Page 1

1970

Owner’s Manual

Harley-Davidson Motor

~~

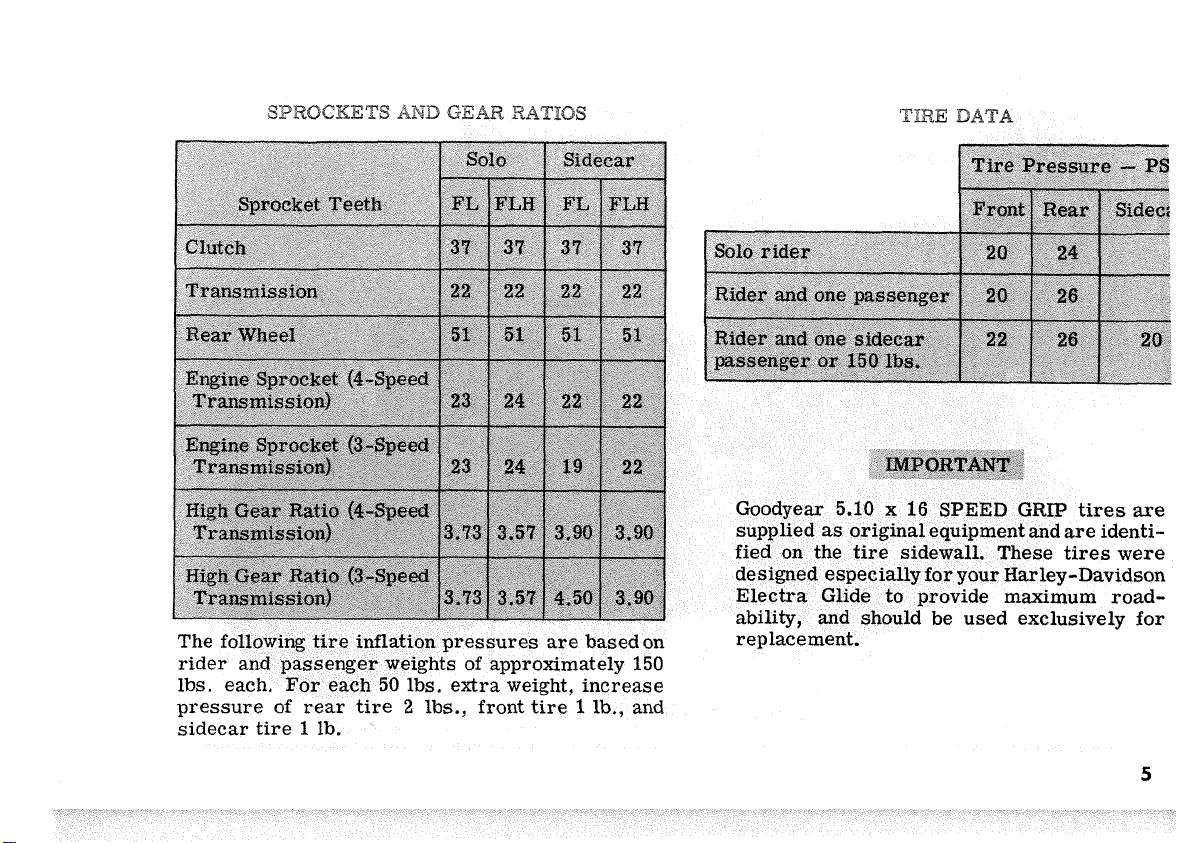

Co.,

Page 2

HARLEY-DAVIDSON

Harley-Davidson products are

manufactured under one or more

of

the following patents:

Patents

2574739, 2770869, 2783927,

2788676, 2872660, 2986162,

2987934, 2998809, 3116089,

3144631, 3144860, 3226994,

3229792.

487981, 490652.

-

D-199,479,2510222,

Canadian Patents

U.

1

S.

-

Page 3

YO

Welcome to the Harley-Davidson Motorcycling Family! Your new Harley-Davidson Electra-Glide motorcycle is designed

and manufactured to

understandable guide for your motorcycle's operation and care. Follow the instructions carefully for its maximum per-

formance and your personal motorcycling pleasure.

Your owner's manual contains instructions for owner care and maintenance of

of major units such

quires the attention of

facilities, experience and genuine Harley-Davidson parts necessary

'S

AL

be

the finest in its field. The instructions in this book have been prepared to provide a simple and

as

engine, transmission, etc.

a

skilled mechanic and the

a

is

provided in the Harley-Davidson Service Manual. Work of this kind re-

use

of special tools and equipment. Your Harley-Davidson dealer has the

to

properly render this valuable service.

1970

Owner's Manual

minor nature. Information covering repair

OF

TABLE

MOTORCYCLE SAFETY

SAFEGUARD MAINTENANCE

SPECIFICATIONS

CONTROLS

RIDING

CONTENTS

Section Page

.............

...................

.........................

...........................

.........

15

Harley-Davidson Motor

Subsidiary

2

SERVICE AND MAINTENANCE

3

4

9

of

American Machine & Foundry

ENGINE

TRANSMISSION

CHASSIS

ELECTRICAL

.......................

........................

Co.,

lnc.

Co.

Section Page

.......

.................

...................

21

24

27

29

52

Page 4

Harley-Davidson motorcycles are designed

and built according to our

all

standards and

Vehicle Safety Standards.

applicable Federal Motor

own

rigid safety

2

Because of

inherently one of the safest vehicles designed for use on the highway. However, any

vehicle can only be

skill

and judgement.

It must be remembered

that being a two-wheeled vehicle, it requires different

from those needed to safely operate a four-wheeled vehicle.

We urge that you consult your Harley Davidson dealer who can

cycle traffic

to your riding requirements, and who can provide literature or training in the safe operation of your motorcycle.

its

acceleration, maneuverability and ease of handling, the motorcycle

as

safe

as

the person who operates

-

especially by those not familiar

laws

in your area, who has the necessary clothing, helmet, etc. best suited

it

and depends primarily upon

with

motorcycle operation

skills

and operating procedures

advise

you about the motor-

is

-

Page 5

In

addition to this owner's manual, a Safeguard Main-

is

tenance booklet

owner. The booklet contains your new motorcycle

Warranty, a Warranty Registration card, and

ber of tear-out service coupons.

The approved service and maintenance procedures on each

coupon and the mileage intervals have been worked out by

Harley-Davidson service personnel,

are the owner's responsibility to have taken care

provided each new Harley-Davidson

a

num-

and

cover items which

of.

Bring the coupon booklet along when you vi

mileages to have your motorcycle ins

Dealer charges for "Safeguard Maintenance" are nominal

with long, trouble-free service and

Harley -Davidson product.

Tools for owner use,

service and minor repairs,

can be purchased from your Harley-Davidson dealer.

will

protect your investment

as

recommended in this handbook for

are

supplied in a tool kit which

it

your dealer at the specified

1

ected and serviced properly.

-

you

will

in

be repaid

a

quality

3

Page 6

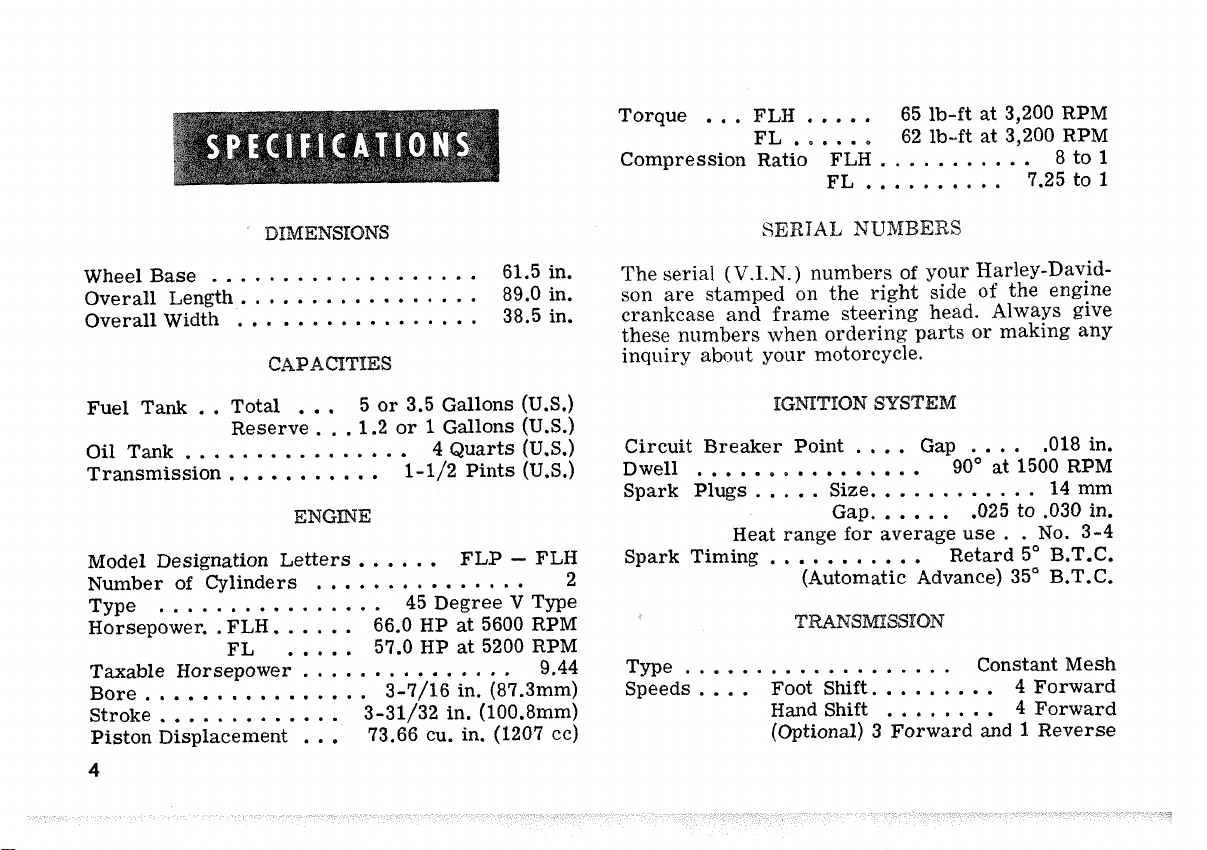

Torque

Compression Ratio FLH

...

