Page 1

R

USERS

’

MANUAL

®

MICROLAB 500B/C

Page 2

The MICROLAB ® 500 Series:

MICROLAB 510B, 530B, and 540B

and MICROLAB 511C, 531C, and 541C

User’s Manual

THE M

EASURE OF EXCELLENCE

Part Number 69176 (Rev. D)

R

SM

.

Page 3

B Hamilton Company Instrument Warranty

Hamilton Company warrants this equipment (except valves*) to be free of defects in material

and workmanship for 12 months from the date of receipt. This warranty is extended to the buyer

of record on the original purchase order to Hamilton Company. Hamilton Company or an

authorized Hamilton representative agrees to repair or replace, at its option and free of charge

to the buyer at a normal place of business or at a Hamilton repair facility, any part or parts that

under proper and normal use prove to be defective during the warranty period.** Abuse,

unauthorized replacement of parts, modifications, or adjustments made by other than Company

or its assigned representatives voids this warranty.

This warranty gives you specific rights. No other warranties, expressed or implied, including

implications of warranties of merchantability and fitness for a particular product, are made.

Hamilton Company's liability on the sale of all products shall be limited to repair, replacement,

or refund of price of any defective product.**

Hamilton Company endeavors to provide prompt and satisfactory service.

*All Hamilton Company valves are warranted to be free of defects in material and

workmanship at the time of delivery.

**Hamilton Company reserves the right to refuse to accept the return of any instrument or valve

that has been used with radioactive or microbiological substances, or any other material that

may be deemed hazardous to employees of Hamilton Company.

© July 1999 by Hamilton Company

GASTIGHT is a registered trademark of Hamilton Company.

MICROLAB is a registered trademark licensed to Hamilton Company.

SANI-CLOTH is a registered trademark of Professional Disposables, Inc.

Page 4

Instruction to the User

This equipment has been tested and found to comply with the limits for a class B

digital device, pursuant to part 15 of the FCC Rules. These limits are designed to

provide reasonable protection against harmful interference in an installation. This

equipment generates, uses, and can radiate radio frequency energy, and if not

installed and used in accordance with the instructions, may cause harmful

interference to radio communications. However, there is no guarantee that

interference will not occur in a particular installation. If this equipment does cause

harmful interference to radio or television reception, which can be determined by

turning the equipment off and on, the user is encouraged to try to correct the

interference by one or more of the following measures:

• Reorient or relocate the receiving antenna.

• Increase the separation between the equipment and receiver.

• Connect the equipment into an outlet on a circuit different from that to which

the receiver is connected.

• Consult the dealer or an experienced radio/TV technician for help.

This equipment has been verified to comply with the limits for a class B

computing device, pursuant to FCC Rules. In order to maintain compliance

with the FCC regulations, shielded cables must be used with this equipment .

Operation with non-approved equipment or unshielded cables is likely to

result in interference to radio and TV reception. The user is cautioned that

changes and modifications made to the equipment without the approval of

the manufacturer could void the user’s authority to operate this equipment.

Page 5

Page 6

Contents

Figures and Tables..................................................................xi

Preface ....................................................................PR–1

About the MICROLAB 500 Series of Instruments.....................PR–2

Upgrading Your MICROLAB 500 System..............................PR–3

About This Manual.................................................................PR–4

Conventions Used in This Manual ...........................................PR–5

A Word About Single Syringe Instruments ...............................PR–5

Chapter 1 Getting Started..................................................1–1

MICROLAB 500 Parts Lists.......................................................1–2

A Brief Introduction to the MICROLAB 500B..............................1 –8

Drive Unit..............................................................................1–8

Power Cord Connector Receptacle ................................... 1–13

Hand Probe or Footswitch Connector Receptacle..............1–13

Fuse Box.........................................................................1–13

Communications Settings.................................................1–13

Power On/Off Switch and Power Indicator Light.................1–14

Step/Prime Switch...........................................................1–14

Valve Assembly...............................................................1–15

Syringe Drive Arms........................................................... 1–15

Controller Unit........................................................................1–16

Pipettors/Probes...................................................................1–18

Concorde Push-button Hand Pipettor/Probe.....................1–18

Dual Push-button Hand Pipettor/Probe ............................. 1–18

v

Page 7

Disposable Tip Push-button Hand Pipettor/Probes ............ 1–19

Luer Lock Tip Push-button Pipette Hand Pipettor/Probe....1–19

Viscous Sample Push-button Hand Pipette

Pipettor/Probe.................................................................1–20

Footswitch..........................................................................1–20

Probe Button Functions ...................................................... 1–20

Chapter 2 Installing the MICROLAB 500 System ....................2–1

Overview of Installation Procedures...........................................2–3

Selecting a Location.................................................................2–3

Installing the Accessory Holder.................................................2– 3

Selecting Communications Options..........................................2 – 4

Installing Electrical Connections................................................2 –6

Installing Valve Assemblies.......................................................2–8

Installing the Valve Assembly on the ML 510B/511C...............2 – 8

Installing Valve Assemblies on the

ML530B/531C and 540B/541C ............................................. 2– 9

Selecting, Installing, and Removing Syringes...........................2–10

Preparing Syringes for Installation........................................2–12

Installing Syringes...............................................................2–12

Removing Syringes.............................................................2–14

Selecting and Installing Tubing...............................................2–16

Selecting Tubing................................................................2–16

Installing Tubing..................................................................2–17

Chapter 3 Programming and Using the

MICROLAB 500B System.....................................3–1

Using the Controller Unit...........................................................3–3

Using the Arrow Keys............................................................3–3

vi MICROLAB 510B/511C, 530B/531C, and 540B/541C User’s Manual

Page 8

Using the Numeric Keypad....................................................3–4

Using the Run/Stop Key........................................................3 – 4

Using the Function Keys.......................................................3 – 4

Editing Conventions............................................................. 3 –5

Powering on the MICROLAB 500..............................................3 – 6

The Main Menu........................................................................3–7

Priming the MICROLAB 500.....................................................3–8

Preparing to Prime................................................................3–8

Using the Prime Function from the Main Menu......................3–11

Creating a New Method..........................................................3–13

Creating an Aliquot Dispense Method..................................3–17

Creating a Serial Dispense Method.......................................3–18

Creating a Dilution Method...................................................3–20

Creating a Pipette Method...................................................3–23

Creating a Titrate Method.....................................................3–25

Creating a Custom Method..................................................3–28

Running an Existing Method...................................................3 –30

Editing an Existing Method .....................................................3–32

Performing Manual Dilutions...................................................3–33

Performing Manual Dispenses................................................3–35

The Utilities Menu..................................................................3–37

Renaming an Existing Method.............................................3 –38

Deleting an Existing Method ................................................3–40

Copying a Method to a Custom Method................................3–41

Downloading a Method to the Drive unit................................3–42

Diagnostic and Configuration Menu......................................3–44

Changing the Default Language.......................................3–44

Contents vii

Page 9

Setting the Baud Rate to the Drive Unit..............................3–45

Turning Caps Lock On and Off..........................................3–46

Performing the Display Test..............................................3–46

Performing the Keyboard Test .......................................... 3–46

Sample MICROLAB 510B Application Configurations...............3–47

Single Syringe Dispensing............................................3–47

Sample MICROLAB 530B Application Configurations...............3–48

Example 1: Dilutions......................................................3–48

Example 2: Dilutions......................................................3–49

Sample MICROLAB 540B Application Configurations...............3–50

Example 1: Dual Dispensing..........................................3–50

Example 2: Using the Dual Dispenser for

Single Dispensing......................................................... 3–50

Chapter 4 Caring for the MICROLAB 500..............................4–1

Deciding When to Clean the MICROLAB 500.............................4–2

Cleaning the Fluid Path of the MICROLAB 500..........................4 –2

Cleaning Syringes and Tubing..................................................4 – 3

Cleaning the Exterior of the MICROLAB 500..............................4– 4

Chemical Compatibility..............................................................4– 5

Storing the MICROLAB 500......................................................4 – 6

Replacing Batteries..................................................................4–6

Chapter 5 Troubleshooting the MICROLAB 500.................... 5 –1

Error Message Code Guide.......................................................5–2

Audible Messages.................................................................5–10

Troubleshooting Guide.......................................................... 5–11

Getting Technical Support ......................................................5–15

Returning Instruments for Repair.............................................5–16

viii MICROLAB 510B/511C, 530B/531C, and 540B/541C User’s Manual

Page 10

Appendixes

Appendix A Technical Specifications for the MICROLAB 500........................ A –1

Pin Outs for RS-232 and TTL Ports........................................... A–3

Appendix B Instrument Performance Test Reports.......................................B –1

Appendix C Ordering Parts and Accessories for the MICROLAB 500.............C–1

Appendix D Chemical Compatibility of the MICROLAB 500............................ D –1

Appendix E Communication Protocols.........................................................E – 1

Hamilton Protocol 1/RNO+ Syntax Overview.......................... E –1

Auto-addressing ................................................................E–2

Data Transfer Format ...........................................................E-4

Data String Components..................................................... E-5

DIN Protocol/BDZ+ Syntax..................................................... E–7

Hardwire-addressing..........................................................E–8

Auto-addressing .................................................................E-8

Extablishing a Data Transfer Session....................................E-9

Terminating a Data Transfer Session................................... E-10

Data Transfer Session......................................................E–10

Data Block Format............................................................E–10

Data String Components................................................... E-11

Broadcast Addressing ....................................................... E-16

Stored Methods................................................................E-16

Stored Method Definition..................................................E-16

Creating Stored Methods.................................................. E-16

Stored Method Execution.................................................E-17

Appendix F Protocol Command Summary....................................................F–1

Channel Selection Commands.............................................F-2

Contents ix

Page 11

Initialization Commands .......................................................F-3

Syringe Positioning Commands ........................................... F-4

Valve Positioning Commands..............................................F-5

Timer and Digital I/O Commands...........................................F-6

Execution Commands ......................................................... F-7

Instrument Control Commands.............................................F-8

Syringe Parameter Change..................................................F-9

Valve Parameter Change...................................................F-10

Stored Method Parameter Change.....................................F-11

Instrument Information Requests.......................................F-11

Instrument Status Requests..............................................F-13

Syringe Parameter Request...............................................F-19

Valve Parameter Request..................................................F-20

Timer and Digital I/O Requests...........................................F-21

Firmware Version Request.................................................F-22

ASCII Chart..........................................................................F-22

ML500B Default Environmental Parameters...........................F-26

ML500B Command Buffer .................................................... F-26

ML500B Methods ................................................................ F-27

ML500B Specific Protocol Information...................................F-27

Glossary ....................................................................GL–1

