Page 1

2008 FLHTCUSE3 Model Service Manual Supplement

99500-08

©2007 H-D.

Page 2

Harley-Davidson motorcycles conform to all applicable U.S.A. Federal Motor Vehicle Safety Standards

and U.S.A. Environmental Protection Agency regulations effective on the date of manufacture.

To maintain the safety, dependability, and emission and noise control performance, it is essential that

the procedures, specifications and service instructions in this manual are followed.

Any substitution, alteration or adjustment of emission system and noise control components outside of

factory specifications may be prohibited by law.

IMPORTANT NOTICE

Harley-Davidson Motor Company

Page 3

2008 FLHTCUSE3 Model

Service Manual Supplement

©2007 H-D.

ALL RIGHTS RESERVED

99500-08

Printed in the U.S.A.

VISIT THE HARLEY-DAVIDSON WEB SITE

http://www.harley-davidson.com

Page 4

Blank Text Here

Page 5

Blank Text Here

READER COMMENTS

Please comment on the completeness, accuracy, organization, usability, and readability of this manual.

Please list the page, item, and part number(s) of any errors you find in this manual.

Please tell us how we can improve this manual.

Occupation:

Name: Dealership:

Street: Department:

City: State: Zip:

Please clip out and mail to:

Service Communications Department

Harley-Davidson Motor Company

P.O. Box 653

Milwaukee, WI USA 53201

The Harley-Davidson Service Communications Department maintains a continuous effort to improve the quality

and usefulness of its publications. To do this effectively, we need user feedback - your critical evaluation of

this manual.

2008 FLHTCUSE3 Model Service Manual Supplement (99500-08)

Page 6

NOTES

Page 7

ABOUT THIS MANUAL

GENERAL

This Service Manual Supplement has been designed to be

used with the current Service Manual and has been prepared

with two purposes in mind. First, it will acquaint the user with

the construction of the Harley-Davidson product and assist in

the performance of basic maintenance and repair. Secondly,

it will introduce to the professional Harley-Davidson Technician

the latest field-tested and factory-approved major repair

methods.We sincerely believe that this Service Manual Supplement will make your association with Harley-Davidson

products more pleasant and profitable.

NOTE

This Service Manual Supplement provides information unique

to this model motorcycle. Any information not presented in this

supplement can be found in the appropriate Service Manual

or Electrical Diagnostic Manual.

HOW TO USE YOUR SERVICE MANUAL

SUPPLEMENT

Use the TABLE OF CONTENTS (which follows this FOREWORD) and the INDEX (at the back of this manual) to quickly

locate subjects. Sections and topics in this manual are

sequentially numbered for easy navigation.

CHAPTERNO.

Maintenance1

Chassis2

Engine3

Fuel System4

Electric Starter5

Drive6

Transmission7

Electrical8

Appendix A WiringA

Appendix B GlossaryB

For example, a cross-reference shown as 2.1 SPECIFICA-

TIONS refers to chapter 2 CHASSIS, heading 2.1 SPECIFICATIONS.

If the subject you seek is not in this supplement, refer to the

corresponding section in the appropriate Service Manual.

Check the title page located in the front of each section to find

the subject.

For quick and easy reference, all pages contain a section

number followed by a page number. For example, page 3-5

refers to page 5 in section 3.

In figure legends, the number following the name of a part

indicates the quantity necessary for one complete assembly.

PREPARATION FOR SERVICE

Stop the engine when refueling or servicing the fuel

system. Do not smoke or allow open flame or sparks near

gasoline. Gasoline is extremely flammable and highly

explosive, which could result in death or serious injury.

(00002a)

Good preparation is very important for efficient service work.

A clean work area at the start of each job will allow you to

perform the repair as easily and quickly as possible, and will

reduce the incidence of misplaced tools and parts. A motorcycle

that is excessively dirty should be cleaned before work starts.

Cleaning will occasionally uncover sources of trouble. Tools,

instruments and any parts needed for the job should be

gathered before work is started. Interrupting a job to locate

tools or parts is a distraction and causes needless delay.

NOTES

• To avoid unnecessary disassembly, carefully read all relative service information before repair work is started.

• In figure legends, the number which follows the name of

a part indicates the quantity necessary for one complete

assembly.

• When servicing a vehicle equipped with the HarleyDavidson Smart Security System (H-DSSS), you must

first disarm the security system. Either keep the fob in

close proximity to the vehicle, or use Digital Technician to

disable the security system while the vehicle is being serviced and re-enable the system after service is completed.

SERVICE BULLETINS

In addition to the information presented in this Service Manual

Supplement and the appropriate Service Manual, HarleyDavidson Motor Company will periodically issue Service Bulletins to Harley-Davidson dealers. Service Bulletins cover

interim engineering changes and supplementary information.

Consult the Service Bulletins to keep your product knowledge

current and complete.

USE GENUINE REPLACEMENT PARTS

Do not use aftermarket parts and custom made front forks

which can adversely affect performance and handling.

Removing or altering factory installed parts can adversely

affect performance and could result in death or serious

injury. (00001a)

To ensure satisfactory and lasting repairs, carefully follow the

Service Manual instructions and use only genuine HarleyDavidson replacement parts. Behind the emblem bearing the

words GENUINE HARLEY-DAVIDSON stand more than 100

years of design, research, manufacturing, testing and inspecting

experience.This is your assurance that the parts you are using

will fit right, operate properly and last longer.

FOREWORD

WARNINGS AND CAUTIONS

Statements in this service manual preceded by the following

words are of special significance.

I

Page 8

WARNING indicates a potentially hazardous situation

which, if not avoided, could result in death or serious

injury. (00119a)

CAUTION indicates a potentially hazardous situation

which, if not avoided, may result in minor or moderate

injury. (00139a)

CAUTION used without the safety alert symbol indicates

a potentially hazardous situation which, if not avoided,

may result in property damage. (00140a)

NOTE

Refers to important information, and is placed in italic type. It

is recommended that you take special notice of these items.

Proper service and repair is important for the safe, reliable

operation of all mechanical products.The service procedures

recommended and described in this service manual are

effective methods for performing service operations.

When reference is made in this manual to a specific brand

name product, tool or instrument, an equivalent product, tool

or instrument may be substituted.

Kent-Moore Products

All tools mentioned in this manual with an "HD", "J" or "B"

preface must be ordered through SPX K ent-Moore. For ordering

information or product returns, warranty or otherwise, visit

www.spx.com.

Loctite Sealing and Threadlocking Pr oducts

Some procedures in this manual call for the use of Loctite

products. If you have any questions regarding Loctite product

usage or retailer/wholesaler locations, please contact Loctite

Corp. at www.loctite.com.

PRODUCT REGISTERED MARKS

Allen, Amp Multilock, Bluetooth, Brembo, Delphi, Deutsch,

Dunlop, Dynojet, Fluke, G.E. Versilube, Gunk, Hydroseal,

Hylomar, Kevlar, Lexan, Loctite, Lubriplate, Keps, K&N, Magnaflux, Marson Thread-Setter Tool Kit, MAXI fuse, Molex, MPZ,

Mulitilock, Novus, Packard, Pirelli, Permatex, Philips, PJ1,

Pozidriv , Robinair , S100, Sems, Snap-on, Teflon, Threadlocker ,

Torca, Torco, TORX, Tufoil, Tyco, Ultratorch, Velcro, X-Acto,

and XM Satellite Radio are among the trademarks of their

respective owners.

Always wear proper ey e protection when using hammer s,

arbor or hydraulic presses, gear pullers, spring compressors, slide hammers and similar tools. Flying parts

could result in death or serious injury. (00496b)

Some of these service operations require the use of tools

specially designed for the purpose.These special tools should

be used when and as recommended. It is important to note

that some warnings against the use of specific service methods,

which could damage the motorcycle or render it unsafe, are

stated in this service manual. Howe v er, please remember that

these warnings are not all-inclusive. Inadequate safety precautions could result in death or serious injury.

Since Harley-Davidson could not possibly know, evaluate or

advise the service trade of all possible ways in which service

might be performed, or of the possible hazardous consequences of each method, we have not undertaken any such

broad evaluation. Accordingly, anyone who uses a service

procedure or tool which is not recommended by HarleyDavidson must first thoroughly satisfy himself that neither his

nor the operator's safety will be jeopardized as a result. F ailure

to do so could result in death or serious injury.

PRODUCT REFERENCES

H-D MICHIGAN, INC.TRADEMARK

INFORMATION

Harley, Harley-Davidson, H-D, Bar & Shield, Digital Tech,

Digital Technician, Destroyer, Deuce, Dyna, Electra Glide,

Evolution, F at Boy, Glaze, Gloss, H-D, H-Dnet.com, HD , Harley,

Heritage Softail, Heritage Springer, Low Rider, Night Rod, Night

Train, Profile, Revolution, Road Glide, Road King, Rocker,

Softail, Sportster, Sun Ray, Sunwash, Tech Link, Twin Cam

88, Twin Cam 88B, Twin Cam 96, Twin Cam 96B, Twin Cam

103, Twin Cam 103B, Twin Cam 110, Twin Cam 110B, TourPak, Screamin' Eagle, Softail, Super Guide, Super Premium,

SYN3, Ultra Glide, V-Rod, VRSC, Wide Glide, and HarleyDavidson Genuine Motor Parts and Genuine Motor Accessories

are among the trademarks of H-D Michigan, Inc.

CONTENTS

All photographs, illustrations and procedures may not necessarily depict the most current model or component, but are

based on the latest production information available at the time

of publication.

Since product improvement is our continual goal, HarleyDavidson reserves the right to change specifications, equipment

or designs at any time without notice and without incurring

obligation.

Read and follow warnings and directions on all products.

Failure to follow warnings and directions can result in

death or serious injury. (00470b)

II FOREWORD

Page 9

MAINTENANCE

1.1 SCHEDULED MAINTENANCE

General...............................................................................1-1

1.2 HYDRAULIC CLUTCH FLUID

General...............................................................................1-2

Clutch Fluid Level...............................................................1-2

1.3 BLEEDING CLUTCH FLUID LINE

Draining and Filling.............................................................1-3

Bleed Clutch Master Cylinder.............................................1-4

Bleed Fluid Line and Actuator............................................1-4

Return Motorcycle to Service.............................................1-4

1.4 ENGINE LUBRICATION SYSTEM

General...............................................................................1-5

1.5 CRITICAL FASTENERS

Inspection...........................................................................1-6

CHASSIS

2.1 SPECIFICATIONS: CHASSIS

General...............................................................................2-1

2.2 VEHICLE IDENTIFICATION NUMBER

(V.I.N.)

Vehicle Identification Number (V.I.N.): FLHTCUSE3..........2-2

General........................................................................2-2

Location.......................................................................2-2

Abbreviated V.I.N.........................................................2-2

2.3 FOOTBOARDS AND CONTROLS

Rider Footboards................................................................2-3

Removal......................................................................2-3

Installation...................................................................2-4

Shift Levers.........................................................................2-5

Replace Pegs..............................................................2-5

Replace Heel-Toe Shift Levers....................................2-5

Rear Brake Pedal...............................................................2-6

Adjustable Passenger Footboards......................................2-6

Remove.......................................................................2-6

Disassemble................................................................2-6

Assemble.....................................................................2-7

Install...........................................................................2-8

Adjust..........................................................................2-8

2.4 HIGHWAY PEGS

Disassembly.......................................................................2-9

Removing Clamp................................................................2-9

Installing Clamp..................................................................2-9

Assembly..........................................................................2-10

2.5 FRONT AXLE COVERS

Replacement....................................................................2-11

Assembly..........................................................................2-14

Pull Wire Leads.........................................................2-14

Install Switch Housings.............................................2-15

Install Wire Lead Ter minals.......................................2-16

Installing Handlebars........................................................2-17

Clamp Handlebars to Risers.....................................2-17

Assemble Brake Controls..........................................2-17

Assemble Clutch Controls.........................................2-18

Returning to Service.........................................................2-19

2.8 HANDGRIPS

General.............................................................................2-20

Preparing Motorcycle.......................................................2-20

Separating Connectors.....................................................2-20

Replacing Handgrips........................................................2-20

Remove Left Handgrip..............................................2-20

Install Left Handgrip..................................................2-21

Remove Right Handgrip............................................2-22

Install Right Handgrip................................................2-22

Mating Connectors...........................................................2-23

Returning to Service.........................................................2-23

2.9 CLUTCH MASTER CYLINDER AND

RESERVOIR

General.............................................................................2-24

Removal...........................................................................2-24

Disassembly.....................................................................2-25

Assembly..........................................................................2-26

Installation........................................................................2-26

2.10 CLUTCH HAND LEVER

Removal...........................................................................2-28

Installation........................................................................2-28

2.11 CLUTCH FLUID LINE

Removal...........................................................................2-29

Installation........................................................................2-29

2.12 SEAT

General.............................................................................2-31

Removal...........................................................................2-31

Cleaning and Inspection...................................................2-32

Installation........................................................................2-32

2.13 RIDER BACKREST

General.............................................................................2-33

Removal...........................................................................2-33

Installation........................................................................2-33

Adjusting Tilt Angle...........................................................2-33

Adjusting Front to Rear.....................................................2-33

2.14 TOUR-PAK

Removal...........................................................................2-35

Installation........................................................................2-36

2.15 SADDLEBAGS

Removal...........................................................................2-38

Installation........................................................................2-38

TABLE OF CONTENTS

2.6 LOWER TRIPLE CLAMP COVER

Replacement....................................................................2-12

2.7 HANDLEBARS

Removal...........................................................................2-13

Disassembly.....................................................................2-14

2.16 SADDLEBAGS LATCH

Removal...........................................................................2-39

Installation........................................................................2-39

2.17 SADDLEBAG SUPPORTS

Removal...........................................................................2-40

III

Page 10

TABLE OF CONTENTS

Installation........................................................................2-40

2.18 MUFFLER END CAP

Replacement....................................................................2-42

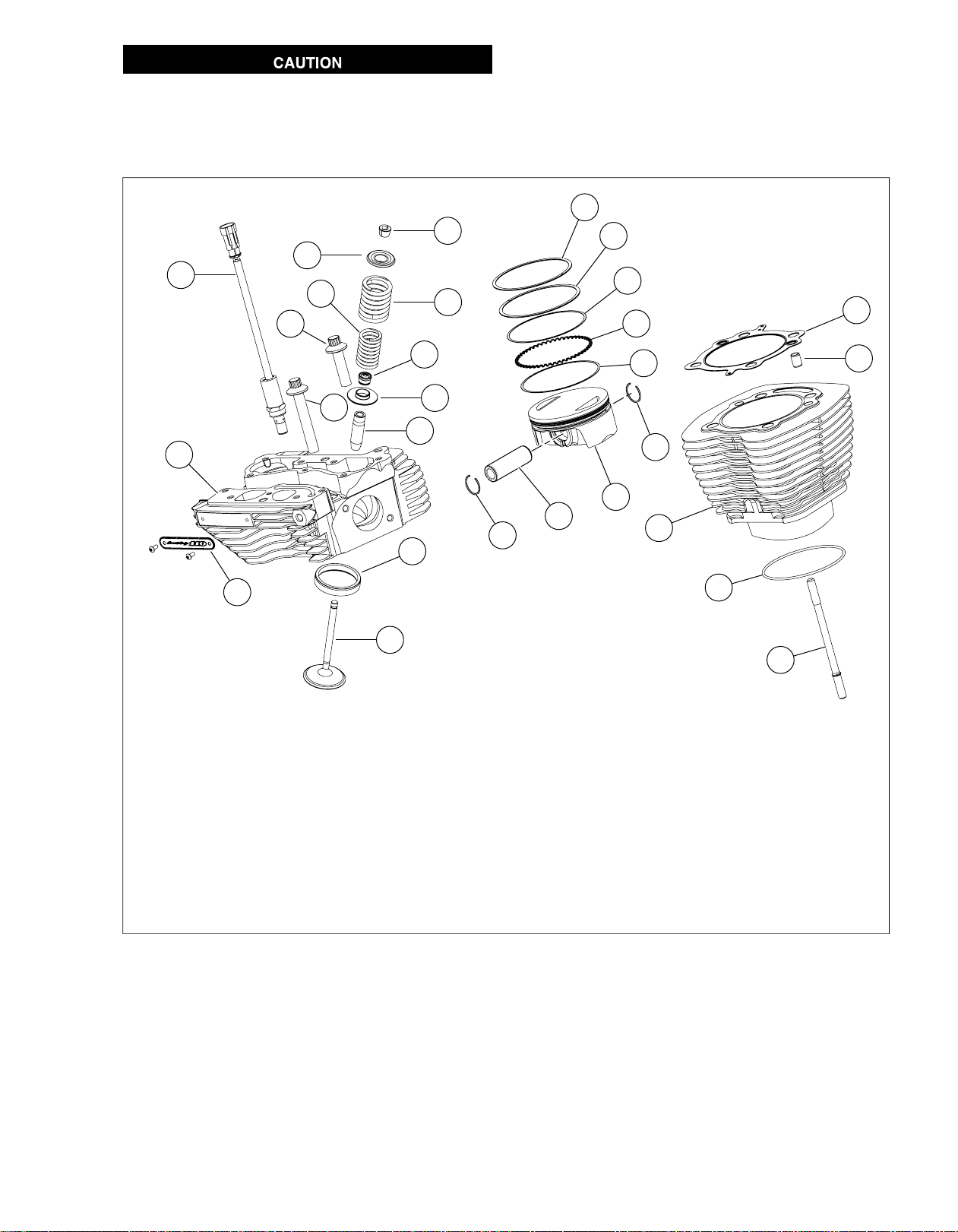

ENGINE

3.1 SPECIFICATIONS: ENGINE

General...............................................................................3-1

Manufacturing Tolerances...................................................3-1

3.2 SERVICE WEAR LIMITS

General...............................................................................3-3

3.3 CYLINDER HEAD

General...............................................................................3-5

Removal.............................................................................3-5

Determining Service...........................................................3-5

Disassembly.......................................................................3-5

Cleaning.............................................................................3-6

Inspection...........................................................................3-8

Cylinder Head..............................................................3-8

Valve Guides...............................................................3-8

Valves..........................................................................3-8

Valve Springs..............................................................3-8

Tapered Keepers.........................................................3-8

Valve Seats.................................................................3-8

Replacing Valve Guides......................................................3-9

Removal......................................................................3-9

Installation.................................................................3-10

Assembly..........................................................................3-13

Installation........................................................................3-15

3.4 PISTONS

General.............................................................................3-16

Measuring Piston..............................................................3-16

3.5 BORING AND HONING CYLINDERS

Inspection.........................................................................3-17

Cylinder Bore Finished Size.............................................3-18

Piston Orientation.............................................................3-19

FUEL SYSTEM

4.1 AIR CLEANER COVER

General...............................................................................4-1

Removal.............................................................................4-1

Installation..........................................................................4-1

ELECTRIC STARTER

5.1 SPECIFICATIONS: STARTER

General...............................................................................5-1

DRIVE

6.1 SPECIFICATIONS: DRIVE

General...............................................................................6-1

6.2 CLUTCH RELEASE BEARING AND

PUSHROD

Removal.............................................................................6-2

Installation..........................................................................6-2

Measure Release Plate Movement.............................6-2

Install Clutch Inspection Cover....................................6-2

TRANSMISSION

7.1 SPECIFICATIONS:TRANSMISSION

General...............................................................................7-1

7.2 CLUTCH RELEASE COVER

Removal.............................................................................7-2

Installation..........................................................................7-2

Fill and Bleed......................................................................7-3

7.3 SECONDARY CLUTCH ACTUATOR

Replacement......................................................................7-4

ELECTRICAL

3.6 CRANKCASE ASSEMBLY

General.............................................................................3-20

Assembly..........................................................................3-20