FLH

FL

......

.....

FL

65

lb-ft

at 3,200 RPM

62 lb-ft at 3,200 RPM

...........

..........

7.25

8 to

to

1

1

Wheel Base

Overall Length.

Overall Width

Fuel Tank

Oil Tank

Transmission

Model Designation Letters.

Number of Cylinders

Type

Horsepower.

Taxable Horsepower

................

Bore

Stroke

Piston Displacement

4

...................

................

.................

..

Total

Reserve.

...

..

................

...........

...............

................

.

FLH.

FL

.....

.....

...............

.............

...

61.5 in.

89.0 in.

38.5 in.

5 or 3.5 Gallons

1.2

or 1 Gallons

4 Quarts

1-1/2 Pints

E

.....

66.0

57.0

3-7/16 in.

3-31/32 in.

73.66 cu. in. (1207 cc)

FLP

45 Degree V Type

HP

at

HP

at

(US)

(U.S.)

(U.S.)

(U.S.)

-

FLH

5600 RPM

5200 RPM

9.44

(87.3mm)

(100.8mm)

SERIAL

The serial

son are stamped

crankcase and frame steering head. Always give

these numbers when ordering parts or making any

inquiry about your motorcycle.

Circuit Breaker Point

Dwell

Spark Plugs..

Spark Timing

2

Type

Speeds

(V.I.N.)

................

...

Heat range for average use

...........

T

...................

....

Foot Shift.

Hand Shift

(Optional) 3 Forward

NU

numbers of your Harley-David-

on

the right side

ION

SYS

....

Size..

Gap.

.....

(Automatic Advance) 35" B.T.C.

S

of

Gap

....

90"

at

..........

,025 to .030 in.

Retard 5" B.T.C.

Constant Mesh

........

........

and

the engine

,018 in.

1500 RPM

14 mm

. .

No.

3-4

4 Forward

4

Forward

1

Reverse

Page 7

s

Page 8

Tail

1.

2.

3.

4.

5.

6.

7.

Lamp

Oil

Filter

Carburetor Air Cleaner

Hydrau

I

ic

Fork

Safety Guard

Brake

Master Cylinder

8.

Ignition Circuit Breaker Cover

9.

Oil

Pump and Pressure Switch

10.

Starter Motor and Relay

11.

Transmission

12.

Battery

13.

Hydraulic Shock Absorber

Oil

Filler

Plug

FIGURE

1.

RIGHT

SIDE

VIEW

Page 9

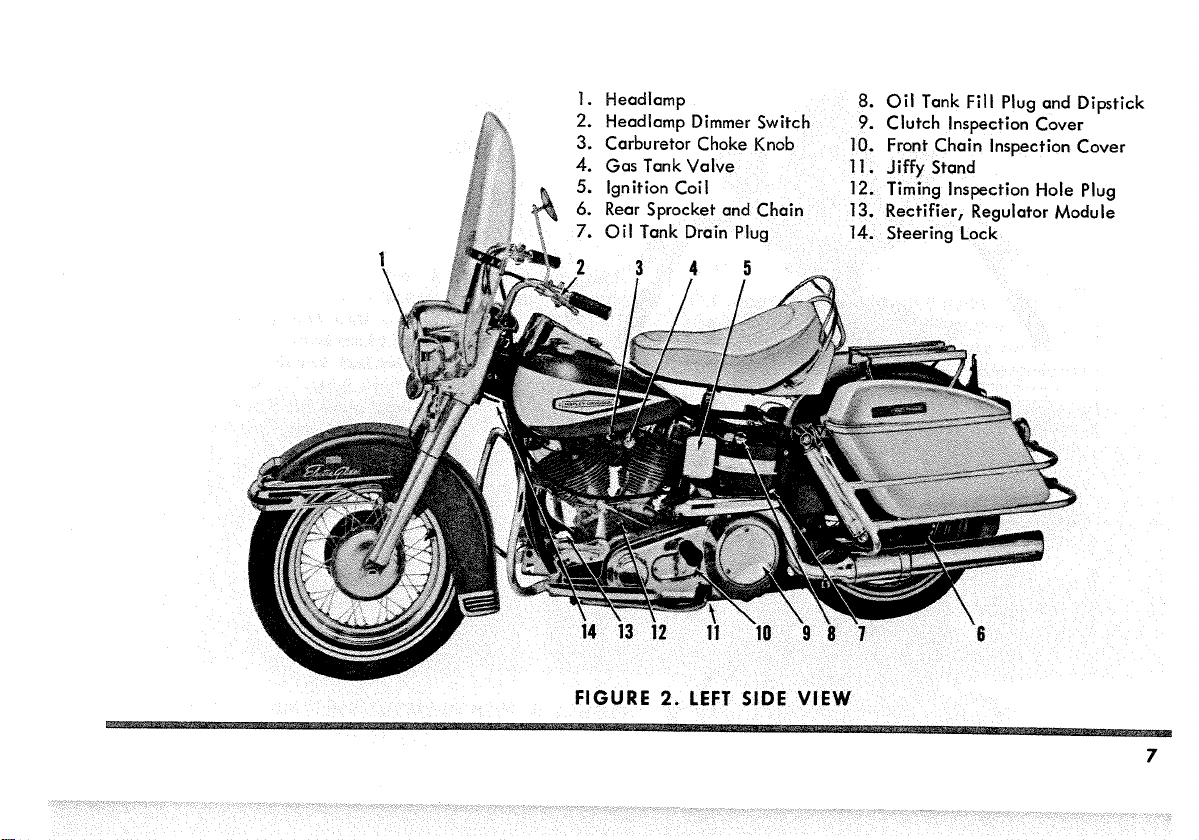

3.

Carburetor

4.

Gas

C

TankVa

7

Page 10

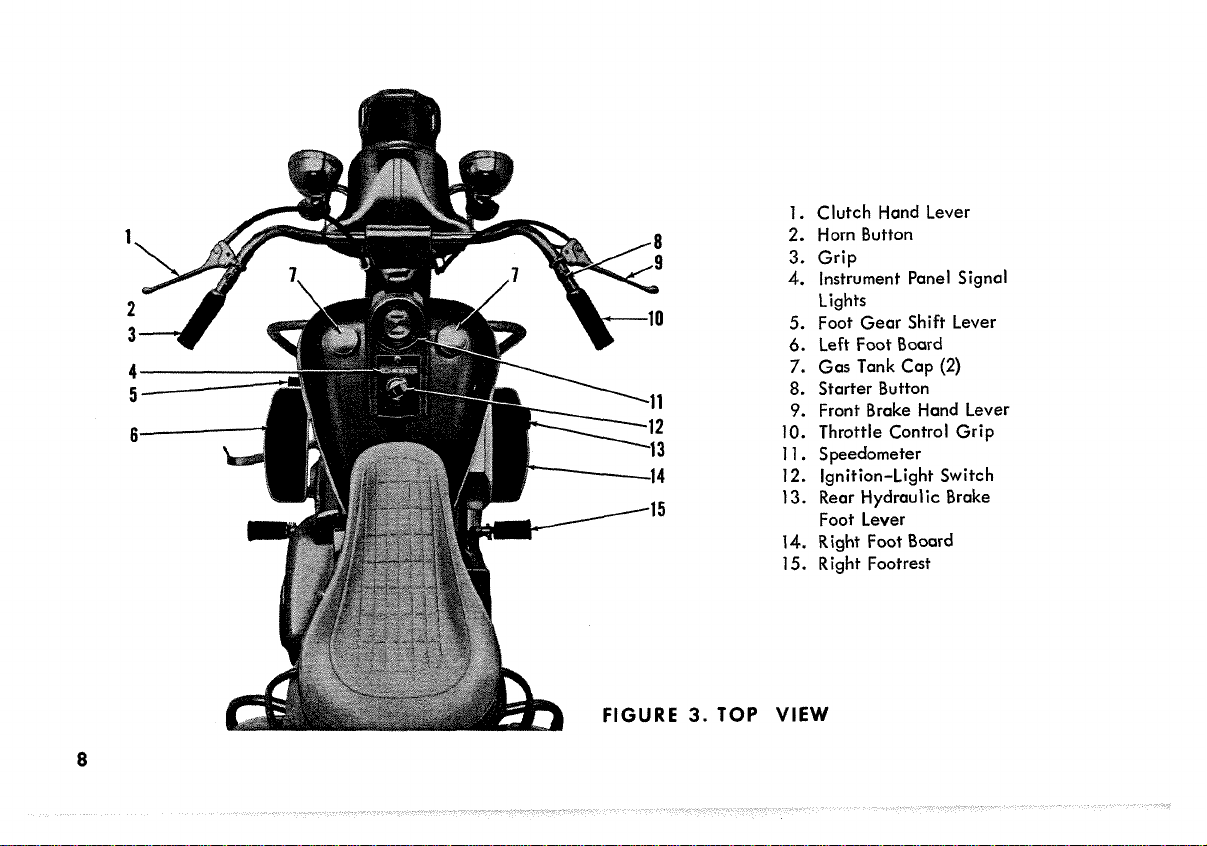

1,

2

3

1.

Clutch Hand Lever

2.

Horn Button

3.

Grip

4.

Instrument Panel Signal

Lights

5.

Foot Gear Shift Lever

6.

Left Foot Board

7.

Gas Tank Cap

8.

Starter Button

9.

Front Brake Hand Lever

10.

Throttle Control Grip

11.

Speedometer

12.

Ignition-Light Switch

13.

Rear Hydraulic Brake

Foot Lever

14.

Right Foot Board

15.

