Page 1

Instruction ManualInstruction Manual

Instruction Manual

Instruction ManualInstruction Manual

HH

II

84108410

H

I

8410

HH

II

84108410

Dissolved OxygenDissolved Oxygen

Dissolved Oxygen

Dissolved OxygenDissolved Oxygen

PP

rocess Controllerrocess Controller

P

rocess Controller

PP

rocess Controllerrocess Controller

www.hannainst.comwww.hannainst.com

www.hannainst.com

www.hannainst.comwww.hannainst.com

1

Page 2

Dear Customer,

Thank you for choosing a HANNA instruments® product.

Please read this instruction manual carefully before using the instrument.

This manual will provide you with all the necessary information for

correct use of the instruments, as well as a precise idea of thier

versatility in a wide range of applications.

If you need additional technical information, do not hesitate to e-mail

tech@hannainst.comtech@hannainst.com

us at

tech@hannainst.com

tech@hannainst.comtech@hannainst.com

These instruments are in compliance with the directives.

TABLE OF CONTENTSTABLE OF CONTENTS

TABLE OF CONTENTS

TABLE OF CONTENTSTABLE OF CONTENTS

Preliminary Examination ............................................................. 3

General Description .................................................................... 3

Functional Description HI 8410 ................................................... 4

D.O. Probes ............................................................................... 8

Specifications HI 8410 ............................................................... 9

Connections ............................................................................. 10

Operational Guide .................................................................... 12

Taking Measurements with HI 8410........................................... 15

Calibration Procedure ................................................................ 16

Diagnostic Tests ....................................................................... 16

LED Indication ......................................................................... 17

Probe Maintenance & Cleaning .................................................. 18

Accessories .............................................................................. 18

Warranty ................................................................................. 19

2

2

Page 3

PRELIMINARY EXAMINATIONPRELIMINARY EXAMINATION

PRELIMINARY EXAMINATION

PRELIMINARY EXAMINATIONPRELIMINARY EXAMINATION

Remove the instrument from the packing material and examine it carefully to make sure that no damage has occurred during shipping. If there

is any damage, notify your dealer.

The meter is supplied complete with

• Mounting brackets

• Transport splash-proof cover

• Instructions manual.

Note: Conserve all packing material until the instrument has been

observed to function correctly. Any defective item must be

returned in its original packing.

GENERAL DESCRIPTIONGENERAL DESCRIPTION

GENERAL DESCRIPTION

GENERAL DESCRIPTIONGENERAL DESCRIPTION

HI 8410 is a panel-mounted DO controller designed for simplicity of

use in a wide range of industrial process applications.

Dissolved Oxygen is indicated in mg/L (ppm) or in % of saturation in accor-

dance with the selection switch on the front panel. The temperature can be

measured in the range from -5 to 50 °C. The Dissolved Oxygen readings are

automatically compensated for the temperature effects on the oxygen solubility and membrane permeability. Moreover, the salinity compensation

feature allows the determination of Dissolved Oxygen even in salty waters.

The instruments are designed with a standard DIN panel mount with

membrane keypads and large LCD with backlight on the front, and provide a series of auto-diagnostic functions.

Probes, power supply, contacts and recorders are connected on the rear

panel through screw terminals.

For control applications use the HI 76410/4 or HI 76410/10 galvanic probes.

The D.O. probe is provided with a membrane covering the galvanic sen-

sor and a built-in thermistor for temperature measurement and compensation. The Oxygen that passes through the membrane causes an electric

current flow, from which the oxygen concentration is determined.

Other features include: recorder output in 0-20 mA or 4-20 mA configuration; LED indicators which identify whether the controller is in operation

mode or setup selection mode; overtime control function; hysteresis setting.

The instrument is supplied with a plastic front cover and two mounting

brackets. Power cables are not included.

Note:In order to avoid erroneous readings never use both 0-20 mA and

4-20 mA recorder outputs at the same time.

