Page 1

SERVICE

MANAUL

HW50-1002W

Front Load Washing Machine

1

SERVICE MANUAL

This service information is designed for experienced repair technicians only and is not designed for use by the general public. It does not

contain warnings or cautions to advise non-technical individuals of potential dangers in attempting to service a product. Products powered by

electricity should be serviced or repaired only by experienced professional technicians. Any attempt to service or repair the product or

products dealt with in this service information by anyone else could result in serious injury or death

MODEL: HW50-1002W

Front Load Washing Machine

Order No.

FL0911008V1.1

©2010 Front Load Washing Machine

All rights reserved. Unauthorized copying and distribution is a violation of law.

WARNING

Page 2

SERVICE

MANAUL

HW50-1002W

Front Load Washing Machine

2

Contents

Chapter 1 General Information ________________________________________________ 4

1-1. General Guidelines_____________________________________________________ 4

1-2. Caution and Warning symbols ____________________________________________4

1-3. Function indication symbols ______________________________________________4

Chapter 2 Product Feature ___________________________________________________ 5

2-1. Features _____________________________________________________________5

2-2. Specification __________________________________________________________6

Chapter 3 Matters needing attention ___________________________________________ 8

3-1. Safety _______________________________________________________________8

3-2. During Use _________________________________________________________ 9

Chapter 4 Operational Guidance ____________________________________________

10

Chapter 5 Program Introduction_____________________________________________

Chapter 6 Washing Mathods________________________________________________

6-1. Loading____________________________________________________________

6-2. Adding detergent ____________________________________________________

6-3. Selecting washing program ____________________________________________

Chapter 7 Appearance brief introduction _____________________________________

7-1. Name of parts _______________________________________________________

7-2. Net dimension_______________________________________________________

12

13

13

13

13

14

14

15

Page 3

SERVICE

MANAUL

HW50-1002W

Front Load Washing Machine

3

Chapter 8 Disassembly and Installation ______________________________________

8-1. Remove packing materials _____________________________________________

8-2. Adjusting the washing machine _________________________________________

8-3. Joining the Inlet Hose to the Washing Machine _____________________________

8-4. Drainage Hose ______________________________________________________

8-5. Connecting to the Power Supply ________________________________________

Chapter 9 Wiring circuit and Self check ______________________________________

9-1. Wiring circuit ________________________________________________________

9-2. Self check __________________________________________________________

Chapter 10 Error Display and troubleshooting _________________________________

10-1. Error Display_______________________________________________________

10-2. Examination & Troubleshooting ________________________________________

10-2-1. Display nothing__________________________________________________

10-2-2. No water inletting ________________________________________________

10-2-3. No draining _____________________________________________________

10-2-4. Abnormal noise and vibration_______________________________________

10-2-5. Water leaking ___________________________________________________

16

16

17

17

18

19

20

20

21

22

22

26

26

27

28

28

29

Page 4

SERVICE

MANAUL

HW50-1002W

Front Load Washing Machine

4

Chapter 1 General Information

1-1. General Guidelines

When servicing,observe the original lead dress.If a short circuit is found, replace all parts which are

overheated or damaged by the short circuit.After servicing ,see to it that all the protective devices such as

insulation barriers ,insulation papers shields are properly installed .Confirm that the screws,parts and wiring

which were removed in order to service are put in the original positions, or whether there are the portions

which are deteriorated around the service places serviced or not. And be sure safety of that.

1-2. Caution and Warning symbols

(You will see them in “Matters needing attention”)

Any instructions in this service manual with this “Warning “sign must be followed strictly.

To prevent damage to the washing machine, any instructions in this manual with this “Stop “sign

must be followed strictly.

1-3. Function indication symbols

(You will see them in the specification table)

Signify the washing machine has this function.

Signify the washing machine doesn’t have this function.

Page 5

SERVICE

MANAUL

HW50-1002W

Front Load Washing Machine

5

Chapter 2 Product Feature

2-1. Features

(1). 300mm diameter porthole, door may be open at a 180 degrees.

Facilitate view of wash process, facilitate unloading and easy to use with large port.

(2). Class A energy-saving

Scientific design for tub can reduce the use of water heavy during washing, consequently upgrade the

energy efficiency class to A,also use scientific washing

(3). Multi-gear speed controller

According to different costuming,you can select corresponding spin speed,from 0 to 1000 rpm.

(4). Unique gasket design featuring no residual water hidden inside.

By the unique gasket,washing machine can left no residual water hidden between outer drum and front

board.