Right Footrest

(2)

8

E

3.

TOP

VIEW

Page 11

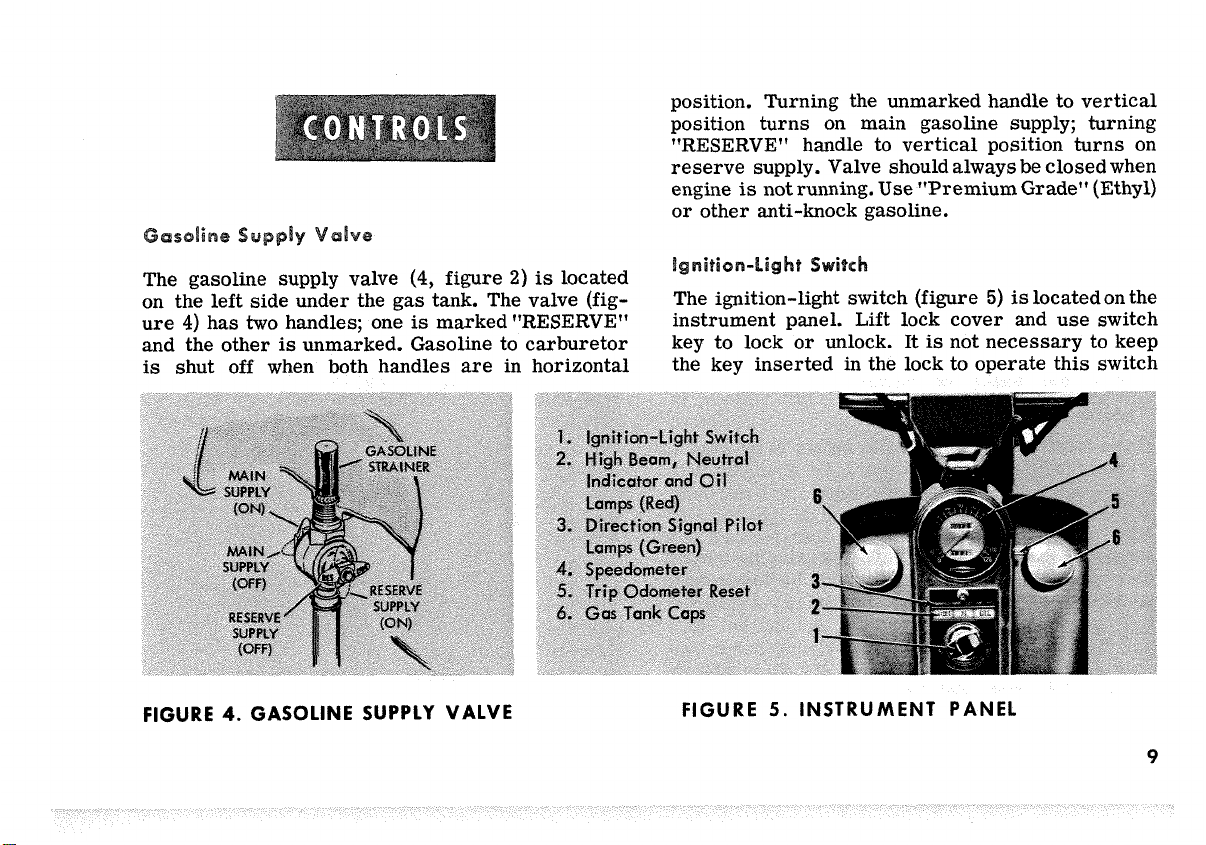

position. Turning the unmarked handle to vertical

position turns on main gasoline supply; turning

"RESERVE" handle to vertical position turns on

reserve supply. Valve should always be closed when

is

engine

or

other anti-knock gasoline.

not running.

Use

"Premium Grade" (Ethyl)

The gasoline supply valve

left

on the

ure

4)

and the other

is

shut off when both handles are in horizontal

FIGURE

side under the gas tank. The valve (fig-

has

two

handles; one

is

unmarked. Gasoline to carburetor

4.

GASOLINE SUPPLY VALVE

(4,

figure

is

marked "RESERVE"

2)

