Page 1

SolderingStation

Instruction Manual

●

ThankyouforpurchasingtheHAKKOFX-801SolderingStation.

PleasereadthismanualbeforeoperatingtheHAKKOFX-801.

Keepthismanualreadilyaccesibleforreference.

●

TABLEOFCONTENTS

1. PACKING LIST

2. SPECIFICATIONS

3. WARNINGS, CAUTIONS AND NOTES

4. PART NAMES

5. INITIAL SETUP

6. OPERATION

7. PARAMETER SETTING

8. MAINTENANCE

9. CHECKING PROCEDURE

10. ERROR MESSAGES

11. TROUBLE SHOOTING GUIDE

12. PARTS LIST

13. WIRING DIAGRAM

........................................................ 1

................................................... 1

......................................................... 3

........................................................ 4

............................................................ 5

........................................ 10

..................................................... 16

.................................... 17

............................................. 18

............................. 19

.......................................................... 21

................................................ 23

.................. 2

Page 2

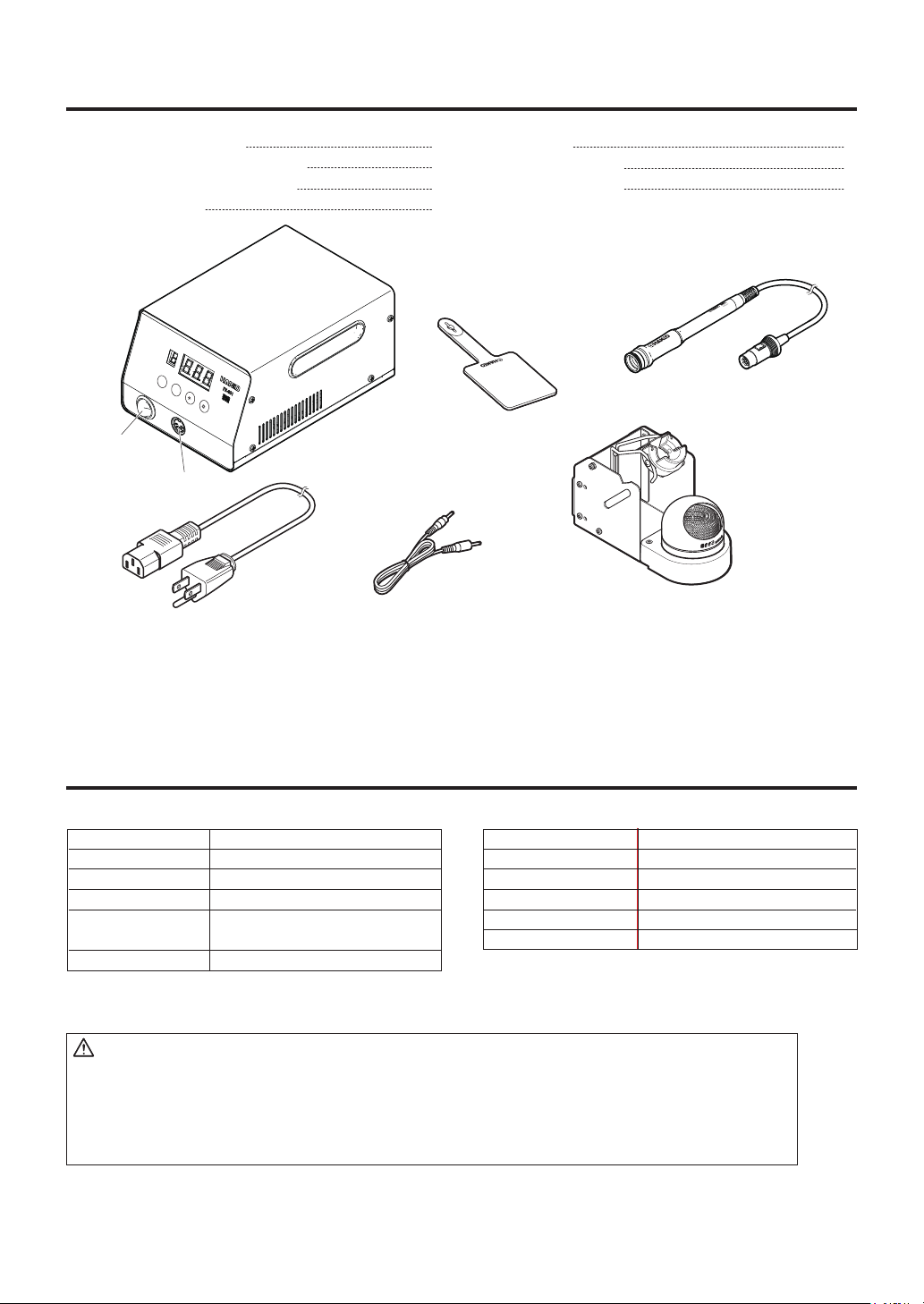

1. PACKING LIST

Please check to make sure that all items listed

below are included in the package.

HAKKO FX-801 Station

HAKKO FX-8002 Soldering iron

Iron holder (with cleaning wire)

Connecting cable

UP

DOWN

Power

switch

Receptacle

Power cord

HAKKO FX-801

Power cord

1

Heat resistant pad

1

Instruction manual

1

1

Heat resistant pad

Connecting cable

1

1

1

FX-8002

HAKKO FX-8002

Iron holder

* Tip (T33 series) is optionally

available.

2. SPECIFICATIONS

● HAKKO FX-801

Power consumption

Temperature range

Temperature stability

Output Voltage

Dimensions

Weight

* The temperature was measured using the FG-100 thermometer.

* This product is protected against electrostatic discharge.

* Specifications and design are subject to change without notice.

300W

50 - 500℃ (120 - 940℉)

± 5℃ (± 9℉) at idle temperature

AC 29V

145(W)×107(H)×211(D) mm

(5.7 × 4.2 × 8.3 in.)

3.9 kg (8.6 lb.)

CAUTION

This product includes such features as electrically conductive plastic parts and grounding of the handpiece and station as

measures to protect the device to be soldered from the effects of static electricity. Be sure to observe the following instructions:

1. The handle and other plastic parts are not insulators, they are conductors. When replacing parts or repairing,

take sufficient care not to expose live electrical parts or damage insulation materials.