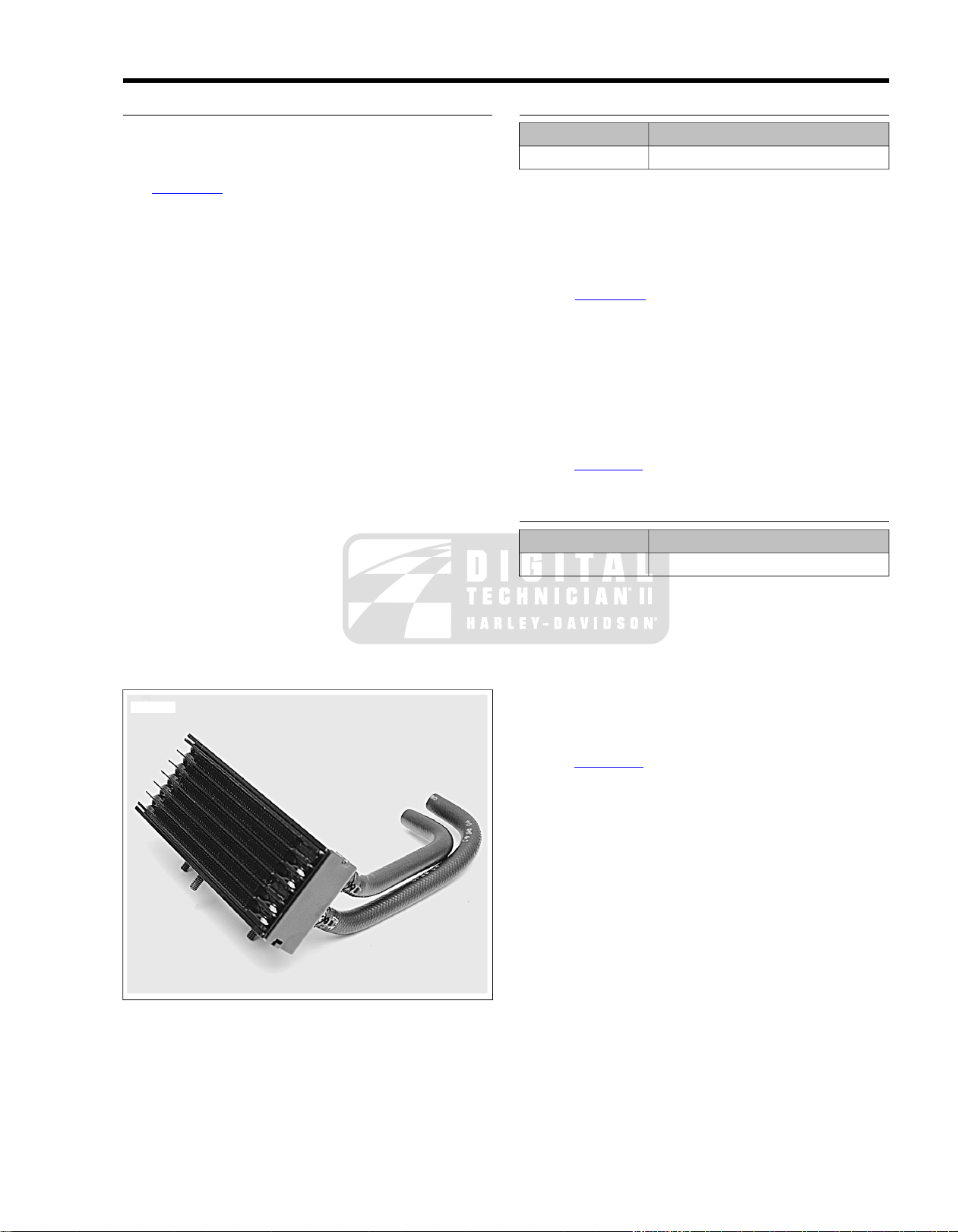

3.7 OIL COOLER

Operation..........................................................................3-23

Removal...........................................................................3-23

Installation........................................................................3-23

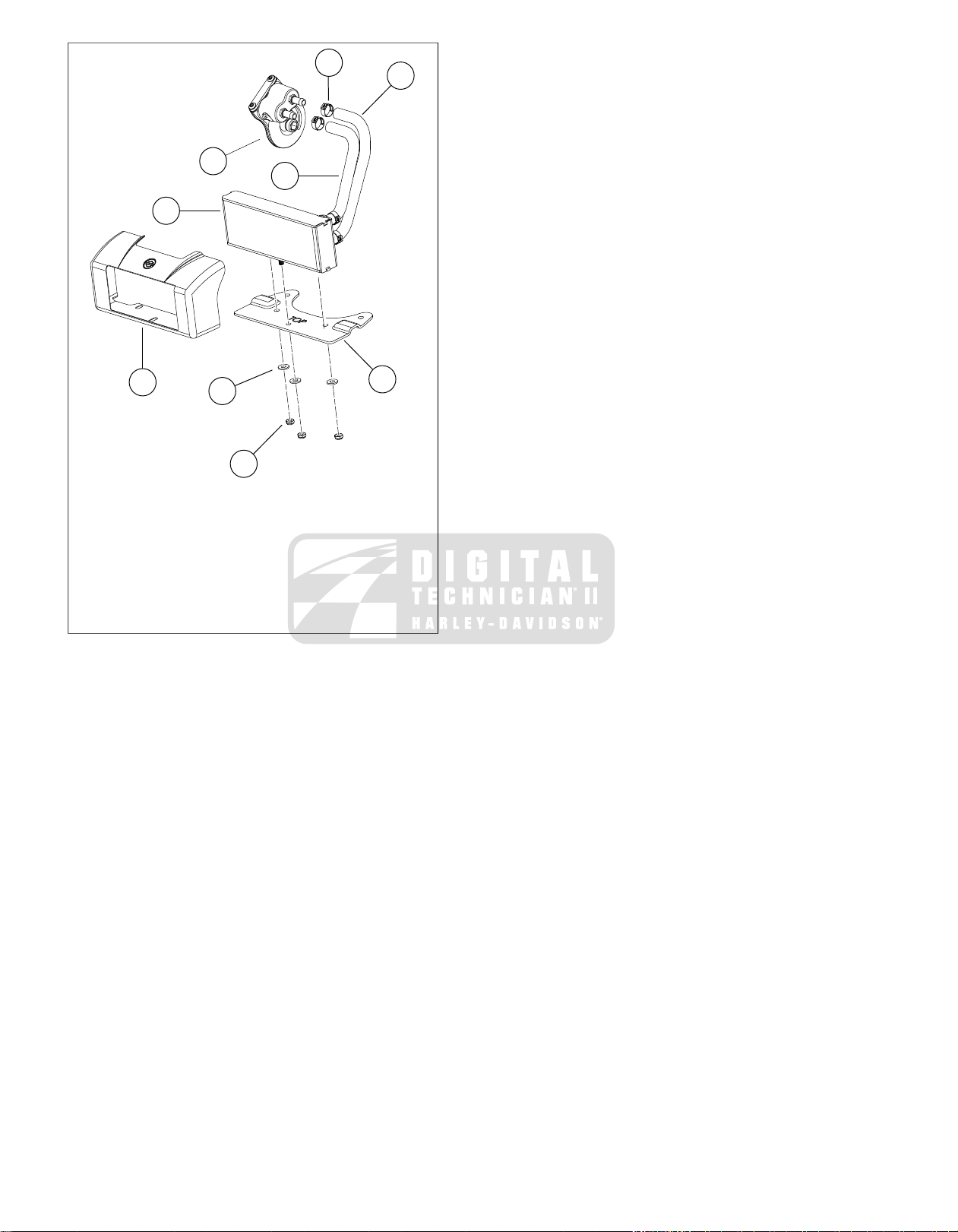

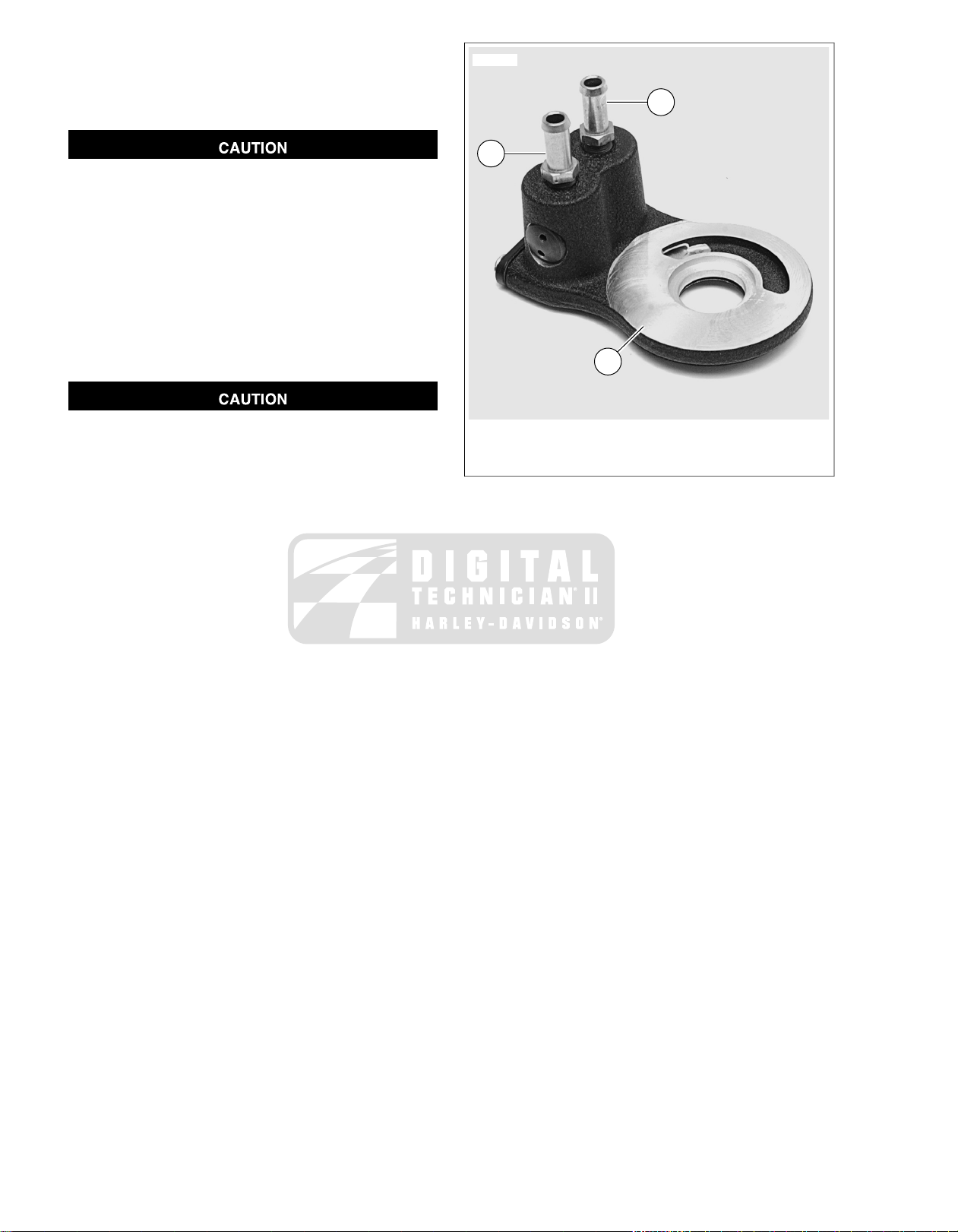

3.8 OIL COOLER ADAPTER

Removal...........................................................................3-25

Disassembly.....................................................................3-25

Assembly..........................................................................3-25

Installation........................................................................3-25

IV TABLE OF CONTENTS

8.1 ELECTRICAL PROTECTION

Fuses and Relays...............................................................8-1

8.2 BULB CHART

General...............................................................................8-3

8.3 HEADLAMP

General...............................................................................8-4

Removal.............................................................................8-4

Installation..........................................................................8-5

8.4 AUXILIARY LAMPS AND BRACKETS

Removing Lamps................................................................8-7

Removing Lamp Bracket....................................................8-8

Installing Lamp Bracket......................................................8-8

Installing Lamps.................................................................8-8

Mount Lamp................................................................8-8

Final Assembly............................................................8-8

Page 11

TABLE OF CONTENTS

Align Lamps................................................................8-9

Replacing Bulb.................................................................8-10

8.5 FRONT TURN SIGNALS

Removal...........................................................................8-12

Installation........................................................................8-12

8.6 HEATED SEAT

General.............................................................................8-14

Controls.....................................................................8-14

Warm-Up...................................................................8-14

Diagnostics.......................................................................8-14

Diagnostic Tips..........................................................8-14

Diagnostic Notes.......................................................8-14

8.7 HEATED HANDGRIPS

General.............................................................................8-17

Diagnostics.......................................................................8-17

Diagnostic Tips..........................................................8-17

Diagnostic Notes.......................................................8-17

8.8 FAIRING CAP AND SWITCHES

Removal...........................................................................8-21

Installation........................................................................8-21

8.9 PASSENGER HEADSET RECEPTACLE

Repair...............................................................................8-23

Replace Weather Cap...............................................8-23

8.14 ADVANCED AUDIO AMPLIFIER

General.............................................................................8-33

Removal...........................................................................8-33

Installation........................................................................8-33

8.15 GARAGE DOOR OPENER

Transmitter........................................................................8-35

Removal....................................................................8-35

Installation.................................................................8-35

Receiver...........................................................................8-35

Installation.................................................................8-35

Remote Control Garage Door Opener..............................8-36

FCC Notices..............................................................8-36

Program the Receiver and Transmitter......................8-36

8.16 AUT OMA TIC COMPRESSION RELEASE

General.............................................................................8-37

Removal...........................................................................8-37

Installation........................................................................8-37

Compression Test.............................................................8-38

Diagnostics.......................................................................8-39

Diagnostic Tips..........................................................8-39

Diagnostic Notes.......................................................8-39

8.17 TWIST GRIP SENSOR (TGS)

Removal...........................................................................8-42

Installation........................................................................8-42

Reset TGS/ECM........................................................8-43

8.10 XM SATELLITE RADIO

General.............................................................................8-24

XM Antenna......................................................................8-24

Remove.....................................................................8-24

Installation.................................................................8-24

XM Module.......................................................................8-25

Removal....................................................................8-25

Installation.................................................................8-25

Activation..........................................................................8-25

8.11 GPS NAVIGATION

General.............................................................................8-27

GPS Antenna...................................................................8-27

Removal....................................................................8-27

Installation.................................................................8-27

GPS Navigation Module...................................................8-28

Removal....................................................................8-28

Installation.................................................................8-28

8.12 RADIO SOFTWARE UPDATE

General.............................................................................8-29

Opening Diag Test Display...............................................8-29

Identifying Version Number...............................................8-29

Updating Receiver Software.............................................8-29

Confirming Version Number.............................................8-30

8.13 ADVANCED AUDIO RADIO

Removing Advanced Audio..............................................8-31

Installing Advanced Audio................................................8-31

8.18 POWER LOCKS

General.............................................................................8-44

Power Lock Lockset:Tour-Pak..........................................8-44

Removal....................................................................8-44

Installation.................................................................8-44

Actuator: Tour-Pak............................................................8-44

Removal....................................................................8-44

Assembly...................................................................8-45

Power Locks: Saddlebags................................................8-45

Removal....................................................................8-45

Installation.................................................................8-45

Actuator: Saddlebag.........................................................8-46

Disassembly..............................................................8-46

Assembly...................................................................8-47

Power Lock Module..........................................................8-48

Removal....................................................................8-48

Installation.................................................................8-48

Power Lock Fob................................................................8-48

General......................................................................8-48

Entering Program Mode............................................8-48

Program Mode...........................................................8-48

Replacing the Battery................................................8-49

Diagnostics.......................................................................8-49

Diagnostic Tips..........................................................8-49

Diagnostic Notes.......................................................8-49

8.19 HARLEY-DA VIDSON SMART SECURITY

SYSTEM

General.............................................................................8-52

HFSM...............................................................................8-52

Removal....................................................................8-52

Installation.................................................................8-52

TABLE OF CONTENTS V

Page 12

TABLE OF CONTENTS

Antenna............................................................................8-52

Remove.....................................................................8-52

Install.........................................................................8-52

Smart Siren......................................................................8-53

Remove.....................................................................8-53

Install.........................................................................8-53

Replace Battery.........................................................8-53

Troubleshooting................................................................8-54

APPENDIX A WIRING

A.1 CONNECTORS

Connectors.........................................................................A-1

Function and Location................................................A-1

Place and Color..........................................................A-1

Connector Number......................................................A-1

Repair Instructions......................................................A-1

A.2 WIRING DIAGRAMS

Wiring Diagram Information...............................................A-2

Wire Color Codes........................................................A-2

Wiring Diagram Symbols............................................A-2

Wiring Diagrams.................................................................A-3

APPENDIX B GLOSSARY

B.1 GLOSSARY

Acronyms and Abbreviations..............................................B-1

REFERENCE MATERIAL

TOOLS...........................................................I

TORQUE VALUES.......................................III

INDEX.........................................................VII

VI TABLE OF CONTENTS

Page 13

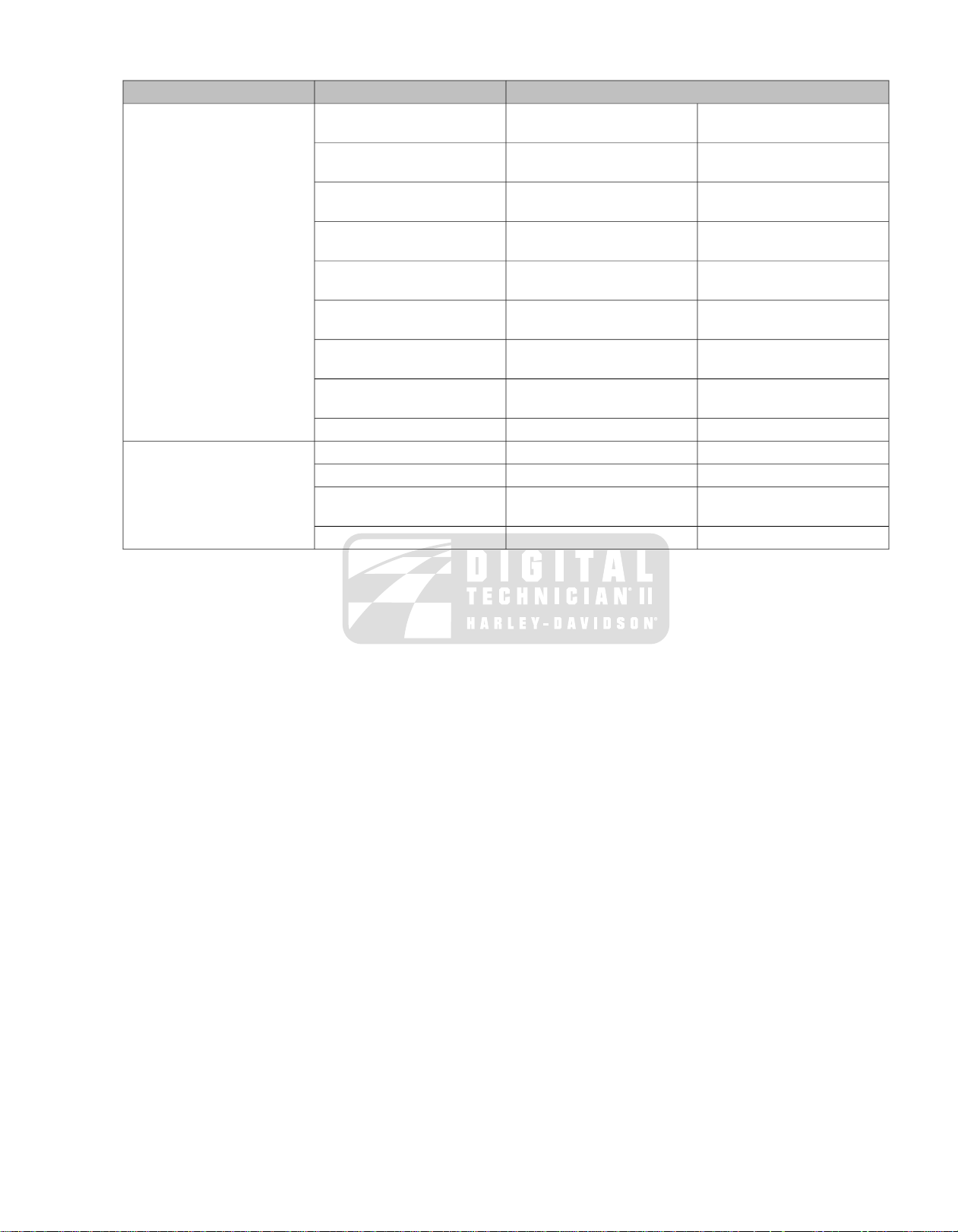

SUBJECT............................................................................................................................PAGE NO.

