Page 1

Instruction Manual

HI 83207

Multiparameter Bench

Photometer

for Industrial Wastewater

www.hannainst.com

1

Page 2

Dear Customer,

Thank you for choosing a Hanna product. Please read this instruction manual carefully before using the

instrument. This manual will provide you with the necessary information for the correct use of the

instrument. If you need additional technical information, do not hesitate to e-mail us at tech@hannainst.com.

TABLE OF CONTENTS

PRELIMINARY EXAMINATION ............................................. 3

ABBREVIATIONS ............................................................... 3

GENERAL DESCRIPTION ..................................................... 3

SPECIFICATIONS .............................................................. 4

PRECISION AND ACCURACY ............................................... 4

PRINCIPLE OF OPERATION ................................................ 4

FUNCTIONAL DESCRIPTION ............................................... 6

TIPS FOR AN ACCURATE MEASUREMENT ........................... 8

HEALTH & SAFETY ..........................................................11

METHOD REFERENCE TABLE ............................................. 11

OPERATIONAL GUIDE ....................................................... 12

SETUP ........................................................................... 14

HELP MODE ................................................................... 16

ALUMINUM ....................................................................17

FREE CHLORINE ............................................................. 19

TOTAL CHLORINE ............................................................22

COLOR OF WATER ........................................................... 25

COPPER HR ....................................................................27

COPPER LR .................................................................... 29

FLUORIDE ...................................................................... 31

MANGANESE HR ............................................................. 33

MANGANESE LR ............................................................. 35

MOLYBDENUM ............................................................... 38

NICKEL HR ..................................................................... 41

NICKEL LR ...................................................................... 43

NITRATE .........................................................................46

DISSOLVED OXYGEN ........................................................48

pH ................................................................................50

PHOSPHATE HR ..............................................................52

PHOSPHATE LR ...............................................................54

PHOSPHORUS ...............................................................56

SILVER ..........................................................................58

ZINC ..............................................................................61

ERRORS AND WARNINGS ................................................. 63

DATA MANAGEMENT ........................................................ 64

STANDARD METHODS ......................................................64

ACCESSORIES ................................................................65

WARRANTY .................................................................... 67

HANNA LITERATURE ........................................................ 67

All rights are reserved. Reproduction in whole or in part is prohibited without the written consent of the copyright owner, Hanna

Instruments Inc., Woonsocket, Rhode Island, 02895 , USA.

2

Page 3

PRELIMINARY EXAMINATION

Please examine this product carefully. Make sure that the instrument is not damaged. If any damage

occurred during shipment, please notify your local Hanna Office.

Each Meter is supplied complete with:

• Three Sample Cuvettes and Caps

• Cloth for wiping cuvettes (1 pcs)

• Scissors

• AC/DC Power Adapter

• Instruction Manual

Note: Save all packing material until you are sure that the instrument works correctly. Any defective item

must be returned in its original packing with the supplied accessories.

ABBREVIATIONS

EPA: US Environmental Protection Agency

°C: degree Celsius

°F: degree Fahrenheit

μg/L: micrograms per liter (ppb)

mg/L: milligrams per liter (ppm)

g/L: grams per liter (ppt)

mL: milliliter

HR: high range

MR: medium range

LR: low range

PAN: 1-(2-pyridylazo)-2-naphtol

GENERAL DESCRIPTION

HI 83207 is a multiparameter bench photometer dedicated for Industrial Wastewater analysis. It measures

20 different methods using specific liquid or powder reagents. The amount of reagent is precisely dosed to

ensure maximum reproducibility.

HI 83207 bench photometer can be connected to a PC via an USB cable. The optional HI 92000

Windows® Compatible Software helps users manage all their results.

HI 83207 has a powerful interactive user support that assists the user during the analysis process.

Each step in the measurement process is help supported. A tutorial mode is available in the Setup Menu.

3

Page 4

SPECIFICATIONS

Light Life Life of the instrument

Light Detector Silicon Photocell

Environment 0 to 50°C (32 to 122°F);

max 90% RH non-condensing

Power Supply external 12 Vdc power adapter

built-in rechargeable battery

Dimensions 235 x 200 x 110 mm (9.2 x 7.87 x 4.33")

Weight 0.9 Kg

For specifications related to each method (e.g. range, resolution, etc.) refer to the related measurement

section.

PRECISION AND ACCURACY

Precision is how closely repeated measurements agree

with each other. Precision is usually expressed as

standard deviation (SD).

Accuracy is defined as the nearness of a test result to

the true value.

Although good precision suggests good accuracy, precise

results can be inaccurate. The figure explains these

definitions.

For each method, the precision is expressed in the

related measurement section.

PRINCIPLE OF OPERATION

Absorption of light is a typical phenomenon of interaction between electromagnetic radiation and matter.

When a light beam crosses a substance, some of the radiation may be absorbed by atoms, molecules or

crystal lattices.

If pure absorption occurs, the fraction of light absorbed depends both on the optical path length through the

matter and on the physical-chemical characteristics of substance according to the Lambert-Beer Law:

-log I/Io = ε

A = ε

c d

λ

or

c d

λ

4

Page 5

Where:

-log I/I

= Absorbance (A)

o

Io= intensity of incident light beam

I = intensity of light beam after absorption

ε

= molar extinction coefficient at wavelength λ

λ

c = molar concentration of the substance

d = optical path through the substance

Therefore, the concentration "c" can be calculated from the absorbance of the substance as the other factors

are known.

Photometric chemical analysis is based on the possibility to develop an absorbing compound from a specific

chemical reaction between sample and reagents.

Given that the absorption of a compound strictly depends on the wavelength of the incident light beam, a

narrow spectral bandwidth should be selected as well as a proper central wavelength to optimize measurements.

The optical system of HI 83207 is based on special subminiature tungsten lamps and narrow-band

interference filters to guarantee both high performance and reliable results.

Four measuring channels allow a wide range of tests.

Instrument block diagram (optical layout)

A microprocessor controlled special tungsten lamp emits radiation which is first optically conditioned and

beamed trough the sample contained in the cuvette. The optical path is fixed by the diameter of the

cuvette. Then the light is spectrally filtered to a narrow spectral bandwidth, to obtain a light beam of

intensity Io or I.

The photoelectric cell collects the radiation I that is not absorbed by the sample and converts it into an

electric current, producing a potential in the mV range.

The microprocessor uses this potential to convert the incoming value into the desired measuring unit and to

display it on the LCD.

The measurement process is carried out in two phases: first the meter is zeroed and then the actual

measurement is performed.

The cuvette has a very important role because it is an optical element and thus requires particular attention. It

is important that both the measurement and the calibration (zeroing) cuvette are optically identical to provide the

same measurement conditions. Most methods use the same cuvette for both, so it is important that measurements

are taken at the same optical point. The instrument and the cuvette cap have special marks that must be

aligned in order to obtain better reproducibility.

The surface of the cuvette must be clean and not scratched. This is to avoid measurement interference due to

unwanted reflection and absorption of light. It is recommended not to touch the cuvette walls with hands.

Furthermore, in order to maintain the same conditions during the zeroing and the measurement phases,

it is necessary to cap the cuvette to prevent any contamination.

5

Page 6

FUNCTIONAL DESCRIPTION

INSTRUMENT DESCRIPTION

1) Open Cuvette Lid

2) Indexing mark

3) Cuvette point

4) Liquid Crystal Display (LCD).

5) Splash proof keypad.

6) ON/OFF power switch

7) Power input connector

8) USB connector

6

Page 7

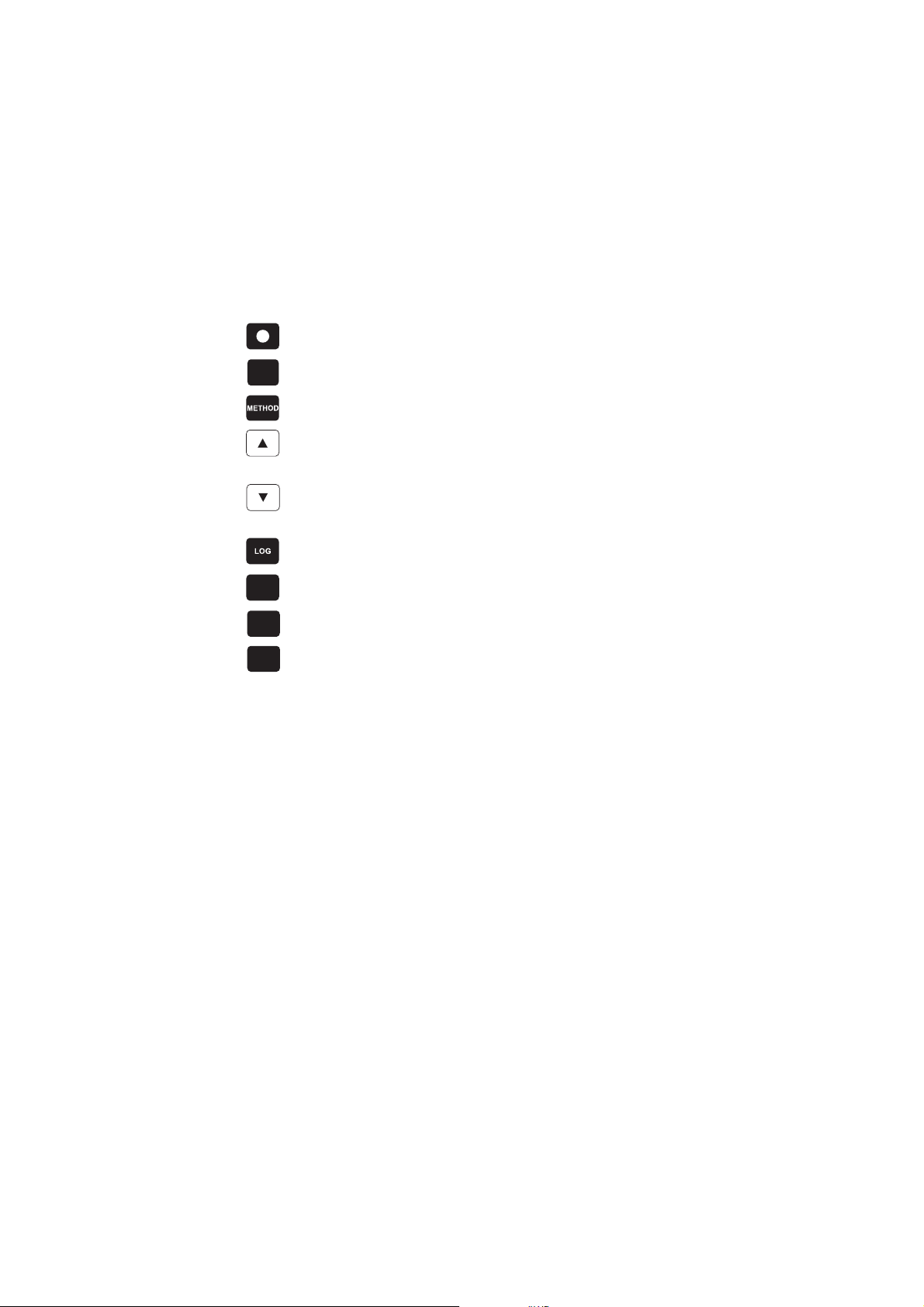

KEYPAD DESCRIPTION

The keypad contains 8 direct keys and 3 functional keys with the following functions:

Press to perform the function displayed above it on the LCD.

ESC

Press to exit the current screen.

Press to access the select method menu.

Press to move up in a menu or a help screen, to increment a set value, to access second level

functions.

Press to move down in a menu or a help screen, to decrement a set value, to access second

level functions.

Press to log the current reading.

RCL

Press to recall the log.

HELP

SETUP

Press to display the help screen.

Press to access the setup screen.

7

Page 8

TIPS FOR AN ACCURATE MEASUREMENT

The instructions listed below should be carefully followed during testing to ensure most accurate results.

• Color or suspended matter in large amounts may cause interference, and should be removed by

treatment with active carbon and filtration.

• Ensure the cuvette is filled correctly: the liquid in the cuvette forms a convexity on the top; the bottom

of this convexity must be at the same level as the 10 mL mark.