Page 6

SERVICE

MANAUL

HW50-1002W

Front Load Washing Machine

6

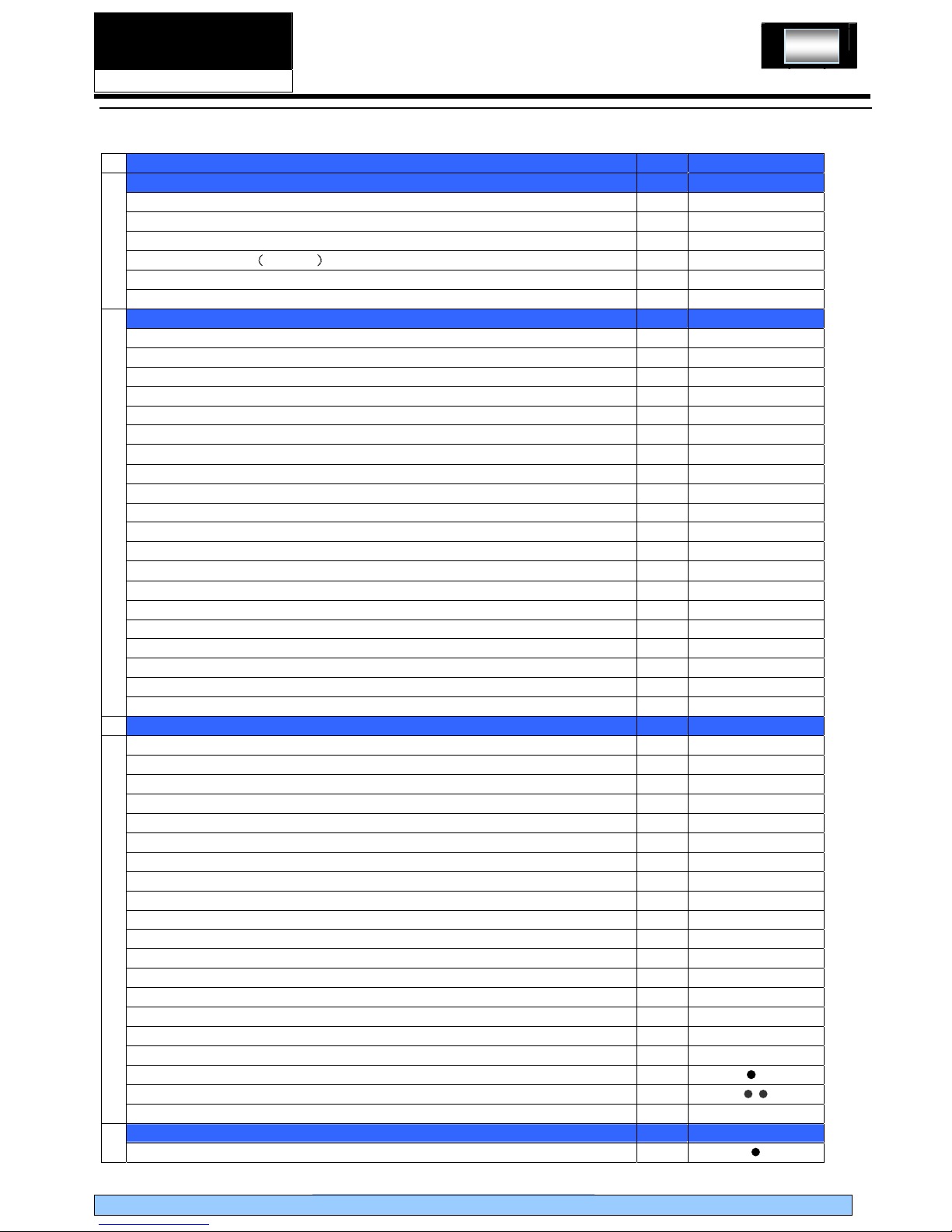

2-2. Specification

washing machines

HW50-1002W

Product identification

Description of appliance Washing machine

Type of appliance(FS = standing, BI = built-in) FS

Supplier own brand Haier

Supplier bar code(Europe)

EAN

Commercial Brand / Model

1.

Commercial bar code EAN TBC

Key-Features

Energy efficiency class A

Washing performance class A

Spin efficiency class C

Programs n° 11

Capacity Kg 5

Spin speed (max.) rpm 1000

Noise level(sound pressure level)

dB(A) 71

Energy consumption per wash circle kWh 0.95

94 l elcyc hsaw rep noitpmusnoc retaW

Annual average energy consumption * kWh 190

Annual average water consumption* l 10800

Residual dampness (spin result) % 60%

Adjustable thermostat (water temp. adjust from - to) °C

90 -※

Drum capacity dry laundry / water kg / l 5/42

Auto water level adjust (depending on volume of filled in laundry)

AWL

l

Washing time (max.) min 196

Washing temperatures (program-controlled) °C 30/40/ 60 /90

Certification's (CE) CE

Approvals (VDE/GS / TÜV/GS / IMQ)

2.

* per average 200 wash cycles (EN50242) T= COLD

3.

Basics data

025x595x058 mm )D x W x H( snoisnemid tinU

Net weight kg 65

Voltage/frequency V/Hz 220V-240V~/50Hz

Input power / main fuse (intensity) W / A 2000/10

Work top / removable l/l

Control M = electromechanical, E = electronic, F = fuzzy E

Drum S = stainless steel / Z = zinc coated S

Tub P = Polyprop./ S = stainless steel P

Door:

aesthetic (R = round, Y = big eye, Q = square) R

Diameter cm 30

Outer door frame S= stainless steel / M = metal / P = plastic

P

Inner door G= glass / P= plastic G

Detergent compartments n° 3

Removable compartment for liquid detergent Delay timer (from - to) h Self cleaning suds pump Water inlet hose cold water / hot water

/-

Water drain hose / -support

/

Adjustable feet n° 4

Safety systems

4.

Auto door lock

ADL

Page 7

SERVICE

MANAUL

HW50-1002W

Front Load Washing Machine

7

Motor overheating protection

MOP

No heating without water

NHW

Auto water cool-down (before drain 90°C boiled water)

AWC

Water overflow protection

WRP

Acqua Stop kit

-

Child protection

Programs

1) Strong action /cotton cycles

n° /

2) Normal action / synthetics

n° /

3) Delicate action / wool or cashmere cycles

n° /

4) Delicates silk

n°

5) Speedy

n°

6) Sport

n° -

7) Hand wash

n° -

8) Underwear

-

9) Jeans

-

10) Duvet

-

11) Special programs

n°

4

Single Rinse n°

Single Spin n°

Single Drain

Single Wash

Optional function keys (additional program settings)

ON/OFF

Start / Pause

Delay

Extra Rinse

-

Rinse Hold (or Soak)

-

Eco Time

-

Spin Select

Temperature Select

Baby Care

-

hsaw dloC

-

Super Wash

-

Pre-wash

-

5.

