Page 1

Instruction Manual

Thank you for purchasing the HAKKO FX-889 Soldering Station.

Please read this manual before operating the HAKKO FX-889.

Keep this manual readily accessible for reference.

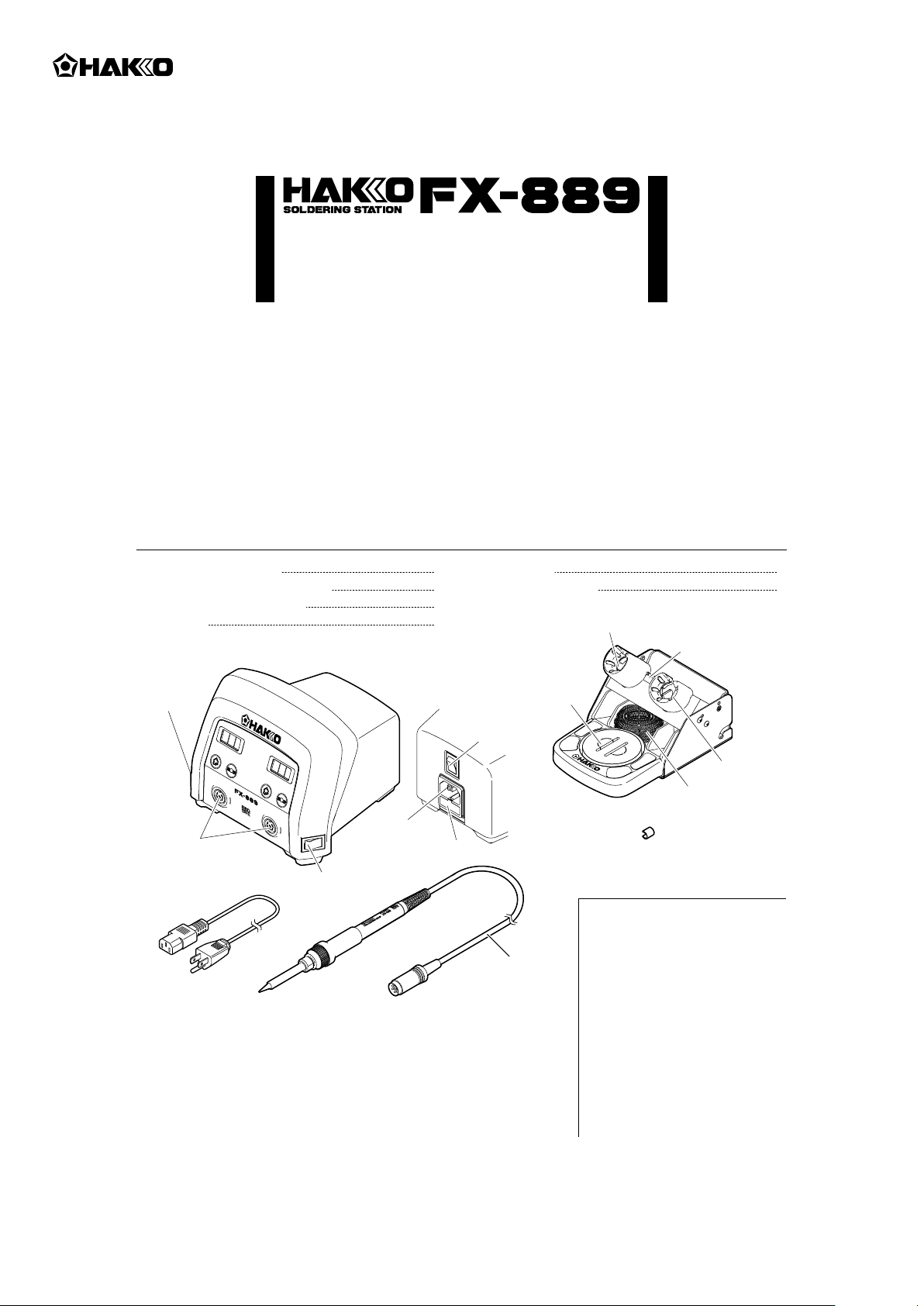

1. PACKING LIST AND PART NAMES

Color band

HAKKO FX-889 Station

HAKKO FX-8801 Soldering iron

HAKKO FH-801 Iron holder

Power cord

1

Instruction manual

1

1

1

Please check to make sure that all items listed

below are included in the package.

2

1

Iron receptacle

Rubber plate

Power switch

(for A.IRON)

Power switch

(Main)

Power cord

Receptacle

HAKKO

FX-889

Power switch

(for B.IRON)

Power cord

When using the HAKKO FX-8803 / FX-8804, please use

●

receptacle

Fuse

Cord assembly

HAKKO FX-8801

the applicable iron holder.

Each Hakko handpiece with the exception of the HAKKO FX-8801 /

●

FX-8805 has their own instruction manual. Please refer to this

manual for specifications and replacement parts.

Cleaning

sponge

HAKKO

FH-801 Iron holder

Color band

(×2)

※

Use this product with the

following models.

• HAKKO FX-8801

{Soldering iron (M)}

• HAKKO FX-8802

(Soldering iron N

• HAKKO FX-8803

(Soldering gun)

• HAKKO FX-8804

(SMD Hot tweezer)

• HAKKO FX-8805

{Soldering iron (L)}

Iron receptacle

Cleaning

wire

Type)

2

Page 2

2. SPECIFICATIONS

Power consumption 135W

● Station

Output

Temperature range

Temperature stability

Dimensions (W × H × D)

Weight (w/o cord)

* The temperature was measured using the FG-100 thermometer. * This product is protected against electrostatic discharge.

* Specifications and design are subject to change without notice.

AC26V

50 - 480℃ (120 - 899℉)

±1℃ (±1.8℉) at idle temperature

{When set to 200-480℃ (400-899℉)}

157(W) × 121(H) × 149(D) mm

(6.2 × 4.8 × 5.9 in.)

2.1 kg (4.6 lb.)

● HAKKO FX-8801 Soldering iron

Power consumption

Tip to ground resistance

Tip to ground potential

Heating element

Cord

Total length (w/o cord)

Weight (w/o cord)

AC26V 65W

< 2 Ω

< 2 mV

Ceramic heater

1.2 m (3.9 ft.)

217 mm (8.5 in.) with B tip

46 g (0.10 lb.) with B tip

■ Electrostatic Protection

This product includes such features as electrically conductive plastic parts and grounding of the unit

as measures to protect the device to be soldered from the effects of static electricity. Be sure to observe

the following instructions:

1. The plastic parts are not insulators, they are conductors. When making repairs or replacing parts,

take sufficient care not to expose live electrical parts or damage insulation materials.