3

Page 4

FUNCTIONAL DESCRIPTION HFUNCTIONAL DESCRIPTION H

FUNCTIONAL DESCRIPTION H

FUNCTIONAL DESCRIPTION HFUNCTIONAL DESCRIPTION H

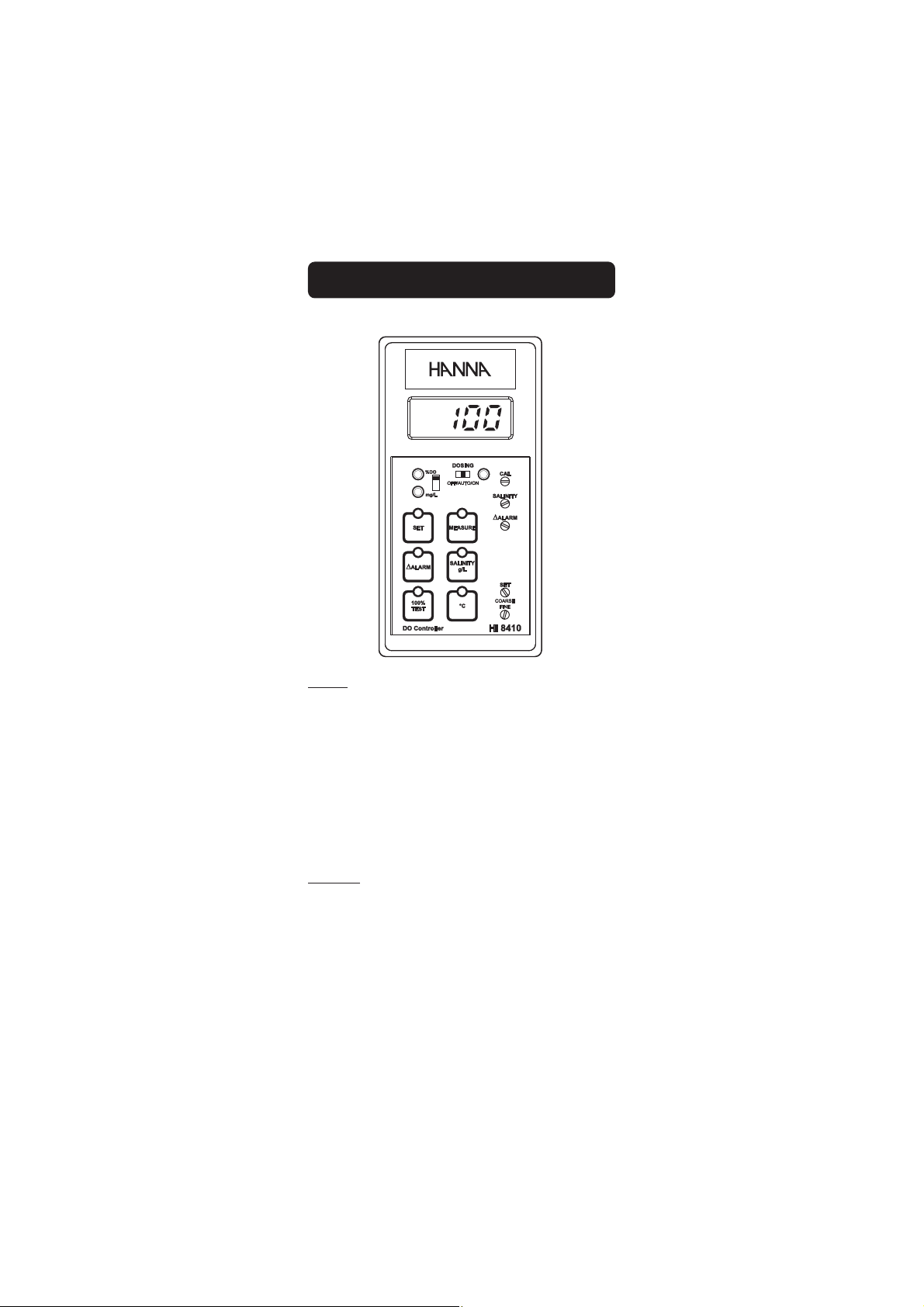

KEYPAD

MEASURE To read measurements and enable diagnostic tests

ΔALARM To display and set the tolerance of the alarm

SET To display and set the working dosing point

SALINITY g/L To display and set the salinity factor (active only

in mg/L range)

