Page 1

Instruction Manual

HI 8050 & HI 8060

Fertigation Controllers

Manufacturers since 1978

These Instruments are in

Compliance with the CE Directives

1

Page 2

Dear Customer,

Thank you for choosing a Hanna Product. Please read this instruction

manual carefully before using the controller.

This manual will provide you with the necessary information for a correct use

of the controller, as well as a precise idea of its versatility.

If you need more technical information, do not hesitate to e-mail us at

tech@hannainst.com.

These instruments are in compliance with

TT

ABLE OF CONTENTSABLE OF CONTENTS

T

ABLE OF CONTENTS

TT

ABLE OF CONTENTSABLE OF CONTENTS

THEORY OF FUNCTION ...................................................................4

GENERAL DESCRIPTION ...................................................................5

FUNCTIONAL DESCRIPTION ........................................................... 6

Irrigation Control ......................................................................... 6

Fertilization Control ...................................................................... 8

pH Control ................................................................................. 9

Proportional Control ..................................................................... 10

Agitator Control ........................................................................ 13

Filter Control ............................................................................ 13

Manual Functions ..................................................................... 13

Alarms ..................................................................................... 14

Logging (Diary) Functions ............................................................. 14

Date and time controller settings ................................................... 15

Password setup .......................................................................... 15

Serial Communication ................................................................... 15

USER INTERFACE ......................................................................... 16

Keyboard Structure ..................................................................... 16

Operating Modes ...................................................................... 16

Panels Browsing Methods ........................................................... 18