2. Be sure to ground the unit during use.

1

● HAKKO FX-8002

Power Consumption

Tip to Ground Resistance

Tip to Ground Potential

Cord

Total Length (w/o cord)

Weight (w/o cord)

260W (29V)

< 2 Ω

< 2 mV

1.2 m (4 ft)

228 mm (9.0 in.) with 4BC tip

50 g (0.11 lb.) with 4BC tip

Page 3

3. WARNINGS, CAUTIONS AND NOTES

Warnings, cautions and notes are placed at critical points in this manual to direct the

operator’s attention to significant items. They are defined as follows:

Failure to comply with a WARNING may result in serious injury or death.WARNING:

CAUTION :

Failure to comply with a CAUTION may result in injury to the operator, or damage to the

items involved.

WARNING

When power is ON, the tip will be hot.

To avoid injury or damage to personnel and items in the work area, observe the following:

● Do not touch the tip or the metal parts near the tip.

● Do not allow the tip to come close to, or touch, flammable materials.

● Inform others in the area that the unit is hot and should not be touched.

● Turn the power off when not in use, or left unattended.

● Turn the power off when changing parts or storing the HAKKO FX-801.

● This appliance can be used by children aged from 8 years and above and

persons with reduced physical, sensory or mental capabilities or lack of

experience and knowledge if they have been given supervision or instruction

concerning use of the appliance in safe way and understand the hazards

involved.

● Children shall not play with the appliance.

●

Cleaning and user maintenance shall not be made by children without supervision.

● The unit is for a counter or workbench use only.

To prevent accidents or damage to the HAKKO FX-801, be sure to observe the following:

CAUTION

● Do not use the HAKKO FX-801 for applications other than soldering.

● Do not strike the iron against hard objects to remove excess solder.

This will damage the iron.

● Do not modify the HAKKO FX-801.

● Use only genuine Hakko replacement parts.

● Do not allow the HAKKO FX-801 to become wet, or use it with wet hands.

● Remove power and iron cords by holding onto the plug.

● Be sure the work area is well ventilated. Soldering produces smoke.

● Be sure the cooling fan at the rear of the station is unrestricted.

● While using the HAKKO FX-801, don’t do anything which may cause bodily harm or

physical damage.