Index .....................................................................IN–1

x MICROLAB 510B/511C, 530B/531C, and 540B/541C User’s Manual

Page 12

Figures and Tables

Preface

Figure PR–1 The MICROLAB 500 Series of Instruments.........PR–2

Chapter 1

Figure 1–1 MICROLAB 500B System Components...............1–3

Figure 1–2 MICROLAB 500B Shipping Kit Components........1– 5

Figure 1–3 Small Parts Kit.....................................................1 –6

Figure 1–4 Tubing Kit........................................................... 1 –7

Figure 1–5 Front View of theML510B Single

Syringe Dispenser..............................................1 – 9

Figure 1–6 Front View of the ML530B Dual Syringe Diluter... 1–10

Figure 1–7 Front View of the ML540B Dual

Syringe Dispenser............................................1–11

Figure 1–8 Rear View of the ML510B, 530B, and 540B........1–12

Figure 1–9 The Controller Unit............................................1–17

Figure 1–10 The Concorde, the Disposable Tip, and the Dual Hand

Pipettor/Probes ................................................1–19

Chapter 2

Table 1–1 MICROLAB 500 System Descriptions...................1 – 2

Table 1–2 MICROLAB 500B Shipping Kit............................. 1 – 4

Table 1–3 Small Parts Kit #35888 (For All Models).................1–6

Table 1–4 Tubing Kit #35887 (For All Models)...................... 1 – 7

Figure 2–1 Overview of Installation Procedures......................2–2

Figure 2–2 Installing Electrical Connections...........................2–7

Figure 2–3 Installing a Valve Assembly on the ML510B..........2–8

Figures and Tables xi

Page 13

Figure 2–4 Installing a Valve Assembly on the

ML530B and 540B..............................................2 –9

Figure 2–5 The TLL-type Dispenser/Diluent Syringe............ 2–11

Figure 2–6 The TLLX-type Dispenser/Diluent Syringe.......... 2–11

Figure 2–7 The DX-type Sample Syringe.............................2–11

Figure 2–8 Installing a Syringe ............................................2–13

Figure 2–9 Removing a Syringe..........................................2–15

Figure 2–10 ML510B Valve and Tubing Connections ............ 2–18

Figure 2–11 ML530B Valve with a D Configuration Syringe.....2–19

Figure 2–12 ML530B Valve with Two TLLX or TLL Syringes...2–19

Figure 2–13 ML540B Valve and Tubing Connectors .............. 2–20

Figure 2–14 Using the Tubing Reducer with the

Dual Hand Probe...............................................2–21

Table 2–1 Communications Switches and Ports....................2 –4

Table 2–2 Reagent/Diluent Syringes

(TLL and TLLX-types)........................................2–10

Table 2–3 Sample Syringes (DX-type)................................2–11

Table 2–4 Tubing Selection Guide.....................................2–16

Chapter 3

Figure 3–1 Using the MICROLAB 500B.................................3– 1

Figure 3–2 Overview of MICROLAB 500B Functions..............3– 2

Figure 3–3 The Controller Unit..............................................3– 3

Figure 3–4 Priming the MICROLAB 500..............................3–10

Figure 3–5 The Utilities Menu.............................................3–37

Figure 3–6 Single Syringe Dispensing ................................ 3–47

Figure 3–7 Dilutions ........................................................... 3–48

Figure 3–8 Serial Dilutions..................................................3–49

Figure 3–9 Dual Dispensing................................................ 3–50

Figure 3–10 Using the Dual Dispenser for Single Dispensing.. 3–51

xii MICROLAB 510B/511C, 530B/531C, and 540B/541C User’s Manual

Page 14

Chapter 5

Appendix A

Appendix B

Appendix C

Table 3–1 Function Key Actions .......................................... 3– 4

Table 5-1 Error Message Code Guide..................................5–2

Table 5–2 Audible System Messages ................................5–10

Table 5–3 Troubleshooting Guide .....................................5–11

Table A–1 Technical Specifications for the MICROLAB 500...A–1

Table A–2 Accuracy and Precision.......................................A– 2

Figure B–1 Sample Performance Test Report........................B–2

Table C–1 Reagent/Diluent Syringe Replacement Parts ........C–1

Table C–2 Sample Syringe Replacement Parts .....................C–2

Table C–3 Valve Assemblies................................................C–2

Table C–4 Tubing ............................................................... C –2

Table C–5 Pipettors/Probes ...............................................C –3

Table C–6 Parts and Accessories.........................................C–3

Appendix D

Appendix E

Appendix F

Table D–1 Chemical Compatibility.........................................D–1

Table E–1 Protocol 1/RNO+ Control Characters....................E – 2

Table E–2 DIN Protocol/BDZ+ Control Characters.................E–8

Table F-1 Channel Selection Commands.............................F–2

Table F-2 Initialization Commands........................................F-3

Table F-3 Syringe Positioning Commands............................ F-4

Figures and Tables xiii

Page 15

Table F-4 Valve Positioning Commands ............................... F-5

Table F-5 Timer and Digital I/O Commands............................F-6

Table F-6 Execution Commands.......................................... F-7

Table F-7 Instrument Control Commands.............................. F-8

Table F-8 Syringe Parameter Change................................... F-9

Table F-9 Valve Parameter Change.................................... F-10

Table F-10 Stored Method Parameter Change......................F-11

Table F-11 Instrument Information Requests ........................F-11

Table F-12 Instrument Status Request.................................F-13

Table F-13 Syringe Parameter Request................................ F-19

Table F-14 Valve Parameter Request...................................F-20

Table F-15 Timer and Digital I/O Requests ............................F-21

Table F-16 Firmware Version Request..................................F-22

Table F-17 ASCII Chart........................................................F-23

xiv MICROLAB 510B/511C, 530B/531C, and 540B/541C User’s Manual

Page 16

Preface Welcome to the World of

Hamilton Precision

Instruments

Congratulations on your purchase of a Hamilton MICROLAB 500

system. The Hamilton MICROLAB 500 is a versatile, semiautomatic, precision liquid processor. Various models of the

MICROLAB 500 function as either single- or dual-syringe

diluter/dispensers.

The MICROLAB 500 functions on the principal of liquid/liquid

displacement. At the heart of each MICROLAB 500 system is a

highly efficient, precision stepper motor drive that is combined

with world-famous Hamilton GASTIGHT syringes. The result is

a precise and accurate instrument that is very easy to set up

and use.

With proper care and maintenance, your new MICROLAB 500

system will serve you faithfully. To learn about the proper care

and maintenance of your investment, please take the time to read

this manual. Also, please read the warranty information that

appears on the copyright page in this manual and on the

separate warranty sheet that is included in your MICROLAB 500

shipping kit.

The Hamilton Company thanks you for purchasing this

Hamilton product. Welcome to the world of Hamilton precision

instruments!

PR–1

Page 17

About the MICROLAB 500 Series of Instruments

All of the MICROLAB 500 systems feature four common pipette modes: fill,

dispense, auto-refill, and prime. The systems are capable of performing accurate

and precise transfer pipetting, and of performing automated dilutions up to 1:25,000.

The instruments can also dispense up to 50 mL per cycle. Figure PR–1 provides an

overview of the MICROLAB 500 Series of Instruments.

Figure PR–1 The MICROLAB 500 Series of Instruments

The Microlab 500 Series of Instruments

Single Syringe Instruments

Controller without memory:

• Microlab 501A dispenser

Controller with memory:

• Microlab 510B diluter/dispenser

Computer-controlled:

• Microlab 511C diluter/dispenser

Dual Syringe Instruments

Controller without memory:

• Microlab 503A diluter

• Microlab 504A dispenser

Controller with memory:

• Microlab 530B diluter/dispenser

• Microlab 540B dispenser

Computer-controlled:

• Microlab 531C diluter/dispenser

• Microlab 541C dispenser

PR–2 MICROLAB 510B/511C, 530B/531C, and 540B/541C User’s Manual

Page 18

The MICROLAB 500 Series of instruments consists of three different lines of

diluter/dispensers.

• Controller without memory: Use the controller unit to manually enter methods.

This controller unit does not have memory, so methods cannot be stored.

• Controller with memory: This controller unit has memory, allowing you to

program and store your own custom methods. Or, use the controller unit to run

manual methods. Any instrument that uses this controller can also be computer

controlled.

• Computer controlled: No controller unit is included; use a computer to operate

the instrument.

The MICROLAB 510B/511C, 530B/531C, and 540B/541C are described in this

manual.

• The MICROLAB 510B/511C is a single syringe dispenser designed for single

precision dispensing applications.

• The MICROLAB 530B/531C is a dual syringe diluter designed for repetitive

dilution applications.

• The MICROLAB 540B/541C is a dual syringe dispenser designed for precision

dispensing applications that require more than one liquid to be dispensed at a

time.

Upgrading Your MICROLAB 500 System

Both the MICROLAB 510B/511C and 530B/531C systems can be upgraded to

MICROLAB 540B/541C systems. For upgrade information or for information about

purchasing any of the MICROLAB 500 models, contact your authorized Hamilton

sales representative or contact Hamilton Company.

In the United States:

Hamilton Company, P.O. Box 10030, Reno, Nevada 89520–0012

Telephone Numbers (in the USA and Canada):

Technical/Customer Service 1–800–648–5950 8 a.m. to 5 p.m. PST

Instrument Service 1–800–527–5269

Preface PR–3

Page 19

Outside the USA and Canada:

+1–775–858–3000

Fax Number: +1–775–856–7259

In Switzerland:

Hamilton Bonaduz AG, Ch–7402, P.O. Box 26,

Bonaduz, Switzerland

Telephone Number: +41–81–660–60–60

Fax Number: +41–81–660–60–70

About This Manual

This manual provides technical information about the MICROLAB 510B/511C,

530B/531C, and 540B/541C, and is divided into chapters that cover the following

topics:

• Chapter 1, Getting Started, provides an overview of the MICROLAB 500

system, including a complete parts list and a brief description of the system

components.

• Chapter 2, Installing the MICROLAB 500, describes how to set up the system.

• Chapter 3, Using the MICROLAB 500, provides step-by-step instructions for

using the system. It also provides sample applications.

• Chapter 4, Caring for the MICROLAB 500, describes everyday maintenance

techniques.

• Chapter 5, Troubleshooting, contains tables that list system messages and their

meanings, and common problems and their solutions.

• The Appendixes provide detailed information, such as technical specifications,

ordering information, etc.

• The Glossary defines terms used in this manual.

• The Index provides a quick-reference to the topics described in this manual.

PR–4 MICROLAB 510B/511C, 530B/531C, and 540B/541C User’s Manual

Page 20

Conventions Used in This Manual

Throughout this manual symbols are used to call your attention to various kinds of

information.

A Warning! Information that is essential for avoiding personal

injury is flagged with the International Warning

Symbol and appears like this in the text.

▲ Important Information that is essential for avoiding damage to

equipment appears like this in the text.

✱ Note: Interesting information or information that can help

improve system performance appears like this in the text. ✱

System messages and prompts that appear on the controller unit’s display screen

are shown in courier font. Items that are selected and user input appear in

boldface courier.

