Page 1

Microlab F.A.M.E.

USER MANUAL

Version 2.0

Page 2

P/N 610520/02 05/01

Important Notice

This manual may not be used or reproduced in any way whatsoever without the express

written consent of Hamilton Bonaduz AG.

Copyright ã 1995, 1996, 1997, 1998, 1999 Hamilton Bonaduz AG, All Rights Reserved.

Microlab is a registered trade mark of Hamilton Bonaduz AG.

IBM, OS/2, DATABASE 2 and DB2 are registered trademarks of International Business

Machines Corporation.

MICROTITER is a registered trademark of Dynatech Laboratories.

Page 3

Microlab F.A.M.E. User Manual V2.0 ——————————————————————————— Master Table of Contents ——

Master Table of Contents

1 - ML F.A.M.E. Overview .................................................................1

Cook Book - Chapter 2 to 8

2 - Cook Book Introduction............................................................25

3 - ML F.A.M.E. Methods ................................................................27

4 - Daily Work Routine....................................................................41

5 - Test Results & ML F.A.M.E. Traces............................................55

6 - Instrument Status ......................................................................63

7 - ML F.A.M.E. Verification.............................................................65

8 - ML F.A.M.E. Maintenance .........................................................69

Reference Guide - Chapter 9 to 17

9 - Reference Guide Introduction...................................................81

10 - ML F.A.M.E. Methods ..............................................................83

11 - Daily Work Routine................................................................105

12 - Test Results & ML F.A.M.E. Traces........................................129

13 - ML F.A.M.E. Functions & Requirements ...............................137

14 - ML F.A.M.E. Verification.........................................................147

15 - ML F.A.M.E. Maintenance .....................................................169

16 - Technical Specifications........................................................183

17 - Troubleshooting & Error Handling........................................199

Appendices - A1 to A8

A1 - Error & Trace Codes Messages............................................213

A2 - Glossary................................................................................237

A3 - Frequently Asked Questions ................................................247

A4 - Anomalies .............................................................................249

A5 - Forms....................................................................................251

A6 - News Letters .........................................................................261

A7 - User Manual Update Information .........................................263

A8 - Index .....................................................................................265

P/N 610520/02 05/01

Page 4

Microlab F.A.M.E. User Manual V2.0 ——————————————————————————— Master Table of Contents ——

P/N 610520/02 05/01

Page 5

Microlab F.A.M.E. User Manual V2.0 —————————————————————————— ML F.A.M.E. Overview ——

Chapter

1 ML F.A.M.E. Overview

Table of Contents

1.1 - About the Microlab F.A.M.E. ....................................................2

1.1.1 - Basic Concepts ..................................................................2

1.2 - Using This Manual....................................................................3

1.2.1 - User Manual Symbols ........................................................3

1.3 - ML F.A.M.E. Components ........................................................4

1.3.1 - The ML F.A.M.E. Instrument ...............................................4

1.3.2 - The ML F.A.M.E. Workstation .............................................9

1.4 - General Information ...............................................................12

1.4.1 - Warranty............................................................................12

1.4.2 - Ordering Information ........................................................13

1.4.3 - Definition of Terms............................................................17

1.4.4 - Safety Precautions and Hazards......................................17

P/N 610520/02 05/01

1-1

Page 6

Microlab F.A.M.E. User Manual V2.0 —————————————————————————— ML F.A.M.E. Overview ——

1.1 About the Microlab F.A.M.E.

1.1.1 Basic Concepts

The Microlab F.A.M.E. (ML F.A.M.E.) is a diagnostic instrument

used to analyze blood samples for the presence of certain biological elements.

This analysis is performed using the ELISA (Enzyme Linked

Immuno Sorbent Assay) testing process. This process requires

samples to be manipulated in various ways, i.e. incubating, washing, dispensing, mixing, photometric measurement, etc.

The ML F.A.M.E. has been developed with a modular design, incorporating all functions necessary to perform these sample manipulations.

The test process is controlled by a highly developed software

pakkage allowing:

r Simultaneous processing of tests from different manufacturers.

r Easy adaptation of various tests using the ML F.A.M.E. Method

Editor.

r Automatic schedule optimization and work list visualization.

r Full traceability and documentation of sample processing and

of individual instrument functions.

1.1.1.1 Intended Use

The intended use of the ML F.A.M.E. is to process microplate

based ELISA assays for screening blood and blood products for

the presence of any blood-borne pathogen, primarily in screening

centers, plasma centers, hospitals, public health centers and reference laboratories.

1.1.1.2 ML F.A.M.E. Operator

Any persons operating the ML F.A.M.E. and ML F.A.M.E. workstation must have attended a certified training course. Any departure

from the following texts could lead to erroneous results or ML

F. A.M . E . m a l fu n c ti o n .

1-2

P/N 610520/02 05/01

Page 7

Microlab F.A.M.E. User Manual V2.0 —————————————————————————— ML F.A.M.E. Overview ——

1.2 Using This Manual

This manual has been developed for use with ML F.A.M.E. version

2.0 and should not be used with any other software version unless

previously announced by the supplier.

The documentation set has been designed to allow various levels

of ML F.A.M.E. operator to access the required information as they

progress in their knowledge of the environment.

This has been achieved using a three part structure:

r ML F.A.M.E. Overview

The ML F.A.M.E. Overview gives general information about

the ML F.A.M.E., its computer environment, functions and

intended use.

r Cook Book

The Cook Book defines the ML F.A.M.E. operator related

tasks in a step-by-step guide.

In each section there is an introduction explaining the task

then a table structure defining a question and then an

explanation of the procedures needed to achieve this task.

Where necessary there are “Notes” and “Attention”

paragraphs to bring certain information to the ML F.A.M.E.

operator. These paragraphs are positioned in the left column

to avoid any interruption in the flow of the step by step

process.

r Reference Guide

The Reference Guide gives full technical information on all

functions of the ML F.A.M.E. and is designed to be used as

both support for the Cook Book (through extensive cross

referencing) and as a stand alone reference work.

“Notes” and “Attention” paragraphs, similar to those used in

the Cook Book are also used in the Reference Guide.

1.2.1 User Manual Symbols

P/N 610520/02 05/01

ATTENTION

ATTENTION: Any special problems, warnings or important information will be accompanied by this symbol. Read these carefully as

they can easly help to understand particular issues.

NOTE: This is used to give information to the ML F.A.M.E. operator

that is useful but not essential to the task at hand. Read these carefully as they can easly help to understand particular issues.

NOTE

1-3

Page 8

Microlab F.A.M.E. User Manual V2.0 —————————————————————————— ML F.A.M.E. Overview ——

(

)

1.3 ML F.A.M.E. Components

The ML F.A.M.E. consists of two parts:

r The ML F.A.M.E. Instrument.

and

r The ML F.A.M.E. Workstation (including ML F.A.M.E. software).