is

located

..

~~~~

itc

The ignition-light switch (figure

instrument panel.

key to lock

or

the key inserted

FIGURE

5.

Lift lock cover and use switch

unlock.

INSTRUMENT PANEL

It

is

not necessary to keep

in

the lock to operate this switch

5)

is

locatedon the

9

Page 12

after

it

has been unlocked. The center position of

the switch

is

the off position for both lights and

ignition. The right (counter-clockwise) of center

position

(clockwise) position

second

The switch can be locked only in the

is

for parking lights only; the

is

for ignition only and the

left

position, for ignition and running lights.

off

and the park

first

left

positions. Remember that lighting the headlamp

is

when the engine

on. The headlamp upper and lower beams

trolled by

a

handlebar. High beam indicator lamp (figure

cates upper beam. Make

that

it

can easily be replaced in case of loss.

Throttle Control Grip

Turn throttle control grip

close throttle; turn

not running also turns the ignition

toggle switch

(2,

figure

a

record of key number

(10,

figure

it

inward to open throttle.

2)

3)

are

con-

on the left

5)

indi-

so

outward to

Clutch

The clutch foot pedal

where

foot. The clutch

Foot

Pedal

is

located on the

it

may be conveniently operated by the

is

engaged when the toe

and released when the heel

Hand

Gear Shift lever

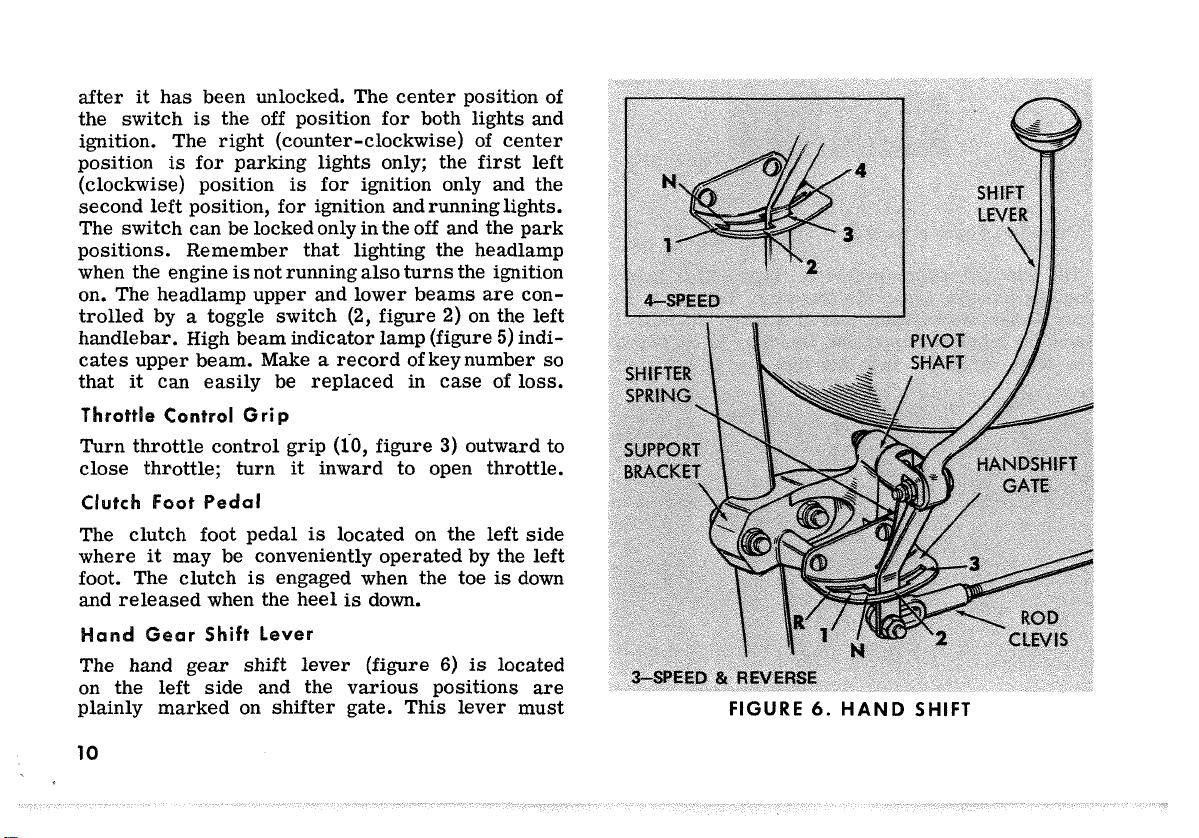

The hand gear shift lever

on the

plainly marked

10

left

side and the various positions are

on

shifter gate. This lever must

is

down.

(figure

6)

left

is

is

side

left

down

located

FIGURE

6.

HAND

SHIFT

Page 13

be

at

neutral

(N)

and the clutch engaged when starting the engine. FULLY RELEASE THE CLUTCH

BEFORE SHIFTING. To shift gears, move upper

or

end of lever forward

rearward. This moves

lower portion of lever in opposite direction against

are

stops in gate where gear positions

VBfC

The clutch hand lever

the left handle bar where

(1,

figure

it

3)

can be conveniently

operated with the left hand. The clutch

marked.

is

located on

is

released

by squeezing the control lever toward the handle

bar. The clutch

control lever to

The foot gear

the

on

left

operated by

the

way down (full stroke)

into the next lower gear;

is

engaged by slowly releasing the

its

extended position.

shift

lever

side where

the

left foot. Pushing foot lever

(5,

figure

it

may be conveniently

shifts

transmission

lifting foot lever

3)

is

located

all

all

the

way up [full stroke) shifts transmission into the

next higher gear. The operator must release foot

it

lever after each gear change to allow

to

its

central position before another gear change

or

can be attempted

Neutral position

gears, and

is

indicated by center light (figure

made.

is

between

first

(low) and second

the instrument panel when ignition-light switch

turned on. First gear

is

the

last

to return

5)

on

is

gear position

obtained by pushing foot lever full strokes down-

ward.

foot lever one

To shift from

half

first

gear to neutral,

of its full stroke. The

lift

shift

to neutral can also be made from second gear

half

its

by pushing foot lever downward one

full

stroke.

With

the motorcycle standing

not running,

it usually

will

the motorcycle backward

clutch fully disengaged while maintaining

the

foot

pressure on

shift

still

and the engine

be necessary to move

or

forward with the

a

slight

lever before

a

shift

from one gear to +other can be made. Even

with

the engine running, clutch disengaged and

it

the motorcycle standing still,

shift

to

gears because transmission gears are

may be difficult

not turning and shifting parts are not lined up

to permit engagement. When this happens, do not

11

Page 14

under any circumstances force the shift by t'roughing" the foot lever; the results of such abuse

will

be

a

damaged or broken shift mechanism.

as

Either roll the motorcycle

if

or,

the engine

is

running, engage the clutch

indicated above

very slightly and at the same time apply light

pressure to the foot lever to make the shift.

Both these procedures

set

the transmission gears

in motion and permit the shift to be made easily.

r

The starter button

right handlebar. With ignition

(8,

figure

3)

is

located on the

ON

and transmission

in neutral, push button to operate starting motor.

ci

S

The brake foot pedal

hand side operates the

while a convenient hand lever

the front wheel mechanical

The steering lock

left

side of the lower front fork bracket. Turning

left

fork to the

steering head.

aligns hole in bracket with hole in

A

(13,

(14,

figure

rear

wheel hydraulic brake

brake.

figure

(9,

2)

3)

on the right

figure

is

located

3)

padlock can be used to lock the

fork in this position.

12

operates

on

the

Steering damper

head. Turn steering damper adjusting

is

located directly over steering

knob

clockwise to apply dampening action and counterclockwise to reduce dampening action.

For

solo riding,

apply steering damper only when operating under

conditions where some degree of dampening stabi-

lizes

tageous to keep the damper set

steering. Sidecar users will find

a

little

it

advan-

snug at

all times.

The horn

3)

on the

is

operated by the horn button

left

handlebar. Tone can be set

(2,

as

desired

figure

by turning the adjusting screw back of horn.

Page 15

655

The oil pressure signal light

strument panel (figure

Light

will

go on when the ignition-light switch

5)

is

located on the in-

and

is

marked

OIL.

is

turned on before starting the engine. After the engine has started, light should go off except

it

may

flicker on and off at very slow idling speeds.

turns to the

tank,

stop the engine at once and do

not drive farther until the trouble

and the necessary repairs

are

QP

made.

is

located

A

the oil.

y

signal switch,

ck the oil supply

if

oil supply

is

normal and the light

not go out, lo oil tank and see

the oil return from the outlet

the oil return e engine

If

it

is

returnin there

grounded

first,

still

is

running.

is

some circu-

or

Then,

does

if

of

lation, and you may drive slowly to the nearest

Harley-Davidson dealer to have the oiling system

as

checked and serviced,

needed.

If

no oil re-

This type fork

for sidecar service. The forks are pivoted

is

used on motorcycles intended

so

that

the wheel can be adjusted forward for less trail

or

(in sidecar service),

justed rearward for more

this

Normally,

as

shipped from the factory, and must be read-

fork

justed for sidecar service

1.

Raise

is

is

with

front end of motorcycle

free. Underneath fork head lower bracket

a

large bolt with castellated nut locked

a

cotter pin. This bolt fastens lower

the wheel can be ad-

trail

(in solo service).

is

adjusted for solo service

as

follows:

so

front wheel

fork bracket to fork stem bracket which has

a slotted hole for the bolt. Remove cotter

far

pin from nut and back off nut

so

that

lock plates underneath bolt head and

enough

bolt nut can be disengaged from slots in

each side of fork bracket. Now grasp front

13

Page 16

wheel and pull fork sides forward

as

far

as

elongated holes in bracket will permit. Reengage lock plates in elongated holes with

plate engaging to the front. Securely tighten

nut and insert cotter pin.

2.

Re-aim headlamp after fork

(See page

3.

For solo service, when sidecar

52.)

is

readjusted.

is

removed,

move fork back by reversing above procedure.

t

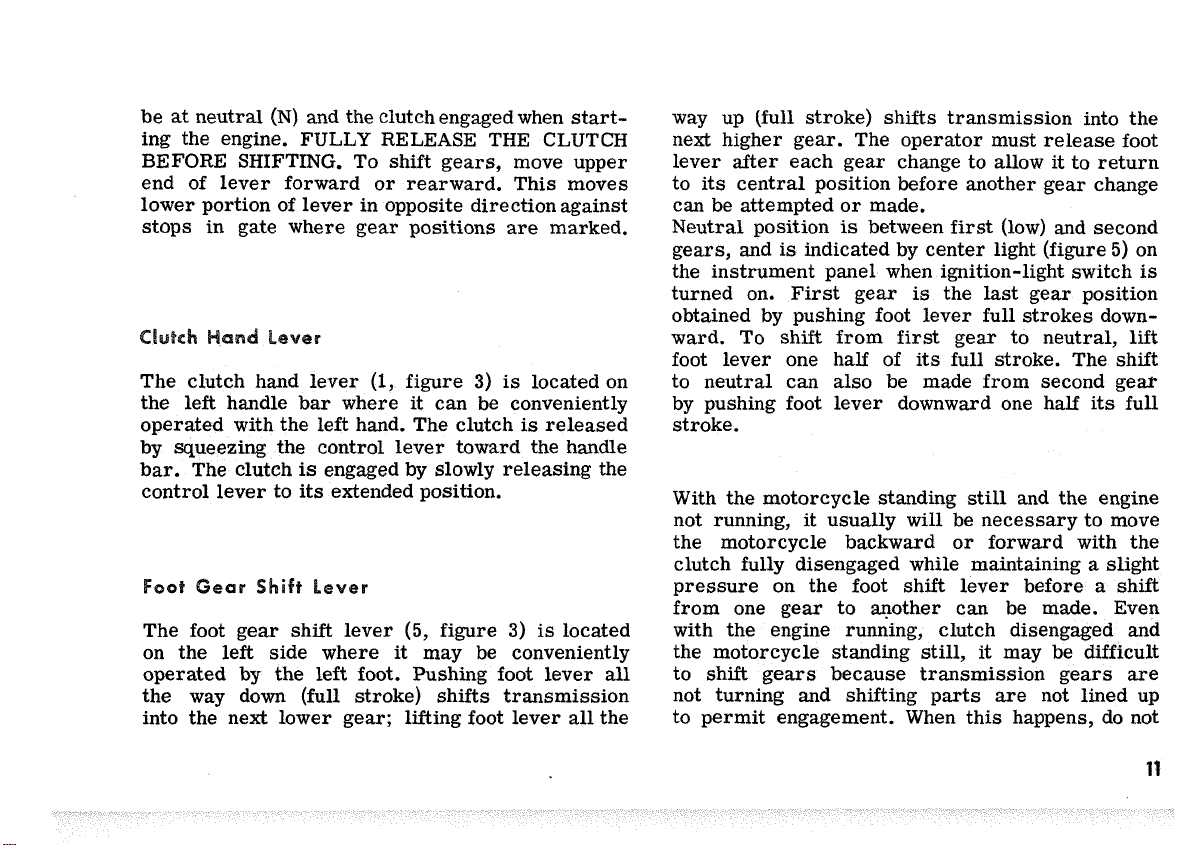

The rear shock absorber springs can be adjusted

ta

three positions for the weight the motorcycle

is

to carry. The average weight solo

use the extended spring position

(off

rider

cam).

would

A

heavy solo rider might require the position with

springs slightly compressed (first cam step);

seat

buddy

riders require the fully compressed

spring position (second cam step).

To

adjust the rear shock absorber springs, turn

cam

cushion spring adjusting

(figure

7)

to desired

position with spanner wrench. Both cushion spring

adjusting cams must be adjusted to the same

position. When returning to off cam position, cams

A

should be backed off in opposite direction.

is

ner wrench for this purpose

available from

span-

your Harley-DaTidson dealer.

EAR

SHOCK

SPRING ADJUSTMENT

ABSORBER

14

Page 17

IMPORTANT

If

you are not familiar with operating the

motorcycle, read paragraphs on "SAFETY"

(page

2)

and

"CONTROLS"

(page

9)

before

riding this motorcycle.

irst

5

es

The sound design, quality materials, and workman-

that

is

ship

will

give you high performance rightfromthe

However, for the

built into your new Harley-Davidson

start.

first

few hundered miles, to wear-

in critical parts, observe the few simple driving

will

rules below. This

guarantee future performance

and durability.

1.

During the

45

miles per hour.

2.

Up to

first

50

miles, keep the speedbelow

500

miles, vary the speed, avoiding any

steady speed for long distances. Any speed up

to the maximum legal limit

is

permissible

for short distances.

3.

Avoid

fast

starts

at

wide open throttle and

over-speeding engine in lower gears. Drive

slowly until engine warms up.

ing

lns~ruct~~ns

IMPORTANT

Use recommen ation to predominating temperatures. See engine lubrication, page

24.

When starting the engine determine thatthe motor-

cycle

is

in neutral and

that

the clutch

is

fully

engaged.

is

The carburetor choke control knob

the

left

side

under the gas tankon

To

start a cold engine, move the knob outward to

of the motorcycle.

located just

15

Page 18

the fully closed (choke) position; with throttle

to

1/4

open, turn ignition switch on and operate

the

starter.

To

start

a

warm

or

hot engine move choke knob out-

1/2

ward to

turn on ignition switch and operate the

soon

as

enough to keep

ready to

warms up and misfires, because of the over-rich

mixture, gradually open choke by moving choke knob

inward.

choke knob should be all the way in.

When the engine does not

revolutions

but engine does not

cause ,of an over-rich (flooded) condition.

This

the engine

turn ignition on and operate

choke and throttle wide open.

closed position,

the engine

set

the motorcycle in motion.

After

the engine has thoroughly warmedup,