Easy ironing

-

Packing dimensions & loadability

065x056x098 mm )D x W x H( snoisnemid gnikcaP

Gross weight kg 68

6.

40' Container load pcs 220

Logistic / recicling information

RS

Packing weight kg 2

Packing materials / Recycling symbols

Carton (weight) gr Shrink package

Polistyren (weight) gr 1800

Polyetylene foil (weight) gr 100

Other packing materials (weight) gr 100

7.

Wood (weight) kg

-

Service RS

User instruction (languages)

8.

Max. failure rate (12 Months after sales to end customer) %

9.

Delivery Time of First Batch Available

Page 8

SERVICE MANUAL

Front Load Washing Machine

Chapter 3 Matters needing attention

3-1. Safety

HW50-1002W

Safety Information

Important – Please read these instructions fully before installation

• The installation of this appliance is best carried

out by 2 people.

• Dispose of all packaging car efully and

responsibly.

• This appliance is for indoor use only . Only install

in a dry indoor environment.

• The appliance MUST be positioned on a firm

level base.

• Do not position the appliance wher e it is exposed

to direct sunlight or heat sour ces as this will age the

plastic and rubber components.

• Warning: Ensure all 3 packing bolts have been

removed.

• Ensure the appliance is connected dir ectly to a

domestic mains water supply .

• Warning: This washing machine MUST only be

connected to a cold water supply .

• Ensure all electrical connections are as stated in

this document.

• Ensure the appliance is plugged into a separate

earthed socket that is easily accessible.

• Ensure the power lead is not trapped under the

appliance.

• Do not connect the appliance to the power

supply until installation is complete.

• This appliance is for domestic/household use only

and is not suitable for commer cial use.

• Check that the water hose joints and connections

are secure and there are no leaks. If the hoses leak,

do not use until the leaks have been stopped.

• This appliance is not to be used by childr en or

persons with reduced physical, sensory or mental

capabilities, or lack of experience and knowledge,

unless they have been given supervision or

instruction. Children should be supervised to ensure

that they to not play with the appliance.

• Do not use if the power lead is damaged. It must

be replaced by the manufactur er, their approved

service agent or similarly qualified person.

• Do not use this appliance if there are any missing

or damaged parts.

• Only use deter gents which ar e suitable for

automatic washing machines and follow the

detergent manufacturers recommendations.

• Do not place heavy objects or sour ces of heat

or damp on top of the washing machine.

• Do not cover the appliance during use, as this

may block the ventilation holes.

• Do not touch or use the appliance when bar efoot

or with wet or damp hands.

• Do not open the detergent drawer during a

wash cycle.

• Do not touch the porthole (door) during the

washing cycle - it gets hot.

• Do not force the door open. The door is fitted

with a self-lock device and will not open until 2-3

minutes after the washing machine stops.

• Do not open the door if water is visible thr ough

the porthole.

• Do not wash foam rubber or sponge like

materials on a hot wash.

• Do not remove or insert the plug in the pr esence

of flammable gas.

• Do not use flammable detergent, sprays or dry

cleaning agents in or near to the appliance.

• Do not attempt to r epair the appliance yourself.

Contact the manufactur er, their approved service

agent or the Customer Helpline: 0845 600 4632.