A

▲

A Word About Single Syringe Instruments

Throughout this manual you will see references to multiple syringes, volumes,

speeds, and to the right-side controls. All screen examples show the use of dual

syringe instruments. If you are using a MICROLAB 510B/511C single syringe

dispenser, please disregard these references. The right-side functions are not

available on single syringe instruments.

Any operational differences between the single and the dual syringe instruments

are called out in the text.

Preface PR–5

Page 21

Page 22

Chapter 1 Getting Started

This chapter provides a brief overview of the MICROLAB 500

system. Information in this chapter includes:

• MICROLAB 500 parts lists

• MICROLAB 500 components

– the drive unit

– the controller unit

– hand pipettors/probes

All MICROLAB 500 instruments come with everything you need

to start using the system, with the exception of syringes. You

must separately purchase syringes for use with the MICROLAB

500 systems. For complete lists of syringes, accessories, and

replacement parts for the MICROLAB 500, see Appendix C,

Ordering Parts and Accessories for the MICROLAB 500.

✱ Note: Contact your local delivery company if you

notice any visual damage to the MICROLAB 500

shipping package or to its contents. Also, you

may want to save the shipping container in case

you ever need to return the instrument for

service. ✱

1–1

Page 23

MICROLAB 500 Parts Lists

This section includes complete parts lists for the MICROLAB 500 systems. After you

unpack your MICROLAB 500, check to see that you have received all parts before

attempting to set up the system. The parts lists are presented in four separate tables

with four corresponding figures.

Table 1–1 lists the programmable models in the MICROLAB 500 series, their

components, and each component’s part number. Figure 1–1 shows these components.

Table 1–1 MICROLAB 500 System Descriptions

Model* Part # Drive

MICROLAB

510B 115V

MICROLAB

510B 220V

MICROLAB

530B 115V

MICROLAB

530B 220V

MICROLAB

540B 115V

MICROLAB

540B 220V

ML510115 35890 35893 69176 (English)

ML510220 35890 35893 same as above 355010 35792

ML530115 35891 35893 same as above 6541000 35793

ML530220 35891 35893 same as above 355010 35793

ML540115 35892 35893 same as above 6541000 35794

ML540220 35892 35893 same as above 355010 35794

Unit

Part #

Controller

Unit &

Cord

Part #

Manual Part # Power

69182 (French)

69180 (German)

69186 (Portuguese)

69188 (Spanish)

Shipping

Cord

6541000 35792

Kit

Part #

* All MICROLAB 500C models come with the drive unit, the manual, a power cord,

and a valve. The MICROLAB 500 C does not come with a controller or a shipping

kit.

1–2 MICROLAB 510B/511C, 530B/531C, and 540B/541C User’s Manual

Page 24

Figure 1–1 MICROLAB 500 System Components (items shown are

R

R

not to scale)

R

R

1

2

3

4

5

6

7

8

9

.

STEP

PRIME

POWER

Dual Drive Unit

Part # 35891 or 35892

(Microlab 530B/531C or 540B/541C)

0

Controller Unit and Cord

Part # 35893

(not with 500C models)

Stop

Run

R

Power Cord

Part # 6541000 or 355010

Shipping Kit

Part # 35792 (Microlab 510B)

R

STEP

PRIME

POWER

Part # 35793 (Microlab 530B)

Part # 35794 (Microlab 540B)

R

Single Drive Unit

Part # 35890

(Microlab 510B/511C)

Manual

Part # 69176

Chapter 1 Getting Started 1–3

Page 25

Table 1–2 lists the components that make up the MICROLAB 500B Shipping Kit

(shown as a box in Figure 1–1). Figure 1–2 shows these components.

Table 1–2 MICROLAB 500B Shipping Kit

Shipping Kit*

Part #

MICROLAB

510B

35792

MICROLAB

530B

35793

MICROLAB

540B

35794

Valve Part # Hand Probe Part

#

HV Valve

35825

Concorde

Probe

35529

Diluter

Valve

35844

Dispenser

Valve

35842

Concorde

Probe

35529

Dual Hand

Probe

35767

Small Parts Kit

Part #

35888 35887

35888 35887

35888 35887

Tubing Kit

Part #

2 items

*The MICROLAB 500C is standard with only the valve. All other parts must be

ordered separately.

1–4 MICROLAB 510B/511C, 530B/531C, and 540B/541C User’s Manual

Page 26

Figure 1–2 MICROLAB 500B Shipping Kit Components (items

R

shown are not to scale)

Small Parts Kit

Part # 35888

Concorde Probe

(Microlab 510B/511C or 530B/531C)

Part # 35529

Tubing Kit

Part # 35887

Dispenser Valve

Dual Hand Probe

Part # 35842

Part # 35767

(Microlab 540B/541C)

HV Valve

Part # 35825

(Microlab 510B/511C)

Diluter Valve

Part # 35844

Chapter 1 Getting Started 1–5

Page 27

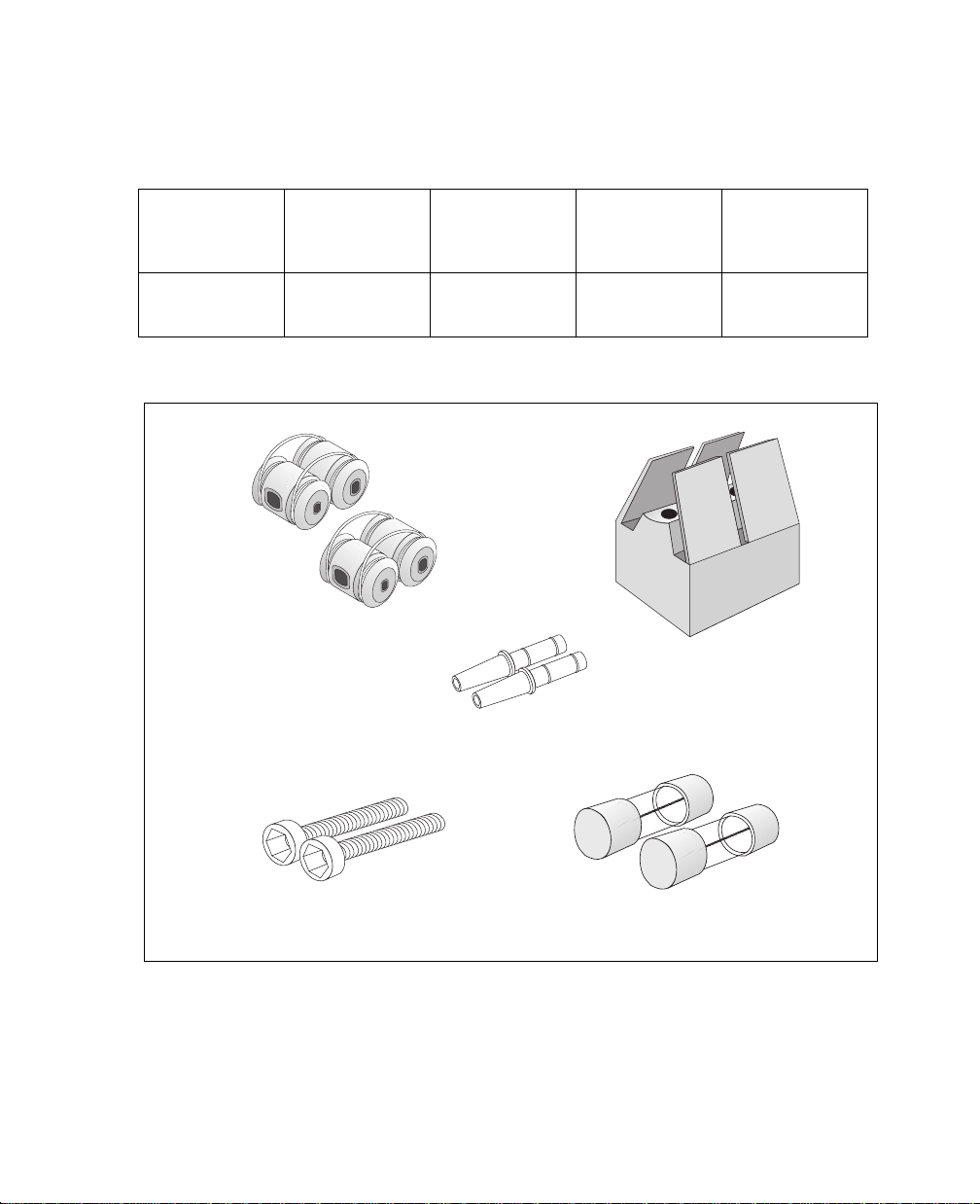

Table 1–3 lists the components that make up the MICROLAB 500B Small Parts Kit

(shown as a box in Figure 1–2). Figure 1–3 shows these components.

Table 1–3 Small Parts Kit #35888 (For All 500B Models)

Tubing Clips

Part #

230010

2 items

1 AMP Fuses

Part #

1524-01

2 items

Accessory

Holder

Part #

35783

1 item

Screws

Part #

16500

2 items

Figure 1–3 Small Parts Kit (items shown are not to scale)

(2) Tubing Clips

Part # 230010

Tubing Reducers

Part # 35770

Accessory

Holder

Part # 35783

Tubing

Reducers

Part #

35770

2 items

(2) Screws

Part # 16500

(2) Fuses

Part # 1524-01

1–6 MICROLAB 510B/511C, 530B/531C, and 540B/541C User’s Manual

Page 28

Table 1–4 lists the components that make up the MICROLAB 500 Tubing Kit (shown

as a box in Figure 1–2). Figure 1–4 shows these components.

Table 1–4 Tubing Kit #35887 (For All 500B Models)

12 ga. x 650 mm

Fill Tubing (not

tapered)

Part #

18 ga. x 650 mm

Fill Tubing (not

tapered)

Part #

12 ga. x 900 mm

Dispense Tubing

(tapered)

Part #

18 ga. x 900 mm

Dispense Tubing

(tapered)

Part #

240000* 240010* 240360* 240130*

* M6 threaded hubs are used on all tubing.

Figure 1–4 Tubing Kit (items shown are not to scale)

12 ga. Fill Tubing

Part # 240000

12 ga. Dispense Tubing

Part # 240360

18 ga. Fill Tubing

Part # 240010

18 ga. Dispense Tubing

Part # 240130

For complete lists of syringes, accessories, and replacement parts for the

MICROLAB 500, see Appendix C, Ordering Parts and Accessories for the

MICROLAB 500.

Chapter 1 Getting Started 1–7

Page 29

A Brief Introduction to the MICROLAB 500B

The MICROLAB 510B, 530B, and 540B systems each consist of three basic units.

These units include:

• a drive unit

• a controller unit

• a hand probe

This section briefly describes these units and the individual components that

comprise each unit. See Chapter 2, Installing the MICROLAB 500, for complete

installation instructions; see Chapter 3, Using the MICROLAB 500, for complete

usage instructions.