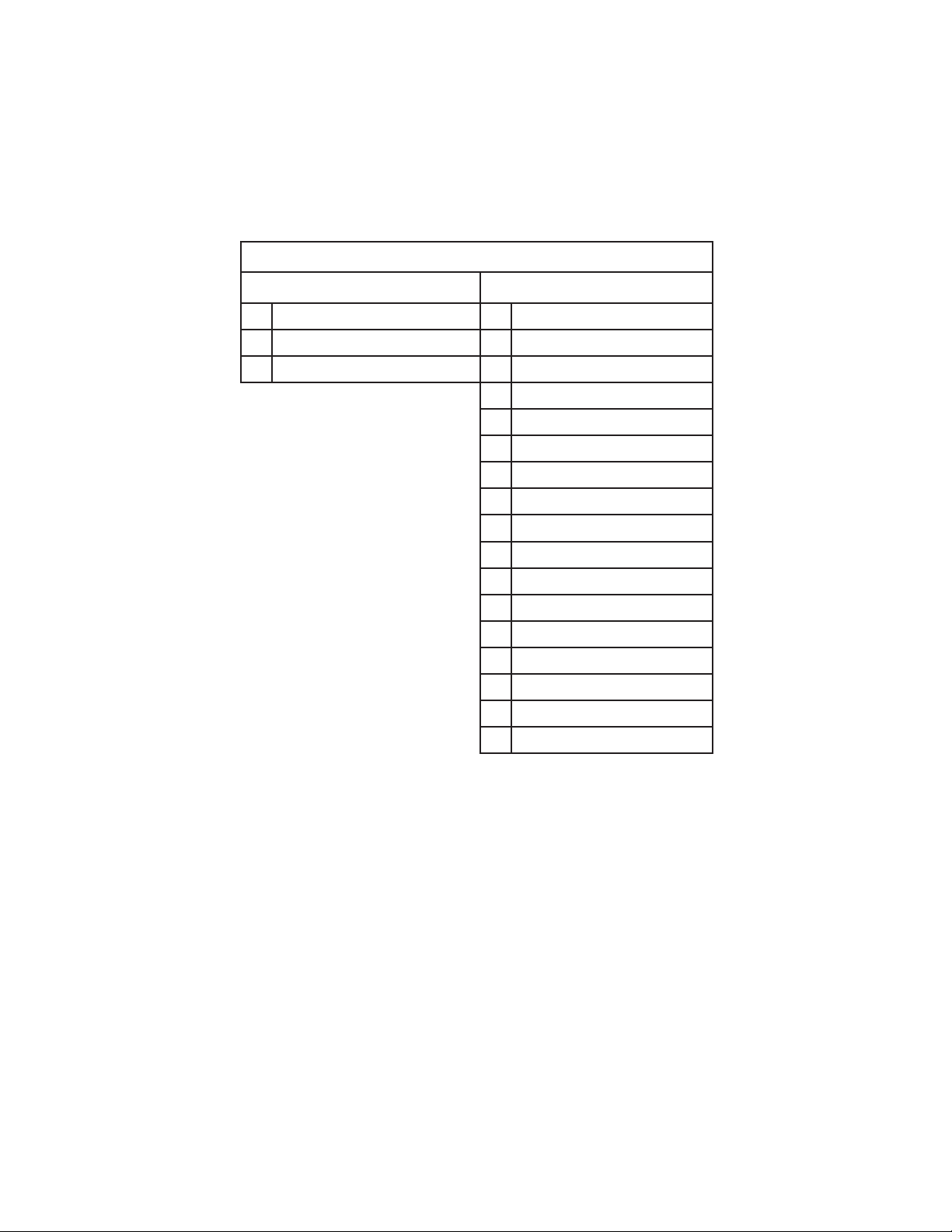

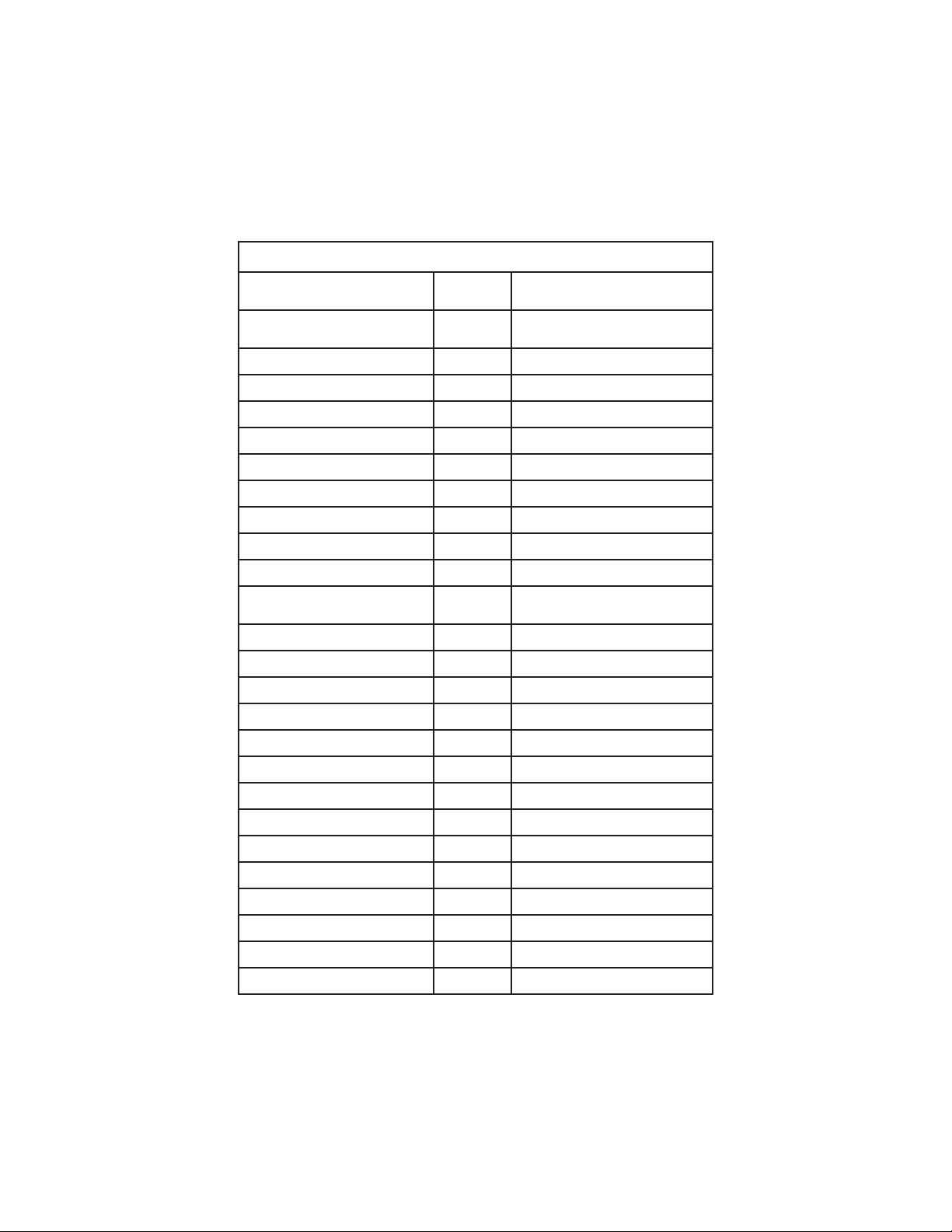

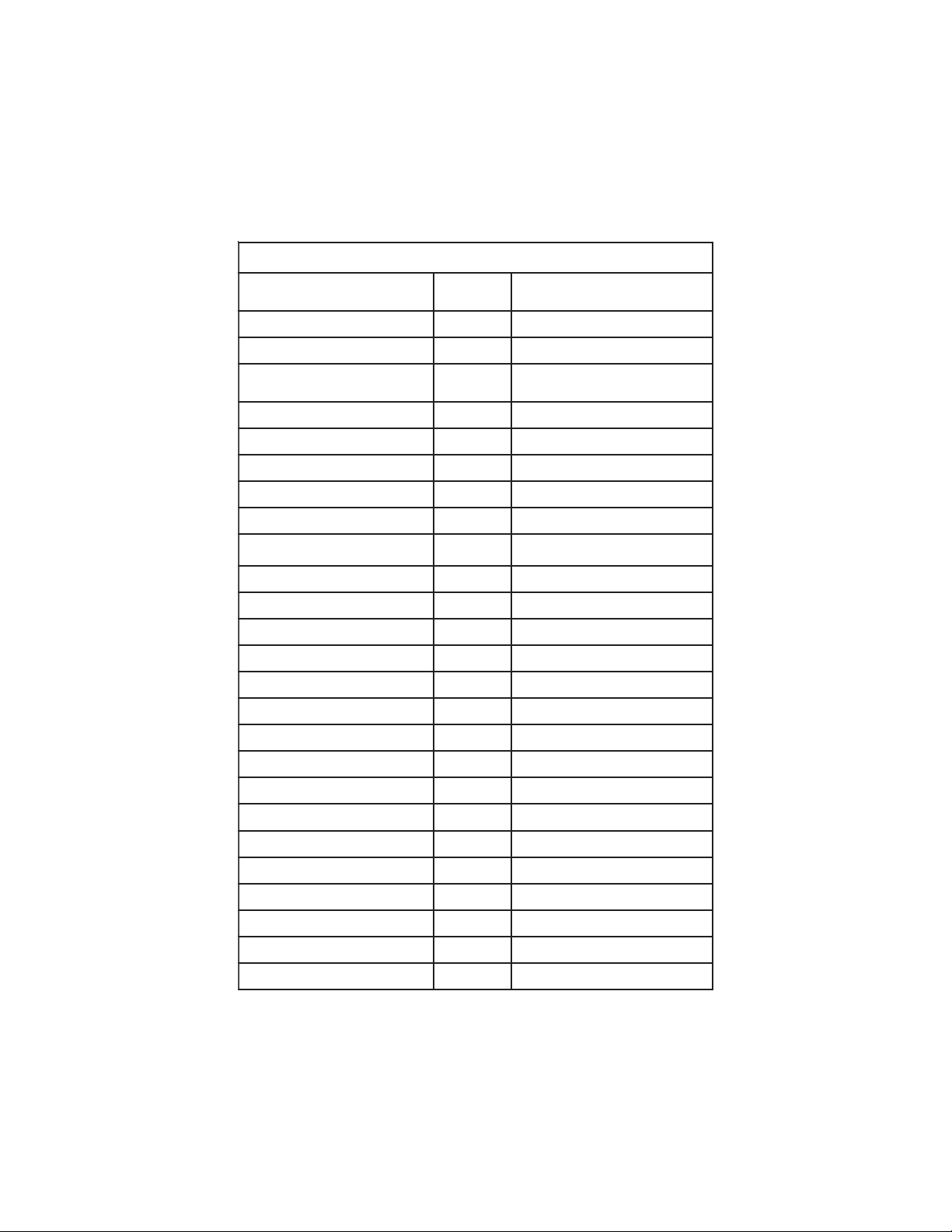

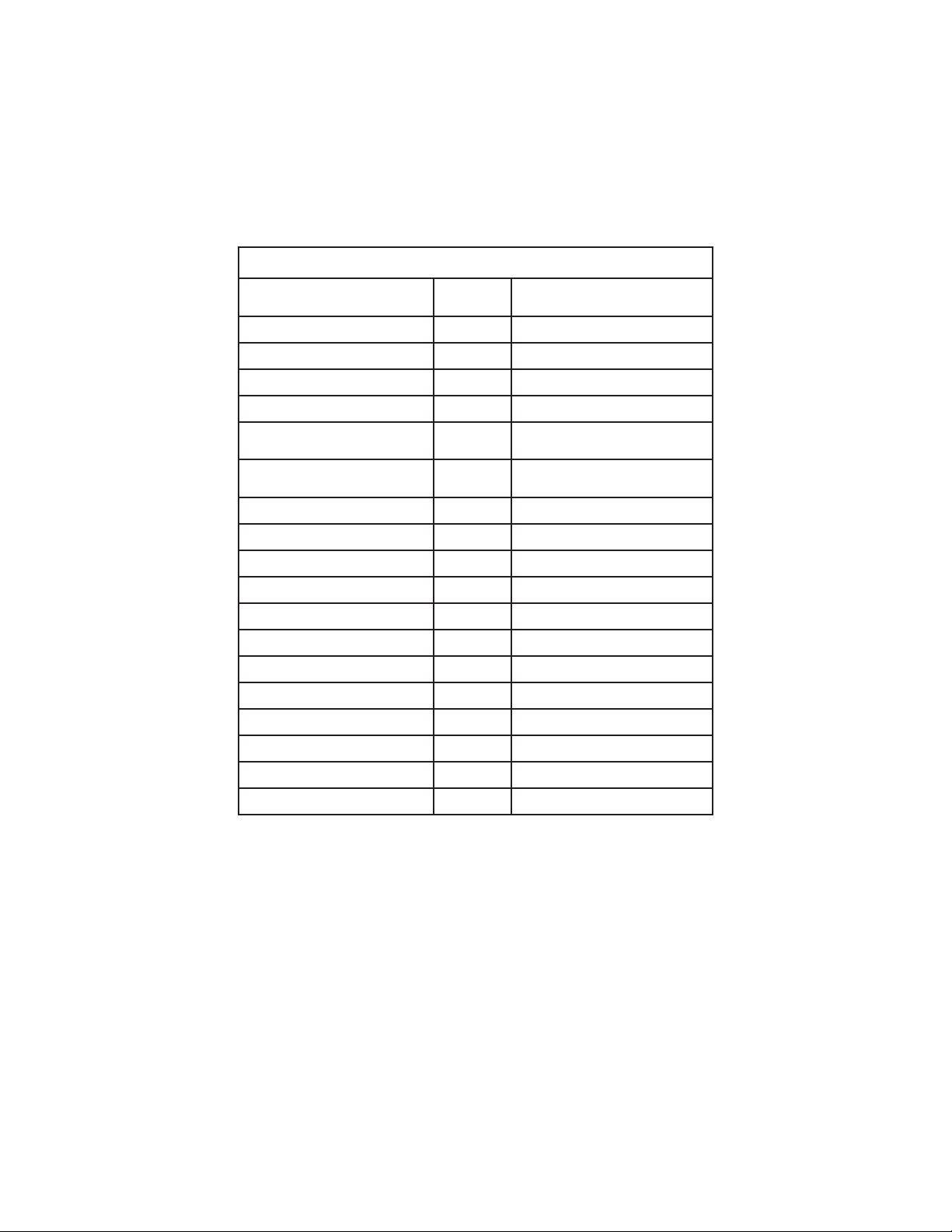

Panel List .................................................................................. 19

PANEL DESCRIPTIONS .................................................................... 24

Initialization Panels ...................................................................... 24

Consulting Panels ...................................................................... 25

directives.

2

Page 3

Setting Panels ............................................................................. 38

CALIBRATION PROCEDURES ........................................................... 57

Sensor Calibration Procedure ........................................................ 57

ALARMS DESCRIPTION ................................................................... 58

TROUBLESHOOTING GUIDE ........................................................... 60

APPENDIXES ............................................................................... 62

Panel list .................................................................................. 62

Keyboard operating modes ............................................................ 69

Outlet assignment table ................................................................ 70

Installation block diagram ............................................................ 72

Electrical connection diagram ....................................................... 74

Digital sensor connection diagram ................................................ 76

Analog sensor connection diagram ............................................... 78

Digital input connection diagram .................................................. 78

WARRANTY ................................................................................ 79

3

Page 4

THEORY OF FUNCTIONTHEORY OF FUNCTION

THEORY OF FUNCTION

THEORY OF FUNCTIONTHEORY OF FUNCTION

Irrigation is one of the most important operation in agriculture. With proper

irrigation the quality and quantity of crops can be significantly enhanced.

Correct irrigation is not a simple process: the quantity of water must be sufficient for crops, and if not, photosynthesis and overall growth is impeded.

However, if the amount of water is more than required, plant growth may

become excessive producing a taller, softer and/or damaged product. The

Fertigation Controller can control the quantity of irrigation water based on

time or volume. Different sectors can be irrigated at different times during a

day with different water quantities. In the Fertigation Controller each irrigation

program provides control of pH and of the amount of fertilizer released to the

fields. When necessary, a specific program performs a pH correction by the

introduction of an acid or base into the irrigation water. pH control is based

on sensor input and a specified set point, while fertilizer control is based on

sensor input and setpoint or based on volume measuring. When the Fertigation Controller commands the addition of 1 or multiple fertilizers to the irrigation stream, digital counters continuously monitor the quantity of fertilizer released in the irrigation stream and the overall amount of fertilizer is maintained based on a target prescription. Fertilization can be also controlled

based on conductivity of stream. The Fertigation Controller can command the

addition of multiple (1 to 4) fertilizers to irrigation water. The amount of fertilizer is set by the user for and controlled by a specific program (based on a

prescription). If a pH or conductivity control problem arises, the program

generates an alarm to inform the user. All operations of both control processes are stored in memory and if needed takes the proper action. The Fertigation Controller performs all necessary operations in the monitoring and

control of irrigation and fertilization processes. These operations are conducted continuously throughout the day, month and year. To use and manage

the system properly, all the necessary control values must be set (Setup mode).

During monitoring operations (Consulting mode) the user can obtain information about how the system and irrigation process are functioning, in addition to the history of all operations for current and previous days. To view the

required information on the display or set a specific parameter, the appropriate display panel has to be selected, as explained in this manual.

4

Page 5

GENERAL DESCRIPTIONGENERAL DESCRIPTION

GENERAL DESCRIPTION

GENERAL DESCRIPTIONGENERAL DESCRIPTION

The Fertigation Controller is a micro-processor-based system used in fertilization and irrigation control for greenhouses or open fields with powerful, flexible programming features.

The main function of the Fertigation Controller is supplying and controlling

the necessary water and fertilizers for crops according to several parameters

such as acidity, conductivity and ambient temperature.

The user interface is structured in two parts:

1. Consulting (numbered panels indicated by Cxx)

2. Setting (numbered panels indicated by Sxx).

This instruction manual will present the interface in 2 forms:

1. Fertigation Controller functions

2. Panel order

Fertigation Controller is capable of executing the following functions:

- Irrigation control by time or by volume

- pH control

- Fertilization control

- Manual correction

- Agitator control

- Filter control

- Water supply control

- Pumps control

- Sector control

- Serial communication

- Alarm function

- Logging function

5

Page 6

FUNCTIONAL DESCRIPTIONFUNCTIONAL DESCRIPTION

FUNCTIONAL DESCRIPTION

FUNCTIONAL DESCRIPTIONFUNCTIONAL DESCRIPTION

In this chapter the main functions of the Fertigation Controller are presented. For a better understanding see the typical installation schemes

utilized for irrigation and fertilization presented in the Appendixes, Installation Block Diagram.

IRRIGAIRRIGA

IRRIGA

IRRIGAIRRIGA

The Fertigation Controller can control up to 24 sectors (one valve per

sector) for each of the ten irrigation programs:

24 valves (sectors) can be selected specifying the sector’s number and the

desired value of irrigation time or volume for a specified irrigation program using

set sectors for the respective irrigation program.

Panel

irrigation extension and “Done” time or volume value) for the selected

irrigation program and sector.

Irrigation can be controlled by time or volume – irrigation control mode

can be switched between time and volume using panel

MODE).

Each irrigation program can be started by:

•

using panel

option on panel

•

signed the external tank (level indication) input which can start the specified irrigation program – this option is set using panel

DITION).

•

S47 S47

S47 (PROG MAN START). A program can be stopped using panel

S47 S47

(PROG MAN STOP).

Each irrigation program can be repeated a specified number of repetitions. The number of repetitions as well as pause time between two repetitions can be specified using panel

Each irrigation program can be given a priority in relation to others (6

priority levels). Priorities and maximum open sectors per group can be

specified for each program and can be set using panel

ITY).

TION CONTROLTION CONTROL

TION CONTROL

TION CONTROLTION CONTROL

S43 S43

Panel

S43 (SET SECTORS). The panel displays the number of

S43 S43

C13 C13

C13 (SECTOR STATE) displays the current status (set value plus

C13 C13

S55 S55

S55 (IRRIG CTRL

S55 S55

TIME:TIME:

TIME: 1 to 6 different timetables (values) per program can be set

TIME:TIME:

S33 S33

S33 (SET START TIME). “Start cond” must be the selected

S33 S33

S32 S32

S32 (START CONDITION).

S32 S32

EXTERNAL TEXTERNAL T

EXTERNAL T

EXTERNAL TEXTERNAL T

MANUMANU

MANU

MANUMANU

ANK LEVELANK LEVEL

ANK LEVEL: Each irrigation program can be as-

ANK LEVELANK LEVEL

S32 S32

S32 (START CON-

S32 S32

AL AAL A

CTIVCTIV

AA

TIONTION

AL A

AL AAL A

CTIV

CTIVCTIV

: :

A

TION

: A program can be started using panel

AA

TIONTION

: :

S34 S34

S34 (PROGRAM REPEATS).