is

especially true of a hot engine.

is

starts,

it

running while warming up

or

if

one cylinder

flooded, open choke

set

throttle

open throttle just

As

start

after afew

fires

start,

it

is

usually be-

all

starter

starter.

the engine

weakly

the way,

1/4

or

1/8

open,

As

far

until

If

with

Start the engine, fully release the clutch, shift

into

first

desired speed

the clutch,

shift into second and again engage clutch. Shift

in like manner for third and fourth gears.

DO

NOT SHIFT GEARS WITHOUT FULLY DIS-

ENGAGING THE CLUTCH.

When the motorcycle

is

shift from "third" to "second" until speed

is

from "second" to

duced to below

gears when speeds

in

Stopping the Engine

and slowly engage the clutch.

is

attained in

lift

the foot lever

desired to shift to lower gears, do not

reduced to

20

mph

"first"

10

damage to the transmission.

first,

fully disengage

all

the way up to

is

in motion and it

or

less;

do

not shift

until speed

mph. Shifting to lower

are

too high may result

is

re-

After

Operation

With motorcycle standing (engine stopped) proceed

as

follows to get under way. Determine that trans-

is

mission

16

in neutral and clutch

is

fully engaged.

Stop the engine by turning off the ignition switch.

If

the engine should be stalled

other way than with the switch, turn off the switch

at

once to prevent battery discharge through the

circuit breaker points.

or

stopped in any

Page 19

5

To prevent possible vapor lock with a hot engine

start

in very warm weather,

and leave

richer mixture and cool carburetor. Develop the

habit

instant when running

additional lubrication to pistons and cylinders and

helps cooling.

Do not idle engine unnecessarily with motorcycle

standing.

is

thoroughly warmed up to avoid possible damage

to pistons, rings, and other parts before oil

enough to circulate freely.

An

speed, particularly in sidecar service, must be

given closer than ordinary attention to avoid over-

heating and possible consequent damage. Have the

engine checked regularly and keep

Valve seating and good compression

larly important. The carburetor intermediate speed

needle should be adjusted moderately rich rather

than lean.

suit type of service. This applies particularly to

motorcycle equipped with windshield and splash

shields-or lap apron.

at

half choke for a few blocks to provide

of

frequently snapping the throttle shut for

at

In

cold weather

engine which has run long distances

Use

correct heat range spark plugs to

engine

high speed. This draws

run

engine slowly until

at

half choke

is

at

it

well tuned.

are

particu-

an

it

warm

high

The spark plugs originally installed in the engine

are of the proper heat range for most normal operating conditions. However, more severe than average

or

service

plug

of

in the case of very severe

case

When plugs need to be replaced, get them from

your Harley-Davidson dealer. He can supply you

with the type of plug

ments. Experimenting with plugs of unproven quality

and suitability

loc~ting Operating Troubles

The following check

their probable causes will be helpful in keeping

your motorcycle in good operating condition. Remember that more than one of these conditions

may be causing the trouble and

carefully checked.

df

engine

1.

Spark plugs in bad condition

a

gap

2.

Circuit breaker points out of adiustment

need

very light service may call for a spark

adifferent heat range to prevent overheating,

of very light service.

best

is

inviting trouble.

list

starts

hard

or

runs unevenly

service

suited to your require-

of

operating troubles and

orfouling in the

all

or

have improper

-

of

cleaning.

should

or

misses:

or

be

in

17

Page 20

Condenser connection loose.

3.

Battery nearly discharged.

4.

Loose wire connection

5.

at

minals or

Water or dirt

6.

Gasline tank cap vent plugged

7,

vent line closed

Carburetor not adjusted correctly.

a.

Engine and transmission oil too heavy (winter

9.

operation).

df

cranking motor does not operate:

1.

Ignition switch

2.

Starter button or relay defective.

3.

Discharged battery, or loose or corroded cable

connections (solenoid chatters).

4.

Starter control circuit wiring defective.

/

dIf

engine turns over but does not

Gasoline tank empty, valve shut off or gaso-

1.

line line clogged.

Fouled spark plugs or shorted spark plug

2.

wires.

Circuit breaker points

3.

Loose wire connection at coil or circuit

4.

breaker

coil or circuit breaker.

in

fuel system and carburetor.

off

is

not on.

.

at

one of battery ter-

or

carburetor

restricting fuel flow.

start:

badly

out

of

adjustment.

5.

Sticking valves or tappets set too tight.

.

Engine flooded

a

spark plug fouls repeatedly:

1.

Too

cold a plug for the kind of service.

2.

Piston rings badly worn or

engine pre-ignites:

1.

Excessive carbon on piston head or in com-

bustion chamber.

2.

Too

hot a spark plug for the kind of service.

3.

Defective spark piugs.

/

If engine overheats:

1.

Insufficient oil supply or oil not circulating.

2.

Carburetor high speed adjustment too lean.

3.

Ignition timing too late,

df

engine detonates:

1.

Unsuitable fuel (octane rating too low).

2.

Heavy deposit of carbon on piston and in com-

bustion chamber.

3.

Defective spark plug or of wrong heat range.

4.

Ignition timing too early.

f

oil does not return to oil tank:

1.

Oil tank empty.

2.

Oil pump not functioning.

as

a

result of overchoking.

in

bad condition.

18

Page 21

engine uses too much oil:

1.

Piston rings badly worn

2.

One

or

more push rod cover cork washers in

bad condition

properly against

3.

Rear chain oiler setfor excessive amount of oil.

vibration

.

Cylinder bracket loose

2.

Engine mounting bolts loose.

3.

Transmission and/or transmission submount-

ing plate loose.

4.

Tires

is

or

or

a

its

excessive:

wheels defective.

or

in bad condition.

push rod cover not seating

washer.

or

broken.

transmission shifts hard

1.

Bent shifter rod.

2.

Clutch dragging slightly.

.

Transmission oil too heavy (winter operation).

transmission jumps out of gear:

1.

Shifter rod improperly adjusted.

2.

Shifter clutch dogs and/or dogs on

gear badly worn.

clutch slips:

.

Clutch controls improperly adjusted.

2.

Insufficient clutch spring tension.

3.

Friction discs oily.

its

mating

If

alternator does not charge

below normal:

1.

Defective regulator-rectifier module.

2.

Loose, broken,

to module circuit;

3.

Defective alternator stator

carburetor floods:

1.

Inlet valve and/or valve

2.

Dirt between float valve and

3.

Excessive "pumping"

or

shorted

or

or

module to battery circuit.

seat

of

hand throttle grip.

charging rate

wires

in alternator

or

rotor.

worn

or

its

seat.

is

damaged.

clutch drags

.

Clutch controls improperly adjusted.

2.

Clutch spring tension too tight.

3.

Friction discs gummy

brakes do not hold normally:

1.

Brake improperly adjusted.

2.

Brake controls binding

lubrication

3.

Brake linings badly worn

4.

Hydraulic system contains

inder reservoir low on hydraulic brake fluid.

5.

Leak in hydraulic system.

or

does not

or

damage.

release:

or

oily.

as

result of improper

or

glazed.

air

or

master cyl-

1

Page 22

Keep on the right side of the road when meet-

1.

ing other vehicles coming in the opposite

direction.

Always sound your horn and pass on the left

2.

side when passing other vehicles going in

the same direction. Never try to pass an-

other vehicle going in the same direction

at

street

going up

3.

At

street intersections give the right-of-way

to the vehicle on your right.

intersections, on curves,

or

down

a

hill.

Do

or

not presume

too much when you have the right-of-way; the

other driver may not know you have it.

Always signal when preparing to stop, start,

4.

or

turn.

All

5.

traffic signs, including those used for the

control of traffic

at

intersections, should be

obeyed promptly and to the letter. "Slow Down''

signs near schools and caution signs

at

road crossings should always be observed and

your actions governed accordingly.

when

rail-

6.

Never "crash" a light. When a c

cated from

the traffic control systems

await

the change.

7.

When intending to turn to the left, give signal

at

least

q'Go" to "Stop"

100

feet before reaching the turning

(or

vice versa) in

at

intersections,

point. Move over to the center line of the

street (unless local rules require otherwise),

slow down passing the intersection

street and then turn carefully to the

8.

In turning either right

destrians

9.

Do not leave the curb

as

well

as

signaling and seeing that your way

drive into moving

or

left, watch for pe-

vehicles.

or

parking area without

traffic.

A

moving line of

is

traffic has the right-of-way.

10.

See that your license tags are installed in

the position specified by law and that they

are

clearly visible under

all

conditions. Keep

them clean.

11.

Ride

at a

safe speed

the type of highway you

whether the road

condition on

the

-

a

speed consistent with

are

on, and always note

is

dry

or

wet. Each varying

highway means adjusting your

speed accordingly.

of

the

left.

clear to

20

Page 23

re:

After

a

new motorcycle has been driven

500 miles and again

its

at

approximately 1000 miles,

first

the motorcycle should be taken to the dealer from

whom

operations with which the dealer

If

dealer

owner should

attention,

it

was purchased for certain initial service

is

familiar.

it

is

impossible to take the motorcycle to

at

the mileage intervals mentioned, the

at

least give the following outlined

or

arrange to have

it

given, and take

a

the motorcycle to the dealer for more complete

servicing

1.

Drain oil tank through drain plug

later

on

when convenient to do

(7,

figure

so.

2)

flush tank and refill with fresh oil.

2.

Clean oil filter, crankcase screen for overhead

and tappet oil supply and magnetic plug in

chain housing.

3.

Drain transmission through drain plug and

refill

to level

of

filler

opening with fresh oil.

Use same grade oil used in engine.

4. Lubricate

attention in the SERVICE

all

points indicated for

AND

2000

mile

MAINTENANCE

CHART.

5. Aim headlight.

6.

Check front fork bearing adjustment.

7.

