Page 1

®

3. SAFETY INSTRUCTIONS

4. OPERATION

N2 generator

Instruction Manual

1. PACKING LIST AND PART NAMES

Please check to make sure that all items listed below are included in the package.

N2 generator 1

Racks for station 2

N2 outlet socket

Compressed air inlet socket

Compressed air inlet valve

WARNING

Warnings, cautions and notes are placed at critical points in this manual to direct the

operator’s attention to significant items. They are defined as follows:

WARNING: Failure to comply with a WARNING may result in serious injury or death.

CAUTION : Failure to comply with a CAUTION may result in injury to the operator, or

damage to the items involved. Two examples are given below.

● Be sure to comply with the following WARNINGS and CAUTIONS for your safety.

CAUTION

This N2 generator uses membrane technology, which generates the nitrogen gas from

externally-supplied compressed air.

● Cautions for handling the product

•

Carefully handle the product, avoiding impact, such as a blow or dropping.

• Avoid rapid heating or cooling.

• Do not disassemble or modify the main body.

• Store the product indoors avoiding high temperature and humidity environments.

● Cautions for using the product

1. Follow the instructions below when using the product. The nitrogen gas can cause

oxygen deprivation.

• Use in a well-ventilated area.

• Regularly check nitrogen gas discharge piping for leaks.

2. Be sure to note the following points when installing the product. Highly-concentrated

nitrogen gas is discharged from the product into the surrounding area.

• Keep away from flame and flammables.

• Ventilate the work area when in use.

3. The product is intended to generate the highly-concentrated nitrogen gas from

compressed air. Never use it for other than the intended application.