S34 S34

S31 S31

S31 (SET PRIOR-

S31 S31

S48S48

S48

S48S48

6

Page 7

The following are setting requirements for each irrigation program:

- the working period (between start date (day/month) and end date

(day/month)) – use panel

- the working time during a day (between start time and end time) – use

S29 S29

panel

S29 (ACTIVE TIMETABLE)

S29 S29

- the cycle work / rest day can be set using panel

- the working days in a week – use panel

Working time status for each irrigation program, if selected (irrigation

program is in work period of month, day and week) is displayed in panel

C07 C07

C07 (WORK TIME COND).

C07 C07

The percent of irrigation time or set volume can be automatically modified

by the following:

MANU MANU

-

MANU

MANU MANU

TEMPERA TEMPERA

-

TEMPERA

TEMPERA TEMPERA

Total correction percentage, time or volume value is displayed on panel

C11 C11

C11 (TOTAL CORRECTION).

C11 C11

In each irrigation program the pre-irrigation and post-irrigation time or

volume value (used to clean the irrigation pipes with pre-irrigation water)

can be set using panel

Panel

active sectors.

The active irrigation program is displayed on panel

Related data regarding the active irrigation program (active irrigation program number, last start condition and current / set repetition number) are

displayed on panel

Information about selected irrigation program, priority and irrigation program conflict are displayed on panel

value data, correction value and irrigation completion (“Done”) value

are displayed on panel

Information about each program’s previous start condition, date and time

are displayed on panel

Total accumulation value from a previous date is displayed on panel

(TOTAL ACCUMUL).

Accumulation value from previous date and activation number for a selected irrigation program are displayed on panel

ACCUMUL).

Accumulation value from previous date, for selected sector, is displayed in

AL FAL F

AA

CTCT

AL F

AL FAL F

GATION CORR). Percentage and corresponding value of time or

volume can be viewed using panel

TION CORR).

C01 C01

C01 (GENERAL INFO) displays the active irrigation program and

C01 C01

OROR

A

CT

OR: This option can be set using panel

AA

CTCT

OROR

TURETURE

TURE: This option can be set using panel

TURETURE

S35 S35

S35 (PRE/POST IRRIG).

S35 S35

C04 C04

C04 (PROGRAM STATE).

C04 C04

C9 C9

C9 (IRRIG STATE).

C9 C9

C16 C16

C16 (PROG LAST START).

C16 C16

S29 S29

S29 (ACTIVE TIMETABLE)

S29 S29

S30 S30

S30 (WORKDAY)

S30 S30

S30 S30

S30 (WORKDAY)

S30 S30

C10 C10

C10 (MAN CORRECTION).

C10 C10

C03 C03

C03 (SENSORS STATE).

C03 C03

C08 C08

C08 (PRIOR&CONFLICTS).

C08 C08

C18 C18

C18 (PROGRAM

C18 C18

S44 S44

S44 (IRRI-

S44 S44

S44S44

S44 (IRRIGA-

S44S44

Set

C17C17

C17

C17C17

7

Page 8

C19 C19

panel

C19 (SECTOR ACCUMUL). In addition, this panel displays the

C19 C19

valve number assigned with the corresponding sector.

Accumulations erase mode can be chosen on panel

TICS). The accumulation erase can be performed for all programs and

sectors using one of the following ways:

- Manually

- Every day at specified hour

- Automatically whether the accumulations counter values overflows

S65S65

S65 (ERASE STATIS-

S65S65

FERTILIZAFERTILIZA

FERTILIZA

FERTILIZAFERTILIZA

Fertilization can be made mixing the irrigation water with 4 types of fertilizers from 4 tanks. Dosing of these fertilizers is controlled by conductivity

or by volume (ratiometric or volume). Volume fertilizer control mode is

available only if the program works in volume irrgation mode. In all cases

is available a correction of fertilization with temperature. The temperatures

for correction of fertilization are set in panel

The type of control used for fertilization is selected in panel

CTRL MODE):

•

Conductivity control is used to control fertilization based on the conductivity of irrigation water. A reference for the conductivity is set in

CONTROL) and a prescription for the proportion of fertilizers is set in

(SET FERTILIZERS) and the controller will dose the prescribed proportion of

fertilizers in such a manner to keep the EC water within specified range:

EC refernce minus or plus minimum and maximum offset values. In addition to this mode a differential conductivity control is available (set in

(EC DIFF CTRL CFG). In this mode the controller will dose the fertilizers in

a way that the irrigation water will have the conductivity of reference added

with the conductivity of input water. In this way the amount of fertilizer

dosed is the same even if the input water is contaminated with some substances that produce the rising of EC. Conductivity sensor status and

conductivity reference are displayed on panel

tion, the conductivity sensor value is displayed on panels

ERAL INFO) and

tion and input EC are displayed on panel

The conductivity control is made in accordance with a preset conductivity

reference value, specific for each irrigation program. In addition, the conductivity reference has a proportional band and a dead band that can be

set using panel S38(EC CONTROL). If the difference between setpoint and

the EC of the water is greater than the dead band for a period of time an

TION CONTROLTION CONTROL

TION CONTROL

TION CONTROLTION CONTROL

CONDUCTIVITY CONTROLCONDUCTIVITY CONTROL

CONDUCTIVITY CONTROL

CONDUCTIVITY CONTROLCONDUCTIVITY CONTROL

C03C03

C03 (SENSORS STATE). Temperature reference correc-

C03C03

S44S44

S44 (IRRIGATION CORR).

S44S44

S37 S37

S37 (FERT

S37 S37

S38S38

S38 (EC

S38S38

C06C06

C06 (EC STATE). In addi-

C06C06

C01 C01

C01 (GEN-

C01 C01

C12C12

C12 (EC CORRECTION).

C12C12

S39S39

S39

S39S39

S40S40

S40

S40S40

8

Page 9

alarm is triggered. For more information on the propotional band please

consult the proportional control section.

Given a conductivity alarm condition, conductivity control can be maintained if “Ctrl on EC alarm” is selected using panel number

BEHAVIOR).

Statistical values of total conductivity are displayed on panel

AVERAGES). For the average conductivity of each irrigation program see

C21C21

panel

C21 (PROGRAM AVERAGES) and for average conductivity of each

C21C21

individual sector see panel

RARA

•

In this mode the user has to specify for each program the quantity of each

fertilizer to be dosed. The quantity can be specified in volume or in weight

of active substance. All these settings are made in panel

CTRL). If the volume is set Y, the proportion is dosed for each fertilizer as

volume of fertilizer solution in volume of irrigation water. If the volume is

set to N, the weight of active substance is specified together with the concentration of fertilizer solution. The controller will dose then the volume of

fertilizer that contains the specified active substance.

•

This mode is available only if the program works with irrigation in volume.

The settings are made in panel

the volume of fertilizer solution and the volume of irrigation water in which

is to be mixed.

TIOMETRIC CONTROLTIOMETRIC CONTROL

RA

TIOMETRIC CONTROL

RARA

TIOMETRIC CONTROLTIOMETRIC CONTROL

VOLUME CONTROLVOLUME CONTROL

VOLUME CONTROL

VOLUME CONTROLVOLUME CONTROL

C22C22

C22 (SECTOR AVERAGES).

C22C22

S42S42

S42 (FERT VOL CTRL). Here is specified

S42S42

S54S54

S54 (ALARM

S54S54

C20C20

C20 (TOTAL

C20C20

S41 S41

S41 (RATIOMETRIC

S41 S41

PH CONTROLPH CONTROL

PH CONTROL

PH CONTROLPH CONTROL

pH control is necessary to correct and maintain the pH of irrigation water

within specified range: pH reference minus or plus dead band value.

The pH control also has a dead band and a proportional band. These

values are set using panel

The value of pH sensor and the reference value are displayed on panel

C05C05

C05 (pH STATE).

C05C05

pH sensor value is displayed also on panel

C01C01

C01 (GENERAL INFO).

C01C01

pH control will generate a pH alarm if for a period of time (more than the

time specified using panel

specified range. Given a pH alarm condition, pH control can be maintained if “Ctrl on PH alarm” is selected using panel number

BEHAVIOR). Also given a pH alarm condition, irrigation can be maintained if “Irrig on PH alarm” is selected using panel number

BEHAVIOR).

S36S36

S36 (pH CONTROL).

S36S36

C03C03

C03 (SENSORS STATE) and in

C03C03

S36S36

S36 (PH CONTROL)) the pH is not within the

S36S36

S54S54

S54 (ALARM

S54S54

S54S54

S54 (ALARM

S54S54

9

Page 10

Statistical values of pH are displayed on panel

For each irrigation program the pH average is available on panel

C20C20

C20 (TOTAL AVERAGES).

C20C20

C21C21

C21

C21C21

(PROGRAM AVERAGES) and for each individual sector the pH average

is available on panel

be deleted manually or at specified time of day using panel

C22C22

C22 (SECTOR AVERAGES). All pH averages can

C22C22

S65 S65

S65 (ERASE

S65 S65

STATISTICS)

PROPORTIONAL CONTROLPROPORTIONAL CONTROL

PROPORTIONAL CONTROL

PROPORTIONAL CONTROLPROPORTIONAL CONTROL

EC and pH control is performed using a proportional controller.

The role of this controller is to maintain a pH and EC value of the irrigation water (see diagram). The control of pH and EC is made separately.

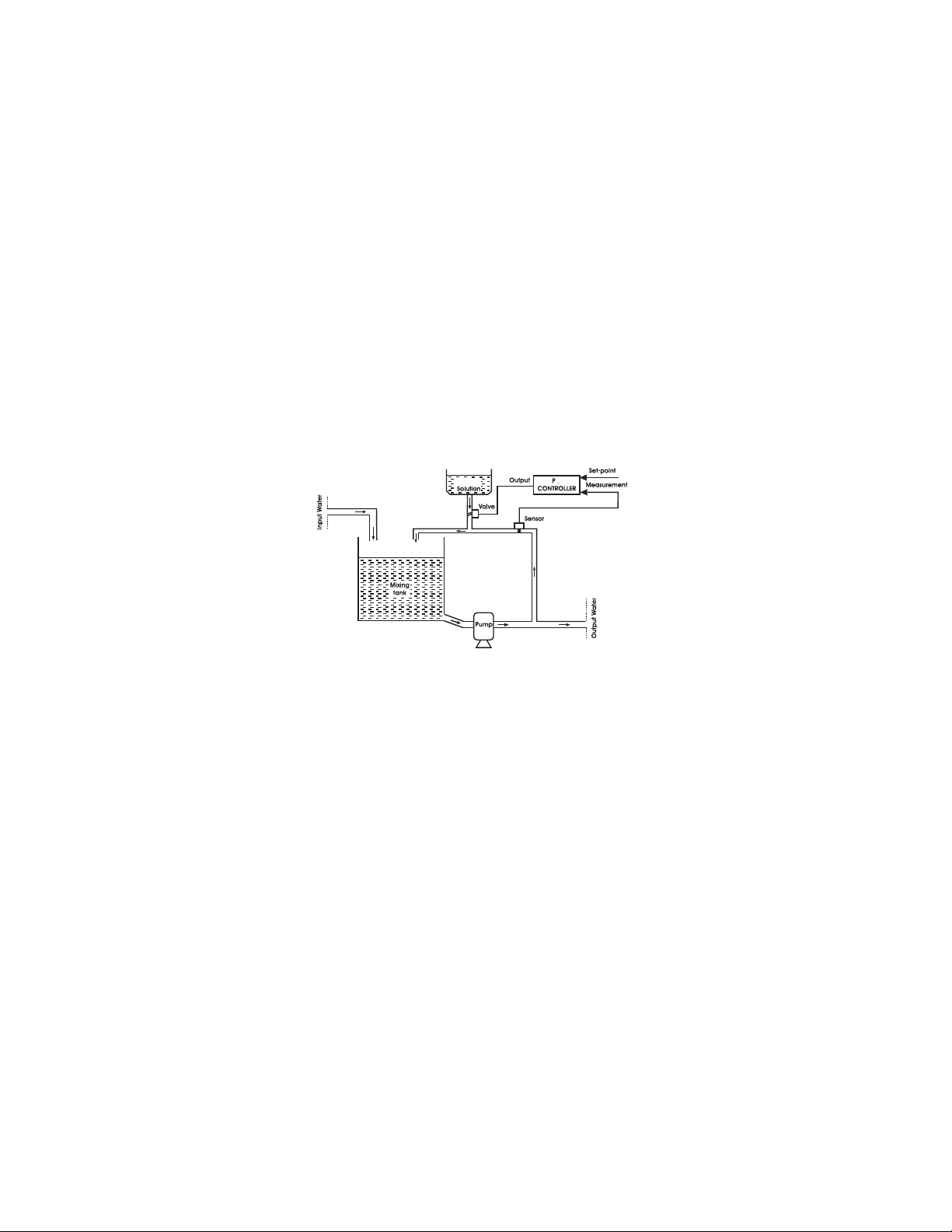

Reagent

A simplified schematic of the process (pH and EC) is presented above.

The components are as follows:

−The mixing tank where input water and additives are combined.

−The additive solution tank containing an acid, base or fertilizer

−The valve for introducing the additive solution into the mixing tank con-

trolled by the proportional controller.

−P(proportional) Controller

−The input water source.

−The irrigation pump used to pump water from the mixing tank to the

irrigation sectors.

The Fertigation controller automatically provides a command output signal to a control element such as a pump or valve based on a sensor input

signal. The function of the proportional controller is to control the dosage

of acid/base or fertilizer in such a way that pH and EC of the process will

have the values close to specified set point. The output signal commands

the opening and closing of a valve through which the additive solution is

10

Page 11

circulated. The amount of additive solution added is relative to the opening of the valve, which is directly proportional to the magnitude of difference between the “water pool” pH and the set point.

Set point (reference value) is the desired value of the measurement.

Error is define as the difference between set point and measurement:

Error = setpoint – measurementError = setpoint – measurement

Error = setpoint – measurement

Error = setpoint – measurementError = setpoint – measurement

The descriptions and definitions of the individual control actions are as

follows:

Proportional control so called because the controller output is proportional to the magnitude of error. However, proportional control is subject

to one major limitation, steady state offset (steady deviation from the set

point). Increasing the sensitivity of the controller (controller gain) can

reduce the steady state offset but only with slow processes. Because of this

proportional control by itself is used primarily for slow, consistent processes that can tolerate high controller gain (like the control of pH and EC

in irrigation applications), which minimizes steady state offset. Both pH

and EC are controlled by using the same proportional control method.

The proportional control acts on the closing and opening timings of the

motorized valves.

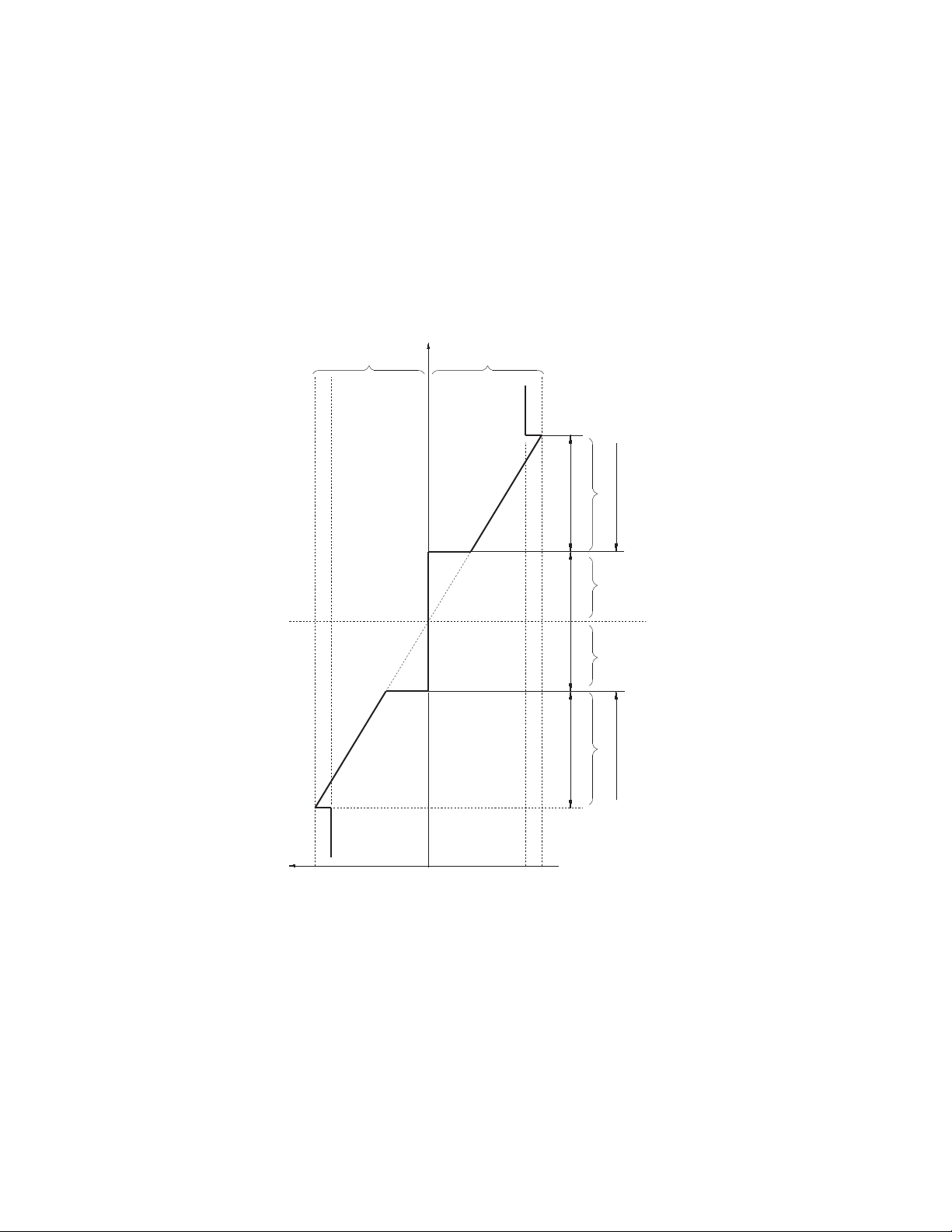

The control cycle used for the pH and EC control can be set by using

panel S60 (SET PROP CTRL). To regulate the aperture of the motorized

valves the proportional control will control the opening and closing times.

These timings are in fact pecentages from the control cycle length.

The sensivity factor simply divides the times used for the actual command

of the motorized valves. It can be used for a fine time of the proportional

control. For each program and for each of the controls (pH or EC) two

parameters define the behavior of thecontroller around a designated setpoint:

- the dead band is the area around the setpoint where the dosage is “in

limits” therefore the actuators need not to change their position.

- the proportional band is the an area around the setpoint where the

proportional control takes place. Outside of these two areas the controller

will open or close the motrized valve with 80% of the control cycle.

11

Page 12

Valve

Opening

pH, EC

Max pH

Max EC

Setpoint

Valve

Opening

P Control

No Valve Control

P Control

Proportional Band

Dead Band Dead Band

Proportional Band

High Alarm Area

Low Alarm Area

Control cycle

percentage

80%

100%

0

80%

100%

12

Page 13

AGITAGIT

AA

AGIT

AGITAGIT

For HI8060:For HI8060:

For HI8060:

For HI8060:For HI8060:

The agitator output is active in the irrigation phase of a program if the fertilizer

control is enabled. This output also commands the fertilization pumps.

For HI8050:For HI8050:

For HI8050:

For HI8050:For HI8050:

During the irrigation program, the agitators can be stopped (if working time is

zero), work continuously (if pause time is zero) or intermittently (if working time

and pause is different than zero) and can start during preirrigation, before the

fertilizer tanks are used. The agitators are set using panel S45 and can be

consulted using panel C15.

FILTER CONTROLFILTER CONTROL

FILTER CONTROL

FILTER CONTROLFILTER CONTROL

Fertigation Controller has the capability to check and automatically clean

two filters controlled by two filter-cleaning programs. Each filter cleaning

program can be started by the following conditions:

1. Following one specified irrigation program. This irrigation program

2. When a “dirty filter” alarm is activated. Cleaning by this option is set

The working time for filter cleaning programs can be set using panel

(FIL(FIL

(FIL

(FIL(FIL

MANUAL FUNCTIONSMANUAL FUNCTIONS

MANUAL FUNCTIONS

MANUAL FUNCTIONSMANUAL FUNCTIONS

TOR CONTROLTOR CONTROL

A

TOR CONTROL

AA

TOR CONTROLTOR CONTROL

can be set in panel

using panel

TERS CTRL).TERS CTRL).

TERS CTRL).

TERS CTRL).TERS CTRL).

S46 S46

S46 (FILTERS CTRL).

S46 S46

S46 S46

S46 (FILTERS CTRL).

S46 S46

S45S45

S45

S45S45

The Fertigation Controller has the following Manual function capabilities:

− To switch the controller state between STOP, WORK and INIT, use panel

S49 S49

S49 (CONTROLLER STATE). The controller state can be checked using

S49 S49

C01 C01

panel

C01 (GENERAL INFO)

C01 C01

− To manually start a program use panel

− To manually stop a program use panel

− To check and to change the value for each of the outputs, use panel

S50 S50

S50 (OUTLET MAN CTRL)

S50 S50

− To erase all statistics, use panel

cates pH and conductivity averages for all irrigation programs and sectors in addition to average total irrigation accumulation. They also show

the volume of water and fertilizers on sectors, on programs and total

volumes.

− To erase the settings of one irrigation program or to erase all settings for

all irrigation programs, use panel

S65 S65

S65 (ERASE STATISTICS).

S65 S65

S47 S47

S47 (PROG MAN START)

S47 S47

S48 S48

S48 (PROG MAN STOP)

S48 S48

S66 S66

S66 (ERASE SETTINGS).

S66 S66

13

Statistics indi-

Page 14

ALARMSALARMS

ALARMS

ALARMSALARMS

Fertigation controller has the capability to supervise and generate an alarm

for the following conditions:

- Conductivity sensor out of range. Reference, minimal and maximal offset

and time-out for conductivity alarm are set using panel

TROL). The current values of conductivity sensors are displayed on panel

C06 C06

C06 (EC STATE)

C06 C06

− pH sensor out of range. Reference, minimum and maximum offset and

time-out for pH alarm are set using panel

current values of pH sensors are displayed on panel

− Problems with the water supply.

− Dirty filters.

− Low levels in fertilizer and acid tanks.

− Waste of fertilizers.

− Main irrigation counter fail.

− Overdose and underdose of fertilizer.

The system will take appropriate action and record the alarm. These actions can be:

..

.

..

S36 S36

S36 (PH CONTROL).

S36 S36

S38 S38

S38 (EC CON-

S38 S38

The

C05 C05

C05 (pH STATE)

C05 C05

• Given a pH alarm condition, the irrigation process can be set to

stop or continue using panel

S54 S54

S54 (ALARM BEHAVIOR).