Drive Unit

The drive unit is the heart of each MICROLAB 500 system. The drive unit contains

a precision drive motor, the syringe drive arms, the valve assembly, the power

switches, and the connector receptacles. These features allow you to control other

sub-assemblies, and together they create a very versatile and functional

instrument.

Figure 1– 5 shows the front view of the MICROLAB 510B single syringe

diluter/dispenser. In this figure, the controller unit rests on top of the drive unit and

a syringe is attached to the syringe drive arm.

A Warning! This warning label appears on the front panel of the

ML500. It indicates that a pinch hazard exists when

the syringe drive is moving.

1–8 MICROLAB 510B/511C, 530B/531C, and 540B/541C User’s Manual

A

Page 30

Figure 1–5 Front View of the MICROLAB 510B Single Syringe

Diluter/Dispenser

Input

12

4

7

.

56

89

0

R

R

3

Run

Stop

R

R

Hand Probe

Connector

Receptacle

Output

R

STEP

PRIME

Step/Prime

Switch

Power

Indicator

Light

Power

POWER

On/Off

Switch

Chapter 1 Getting Started 1–9

Page 31

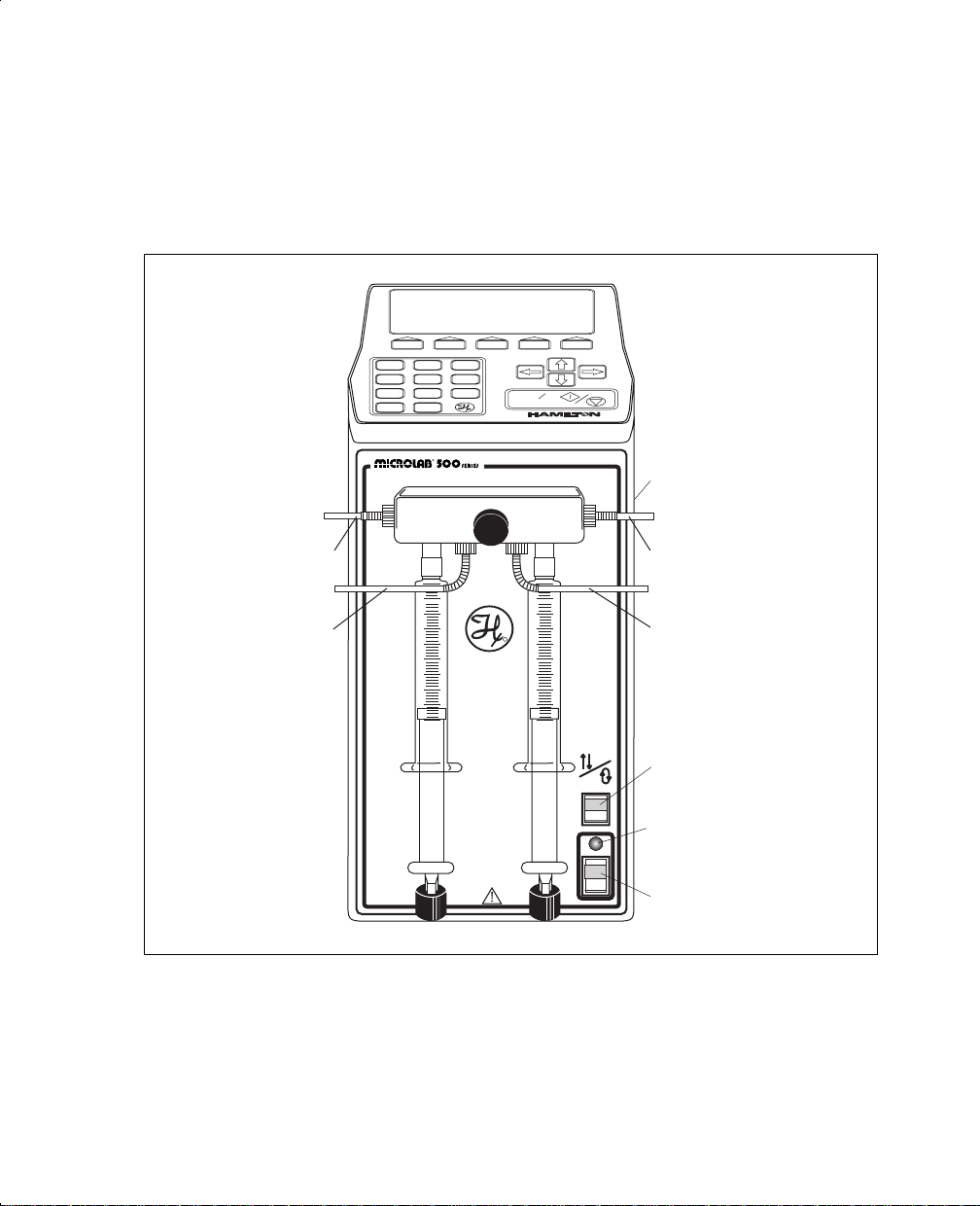

Figure 1–6 shows the front view of the MICROLAB 530B dual syringe diluter. In

this figure, the controller unit rests on top of the drive unit and syringes are

attached to the syringe drive arms.

Figure 1–6 Front View of the MICROLAB 530B Dual Syringe Diluter

12

4

7

.

56

89

0

R

3

Run

Stop

R

R

Hand Probe

Connector

Receptacle

OutputInput

R

STEP

Step/Prime

PRIME

Switch

Power

Indicator

Light

Power

POWER

On/Off

Switch

1–10 MICROLAB 510B/511C, 530B/531C, and 540B/541C User’s Manual

Page 32

Figure 1–7 shows the front view of the MICROLAB 540B dual syringe dispenser. In

this figure, the controller unit rests on top of the drive unit and syringes are

attached to the syringe drive arms.

Figure 1–7 Front View of the MICROLAB 540B Dual Syringe

Dispenser

Input

Output

12

4

7

.

56

89

0

R

3

Run

Stop

R

R

Hand Probe

Connector

Receptacle

Input

R

STEP

PRIME

Output

Step/Prime

Switch

Power

Indicator

Light

Power

POWER

On/Off

Switch

Chapter 1 Getting Started 1–11

Page 33

Figure 1–8 shows the rear view of all units.

Figure 1–8 Rear View of the MICROLAB 500.

Hand Probe

Connector

Receptacle

LR-52122

RENO, NEVADA

BAUD

!

6

5

7

4

3

9

2

0

1

R

R

UNIT #

Baud Rate

Switch

!

Protocol

9

8

A

7

B

6

5

C

8

4

D

3

E

2

1

F

0

Switch

Loopback

Switch

TTL Port

RS-232 OUT

Receptacle

Controller Unit

Connector

Receptacle

(RS-232 IN)

Fuse Box

Power Cord

Connector

R

RS-232

OUT

PART

NO.

MANUFACTURED BY

TTL

!

SERIAL

NO.

WARNING: DISCONNECT SUPPLY BEFORE SERVICING.

HIGH LEAKAGE CURRENT-ENSURE PROPER GROUNDING.

AVERTISSEMENT: COUPER LALIMENTATION AVANT L ENTRETIEN ET DEPANNAGE.

!

COURANT DEFUITE ELEVE-FOURNIER UNE MISE A LA TERRE EFFICACE.

WARNUNG: FUER SERVICEARBEITEN STROMZUFUHR UNTERBRECHEN.

HOHER LECKSTROM-GUTER ERDUNGSANSCHLUSS GEWAEHRLEISTEN.

100-240 V 50-60 HZ 150 VA

FUSE: T 1A/250 V

LABEL NO. 10650

RS-232

IN

Receptacle

1–12 MICROLAB 510B/511C, 530B/531C, and 540B/541C User’s Manual

Page 34

Power Cord Connector Receptacle

The power cord connector receptacle is located on the back of the drive unit; the

power cord fits into this receptacle only one way. The receptacle accepts cords for

either 115V or 220V without any adaptation of the drive unit. See Figure 1–8 for

the location of the power cord connector receptacle.

Hand Probe or Footswitch Connector Receptacle

The hand probe connector receptacle is located on the upper right side of the drive

unit. You can insert either a hand probe jack or a footswitch jack into this

receptacle. See Figures 1–5 through 1–8 for the location of the hand probe connector

receptacle.

Fuse Box

The fuse box is located at the top of the power cord connector receptacle. To gain

access to the fuse box, you must first remove the power cord. See Figure 1–8 for the

location of the fuse box.

Communications Settings

All communications switches and ports are located on the back of the drive unit

beneath the serial number label. These items are listed here; refer to “Selecting

Communications Options” in Chapter 2 for complete information about setting and

using these receptacles and switches.

• The RS/232 IN receptacle handles incoming communications.

• The RS/232 OUT receptacle handles outgoing communications.

• The TTL port allows peripheral devices to attach to the drive unit.

• The Loopback switch allows the drive unit to daisy-chain to other units.

• The Baud Rate switch controls the speed at which the drive unit communicates

with other devices.

• The Protocol switch determines the hardware address and protocol of the drive

unit.

Chapter 1 Getting Started 1–13

Page 35

Power On/Off Switch and Power Indicator Light

The Power On/Off switch and the Power Indicator light are located on the front of

the drive unit in the lower right-hand corner. See Figures 1–5 through 1–7 for the

locations of the switch and the indicator light.

The Power On/Off switch is a two-position rocker switch.

• To power-on the MICROLAB 500, press the upper half of the switch. The

system beeps twice when it is powered on.

• To power-off the MICROLAB 500, press the lower half of the switch.

The Power Indicator light is a small green LED located directly above the

Power On/Off switch. It is lit when the unit is powered on.

Step/Prime Switch

The Step/Prime switch is located on the front of the drive unit in

C / D

The Step/Prime switch is a three-position rocker switch.

the lower right-hand corner, directly above the power indicator

light. See Figures 1–5 through 1–7.

• When the Step/Prime switch is in the middle position, the switch is inactive.

1–14 MICROLAB 510B/511C, 530B/531C, and 540B/541C User’s Manual

Page 36

• When you press the lower part of the Step/Prime switch , the

D

C

Use the Step mode to move the syringe drive arm down and away from the

home position before installing or removing syringes.

Valve Assembly

The valve assembly controls the flow of liquid through the fluid path. The

510B/511C, 530B/531C, and 540B/541C models each use a different valve assembly;

you must attach the assembly to the drive unit. See Figures 1–5 through 1–7 for the

location of the valve assembly. See “Installing the Valve Assembly” in Chapter 2

for installation instructions.

ML500 goes into prime mode. When in prime mode, the syringe

drive arms automatically move up and down, opening the

valve ports, and moving fluid through the system. The ML500

stays in prime mode until you press the upper or the middle

part of the Step/Prime switch. The syringe will return to

home position.