2. Be sure to ground the unit during use.

3. WARNINGS, CAUTIONS AND NOTES

Warnings, cautions and notes are placed at critical points in this manual to direct the operator’s

attention to significant items. They are defined as follows:

WARNING: Failure to comply with a WARNING may result in serious injury or death.

CAUTION: Failure to comply with a CAUTION may result in injury to the operator, or damage to the

items involved.

WARNING

When power is ON, tip temperatures will be between 50 and 480℃. (120 to 899℉)

To avoid injury or damage to personnel and items in the work area, observe the

following:

● Do not touch the tip or the metal parts near the tip.

● Do not allow the tip to come close to, or touch, flammable materials.

● Inform others in the area that the unit is hot and should not be touched.

● Turn the power off when not in use, or left unattended.

● Turn the power off when changing parts or storing the HAKKO FX-889.

● This unit is for counter or workbench use only.

● This appliance can be used by children aged from 8 years and above and

persons with reduced physical, sensory or mental capabilities or lack of

experience and knowledge if they have been given supervision or instruction

concerning use of the appliance in safe way and understand the hazards

involved.

● Children shall not play with the appliance.

● Cleaning and user maintenance shall not be made by children without

supervision.

To prevent accidents or damage to the HAKKO FX-889, be sure to observe the following:

● Do not use the HAKKO FX-889 for applications other than soldering.

● Do not strike the iron against hard objects to remove excess solder. This will damage the iron.

● Do not modify the HAKKO FX-889.

● Use only genuine HAKKO replacement parts.

● Do not allow the HAKKO FX-889 to become wet, or use it with wet hands.

● Remove power and iron cords by holding the plug, not the wires.

● Be sure the work area is well ventilated. Soldering produces smoke.

● While using the HAKKO FX-889, don’t do anything which may cause bodily harm or physical damage.

1

Page 3

4. INITIAL SETUP

A. Setup the iron holder

(1) Cleaning Sponge

1. Fit the small sponge pieces into the hollows of the

iron holder base.

2. Add an appropriate amount of water into the iron

holder base. The small sponge will absorb water

and help keep the large sponge damp at all times.

3. Dampen the large sponge and place it on the iron

holder base.

(2) Cleaning Wire

Place it in the iron holder as shown on the right.

See “B. Using the cleaning wire” in section

“7. MAINTENANCE”.

The angle of the iron receptacles is adjustable by

changing the fastening position of the screws.

CAUTION

Increasing the angle of the iron receptacle will

cause an increase in the iron grip temperature.

B. Connect the iron to the station

1. Connect the cord assembly to the receptacle.

2. Place the iron into the iron holder.

3. Plug the power cord into an appropriate power

supply.

CAUTION

Be sure the sponge is moistened with water

before use to avoid damaging the tip.

Push on the plug until

it stops, making sure it is

securely connected.

To disconnect, hold the plug

and pull it out of the receptacle.

Receptacle

(2)

(1)

CAUTION

• Be sure to turn off the power before connecting or

disconnecting the cord assembly for the iron to and

from the receptacle to avoid damaging the circuit

board.

• Do not use any iron other than those listed in Section

1 of this manual. Doing so may result in inadequate

performance and / or possible damage to the unit.

• The unit is protected against electrostatic discharge

and must be grounded for full efficiency.

※

When using two soldering irons simultaneously

Attachment of the color bands to one of the soldering irons will help identify which soldering

iron is connected to receptacle “A.IRON” and “B.IRON”.