COLLECTING AND MEASURING SAMPLES

• In order to measure exactly 0.5 mL of reagent with the 1 mL syringe:

(a) push the plunger completely into the syringe and insert the tip into the solution.

(b) pull the plunger up until the lower edge of the seal is exactly on the 0.0 mL mark.

(c) take out the syringe and clean the outside of the syringe tip. Be sure that no drops are hanging

on the tip of the syringe, if so eliminate them. Then, keeping the syringe in vertical position above

the cuvette, push the plunger down into the syringe until the lower edge of the seal is exactly on

the 0.5 mL mark. Now the exact amount of 0.5 mL has been added to the cuvette, even if the

tip still contains some solution.

USING LIQUID AND POWDER REAGENTS

• Proper use of the dropper:

(a) for reproducible results, tap the dropper on the table for several times and wipe the outside of the

dropper tip with a cloth.

(b) always keep the dropper bottle in a vertical position while dosing the reagent.

(a) (b)

8

Page 9

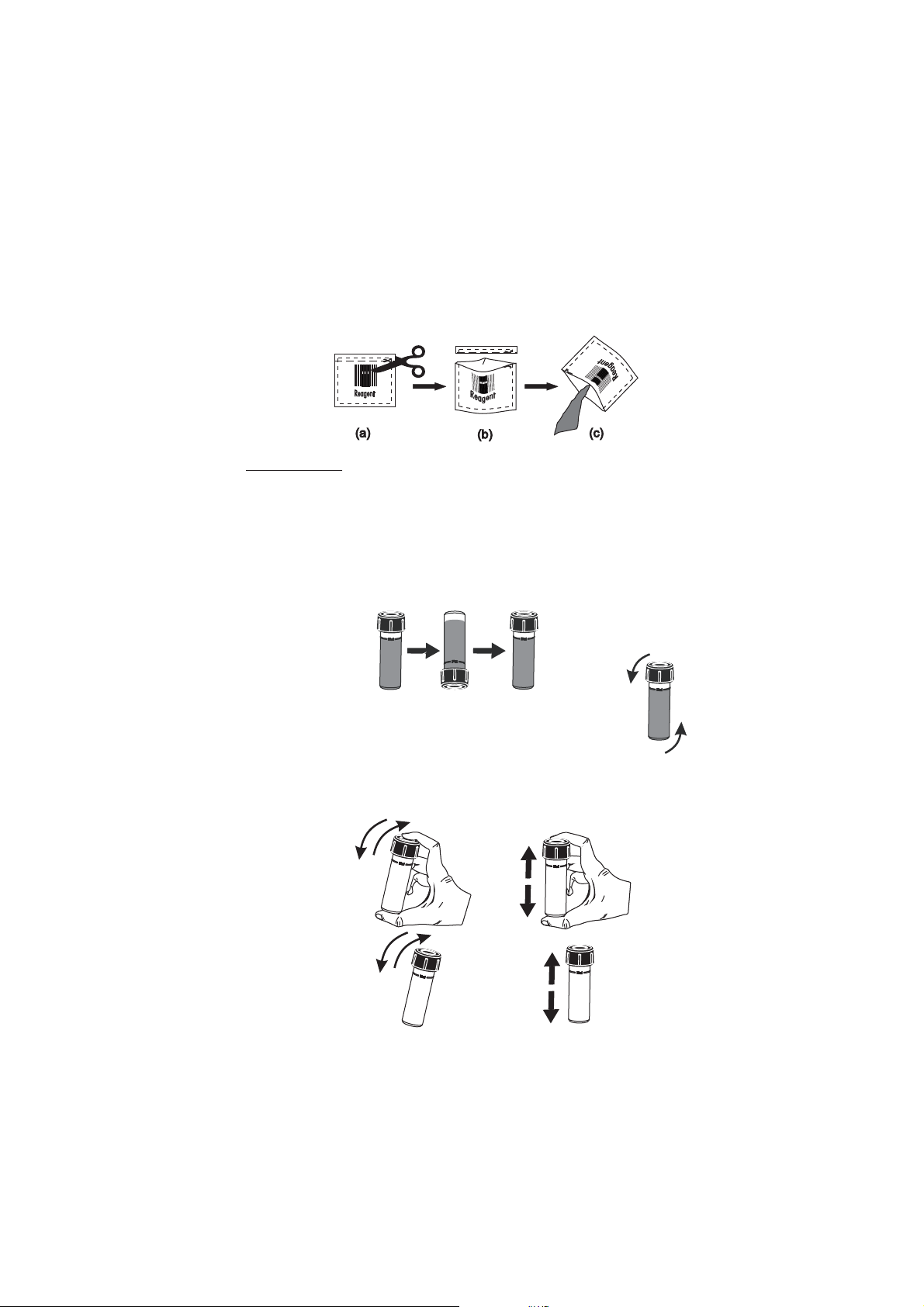

• Proper use of the powder reagent packet:

(a) use scissors to open the powder packet;

(b) push the edges of the packet to form a spout;

(c) pour out the content of the packet.

USING CUVETTES

• Proper mixing is very important for reproducibility of the measurements. The right way of mixing a

cuvette is specified for each method in the related chapter.

(a) invert the cuvette a couple of times or for a specified time: hold the cuvette in the vertical position. Turn

the cuvette upside-down and wait for all of the solution to flow to the cap end, then return the cuvette

to the upright vertical position and wait for all of the solution to flow to the cuvette bottom. This is one

inversion. The correct speed for this mixing technique is 10-15 complete inversions in 30 seconds.

This mixing technique is indicated with “invert to mix” and the following icon:

(b) shaking the cuvette, moving the cuvette up and down. The movement may be gentle or vigorous.

This mixing method is indicated with “shake gently” or “shake vigorously”, and one of the following

icons:

shake gently shake vigorously

9

Page 10

• Pay attention to push the cuvette completely down in the holder and to align the white point on the

cap to the indexing mark on the meter.

• In order to avoid reagent leaking and to obtain more accurate

measurements, close the cuvette first with the supplied HDPE plastic

stopper and then the black cap.

• Each time the cuvette is used, the cap must be tightened to the same

degree.

• Whenever the cuvette is placed into the measurement cell, it must be dry

outside, and free of fingerprints, oil or dirt. Wipe it thoroughly with

HI 731318 or a lint-free cloth prior to insertion.

• Shaking the cuvette can generate bubbles in the sample, causing

higher readings. To obtain accurate measurements, remove such bubbles

by swirling or by gently tapping the cuvette.

• Do not let the reacted sample stand too long after reagent is added. For

best accuracy, respect the timings described in each specific method.

• It is possible to take multiple readings in a row, but it is recommended

to take a new zero reading for each sample and to use the same cuvette

for zeroing and measurement when possible (for most precise results

follow the measurement procedures carefully).

• Discard the sample immediately after the reading is taken, or the glass might become permanently

stained.

• All the reaction times reported in this manual are at 25 °C (77 °F). In general, the reaction time

should be increased for temperatures lower than 20 °C (68 °F), and decreased for temperatures higher

than 25 °C (77 °F).

INTERFERENCES

• In the method measurement section the most common interferences that may be present in an average

wastewater matrix have been reported. It may be that for a particular treatment process other

compounds do interfere with the method of analysis.

10

Page 11

HEALTH & SAFETY

• The chemicals contained in the reagent kits may be hazardous if improperly handled.

• Read the Material Safety Data Sheet (MSDS) before performing tests.

• Safety equipment: Wear suitable eye protection and clothing when required, and follow instructions

carefully.

• Reagent spills: If a reagent spill occurs, wipe up immediately and rinse with plenty of water.

If reagent contacts skin, rinse the affected area thoroughly with water. Avoid breathing released vapors.

• Waste disposal: for proper disposal of reagent kits and reacted samples, refer to the Material Safety

Data Sheet (MSDS).

METHOD REFERENCE TABLE

Method Method Page

description

1 Aluminum 17

2 Free Chlorine 19

3 Total Chlorine 22

4 Color of Water 25

5 Copper HR 27

6 Copper LR 29

7 Fluoride 31

8 Manganese HR 33

9 Manganese LR 35

10 Molybdenum 38

11 Nickel HR 41

12 Nickel LR 43

13 Nitrate 46

14 Dissolved Oxygen 48

15 p H 50

16 Phosphate HR 52

17 Phosphate LR 54

18 Phosphorus 56

19 Silver 58

20 Zinc 61

11

Page 12

OPERATIONAL GUIDE

POWER CONNECTION AND BATTERY MANAGEMENT

The meter can be powered from an AC/DC adapter (included) or from the built-in rechargeable battery.

Note: Always turn the meter off before unplugging it to ensure no data is lost.

When the meter switches ON, it verifies if the power supply adapter is connected. The battery icon on the

LCD will indicate the battery status:

- battery is charging from external adapter - battery fully charged (meter connected to AC/DC adapter)

- battery capacity (no external adapter) - battery Low (no external adapter)

- battery Dead (no external adapter)

METHOD SELECTION

• Turn ON the instrument via the ON/OFF power switch.

• The meter will perform an autodiagnostic test. During this test, the Hanna Instrument logo will appear on

the LCD. After 5 seconds, if the test was successful, the last selected method will appear on the display.

• In order to select the desired method press the METHOD key and a screen with the available methods

will appear.

• Press the keys to highlight the desired method. Press Select.

12

Page 13

• After the desired method is selected, follow the measurement described in the related section.

• Before performing a test you should read all the instructions carefully.

DATA MANAGEMENT

The instrument features a data log function to help you keep track of all your analysis. The data log can

hold 200 individual measurements. Storing, viewing and deleting the data is possible using the LOG

and

RCL keys

Storing data

stored with date and time stamps.

..

.

..

: You can store only a valid measurement. Press LOG

and the last valid measurement will be

Viewing and deleting

the last saved measurement. Additionally, you can delete the data records all at once.

: You can view and delete the data log by pressing the RCL key. You can only delete

CHEMICAL FORM

Chemical form conversion factors are pre-programmed into the instrument and are method specific. In order

to view the displayed result in the desired chemical form press or to access the second level function

and then press the Chem Frm key to toggle between the available chemical forms for the selected method.