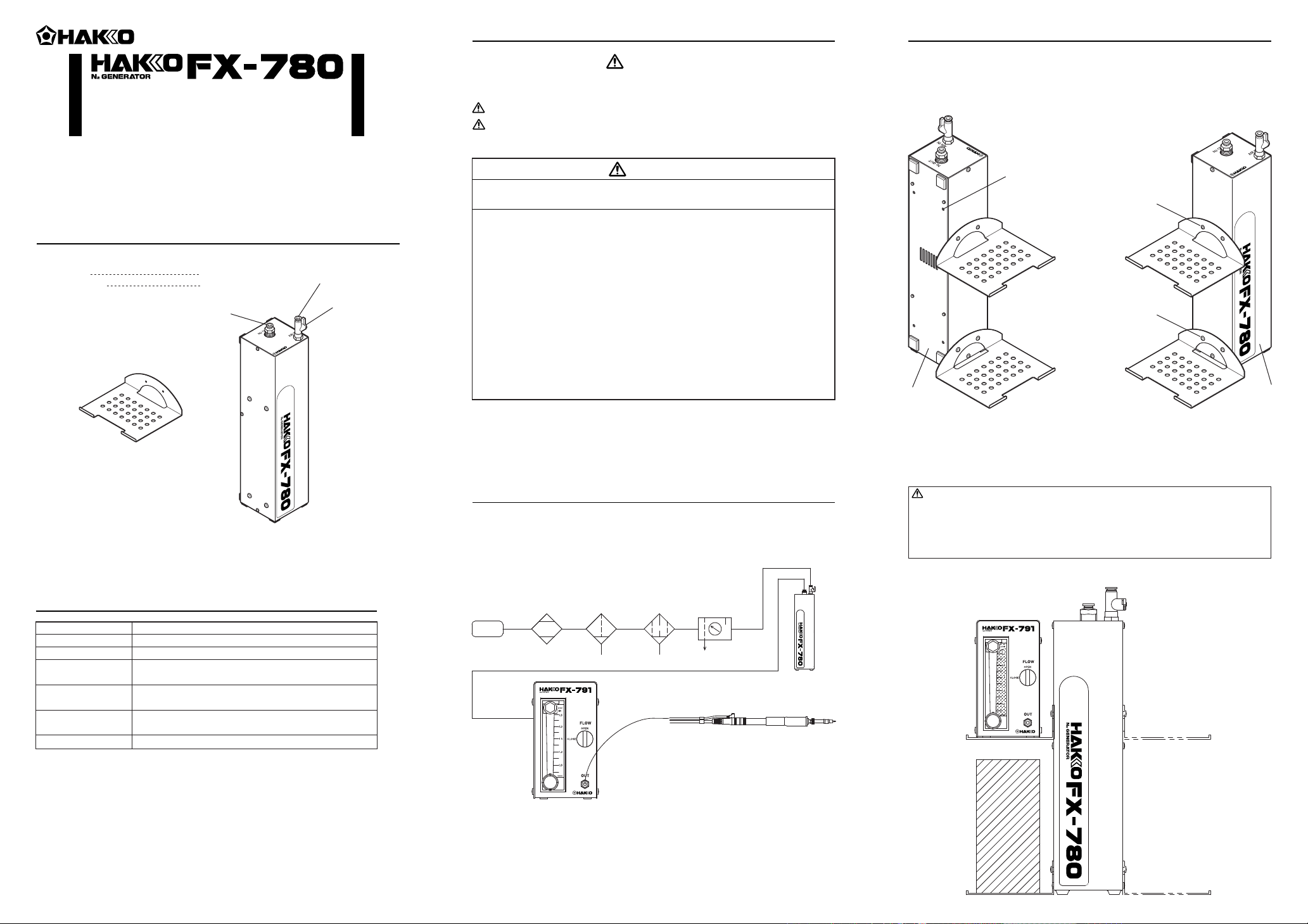

2. An example of setting-up

When the HAKKO FX-791 (N2 station) is used as the nitrogen gas flow rate controller, the

entire apparatus can be set up as shown in the figure below.

For M4 screw (4 pcs.)

*The read view is available

to secure the generator to

the work bench with M4

screws.

Binding screws

M3 × 6 (2)

Binding screws

M3 × 6 (2)

Rear view

Front view

Racks for station

2. SPECIFICATIONS

Name

Product number

Air supply pressure

Concentration of

generated N

Amount of generated

N

2

External dimensions

(w/o sockets and valve)

Weight (w/o racks)

*Specifications and design are subject to change without notice.

2

HAKKO FX-780

FX780-01

0.3 ~ 0.7MPa

99.9% (Max.)

1.5l/min. (When compressed air of 0.5MPa is supplied at

25°C(77°F), the concentration of generated nitrogen is 98%.)

73 (W) × 282 (H) × 71 (L) mm / 2.9 x 11.1 x 2.8 (in.)

Approx.1.5 kg (3.3lb.)

4. OPERATION

1. Connection

See the schematic diagram below for connection. To start discharging nitrogen gas, open

the air IN valve and supply compressed air to the N

Air dryerCompressor Air filter

0.3µm

Water filter

0.01µm

2 generator (HAKKO FX-780).

Regulator

N2 soldering iron

HAKKO FM-2026

N2 OUT

N2 generator

HAKKO FX-780

*Secure the racks on the HAKKO FX-780 using M3 screws.

CAUTION

When using the HAKKO FX-791, place it on the upper rack and the HAKKO soldering station on the lower rack (diagonally shaded area). The HAKKO FX-791 and HAKKO soldering station can also be placed on the right side of the HAKKO FX-780.

If the soldering station is not placed on the lower rack the HAKKO FX-780 can become unstable and topple over. Always place the soldering station on the lower rack when operating.

AIR IN

N2 station

HAKKO FX-791

<Schematic diagram>

Page 2

4. OPERATION

5. TROUBLESHOOTING

7. PARTS LIST

3. Adjustment of the flow rate

The flow rate of nitrogen gas is adjusted through the flow rate control valve shown in the

schematic diagram.

The determination of the concentration of nitrogen gas generated by the HAKKO FX-780

depends on the pressure of supplied compressed air and the amount of discharged nitrogen gas. See the table below for detailed information.

Concentration of N2

Amount of discharged N2 re-

mains constant.

Pressure of supplied com-

pressed air remains constant

Pressure of supplied compressed air is high.

Pressure of supplied compressed air is low.

Discharged nitrogen gas is small in amount.

Discharged nitrogen gas is large in amount.

High

Low

High

Low

Determine the pressure of supplied compressed air and the amount of discharged nitrogen gas according to the HAKKO FX-780 performance table.