With color bands

Without color band

2

Page 4

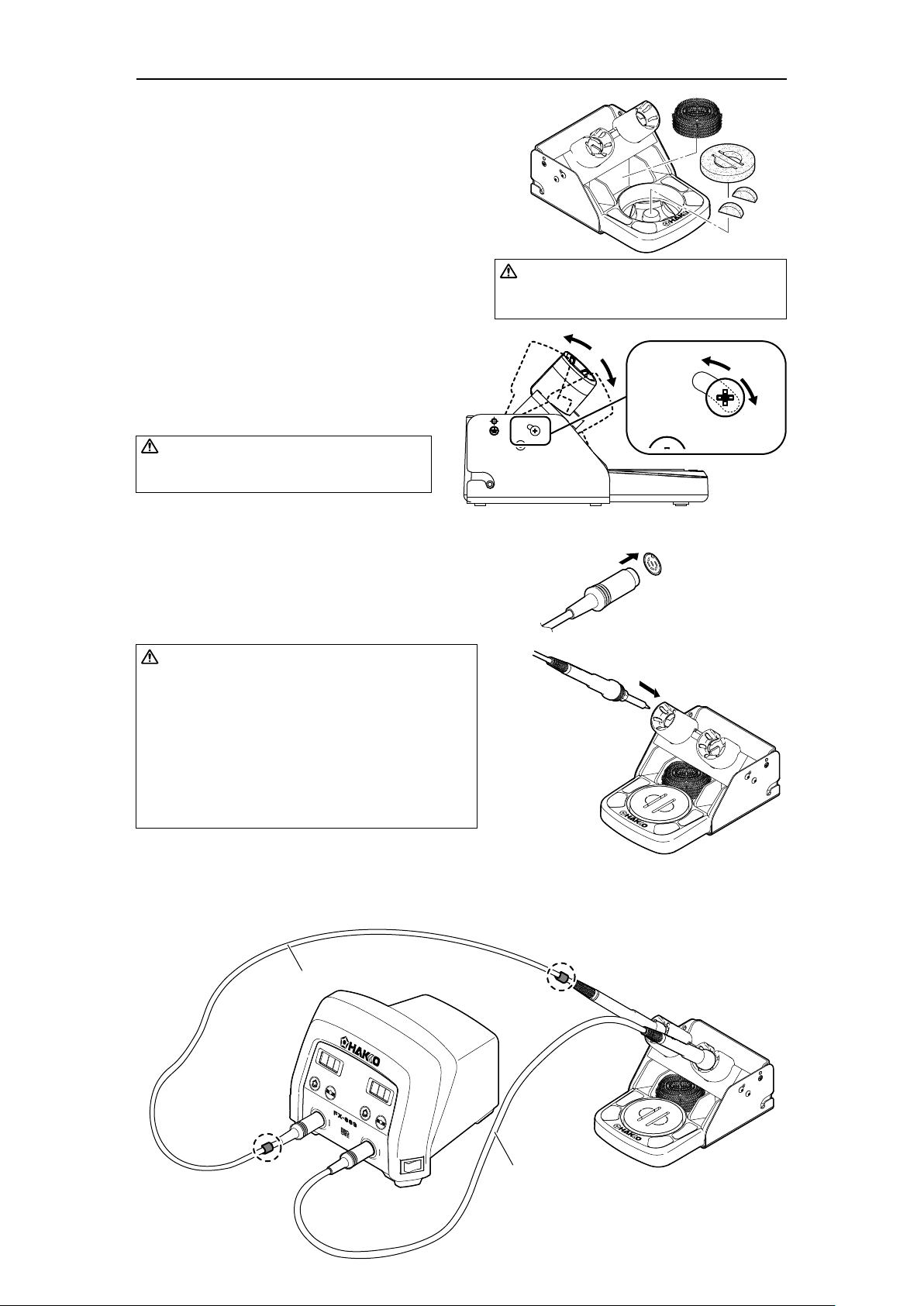

5. OPERATION

● Operation and indication

Switch and control button

ENTER

UP

ENTER

UP

The front panel of HAKKO FX-889 has two control buttons each for “A.IRON” and “B.IRON.”

– Use this button to select and change settings.

UP

• In the temperature preset mode, pressing this button will change the selected preset temperature

while the unit is in operation.

• Pressing and holding the button will start the adjustment mode.

ENTER

– Use this button to make and confirm selections.

• Pressing this button will display the current set temperature.

• Pressing and holding the button will start the temperature setting mode.

A. Operation

1. Turn on the power switch (main) located on the back.

2. Turn on either one of power switches located on each side depending

on which receptacle of “A.IRON” or “B.IRON” is used.

After turning on the power switch, will be displayed

for two seconds, and current temperature will be displayed.

When the display stabilizes, the LED heater lamp will begin to flash.

LED heater lamp

CAUTION

Place the iron in the iron holder when not in use. Turn the power off

when the HAKKO FX-889 is not in use for an extended period.

B. After use

Always clean the tip and coat it with fresh solder after use.

(Refer to “Tip Maintenance.”)

● Making Changes to Settings

CAUTION

If no buttons are pressed for at least one minute during the process of changing settings of the unit,

the system will exit and return to operating mode and display the current temperature.

A. Changing the set temperature

The temperature setting range is from 50 to 480℃. (from 120 to 899℉)

By default, the temperature is set to 350℃. (662℉)

Example : Changing from 350℃ to 400℃

Press and hold the

ENTER

button for at

least one second.

Press the button

five times.

UP

Press the button

once.

Press the button

once.

UP

ENTER

Press the button

once.

Press the button

once.

ENTER

ENTER

The desired temperature is saved to the system memory.

3

Heater control will begin after the new set temperature is displayed.