Before use During use

Page 9

SERVICE MANUAL

Front Load Washing Machine

3-2. During Use

HW50-1002W

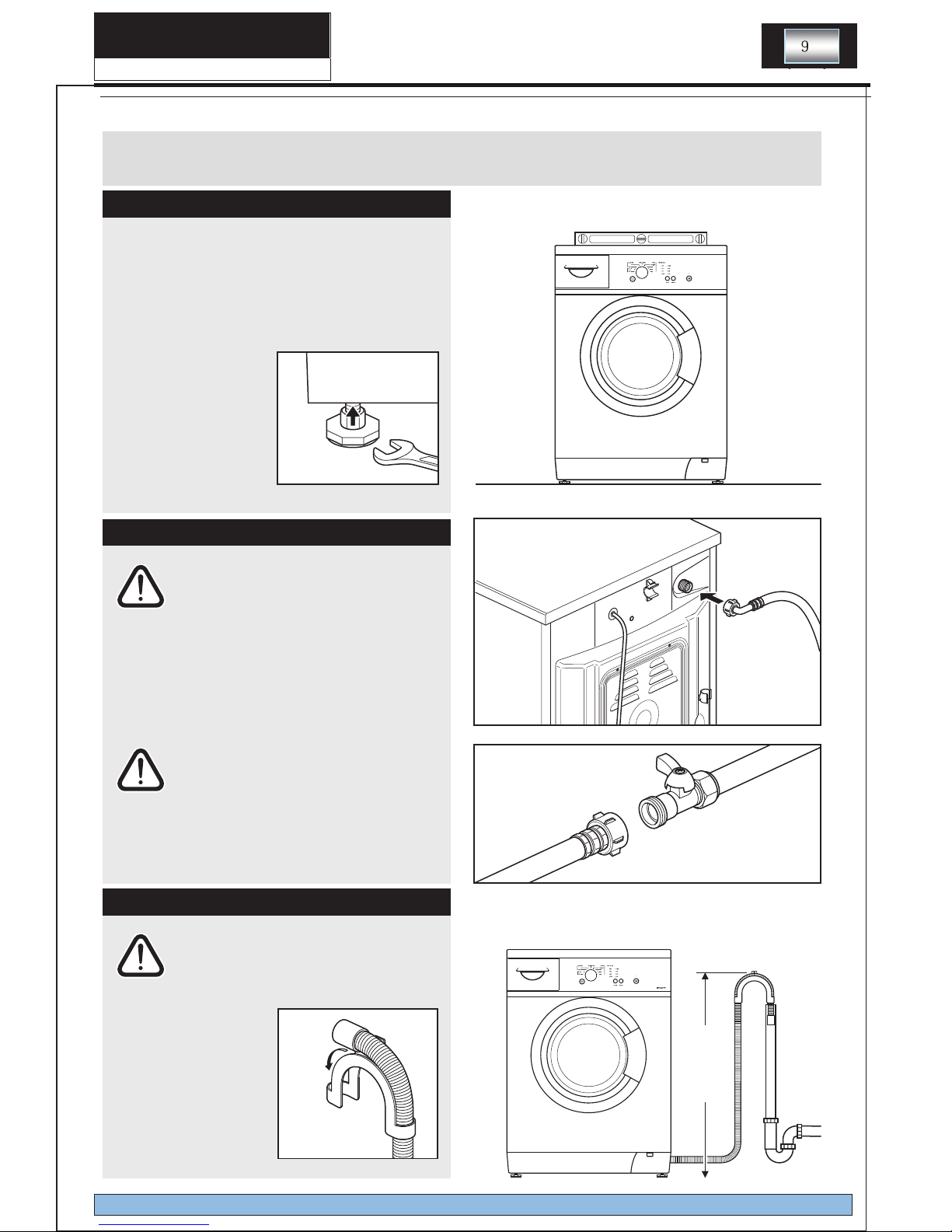

Installation

Levelling your washing machine

Before use you MUST ensure the washing

machine is level, check with a spirit level (5).

This will minimise vibrations and noise during

use plus reduce wear and tear.

Level by adjusting the feet under the appliance.

First adjust the feet

by hand to get the

appliance level then

tighten the nuts up to

the underside of the

appliance body using

a 16mm spanner (6).

Water inlet hose connection

Important: This washing machine

MUST only be connected to a cold

water supply.

Connect the water inlet hose, the angled

connection attaches to the water inlet on the

back of the washing machine (7). The straight

connection attaches to the water supply

valve (8). Ensure all seals are in place before

connecting.

Important: Only tighten the hose

connection nut by hand - do not

overtighten.

Important: The height of the top of

the curve in the drain hose MUST

be between 80 - 100cm from the

floor (9).

Fit the drain hose into

the hose clip (10) and

attach to the wall etc.

at the correct height.

Water

inlet

hose

Water

supply

valve

Water

inlet

hose

Max.

100cm

Min.