13

Page 14

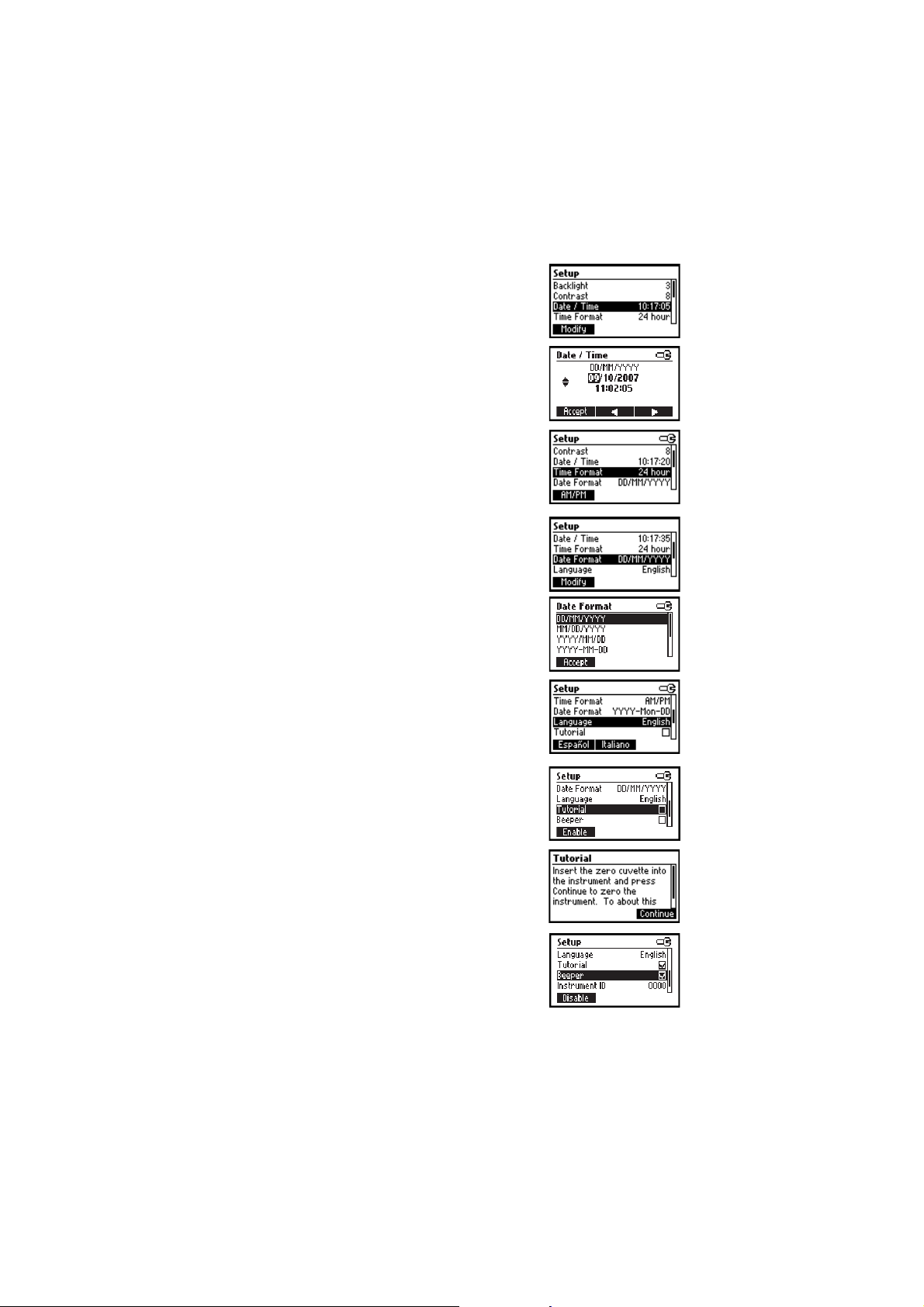

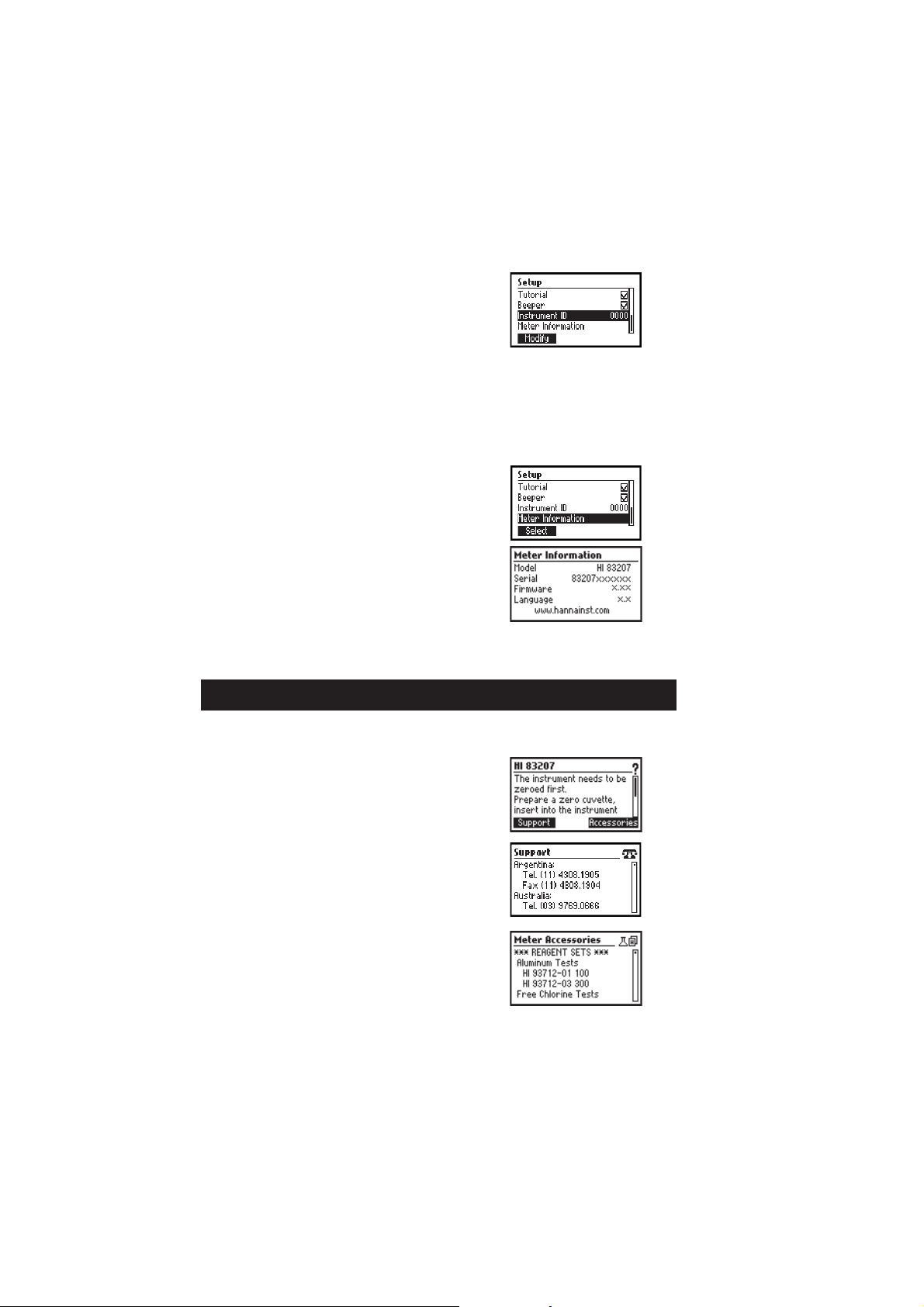

SETUPSETUP

SETUP

SETUPSETUP

In the Setup mode the instrument’s parameters can be changed. Some parameters affect the measuring

sequence and others are general parameters that change the behavior or appearance of the instrument.

Press SETUP to enter the setup mode.

Press ESC or SETUP to return to the main screen.

A list of setup parameters will be displayed with currently

configured settings. Press HELP for additional information.

Press the keys to select the parameter and select a

new value as follows:

Backlight

Values: 0 to 8.

Press the Modify key to access the backlight value.

Use the W X functional keys or the keys to increase or

decrease the value.

Press the Accept key to confirm or ESC to return to the setup

menu without saving the new value.

Contrast

Values: 0 to 20.

This option is used to set the display’s contrast.

Press the Modify key to change the display’s contrast.

Use the W X functional keys or the keys to increase or

decrease the value.

Press the Accept key to confirm the value or ESC to return to the

setup menu without saving the new value.

14

Page 15

Date / Time

This option is used to set the instrument’s date and time.

Press the Modify key to change the date/time.

Press the W X functional keys to highlight the value to be

modified (year, month, day, hour, minute or second). Use the

keys to change the value.

Press the Accept key to confirm or ESC to return to the setup

without saving the new date or time.

Time format

Option: AM/PM or 24 hour.

Press the functional key to select the desired time format.

Date format

Press Modify key to change the Date Format.

Use the keys to select the desired format.

Press the Accept key to confirm or ESC to return to the setup

menu without saving the new format.

Language

Press the corresponding functional key to change the option.

If the new selected language cannot be loaded, the previously

selected language will be reloaded.

Tutorial

Option: Enable or Disable.

If enabled this option will provide the user short guides, related

to the current screen.

Press the functional key to enable/disable the tutorial mode.

Beeper

Option: Enable or Disable.

When enabled, a short beep is heard every time a key is pressed.

A long beep alert sounds when the pressed key is not active or an

error is detected.

Press the functional key to enable/disable the beeper.

15

Page 16

Instrument ID

Option: 0 to 9999.

This option is used to set the instrument’s ID (identification

number). The instrument ID is used while exchanging data with

a PC.

Press the Modify key to access the instrument ID screen. Press

the keys in order to set the desired value.

Press the Accept key to confirm the value or ESC to return to the

setup menu without saving the new value.

Meter information

Press the Select key to view the Instrument model, firmware

version, language version and instrument serial number.

Press ESC to return to the Setup mode.

HELP MODEHELP MODE

HELP MODE

HELP MODEHELP MODE

HELP MODE

HI 83207 offers an interactive contextual help mode that assists the user at any time.

To access help screens press HELP.

The instrument will display additional information related to the

current screen. To read all available information, scroll the text

using the keys.

Press the Support key to access a screen with Hanna service

centers and their contact details.

Press the Accessories key to access a list of instrument reagents

and accessories.

To exit support or accessories screens press ESC and the

instrument will return to the previous help screen.

To exit help mode press the HELP or ESC key again and the

meter will return to the previously selected screen.

16

Page 17

ALUMINUM

SPECIFICATIONS

Range 0.00 to 1.00 mg/L

Resolution 0.01 mg/L

Accuracy ±0.02 mg/L ±4% of reading at 25 °C

Typical EMC ±0.01 mg/L

Deviation

Light Source Tungsten lamp with narrow band interference filter @ 525 nm

Method Adaptation of the aluminon method. The reaction between aluminum and reagents

causes a reddish tint in the sample.

REQUIRED REAGENTS

Code Description Quantity

HI 93712A-0 Ascorbic acid 1 packet

HI 93712B-0 Aluminon reagent 1 packet

HI 93712C-0 Bleaching powder 1 packet

REAGENT SETS

HI 93712-01 Reagents for 100 tests

HI 93712-03 Reagents for 300 tests

For other accessories see page 65.

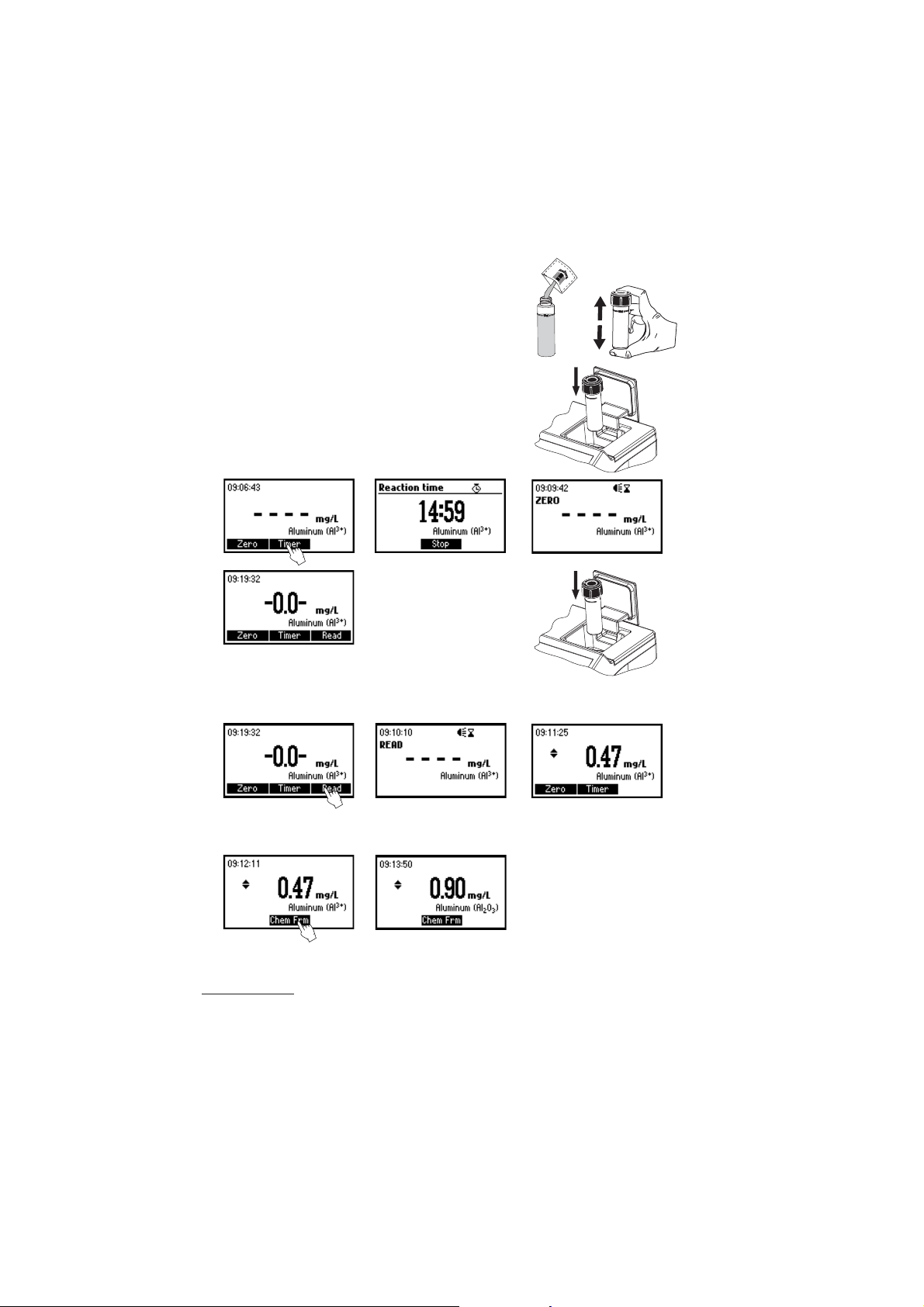

MEASUREMENT PROCEDURE

• Select the

Method Selection

Aluminum

method using the procedure described in the

section (see page 12).

• Fill a graduated beaker with 50 mL of sample.

• Add the content of one packet of HI 93712A-0 Ascorbic acid and mix

until completely dissolved.

• Add the content of one packet of HI 93712B-0 Aluminon reagent

and mix until completely dissolved. This is the sample.

• Fill two cuvettes with 10 mL of sample each (up to the mark).

17

10 mL

# 1

10 mL

# 2

Aluminum

Page 18

• Add the content of one packet of HI 93712C-0 Bleaching

powder to one of the two cuvettes. Replace the cap and shake

vigorously until completely dissolved. This is the blank.

• Place the blank into the holder and close the lid.

# 1

• Press Timer and the display will show the countdown prior to

# 1

zeroing the blank. Alternatively wait for 15 minutes and then press

Zero. The display will show “-0.0-” when the meter is zeroed and

ready for measurement.

# 2

• Remove the blank and insert the other cuvette into the instrument.

• Press the Read key and the meter will perform the reading. The instrument displays the results in

mg/L of aluminum.

• Press or to access the second level functions.

• Press the Chem Frm key to convert the result in mg/L of Al2O3.

• Press or to return to the measurement screen.

INTERFERENCES

Interference may be caused by:

Iron above 20 mg/L, Alkalinity above 1000 mg/L, Phosphate above 50 mg/L, Fluoride must be absent.

Aluminum

18

Page 19

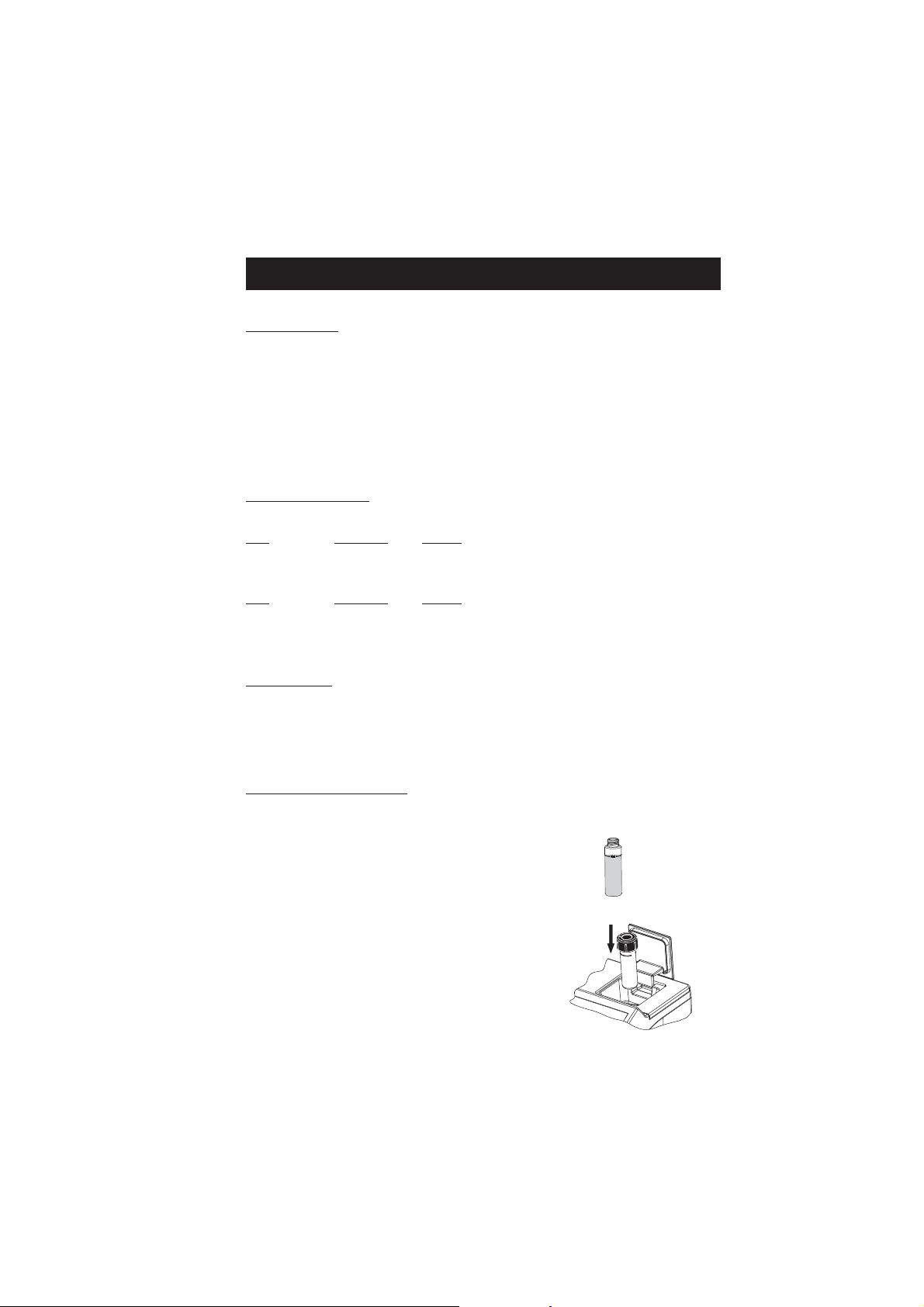

FREE CHLORINE

FREE CHLORINEFREE CHLORINE

FREE CHLORINE

FREE CHLORINEFREE CHLORINE

SPECIFICATIONS

Range 0.00 to 2.50 mg/L

Resolution 0.01 mg/L

Accuracy ±0.03 mg/L ±3% of reading at 25 °C

Typical EMC ±0.01 mg/L

Deviation

Light Source Tungsten lamp with narrow band interference filter @ 525 nm

Method Adaptation of the

DPD reagent causes a pink tint in the sample.

EPA DPD method 330.5.

The reaction between free chlorine and the

REQUIRED REAGENTS

POWDER:

Code Description Quantity

HI 93701-0 DPD 1 packet

LIQUID:

Code Description Quantity

HI 93701A-F DPD1 Indicator 3 drops

HI 93701B-F DPD1 Buffer 3 drops

REAGENT SETS

HI 93701-F Reagents for 300 tests (liquid)

HI 93701-01 Reagents for 100 tests (powder)

HI 93701-03 Reagents for 300 tests (powder)

For other accessories see page 65.

MEASUREMENT PROCEDURE

• Select the

in the

• Fill the cuvette with 10 mL of unreacted sample (up to the

mark) and replace the cap.

• Place the cuvette into the holder and close the lid.

Free Chlorine

Method Selection

method using the procedure described

section (see page 12).

19

10 mL

Free Chlorine

Page 20

• Press the Zero key. The meter will show “-0.0-” when the meter is zeroed and ready for measurement.

• Remove the cuvette.

Powder reagents procedure

• Add the content of one packet of HI 93701 DPD reagent. Replace the

cap and shake gently for 20 seconds (or 2 minutes for seawater

analysis).

• Reinsert the cuvette into the instrument.

• Press Timer and the display will show the countdown prior to the measurement or, alternatively, wait

for 1 minute and press Read. When the timer ends the meter will perform the reading. The instrument

displays the results in mg/L of free chlorine.

Liquid reagents procedure

• To an empty cuvette add 3 drops of HI 93701A-F DPD1

indicator and 3 drops of HI 93701B-F DPD1 buffer. Swirl

gently to mix, and immediately add 10 mL of unreacted

sample. Replace the cap and shake gently again.

Free Chlorine

20

Page 21

• Reinsert the cuvette into the instrument.

• Press Read to start the reading. The instrument displays the results in mg/L of free chlorine.

INTERFERENCES

Interference may be caused by: Bromine, Iodine, Ozone, Oxidized forms of Chromium and Manganese.

In case of water with hardness greater than 500 mg/L CaCO3, shake the sample for approximately

2 minutes after adding the powder reagent.

In case of water with alkalinity greater than 250 mg/L CaCO3 or acidity greater than 150 mg/L CaCO3,

the color of the sample may develop only partially, or may rapidly fade. To resolve this, neutralize the

sample with diluted HCl or NaOH.

21

Free Chlorine

Page 22

TOTAL CHLORINE

SPECIFICATIONS

Range 0.00 to 3.50 mg/L

Resolution 0.01 mg/L

Accuracy ±0.03 mg/L ±3% of reading at 25 °C

Typical EMC ±0.01 mg/L

Deviation

Light Source Tungsten lamp with narrow band interference filter @ 525 nm

Method Adaptation of the

DPD reagent causes a pink tint in the sample.

REQUIRED REAGENTS

POWDER:

Code Description Quantity

HI 93711-0 DPD 1 packet

LIQUID:

Code Description Quantity

HI 93701A-T DPD1 indicator 3 drops

HI 93701B-T DPD1 buffer 3 drops

HI 93701C DPD3 solution 1 drop

REAGENT SETS

HI 93701-T Reagents for 300 total chlorine tests (liquid)

HI 93711-01 Reagents for 100 total chlorine tests (powder)

HI 93711-03 Reagents for 300 total chlorine tests (powder)

For other accessories see page 65.

EPA DPD method 330.5.

The reaction between the chlorine and the

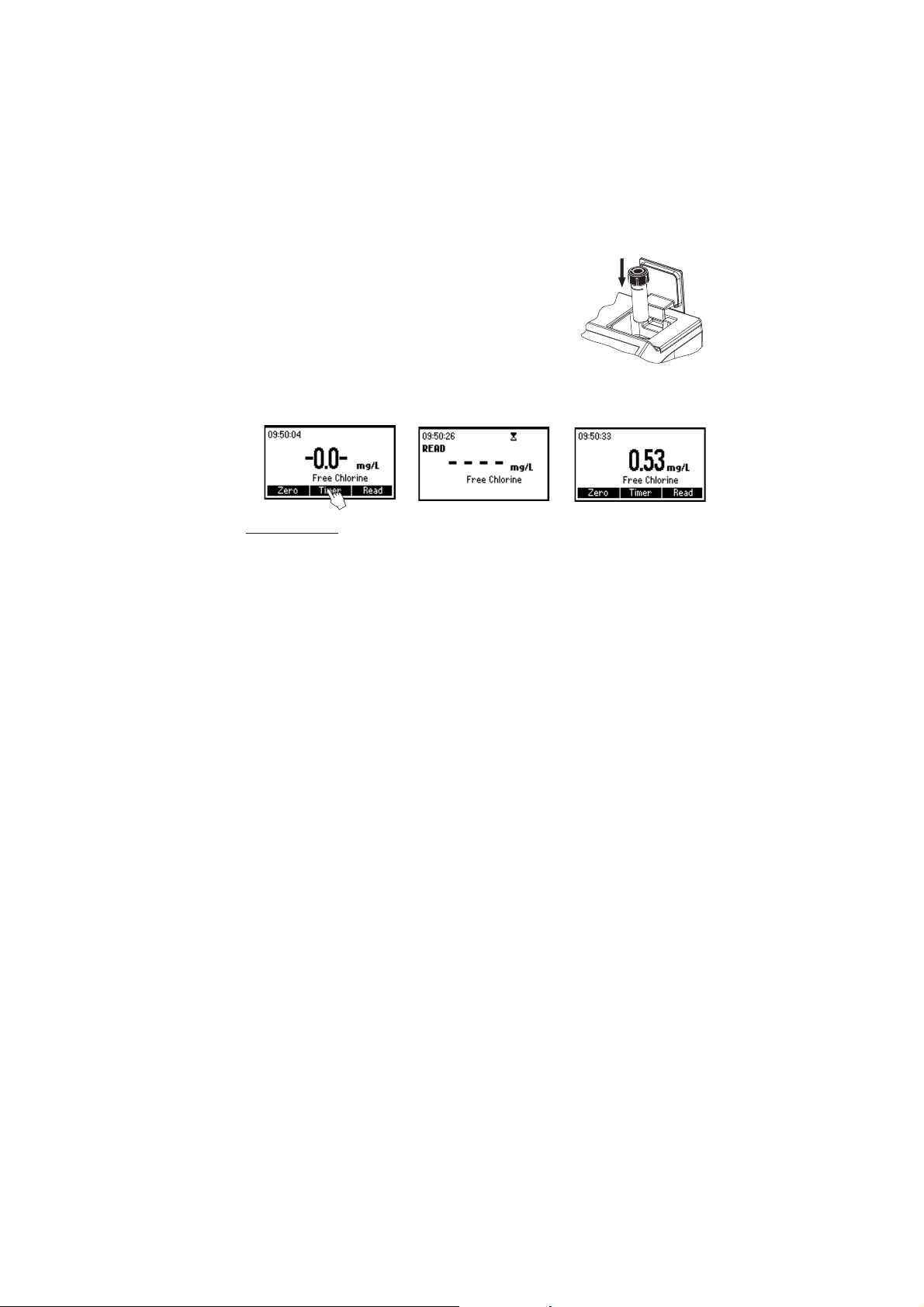

MEASUREMENT PROCEDURE

• Select the

described in the

• Fill the cuvette with 10 mL of unreacted sample (up to the

mark) and replace the cap.

• Place the cuvette into the holder and close the lid.

Total Chlorine

Total Chlorine

Method Selection

method using the procedure

section (see page 12).

22

10 mL

Page 23

• Press the Zero key. The meter will show “-0.0-” when the meter is zeroed and ready for measurement.

• Remove the cuvette.

Powder reagents procedure

• Add 1 packet of HI 93711 DPD reagent. Replace the cap and

shake gently for 20 seconds (or 2 minutes for seawater analysis).

• Reinsert the cuvette into the instrument.

• Press Timer and the display will show the countdown prior to the

measurement or, alternatively, wait for 2 minutes and 30 seconds

and press Read. When the timer ends the meter will perform the

reading. The instrument displays the results in mg/L of total

chlorine.

Liquid reagents procedure

• To an empty cuvette add 3 drops of HI 93701A-T

DPD1 indicator, 3 drops of HI 93701B-T DPD1 buffer and

1 drop of HI 93701C DPD3 solution. Swirl gently to mix

and immediately add 10 mL of unreacted sample.

Replace the cap and shake gently again.

• Reinsert the cuvette into the instrument.

23

Total Chlorine

Page 24

• Press Timer and the display will show the countdown prior to the measurement or, alternatively, wait

for 2 minutes and 30 seconds and press Read. When the timer ends the meter will perform the

reading.

• The instrument displays the results in mg/L of total chlorine.

Note: Free and total chlorine have to be measured separately with fresh unreacted samples following

the related procedure if both values are requested.

INTERFERENCES

Interference may be caused by: Bromine, Iodine, Ozone, Oxidized forms of Chromium and Manganese.

In case of water with hardness greater than 500 mg/L CaCO3, shake the sample for approximately

2 minutes after adding the powder reagent.

In case of water with alkalinity greater than 250 mg/L CaCO3 or acidity greater than 150 mg/L CaCO3,

the color of the sample may develop only partially, or may rapidly fade. To resolve this, neutralize the

sample with diluted HCl or NaOH.

Total Chlorine

24

Page 25

COLOR OF WATER

SPECIFICATIONS

Range 0 to 500 PCU (Platinum Cobalt Units)

Resolution 1 PCU

Accuracy ±10 PCU ±5% of reading at 25 °C

Typical EMC ± 1 PCU

Deviation

Light Source Tungsten lamp with narrow band interference filter @ 420 nm

Method Adaptation of the

18th edition

REQUIRED ACCESSORIES

0.45 μm membrane for true color measurement.

For other accessories see page 65.

MEASUREMENT PROCEDURE

• Select the

the

• Fill one cuvette up to the mark with deionized water and replace

the cap. This is the blank.

• Place the blank (# 1) into the holder and close the lid.

Color of Water

Method Selection

section (see page 12).

Standard Methods for the Examination of Water and Wastewater,

, Colorimetric Platinum Cobalt method.

method using the procedure described in

# 1

10 mL

# 1

• Press the Zero key. The meter will show “-0.0-” when the meter is zeroed and ready for measurement.

• Remove the blank.

25

Color of Water

Page 26

• Fill the second cuvette up to the mark with unfiltered sample

and replace the cap. This is the apparent color.

• Filter 10 mL of sample through a filter with a 0.45 μm

membrane into the third cuvette, up to the 10 mL mark and

replace the cap. This is the true color.

10 mL

# 2

# 3

• Insert the apparent color cuvette (# 2) into the instrument

# 2

and close the lid.

• Press Read to start the reading.

• The meter displays the value of apparent color in PCU.

• Remove the cuvette, insert the true color cuvette (# 3) into the

instrument and ensure that the notch on the cap is positioned

# 3

securely into the groove.

• Press Read to start the reading. The meter displays the value of true color in PCU.

Color of Water

26

Page 27

COPPER HIGH RANGE

SPECIFICATIONS

Range 0.00 to 5.00 mg/L

Resolution 0.01 mg/L

Accuracy ±0.02 mg/L ±4% of reading at 25 °C

Typical EMC ±0.01 mg/L

Deviation

Light Source Tungsten lamp with narrow band interference filter @ 575 nm

Method Adaptation of the

reagent causes a purple tint in the sample.

REQUIRED REAGENTS

Code Description Quantity

HI 93702-0 Bicinchoninate 1 packet

REAGENT SETS

HI 93702-01 Reagents for 100 tests

HI 93702-03 Reagents for 300 tests

For other accessories see page 65.

MEASUREMENT PROCEDURE

• Select the

Method Selection

• Fill the cuvette with 10 mL of unreacted sample (up to the mark)

and replace the cap.

Copper HR

method using the procedure described in the

section (see page 12).

EPA method.

The reaction between copper and the bicinchoninate

10 mL

• Place the cuvette into the holder and close the lid.

• Press the Zero key. The meter will show “-0.0-”” when the meter is zeroed and ready for

measurement.

27

Copper HR

Page 28

• Remove the cuvette.

• Add the content of one packet of HI 93702-0 Bicinchoninate.

Replace the cap and shake gently for about 15 seconds.

• Reinsert the cuvette into the instrument.

• Press Timer and the display will show the countdown prior to the measurement or, alternatively, wait

for 45 seconds and press Read. When the timer ends the meter will perform the reading.

• The instrument displays the results in mg/L of copper.

INTERFERENCES

Interference may be caused by:

Silver

Cyanide

For samples overcoming buffering capacity of reagent (around pH 6.8), pH should be adjusted between

6 and 8.

Copper HR

28

Page 29

COPPER LOW RANGE

SPECIFICATIONS

Range 0 to 1000 μg/L

Resolution 1 μg/L

Accuracy ±10 μg/L ±5% of reading at 25 °C

Typical EMC ±1 μg/L

Deviation

Light Source Tungsten lamp with narrow band interference filter @ 575 nm

Method Adaptation of the

reagent causes a purple tint in the sample.

REQUIRED REAGENTS

Code Description Quantity

HI 95747-0 Bicinchoninate 1 packet

REAGENT SETS

HI 95747-01 Reagents for 100 tests

HI 95747-03 Reagents for 300 tests

For other accessories see page 65.

MEASUREMENT PROCEDURE

• Select the

the

• Fill the cuvette with 10 mL of unreacted sample (up to the

mark) and replace the cap.

Copper LR

Method Selection

method using the procedure described in

section (see page 12).

EPA method.

The reaction between copper and the bicinchoninate

10 mL

• Place the cuvette into the holder and close the lid.

• Press the Zero key. The meter will show “-0.0-” when the meter is zeroed and ready for measurement.

29

Copper LR

Page 30

• Remove the cuvette.

• Add the content of one packet of HI 95747-0 Bicinchoninate.

Replace the cap and shake gently for about 15 seconds.

• Reinsert the cuvette into the instrument.

• Press Timer and the display will show the countdown prior to the measurement or, alternatively, wait

for 45 seconds and press Read. When the timer ends the meter will perform the reading.

• The instrument displays the results in

μμ

μg/L of copper.

μμ

INTERFERENCES

Interference may be caused by:

Silver

Cyanide

For samples overcoming buffering capacity of reagent (around pH 6.8), pH should be adjusted between

6 and 8.

Copper LR

30

Page 31

FLUORIDE

SPECIFICATIONS

Range 0.00 to 2.00 mg/L

Resolution 0.01 mg/L

Accuracy ±0.03 mg/L ±3% of reading at 25 °C

Typical EMC ±0.01 mg/L

Deviation

Light Source Tungsten lamp with narrow band interference filter @ 575 nm

Method Adaptation of the

18th edition

causes a red tint in the sample.

REQUIRED REAGENT

Code Description Quantity

HI 93729-0 SPADNS Reagent 4 mL

REAGENT SETS

HI 93729-01 Reagents for 100 tests

HI 93729-03 Reagents for 300 tests

For other accessories see page 65.

MEASUREMENT PROCEDURE

• Select the

Fluoride

Method Selection

method using the procedure described in the

section (see page 12).

Standard Methods for the Examination of Water and Wastewater,

, SPADNS method. The reaction between fluoride and the liquid reagent

• Add 2 mL of HI 93729-0 SPADNS Reagent to two cuvettes.

• Fill one of the cuvettes with distilled water up to the mark,

replace the cap and invert several times to mix.

• Fill the other cuvette with sample up to the mark, replace the

cap and invert several times to mix.

• Place the cuvette with the reacted distilled water (# 1) into

the holder and close the lid.

31

# 1

# 1

2 mL

10 mL10 mL

# 2

Fluoride

Page 32

• Press Timer and the display will show the countdown prior to zeroing the blank or, alternatively, wait

for two minutes and press Zero. The display will show “-0.0-” when the meter is zeroed and ready for

measurement.

# 2

• Remove the cuvette.

• Insert the other cuvette (# 2) with the reacted sample into the

instrument.

• Press Read to start reading. The instrument displays the results in mg/L of fluoride.

Note: For wastewater or seawater samples, before performing measurements, distillation is required.

For most accurate results, use two graduated pipettes to deliver exactly 8 mL of distilled water and

8 mL of sample.

INTERFERENCES

Interferences may be caused by:

Alkalinity (as CaCO3) above 5000 mg/L

Aluminum above 0.1 mg/L

Iron, ferric above 10 mg/L

Chloride above 700 mg/L

Phosphate, ortho above 16 mg/L

Sodium hexametaphosphate above 1.0 mg/L

Sulfate above 200 mg/L

Highly colored and turbid samples may require distillation

Highly alkaline samples can be neutralized with nitric acid.

Fluoride

32

Page 33

MANGANESE HIGH RANGE

SPECIFICATIONS

Range 0.0 to 20.0 mg/L

Resolution 0.1 mg/L

Accuracy ±0.2 mg/L ±3% of reading at 25 °C

Typical EMC ±0.1 mg/L

Deviation

Light Source Tungsten lamp with narrow band interference filter @ 525 nm

Method Adaptation of the

18th edition,

a pink tint in the sample.

REQUIRED REAGENTS

Code Description Quantity

HI 93709A-0 Citrate 1 packet

HI 93709B-0 Sodium periodate 1 packet

REAGENT SETS

HI 93709-01 Reagents for 100 tests

HI 93709-03 Reagents for 300 tests

For other accessories see page 65.

MEASUREMENT PROCEDURE

• Select the

• Fill the cuvette with 10 mL of unreacted sample (up to the

Manganese HR

the

Method Selection

mark) and replace the cap.

method using the procedure described in

section (see page 12).

Standard Methods for the Examination of Water and Wastewater,

Periodate method. The reaction between manganese and reagents causes

10 mL

• Place the cuvette into the holder and close the lid.

• Press the Zero key. The display will show “-0.0-” when the meter is zeroed and ready for

measurement.

• Remove the cuvette.

• Add the content of one packet of HI 93709A-0 Citrate reagent.

Replace the cap and invert to mix with gently movements for

2 minutes.

33

Manganese HR

Page 34

• Add the content of one packet of HI 93709B-0 Sodium

Periodate reagent. Replace the cap and invert to mix with

gently movements for 2 minutes.

• Reinsert the cuvette into the instrument.

• Press Timer and the display will show the countdown prior to the measurement or, alternatively, wait

for 1 minute and 30 seconds and press Read. When the timer ends the meter will perform the reading.

The instrument displays the results in mg/L of manganese.

• Press or to access the second level functions.

• Press the Chem Frm key to convert the result in mg/L of potassium permanganate (KMnO4) and

permanganate (MnO4).

• Press or to return to the measurement screen.

INTERFERENCES

Interference may be caused by:

Calcium above 700 mg/L

Chloride above 70000 mg/L

Iron above 5 mg/L

Magnesium above 100000 mg/L.

Manganese HR

34

Page 35

MANGANESE LOW RANGE

SPECIFICATIONS

Range 0 to 300 μg/L

Resolution 1 μg/L

Accuracy ±10 μg/L ±3% of reading at 25 °C

Typical EMC ±1 μg/L

Deviation

Light Source Tungsten lamp with narrow band interference filter @ 575 nm

Method Adaptation of the PAN Method. The reaction between manganese and the reagents

causes an orange tint in the sample.

REQUIRED REAGENT

Code Description Quantity

HI 93748A-0 Ascorbic acid 2 packets

HI 93748B-0 Alkaline-cyanide sol. 0.40 mL

HI 93748C-0 0.1% PAN indicator 2 mL

HI 93703-51 Dispersing Agent 4-6 drops (only when necessary, see note)

REAGENT SETS

HI 93748-01 Reagents for 50 tests

HI 93748-03 Reagents for 150 tests

For other accessories see page 65.

MEASUREMENT PROCEDURE

• Select the

page 12).

Manganese LR

method using the procedure described in the

Method Selection

section (see

• Fill one cuvette with 10 mL of deionized water (up to the mark).

• Fill a second cuvette with 10 mL of sample (up to the mark).

• Add the content of one packet of HI 93748A-0 Ascorbic acid to

each cuvette, replace the caps and shake gently until completely

dissolved.

35

10 mL

10 mL

Manganese LR

Page 36

• Add 0.2 mL of the HI 93748B-0 Alkaline-cyanide reagent

solution to each cuvette, replace the caps and invert gently

to mix for about 30 seconds.

• Add 1 mL of the HI 93748C-0 0.1% PAN indicator

solution to each cuvette, replace the caps and shake

gently.

• Add 3 drops of Dispersing Agent (HI 93703-51) to each

cuvette, replace the caps and invert gently to mix for

about 30 seconds.

• Place the cuvette with the reacted deionized water (blank)

into the holder and close the lid.

• Press Timer and the display will show the countdown prior to zeroing the blank. Alternatively wait for

2 minutes and then press Zero. The display will show “-0.0-” when the meter is zeroed and ready for

measurement.

Manganese LR

36

Page 37

• Insert the second cuvette with the reacted sample into the instrument.

• Press Read to start the reading. The instrument displays the results in

μμ

μg/L of manganese.

μμ

• Press or to access the second level functions.

• Press the Chem Frm key to convert the result in mg/L of potassium permanganate (KMnO4) and

permanganate (MnO4).

• Press or to return to the measurement screen.

INTERFERENCES

Interference may be caused by:

Aluminum above 20 mg/L

Cadmium above 10 mg/L

Calcium above 200 mg/L as CaCO

Cobalt above 20 mg/L

Copper above 50 mg/L

Iron above 10 mg/L

Lead above 0.5 mg/L

Magnesium above 100 mg/L as CaCO

Nickel above 40 mg/L

Zinc above 15 mg/L.

3

3

37

Manganese LR

Page 38

MOLYBDENUM

SPECIFICATIONS

Range 0.0 to 40.0 mg/L

Resolution 0.1 mg/L

Accuracy ±0.3 mg/L ±5% of reading at 25 °C

Typical EMC ±0.1 mg/L

Deviation

Light Source Tungsten lamp with narrow band interference filter @ 420 nm

Method Adaptation of the mercaptoacetic acid method. The reaction between molybdenum and

the reagents causes a yellow tint in the sample.

REQUIRED REAGENT

Code Description Quantity

HI 93730A-0 Reagent A 1 packet

HI 93730B-0 Reagent B 1 packet

HI 93730C-0 Reagent C 1 packet

REAGENT SETS

HI 93730-01 Reagents for 100 tests

HI 93730-03 Reagents for 300 tests

For other accessories see page 65.

MEASUREMENT PROCEDURE

• Select the

described in the

• Fill the cuvette with 10 mL of unreacted sample (up to

the mark) and replace the cap.

Molybdenum

Method Selection

method using the procedure

section (see page 12).

10 mL

• Place the cuvette into the holder and close the lid.

• Press the Zero key. The display will show “-0.0-” when the meter is zeroed and ready for

measurement.

Molybdenum

38

Page 39

• Fill one graduated mixing cylinder up to the 25 mL

mark with the sample.

• Add the content of one packet of HI 93730A-0

molybdenum reagent, close the cylinder and invert

it several times until completely dissolved.

• Add the content of one packet of HI 93730B-0

molybdenum reagent to the cylinder, close and

invert it several times until completely dissolved.

• Add the content of one packet of HI 93730C-0

molybdenum reagent to the cylinder, close and

shake it vigorously.

25 mL

• Fill an empty cuvette with 10 mL of sample up to

the mark and replace the cap.

• Insert the cuvette into the instrument.

39

10 mL

Molybdenum

Page 40

• Press Timer and the display will show the countdown prior to the measurement or, alternatively, wait

for five minutes and press Read. When the timer ends the meter will perform the reading. The

instrument displays concentration in mg/L of molybdenum.

• Press or to access the second level functions.

• Press the Chem Frm key to convert the result in mg/L of molybdate (MoO4) and sodium molybdate

(Na2MoO4).

• Press or to return to the measurement screen.

INTERFERENCES

Interference may be caused by:

Aluminum above 50 mg/L

Chromium above 1000 mg/L

Copper above 10 mg/L

Iron above 50 mg/L

Nickel above 50 mg/L

Nitrite, as NO2¯

Sulfate above 200 mg/L

Highly buffered samples or with extreme pH may exceed the buffering capacity of the reagents.

Molybdenum

40

Page 41

NICKEL HIGH RANGE

SPECIFICATIONS

Range 0.00 to 7.00 g/L

Resolution 0.01 g/L

Accuracy ±0.07 ±4% of reading at 25 °C

Typical EMC ±0.02 g/L

Deviation

Light Source Tungsten lamp with narrow band interference filter @ 575 nm

Method Adaptation of the photometric method. The reaction between nickel and the reagent

causes a blue tint in the sample.

REQUIRED REAGENTS

Code Description Quantity

HI 93726-0 Powder reagent 1 packet

REAGENT SETS

HI 93726-01 Reagents for 100 tests

HI 93726-03 Reagents for 300 tests

For other accessories see page 65.

MEASUREMENT PROCEDURE

• Select the

• Fill the cuvette up to the mark with 10 mL of unreacted

Nickel HR

method using the procedure described in the

sample and replace the cap.

Method Selection

section (see page 12).

10 mL

• Place the cuvette into the holder and close the lid.

• Press the Zero key. The display will show “-0.0-” when the meter is zeroed and ready for

measurement.

41

Nickel HR

Page 42

• Remove the cuvette and add the content of one packet of

HI 93726-0 reagent. Replace the cap and shake gently until

completely dissolved.

• Reinsert the cuvette into the instrument.

• Press Timer and the display will show the countdown prior to the measurement or, alternatively, wait

for 1 minute and press Read. When the timer ends the meter will perform the reading.

• The instrument displays concentration in g/L of nickel.

INTERFERENCES

Interference may be caused by copper.

Nickel HR

42

Page 43

NICKEL LOW RANGE

SPECIFICATIONS

Range 0.000 to 1.000 mg/L

Resolution 0.001 mg/L

Accuracy ±0.010 mg/L ±7% of reading at 25 °C

Typical EMC ±0.001 mg/L

Deviation

Light Source Tungsten lamp with narrow band interference filter @ 575 nm

Method Adaptation of the PAN method. The reaction between nickel and the reagents causes

an orange tint in the sample.

REQUIRED REAGENTS

Code Description Quantity

HI 93740A-0 Phthalate-phosphate 2 packets

HI 93740B-0 0.3% PAN indicator 2 mL

HI 93740C-0 EDTA 2 packets

HI 93703-51 Dispersing Agent 4-6 drops (only when necessary, see note)

REAGENT SETS

HI 93740-01 Reagents for 50 tests

HI 93740-03 Reagents for 150 tests

For other accessories see page 65.

MEASUREMENT PROCEDURE

• Select the

described in the

Note: For best results perform your tests between 20-24°C.

Nickel LR

method using the procedure

Method Selection

section (see page 12).

• Fill one graduated beaker with 25 mL of deionized

water (blank) and another one with 25 mL of sample.

• Add the content of one packet of HI 93740A-0

Phthalate-phosphate reagent to each beaker. Cap

and swirl gently until the reagent is dissolved.

Note: If sample contains iron (Fe3+), it is important

that all powder be dissolved completely before continuing

with following step.

• Add 1 mL of HI 93740B-0 0.3% PAN solution to each

beaker, cap and swirl to mix.

43

Nickel LR

Page 44

• Press Timer and the display will show a countdown prior to adding reagent C or, alternatively, wait

for 15 minutes. Add one packet of HI 93740C-0 EDTA reagent to each beaker, cap and swirl to mix

until completely dissolved.

• Fill one cuvette up to the mark with 10 mL of the blank.

10 mL

• Place the cuvette into the holder and close the lid.

• Press the Zero key. The display will show “-0.0-” when the meter is zeroed and ready for

measurement.

• Fill a second cuvette up to the mark with 10 mL of the reacted sample.

10 mL

• Insert the second cuvette into the instrument.

• Press Read to start the reading. The instrument displays the results in mg/L of nickel.

Note: a temperature above 30°C may cause turbidity. In this case, before zeroing and taking

readings, add 2-3 drops of Dispersing Agent (HI 93703-51) to each cuvette and swirl until turbidity

is removed.

Nickel LR

44

Page 45

INTERFERENCES

Interference may be caused by:

Co2+ must not be present

Fe2+ must not be present

Al3+ above 32 mg/L

Ca2+ above 1000 mg/L (as CaCO3)

Cd2+ above 20 mg/L

Cl¯ above 8000 mg/L

Cr3+ above 20 mg/L

Cr6+ above 40 mg/L

Cu2+ above 15 mg/L

F¯ above 20 mg/L

Fe3+ above 10 mg/L

K+ above 500 mg/L

Mg2+ above 400 mg/L

Mn2+ above 25 mg/L

Mo6+ above 60 mg/L

Na+ above 5000 mg/L

Pb2+ above 20 mg/L

Zn2+ above 30 mg/L

45

Nickel LR

Page 46

NITRATE

SPECIFICATIONS

Range 0.0 to 30.0 mg/L

Resolution 0.1 mg/L

Accuracy ±0.5 mg/L ±10% of reading at 25 °C

Typical EMC ±0.1 mg/L

Deviation

Light Source Tungsten lamp with narrow band interference filter @ 525 nm

Method Adaptation of the cadmium reduction method. The reaction between nitrate and the

reagent causes an amber tint in the sample.