2

Page 4

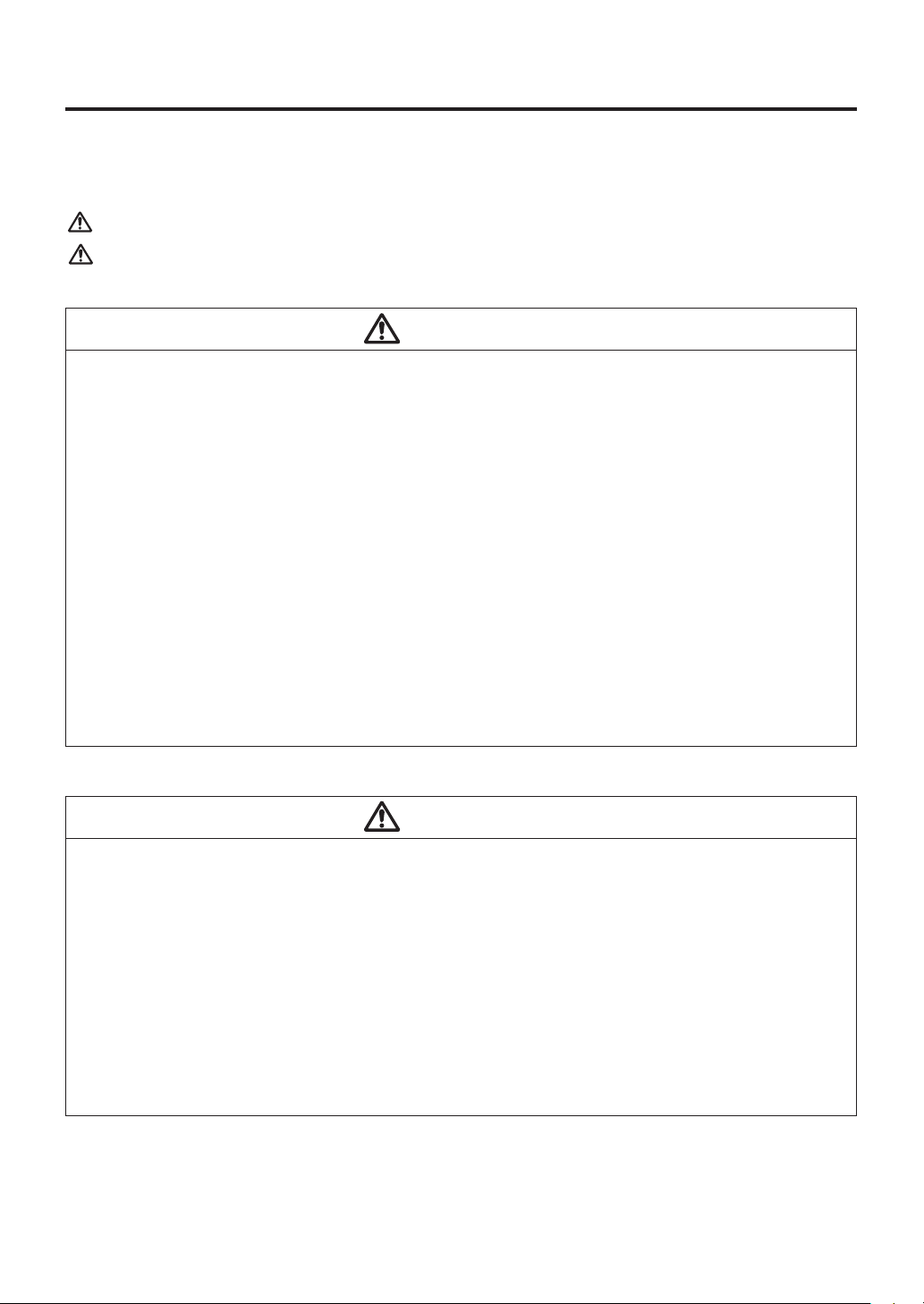

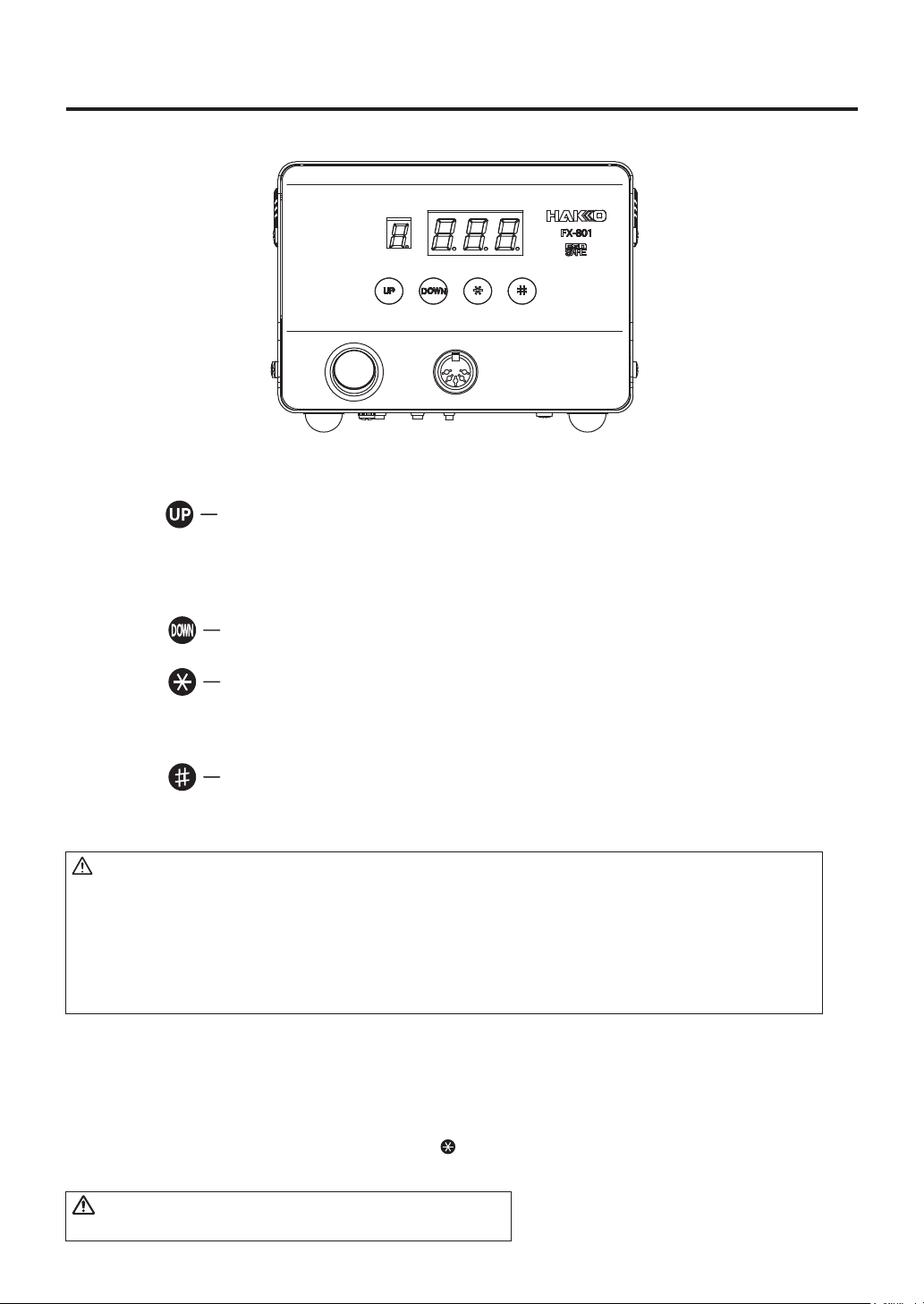

4. PART NAMES

● HAKKO FX-801

Preset number display

Setting display

Control buttons

Power switch

Jack

(for connecting

cable)

Receptacle

Power cord

receptacle

Fuse

3

Page 5

5. INITIAL SETUP

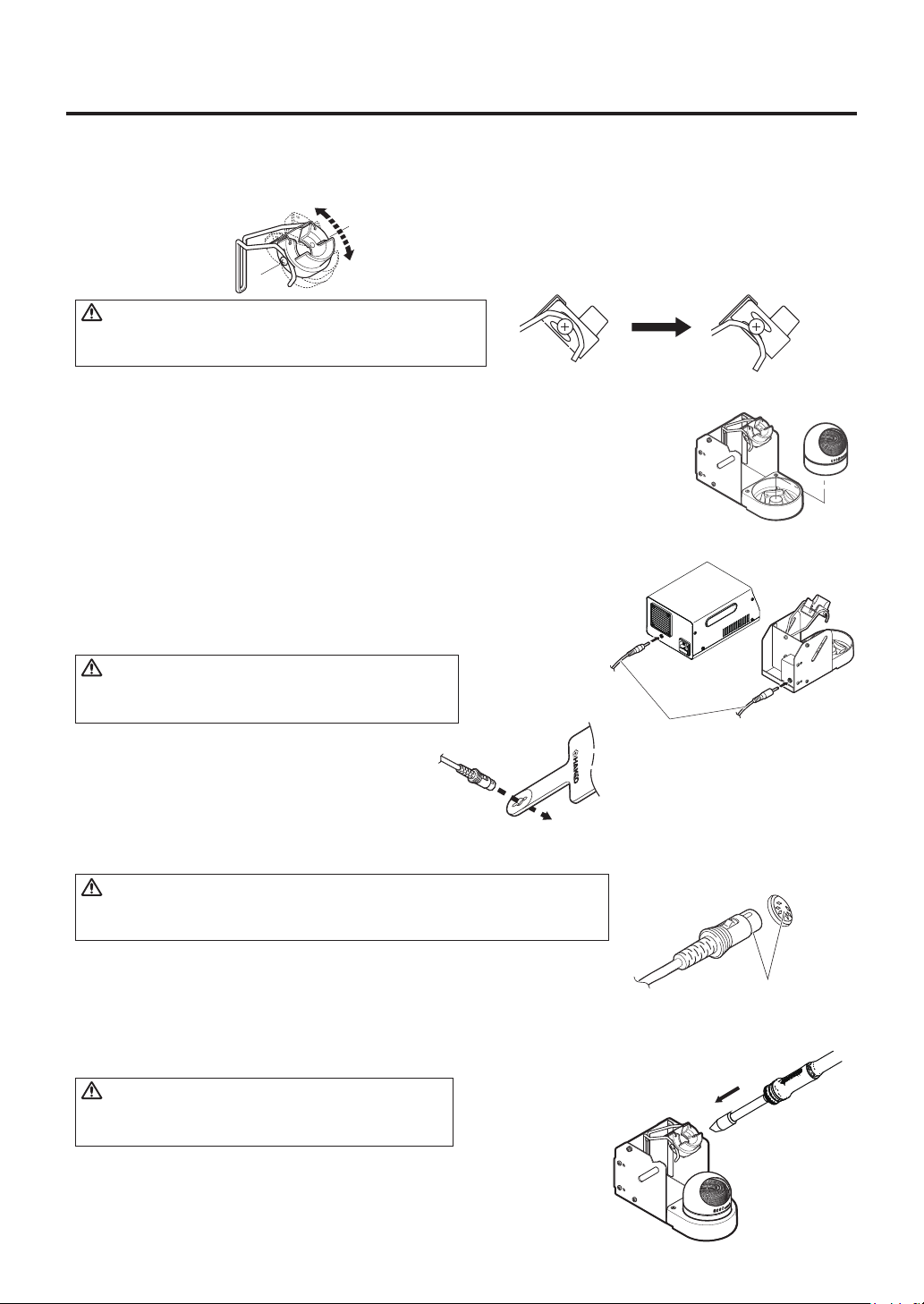

A. Iron holder

● Loosen the adjusting screws to change the angle

of the iron receptacle as you like, then tighten the

screws.

CAUTION

Do not set up the iron receptacle too high, the

temperature of the soldering iron will become very hot.

1. Assemble as shown:

● Insert the tip cleaner securely into the Iron holder base.

2. Operation:

First, remove any excess solder from the tip by thrusting the tip into the cleaning

wire. (Do not wipe the tip against the wire. This may cause molten solder to

spatter.) When the wire becomes dirty or loaded with solder, turn the wire until a

clean surface is presented. When changing the cleaning wire, lift the case top

vertically to prevent solder debris from falling out.

● Use of the sleep function.

When using the sleep function, insert one end of the connecting cable

into the jack at the back of the iron holder and the other end into the

jack at the back of the soldering station to connect them.

CAUTION

Be sure to turn off the power before connecting or

disconnecting the connecting cable.

The iron receptacle has two grooves. If the edge

of the iron tip is likely to come into contact with the

iron holder or the iron holder becomes hot, use the

alternate groove to attach the iron receptacle.

Normal conditions

If the iron holder

becomes hot

Connecting cable

B. Handpiece cord assembly

Pass the iron cord through the hole in the heat

resistant pad.

C. Soldering station

CAUTION

Be sure the power switch is OFF before connecting or disconnecting the

soldering iron cord. Failure to do so may result in damage to the circuit board.

1. Insert the power cord into the receptacle at the back of the station.

Insert the soldering iron cord into the receptacle at the front of the

station.

2. Set the iron in the iron holder.

3. Plug the power cord into a grounded wall socket.

CAUTION

The HAKKO FX-801 is protected against electrostatic

discharge and must be grounded for full efficiency.

Insert the plug into

the receptacle until

it clicks.

To disconnect, pull the plug

from the receptacle while

pressing down the tab on

the plug.

4

Page 6

6. OPERATION

The HAKKO FX-801 has the following four control buttons.

Press for less than one second to enter preset number selection screen.

Press and hold for at least one second to enter preset temperature

changing screen.

Use to increase the value in the appropriate display window.

Use to decrease the value in the appropriate display window.

Press for less than one second to display the current set temperature.

Press and hold for at least one second to enter temperature setting mode.

Use to end the current operation.

Press for less than one second to display the current offset value.

Press and hold for at least one second to enter offset mode.

CAUTION

An audible buzzer is provided to alert the operator when:

● The station has reached the set temperature, a buzzer will sound once.

● The low temperature threshold has been crossed, a buzzer will sound continuously.

This buzzer will shutoff when the sensed temperature returns to the acceptable range.

● There is the possibility that a failure has occured in the sensor or heater, a buzzer will

sound continuously.

Operation

1. Turn on the power switch.

2. Once the set temperature is reached, a buzzer sounds once.

By default, the temperature is set to 350℃ (750℉ for US model).

Check the temperature setting by pressing the button.

The set temperature will be displayed for two seconds.

WARNING

Place soldering iron in iron holder when not in use.