TEST 100% Diagnostic function (active only in % DO range)

°C To display the temperature reading

When a key is pressed, the corresponding LED lights up to indicate that

the function is active.

II

I

II

84108410

8410

84108410

TRIMMERS

CAL For 100% D.O. calibration

SALINITY To set the salinity concentration (g/L)

ΔALARM To set the alarm tolerance

SET COARSE To coarsely adjust the set point

SET FINE To finely adjust the set point

4

Page 5

LEDS

% DO To indicate that the D.O. is displayed in % of

saturation

mg/L To indicate that the D.O. is displayed in mg/L

SET To indicate that the dosage is active

ΔALARM To indicate an alarm condition

DOSAGE MODE SWITCH To indicate that the continuous ON or OFF

mode is selected from dosing switch

SWITCHES

OFF/AUTO/ON To select the dosing mode:

• OFF - dosing is disabled

• AUTO - automatic dosage, depending on

setpoint and reading values

• ON - dosing always active

% DO/mg/L To select % DO saturation or mg/L range

5

Page 6

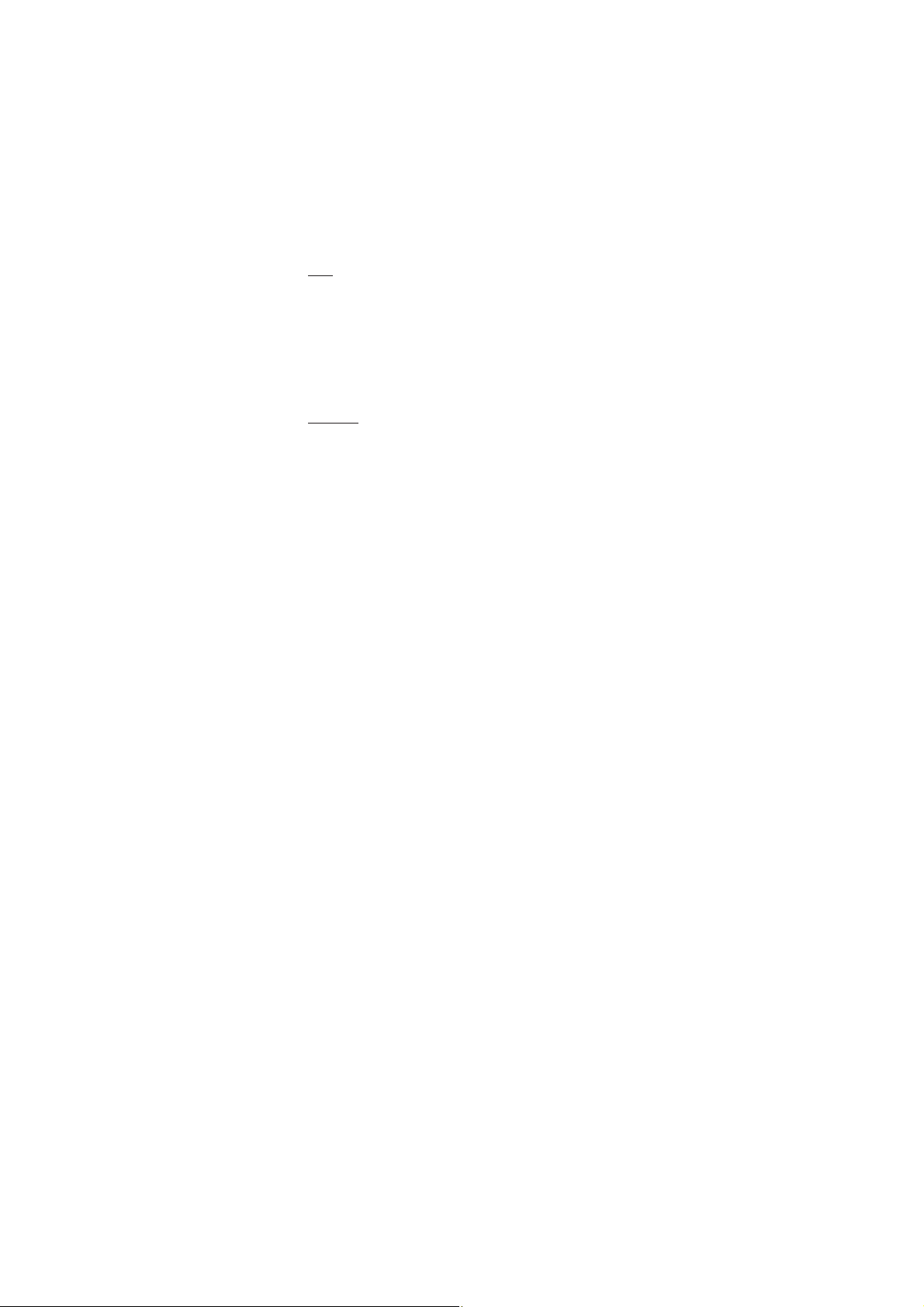

REAR PANEL OF HI 8410

1. DO probe connection terminals

2. SET terminals for connection to a dosing pump

3. ALARM terminals for connection to an external alarm device

4. Power supply terminals

5. Fuse holder

6. mA OUTPUT terminals for connection to a recorder

7. Hysteresis set knob (0.5 to 2.4 mg/L)

8. Disable overtime dosing connection