REQUIRED REAGENTS

Code Description Quantity

HI 93728-0 Powder reagent 1 packet

REAGENT SETS

HI 93728-01 Reagents for 100 tests

HI 93728-03 Reagents for 300 tests

For other accessories see page 65.

MEASUREMENT PROCEDURE

• Select the

the

• Using the pipette, fill the cuvette with 6 ml of sample, up to

half of its height, and replace the cap.

Nitrate

method using the procedure described in

Method Selection

section (see page 12).

6 mL

• Place the cuvette into the holder and close the lid.

• Press the Zero key. The display will show “-0.0-” when the meter is zeroed and ready for

measurement.

• Remove the cuvette and add the content of one packet of

HI 93728-0 reagent.

Nitrate

46

Page 47

• Replace the cap and immediately shake vigorously up

and down for exactly 10 seconds. Continue to mix by

inverting the cuvette gently for 50 seconds, while

taking care not to induce air bubbles. Powder will not

completely dissolve. Time and way of shaking could

sensitively affect the measurement.

• Reinsert the cuvette into the instrument, taking care

not to shake it.

• Press Timer and the display will show the countdown prior

to the measurement or, alternatively, wait for 4 minutes and

30 seconds and press Read. When the timer ends the

meter will perform the reading. The instrument displays

the results in mg/L of nitrate-nitrogen.

• Press or to access the second level functions.

• Press the Chem Frm key to convert the result in mg/L of nitrate (NO3¯).

• Press or to return to the measurement screen.

INTERFERENCES

Interference may be caused by:

Ammonia and amines, as urea and primary aliphatic amines

Chloride above 100 ppm

Chlorine above 2 ppm

Copper

Iron(III)

Strong oxidizing and reducing substances

Sulfide must be absent

47

Nitrate

Page 48

DISSOLVED OXYGEN

SPECIFICATIONS

Range 0.0 to 10.0 mg/L

Resolution 0.1 mg/L

Accuracy ±0.4 mg/L ±3% of reading at 25 °C

Typical EMC ± 0.1 mg/L

Deviation

Light Source Tungsten lamp with narrow band interference filter @ 420 nm

Method Adaptation of the

18th edition,

and the reagents causes a yellow tint in the sample.

REQUIRED REAGENTS

Code Description Quantity

HI 93732A-0 Reagent A 5 drops

HI 93732B-0 Reagent B 5 drops

HI 93732C-0 Reagent C 10 drops

REAGENT SET

HI 93732-01 Reagents for 100 tests

HI 93732-03 Reagents for 300 tests

For other accessories see page 65.

MEASUREMENT PROCEDURE

• Select the

Dissolved Oxygen

the

Method Selection

section (see page 12).

Standard Methods for the Examination of Water and Wastewater,

Azide modified Winkler method. The reaction between dissolved oxygen

method using the procedure described in

• Fill one 60 mL glass bottle completely with the unreacted sample.

• Replace the cap and ensure that a small part of the sample spills

over.

• Remove the cap and add 5 drops of HI 93732A-0 and 5 drops of

HI 93732B-0.

• Add more sample, to fill the bottle completely. Replace the cap

again and ensure that a part of the sample spills over. This is to

make sure that no air bubbles have been trapped inside, which

could alter the reading.

• Invert several times the bottle. The sample becomes orange-yellow

and a flocculent agent will appear.

Dissolved Oxygen

48

Page 49

• Let the sample stand and the flocculent agent will start to settle.

• After approximately 2 minutes, when the upper half of the bottle becomes limpid,

add 10 drops of HI 93732C-0.

• Replace the cap and invert the bottle until the settled flocculent dissolves completely.

The sample is ready for measurement when it is yellow and completely limpid.

• Fill the cuvette up to the mark with 10 mL of the unreacted

(original) sample, and replace the cap. This is the blank.

• Place the cuvette into the holder and close the lid.

• Press the Zero key. The display will show “-0.0-” when the

meter is zeroed and ready for measurement.

10 mL

• Remove the cuvette.

• Fill another cuvette up to the mark with 10 mL of the reacted

sample and replace the cap.

• Reinsert the cuvette into the instrument.

• Press Read to start the reading. The instrument will display the results in mg/L of dissolved oxygen.

INTERFERENCES

Interferences may be caused by reducing and oxidizing materials.

49

Dissolved Oxygen

Page 50

pH

SPECIFICATIONS

Range 6.5 to 8.5 pH

Resolution 0.1 pH

Accuracy ±0.1 pH at 25 °C

Typical EMC ±0.1 pH

Deviation

Light Source Tungsten lamp with narrow band interference filter @ 525 nm

Method Adaptation of the Phenol Red method. The reaction with the reagent causes a yellow

to red tint in the sample.

REQUIRED REAGENTS

Code Description Quantity

HI 93710-0 Phenol Red Indicator 5 drops

REAGENT SETS

HI 93710-01 Reagents for 100 pH tests

HI 93710-03 Reagents for 300 pH tests

For other accessories see page 65.

MEASUREMENT PROCEDURE

• Select the pH method using the procedure described in the

Method Selection

• Fill the cuvette with 10 mL of unreacted sample (up to the

mark) and replace the cap.

section (see page 12).

10 mL

• Place the cuvette into the holder and close the lid.

• Press the Zero key. The display will show “-0.0-” when the meter is zeroed and ready for

measurement.

pH

50

Page 51

• Remove the cuvette and add 5 drops of HI 93710-0 Phenol

Red Indicator. Replace the cap and mix the solution.

• Reinsert the cuvette into the instrument.

• Press the Read key to start the reading. The instrument displays the pH value.

51

pH

Page 52

PHOSPHATE HIGH RANGE

SPECIFICATIONS

Range 0.0 to 30.0 mg/L

Resolution 0.1 mg/L

Accuracy ±1 mg/L ±4% of reading at 25 °C

Typical EMC Dev. ±0.1 mg/L

Light Source Tungsten lamp with narrow band interference filter @ 525 nm

Method Adaptation of the

18th edition,

causes a blue tint in the sample.

REQUIRED REAGENTS

Code Description Quantity

HI 93717A-0 Molybdate 10 drops

HI 93717B-0 Reagent B 1 packet

REAGENT SETS

HI 93717-01 Reagents for 100 tests

HI 93717-03 Reagents for 300 tests

For other accessories see page 65.

MEASUREMENT PROCEDURE

• Select the

in the

• Fill the cuvette with 10 mL of unreacted sample (up to the

mark) and replace the cap.

Phosphate HR

Method Selection

method using the procedure described

section (see page 12).

Standard Methods for the Examination of Water and Wastewater,

Amino Acid method. The reaction between phosphate and reagents

10 mL

• Place the cuvette into the holder and close the lid.

• Press the Zero key. The display will show “-0.0-” when the meter is zeroed and ready for

measurement.

• Remove the cuvette.

• Add 10 drops of HI 93717A-0 Molybdate reagent.

Phosphate HR

52

Page 53

• Add the content of one packet of HI 93717B-0 Phosphate

HR Reagent B to the cuvette. Replace the cap and shake

gently until completely dissolved.

• Reinsert the cuvette into the instrument.

• Press Timer and the display will show the countdown prior to the measurement or, alternatively, wait

for 5 minutes and press Read. When the timer ends the meter will perform the reading. The instrument

displays the results in mg/L of phosphate (PO

3

¯).

4

• Press or to access the second level functions.

• Press the Chem Frm key to convert the result in mg/L of phosphorus (P) and phosphorus pentoxide

(P2O5).

• Press or to return to the measurement screen.

INTERFERENCES

Sulfide

Chloride above 150000 mg/L )

Calcium above 10000 mg/L as CaCO

Magnesium above 40000 mg/L as CaCO

Ferrous iron above 100 mg/L

3

3

53

Phosphate HR

Page 54

PHOSPHATE LOW RANGE

SPECIFICATIONS

Range 0.00 to 2.50 mg/L

Resolution 0.01 mg/L

Accuracy ±0.04 mg/L ±4% of reading at 25 °C

Typical EMC Dev. ±0.01 mg/L

Light Source Tungsten lamp with narrow band interference filter @ 610 nm

Method Adaptation of the Ascorbic Acid method. The reaction between phosphate and the

reagent causes a blue tint in the sample.

REQUIRED REAGENTS

Code Description Quantity

HI 93713-0 Powder reagent 1 packet

REAGENT SETS

HI 93713-01 Reagents for 100 tests

HI 93713-03 Reagents for 300 tests

For other accessories see page 65.

MEASUREMENT PROCEDURE

• Select the

described in the

• Rinse, cap and shake the cuvette several times with unreacted

sample. Fill the cuvette with 10 mL of sample up to the

mark and replace the cap.

Phosphate LR

Method Selection

method using the procedure

section (see page 12).

10 mL

• Place the cuvette into the holder and close the lid.

• Press the Zero key. The display will show “-0.0-” when the meter is zeroed and ready for

measurement.

• Remove the cuvette and add the content of one packet of

HI 93713-0 reagent. Replace the cap and shake gently (for

about 2 minutes) until the powder is completely dissolved.

Phosphate LR

54

Page 55

• Reinsert the cuvette into the instrument.

• Press Timer and the display will show the countdown prior to the measurement or, alternatively, wait

for 3 minutes and press Read. When the timer ends the meter will perform the reading. The instrument

displays concentration in mg/L of phosphate (PO

3

¯).

4

• Press or to access the second level functions.

• Press the Chem Frm key to convert the result in mg/L of phosphorus (P) and phosphorus pentoxide

(P2O5).

• Press or to return to the measurement screen.

INTERFERENCES

Interference may be caused by:

Iron above 50 mg/L

Silica above 50 mg/L

Silicate above 10 mg/L

Copper above 10 mg/L

Hydrogen sulfide, arsenate, turbid sample and highly buffered samples also interfere.

55

Phosphate LR

Page 56

PHOSPHORUS

SPECIFICATIONS

Range 0.0 to 15.0 mg/L

Resolution 0.1 mg/L

Accuracy ±0.3 mg/L ±4% of reading at 25 °C

Typical EMC Dev. ±0.2 mg/L

Light Source Tungsten lamp with narrow band interference filter @ 525 nm

Method Adaptation of the

18th edition,

causes a blue tint in the sample.

REQUIRED REAGENTS

Code Description Quantity

HI 93706A-0 Molybdate 10 drops

HI 93706B-0 Amino Acid Powder 1 packet

REAGENT SETS

HI 93706-01 Reagents for 100 tests

HI 93706-03 Reagents for 300 tests

For other accessories see page 65.

MEASUREMENT PROCEDURE

• Select the

the

• Fill the cuvette with 10 mL of unreacted sample (up to the

mark) and replace the cap.

Phosphorus

Method Selection

method using the procedure described in

section (see page 12).

Standard Methods for the Examination of Water and Wastewater,

Amino Acid method. The reaction between phosphate and reagents

10 mL

• Place the cuvette into the holder and close the lid.

• Press the Zero key. The display will show “-0.0-” when the meter is zeroed and ready for

measurement.

• Remove the cuvette.

• Add 10 drops of HI 937O6A-0 Molybdate reagent.

Phosphorus

56

Page 57

• Add the content of one packet of HI 93706B-0 Phosphorus

Reagent B (Amino Acid) to the cuvette. Replace the cap and

shake gently until completely dissolved.

• Reinsert the cuvette into the instrument.

• Press Timer and the display will show the countdown prior to the measurement or, alternatively, wait

for 5 minutes and press Read. When the timer ends the meter will perform the reading. The instrument

displays the results in mg/L of phosphorus (P).

• Press or to access the second level functions.