1.1 SCHEDULED MAINTENANCE.................................................................................................1-1

1.2 HYDRAULIC CLUTCH FLUID...................................................................................................1-2

1.3 BLEEDING CLUTCH FLUID LINE............................................................................................1-3

1.4 ENGINE LUBRICATION SYSTEM............................................................................................1-5

1.5 CRITICAL FASTENERS............................................................................................................1-6

MAINTENANCE

Page 14

NOTES

Page 15

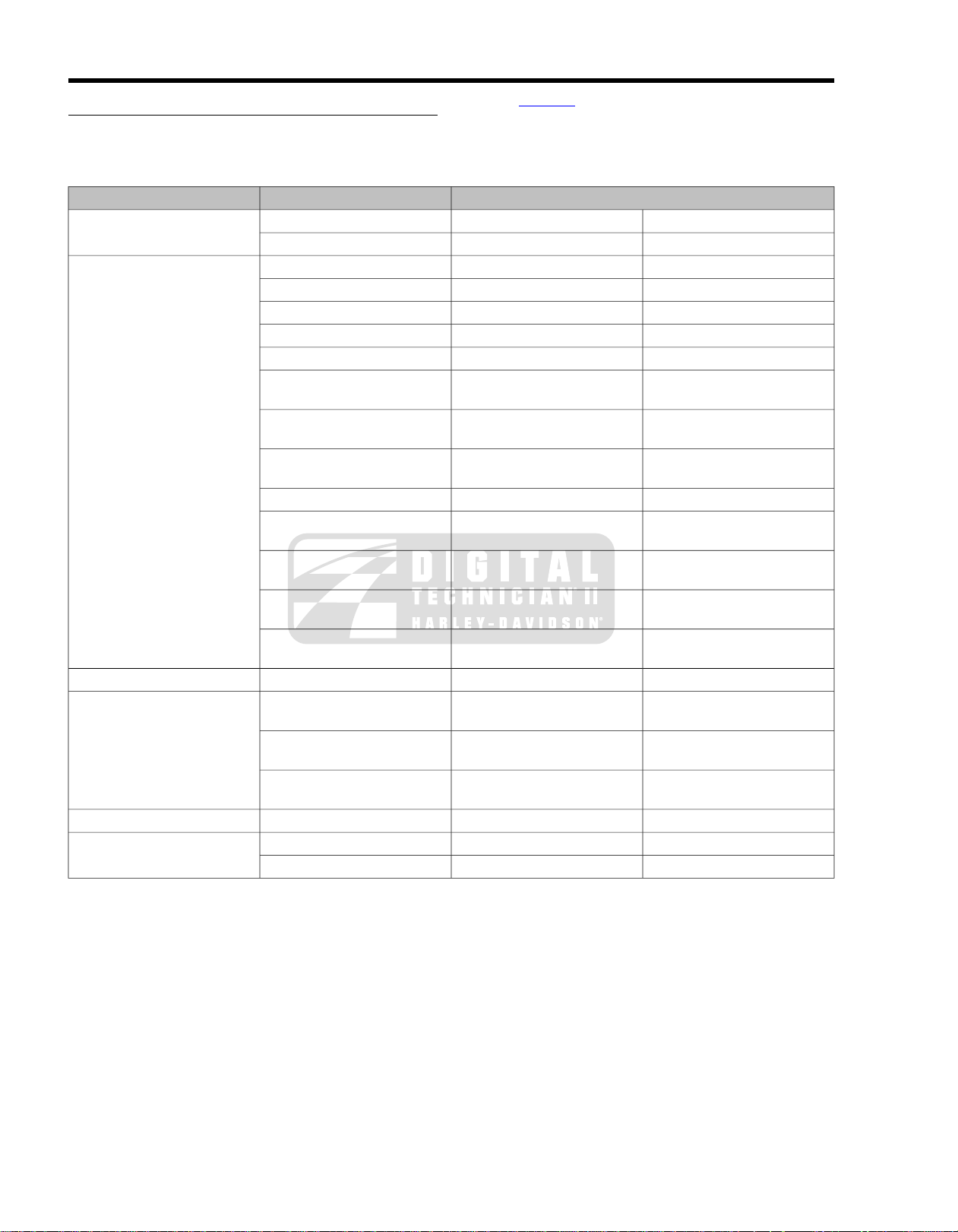

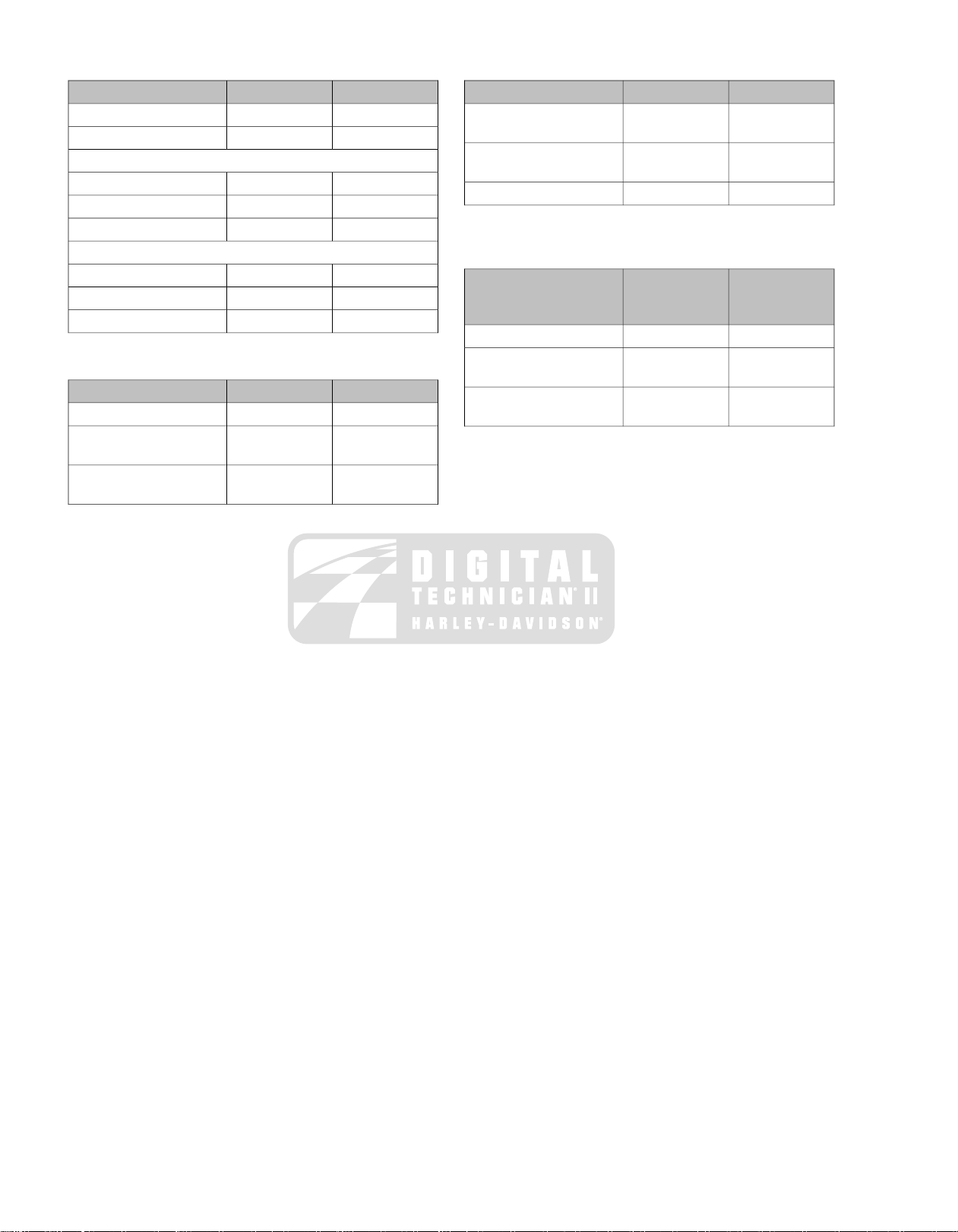

1.1SCHEDULED MAINTENANCE

GENERAL

The scheduled maintenance table in this section lists the

maintenance requirements for the FLHTCUSE3. Refer to

Table 1-1. Scheduled Maintenance Intervals

1000 MI.

1600 KM

Tires

ators

switches

Air suspension

applicable)

bags

stablizers

Battery

Exhaust system

Road test

NOTES:

PROCEDUREITEM SERVICED

tread

and leakage

connections

loose or missing fasteners or

heat shields

system functions

1. Should be performed by an authorized Harley-Da vidson dealer , unless you hav e the proper tools, service data and are mechanically

qualified.

2. Disassemble, lubricate and inspect every 50,000 miles (80,000 kilometers).

3. Perform annually.

4. Change D.O.T. 4 and flush brake system every two years.

5. Perform at each rear tire change.

Table 1-1. In addition to this supplement, see the Touring

Models Service Manual for service procedures.

5000 MI.

8000 KM

10,000 MI.

16,000 KM

15,000 MI.

24,000 KM

20,000 MI.

32,000 KM

XXXReplacePrimary chaincase lubricant

XXReplaceTransmission lubricant

XReplace

40,000 KM

XXXXXXReplaceEngine oil and filter

XXXXXXInspect, service as requiredAir cleaner

XXXXXXCheck pressure, inspect

XXXXXXInspect for wearBrake pads and discs

XXXXXInspectSpark plugs

XXXXXXCheck operationElectrical equipment and

XXXXXXLubricate hinges and latchesFuel door, Tour-Pak, saddle-

XXXXXXVerify component and

NOTES25,000 MI.

1XXXXXXInspect for leaksOil lines and brake system

4ReplaceClutch fluid

1XXXXXXInspect, adjust beltRear belt and sprockets

5Inspect for wearRear wheel sprocket isol-

1XXXXXXCheck, adjust and lubricateBrake and clutch controls

1XXXXXXInspect and lubricateJiffy stand

1XXXXXXInspect for leaksFuel lines and fittings

1XReplaceFuel tank filter

4XXXXXXCheck levels and conditionBrake fluid

1, 2ReplaceFront fork oil

2XXXLubricateSteering head bearings

1XAdjust

1XXXXXXCheck pressure, operation

1XXInspectWindshield bushings (if

1XXXCheck tightnessCritical fasteners

1XXInspectEngine mounts and

3Check battery and clean

3XXXXXXInspect for leaks, crac ks, and

2008 FLHTCUSE3 Service: Maintenance 1-1

Page 16

GENERAL

sm01748

1.2HYDRAULIC CLUTCH FLUID

The clutch is hydraulically actuated.The hand lever actuated

master cylinder creates pressure in the clutch fluid line that

activates a secondary clutch actuator mounted in the clutch

release cover. The secondary clutch actuator piston extends

and contacts a pushrod to disengage the clutch.

D.O.T. 4 hydraulic brake fluid is used in the hydraulic

clutch. Do not use other types of fluids as they are not

compatible and could cause equipment damage. (00353a)

D.O.T. 4 brake fluid will damage painted and body panel

surfaces it comes in contact with. Alwa ys use caution and

protect surfaces from spills whenever brake work is performed. F ailure to comply can result in cosmetic damage.

(00239b)

• Do not wipe any spilled brake fluid off of finished surf aces.

Always flush the affected components with water (not

soapy).

Direct contact of D.O.T. 4 brake fluid with eyes can cause

irritation. Avoid eye contact. In case of eye contact flush

with large amounts of water and get medical attention.

Swallowing large amounts of D.O .T . 4 brake fluid can cause

digestive discomfort. If swallowed, obtain medical attention. Use in well ventilated area. KEEP OUT OF REACH OF

CHILDREN. (00240a)

Do not allow dirt or debris to enter the master cylinder

reservoir . Dirt or debris in the reservoir can cause improper

operation and equipment damage. (00205c)

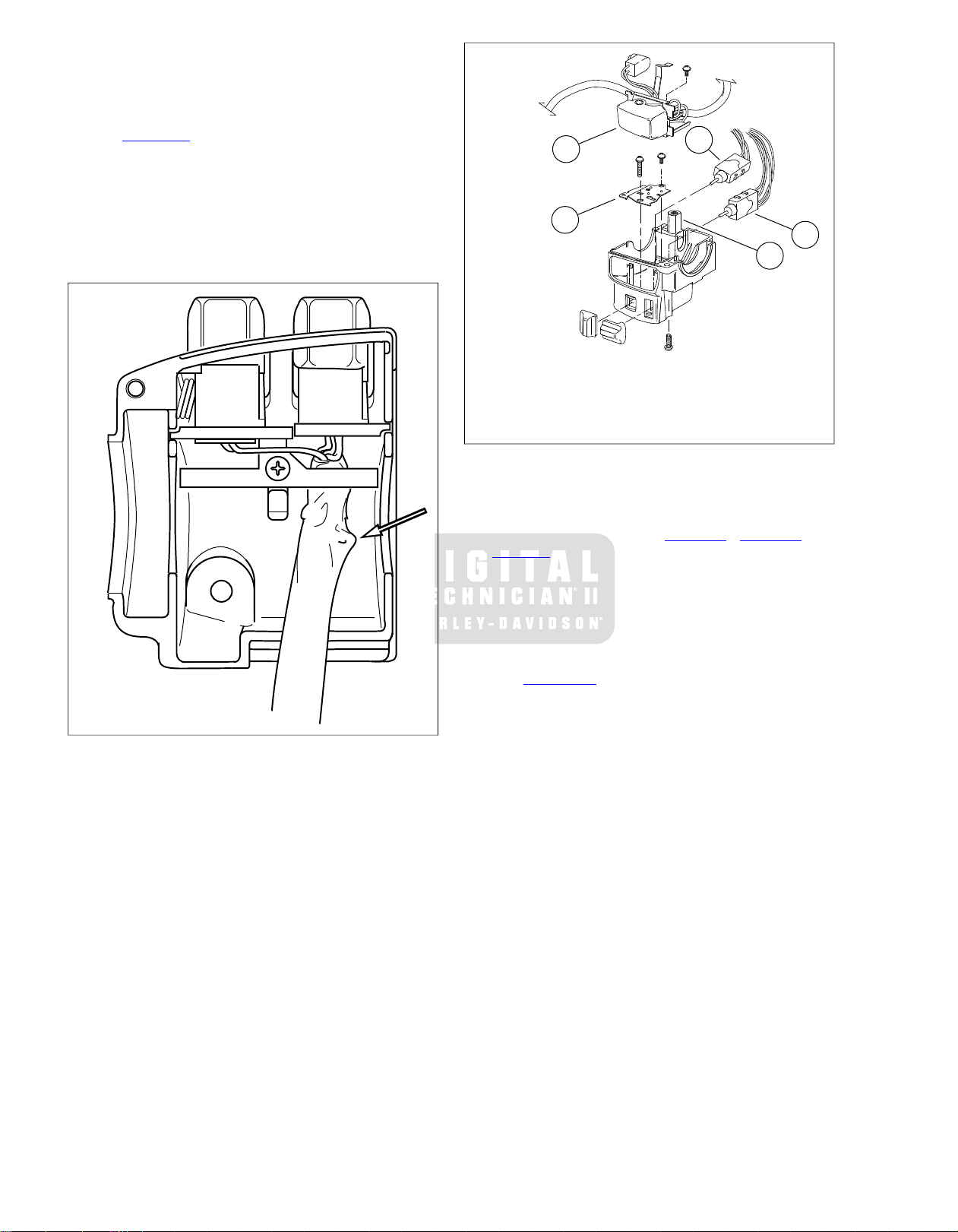

1. Stand motorcycle upright.Turn handlebars to level reservoir.

2. Remove two screws , clutch master cylinder/reservoir cover

and cover gasket.

NOTE

Clutch fluid volume in reservoir actually increases with clutch

wear. Do NOT overfill reservoir.

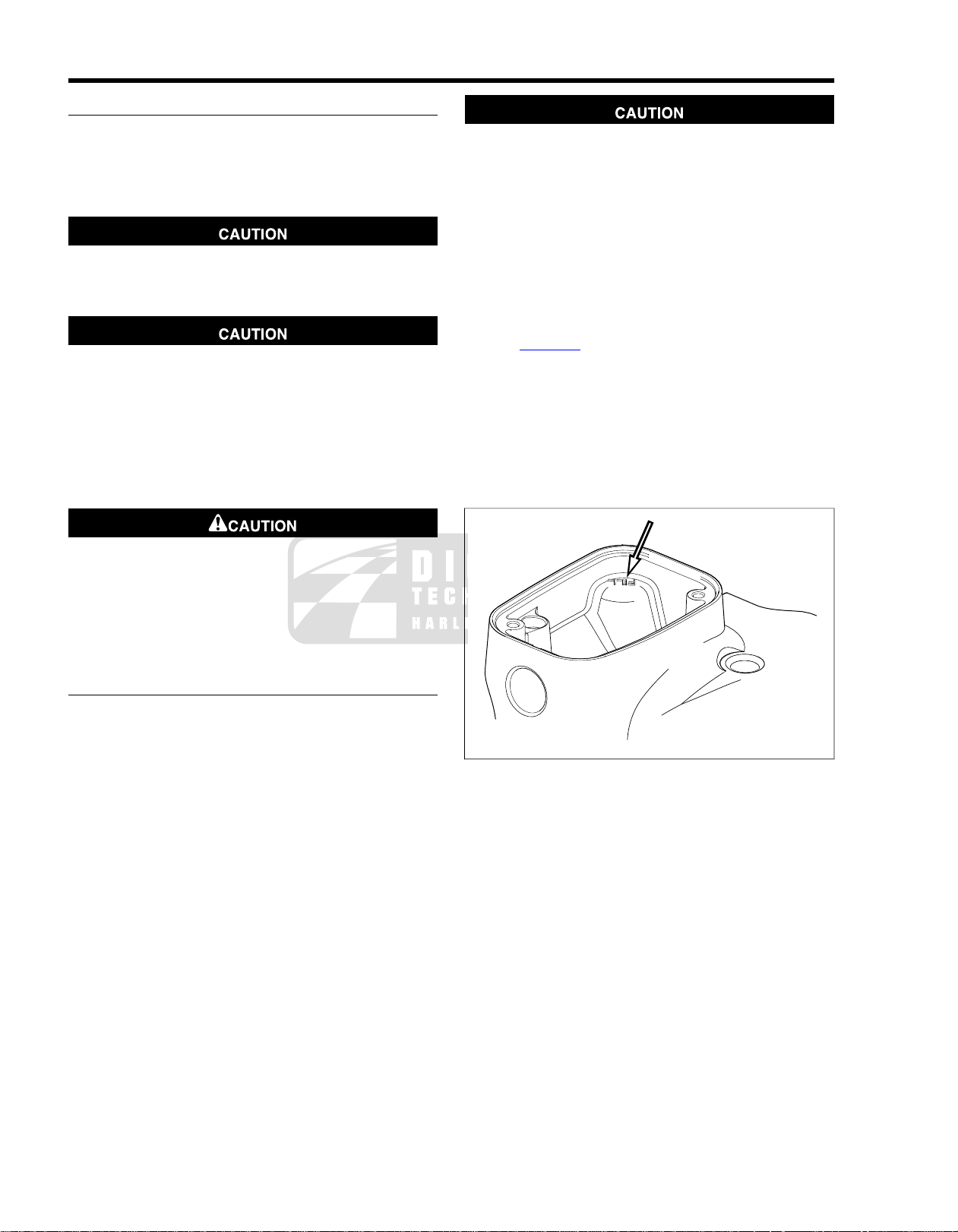

3. See Figure 1-1. If fluid le vel is below FILL LEVEL on ledge

in reservoir, add D.O.T. 4 HYDRAULIC BRAKE FLUID

(Part No. 99953-99A) to raise fluid level. Do not exceed

FILL LEVEL.