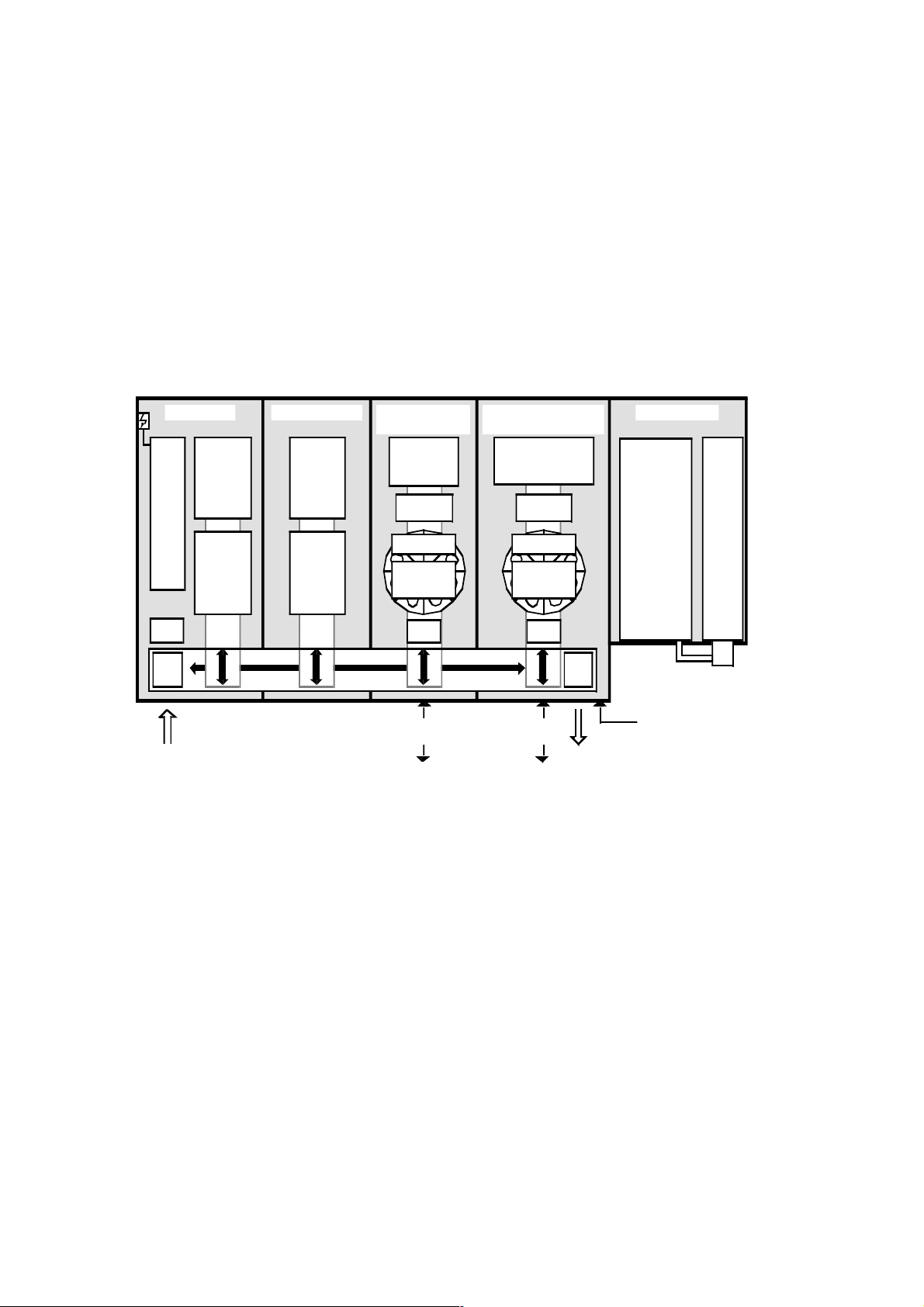

1.3.1 The ML F.A.M.E. Instrument

Entr y Mo dul e Incubator Module

Power

Supply

230/

115 V

Plate

Barco de

Reader

Ent r y

Lif t/

Stac k

MTP Loading

max 4 per stack

Rear

Incubator

To wer

5 Slo ts

temper atur e-

cont r ol led

Fr ont

Incubator

To wer

5 Slo ts

ambi ent

temperature

Module

Mai n Shuttle Rail

Trans port

Washer/ Dispenser

(Di spenser/Photometer)

Photometer

Mi xer

Dispen ser

Re age nt

Cont a iner

1818

Carousel

Reag ent

Ba rc ode

Reader

Exi t

Stack/

Manipul ation

Posi t i o n

Module

Trans port

Draw erDr awe r

MTP Exit

Re ar

Incubat or

Tower

5 Slot s

temp erat ur e-

controlled

Front

Incubat or

Tower

5 Slot s

temp erat ur e-

controlled

Module

Mo du l e

Was h e r

24 ch annel

man i fo l d

Mixer

Di sp ens er

Reagent

Cont ai ner

Caro us el

Reagen t

Barcode

Rea der

Module

Trans port

Trans port

Reagent Re agent

Figure 1.1 16/20 configuration (top view)

The primary functions of the ML F.A.M.E. include:

Cont ai ner St ackEnd Module

Wash/Rinse

Fl ui d

Containers

1-4

PC Connectio n

Ext.

Pump

Stati on

r Positive plate identification.

r Incubation (temperature-controlled or ambient).

r Washing (with liquid level detection).

r Dispensing (including positive reagent identification and liquid

level detection).

r Photometric measurement.

1.3.1.1 Configurations

All instrument configurations consist of a combination of four different modules.

1-4

P/N 610520/02 05/01

Page 9

Microlab F.A.M.E. User Manual V2.0 —————————————————————————— ML F.A.M.E. Overview ——

r Entry Module - 10 incubation slots

r Incubator Module - 10 incubation slots

r Washer/Dispenser Module with External Pump Station

r End Module

These four basic modules connected to the chassis, plus a container stack, complete the basic instrument configuration 16/20 - 16

reagent positions and 20 incubator slots.

By adding an extra incubator module and/or an extra washer/dispenser module to the chassis, the following three instrument configurations are also possible:

r 16/30 - 2 incubator modules giving 30 incubation slots

r 24/20 - 2 washer/dispenser modules giving 24 reagent positions

r 24/30 - 2 incubator modules and 2 washer/dispenser modules

Upgrade from one configuration to a higher specification instrument is possible in the field.

1.3.1.2 Entry Module

The main functions of the Entry Module are:

r Loading of the plates

r Plate barcode reading (positive plate identification)

r Incubation

The Entry Module consists of the following components:

1.3.1.2.1 Entry Section

The entry platform is used to load plates onto the instrument. All

plates are placed manually onto the entry platform.

There are two ways of loading plates:

1 Place a single plate directly onto the entry platform. 2 Place an entry stack (which accommodates up to 4 plates) onto

the entry platform.

P/N 610520/02 05/01

1.3.1.2.2 Plate Barcode Reader

The function of the plate barcode reader is to identify barcodes on

the plates. Barcode information is also used to select the test

method and or kit lot to be used.

After reading, the plate is transported automatically, according to

the selected method, to the defined modules for processing, e.g.

incubator, washer, etc.

1-5

Page 10

Microlab F.A.M.E. User Manual V2.0 —————————————————————————— ML F.A.M.E. Overview ——

1.3.1.2.3 Incubators

NOTE

Slots within the same incubator

tower cannot be individually

programmed. However, each

slot is individually temperaturecontrolled.

The Entry Module contains two incubator towers each with 5 incubation slots.

The front tower is used for ambient temperature incubation only.

The rear tower is used for ambient temperature or for temperaturecontrolled incubation.

The temperature can be set between ambient and 45°C. A plate

can be loaded individually into each slot.

1.3.1.2.4 Power Distribution

The power supply for all the modules is built into the Entry Module.

The mains power connector and the on/off switch are located on

the left hand side of this module towards the rear.

The primary and secondary protection switches (circuit breakers),

and the voltage selector switch (230/115V) are also located in this

area, behind the instrument side panel.

1.3.1.3 Incubator Module

NOTE

Slots within the same incubator

tower cannot be individually programmed. However, each slot is

individually temperature controlled.

1.3.1.4 Washer/Dispenser Module

1.3.1.4.1 Washer

The Incubator Module contains two temperature-controlled incubator towers each with 5 incubation slots.

The temperature of both towers is programmable up to 70°C (maximum allowed temperature difference between the two towers:

25°C).

An individual plate can be loaded into each incubator slot.

The main functions of the Washer/Dispenser Module are:

r Plate washing

r Dispensing of reagents

r Mixing (shaking of plates)

Washer/Dispenser Modules consist of the following components:

The washer comprises a 24-channel manifold consisting of 3 rows

of 8 needles. Each of the 24 wells is washed simultaneously.

1-6

An adjustment of the manifold liquid level detection system is executed automatically during every cold start of the system.

Each needle has liquid level detection. If a well cannot be properly

washed, the liquid level detector produces an error which is documented as a message in a trace file.

P/N 610520/02 05/01

Page 11

Microlab F.A.M.E. User Manual V2.0 —————————————————————————— ML F.A.M.E. Overview ——

Three different wash solutions (up to 3 liters each) and one rinse

fluid (up to 3 liters) can be loaded into the container stack situated

next to the End Module. All wash fluid containers have liquid level

detection. All wash functions and liquid definitions are programmable by the user software in the Method Definition. For example:

r Wash mode

r Number of wash cycles

r Soak time

r Volume of liquid

r Solution name

1.3.1.4.2 Waste Container

The waste container holds the fluid that is aspirated from the plates

during washing and has a capacity of 10 liters. A liquid level detector is incorporated in the waste cap. When the container is full, a

message appears on the workstation screen. Exchanging of waste

containers is possible without interrupting instrument operation.

1.3.1.4.3 External Water Separator

The external water separator holds fluid that is expelled from the

venting tube.

1.3.1.4.4 Dispenser

A single channel dispenser, using disposable syringes and reagent

containers dispenses the required reagents into the plates.

Carry-over is eliminated by the use of Hamilton Reagent Container

Systems with dedicated syringes for each reagent liquid.

Liquid Level Detection is used during the reagent’s distribution process.

1.3.1.4.5 Reagent Container System

Each Reagent Container System consists of:

r A reagent container

r A dedicated disposable syringe

r A barcode label

P/N 610520/02 05/01

In total, 8 reagent container systems can be positioned in segments on the reagent container carousel. The carousel is then

placed into the reagent drawer.

Several reagent container carousels can be utilized. Single reagent

container systems or complete reagent container carousels can be

exchanged and kept in a refrigerator.

1-7

Page 12

Microlab F.A.M.E. User Manual V2.0 —————————————————————————— ML F.A.M.E. Overview ——

1.3.1.4.6 Reagent Container Identification

Each reagent container is identified by a clear text label and a barcode. A barcode reader located in each reagent drawer identifies

the reagents.

Barcodes are supplied for containers. You may use other barcode

labels providing that they comply with ML F.A.M.E. specifications,

see Reference Guide Section 16.3.2 on page 193.

