Page 1

2008 FLT Police Models Service Manual Supplement

99483-08SP

©2007 H-D.

Page 2

Harley-Davidson motorcycles conform to all applicable U.S.A. Federal Motor Vehicle Safety Standards

and U.S.A. Environmental Protection Agency regulations effective on the date of manufacture.

To maintain the safety, dependability, and emission and noise control performance, it is essential that

the procedures, specifications and service instructions in this manual are followed.

Any substitution, alteration or adjustment of emission system and noise control components outside of

factory specifications may be prohibited by law.

IMPORTANT NOTICE

Harley-Davidson Motor Company

Page 3

2008 FLT Police Models

Service Manual Supplement

©2007 H-D.

ALL RIGHTS RESERVED

99483-08SP

Printed in the U.S.A.

VISIT THE HARLEY-DAVIDSON WEB SITE

http://www.harley-davidson.com

Page 4

Blank Text Here

Page 5

Blank Text Here

READER COMMENTS

Please comment on the completeness, accuracy, organization, usability, and readability of this manual.

Please list the page, item, and part number(s) of any errors you find in this manual.

Please tell us how we can improve this manual.

Occupation:

Name: Dealership:

Street: Department:

City: State: Zip:

Please clip out and mail to:

Service Communications Department

Harley-Davidson Motor Company

P.O. Box 653

Milwaukee, WI USA 53201

The Harley-Davidson Service Communications Department maintains a continuous effort to improve the quality

and usefulness of its publications. To do this effectively, we need user feedback - your critical evaluation of

this manual.

2008 FLT Police Models Service Manual Supplement (99483-08SP)

Page 6

NOTES

Page 7

ABOUT THIS MANUAL

GENERAL

This Service Manual Supplement has been designed to be

used with the current Service Manual and has been prepared

with two purposes in mind. First, it will acquaint the user with

the construction of the Harley-Davidson product and assist in

the performance of basic maintenance and repair. Secondly,

it will introduce to the professional Harley-Davidson Technician

the latest field-tested and factory-approved major repair

methods.We sincerely believe that this Service Manual Supplement will make your association with Harley-Davidson

products more pleasant and profitable.

NOTE

This Service Manual Supplement provides information unique

to this model motorcycle. Any information not presented in this

supplement can be found in the appropriate Service Manual

or Electrical Diagnostic Manual.

HOW TO USE YOUR SERVICE MANUAL

SUPPLEMENT

Use the TABLE OF CONTENTS (which follows this FOREWORD) and the INDEX (at the back of this manual) to quickly

locate subjects. Sections and topics in this manual are

sequentially numbered for easy navigation.

CHAPTERNO.

Maintenance1

Chassis2

Engine3

Fuel System4

Electric Starter5

Drive6

Transmission7

Electrical8

Appendix A WiringA

Appendix B GlossaryB

For example, a cross-reference shown as 2.1 SPECIFICA-

TIONS refers to chapter 2 CHASSIS, heading 2.1 SPECIFICATIONS.

If the subject you seek is not in this supplement, refer to the

corresponding section in the appropriate Service Manual.

Check the title page located in the front of each section to find

the subject.

For quick and easy reference, all pages contain a section

number followed by a page number. For example, page 3-5

refers to page 5 in section 3.

In figure legends, the number following the name of a part

indicates the quantity necessary for one complete assembly.

PREPARATION FOR SERVICE

Stop the engine when refueling or servicing the fuel

system. Do not smoke or allow open flame or sparks near

gasoline. Gasoline is extremely flammable and highly

explosive, which could result in death or serious injury.

(00002a)

Good preparation is very important for efficient service work.

A clean work area at the start of each job will allow you to

perform the repair as easily and quickly as possible, and will

reduce the incidence of misplaced tools and parts. A motorcycle

that is excessively dirty should be cleaned before work starts.

Cleaning will occasionally uncover sources of trouble. Tools,

instruments and any parts needed for the job should be

gathered before work is started. Interrupting a job to locate

tools or parts is a distraction and causes needless delay.

NOTES

• To avoid unnecessary disassembly, carefully read all relative service information before repair work is started.

• In figure legends, the number which follows the name of

a part indicates the quantity necessary for one complete

assembly.

• When servicing a vehicle equipped with the HarleyDavidson Smart Security System (H-DSSS), you must

first disarm the security system. Either keep the fob in

close proximity to the vehicle, or use Digital Technician to

disable the security system while the vehicle is being serviced and re-enable the system after service is completed.

SERVICE BULLETINS

In addition to the information presented in this Service Manual

Supplement and the appropriate Service Manual, HarleyDavidson Motor Company will periodically issue Service Bulletins to Harley-Davidson dealers. Service Bulletins cover

interim engineering changes and supplementary information.

Consult the Service Bulletins to keep your product knowledge

current and complete.

USE GENUINE REPLACEMENT PARTS

Do not use aftermarket parts and custom made front forks

which can adversely affect performance and handling.

Removing or altering factory installed parts can adversely

affect performance and could result in death or serious

injury. (00001a)

To ensure satisfactory and lasting repairs, carefully follow the

Service Manual instructions and use only genuine HarleyDavidson replacement parts. Behind the emblem bearing the

words GENUINE HARLEY-DAVIDSON stand more than 100

years of design, research, manufacturing, testing and inspecting

experience.This is your assurance that the parts you are using

will fit right, operate properly and last longer.

FOREWORD

WARNINGS AND CAUTIONS

Statements in this service manual preceded by the following

words are of special significance.

I

Page 8

WARNING indicates a potentially hazardous situation

which, if not avoided, could result in death or serious

injury. (00119a)

CAUTION indicates a potentially hazardous situation

which, if not avoided, may result in minor or moderate

injury. (00139a)

CAUTION used without the safety alert symbol indicates

a potentially hazardous situation which, if not avoided,

may result in property damage. (00140a)

NOTE

Refers to important information, and is placed in italic type. It

is recommended that you take special notice of these items.

Proper service and repair is important for the safe, reliable

operation of all mechanical products.The service procedures

recommended and described in this service manual are

effective methods for performing service operations.

When reference is made in this manual to a specific brand

name product, tool or instrument, an equivalent product, tool

or instrument may be substituted.

Kent-Moore Products

All tools mentioned in this manual with an "HD", "J" or "B"

preface must be ordered through SPX K ent-Moore. For ordering

information or product returns, warranty or otherwise, visit

www.spx.com.

Loctite Sealing and Threadlocking Pr oducts

Some procedures in this manual call for the use of Loctite

products. If you have any questions regarding Loctite product

usage or retailer/wholesaler locations, please contact Loctite

Corp. at www.loctite.com.

PRODUCT REGISTERED MARKS

Allen, Amp Multilock, Bluetooth, Brembo, Delphi, Deutsch,

Dunlop, Dynojet, Fluke, G.E. Versilube, Gunk, Hydroseal,

Hylomar, Kevlar, Lexan, Loctite, Lubriplate, Keps, K&N, Magnaflux, Marson Thread-Setter Tool Kit, MAXI fuse, Molex, MPZ,

Mulitilock, Novus, Packard, Pirelli, Permatex, Philips, PJ1,

Pozidriv , Robinair , S100, Sems, Snap-on, Teflon, Threadlock er,

Torca, Torco, TORX, Tufoil, Tyco, Ultratorch, Velcro, X-Acto,

and XM Satellite Radio are among the trademarks of their

respective owners.

Always wear proper ey e protection when using hammer s,

arbor or hydraulic presses, gear pullers, spring compressors, slide hammers and similar tools. Flying par ts

could result in death or serious injury. (00496b)

Some of these service operations require the use of tools

specially designed for the purpose.These special tools should

be used when and as recommended. It is important to note

that some warnings against the use of specific service methods,

which could damage the motorcycle or render it unsafe, are

stated in this service manual. Howe v er, please remember that

these warnings are not all-inclusive. Inadequate safety precautions could result in death or serious injury.

Since Harley-Davidson could not possibly know, evaluate or

advise the service trade of all possible ways in which service

might be performed, or of the possible hazardous consequences of each method, we have not undertaken any such

broad evaluation. Accordingly, anyone who uses a service

procedure or tool which is not recommended by HarleyDavidson must first thoroughly satisfy himself that neither his

nor the operator's safety will be jeopardized as a result. F ailure

to do so could result in death or serious injury.

PRODUCT REFERENCES

H-D MICHIGAN, INC.TRADEMARK

INFORMATION

Harley, Harley-Davidson, H-D, Bar & Shield, Digital Tech,

Digital Technician, Destroyer, Deuce, Dyna, Electra Glide,

Evolution, F at Boy, Glaze, Gloss, H-D , H-Dnet.com, HD , Harley ,

Heritage Softail, Heritage Springer, Low Rider, Night Rod, Night

Train, Profile, Revolution, Road Glide, Road King, Rocker,

Softail, Sportster, Sun Ray, Sunwash, Tech Link, Twin Cam

88, Twin Cam 88B, Twin Cam 96, Twin Cam 96B, Twin Cam

103, Twin Cam 103B, Twin Cam 110, Twin Cam 110B, TourPak, Screamin' Eagle, Softail, Super Guide, Super Premium,

SYN3, Ultra Glide, V-Rod, VRSC, Wide Glide, and HarleyDavidson Genuine Motor Parts and Genuine Motor Accessories

are among the trademarks of H-D Michigan, Inc.

CONTENTS

All photographs, illustrations and procedures may not necessarily depict the most current model or component, but are

based on the latest production information available at the time

of publication.

Since product improvement is our continual goal, HarleyDavidson reserves the right to change specifications, equipment

or designs at any time without notice and without incurring

obligation.

Read and follow warnings and directions on all products.

Failure to follow warnings and directions can result in

death or serious injury. (00470b)

II FOREWORD

Page 9

MAINTENANCE

1.1 SCHEDULED MAINTENANCE

General...............................................................................1-1

CHASSIS

2.1 SPECIFICATIONS: CHASSIS

General...............................................................................2-1

2.2 VEHICLE IDENTIFICATION NUMBER

(V.I.N.)

General...............................................................................2-2

Manufacturing Tolerances...................................................3-1

3.2 SERVICE WEAR LIMITS

General...............................................................................3-2

3.3 OIL COOLER

Operation............................................................................3-3

Removal.............................................................................3-3

Cleaning and Inspection.....................................................3-4

Installation..........................................................................3-4

Oil Cooler Adapter and Thermostat Replacement..............3-4

Removal......................................................................3-4

Installation...................................................................3-4

FUEL SYSTEM

2.3 TIRES

General...............................................................................2-3

2.4 SEAT

General...............................................................................2-4

Seat Removal.....................................................................2-6

Seat Installation..................................................................2-6

Air Spring Replacement.....................................................2-6

Removal......................................................................2-6

Installation...................................................................2-6

Seat Bracket Mount Replacement......................................2-7

Removal......................................................................2-7

Installation...................................................................2-7

2.5 AIR SEAT RESERVOIR

Removal.............................................................................2-8

Installation..........................................................................2-9

2.6 SADDLEBAGS

Lockset.............................................................................2-11

Removal....................................................................2-11

Installation.................................................................2-11

Lockset Catch...................................................................2-11

Removal....................................................................2-11

Installation.................................................................2-11

Hinges..............................................................................2-11

Removal....................................................................2-11

Installation.................................................................2-12

Tether................................................................................2-12

Removal....................................................................2-12

Installation.................................................................2-12

Tether Brackets.................................................................2-12

Removal....................................................................2-12

Installation.................................................................2-12

Knob and Spring Latch.....................................................2-12

Removal....................................................................2-12

Installation.................................................................2-13

Spring Latch Bracket........................................................2-13

Removal....................................................................2-13

Installation.................................................................2-13

2.7 TACHOMETER BRACKET: FLHP/E

Removal...........................................................................2-14

Installation........................................................................2-15

ENGINE

4.1 FUEL SYSTEM

No Unique Content.............................................................4-1

ELECTRIC STARTER

5.1 ELECTRIC STARTER

No Unique Content.............................................................5-1

DRIVE

6.1 DRIVE

No Unique Content.............................................................6-1

TRANSMISSION

7.1 TRANSMISSION

No Unique Content.............................................................7-1

ELECTRICAL

8.1 BULB CHART

General...............................................................................8-1

8.2 SYSTEM FUSES AND RELAYS

System Fuses.....................................................................8-3

Removal......................................................................8-3

Installation...................................................................8-4

8.3 REAR MARKER LIGHTS

Marker Lights Replacement................................................8-5

Removal.............................................................................8-5

Installation..........................................................................8-5

8.4 HANDLEBAR SWITCHES

Horn and Siren Yelp Switch................................................8-6

Removal......................................................................8-6

Installation...................................................................8-6

Clutch Interlock Switch.......................................................8-7

Removal......................................................................8-7

Installation...................................................................8-7

Pursuit and Auxiliary Switch...............................................8-8

Removal......................................................................8-8

Installation...................................................................8-8

TABLE OF CONTENTS

3.1 SPECIFICATIONS: ENGINE

General...............................................................................3-1

8.5 AUTOMATIC COMPRESSION RELEASE

General.............................................................................8-10

Removal...........................................................................8-10

III

Page 10

TABLE OF CONTENTS

Installation........................................................................8-10

Compression Test.............................................................8-11

Diagnostics.......................................................................8-12