80cm

Drain hose connection

5

7

8

9

6

10

C

。

90

C

。

60

C

。

40

C

。

40

C

。

30

HW50-1010W

C

。

90

C

。

60

C

。

40

C

。

40

C

。

30

Page 10

SERVICE MANUAL

Front Load Washing Machine

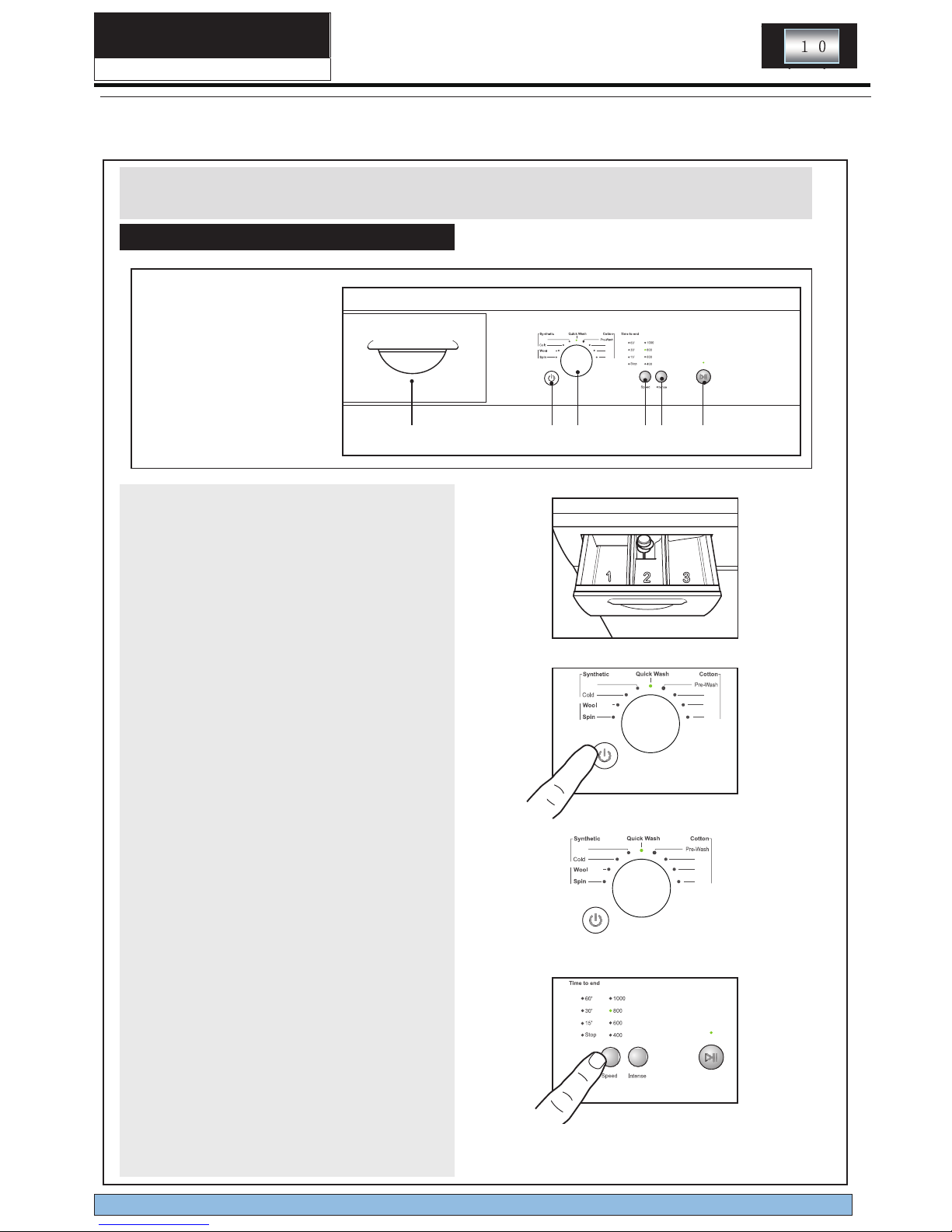

Chapter 4 Operational Guidance

HW50-1002W

Control Panel Functions

1. Detergent drawer

The drawer contains three compartments:

1: Main wash detergent

2: Fabric softener

3: Prewash detergent

2. Power button

Press this button to switch on the washing

machine. Press and hold 2s to switch it off.

3. Programme knob

By turning the knob clockwise/counterclockwise, the required program can be selected.

There are 9 programs available. After a program is selected, the corresponding light will

go on.

4. Speed button

Touch this button lightly to select the desired

speed. When a speed is set, the indicator light

will be light on.

1. Detergent drawer

2. Power button (& light)

3.

4. Speed button

5. Intense button

6. Start/pause button

Programme knob

1 53 4

Continued on next page

2

4

3

1

C

。

90

C

。

60

C

。

40

C

。

40

C

。

30

2

6

C

。

90

C

。

60

C

。

40

C

。

40

C

。

30

C

。

90

C

。

60

C

。

40

C

。

40

C

。

30

Page 11

SERVICE MANUAL

Front Load Washing Machine

HW50-1002W

Control Panel Functions

5. Intense button

Touch this button lightly, the indicator light will

be light on . you can increase the washing time,

rinsing times in main wash stage of the selected

program, which is suitable for dirty clothes.

6. Start/pause

When the washing machine is connected to

the power socket and a program is selected,

lightly touch this button to start operation. During a wash cycle, touch it lightly ,operation

will stop and the indicator light start blinking.

Touch it again to resume operation. To cancel

a wash program during a wash cycle, touch

this button, when the indicator light start blinking, press the Power switch, the program will

be cancelled.

6

5

Page 12

SERVICE MANUAL

Front Load Washing Machine

Chapter 5 Program Introduction

HW50-1002W

Programme Selection Guide

Programme setting Laundry

Temperatur e

Detergent compartments

Max.

load

(kg)

1

Detergent2Softener

3

Prewash

NOTTOC

1

2

Prewash Very heavy soiling 60

•

O

•

around

136

5

3

90°C 90

•

O X

around

128

5

4

60°C

Non-fade and

medium soiled

cotton

60

•

O X

around

119

5

40°C

•

O X

around

107

5

CITEHTNYS

6

30°C

Non-fade heavily

soiled synthetic

fibre

30

•

O X

around

70

3

7

Cold

Fade and

medium soiled

synthetic fibre

•

O X

around

60

3

8

Wool 40°C

Fade and

medium soiled

synthetic fibre

•

O X

around

50

2

9

Spin

X X X 5

Note:

‘O’ means - softener can be added when necessary .

‘

• ’ means - detergent can be added when necessary.

‘X’ means - detergent MUST NOT be added.

40

5

Quick wash

Medium soiled

laundry

40

•

O X

around

29

2.5

Heavy soiling

Soiled cotton

around

12

40

Base on full

loading of 5kg

approximate

washing

time(mins.)

Page 13

SERVICE MANUAL

Front Load Washing Machine

Chapter 6 Washing Mathods

6-1. Loading

6-2. Adding detergent

6-3. Selecting washing program

HW50-1002W

Synthetic

y

conditioner

conditioner

Page 14

SERVICE MANUAL

Front Load Washing Machine

Chapter 7 Appearance brief introduction

7-1. Name of parts

HW50-1002W

C

。

90

C

。

60

C

。

40

C

。

40

C

。

30

Accessories included

Front

1. Detergent drawer

2. Top panel

3. Power button

4.

Start/pause button

5.

Programme selection dial

6.

Door

7.