S54 S54

• Given an EC alarm condition, the irrigation process can be set to

stop or continue using panel

S54 S54

S54 (ALARM BEHAVIOR).

S54 S54

• Given a dirty filter alarm condition, start the filter cleaning program

in accordance with the priority and working time settings

• Given a water supply alarm situation the controller goes in BLOCK state.

• All alarm situations are displayed on panel

All anomalies (old alarm conditions) are displayed in panel

(ANOMALY).

C23 C23

C23 (ALARM).

C23 C23

C25C25

C25

C25C25

LOGGING (DIARY) FUNCTIONS LOGGING (DIARY) FUNCTIONS

LOGGING (DIARY) FUNCTIONS

LOGGING (DIARY) FUNCTIONS LOGGING (DIARY) FUNCTIONS

− The Fertigation controller has the capability to log the most important

occurred events and values of different parameters that can offer a description of the evolution of the entire process;

− The most important values are:

- Number and time period of every program activation;

- Filter cleanings;

- Averages of pH, conductivity and temperature;

- Accumulations;

14

Page 15

- Values of sensors.

- Sectors irrigated by a program.

- Alarms;

The records of log can be searched by date. To start a search set the desired

date in panel C24 (VIEW LOG DATE). Logging records are displayed on

panel C26 (LOG).

The average value of sensors and accumulation of volumes are available

through panes C17 (TOTAL ACCUMUL) to C22 (SECTOR AVERAGES).

DADA

TE AND TIME CONTROLLER SETTINGSTE AND TIME CONTROLLER SETTINGS

DA

TE AND TIME CONTROLLER SETTINGS

DADA

TE AND TIME CONTROLLER SETTINGSTE AND TIME CONTROLLER SETTINGS

The controller date and time can be consulted on panel

INFO) and can be set using panel

PASSWORD SETUP PASSWORD SETUP

PASSWORD SETUP

PASSWORD SETUP PASSWORD SETUP

Access to Fertigation Controller can be restricted by a password. This

password can be set using panel

can be disabled using the same panel.

SERIAL COMMUNICASERIAL COMMUNICA

SERIAL COMMUNICA

SERIAL COMMUNICASERIAL COMMUNICA

The fertigation controller is able to connect with a PC and can be remotely

controlled by the PC through the Agricare program. To be able to connect

the PC must have a serial port available and a Windows operating system. The serial cable must be crossover and with male – female connector. For more details please consult the help of the Agricare program.

S28 S28

S28 (SET DATE & TIME).

S28 S28

S64 S64

S64 (SET PASSWORD). The password

S64 S64

TIONTION

TION

TIONTION

C01 C01

C01 (GENERAL

C01 C01

15

Page 16

USER INTERFACEUSER INTERFACE

USER INTERFACE

USER INTERFACEUSER INTERFACE

The user interface of the Fertigation Controller consists of a 4 x 20 character LCD and a 23 key keyboard (see depiction below).

KEYBOARD STRUCTUREKEYBOARD STRUCTURE

KEYBOARD STRUCTURE

KEYBOARD STRUCTUREKEYBOARD STRUCTURE

Fig. 1.1: Fig. 1.1:

Fig. 1.1: Keyboard layout.

Fig. 1.1: Fig. 1.1:

OPERAOPERA

OPERA

OPERAOPERA

The Fertigation controller operates primarily in two major modes: Consulting Mode and Setting Mode. User interface panels (screens) are broken

down into two categories:

1. CONSULTING PANELS

2. SETTING PANELS

Both modes of operation a readily available to the user.

TING MODESTING MODES

TING MODES

TING MODESTING MODES

1. CONSUL TING MODE:

The consulting mode allows the user to view the current state and set

conditions of the Fertigation Controller. While in consulting mode (

key not pressed) all 68 panels can be viewed by one of 2 browsing methods. The primary consulting screens are designated from C

2727

C

27. The following outline highlights the functions of the consulting mode.

2727

PP

− two browsing methods are enabled. See Section

METHODSMETHODS

METHODS for more details.

METHODSMETHODS

ARROWS KEYSARROWS KEYS

−

ARROWS KEYS can be used to move the cursor within a currently

ARROWS KEYSARROWS KEYS

selected panel to select specific data (only if data items are selectable) to

be viewed.

16

ANEL BROWSINGANEL BROWSING

P

ANEL BROWSING

PP

ANEL BROWSINGANEL BROWSING

0101

01 through

0101

SETSET

SET

SETSET

Page 17

ESCESC

−

ESC key can be used as a shortcut key to access the

ESCESC

STATE) panel from any currently viewed panel.

HOMEHOME

−

HOME key can be used as a shortcut key to access the

HOMEHOME

ERAL INFO) panel from any currently viewed panel.

ENDEND

−

END key can be used as a shortcut key to access the

ENDEND

STOP) panel from any currently viewed panel.

TT

ABAB

−

T

AB key can be used to switch the focus between the

TT

ABAB

objectobject

object and the

objectobject

dexed. If there is no index parameter present on the current panel, the

TT

ABAB

T

AB key has no effect. The program number indexes panels. For ex-

TT

ABAB

ample, panel

each program. Once panel

the focus (cursor) is shifted from the panel number to the program number “Prog 01”. The

each program state consecutively without leaving the panel.

ENTERENTER

−

ENTER key is used to confirm any new values entered in any of the

ENTERENTER

selected panels. This is only possible if data items on a panel (screen) are

selectable.

panels index parameterpanels index parameter

panels index parameter if the current panel is in-

panels index parameterpanels index parameter

C04 C04

C04 (PROGRAM STATE) displays the current state for

C04 C04

C04C04

C04 is selected and the

C04C04

ARROW KEYSARROW KEYS

ARROW KEYS can now be used to scroll through

ARROW KEYSARROW KEYS

C04C04

C04 (PROGRAM

C04C04

C01 C01

C01 (GEN-

C01 C01

S48 S48

S48 (PROG MAN

S48 S48

panel numberpanel number

panel number

panel numberpanel number

TT

ABAB

T

AB key pressed,

TT

ABAB

2. SETTING MODE:

The setting mode allows configuration of all adjustable parameters of the

S28S28

Fertigation controller. The setting screens are designated from

All 68 panels can be viewed by one of 2 browsing methods. The setting

mode is executed by selecting the appropriate screen and pressing the

SETSET

SET key. Once the setting mode is entered both panel-browsing methods

SETSET

are disabled and navigation is allowed only within the currently selected

panel. The following outline highlights the functions of the Setting Mode.

− Both panel (screen) browsing methods are disabled. See Section

BROWSING METHODSBROWSING METHODS

BROWSING METHODS

BROWSING METHODSBROWSING METHODS

− Focus (cursor location) is automatically shifted to the first editable data

object on the selected panel.

UPUP

, DOWN, DOWN

−

UP

, DOWN

UPUP

, DOWN, DOWN

objects within the current panel.

LEFTLEFT

, RIGHT arrow keys, RIGHT arrow keys

−

LEFT

, RIGHT arrow keys allow navigation within the currently fo-

LEFTLEFT

, RIGHT arrow keys, RIGHT arrow keys

cused

object then the focus is transferred to the previous or next editable item

within the current panel.

TT

ABAB

−

T

AB key can be used to move only in a forward direction, from one data

TT

ABAB

object to the next within the selected panel.

ENTERENTER

−

ENTER key confirms all data entered in a current panel. Once the

ENTERENTER

arrow keysarrow keys

arrow keys allows navigation between all editable data

arrow keysarrow keys

data object.data object.

data object. If the cursor exceeds the boundaries of the data

data object.data object.

S28 to

S28S28

S68S68

S68.

S68S68

PP

ANELANEL

P

ANEL

PP

ANELANEL

17

Page 18

ENTERENTER

ENTER key is pressed and data confirmed, the controller reverts to con-

ENTERENTER

sulting mode. The

ESCESC

−

ESC key cancels new data entered in the currently focused data object

ESCESC

and exits the setting mode. The change of data is not saved in the current

object and the previous setting is maintained.

NONO

TETE

NO

TE: Data that has been changed in an editable data object is saved

NONO

TETE

once focus has been removed from that object by pressing the

KEYSKEYS

KEYS or

KEYSKEYS

PP

ANELS BROWSING METHODSANELS BROWSING METHODS

P

ANELS BROWSING METHODS

PP

ANELS BROWSING METHODSANELS BROWSING METHODS

In consulting mode, 2 browsing methods are available to view each of the

68 panels (screens) of the Fertigation controller.

−

keys allows consecutive navigation from one panel to the next. Direction

is dependent upon which key is selected.

−

entered directly using the panel number located on the bottom right corner of every panel, prefixed by a

initially focused object on each screen. After entering the value by using

the key pad and

panel.

NONO

NO

NONO

setting mode, both browsing methods are disabled.

TT

ABAB

T

AB.

TT

ABAB

StepStep

-by-by

--

Step

StepStep

Direct access browsingDirect access browsing

Direct access browsing: the number of the desired panel can be

Direct access browsingDirect access browsing

TETE

TE

TETE

step browsingstep browsing

-by

-

step browsing: pressing

-by-by

--

step browsingstep browsing

: :

: If a panel is selected and the

: :

SETSET

SET key must be pressed to re-enter setting mode.

SETSET

ARROWARROW

ARROW

ARROWARROW

PP

AA

CC

C or

CC

arrow keysarrow keys

arrow keys, press the

arrow keysarrow keys

GE UPGE UP

P

A

GE UP and

PP

AA

GE UPGE UP

SS

S. The panel number object is the

SS

ENTERENTER

ENTER key to view the selected

ENTERENTER

SETSET

SET key is pressed, entering the

SETSET

PP

AA

GE DOWNGE DOWN

P

A

GE DOWN

PP

AA

GE DOWNGE DOWN

18

Page 19

PP

ANEL LISTANEL LIST

P

ANEL LIST

PP

ANEL LISTANEL LIST

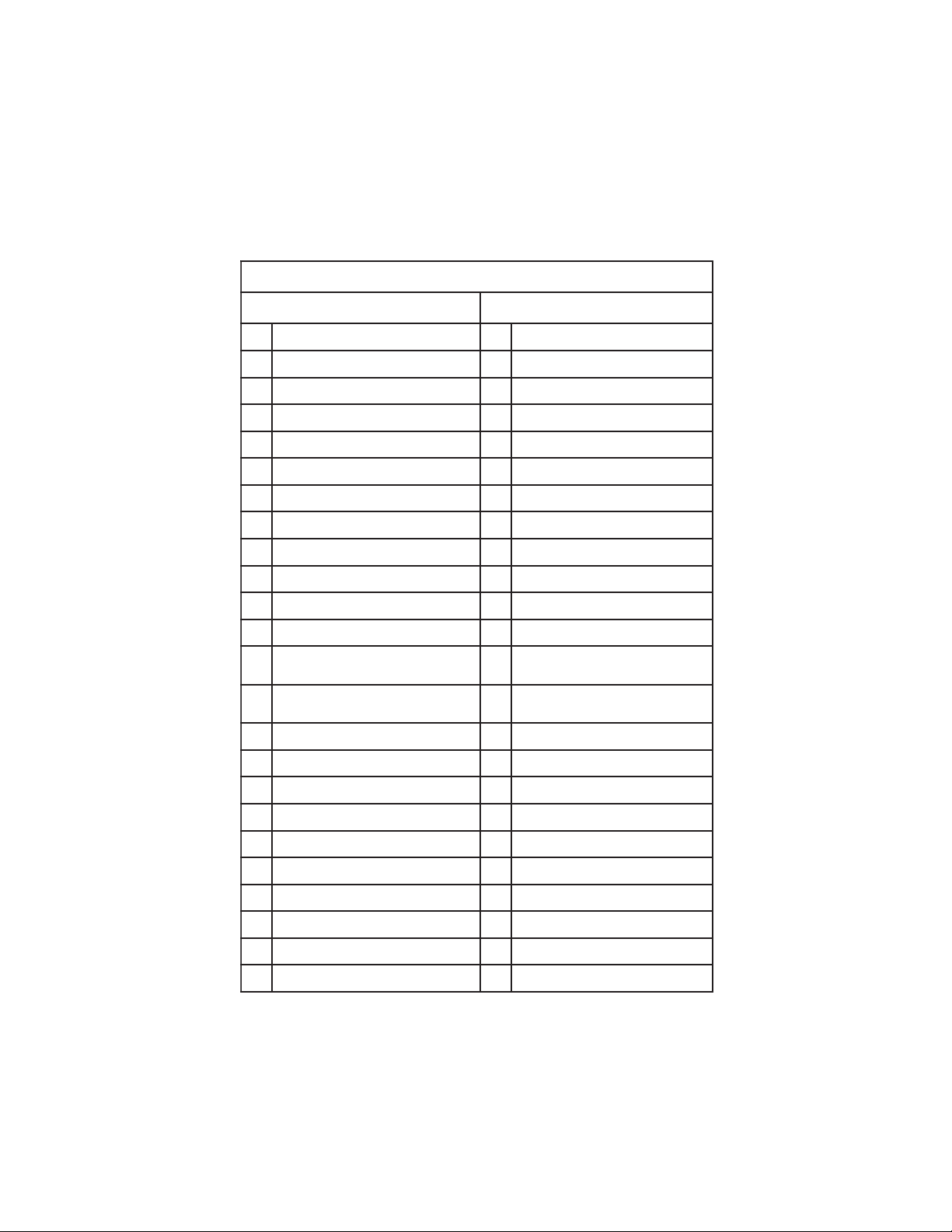

REBMUNYBELBATLENAPREBMUNYBELBATLENAP

REBMUNYBELBATLENAPREBMUNYBELBATLENAP

REBMUNYBELBATLENAP

NOCSLENAPGNITLUSNOC

10OFNILARENEGNOITAMR82EMIT&ETADTES

20ETATSEMULOV92ELBATEMITEVITCA

30ETATSSROSNES03YADKR

40ETATSMARGORP13YTIROIRPTES

50ETATSHp23SNOITIDNOCTRATS

60ETATSCE33EMITTRATSTES

70SNOITIDNOCEMITKROW43STAEPERMARGOR

80STCILFNOC&YTIROIRP53NOITAGIRRITSOP/ERP

90ETATSNOITAGIRRI63LORTNOCHp

01ROTCAFNOITCERROCLAUNAM73EDOMLORTNOCREZI

11NOITCERROCLATOT83LORTNOCCE

21SNOITCERROCCE93SREZILITREFTES

31ETATSSROTCES04

41ETATSREZILITREF14

51ETATSROTATIGA24LORTNOCREZILITREFEMULOV

SLENAPGNITLUS

SLENAPGNITLUSNOCSLENAPGNITLUSNOCSLENAPGNITTESSLENAPGNITTES

SLENAPGNITLUSNOC

OW

P

S

LITREF

GIFNOC

LORTNOC

SLENAPGNITTESSLENAPGNITTES

SLENAPGNITTE

LORTNOCLAITNEREFFIDCE

NOITARU

REZILITREFCIRTEMOITAR

GORP34SROTCESTES

61TRATSTSALMAR

71NOITALUMUCCALATOT44NOITCERROCNOITAGIRRI

81NOITALUMUCCAMARGORP54SROTATIGATES

ES64LORTNOCSRETLIF

91NOITALUMUCCAROTC

02SEGAREVALATOT74TRATSLAUNAMMARGORP

12SEGAREVAMARGORP84POTSLAUNAMMARGORP

22SEGAREVAROTCES94ETATS

32MRALA05LORTNOCLAUNAMSTELTUO

42ETADGOLWEIV15SNOITPOLORTNOCHp

RELLORTNOC

19

Page 20

REBMUNYBELBATLENAPREBMUNYBELBATLENAP

REBMUNYBELBATLENAPREBMUNYBELBATLENAP

REBMUNYBELBATLENAP

NOCSLENAPGNITLUSNOC

52SEILAMONA25SMRALAGNISODEMULOV

62GOL35SMRALAEMULOVNOPOTS

72ECITCARPYROTAROBALDOOG45RO

SLENAPGNITLUS

SLENAPGNITLUSNOCSLENAPGNITLUSNOCSLENAPGNITTESSLENAPGNITTES

SLENAPGNITLUSNOC

55EDOMLORTNOCNOITAGIRRI

65SRETEMARAPWOLFTES

75SGNITTESRETNUOC

85NOITCELESSPMUP

95SEVLAVDEZIROTOM

06LR

16SGNIMITTES

26LORTNOCELBANE

36TESSROSNESGNGIGOL

46DROWSSAPTES

56SCITSITATSESARE

66SGNITTESESARE

76SROSNE

S

IVAHEBMRALA

TCPORPTES

SETARBILAC

SLENAPGNITTESSLENAPGNITTES

SLENAPGNITTE

20

86NOITACIFITNEDIRELLORTNOC

Page 21

GLARENE)RELLORTNOC(

NOITCNUFYBELBATLENAPNOITCNUFYBELBATLENAP

NOITCNUFYBELBATLENAPNOITCNUFYBELBATLENAP

NOITCNUFYBELBATLENAP

LENAPLENAP

LENAPLENAP

TCNUFLENAPNOITCNUFLENAP

NOITCNUFLENAPNOITCNUFLENAP

NOI

NOITCNUFLENAP

GNITLUSNOC

GNITLUSNOCMARGORP20ETATSEMULOV

LENAP

REBMUNREBMUN

R

EBMUNREBMUN

REBMUN

10NOITAMROFNILARENEG

30E

72ECITCARPYROTAROBALDOOG

40ETATSMARGORP

50ETATSHp

60ETATSCE

TATSSROSNES

EMANLENAPEMANLENAP

EMANLENAPEMANLENAP

EMANLENAP

70SNOITIDNO

80STCILFNOCDNAYTIROIRP

90ETATSNOITAGIRRI

01

11NOITCERROCLATOT

21SNOITCERROCCE

1ETATSSROSNES

3

41ETATSREZILITREF

51ETATSROTATIGA

61TRATSTSALMARGORP

GNITLUSNOCSCITSITATS71NOITALUMUCCALATOT

81NOIT

91NOITALUMUCCAROTCES

02SEGAREVALATOT

12SEGAREVAMARGORP

22SEGAREVAROTCES

32MRALA

CEMITKROW

NOITCERROCLAUNAM

ROTCAF

ALUMUCCAMARGORP

42ETADGOLWEIV

21

Page 22

NOITCNUFYBELBATLENAPNOITCNUFYBELBATLENAP

NOITCNUFYBELBATLENAPNOITCNUFYBELBATLENAP

NOITCNUFYBELBATLENAP

LENAPLENAP

LENAPLENAP

TCNUFLENAPNOITCNUFLENAP

NOITCNUFLENAPNOITCNUFLENAP

NOI

NOITCNUFLENAP

)RELLORTNOC(LARENEG

SGNITTES

LENAP

REBMUNREBMUN

REBMUNREBMUN

REBMUN

52SEILAMONA

62GOL

82EMIT&E

73EDOMLORTNOCREZILITREF

64LORTNOCSRETLIF

15SNOITPOLORTNOCHp

25SMRALAGNISODEMULOV

35SMRALAEMULOVNOPOTS

TADTES

EMANLENAPEMANLENAP

EMANLENAPEMANLENAP

EMANLENAP

45RO

65SRETEMARAPWOLFTES

75SGNITTESRETNUOC

95SEVLAVDEZIROTOM

06LRTCPOPPTES

16SGNIMITTES

26LORTNOCELBANE

36TE

46DROWSSAPTES

76SROSNESETARBILAC

86NOITACIFITNEDIRELLORTNOC

SGNITTESMARGORP92ELBATEMITEVITCA

03Y

13YTIROIRPTES

23SNOITIDNOCTRATS

33EMITTRATSTES

43STAEPERMARGORP

IVAHEBMRALA

SSROSNESGNIGGOL

ADKROW

22

Page 23

NOITCNUFYBELBATLENAPNOITCNUFYBELBATLENAP

NOITCNUFYBELBATLENAPNOITCNUFYBELBATLENAP

NOITCNUFYBELBATLENAP

LENAPLENAP

LENAPLENAP

TCNUFLENAPNOITCNUFLENAP

NOITCNUFLENAPNOITCNUFLENAP

NOI

NOITCNUFLENAP

LENAP

REBMUNREBMUN

R

EBMUNREBMUN

REBMUN

53NOITAGIRRITSOP/ERP

63HpLORTNOC

83LORTNOCCE

EMANLENAPEMANLENAP

EMANLENAPEMANLENAP

EMANLENAP

93SREZILITR

04

14

24LORTNOCREZILITREFEMULOV

34SROTC

44NOITCERROCNOITAGIRRI

54SROTATIGATES

55EDOMLORTNOCNOITAGIRRI

85NOITCELESSPMUP

SNOITCNUFLAUNAM74TRATSLAUNA

84POTSLAUNAMMARGORP

94ETATSRELLORTNOC

05LORTNOCLAUNAMSTELTUO

56SCITSITATSESARE

66SGNITTESESARE

EFTES

LORTNOC

ESTES

MMARGORP

LORTNOCLAITNEREFFIDCE

NOITARUGIFNOC

REZILITREFCIRTEMOITAR

23

Page 24

PANEL DESCRIPTIONSPANEL DESCRIPTIONS

PANEL DESCRIPTIONS

PANEL DESCRIPTIONSPANEL DESCRIPTIONS

Below are described all the panels in the controllers. The panels are divided in

three sections: Initialization panels, consulting panels and setting panels. The

data fields within each panel are described from left to right unless otherwise

specified.

INITIALIZAINITIALIZA

INITIALIZA

INITIALIZAINITIALIZA

INITIALIZATION PANEL

This panel is shown during Fertigation Controller INITIALIZATION state and

contains the HANNA INSTRUMENTS logo and the name of the controller.

The last line is used to display the current status of the initialization sequence.

This panel is also used to display any possible errors that may occur during

the start up sequence.

START PANEL

This panel is displayed after successful initialization or whenever the password

authentication sequence fails (user will be logged off due to incorrect password entry). This panel displays the date and time and the bottom left corner

it is shown the Fertigation Controller functional state.

It is important to note that the Fertigation Controller is normallyIt is important to note that the Fertigation Controller is normally

It is important to note that the Fertigation Controller is normally

It is important to note that the Fertigation Controller is normallyIt is important to note that the Fertigation Controller is normally

functioning at this point if the required external conditions arefunctioning at this point if the required external conditions are

functioning at this point if the required external conditions are

functioning at this point if the required external conditions arefunctioning at this point if the required external conditions are

met even if the user is logged off.met even if the user is logged off.

met even if the user is logged off. At this stage, when the user presses

met even if the user is logged off.met even if the user is logged off.

ENTERENTER

the

ENTER key another login opportunity will be given if the password au-

ENTERENTER

thentication process is enabled. This feature can be specified via panel

(SET PASSWORD).

TION PTION P

TION P

TION PTION P

HANNA INSTRUMENTS

HI8050 V00.01-004E

INITIALIZATION:

Loading StringTable

HANNA INSTRUMENTS

HI8050 CONTROLLER

Fri 15-03-2000 13:15

STOP PRESS ENTER

ANELSANELS

ANELS

ANELSANELS

S64S64

S64

S64S64

24

Page 25

INPUT PASSWORD PANEL

Enter password:

****

This panel is displayed during the password authentication sequence. If this

STST

ARAR

sequence fails the user will be logged off and the

played. If the password is correct panel

The default password is

00000000

0000. See section Setting Password for instructions

00000000

C01C01

C01 (GENERAL INFO) is displayed.

C01C01

TT

ST

AR

T panel will be dis-

STST

ARAR

TT

on setting this feature.

Although access to the controllers features are denied the functionality of the

controller is not directly affected if a password authentication sequence fails.

CONSUL CONSUL

CONSUL

CONSUL CONSUL

TING PTING P

TING P

TING PTING P

ANELSANELS

ANELS

ANELSANELS

GENERAL INFO – C01

WORK Anomalies 00

Prog 08 06.4pH

Sect 07 02.1mS 13:15

GENERAL INFO C01

This panel displays the following information from top left:

Fertigation Controller Functional State (top left corner) Fertigation Controller Functional State (top left corner)

−

Fertigation Controller Functional State (top left corner) - When

Fertigation Controller Functional State (top left corner) Fertigation Controller Functional State (top left corner)

WORKWORK

WORKWORK

INITIAL-INITIAL-

INITIAL-

INITIAL-INITIAL-

the controller is running it can be in one of the following states:

IZAIZA

TIONTION

, ST, ST

OPOP

IZA

IZAIZA

TION

TIONTION

, ST

, ST, ST

, WORK, WORK

OP

, WORK

OPOP

, WORK, WORK

first powered on the first state is

performs internal tests. In

normal conditions the functional state is

, BL, BL

OCKOCK

, BL

, BL, BL

STST

ST

STST

..

OCK

. When the Fertigation Controller is

OCKOCK

..

INITIALIZAINITIALIZA

INITIALIZA

INITIALIZAINITIALIZA

OPOP

OP state all programs are suspended. Under

OPOP

TIONTION

TION. In this state the unit

TIONTION

WORKWORK

WORK. In the

WORKWORK

WORK state all

irrigation and fertilization programs are executed. If an alarm occurs the

Fertigation Controller enters the

BLOCKBLOCK

BLOCK state until the alarm condition is

BLOCKBLOCK

corrected. The user can customize the alarm management system behavior using setting panels

S54S54

S54 (ALARM BEHAVIOR).

S54S54

Anomalies (top right corner) - Anomalies (top right corner) -

−

Anomalies (top right corner) - The anomalies counter represents the

Anomalies (top right corner) - Anomalies (top right corner) -

S36, S38S36, S38

S36, S38 (pH and EC CONTROL) and panel

S36, S38S36, S38

number of alarms triggered since the last reset of the counter. This counter

can be customized and cleared along with all system statistics via setting

panel S65 (ERASE STATISTICS).

25

Page 26

Program NumberProgram Number

−

Program Number - The active program is displayed. If no program is

Program NumberProgram Number

active this field is not visible.

pH sensor readingpH sensor reading

−

pH sensor reading - The reading of pH sensor.

pH sensor readingpH sensor reading

Sector NumbersSector Numbers

−

Sector Numbers - All sectors assigned to the active program are dis-

Sector NumbersSector Numbers

played (cyclically) and only when an active program is running. If no

program is active no number is visible.

EC sensor reading - EC sensor reading -

−

EC sensor reading - The reading of EC sensor.

EC sensor reading - EC sensor reading -

System clock.System clock.

−

System clock.

System clock.System clock.

If an alarm condition is present the time indication will also flash “ALARM”

to alert the user.

NONO

TETE

::

NO

TE

: If the user is logged in and the operational mode is

NONO

TETE

::

MODEMODE

MODE, this panel can be accessed anytime and from any panel using the

MODEMODE

HOMEHOME

HOME key as a shortcut.

HOMEHOME

NONO

TETE

::

NO

TE

: The Clock, pH and EC sensors are always visible regardless of state.

NONO

TETE

::

CONSULCONSUL

CONSUL

CONSULCONSUL

TINGTING

TING

TINGTING

VOLUME STATE - C02

Irr:0114320L Prog:01

F1:00050L F2:00500L

F3:00370L F4:00000L

VOLUME STATE C02

The purpose of this panel is to allow the user to inspect the volumes of irrigation water and fertilizers that have been dosed since the current program was

launched in execution. If the current program is not READY, ACTIVE or WAIT

in the place of volume values will be nothing. This panel contains the following information:

Program NumberProgram Number

−

Program Number - the current program (the one for which the volume

Program NumberProgram Number

values are).

Irrigation volume Irrigation volume

−

Irrigation volume – the volume of irrigation water.

Irrigation volume Irrigation volume

Fertilizer n volumeFertilizer n volume

−

Fertilizer n volume – the volume of fertilizer from tank n.

Fertilizer n volumeFertilizer n volume

SENSORS STATE – C03

Active Program: 04

06.3pH +22C

06.4mS 13:15

SENSORS STATE C03

This panel provides an overview of the real time values of the system sensors.

26

Page 27

This panel contains the following information:

Active program number Active program number

−

Active program number - displays the number of the executing pro-

Active program number Active program number

gram. If no program is running no number is displayed.

− −

pH sensor readingpH sensor reading

−

pH sensor reading

− −

pH sensor readingpH sensor reading

− −

TT

emperature sensor readingemperature sensor reading

−

T

emperature sensor reading

− −

TT

emperature sensor readingemperature sensor reading

− −

EC sensor readingEC sensor reading

−

EC sensor reading

− −

EC sensor readingEC sensor reading

− −

System clock.System clock.

−

System clock.

− −

System clock.System clock.

PROGRAM STATE – C04

Prog 08 Active

Started by Time Cond

Repeat 02/05 13:15

PROGRAM STATE C04

The purpose of this panel is to allow the user to inspect the status and settings

of a particular program. The program number indexes this panel. This panel

contains the following information:

Program NumberProgram Number

−

Program Number – The current selected program. Act as index for the

Program NumberProgram Number

panel (used to view settings for all programs).

NOTE: This is the only panel where the current program can be changed.

Program StateProgram State

−

Program State - During the lifetime of a program it cycles through several

Program StateProgram State

states. Each program is initially in NO SET state which means no settings

have been applied to the program by the user. Once the settings have

been applied the program is considered in SET state. Once a specific

condition such as start time is met the program passes to READY state to

await execution. Once the program reaches the highest priority and the

start time is met, the program passes to ACTIVE state and executes. The

program may be suspended and placed in WAIT state due to a higher

priority program moving to ACTIVE state or a specific alarm condition

triggering. When a program completes execution it is placed in FINISHED state. The cycle may be repeated and the program returned to

ready state if the program repeats were specified after a set delay period.

Program Started by Program Started by

−

Program Started by - Displays how the last program start was triggered.

Program Started by Program Started by

Programs can be started by a met time condition, manual start, low level

in external tank, or directly after the completion of another program. If the

program is in NO SET (no settings applied to program) or in SET (settings

applied but conditions not met) state, .Started by field is blank.

RepeatRepeat

−

Repeat - Displays the current repetition followed by (/) the maximum num-

RepeatRepeat

ber of the programmed repetitions.

27

Page 28

− −

System clockSystem clock

−

System clock

− −

System clockSystem clock

REMINDER: In CONSULTING MODE the ESC key can be used as a

shortcut key to access this panel from any panel.

PH STATE – C05

Prog 08 Ref=06.4pH

pHout:06.4pH 13:15

PH STATE C05

The purpose of this panel is to allow the user to inspect the current pH reference point for a specific program and the real time pH sensor readings. The

program number indexes this panel. This panel contains the following information:

Program NumberProgram Number

−

Program Number – The current selected program. Act as index for the

Program NumberProgram Number

panel (used to view settings for all programs).

RefRef

−

Ref = Reference or set point pH value for the specified program.

RefRef

PhoutPhout

−

Phout - Real time value of pH sensor. This reading applies to the entire

PhoutPhout

process and is not program specific.

− −

System clockSystem clock

−

System clock

− −

System clockSystem clock

EC STATE – C06

Prog 08 Ref=05.6mS

ECin :01.1mS

Count:02.0mS 13:15

EC STATE C06

The purpose of this panel is to allow the user to inspect the current EC reference point for a specific program and the real time EC sensor readings. The

program number indexes this panel. This panel contains the following information:

PP

rogram Numberrogram Number

−

P

rogram Number - Panel index (used to view settings for all programs).

PP

rogram Numberrogram Number

RefRef

−

Ref - Reference or set point EC value for the specified program.

RefRef

EcoutEcout

−

Ecout - Real time value of EC sensor. This reading applies to the entire

EcoutEcout

process and is not program specific.

− EC in - Real time value of EC input sensor. This sensor measure the conductivity of the incoming water supply. This reading applies to the entire

process and is not program specific.

− System clock

28

Page 29

WORK TIME COND – C07

Prog 08 Time Y

Day Y

Period Y 13:15

WORK TIME COND C07

The program number indexes this panel. This panel contains the following

information:

PP

rogram Numberrogram Number

−

P

rogram Number - Panel index (used to view settings for all programs).

PP

rogram Numberrogram Number

− Time - Indicates if the selected program’s daily schedule is met at the actual

moment

− Day - Indicates if the selected program’s monthly schedule is met at the

actual moment

− Period - Indicates if the selected program’s yearly schedule is met at the

actual moment

− System clock

PRIOR&CONFLICTS – C08

Prog 08 Priority 06

Conflict Programs 09

13:15

PRIOR&CONFLICTS C08

This panel indicates the priority level of the indexed program. Priority settings

play a roll in program execution when two or more programs have similar

starting conditions. The priority for a given program can be set using panel

S31S31

S31 (SET PRIORITY). The Conflict Programs counter cyclically displays all

S31S31

programs that are in conflict with the currently active program. Programs can

be in conflict if their specific start and running conditions are synchronous.

Given this scenario, the program having the highest priority will become active.

The program number indexes this panel. This panel contains the following

information:

PP

rogram Numberrogram Number

−

P

rogram Number - Panel index (used to view settings for all programs).

PP

rogram Numberrogram Number

PriorityPriority

−

Priority - Displays priority of indexed program

PriorityPriority

Conflict ProgramsConflict Programs

−

Conflict Programs - Cyclically displays the program number of programs

Conflict ProgramsConflict Programs

in conflict with the currently active program.

System clockSystem clock

−

System clock.

System clockSystem clock

29

Page 30

IRRIG STATE – C09

Prog 08 IRRIG

Set 01:15:20+005:55

Done 00:45:10 13:15

IRRIG STATE C09

This panel displays the current irrigation state of the indexed program. Time or

volume can control irrigation and the above panel displays the set value and

the amount of irrigation currently completed. The mode of irrigation (time or

volume) can be selected using panel

S55S55

S55 (IRRIG CTRL MODE). The program

S55S55

number indexes this panel. This panel contains the following information:

PP

rogram Numberrogram Number

−

P

rogram Number - Panel index (used to view settings for all programs).