Diagnostic Tips..........................................................8-12

Diagnostic Notes.......................................................8-12

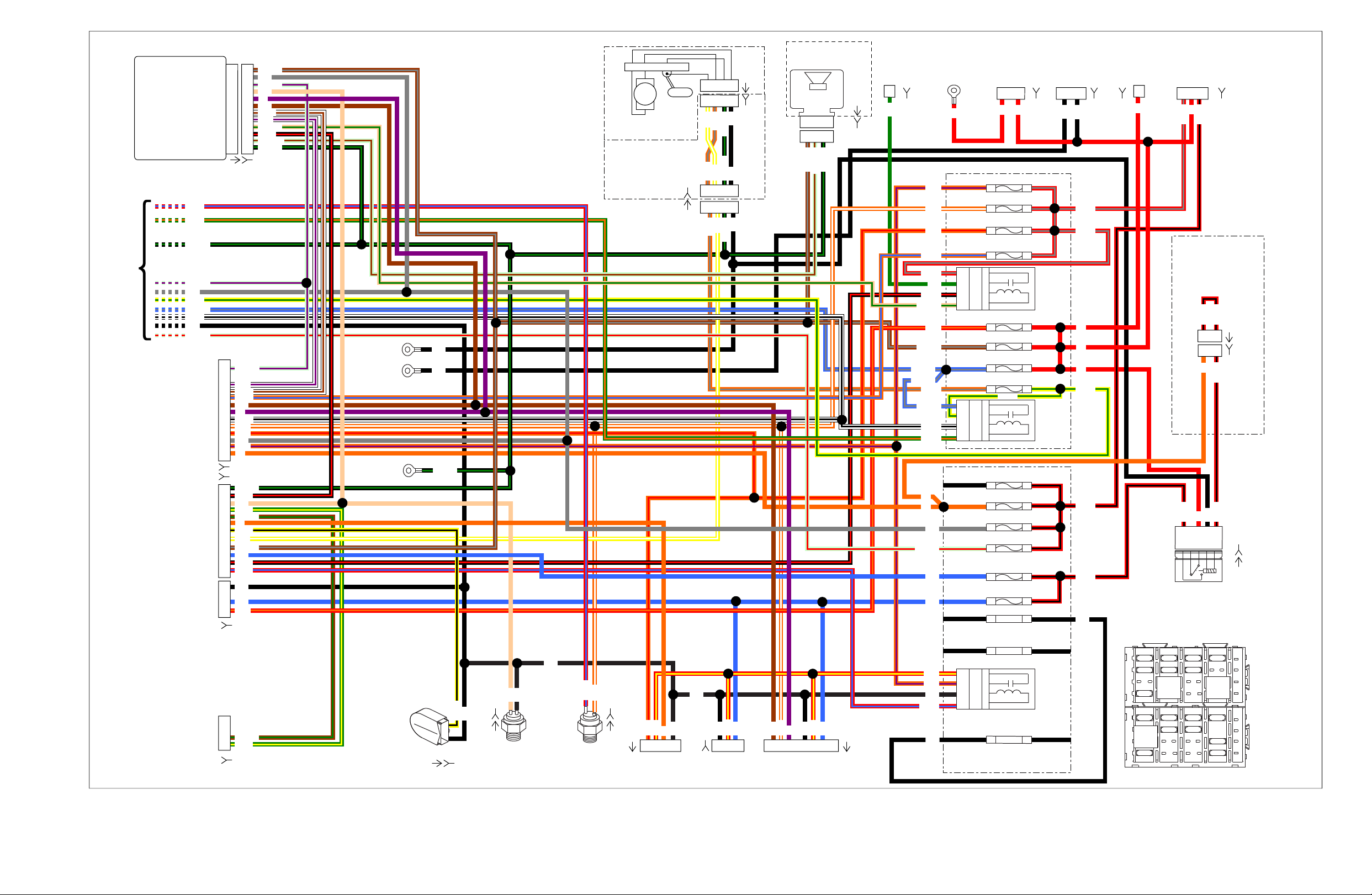

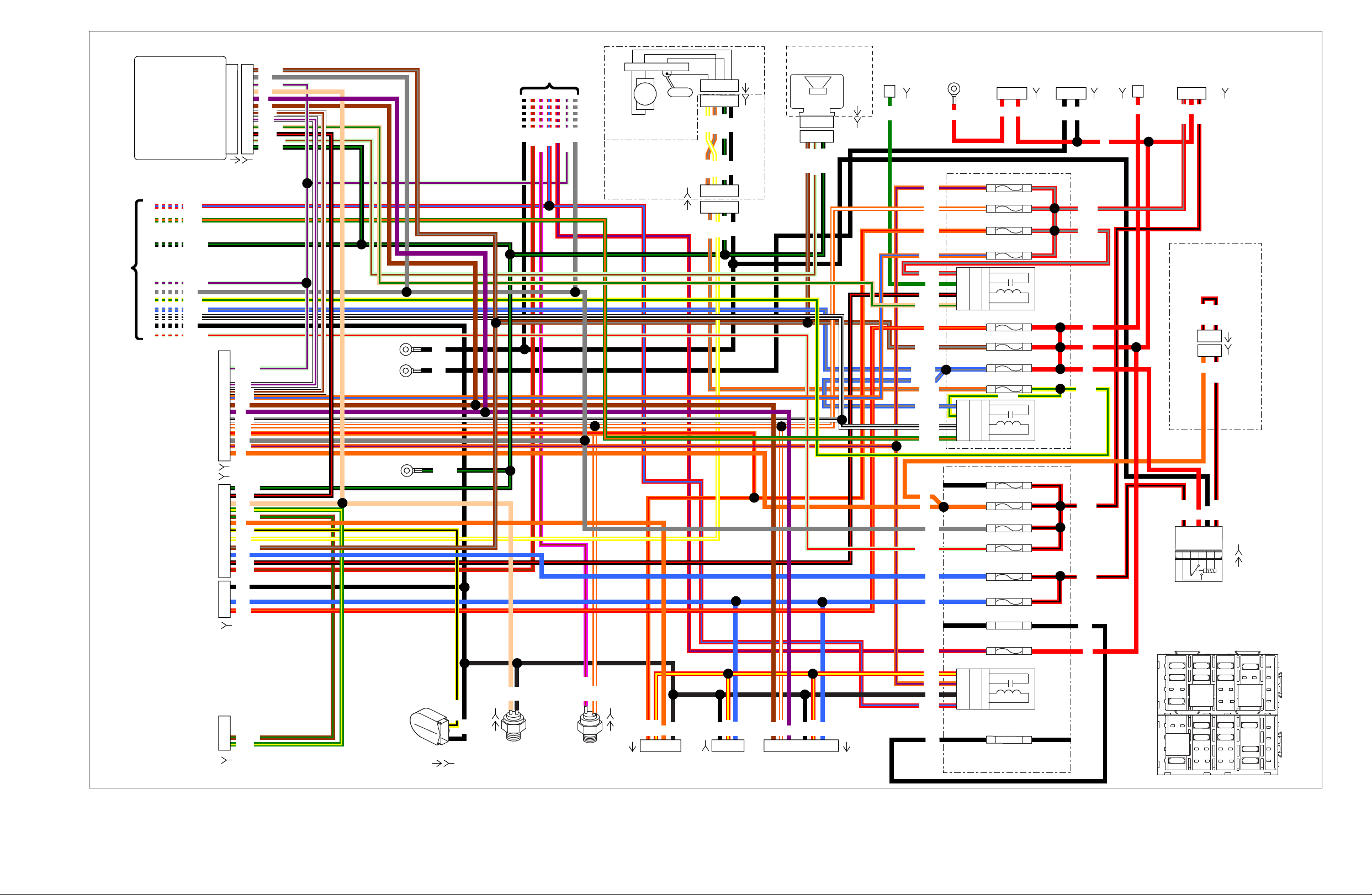

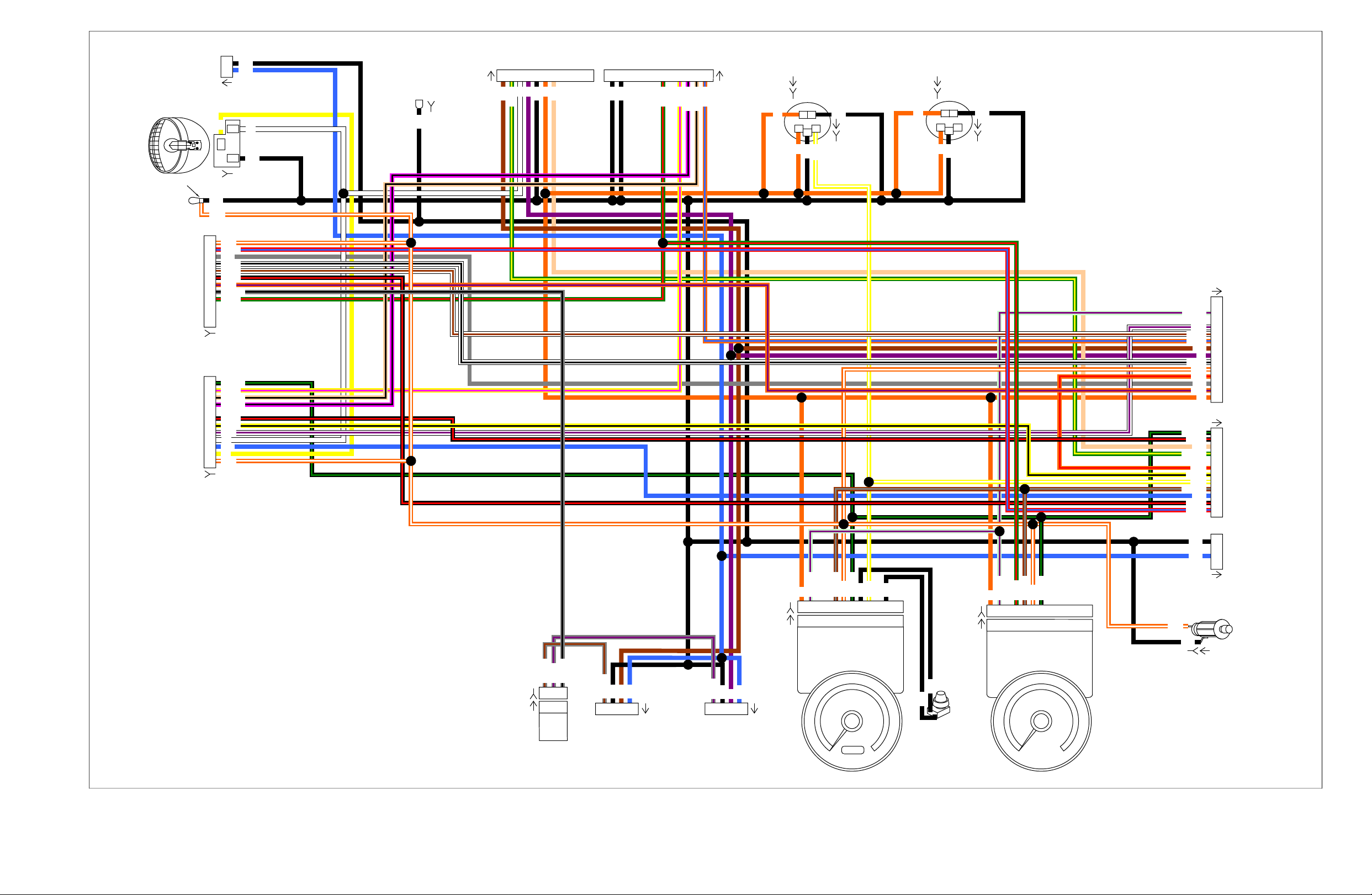

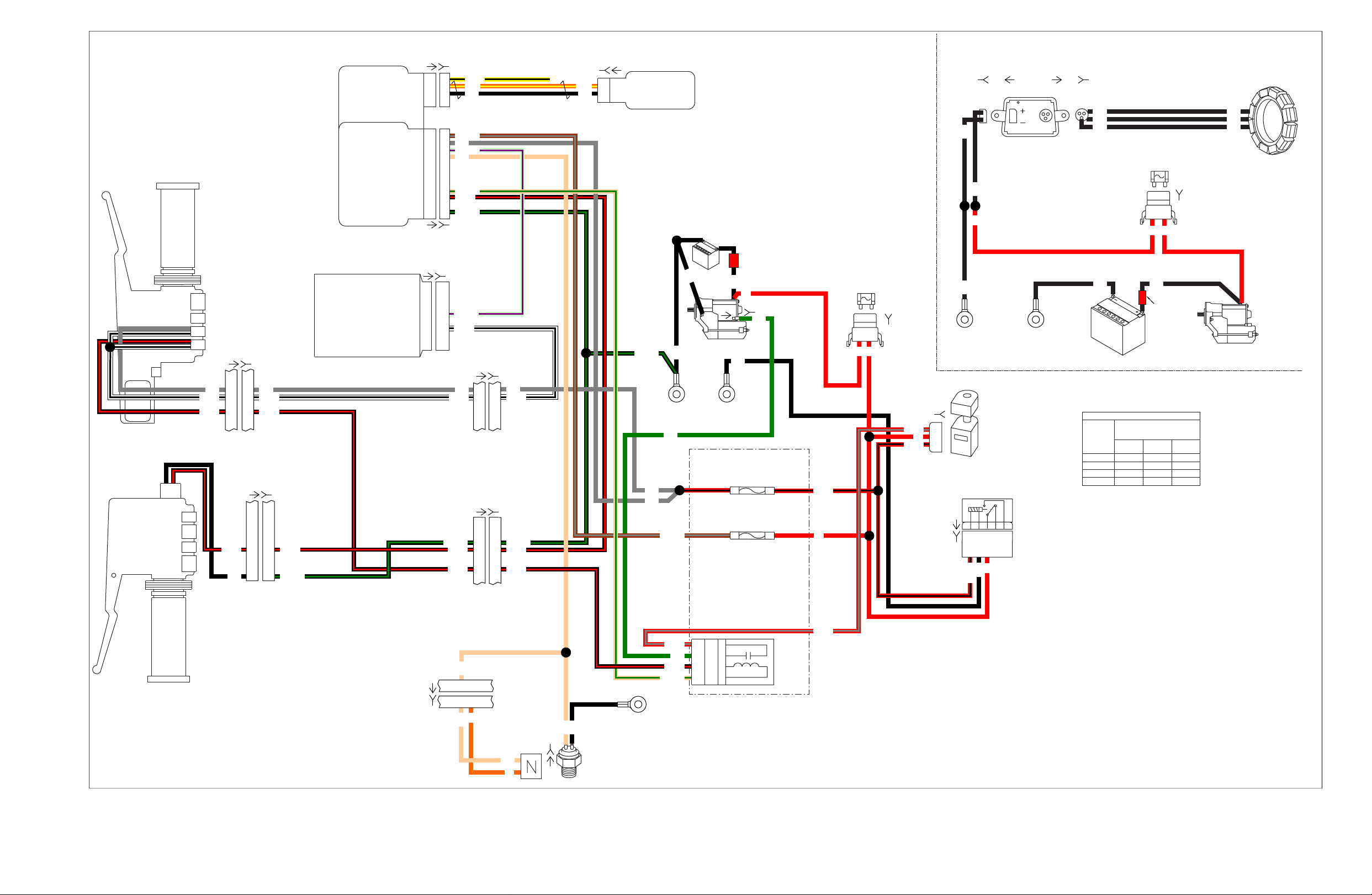

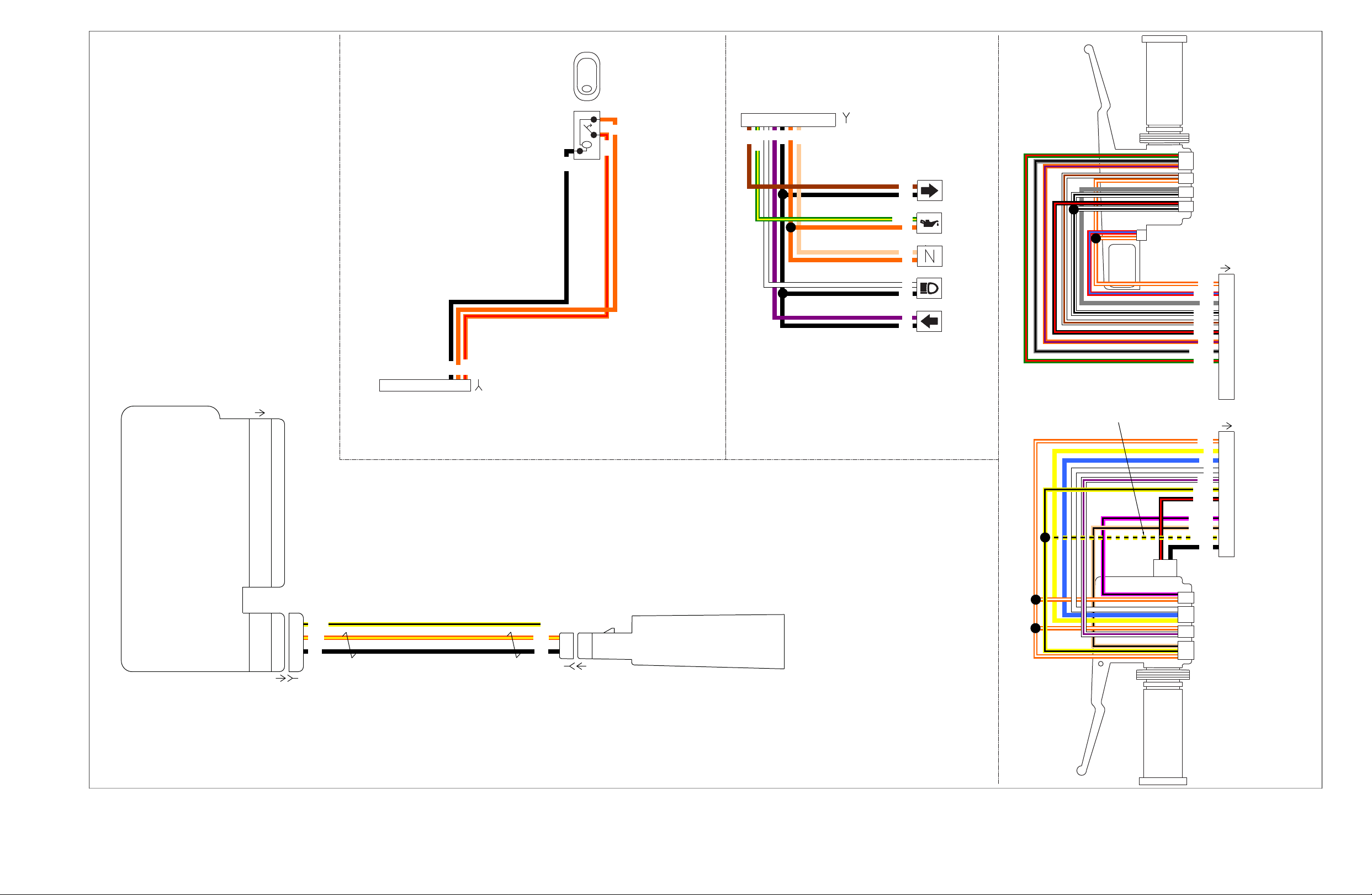

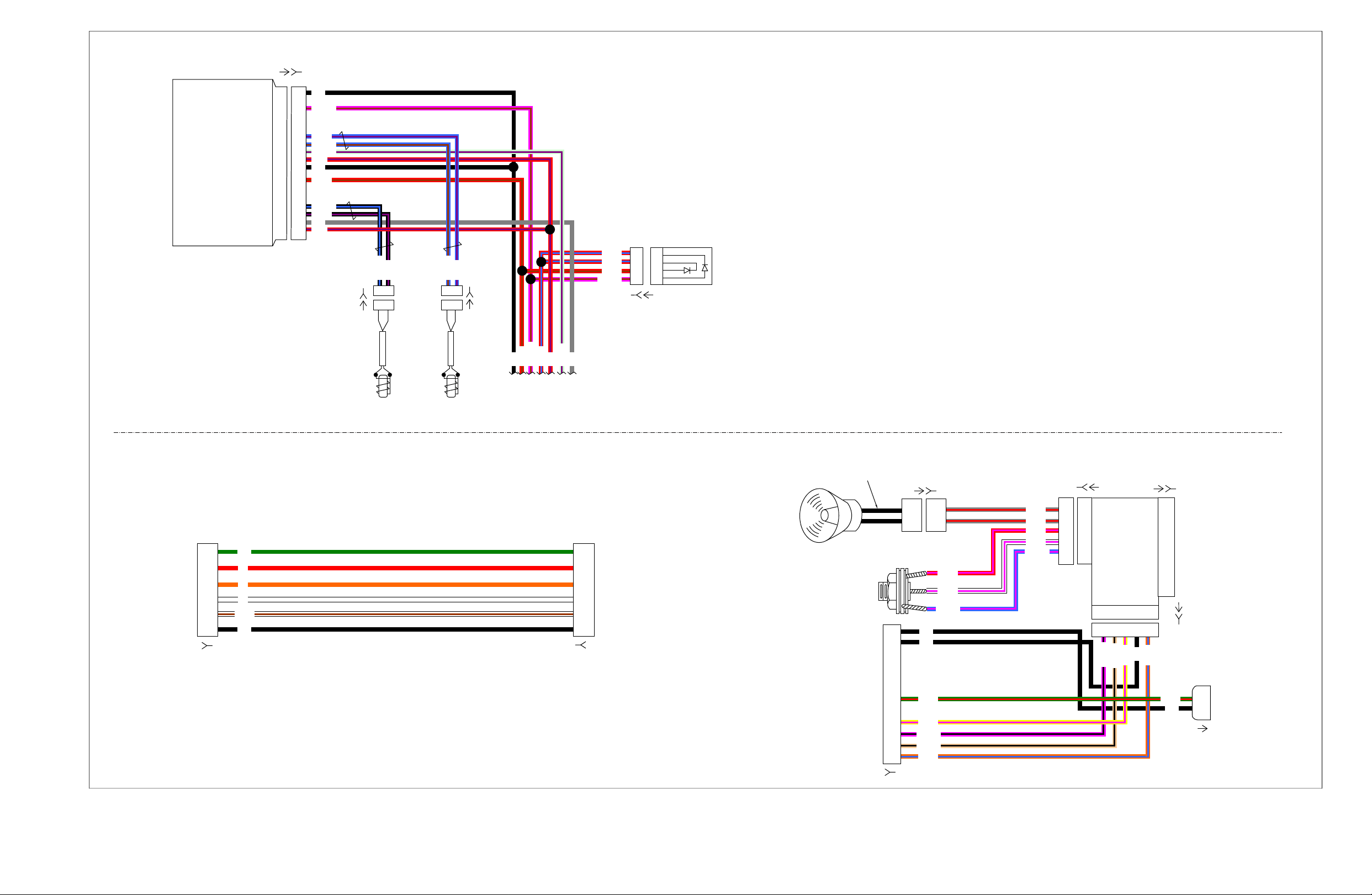

APPENDIX A WIRING

A.1 CONNECTORS

Connectors.........................................................................A-1

A.2 INDEX TO WIRING DIAGRAMS

Wiring Diagram Information...............................................A-7

Wire Color Codes........................................................A-7

Wiring Diagram Symbols............................................A-7

Wiring Diagrams.................................................................A-8

APPENDIX B GLOSSARY

B.1 GLOSSARY

Acronyms and Abbreviations..............................................B-1

REFERENCE MATERIAL

TOOLS...........................................................I

TORQUE VALUES.......................................III

INDEX...........................................................V

IV TABLE OF CONTENTS

Page 11

SUBJECT............................................................................................................................PAGE NO.