9. Overtime dosing set knob (about 5 to 60 min)

Unplug the instrument from power supply before replacing the fuse.

Only one of recorder output connections (0-20 mA or 4-20 mA) can

be used at a moment. Leave unconnected the unused terminal.

6

Page 7

MECHANICAL DIMENSIONS

OF HI 8410

Front view of the panel-mounted unit

These dimensions show the cutout size for the installation.

Side view of the panel-mounted unit

Adjustable location brackets (supplied with the meter) allow the indicator

to slide into the cutout and will hold the unit securely in place. 190 mm

(7.50") is the minimum amount of room required to install the indicator

with the cables connected.

7

Page 8

D.O. PROBESD.O. PROBES

D.O. PROBES

D.O. PROBESD.O. PROBES

All Hanna D.O. probes are shipped dry. To hydrate the probe and prepare

it for use proceed as follows:

1. Remove the black & red plastic cap. This cap is used for shipping purposes only and can be thrown away.

2. Insert the supplied O-ring in the membrane

(see figure).

3. Rinse the supplied membrane (HI 76410A) with electrolyte

while shaking it gently. Refill with clean electrolyte. Gently tap

the membrane over a surface to ensure that no air bubbles

remain trapped. To avoid damaging the membrane, do not

touch it with your fingers.

4. With the sensor facing down screw the cap clockwise to the end

of the threads. Some electrolyte will overflow.