PP

rogram Numberrogram Number

IrrigIrrig

−

Irrig - the state of the program

IrrigIrrig

: :

: Irrig - irrigating; Preirrig - preirrigating;

: :

Postirrig - postirrigation; Idle - irrigating or waiting for irrigation

Set - Set -

−

Set - Displays the required (set) value of irrigation in time or volume.

Set - Set -

Irrigation correction value Irrigation correction value

−

Irrigation correction value (number directly following Set value)

Irrigation correction value Irrigation correction value

DoneDone

−

Done - Displays the value already done of irrigation time or volume.

DoneDone

System clockSystem clock

−

System clock

System clockSystem clock

MAN CORRECTION – C10

Prog 08

+015%

+00:15:55 13:15

MAN CORRECTION C10

This panel displays how much the programmed irrigation parameters are

manually modified (corrected). The program number indexes this panel. This

panel contains the following information:

PP

rogram Numberrogram Number

−

P

rogram Number - Panel index (used to view settings for all programs).

PP

rogram Numberrogram Number

Irrigation extension percentageIrrigation extension percentage

−

Irrigation extension percentage - Displays the overall extension per-

Irrigation extension percentageIrrigation extension percentage

centage of irrigation for the selected program due to manual correction.

Irrigation extension value Irrigation extension value

−

Irrigation extension value - Displays (in time or volume) the extension

Irrigation extension value Irrigation extension value

value of irrigation for the selected program due to manual correction.

System clockSystem clock

−

System clock

System clockSystem clock

TOTAL CORRECTION – C11

Prog 08

+035%

+02:00:13 13:15

TOTAL CORRECTION C11

30

Page 31

This panel displays how much the programmed irrigation parameters are

modified due to both manual and temperature corrections. The program number

indexes this panel. This panel contains the following information:

PP

rogram Numberrogram Number

−

P

rogram Number - Panel index (used to view settings for all programs).

PP

rogram Numberrogram Number

Irrigation extension percentageIrrigation extension percentage

−

Irrigation extension percentage - Displays the overall extension per-

Irrigation extension percentageIrrigation extension percentage

centage for a selected program.

Irrigation extension valueIrrigation extension value

−

Irrigation extension value - Displays (time or volume) the total extension

Irrigation extension valueIrrigation extension value

value of irrigation for the selected program.

System clockSystem clock

−

System clock

System clockSystem clock

EC CORRECTION - C12

Prog 08 Ref=02.1mS

TCorr:-00.3mS

Input:+01.2mS 13:15

EC CORRECTIONS C12

This panel shows the correction of EC with temperature and with the EC of the

input water. The program number indexes this panel. This panel contains the

following information:

PP

rogram Numberrogram Number

−

P

rogram Number - Panel index (used to view settings for all programs).

PP

rogram Numberrogram Number

TT

emperature correctionemperature correction

−

T

emperature correction - Displays the amount with which the reference is

TT

emperature correctionemperature correction

decreased because of temperature rise.

Input EC correctionInput EC correction

−

Input EC correction - Displays the amount of which the EC reference is

Input EC correctionInput EC correction

corrected due to a deviation of the EC of the input water adverse to the

EC input setpoint.

System clockSystem clock

−

System clock

System clockSystem clock

SECTOR STATE – C13

Prog 08 Sect 33/21

Set 00:10:30+009:45

Done 00:03:10 13:15

SECTOR STATE C13

This panel displays the state of each sector. Each sector has an electro-valve

assigned. When a particular sector requires irrigation its corresponding electrovalve is opened for a specified period of time. Sector label along with valve

number (upper right corner of display) indexes this panel. This panel contains

the following information:

- Program Number - Program Number

- Program Number - Reflects the selected program (can be selected only

- Program Number - Program Number

inside panel C 04).

- Sect - Sect

- Sect - The first number displayed is the sector number followed by ‘/’ the

- Sect - Sect

31

Page 32

valve number assigned to that sector. This parameter indexes the sectors

for this panel.

SetSet

−

Set - Displays the amount of irrigation water set in time or volume for the

SetSet

selected sector/valve of the indicated program.

Irrigation correction value Irrigation correction value

−

Irrigation correction value (number directly following Set value) - Dis-

Irrigation correction value Irrigation correction value

plays correction value in time or volume for the selected sector/valve of

the indicated program.

DoneDone

−

Done - Displays the current point of irrigation in time or volume

DoneDone

for the

selected sector/valve of the indicated program.

− −

System clockSystem clock

−

System clock

− −

System clockSystem clock

NONO

TETE

::

NO

TE

: The label of sector consists of a numeric “tag” for the assigned valve.

NONO

TETE

::

Sector labels can be specified using panel

S43 S43

S43 (SET SECTORS). As default the

S43 S43

sector label will be identical to the corresponding valve number.

FERTILIZ STATE – C14

Prog 02 Fert 02

Set 40%

Current 20% 13:15

FERTILIZ STATE C14

This panel displays the set and current amount of fertilizer used for a specific

program. The Fertigation Controller controls the dosing of 4 fertilizers. In this

panel the fertilizer number is used as the index, allowing inspection of the

percent values for one up to four fertilizer tanks involved in the selected irrigation program. This panel contains the following information:

- Program Number- Program Number

- Program Number

- Program Number- Program Number

- F- F

ertert

- F

ert - Panel index. Fertilizer tank number. Each program can control 1 to 4

- F- F

ertert

fertilizer tanks.

- Set- Set

- Set - The set percentage of one of four selected fertilizers to be dosed.

- Set- Set

- Current- Current

- Current - The current dosage percentage of one of selected fertilizer, if the

- Current- Current

fertilizer control mode is EC. If the fertilizer control is ratiometric or volume, then it will display “- -”.

- System clock.- System clock.

- System clock.

- System clock.- System clock.

NONO

TETE

: :

NO

TE

: The fertilizers percentage values can be specified using the

NONO

TETE

: :

FERTILIZERS).

AGITATOR STATE – C15 (only for HI8050)

Prog 08

WORK 00:03 WORK

PAUSE 00:02 13:15

AGITATOR STATE C15

32

S39S39

S39 (SET

S39S39

Page 33

This panel displays the state of the agitator for the current selected program.

The agitators can be activated before dosing of a fertilizer, during dosing, or

intermittently throughout the program. The program number indexes this panel.

This panel contains the following information:

PP

rogram Numberrogram Number

−

P

rogram Number - Panel index (used to view settings for all programs).

PP

rogram Numberrogram Number

WW

orkork

−

W

ork – the set working time for the agitator.

WW

orkork

PP

auseause

−

P

ause – the set pause time for the agitator.

PP

auseause

− −

System clock.System clock.

−

System clock.

− −

System clock.System clock.

NONO

TETE

::

NO

TE

: For HI8060 the agitators are wired to the fertilizer pump control signal.

NONO

TETE

::

PROG LAST START – C16

Prog 08 Filter -Last start Manual

At 28-08 18:32 13:15

PROG LAST START C16

This panel displays the starting reason and the time moment of the indexed

program’s previous start, including filter-cleaning programs. There are 2 filter-cleaning programs one for each filter. The filter programs follow the indexed irrigation programs. For example, if the Fertigation Controller is equipped

with 10 irrigation programs, “Prog” number 11 and 12 will be designated for

the two filter cleaning programs on the above panel. In this case the first 10

program numbers will indicate the last start data for the irrigation process and

programs 11 and 12 will indicate the last start data for filter cleaning. The

program number indexes this panel. This panel contains the following information:

PP

rogram Numberrogram Number

−

P

rogram Number - Panel index (used to view settings for all programs).

PP

rogram Numberrogram Number

FilterFilter

−

Filter - Filter number

FilterFilter

Last StartLast Start

−

Last Start - The previous start trigger for the indexed program (irrigation or

Last StartLast Start

filter cleaning).

AtAt

−

At - The date and time moment of the previous start for the indexed pro-

AtAt

gram.

− −

System clock.System clock.

−

System clock.

− −

System clock.System clock.

TOTAL ACCUMUL – C17

From: 09-26 13:37:12

0007654L Irrig

13:15

TOTAL ACCUMUL C17

This panel provides a total (in time or volume) of the entire irrigation process

33

Page 34

(all programs) from the reset time. All Fertigation Controller’s statistics including accumulations can be erased (manually, daily at specified hour, on overflow ) within panel S 65 (ERASE STATISTICS).

This panel contains the following information:

--

FF

romrom

-

F

rom - Time stamp indicating the beginning of the overall irrigation process.

--

FF

romrom

--

AccumulationAccumulation

-

Accumulation - Total accumulation in time or volume

--

AccumulationAccumulation

--

Accumulation labelAccumulation label

-

Accumulation label - Accumulation label can be changed by using

--

Accumulation labelAccumulation label

the up and down arrows. This label indicates the type of accumulation

showed in this panel. This setting will also indicate the type of accumulation for panels 18 and 19.

Labels can be:

- Irrig - will show total water accumulation or total irrigation time

- Fert1 - fertilizer 1 total volume accumulation

- Fert2 - fertilizer 2 total volume accumulation

- Fert3 - fertilizer 3 total volume accumulation

- Fert4 - fertilizer 4 total volume accumulation

- Acid - acid/alkaline total volume accumulation

--

System clockSystem clock

-

System clock

--

System clockSystem clock

PROGRAM ACCUMUL – C18

From: 09-26 13:37:12

0007654L Prog 01

Activations 03 13:15

PROGRAM ACCUMUL C18

This panel provides a total (in time or volume) for each of the irrigation programs. The program number indexes this panel. This panel contains the following information:

FF

romrom

−

F

rom - Time stamp indicating the start of recording (statistics)

FF

romrom

AccumulationAccumulation

−

Accumulation - Total accumulation in time or volume for the indexed

AccumulationAccumulation

program

PP

rogram Numberrogram Number

−

P

rogram Number - Panel index (used to view settings for all programs).

PP

rogram Numberrogram Number

ActivationsActivations

−

Activations - The number of activations of the indexed program since the

ActivationsActivations

start of recording.

− −

System clock.System clock.

−

System clock.

− −

System clock.System clock.

SECTOR ACCUMUL – C19

From: 09-26 13:37:12

0123456L Sect 01/01

13:15

SECTOR ACCUMUL C19

34

Page 35

This panel provides a total (in time or volume) for each of the irrigation sectors. The valve number indexes this panel. This panel contains the following

information:

FF

romrom

−

F

rom - Time stamp indicating the start of recording (statistics)

FF

romrom

Accumulation -Accumulation -

−

Accumulation - Total accumulation in time or volume for the indexed

Accumulation -Accumulation -

valve and type of accumulation selected on panel C17 (TOTAL

ACCUMUL).

SectSect

−

Sect - The sector number (label) / valve number (index for this panel).

SectSect

− −

System clock.System clock.

−

System clock.

− −

System clock.System clock.

TOTAL AVERAGES – C20

From: 09-26 13:37:12

05.3pH

02.1mS +21C 13:15

TOTAL AVERAGES C20

This panel indicates the overall average of pH, conductivity and temperature

for the entire irrigation process. This panel contains the following information:

FF

romrom

−

F

rom - Time stamp indicating the start of recording (statistics)

FF

romrom

pHpH

−

pH - The pH total average

pHpH

mSmS

−

mS - The EC total average

mSmS

CC

−

C – The temperature total average

CC

− −

System clock.System clock.

−

System clock.

− −

System clock.System clock.

PROGRAM AVERAGES – C21

From: 09-26 13:37:12

05.3pH Prog 01

02.1mS +21C 13:15

PROGRAM AVERAGES C21