Filter

Back

10. Back plate

11. Packing bolt x 3

12. Earth terminal

13. Water inlet

14. Power lead

15. Drain hose

16. Back plate screw x 3

Hose clip x 1

Water inlet hose x 1 Plastic plug x 3

1

3 5

9

8

2

10

13

14

15

12

Tools required for installation

Phillips screwdriver (medium)

Flatblade screwdriver (large)

Spirit level

13mm & 16mm Spanners

11

11

11

16

4

6

7

Speed button

intense button

8.

9.

Page 15

SERVICE MANUAL

Front Load Washing Machine

7-2. Net dimension

520

HW50-1002W

height:850mm / width:595mm / depth:520mm

C

90

C

60

C

40

C

40

C

30

595

850

Page 16

SERVICE MANUAL

Front Load Washing Machine

Chapter 8 Disassembly and Installation

8-1. Remove packing materials

HW50-1002W

Installation

Unpacking your washing machine

Caution: 2 people are required to

unpack and handle the washing

machine, it is recommended that

gloves are worn.

a: Carefully remove all packaging materials

including the foam base, dispose of correctly .

Note: When opened, water droplets may be

visible in the drum etc. this is normal as each

appliance is factory tested.

b: Remove the drain hose and power cable from

the clips on the back of the machine (1).

Removing the packing bolts

Important: The packing bolts ar e

designed to support the internal

components during transit, these

MUST be removed befor e use.

a: Remove the back cover plate, by r emoving

the 3 screws shown and sliding down the back

cover plate (2 & 3).

b: Remove all 3 packing bolts fr om the back

using a 13mm spanner or large flatblade

screwdriver. Remove the 3 rubber spacers from

inside the back of the washing machine (4).

Note: Keep the packing bolts and rubber

spacers in a safe place for possible later use.

c: Replace the back cover plate and refit the

screws.

d: Push fit the plastic plugs into the holes left by

the packing bolts (insert - 4).

Hose/

cable

clips

1

2 3

4

Page 17

SERVICE MANUAL

Front Load Washing Machine

8-2. Adjusting the washing machine

8-3. Joining the Inlet Hose to the Washing Machine

HW50-1002W

Levelling your washing machine

Before use you MUST ensure the washing

machine is level, check with a spirit level (5).

This will minimise vibrations and noise during

use plus reduce wear and tear.

Level by adjusting the feet under the appliance.

First adjust the feet

by hand to get the

appliance level then

tighten the nuts up to

the underside of the

appliance body using

a 16mm spanner (6).

5

6

C

。

90

C

。

60

C

。

40

C

。

40

C

。

30

Water inlet hose connection

Important: This washing machine

MUST only be connected to a cold

water supply.

Connect the water inlet hose, the angled

connection attaches to the water inlet on the

back of the washing machine (7). The straight

connection attaches to the water supply

valve (8). Ensure all seals are in place before

connecting.

Important: Only tighten the hose

connection nut by hand - do not

overtighten.

Water

inlet

hose

Water

supply

valve

Water

inlet

hose

7

8

Page 18

SERVICE MANUAL

Front Load Washing Machine

HW50-1002W

Important: The height of the top of

the curve in the drain hose MUST

be between 80 - 100cm from the

floor (9).

Fit the drain hose into

the hose clip (10) and

attach to the wall etc.

at the correct height.

Max.

100cm

Min.

80cm

Drain hose connection

9

10

HW50-1010W

C

。

90

C

。

60

C

。

40

C

。

40

C

。

30

8- 4. Drainage Hose

Page 19

SERVICE MANUAL

Front Load Washing Machine

8-5. Connecting to the Power Supply

HW50-1002W

(page 6) and the

Page 20

SERVICE MANUAL

Front Load Washing Machine

Chapter 9 Wiring circuit and Self check

9-1. Wiring circuit

PCB-Printed Circuit Board

NTC-Temperature Sensor

FA-Interference Suppresser

Door-Door Lock

Main inlet valve/pre inlet valve -Water Inlet Magnetic Valve

Water level Switch - Pressure Switch

Drain pump-Drainage Pump

Heater-Heating element

Motor –Motor

HW50-1002W

FA

N N

G

FA1

FA2

MRN

MRL

Water level swith

Heater

Fuse

FUSE

NTC

MRC

DOOR

L

L

Main inlet valve

Drainge pump

Pre inlet valve

Page 21

SERVICE

MANAUL

HW50-1002W

Front Load Washing Machine

21

9-2. Self check

Press “Intense” button, and plug in, then the WM will be on self-inspection mode,

all the indication light will be on. Press start/pause button starts the Testing Program.

1.Door lock switch testing, if the door is unlooked, The start indicator wasn't

lighted,and the buzzer sound abnormally.

2.Water inlet for main wash valve 5S, Water inlet for prewash valve 5S, and hot

water inlet 5S, if it can’t reach the 1st water level within 2 Mins, The start indicator

lighted on 0.2s and off 0.2s for 5 times, repeat 4s later.

3.Heat the water for 10 Secs.

4.Water drainage to empty cylinder water level, if it can’t reach the empty cylinder

water level within 2 Mins, The start indicator lighted on 0.2s and off 0.2s for twice,

repeat 4s later.

5.Spin speed to the Max RPM of this Model.

6.Unlock program finishes, all the indication light is off except the “stop” indication

light.

If it’s necessary to stop

the program during the testing, press the start/pause button or

makes power off; if there’s failure alarm during the testing, pls deal with it according

to the Alarm Handling Methods.

7. Model selection

Press the “Speed” and “Intense” button, the machine will be on Model Selection

mode, the Buzzer beeps one time.