• When you press the upper part of the Step/Prime switch , the

ML500 goes into Step mode. When in Step mode, the drive

arms move only as long as you press the Step/Prime switch.

When you release the switch, movement stops.

Syringe Drive Arms

You attach syringes to the MICROLAB ’s syringe drive arms. The syringe drive

arms are engineered to drive Hamilton precision syringes with high-resolution

stepper motors; the motors and drive arms are connected by a precision lead screw.

See “Selecting, Installing, and Removing Syringes” in Chapter 2 for syringe

installation instructions.

Chapter 1 Getting Started 1–15

Page 37

Controller Unit (for MICROLAB 500B Models)

The controller unit is a portable device that connects to the syringe drive unit via

the controller connector cord. Use the controller unit to program and store methods

and send information and instructions to the drive unit. For ease of use and for

everyday storage, the controller unit fits on top of the drive unit. Figure 1–9 shows

the controller unit.

The display screen and controls and are located on the unit:

• display screen—The display screen is located at the top of the unit. It shows

the status of the instrument and provides information about current methods.

• function keys—The function keys are located directly beneath the display

screen. Use these keys to perform the various operations shown on the

display screen.

• numeric keypad—The numeric keypad is located in the lower left corner of the

controller unit. Use the numeric keypad characters to enter numeric data into

the methods that you create or run.

• arrow keys—The arrow keys are located on the right side of the controller unit.

Use these keys to move from field to field on the display screen.

• Run/Stop key—The Run/Stop key is located in the bottom right corner of the

controller unit. This key generates a command signal that activates the next

step of an operation.

See Chapter 3, Programming and Using the MICROLAB 500 System, for complete

instructions about using the controller unit’s various keys.

✽ Note: 500C models may be operated with the controller unit; However,

the controller is not included in the standard 500C package.

1–16 MICROLAB 510B/511C, 530B/531C, and 540B/541C User’s Manual

✽

Page 38

Figure 1–9 The Controller Unit

Display

Screen

12

56

4

89

Numeric

Keypad

7

0

.

Function

Keys

Arrows

3

Run

Stop

R

R

Keys

Run/Stop

Key

Chapter 1 Getting Started 1–17

Page 39

Pipettors/Probes

Each MICROLAB 500B system comes with a remote push-button, hand-held

pipettor/probe. The standard accessory probes include:

• the Concorde Push-button Hand Pipettor/Probe (ships with MICROLAB 510B

and 530B; must be ordered separately for 500C models)

• the Dual Push-button Hand Pipettor/Probe (ships with MICROLAB 540B; must

order separately for the 541C model)

Additionally, three other optional probes may be ordered separately for use with

any MICROLAB 500 system. These probes include:

• the Disposable Tip Push-button Hand Pipettor/Probe

• the Luer Lock Tip Push-button Pipette Hand Pipettor/Probe

• the Viscous Sample Push-button Hand Pipettor/Probe

Concorde Push-button Hand Pipettor/Probe

The Concorde Push-button Hand Pipettor/Probe is a single-dispense pipette probe

that features a slim, comfortable design. Use this probe with MICROLAB 501 and

503 systems. The Concorde probe attaches directly to a sampling syringe or to the

valve assembly (output port). This probe accommodates both 12- or 18-gauge tubing

and features adjustable extension lengths beyond the probe tip. See Figure 1–10.

Dual Push-button Hand Pipettor/Probe

The Dual Push-button Hand Pipette Probe is a dual-dispense pipette that features

a pistol grip design with push-button actuator. Use this probe with MICROLAB 504

systems. This probe accommodates both 12- and 18-gauge tapered tubing lines with

independent extensions. You can extend the tubing out the end of the probe to the

length that is convenient for your application; either the right-side or the left-side

tubing can be extended to pick up sample. Figure 1–10 shows the Dual Push-button

Hand Pipette Probe.

1–18 MICROLAB 510B/511C, 530B/531C, and 540B/541C User’s Manual

Page 40

Disposable Tip Push-button Hand Pipettor/Probes

The Disposable Tip Push-button Hand Pipette Probe is a single-dispense tube

pipette that features disposable tips and push-button tip ejection. The Disposable

Tip Push-button Hand Pipette Pipettor/Probe is an optional accessory. Use this

probe when sample-to-sample carryover is a concern. See Figure 1–10.

Figure 1–10 shows the Concorde, the Disposable Tip, and the Dual Hand

Pipettor/Probe.

Figure 1–10 The Concorde, the Disposable Tip, and the Dual Hand

Pipettor/Probes

Concorde

Pipettor

Probe

Disposable Tip

Pipettor

Probe

Dual Hand

Pipettor

Probe

Luer Lock Tip Push-button Pipette Hand Pipettor/Probe

The Luer Lock Tip Push-button Pipette Hand Pipettor/Probe is an optional

accessory that dispenses liquids through needles of different lengths and gauges.

This probe is useful for controlling very small dispense volumes with a high degree

of accuracy. It is also ideal for administering injections to small animals and for

piercing septa.

Chapter 1 Getting Started 1–19

Page 41

Viscous Sample Push-button Hand Pipette Pipettor/Probe

The Viscous Sample Push-button Hand Pipettor/Probe is an optional accessory.

This single-dispense tube pipette is designed to accommodate highly viscous

samples, such as motor oil. This accessory features a disposable 5 mL tip that

eliminates sample carryover. Air displacement ensures accurate dilutions.

Footswitch

In addition to the hand-activated probes, a footswitch is also available. The

footswitch allows you to operate the MICROLAB 500 via a foot-activated control

pedal. This is useful when you need to keep both hands free, as when doing handsampling.

Refer to Appendix C for information about ordering the footswitch or any other

optional accessories.

Probe Button Functions

The probe button (on any model of hand probe) serves basically the same function as

the Run/Stop key on the controller unit. However, you cannot use the probe button to

pause an operation or to reinitialize the system after an error occurs.

1–20 MICROLAB 510B/511C, 530B/531C, and 540B/541C User’s Manual

Page 42

Chapter 2 Installing the MICROLAB 500

System

This chapter contains information about installing the

MICROLAB 500 system, including the following topics:

• an overview of installation procedures

• selecting an installation location

• installing the accessory holder

• determining communications settings

• installing electrical connections

• installing the valve assembly

• selecting, installing , and removing syringes

• selecting and installing tubing

▲ Important Be sure to read the instructions in this chapter before

installing your MICROLAB system.

• Never install or use syringes incorrectly. Incorrect use

may result in damage to the syringes. See “Selecting,

Installing, and Removing Syringes” later in this chapter

for more information.

• Never over-tighten tubing. Over-tightening may result in

damage to the valves or tubing. See “Selecting and

Installing Tubing” later in this chapter for more

information.

• Call Hamilton Company’s Technical/Customer Service

Department at (800) 648–5950 (in the United States and

Canada) if you have questions about installing your

MICROLAB 500 system.

▲

2–1

Page 43

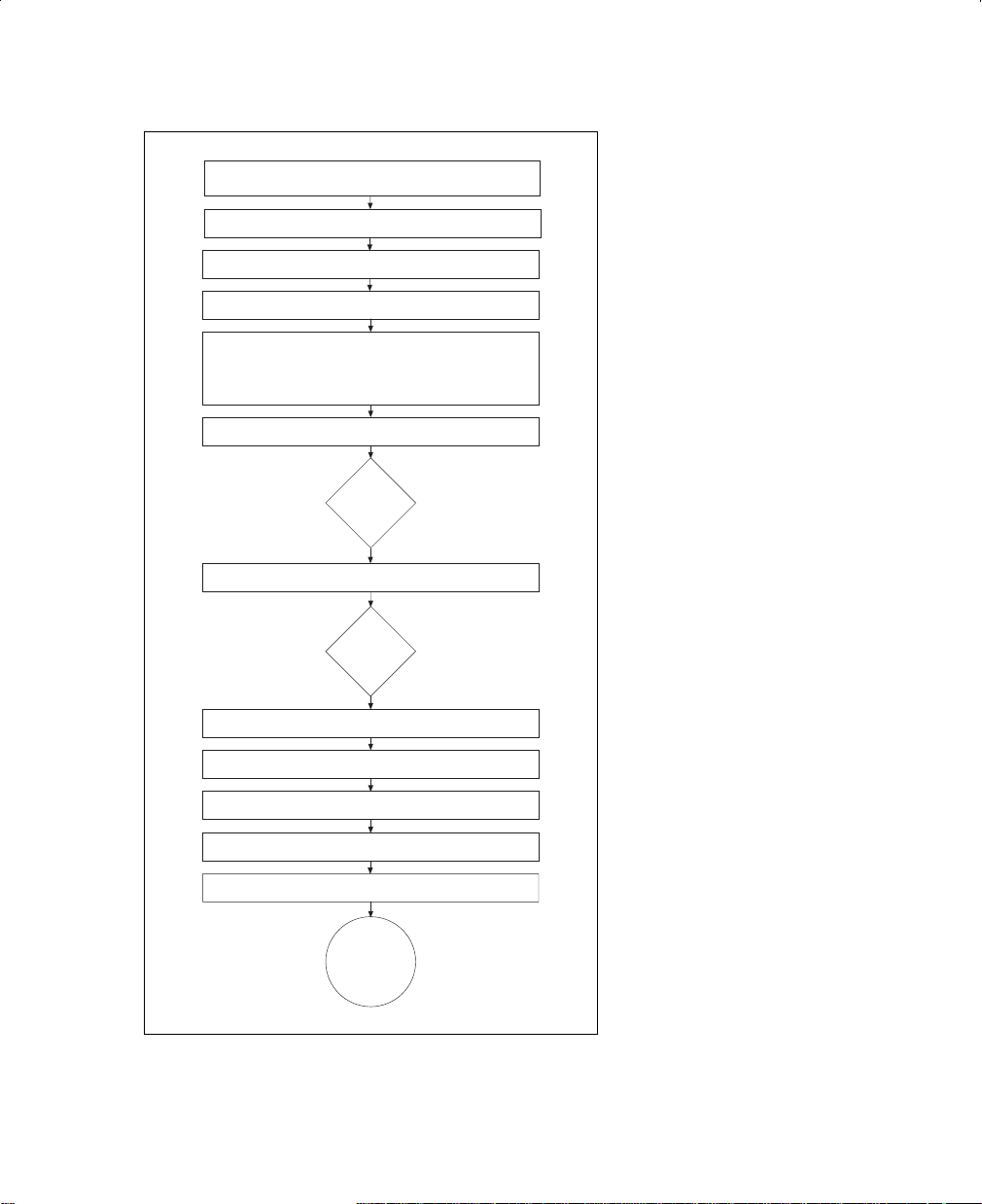

Figure 2–1 Overview of Installation Procedures

Unpack the instrument;

check all parts against packing list

Select an installation location

Install the accessory holder

Determine the communications settings

Plug in electrical connections:

• power cord • hand probe

• controller unit cord

• alternate communications cords

Install the valve assembly

OR

Select

syringe

sizes

Install syringe(s)

Select

tubing

sizes

Install the fill tubing

Install the tubing clip

Install the dispense tubing

Run the dispense tubing through the hand probe

Fill out and return warranty card

Installation

is complete

2–2 MICROLAB 510B/511C, 530B/531C, and 540B/541C User’s Manual

Page 44

Overview of Installation Procedures

Figure 2–1 provides an overview of the MICROLAB 500B installation procedures.