5

Page 7

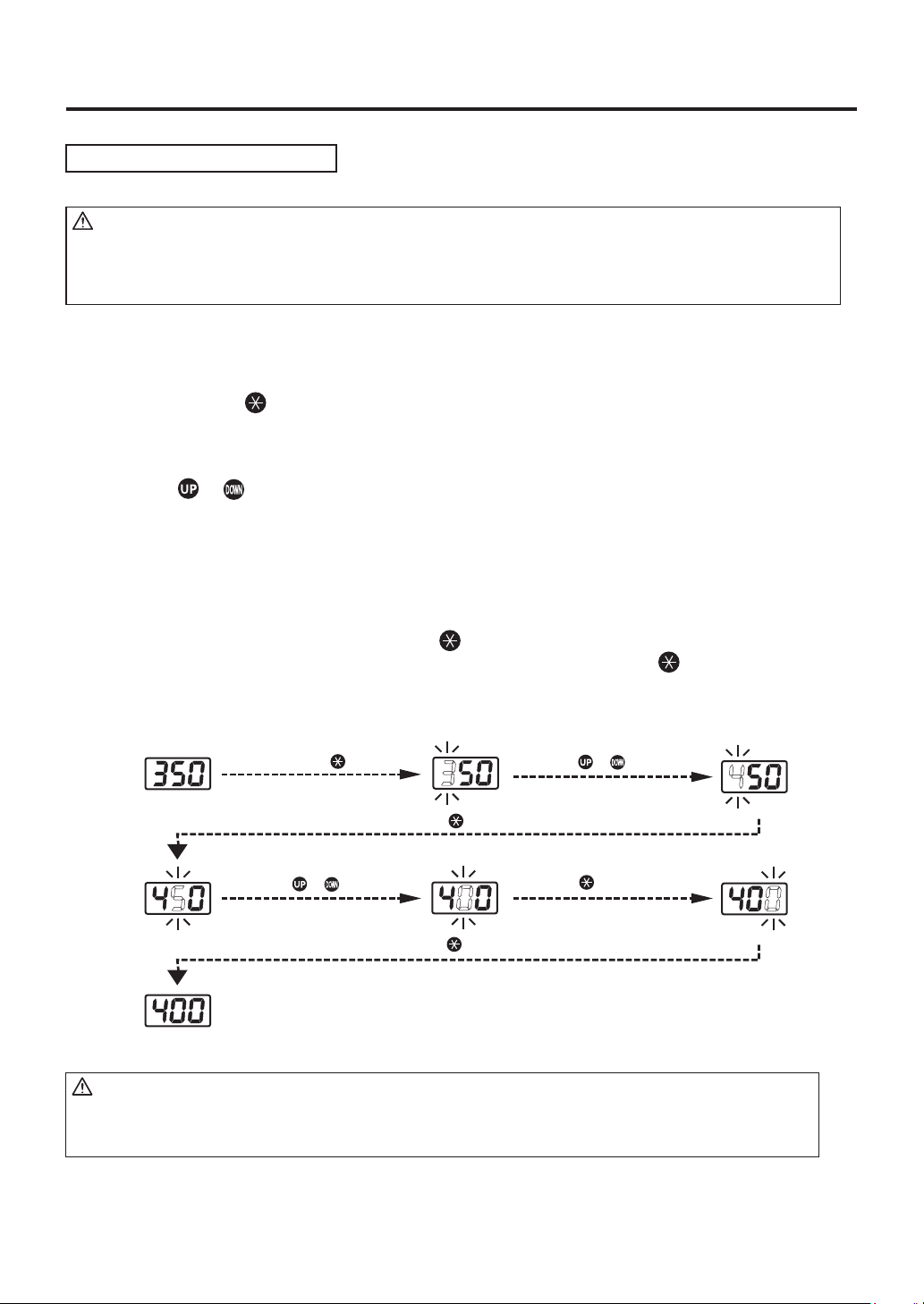

Changing temperature setting

CAUTION

The temperature setting range is from 50℃ to 500℃. (120℉ to 940℉)

●If you enter a value outside the temperature setting range, the display returns to the hundreds

digit, and you have to enter a correct value.

Example:Changing set temperature from 350 to 400℃

1.Press and hold the button for at least one second.

The hundreds digit will begin to flash.

2. Entering the value.

Press the or to set the value of the digit that is flashing.

Only values from 0 to 5 can be selected when entering the hundreds digit.

(In ℉ mode, values from 1 to 9 can be selected.)

Values from 0 to 9 can be selected when entering the tens or ones digit.

(The same values can be selected in ℉ mode.)

When desired figure is displayed, press the button to accept the value.

The next digit will begin to flash. After entering the ones digit, press the button to save

the value to the system memory and begin heater control with new setting temperature.

Press and hold the button

for at least one second.

Press the button once.

Press the or button.

Press the button once.

Press the or button.

Press the button once.

CAUTION

If power is switched off or lost during the execution of this procedure, no data will be entered.

The entire procedure must be repeated from step 1.

6

Page 8

Selecting the preset number

You can quickly select one of six user programmable preset temperatures.

Initial preset temperatures are: 0:300℃, 1:350℃, 2:375℃, 3:400℃, 4:450℃ and 5:500℃.

Example:Changing preset No. 0 (300℃) to No. 3 (400℃)

1. Press the button once.

Preset number display will begin to flash.

2. Press the button three times to change the preset number display to .

3. Press the to set the value.

Press the button

once.

Press the button

three times.

Press the button

once.

Changing the preset temperature

You can change any of the six available preset temperatures. (Preset No. 0 to No. 5)

Example:Changing Preset No. 3 temperature from 400℃ to 410℃.

1. Press and hold the button for at least one second.

Both preset number display and setting display will begin to flash.

2. Press the button three times to change the preset number display to .

3. Press the button to set the value.

4. Use the method for setting the temperature to enter and set the preset temperature.

Press and hold the button

for at least one second.

Press the button once.

Press the button

three times.

Press the button once.

Press the button once.

Press the button once.

Press the button once.

7

Page 9

Entering the tip offset value

Example:If the measured temperature is 410℃ and set temperature is 400℃, the difference

is -10℃ (need to decrease by 10℃). So enter a value so 10 is deducted from present

offset value.

1. Press and hold the button for at least one second.

The hundreds digit will begin to flash, the unit will enter the offset mode.

2. Enter the offset value (-10) which is the difference between tip temperature and set temperature.

The allowable ranges for offset values are from -50 to +50℃ (In ℉ mode, from -90 to +90℉)

If you enter a value outside the offset value range, the display returns to the hundreds digit,

and you have to enter a correct value.

3. Entering the value.

Press the or button to set the desired figure.

The hundreds digit can display 0 (for positive value) or minus sign (for negative value)

(Same values can be selected in ℉ mode.)

Values from 0 to 5 can be selected when entering the tens digit.

(In ℉ mode, values from 0 to 9 can be selected.)

Values from 0 to 9 can be selected when entering the ones digit.

(Same values can be selected in ℉ mode.)

After entering the ones digit, press the button to save the value to the system memory

and begin heater control with the new offset value.

Press and hold the button

for at least one second.

Press the button

once.

Press the button

once.

Press the button

once.

Press the button

once.

CAUTION

Do not enter an offset that allows the tip to exceed 500 ℃.

8

Page 10

Restriction on setting changes (Password function)

It is possible to restrict certain setting changes to the unit.

There are three choices for the password setting. (The factory default is "0 : Open")

0 : Open

Parameter setting mode

Temperature setting mode

Preset selection mode

Offset mode

○

○

○

○

○ : You can make changes without entering a password.

△ : You can choose whether or not a password is needed to make changes.

×: A password is required to make changes.

Select and input three letters for the password

from six letters on the right.

Example : The procedure for changing the set temperature when the unit is restricted by a password.

(Password is "AbC")

1 : Partial

×

△

△

△

2 : Restricted

×

×

×

×

Press and hold the button

for at least one second.

Press the button once.

Press the button twice.

Press the button three times.

Press the button once.

Press the button once.

CAUTION

・If the password you entered is incorrect, the

Press the button once.

display will show three dashes for you to re-enter

the password.

・If you enter the password incorrectly twice in a

row, the display will return to the previous screen.

The unit will enter the change setting screen for each mode after entering the password.

Please change the setting for each mode according to the procedure.

(In the above example, please refer to the procedure for setting the temperature.)

Enter the parameter setting to change the mode. (Please refer to [7. PARAMETER SETTING])

9

Page 11

7. PARAMETER SETTING

Parameter name

Temperature display

Auto sleep time setting

Low temperature error setting

Buzzer setting

(S-E sound , C-E sound)

Buzzer setting

(set temperature achieving alert)

Auto sleep on/off setting

Auto shutoff on/off setting

Power-mode setting

Auto sleep temperature setting

Password lock setting

Changing the set temperature

Changing the preset number

Changing the offset value

Password

Auto shutoff time setting

* ○ : Password not required × : Password required

** For U.S.A.

Parameter number

Settings

℉( )/℃( )

0 - 29 min.

30 - 300℃ (54 - 540℉)

OFF( )/ON( )

OFF( )/ON( )

OFF( )/ON( )

OFF( )/ON( )

High power( )/Normal power( )

200 - 300℃ (390 - 580℉)

Open

( ) /

: ○* / : ×*

: ○* / : ×*

: ○* / : ×*

30 - 60 min.

Partial

( ) /

Select three letters

Restricted

Initial value

℃ (℉**)

6 min.

300℃ (540℉**)

ON ( )

ON ( )

ON ( )

OFF ( )

High power( )

200℃ (400℉**)

Open( )

( )

30 min.

Turn on the power switch while pressing the button, the station will enter the parameter

setting mode. (When the display shows flashing, the station is in the parameter setting mode.)

Use the or button to select parameter number and press the button to move to next step.

Use the or button to select and press the button to set the desired parameter value.

After the necessary parameters are set, press and hold the button for at least one second.

The display changes to (Yes) and press the button to exit the parameter entry mode.

If you press the or button to select (No), you will return to previous screen.

CAUTION

If the power is switched off or lost during the execution of this procedure, no data will be entered.

10

Page 12

● :℃ or ℉ temperature display selection

1. In display setting mode, either

or

is displayed

: The display shows temperatures in Celsius

: The display shows temperatures in Fahrenheit

2.

3. The display will return to

and

will be switched alternately if you press the ( ) button.

if you press the button after selection.

● :Auto sleep time setting

Set the time until the auto sleep function activates after the soldering iron is set on the iron holder.

Auto sleep examples:

NOTE:The auto sleep time can be set in units of minutes (up to 29 minutes).

When the display is

Sleep activated (immediately after the iron is set on the iron holder)

Sleep activated (10 minutes after the iron is set on the iron holder)

, press the or button, or remove the soldering iron from the

iron holder to resume power to the heater.

Select a parameter

number 02

The display will return to

Press the or botton

Press the button once

Press the button once

Press the or botton

if you press the button after selection.

CAUTION

• When the temperature setting is 300ºC (570ºF) or less, the sleep function will not activate

Sleep even if the sleep function is turned ON.

• The tip temperature will rise to the set temperature during the initial power up even if the sleep

time is set to “0” . The tip temperature will be reduced to the sleep temperature after the

temperature reaches the set temperature.

11

Page 13

● : Low temperature error setting

When the temperature drops below a set limit, an error is displayed and the buzzer sounds.

When the temperature returns within the allowable range, the buzzer stops.

Low temperature setting range : for Celsius: 30 to 300ºC

for Fahrenheit: 54 to 540ºF

Example : When the set temperature is 350ºC and the low temperature error setting is 100ºC, a

warning buzzer sounds when the temperature drops to 250ºC.

1. The hundreds digit begins to flash when entering the low temperature setting.

2. If you enter a value outside the low temperature setting range (see the acceptable range above),

the display returns to the hundreds digit, and you have to enter a correct value.

3. The display will return to

if you press the button after selection.

● : S-E, C-E Buzzer sound setting mode

1. In the buzzer sound setting mode, either

: The buzzer does not sound if a sensor or connector error occurs.

: The buzzer sounds if a sensor or connector error occurs.

2.

3. The display will return to

and

will be switched alternately if you press the ( ) button.

if you press the button after selection.

or

is displayed.

● : Set temperature alert setting mode

1. In the set temperature alert setting mode, either

: The buzzer does not sound when the soldering iron reaches the set temperature.

: The buzzer sounds when the soldering iron reaches the set temperature.

2.

3. The display will return to

and

will be switched alternately if you press the ( ) button.

if you press the button after selection.

or

is displayed.

● : Auto sleep on/off setting

NOTE: When the auto sleep function is on, removing the iron from the iron holder or pressing the

button resumes operations.

1. In the auto sleep setting mode, either

: The auto sleep function is off, regardless of the auto sleep set time.

: The auto sleep function is on, and the auto sleep time is activated.

2.

3. The display will return to

and

will be switched alternately if you press the ( ) button.

if you press the button after selection.

or

is displayed.

12

Page 14

● : Auto shutoff on/off setting

When the auto shutoff function is set to on and no operation is performed for 30 minutes (

) after the iron is set in the iron holder, the buzzer sounds and the auto shutoff function will be

value

enabled. Leaving the iron in the iron holder as it is, the buzzer sounds every 30 minutes.

1. In the auto shutoff setting mode, either

: The auto shutoff function is off, regardless of the auto sleep function set time.

: The auto shutoff function is on, and the auto shutoff time is activated.

2.

3. The display will return to

and

will be switched alternately if you press the ( ) button.

if you press the button after selection.

or

is displayed.

Initial

● : Power-mode setting

NOTE: High-power mode is mainly suited for applications that require large heat capacity such

as quick soldering of ground patterns or cast metal products.

1. In the Power-mode setting mode, either

: Selects High power mode.

: Selects Normal power mode.

or

is displayed.

2.

3. The display will return to

CAUTION

If the tip is overloaded, it may cause overshooting.

and

will be switched alternately if you press the ( ) button.

if you press the button after selection.

● : Auto sleep temperature setting

Sets the auto sleep temperature. Setting a high sleep temperature enables shorter start up time

when the unit recovers from sleep mode.

CAUTION

Setting the sleep temperature too high will shorten tip life.

Auto sleep temperature setting range : for Celsius: 200ºC to 300ºC

for Fahrenheit: 390ºF to 580ºF

1. When the unit enters auto sleep temperature setting mode, the hundreds digit starts flashing. Enter

a desired value within the auto sleep temperature setting range.

2. If the entered value exceeds the auto sleep temperature setting range (see acceptable values

above), the hundreds digit starts flashing again. If this happens, enter a correct value.

3. The display will return to

if you press the button after selection.

13

Page 15

● : Password setting

If selecting Restricted, perform the setting for password. If selecting Partial, choose whether or not

the password function is needed when changing the set temperature, the preset number and the

offset value and set the password.

1. Either , or will be displayed if you press the button when is

displayed.

2. If you press the ( ) button, (Open), (Partial) and (Restricted) will

be switched alternately.

3. The display will return to

*1 The display will move to the following selection screen if you select (Partial).

4. After pressing the button, you will be asked whether or not the password function is needed when

moving to the temperature setting mode.

5. Either (without password) or (with password) will be displayed if you press the

( ) button.

6. If you press the button after selecting, you will be asked whether or not the password function is

needed when moving to the preset selection mode.

7. Either (without password) or (with password) will be displayed if you press the

( ) button.

8. If you press the button after selecting, you will be asked whether or not the password function is

needed when moving to the offset mode.

9. Either (without password) or (with password) will be displayed if you press the

( ) button.

10. The display will return to 14 after pressing the button.

if you press the button after selection.

*1, 2

*2

If you select (Restricted), the display will move to the following password setting screen.

If you select (Partial), the display will move to the following the password setting screen

after completing ※1.

11. The hundreds digits in the display will begin to flash. It indicates that you can enter the letter.

Press the ( ) button to enter the letter you required.

12. The tens digits in the display will begin to flash if you press the button after entering.

Use the same procedure to enter the letters for tens and ones digit.

13. The display will return to if you press the button after entering the ones digit.

14

Page 16

● : Auto shutoff time setting

Set auto shutoff time. The setting is possible within 30 to 60 minutes, in one minute increments.

1. Auto shutoff time (Initial value is 30 minutes) will be displayed if you press the button when

is displayed.

2. Press the ( ) button, you can change to the desired value. Enter a value from 30 to

60 (minutes).

3. The display will return to

if you press the button after selection.

15

Page 17

8. MAINTENANCE

Performing proper and periodic maintenance extends product life and contributes to the quality

of soldering work. Efficient soldering depends upon the temperature, the quality and quantity

of the solder and flux. Apply the following service procedure as dictated by the conditions of the usage.

WARNING

Since the soldering iron can reach a very high temperature, please work carefully.

Except where indicated, always turn the power switch OFF and disconnect the

power plug before performing any maintenance procedure.

●Tip maintenance

1. Tip temperature

High temperatures shorten tip life and may cause thermal shock to components. Always use the

lowest

HAKKO FX-801

2. Cleaning

Always clean the soldering iron tip before use, to remove any residual solder or flux adhering to it

by using a tip cleaner. Contaminants on the tip have many deleterious effects, including reduced

heat conductivity, which contribute to poor soldering performance.

possible temperature when soldering. The excellent thermal recovery characteristics of the

ensures effective soldering at low temperatures.

3. After use

Always clean the tip and coat it with fresh solder after use.

This guards against oxidation.

4. When the unit is not being used

Never allow the unit to idle at a high temperature for extended periods. This will cause the tip to

become oxidized. Turn the power switch OFF. If it is to be out of service for several hours, it is

advised to disconnect the power plug as well.

5. Inspecting and cleaning the tip

If followed daily, this procedure will materially add to tip life.

a. Set the temperature to 250℃ (482℉).

b. When the temperature stabilizes, clean the tip and check the condition of the tip.

If the tip is badly worn or deformed, replace it.

c. If the solder plated part of the tip is covered with black oxide, apply fresh solder, containing flux,

and clean the tip again. Repeat until all the oxide is removed, then coat the tip with fresh solder.

d. Turn the power OFF and remove the tip, using the heat resistant pad. Set the tip aside to cool.

Remaining oxides can be removed with isopropyl alcohol.

CAUTION

NEVER file or use abrasive materials on the tip to remove oxides!

16

Page 18

9. CHECKING PROCEDURE

WARNING

Unless otherwise directed, carry out these procedures with power switch OFF and the power UNPLUGGED.

■Check for a broken heater or sensor

Verify the electrical integrity of the heater and sensor.

Measure the resistance of the heater and sensor while at room temperature (15℃ to 25℃; 59℉ to 77℉)

It should be 3.4Ω±10%. If the resistance exceeds these limits, replace it.

Measure the heater/sensor resistance between these points.

■Check the grounding line

1. Unplug the iron cable from the station.

2. Measure the resistance between pin #2 and the soldering iron tip (with iron cable connected to

the HAKKO FX-8002).

3. If the value exceeds 2Ω (at room temperature), perform the tip maintenance in page 16.

If the value still does not decrease, check the connection cord for breakage.

2

■Check the iron cable for breakage

Measure the resistance of the connector pin.

Between Pin #1 to Pin #3 - 3.0 to 3.8Ω

If the resistance exceeds these limits, replace the iron cable.

Contact your HAKKO representative.

5

3

7

4

1

8

6

■Replace the fuse

1. Unplug the power cord from the power receptacle.

2. Remove the fuse holder.

3. Replace the fuse.

4. Put the fuse holder back in place.

17

Page 19

10. ERROR MESSAGES

● Sensor error

● Soldering iron error

● Low-temperature alarm

tolerance error

When there is a possibility that a failure has occured

in the sensor or heater (including the sensor circuit),

is displayed and a buzzer sounds.

is displayed and a buzzer sounds if the iron cable

is not attached to the station or a wrong soldering iron

is connected.

If the tip temperature falls below the low-temperature

alarm limit, is displayed and a buzzer sounds.

When the tip temperature rises above the lowtemperature alarm limit, the buzzer will stop.

Example:

350°C (400°C – 50°C)

Set temperature

Low-temperature alarm tolerance

● Heater terminal short

circuit error

● System error

is displayed and a buzzer sounds when the tip is

inserted incorrectly, an incompatible tip is inserted,

or when a foreign object has found its way into the

connector.

When a system error occurs such as data flash,

the soldering iron is immediately de-energized and

is displayed.

18

Page 20

11. TROUBLE SHOOTING GUIDE

● The unit does not operate when the power switch is turned ON.

CHECK : Is the power cord and/or the connection plug disconnected?

ACTION:Correctly connect the power cord.

CHECK:Is the fuse down?

ACTION:Investigate why the fuse blew and then replace the fuse.

If the fuse blows again, send the unit in for repair.

● The tip does not heat up.