1.1 SCHEDULED MAINTENANCE.................................................................................................1-1

MAINTENANCE

Page 12

NOTES

Page 13

1.1SCHEDULED MAINTENANCE

GENERAL

The table below lists the maintenance requirements for police

motorcycles. If you are familiar with the procedures, refer to

the table for the recommended service interval. If necessary,

refer to the quick reference table (Table 1-2) for the required

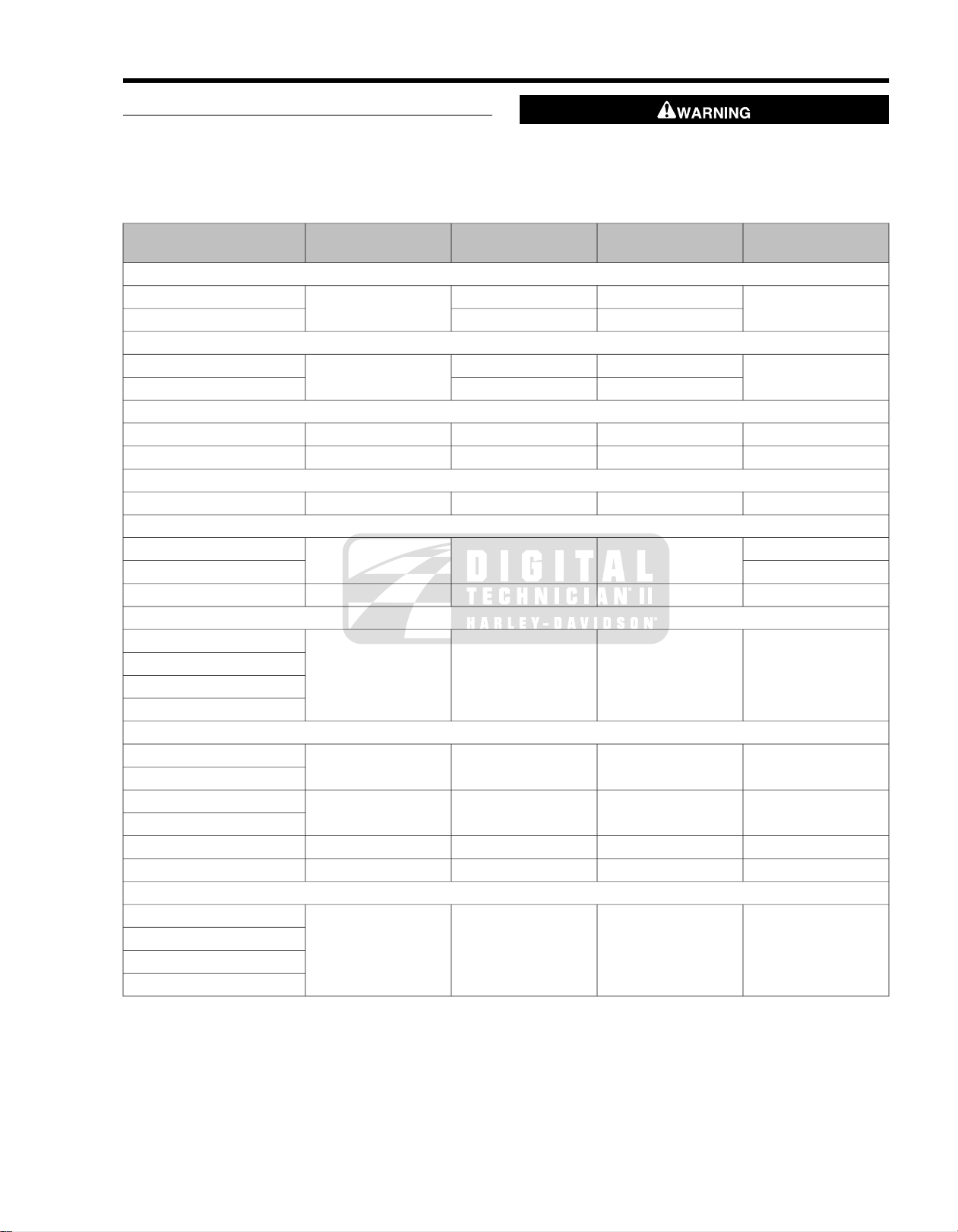

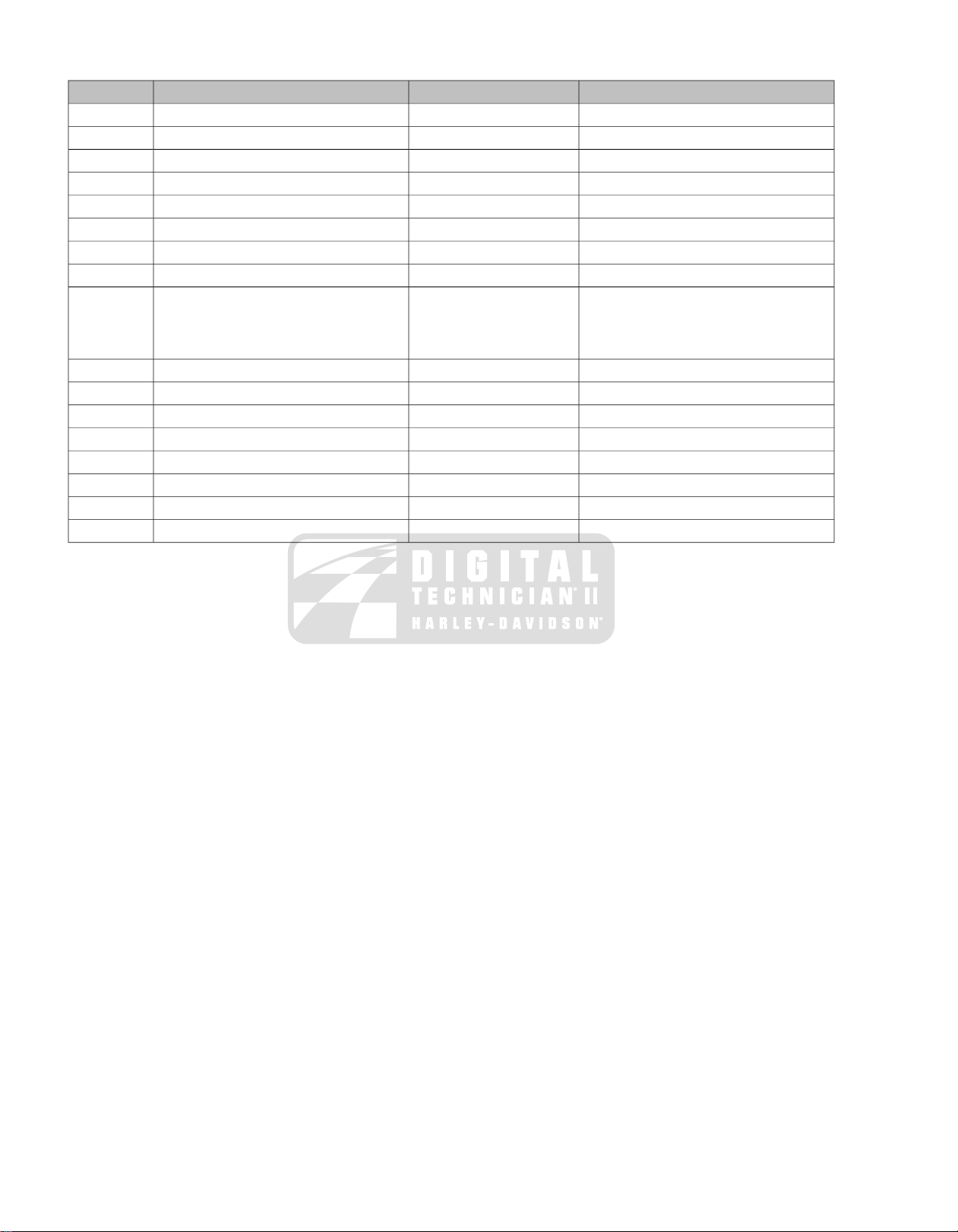

Table 1-1. Regular Service Intervals: 2008 Touring Models

1000 MI.

1600 KM

Tires

sprocket

ators

switches

Air suspension

applicable)

bags

stablizers

Battery

Exhaust system

Road test

NOTES:

PROCEDUREITEM SERVICED

tread

and leakage

connections

loose or missing fasteners or

heat shields

system functions

1. Should be performed by an authorized Harley-Da vidson dealer , unless you hav e the proper tools, service data and are mechanically

qualified.

2. Disassemble, lubricate and inspect every 50,000 miles (80,000 kilometers).

3. Perform annually.

4. Change D.O.T. 4 and flush brake system every two years.

5. Perform at each rear tire change.

specifications. If more detailed information is needed, turn to

the Touring Models Service Manual for step-by-step instructions.

Various lubricants, sealants and greases are recommended

in certain service operations. Refer to Table 1-3 for the appro-

priate part numbers for these items.

5000 MI.

8000 KM

10,000 MI.

16,000 KM

15,000 MI.

24,000 KM

20,000 MI.

32,000 KM

XXXReplacePrimary chaincase lubricant

XXReplaceTransmission lubricant

XReplace

40,000 KM

XXXXXXReplaceEngine oil and filter

XXXXXXInspect, service as requiredAir cleaner

XXXXXXCheck pressure, inspect

XXXXXXInspect for wearBrake pads and discs

XXXXXInspectSpark plugs

XXXXXXCheck operationElectrical equipment and

XXXXXXLubricate hinges and latchesFuel door, Tour-Pak, saddle-

XXXXXXVerify component and

NOTES25,000 MI.

1XXXXXXInspect for leaksOil lines and brake system

1XXXCheck tightnessWheel spokes

1XXXXXXCheck adjustmentClutch

1XXXXXXInspect, adjust beltDrive belt and compensator

5Inspect for wearCompensator sprocket isol-

1XXXXXXCheck, adjust and lubricateBrake and clutch controls

1XXXXXXInspect and lubricateJiffy stand

1XXXXXXInspect for leaksFuel lines and fittings

1XReplaceFuel tank filter

4XXXXXXCheck levels and conditionBrake fluid

1, 2ReplaceFront fork oil

2XXXLubricateSteering head bearings

1XAdjust

1XXXXXXCheck pressure, operation

1XXInspectWindshield bushings (if

1XXXCheck tightnessCritical fasteners

1XXInspect, check tightnessEngine mounts and

3Check battery and clean

3XXXXXXInspect for leaks, cracks, and

2008 FLT Police Service: Maintenance 1-1

Page 14

Drive belt deflection

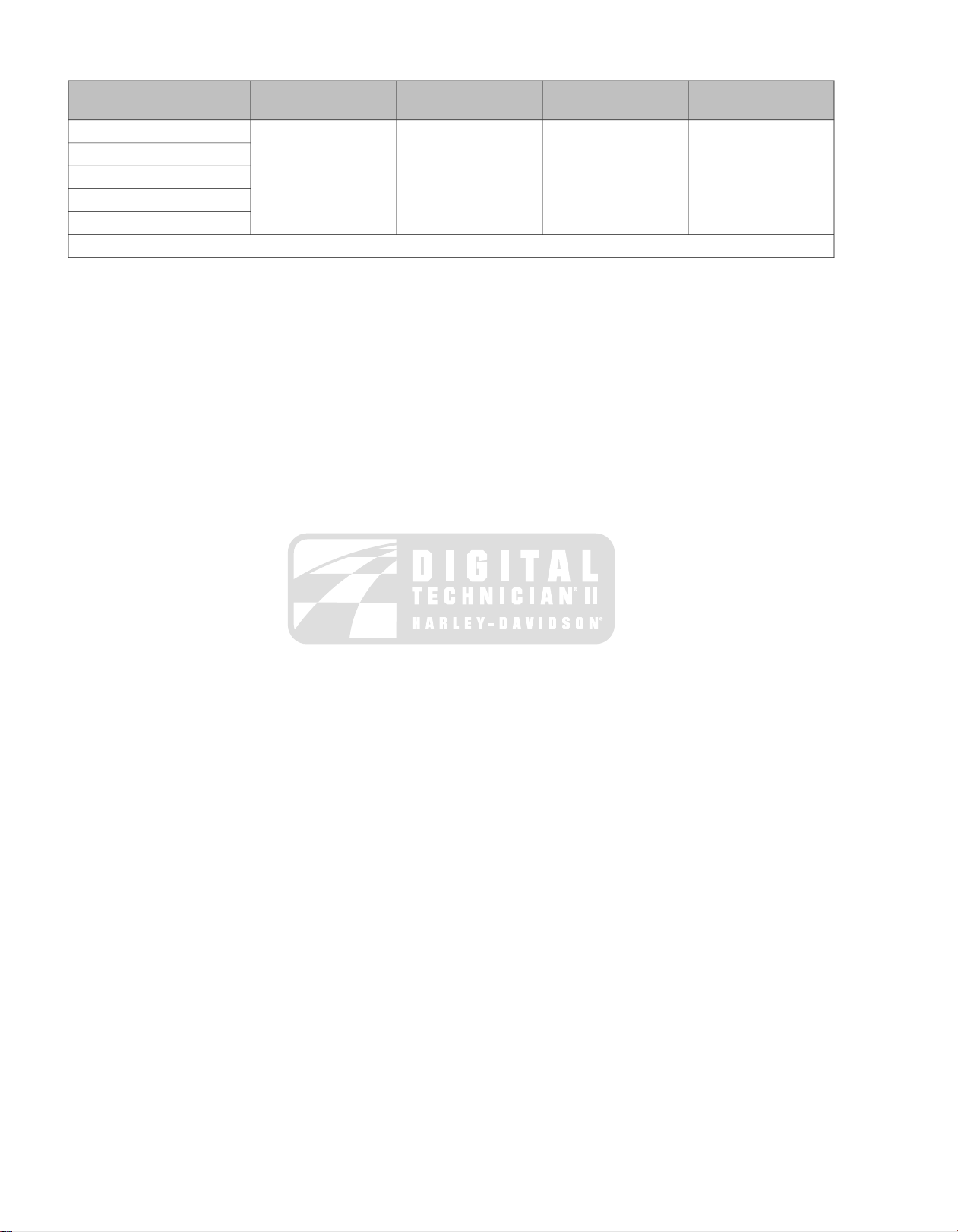

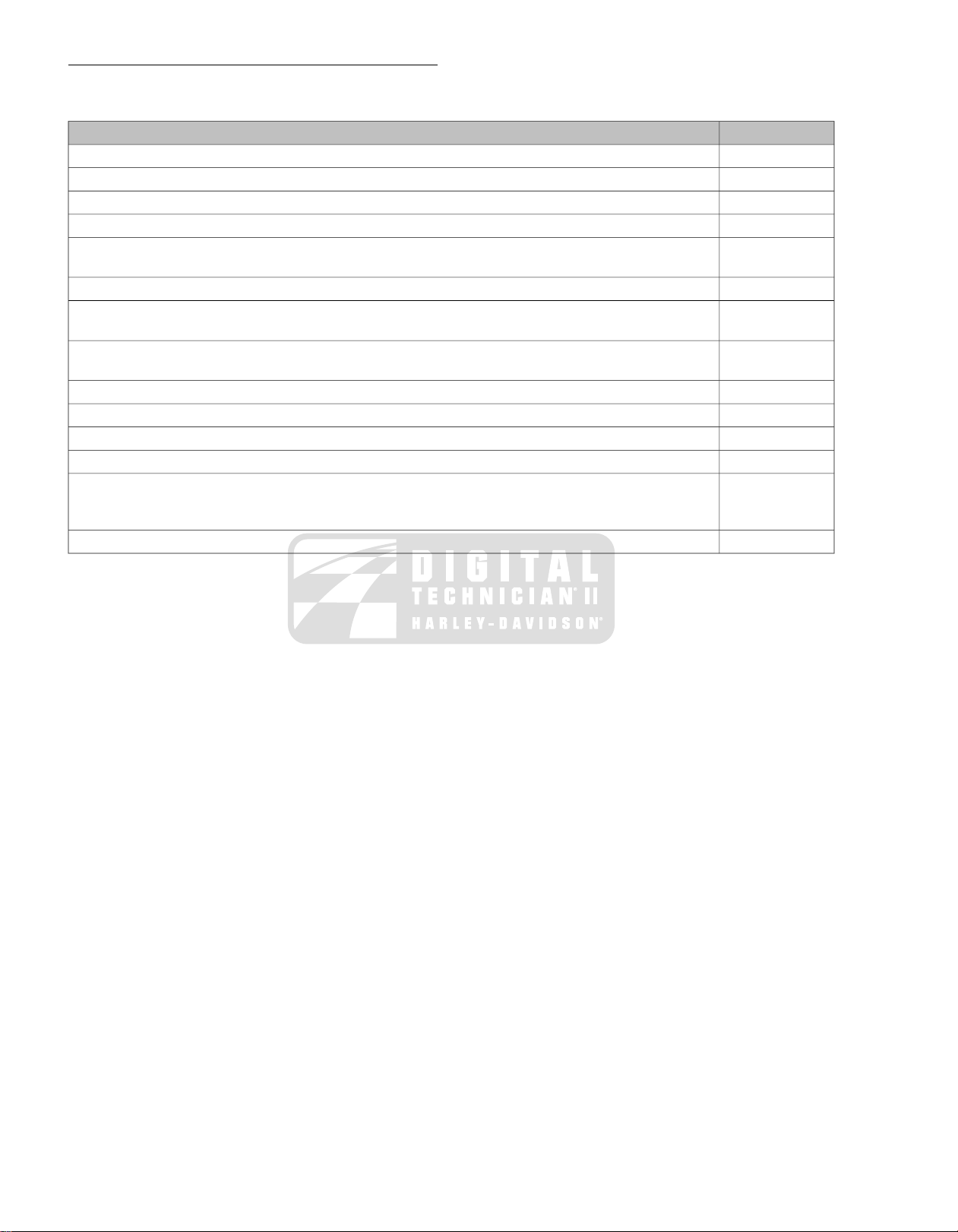

Table 1-2. Quick Reference Maintenance Chart: 2008 Police Models

DATASPECIFICATIONITEM SERVICED

14-21 ft-lbs (19.0-28.5 Nm)Drain plug torqueEngine oil and filter

4 qt. (3.8 L)Oil capacity

Hand tighten 1/2-3/4 turn after gasket contactFilter

63798-99AChrome filter part number

63731-99ABlack filter part number

Lubricant type and capacityPrimary chain lubricant

Lubricant levelTransmission lubricant

Lubricant type and capacity

Wear

strand

Air cleaner cover screw Threadlocker

Lubricant part numberClutch cable

FORMULA+ TRANSMISSION AND PRIMARY

CHAIN LUBRICATION (Part No. 99851-05)

Wet: 38 oz. (1124 ml)

Dry: 45 oz. (1331 ml)

14-21 ft-lbs (19.0-28.5 Nm)Primary chaincase drain plug torque

1/2-1 turnAdjuster screw free playClutch adjustment

72-120 in-lbs (8.1-13.6 Nm)Adjuster screw locknut torque

1/16-1/8 in. (1.6-3.2 mm)Free play at hand lever

84-108 in-lbs (9.5-12.2 Nm)Clutch inspection cover torque

Dipstick at FULL with motorcycle on jiffy stand and

filler plug resting on threads.