1.3.1.4.7 Mixer

The mixer is used for horizontal shaking of the plate in the lengthwise direction. The mix intensity and the mix time are programmable.

1.3.1.5 End Module

The main functions of the End Module are:

r Reagent dispensing

r Photometric measurement

r Mixing (shaking of the plate)

The Exit Stack is also located in this module allowing plates to be

removed from the instrument.

The End Module comprises the following components:

1.3.1.5.1 Dispenser

The function of the dispenser is the same as the one in the Washer/

Dispenser module.

1.3.1.5.2 Mixer

The mixer is identical to the one in the Washer/Dispenser module.

1.3.1.5.3 Photometer

The photometer has 8 measuring channels (i.e. 8 wells can be

measured simultaneously) and one additional reference channel.

There are 5 filters incorporated with the following wavelengths:

r 340 nm

1-8

r 405 nm

r 450 nm

r 492 nm

r 620 nm

Up to 8 filters can be used. These may have wavelengths ranging

from 340 nm to 750 nm.

P/N 610520/02 05/01

Page 13

Microlab F.A.M.E. User Manual V2.0 —————————————————————————— ML F.A.M.E. Overview ——

The following parameters are programmable via the user software:

r Measurement wavelength

r Reference wavelength

1.3.1.5.4 Exit Stack

The exit stack is where the instrument stores finished plates (i.e.

plates which have had all processing steps performed on them).

From here the plates can be removed and disposed of.

Approximately 10 plates can be stored in the exit stack. Bristles

hold the plates in place in the exit stack. A sensor controls the exit

status.

If the stack is nearly full, a warning message is displayed by the

user software. Plates can be removed at any time without interrupting processing.

1.3.2 The ML F.A.M.E. Workstation

The ML F.A.M.E. Workstation is an IBM compatible personal computer (PC), to the specification listed in section 1.3.2.1 en la página

1-9, running the IBM operating system OS/2 WARP with IBM’s DB2/

2 and version 2.0 of the ML F.A.M.E. software.

1.3.2.1 The Computer

The specification of the personal computer required for use with

the ML F.A.M.E. is listed in Reference Guide Section 16.4 on page

196 and it is highly recommended to use a system as similar as

possible.

1.3.2.2 The Operating System

An operating system is a software application allowing the system

operator to access installed software and to write and read information to a storage device, i.e. floppy or fixed disk.

This software application has been designed and created to run

with IBM’s OS/2 operating system (WARP). It also utilizes IBM’s

data storage retrieval system DB2/2.

P/N 610520/02 05/01

OS/2 is a Graphic User Interface (GUI) operating environment

which means the ML F.A.M.E. operator can access the required

functions using an object oriented control method, i.e. to access a

function the ML F.A.M.E. operator will physically select the command for that function using a pointing device, e.g. a mouse.

For further information on using OS/2 and DB2/2 please consult

the supplier or the documentation supplied with the product.

1-9

Page 14

Microlab F.A.M.E. User Manual V2.0 —————————————————————————— ML F.A.M.E. Overview ——

1.3.2.3 The ML F.A.M.E. Software

NOTE

The standard Microlab F.A.M.E.

software does not include the

Active Kit Lot Check and Sample

and Reagent Addition Monitoring

(SRAM) features. If Hamilton

users need these features,

authorization from Hamilton and

OCD is required for blood banks

in specific territories. Please

contact the Product Manager at

Hamilton Bonaduz to obtain the

special disk set.

The ML F.A.M.E. software is an application with various access

rights assigned to the various levels of ML F.A.M.E. operator giving

them software control on a need-to-use basis.

Main features of the software include:

r Full operations tracing (ML F.A.M.E. operator, ML F.A.M.E. soft-

ware and ML F.A.M.E. functions and actions).

r Full sample tracing (from entire plates to individual wells).

r Temporary storage of processed plates’ data.

r Method definition and editing.

r Scheduling with re-scheduling options.

r Graphical representation of daily work routine.

ATTENTION

For further information on

installation please see the

separate Installation Guide. It is

the responsibility of the

laboratory manager which

installation options are selected.

ATTENTION

With this option on it is possible

to operate an “un-verified”

instrument.

1.3.2.4 Installation Options

r Extensive error handling and recovery routines.

r Complete instrument maintenance and verification procedures.

During the installation procedure for the ML F.A.M.E. software a

number of features exist allowing the customizing of the installation.

The installation options are as follows:

r Verification Restrictive:

With this option selected the ML F.A.M.E. operator will be

prompted when trying to start a run, if there are verification procedures required. It is not possible to run ML F.A.M.E. if the

required verification for any module is not completed. The only

exception is if the ML F.A.M.E. operator is asked whether or not

to run verification on an incubator slot and answers "no" then

that slot will be locked, although a run can be started.

r Verification Non-restrictive:

With this option selected the ML F.A.M.E. operator will be

prompted when trying to start a run, if there are verification procedures required. It is still possible to use ML F.A.M.E. modules

if the required verification for that module is not completed, e.g,

if the ML F.A.M.E. operator is asked whether or not to run verification on an incubator slot and answers "no" then that slot will

be not locked, however, the error status of a test will be set to

trace and all test traces will contain a warning indicating the

required function was not verified when requested.

1-10

r Plate Access Off:

With this option selected the ML F.A.M.E. software must find the

pipetting information on the first try or else the plate will not be

accepted for processing. No other options are allowed.

P/N 610520/02 05/01

Page 15

Microlab F.A.M.E. User Manual V2.0 —————————————————————————— ML F.A.M.E. Overview ——

r Plate Access On:

With this option selected the ML F.A.M.E. software will allow the

ML F.A.M.E. operator to process plates when no pipetting infor-

ATTENTION

Please ensure that the correct

sample barcodes are entered.

mation is found. Options include retry or searching for the barcode information along a path, using an editor to include or

exclude wells or to enter the well barcodes after plate loading.

Sample barcodes from the plate

barcode file are write protected.

r Active Kit Lot Check:

With this option selected the master kit lot number included in

the plate barcode or in the pipetting file will be checked against

the defined one. The kit lot file must be provided by the higher

system, no access is given to the editor.

ATTENTION

Please ensure that the correct kit

lot data is defined in the kit lot

editor.

r Kit Lot Documentation:

With this option selected the ML F.A.M.E. operator will have

access to the Kit Lot Editor allowing editing or creating of kit lot

information file. However, the defined kit lot will be documented,

but no check is made of the loaded lot.

r User Access Editor Off:

ATTENTION

Please ensure that the default

users are deleted and the

correct lab specific users and

access rights are defined.

Disables the User Access Editor.

r User Access Editor On:

Enables the User Access Editor where it is possible to establish a list of ML F.A.M.E. operators and their security level.

P/N 610520/02 05/01

1-11

Page 16

Microlab F.A.M.E. User Manual V2.0 —————————————————————————— ML F.A.M.E. Overview ——

1.4 General Information

1.4.1 Warranty

HAMILTON warrants this product to be free of defects in material

and workmanship for a period of 12 months from the date of delivery.

HAMILTON or an authorized HAMILTON representative will repair

or replace, at its option and free of charge, any product that under

proper and normal use proves to be defective during the warranty

period.

HAMILTON shall in no event be liable or responsible for any incidental or consequential damage, either direct or contingent.

HAMILTON consumable products such as syringes, valves, tubing,

disposable tips, etc. are warranted to be free of defects in material

and workmanship at the time of delivery only.

This warranty shall not apply if:

1 the product has not been operated in accordance with the ML

F.A.M.E. operator manual

2 the product is not regularly and correctly maintained

3 the product is not maintained, repaired or modified by a HAMIL-

TON authorized representative or ML F.A.M.E. operator

4 parts other than original-HAMILTON parts are used

5 the product and parts thereof have been altered without written

authorization from HAMILTON

6 the product is not returned properly packed in the original

HAMILTON packaging

HAMILTON reserves the right to refuse to accept the return of any

product that has been used with radioactive or microbiological

substances, or any other material that may be deemed hazardous

to employees of HAMILTON. Such a product has to be properly

decontaminated and marked.

HAMILTON endeavors to provide prompt and satisfactory service.

1-12

P/N 610520/02 05/01

Page 17

Microlab F.A.M.E. User Manual V2.0 —————————————————————————— ML F.A.M.E. Overview ——

1.4.2 Ordering Information

Instruments

Part No. Description

146 000 Microlab F.A.M.E. 16/20

146 001 Microlab F.A.M.E. 16/30

146 002 Microlab F.A.M.E. 24/20

146 003 Microlab F.A.M.E. 24/30

Disposables for Microlab F.A.M.E.

Part No. Description

147 624 Wash Fluid Container

147 930 Reagent Container Set (8 pcs.)

147 931 Disposable Syringe Set (8 pcs.)

147 933 Reagent Barcode Label Set (52 pcs.)