Page 5

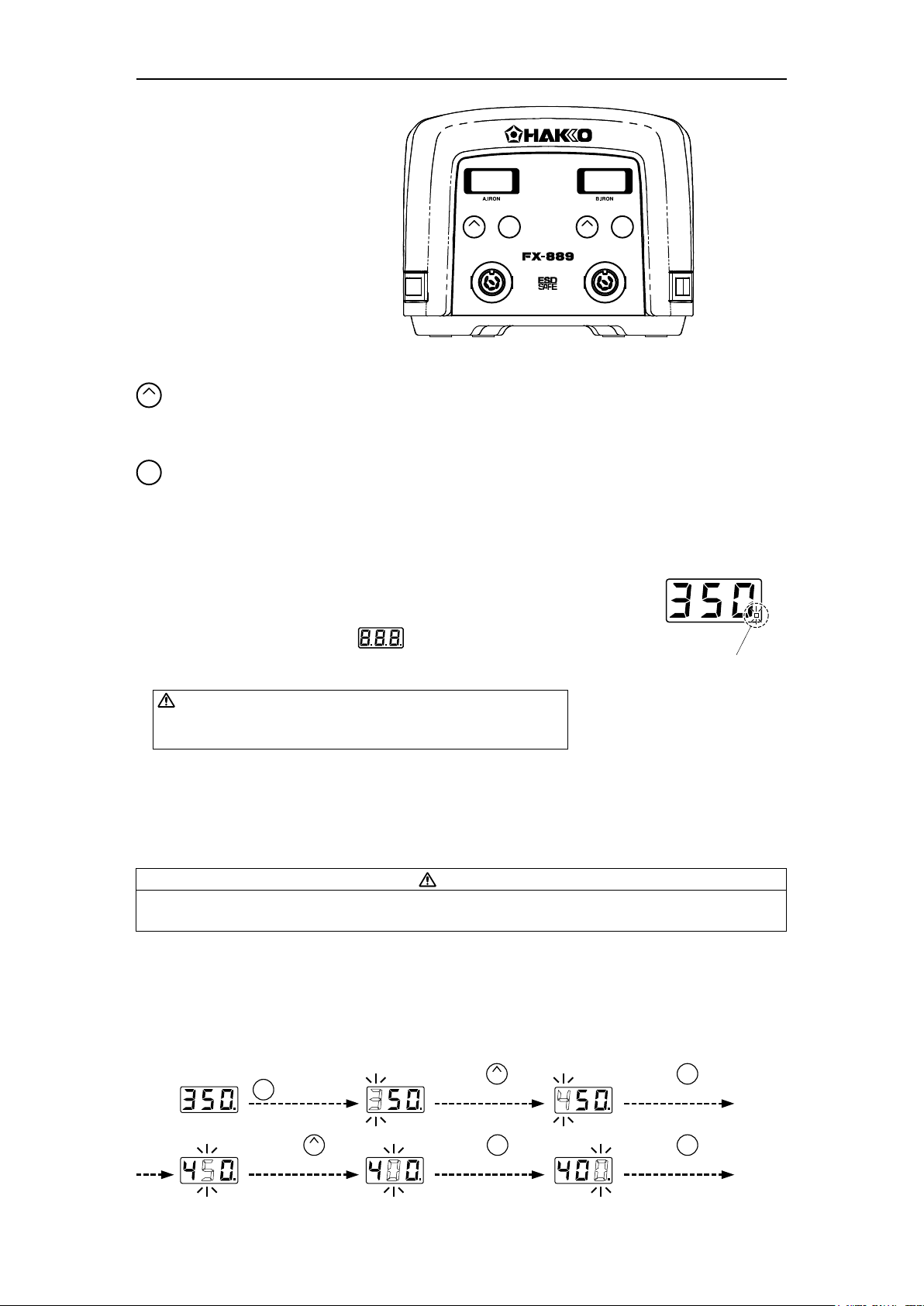

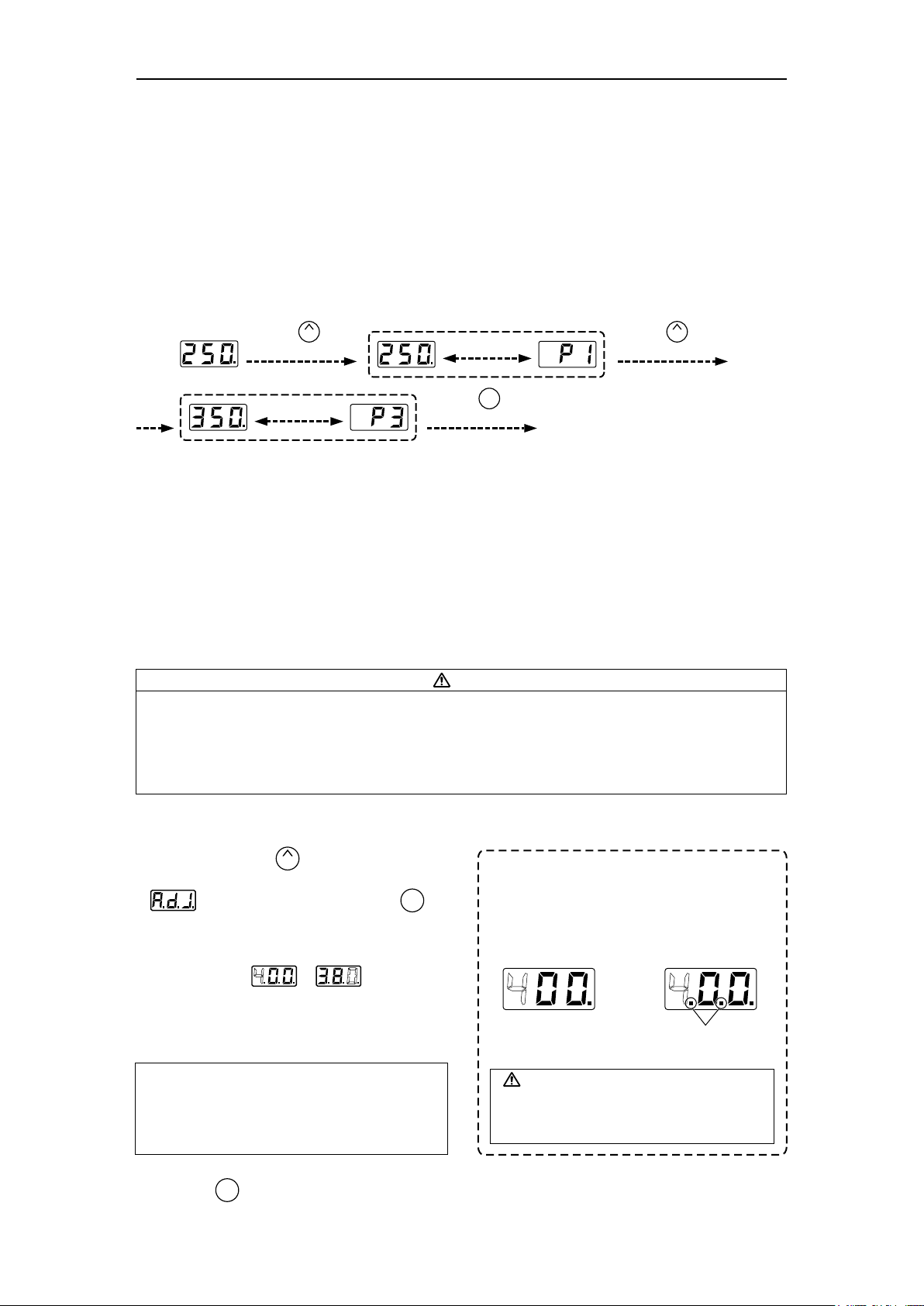

B. The preset mode

The HAKKO FX-889 has a preset mode that will allow the unit to store up to 5 preset temperatures you

can change between instead of using the above normal mode.

Initial preset temperatures

P1: 250℃ (482℉), P2: 300℃ (572℉), P3: 350℃ (662℉), P4: 400℃ (752℉), P5: 450℃ (842℉)

The initial number of active presets is set to 5 at the factory.

The default selected preset is set to P3 at the factory.

Example : Changing preset temperature from preset No.1 (250℃) to No.3 (350℃).

Press the button

once.

UP

Be displayed

alternately.

*Preset selection screen

Be displayed

alternately.

Press the button

once.

ENTER

Press the button

twice.

UP

Heater control will begin with new preset temperature.

The procedure for making changes to the preset temperatures is the same with “A. Changing the set

temperature” in 5. OPERATION. Enter the parameter setting to change the mode. (Please refer to [6.

PARAMETER SETTING])

C. Performing the temperature adjustment

When replacing the iron, heater or tip, a temperature adjustment may be required.

Use adjustment mode to perform the temperature adjustment.

CAUTION

• Enter the observed value in the adjustment mode after the tip temperature stabilizes.

• The maximum single adjustment that can be made is ±150℃ (270℉) relative to the set temperature.

If a larger adjustment is needed, make the first adjustment at the maximum value of 150℃ (270℉),

then repeat the adjustment process.

• When a new soldering iron is used or insertion position is changed from A.IRON to B.IRON (and vice

versa), temperature adjustment is always required.

Example : If the measured temperature is 380℃, and the set temperature is 400℃.

1. Press and hold the button for at least

two seconds.

● is displayed. When you press the

button, the display will move to the adjust mode.

UP

* How to distinguish between Temperature

Setting Mode and Adjustment Mode.

ENTER

The display differs in the temperature setting

and the adjustment mode.

In the Temperature

Setting Mode

2. Changing from to .

● The procedure for changing the value in

adjustment mode is the same as setting the

temperature in normal mode.

Please refer to Section 5 - OPERATION.

NOTE:

During adjustment mode, the hundreds digit will

accept values from 0 through 6 if the temperature

is set to display in ℃, or the values 0 through 9

if the temperature is set to display in ℉.

3. Press the button to exit the setting after

ENTER

CAUTION

Please be sure to confirm the status of the

identification lamps so that you do not enter

a value in the wrong mode.

Identification lamps are on

in the adjustment mode.

changing the values.

● The tip temperature will be adjusted accordingly.