CAUTION

When using the HAKKO FX-791, the pressure of the HAKKO FX-780 will increase

when the valve is closed. Close the compressed air IN valve of the HAKKO FX-780 to

shut down the supply of compressed air if the flow control valve remains closed for a

long period of time during operating.

4. End of the operation

Close the compressed air IN valve of the HAKKO FX-780.

Open the valves on the side where the gas is discharged, including the flow rate control

valve.

CAUTION

When the N2 generator is not used for a prolonged period of time, stop supplying compressed air to the HAKKO FX-780 and open the valves on the side where the gas is

discharged.

● Nitrogen gas is not

discharged.

CHECK : Is each component properly connected?

ACTION : Verify that air is supplied to the HAKKO FX-780

per the schematic diagram.

CHECK : Is the dust or air filter dirty?

ACTION : Clean or replace the dirty filter.

CHECK : Do the regulator and valves function properly?

ACTION : Repair or replace the nonfunctioning valve(s).

CAUTOIN

If nitrogen gas is not discharged even with a properly-compressed air supplied, the supplied air may be contaminated with dust or moisture. In such a case, the internal module of

the HAKKO FX-780 needs to be replaced by the manufacturer. Module replacement is also required if the amount of discharged nitrogen gas is small or completely zero due to

supply of one of the aggressive gases mentioned in “Conditions of supplied compressed

air” above.

● N2 generator

Part No.

FX780-01

HAKKO FX-780

● Optional parts

Part No.

B3024

Rack for station

Part Name

Part Name

Specifications

With racks

Specifications

With screws

Binding screws

M3 × 6 (2)

● Compressed air

1. Requirements on compressed air supplied to the HAKKO FX-780

Pressure of supplied compressed air 0.3 ~ 0.7MPa

Amount of compressed air needed to be supplied 10l/min. or more

Temperature of the supplied compressed air 5 ~ 50°C (41~ 122°F)

Maximum operating temperature 60°C (140°F)

2. Conditions of supplied compressed air

• Clean, dry air with a relative humidity of 80% or lower

Air filter Pore size of the filter should not exceed 0.3µm.

Water filter Pore size of the filter should not exceed 0.01µm.

The air supply shall not contain any of the following:

• Hydrocarbons

• Any corrosive gases (strong acid gases, such as hydrogen sulfide, sulfurous acid

gas, hydrogen chloride and fluorine)

• Strongly alkaline gases (such as amines, ammonia and caustic soda)

6. MAINTENANCE

• Check if the air dryer, air filter, water filter, regulator and valves function properly.

• Check piping for leaks.