FORMULA+ TRANSMISSION AND PRIMARY

CHAIN LUBRICATION (Part No. 99851-05)

32 oz (0.95 liters)

14-21 ft-lbs (19.0-28.5 Nm)Transmission drain plug torque

25-75 in-lbs (2.8-8.5 Nm)Transmission filler plug/dipstick torque

Front: 36 psi (248 kPA)Pressure: solo riderTire pressure and wear

Rear: 36-40 psi (248-276 kPA)

Replace if less than 1/32 in. (0.8 mm) of tread

pattern

55 in-lbs (6.2 Nm) minimumSpoke nipple torqueWheel spokes

99953-99A (12 oz.)D.O.T. 4 hydraulic brake fluid part numberBrake fluid level

Front: 0.20 in. (5.0 mm)Fluid level (from top of master cylinder reservoir)

Rear: 0.26 in. (6.5 mm)

Front:7-10 in-lbs (0.8-1.1 Nm)Master cylinder reservoir cover screw torque

Rear: 12-15 in-lbs (1.4-1.7 Nm)

0.016 in. (0.4 mm)Minimum brake pad thicknessBrake pads and discs

75-102 in-lbs (8.5.-11.5 Nm)Brake caliper pad pin torque

Front: 0.18 in. (4.5 mm)Minimum brake disc thickness

Rear: 0.25 in. (6.3 mm)

0.008 in. (0.2 mm)Maximum brake disc lateral runout (warpage)

10 lb. (4.5 kg)Upward force applied at midpoint of bottom belt

3/8-7/16 in. (9.5-11.1 mm)FLHTP

1/4-5/16 in. (6.4-7.9 mm)FLHP/FLHPE

40-60 in-lbs (4.5-6.8 Nm)Air cleaner cover bracket screw torqueAir cleaner

36-60 in-lbs (4.1-6.8 Nm)Air cleaner cover screw torque

LOCTITE MEDIUM STRENGTH THREADLOCKER

243 (BLUE)

Part No. 99642-97 (6 ml)

LUBIT-8 SUPER OIL, Part No. 94968-85TV (1/4

fl. oz.)

35-45 in-lbs (4.0-5.1 Nm)Handlebar switch housing screw torque

1-2 2008 FLT Police Service: Maintenance

Page 15

Table 1-2. Quick Reference Maintenance Chart: 2008 Police Models

CCI #20 Brake Grease

Transmission and Primary Chaincase

Lubricant

Loctite Prism Primer (770)

Loctite Prism Superbonder (411)

Loctite Superbonder 420 Adhesive

DATASPECIFICATIONITEM SERVICED

HD-6R12TypeSpark plugs

0.038-0.043 in. (0.97-1.09 mm)Gap

12-18 ft-lbs (16.3-24.4 Nm)Torque

See FRONT FORK in the Touring Service Manual.AmountFront fork oil

HYDRAULIC FORK OIL (TYPE E)Type and part number

Part No. 99884-80 (16 oz.)

60-96 in-lbs (6.8-10.9 Nm)Terminal bolt torqueBattery

15-20 ft-lbs (20-27 Nm)Top caddy clamp screw torque

Table 1-3. Lubricants, Greases, Sealants

PACKAGEPART NUMBERITEM

1 oz squeeze tube98960-97Anti-Seize Lubricant

squeeze packet42830-05 (included in master cylinder

rebuild kit)

12 oz. bottle99953-99AD.O.T. 4 Brake Fluid

1 oz squeeze tube99861-02Electrical Contact Lubricant

1 qt bottle99851-05Genuine Harley-Davidson Formula+

squeeze packet42820-04G40M Brake Grease

1.9 oz squeeze tube99650-02Gray High Performance Sealant

3.5 oz tube99653-85HYLOMAR Gasket and Thread Sealant

6 ml squeeze tube99818-97Loctite Pipe Sealant With Teflon 565

6 ml squeeze tube99642-97Loctite Threadlocker 243 (blue)

6 ml squeeze tube94759-99Loctite Threadlocker 262 (red)

10 ml bottle98618-03Loctite Threadlocker 272

14 oz. cartridge99857-97Special Purpose Grease

1/4 fl. oz94968-85TVSuper Oil

16 oz bottle99884-80Type "E" Hydraulic Fork Oil

2008 FLT Police Service: Maintenance 1-3

Page 16

NOTES

1-4 2008 FLT Police Service: Maintenance

Page 17

SUBJECT............................................................................................................................PAGE NO.

2.1 SPECIFICATIONS: CHASSIS...................................................................................................2-1

2.2 VEHICLE IDENTIFICATION NUMBER (V.I.N.)..........................................................................2-2

2.3 TIRES........................................................................................................................................2-3

2.4 SEAT..........................................................................................................................................2-4

2.5 AIR SEAT RESERVOIR.............................................................................................................2-8

2.6 SADDLEBAGS........................................................................................................................2-11

2.7 TACHOMETER BRACKET: FLHP/E........................................................................................2-14

CHASSIS

Page 18

NOTES

Page 19

2.1SPECIFICATIONS: CHASSIS

GENERAL

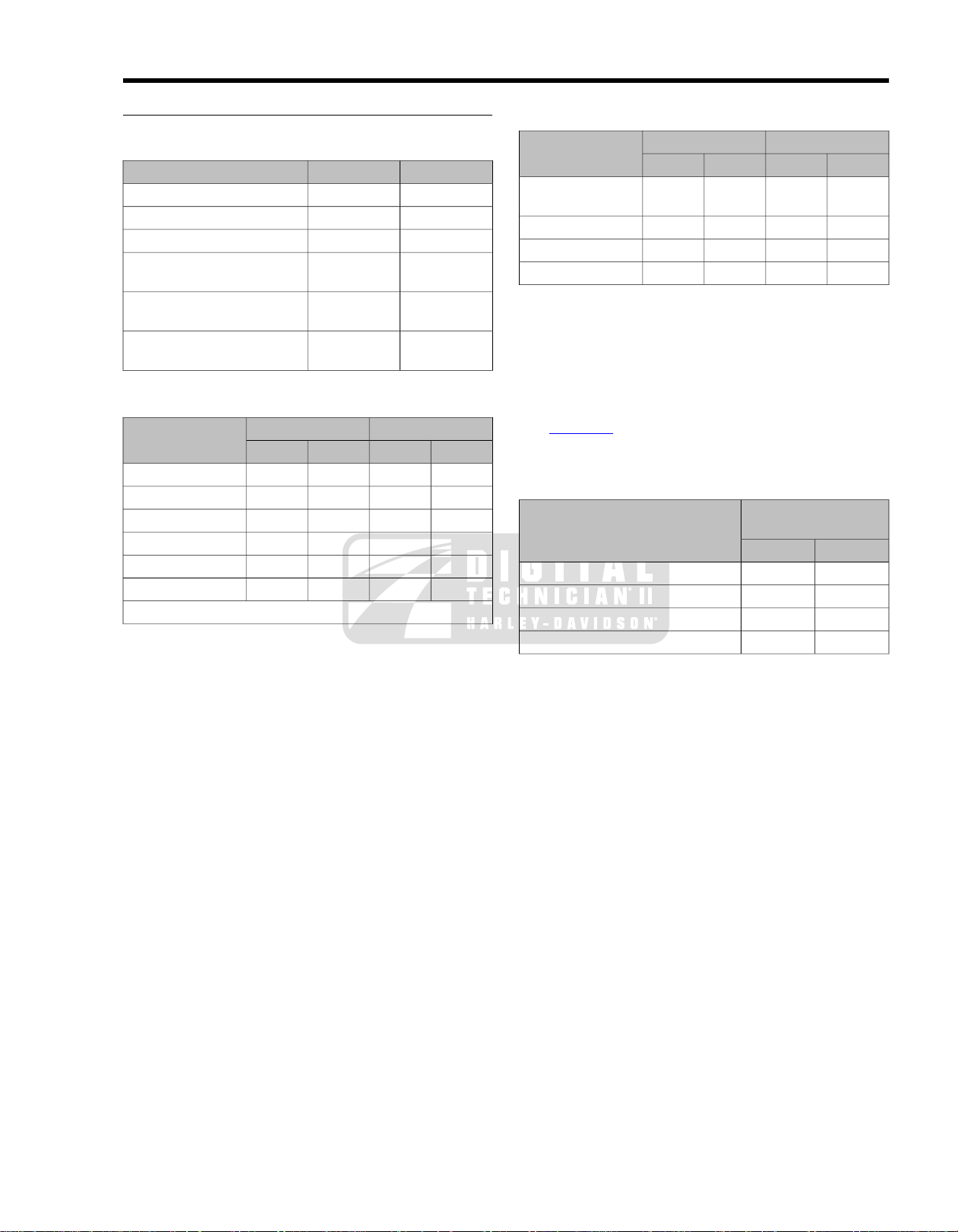

Table 2-1. Capacities: 2008 Police Models

(approximate)

(drained)

(cover removed)

Table 2-2. Dimensions: 2008 Police Models

*With 180 lb. ( 81.7 kg) rider on seat.

Table 2-3.Weights: 2008 Police Models

FLHPFLHTPITEM

LITERSU.S.ITEM

22.76.0 galFuel tank (total)

3.81.0 galLow fuel warning lamp on

3.84.0 U.S. qt.Oil tank with filter

0.9532.0 fl. oz.Transmission

1.1238.0 fl. oz.Primary chaincase

1.3345.0 fl. oz.Primary chaincase

FLHPFLHTPITEM

MMIN.MMIN.

1612.963.51612.963.5Wheel base

238093.7238093.7Overall length

876.334.5990.639.0Overall width

129.55.1129.55.1Road clearance

1399.555.11549.461.0Overall height

693.427.3693.427.3Saddle height*

from factory

NOTE

Gross vehicle weight rating (GVWR) (maximum allowable

loaded vehicle weight) and corresponding gross axle weight

rating (GAWR) are printed on a label fix ed to the bottom of the

right front frame downtube.

NOTE

See 2.3 TIRES for important information regarding tire data

and tire inflation.

Table 2-4. Rear Air Suspension Pressures

SHOCK LOADING

RECOMMENDED

PRESSURES

KG.LB.KG.LB.

335739347764Weight as shipped

54412005441200GVWR

227500227500GAWR front

375827375827GAWR rear

kPa 0-241PSI 0-35

00Solo rider up to 150 lbs. (68 kg)

0-690-10Solo rider 150-200 lbs. (68-91 kg)

35-1035-15Solo rider 200-250 lbs. (91-113 kg)

138-24120-35At maximum GVWR

NOTE

Initial suspension fill pressure for a normally equipped police

motorcycle is 25 psi (172.4 kPa).

2008 FLT Police Service: Chassis 2-1

Page 20

2.2VEHICLE IDENTIFICATION NUMBER (V.I.N.)

1HD 1 FM M 1 3 8 Y 111000

1 2 3 4 5 6 7 8 9 10

om01103

GENERAL

See Figure 2-1. The full 17-digit serial number, or Vehicle

Identification Number (V.I.N.), is stamped on the right side of

the frame backbone at the rear of the steering head (and under

the main harness conduit). A label bearing the V.I.N. code is

also affixed to the left side of the steering head. An abbreviated

V.I.N. is stamped between the front and rear cylinders on the

left side of the crankcase.

Figure 2-1.Typical Harley-Davidson V.I.N.: 2008 Police Models

Sample V.I.N. as it appears on the steering head -

1HD1FHM137Y110000

Sample abbreviated V.I.N. as it appears on the crankcase -

FHM7110000

NOTE

Always give the complete V.I.N. when ordering parts or making

an inquiry about your motorcycle.

Table 2-5. Harley-Davidson V.I.N. Breakdown: 2008 Police Models

POSSIBLE VALUESDESCRIPTIONPOSITION

1=Originally manufactured for sale within the United StatesMarket designation1

5=Originally manufactured for sale outside of the United States

HD=Harley-DavidsonManufacturer2

1=Heavyweight motorcycle (901cc or larger)Motorcycle type3

See V.I.N. model tableModel4

M=Twin Cam 103™ 1690cc air-cooled, fuel injectedEngine type5

1=RegularIntroduction date6

2=Mid-year

3=California/regular

4=Cosmetic changes and/or special introductory date

5=California/cosmetic changes and/or special introductory date

6=California/mid-year

Can be 0-9 or XV.I.N. check digit7

8=2008Model year8

Y=York, PA U.S.A.Assembly plant9

VariesSequential number10

Table 2-6.V.I.N. Model Codes: 2008 Police Models

MODELCODE

FLHTPFM

FLHPFH

FLHPEFT

2-2 2008 FLT Police Service: Chassis

Page 21

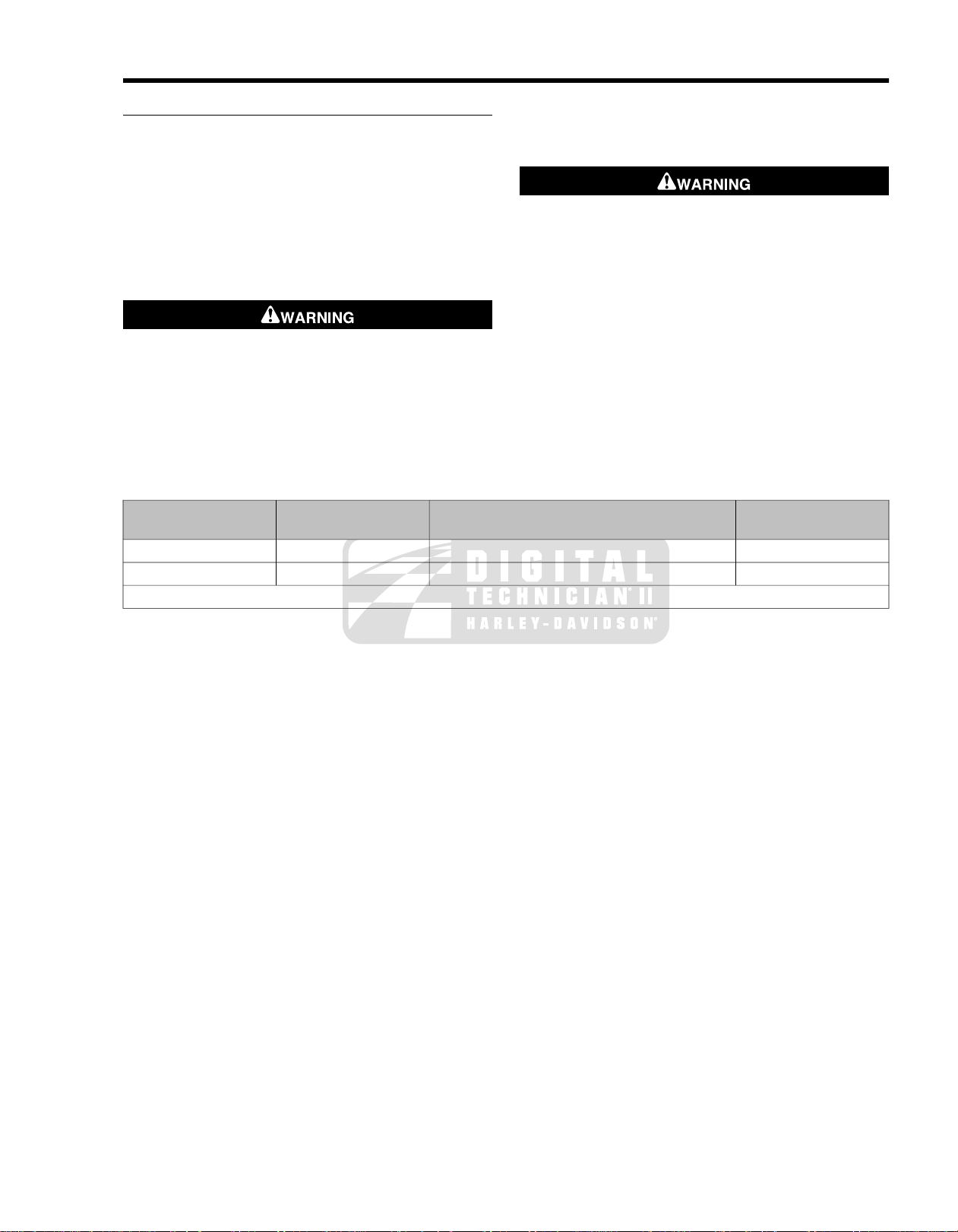

2.3TIRES

GENERAL

The rear tire on FL police model motorcycles is fit for solo riding

only. If converted to a two-up bike, that is, configured for passenger use (with luggage), then the rear tire needs to be

changed to one with a higher weight rating. Since it has long

been Harley-Davidson policy not to mix different types of tires

on the same vehicle, we strongly recommend that both front

and rear tires be replaced. In order to alert the customer to this

safety issue, the f ollo wing w arning appears on a label fitted to

the rear fender approximately 1/4 inch (6.4 mm) behind the

domestic seat mounting hole.