In the Adjustment

Mode

4

Page 6

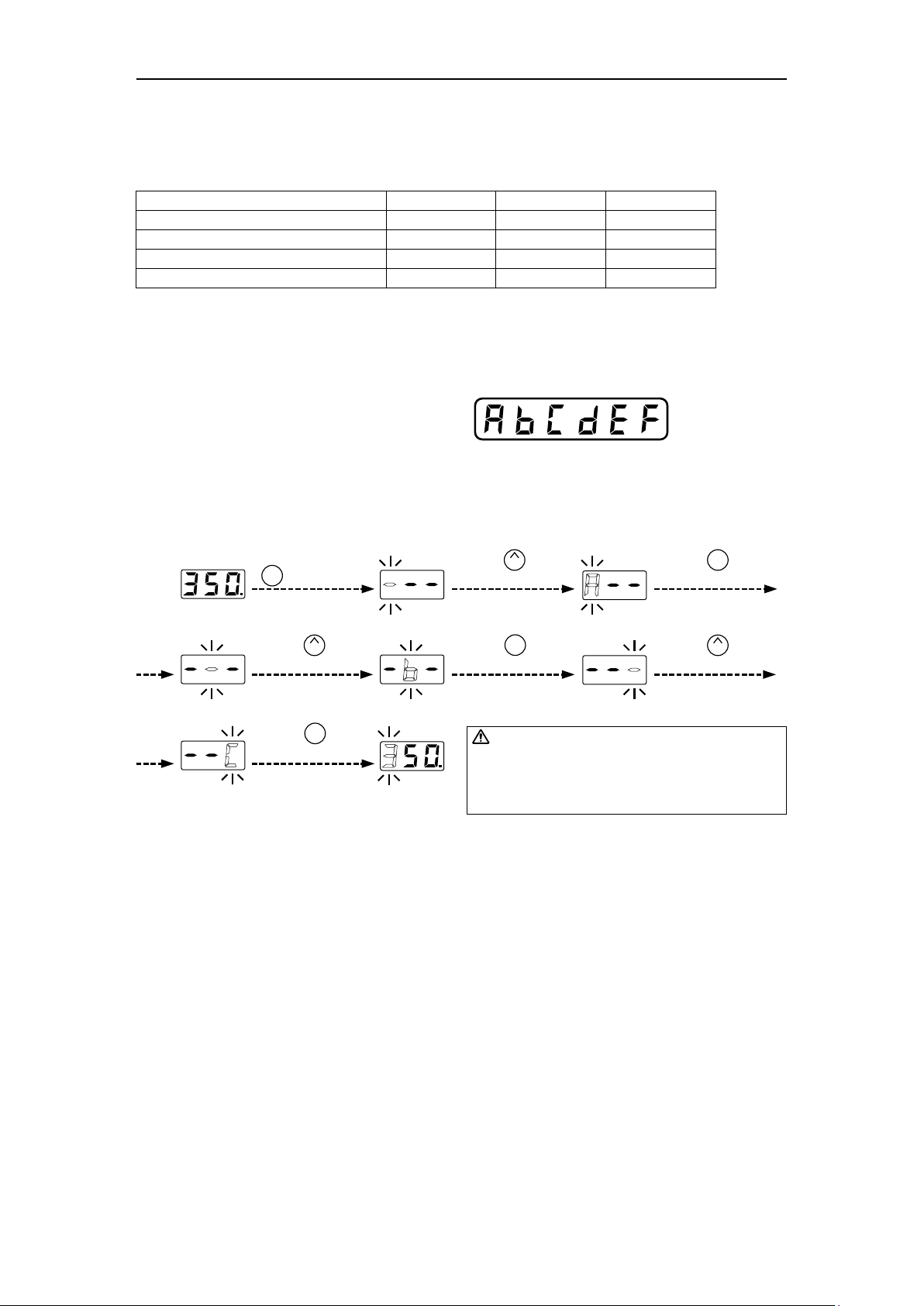

D. Restriction on setting changes (Password function)

It is possible to restrict certain setting changes to the unit.

There are three choices for the password setting. (The factory default is "0 : Open")

Move to the parameter setting mode

Move to the temperature setting mode

Move to the preset selection mode

Move to the adjust mode

0 : Open

○

○

○

○

1 : Partial

×

△

△

△

2 : Restricted

×

×

×

×

○ : You can make changes without entering a password.

△ : You can choose whether or not a password is needed to make changes.

× : A password is required to make changes.

Select and input three letters for password

from six letters on the right.

The letters

for password

Example: The procedure for changing the set temperature when the unit is restricted by a password.

(Password is “AbC”)

Press and hold the

ENTER

button for at

least one second.

Press the button

twice.

UP

Press the button

once.

Press the button

once.

UP

ENTER

Press the button

once.

Press the button

three times.

ENTER

UP

Press the button

once.

ENTER

CAUTION

• If the password you entered is incorrect, the display will

show three dashes for you to re-enter the password.

• If you enter the password incorrectly twice in a row, the

display will return to the previous screen.

The unit will move to the change setting screen for each mode after entering the password.

Please change the setting for each mode according to the procedure.

Enter the parameter setting to change the mode. (Please refer to [6. PARAMETER SETTING])

5

Page 7

6. PARAMETER SETTING

The HAKKO FX-889 has the following parameters.

1

※

2

Parameter No.

※

2

Value

°C / °F

54 – 270°F (30 – 150°C)

0: The normal mode / 1: The preset mode

(2 pcs.) – (5 pcs.)

0: Open / 1: Partial / 2: Restricted

: ○

: ○

: ○

※

4

/ : ×

※

4

/ : ×

※

4

/ : ×

※

4

※

4

※

4

Select three letters

Parameter name

℃/F selection

Low temperature error setting

Setting mode selection

The number of preset

※

Password setting

Temperature setting mode

Preset selection mode

※

Adjust mode

Password

※

1 It is displayed only when “1: Preset mode” is selected in the setting mode.

※

2 It is displayed only when “1: Custom” is selected in the password setting.

※

3 It is displayed only when either “1: Custom” or “2: valid” is selected in the password setting.

※

4 ○: Password not required ×: Password required

2

※

3

● Changing Parameter Setting

The HAKKO FX-889 has four parameters. Parameter settings can be set for A. IRON and B. IRON

respectively.

Initial value

℃

150°C

0

0

-

● : ℃ or ℉ temperature display seletion

The displayed temperature can be switched between Celsius and Fahrenheit.

● : Low temperature error setting

If the sensor temperature goes below the low-limit temperature although heating element is on, an error

will be displayed.

● : Setting mode selection

Temperature setting can be switched between the normal mode and the preset mode.