8

Page 9

SPECIFICATIONS HSPECIFICATIONS H

SPECIFICATIONS H

SPECIFICATIONS HSPECIFICATIONS H

II

84108410

I

8410

II

84108410

Range

Resolution

Accuracy

Calibration

Temp. Compensation

Salinity Compensation

Probe (not included)

Recorder Output

Setpoint Relay and

Alarm Relay

Setpoint Range

Alarm Range

Hysteresis Range

Dosing Control

Over Dosing Control

Backlight

Power Supply

Enclosure

Environment

Panel Cutout

Weight

0.0 to 50.0 mg/L (ppm) O

0 to 600 % O

2

2

-5.0 to 50.0 °C

0.1 mg/L or 1% (O2) / 0.1 °C

±1% of reading (O2) / ±0.2 °C

Manual, one point, in saturated air

Automatic, from -5 to 50°C (23 to 122 °F)

0 to 51 g/L (resolution 1 g/L)

HI 76410/4 with 4 m cable or

HI 76410/10 with 10 m cable

0 to 20 mA or 4 to 20 mA (isolated)

1, Isolated, 2A, Max. 240V, resistive load,

1,000,000 strokes

1 to 600 % O

0.1to 50.0 mg/L (ppm) O

1.0 to 5.0 mg/L (ppm) O

0.5 to 2.4 mg/L (ppm) O

2

2

2

2

OFF/AUTO/ON with selection switch

Adjustable, from 5 min to 60 min with knob or

Disable by wire strap - on rear panel

Continuous ON

115 or 230 Vac ±10%

(user selectable); 60/50 Hz

Black anodized aluminum body;

front and back with ABS;

transparent splash-proof front cover

-10 to 50°C (14 to 122°F); RH 95%

141 x 69 mm (5.6 x 2.7")

1 kg (2.2 lb.)

9

Page 10

CONNECTIONSCONNECTIONS

CONNECTIONS

CONNECTIONSCONNECTIONS

REAR CONNECTIONS FOR HI 8410

• Power Connection Terminals

4-screw-terminal-strip for connection

to a 3-wire power cable according to

the indicated voltage (115 or 230V).

• Probe connection

For connection of the HI76410 DO

probe. Connect the wires according with

the indicated color.

• Set Contacts

Dosing pumps or other control equipment may be connected to the "SET"

(Max. 2A, 240 V) terminals (1, 2).

These contacts act only as a "dry"

switch allowing electrical continuity,

not as a power supply.

• Recorder Output (terminals 1, 2, 3)

These contacts are used for connection to a recorder output. The output

can be 0-20 mA or 4-20 mA and is proportional to the measured Dissolved

Oxygen values.

Connect the “+” wire from the recorder to terminal 1 on the instrument and the other wire (common) to terminal 2 for 4-20 mA recorder output or terminal 3 for 0-20 mA recorder output.

Note:Only one recorder output connection is permited. In order to avoid

malfunction leave unconnected the unused terminal.

10

Page 11

• Alarm Contacts (terminals 5, 6)

During normal operation these terminals

remain closed.

If the measured D.O. level is not within the

tolerance of the set value, the alarm contact is open. These contacts act only as a

switch. See also page 15.

• Overtime dosing

When enabled this feature ensures that overdosage is avoided. Select a desired maximum dosage period. If the dosage relay is active

more than the selected period an alarm condition is activated and the

dosage relay is deactivated.

To leave the overtime dosage alarm status change the position of the

OFF/AUTO/ON switch to OFF and then to AUTO again. The overtime

counter is restarted.

To set the overtime dosing period rotate the overtime knob to the

proper position. The time can be set between approx. 5 min to 60 min

(from MIN to MAX position).

To disable the overtime dosage feature make

a short with a jumper wire between the terminals of the proper connectors. (see picture,

terminals 1, 2)

• Hysteresis knob

Put the hysteresis knob in the desired position. The dosage will be active according to

the DO reading, set point value and the hys-

teresis set value.

DOSING MODE SELECTION

The DOSAGE switch and the corresponding right side LED on the front

panel are used to select and indicate the dosing mode.

OFF mode

The dosage is disabled. The corresponding

DOSAGE MODE LED blinks.

11

Page 12

AUTO

mode

The dosage is activated and deactivated according with the selected setpoint. The corresponding DOSAGE MODE LED (right side of

the switch) is off.

Be sure that the DOSAGE switch is in AUTO

position when the meter is in normal operating mode.