Clean carburetor gas strainer.

8.

Clean chain housing magnetic drain plug.

9.

Inspect and clean spark plugs.

10, Check ignition timing and circuit breaker

point gap.

11.

Oil

all

control joints and parts indicated for

2000

mile attention.

12.

Inspect and service

13.

Check adjustment of chains and readjust

air

cleaner

if

needed.

if

necessary.

14. Check lubrication of chains.

15. Check

all

nuts, bolts and screws, and tighten

any found loose.

16. Check wheel mounting socket bolts and tighten

if

needed. These bolts must be kept very tight.

17. Check and tighten wheel spokes.

21

Page 24

18. Check level of solution in battery and add

if

distilled water

needed. See that terminals

are clean and connections tight.

19. Check tightness of

and

all

cylinder base nuts, and tighten where

all

cylinder head bolts

necessary.

20. Check brake adjustment and hydraulic fluid

level.

21.

Check clutch adjustment.

22. Check tire pressure and inspect tread.

23. Road test.

FI

1.

Drain oil tank and refill with fresh oil.

2. Clean oil filter.

3. Check level of oil in transmission and add

if

oil

engine.

4.

5.

6.

7.

needed. Use same grade of oil used in

Service

air

cleaner.

Check circuit breaker point gap.

Check adjustment of chains and adjust ifneces-

sary.

Check lubrication of chains.

8. Check level of solution in battery, and add

distilled water

are

clean and connections tight.

if

needed. See that terminals

..

9. Check brake adjustment and hydraulic fluid

level.

10. Check clutch adjustment.

11.

Check tire pressure and inspect tread.

12. Road

test.

s

Regular motorcycle lubrication and maintenance

will help you keep your new Harley-Davidson

operating

lower operating costs, longer motorcycle

at

peak performance, and will give you

life,

and greater riding pleasure. Your Harley-Davidson

dealer knows best how to service your motorcycle

with factory approved methods and equipment

as-

suring you of thorough and competent workman-

ship for every job.

The chart on the next page shows the regular

at

intervals

should be performed.

which specified service operations

For

more detailed description

of the service and maintenance procedures specified,

refer

to information following after chart.

22

Page 25

S

CE

23

Page 26

Run engine until

1.

ture.

Remove fuel supply hose at tank and drain gas

2.

tank, including reserve supply

Mix about

3.

of gasoline and put in gas

Run engine with gas-oil mix for several minutes

4.

until exhaust smokes.

Remove spark plugs, inject

5.

cycle oil into each cylinder and crank engine

or

6

5

Drain oil tank.

6.

See that rear chain

7.

Wax chrome plated surfaces and apply some oil

8.

to exposed unpainted surfaces.

Store battery above freezing temperature,

9.

trickle charge at least once

water level above plates.

from motorcycle

on ground or concrete.

When riding time comes again, your motorcycle

be

will

24

revolutions.

ready. Just

it

reaches operating tempera-

-

replace hose.

4

ounces of 2-cycle oil in one quart

tank.

a

few squirts of

Clean and replace plugs.

is

clean and well lubricated.

a

month, and keep

If

battery

it

must not be placed directly

fill

the oil tank,

start

is

removed

up and go

2-

Your Harley-Davidson dealer has the proper grade

oil to suit your requirements.

indiscriminately

chemically when mixed.

The oil tank capacity

full when the oil level

stick. Tighten the cap securely to prevent leakage.

The oil signal light

cates oil circulation. Oil mileage normally varies

from 250 to

nature

driving, and

mileage

!

of

service, solo

is

not within this range, see your dealer.

-

some oils tend

is

4

is

on

500

miles per quart depending on the

or

how^

well the engine

Do

not switchbrands

to

quarts and

at

upper mark on the dip-

the instrument panel indi-

sidecar,

is

considered

fast

or

is

kept tuned.

interact

moderate

If

Page 27

Remove tank cap

MORE THAN

REFILL.

If

and

CHECK OIL SUPPLY NOT Oil will run cooler and mileage

300

MILES AFTER EA COMPLETE

oil level

is

at

lower m on dipstick,

higher with oil level well up

unless oil tank

two quarts can be added. ing of oil level

chance of running dry.

will

be somewhat

in

tank. Furthermore,

is

kept well filled, frequent check-

will

be necessary to avoid any

Do not allow oil level to go below the lower

Oil should be changed after the

1000

and

at

at

about

warm

miles for a new engine, and thereafter

2000

mile intervals in normal service

or

moderate temperatures. Oil change

first

500

miles

mark on gauge rod. intervals should be shorter in cold weather

See 'Winter Lubrication." Completely drain oil

tank of used oil and refill with fresh oil.

vice

is

extremely hard

competition, drain and

Draining should be done after

It

is

not necessary to drain the crankcase

or

on dusty roads

refill

at

shorter intervals.

a

run while oil

not accumulate used oil. At the time of the

mile oil change, and along with

at

least every second

as

first

If

is

it

ser-

or

does

oil change thereafter, thoroughly flush and clean

tank with kerosene to remove any sediment and

sludge that may have accumulated. Your dealer has

facilities for quick flushing and cleaningof oil tank.

UPPER

MARK

(FULL)

LOWER

MARK (ADD OIL)

-

in

hot.

500

out

25

Page 28

Oil filter

service the filter, unscrew wing nut and remove

filter cup from oil

from top of filter anddisassemble. Thoroughly wash

the filter element in clean gasoline

least once every

changed. Renew filter element every

Overhead and tappet oil filter screen

is

located in crankcase above oil pump. Unscrew

slotted plug, remove and clean

The chain housing magnetic drain plug

13)

is

screw plug and remove foreign material from end

of plug. This should be done when engine oil

changed initially

thereafter.

Combustion in any engine generates water vapor.

When starting and warmingup in cold weather, much

of the vapor condenses to water on relatively cool

metal surfaces.

crankcase thoroughly warmed up, frequently, most

is

located

located

2,000

at

bottom

at

If

engine

at

the top of the oil

tank,

remove retaining spring

or

miles when the engineoil

5,000

ic

(3,

or

replace screen.

(11,

rear

of chain housing. Un-

500

miles and every

is

driven enough to get the

2,000

tank.

solvent

miles.

figure

figure

miles

To

at

is

9)

is

of

this water

through the breather. owever,

engine, making only short runs now and then and seldom being thoroughly warmed up,

mulate an increasing amount of water in the oil tank.

This water will, in freezing weather, become slush

or

ice and

block oil lines

mixed with oil for some time forms sludge that

harrnful to the engine and causes undue

ious working parts. Therefore, in winter the oil

change interval should be shorter than normal for

all

engines, and any engine used only for short runs,

particularly in commercial service, must have oil

changed frequently along with

out to remove any water and sludge, beforenew oil

is

put in tank. The farther below freezing the tem-

perature drops, the shorter the oil change interval

should be.

In

normal service on hard surfaced roads, remove

air

cleaner mesh, wash in gasoline, and saturate

with engine oil

under dusty service conditions.

service, clean and oil filter mesh every

or

at

least

is

again vaporized and blown out

a

moderately driven

is

likely to accu-

if

allowed to accumulate too long,

and

damage the engine. Also, water

a

thorough tankflush-

at

least

every

1000

miles,

In

extremely dusty

once a day.

wear

or

100

will

is

of

var-

oftener

miles

26

Page 29

The gasoline strainer

is

located on top of the

gasoline supply valve inside the gasoline tank

(see

figure

as

indicated by irregular carburetion, remove the

4).

If

the supply of gasoline

is

impeded,

gasoline supply valve from the tank and thoroughly

clean the gasoline strainer. Be sure to drain the

tank before removing the gasoline supply valve.

1'

2

1.

Chain Inspection Cover

3.

Chain Housing Cover Screws

FIGURE

5.

Clutch Cover Screws

8.

CHAIN INSPECTION COVER

3'

2.

4'

Inspection Cover Screws

(8)

4.

Clutch Cover

(3)

(4)

Use

same grade of oil used in engine.

Remove transmission oil filler plug

(11,

figure

1)

and check oil level every month or every 10

miles, whichever comes

fill

and

to the level of the filler opening. The

motorcycle should be standing

Add oil

STRAIGHT

if

necessary

UP,

not

first.

leaning on jiffy stand, when adding oil to the

transmission. Drain transmission and

refill

to

correct level with fresh, clean oil after the first

500 miles, and thereafter seasonally or every

5,000 miles, whichever comes

should become submerged in water, drain

first.

If

transmission

it

im-

mediately and refill to proper level.

is

A fixed amount of oil

line from

a

metering orifice in the oil pump. Oil

supplied through an oil

drops on front chain from oiler outlet tube (10,

figure 13). Excess oil collects

is

compartment and

drawn back into engine gear

at

rear of chain

case breather.

27

Page 30

When the front chain adjustment

2000 mile intervals (see page

to

see

that oil comes out of oiler tube when

is

engine

inspection hole

from oiler, supply orifice

running, when viewing through cover

(1,

figure

8).

at

is

checked

43)

,

also check

If

oil does not come

pump

is

probably

at

blocked due to accumulation of dirt, and requires

cleaning.

To

do this, remove orifice screw and

washer from oil pump and blow out passage to

chain compartment with compressed

air.

Motorcycle

At

regular 2,000 mile intervals, make a close

inspection of

appear to be getting sufficient lubrication, or

there

is

is

evidence of

equipped with

rear

chain.

an

a

rear

chain oiler.

If

rear

chain does not

if

over-supply of oil, re-

adjustment should be made with rear chain oiler

adjusting screw. The

the oil pump

is

1/4

turn open which provides 2

minute.

as

shown in

If

oiler should become blocked, remove

chain oiler

figure

is

locatedon

9.

Normal setting

or

3

drops per

rear

screw and clean orifice.

If

chain oiler

chain and lubricate

is

not being used, brush dirt off

at

1000

mile intervals with

Harley-Davidson "Chain Saver," "Chain Spray" or

28

3.

1.

Rear Chain Oiler Adjusting