If selecting the preset mode, you will be asked for the number of preset you required.

Press the button to set the number.

UP

● : Password setting

Select “Open”, “Partial” or “Restricted” for password setting.If selecting the Restricted, perform the

setting for password. If selecting the partial, choose whether or not the password function is needed

when moving to the temperature setting mode, the preset mode and the adjust mode and set the

password.

● Parameter entering mode

1. Turn off the power switch.

2. Turn on the power switch while pressing the button.

UP

3. When the display shows , the station is in parameter entering mode.

6

Page 8

A. ℃ or ℉ temperature display selection

1. Either or will be displayed if you press the button when is displayed.

ENTER

2. and will be switched alternately If you press the button.

3. The display will return to if you press the button after selecting.

ENTER

UP

B. Low temperature error setting

1. Press the button to change the display to .

2. The low-limit temperature will be displayed if you press the button. Enter the value in the same

UP

ENTER

manner as described in the normal mode [5. OPERATION ●The normal mode]

3. The display will return to if you press the button after setting.

ENTER

C. Setting mode selection

1. Press the button to change the display to .

2. If you press the button, the display will move to the setting mode selection screen. If you press

the button, (The normal mode) and (The preset mode) will be switched alternately.

3. The display will return to if you press the button after selecting.

UP

ENTER

UP

ENTER

※

※

If you select the preset mode, the display will move to the preset selection screen.

4. The number of active preset will be displayed If you press the button at 3.

ENTER

(Example : If the number is three, is displayed.)

5. Press the button to change the value and select the number of active preset you required.

UP

The unit will accept values from 2 through 5.

6. The display will return to if you press the button after selecting.

ENTER

7

Page 9

D. Password setting

1. Press the button to change the display to .

2. If you press the button, the display will move to the setting mode selection screen.

If you press the button, (Open), (Partial) and (Restricted) will be switched

UP

ENTER

UP

alternately.

3. If you press the button after selecting, the display will return to . ※1, 2

※

1 The display will move to the following selection screen if you select (Partial).

4. If you press the button at 3, you will be asked whether or not the password function is needed

ENTER

ENTER

when moving to the temperature setting mode.

5. Either (without password) or (with password) will be displayed if you press the

UP

button.

6. If you press the button after selecting, you will be asked whether or not the password function is

ENTER

needed when moving to the preset selection mode.

7. Either (without password) or (with password) will be displayed if you press the

UP

button.

8. If you press the button after selecting, you will be asked whether or not the password function is

ENTER

needed when moving to the adjust mode.

9. Either (without password) or (with password) will be displayed if you press the

UP

button.

10. If you press the button after selecting, the display will move to password setting screen.

※

2 If you select (Restricted), the display will move to the following password setting

ENTER

screen.

If you select (Partial), the display will move to the following the password setting

screen after selecting ※1.

11. The hundreds digits in the display will begin to flash. It indicates that you can enter the value.

Press the button to enter the letter you required.

12. The tens digits in the display will begin to flash if you press the button after entering.

UP

ENTER

Use the same procedure to enter the letters for tens and units digit.

13. The display will return to if you press the button after entering the units digit.

After changing parameters, press and hold the button down for at least two seconds until is

displayed. At this time, you can switch between and by pressing the button. Select

ENTER

ENTER

UP

if you are finished making changes or if you need to go back and make more changes. Press the

ENTER

button to confirm you selection.

Changes will not be completed until is displayed and you press the button.

ENTER

Please note that no changes will be made if you turn off the power while making changes.

8

Page 10

7. MAINTENANCE

Performing proper and periodic maintenance extends product life. Efficient soldering depends upon the

temperature, quality and quantity of the solder and flux.

Apply the following service procedure as dictated by the conditions of usage.

WARNING

Since the soldering iron can reach a very high temperature, please work carefully.

Except the case especially indicated, always turn the power switch OFF and disconnect the

power plug before performing any maintenance procedure.

Tip Maintenance

1. Set the temperature to 250℃ (482℉).

2. When the temperature stabilizes, clean the tip with the cleaning sponge and check the condition of the tip.

3. If the solder plated part of the tip is covered with black oxide, apply fresh solder containing flux, and clean

the tip again. Repeat until all the oxide is removed, then coat the tip with fresh solder.

4. If the tip is deformed or heavily eroded, replace it with a new one.

CAUTION

Do not file the tip in an attempt to remove the black oxide.

● Cleaning the tip using the iron holder

A. Using the cleaning sponge

Use the cleaning sponge that comes with the product to

clean the tip. It offers wide-ranging uses, from simple

C

B

A

● Cleaning of solder fragments

HAKKO FH-801 iron holder has a removable holder base. When solder debris

accumulates, remove the holder base, and properly dispose of the contents.

removal of excess solder to complete elimination of matter

occurring as a result of oxidization.

B. Using the cleaning wire

Material that is not removed easily with the cleaning

sponge can likely be removed using the cleaning wire.

C. Using the rubber plate

Wipe the iron lightly across the rubber ring to remove

excess solder from the tip.

Holder base

Remove

9

Page 11

8. CHECKING PROCEDURE

Disconnect the plug of the cord assembly and

measure the resistance value between the ping

of the connecting plug as follows.

If the values of “a” and “b” are outside the value

in the table, replace the heating element

(sensor) and/or cord assembly.

If the value of “c” is over the value in the table,

remove the oxidization film by lightly rubbing with

sand-paper or steel wool the points shown in the

drawing on the right.

A. Broken Heating Element/Sensor

● Disassembling

a. Between pins 4 & 5

(Heating Element)

b. Between pins 1 & 2 (sensor)

c. Between pin 3 & Tip

2.5 – 3.5 Ω

(at time of room temperature)

43 – 58 Ω

2 Ω or less

Buff lightly.

1. Turn the nut ① counterclockwise and remove the

tip enclosure ② and the tip ③.

2. Turn the nipple ④ counterclockwise and remove it

from the iron.

3. Pull both the heaing element ⑥ and the cord

assembly ⑦ out of the handle ⑧. (Toward the tip of

the iron).

4. Pull the grounding spring ⑤ out of the sleeve of the

terminal ⑨.

Heating element

resistance (red)

Sensor resistance

(blue)

* Measure when the heating element is at room

temperature.

1. Heating element resistance (red) 2.5 – 3.5 Ω

2. Sensor resistance (blue) 43 – 58 Ω

If the resistance value is not normal, replace the

heating element. (Refer to the instructions included

with the replacement part.)

After replacement

1. Measure the resistance between pins 4 and 1, 4 and 2, 5 and 1, and 5 and 2. If it is not ∞, the heating

element and sensor are touching. This will damage the circuit board.

