Page 1

SALES AND TECHNICAL SERVICE CONTACTSSALES AND TECHNICAL SERVICE CONTACTS

SALES AND TECHNICAL SERVICE CONTACTS

SALES AND TECHNICAL SERVICE CONTACTSSALES AND TECHNICAL SERVICE CONTACTS

Australia:

Tel. (03) 9769.0666 • Fax (03) 9769.0699

China:

Tel. (10) 88570068 • Fax (10) 88570060

Egypt:

Tel. & Fax (02) 2758.683

Germany:

Tel. (07851) 9129-0 • Fax (07851) 9129-99

Greece:

Tel. (210) 823.5192 • Fax (210) 884.0210

Indonesia:

Tel. (21) 4584.2941 • Fax (21) 4584.2942

Japan:

Tel. (03) 3258.9565 • Fax (03) 3258.9567

Korea:

Tel. (02) 2278.5147 • Fax (02) 2264.1729

Malaysia:

Tel. (603) 5638.9940 • Fax (603) 5638.9829

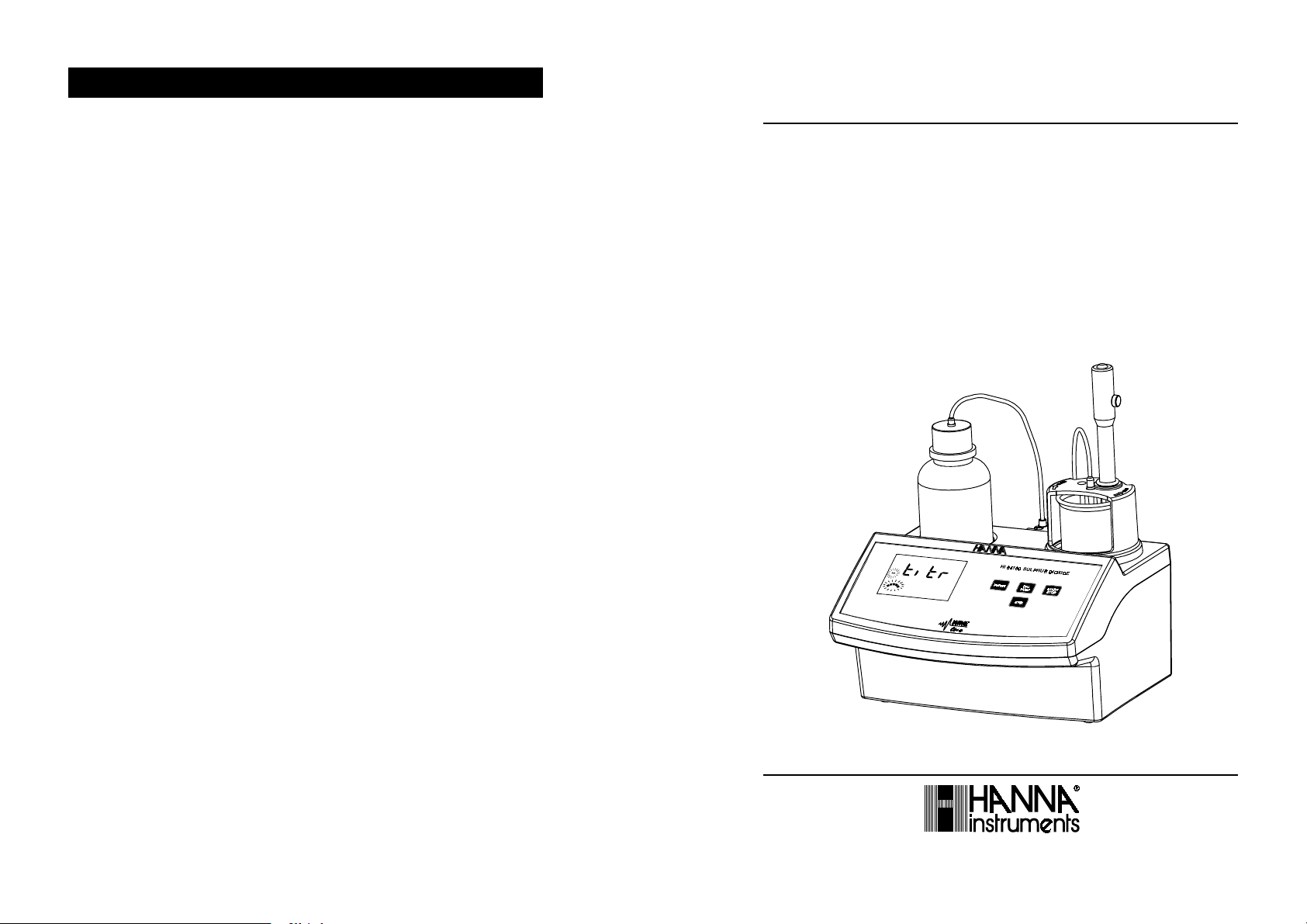

Instruction Manual

HI 84100

FREE & TOTAL SULPHUR DIOXIDE

MINITITRATOR

for wine analysis

Singapore:

Tel. 6296.7118 • Fax 6291.6906

South Africa:

Tel. (011) 615.6076 • Fax (011) 615.8582

Taiwan:

Tel. 886.2.2739.3014 • Fax 886.2.2739.2983

Thailand:

Tel. 66.2619.0708 • Fax 66.2619.0061

United Kingdom:

Tel. (01525) 850.855 • Fax (01525) 853.668

USA:

Tel. (401) 765.7500 • Fax (401) 765.7575

For e-mail contacts and a complete list of Sales and Technical offices, please see

www.hannainst.com.

09/05

20

MAN84100

www.hannainst.com

1

Page 2

Dear Customer,

Thank you for choosing a Hanna product. This manual will provide you with the necessary

information for the correct use of the instrument. Please read it carefully before using the meter. If

you need additional technical information, do not hesitate to e-mail us at tech@hannainst.com.

This instrument is in compliance with

directives.

TABLE OF CONTENTS

PRELIMINARY EXAMINATION................................................................................................. 3

GENERAL DESCRIPTION ........................................................................................................ 3

SPECIFICATIONS ................................................................................................................... 5

PRINCIPLE OF OPERATION .................................................................................................... 6

FUNCTIONAL DESCRIPTION................................................................................................... 7

START UP ............................................................................................................................ 9

GUIDE TO DISPLAY CODES ................................................................................................... 10

TIPS FOR AN ACCURATE MEASUREMENT ............................................................................. 12

FREE SO

MEASUREMENT PROCEDURE................................................................................ 12

2

TOTAL SO

PUMP CALIBRATION PROCEDURE ........................................................................................ 15

PUMP TUBE REPLACEMENT ................................................................................................ 15

FUSE REPLACEMENT .......................................................................................................... 16

ELECTRODE CONDITIONING AND MAINTENANCE .................................................................. 16

ACCESSORIES .....................................................................................................................18

WARRANTY........................................................................................................................19

MEASUREMENT PROCEDURE .............................................................................. 13

2

WARRANTY

HI 84100 is warranted for two years against defects in workmanship and materials when used

for its intended purpose and maintained according to the instructions.

This warranty is limited to repair or replacement free of charge.

Damage due to accident, misuse, tampering or lack of prescribed maintenance is not covered.

If service is required, contact your dealer. If under warranty, report the model number, date of

purchase, serial number and the nature of the failure. If the repair is not covered by the warranty,

you will be notified of the charges incurred.

If the instrument is to be returned to Hanna Instruments, first obtain a Returned Goods Authorization

Number from the Customer Service Department and then send it with shipment costs prepaid.

When shipping any instrument, make sure it is properly packaged for complete protection.

To validate your warranty, fill out and return the enclosed warranty card within 14 days from the

date of purchase.

All rights are reserved. Reproduction in whole or in part is prohibited without the written consent

of the copyright owner, Hanna Instruments Inc., Woonsocket, Rhode Island, 02895 , USA.

2

WARRANTY

Hanna Instruments reserves the right to modify the design, construction and appearance of its products

without advance notice.

19

Page 3

ACCESSORIES

PRELIMINARY EXAMINATION

REAGENT SETS

HI 70300L Electrode storage solution (500 mL)

HI 70635L Cleaning solution for wine deposits (500 mL)

HI 70636L Cleaning solution for wine stains (500 mL)

HI 7082 Electrode filling solution (4 X 30 mL)

HI 84100-50 Titrant solution (100 mL)

HI 84100-51 Alkaline reagent (500 mL)

HI 84100-52 Acid reagent for Total SO

HI 84100-53 Acid reagent for Free SO

determination (500 mL)

2

determination (500 mL)

2

HI 84100-54 Stabilizer reagent (25 pcs.)

HI 84100-55 Calibration standard (500 mL)

OTHER ACCESSORIES

HI 3148B /50 ORP probe with 50 cm cable

HI 70483T Tube set with cap for titrant bottle and tip

HI 731316 Stir bar (5 pcs.)

HI 740036P Beaker 50 mL (10 pcs.)

HI 740037P Beaker 20 mL (10 pcs.)

HI 740198 Power cable

Please examine this product carefully. Make sure that the instrument is not damaged. If any

damage occured during shipment, please notify your Dealer.

Each HI 84100 minititrator is supplied complete with:

• Reagents set for 20 titrations

• Two 50 mL beakers

• Two 20 mL beakers

• Scissors

• Tubes set with cap

• ORP probe

• Stir bar

• Power cable

• One 30 mL bottle of Refill Solution

• One 1 mL syringe

• Two sachets of cleaning solution for wine deposits

• Two sachets of cleaning solution for wine stains

• Instruction manual

Note:Save all packing material until you are sure that the instrument works correctly.

Any defective item must be returned in its original packing.

GENERAL DESCRIPTION

Recommendations for Users

Before using this product, make sure that it is entirely suitable for your specific application and

for the environment in which it is used.

Operation of this instrument may cause unacceptable interferences to other electronic equipments,

this requiring the operator to take all necessary steps to correct interferences.

Any variation introduced by the user to the supplied equipment may degrade the instrument EMC

performance.

To avoid damages or burns, do not put the instrument in microwave ovens. For yours and the

instrument safety do not use or store the instrument in hazardous environments.

18

The HI 84100 is a low-cost, easy to use, microprocessor-based automatic titrator that benefits

from Hanna’s years of experience as a manufacturer of analytical instruments.

It has a simple and reliable peristaltic pump that ensure high dosing repeatability. By

performing pump calibration with the provided Hanna standards, the instrument accuracy is

assured.

The instrument comes with a pre-programmed analysis method designed for Free and Total

Sulphur Dioxide measurements on wine samples. The instrument has a powerful and effective

built-in algorithm to analyze the shape of the electrode response and to determine the reaction

completion. This algorithm automatize the analysis, makes all the necessary calculations and

assures a simple and effective interface for the user.

By simply pressing the START STOP button, the instrument will automatically make the titration

up to the equivalence point. The result is immediately displayed in convenient units, then the

instrument is ready for another titration.

3

Page 4

SIGNIFICANCE OF USE

An important reason for adding SO

is to avoid oxidation. When there is oxygen around, SO2 itself

2

becomes oxidized before phenol compounds in the wine , and so acts as an oxygen scavenger. Also

SO2 suppresses the activity of enzymes that cause browning and other problems.

What is really protecting your wine is molecular SO

. When you add SO2, depending of circum-

2

stances, some of it immediately becomes bound. The relationship between the amount of added SO

and the amount of SO2 remaining free is complex. It is clear, however, that it is largely governed by

the total SO2 content of the wine. The rate of binding decreases as the free SO2 concentration

increases. The exact relationship between free and bound (total - free) SO2 will vary from wine to

wine.

Below 30-60 ppm, 33% to 50% of SO

addition becomes bounded. What remains is called “free”

2

and it is divided in two parts. The larger, and relatively ineffective free part is “bisulphite” (HSO3-). The

smaller part of the free is the active molecular SO2. The amount of molecular SO2 in your wine

depends both on the level of free SO2 present as well as pH. For instance, at pH 3.2, the amount of

free SO2 for 0.8 ppm molecular SO2 is 22 ppm. At pH 3.5, you will need 43 ppm free - essentially

double.

Free SO2 concentration (ppm) for 0.8 ppm molecular SO2:

pH 3.0 3.1 3.2 3.3 3.4 3.5 3.6 3.7 3.8 3.9

Free SO

In most situations, 0.8 ppm molecular SO

14 18 22 28 35 44 55 69 87 109

2

during bulk storage and at bottling will provide you with

2

adequate protection from oxidation and bacterial action. This includes prevention of malolactic

bacteria as well.

It is important to remember that the amount of free SO

in the wine depends on three things: how

2

much is added, how much was present before the addition and how much of your addition promptly

becomes bound.

The level at which molecular SO

can be detected by the human senses is about 2.0 ppm. This is also

2

the level which is needed for maximum protection of your wine. This is particularly true in the case

of sweet, and most notably, botrytised wines.

The Hanna HI 84100 offers the possibility to test free or total SO2 in all the wines including the red

ones, that are difficult to test with manual methods because the color changes are hardly seen.

For faster response, unscrew the fill hole screw during measurements.

STORAGE PROCEDURE

To minimize clogging and assure a quick response time, the glass bulb and the junction of the

electrode should be kept moist and not allowed to dry out.

Replace the solution in the protective cap with a few drops of HI 70300 Storage Solution or, in its

2

absence, Filling Solution (HI 7082). Follow the Preparation Procedure before taking measurements.

Note: NEVER STORE THE ELECTRODE IN DISTILLED OR DEIONIZED WATER.

PERIODIC MAINTENANCE

Inspect the electrode and the cable. The cable used for connection to the instrument must be

intact and there must be no points of broken insulation on the cable or cracks on the electrode

stem or bulb. Connectors must be perfectly clean and dry. If any scratches or cracks are present,

replace the electrode. Rinse off any salt deposits with water.

Probe Maintenance

Refill the reference chamber with fresh electrolyte (HI 7082). Allow the electrode to stand

upright for 1 hour. Follow the Storage Procedure above.

CLEANING PROCEDURE

• Wine deposits Soak in Hanna HI 70635 cleaning solution for 15 minutes

• Wine stains Soak in Hanna HI 70636 cleaning solution for 15 minutes

IMPORTANT: After performing any of the cleaning procedures, rinse the electrode thoroughly

with distilled water, refill the reference chamber with fresh electrolyte and soak the electrode in

HI 70300 Storage Solution for at least 1 hour before taking measurements.

4

17

Page 5

FUSE REPLACEMENT

SPECIFICATIONS

To change the fuse follow next steps:

• Disconnect the power cord from the rear panel of

the instrument.

• Pull out the fuse holder located near the power cord

connector.

• Replace the fuse with a similar one.

• Push the fuse holder with the fuse in the appropriate

place.

ELECTRODE CONDITIONING & MAINTENANCE

Range 0 to 400 ppm of SO

2

Resolution 1 ppm

Accuracy 5% of reading

Method Ripper titrimetric method

Principle Equivalence point redox titration

Sample volume 50 mL

ORP Electrode HI 3148B (included)

Pump debit 0.5 mL/min

Stirring speed 1500 rpm

Environment 0 to 50 °C (32 to 122 °F); max 95% RH non-condensing

Power supply 220V/50Hz; 10VA

Dimensions 208 x 214 x 163 mm (8.2 x 8.4 x 6.4") (with beaker)

Weight 2200 g (77.6 oz.)

REQUIRED REAGENTS

Code Description Quantity/test

HI 84100-50 Titrant (for Free & Total SO

HI 84100-51 Alkaline Reagent (for Total SO

HI 84100-52 Acid Reagent (for Total SO

HI 84100-53 Acid Reagent (for Free SO

HI 84100-54 Stabilizer (for Free & Total SO

HI 84100-55 Standard (for Free & Total SO

)

2

)5 mL

2

)5 mL

2

)5 mL

2

) 1 packet

2

) 50 mL

2

PREPARATION PROCEDURE

Remove the protective cap of the ORP electrode (HI 3148B).

DO NOT BE ALARMED IF SALT DEPOSITS ARE PRESENT. This is normal with electrodes. They will

disappear when rinsed with water.

During transport, tiny bubbles of air may form inside the glass bulb affecting proper functioning of

the electrode. These bubbles can be removed by “shaking down” the electrode as you would do

with a glass thermometer.

If the bulb and/or junction is dry, soak the electrode in HI 70300 Storage Solution for at least one hour.

If the filling solution (electrolyte) is more than 2½ cm (1”) below the fill hole, add HI 7082 3.5M

KCl Electrolyte Solution.

16

5

Page 6

PRINCIPLE OF OPERATION

PUMP CALIBRATION PROCEDURE

Determination of sulphur dioxide in wine samples is made by titration of the sulphur dioxide present

in wine with iodate. In this procedure an excess of iodine is added to the wine sample and it is

titrated with iodate.

The iodate reacts with iodide and the sulphuric acid present in the wine and produces iodine:

+ 5I- + 6H

IO

3

+

= 3I2 + 3H2O

The iodine produced in the reaction above reacts then with the sulphur dioxide:

H

+ I2 + H2O = H2SO4 + 2HI

2SO3

For precise results it is very important to know the exact sample volume, titrant volume and

concentration.

The peristaltic pump has a good repeatability but the dosing volume depends on many factors as the

diameter of the tube or the tube stretching. To compensate for all this errors, the pump need to be

calibrated. The calibration of the pump is also needed in order to have high precision of the titrations.

The calibration procedure is in fact the analysis of a known solution. By doing this, the instrument

makes a differential analysis between the standard and the wine sample. The pump volumetric debit

and the real concentration of the titrant is compensated. Only the sample volume has to be precisely

known.

Warning: The calibration of the pump must be performed each time the pump tube, the reagent

bottle or the pH electrode is changed. It is recommended to perform the pump calibration before each

set of measurements.

• To prepare the sample for calibration, follow the

measurement procedure for Free or Total SO

2

measurements by using HI 84100-55 Standard

instead of wine sample.

• After sample preparation, press the CAL PUMP button.

Std will blink on the screen.

• Press START STOP in order to start the system

calibration.

• At the end of the calibration procedure done appears

for a few seconds and then the meter automatically

returns to measurement mode.

PUMP TUBE REPLACEMENT

To remove the tube of the peristaltic pump follow next steps:

• Detach the old tube system from the reagent bottle.

• Grasp one fixing ring of the peristaltic pump tube.

• Pull the tube until it’s taken out from its location.

• Remove the other side of the tube.

To mount the new peristaltic pump tube follow next steps:

• Position one peristaltic pump fixing ring on its location.

• Stretch the tube over the peristaltic pump cylinders.

• Fix the second pump fixing ring on its location.

• Attach the tube to the reagent bottle.

Note: Purge the peristaltic pump until drops of reagent appears on the dosing tip by pressing the

PURGE button.

6

15

Page 7

• Add the content of one powder packet of HI 84100-54

Stabilizer into the beaker.

• Place the probe holder on the top of the beaker and

secure it by turning clockwise.

• Immerse the ORP electrode approximately 2 cm

(0.8”) into the sample to be tested while paying

attention to not touch the stir bar.

• Insert the dosing tip in the appropriate holder place

and pay attention to not be immersed into solution.

FUNCTIONAL DESCRIPTION

INSTRUMENT DESCRIPTION

FRONT PANELFRONT PANEL

FRONT PANEL

FRONT PANELFRONT PANEL

• Press the START STOP button to start the titration.

The display will show “titr” during titration, along

with stirrer and pump tags blinking on the LCD.

• At the end of the titration, the Sulphur Dioxide

concentration is displayed in ppm (mg/L).

Note: If the equivalence point is not reached or it is not

recognized because of the noisy solution, an error

message will be displayed.

1) Titrant bottle

2) Liquid Crystal Display (LCD)

3) Keypad

4) Electrode holder

5) Peristaltic pump tube

REAR PANELREAR PANEL

REAR PANEL

REAR PANELREAR PANEL

14

7

Page 8

6) ORP Electrode

7) Beaker

8) BNC electrode connector

9) Fuse

10) Power switch

11) Power cable connector

12) Peristaltic pump

KEYPAD DESCRIPTION

• Immerse the ORP electrode approximately 2 cm

(0.8”) into the sample to be tested while paying

attention to not touch the stir bar.

• Insert the dosing tip in the appropriate holder place

and pay attention to not be immersed into solution.

• Press the START STOP button to start the titration.

The display will show “titr” during titration, along

with stirrer and pump tags blinking on the LCD.

• At the end of the titration, the Sulphur Dioxide

concentration is displayed in mg/L (ppm).

1) PURGE - to start/stop purging (max purging time is 5 min)

2) CAL PUMP - to enter pump calibration mode

3) START STOP - to start/stop titration or pump calibration

4) STIR - to start/stop the stirrer while in measurement or purging mode

LCD DESCRIPTION

1) Stability indicator: when the pump calibration is in progress

2) Stirrer active tags

3) Calibration messages

4) Pump active tags

5) Four digit secondary display

6) “Time” tag: when the time is displayed on the secondary display

7) “ppm” tag: when the titration result is displayed on the primary display

8) Four digit and half main display

Note: If the equivalence point is not reached or it is not

recognized because of the noisy solution, an error

message will be displayed.

TOTAL SO2 MEASUREMENT PROCEDURE

• Fill the 50 mL beaker up to the 50 mL mark with

the wine sample, place the stir bar into the beaker

and put the beaker in the appropriate place on the

minititrator top.

• Fill the 20 mL beaker up to the 5 mL mark with the

HI 84100-51 Alkaline Reagent and add the content

to the 50 mL beaker.

• Swirl the beaker and wait for 15 minutes.

• Fill the 20 mL beaker up to the 5 mL mark with the

HI 84100-52 Acid Reagent and add the content to

the 50 mL beaker.

8

13

Page 9

TIPS FOR AN ACCURATE MEASUREMENT

START UP

The instructions listed below should be carefully followed during testing to ensure best accuracy.

• Purge the peristaltic pump to have fresh titrant when starting a new analysis or calibration.

• Calibrate the peristaltic pump before performing an analysis.

• Analyze the wine immediately after the sample is obtained.

• Clean the electrode with the HI 700635 or HI 700636 cleaning solution, specially made for

wine industry, if it was unused for a long time.

FREE SO2 MEASUREMENT PROCEDURE

Warning: Make sure the pump was calibrated before performing sulphur dioxide wine sample

analysis.

• Fill the 50 mL beaker up to the 50 mL mark with

the wine sample, place the stir bar into the beaker

and put the beaker in the appropriate place on the

minititrator top.

• Fill the 20 mL beaker up to the 5 mL mark with the

HI 84100-53 Acid Reagent and add the content to

the 50 mL beaker.

• Place the instrument on a flat table. Do not place the instrument on direct sun light.

• Connect the titrator to mains socket with ground connection and the correct voltage and

frequency. See the label on the instrument rear for this.

• Place the peristaltic pump tube on the pump. See the Pump Tube Replacement section for the

procedure.

• Remove the reagent bottle cap and place the bottle cap of the tubes set. Place the reagent

bottle in the appropriate place on the titrator top.

• Connect the tubes with the peristaltic pump (inlet tube is connected with the reagent bottle,

outlet tube is connected with the dosing tip).

• Turn the instrument ON using the power switch from the rear panel of the instrument and

wait until it displays dashes.

• Add the content of one powder packet of HI 84100-54

Stabilizer into the beaker.

• Place the probe holder on the top of the beaker and

secure it by turning clockwise.

12

9

Page 10

GUIDE TO DISPLAY CODES

This prompt appears for a few seconds each time the instrument

is turned ON.

Main screen display.

Main screen display with stirrer active.

This error message appears when the sample concentration exceeds

400 ppm.

The used standard solution is wrong.

This error message appears when the input readings (mV) exceed

0÷

the input limits (

TITRATION MESSAGES

1000mV).

Purging mode message.

PUMP CALIBRATION MESSAGES

This screen appears each time the meter enters pump calibration

mode. The meter is ready to start pump calibration by pressing

the START STOP button.

This screen appears while pump calibration is in progress. Pressing

CAL PUMP or START STOP button, the minititrator returns to the

main screen.

This prompt appears for a few seconds before returning to the

main screen, when pump calibration is done.

This screen appears each time the minititrator enters TITRATION

mode. Press the START STOP button in order to stop the titration and

return to the main screen.

The titration result, expressed as concentration of sulphur dioxide in

ppm(mg/L), is displayed at the end of the titration process. Press the

START STOP button to return to the main screen.

This error message appears when the input reading exceeds the

input limits (0÷1000mV).

This screen appears when the sample concentration exceeds 400 ppm.

10

11

Loading...

Loading...