Screw Tappet and Overhead

2.

Rear Chain

Screw Locknut

Oiler

FIGURE

Adjusting

9.

REAR

Cover Plug

Oil

CHAIN

OILER

for

Supply Screen

Page 31

"Chain Grease"

engine oil.

If

the motorcycle

dusty

lubrication of the

time to time. Under these conditions, proceed

follows:

Remove chain from motorcycle.

thoroughly in a pan of kerosene. Remove chain

from kerosene and hang

kerosene to drain off. Immerse for

in

engine oil.

not

move chain around to

oil works through

from hot grease

wipe

of

connecting link and spring clip closely

condition. Replace

spring clip

pin ends.

or

dirty conditions, thorough cleaning and

a

pan of grease heated to consistency of light

at

hand, substitute engine oil. While immersed,

all

surplus grease

the chain. Install chain on motorcycle. Inspect

if

available;

is

operated under extremely

rear

chain may be advisable from

If

grease and facilities for heating are

be

all

inside parts. After removing

or

oil, allow chain to drain and

if

not available, use

Soak

and wash

it

up for a time to allow

a

short time

sure that hot grease

or

oil from the surface

for

if

at

all

questionable. Be sure

is

properly and securely locked on

as

it

or

bad

ey-Davidson "Grease All" for greasing

requirements.

All chassis bearings requiring frequent applications of grease are provided with grease gun

fittings. Locations and recommended greasing

intervals

TENANCE CHART (Page

Use

Excess grease produces

Remove and grease handlebar throttle grip spiral

with fresh grease every

operation

Remove and grease speedometer and tachometer

drive cables every

On grease fitting of

apply

of

grease gun) to fitting

with hand grease gun.

are

listed in the SERVICE AND MAIN-

23).

a

hand grease gun to avoid over-greasing.

a

messy condition.

5,000

of

grip indicates lubrication

5,000

miles.

rear

fork

a

very small quantity of grease (one stroke

at

miles, or when

is

necessary.

pivot bearing housing,

2,000

mile intervals

29

Page 32

CAUTION

an appreciable amount of oil leakage should de-

attention should

e given by an authorized

y-Davidson dealer.

Over-greasing will damage seals.

Pack the steering head bearings with fresh grease

at

50,000

miles.

Incorrect recoil action will result

sufficient oil in either side of the fork.

the amount, completely drain the oil and then

pour back into each side

6-1/2 to

if

there

To

7

ounces of

is

in-

check

Harley-Davidson Hydraulic Fork Oil. Oil drained

from the fork may be used again provided

does not appear to be contaminated by water or

other foreign matter. Add only enough fresh oil

All control connections and parts

as

indicated in

to provide the required amount.

the SERVICE AND MAINTENANCE CHART (Page

23)

should

be oiled regularly, particularly after

washing motorcycle

Pa-

or

driving in wet weather.

fork should

water, drain and

In

an

emergency, when Harley-Davidson Hydraulic

Fork Oil

at

any time become submerged in

refill

immediately.

is

not available, use the lightest auto-

If

The Hydra-Glide fork requires very little main- mobile engine oil obtainable. Do not use shocktenance or attention. It requires no greasing.

fork does not appear to be working properly, or drain and replace with Hydraulic Fork

If

absorber fluid.

If

engine oil

is

used, however,

Oil

as

soon

30

it

Page 33

consistency of engine oil varies

changes, and

a

rough ride will

and

emper atur e changes

ommended oil.

To

drain and refill fork, remove headlamp and

headlamp housing, then remove the hex headcap

at

screw

drain plug

3/16 inch Allen wrench, and drain the oil into

clean container. Add oil to container,

to make up the required amount. Replace the

drajn plugs and add 6-1/2 to

through the hole in the upper end of eachfork

tube. Then install the cap screw and tighten

securely.

Filling the fork using only

slow job because the

are

air

locked. It

Harley-Davidson dealer when this service

quired,

the job cleanly and quickly.

The adjustable

equipment for sidecar service) does not have

hex head cap screw

but has oil

the top

at

small and the

as

he

of

each fork side. Remove the

the lower end of each slider with

filler

filler

is

recommended that you see your

has

the necessary equipment to do

trail

filler

plugs

channel tends to become

Hydra-Glide Fork (special

at

the top of each fork side,

at

stiff

recoil action

at

lower temperatures.

little

effect on the rec-

if

necessary,

7

ounces of oil

a

funnel

openings in the fork

the rear of each fork

is

a

rather

is

a

a

re-

a

e

removed with a large screw-

Every

cylinder

brake foot pedal. When removing

sure that

plug to prevent entrance into reservoir. Level

should be 1/4 inch from top of cover.

HYDRAULIC

for use in hydraulic brake systems.

It

and miles of service, which

in determining

so

Inspect level of battery solution

week during motorcycle operation, adding distilled

or

keep the solution above the plates.

cycle

check solution level before placing in service.

Remove battery cover and take out 6 screw end

filler

1000

miles, check fluid level in master

(6,

figure

all

dirt

BRAKE

is

the

care

lilt

ion

other approved water

is

not used for an extended period of time,

plugs. With a hydrometer

1)

located just ahead of re

is

removed from around

FLUID, which

given a battery, rather than time

its

life.

as

filler

is

is

most important

at

least

often

as

necessary to

If

or

syringe, add

plug,

filler

Use

only

approved

once

the motor-

a

31

Page 34

water to each cell to

triangle or circle

at

base of filler hole.

raise

level of solution up to

is

especially important that the battery be kept

well charged in below freezing weather. A low or

discharged battery

very likely to

be

frozen

is

and ruined.

If

battery

of the solution

the vent holes when battery

This

is

filled

will

not only weaken the solution,

to a higher lever, some

will

be

forced out through

is

charging.

but also may damage parts near the battery.

Avoid getting battery acid on clothing

other

fabrics.

Keep battery clean and ter-

or

minal connections tight.

hwgin

Check solution in each cell

drometer.

If

hydrometer reading

remove battery and charge

source. The charging current should be

with

a

battery hy-

is

below

it

from an outside

1.200,

12

volt

direct current and charging rate should not be

allowed to go over

4

amperes.

A higher battery charge rate may heat and damage

the battery.

E'or

this

reason, do not allow the

motorcycle battery to be charged in the same

line with auto batteries. Hydrometer reading of

fully charged battery in good condition will be

from

1.265

to

1.300.

Allowing battery to remain in a discharged con-

its

dition for any length of time shortens

life. It

32

CIS

Keeping the motorcycle clean on the outside

well

as

on the inside not only

maintenance, it

$

good maintenance. To

keeping your motorcycle clean

Davidson

dealer

for the following:

is

a

sign

aid

see

your Harley-

as

of good

you in

leam?.r

Harley-Davidson trGunk" will quickly and efficiently

remove grease and oil from the metal parts of

your motorcycle leaving

a

clean, bright finish. For

unpainted metal surfaces, use full strength. For

enameled surfaces, dilute according to instructions

on can.

Do

not allow "Gunk" cleaner to come in

contact with any plastic parts such

as

windshield, trim strips, seat or saddlebags,

since

deterioration.

it

will discolor

Use

the

surface or cause

Harley-Davidson "Plastic

Cleaner" or mild soap and water to clean

these materials.

Page 35

ley-Davidson "Chrome Cleaner" to make

the chrome parts of your motorcycle glitter and

sparkle.

-

...-

.

. . . . . - .- .

L

.

..

'

-.

__

-

...

*,

,

.:.

.

.

~

. .

.

,

:

,,

.. . ..

A..L

.,

.l-,l

.

.

.?-

\'-

,I

..

.(

is

arley-Davidson "Polish and Cleaner"

made to

clean and polish the enamel parts to maintain or

restore these parts

close

as

possible to their

as

original luster.

Harley-Davidson Plastic Cleaner,

64

is

recommended for cleaning of vinyl plastic

seats. Cleaner comes in

spray on and allow to

wipe clean with

a

15

02.

set

for a few seconds. Then

damp cloth

Part

No.

98680-

spray can. To use,

or

sponge. Full in-

structions appear on the can.

oe

Use mild soap

plastic windshield. Flush with water

-

dirt

then wipe clean with sponge

or

detergent with water to clean

first

to soften

or

soft cloth

using plenty of water. Do not wipe windshield when

or

dry

with dry towel because dirt particles may

scratch surface.

To

obtain

the longest possible

possible performance from your motorcycle

necessary not only to keep

but also correctly adjusted to the tolerances

which

it

was manufactured. The following

life

and

the best

it

adequately service

are

it

the

is

to

adjustments and general maintenance facts pertaining to your motorcycle.

s

Keep plugs clean and the gap between the

trodes adjusted to

a

with

Be

sand blast cleaner.

sure

your motorcycle

.025

inch to

is

.030

inch. Clean

operating with the

elec-

correct heat range plug best suited to your type

If

of riding.

dealer.

installed every

in doubt see your Harley-Davidson

It

is

recommended that new plugs

5000

miles.

are

33

Page 36

The carburetor, once properly adjusted, requires

little

if

any readjustment. It should not be neces-

the

sary to adjust

1/8

turn and the intermediate speed needle

1/4

than

ture

turn, richer or leaner, to correct the mix-

f9r

a

change

low speed needle

in

weather conditions.

tinually tamper with carburetor adjustments.

gine does not

start

and run right,

(1)

more than

Do

first

(2)

more

not con-

If

en-

look

for

trouble elsewhere, before checking carburetor.

Inlet fitting

and vent fitting

(8)

have strainer

(7)

screens located in threaded holes in carburetor

body.

passages with an

If

faulty carburetion indicates fuelflow

stricted, remove elbow fittings

a

extract both screens with

air

bent wire, andblow

hose. Replace screens and

(7

and

8)

is

frombody,

elbows, being sure that screens are not bent

damaged

so

as

to allow dirt to pass through.

re-

out

or

34

FIGURE

10.

CARBURETOR

Carburetor

We

suggest having carburetor adjustments made by

Adjustments (see