2. Measure the resitance “a,” “b,” and “c” to confirm that the leads are not twisted and that the grounding

spring is properly connected.

B. Broken Cord Assembly

There are two methods of testing the cord

assembly.

1. Turn the unit ON and set the temperature control

knob to 480℃. Then bend the iron cord at various

locations along its length, including in the strain

relief area. The cord assembly needs to be

replaced if S-E is displayed or although the LED

heater lamp flashes, the tip temperature doesn’t

rise.

CAUTION

The power lamp starts to flash when the

temperature reaches 480°C (880°F) regardless

of the condition of the cord.

2. Check the resistance between the plug pin and the

terminal lead.

Pin 1: Red Pin 2: Blue Pin 3: Green Pin 4: White

Pin 5: Black

Resistance: 0 Ω.

If it is higher than 0 Ω or is ∞, the cord should be

replaced.

10

Page 12

9. ERROR MESSAGES

● Sensor Error

● Low-temperature alarm

tolerance error

EXAMPLE:

350°C (400°C – 50°C)

Set temperature

650°F (750°F – 100°F)

Set temperature Low-temperature

Low-temperature

alarm tolerance

OR

alarm tolerance

When there is the possibility that a failure has occurred in the sensor or

heater (including the sensor circuit), is displayed and the power is

shut down.

CAUTION

The sensor error also occurs if the tip is not inserted properly.

If the sensor temperature falls below the difference between the current

temperature setting and the low-temperature alarm tolerance, is

displayed and the warning buzzer sounds. When the tip temperature

rises to a value within the set tolerance, the buzzer will stop sounding.

EXAMPLE:

Assume that the temperature setting is 400°C/750°F and the

tolerance 50°C/100°F. If the temperature continues to decrease and

finally falls below the value indicated below while the heating element

is on, the displayed value starts blinking to indicate that the tip

temperature has dropped.

11

Page 13

10. TROUBLE SHOOTING GUIDE

WARNING

Before checking the inside of the HAKKO FX-889 or replacing parts, be sure to disconnect the power plug.

● Nothing happens when the power

switch is turned on.

● The heater lamp lights up but the tip

does not heat up.

● The Heater-error is displayed.

● The tip heats up intermittently.

CHECK : Is the power cord and/or connecting plug disconnected?

ACTION : Connect it.

CHECK : Is the fuse blown?

ACTION : Determine why the fue blew and eliminate the cause, then

replace the fuse.

a. Is the inside of the iron short-circuited?

b. Is the grounding spring touching the heating element?

c. Is the heating element lead twisted and short-circuited?

Try replacing the fuse even if the cause cannot be identified.

If it still blows, return the product for repair.

CHECK : Is the cord assembly broken? Is the heating element/

sensor broken?

ACTION : If the cord assembly is broken, replace the HAKKO FX-8801.

If the heating element / sensor is broken, replace the heating

element.

a. Between pins 4 & 5 (Heating Element) 2.5 - 3.5 Ω (at time of room temperature)

b.

Between pins 1 & 2 (sensor) 43 - 58 Ω

c.

Between pin 3 & Tip 2 Ω or less

CHECK : Is the heater broken?

ACTION : If the heater is broken, replace the heating element.

CHECK :

ACTION : Increase the setting value.

CHECK : Is the cord assembly broken?

ACTION : If the cord assembly is broken, replace the HAKKO FX-8801.

Is the setting value for the low-temperature alarm tolerance too low?

● Solder does not wet to the tip.

● The tip temperature is too low.

● The tip can not be pulled off.

● The tip doesn’t hold the desired

temperature.

CHECK : Is the tip temperature too high?

ACTION : Set an appropriate temperature.

CHECK : Is the tip coated with black oxide?

ACTION : Remove the black oxide. (Refer to “Tip Maintenance.”)

CHECK : Is the tip coated with black oxide?

ACTION : Remove the black oxide. (Refer to “Tip Maintenance.”)

CHECK : Is the iron temperature adjusted correctly?

ACTION : Perform the temperature adjustment.

CHECK : Is the tip seized? Is the tip swollen because of deterioration?

ACTION : Replace the tip and the heating element.

CHECK : Is the iron temperature adjusted correctly?

ACTION : Perform the temperature adjustment.

12

Page 14

11. PARTS LIST (Station)

②

SEMS screw

M4×8 (4) P3

⑨

⑥

Tapping screw

P tight

DN4×10 (4)

External tooth lock washer

DN4 (1)

⑩

SEMS screw

M4×8 (2) P2

⑦

External tooth

lock washer

DN4 (1)

⑧

Tapping screw

P tight

DN3×6 (8)

External tooth

lock washer

DN4 (1)

④

③

13

①

⑥

⑤

⑤

● HAKKO FX-889 station

Item No.

1

2

3

4

5

6

7

8

9

Part No.

B5110

B5 111

B3736

B5112

B5113

B5114

B3463

B5123

B5279

B5280

B2468

B5124

B5125

Part Name

Front panel

Cover

P.W.B.

Transformer

Transformer

Transformer

Receptacle

Switch

Inlet/100 - 120V

Inlet/200 - 240V

Fuse

Fuse

Color band

⑥

Specifications

for temperature control

100 - 110V

120V

220 - 240V

with varistor

with varistor

100 - 120V

220 - 240V

set of 2

③

Item No.

10

Part No.

B2419

B2421

B2422

B2424

B2425

B2436

B2426

B3508

B3550

Tapping screw

P tight

DN4×10 (4)

Part Name

Power cord, 3-wire cord

& American plug

Power cord, 3-wire cord

but no plug

Power cord, 3-wire cord

& BS plug

Power cord, 3-wire cord

& European plug CE

Power cord, 3-wire cord

& BS plug CE

Power cord, 3-wire cord

& Chinese plug

Power cord, 3-wire cord

& Australian plug

Power cord, 3-wire cord

& American plug (B)

Power cord, 3-wire cord

& SI plug

Specifications

USA

220-240V

India

220VKTL,230VCE

230VCE,U.K

China

Page 15

12. PARTS LIST (Soldering iron)

●

Item No.

1 ~ 11

●

Item No.

HAKKO FX-8801 Soldering iron

Part No.

FX8801-01

Part Name

HAKKO FX-8801

Soldering iron parts

Part No.