These procedures are described in detail in this chapter.

Selecting a Location

Install your MICROLAB 500 system in a clean, dry, level area away from

hazardous fumes. Leave space around the unit for ventilation; three inches is

sufficient.

Installing the Accessory Holder

All MICROLAB systems come with an accessory holder. You can mount the

accessory holder on either the right or the left side of the instrument. Generally,

the accessory holder is mounted on the right side and is used to hold a hand probe

when the probe is not in use. To install the accessory holder, follow these steps:

1. Locate the threaded holes on either the right or the left side of the instrument.

2. Use a hex wrench and screws (screws are provided) to attach the holder.

Chapter 2 Installing the MICROLAB 500 System 2–3

Page 45

Selecting Communications Options

To select communications options, you must first decide how you will use the

instrument. That is, will it be a used as standalone device or will it be on a daisy

chain? Based on its use, select the appropriate communications settings. See Figure

2–2 for the location of the communication switches and ports. Table 2–1 describes

the purposes of these switches and ports.

To change a switch’s position, power the instrument off. Then use a screwdriver to

change the switch position. The small bump on the switch indicates the selected

position. After you change a switch’s position, power the instrument back on again.

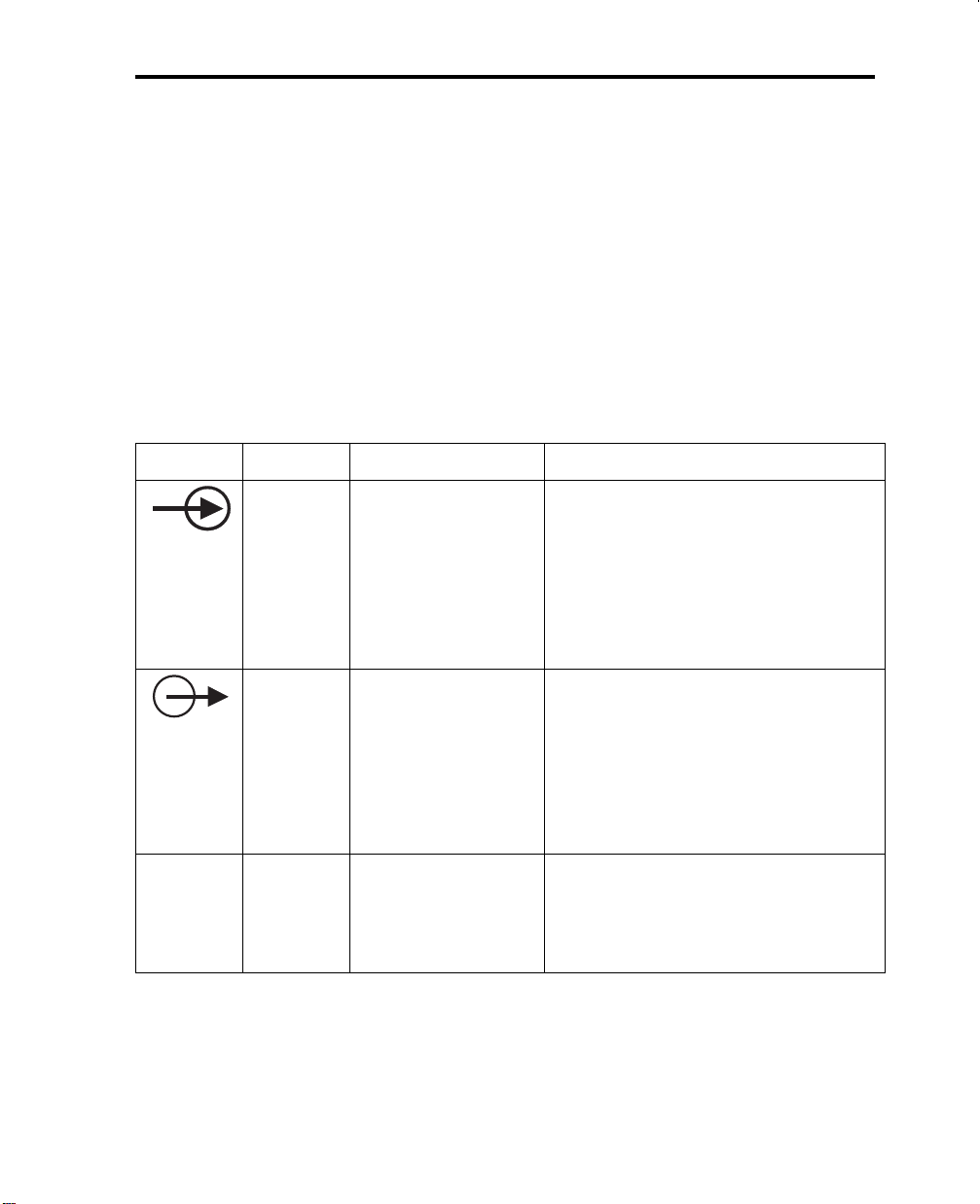

Table 2–1 Communications Switches and Ports

Icon Item Purpose Possible Settings and Uses

TTL

A

RS-232 IN

receptacle

RS-232

OUT

receptacle

TTL port allows peripheral

controller or RS232 three possible uses:

handles outgoing

communications

devices to attach to

the drive unit

1. controller via coiled cord

2. connects to the communications

port on a PC

3. if on a daisy chain, connects to

the RS232 OUT port of the

previous unit on the chain

two possible uses:

1. if not on a daisy chain, is left

open

2. if on a daisy chain, connects to

the RS232 IN port of the next

chained device; is left open if it

is the last unit on the chain

attach digitally-controlled

devices such as pumps, monitors,

etc.; is left open if no peripherals

are attached

2–4 MICROLAB 510B/511C, 530B/531C, and 540B/541C User’s Manual

Page 46

Table 2–1 Communications Switches and Ports

Icon Item Purpose Possible Settings and Uses

(continued)

BAUD

A

UNIT #

A

Loopback

switch

Baud

Rate

switch

Protocol

switch

allows the drive

unit to daisy-chain

to other units

controls the speed

at which the drive

unit communicates

with other devices

baud rate on the

controller unit must

match the baud rate

on the drive unit at

startup time; the

default is 9600

determines the

hardware address

and protocol of the

drive unit; the

default is Protocol 1

(position 0)

two possibilities:

1. UP: indicates the unit is a

standalone unit OR the last

item on a daisy chain

2. DOWN: indicates the unit is a

member of a daisy chain, in any

position except the last position

six possibilities:

0 = 1200

1 = 2400

2 = 4800

3 = 9600 (system default value)

4 = 19200

5 = 38400

6 = Unused

7 = Unused

8 = Unused

9 = Unused

two possibilities:

0 = Protocol 1/RNO+Syntax

(system default value)

• maximum items on a chain is 16

1–F = DIN Protocol

• if the drive unit is a member of a

daisy chain then each member

of the chain must have its own

unique address

• hardware address may/may

not be out of sequence

• maximum items on a chain is 15

Chapter 2 Installing the MICROLAB 500 System 2–5

Page 47

Refer to Appendix E, RS-232 Communications with Manual ASCII Commands, and

Appendix F, Protocols, for more detailed information about MICROLAB 500 system

communications. Refer to Chapter 3, Programming and Using the MICROLAB 500

System, for more information about baud rate settings.

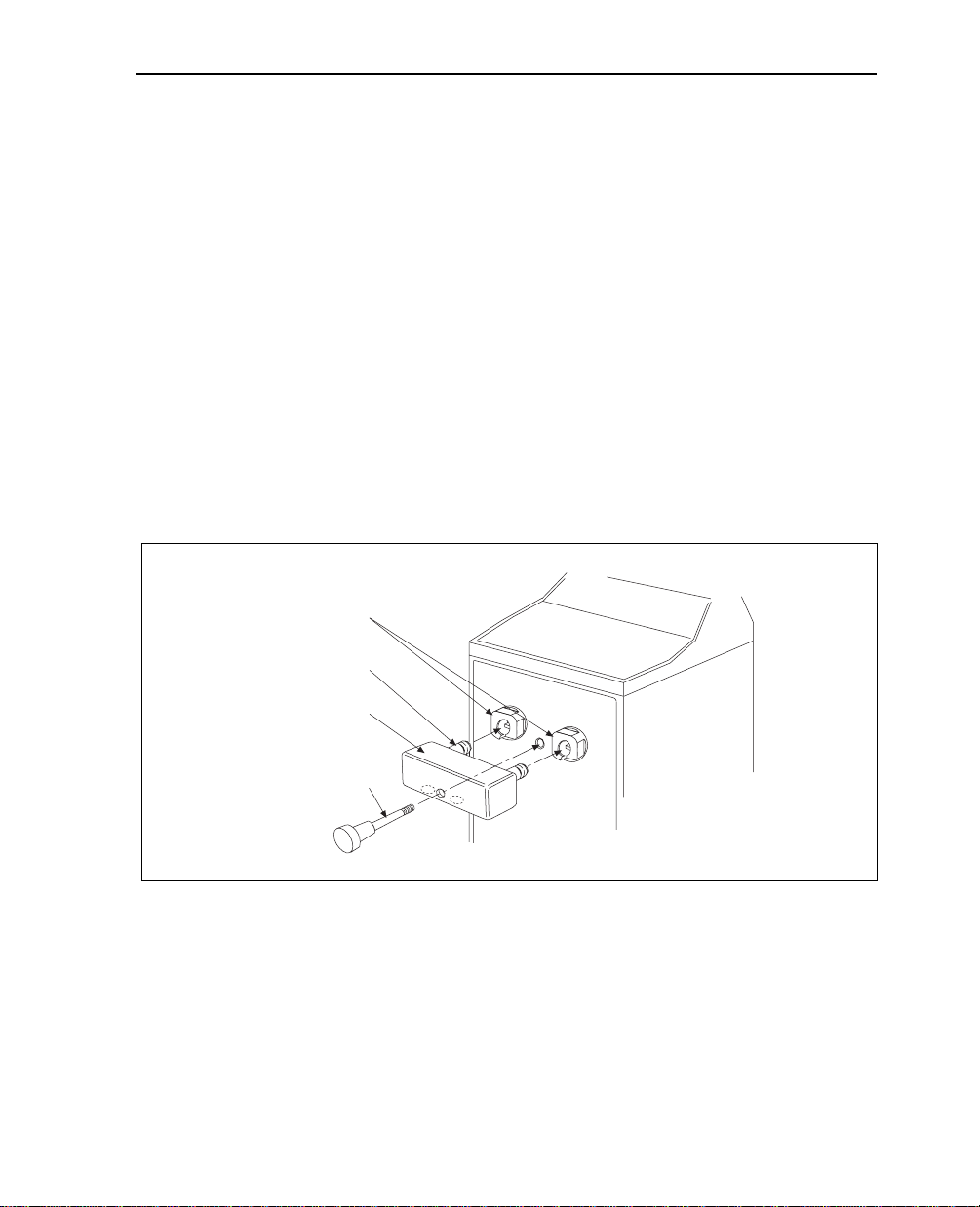

Installing Electrical Connections

A Warning! Always make sure that the instrument is powered off

before installing or removing any electrical

connections.