This vehicle has tires with weight ratings for one person

operation. If this vehicle is modified to carry two people,

the tires must be changed. See a Harley-Davidson dealer

for proper replacement tires. Using improper tires can

cause tire failure which could result in death or serious

injury. (00096a)

Table 2-7.Tire Data

MANUFACTURER'S DESIGNATIONSIZETIRE LOCATION

All 2008 vehicles use only Dunlop Harley-Davidson tires.

NOTE

Use the tires recommended for civilian/pleasure vehicles of

the same year and model family.

Harley-Davidson front and rear tires are not the same.

Interchanging front and rear tires can cause tire failure,

which could result in death or serious injury. (00026a)

Tire size, manufacturer's description and inflation pressure are

listed below.

NOTE

ABS motorcycles must always use tires and wheels that are

the same as the original equipment. The ABS monitors the

rotational speed of the wheels through individual wheel speed

sensors. Changing to different diameter wheels or different

size tires can alter the rotational speed. This can upset the

calibration of the ABS and have an adv erse eff ect on its ability

to detect and prevent lockups. Tire inflation pressure that is

significantly low also can have an adverse effect.

TIRE PRESSURE

(COLD)

36 psi (248 kPa)Dunlop D402F PTMT90B 16 72HFront

36-40 psi (248-276 kPa)Dunlop D402 PTMT90B 16 72HRear

2008 FLT Police Service: Chassis 2-3

Page 22

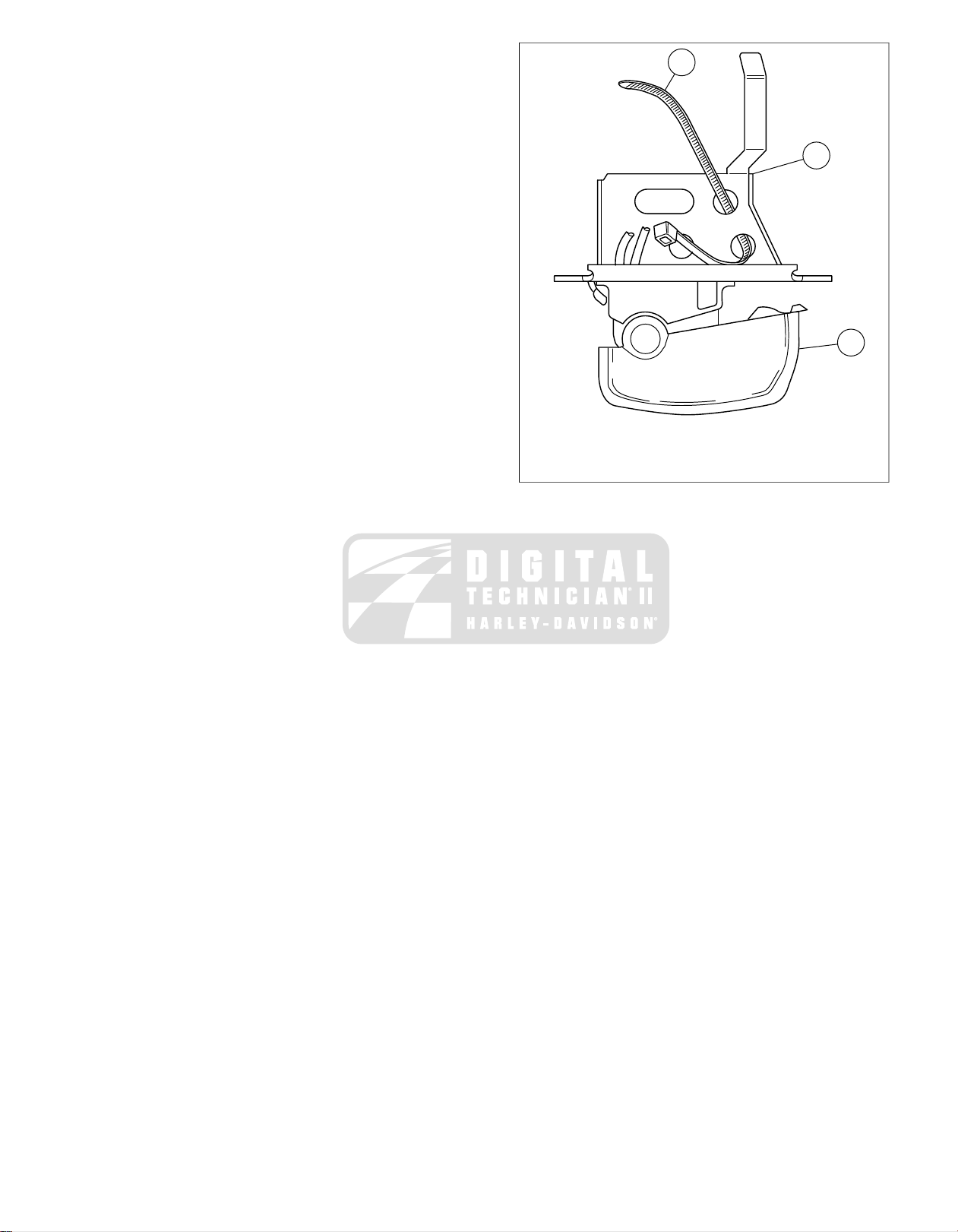

GENERAL

1

3

2

om00451

Maximum air pressure for the seat is 100 psi (689 kPa).

Normal air pressure is 30-45 psi (207-310 kPa). Do not

operate with air pressure so low that system bottoms out

on bumpy roads. (00167a)

NOTES

• Initially pressurize the seat air suspension system to 40

psi (275.8 kPa), then add or remov e pressure to the rider's

comfort. DO NO T oper ate motorcycle with system underinflated.

• T o chec k minimum air pressure, ha ve rider sit on seat and

bounce to simulate riding conditions. Visually check for

any contact between air spring and frame components.

Add air as necessary.

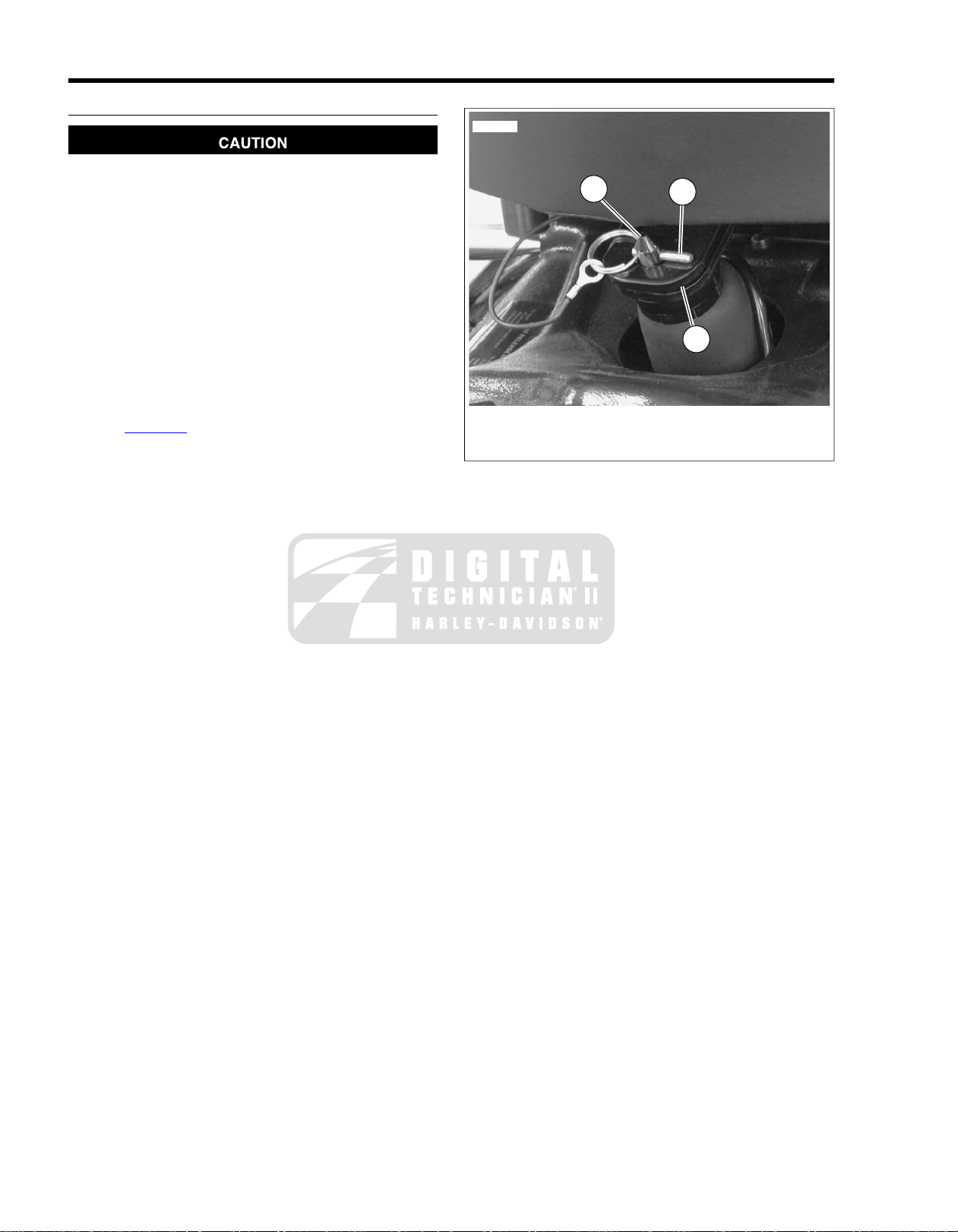

• See Figure 2-2. Removal and installation of retaining pin

(1) requires that the air pressure be removed from the seat

air suspension system. The seat will no longer pivot up

because the front of the seat will hit the fuel tank. Retaining

pin (1) should not be removed unless the seat is to be

removed.

• The seat does not adjust forward or rearward.

2.4SEAT

1. Retaining pin

2. Rear seat bracket

3. Support post

Figure 2-2. Seat Latch: Police Models

2-4 2008 FLT Police Service: Chassis

Page 23

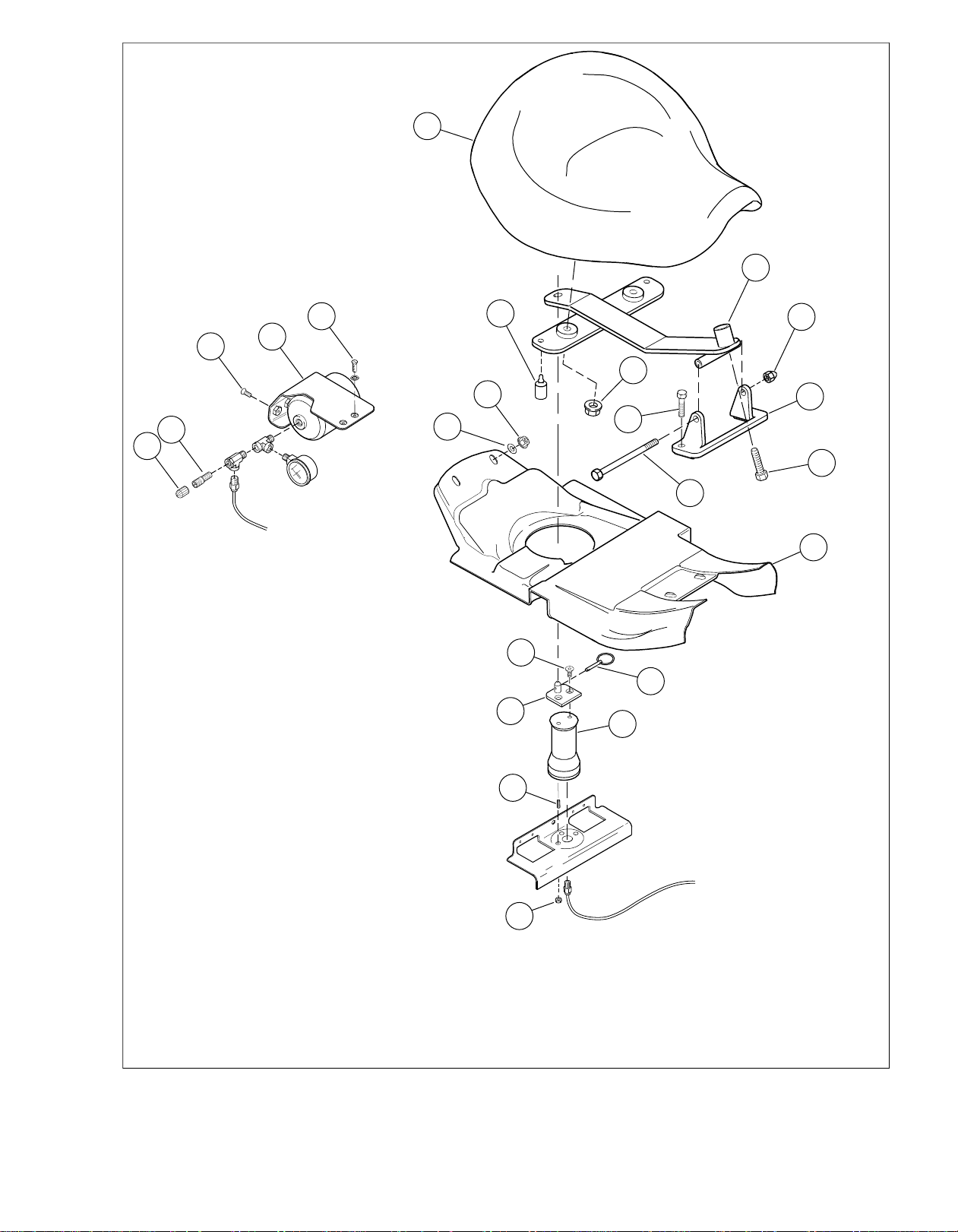

1

2

3

4

5

7

6

8

11

12

10

13

14

17

18

19

22

20

23

21

15

16

9

sm04695

2. 18.10.Air fitting Retaining pinSeat bracket

5. 21.13.Fastener (2) Set screwAcorn Nut

8. 16.Rubber bumper (2) Pivot bolt

11.3. 19.Flange nut (2)Fastener (2) Air spring

14.6. 22.Seat bracket mountFlat Washer Top plate

Figure 2-3. Air Seat Assembly

17.9.1. Seat fairingSeatCap

20.12.4. Nut (2)Fastener (2)Air reservoir

23.15.7. FastenerHex scrweFlange nut (2)

2008 FLT Police Service: Chassis 2-5

Page 24

SEAT REMOVAL

sm04699

1. Remove air pressure from air spring and reservoir.

2. See Figure 2-2. Standing on left side of motorcycle , press

down on rear of seat and pull pin (1) from post (3) on top

plate.

3. See Figure 2-3. Remo ve front piv ot bolt (16) and n ut (13).

4. Lift seat and bracket assembly from motorcycle.

5. Remove two flange nuts (11) and he x screw (15) to release

seat from seat bracket (10).

6. Inspect two rubber bumpers (8) on seat bracket for cuts,

tears or general deterioration. If damaged, deteriorated or

missing, replace as follows:

a. Remove old rubber bumper and discard.

b. Moisten bead on new rubber bumper with soapy

water. Place rubber bumper into position at bottom

of seat bracket. Feed tail on bead up through hole in

seat bracket. Using a needle nose pliers, grasp tail

as close to bead as possible, and then pull bead up

through hole in seat bracket.

7. If necessary, remove two flange nuts (7) and washers (6)

and remove seat fairing (17) under seat.

SEAT INSTALLATION

Disconnect negative (-) battery cable first. If positive (+)

cable should contact ground with negative (-) cable connected, the resulting sparks can cause a battery explosion,

which could result in death or serious injury. (00049a)

2. Disconnect battery, negative (-) cable first.

3. Remove battery from battery box.

4. Remove air pressure from air spring and reservoir.

5. Depress collar on compression fitting and remove air tube

from air reservoir.

6. See Figure 2-3. Holding air spring to prevent twisting,

remove two fasteners (23) to release top plate (22) from

air spring (19).

7. Remove two flange nuts (20) under frame weldment (at

rear of battery box). Remove air spring from motorcycle.

1. See Figure 2-3. If removed, install seat fairing (17) under

seat. Tighten flange nuts (7) to 60-120 in-lbs (6.8-13.6

Nm).

2. Install seat onto seat bracket and start two flange nuts

(11). Align threaded hole in seat with hole in front of seat

bracket and start hex screw (15).

3. Tighten flange nuts to 96-144 in-lbs (10.9-16.3 Nm).

4. Tighten hex screw to 60-120 in-lbs (6.8-13.6 Nm).

5. Place seat and bracket assembly on motorcycle and install

front pivot bolt (16).Tighten nut (13) to 48-84 in-lbs (5.4-

9.5 Nm).

6. See Figure 2-2. Align post (3) on top plate with hole in rear

seat bracket.While pressing down on rear of seat, insert

pin (1) into post on top plate.

Maximum air pressure for the seat is 100 psi (689 kPa).

Normal air pressure is 30-45 psi (207-310 kPa). Do not

operate with air pressure so low that system bottoms out

on bumpy roads. (00167a)

7. Fill air reservoir to 40 psi (275.8 kPa), then add or remov e

pressure to the rider's comfort. Install protective cap on

air fitting.

AIR SPRING REPLACEMENT

Figure 2-4. Air Spring Assembly

Installation

1. Feed air tube through large center hole in frame weldment

(at rear of battery box) and then route rearward following

inboard side of right upper frame tube to air reservoir.