ON mode

The dosage is always activated. The corresponding DOSAGE MODE LED blinks.

OPERATIONAL GUIDEOPERATIONAL GUIDE

OPERATIONAL GUIDE

OPERATIONAL GUIDEOPERATIONAL GUIDE

INITIAL PREPARATION & INSTALLATION

Material needed:

• a 3-wire power cable to connect HI 8410

Ensure the controller has been calibrated. Ensure the D.O. probe is

immersed in the sample to be tested.

The D.O. reading can be displayed in % air saturation or in ppm (mg/L)

according to the range selection switch. The corresponding LED is ON.

For accurate dissolved oxygen measurements a water flow of at least

5-7 cm/sec is required. In this way a constant replenishment of the

oxygen-depleted membrane surface is ensured.

Accurate readings are not possible in still water.

Note: For some particular applications, such as fish farming, the mem-

brane can be sterilized with stabilized iodine (20 to 50 ppm),

typically used for this purpose.

Note: For use in harsh environments, it is recommended to protect

the membrane with the optional HI 76410-0 sleeve. The response time will slightly slow down.

12

Page 13

Ensure that the HI 76410 DO probe

is connected to the meter according

with the colors indicated on the mask.

OPERATING INFORMATION

All parameters are set through the front panel keys and trimmers.

When any key is pressed, the corresponding LED lights up to indicate

that the function is active.

SET POINT

To set the working point of the controller, press the SET key. The display

will indicate the current set value.

Use a small screwdriver to adjust the COARSE and FINE trimmers until

the desired value is displayed in units according with the range switch

(the corresponding % DO or mg/L LED is ON).

The dosing will be active when the DO reading is lower than the set point

(set point + hysteresis overpassed = stop dosing; set point = start

dosing)

SALINITY g/L SET (mg/L range only)

Oxygen measurements can be compensated for salinity concentration and

this correction value can be set by the user.

Select the mg/L mode by using the corresponding switch.

13

Page 14

Press the SALINITY g/L and the display will show the salinity. Use a small

screw driver to adjust the SALINITY trimmer to display the desired salinity

value (within the 0 to 51 g/L range).

ALTITUDE COMPENSATION (mg/L range only)

When salinity compensation is not required (i.e. not salty water), the

SALINITY trimmer can be used to set the altitude correction value.

Enter the mg/L mode.

Press the SALINITY g/L button. Turn the SALINITY trimmer to display the

salinity value corresponding to the desired altitude.

See below table for reference:

ALARM

Press the "ΔALARM" key and the

display will show the set tolerance for

the alarm.

Use a small screwdriver to adjust the

"ΔALARM" trimmer until the desired

tolerance is displayed.

For example, if the set value is 10 mg/L

and a ΔAlarm of 2 mg /L is set, an alarm

will be activated every time the measured

value is lower than 8 mg/L.

When an alarm occurs, the "ALARM"

LED lights up.

14

Page 15

The alarm contacts of HI 8410 remain closed during normal operation. If

the measured conductivity level is not within the tolerance of the set value,

the alarm contact will be open.

HYSTERESIS SET

Turn the hysteresis knob (rear panel) in the desired position (from 0.5 to

2.4 mg/L range)

The dosage will be active according to the DO reading set point value and

hysteresis set value.

TAKING MEASUREMENTS WITH HI 8410TAKING MEASUREMENTS WITH HI 8410

TAKING MEASUREMENTS WITH HI 8410

TAKING MEASUREMENTS WITH HI 8410TAKING MEASUREMENTS WITH HI 8410

After selecting the range (mg/L or % DO), setting the working point,

hysteresis, salinity factor and alarm value, press the "MEASURE" key. The

DO value of the test solution will be displayed.

If the reading is out of range the instrument displays:

TEMPERATURE MEASUREMENT

Press and hold the "°C" key and the display should indicate the temperature of the tested solution.