4. Carefully place cover gasket and cover on clutch master

cylinder/reservoir.

5. Secure cover with two screws. Tighten screws to 6-8 in-

lbs (0.7-0.9 Nm).

CLUTCH FLUID LEVEL

Even though a clear sight glass in the reservoir cover indicates

low clutch fluid, remove the reservoir cov er to check fluid le vel.

Figure 1-1. Fill Level (Reservoir Cover Removed)

1-2 2008 FLHTCUSE3 Service: Maintenance

Page 17

1.3BLEEDING CLUTCH FLUID LINE

sm03946

1

2

sm03947

DRAINING AND FILLING

Be sure no clutch fluid gets on tires, wheels or brakes

when adding fluid. Traction can be adversely affected,

which could result in loss of control and death or serious

injury. (00294a)

Direct contact of D.O.T. 4 brake fluid with eyes can cause

irritation. Avoid eye contact. In case of eye contact flush

with large amounts of water and get medical attention.

Swallowing large amounts of D.O .T . 4 brake fluid can cause

digestive discomfort. If swallowed, obtain medical attention. Use in well ventilated area. KEEP OUT OF REACH OF

CHILDREN. (00240a)

D.O.T. 4 brake fluid will damage painted and body panel

surfaces it comes in contact with. Alwa ys use caution and

protect surfaces from spills whenever brake work is performed. F ailure to comply can result in cosmetic damage.

(00239b)

• Do not wipe any spilled brake fluid off of finished surf aces.

Always flush the affected components with water (not

soapy).

9. Fill clutch master cylinder/reservoir with D.O.T. 4

HYDRAULIC BRAKE FLUID (Part No. 99953-99A). Initial

fluid level should not exceed FILL LEVEL with reservoir

in a level position.

NOTE

The shelf life of a bottle of unopened D.O.T. 4 HYDRAULIC

BRAKE FLUID is one year.The shelf life of an uncontaminated

bottle that has been resealed is one week.

10. Bleed master cylinder. See 1.3 BLEEDING CLUTCH

FLUID LINE, Bleed Clutch Master Cylinder.

11. Bleed clutch fluid line and secondary actuator. See

1.3 BLEEDING CLUTCH FLUID LINE, Bleed Fluid Line

and Actuator.

Do not allow dirt or debris to enter the master cylinder

reservoir . Dirt or debris in the reservoir can cause improper

operation and equipment damage. (00205c)

1. Cover exhaust with towel and place a suitable pan under

clutch release cover to catch excess clutch fluid.

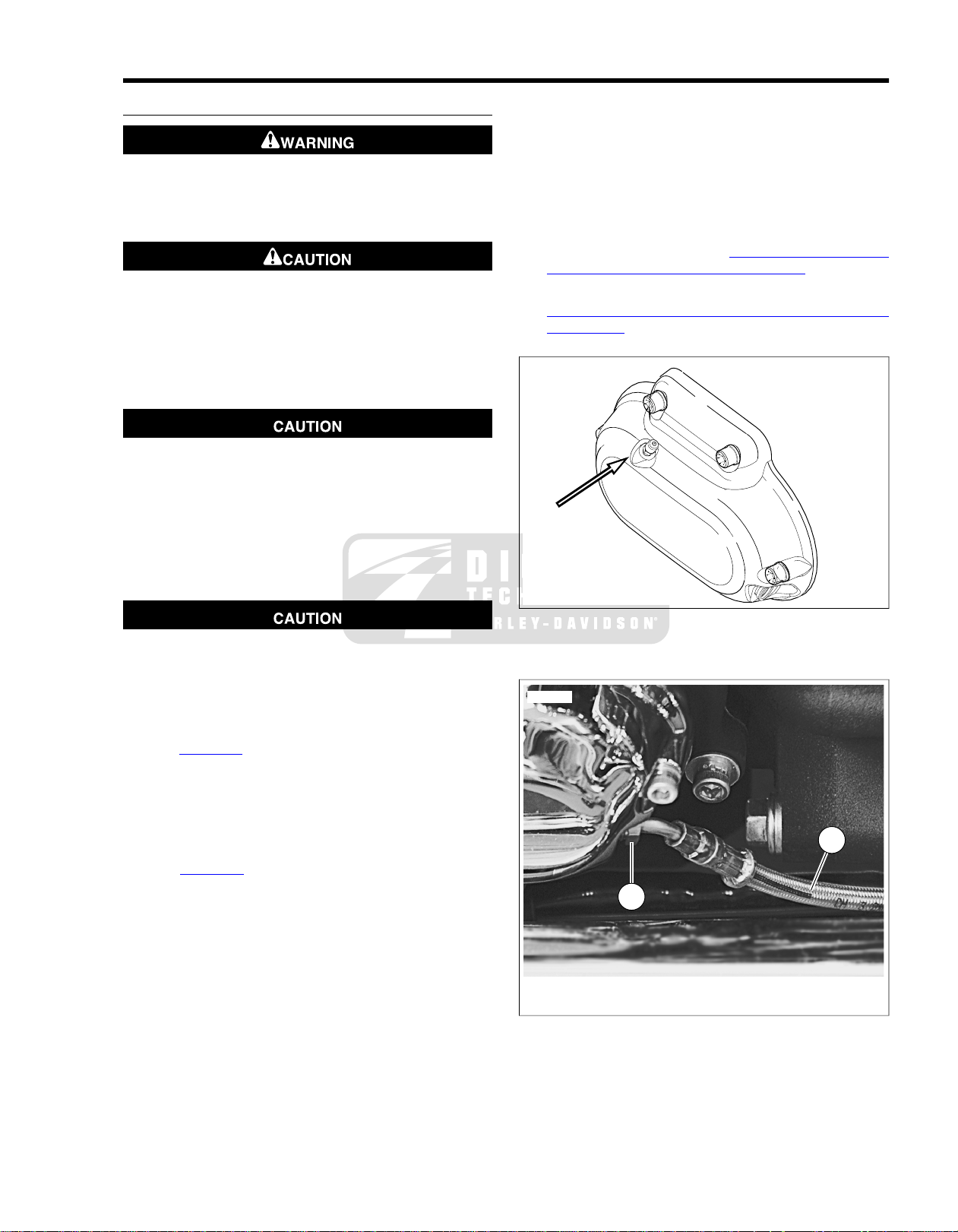

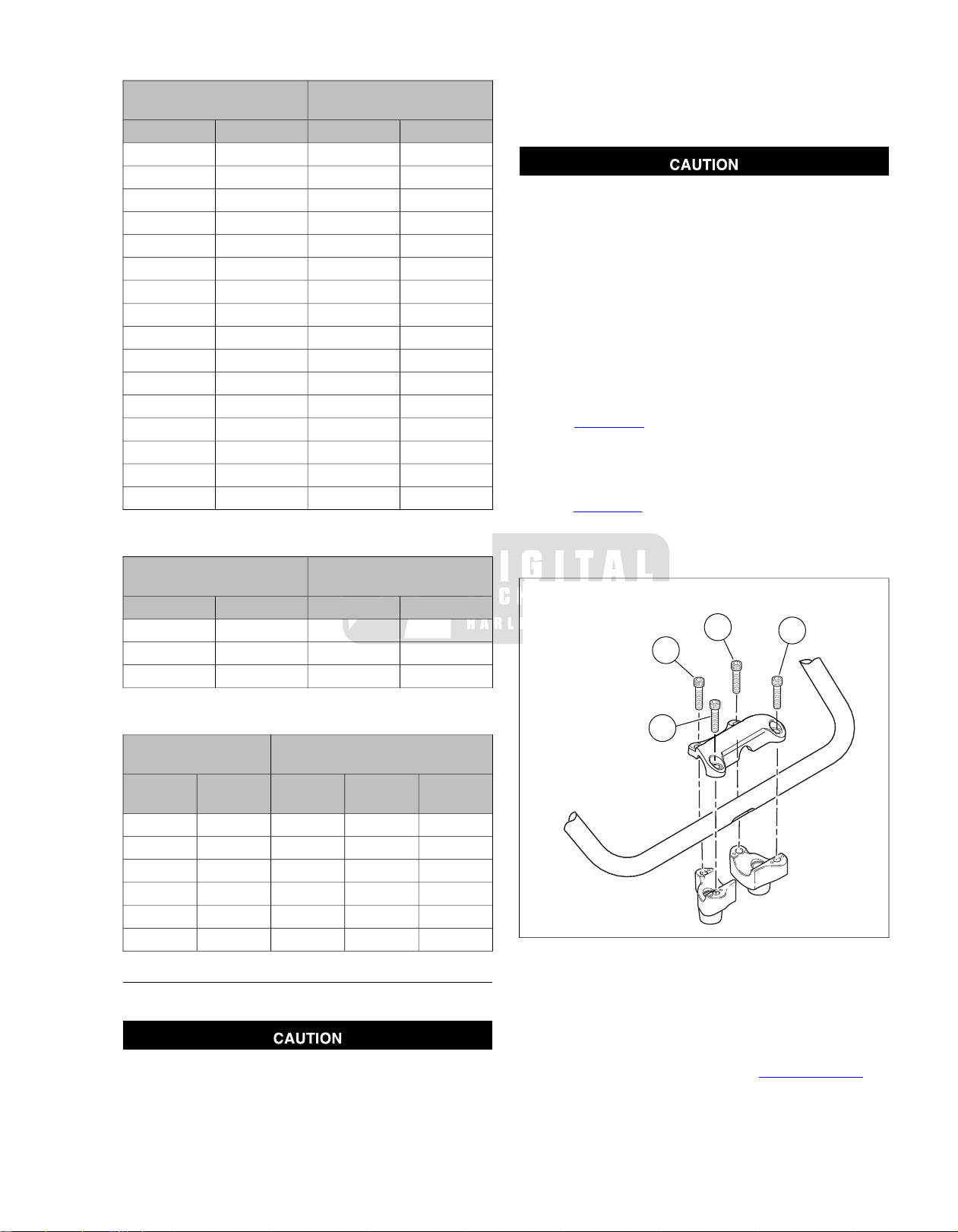

2. See Figure 1-2. Remove plastic cap and loosen bleeder

valve.

3. Run hose from bleeder valve to pan.

4. Loosen the clutch master cylinder/reservoir cover.

5. Allow clutch fluid to drain into pan.

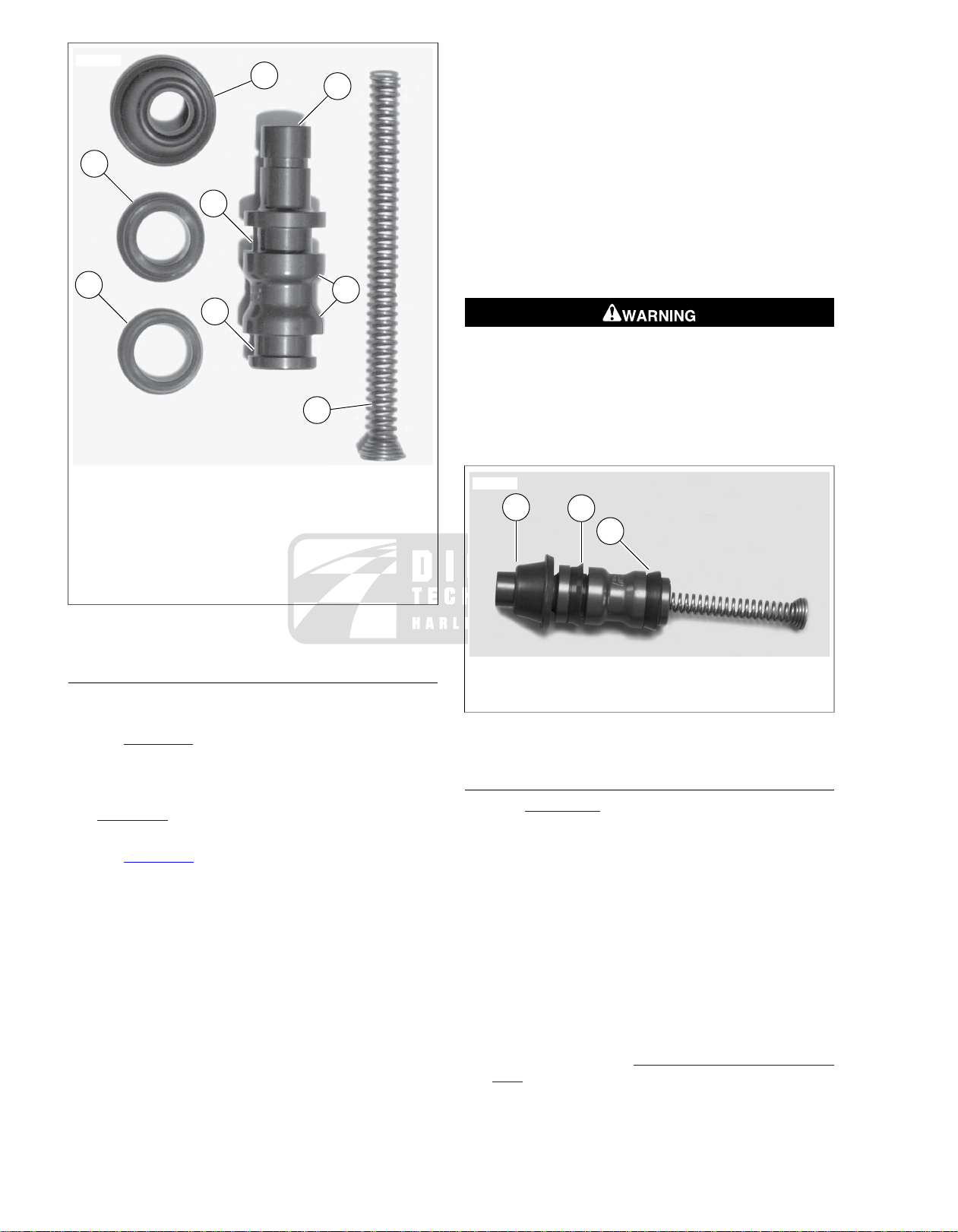

6. See Figure 1-3. Remove flare nut (1) on outside of the

clutch release cover . Discard o-ring and drain fluid line (2)

into pan.

NOTE

Dispose of clutch fluid in accordance with local regulations.

7. Hand tighten valve and replace cap.

8. Install clutch line flare nut with a new o-ring and tighten

to 72-120 in-lbs (8.1-13.6 Nm).

NOTE

When filling an empty clutch fluid line, a Snap-on Basic V acuum

Brake Bleeder with a fitting that mates to the secondary actuator bleeder valve can be used to initially draw the fluid down

the clutch line.

Figure 1-2. Actuator Bleeder Valve

1. Flare nut

2. Clutch fluid line

Figure 1-3. Clutch Fluid Line and Flare Nut

2008 FLHTCUSE3 Service: Maintenance 1-3

Page 18

BLEED CLUTCH MASTER CYLINDER

NOTE

Clutch fluid volume in reservoir actually increases with clutch

wear. Do NOT overfill clutch reservoir.

1. Stand motorcycle upright.Turn handlebars to level reservoir.

2. Add D.O.T. 4 HYDRAULIC BRAKE FLUID (Part No.

99953-99A) to clutch master cylinder/reservoir. Initial fluid

level should not exceed FILL LEVEL with reservoir in a

level position.

NOTE

The shelf life of a bottle of unopened D.O.T. 4 HYDRAULIC

BRAKE FLUID is one year.The shelf life of an uncontaminated

bottle that has been resealed is one week.

D.O.T. 4 brake fluid will damage painted and body panel

surfaces it comes in contact with. Alwa ys use caution and

protect surfaces from spills whenever brake work is performed. F ailure to comply can result in cosmetic damage.

(00239b)

• Do not wipe any spilled brake fluid off of finished surf aces.

Always flush the affected components with water (not

soapy).

4. Fill reservoir to FILL LEVEL and repeat the previous step

three times or more until only a steady flow of clutch fluid

escapes banjo fitting and fluid level in reservoir is at FILL

LEVEL with motorcycle in an upright position.

BLEED FLUID LINE AND ACTUATOR

1. While holding reservoir cover in place:

a. Pump clutch hand lever 5 times.

b. Hold clutch hand lever against handlebar.

c. Run hose from bleeder valve to suitable container.

d. Loosen actuator bleeder valve.

e. Watch bleeder valve for air bubbles.

f. Tighten bleeder valve.

g. Release clutch hand lever.

NOTE

Clutch fluid volume in reservoir actually increases with clutch

wear. Do NOT overfill clutch reservoir.

2. With reservoir level, fill reservoir to FILL LEVEL and repeat

the previous step three times or more until only a steady

flow of clutch fluid escapes bleeder valve and fluid level

in reservoir is at FILL LEVEL with motorcycle in an upright

position.

RETURN MOTORCYCLE TO SERVICE

NOTE

Loosen banjo bolt only enough to allow air bubbles to escape .

Clutch fluid under pressure can squirt a steady stream several

feet.

3. While holding reservoir cover in place:

a. Pump clutch hand lever 5 times.

b. Hold clutch hand lever against handlebar.

c. Hold shop towel under fitting and loosen master cyl-

inder banjo bolt.

d. Watch banjo fitting for air bubbles.

e. Retighten banjo fitting.

f. Release hand lever.

1. Test pressure by squeezing clutch hand lever.

2. Tighten fasteners as follows:

a. Clutch master cylinder banjo bolt to 12.5-14.5 ft-

lbs (16.9-19.7 Nm).

b. Clutch line flare nut to 72-120 in-lbs (8.1-13.6 Nm).

c. Actuator bleeder valve to 12-15 in-lbs (1.4-1.7 Nm).

d. Reservoir cover screws to 6-8 in-lbs (0.7-0.9 Nm).

3. Remove hose from bleeder valve and replace protective

cap.

4. Test ride motorcycle. Incorrect pressure or fluid level can

cause:

a. Dragging clutch.

b. Hard shifting.