When it comes in the Model selection mode, the 55cm 6kg 1200 rpm model is set as

default, during the following time, all the indication light is on alternately, the light of

spin exclusion is on; the light of speed is all on. Press “speed” button, makes 5kg and

6kg switch over.

Speed indication

light status

Corresponding Model

all on 6kg

all off 5kg

X.2 The speed of the model can be adjustable bwtween

1250/1050/950/850/750/650/1350 under the condition that all the speed light is off,

while the speed can be adjustable between 1260/1060/960/860/760/660/1360 with all

the speed light on.

washing program indication

light

Corresponding spin

speed

Light of spin exclusion on 1350/1360

light of wool wash on 1250/1260

Page 22

SERVICE

MANAUL

HW50-1002W

Front Load Washing Machine

22

light of synthetic 0 ℃ on

1050/1060

light of synthetic 30 ℃ on

950/960

light of quick wash on 850/860

light of cotton pre-wash on 750/760

light of cotton & flax 90 on 650/660

washing program indication

light

Corresponding spin

speed

X.3 The model can only be selected from high spin speed to lower spin speed, once

saved, it can’t reverse adjust, however, when the Temperature sensor is off, it can.

Chapter 10 Error Display and troubleshooting

10-1. The start indicator lighted on 0.2s and off 0.2s for twice, repeat 4s

later

Error 1

The start indicator wasn't lighted,and thebuzzer sound abnormally.

Error message:Door is not properly shut 20s after program is started.

Troubleshooting:

Error 2

The start indicator lighted on 0.2s andoff 0.2s for twice,repeat 4s later .

Error message: Drainage error, water not emptied wit

hin 4 min.

Pushing the door to Check Whether

Door is properly shut or not

Y

Shut the door properly

Door lock is broken and need replacing,

then make sure wire is connected

properly.

Check the voltage between 12-3 and

12-12 of PCB, is it between AC

220-240V?

Cut off the power and then turn on again.

Check the voltage between brown wire

and blue wire of door lock, is it between

AC 220-240V?

N

Replace

PCB

N

Connect the wire properly

Check if the wire connecting door lock

and PCB is loose

N

Y

Y

Page 23

SERVICE

MANAUL

HW50-1002W

Front Load Washing Machine

23

Troubleshooting:

Error 3

The start indicator lighted on 0.2s andoff 0.2s for 3 times,repeat 4s later .

Error message:Temperature sensor is not properly connected or damaged (display at the end of a

program).

Troubleshooting:

N

Check if drain pump acts by touching

pump position

Y

Check if drain pump or

drain pipe is jammed,

And open the filter and

clean

N

Cut off the power and choose spin

program to start ,then check the import

voltage of drain pump, is it between

AC 220-2240 V?

Replace drain pump

N

Cut off power and pull out water level

pressure switch wire connection. Set

spin program to start. Check the export

voltage to drain pump, is it between AC

220-240V?

Replace PCB

NTC exist open circuit. Replace it

Y

Y

Check if NTC is connected properly

Cut off power and measure the resistance

of temperature sensor by

multimeter, is

it between 5-14kΩ ?

Y

N

Connect NTC well

N

N

Replace PCB

Check if water is emptied

Y

Cut off power and water level pressure switch wire

connection, measure the resistance of 11 and14 pin,

is it infinite? If not, it is water level pressure switch

failure and replaces it. If it is, then repair and check

PCB and wire as followed.

N

Y

The wire between PCB

and drain pump is not

connected properly.

Replace the wire.

Check the white wire and black wire of NTC,

are they connected well?

Connect all wires well

Disconnect the white wire and black wire

from PCB, and measure if the resistance

between white wire and black wire of PCB, is

it infinite?

Y

N

Y

Replace wire

Page 24

SERVICE

MANAUL

HW50-1002W

Front Load Washing Machine

24

Error 4

The start indicator lighted on 0.2s andoff 0.2s for 4 times,repeat 4s later .

Error message:The heater may be broken

Troubleshooting:

N

Error 5

The start indicator lighted on 0.2s andoff 0.2s for 5 times,repeate 4s later .

Error message: The required water level is not reached within 8 min, or the water level exceeds the

protection value

Troubleshooting:

Y

Cut off power, check the resistance of

two pins of heater element by

multimeter, is it between 32-35Ω?

Heater element must

be broken, please

replace it

N

Check if inlet valve is jammed

Clean inlet valve

N

Draw out the dispenser and check if

water is entering

Observe if the

height of drain pipe

not reach 80 cm. If

water level pressure

switch and the hose

is leakin

g g

as

N

Check if tap is closed or water

pressure is too low (usual

between0.2 -1 MPa)

Open the tap or wait for normal water

pressure to use

N

The control wire may be broken,

Otherwise the PCB must be broken;

Please replace the broken.

Y

Y

Y

Check if water is leaking from washer

bottom. Inlet pipe. drain pipe or

other pipe connection

Y

N

Check if overload laundry. Reduce the laundry

Y

Connect it well.

Page 25

SERVICE

MANAUL

HW50-1002W

Front Load Washing Machine

25

Error 7

The start indicator lighted on 0.2s andoff 0.2s for 7 times,repeate 4s later .

Error message. Motor overheat protection or is damaged.

Troubleshooting:

Error 8

The start indicator lighted on 0.2s andoff 0.2s for 8 times,repeate 4s later .

Error message. Water level exceeds protection value.

N

Turn on power, and set pre-wash

mode, then start. Check the import

voltage of electromagnetic valve by

multimeter is it between AC

220-240V?