15

Page 16

CALIBRATION PROCEDURECALIBRATION PROCEDURE

CALIBRATION PROCEDURE

CALIBRATION PROCEDURECALIBRATION PROCEDURE

Calibration is a very simple 1-point procedure, performed in air.

Ensure the probe is ready for measurements, i.e. the membrane is filled

with electrolyte (see “Probe Preparation” section for details).

Switch the meter on, select the % DO mode and turn the CAL trimmer to

display 100%.

If the environmental relative humidity is lower than

30%, pour some deionized water (approx. 3 mm) in

the white cap supplied with the membrane. Insert the

probe in the cap and calibrate.

Keep the probe in vertical position to avoid any contact

of the membrane with the water.

Note: For best accuracy, calibration should be performed on the measurement

site, and the probe should be at the same temperature as the air.

Note: After replacing the membrane or the electrolyte solution, wait a

few minutes for the reading to stabilize.

DIAGNOSTIC TESTSDIAGNOSTIC TESTS

DIAGNOSTIC TESTS

DIAGNOSTIC TESTSDIAGNOSTIC TESTS

The HI 8410 controllers are designed with built-in diagnostic functions to

enable the user to check and troubleshoot the instrument. The checks

performed are through the front panel keys and can be used to isolate the

cause of malfunction.

Press the "MEASURE" key before proceeding

with the following tests.

100% Test

Select the % DO display mode.

Press the 100% TEST key and the display should indicate a value in the

interval between 30% and 200% DO.

16

Page 17

LED INDICATIONLED INDICATION

LED INDICATION

LED INDICATIONLED INDICATION

All LEDs above the keys or near switches indicate the state of each

function, whether it is active or the display is indicating the mode.

% DO LED It is on if the mode selection switch is in the upper

position, indicating that the selected range is % DO.

mg/L LED It is on if the mode selection switch is in the lower

position, indicating that the selected range is mg/L.

OFF/AUTO/ON LED It is on when the switch is in OFF (dosage disabled)

or in ON (dosage continuous enabled) position.

SET LED In MEASURE mode it is OFF or blinking (25% ON) in

accordance with the dosage relay status (inactive/

active).

In SET mode it is ON or blinking (75% ON) in

accordance with the dosage relay status (inactive/

active).

ΔALARM LED In MEASURE mode it is OFF or blinking (25% ON) in

accordance with the alarm status (inactive/active).

In ΔALARM set mode it is ON or blinking (75% ON)

in accordance with the alarm status (inactive/active).

MEASURE LED It is ON while the instrument is in MEASURE

mode.

SALINITY g/L LED It is ON while the instrument is in SALINITY set

mode.

100% TEST LED It is ON when the 100% TEST key is pressed.

°C LED It is on when the °C key is pressed and the

temperature is displayed.

17

Page 18

PROBE MAINTENANCE & CLEANINGPROBE MAINTENANCE & CLEANING

PROBE MAINTENANCE & CLEANING

PROBE MAINTENANCE & CLEANINGPROBE MAINTENANCE & CLEANING

For a top performance probe, it is recommended to replace the membrane

every 2 months and the electrolyte once a month.

Proceed as follows:

• Unscrew the membrane by turning it counterclockwise.

• Rinse the supplied spare membrane (HI 76410A) with some

electrolyte solution while shaking it gently. Refill with clean

electrolyte.

• Gently tap the membrane over a surface to ensure that no air

bubbles remain trapped.

• With the sensor facing down screw the cap clockwise to the end

of the threads. Some electrolyte will overflow.

If any deposit scales the sensors, gently brush the sensor surface with the

supplied scouring pad, while paying attention to not damage the plastic

body.

ACCESSORIESACCESSORIES

ACCESSORIES

ACCESSORIESACCESSORIES

HI 76410/4* Galvanic D.O. probe with built-in temperature sensor and

4 m cable

HI 76410/10*Galvanic D.O. probe with built-in temperature sensor and

10 m cable

HI 76410-0 Protective sleeve for HI 76410 probes series

HI 76410A/P Membrane for HI 76410 probes series, 5 pcs.