Refer to Figure 2–2 and follow these steps to install electrical connections:

1. Plug the power cord into the power connector receptacle on the back of the drive

unit. The power cord fits into the receptacle only one way.

The power connector receptacle accepts cords for either 115V or 220V.

2. Plug the hand probe (or foot pedal) jack into the probe connector receptacle. The

probe connector receptacle is located on the upper right side of the drive unit.

3. The controller connector receptacle is located on the back of the drive unit below

the serial number plate.

A

If you will be using the controller unit to communicate to the base unit, plug the

controller cord into the receptacle just as you plug a telephone cord into a

telephone outlet. Pinch the plastic locking device on the cord and insert it into

the connector receptacle. Then release the plastic locking device, firmly

attaching the cord.

4. If you will be using the drive unit to communicate to other devices, attach the

appropriate cords.

– To use the drive unit on a daisy chain, do not install the controller unit.

Instead, install the interconnect cord (Part # 35833) and connect it to the

RS-232 IN receptacle of the next device on the daisy chain. Leave

the RS-232 OUT receptacle open if the drive unit is the last unit on the

daisy chain.

2–6 MICROLAB 510B/511C, 530B/531C, and 540B/541C User’s Manual

Page 48

For more information about possible communications options, refer to Table 2–1,

Communications Switches and Ports.

Figure 2–2 Installing Electrical Connections

Hand Probe

Connector

Receptacle

RS-232 OUT

Receptacle

Controller Unit

Connector

Receptacle

(RS-232 IN)

Fuse Box

Power Cord

Connector

Receptacle

R

RS-232

OUT

PART

NO.

MANUFACTURED BY

TTL

!

SERIAL

NO.

WARNING: DISCONNECT SUPPLY BEFORE SERVICING.

HIGH LEAKAGE CURRENT-ENSURE PROPER GROUNDING.

AVERTISSEMENT: COUPER LALIMENTATION AVANT L ENTRETIEN ET DEPANNAGE.

!

COURANT DEFUITE ELEVE-FOURNIER UNE MISE A LA TERRE EFFICACE.

WARNUNG: FUER SERVICEARBEITEN STROMZUFUHR UNTERBRECHEN.

HOHER LECKSTROM-GUTER ERDUNGSANSCHLUSS GEWAEHRLEISTEN.

100-240 V 50-60 HZ 150 VA

FUSE: T 1A/250 V

LABEL NO. 10650

RS-232

IN

LR-52122

RENO, NEVADA

BAUD

!

6

5

7

4

3

9

2

0

1

Accessory

Holder

R

R

UNIT #

Baud Rate

Switch

!

Protocol

9

8

A

7

B

6

5

C

8

4

D

3

E

2

1

F

0

Switch

Loopback

Switch

TTL Port

Chapter 2 Installing the MICROLAB 500 System 2–7

Page 49

Installing Valve Assemblies

R

R

There are three types of valve assemblies for the MICROLAB 500 series.

Instructions for installing valve assemblies follow.

Installing the Valve Assembly on the MICROLAB 510B/511C

The MICROLAB 510B/511C uses a single active valve assembly. To install the

valve assembly, follow these steps:

1. Pick up the valve assembly. Make sure the PTFE luer fitting that attaches

to the syringe is on the bottom of the assembly.

2. Holding the valve assembly, align the valve stem opening with the valve

motor drive port on the drive unit. Press the valve assembly into place.

3. Push down on the valve lever to lock the valve assembly to the drive unit.

Figure 2–3 Installing a Valve Assembly on the MICROLAB 510B/511C

Valve Stem

Valve

PTFE

Luer Fitting

Valve Motor

Drive Port

Valve Lever

Lock

2–8 MICROLAB 510B/511C, 530B/531C, and 540B/541C User’s Manual

Page 50

Installing Valve Assemblies on the MICROLAB 530B/531C

and 540B/541C

Although the valve assemblies for the 530B/531C and 540B/541C units are

different from one another, their installation procedures are the same. To install a

valve assembly on either the MICROLAB 530B or 540B, follow these steps:

1. Pick up the valve assembly. Make sure the PTFE luer fittings that attach to

the syringes are on the bottom of the assembly.

2. Insert the valve assembly into the valve motor drive ports and press the valve

assembly into place.

3. Tighten the thumbscrew until it is finger-tight to secure the valve assembly to

the drive unit.

Figure 2–4 Installing a Valve Assembly on the MICROLAB 530B/531C and

540B/541C

Valve Motor

Drive Ports

Valve Stem

Valve

Thumbscrew

Chapter 2 Installing the MICROLAB 500 System 2–9

Page 51

Selecting, Installing, and Removing Syringes

Before you install syringes on any MICROLAB instrument, you must first decide

what syringes to use. Use Tables 2–2 and 2– 3 to select the best syringe for your

application. See Figures 2–5 through 2–7 for examples of different syringe types.

• The MICROLAB 510B/511C uses one dispenser/diluent-type syringe in the left

position (TLL-type or TLLX-type syringes).

• The MICROLAB 540B/541C uses two dispenser/diluent-type syringes—one

each in the left and right positions (TLL or TLLX).

• The MICROLAB 530B/531C uses one reagent/diluent syringe in the left position

and one sample syringe in the right position (DX, TLL, or TLLX).

• As a general rule, to ensure high accuracy and precision, try to use 10% or more

of a syringe’s total volume. Consider using a different size syringe if your

application calls for driving a syringe less than 10% of its total volume, and

high accuracy and precision are required.

Table 2–2 Reagent/Diluent Syringes (TLL- and TLLX-types)

Syringe Sizes Model Number Part Number Optimal Ranges

(µL)

25 µL 1702 TLLX 80222 2.5–25

50 µL 1705 TLLX 80922 5–50

100 µL 1710 TLLX 81022 10–100

250 µL 1725 TLLX 81122 25–250

500 µL 1750 TLLX 81222 50–500

1 m L 1001 TLLX 81323 100–1000

2.5 mL 1002 TLL 81420 250–2500

5 m L 1005 TLL 81520 500–5000

10 m L 1010 TLL 81620 1000–10,000

25 m L 1025 TLL 82521 2500–25,000

2–10 MICROLAB 510B/511C, 530B/531C, and 540B/541C User’s Manual

Page 52

Table 2–3 Sample Syringes (DX-type)

Syringe Sizes Model Number Part Number Optimal Ranges

(µL)

25 µL 1702 DX 80226 2.5–25

50 µL 1705 DX 80926 5–50

100 µL 1710 DX 81026 10–100

250 µL 1725 DX 81126 25–250

500 µL 1750 DX 81226 50–500

1 m L 1001 DX 81326 100–1000

See Appendix C for information regarding replacement parts for TLL, TLLX, and

DX syringes.

Figure 2–5 The TLL-type Dispenser/Diluent Syringe

Figure 2–6 The TLLX-type Dispenser/Diluent Syringe

Figure 2–7 The DX-type Sample Syringe

Chapter 2 Installing the MICROLAB 500 System 2–11

Page 53

Preparing Syringes for Installation

When you unpack a new syringe, notice that the syringe plunger is packed

separately from the syringe barrel. You must condition the plunger tip before

inserting the plunger into the barrel.

▲ Important Before using a new syringe for the first time, you

must condition the syringe’s PTFE plunger tip and

glass barrel. To condition the tip and barrel, wet the

plunger tip with distilled water or a solvent. (Medicaltype silicone lubricants may be used to extend the

lives of PTFE plunger tips. However, silicone may

contaminate the process fluid.) Do NOT use viscous

oils to lubricate plunger tips.

After wetting the plunger tip, insert the plunger into

the glass barrel. Move the plunger in and out of the

glass barrel approximately 10 times. Apply steady

and even pressure; avoid twisting movements.

▲

Installing Syringes

Follow these steps to install syringes on any MICROLAB 500 system.

1. Condition all syringes before installation by following the procedure described

in “Preparing Syringes for Installation.”

2. Power on the MICROLAB system using the Power On/Off switch.

3. Press and hold the Step/Prime switch in the Step position, and move the

syringe drive arm down from the Home position. Release the switch when the

drive arm is about half-way between Home and the Down position.

2–12 MICROLAB 510B/511C, 530B/531C, and 540B/541C User’s Manual

Page 54

4. Fasten the thumbscrew on the drive arm to the bottom of the syringe plunger. To

fasten the thumbscrew, hold the plunger and screw the thumbscrew into the

threaded fitting at the bottom of the syringe.

5. Pull the glass barrel up straight to the threaded female luer fitting that

extends down from the bottom of the valve. Insert the male luer fitting into the

valve fitting and turn the glass barrel clockwise until it is “finger-tight.”

See Figure 2–8, Installing a Syringe, for an illustration of these steps.

Figure 2–8 Installing a Syringe

Then, mount the Luer

First, mount the

Lock.

Thumbscrew.

Chapter 2 Installing the MICROLAB 500 System 2–13

Page 55

▲ Important Always tighten syringes so they are “finger-tight.”

Syringes that are over- or under-tightened can cause

problems for your MICROLAB 500 system.

• Syringes that are over-tightened may cause leaks

or may damage the valve.

• Syringes that are under-tightened may cause

leaks.

• Syringes that are not screwed on straight may leak

and cause lateral strain on the syringe luer fitting

as it connects to the bottom of the valve.

▲

Removing Syringes

To remove syringes, reverse the installation procedure.

1. Power on the system using the Power On/Off switch.

2. Use the Step/Prime switch to move the syringe drive arm down from the Home

position. Release the switch when the drive arm is about half way between

Home and the Down position.

▲ Important Before you use the Prime function, direct the probe

toward a liquid waste container or reservoir since

initialization may expel any fluid remaining in the

syringes.

3. Release the glass barrel by turning it counterclockwise.

4. Unfasten the thumbscrew on the drive arm at the bottom of the syringe plunger.

To unfasten the thumbscrew, hold the plunger and unscrew the thumbscrew from

the threaded fitting at the bottom of the syringe.