Electromagnetic valve must be broken, please

replace it.

The wire connected PCB and inlet valve is not

properly. Please reconnect it or replace it.

Y

Cut off power and check if motor wires

are connected well

Reconnect well

Y

Measure if the resistance of motor

binding by multimeter, is it as followed?

5 -10

[1.68±8%Ω (at 20°C)]

;

8 -9[2.00±8%Ω (at 20°C)]

;

Y

Y

N

N

Y

Replace PCB

Check if export voltage from PCB to

electromagnetic valve, is it between

AC 220-240V?

N

Put the motor in normal temperature

about ten minutes, and then test

again. If the resistance is natural, it

is caused by overheated protection.

Then check and deal with

overload, abnormal voltage. If not,

please replace motor

Repair wires

Pull out the wire connection of motor

and driving computer board. Then

check if circuit is open by multimeter

Page 26

SERVICE

MANAUL

HW50-1002W

Front Load Washing Machine

26

Troubleshooting:

10-2. Examination & Troubleshooting

10-2-1. Display nothing

Troubleshooting:

10-2-2. No water inletting

N

Check if water switch hose and air collector

are jammed

Clean water switch hose and air

collector

N

Pull out water switch inserts and turn on

power, then set wash mode. while water

is entering at the position of 3/4 glass

window, check the resistance between 11

and 16, is it 0 ? Check the resistance

between 11and 14 ,is it infinite?

Replace water pressure switch

Y

Y

Without starting but electrifying, measure

the import voltage of inlet valve, is it

between AC 220-240V?

Replace PCB

Y

N

Without power ,connect inlet pipe to inlet

valve, then open the tap and observe if

water is entering in dispenser

Y

Replace inlet valve

Measure the power supply ,is it exists

220V-240V AC voltage?

Y

Repair power supply

N

Press the power switch

Check if power plug exists 220V-240V

AC voltage at the import pin

Is power switch on?

Y

N

Insert the plug well and test

N

Press power switch and check the

voltage between two pins of power

switch. Is there 220-240V AC

volta

g

e?

N

Make sure power supply cable

assembly is connected well and then

replace power switch.

Cut off power and check if plugs are

connected well by pulling the plug of

PCB.

Y

N

Y

Replace PCB

Page 27

SERVICE

MANAUL

HW50-1002W

Front Load Washing Machine

27

Troubleshooting:

N

Is the tap shut off or the water pressure

too low?

Y

Open tap or wait for normal water

pressure

N

Check if water is leaking from washer

connection, especially between inlet pipe

and tap. to make sure of no bends.

Reconnect inlet pipe.

N

Check if filter of electromagnetic valve

is jammed

Clean filter

Choose pre-wash program and start,

then check if there is 220-240V at

ex

p

ort pin of electromagnetic valve

Y

Y

Choose pre-wash program and start,

Check if there is 220-240V at import

pin of electromagnetic valve

Is there open circuit between

electromagnetic valve and PCB?

Y

N

Replace electromagnetic valve

Reconnect the wire

Replace PCB

N

N

Y

Page 28

SERVICE

MANAUL

HW50-1002W

Front Load Washing Machine

28

10-2-3. No draining

roubleshooting:

10-2-4. Abnormal noise and vibration

Troubleshooting:

Turn filter anticlockwise , open and

check if filter is jammed

Clean and tighten filter clockwise.

Y

Is the pack screws dismantled?

Dismantle the screws

Clean

N

Is the height of drain pipe too high?

N

Adjust the height of drainpipe to

80-100 cm

Y

Y

Arrange hose and clean

Adjust adjustable feet

Is washer in balance?

Y

Turn on power and set spin program,

then start,check if there is different

noise from motor

Check if hose-connecting cylinder to

pump is bent or jammed

Turn on power and choose spin

program to start. Measure if import

voltage of drain pump is 220-240V

Cut off and check if the connection

between drain pump and PCB is open

Replace drain pump

Replace the wire .

N

Replace

PCB

Is belt loose or worn?

Remove belt and turn belt pulley by hand,

and then check if there is different noise

Y

Y

Replace it

Dismantle triangle and

check the bearing. If it is

broken, replace it.

Replace motor

N

N

N

Is there foreign material in the washer ?

N

N

Y

Y

Y

N

Y

N

Y

Turn on and select spin program to start,

Measure export voltage of PCB to the

drain pump, is it 220-240V?

N

Page 29

SERVICE

MANAUL

HW50-1002W

Front Load Washing Machine

29

N

10-2-5. Water leaking

Troubleshooting:

Y

Is drain pipe broken?

Readjust it

Is cushion of sight window broken?

Replace drainpipe

Reassemble or repair

Is water leaking from outer cylinder?

Remove clothes

Y

Y

Check if water is leaking from the inlet pipe

or the tap

N

Check if there is foreign material nipped

between cushion of sight window and

sight window

Check if all tubes and tie-in is leaking

water, including the connecting of tube

and valve, dispenser, tube and dispenser,

outer cylinder-cushion of sight

window-hose and outer cylinder, drain

pump and gas valve

Y

Y

Replace outer cylinder

N

N

N

Page 30

SERVICE MANUAL

Front Load Washing Machine

Chapter 11 Maintenance

HW50-1010

Page 31

SERVICE MANUAL

Front Load Washing Machine

HW50-1002W

Page 32

SERVICE

MANAUL

HW50-1002W

Front Load Washing Machine

32

Sincere Forever

Loading...

Loading...