・The sensor error is displayed.

CHECK:Is the tip inserted properly?

ACTION:Insert the tip completely.

CHECK:Check the iron cable and/or the heater/sensor for breakage.

ACTION:See “■ Checking the iron cable for breakage” and “■ Check for a

broken heater or sensor” in page 17. Replace any faulty part.

● Solder does not wet the tip.

CHECK:Is the tip temperature too high?

ACTION:Set the appropriate temperature.

CHECK:Is the tip contaminated with oxide?

ACTION:

(See “● Tip maintenance” in page 16.)

Remove the oxide.

● The tip temperature is too high

CHECK:Is the iron cable broken?

ACTION:See “■ Checking the iron cable for breakage” in page 17.

CHECK:Is the entered offset value correct?

ACTION:Enter the correct offset value.

● The tip temperature is too low.

CHECK:Is the tip contaminated with oxide?

ACTION:Remove the oxide.

(See “● Tip maintenance” in page 16.)

CHECK: Is the entered offset value correct?

ACTION: Enter the correct offset value.

● The soldering iron error is displayed.

CHECK:Is the proper soldering iron connected? Or, is the iron cable properly

connected?

ACTION:Re-connect the HAKKO FX-8002 iron cable to the station.

19

Page 21

●The low-temperature alarm tolerance error is displayed frequently.

CHECK : Is the tip too small for the work being soldered?

ACTION:Use a tip with a larger thermal capacity.

CHECK:Is the setting value for the low-temperature alarm tolerance too low?

ACTION:Increase the setting value.

●Heater terminal short circuit error is displayed.

CHECK: Is the tip for the HAKKO FX-8002?

ACTION:Turn the power switch OFF and insert the genuine HAKKO FX-8002

tip. Turn the power switch ON.

●System error is displayed.

ACTION: Contact your HAKKO representative.

https://doc.hakko.com

20

Page 22

12. PARTS LIST

For more information about replacement parts or latest information , please visit

our website (http://www.hakko.com) or HAKKO Document Portal. (see below)

1

● HAKKO FX-801

Item No.

1

2

3

21

Part No.

B3674

B3675

B3253

B2419

B2421

B2422

Part Name

Fuse/250V-7A

Fuse/250V-4A

Connecting cable

Power cord, 3-wire

cord & American plug

Power cord, 3-wire

cord but no plug

Power cord, 3-wire

cord & BS plug

Specifications

100 - 120V

220 - 240V

120V USA

India

2

Item No.

3

Part No.

B2424

B2425

B2436

B2426

B3508

B3550

3

Part Name

Power cord, 3-wire

cord & European plug

Power cord, 3-wire

cord & BS plug

Power cord, 3-wire

cord & Chinese plug

Power cord, 3-wire

cord & Australian plug

Power cord, 3-wire cord

& American plug (B)

Power cord, 3-wire

cord & SI plug

Specifications

220V KTL

230V CE

230V CE

China

Page 23

4

3

2

1

5

● HAKKO FX-8002

Item No. Part No. Part Name Specifications

1

2〜4

2 3

3

5

FX8002-81

B5071

B2578

B2300

Tip

HAKKO FX-8002

Nipple

O-ring

Heat resistant pad

See section "TIP STYLE"

29V-260W

With O-ring

6

3

2

● Iron holder

1

7

8

Item No.

1 〜 9

9

Part No.

FH200-83

Part Name

HAKKO FH-200

Specifications

with Cleaning wire

● Iron holder parts

Item No.

4

5

Part No.

1

B5083

2

B2791

3

B5084

4

B3251

5

B3249

6

B3250

7

B3252

8

599B-02

9

599-029

Part Name

Iron receptacle

Tip fixing spring

Holder for iron receptacle

Iron holder base

Cleaner base

Stay

Switch case assembly

Tip cleaner

Cleaning wire

Specifications

With Screws

With Screws

With Rubber foot

With Rubber foot

22

Page 24

13. WIRING DIAGRAM

Control P.W.B.

Power

receptacle

Power

switch

Black

Jack

White

Black

Red

Fan

Control power P.W.B.

23

Page 25

TIP STYLES

ø10.5

(0.41)

102

(4.02)

Unit:mm (in.)

T33-BC2 SHAPE-2BC T33-BC4 SHAPE-4BC

ø2

(0.08)

45°

17

2.6

(0.67)

(0.1)

T33-BC5 SHAPE-5BC

ø5

(0.2)

6.2

(0.24)

45°

13

(0.51)

T33-BC3 SHAPE-3BC

ø3

(0.12)

45°

17

3.8

(0.67)

(0.15)

T33-BC6 SHAPE-6BC

ø6

(0.24)

45°

13

6.7

(0.51)

ø4

(0.16)

45°

13

5.2

(0.51)

(0.2)

T33-D24 SHAPE-2.4D

ø2.4

(0.09)

171

(0.04)

(0.67)

(0.26)

T33-D32 SHAPE-3.2D

ø3.2

(0.13)

T33-D5 SHAPE-5D

ø5

(0.2)

T33-D6 SHAPE-6D

ø6

(0.24)

1 1.5 1.5

13

13

(0.04) (0.06) (0.06)

13

(0.51)(0.51)(0.51)

24

Page 26

焊鐵部

插頭

電路板

HEAD OFFICE

4-5, Shiokusa 2-chome, Naniwa-ku, Osaka 556-0024 JAPAN

TEL:+81-6-6561-3225 FAX:+81-6-6561-8466

http://www.hakko.com E-mail:sales@hakko.com

OVERSEAS AFFILIATES

U.S.A.: AMERICAN HAKKO PRODUCTS, INC.

TEL: (661) 294-0090 FAX: (661) 294-0096

Toll Free (800)88-HAKKO

4 2 5 5 6

http://www.hakkousa.com

HONG KONG: HAKKO DEVELOPMENT CO., LTD.

TEL: 2811-5588 FAX: 2590-0217

http://www.hakko.com.hk

E-mail:info@hakko.com.hk

SINGAPORE: HAKKO PRODUCTS PTE LTD.

TEL: 6748-2277 FAX: 6744-0033

http://www.hakko.com.sg

E-mail:sales@hakko.com.sg

Please access to the following address for the other Sales affiliates.

http://www.hakko.com

Copyright © 2015 HAKKO Corporation. All Rights Reserved.

2015.5

MA02703XZ150515

Loading...

Loading...