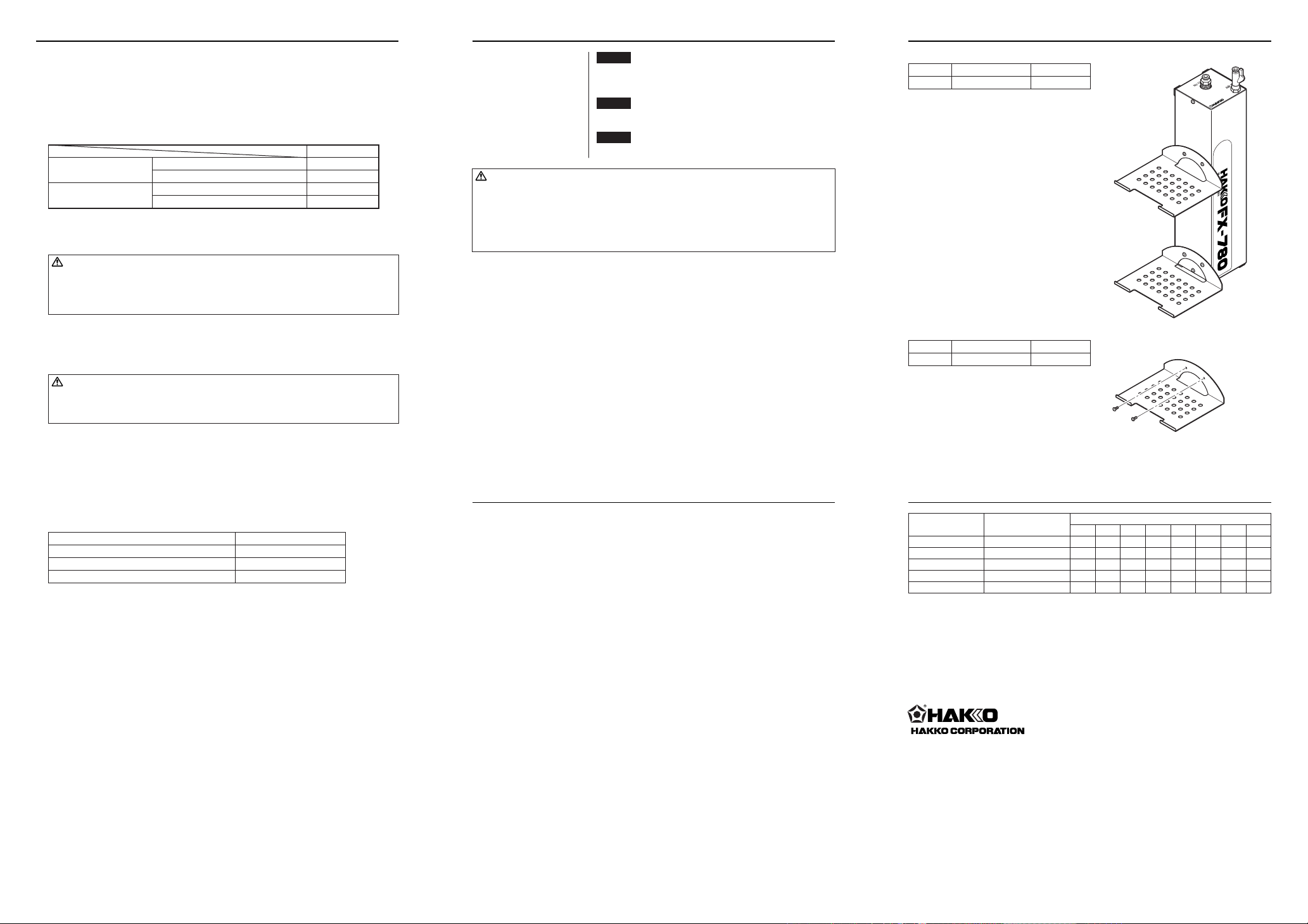

8. HAKKO FX-780 PERFORMANCE TABLE

Supplied air pressure

(MPa)

0.3

0.4

0.5

0.6

0.7

HEAD OFFICE

TEL:+81-6-6561-3225 FAX:+81-6-6561-8466

http://www.hakko.com E-mail:sales@hakko.com

OVERSEAS AFFILIATES

U.S.A.: AMERICAN HAKKO PRODUCTS, INC.

TEL: (661) 294-0090 FAX: (661) 294-0096

Toll Free (800)88-HAKKO

4 2 5 5 6

http://www.hakkousa.com

HONG KONG: HAKKO DEVELOPMENT CO., LTD.

TEL: 2811-5588 FAX: 2590-0217

http://www.hakko.com.hk

E-mail:info@hakko.com.hk

SINGAPORE: HAKKO PRODUCTS PTE., LTD.

TEL: 6748-2277 FAX: 6744-0033

http://www.hakko.com.sg

E-mail:sales@hakko.com.sg

Please access to the following address for the other Sales affiliates.

http://www.hakko.com/address

Copyright © 2005 HAKKO Corporation. All Rights Reserved.

Concentration of N2

(%)

Amount of generated N2

Amount of generated N2

Amount of generated N2

Amount of generated N2

Amount of generated N2

Generated introgen l/min. at 25°C (77°F)

99.9

0.15

0.24

0.35

0.48

0.55

99.5

0.37

0.57

0.75

0.97

1.2

99.0

0.48

0.77

1.1

1.3

1.6

98.0

0.66

1.1

1.5

1.8

2.2

97.0

0.88

1.4

1.9

2.4

3.1

96.0

95.0

1.3

2.0

2.9

3.5

4.2

90.0

2.6

4.4

5.9

7.5

9.2

2005.1

1.1

1.7

2.2

3.1

3.7

MA01356JZ050105

Loading...

Loading...