281 110 Manifold Plug

281 153 Sterile Filter

281 242 Microlab™ Detergent & Disinfectant Kit

281 243 Microlab™ Disinfectant Spray Kit

281 245 Microlab™ Disinfectant Starter Kit

P/N 610520/02 05/01

1-13

Page 18

Microlab F.A.M.E. User Manual V2.0 —————————————————————————— ML F.A.M.E. Overview ——

Accessories for Microlab F.A.M.E.

Part No. Description

281 107 Waste Container

147 660 Entry Stack

147 179 Reagent Container Carousel

148 309 Washer Manifold complete

235 524 Filter Strip

147 256 Filter Case

147 936 Manifold Cleaning Set

148 333 Spillage Tray

230 005 Check Plates for Cold Start Maintenance

146 373 Substitute Plug

146 385 Computer Cable

255 634 Reagent Labels Drawer

255 653 Label Warning PC

148 417 External Water Separator

148 335 Waste Cap

610 520 User Manual (English)

230 006 Upgrade Kit V2.0 for 16/20 or 16/30

230 007 Upgrade Kit V2.0 for 24/20 or 24/30

1-14

P/N 610520/02 05/01

Page 19

Microlab F.A.M.E. User Manual V2.0 —————————————————————————— ML F.A.M.E. Overview ——

Barcodes for Wash System

Part No. Description

255 734 External Pump Station - Washer 1

255 735 External Pump Station - Washer 2

255 736 Ortho Specific Wash Fluids - Washer 1

255 737 Ortho Specific Wash Fluids - Washer 2

255 738 Maintenance Fluids - Washer 1

255 739 Maintenance Fluids - Washer 2

255 740 Generic Wash Fluids

Verification Kit

Part No. Description

148 381 Verification Kit

148 383 Washer/Dispenser Verification Kit

148 405 Incubator Check Plate

Modules

Part No. Description

148 301 Expansion 16/20 to 16/30 configuration

148 302 Expansion 16/20 to 24/20 configuration

148 303 Expansion 16/20 to 24/30 configuration

P/N 610520/02 05/01

148 304 Expansion 16/30 to 24/30 configuration

148 320 Expansion 24/20 to 24/30 configuration

1-15

Page 20

Microlab F.A.M.E. User Manual V2.0 —————————————————————————— ML F.A.M.E. Overview ——

Photometer Filters for Microlab F.A.M.E.

Part No. Description

235 511 340 nm

235 504 405 nm

235 505 450 nm

235 506 492 nm

235 509 620 nm

Optional Filters for Microlab F.A.M.E.

Part No. Description

235 521 570 nm

235 525 610 nm

235 510 690 nm

- Other filters available on request.

Microlab F.A.M.E. Software

Part No. Description

910 034 User Software (English) including firmware

1-16

P/N 610520/02 05/01

Page 21

Microlab F.A.M.E. User Manual V2.0 —————————————————————————— ML F.A.M.E. Overview ——

1.4.3 Definition of Terms

The terms Microplate and MTP are the same and will otherwise be

referred to as plate.

The term ML F.A.M.E. refers to the Microlab F.A.M.E. instrument.

The term ML F.A.M.E. software refers to the Microlab F.A.M.E. user

software.

The term ML F.A.M.E. database refers to the Microlab F.A.M.E. data-

base.

The term ML F.A.M.E. workstation refers to the PC running the ML

F.A.M.E. software and the cable connecting this to the ML F.A.M.E..

The term ML F.A.M.E. operator refers to the person who operates

the ML F.A.M.E. and ML F.A.M.E. software.

The term “Test Kit” refers to the package containing all necessary

components for one or several assays of a kind.

1.4.4 Safety Precautions and Hazards

Read the following safety notices very carefully before using

the ML F.A.M.E..

1.4.4.1 General Precautions

1 When using the ML F.A.M.E., good laboratory working practices

should be observed. Suitable protective clothing, safety glasses

and protective gloves should be worn, particularly when dealing

with a malfunction of the instrument where the risk of contami-

nation from spilled liquids exists.

2 Only certified technicians are authorized to perform mechanical

maintenance on the ML F.A.M.E..

3 While extensive efforts have been made to ensure error-free test

processing and general system security, any manual manipula-

tion of ML F.A.M.E. data files or other information pertaining to

ML F.A.M.E. functions can result in erroneous test results or ML

F. A.M . E . f ai lur e .

4 During instrument operation, do not place hands in the way of

moving parts or microplates. Do not touch the incubator towers

with bare hands as these may cause burns (max. temp: 70°C).

5 Smoking and eating in the vicinity of the instrument and in

rooms in which samples or reagents are handled is forbidden

(see also warning notices and precautionary measures in the

test kit pakkage inserts).

6 During operation, the instrument should be shielded from direct

sunlight and intense artificial light.

7 Nothing should be attached to a microplate when it is loaded

into the instrument (except one barcode).

8 Each plate barcode must be unique.

P/N 610520/02 05/01

1-17

Page 22

Microlab F.A.M.E. User Manual V2.0 —————————————————————————— ML F.A.M.E. Overview ——

9 Ensure that barcode labels do not protrude above or below the

level of the surface of the microplates.

10 Microplates must be placed in the entry stack or on the entry

platform such that well A1 is in the front left position.

11 Under normal operating conditions microplates should only be

loaded into the instrument via the entry platform or entry stack

and removed via the exit stack. Only when specifically

instructed by the ML F.A.M.E. software may plates be directly

placed in or removed from the instrument.

12 Do not swap plates on the entry stack after loading (i.e. after

pressing the load button).

13 Do not open the transparent cover unless instructed by the user

software as processing may be interrupted leading to aborted

plates. An open transparent cover causes the main shuttle to

stop (i.e. the part that moves plates from module to module) but

all functions within modules continue (moving parts).

14 The pause button should generally not be pressed unless

instructed by the ML F.A.M.E. software or in case of an emer-

gency stop situation, as plate processing may be interrupted

leading to aborted plates. Carefully follow the on screen instruc-

tions.

15 Pay close attention to all instructions and parameters given in

test kit package inserts when programming test methods for the

ML F.A.M.E. and when preparing said test kits for use with a

test.

16 A newly programmed test method should first be run on the

system using deionized water containing 0.9% NaCl in place of

all reagents and wash solutions, to verify correct test definition

and operation prior to the verification/validation of the method.

This run should be overseen by the method programmer.

17 Only original ML F.A.M.E. specific parts and tools may be used

with the ML F.A.M.E., i.e. syringes, reagent containers, wash

containers and waste containers.

18 Never lift a fully installed (assembled) instrument from one place

to another. It must first be dismantled (only by an authorized

technician) and then reinstalled in the new work place.

19 The instrument weighs in excess of 220 kg. Necessary precau-

tions should be taken when carrying individual modules and

when transporting the instrument.

20 After repair/service/module exchange, the instrument should be

verified using the verification kit.

21 For reasons of data security and integrity it is recommend to

use the system with an uninterruptable power supply (UPS)

since a loss of power may cause data to be lost or corrupted.

1.4.4.2 Electrical Safety Precautions

ATTENTION

Before connecting and switching

on the instrument, check the

setting of the voltage selector

switch and if necessary, switch

1-18

Severe damage will occur to an instrument set to 115V which is

connected to a 230V mains electricity supply!

Before removing a mechanical or electrical component, the instrument must first be switched off and disconnected from the mains

electricity supply and PC.

P/N 610520/02 05/01

Page 23

Microlab F.A.M.E. User Manual V2.0 —————————————————————————— ML F.A.M.E. Overview ——

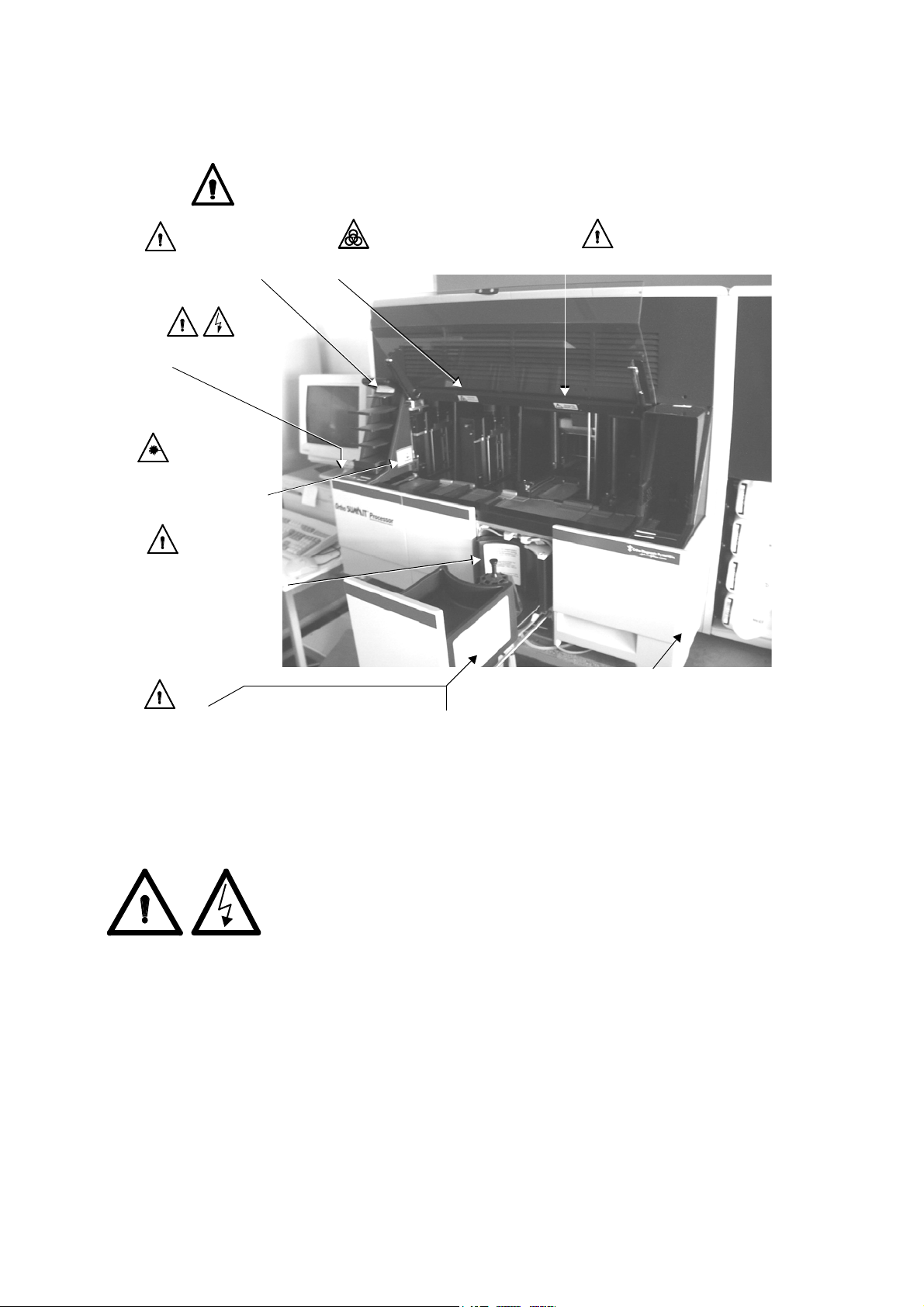

1.4.4.3 Hazards

Location of warning and attention labels and general location information:

Warning

Do not swap plates after loading.

Power Supply

(on left side) and

Instrument Serial Number

(on back side).

Warning

Laser Beam

Do not stare into beam

Class 2 Laser.

Warning

Do not overfill reagent container.

Close the reagent drawer gently

to prevent spillage.

Warning

Turn carousel untill it drops into locked

position. Ensure all plungers are pushed

down and caps are properly closed.

Warning

Biohazard (inside transparent cover).

Warning

Moving Parts (inside transparent cover).

Before removing the module,

decontaminate the instrument, unplug all

connectors and seal the fluid system as

described in the manual.

Pause

Instrument pause button.

P/N 610520/02 05/01

Figure 1.2 Warning Labels and general locations

Explanation of warning and attention labels

Power Connection:

Connect only to earth grounded outlet

115V~/...A 60Hz

230V~/...A 50Hz

1-19

Page 24

Microlab F.A.M.E. User Manual V2.0 —————————————————————————— ML F.A.M.E. Overview ——

Warning Symbols

General

Warning

Bio-Hazard

Danger

High Voltage

Danger

Laser

If the instrument becomes contaminated with liquids, it should be

cleaned in accordance with the maintenance procedures, see Reference Guide Section 15.1.6 on page 173.

Certain parts of the instrument are biohazardous. Observe and

carry out the maintenance procedures, see Reference Guide Section 15.1.6 on page 173 paying particular regard to cleaning and

decontamination.

Do not use disinfecting materials which contain hypochlorite (Javelle water, Chlorox) or bleaching fluids.

Failure to observe and carry out the maintenance procedures may

impair the reliability and correct functioning of the instrument.

Wear gloves when exchanging the sterile filter and handling the

venting tube as any liquid which is released is biohazardous.

Any surfaces on which liquid is spilled must be decontaminated.

1.4.4.4 Software Precautions

The ML F.A.M.E. Workstation should not be used for running any

other applications (programs) except those described in 1.3.2 en la

página 1-9.

The ML F.A.M.E. Workstation date and time must not be changed

while the instrument is running tests or while the user software is

running or being started up, otherwise trouble-free operation cannot be guaranteed.

The operating system (OS/2) and database (DB2/2) functions are

optimized to suit the instrument configuration. Changes to the

setup can impair the operational reliability and data security of the

system.

Only the ML F.A.M.E. software may be used to control the ML

F. A . M . E . .

1-20

When running the system 24 hours a day, shut down and restart

the system once a day in order to re-calibrate the washer, photometer, etc. and also carry out cold start maintenance.

P/N 610520/02 05/01

Page 25

Microlab F.A.M.E. User Manual V2.0 —————————————————————————— ML F.A.M.E. Overview ——

The ML F.A.M.E. operator is responsible for the security of communication between the ML F.A.M.E. and any host computer. The ML

F.A.M.E. system creates result files but does not provide the specific communication protocols to ensure reliable and safe transmission of result files.

P/N 610520/02 05/01

1-21

Page 26

Microlab F.A.M.E. User Manual V2.0 —————————————————————————— ML F.A.M.E. Overview ——

1-22

P/N 610520/02 05/01

Page 27

Microlab F.A.M.E. User Manual V2.0 ——————————————————————————————— Cook Book ——

Chapter

2 - 8 Cook Book

Cook Book Sections

2 - Cook Book Introduction............................................................25

3 - ML F.A.M.E. Methods ................................................................27

4 - Daily Work Routine....................................................................41

5 - Test Results & ML F.A.M.E. Traces............................................55

6 - Instrument Status ......................................................................63

7 - ML F.A.M.E. Verification.............................................................65

8 - ML F.A.M.E. Maintenance .........................................................69

P/N 610520/02 05/01

2-23

Page 28

Microlab F.A.M.E. User Manual V2.0 ——————————————————————————————— Cook Book ——

2-24

P/N 610520/02 05/01

Page 29

Microlab F.A.M.E. User Manual V2.0 ———————————————————— Cook Book - Cook Book Introduction ——

Chapter

2 Cook Book Introduction

The purpose of the cook book is to give a step-by-step guide to the

day-to-day operation of the ML F.A.M.E. and the ML F.A.M.E. software version 2.0.

Each section consists of an introduction explaining the basic principles being covered, then a step by step guide to each task in a

tabulated two column format.

r Column 1 - The Task.

r Column 2 - The Procedure.

Any additional information for the operator’s attention is displayed

in the left margin as either a “Note” or an “Attention”.

A certain amount of basic computer understanding will be

assumed throughout these examples and most will assume that a

valid ML F.A.M.E. operator with the necessary access rights is

logged in to the ML F.A.M.E. workstation.

In trying to avoid long-winded explanations and examples, common information, i.e. explanations of common fields, push-buttons,

etc., of a repetitive nature has been omitted (unless applicable) and

is explained in the Reference Guide section of this document set.

Special information, directly related to the task being explained

(but not a step in the procedure) like warnings and notes being

brought to the attention of the user are displayed in the left margin

of this document to avoid breaking the flow of the examples.

P/N 610520/02 05/01

2-25

Page 30

Microlab F.A.M.E. User Manual V2.0 ———————————————————— Cook Book - Cook Book Introduction ——

2-26

P/N 610520/02 05/01

Page 31

Microlab F.A.M.E. User Manual V2.0 ————————————————————— Cook Book - ML F.A.M.E. Methods ——

Chapter

3 ML F.A.M.E. Methods

Table of Contents

3.1 - Overview.................................................................................28

3.1.1 - Method Definition .............................................................28

3.1.2 - Documenting a Test Run ..................................................37

3.1.3 - Method Management .......................................................38

P/N 610520/02 05/01

3-27

Page 32

Microlab F.A.M.E. User Manual V2.0 ————————————————————— Cook Book - ML F.A.M.E. Methods ——

3.1 Overview

A method is a structured group of definitions, stored electronically,

which enables an Immunoassay test to be performed on the ML

F.A.M.E. and includes plate layout information, processing step

definitions and documentation criteria for the test.

For further information on methods see Reference Guide Section -

10.1 on page - 84.

3.1.1 Method Definition

The following section defines the creation of a method as

described in a Test Kit Manufacturer’s Package Insert. Even though

it is not generally possible to create or edit in any way, this is

explained to clarify the structure of the methods.

Example Information Required To Program A Method

NOTE

Only wash solutions that are

specified as suitable by the test

kits’ manufacturer should be

used.

NOTE

Plate dimensions are not nor-

mally included in the package

insert and must be measured by

hand with the vernier caliper.

This is to prevent possible spillage, contamination, or errors

during wash and dispense

steps. The dimensions shown

are given as an example only.