B1785

1

B3469

2

3

B2022

4

B2032

5

A1560

6

B2028

7

B3470

8

B3471

9

B3467

10

B3468

11

Part Name

Nut

Tip enclosure

Tip

Nipple

Grounding spring

Heating element

Terminal board

Handle

Handle cover

Cord bushing

Cord assembly

See “13. TIP STYLES”

26V-65W

with cord stopper

with handle cover

Specifications

Specifications

②

①

Optional Parts

●

Item No.

Part No.

1

B5122

Part Name

Tip enclosure assembly

Specifications

* If you use the capacious tip T19, change to above tip

enclosure

assembly

. Please see the tip styles and tip shape

for T19 from the following URL.

⇨ https://www.hakko.com

● HAKKO FH-801

Part No.

FH801-81

● Iron holder parts

Part No.

Item No.

1

A1519

2

A1561

Part Name

HAKKO FH-801

Part Name

Cleaning sponge

Cleaning wire

Specifications

with cleaning sponge,

cleaning wire

Specifications

14

Page 16

13. TIP STYLES

T18-B Shape-B T18-SB Shape-SB T18-BR02 Shape-0.2BR T18-BL Shape-BL T18-C05 Shape-0.5C

R0.5

(0.020)

14.5

(0.57)

T18-C08 Shape-0.8C T18-C1 Shape-1C

Φ0.8

(0.031)

0.8

45°

(0.031)

T18-C3 Shape-3C

T18-CF3*

3.2

(0.13)

15.5

(0.61)

Φ3

(0.12)

45°

14.5

(0.57)

4.2

(0.17)

R0.2

(0.008)

(0.52)

T18-CF1*

Φ1

(0.04)

60°

1

(0.04)

13.5

(0.53)

T18-C4 Shape-4C

T18-CF4*

Φ4

(0.16)

45°

14.5

(0.57)

13.2

4

(0.16)

30°

R0.2

10.5

(0.008)

(0.41)

T18-CF15* Shape-1.5C T18-C2 Shape-2C

Φ1.5

(0.06)

60°

1.6

(0.06)

13.5

(0.53)

T18-C5 Shape-5C T18-K Shape-K T18-D08 Shape-0.8D

Φ5

(0.20)

5

45°

(0.20)

14.5

(0.57)

R0.2

(0.008)

T18-CF2*

2.1

(0.08)

(0.08)

Φ0.5

(0.020)

0.5

45°

22.5

(0.89)

(0.020)

13.5

(0.53)

T18-CSF25* Shape-2.5CS

Φ2

(0.08)

45°

14.5

(0.57)

Φ5

(0.20)

45°

2

14

(0.55)

2.5

(0.10)

0.6

(0.024)

Φ0.8

Φ2.5

(0.031)

(0.10)

45°

(0.39)

14.5

(0.57)

10

T18-D12 Shape-1.2D T18-D16 Shape-1.6D T18-D24 Shape-2.4D T18-D32 Shape-3.2D T18-DL12 Shape-1.2DL

Φ1.2

(0.05)

0.7 14.5

(0.028)

(0.57)

Φ1.6

(0.06)

0.5 14.5

(0.020) (0.57)

Φ2.4

(0.09)

0.5 14.5

(0.020)

(0.57)

Φ3.2

(0.13)

14.5

0.5

(0.57)(0.020)

0.7

(0.028)

Φ1.2

(0.05)

22.5

(0.89)

T18-DL2 Shape-2DL T18-DL32 Shape-3.2DL T18-S3 Shape-S3 T18-S4 Shape-S4 T18-S6 Shape-S6

(0.04)

Φ2

(0.08)

1

22.5

(0.89)

(0.04)

Φ3.2

(0.13)

1

22.5

(0.89)

(0.04)

Φ5.2

(0.20)

1

18

(0.71)

R0.125

(0.005)

14.5

(0.57)

Φ1.3

(0.05)

60°

1.7

(0.07)

16.5

(0.65)

T18-S9 Shape-S9 T18-I Shape-I

R0.2

(0.008)

14.5

(0.57)

* Tinned on the soldering surface only.

● Use only genuine HAKKO soldering iron tips. Replacement tips

for the HAKKO FX-8801 are designated the T18 series.

0.4

(0.016)

Φ1.2

(0.05)

15.5

(0.61)

15

Page 17

14. WIRING DIAGRAM

Ground(Chassis) Ground(Chassis)

Receptacle

1

2

P.W.B.

Black

5

Black

4

3

Green/Yellow

Switch

Black

Red

H1H226V 0V

SE1

SE2

Red

White

White

White

White

Receptacle

1

2

P.W.B.

Black

5

Black

4

3

Green/Yellow

Switch

Black

Ground(Chassis)

0V26VH2H1

Black

Red

Red

Black

Transformer

SE2

SE1

Red

Green/Yellow

White

Varistor

Black

Power receptacle

Main power-supply

switch

16

Page 18

※各言語(日本語、英語、中国語、フランス語、ドイツ語、韓国語)の取扱説明書は以下の URL、

HAKKODocumentPortal からダウンロードしてご覧いただけます。

(商品によっては設定の無い言語がありますが、ご了承ください。)

* 各國語言(日語、英語、中文、法語、德語、韓語)的使用説明書可以通過以下网站的 HAKKO

DocumentPortal下載參閲。

(有一部分的產品沒有設定外語對應、請見諒)

* Instruction manual in the language of Japanese, English, Chinese, French, German, and Korean

can be downloaded from the HAKKO Document Portal.

(Please note that some languages may not be available depending on the product.)

https://doc.hakko.com

HEAD OFFICE

4-5, Shiokusa 2-chome, Naniwa-ku, Osaka 556-0024 JAPAN

TEL: +81-6-6561-3225 FAX: +81-6-6561-8466

https:// www.hakko.com E-mail: sales@hakko.com

OVERSEAS AFFILIATES

U.S.A.: AMERICAN HAKKO PRODUCTS, INC.

TEL: (661) 294-0090 FAX: (661) 294-0096

Toll Free (800) 88-HAKKO

4 2 5 5 6

https:// www.HakkoUSA.com E-mail: Support@HakkoUSA.com

HONG KONG: HAKKO DEVELOPMENT CO., LTD.

TEL: 2811-5588 FAX: 2590-0217

https:// www.hakko.com.cn E-mail: info@hakko.com.hk

SINGAPORE: HAKKO PRODUCTS PTE., LTD.

TEL: 6748-2277 FAX: 6744-0033

https:// www.hakko.com.sg E-mail: sales@hakko.com.sg

Please access the web address below for other distributors.

https://www.hakko.com

© 2016-2020 HAKKO Corporation. All Rights Reserved.

MA02818XZ200326

2020.3

Loading...

Loading...