HI 7042S Electrolyte solution, 30 ml bottle

HI 710015 Shockproof rubber boot, blue color

HI 710016 Shockproof rubber boot, orange color

HI 731326 Calibration screwdriver (20 pcs)

* To be replaced by authorized technical personnel only.

Hanna Instruments reserves the right to modify the design,

construction and appearance of its products without advance

notice.

18

Page 19

WARRANTYWARRANTY

WARRANTY

WARRANTYWARRANTY

All HANNA instruments® meters are warranted for two years against

defects in workmanship and materials when used for their intended

purpose and maintained according to instructions.

The probes are warranted for a period of one year.

This warranty is limited to repair or replacement free of charge.

Damages due to accident, misuse, tampering or lack of prescribed

maintenance are not covered.

If service is required, contact the dealer from whom you purchased the

instrument. If under warranty, report the model number, date of purchase,

serial number and the nature of the failure. If the repair is not covered by

the warranty, you will be notified of the charges incurred.

If the instrument is to be returned to HANNA instruments®, first obtain a

Returned Goods Authorization Number from the Customer Service department and then send it with shipment costs prepaid.

When shipping any instrument, make sure it is properly packaged for

complete protection.

Recommendations for Users

Before using these products, make sure that they are entirely suitable for the

environment in which they are used.

Operation of these instruments in residential area could cause unacceptable

interferences to radio and TV equipments, requiring the operator to take all

necessary steps to correct interferences.

The trimmers are sensitive to electrostatic discharges. It is recommended to use

anti-static screwdrivers.

Unplug the instrument from the power supply before replacing the fuse. External

cables to be connected to the rear panel should end with cable lugs.

To maintain the EMC performance of this equipment, use the proper cables.

Any variation introduced by the user to the supplied equipment may degrade the

instruments' EMC performance.

To avoid electrical shock, do not use these instruments when voltages at the

measurement surface exceed 24 Vac or 60 Vdc.

To avoid damages or burns, do not perform any measurement in microwave ovens.

All rights are reserved. Reproduction in whole or in part is prohibited

without the written consent of the copyright owner.

19

Page 20

SALES & TECHNICAL SERVICE CONTACTSSALES & TECHNICAL SERVICE CONTACTS

SALES & TECHNICAL SERVICE CONTACTS

SALES & TECHNICAL SERVICE CONTACTSSALES & TECHNICAL SERVICE CONTACTS

Australia:

Tel. (03) 9769.0666 • Fax (03) 9769.0699

China:

Tel. (10) 88570068 • Fax (10) 88570060

Egypt:

Tel. & Fax (02) 2758.683

Germany:

Tel. (07851) 9129-0 • Fax (07851) 9129-99

Greece:

Tel. (210) 823.5192 • Fax (210) 884.0210

Indonesia:

Tel. (21) 4584.2941 • Fax (21) 4584.2942

Japan:

Tel. (03) 3258.9565 • Fax (03) 3258.9567

Korea:

Tel. (02) 2278.5147 • Fax (02) 2264.1729

Malaysia:

Tel. (603) 5638.9940 • Fax (603) 5638.9829

Singapore:

Tel. 6296.7118 • Fax 6291.6906

South Africa:

Tel. (011) 615.6076 • Fax (011) 615.8582

Taiwan:

Tel. 886.2.2739.3014 • Fax 886.2.2739.2983

Thailand:

Tel. 66.2619.0708 • Fax 66.2619.0061

United Kingdom:

Tel. (01525) 850.855 • Fax (01525) 853.668

USA:

Tel. (401) 765.7500 • Fax (401) 765.7575

For e-mail contacts and complete list of Sales and

Technical offices, please see www.hannainst.com

20

MAN8410 04/08

Loading...

Loading...