1-4 2008 FLHTCUSE3 Service: Maintenance

Page 19

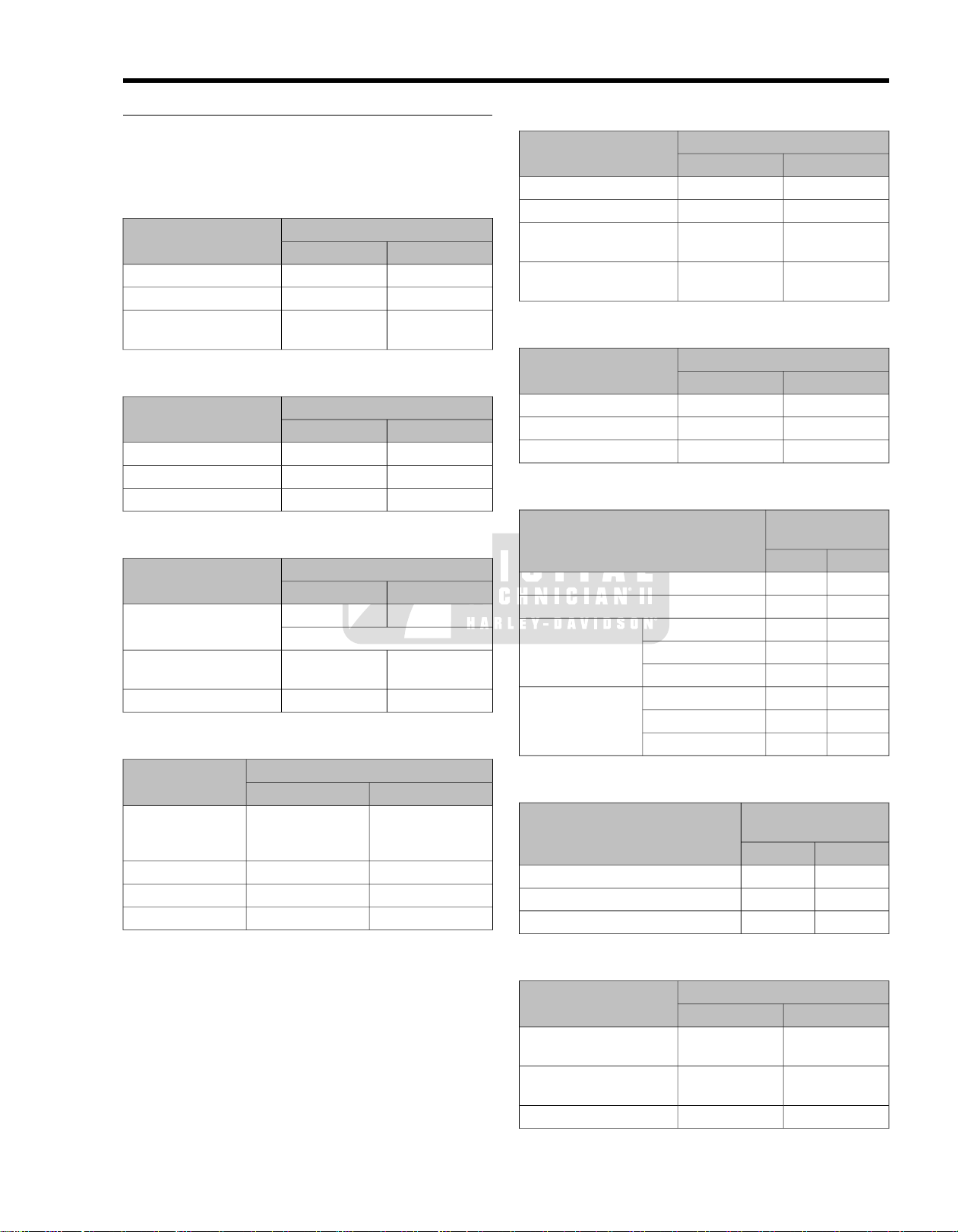

GENERAL

1.4ENGINE LUBRICATION SYSTEM

The engine of this model is initially filled with Screamin' Eagle

SYN3 Synthetic Motorcycle Lubricant.

If oil needs to be added to the engine to bring the fill level to

FULL on the dipstick and SYN3 is not availab le, the first choice

would be to add H-D 360 SAE 20W50 to the SYN3 for engine

lubrication. Although H-D 360 is compatible with SYN3, we

suggest the mixture of the fluids be changed as soon as possible.

If H-D 360 is not available , the second choice would be to add

an acceptable diesel engine oil.We again suggest the mixture

of the fluids be changed as soon as possible. DO NOT add

diesel engine oil to the primary chaincase or transmission.

Refer to Table 1-2.To switch lubricant to H-D 360, completely

drain the SYN3 before filling with H-D 360. A residual amount

of fluid will remain. It is not required to flush out the residual

fluid.

Prolonged or repeated contact with used motor oil may

be harmful to skin and could cause skin cancer. Pr omptl y

wash affected areas with soap and water. (00358b)

If swallowed, do not induce v omiting. Contact a ph ysician

immediately. In case of contact with eyes, immediateley

flush with water. Contact a physician if irritation persists.

(00357b)

Do not switch lubricant brands indiscriminately because

some lubricants interact chemically when mixed. Use of

inferior lubricants can damage the engine. (00184a)

If it is necessary to add oil and the recommended HarleyDavidson lubricant is not available , use an oil certified for diesel

engines.

At the first opportunity, see a Harley-Da vidson dealer to change

back to 100 percent Harley-Davidson oil.

Acceptable diesel engine oil designations include:

• CF-4

• CG-4

• CH-4

• CI-4

The preferred viscosities for the diesel engine oils, in descending order are:

• 20W50

• 15W40

• 10W40

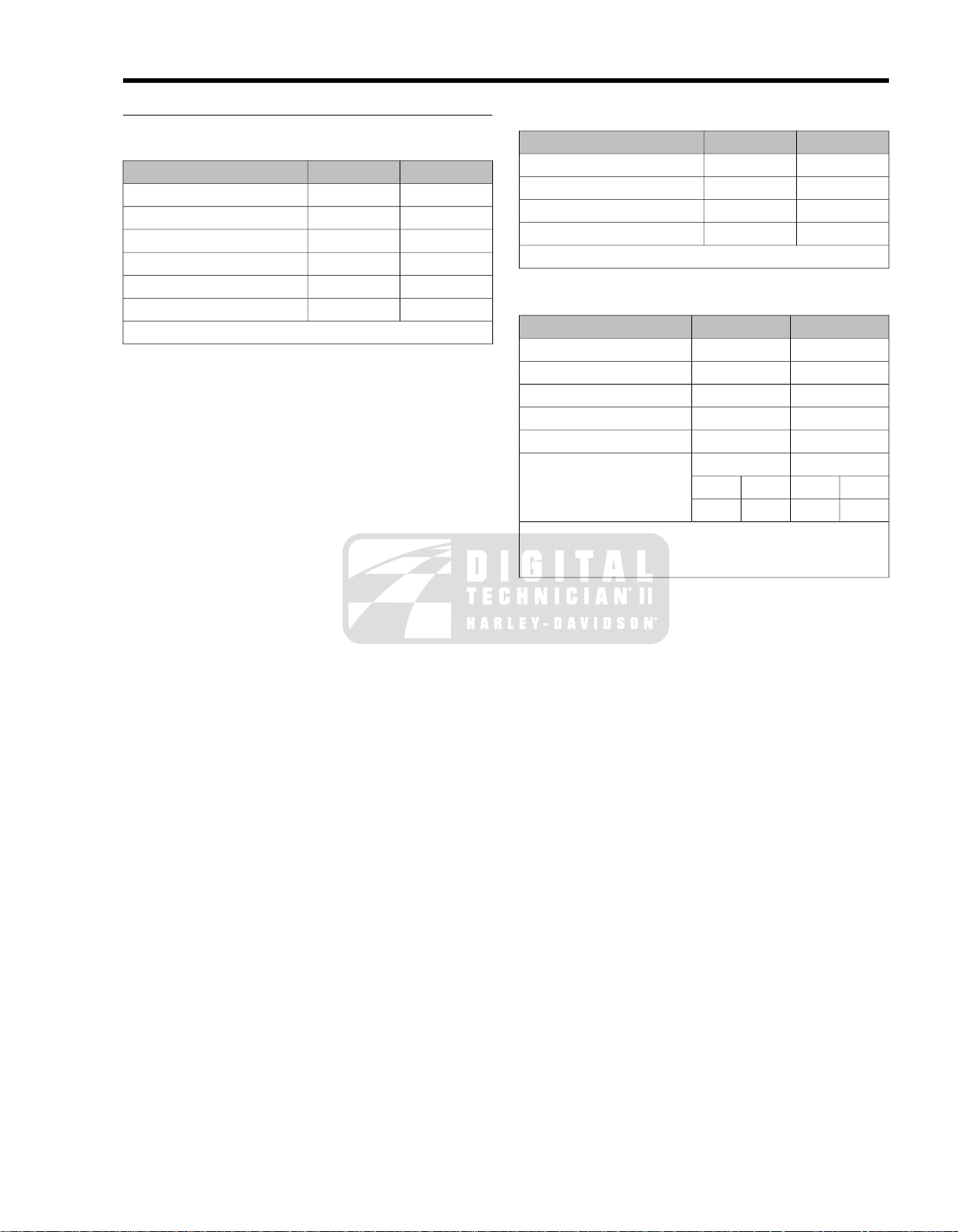

Lubricant

DAVIDSON TYPE

Table 1-2. Recommended Oil Grades

VISCOSITYHARLEY-

HARLEY-

DAVIDSON

RATING

LOWEST

AMBIENT

TEMPERATURE

COLD

WEATHER

STARTS

BELOW

50°F (10°C)

ExcellentAbove 40°F (4°C)HD 360SAE 20W50Screamin' Eagle® SYN3 Synthetic Motorcycle

ExcellentBelow 40°F (4°C)HD 360SAE 10W40H.D. Multi-Grade

GoodAbove 40°F (4°C)HD 360SAE 20W50H.D. Multi-Grade

PoorAbove 60°F (16°C)HD 360SAE 50H.D. Regular Heavy

PoorAbove 80°F (27°C)HD 360SAE 60H.D. Extra Heavy

2008 FLHTCUSE3 Service: Maintenance 1-5

Page 20

1.5CRITICAL FASTENERS

INSPECTION

Inspect critical fasteners, except head bolts:

Table 1-3. Critical Fasteners: 2008 Touring Models

screws

bolts

bolts

screws

nut

master cylinder

master cylinder

Hand controls

inder/handlebar clamp

inder/handlebar clamp screws

screws

Refer to Table 1-3. Tighten all critical fasteners, except head

bolts, to service manual specifications. Replace an y damaged

or missing hardware.

TORQUEFASTENERSYSTEM

81.3-88.1 Nm60-65 ft-lbsFront axle nutAxle

129-142 Nm95-105 ft-lbsRear axle cone nut

16.9-19.7 Nm12.5-14.5 ft-lbsBanjo bolt, rear master cylinderBrakes

19.7-21.7 Nm14.5-16.0 ft-lbsBanjo bolt, front master cylinder

19.7-29.8 Nm14.5-22.0 ft-lbsBanjo bolts, ABS housing

23.1-25.8 Nm17-19 ft-lbsBanjo bolt, brake caliper

9.1-11.3 Nm80-100 in-lbsBrake bleeders

21.7-32.5 Nm16-24 ft-lbsFront brake disc mounting

38.0-51.6 Nm28-38 ft-lbsFront brake caliper mounting

58.3-65.1 Nm43-48 ft-lbsRear brake caliper mounting

8.5-11.5 Nm75-102 in-lbsBrake caliper pad pins

40.7-61.1 Nm30-45 ft-lbsRear brake disc mounting

14.2-16.9 Nm10.5-12.5 ft-lbsRear master cylinder mounting

1.4-1.7 Nm12-15 in-lbsReservoir cover screws, rear

0.9-1.1 Nm8-10 in-lbsReservoir cover screws, front

14.9-20.4 Nm132-180 in-lbsAxle holder nutsFront forks

8.1-9.5 Nm72-84 in-lbsClutch master cyl-

8.1-9.5 Nm72-84 in-lbsBrake master cyl-

4.0-5.1 Nm35-45 in-lbsUpper/lower switch housing

40.7-54.3 Nm30-40 ft-lbsLower clamp (riser) boltsHandlebars

58.3-63.7 Nm43-47 ft-lbsLocknutRear fork pivot shaft

40.7-54.2 Nm30-40 ft-lbsSwingarm bracket bolts

1-6 2008 FLHTCUSE3 Service: Maintenance

Page 21

Engine

Table 1-3. Critical Fasteners: 2008 Touring Models

TORQUEFASTENERSYSTEM

40.7-47.5 Nm30-35 ft-lbsEngine mounting bracket to

cylinder head bolts

24.4-29.9 Nm18-22 ft-lbsTop stabilizer link to top engine

mounting bracket bolt

24.4-29.9 Nm18-22 ft-lbsTop stabilizer link to frame

weldment bolt

24.4-29.9 Nm18-22 ft-lbsFront stabilizer link to frame

weldment bolt

24.4-29.9 Nm18-22 ft-lbsFront stabilizer link to front

engine mounting bracket bolt

20.3-27.1 Nm15-20 ft-lbsCenter front engine mounting

bracket to rubber mount bolt

20.4-27.1 Nm15-20 ft-lbsFront engine mount to frame

crossmember bolts

48.9-54.2 Nm36-40 ft-lbsEngine to front engine mounting

bracket bolts

40.7-47.5 Nm30-35 ft-lbsEngine to transmission bolts

16.9-19.7 Nm12.5-14.5 ft-lbsBanjo boltClutch

8.1-13.6 Nm72-120 in-lbsClutch fluid line flare nut

1.4-1.7 Nm12-15 in-lbsSecondary actuator bleeder

valve

0.7-0.9 Nm6-8 in-lbsReservoir cover screws

2008 FLHTCUSE3 Service: Maintenance 1-7

Page 22

NOTES

1-8 2008 FLHTCUSE3 Service: Maintenance

Page 23

SUBJECT............................................................................................................................PAGE NO.

2.1 SPECIFICATIONS: CHASSIS...................................................................................................2-1

2.2 VEHICLE IDENTIFICATION NUMBER (V.I.N.)..........................................................................2-2

2.3 FOOTBOARDS AND CONTROLS............................................................................................2-3

2.4 HIGHWAY PEGS.......................................................................................................................2-9

2.5 FRONT AXLE COVERS..........................................................................................................2-11

2.6 LOWER TRIPLE CLAMP COVER...........................................................................................2-12

2.7 HANDLEBARS........................................................................................................................2-13

2.8 HANDGRIPS...........................................................................................................................2-20

2.9 CLUTCH MASTER CYLINDER AND RESERVOIR................................................................2-24

2.10 CLUTCH HAND LEVER........................................................................................................2-28

2.11 CLUTCH FLUID LINE............................................................................................................2-29

2.12 SEAT......................................................................................................................................2-31

2.13 RIDER BACKREST...............................................................................................................2-33

2.14 TOUR-PAK.............................................................................................................................2-35

2.15 SADDLEBAGS......................................................................................................................2-38

2.16 SADDLEBAGS LATCH..........................................................................................................2-39

2.17 SADDLEBAG SUPPORTS....................................................................................................2-40

2.18 MUFFLER END CAP.............................................................................................................2-42

CHASSIS

Page 24

NOTES

Page 25

2.1SPECIFICATIONS: CHASSIS

GENERAL

Table 2-1. Dimensions: 2008 FLHTCUSE3

*With 180 lb. (81.7 kg) rider.

Table 2-2.Weight

KGLB.ITEM

MMIN.ITEM

161363.5Wheel base

247897.57Overall length

97038.2Overall width

124.54.9Road clearance

145057.1Overall height

72928.7Saddle height*

* As shipped from the factory

Table 2-3. Capacities

* Front fork is functionally identical to FLHTCU. See Touring

Models Service Manual for appropriate front fork service

procedures.

392864Dry Weight*

5721259GVWR

227500GAWR - Front

375827GAWR - Rear

LITERSU.S.ITEM

22.76 galFuel tank (total)

3.78 L4.0 quartsOil tank with filter

946 mL32 fl. oz.T ransmission (appro ximate)

1100 mL38 fl. oz.Primary (drained)

1330 mL45 fl. oz.Primary (cover removed)

HEIGHTVOLUMEFront Fork*

MMIN.MLOZ

1425.5931910.8

NOTE

Gross Vehicle Weight Rating (GVWR) (maximum allowable

loaded vehicle weight) and corresponding Gross Axle Weight

Ratings (GAWR) are given on a label located on the inside of

the right front frame downtube.

2008 FLHTCUSE3 Service: Chassis 2-1

Page 26

2.2VEHICLE IDENTIFICATION NUMBER (V.I.N.)

1 HD 1 PR 8 1 7 8 Y 111000

1

2

3

4

5

6

7

8

9

10

om00927

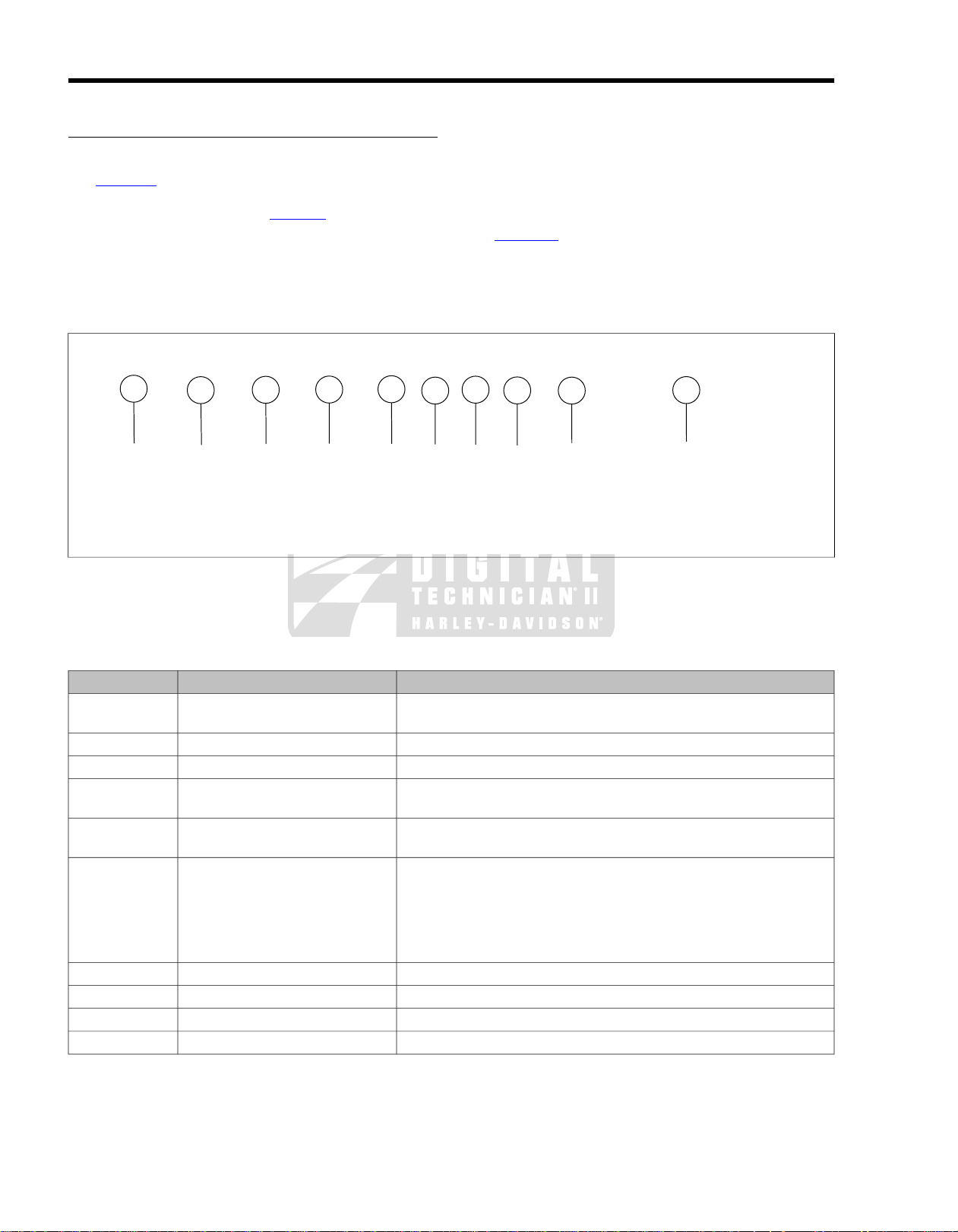

VEHICLE IDENTIFICA TION NUMBER (V.I.N.): FLHTCUSE3

General

See Figure 2-1. A unique 17-digit serial or V ehicle Identification

Number (V .I.N.) is f ound on each motorcycle. F or a description

of each item in the V.I.N., refer to Table 2-4.

Location

The full 17-digit serial or Vehicle Identification Number (V.I.N.)

is stamped on the right side of the frame backbone at the rear

of the steering head under the main wiring harness. A label

bearing the V.I.N. code is also affixed to the left side of the

steering head.

Abbreviated V.I.N.

An abbreviated V.I.N. is stamped on the left side of the crankcase below the engine cylinders.

Example: PR88111000

See Figure 2-1 for the complete V.I.N. as it appears on the

steering head.

NOTE

Always give the full 17-digit Vehicle Identification Number when

ordering parts or making any inquiry about your motorcycle.