2. Depress collar on compression fitting of air seat reservoir,

and insert air tube until it bottoms. Gently tug on tube to

verify that it is locked in place.

3. Connect air tube to compression fitting at bottom of air

spring, if removed.

4. See Figure 2-3. Place air spring on frame weldment while

engaging the two set screws.

5. Install two flange nuts (20) onto set screws (21).Tighten

flange nuts to 50-70 in-lbs (5.7-7.9 Nm).

6. Position top plate (22) onto air spring and start two

fasteners (23). Holding air spring to prevent twisting,

tighten screws to 36-60 in-lbs (4.1-6.8 Nm).

7. Place battery into battery box, terminal side forward.

Removal

1. Remove seat and seat fairing. See 2.4 SEAT, Seat

Removal.

2-6 2008 FLT Police Service: Chassis

Connect positive (+) battery cable first. If positive (+) cable

should contact ground with negative (-) cable connected,

the resulting sparks can cause a battery explosion, which

could result in death or serious injury. (00068a)

Page 25

8. Connect battery cables, positive (+) cable first.Tighten to

60-96 in-lbs (6.8-10.9 Nm).

9. Apply a light coat of petroleum jelly or ELECTRICAL

CONTACT LUBRICANT, Part No. 99861-02 (1 oz. tube),

to both battery terminals.

10. Install hold-down clamp so that the lip (with rubber pad)

rests on the edge of the battery.Tighten T40 T ORX screw

to 15-20 ft-lbs (20-27 Nm).

11. Install seat fairing.Tighten fasteners to 60-120 in-lbs (6.8-

13.6 Nm).

12. Install seat and inser t pin into post on top plate or air

spring. See 2.4 SEAT, Seat Installation.

Maximum air pressure for the seat is 100 psi (689 kPa).

Normal air pressure is 30-45 psi (207-310 kPa). Do not

operate with air pressure so low that system bottoms out

on bumpy roads. (00167a)

13. Fill air reservoir to 40 psi (275.8 kPa), then add or remov e

pressure to the rider's comfort. Install protective cap on

air valve.

SEAT BRACKET MOUNT REPLACEMENT

Removal

1. Remove seat. See 2.4 SEAT, Seat Removal.

2. See Figure 2-3. Remove two fasteners (12) to release

seat bracket mount from frame backbone.

Installation

1. Install seat bracket mount using two f asteners (12).Tighten

fasteners to 15-20 ft-lbs (20.3-27.1 Nm).

2. Install seat and insert pin into post on top plate of air

spring. See 2.4 SEAT, Seat Installation.

2008 FLT Police Service: Chassis 2-7

Page 26

REMOVAL

1

2

3

om00465

om00282

sm04700

1. Remove both saddlebags.

2. On the right side of the motorcycle, locate the air seat

reservoir air valve under the luggage rac k, and on the left

side, the rear shock air valv e just below the chrome frame

cover. See Figure 2-5 and Figure 2-6.

Use caution when bleeding air from the suspension.

Moisture combined with lubricant may leak onto the rear

wheel, tire and/or brake components and adversel y affect

traction, which could result in death or serious injury.

(00084a)

2.5AIR SEAT RESERVOIR

Figure 2-6. Rear Air Suspension Air Valve

1. Air reservoir

2. Air pressure gauge

3. Seat air valve

Figure 2-5. Seat Air Valve: Police Models

Figure 2-7. Raise Luggage Rack

3. Remove protective cap from each air valve and depress

pin to bleed air from both reservoir and shocks.To purge

rear air suspension lines of any oil, add 3-5 psi (20.7-34.5

kPa) before releasing air . Depress collar on each compression fitting and pull out air tube.

4. Remove bolt (with flat washer) to remov e saddlebag front

mounting bracket from chrome frame tube co ver . Remov e

2-8 2008 FLT Police Service: Chassis

Page 27

Phillips screw and chrome frame tube cover. Repeat step

sm04701

on opposite side of motorcycle.

5. At inboard side of rear marker lights bracket, carefully pull

left and right rear marker lights connectors.

6. Remove two hex bolts to free license plate bracket from

bottom support tube.

7. Remove T40 TORX screws (with spacers) on each side

of motorcycle to release ends of luggage rack from frame

tube weldments.

8. Raise luggage rack high enough to access air reservoir.

See Figure 2-7.

9. Remove two Phillips screws (with external tooth lockwashers) from mounting plate (pole lamp) at top of luggage

rack to release air reservoir bracket.

10. Remove two Phillips screws from license plate bracket to

free rear of air reservoir bracket. Be sure to hold reservoir

as the last screw is removed or damage to fender paint

can occur if assembly is dropped. See Figure 2-8.

11. Remove fittings and/or air pressure gauge from reservoir,

if necessary.

bracket. Alter nately tighten screws to 20-30 in-lbs (2.3-

3.4 Nm).

5. Place luggage rack into position inboard of frame tubes.

6. Install T40 TORX screws (with spacers) on each side of

motorcycle to secure ends of luggage rack to frame tube

weldments. Alternately tighten screws to 15-20 ft-lbs (20.3-

27.1 Nm).

7. Install two hex bolts to fasten license plate bracket to

bottom support tube. Alternately tighten screws to 15-20

ft-lbs (20.3-27.1 Nm).

8. At inboard side of rear marker lights bracket, connect left

and right rear marker lights connectors.

9. Install chrome frame tube cover on frame tube. Install

Phillips screw and tighten to 25-40 in-lbs (2.8-4.5 Nm).

Repeat step on opposite side of motorcycle.

10. Install bolt (with flat washer) to install saddlebag front

mounting bracket, but do not tighten. Repeat step on

opposite side of motorcycle.

11. Depress collar on compression fitting of air seat reservoir,

and insert air tube until it bottoms. Gently tug on tube to

verify that it is locked in place.

Figure 2-8. Air Seat Reservoir Assembly

INSTALLATION

TOOL NAMEPART NUMBER

HD-34633

1. Reassemble fittings and/or air pressure gauge onto air

reservoir, if remov ed. Orient parts as shown in Figure 2-8.

Apply PIPE SEALANT WITH TEFLON to threads before

assembly.

2. Position air reservoir beneath luggage rack exercising

caution to avoid scratching fender paint.

3. Slide two Phillips screws through holes in license plate

bracket engaging weld nuts at rear of air reservoir br acket.

Alternately tighten screws to 20-30 in-lbs (2.3-3.4 Nm).

4. Slide two Phillips screws (with external tooth lockwashers)

through holes in mounting plate (pole lamp) at top of luggage rack engaging weld nuts at top of air reservoir

AIR SUSPENSION PUMP AND

GAUGE

Maximum air pressure for the seat is 100 psi (689 kPa).

Normal air pressure is 30-45 psi (207-310 kPa). Do not

operate with air pressure so low that system bottoms out

on bumpy roads. (00167a)

12. Fill air reservoir to 40 psi (275.8 kPa), then add or remov e

pressure to the rider's comfort. Install protective cap on

air valve. See Figure 2-5.

NOTE

T o set minimum air pressure , have rider sit on seat and bounce

to simulate riding conditions. Visually check for any contact

between air spring and frame components. Add air as necessary.

13. Observe air pressure gauge. If leakage occurs, then

remove tube and inspect end for b urrs or damage. If either

condition is found, snip off end of tube and insert back into

fitting.

14. Depress collar on compression fitting of each shock and

insert air tube until it bottoms. Gently tug on tube to verify

that it is locked in place.

Do not exceed maximum air pressure for rear suspension.

Air components fill rapidly. Therefore, use low air line

pressure. Failure to do so may result in possible damage

to components. (00165a)

NOTE

Initial suspension fill pressure for a normally equipped police

motorcycle is 25 psi (172.4 kPa).

15. Fill shocks to 25 psi (172.4 kPa), then add or remove

pressure to the rider's comfort. Refer to Table 2-8.

2008 FLT Police Service: Chassis 2-9

Page 28

Table 2-8. Rear Air Suspension Pressures

SHOCK LOADING

ATIONS: CHASSIS)

Do not exceed the motorcycle's Gross Vehicle Weight

Rating (GVWR) or Gross Axle Weight Rating (GAWR).

Exceeding these weight ratings can affect stability and

handling, which could result in death or serious injury.

(00016e)

RECOMMENDED

PRESSURES

kPa 0-241PSI 0-35

00Solo rider up to 150 lbs. (68 kg)

0-690-10Solo rider 150-200 lbs. (68-91 kg)

35-1035-15Solo rider 200-250 lbs. (91-113 kg)

138-24120-35Maximum GVWR (see 2.1 SPECIFIC-

NOTE

An AIR SUSPENSION PUMP AND GAUGE (Part No. HD-

34633) is available at your Harley-Davidson dealer.

16. Observe air pressure gauge while filling. If leakage occurs,

remove tubes and inspect ends for burrs or damage. If

either condition is found, snip off end of tube and insert

back into fitting.

17. When air pressure remains constant, install protective cap

on air valve.

18. Install saddlebags. Tighten saddlebag front mounting

bracket bolts to 60-96 in-lbs (6.8-10.8 Nm).

2-10 2008 FLT Police Service: Chassis

Page 29

LOCKSET

1

4

5

7

6

3

2

sm03550

1

3

2

5

4

sm04804

Removal

1. At inside of saddlebag lid, remove hex nut, internal tooth

lockwasher, cam hook and cam washer. Remove jam nut

and lock guide. See Figure 2-9.

2. At outside of saddlebag lid, remove lockset. See

Figure 2-10.

Installation

1. With cam stop facing outboard side of saddlebag lid, install

lockset into hole. See Figure 2-10.

2. Install lock guide over threaded body of lockset oriented

with finger on inboard side of saddlebag lid and pointing

toward bottom. See Figure 2-9.

3. Install jam nut and tighten to 30-45 in-lbs (3.4-5.1 Nm).

4. Verify that groove in threaded stud of lockset is facing

inboard side of saddlebag lid. Use key to rotate threaded

stud, if necessary.

5. Align cam hook and cam washer as shown in Figure 2-10.

With the cam hook toward the outboard side of saddlebag

lid and cam washer on the inboard side, slide assembly

down threaded stud.

6. Install internal tooth lockwasher and hex nut onto threaded

stud.Tighten hex nut to 25-35 in-lbs (2.8-4.0 Nm).

2.6SADDLEBAGS

1. Lockset

2. Thin washer

3. Cam stop

4. Threaded stud

5. Cam washer

6. Cam hook

Figure 2-10. Lockset Mechanism

LOCKSET CATCH

Removal

1. Drill out two rivets using a 5/32 inch drill bit.

2. Remove backplate, lockset catch and flat washers.

Installation

1. Slide two new rivets through holes in backplate,

saddlebag, lockset catch and flat washers.

2. Compress rivets using a suitable rivet tool.

HINGES

TOOL NAMEPART NUMBER

RIVET TOOLHD-39787A

Removal

1. Remove tether. See 2.6 SADDLEBAGS, Tether.

2. Drill off peened end of hinge pin rivet using a 3/8 inch drill

1. Lock guide

2. Jam nut

3. Lockset

4. Cam washer

5. Cam hook

6. Lockwasher

7. Hex nut

Figure 2-9. Lockset Assembly

bit. Use a punch to tap rivet shaft out of hinge.

3. Drill out eight rivets using a 3/16 inch drill bit.

4. Remove hinge and backplates.

2008 FLT Police Service: Chassis 2-11

Page 30

2

1

sm03552

2

1

5

4

3

sm04702

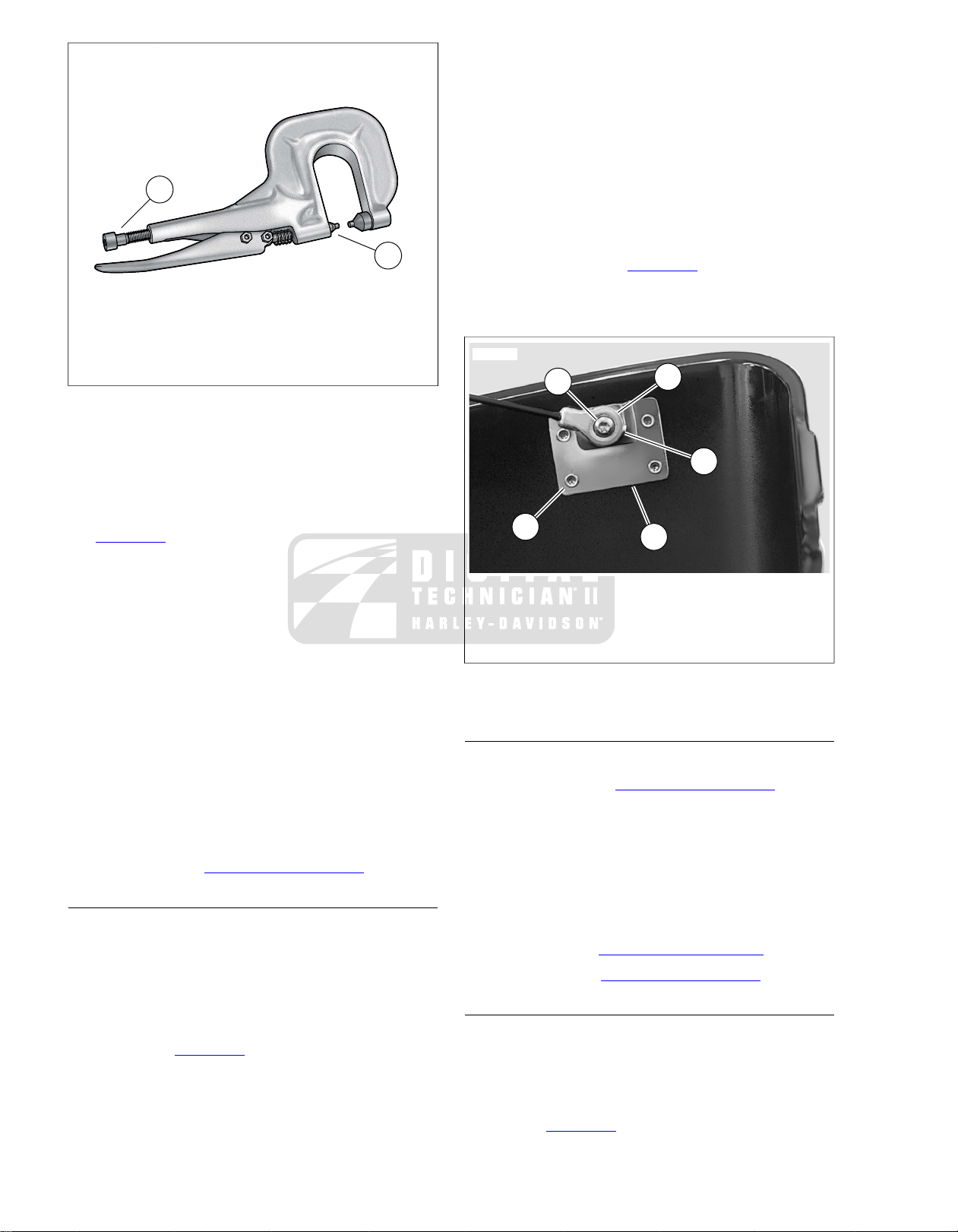

1. Adjuster thumbscrew

2. Drive head

Figure 2-11. Rivet Tool (HD-39787A)

Installation

1. Slide new rivet through holes in hinge, saddlebag and

backplate.

2. Obtain RIVET TOOL (Part No. HD-39787A). See

Figure 2-11.

3. Orient tool so that head of rivet is seated in depression of

drive head.Turn adjuster thumbscrew in or out of handle

until both ends of rivet are captured.

4. Slowly squeeze handle of tool to compress rivet. Turn

adjuster thumbscrew slightly in a clockwise direction and

then squeeze handle again to further compress rivet.

Repeat step as necessary until rivet is fully installed.

NOTE

Compress rivet in small increments only .This method provides

for best retention and alignment of parts and avoids possible

damage to tool and painted surfaces of saddlebag.

5. Repeat previous steps to install remaining rivets.

6. Install lid onto saddlebag engaging upper and lower

hinges.

7. Compress new hinge pin rivet using a suitable rivet tool.

8. Install tether. See 2.6 SADDLEBAGS, Tether.

TETHER

Removal

NOTE

When the tether is removed, use caution to keep lid from

opening beyond its normal travel or damage to painted surf aces

or hinges can occur.

1. Remove T15 TORX screw from threaded boss on tether

bracket. See Figure 2-12.

2. Remove tether eyelet and wave spring from threaded

boss.

3. Repeat previous steps to remove opposite end of tether

from second tether bracket.

Installation

1. With the concave side toward the tether bracket, install

wave spring onto threaded boss.

2. Install tether eyelet onto threaded boss.

3. Apply a small dab of LOCTITE HIGH STRENGTH

THREADLOCKER 262 (red) to threads of T15 TORX

screw.

4. Install screw into threaded boss and tighten to 20-25 in-

lbs (2.3-2.8 Nm). See Figure 2-12.

5. Repeat this procedure to fasten opposite end of tether to

second tether bracket.

1. Tether bracket

2. Rivet (4)

3. T15 TORX screw

4. Tether eyelet

5. Wave spring

Figure 2-12.Tether and Tether Bracket

TETHER BRACKETS

Removal

1. Remove tether. See 2.6 SADDLEBAGS, Tether

2. Drill out four rivets using a 3/16 inch drill bit.

3. Remove tether bracket and backplate.

Installation

1. Slide new rivets through holes in backplate,

saddlebag/saddlebag lid and tether bracket (with the

threaded boss on the outboard side).

2. Install rivets. See 2.6 SADDLEBAGS, Hinges.

3. Install tether. See 2.6 SADDLEBAGS, Tether.

KNOB AND SPRING LATCH

Removal

1. Place multiple strips of masking tape on each side of knob

to protect finished surfaces from scratches and other

damage. Using a large flat blade screwdriver, alternately

pry up each side of knob until free of post. See upper

frame of Figure 2-13.

2-12 2008 FLT Police Service: Chassis

Page 31

2. Remove knob seal and masking tape. Remove any

sm04703

sm04704

1

2

3

sm04705

residual adhesive with 3M general Purpose adhesive

remover (Part No. 051135). See lower frame of

Figure 2-13.