Method Name: Example ELISA.

Manufacturer: Example Company.

Parameter: Hepatitis B Antigen.

Tes t K i t: The Test Kit contains all necessary reagents

except wash and stop solution, which is

available separately. Note that the substrate

solution should be used within 60 mins of

preparation.

Ambient

Temperature

Conditions: 15 - 30°C

Plate

Dimensions : Plate Length: 127.5 mm

Plate Height: 14.5 mm

Well Diameter: 6.6 mm

Well Depth: 11.4 mm

Well Shape: Flat

Strip Direction: A - H

3-28

Assay

Procedure:

Sample Filling Direction: A - H

1 Dispense 50 ml of conjugate solution into

each well of the plate except the blank.

P/N 610520/02 05/01

Page 33

Microlab F.A.M.E. User Manual V2.0 ————————————————————— Cook Book - ML F.A.M.E. Methods ——

Example Information Required To Program A Method

2 Pipette controls and samples as follows:

- A1 Substrate Blank (BL)

- B1, C1 & D1 (100 ml) - Negative Control

(NC)

- E1 & F1 (100 ml) - Positive Control

(PC)

- G1 & H1 keep empty (##)

- Pipette all remaining wells with 100 ml of

the SAmples to be tested

3 SRAM (measuring filter - 450 nm) see

Reference Guide Section - 10.2.3.3 on page

- 95 for further information on this step.

4 Place the plate in the incubator as soon as

possible, max. 30 min after completion of

the sample distribution step.

5 Incubate at 37 +/- 1°C for 30 +/- 5 min.

6 Wash plate 5 times: completely aspirate the

liquid from all wells and fill the wells with

370 ml of wash solution. The washing

solution should be allowed to remain for 20

seconds in the wells before being removed.

(CONTINUED)

7 Dispense 200 ml of the substrate solution

into each well.

8 SRAM (measuring filter - 450 nm).

9 Incubate the plate at room temperature for

30 +/- 2 min.

10 Reidentify the plate.

11 Stop the reaction by adding 50 ml 2 mol/l

sulphuric acid to each well.

12 Shake the plate for 10 seconds.

13 Read the optical density at 492 nm, with 620

nm as the reference wavelength.

P/N 610520/02 05/01

3-29

Page 34

Microlab F.A.M.E. User Manual V2.0 ————————————————————— Cook Book - ML F.A.M.E. Methods ——

The following table defines, step by step, how to create this

method as per the above method programming information.

Table 3.1.1.1 - Method Definition Process

To... Do This...

Create a method .1) Select the New menu choice from the

Methods pull-down menu. The

Method - New dialog box is then

displayed. Enter the name “Example

ELISA”.

NOTE

The Barcode Mask (see Refer-

ence Guide Section - 10.2.1 on

page - 86) must be unique and

must correspond exactly to the

barcodes used on the plates.

For further information on Plate

hold time and Pipetting delay

see Reference Guide Section -

10.2.1 on page - 86.

ATTENTION

The plate dimensions specified in

the plate configuration must

correspond to dimensions of

the plate, otherwise

contamination, spillage or errors

may occur during wash and

dispense steps.

Method

identification

information

.2) The Method information dialog box

(see Reference Guide Section - 10.2.1

on page - 86) is displayed, enter the

Manufacturer:

Example Company

Parameter: Hepatitis B Antigen

Barcode Mask:

HB#######?????****

Plate Hold Time: 30 mins

Pipetting Delay: 5 mins

Read Access: 2

Write Access: 6

.3) Confirm the Method Information

dialog box definition by selecting the

OK push button.

Layout editor .4) The Layout editor allows the ML

F.A.M.E. operator to define what goes

where in the plate.

Plate

configuration

.5) From the Configuration menu select

the Set Plate Dimensions menu

choice.

.6) Enter the plate’s dimensions in the

appropriate entry fields.

Arranging sample

well types

.7) First select the filling direction from the

Configuration menu, either vertical

(A-H) or horizontal (1-12). A marker

on the menu shows which direction is

selected. For this example select A -

H.

3-30

.8) Next select the required Replica

Number from the Samples menu to

define the number of replicas of each

sample (a value of 1 gives 1 well per

sample. A value of 2 gives 2 wells per

sample, etc.). In this case a value of 1

is required.

P/N 610520/02 05/01

Page 35

Microlab F.A.M.E. User Manual V2.0 ————————————————————— Cook Book - ML F.A.M.E. Methods ——

Table 3.1.1.1 - Method Definition Process (CONTINUED)

To... Do This...

Defining control well

types

Deleting well types .11) Delete any well types that will not be

Assigning control

well types

.9) For this example the required well

types are Positive Control (PC),

Negative Control (NC), Samples (SA)

and Blank (BL). Except for Blank well

types, all the above are ML F.A.M.E.

software defaults.

.10) From the Edit menu select the Edit

Well Types menu choice.

Select the Insert push button. A new

line is created in the table.

Enter BL in the abbreviation entry

field, Blank in the Used as entry field

and an optional comment.

Confirm the definition with the OK

push button.

required for the test.

From the Edit menu select the Edit

Well Types menu choice.

Select the well types to be deleted

and select the Delete push button.

.12) Choose a well type from the Select

Well Type drop-down list.

NOTE

If there are any unused well types

in the layout, they must be

deleted.

Remember to rearrange the layout again if well types have

been deleted.

.13) The cursor icon will change from an

arrow to a Pencil (

edit mode, then select a well to

allocate its selected well type as per

the desired layout.

Completing the

layout

Checking the layout .15) Finally select the Check Layout menu

Test processing

editor

Prepare plate .17) This is carried out external to the ML

.14) Select the Arrange Samples menu

choice from the Samples menu to

automatically complete the plate

layout, assigning all remaining empty

wells as sample wells. This is always

the last action in laying out a plate.

choice from the File menu to

automatically check the plate layout

for errors.

.16) Activate the Test Processing Editor by

double clicking on its icon.

F.A.M.E. and the ML F.A.M.E. operator

only needs to define the approximate

time required to fill the plate with

samples (in this example 10 minutes).

!) indicating well

P/N 610520/02 05/01

3-31

Page 36

Microlab F.A.M.E. User Manual V2.0 ————————————————————— Cook Book - ML F.A.M.E. Methods ——

Table 3.1.1.1 - Method Definition Process (CONTINUED)

To... Do This...

NOTE

Sample and Reagent Addition

Monitoring is used to check dis-

pensing and can be used at any

time in a test run (for fur ther

information on the SRAM step

and additional functions see

Reference Guide Section -

10.2.3.3 on page - 95).

NOTE

For incubation times of 30 min-

utes and less, fast heating up is

recommended.

SRAM .18) From the Steps menu select the

Sample and Reagent Addition

Monitoring menu choice.

.19) In the displayed dialog box select a

Measuring Filter of 450 nm, an

optional Reference Measurement

Filter and range check criteria.

Incubate .20) From the Steps menu select the

Incubate menu choice.

.21) In the displayed dialog box select the

Temperature controlled incubation

radio button.

.22) Enter a temperature of 37°C (default

setting).

.23) An operating temperature tolerance

must be set defining the maximum

variation in temperature (between 1°C

and 5°C).

.24) Select the Fast option from the

Heating up drop-down list.

.25) Enter the required incubation and

tolerance times (in this example 30

minutes and 5 minutes).

NOTE

Global Fluids are designated by a

preceding asterisk (*) in their

name.

Wash .26) From the Steps menu select the

Wash menu choice.

.27) Select the Plate wash option.

.28) Before the wash step can be used a

wash solution must be defined.

Define global fluid .29) From the Test Processing Editor -

Wash dialog box select the Edit

Global push button, then in the

displayed dialog box select the New

push button. The Edit Global Fluid

dialog box is displayed.

.30) Enter the Wash Fluid name - OCD-01

- and a preparation time of 10 mins.

.31) Confirm this with the OK push button

and the new fluid will appear in the

display of the Edit Global Fluids dialog

box.

3-32

P/N 610520/02 05/01

Page 37

Microlab F.A.M.E. User Manual V2.0 ————————————————————— Cook Book - ML F.A.M.E. Methods ——

Table 3.1.1.1 - Method Definition Process (CONTINUED)

To... Do This...

.32) Return to the Test Processing Editor -

Wash dialog box by selecting the

Close push button.

NOTE

In this example, no wash options

are selected. To select a wash

option, select the Wash

Options... push button, additional wash options include

Continuous wash, Bottom

wash, Bottom sweep and

Pump power (see Reference

Guide Section - 10.2.3.3 on

page - 95).

Dispense .35) From the Steps menu select the

.33) Select the new wash solution from the

drop down list.

Enter the required wash/dispense

volume or select it from the dropdown list (In this example 370 ml) then

the Number of Cycles (5 in this

example), Soak Time (20 sec.) and

Aspiration Height (0.3 mm).

.34) To enter this step in the test process

definition select the OK push button.

Dispense menu choice.