Figure 2-1.Typical Harley-Davidson V.I.N.: 2008 FLHTCUSE3 Models

Table 2-4. Harley-Davidson V.I.N. Breakdown: 2008 FLHTCUSE3 Models

POSSIBLE VALUESDESCRIPTIONPOSITION

1=Originally manufactured for sale within the United StatesMarket designation1

5=Originally manufactured for sale outside of the United States

HD=Harley-DavidsonManufacturer2

1=Heavyweight motorcycle (901 cc or larger)Motorcycle type3

Model4

PR=FLHTCUSE3 Screamin' Eagle® Ultra Classic® Electra Glide

PR=FLHTCU3-CVO (Japan only)

4=96 cu. in. (1584 cc) air cooled, fuel injectedEngine type5

8=110 cu. in. (1800 cc) air cooled, fuel injected

1=RegularIntroduction date6

2=Mid-year

3=California/regular

4=Cosmetic changes and/or special introductory date

5=California/cosmetic changes and/or special introductory date

6=California/mid-year

Can be 0-9 or XV.I.N. check digit7

8=2008Model year8

Y=York, PA U.S.A.Assembly plant9

VariesSequential number10

®

2-2 2008 FLHTCUSE3 Service: Chassis

Page 27

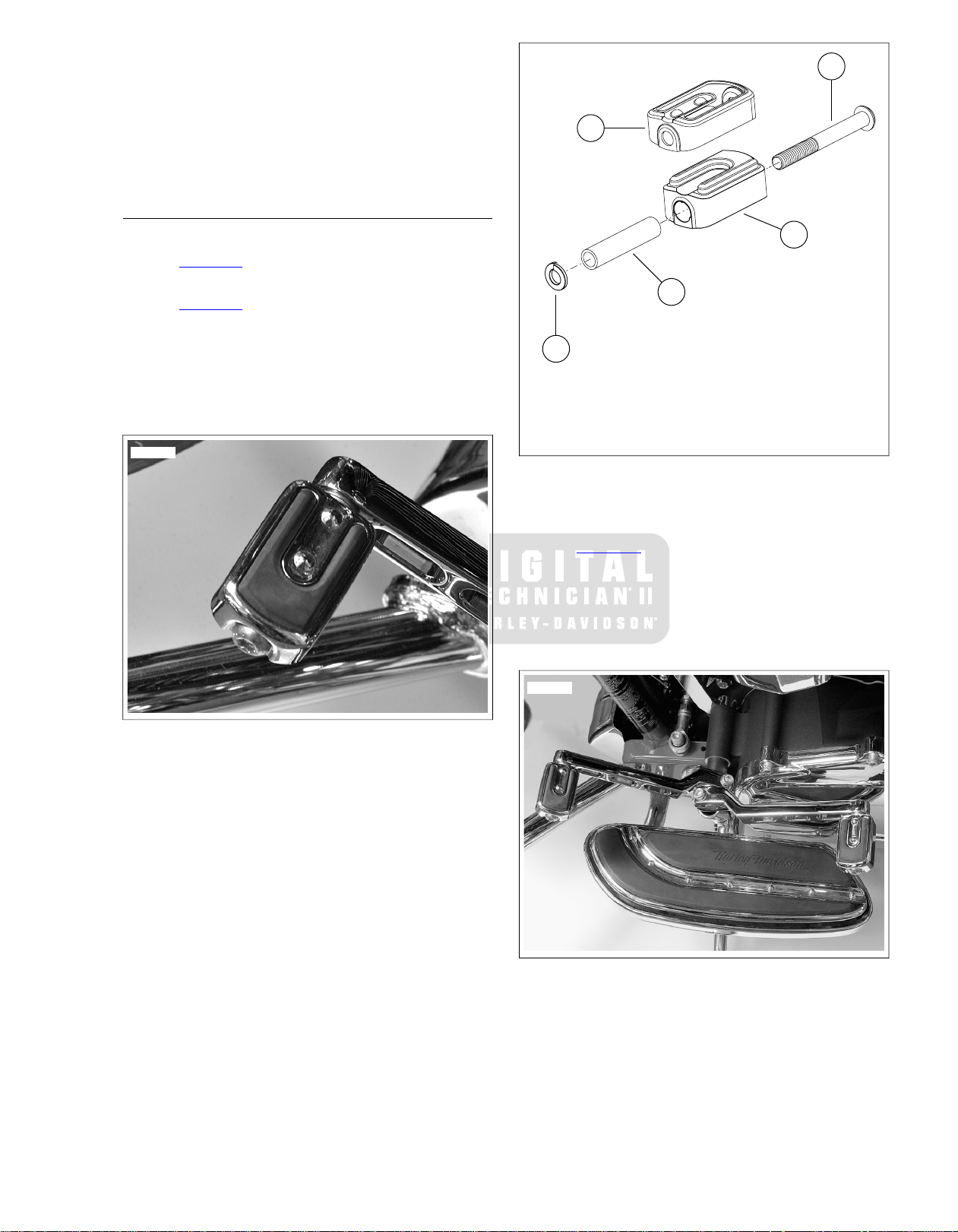

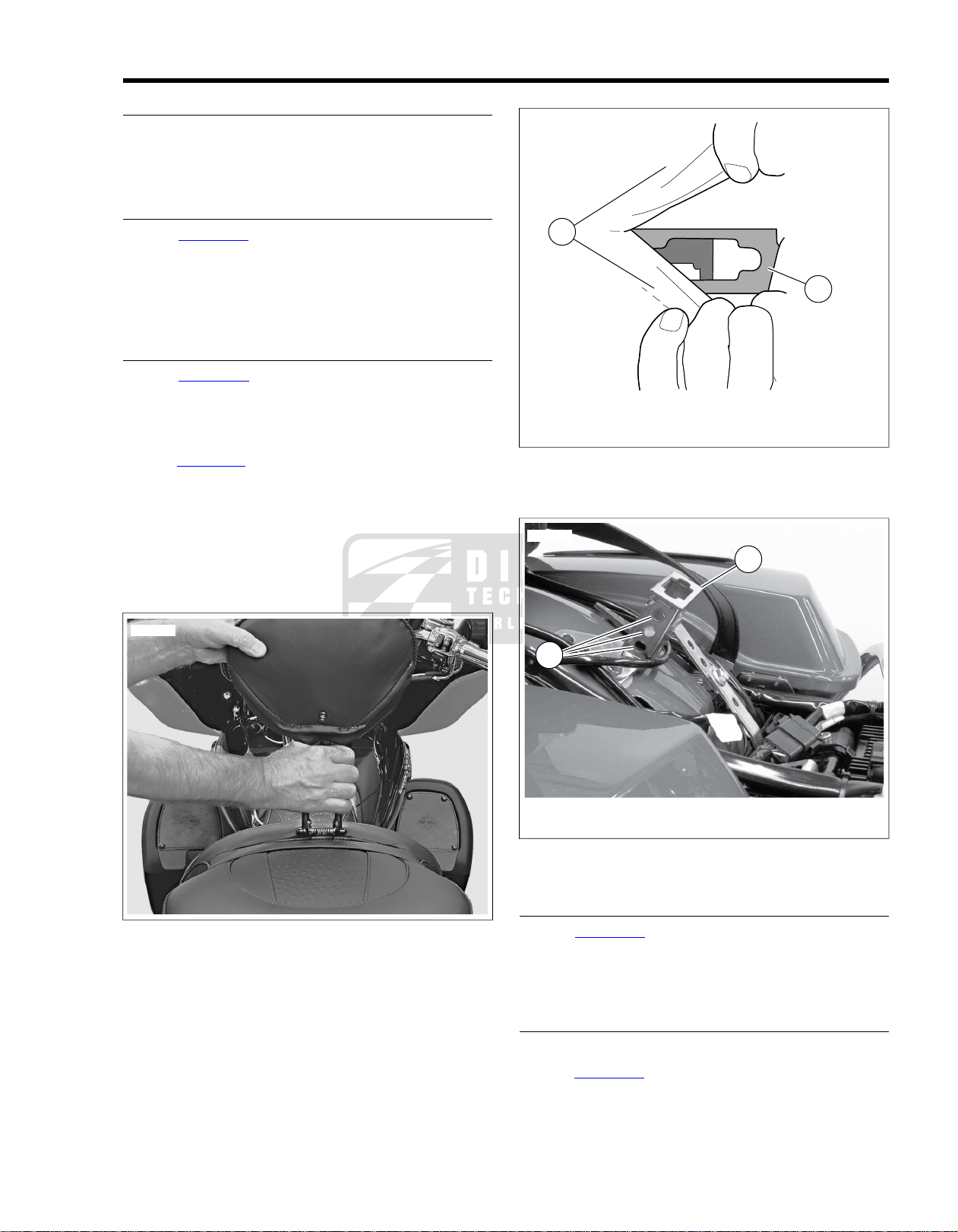

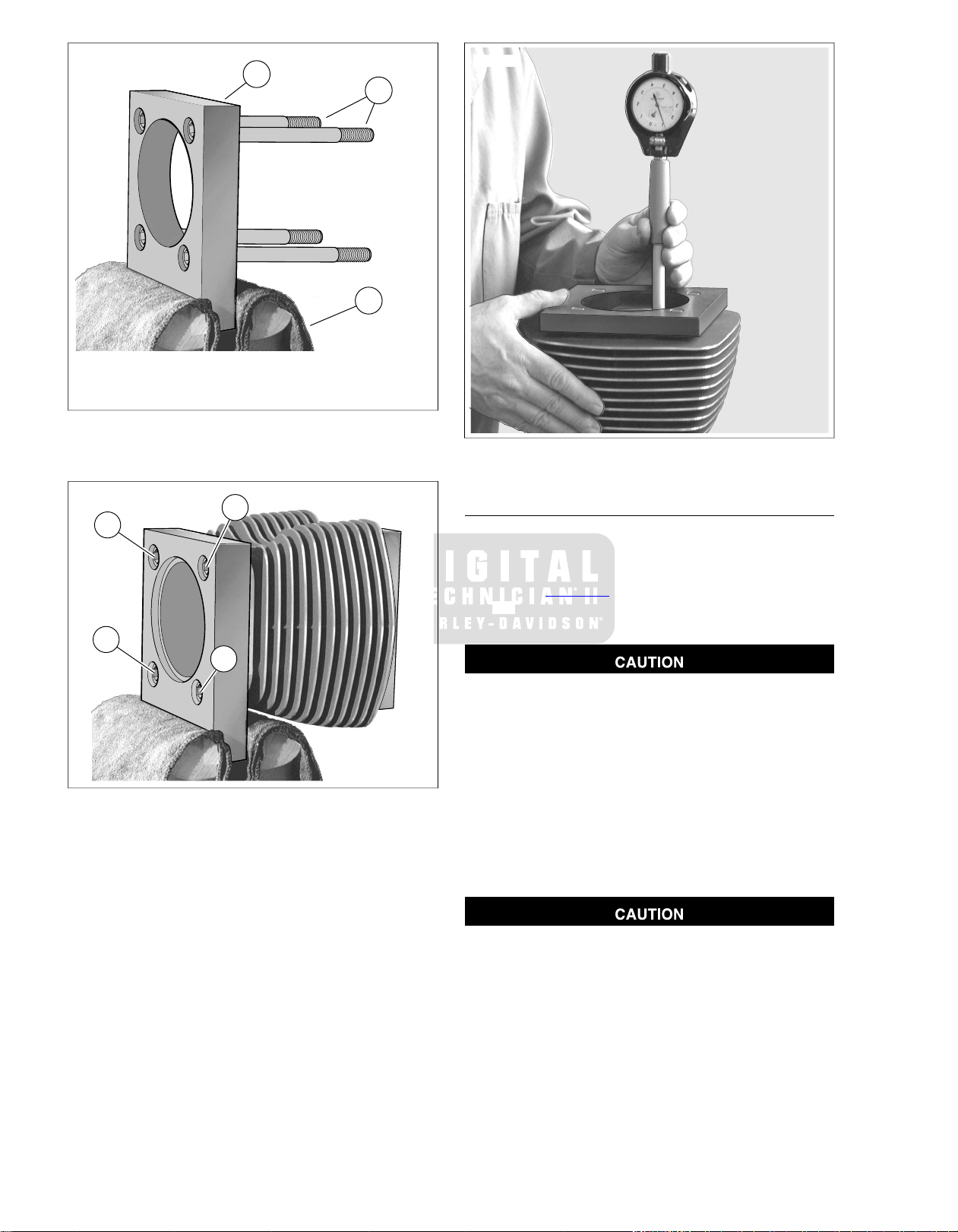

RIDER FOOTBOARDS

sm03952

sm03953

Removal

NOTES

• Unless the footboards are being replaced, they do not

have to be removed from footboard brackets.

• See Figure 2-2.The right and left footboard frame mounts

allow a small variance in height and angle of footboards.

If footboard brack ets are to be remov ed, note the position

in the adjustment holes in the frame mounts. Reinstall

footboard brackets in same positions.

1. Position motorcycle upright on a lift or jack stand so that

the motorcycle is not resting on jiffy stand.

2. See Figure 2-3. With footboards in up position, use a

screwdriver to work cover rubber collars out through f ootboards.

3. See Figure 2-4. Remove front and rear footboard pivot

bolts (3) and nuts (4) and remove footboards.

4. Remove fasteners (12), lockwasher (8) and left rear footboard bracket (14).

NOTE

Fasteners for left rear bracket thread through the jiffy stand

bracket.

5. Remove screw (7), lockwasher (8), washer (9) and left

front footboard bracket (13).

6. Remove screws (7), lockwashers (8), washers (9) and

both front (10) and rear (11) right footboard brackets.

2.3FOOTBOARDS AND CONTROLS

Figure 2-2. Footboard Position Adjustment Holes

Figure 2-3. Footboard Insert Rubber Collars

2008 FLHTCUSE3 Service: Chassis 2-3

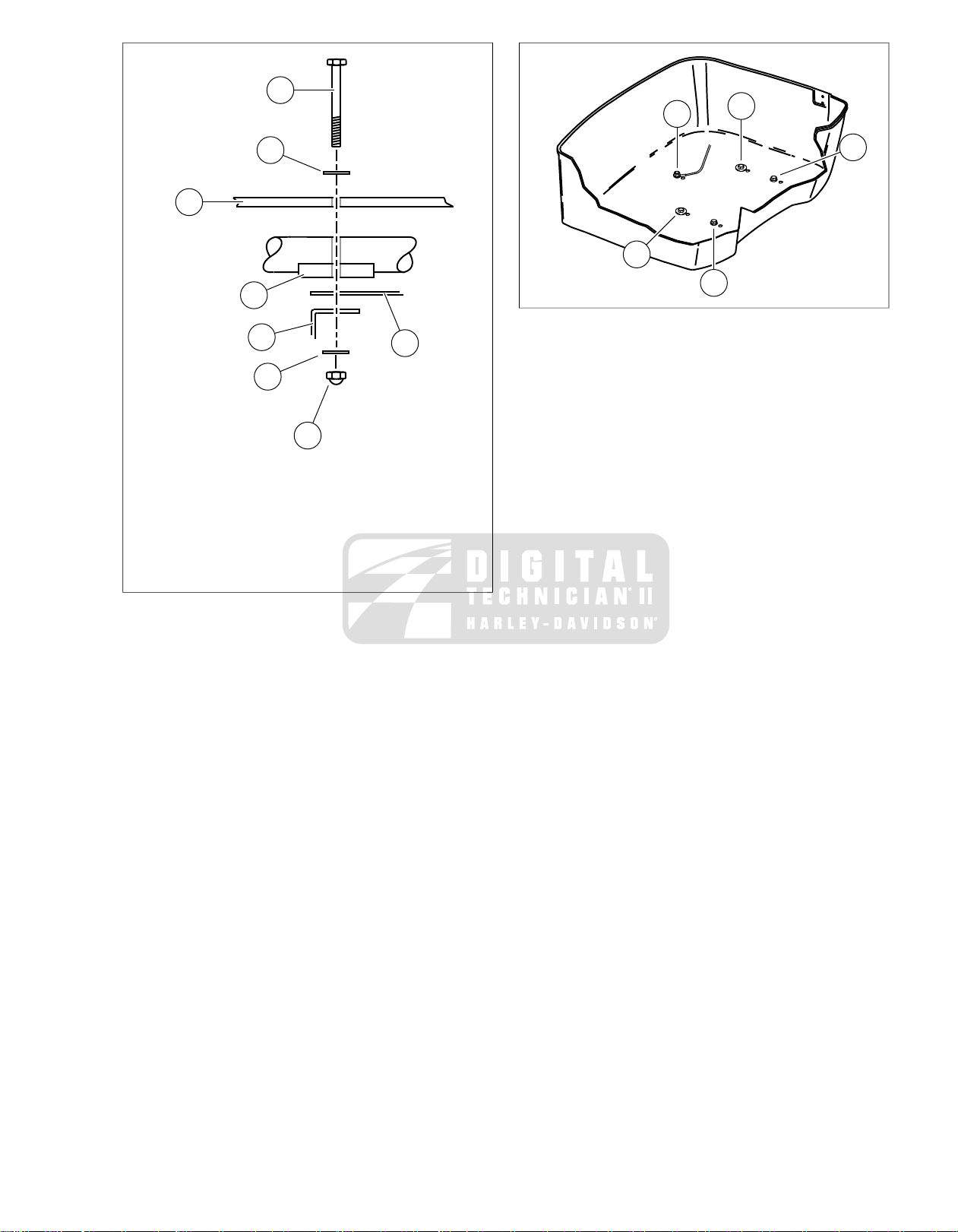

Page 28

2

11

4

5

8

14

8

3

9

7

13

10

6

1

8

9

12

sm03954

8.1. Lockwasher (5)Footboard insert (RH)

2. 9.Footboard insert (LH) Washer (3)

10.3. Front support bracket (RH)Pivot bolt (4)

4. 11.Locknut (4) Rear support bracket (RH)

12.5. Fastener (2)Footboard bottom (RH)

6. 13.Footboard bottom (LH) Front support bracket (LH)

14.7. Rear support bracket (LH)Screw (3)

Figure 2-4. Rider Footboards

Installation

NOTE

Avoid contacting chrome surfaces with abrasive materials

(stones, sand, etc.) as damage will result.

1. Install left front footboard brack et with washer , lockwasher

and screw.Tighten screw finger-tight.

2. Install fastener and lock washer through the left rear footboard bracket through the jiffy stand brac ket into the boss

in the frame.

3. Install fastener and lockwasher from the inside of the fr ame

through the jiffy stand bracket and into the left rear footboard bracket.

2-4 2008 FLHTCUSE3 Service: Chassis

4. Tighten both left rear footboard bracket fasteners to 1520 ft-lbs (21-27 Nm).

5. Install left footboard bottom assembly onto footboard

brackets. Install and tighten pivot bolts and locknuts to

60-80 in-lbs (6.8-9.0 Nm).

6. Tighten left front footboard brack et cap screw to 30-35 ftlbs (41-47 Nm).

7. Install right footboard brackets with w ashers, lockwashers ,

and cap screws.Tighten screws finger-tight.

8. Install right footboard bottom assembly onto footboard

brackets. Install and tighten pivot bolts and locknuts to

60-80 in-lbs (6.8-9.0 Nm).

Page 29

9. Tighten right footboard bracket cap screws to 30-35 ft-

sm04242

4

3

2

5

1

sm03963

sm04244

lbs (41-47 Nm).

10. Moisten footboard cover rubber collars with soapy water.

11. With footboard bottom in up position, hold new f ootboard

insert assembly in position.

12. From underside of footboard use a pliers to pull each

rubber collar through footboard hole.

SHIFT LEVERS

Replace Pegs

1. See Figure 2-5. Remove the fastener and the shift lever

peg.

2. See Figure 2-6. Assemble chrome cover (2) over rubber

pad (1).

3. Insert sleeve (4) and fasten to shift le ver with fastener (3)

and lockwasher (5).

4. Rotate pegs for rider posture and tighten Torx fastener to

14-16 ft-lbs (19-21 Nm).

1. Rubber pad

2. Chrome cover

3. Fastener

4. Sleeve

5. Lockwasher

Figure 2-6. Shift Lever Peg

Replace Heel-Toe Shift Levers

1. See Figure 2-8. Loosen and remove Allen head clamp

bolts.