• Press the Chem Frm key to convert the result in mg/L of phosphate (PO

3

¯) and phosphorus pentoxide

4

(P2O5).

• Press or to return to the measurement screen.

INTERFERENCES

Interference may be caused by:

Sulfide

Chloride above 150000 mg/L

Calcium above 10000 mg/L as CaCO

Magnesium above 40000 mg/L as CaCO

Ferrous iron above 100 mg/L

3

3

57

Phosphorus

Page 58

SILVER

SPECIFICATIONS

Range 0.000 to 1.000 mg/L

Resolution 0.005 mg/L

Accuracy ±0.020 mg/L ±5% of reading at 25 °C

Typical EMC ± 0.001 mg/L

Deviation

Light Source Tungsten lamp with narrow band interference filter @ 575 nm.

Method Adaptation of the PAN method. The reaction between silver and reagents causes an

orange tint in the sample.

REQUIRED REAGENTS

Code Description Quantity

HI 93737A-0 Buffer Reagent A 1 mL

HI 93737B-0 Buffer Reagent B 1 mL

HI 93737C-0 Indicator Reagent C 2 mL

HI 93737D-0 Fixing Reagent D 2 mL

HI 93703-51 Dispersing Agent 4-6 drops

(only when necessary, see note)

REAGENT SETS

HI 93737-01 Reagents for 50 tests

HI 93737-03 Reagents for 150 tests

For other accessories see page 65.

MEASUREMENT PROCEDURE

• Select the

Note: for best results perform your tests between 20-24°C.

Silver

method using the procedure described in the

Method Selection

section (see page 12).

• Fill two graduated beakers with 25 mL of sample.

• Add 1.0 mL of HI 93737A-0 Buffer reagent to one beaker (the

blank) and swirl gently to mix.

Silver

58

# 1 # 2

# 1

Page 59

• Add exactly 1.0 mL of HI 93737B-0 Buffer reagent to the second

beaker (the sample) and swirl gently to mix. Press Timer and the

display will show the countdown prior to adding reagent C or,

alternatively, wait for 2 minutes.

• Then add exactly 1.0 mL of HI 93737C-0 Indicator reagent to each

beaker and swirl. Press Timer or, alternatively, wait for

2 minutes.

• Then, in both cases, add 1.0 mL of HI 93737D-0 Fixing reagent

to each beaker and swirl. Press Timer or, alternatively, wait for

2 minutes.

10 mL

# 2

# 2# 1

• Fill one cuvette up to the mark with 10 mL of the blank.

• Add 3 drops of Dispersing Agent (HI 93703-51), replace the cap

and invert gently to mix for about 10 seconds.

• Place the cuvette into the holder and close the lid.

59

# 2# 1

10 mL

# 1

# 1

Silver

Page 60

• Press the Zero key. The display will show “-0.0-” when the meter is zeroed and ready for

measurement.

• Fill a second cuvette up to the mark with 10 mL of the reacted sample.

10 mL

# 2

• Add 3 drops of Dispersing Agent (HI 93703-51),

replace the cap and invert gently to mix for about

10 seconds.

# 2

• Insert the second cuvette into the instrument.

• Press Read to start the reading. The instrument displays the results in mg/L of silver.

INTERFERENCES

Interference may be caused by:

Al3+ above 30 mg/L Fe2+ above 1.5 mg/L

Ca2+ above 1000 mg/L as CaCO3Fe3+ above 10 mg/L

Cd2+ above 20 mg/L K+ above 500 mg/L

Cl¯ above 8000 mg/L Mn2+ above 25 mg/L

Co2+ above 1.5 mg/L Mg2+ above 1000 mg/L as CaCO

Cr3+ above 20 mg/L Na+ above 5000 mg/L

Cr6+ above 40 mg/L Ni2+ above 1.5 mg/L

Cu2+ above 15 mg/L Pb2+ above 20 mg/L

F¯ above 20 mg/L Zn2+ above 30 mg/L

Silver

60

3

Page 61

ZINC

SPECIFICATIONS

Range 0.00 to 3.00 mg/L

Resolution 0.01 mg/L

Accuracy ±0.03 mg/L ±3% of reading at 25 °C

Typical EMC ±0.01 mg/L

Deviation

Light Source Tungsten lamp with narrow band interference filter @ 575 nm

Method Adaptation of the

18th edition,

orange to a dark violet tint in the sample.

REQUIRED REAGENT

Code Description Quantity

HI 93731A-0 Zinc Reagent 1 packet

HI 93731B-0 Cyclohexanone 0.5 mL

REAGENT SETS

HI 93731-01 Reagents for 100 tests

HI 93731-03 Reagents for 300 tests

For other accessories see page 65

MEASUREMENT PROCEDURE

• Select the

the

Zinc

method using the procedure described in

Method Selection

section (see page 12).

Standard Methods for the Examination of Water and Wastewater,

Zincon method. The reaction between zinc and the reagents causes an

• Fill one graduated mixing cylinder up to the 20 mL mark

with the sample.

• Add the content of one packet of HI 93731A-0 Zinc

reagent, close the cylinder and invert several times to mix

until completely dissolved.

• Fill one cuvette with 10 mL of the reacted sample up to

the mark.

61

20 mL

10 mL

Zinc

Page 62

• Place the cap and insert the cuvette into the instrument

and close the lid.

• Press the Zero key. The display will show “-0.0-” when

the meter is zeroed and ready for measurement.

• Remove the cuvette and add 0.5 mL of HI 93731B-0

Cyclohexanone to the cuvette.

Note: To prevent any contamination from the polycarbonate

cap, prior to replacing it, close the sample cuvette with

the supplied HDPE plastic stopper.

• Replace the cap and mix the sample for 15 seconds.

• Insert the sample into the instrument.

• Press Timer and the display will show the countdown

prior to the measurement or, alternatively, wait for

3 minutes and 30 seconds and press Read. When the

timer ends the meter will perform the reading.

• The instrument displays the results in mg/L of zinc.

INTERFERENCES

Interference may be caused by:

Aluminum above 6 mg/L

Cadmium above 0.5 mg/L

Copper above 5 mg/L

Iron above 7 mg/L

Manganese above 5 mg/L

Nickel above 5 mg/L

Zinc

62

Page 63

ERRORS AND WARNINGS

The instrument shows clear warning messages when erroneous conditions appear and when measured values are

outside the expected range. These messages are described bellow.

No Light: The light source is not functioning properly.

Light Leak: There is an excess amount of ambient light reaching the

detector.

Inverted cuvettes: The sample and the zero cuvettes are inverted.

Battery Low: The battery capacity is lower than 10%.

Light Low: The instrument cannot adjust the light level. Please check

that the sample does not contain any debris.

Light High: There is too much light to perform a measurement. Please

check the preparation of the zero cuvette.

63

Page 64

DATA MANAGEMENT

The analyzed data can be managed using Hanna’s product HI92000, Windows® Compatible Software.

STANDARD METHODS

Description Range Method

Aluminum 0.00 to 1.00 mg/L Aluminon

Chlorine, Free 0.00 to 2.50 mg/ L DPD

Chlorine, Total 0.00 to 3.50 mg/L DPD

Color of Water 0 to 500 PCU Colorimetric Platinum Cobalt

Copper HR 0.00 to 5.00 mg/L Bicinchoninate

Copper LR 0 to 1000 μg/L Bicinchoninate

Fluoride 0.00 to 2.00 mg/L SPADNS

Manganese HR 0.0 to 20.0 mg/L Periodate Oxidation

Manganese LR 0 to 300 μg/L PAN

Molybdenum 0.0 to 40.0 mg/L Mercaptoacetic Acid

Nickel HR 0.00 to 7.00 g/L Photometric

Nickel LR 0.000 to 1.000 mg/L PAN

Nitrate 0.0 to 30.0 mg/L Cadmium Reduction

Oxygen, Dissolved 0.0 to 10.0 mg/L Winkler

pH 6.5 to 8.5 pH Phenol Red

Phosphate HR 0.0 to 30.0 mg/L Amino Acid

Phosphate LR 0.00 to 2.50 mg/L Ascorbic Acid

Phosphorus 0.0 to 15.0 mg/L Amino Acid

Silver 0.000 to 1.000 mg/L PAN

Zinc 0.00 to 3.00 mg/L Zincon

Windows® is registered Trademark of "Microsoft Co."

64

Page 65

ACCESSORIES

REAGENT SETS

HI 93701-01 100 free chlorine tests (powder)

HI 93701-03 300 free chlorine tests (powder)

HI 93701-F 300 free chlorine tests (liquid)

HI 93701-T 300 total chlorine tests (liquid)

HI 93702-01 100 copper HR tests

HI 93702-03 300 copper HR tests

HI 93706-01 100 phosphorus tests

HI 93706-03 300 phosphorus tests

HI 93709-01 100 manganese HR tests

HI 93709-03 300 manganese HR tests

HI 93710-01 100 pH tests

HI 93710-03 300 pH tests

HI 93711-01 100 total chlorine tests (powder)

HI 93711-03 300 total chlorine tests (powder)

HI 93712-01 100 aluminum tests

HI 93712-03 300 aluminum tests

HI 93713-01 100 phosphate LR tests

HI 93713-03 300 phosphate LR tests

HI 93717-01 100 phosphate HR tests

HI 93717-03 300 phosphate HR tests

HI 93726-01 100 nickel HR tests

HI 93726-03 300 nickel HR tests

HI 93728-01 100 nitrate tests

HI 93728-03 300 nitrate tests

HI 93729-01 100 fluoride tests

HI 93729-03 300 fluoride tests

HI 93730-01 100 molybdenum tests

HI 93730-03 300 molybdenum tests

HI 93731-01 100 zinc tests

HI 93731-03 300 zinc tests

HI 93732-01 100 dissolved oxygen tests

HI 93732-03 300 dissolved oxygen tests

HI 93737-01 50 silver tests

HI 93737-03 150 silver tests

HI 93740-01 50 nickel LR tests

HI 93740-03 150 nickel LR tests

HI 93748-01 50 manganese LR tests

HI 93748-03 150 manganese LR tests

HI 95747-01 100 copper LR tests

HI 95747-03 300 copper LR tests

65

Page 66

OTHER ACCESSORIES

HI 731318 cloth for wiping cuvettes (4 pcs)

HI 731321 glass cuvettes (4 pcs)

HI 731325W new cap for cuvette (4 pcs)

HI 740034 cap for 100 mL beaker (6 pcs)

HI 740036 100 mL plastic beaker (6 pcs)

HI 740038 60 mL glass bottle and stopper

HI 740142 1 mL graduated syringe

HI 740143 1 mL graduated syringe (6 pcs)

HI 740144 pipette tip (6 pcs)

HI 740157 plastic refilling pipette (20 pcs)

HI 740220 25 mL glass cylinders with caps (2 pcs)

HI 740223 170 mL plastic beaker

HI 740224 170 mL plastic beakers (12 pcs)

HI 740225 60 mL graduated syringe

HI 740226 5 mL graduated syringe

HI 740227 filter assembly

HI 740228 filter discs (25 pcs)

HI 740229 100 mL graduated cylinder

HI 740230 230 mL demineralized water

HI 92000 Windows compatible software

HI 920013 PC connection cable

HI 93703-50 cuvette cleaning solution (230 mL)

HI 93703-54 dried resin (100 g)

HI 93703-55 activated carbon (50 pcs)

66

Page 67

WARRANTY

All Hanna Instruments meters are warranted for two years against defects in workmanship and materials

when used for its intended purpose and maintained according to the instructions.

This warranty is limited to repair or replacement free of charge.

Damages due to accident, misuse, tampering or lack of prescribed maintenance are not covered.

If service is required, contact your dealer. If under warranty, report the model number, date of purchase,

serial number and the nature of the failure. If the repair is not covered by the warranty, you will be notified

of the charges incurred.

If the instrument is to be returned to Hanna Instruments, first obtain a Returned Goods Authorization Number

from the Customer Service Department and then send it with shipment costs prepaid. When shipping any

instrument, make sure it is properly packaged for complete protection.

To validate your warranty, fill out and return the enclosed warranty card within 14 days from the date of

purchase.

Recommendations for Users