Refer to Figure 2–9, Removing a Syringe, for an illustration of the removal

procedure.

2–14 MICROLAB 510B/511C, 530B/531C, and 540B/541C User’s Manual

▲

Page 56

Figure 2–9 Removing a Syringe

First, remove the

Luer Lock

Then, remove the

Thumbscrew.

A

Warning! Avoid the risk of injury or infection! Use extreme

caution when removing cracked or splintered

syringes. Always wear thick gloves and protective

eye wear when replacing syringes.

Chapter 2 Installing the MICROLAB 500 System 2–15

A

Page 57

Selecting and Installing Tubing

This section provides information about selecting and installing tubing on all

MICROLAB 500 systems.

Selecting Tubing

Each MICROLAB system includes two gauges of fill and dispense tubing: 12- and 18gauge. Fill tubing has a 90˚ cut on the end opposite the fitting; dispense tubing has a

tapered end opposite the fitting.

When selecting tubing, consider the volume and the viscosity of the liquid you plan

to pipette. Refer to Table 2–3, Tubing Selection Guide, for help in selecting tubing.

Table 2–4 Tubing Selection Guide

Syringe

Size

Tubing Gauge for

Standard Aqueous

Solutions

Tubing Gauge for

Viscous and

Foaming Liquids

25 µL18 18

50 µL18 18

100 µL18 18

250 µL18 18

500 µL18 18

1 mL 18 18

2.5 mL 18 12

5 mL 12 12

10 mL 12 12

25 mL 12 12

2–16 MICROLAB 510B/511C, 530B/531C, and 540B/541C User’s Manual

Page 58

✱ Note: If you have a MICROLAB 530B/531C diluter and plan to use

syringes of two different sizes, choose tubing to accommodate the

syringe with the larger volume. ✱

See Appendix C for information about ordering extra tubing.

Installing Tubing

1. Before installing tubing lines, wet the tubing fittings.

2. Make sure the tubing lines do not contain crimps or blockages. Crimps or

blockages can cause leaks or can cause the system to overload. If tubing is

crimped, replace it with new tubing.

▲ Important Fasten tubing so it is finger-tight and snug enough to

prevent leaks. Avoid using tools to tighten tubing.

Excessive tightening may damage tubing, valve

fittings, or flanges.

3. Install the fill tubing. You can differentiate fill tubing and dispense tubing since

dispense tubing has a tapered end.

▲

– For all MICROLAB 500 models, install the fill tubing on the left, or input

side of the valve. Thread the tubing fitting into the left valve port, and

screw it in so it is finger-tight.

– For the MICROLAB 540B/541C only, install a second fill tubing line on the

right side of the valve. Thread the tubing fitting into the right valve port,

and screw it in so it is finger-tight, just as you did on the right side.

4. Once the fill tubing is installed, attach a tubing clip to it. Slip the tubing clip

over the end of the tubing, then attach the clip to the side of the reservoir.

Chapter 2 Installing the MICROLAB 500 System 2–17

Page 59

5. Install the dispense tubing. You can recognize dispense tubing by its tapered end.

– If you are using a MICROLAB 510B/511C, install the dispense tubing on the

right side of the valve. Thread the tubing fitting into the right valve port

and screw it in so it is finger-tight. See Figure 2–10 for an illustration of the

valve and tubing connectors.

Figure 2–10 MICROLAB 510B/511C Valve and Tubing Connections

R

Input Side

(Port)

Output Side

(Port)

– If you are using a MICROLAB 530B/531C with a D syringe, install the

dispense tubing on the side port of the D syringe. See Figure 2–11. When

using a TLL syringe as a sampling syringe, install dispense tubing directly

onto the valve assembly. To do this, remove the valve plug and replace the

plug with dispense tubing. See Figure 2–12.

2–18 MICROLAB 510B/511C, 530B/531C, and 540B/541C User’s Manual

Page 60

Figure 2–11 MICROLAB 530B/531C Valve with a D Configuration Syringe

Insert Valve

Plug First

Input Side

(Port)

Output Side

(Port)

Figure 2–12 MICROLAB 530B/531C Valve with Two TLLX or TLL Syringes

Remove Valve

Plug First

Input Side

(Port)

Output Side

(Port)

Chapter 2 Installing the MICROLAB 500 System 2–19

Page 61

– If you are using a MICROLAB 540B/541C, install a tapered dispense tubing

line into each of the valve’s front ports. The front ports are located on the

bottom of the valve between the two syringes. Thread the tubing fittings

into the front ports, and screw the fittings in so they are finger-tight. See

Figure 2–13.

Figure 2–13 MICROLAB 540B/541C Valve and Tubing Connectors

Input Side

(Port)

Input Side

(Port)

Output Ports

✽ Note: It is possible to use the 540B/541C dual dispenser as a single

dispenser. When programming, designate the instrument as a single

dispenser.

6. Install the dispense tubing to the hand probe.

– If you are using the MICROLAB 510B or the MICROLAB 530B, the

Concorde Probe comes as standard equipment. This probe uses a single

dispense tube. To attach the dispense tubing into the probe, loosen the

knurled screw at the upper end of the probe. Slide the tapered end of the

dispense tube through the probe so that the tubing passes out the end of the

probe. When enough tubing for you to work with extends from the probe,

tighten the knurled screw to secure the tubing line.

2–20 MICROLAB 510B/511C, 530B/531C, and 540B/541C User’s Manual

✽

Page 62

– If you are using the MICROLAB 540B, the Dual Hand Probe comes as

standard equipment. This probe is designed for both 18- and 12-gauge

tubing. Use the tubing reducer (Part # 35770) that is provided with the dual

hand probe if you wish to use 18-gauge tubing. See Figure 2–14.

Figure 2–14 Using the Tubing Reducer with the Dual Hand Probe

7. Fill out the warranty card and return it to Hamilton Company.

8. You are now ready to use your MICROLAB 500 system.

Chapter 2 Installing the MICROLAB 500 System 2–21

Page 63

Page 64

Chapter 3 Programming and Using the

MICROLAB 500B System

This chapter contains information about the following topics:

• an overview of the MICROLAB 500 functions

• using the controller unit keys

• accessing the Main menu

• priming and checking the system

• creating methods

• running methods

• using the Utility menu functions

For information on controlling 500C systems, refer to Appendixes

E and F.

Figure 3–1 Using the MICROLAB 500B

Power up the instrument

Prime the instrument

Select a function

from the Main menu

Follow the on-screen instructions

Finished

using the

instrument?

Yes

When finished, flush the fluid line

and turn the instrument off

No

Select

another

function

3–1

Page 65

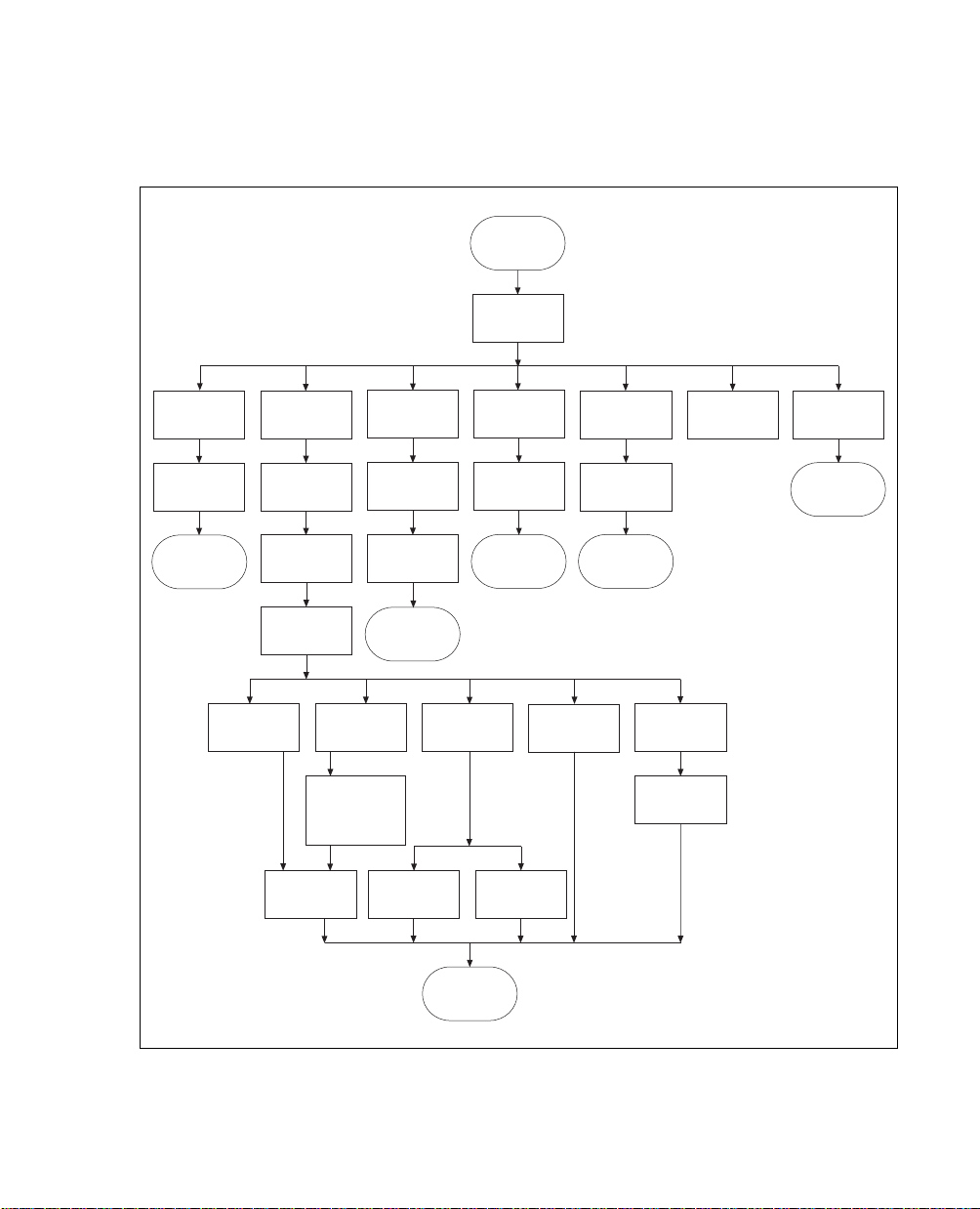

Figure 3–2 provides an overview of the functions available using the MICROLAB

500B. These functions are described in detail later in this chapter.

Figure 3–2 Overview of MICROLAB 500B Functions

Power up/

startup

screen

Main

menu

Run

existing

method

Select

method

Run

Pipette Dilute

Create

new

method

Name

Instrument

configuration:

single/dual

Select

method type

to create

Set:

• Gap

• Speed

• # of Syringes

Wash?

Edit

existing

method

Select

method

Edit

Save and

return to

Main menu

Aliquot

configuration: