw in lower outboard hole (positioning flat washer between adapter and support brace).

The screw hole on the lower inboard side is not used.

5. Using a T25 TORX drive head, tighten the lower speaker

screw to 22-28

upper speaker screws to 35-50

in-lbs

(2.5-3.2 Nm). Tighten the two

in-lbs

(4.0-5.7 Nm).

8-108 2004 Touring: Electrical

Page 11

H

f2192x8x

Console Pod

Cable Conduit

Console Pod

Connector [53]

12-Place Mini-Deutsch

OME

Fuel

Door

Headset

Receptacle

Cap

Console

Figure 8-138. Console Pod Assembly

6. Install the socket terminals onto the speaker spade contacts. Different size spade contacts prevent improper

assembly.

7. Install the outer fairing. See Section 2.29 UPPER FAIR-

ING/WINDSHIELD (FLHT/C/U), OUTER FAIRING/

WINDSHIELD, INSTALLATION.

f2019x8x

Pod

CONSOLE POD ASSEMBLY

5. Carefully cut anchored cable strap securing main harness, audio harness, console pod conduit, fuel level

sender/fuel pump conduit, and fuel vapor vent tube to

left side of frame backbone. Cut cable strap securing

console pod conduit and audio harness to left frame

tube at front of saddlebag rail.

6. Open fuel door on console. Remove two Allen head

screws inboard of rubber bumpers. These screws secure

console to clip nuts on the canopy bracket.

7. Remove Allen head screw to detach flange at rear of

console from clip nut on fuel tank weldment.

8. Lay a clean shop towel on forward part of the rear

fender. Remove filler cap from neck of fuel tank. Remove

console and lay upside down on shop towel. Reinstall

filler cap.

9. Bend back flexible clamp to release pod cable conduit

from bottom of console.

10. Release Console Pod Connector [53], 12-place MiniDeutsch, from attachment clip anchored in hole of frame

crossmember (at rear of battery box). See Figure 8-139.

Depress external latches and use a rocking motion to

separate pin and socket halves.

11. Remove three Phillips screws to release pod from console.

INSTALLATION

1. Feed pin housing and conduit through top of console

seating pod in recess. Install three Phillips screws

screws to secure pod to console. Alternately tighten

screws to 6-11

flexible clamp at bottom of console.

in-lbs

(0.7-1.2 Nm). Capture conduit in

The following instructions may also be used for replacement

of the chrome fuel tank console on which the pod is mounted.

REMOVAL

1. Remove seat. See Section 2.24 SEAT, REMOVAL.

To protect against shock and accidental start-up of vehicle, disconnect the negative battery cable before proceeding. Inadequate safety precautions could result in

death or serious injury.

2. Unthread bolt and remove battery negative cable (black)

3. Remove left side saddlebag. See Section 2.25 SAD-

4. Gently pull side cover from frame downtubes (no tools

NOTE

1WARNING1WARNING

from battery negative (-) terminal.

DLEBAG, REMOVAL.

required).

Figure 8-139. Disconnect Console Pod Connector

2004 Touring: Electrical 8-109

Page 12

H

OME

Fuel

Tank

Fuel Pump,

Fuel Level

Sender Conduit

Console

Pod

f2007x9x

6. Mate pin and socket halves of Console Pod Connector

[53], 12-place Mini-Deutsch. Install connector onto

attachment clip anchored in hole of frame crossmember

(at rear of battery box).

7. Insert bolt through battery negative cable (black) into

threaded hole of battery negative (-) terminal. Tighten

bolt to 60-96

8. Install seat. See Section 2.24 SEAT, INSTALLATION.

9. Align barbed studs in side cover with grommets in frame

downtubes and push firmly into place (no tools

required).

10. Install left side saddlebag. See Section 2.25 SADDLE-

BAG, INSTALLATION.

in-lbs

(6.8-10.9 Nm).

Main

Harness

Bundle

Console

Pod Conduit

Figure 8-140. Console Pod Cable/Hose Routing

Fuel Vapor

Vent Tube

(To Vapor Valve)

Anchored

Cable Strap

(Top View)

Fuel

Overflow

Hose

Main

Harness

Bundle

1WARNING1WARNING

Exercise caution to avoid pinching or kinking the fuel

overflow hose when console is installed. A blocked hose

can cause excess gasoline to remain above the filler

neck insert, while fuel expansion can cause an overfilled

tank to overflow through the filler cap vent. Gasoline is

extremely flammable and highly explosive. Inadequate

safety precautions could result in death or serious

injury.

2. Remove filler cap. Place console over filler neck onto

canopy. Route cables from beneath console as shown in

Figure 8-140. Be sure that hoses and wires are not

pinched by the console during installation. Reinstall filler

cap.

3. Install Allen head screw to fasten rear flange of console

to clip nut on fuel tank weldment. Tighten screw to 25-30

in-lbs

(2.8-3.4 Nm).

4. Open fuel door on console. Install two Allen head screws

to secure front of console to clip nuts on canopy bracket.

Alternately tighten screws to 25-30

5. Snap anchor of

frame backbone. Tighten cable strap capturing main harness, audio harness, console pod conduit, fuel level

sender/fuel pump conduit, and fuel vapor vent tube. See

Figure 8-140. Install

pod conduit and audio harness to left frame tube at front

of saddlebag rail. Cut any excess cable strap material.

new

cable strap into hole on left side of

new

cable strap to secure console

in-lbs

(2.8-3.4 Nm).

FRONT HEADSET RECEPTACLE

REMOVAL

1. Remove console pod. See CONSOLE POD ASSEM-

BLY, REMOVAL, in this section.

2. Remove terminals 6 through 12 from pin housing of 12place Mini-Deutsch connector.

NOTE

For instructions on properly removing wire terminals, see

APPENDIX B.1 DEUTSCH ELECTRICAL CONNECTORS,

REMOVING/INSTALLING PINS.

3. Raise headset receptacle cap. Place pin punch in either

notch of lock ring and rotate in a counterclockwise direction until loose. See Figure 8-141.

4. Remove lock ring and cap from headset receptacle.

5. Remove headset receptacle from pod.

INSTALLATION

1. From inside pod, insert threaded end of headset recep-

tacle through side hole.

Lock Ring

f2020x8x

Figure 8-141. Remove Lock Ring from Receptacle

Using Pin Punch

8-110 2004 Touring: Electrical

Page 13

H

f1492b8x

Speaker

Box

Switch

Bracket

TORX

Screw

OME

2. Place receptacle cap over end of headset receptacle so

that it seats in recess of pod.

3. Open cap, and with the notches on the outboard side,

thread lock ring onto headset receptacle.

4. Place pin punch in either notch of lock ring and rotate in

a clockwise direction until tight.

5. Install terminals 6 through 12 into pin housing of 12place Mini-Deutsch connector.

Table 8-16. Front Headset Receptacle

Wire Color

Blue/Yellow 6

Ye llow/Black 7

Yellow/White 8

Yellow/Red 9

Black 10

Red 11

Black (Thick Insulation) 12

NOTE

For instructions on properly installing wire terminals, see

APPENDIX B.1 DEUTSCH ELECTRICAL CONNECTORS,

REMOVING/INSTALLING PINS.

6. Install console pod. See CONSOLE POD ASSEMBLY,

INSTALLATION, in this section.

7. Test operation of headset receptacle.

Chamber

Number

REAR HEADSET RECEPTACLE

See Section 8.32 WIRING HARNESSES AND CABLES,

AUDIO HARNESS (FLHTCU).

REAR PASSENGER SWITCHES

REMOVAL

NOTE

Right and left side replacement passenger switch assemblies are interchangeable.

1. Remove maxi-fuse. See Section 8.3 SYSTEM FUSES,

MAXI-FUSE, REMOVAL.

2. Open Tour-Pak.

3. Using a T10 TORX drive head, remove four screws and

pull speaker grille from speaker box.

Figure 8-142. Remove Passenger Switch Assembly

(Right Side Speaker Box Shown)

4. Remove speaker from speaker box and carefully pull

socket terminals from speaker spade contacts.

5. Remove trim ring and gently pull on wire harness to

draw 6-place Mini-Deutsch connector out of speaker

box.

6. Depress external latch on socket housing side and use a

rocking motion to separate pin and socket halves of

Mini-Deutsch connector.

7. Draw socket half of Mini-Deutsch connector back into

speaker box and pull out through speaker hole.

8. Using a T25 TORX drive head, remove two screws to

release switch bracket from inside of speaker box.

Remove bracket using slot to free switch wires. See Fig-

ure 8-142.

9. Pull switch housing assembly, wire harness conduit,

speaker terminals and Mini-Deutsch socket from

speaker box using switch housing hole on outboard side.

10. Carefully pull keycap from switch shaft. Remove switch

from switch housing.

11. Remove terminals 1 through 4 from socket housing.

NOTE

For instructions on properly removing wire terminals, see

APPENDIX B.1 DEUTSCH ELECTRICAL CONNECTORS,

REMOVING/INSTALLING SOCKETS.

12. Pulling one wire at a time, remove four wires from conduit.

INSTALLATION

1. Pushing one wire at a time, feed four wires of

through conduit.

new

switch

2004 Touring: Electrical 8-111

Page 14

H

OME

f1494b8x

Passenger

Cavity

Switch

Slot

Slot faces toward the front

on right side switch assembly,

toward the rear on left side.

Switch

Housing

Keycap

DISASSEMBLED

Pink/White

Wire

Rib

f1495x8x

ASSEMBLED

Figure 8-143. Install Switch in Housing

2. Install terminals 1 through 4 into socket housing.

f1491x8x

Figure 8-144. Properly Orient Switch Bracket

Speaker

Box

Switch

Bracket

Slot

Forward

Rib

Bottom

Table 8-17. Rear Passenger Switches

Wire Color

Pink/White 1

Gray/White 2

Violet/Black 3

* Orange/Black 4

Mates to O/BK on [41A], BN/W on [42A].

*

8-112 2004 Touring: Electrical

Chamber

Number

f1492x8x

Figure 8-145. Install Passenger Switch Assembly

(Right Side Speaker Box Shown)

Page 15

H

OME

NOTE

For instructions on properly installing wire terminals, see

APPENDIX B.1 DEUTSCH ELECTRICAL CONNECTORS,

REMOVING/INSTALLING SOCKETS.

3. With the Pink/White wire at the bottom, place switch in

cavity of switch housing. Bottom of the assembly is

determined by location of rib on switch housing. See Fig-

ure 8-143.

4. Note lettering for proper orientation and gently push keycap onto switch shaft. When orienting keycap, remember

that bottom of assembly is determined by location of

switch housing rib.

5. Feed Mini-Deutsch socket connector, speaker terminals

and conduit through switch housing hole on outboard

side of speaker box until switch housing backplate contacts speaker box. Pull harness out through speaker

hole.

6. Reaching into speaker box, align holes in bracket with

holes in switch housing. Using a T25 TORX drive head,

install two bracket screws. See Figure 8-145.

NOTE

To align bracket and switch housing holes, slot in bracket

must face toward the front on right side assembly and toward

the rear on left side. See Figure 8-144. Switch also must be

square in cavity of switch housing or bracket will not fit.

7. Feed Mini-Deutsch socket through speaker hole into

speaker box and pull out through harness hole on

inboard side.

REAR SPEAKERS

REMOVAL

1. Remove maxi-fuse. See Section 8.3 SYSTEM FUSES,

MAXI-FUSE, REMOVAL.

2. Open Tour-Pak.

3. Using a T10 TORX drive head, remove four screws from

speaker grille. Remove speaker grille from speaker box.

4. Remove speaker from speaker box. Carefully pull two

socket terminals from speaker spade contacts.

INSTALLATION

1. Install two socket terminals onto speaker spade contacts. Different size spade contacts prevent improper

assembly.

2. With spade contacts at bottom, install speaker in

speaker box.

3. Align holes in speaker with those in speaker box. Align

holes in grille with those in speaker.

4. Install four screws. Aternately tighten screws using a

T10 TORX drive head.

5. Close Tour-Pak.

6. Install maxi-fuse. See Section 8.3 SYSTEM FUSES,

MAXI-FUSE, INSTALLATION.

7. Test speaker for proper operation.

8. Mate pin and socket halves of Mini-Deutsch connector.

Feed connector back up into speaker box pressing trim

ring into hole.

9. Install socket terminals onto speaker spade contacts. On

right side of vehicle, install socket terminal of the solid

Green wire onto contact next to the red dot. On left side,

install socket terminal of the solid Brown wire onto contact next to the red dot.

10. Align holes in speaker grille with those in speaker and

slide four TORX screws through grille and speaker

holes.

11. With spade contacts at bottom rear corner, position

speaker/grille assembly against speaker box. Thread

four screws into speaker box and tighten using a T10

TORX drive head.

12. Close Tour-Pak.

13. Install maxi-fuse. See Section 8.3 SYSTEM FUSES,

MAXI-FUSE, INSTALLATION.

14. Test switch for proper operation.

CB LOADING COIL

REMOVAL

1. Remove maxi-fuse. See Section 8.3 SYSTEM FUSES,

MAXI-FUSE, REMOVAL.

2. Open Tour-Pak. Open map pocket and remove acorn

nuts. Remove map pocket and molded liner from TourPak.

3. Disconnect 1-place CB antenna cable connector on right

side of Tour-Pak. Release cable from rear clip at bottom

of Tour-Pak.

4. Remove Keps nut, ring terminal and flat washer from

loading coil stud.

5. Holding Phillips screw, remove flange nut at bottom of

Tour-Pak to release loading coil bracket. Remove loading coil from vehicle (with Phillips screw, external tooth

lockwasher and flange nut).

2004 Touring: Electrical 8-113

Page 16

H

OME

INSTALLATION

1. Place

2. Mate pin and socket halves of 1-place CB antenna cable

3. Install flat washer, ring terminal and Keps nut onto load-

4. Install molded liner in Tour-Pak. Install map pocket and

5. Install maxi-fuse. See Section 8.3 SYSTEM FUSES,

6. Check SWR and adjust if necessary. Follow the SWR

new

loading coil into position aligning hole in

bracket with hole in Tour-Pak. Holding flange nut under

To ur-Pak, install Phillips screw with external tooth lockwasher.

connector. Capture antenna cable in rear clip at bottom

of Tour-Pak.

ing coil stud. Tighten hex nut.

secure using acorn nuts. Close Tour-Pak.

MAXI-FUSE, INSTALLATION.

Adjustment procedure in Section 6 of the 2004 ELECTRICAL DIAGNOSTIC MANUAL (Part No. 99497-04).

Remove SWR meter, plug in antenna connector and

tighten antenna connector stud.

AUDIO HARNESS

For removal and installation instructions, see Section 8.32

WIRING HARNESSES AND CABLES, AUDIO HARNESS

(FLHTCU).

RADIO ANTENNA CABLE

For removal and installation, see Section 8.32 WIRING HAR-

NESSES AND CABLES, RADIO ANTENNA CABLE

(FLHTC/U).

CB ANTENNA CABLE

For removal and installation, see Section 8.32 WIRING HAR-

NESSES AND CABLES, CB ANTENNA CABLE (FLHTCU).

8-114 2004 Touring: Electrical

Page 17

H

OME

WIRING HARNESSES AND CABLES 8.32

MAIN HARNESS

REMOVAL- ALL MODELS (PART I)

1. Remove fuel tank. For carbureted models, see Section

4.7 FUEL TANK (CARBURETED), COMPLETE

REMOVAL, FLHT/C or FLHR/S. For fuel injected mod-

els, see Section 9.4 FUEL TANK (FUEL INJECTED),

COMPLETE REMOVAL, FLHT/C/U/I, FLTRI or FLHR/C/

S/I.

2. Unthread bolt and remove battery positive cable (red)

from battery positive (+) terminal. (Battery negative

cable already removed under FUEL TANK, COMPLETE

REMOVAL.)

3. Using a T-40 TORX drive head, loosen bolt to move lip of

hold-down clamp off edge of battery. Remove battery

from battery box.

4. Remove left side saddlebag. See Section 2.25 SAD-

DLEBAG, REMOVAL.

5. Gently pull left side cover from frame downtubes (no

tools required).

6. Repeat steps 4-5 to remove right side saddlebag and

side cover.

NOTE

Depending upon model, continue procedure at REMOVAL-

FLHR/C/S (PART II), REMOVAL- FLTR (PART II), or

REMOVAL- FLHT/C/U (PART II).

REMOVAL- FLHR/C/S (PART II)

1. Remove the Phillips screw at the bottom of the headlamp door (chrome ring). Remove the headlamp door.

2. Remove the eight Phillips screws to free the headlamp

housing from the headlamp nacelle.

3. Squeeze the two external tabs to remove the wire connector at the back of the headlamp bulb. Remove the

headlamp housing assembly from the motorcycle.

4. See Figure 8-146. Reaching inside the headlamp

nacelle, disconnect main harness as follows:

●

Front fender tip lamp connector [32], 2-place Multilock (black); used on FLHR only.

Passing lamps connector [73], 2-place Multilock

●

(white); used on FLHR/C only.

f2212x8x

Right Handlebar

Controls [22]

Passing Lamps

Switch [109]

Used on FLHR/C Only

Cruise Set/Resume

Switch [159]

Used on FLHRC Only

Figure 8-146. Headlamp Nacelle Connectors (FLHR/C/S)

Front Turn

Signals [31]

Passing Lamps [73]

Used on FLHR/C Only

Left Handlebar

Controls [24]

Cruise On/Off

Switch [158]

Used on FLHRC Only

Accessory

Switch [67]

Front Fender

Tip Lamp [32]

Used on FLHR Only

Headlamp [38]

2004 Touring: Electrical 8-115

Page 18

H

OME

f2095x8x

Odometer

Reset Switch

Speedometer

Connector [39]

Figure 8-147. Instrument Console Assembly (FLHR/C)

Passing lamps switch connector [109], 4-place

●

Amp; used on FLHR/C only.

●

Accessory switch connector [67], 4-place Amp.

●

Right handlebar switch controls connector [22], 6place Deutsch (black); T-stud on fork stem nut lock

plate (left side).

●

Cruise set/resume switch connector [159], 2-place

Deutsch (black); used on FLHRC only.

●

Front turn signal lamps connector [31], 6-place Multilock; anchor in hole of fork stem nut lock plate (left

side).

●

Left handlebar switch controls connector [24], 6place Deutsch (gray); T-stud on fork stem nut lock

plate (left side).

●

Cruise on/off switch connector [158], 2-place Deutsch (gray); used on FLHRC only.

5. Carefully pull main harness rearward under right side of

headlamp nacelle allowing conduit and connectors to

hang over top of engine guard.

6. Remove screw and P-clamp to release main harness

from right side of steering head.

7. See Figure 8-147. Moving to inboard side of instrument

console, disconnect main harness as follows:

Ignition/Light Key Switch connector [33], 3-place

●

Packard.

Indicator lights connector [21], 8-place Mini-Deut-

●

sch.

Speedometer connector [39], 12-place Packard.

●

Flexible

Clip

Indicator Lights

Connector [21]

Ignition/Light

Key Switch Connector [33]

Flexible

Clip

Flexible

Clip

Plastic

Clip

8. Unthread rubber boot from odometer reset switch and

pull switch from hole in instrument console.

9. Bend back flexible clamps on inboard side of instrument

console as necessary to release main harness conduit.

Set instrument console aside.

10. Moving rearward, carefully cut

eleven

cable straps

securing main harness to frame backbone and right and

left frame tubes. See Figure 8-148.

NOTE

Continue procedure at REMOVAL- ALL MODELS (PART III).

REMOVAL- FLTR (PART II)

1. Remove the inner fairing. See Section 2.30 UPPER

FAIRING/WINDSHIELD (FLTR), INNER FAIRING,

REMOVAL, steps 1-18.

2. Remove screw, two main harness ground ring terminals

and P-clamp to release main harness bundle from right

side of steering head.

3. Moving rearward, carefully cut

securing main harness to frame backbone and right and

left frame tubes. See Figure 8-148.

NOTE

Continue procedure at REMOVAL- ALL MODELS (PART III).

eleven

cable straps

8-116 2004 Touring: Electrical

Page 19

H

OME

Frame

Backbone

9 A

3 A

1

4 A

2 A

2. See Figure 8-149. Disconnect main harness from interconnect harness as follows:

●

Main to interconnect harness connector [1], 12place Deutsch (black); T-stud at front of right fairing

bracket.

●

Main to interconnect harness connector [2], 12place Deutsch (gray); T-stud on right fairing support

brace.

Main to interconnect harness connector [15], 4-

●

place Packard (black); anchor in hole at bottom of

radio (right side).

Main to interconnect harness connector [156], 6-

●

place Deutsch (gray); T-stud on right fairing support

brace.

10 A

11 A

12

13

f2225x8x

1 Captures main harness, cruise roll-off switch conduit,

audio harness (FLHTCUI only) and frame backbone.

2 Captures ignition/EFI harness only. ANCHORED

3 Captures main harness and audio harness (FLHTCUI

only). ANCHORED

456 Captures main harness, audio harness (FLHTCUI only),

EFI/ignition harness, and conduit to fuel tank harness (all

models except FLHR/C/S). ANCHORED

78 Captures audio harness (FLHTCUI only) and upper frame

tube.

910 Captures main harness and audio harness (FLHTCUI

only). ANCHORED

11 Captures main harness, audio harness (FLHTCUI only),

fuel vapor vent tube and console pod or instrument

console conduit. ANCHORED

12 Captures main harness, audio harness (FLHTCUI only),

console pod or instrument console conduit and upper

frame tube.

13 Captures main harness, audio harness (FLHTCUI only),

console pod conduit (FLHTCUI only) and upper frame

tube.

.

.

5 A

6 A

Saddlebag

7

.

Guard

8

.

.

Figure 8-148. Cable Strap Locations

REMOVAL- FLHT/C/U (PART II)

1. Remove the outer fairing and windshield. See Section

2.29 UPPER FAIRING/WINDSHIELD (FLHT/C/U),

OUTER FAIRING/WINDSHIELD, REMOVAL.

3. See Figure 8-149. Disconnect ignition switch from main

harness. Disconnect radio antenna cable. Proceed as

follows:

Ignition switch connector [33], 4-place Packard

●

(black); anchor in hole at bottom of radio (center).

Radio antenna cable connector [51]; back of radio

●

(left side).

4. Remove screw to release main harness ground ring terminal and brake line P-clamp from front of upper fork

bracket.

5. Carefully pull main harness rearward under right side of

fairing cap allowing conduit and connectors to hang over

top of engine guard.

6. Remove screw, main harness ground ring terminal and

P-clamp to release main harness (and audio harness on

FLHTCU models) from right side of steering head.

7. Moving rearward, carefully cut

eleven

cable straps

securing main harness to frame backbone and right and

left frame tubes. See Figure 8-148. Carefully cut any

cable straps securing main harness to audio harness.

NOTE

Continue procedure at REMOVAL- ALL MODELS (PART III).

REMOVAL- ALL MODELS (PART III)

1. If cruise equipped, locate the cruise control roll-off

switch plumbed into the idle cable on right side of the

steering head. Push rubber boot on switch forward and

remove socket terminals from spade contacts.

2. Moving to left side of motorcycle, remove acorn nut to

release horn bracket from rubber mount stud. Pull elbow

terminals from spade contacts on horn and release conduit from J-clamp.

3. Remove flange nut (10 mm) from left side ground stud

on upper frame crossmember. Remove two main harness ground ring terminals. Repeat step to remove two

main harness ground ring terminals from right side

ground stud.See Figure 8-150.

2004 Touring: Electrical 8-117

Page 20

H

OME

Main to Interconnect

Harness [2]

Main to Interconnect

Harness [156]

Main to Interconnect

Harness [15]

f2238x8x

Main to Interconnect

Harness [1]

Ignition

Switch [33]

Figure 8-149. Inner Fairing - Main Harness Connectors (FLHTC/U)

4. Depress latches on maxi-fuse holder and then slide

cover rearward to disengage tongue from groove in fuse

block cover.

5. Moving to right side of motorcycle, pull back boot at top

of starter housing and remove flange nut and main

power cable ring terminal from post. Release cable from

clip anchored to T-stud at front of battery tray. Draw main

power cable to left side of motorcycle.

6. Carefully cut anchored cable strap to release fuse block

conduit from fuse block bracket. Pull fuse block from

tabs on bracket.

7. Remove the fuse block cover. Raise lipped side slightly

to disengage slots from tabs on fuse block.

8. If cruise equipped, lift the locking latch and remove

cruise module connector [17]. From inside battery box,

remove three flange bolts. Carefully pull cruise module

away from side of battery box exercising caution to avoid

losing grommets.

Radio Antenna

Cable [51]

9. Disconnect the rear fender lights connector [7], 8-place

Multilock, anchored at front of rear fender. Detach pin

housing from anchor.

10. Release ignition keyswitch and starter relays by pulling

anchors on rubber molding from holes in frame weldment at rear of battery box. Remove relays and molding

from connectors. Push connectors down into space

below frame weldment.

11. Locate the turn signal/security module inside hole of

frame weldment on opposite side. Depress tab at front of

spring clip and lift to release legs from holes in weldment. Remove module and disconnect 12-place Deutsch connector [30]. Push connector down into space

below frame weldment.

12. Pull rear fender lights, ignition keyswitch and starter

relays, and turn signal/security module conduit and connectors out through opening above rear of fuse block

bracket and allow to hang on left side of motorcycle.

8-118 2004 Touring: Electrical

Page 21

H

OME

13. Depending upon model, proceed as follows:

FLHR/C/S:

FLTR:

Move to step 14.

a. On left side of motorcycle, remove bolt (with flat

washer) to remove passenger seat strap and saddlebag front mounting bracket. Remove Phillips

screw and chrome frame tube cover.

b. Carefully cut cable strap to release radio antenna

cable from shoulder of upper frame tube (just in

front of air valve mounting bracket). Cut cable strap

to release radio antenna cable from slotted hole in

rear fender support.

c. At bottom of radio antenna bracket, rotate knurled

ring to separate pin and socket halves of radio

antenna cable connector [51].

d. Draw radio antenna cable forward to area of fuse

block bracket and allow to hang with other main harness branches.

FLHTC/U:

a. Open Tour-Pak and proceed as follows:

FLHTC:

f2250x8x

Remove rubber mat.

FLHTCU:

Open map pocket and remove acorn nuts

with flat washers. Remove map pocket and molded

liner from Tour-Pak.

b. Depress external latch and remove bulb socket from

left side of Tour-Pak.

c. Rotate knurled ring in a counterclockwise direction

to separate pin and socket halves of radio antenna

cable connector [51]. Release cable from two clips

at bottom of Tour-Pak.

d. On FLHTCU models, depress button and separate

pin and socket halves of Tour-Pak lights connector

[12], 3-place Multilock, inside Tour-Pak.

e. Pull grommet into Tour-Pak and remove from main

harness conduit.

f. Pull Tour-Pak lights and radio antenna cable con-

nectors through hole at front of Tour-Pak. Cut cable

strap to release conduit from luggage rack rail.

g. Draw Tour-Pak lights and radio antenna cable con-

nectors forward to area of fuse block bracket and

allow to hang with other main harness branches.

Remove flange nuts to release passenger hand rail,

if necessary.

Main Harness

Ground Ring

Terminals (2)

Main Harness

Ground Ring

Terminals (2)

Fuel Tank Harness

Connector [13]

Not Present on FLHR/C/S

B+ Connector [160]

Chassis

Ground Cable

Accessory

Connector [4]

Battery

Positive Cable

Battery

Negative Cable

Figure 8-150. Electrical Connectors - Upper Frame Cross Member (Under Seat)

2004 Touring: Electrical 8-119

Page 22

H

OME

Anchored Cable Strap

Captures Main Harness Conduit,

Neutral Switch Conduit and

Vehicle Speed Sensor Cable

f2276x8x

Battery

Box

See Figure 8-150.

6

Cable Strap

Captures Main Harness Conduit

and Frame Downtube

Captures Rear Brake Light Switch Wires

Cable Strap

and Lower Frame Tube

Cable Strap Anchor

Captures Main Harness Conduit

5

4

and Rear Brake Line

Figure 8-151. Cable Straps (Right Side View)

14. Cut anchored cable strap to release accessory connector [4] and B+ connector [160] from left side of frame

crossmember (in front of battery box). See Figure 8-150.

15. Cut cable strap to release vapor valve from mounting

bracket. Move vapor valve out of the way to facilitate harness removal.

16. Alternately feed branches of main harness hanging on

left side of motorcycle into battery box through opening

above front of fuse block bracket. For best results, feed

one length of conduit through at a time drawing the fuse

block through the opening last. Pulling branches out of

battery box, allow conduit and connectors to hang on left

side of frame backbone.

17. Moving to front right side of motorcycle, locate crankshaft position sensor connector [79], 2-place Mini-Deutsch, fixed to bracket at bottom of voltage regulator. Push

connector toward right side of motorcycle to disengage

small end of slot on attachment clip from T-stud on

bracket. Lift connector off T-stud. Depress button on

socket terminal side and pull apart pin and socket

halves.

18. Locate oil pressure sender at the front right side of the

crankcase. On FLHR/C/S models, pull elbow from post

of oil pressure switch. On FLHT/C/U and FLTR models,

pull external latch outward and use rocking motion to

remove Packard connector from oil pressure sender.

Cable Strap

Captures Main Harness Conduit,

Voltage Regulator Cables and

Lower Frame Tube

3

2

1

Cable Strap Anchor

Captures Main Harness Conduit,

Voltage Regulator Cables and

Rear Brake Line

19. Cut cable strap to free voltage regulator cables and main

harness conduit (leading to oil pressure sender and

crankshaft position sensor connectors) from inboard

side of rear brake pedal weldment. See Figure 8-151.

20. Cut cable straps from two anchors installed on T-studs at

top of lower frame tube.

21. Locate voltage regulator connector [77], 1-place Deutsch, just below the transmission exhaust bracket.

Depress external latch to separate pin and socket housings.

22. Depress external latch and pull solenoid connector from

top of starter housing.

23. Remove two elbow connectors from neutral switch

posts.

24. Pull two socket terminals from spade contacts on rear

brake light switch. Cut cable strap to free rear brake light

switch wires from lower frame tube.

25. Cut cable strap at rear of rear brake light switch bracket

to release main harness conduit from frame downtube.

26. Cut anchored

cable strap in hole of frame downtube

(inboard of rear swingarm bracket) to release vehicle

speed sensor cable, main harness and neutral switch

conduit.

8-120 2004 Touring: Electrical

Page 23

H

8319

8321

Rubber

Boot

OME

27. Pull ignition/EFI harness connector [8] from slot in electrical bracket. Depress external latches and separate pin

and socket halves.

28. Remove two flange nuts to release electrical bracket

from studs on side of battery box. Release security siren

connector and conduit from inboard side of electrical

bracket.

29. Pull ignition/EFI harness connector [8] and security siren

connector [142] and conduit into battery box through

opening at rear of frame crossmember.

30. Draw neutral switch wires out from under starter housing. For best results, move electrical bracket out of the

way and reach in under right side of battery box.

31. Carefully pull rear brake light switch, starter solenoid,

and neutral switch conduit and connectors rearward and

then feed up into battery box through same opening at

rear of frame crossmember. See Figure 8-152.

32. Note that main harness runs forward of the front battery

box TORX screw. Pull harness to the rear of the screw,

and then draw conduit and connectors out of battery box

and allow to hang on right side of frame backbone. See

lower frame of Figure 8-153.

Figure 8-152. Feed Harness Into Battery Box (Right Side)

CAUTION

Damage to wires can result in electrical problems. Be

sure that rubber boot is present on threaded end of battery box TORX screw. Replace rubber boot if absent or

damaged. See upper frame of Figure 8-153.

33. Remove main harness from motorcycle.

INSTALLATION- ALL MODELS (PART I)

NOTE

Disregard references to radio antenna cable and starter relay

connectors when working on FLHR/C/S models. The connectors are not part of the main harness on these motorcyles.

1. Position main harness on motorcycle as follows:

a. Lay main harness on frame backbone so that front

branches hang over top of right engine guard. On

FLHR/C/S models, front branches terminate in

headlamp and handlebar switch control connectors

(see Figure 8-146). On FLTR and FLHT/C/U models, front branches terminate in the ignition switch,

radio antenna cable and interconnect harness connectors (see Figure 8-149).

b. Adjust harness so that left and right side branches

split from main branch at location of anchor at center of frame backbone.

Figure 8-153. Battery Box TORX Screw (Right Side)

NOTE

If reusing the main harness, thread new cable strap through

eye in anchor and loosely capture main harness bundle. If

installing a new harness, remove and discard old anchor and

plug anchor attached to new harness into hole in center of

frame backbone.

Left Side

c. Locate left side branch terminating in rear fender

lights, ignition keyswitch and starter relays, turn signal/security module, fuse block, cruise module (if

equipped) and radio antenna cable connectors.

Feed connectors and conduit into battery box pulling branches out through opening above front of

fuse block bracket. Continue drawing harness out

through opening until two main harness ground ring

terminals are adjacent to left side ground stud on

frame crossmember.

2004 Touring: Electrical 8-121

Page 24

H

OME

d. Feed rear fender lights, ignition keyswitch and

starter relays, and turn signal/security module conduit and connectors through opening above rear of

fuse block bracket to area in front of rear fender.

NOTE

On FLTR and FLHT/C/U models, leave longer conduit of

radio antenna cable hanging outboard of fuse block bracket.

Right Side

e. Feed right side connectors and conduit into battery

box pulling voltage regulator, oil pressure sender

and crankshaft position sensor connectors and conduit out through opening at rear of frame crossmember. Feed connectors and conduit forward and

then downward following front of frame downtube.

Continue drawing harness out through opening in

side of battery box until two main harness ground

ring terminals are adjacent to right side ground stud

on frame crossmember.

2. Returning to left side of motorcycle, route horn conduit in

front of the top stabilizer link and then under the top

engine mounting bracket to back of horn. Install elbow

terminals onto horn spade contacts. Capture conduit in

J-clamp. Slide horn bracket onto rubber mount stud and

install acorn nut with flat washer. Tighten acorn nut to

80-100 in-lbs (9.0-11.3 Nm).

3. Slide two main harness ground ring terminals onto left

side ground stud on upper frame crossmember and

install flange nut (10 mm). Install chassis ground ring terminal onto right side ground stud and then two main harness ground ring terminals and flange nut (10 mm).

Tighten flange nuts to 50-90 in-lbs (5.7-10.2 Nm). See

Figure 8-150.

4. Mate pin and socket halves of rear fender lights connector [7], 8-place Multilock, and attach to anchor at front of

rear fender.

5. At front of rear fender, feed ignition keyswitch and starter

relay connectors up through rectangular shaped hole in

frame weldment. Fit relay connectors into rubber molding and install anchors on molding into holes in frame

weldment. Install relays in connectors.

6. Feed turn signal/security module connector [30] up

through hole on opposite side of frame weldment and

connect to module. Install module into hole in frame

weldment. Insert legs of spring clip into holes in weldment and push down until tab at front snaps in place.

7. If cruise equipped, install grommets into holes on left

side of battery box with the larger OD on the outboard

side. Align threaded holes on inboard side of cruise

module with holes in grommets and install flange bolts

from inside battery box. Alternately tighten flange bolts

to 60-96 in-lbs (6.8-10.9 Nm). Install cruise module connector [17] and engage locking latch.

8. Slide cover over fuse block until slots fully engage tabs

on block. Slide fuse block into position on mounting

bracket. Tabs on bracket fit into slots on each side of

fuse block cover. Install new anchored

hole at rear of fuse block bracket. Tighten cable strap to

capture fuse block conduit.

9. Route main power cable on maxi-fuse holder through

opening above front of fuse block bracket and then forward passing under frame crossmember toward right

side of motorcycle. Pull back boot at top of starter housing and install ring terminal on post. Install flange nut

and tighten to 70-90 in-lbs (7.9-10.2 Nm). Capture cable

in clip anchored to T-stud at front of battery tray.

10. Returning to left side of motorcycle, slide maxi-fuse

cover forward to engage tongue in groove of fuse block

cover and then insert maxi-fuse holder into cover until

latches engage.

11. Install new anchored

side of frame crossmember (in front of battery box).

Tighten cable strap to capture conduit of both accessory

connector [4] and B+ connector [160] approximately one

inch from connector housings. See Figure 8-150.

12. Hold vapor valve in position on left side of mounting

bracket. From right side of bracket, insert end of small

cable strap through hole in arm and then around body of

vapor valve. Mate ends of cable strap and pull tight

engaging strap in slot of arm. Cut any excess cable strap

material.

13. Depending upon model, proceed as follows:

FLHR/C/S: Move to step 14.

FLTR:

a. Feed radio antenna cable and connector rearward

following inboard side of upper frame tube. With the

3-place Multilock connector (unused) positioned

about as far rearward as the rear shock air valve,

install new cable strap to secure radio antenna

cable to shoulder of upper frame tube (just in front

of air valve mounting bracket). Using slotted hole,

install new cable strap to secure radio antenna

cable to rear fender support. See Figure 8-154.

b. At bottom of radio antenna bracket, rotate knurled

ring to mate pin and socket halves of radio antenna

cable connector [51].

c. Install chrome frame tube cover on frame tube.

Install Phillips screw. Install bolt (with flat washer) to

fasten saddlebag front mounting bracket and passenger seat strap to chrome frame tube cover.

cable strap in lower hole on left

cable strap in

8-122 2004 Touring: Electrical

Page 25

H

OME

1

9425

2

Figure 8-154. Capture Radio Antenna Cable (FLTR)

FLHTC/U:

a. Feed Tour-Pak lights and radio antenna cable con-

nectors and conduit through hole at front of TourPak. Capture cable and conduit in grommet. Install

grommet in hole with the larger OD facing inside.

b. Mate pin and socket halves of Tour-Pak lights con-

nector [12], 3-place Multilock, and tuck into cavity

inside Tour-Pak.

c. Rotate knurled ring in a clockwise direction to mate

pin and socket halves of radio antenna cable connector [51]. Capture cable in two clips at bottom of

To u r-Pak.

d. Install bulb socket on left side of Tour-Pak.

e. Loosely install new cable strap to secure main har-

ness conduit to luggage rack rail.

f. Proceed as follows:

FLHTC: Install rubber mat in Tour-Pak. Close TourPak.

FLHTCU: Install molded liner in Tour-Pak. Install

map pocket and secure using acorn nuts (with flat

washers). Close Tour-Pak.

14. Returning to right side of motorcycle, feed voltage regulator, oil pressure sender and crankshaft position sensor

connectors and conduit downward between rear swingarm and oil filler spout until free ends hang below lower

frame tube.

15. Route neutral switch wires under starter housing to

transmission top cover. For best results, move electrical

bracket out of the way and reach in under right side of

battery box. Install two elbow connectors onto posts of

neutral switch.

16. Snap solenoid connector to terminal at top of starter

housing.

17. Install new anchored

cable strap in hole of frame downtube (inboard of rear swingarm bracket) capturing vehicle speed sensor cable, main harness and neutral switch

conduit. See Figure 8-151.

18. Install new cable strap at rear of rear brake light switch

bracket capturing main harness conduit and frame

downtube. Cut any excess cable strap material.

19. Install two socket terminals onto spade contacts of rear

brake light switch. Install new cable strap to secure rear

brake light switch wires to lower frame tube.

20. Route branch of the main harness (terminating in the

voltage regulator, oil pressure sender and crankshaft

position sensor connectors) forward to front of motorcycle following inboard side of lower frame tube.

21. Mate pin and socket housings of voltage regulator connector [77], 1-place Deutsch, just below the transmission

exhaust bracket.

22. Position main harness conduit over two anchors

installed on T-studs at top of lower frame tube. Thread

new cable straps through eyelets in anchors to capture

conduit. Cut any excess cable strap material.

NOTE

In addition to the main harness conduit, rear cable strap

anchor also captures rear brake line, while front anchor captures rear brake line and voltage regulator cables.

23. Route main harness conduit inboard of rear brake pedal

weldment. Capturing main harness conduit and lower

frame tube, install new cable strap through opening in

rear brake pedal weldment. See Figure 8-151. Cut any

excess cable strap material.

NOTE

Cable strap also captures voltage regulator cables.

24. Route oil pressure sender and crankshaft position sensor connectors upward at rear of lower frame crossmember.

25. Mate pin and socket halves of crankshaft position sensor

connector [79]. Place large end of slot on attachment

clip over T-stud on bracket at bottom of voltage regulator.

Push connector toward left side of motorcycle to engage

small end of slot.

26. Install the oil pressure sender connector at the front right

side of the crankcase. On FLHR/C/S models, install

elbow connector on post terminal. On FLHT/C/U and

FLTR models, install 4-place Packard connector.

27. Returning to area of electrical bracket, feed ignition/EFI

harness connector [8] and security siren connector [142]

and conduit through opening to outboard side of battery

box.

2004 Touring: Electrical 8-123

Page 26

H

OME

28. Route siren connector and conduit on inboard side of

electrical bracket and install bracket on studs at side of

battery box. Install flange nuts on studs and tighten to

36-48 in-lbs (4.1-5.4 Nm).

29. Mate pin and socket halves of ignition/EFI harness connector [8]. Install connector into slot of electrical bracket.

30. Pull up on main harness and tuck conduit into space in

front of the battery box TORX screw (along with ignition/

EFI harness). See lower frame of Figure 8-153.

CAUTION

Damage to wires can result in electrical problems. Be