NOTE

For method specific reagents, it is

recommended to include the

method name as part of the

reagent name to make barcode

assignment easier during a run.

Define method

specific fluid

.36) Before the Dispense step can be used

a reagent must be defined.

.37) The reagent is specific to this method

(i.e. not global), select the Edit

Method specific push button. The

Edit Method Specific Fluids dialog box

is displayed.

.38) Select the New push button.

The Edit Method Specific Fluid dialog

box will appear. Enter the name

“SUBSTRATE” in the Name entry field

then the time it will take to prepare the

substrate solution.

.39) In this case the solution is unstable so

select the Reagent Is Unstable check

box and enter the stability time (in this

case 60 minutes).

.40) Confirm this with the OK push button

and the new fluid will appear in the

display of the Edit Method Specific

Fluid dialog box.

.41) Select the Close push button and the

ML F.A.M.E. software returns to the

Dispense dialog box.

P/N 610520/02 05/01

3-33

Page 38

Microlab F.A.M.E. User Manual V2.0 ————————————————————— Cook Book - ML F.A.M.E. Methods ——

Table 3.1.1.1 - Method Definition Process (CONTINUED)

To... Do This...

.42) Select “SUBSTRATE” from the Reagent

name drop-down list and a dispense

volume of 200 ml from the Volume

drop-down list.

Select a Slow aspirate speed from the

drop-down list.

Select a Slow dispense speed from

the drop-down list.

.43) To enter this step in the test process

definition select the OK push button.

SRAM .44) See - Step 3, Item Number 18)

Incubate .45) From the Steps menu select the

Incubate menu choice.

.46) In the displayed dialog box select the

Ambient incubation radio button.

.47) Enter the lower and upper

temperature limits for ambient

incubation given in the package insert

(in this case 15 and 30°C).

.48) Enter the required Incubation and

tolerance times (in this example 30

minutes and 2 minutes) and select the

OK push button.

Re-identify .49) Select the Re-identify menu choice

from the Steps menu to check that the

plate barcode matches the one read

at the start of the run.

Dispense .50) From the Steps menu select the

Dispense menu choice.

.51) Before the dispense step can be used

a reagent must be defined.

This is a global reagent since it is not

specific to any one method.

.52) Select Edit Global... The Edit Global

Fluid dialog box is displayed.

3-34

.53) Select the New push button.

The Edit Global Fluid dialog box will

appear.

P/N 610520/02 05/01

Page 39

Microlab F.A.M.E. User Manual V2.0 ————————————————————— Cook Book - ML F.A.M.E. Methods ——

Table 3.1.1.1 - Method Definition Process (CONTINUED)

To... Do This...

.54) Enter the name “2 MOL/L H2SO4” in the

Name entry field then the time it will

take to prepare (10 mins), select the

OK push button to confirm selection.

Then select the Close push button to

return to the Dispense dialog box.

.55) Select “

2 MOL/L H2SO4” from the

Reagent name drop-down list and a

dispense volume of 50 ml from the

Volume drop-down list.

.56) Select the Well push button to define

into which well types to dispense. The

Select Wells dialog box will appear.

.57) Choose the well types to dispense by

selecting them from the Well Types

drop down list (in this example all well

types should be selected). The

selected wells will appear highlighted

in the plate layout.

.58) Select OK. The message “All types ”

should appear in the Wells field of the

Dispense dialog box.

.59) Select a slow aspiration speed from

the drop-down list.

Select a slow dispense speed from

the drop-down list.

.60) To enter this step in the test

processing definition select the OK

push button.

NOTE

When specifying a Photometer

Filter for an assay it is important

to check that this Photometer

Filter is installed.

P/N 610520/02 05/01

Mix .61) From the Steps menu select the Mix

menu choice.

.62) Select the medium mix intensity.

.63) Select a mix time of 10 seconds, then

click on the OK push button.

Read .64) Select the Read menu choice from

the Steps menu.

.65) Select the 492 nm measuring filter

from the drop-down list.

3-35

Page 40

Microlab F.A.M.E. User Manual V2.0 ————————————————————— Cook Book - ML F.A.M.E. Methods ——

Table 3.1.1.1 - Method Definition Process (CONTINUED)

To... Do This...

.66) The method also requires a reference

measurement. Select the Reference

measurement check box and select

the 620 nm reference filter. Then

select the OK push button.

Check method .67) Once the processing definition is

completed the method must be

checked for errors in the test

processing definition.

.68) Select Check Layout And

Processing Definition... from the File

menu to check the layout and test

NOTE

A method that returns warnings

when checked may still be run

while a method returning errors

will prevent the method being

run.

processing definition.

.69) If errors were found in the layout or

processing definition the ML F.A.M.E.

operator will be prompted as to the

type of error and its location.

.70) Once these errors have been

corrected re-check the method until

no errors are returned.

Defining the first

processing step

.71) From the Edit menu select the Select

First Processing Step menu choice.

A dialog box will be displayed

allowing the ML F.A.M.E. operator to

select the step number that will be

addressed first in the run process

which defines the end of the plate

hold time.

Save method .72) From the File menu select the Save

menu choice and the method is saved

in the data base under the name

entered in the beginning of the

definition in this case Example ELISA.

This completes the test processing (method) definition.

3-36

P/N 610520/02 05/01

Page 41

Microlab F.A.M.E. User Manual V2.0 ————————————————————— Cook Book - ML F.A.M.E. Methods ——

3.1.2 Documenting a Test Run

Information generated by a test run can be handled in a number of

ways. These are called documentation jobs. Documentation jobs

are method specific and can be defined in various ways including

or excluding different information. These are called documentation

formats and are global, i.e. they can be used by multiple methods

by being included in the method specific documentation job.

Table 3.1.2.1 - Documentation Jobs

To... Do This...

Working with

documentation

formats

Create a new or

change an existing

documentation

format

Assigning a

documentation

format to a doc.

job and then a

method

.1) From the Methods menu select the Edit

Globals menu choice then the Formats

sub-menu choice.

.2) The Documentation Formats dialog

box is displayed allowing the ML

F.A.M.E. operator to create new

documentation formats and change or

delete existing ones.

.3) The Documentation Formats dialog

box allows the ML F.A.M.E. operator to

enter a name and comment for the

documentation format then specify the

various information to be contained in

the documentation job, including trace

information, OD values and plate

information.

.4) From the Methods menu select the Edit

menu choice then the Documentation

sub-menu choice.

P/N 610520/02 05/01

.5) A dialog box is displayed listing all

documentation jobs available for use.

This includes the documentation format

used and the destination device of that

information.

New .6) Select the New push button and in the

dialog box, a list of documentation

formats and possible device

destinations is displayed.

.7) Select the desired options and the Save

push button and the new

documentation job is displayed in the

Documentation Job dialog box.

3-37

Page 42

Microlab F.A.M.E. User Manual V2.0 ————————————————————— Cook Book - ML F.A.M.E. Methods ——

Table 3.1.2.1 - Documentation Jobs (CONTINUED)

To... Do This...

Change .8) The Change push button allows the ML

F.A.M.E. operator to edit an existing

Documentation Job’s properties (see

New above).

Delete .9) To delete an existing Documentation

Job select it then select the Delete push

button.

Start

.10) With this option selected the test’s

documentation by

user

information must be released manually

by the ML F.A.M.E. operator as opposed

to automatically at the end of the run

(see Reference Guide Section - 12.2.1

on page - 133).

3.1.3 Method Management

NOTE

When a copy is made of a

method the new method will not

have a barcode mask as no two

methods can use the same barcode mask. It is then necessary

to open the method, define the

new barcode mask then check

the full method definition. For

information on barcode mask

see Reference Guide Section -

10.2.1 on page - 86.

NOTE

An open method’s name will not

appear in the selection dialog

box when Copy, Rename or

Delete are selected. A method

cannot be deleted if test results

for that method exist on the system.

In general, it is only possible for ML F.A.M.E. operators to use the

“Save As, Copy, Rename, Delete, Backup & Restore Methods”

functions. The following table explains these procedures.

As most of the dialog boxes for these procedures are identical the

process will be explained once in entirety then again for each further command using reference to the common elements.

Table 3.1.3.1 - Save As, Copy, Rename, Delete, Backup,

Restore and Print a Method.

To... Do This...

Save as... .1) From the Methods menu in the main ML

F.A.M . E . w in dow s e le ct the Manage

sub-menu then the Save as... menu

choice.

.2) A dialog box is displayed allowing the

ML F.A.M.E. operator to enter a new

name for the method.

Copy... .3) If a method is open for editing the ML

F.A.M.E. operator is prompted for the

new method name. However, when no

method is open, a dialog box is

displayed listing all methods available to

the ML F.A.M.E. operator on the ML

F.A.M.E. database allowing the selection

of the method to be copied and an entry

field for its new name.

3-38

P/N 610520/02 05/01

Page 43

Microlab F.A.M.E. User Manual V2.0 ————————————————————— Cook Book - ML F.A.M.E. Methods ——

Table 3.1.3.1 - Save As, Copy, Rename, Delete, Backup,

Restore and Print a Method. (CONTINUED)

To... Do This...