2. Pull shift levers off splined shaft.

3. Position shift levers on splined shaft for rider posture.

4. Install and tighten clamp bolts to 18-22 ft-lbs (25-29 Nm).

Figure 2-5. Shift Lever Peg

Figure 2-7. Shift Levers

2008 FLHTCUSE3 Service: Chassis 2-5

Page 30

sm03964

1

5

8

2

6

3

4

7

sm03962

Figure 2-8. Heel-Toe Shift Lever Clamp Bolts

REAR BRAKE PEDAL

1. See Figure 2-9. Remove screws (1), brake pedal cover

(2) and pad (3) from metal backing plate (4).

2. Remove acorn nut (5), offset washer (6), metal backing

plate and fastener (7) from foot brake lever (8).

3. Install metal backing plate to foot brak e le ver. Secure with

offset washer and acorn nut. Tighten nut to 25-29 ftlbs (33.9-39.4 Nm).

4. Assemble chrome cover and rubber pad to metal bac king

plate. Secure with screws. Tighten to 20-22 in-lbs (2.3-

2.5 Nm).

1. Screw (2)

2. Chrome cover

3. Rubber pad

4. Metal backing plate

5. Acorn nut

6. Offset washer

7. Fastener

8. Foot brake lever

Figure 2-9. Rear Brake Pedal

ADJUST ABLE PASSENGER FOOTBO ARDS

Remove

1. See Figure 2-10. Remove the upper (1) adjustment bolt,

wave spring and the footboard assembly.

2. Remove the lower adjustment bolt (3), wave spring and

the rotating arm (2).

3. Remove screw and lockwasher to remove footboard

bracket from rear fork pivot bracket.

Disassemble

1. See Figure 2-11. Pivot support 90° to access and back

set screw out of insert.

2. Pull the insert out of the footboard.

3. Press the pivot pins into the center cavity and remove.

NOTE

With the support and the footboard base at 90°, squeeze the

support against the footboard to release tension on the pins.

It maybe necessary to tap the pins with a brass drift.

4. Retain ball and spring from hole in support.

2-6 2008 FLHTCUSE3 Service: Chassis

Page 31

1

3

2

sm03955

1. Upper adjustment bolt

sm03956

1

3

2

sm03957

sm03958

2. Rotating arm

3. Lower adjustment bolt

Figure 2-10. Passenger Footboard Adjustment Bolts

4. See Figure 2-13. Release the support and footboard to

hold the pins centered in the lugs of the footboard.

5. See Figure 2-14.With soapy water, moisten rubber beads

(1) and rubber sockets (2) on new insert.

6. Position in f ootboard and press on insert until beads have

engaged footboard pins and footboard pins ha ve engaged

insert sockets.

Figure 2-11. Insert Set Screw

Assemble

1. See Figure 2-12. Place spring (1) into hole (2) in support

and place ball (3) on top of spring.

2. Orient the support to the footboard to fit the rotating arm.

3. Install pivot pins from the outboard side. Center the pins

To slide the pins in the lugs, squeeze the support against the

footboard to compress the spring and relieve the tension on

the pins. It maybe necessary to tap the pins in place with a

brass drift.

Mate the support to the floorboard to capture the ball and

spring.

in lugs of footboard.

NOTE

1. Spring

2. Hole

3. Ball

Figure 2-12. Support and Footboard

Figure 2-13. Centered Pin

2008 FLHTCUSE3 Service: Chassis 2-7

Page 32

1

2

1

2

1

1

sm03961

1. Rubber beads

2. Rubber sockets

Figure 2-14. Footboard and New Insert

Install

1. Insert locating pin of footboard bracket into hole in rear

fork pivot bracket.

NOTE

Passenger footboards can be installed in one of three positions .

To move footboards to a new position, remove plastic plugs

from holes in rear fork pivot bracket as necessary.

2. Install screw and lockwasher.Tighten to 30-35 ft-lbs (41-

47 Nm).

3. Install rotating arm and lower adjustment bolt with wave

spring.

4. Install footboard assembly with upper adjustment bolt and

wave spring.

Adjust

1. Raise the footboard and loosen the lower adjustment bolt

enough to rotate the rotating arm. Rotate arm to desired

footboard height.

NOTE

Passenger footboards may adjusted to one of five positions.

2. Tighten lower adjustment bolt to 25-30 ft-lbs (34-40 Nm).

3. Loosen upper adjustment bolt enough to allow footboard

mount to be rotated.

NOTE

The horizontal position of tilt of the footboard may be further

adjusted for passenger comfort.

4. Move footboard mount to desired footboard horizontal

position or tilt.

5. Tighten upper adjustment bolt to 25-30 ft-lbs (34-40 Nm).

2-8 2008 FLHTCUSE3 Service: Chassis

Page 33

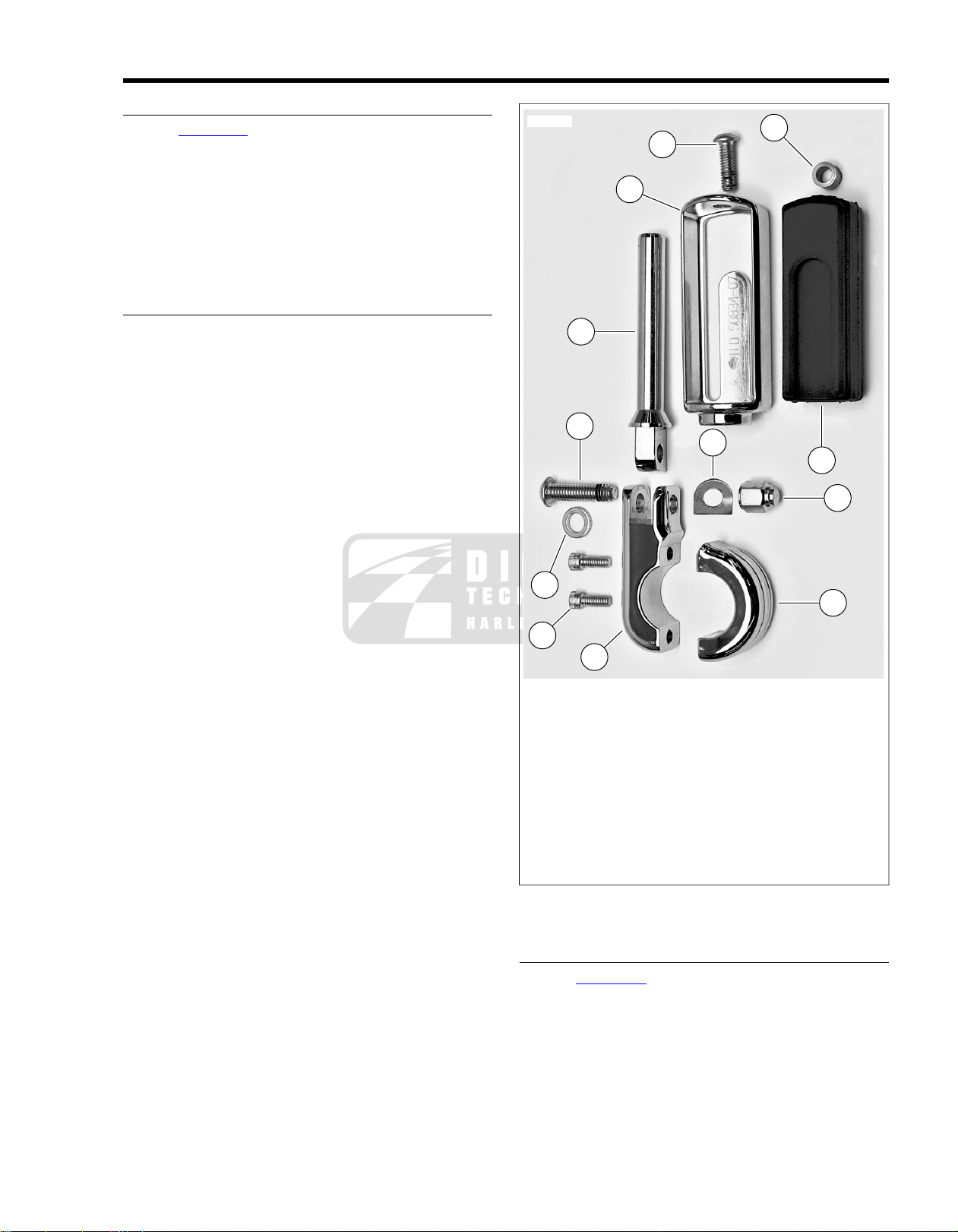

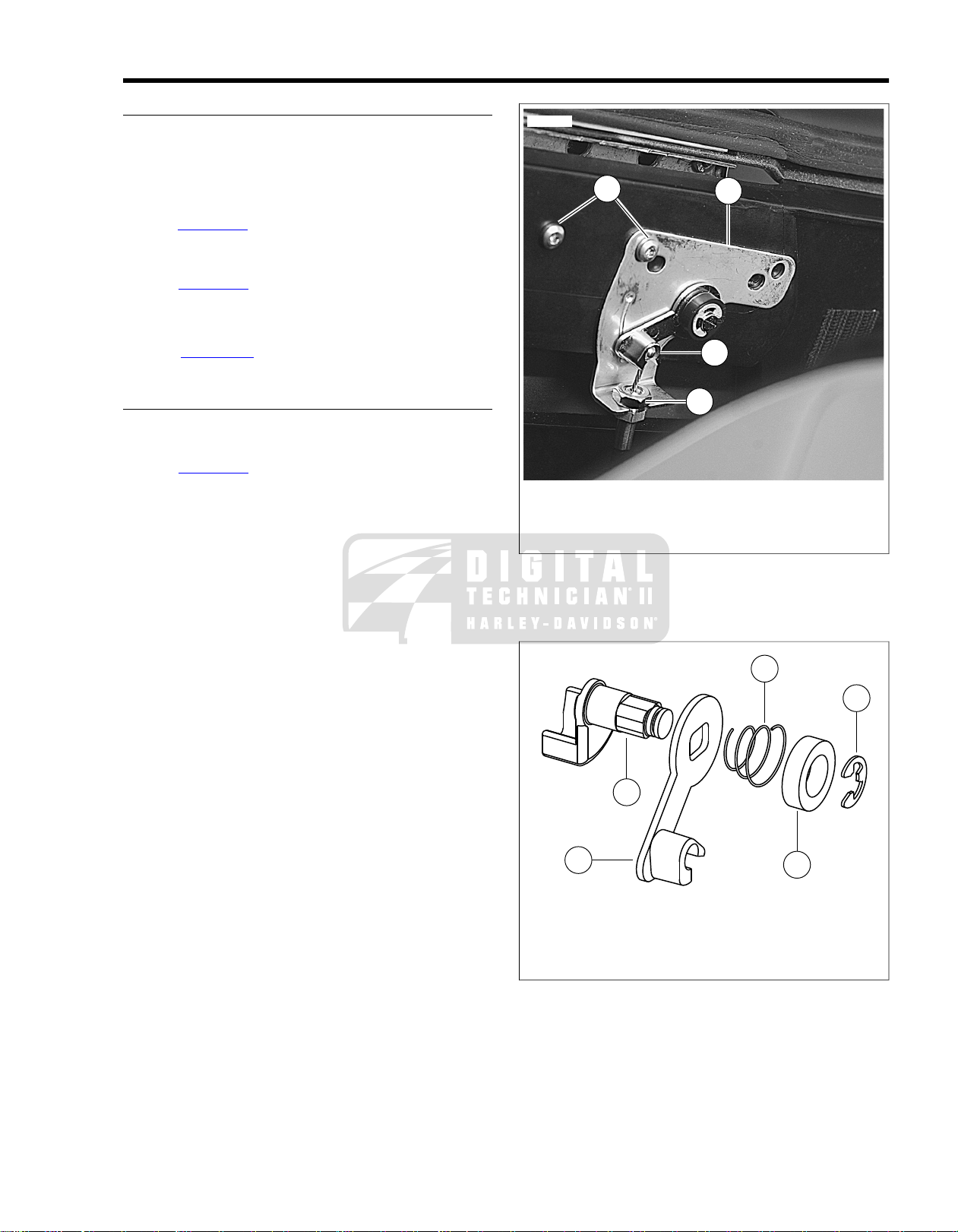

DISASSEMBLY

6

5

4

8

7

11

2

12

3

1

10

9

sm03965

1. See Figure 2-15. Remo ve the end scre w (4) and slide the

chrome housing (5) off the mounting peg (6).

2. Push the rubber pad (7) and the bushing (8) straight out

of the chrome housing.

3. Remove the Allen head screw (9), washer (10) and the

decorative nut (11).

4. Remove the mounting peg and the spring washer (12).

Save the spring washer.

REMOVING CLAMP

1. Remove the Allen head clamp screws (1).

2. Separate the clamp bracket (2) from the mount bracket

(3) to remove the highway peg from the engine guard.

2.4HIGHWAY PEGS

1. Allen head clamp screws

2. Clamp bracket

3. Mount bracket

4. End screw

5. Chrome housing

6. Mounting peg

7. Rubber pad

8. Bushing

9. Allen head screw

10. Washer

11. Nut

12. Spring washer

Figure 2-15. Highway Peg

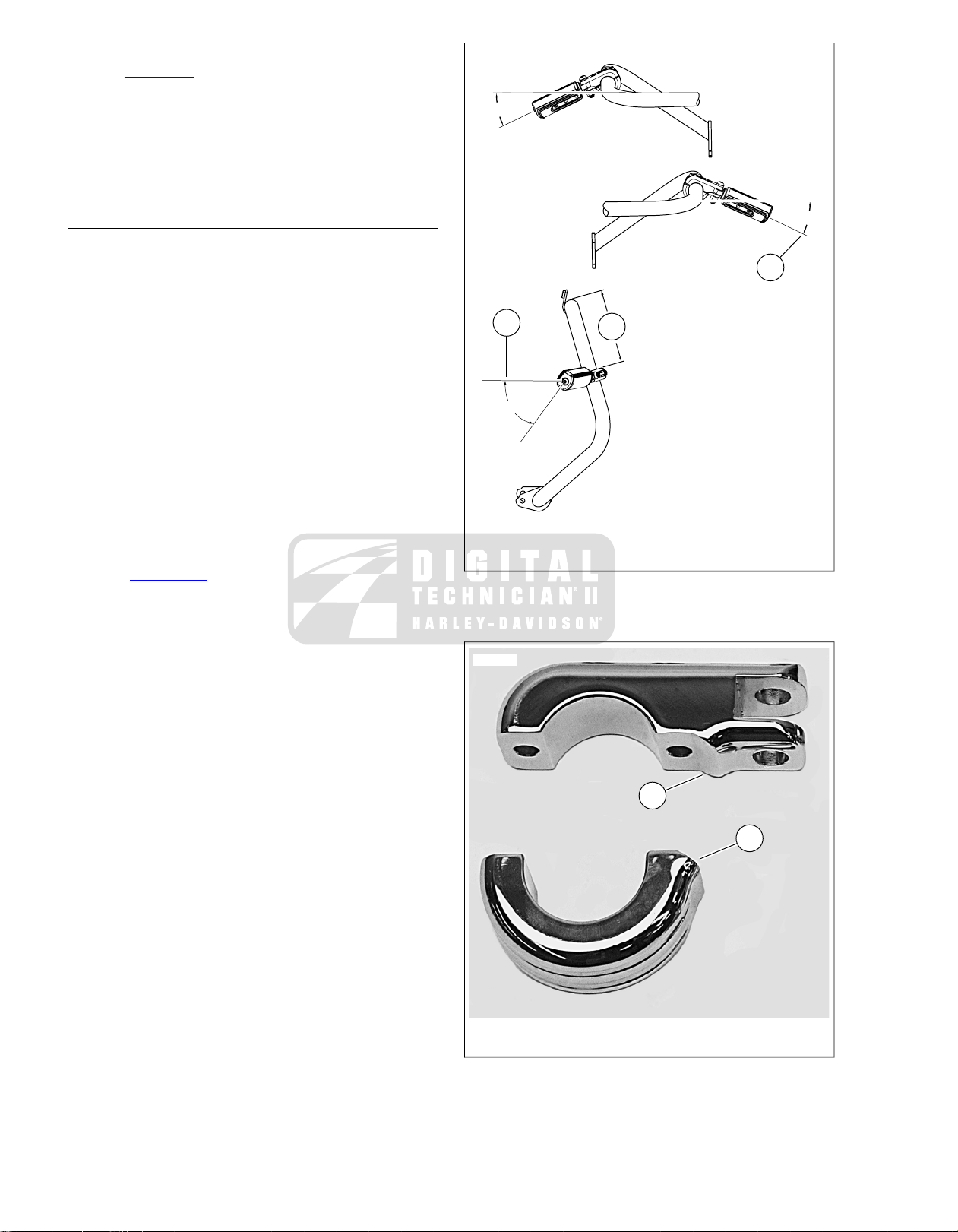

INSTALLING CLAMP

1. See Figure 2-16. Use a grease pencil to draw a line (1)

on engine guard 6.5 in. (165 mm) from top of upper rail.

2. Clamp the brackets to the engine guard just below the line

with the brackets at a 25° (2).

3. Tighten the clamp screws to 14 ft-lbs (19 Nm).

4. Clean off grease pencil mark.

2008 FLHTCUSE3 Service: Chassis 2-9

Page 34

NOTES

25

o

25

o

40

o

2

3

1

sm03966

1

2

sm03967

• See Figure 2-17. Match the flair (1) of the clamp bracket

to the bevel (2) of the mount bracket.

• Orient the highway pegs so that he button head Allen head

screw and the two Allen head bracket fasteners face forward and the decorative nut faces the rider.

• Do not position the highway pegs so that the mounting

brackets contact the fairing lowers.

ASSEMBLY

1. Apply LOCTITE 243 THREADLOCKER (blue) to the end

threads of the Allen head screw.

2. With the square edge of the spring washer facing the slot,

hold the spring washer to the pivot hole of the mounting

peg.

3. Orient the round edge of the pivot flat upward and install

with the Allen head screw , washer and n ut.Tighten to 1419 ft-lbs (19-25 Nm).

4. Slip the bushing into the hole in the rubber pad.

5. Fit the pattern of the rubber pad to the metal tang of the

chrome housing and squeeze the rubber pad and bushing

into the housing.

6. Slide the chrome housing and rubber pad onto the

mounting peg.

7. Apply LOCTITE 243 THREADLOCKER (blue) to the end

screw.

8. See Figure 2-16. For rider posture, rotate footpeg

approximately 40° (3) from horizontal.Tighten end screw

to 19 ft-lbs (26 Nm).

1. 6.5 in. (165 mm)

2. 25°

3. 40°

Figure 2-16. Highway Peg Mounting

2-10 2008 FLHTCUSE3 Service: Chassis

1. Clamp flair

2. Mount bevel

Figure 2-17. Clamp and Mount Brackets

Page 35

REPLACEMENT

sm03968

1. See Figure 2-18. Loosen but do not remove set screw

under cover. Remove cover.

2. Remove set screws from cover.

3. Liberally apply LOCTITE 262 THREADLOCKER (red) to

threads of set screw.

4. Orient cover over axle end so that set screw is on the

bottom and will tighten down against a flat on the axle nut.

5. Install and tighten set screw to 60-84 in-lbs (6.8-9.5 Nm).

6. Repeat for opposite side.

2.5FRONT AXLE COVERS

Figure 2-18. Front Axle Cover Set Screw

2008 FLHTCUSE3 Service: Chassis 2-11

Page 36

REPLACEMENT

1

3

2

5

4

sm03969

1. See Figure 2-19. Loosen b ut do not remove the two scre ws

(1) on the backside of the lower triple clamp cover (3).

2. Remove screw (4) through brake line manifold on bottom

of triple clamp cover.

3. Remove two loosened screws (1) with washers (2) and

remove cover.

4. To replace cover, fit cover inside bottom of nacelle and

around lower triple clamp (5). Hold in place.