3. Drill out two rivets using a 13/64 inch drill bit. Remove

spring latch. See Figure 2-14.

Installation

1. Hold spring latch at bottom of saddlebag lid with the flat

side facing opposite the hinges. See Figure 2-14.

2. Slide two new rivets through holes in saddlebag lid and

spring latch.

3. Compress rivets using a suitable rivet tool.

4. Peel paper backing off adhesive side of knob seal. Place

knob seal over post, so that the adhesive side contacts

the saddlebag lid. Press knob seal firmly into place.

5. Install knob onto post and alternately work each side down

until it bottoms.

Figure 2-14. Spring Latch

SPRING LATCH BRACKET

Removal

1. From outside saddlebag, loosen two Phillips screws.

2. Inside saddlebag, remove two K eps nuts and spring latch

bracket. Remove Phillips screws. See Figure 2-15.

Installation

1. From outside saddlebag, slide two Phillips scre ws through

holes in saddlebag.

2. Inside saddlebag, install spring latch bracket and two K eps

nuts. See Figure 2-15.

3. Alternately tighten Phillips screws until snug.

1. Spring latch bracket

2. Keps nut (2)

3. Phillips screw (2)

Figure 2-15. Spring Latch Bracket

Figure 2-13. Saddlebag Knob and Seal

2008 FLT Police Service: Chassis 2-13

Page 32

REMOVAL

sm04707

NOTE

The two rear holes in the handlebar clamp shroud allow the

rider to adjust the handlebars without having to remove the

shroud. To keep out moisture and debris, be sure to install

plastic plugs back into holes after handlebar adjustment. See

Figure 2-18.

1. Remove windshield. See WINDSHIELD: FLHR/C in the

Touring Models Service Manual.

2. Remove Phillips screw at bottom of headlamp door

(chrome ring). Remove headlamp door.

3. Remove seven Phillips screws to free headlamp housing

from headlamp nacelle.

4. Remove headlamp connector at back of headlamp bulb.

Remove headlamp housing assembly from motorcycle.

5. From inside the headlamp nacelle:

a. Disconnect tachometer harness connector [20], 6-

place Deutsch. See Figure 2-16.

b. Remove flange nut from weld stud to release chrome

strip at top of nacelle.

c. Catch Keps nut and flat washer while removing Phil-

lips screw from tab at front of handlebar clamp shroud.

2.7TACHOMETER BRACKET: FLHP/E

Figure 2-16. Disconnect Tachometer Connector

6. Carefully pry off the fork lock plate at the rear of the

handlebar clamp shroud. Remove two Phillips screws

beneath the lock plate.

7. Remove the handlebar clamp shroud from the motorcycle,

while gently pulling the tachometer harness conduit and

connector out of the headlamp nacelle.

8. Remove two acorn nuts (with flat washers) to release

tachometer bracket from studs at top of handlebar clamp

shroud.

NOTE

Do not operate ABS equipped motorcycles with the tachometer

removed. While the ABS remains operational, the rider will

receive no warning if a malfunction occurs.The means to report

DTC's also will be eliminated.

2-14 2008 FLT Police Service: Chassis

Page 33

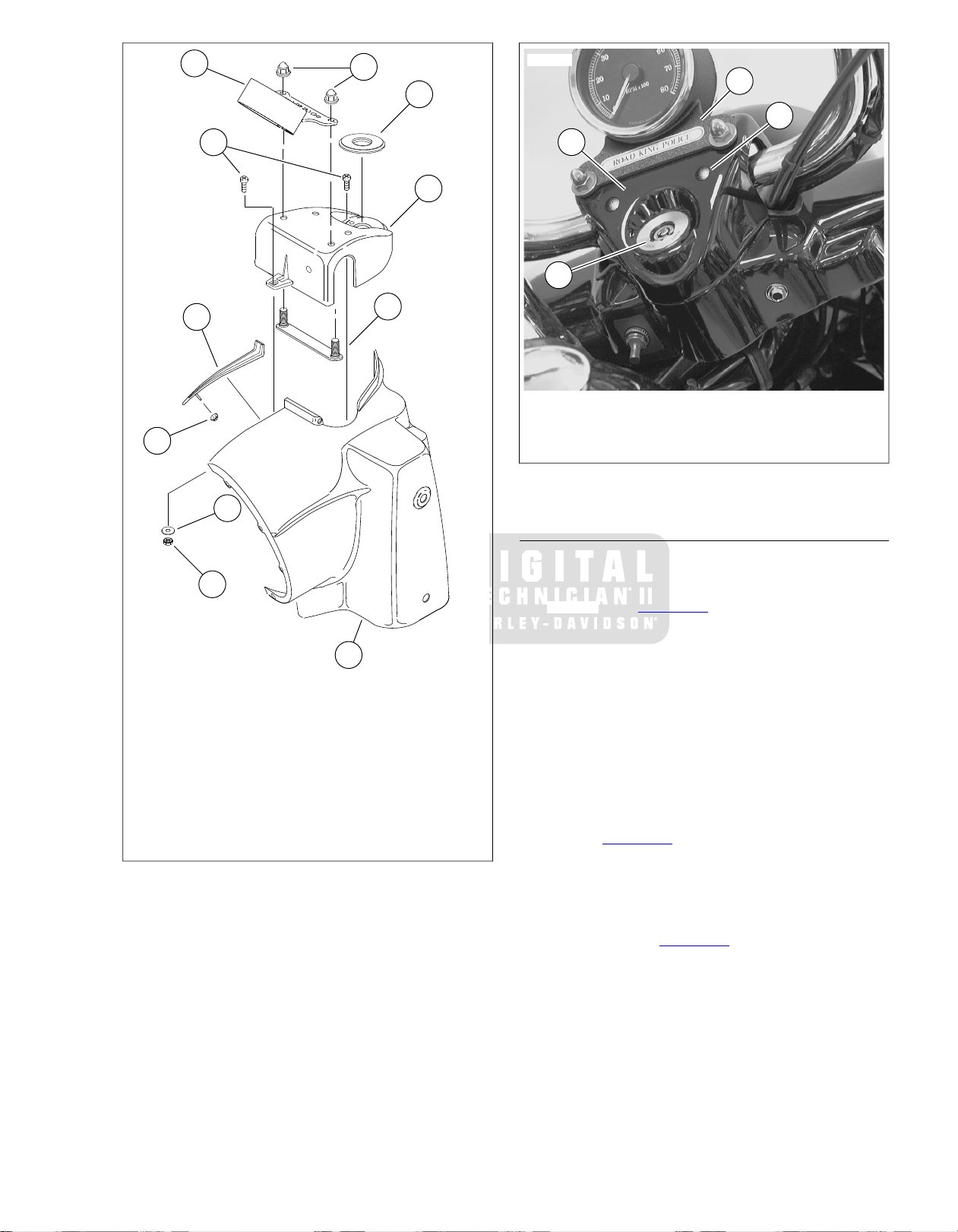

8

9

10

11

1

3

2

4

5

6

7

sm04708

1

4

2

3

sm04709

1. Tachometer bracket

2. Handlebar clamp shroud

3. Fork lock plate

4. Handlebar adjustment access hole plug

Figure 2-18. Install Handlebar Clamp Shroud

INSTALLATION

1. Place tachometer bracket over studs at top of handlebar

clamp shroud. Install two acorn nuts (with flat washers)

onto studs and alternately tighten to 72-108 in-lbs (8.1-

12.2 Nm). See Figure 2-18.

1. Headlamp nacelle

2. Keps nut

3. Flat washer

4. Flange nut

5. Chrome strip

6. Phillips screw (2)

7. Tachometer bracket

8. Acorn nut (2)

9. Fork lock plate

10. Handlebar clamp shroud

11. Stud plate

Figure 2-17. Headlamp Nacelle Assembly

A peel and stick foam tape on the stud plate holds it in place

on the inboard side of the handlebar clamp shroud.

2. Feed tachometer harness connector and conduit through

opening at top of headlamp nacelle. Install handlebar

clamp shroud over mating flange while routing tachometer

harness conduit through opening for left side handlebar.

3. From inside the headlamp nacelle:

a. Start flat washer and Keps nut onto Phillips screw

installed in tab at front of handlebar clamp shroud.

Tighten Phillips screw to 10-20 in-lbs (1.1-2.3 Nm).

See Figure 2-17.

b. Install flange nut onto weld stud of chrome strip

installed into hole at the top of headlamp nacelle.

Tighten flange nut to 15-20 in-lbs (1.7-2.3 Nm).

c. Connect tachometer harness connector [20], 6-place

Deutsch. See Figure 2-16.

NOTE

4. Install two Phillips screws to fasten handlebar clamp

shroud to the fork lock mechanism. Install fork lock plate.

5. Install headlamp connector at back of headlamp bulb.

6. Align holes in headlamp housing with those in headlamp

nacelle (headlamp door bracket at bottom). Install seven

Phillips screws and alternately tighten to 9-18 in-lbs (1.0-

2.0 Nm).

2008 FLT Police Service: Chassis 2-15

Page 34

7. Fit the square-shaped portion of the headlamp door spring

into slot at top of headlamp housing and then snap the

headlamp door (chrome ring) into place. Install Phillips

screw at bottom of headlamp door and tighten to 9-18 in-

lbs (1.0-2.0 Nm).

8. Install windshield. See WINDSHIELD: FLHR/C in the

Touring Models Service Manual.

2-16 2008 FLT Police Service: Chassis

Page 35

SUBJECT............................................................................................................................PAGE NO.

3.1 SPECIFICATIONS: ENGINE.....................................................................................................3-1

3.2 SERVICE WEAR LIMITS...........................................................................................................3-2

3.3 OIL COOLER.............................................................................................................................3-3

ENGINE

Page 36

NOTES

Page 37

3.1SPECIFICATIONS: ENGINE

GENERAL

Table 3-1. Engine: 2008 Police Models

Type

Torque

Pump

Pressure

Filtration

SPECIFICATIONITEM

2Number of cylinders

4-cycle, 45 degree

V-Type, air cooled

9.6-1Compression ratio

98 mm3.875 in.Bore

111 mm4.375 in.Stroke

1690 cc103 cu. in.Displacement

102 ft-lbs @

2500 RPM

Table 3-2. Oiling System

SPECIFICATIONITEM

Twin gerotor, dual scavenge, crank

mounted and driven, internal oil pump,

dry sump

30-38 psi (207-262 kN/m2) at 2000 RPM

and normal operating temperature of

230° F (110° C)

10 micron media, filtered between pump

and engine

Thermostat controlled oil coolerCooling

138 Nm @

2500 RPM

MANUFACTURING TOLERANCES

Table 3-3.Valves

MMIN.ITEM

0.038-0.0840.0015-0.0033Fit in guide (exhaust)

0.020-0.0660.0008-0.0026Fit in guide (intake)

50.55-51.411.990-2.024Stem protrusion from

cylinder head boss

Table 3-4.Valve Spring Assembly

DIMENSIONPRESSUREITEM

1.820 in. (46.2 mm)165 lbs (75 kg)Closed

1.290 in. (32.7 mm)416 lbs (189 kg)Open

2.210 in. (56.1 mm)n/aFree length

Table 3-5. Connecting Rods

MMINCHESITEM

0.008-0.0180.0003-0.0007Piston pin fit (loose)

Table 3-6. Crankshaft/Sprocket Shaft Bearing

MMINCHESITEM

0.0025-0.02540.0001-0.0010Bearing inner race on

crankshaft (tight)

2008 FLT Police Service: Engine 3-1

Page 38

3.2SERVICE WEAR LIMITS

GENERAL

Wear limits can be used as a guide when deciding whether to

reuse engine parts. Replace used parts whenever the f ollowing

wear limits are exceeded.

Table 3-7. Cam Support Plate

REPLACE IF WEAR EXCEEDSITEM

MMINCHES

2.03-2.290.080-0.090Cam chain tensioner

shoe

0.250.010Warpage

0.0203-0.02540.0008-0.001Crankshaft bushing fit

Table 3-8. Cylinder Bore

REPLACE IF WEAR EXCEEDSITEM

Table 3-9. Connecting Rods

REPLACE IF WEAR EXCEEDSITEM

Table 3-10. Crankshaft/Sprocket Shaft Bearing

REPLACE IF WEAR EXCEEDSITEM

Crankshaft runout

(tight)

crankshaft (tight)

Greater than

0.003

MMINCHES

98.483.877Standard

98.603.8820.005 in. oversize

98.733.8870.010 in. oversize

MMINCHES

0.0250.001Piston pin fit (loose)

MMINCHES

Greater than

0.076

0.097-0.1370.0038-0.0054Bearing fit in crankcase

Less than 0.0254Less than 0.0001Bearing inner race on

Table 3-11.Valve Stem to Guide Clearance

REPLACE IF WEAR EXCEEDSITEM

MMINCHES

0.0890.0035Intake

0.1020.0040Exhaust

3-2 2008 FLT Police Service: Engine

Page 39

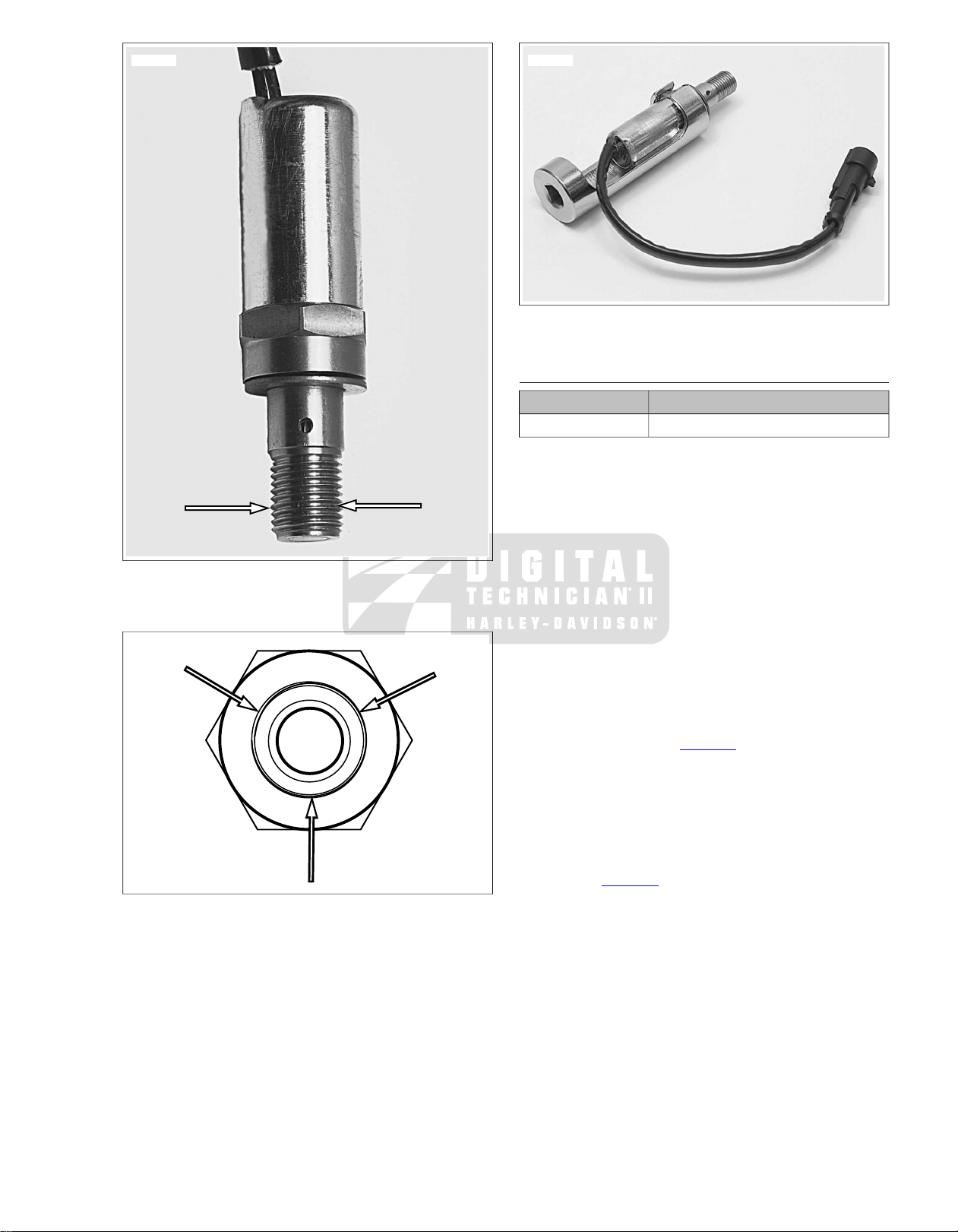

OPERATION

1

2

3

sm04710

8

10

9

5

6

7

1

2

3

4

sm04712

Pressurized oil flows through a hole in the oil filter mount into

a passage in the oil cooler adapter.The oil cooler adapter is

mounted between the oil filter mount and the oil filter.

A thermostat inside the oil cooler adapter controls the flow of

oil to the oil cooler.The ther mostat consists of a temperature

sensitive element compressed between a spring and threaded

plug. See Figure 3-1.

While the engine oil temperature is below 200° F (93° C), the

thermostat is open allowing most of the engine oil to pass from

the supply port directly to the return por t en route to the oil

filter.

When the engine oil temperature reaches 200° F (93° C), the

thermostat closes and the entire flow is directed to the oil cooler

through the supply hose.

The fins on the tubes of the oil cooler dissipate heat before the

flow returns to the oil cooler adapter through the return hose.

The engine oil then passes through the oil filter before returning

to the crankcase.

NOTE

For a complete description of the engine oil flow, see GENERAL INFORMATION in the Touring Models Service Manual.

3.3OIL COOLER

1. Return fitting

2. Supply fitting

3. Thermostat

Figure 3-1. Oil Cooler Adapter

1. Flange nut (3)

2. Flat washer (3)

3. Mounting bracket

4. Oil cooler

5. Supply hose

6. Return hose

7. Hose clamp (4)

8. Oil cooler adapter

9. Oil filter adapter

10. Adhesive gasket

Figure 3-2. Oil Cooler Assembly

REMOVAL

1. Place a suitable drain pan beneath the oil cooler.

2. See Figure 3-2. Remove three flange nuts with flat

washers. Raise oil cooler to free threaded studs from holes

in mounting bracket.