fi

your Harley-Davidson dealer.

The fuel supply for

low

engine speed

is

completely

regulated by the low speed needle. The fuel

for intermediate engine speed

an adjustable needle,

A

fixed

is

also regulated by

jet

supplies the high

speed fuel requirements.

supply

Page 37

Both the intermediate speed needle and low

needle turn inward (to right) to make mixture leaner

at

the respective speeds for which they adjust. Back-

ing them out (to left) makes mixture richer. Closed

throttle idling speed of engine

speed stop screw

A carburetor that

be readjusted

Make sure carburetor control

1.

throttle lever

handlebar grip movement.

Turn both the low speedneedle

2.

mediate speedneedle

Do

not close

damage to needle and seat may result.

Back up (left) both needles about

3.

needles in this position, engine

speed mixture

Start engine and

4.

temperature and choke has been moved toopen

position, adjust throttle control to idle speed

(700

to

900

5.

Turn low speed needle

until mixture becomes

misses and

back needle out

(3).

as

follows:

RPM).

is

is

badly out of adjustment may

(4)

fully closes and opens with

off

either needle too tightly or

will

after

inclined to stop; then, slowly

(to

left)

is

adjusted with idle

is

(1)

andthe inter-

(2)

all

the way in (to right).

7/8

will

start

probably

it

has

(1)

so

until engine hits regu-

be

reached operating

in (to right) slowly

lean that engine

s

adjusted

turn. With

but low

too rich.

so

le

speed. Startin

ill

be better wit

low speed adjustment slightly rich, rather th

lean

as

Adjust throttle lever stop screw

6.

sary, to make engine idle at proper speed with

throttle

Turn screw to right to make engine idle faster

and to left to make engine idle slower.

idle an engine

cause

causes hard starting. Changing the idle speed

with throttle stop screw

low speed mixture slightly. It will, therefore,

be necessary to again check and correct low

speed needle adjustment by the same procedure

followed in making the initial adjustment.

7.

Check intermediate speed adjustment,

speed adjustments have been completed.

motorcycle on the road

Best

be found with the intermediate speed needle

(2)

Changing either mixture setting also

8.

other setting to some degree. Therefore,

be necessary to recheck low speed mixture after

intermediate mixture final setting

as it can be made.

(3)

in

closed position (screw against stop).

at

the slowest possible speed be-

an

extremely slow idling adjustment

is

likely to change the

at

35

miles per hour.

all

around engine performance can usually

set from

3/4

to

7/8

turns open.

as

after

affects

is

obtained.

neces-

Do

not

low

Run

the

it

will

35

Page 38

.

... . .

....

-

ADVANCE MARK POSITION

1.

Contact Point Adjusting

Notch

2.

Moving Contact Point

3.

Stationary Contact Point

Lock Screw

4.

Cam Follower

5.

Breaker Cam

6.

Circuit Breaker Plate

Screw (2)

7.

Condenser

-

RETARD MARK POSITION

8.

Circuit Breaker Plate

9.

Circuit Breaker Plate

Adjusting Notch

10.

Contacts

11.

Timing inspection Hole

(354

(5'

B.

of

Piston Top

Timing

12. Advance

Mark on Flywheel

13.

Retarded

Position

Center Mark on Flywheel

T.

C.

)

36

FIGURE

11.

CIRCUIT

BREAKER

AND TIMING

MARKS

Page 39

Circuit breaker points should be checked for gap

at

500

and contact surface condition initially

1000

miles, and thereafter every 2000 miles. Re-

move spark plugs to permit engine to turn easily

and rotate flywheels

either of the highest points of cam

gap between the contacts (10) with a .018 inch gage

(wire preferred).

the cam follower

(5),

of cam

gap spacing affects ignition timing. To adjust the

points, loosen the lock screw

ary contact plate, using screwdriver in adjusting

notch

tighten the lock screw

to make sure

or worn condition should

Ignition timing

Correct ignition timing and correct setting

circuit breaker contact point gap

necessary for proper engine operation and performance.

adjustment

(1)

to provide correct contact point gap. Re-

it

so

that cam follower

(5).

If

it

is

not exactly .018 inch when

(4)

is

on either of the highest points

is

necessary. Incorrect point

(3)

and move station-

(3)

and again check the gap

remains correct. Points in pitted

be

replaced.

is

controlled by the circuit breaker.

is

and

(4)

is

on

Check the

of

the

absolutely

The spark timing cam

as engine speed increases through action of the

flyweights

sures

speed and high speed requirements.

To

check or reset ignition timing proceed

Remove circuit breaker cover and set circuit

breaker contact gap at exactly .018 inch

under CIRCUIT BREAKER.

Use a strobe flash timing light (timing gun) to view

advanced timing mark (12) on flywheel through accessory plastic view plug screwed into timing in-

spection hole

RPM.

front spark plug, ground and positive red wire to

battery terminal. Light will flash each time front

cylinder spark occurs. Loosen circuit breaker

plate screws

plate (8) can be shiftedusing

(9)

as

timing mark (12) in center of hole. Timingwill

tard

in the circuit breaker base. This in-

correct spark timing to suit starting, low

(11)

Timing light leads should

(6)

light aimed into inspection hole

30"

automatically when engine

is

advanced automatically

while engine

just enough

a

as

follows:

as

outlined

tP

is

running

be

so

circuit breaker

screwdriver in notch

at

2000

connected to

(11)

stops

re-

is

stopped.

37

Page 40

If a strobe timing light

timing can be obtained in an emergency, by using the

following procedure:

Remove screw plug from timing inspection hole

in left side of crankcase. Then remove front push

so

rod cover

observed.

Turn engine in direction in which it runs until front

piston

intake valve closes), and continue turning engine

very slowly (less than

top center timing mark (13) on flywheel

in the inspection hole (11)

The narrow lobe cam

point

at

that opening and closing of valve can be

is

on compression stroke (just after front

which contacts

is

not available, approximate

1/2

revolution)

as

shown.

is

now at the approximate

(10)

open and front cylinder

until

is

aligned

(11)

piston

wide be opens

ition occurs

Connect a circuit tester such

the contact points to determine the exact point of

contact opening. Loosen circuit breaker plate

(6)

screws

(8)

using a screwdriver in notch

will

mark

in figure

(This procedure

and engine can be operated in an emergency for

short period until advanced position timing can

obtained with a strobe timing light.)

At regular intervals

a

year, have your dealer check ignition timing and,

if

necessary, readjust circuit breaker setting to

compensate for wear on circuit breaker that may

have caused a slight change in timing.

just enough to shift circuitbreaker plate

open exactly when piston top center timing

(13)

is

aligned in inspection hole

11.

will

result in approximate timing

of

5000

as

alightbulb across

(9),

so

contacts

(11)

as shown

be

miles or at least once

.

a

38

Page 41

Tappets are self-adjusting, hydraulic type. They

automatically adjust length to compensate for

engine expansion and valve mechanism wear, and

thus keep the valve mechanism free of lash when

is

the engine

quired only in a new engine assembly and when

the engine

readjustment of tappets

When starting an engine which has been shut off

even for

tend to

completely refill with oil.

than for

is

noisy,

hydraulic units may not

Always check the lubricating oil supply in the oil

tank

normal circulation of oil through the engine

necessary for proper operation of the hydraulic

units.

be

passages leading to the lifter units. Oil tank

(2,

be

started, valve mechanism becomes abnormally

it

first

If

functioning properly due to dirt

figure

running. Tappet adjustment

is

reassembled

a

few minutes, the valve mechanism may

slightly noisy until the hydraulic units

a

short period immediately after engine

is

an

indication that one

if

the valve mechanism

there

is

oil in the tank, the units may not

1)

and tappet oil supply

after

repair.

is

required.

If

at any time, other

or

be

functioning properly.

is

in

the oil supply

filter

is

re-

No

further

more of the

noisy, since

is

filter

screen

(3,

figure

speed to the nearest arley-Davidson dealer for

further attention.

The need

be indicated by the clutch slipping under load or

dragging in released position.

first

controls.

Normally the only attention the clutch hand control

requires

adjusting sleeve

mately

handlebar before clutch

Should the need of major readjustment be indicated

by

by excessive gear clash when shifting,or sleeve

adjustment

adjustments should

9)

may require cleaning. Drive at moderate

of

attention to clutch and controls will

In

either

thing to be checked

is

occasional readjustment of control coil

(1,

figure

1/4

inch free movement for hand lever on

a

slipping clutch,

is

completely taken up, the following

or

be

1.

Move end of lever on transmission forward

a

position where

to

is

the adjustment of

12)

to maintain approxi-

starts

made in the order indicated.

it

to disengage.

dragging clutch indicated

becomes firm indicating

case,

the

39

Page 42

1.

Clutch Control Cable Adjusting Sleeve

2.

Locknut

3.

Bracket

4.

Starter Motor

5.

Clutch Actuating Lever

6.

Clutch Adjusting Screw Locknut

7.

Clutch Adjusting Screw

8.

Clutch Plate Spring Tension Nuts

(3)

40

FIGURE

12.

CLUTCH CONTROL ADJUSTME

Page 43

that

all

slack in the actuating mechanism has

been taken up. Measure clearance between

starter motor (4) and clutch lever

1/2

inch.

If

should be

obtain this position of lever follow the instructions in the next step.

necessary to readjust to

(5)

which

Check to determine that foot shift lever positioni

is

mark

Foot pedal can be raised

clevis on shifter rod end.

aligned

with

clamping slot of foot lever.

or

lowered by adjusting

Steps

2.

actuating lever

Loosen control coil adjusting sleeve lock nut (2,

figure 12) and turn control coil adjusting sleeve

(1,

3.

Remove clutch cover, loosen push rod adjusting

screw lock nut

screw

the rear; out (counterclockwise)

lever forward. When 1/2 inch clearance between

lever and

tighten lock nut

Turn

4.

clutch hand lever has