5. Install screws (1) and washers (2). Tighten finger-tight

only. Install screw (4) through brake line manifold and

cover. Tighten finger-tight only. Verify that cover is snug

against rear surface of lower triple clamp.

NOTE

Plastic plugs in locator holes in rear surface of triple clamp can

cause interference with cover.Verify that center plug has been

removed.

6. Tighten screws (1) to 70-110 in-lbs (7.9-12.4 Nm).

7. Tighten screw (4) to 120-180 in-lbs (13.6-20.4 Nm).

8. V erify that brak e line does not rub on cover. Adjust line or

cover as necessary.

2.6LOWER TRIPLE CLAMP COVER

1. Screw (2)

2. Washer (2)

3. Lower triple clamp cover

4. Screw

5. Lower triple clamp

Figure 2-19. Lower Triple Clamp Cover

2-12 2008 FLHTCUSE3 Service: Chassis

Page 37

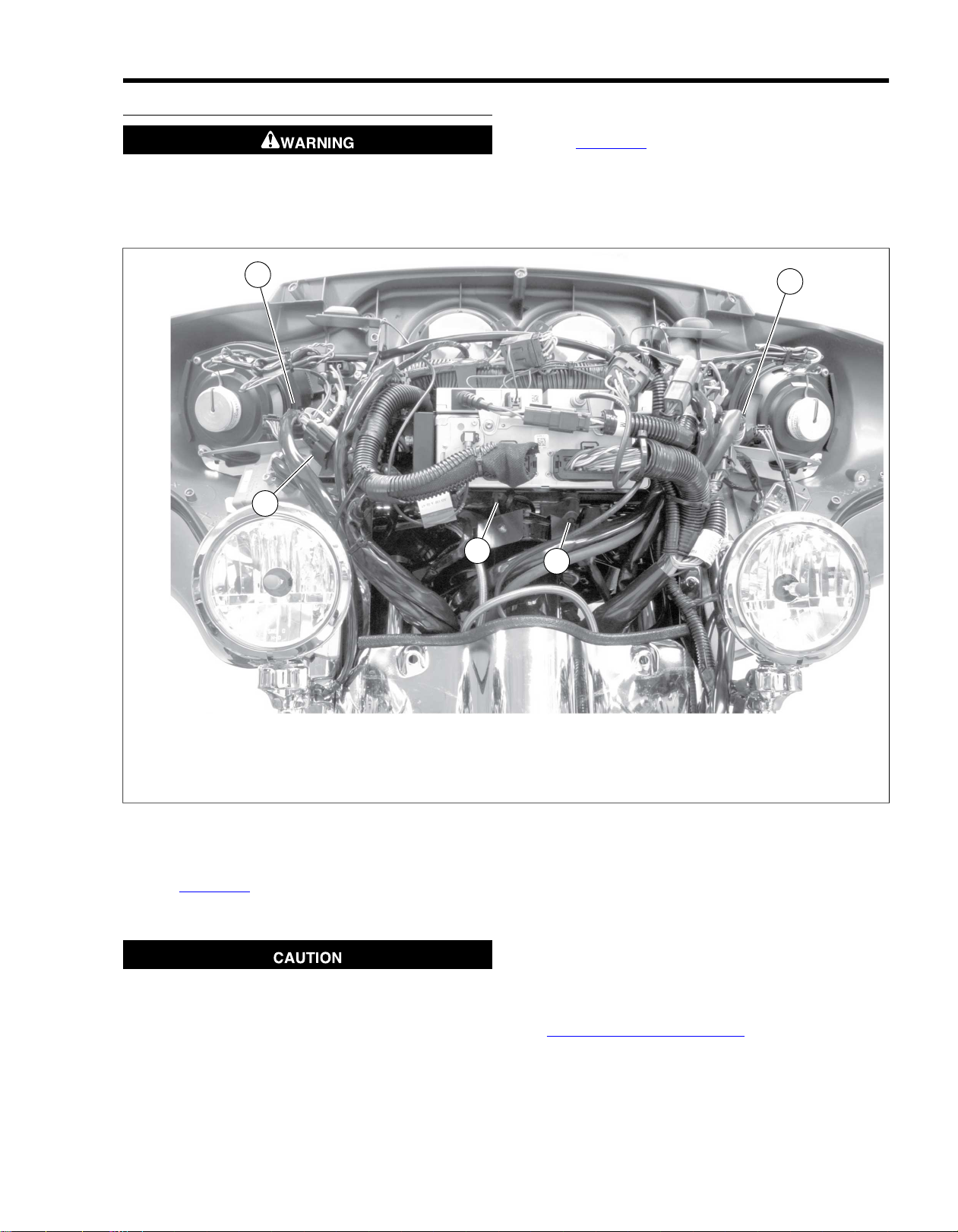

2.7HANDLEBARS

1

5

3

4

2

sm03970

REMOVAL

T o prevent accidental vehic le start-up, whic h could cause

death or serious injury, remove main fuse before proceeding. (00251b)

1. Remove left saddlebag, left side cover and maxi-fuse.

2. Remove outer fairing and fairing cap. See FAIRING CAP

in Touring Models Service Manual.

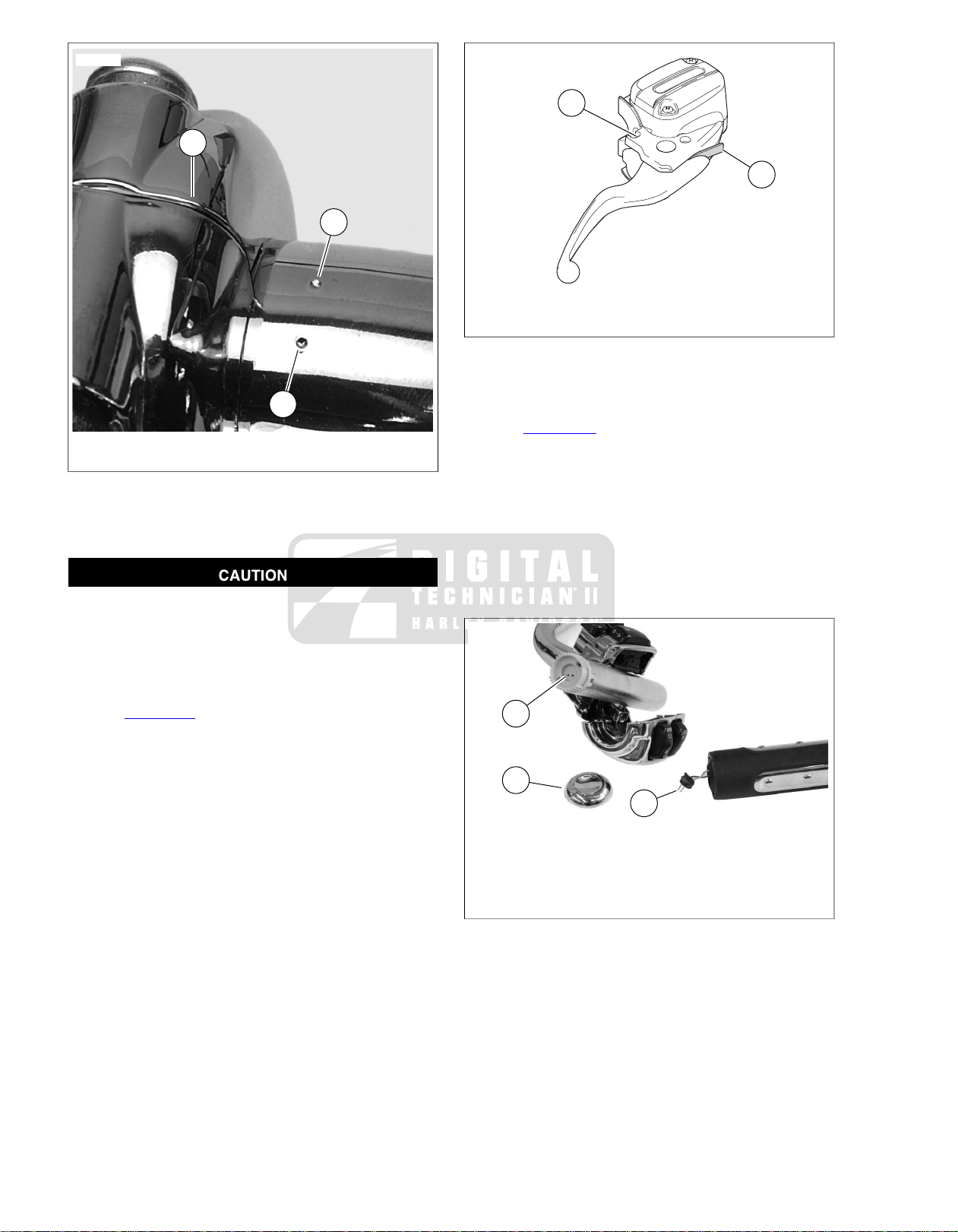

3. See Figure 2-20. Separate handlebar switch connectors

[24] (1) and [22] (2). Separate heated handgrip power

harness connector [189] (3). Disengage connector housings from locating pins. Separate twist grip sensor (TGS)

connector [204] (5).

1. Left handlebar switch connector [24]

2. Right handlebar switch connector [22]

3. Handgrip heater power connector [189]

4. Handgrip heater interconnect [206]

5. Twist grip sensor connector [204]

Figure 2-20. Handlebar Control Connector Locations

4. See Figure 2-21. Squeeze front brake lever and insert a

5/32 in. (4 mm) thick cardboard insert (2) between front

brake lever and lever bracket.

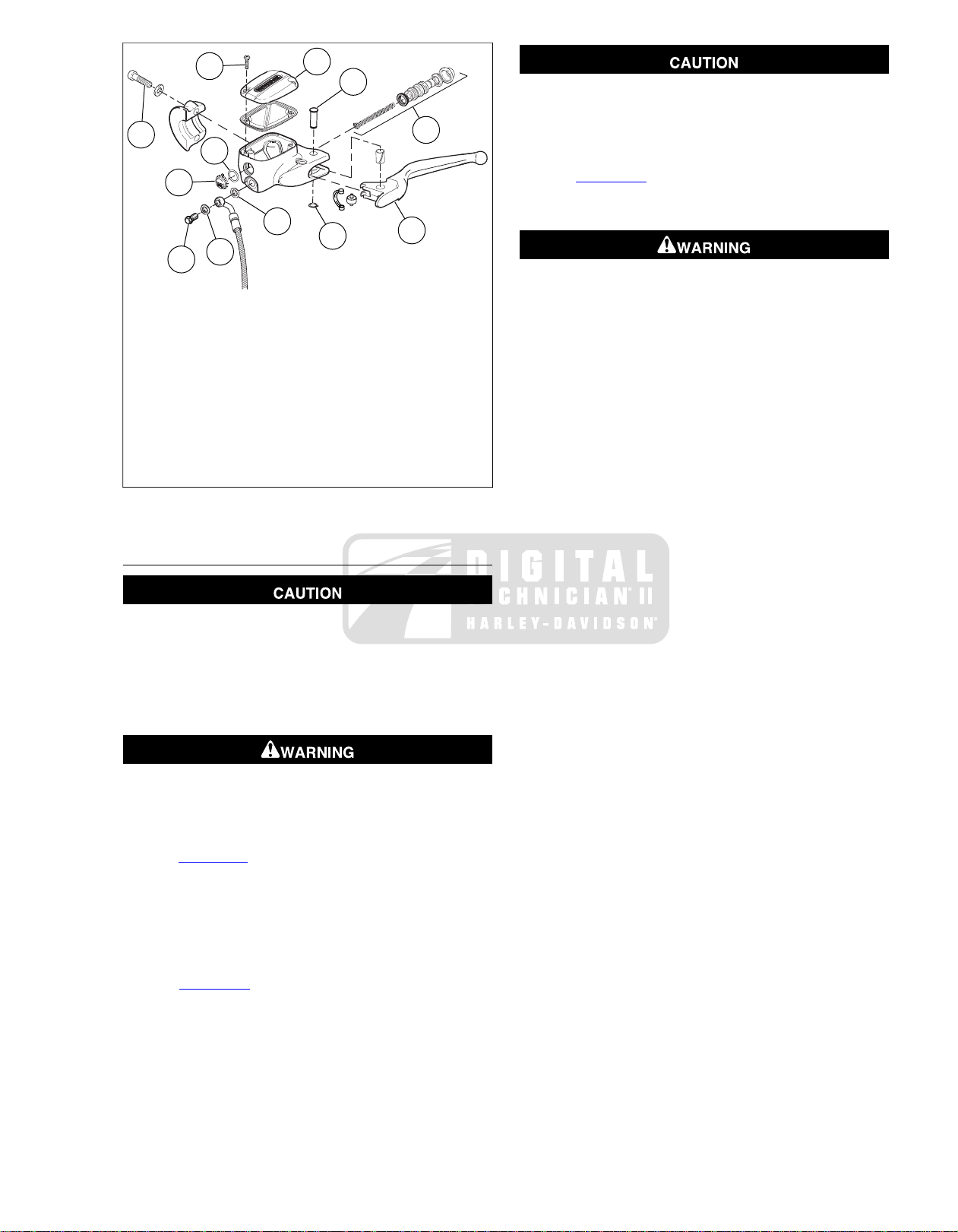

Do not remove or install the master cylinder assembly

without first positioning a 5/32-inch (4 mm) thick insert

between the brake lever and lever bracket. Removing or

installing the master cylinder assembly without the insert

in place may result in damage to the rubber boot and

plunger on the front stoplight switch. (00324a)

5. Remove fasteners securing handlebar clamp to master

cylinder and front brake lever.

6. Protect chrome and painted surfaces and tie master cylinder, reservoir and brake line out of the way.

7. Remove fasteners and w ashers securing handlebar clamp

to clutch lever bracket.

8. Protect chrome and painted surfaces and tie master cylinder, reservoir and clutch fluid line out of the way.

9. Remove Advanced Audio Radio assembly. See

8.13 ADVANCED AUDIO RADIO.

10. Remove upper handlebar clamp and remove handlebar

with wire harnesses from motorcycle.

2008 FLHTCUSE3 Service: Chassis 2-13

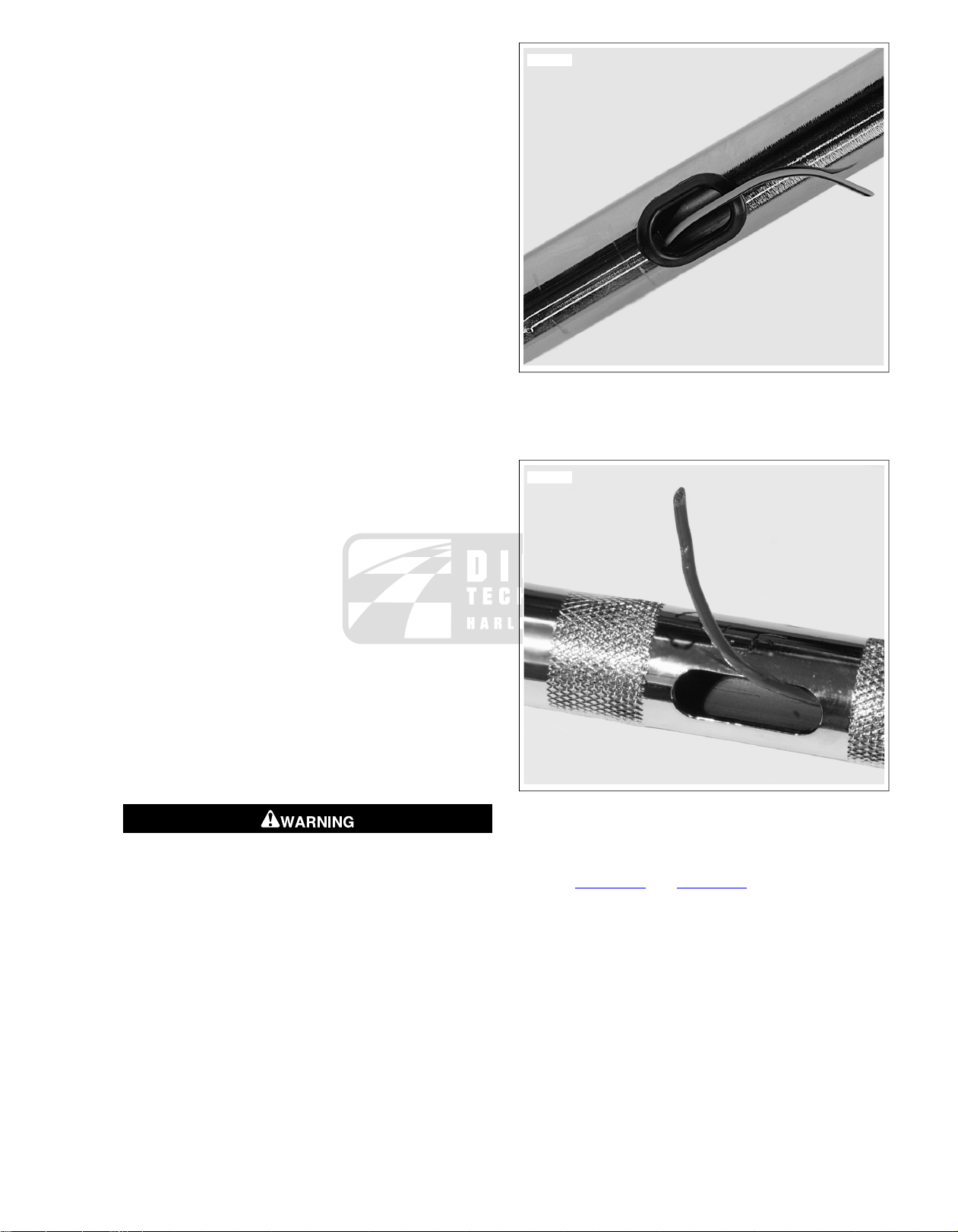

Page 38

NOTE

2

1

sm04667

2

1

3

4

6

5

sm04670

If handlebar rubber mounts require service, see HANDLEBARS

in the Touring Models Service Manual.

1. Groove

2. 5/32 in. (4 mm) thick cardboard insert

Figure 2-21. Cardboard Insert

DISASSEMBLY

NOTE

To release twist grip, a slight tug may be necessary.

9. Pull right grip off end of handlebar.

10. See Figure 2-23. Lightly lubricate conduits and tape with

glass cleaner.

11. Gently pull twist grip sensor (TGS) out of handlebar, along

with the right handgrip heater harness.

12. Gently pull left handgrip out of handlebar, along with left

handgrip heater harness.

13. Pull left and right switch control harnesses through

handlebar.

14. Unwrap electrical tape and wire from terminals.

15. Repair or replace switches and socket wires as necessary.

See HANDLEBAR SWITCHES in Touring Models Service

Manual for handlebar switch repair procedures.

1. Place handlebar assembly on work bench.

2. See Figure 2-22. Cut and discard cable straps.

3. Separate heated handgrip interconnect harness connector

[206] (4).

4. Remove terminals and wire leads from handlebar switch

connectors [22, 24] and twist grip sensor (TGS) connector

[204].

NOTE

See APPENDIX B, MOLEX CONNECTORS in Touring Models

Service Manual for service procedures.

5. Remove terminals and wire leads from heated handgrip

power connector [189] (3) and interconnect harness connector [206] (4).

NOTE

See APPENDIX B DEUTSCH ELECTRICAL CONNECTORS

in Touring Models Service Manual for Service Procedures.

6. Slide boots (2) off switch control wiring harnesses. Save

boots for assembly.

7. Wrap terminal ends of each wiring harness tightly in elec-

trical tape to protect terminals from damage as harness

is removed from handlebar.

NOTES

• Forming too large a bulge with electrical tape at end of

wiring harness can make it difficult to extract harness from

handlebar.

• Option: Attach mechanic's wire to the terminal/wire leads.

After drawing the leads through the handlebar, remove

the tape and leads. Leave the mechanic's wire in the

handlebar for installation.

8. Remove upper and lower f asteners securing left and right

switch control housing halves to handlebar.

1. LH switch control connector [24] (gray)

2. Boot (2)