3. Using a side cutters, cut and remove clamps on oil cooler

adapter side of supply and return hoses. Pull hoses from

fittings.

4. Remove oil cooler from motorcycle.

5. Using a side cutters, cut and remove clamps on oil cooler

side of supply and return hoses. Pull hoses from fittings.

2008 FLT Police Service: Engine 3-3

Page 40

6. Remove mounting bracket as follows:

a. Remove voltage regulator and front electrical caddy.

See VOLTAGE REGULATOR in the Touring Models

Service Manual.

b. Lift mounting bracket off studs on low er frame cross-

member.

CLEANING AND INSPECTION

1. Using a clean shop cloth or soft bristle brush, gently clean

oil cooler fins of dirt and debris.

2. If engine failure and/or oil contamination requires inspection and cleaning of oil passageways, then remove oil

cooler adapter and proceed as follows:

a. See Figure 3-3. Remove two socket screws (3) to

release inspection cover (4) and gasket (2).

b. Thoroughly flush oil passageways with solvent and

blow out with compressed air.

c. Install inspection cover with new gasket.

d. Apply a small dab of Loctite Medium Strength

Threadlocker 243 (blue) to threads of soc k et scre ws .

Install screws and alternately tighten to 90-120 in-

lbs (10.2-13.6 Nm).

INSTALLATION

TOOL NAMEPART NUMBER

HOSE CLAMP PLIERSHD-97087-65B

NOTE

If mounting bracket is already installed, proceed to next step.

1. Install mounting bracket as follows:

a. With the "TOP" stamp facing upw ard, install mounting

bracket onto studs on lower frame crossmember.

b. Install front electrical caddy and voltage regulator.

See VOLTAGE REGULATOR in the Touring Models

Service Manual.

2. Slide new clamp onto oil cooler side of return hose, which

can be identified by the paint stamp reading COOLER

BOTT OM.With the script facing upward, install hose onto

bottom fitting of oil cooler. Crimp clamp using HOSE

CLAMP PLIERS (Part No. HD-97087-65B).

3. Slide new clamp onto oil cooler side of supply hose, which

can be identified by the paint stamp reading COOLER

TOP.With the script facing upward, install hose onto top

fitting of oil cooler. Crimp clamp.

NOTE

If the paint stamps are not present, the long hose is the return

and the short hose is the supply. Install both hoses, so that the

90° bend goes to the oil cooler adapter.

4. Slide threaded studs at bottom of oil cooler through holes

in mounting bracket. Install flat washers and flange nuts

on studs. Alternately tighten flange nuts to 70-100 in-

lbs (7.9-11.3 Nm).

5. Slide new clamp onto free end of return hose (stamped

COOLER BOTTOM). Install hose on upper fitting of oil

cooler adapter. Crimp clamp using HOSE CLAMP

PLIERS (Part No. HD-97087-65B).

6. Slide new clamp onto free end of supply hose (stamped

COOLER TOP). Install hose on lower fitting of oil cooler

adapter. Crimp clamp.

7. Check engine oil level. See ENGINE OIL AND FILTER in

the Touring Models Service Manual.

OIL COOLER ADAPTER AND THERMOST A T REPLACEMENT

TOOL NAMEPART NUMBER

HOSE CLAMP PLIERSHD-97087-65B

Removal

NOTE

A faulty thermostat requires replacement of the oil cooler

adapter.

1. Place a suitable drain pan beneath the oil cooler and oil

filter.

2. Using a side cutters, cut and remove clamps on oil cooler

adapter side of supply and return hoses. Pull hoses from

fittings.

3. Remove the engine oil filter. See ENGINE OIL AND

FILTER in the Touring Models Service Manual.

4. Using internal hex, remove the oil filter adapter. Remove

the oil cooler adapter and gasket. See Figure 3-2.

Installation

NOTE

Skip first step if hose fittings are already installed.

1. Install hose fittings as follows:

a. Install hose fittings until finger tight.

b. Using wrench on flats, rotate hose fittings an addi-

tional 2-3 turns.

2. Position oil cooler adapter flange against oil filter mount.

Index tabs on flange engage a recess on each side of the

oil filter mount oil outlet hole. See Figure 3-3.

3. Apply Loctite High Temperature/Medium Strength

Threadlocker 246 to threads of oil filter adapter.With the

internal hex on the outboard side, thread oil filter adapter

into oil filter mount. Holding the oil cooler adapter to prevent rotation, tighten oil filter adapter to 18-22 ft-lbs (24.4-

29.8 Nm).

4. Slide new clamp onto free end of return hose (stamped

COOLER BOTTOM). Install hose on upper fitting of oil

cooler adapter. Crimp clamp using HOSE CLAMP

PLIERS (Part No. HD-97087-65B).

5. Slide new clamp onto free end of supply hose (stamped

COOLER TOP). Install hose on lower fitting of oil cooler

adapter. Crimp clamp.

6. Install new oil filter and check engine oil level. See

ENGINE OIL AND FILTER in the Touring Models Service

Manual.

7. Start engine and inspect oil cooler/adapter fittings and

hoses for leaks.

3-4 2008 FLT Police Service: Engine

Page 41

1

2

3

4

sm04713

1. Index tabs

2. Adhesive gasket

3. Socket screw (2)

4. Inspection cover

Figure 3-3. Oil Cooler Adapter

2008 FLT Police Service: Engine 3-5

Page 42

NOTES

3-6 2008 FLT Police Service: Engine

Page 43

SUBJECT............................................................................................................................PAGE NO.

4.1 FUEL SYSTEM..........................................................................................................................4-1

FUEL SYSTEM

Page 44

NOTES

Page 45

NO UNIQUE CONTENT

Any information not presented in this supplement can be found

in the Touring Models Service Manual.

4.1FUEL SYSTEM

2008 FLT Police Service: Fuel System 4-1

Page 46

NOTES

4-2 2008 FLT Police Service: Fuel System

Page 47

SUBJECT............................................................................................................................PAGE NO.

5.1 ELECTRIC STARTER................................................................................................................5-1

ELECTRIC STARTER

Page 48

NOTES

Page 49

NO UNIQUE CONTENT

Any information not presented in this supplement can be found

in the Touring Models Service Manual.

5.1ELECTRIC STARTER

2008 FLT Police Service: Electric Starter 5-1

Page 50

NOTES

5-2 2008 FLT Police Service: Electric Starter

Page 51

SUBJECT............................................................................................................................PAGE NO.

6.1 DRIVE........................................................................................................................................6-1

DRIVE

Page 52

NOTES

Page 53

NO UNIQUE CONTENT

Any information not presented in this supplement can be found

in the Touring Models Service Manual.

6.1DRIVE

2008 FLT Police Service: Drive 6-1

Page 54

NOTES

6-2 2008 FLT Police Service: Drive

Page 55

SUBJECT............................................................................................................................PAGE NO.

7.1 TRANSMISSION.......................................................................................................................7-1

TRANSMISSION

Page 56

NOTES

Page 57

NO UNIQUE CONTENT

Any information not presented in this supplement can be found

in the Touring Models Service Manual.

7.1TRANSMISSION

2008 FLT Police Service: Transmission 7-1

Page 58

NOTES

7-2 2008 FLT Police Service: Transmission

Page 59

SUBJECT............................................................................................................................PAGE NO.

8.1 BULB CHART............................................................................................................................8-1

8.2 SYSTEM FUSES AND RELAYS...............................................................................................8-3

8.3 REAR MARKER LIGHTS..........................................................................................................8-5

8.4 HANDLEBAR SWITCHES.........................................................................................................8-6

8.5 AUTOMATIC COMPRESSION RELEASE...............................................................................8-10

ELECTRICAL

Page 60

NOTES

Page 61

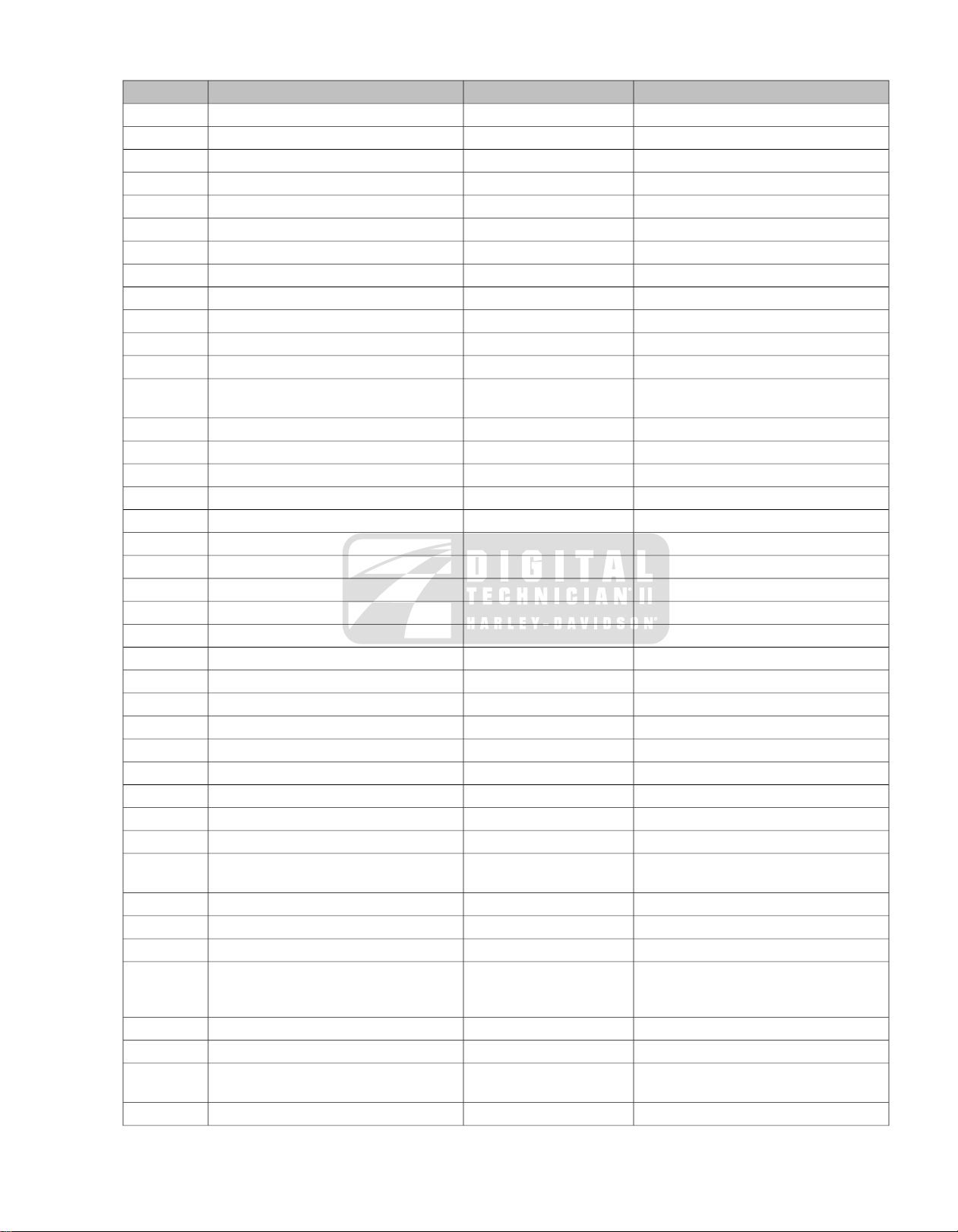

GENERAL

8.1BULB CHART

The table below gives the bulb requirements for FLHTP and

FLHP/E police model motorcycles.

Table 8-1. Bulb Chart FLHTP, FLHP/E

LAMP DESCRIPTION

(ALL LAMPS 12V)

Head Lamp

Tail/Stop Lamp

Turn Signal Lamp

Rear Fender Tip Lamp

Pursuit Lamp

Instrument Panel Lamps-FLHTP Indicator Module (with LEDs)

Oil Pressure Indicator**

Neutral Indicator**

Turn Signal Indicator**

Gauge Lamps-FLHTP

Tachometer**

Fuel Gauge

Instrument/Gauge Lamps-FLHP/E Indicator Module (with LEDs)

Oil Pressure Indicator**

Neutral Indicator**

Turn Signal Indicator**

NUMBER OF BULBS

(REQUIRED)

(AMPERAGE)

The rear strobe is a source of high voltage and must be

off at least 10 minutes before servicing. Inadequate safety

precautions may result in death or serious injury . (00097a)

WATTAGECURRENT DRAW

605.00HIgh Beam

242.10Stop Lamp

HARLEY-DAVIDSON

PART NUMBER

68329-03554.581Low Beam

68167-8860.591Tail Lamp

68168-8927/72.25 / 0.592Front / Running

68572-64B272.252Rear

53439-793.70.332Rear Fender Tip Bulb

68727-64A302.51Left (Red)

68728-64Right (Blue)

67598-8820N/ARear Strobe, if provided

68859-07N/A0.05N/AHigh Beam Indicator**

N/AN/AN/AN/ASpeedometer**

67445-003.40.241Voltmeter

N/AN/AN/AN/AEngine**

68642-961.10.081Pursuit (fairing)

68113-99BN/A0.05N/AHigh Beam Indicator**

2008 FLT Police Service: Electrical 8-1

Page 62

Table 8-1. Bulb Chart FLHTP, FLHP/E

LAMP DESCRIPTION

(ALL LAMPS 12V)

Speedometer**

Odometer**

Engine**

Pursuit**

** LED illuminated. LEDs are not repairable. Assembly must be replaced if LED fails.

NUMBER OF BULBS

(REQUIRED)

(AMPERAGE)

WATTAGECURRENT DRAW

HARLEY-DAVIDSON

PART NUMBER

N/AN/AN/AN/AFuel Gauge**

8-2 2008 FLT Police Service: Electrical

Page 63

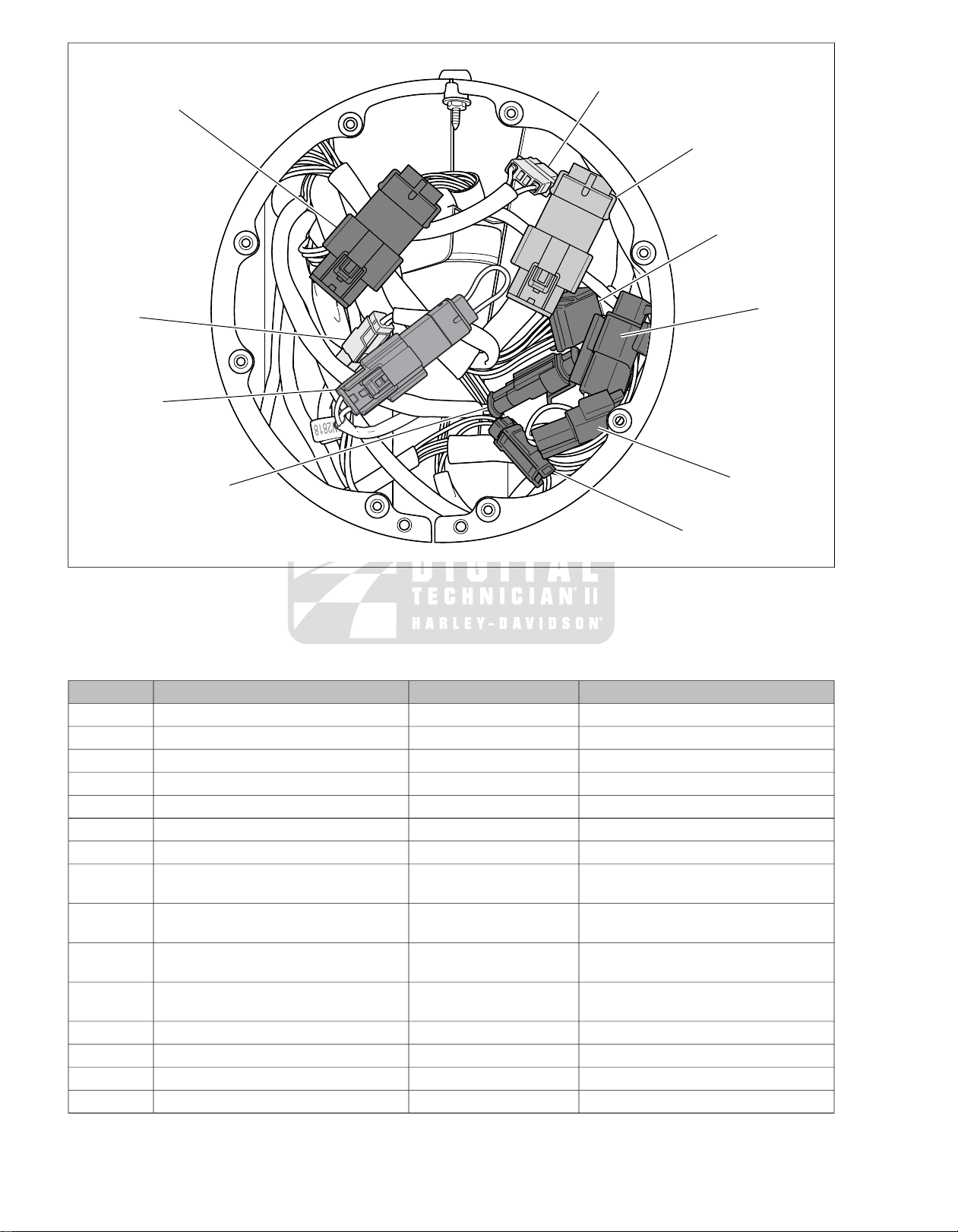

SYSTEM FUSES

ed01646

21

20

18

109

8

5

6

7

4

3

21

17

16

15

11 12 13 14

19

ed01653

8.2SYSTEM FUSES AND RELAYS

Removal

1. Verify that the Ignition/Light Key Switch is turned to the

OFF position.

2. Remove left side saddlebag.

3. See Figure 8-1. Remove wing nut style bolt to release

bottom of siren amplifier mounting bracket from clamp on