Rename... .4) Select the method from the list in the

displayed dialog box and enter the new

name.

Delete... .5) To delete a method select the method

from the displayed list and use the

delete push button. The method will be

removed from the ML F.A.M.E.

database.

Backup... .6) To backup an open method the ML

F.A.M.E. operator must only enter a path

to the desired directory, however if no

method is open the ML F.A.M.E.

operator is asked to first select a

method.

NOTE

The default back-up path for a

method is defined in the Software

Presettings dialog box (see Reference Guide Section - 13.2.5 on

page - 142)

Restore... .7) To restore a backed-up method the ML

F.A.M.E. operator will be prompted for

the backup path. A list of all methods

that have been backed-up will then be

displayed for selection.

Print... .8) With a method open for editing the print

command prints that method, however

with no method open the ML F.A.M.E.

operator is prompted to select the

method to be printed from a dialog box

listing all methods available to that ML

F.A.M . E . o pe rat or.

P/N 610520/02 05/01

3-39

Page 44

Microlab F.A.M.E. User Manual V2.0 ————————————————————— Cook Book - ML F.A.M.E. Methods ——

3-40

P/N 610520/02 05/01

Page 45

Microlab F.A.M.E. User Manual V2.0 —————————————————————— Cook Book - Daily Work Routine ——

Chapter

4 Daily Work Routine

4.1 Concept of the Daily Work Routine

Below is a flow chart giving the logical flow of the daily work routine

for the ML F.A.M.E.. Each of these steps are explained in greater

detail in the following pages.

Concept of the

Daily Work Routine

- Start -

OSP System

Start-Up

Perform

Maintenance

Continued

Prepare, Verify &

Start Work List

Processing

Load all Fluids

Define or Select

Stack Type(s)

Define or Select

Work List

Schedule

Work List

Continued

OSP Processes

all Plates

Perform

Maintenance

OSP System

Shut-Down

Concept of the

Daily Work Routine

- Finish -

P/N 610520/02 05/01

4-41

Page 46

Microlab F.A.M.E. User Manual V2.0 —————————————————————— Cook Book - Daily Work Routine ——

4.1.1 System Start-Up and Shut-Down

This section details the start-up procedure and outlines the tasks

necessary before a test run can be started.

Table 4.2 - Starting-up and Shutting-down the ML F.A.M.E.

To... Do This...

ATTENTION

Do not switch off instrument,

open drawers or transparent

cover, touch load button or any

moving parts during

initialization.

ATTENTION

No other programs or

applications should be started

while the ML F.A.M.E.

software is running.

Start up the ML

F. A . M . E .

.1) Turn on ML F.A.M.E. workstation power

supply.

.2) Turn on ML F.A.M.E. instrument power

supply.

.3) Enter ML F.A.M.E. operator name.

.4) Enter password.

.5) The instrument is then initialized to

check whether the instrument and ML

F.A.M.E. software are in an operable

condition.

.6) The ML F.A.M.E. software will then run a

maintenance status check to establish

the maintenance routines required.

.7) The ML F.A.M.E. operator will be

prompted to run cold start maintenance

if:

a) The instrument has been initialized

for the first time that day.

b) more than 24 hours have passed

since the last cold start

maintenance was run.

ATTENTION

It is very important that the ML

F. A . M . E . operator waits until

prompted by the ML F.A.M.E.

workstation before turning off

the power supply. This is due to

the closing of the ML F.A.M.E.

database and misuse can result

in ML F.A.M.E. database

corruption.

4-42

Shut down the ML

F. A . M . E .

.8) A check is made to ascertain when the

ML F.A.M.E. had its last verification

check. See chapter 7 for further

information on verification.

.9) Exit all windows and editors.

.10) From the File Menu in the main ML

F.A.M . E . w in dow s e le ct the Exit menu

choice.

.11) The ML F.A.M.E. software will then run a

maintenance status check to establish

the maintenance routines required.

P/N 610520/02 05/01

Page 47

Microlab F.A.M.E. User Manual V2.0 —————————————————————— Cook Book - Daily Work Routine ——

4.2.1 Stack Types

Below is a step-by-step guide to working with stack types. For a

general description of and further technical information on stack

types, see Reference Guide Section - 11.1.1 on page - 106.

Table 4.1.2.1 - Define a New Stack Type

To... Do This...

NOTE

The List of Stack types... push

button displays a list of all existing stack types.

The order in which methods are

placed in a stack type does not

define the order in which plates

are processed in a run. The

scheduler decides the optimum

processing order.

Define a new stack

Name the stack

Add methods to

the stack type

Remove methods

from the stack type

Save and exit .5) When all required methods are in the

.1) From the Main ML F.A.M.E. window

type

type

select the Work menu then the Stack

Typ e menu choice then the New sub-

menu choice.

.2) The New Stack Type dialog box is then

displayed, enter the desired (unique)

name for the new stack type (i.e.

Example Stack Type).

.3) From the Method list box select the

method to be added to the stack type

(i.e. Example ELISA), then click the Add

push button. The selected method will

be placed in the Stack Type list box.

Continue this process until the desired

stack type is achieved.

.4) To remove a method from the stack

type, select the method name in the

Stack Type list box and click on the

Remove push button.

stack type contents list box click the

Save/Next push button and then either

exit the dialog box using the Cancel

push button or repeat the above

process to define another stack type.

P/N 610520/02 05/01

4-43

Page 48

Microlab F.A.M.E. User Manual V2.0 —————————————————————— Cook Book - Daily Work Routine ——

Table 4.1.2.2 - Edit a Stack Type

To... Do This...

Edit a stack type .1) From the Main ML F.A.M.E. window

select the Work menu then the Stack

Typ e menu choice then the Edit submenu choice.

.2) The Stack Type Select dialog box is

then displayed, select the desired stack

type from the list box.

.3) Follow the procedures in the above

table to edit and save the stack type.

Table 4.1.2.3 - Print or Delete a Stack Type

To... Do This...

Print or delete a

stack type

4.1.3 Kit Lot Editor

The Kit Lot Editor is only available if the Kit Lot Documentation

option was selected during the installation procedure. When using

the Kit Lot Editor the defined kit lot will be documented and any kit

lot information provided in the plate barcode or in the barcode file

will be ignored.

If this installation option is not selected then the ML F.A.M.E. software will perform an active kit lot check and compare the loaded kit

lot elements with the defined elements.

.1) From the Main ML F.A.M.E. window

select the Work menu then the Stack

Typ e menu choice then the Delete or

Print sub-menu choice.

.2) The Stack Type Delete or Print dialog

box is then displayed, select the desired

stack type from the list box.

.3) Click the Delete or Print push button

and the selected stack type is erased

from the ML F.A.M.E. database or

printed to the OS/2 default printer.

4-44

Table 4.1.3.1 - Working with the Kit Lot Editor

To... Do This...

Define a new kit lot .1) From the Main ML F.A.M.E. window

select the Work menu then the Kit Lot

Editor menu choice.

P/N 610520/02 05/01

Page 49

Microlab F.A.M.E. User Manual V2.0 —————————————————————— Cook Book - Daily Work Routine ——

Table 4.1.3.1 - Working with the Kit Lot Editor

To... Do This...

.2) The Kit Lot Editor is displayed and lists

all currently stored kit lot data on the

system in the path defined in the

software presettings.

Define a kit lot for a

method

Define the kit lot of

a global fluid

4.1.4 Work Lists

.3) From the Edit menu select the Insert

Kit Lot menu choice.

.4) Select a method from the pull-down list

and then select the OK push button.

.5) A dialog box is displayed where the new

kit lot is assigned to an existing method,

its expiration date and components

(with the component lot numbers) can

be defined.

.6) From the Edit menu select the Insert

Global Fluid menu choice.

.7) Here the ML F.A.M.E. operator may

select a global fluid name, its expiration

date, whether it is a single or dual

component and the either a single

component lot number or two lot

numbers if it is a dual component.

Below is a step-by-step guide to working with work lists (for further

information on work lists see Reference Guide Section - 11.1.1 on

page - 106).

For the purposes of these examples it is assumed that all method

data is correct and kit lots exist and are date validated.

Table 4.1.4.1 - Define a New Work List

To... Do This...

Define a new work

Include a stack in

a work list

.1) From the Main ML F.A.M.E. window

list

select the Work menu then the Work

List Manager menu choice.

.2) The Work List Manager window is then

displayed.

.3) From the Edit menu select the Insert

Stack Type menu choice.

.4) A dialog box is displayed listing all

available stack types.

P/N 610520/02 05/01

4-45

Page 50

Microlab F.A.M.E. User Manual V2.0 —————————————————————— Cook Book - Daily Work Routine ——

Table 4.1.4.1 - Define a New Work List (CONTINUED)

To... Do This...

NOTE

Each individual Method’s state is

checked to ensure it is error free