Haier HP200M3, HP250M3, HP250M3C Installation And Service Manual

Heat Pump Water Heater

Installation and Service Manual

Model

HP200M3

HP250M3

HP250M3C

Please read this manual carefully prior to your use of this water heater.

The appearance of the water heater given in this manual is for reference only.

Contents

1. Product safety statement.......................................................................................................... 3

2. Functionings & principles .................................................................................................... 4

3. Technical parameters ............................................................................................................ 5

4. Description of parts and components ................................................................................. 6

5. Installation introduction ........................................................................................................11

6. Operating and settings.............................................................................................................. 22

7. Faults and protection ............................................................................................................... 25

8. Faults and protection .................................................................................................................26

9. The method of dismantling products ........................................................................................33

10. Repairs common tools ............................................................................................................38

2

1. Product safety statement

1. This appliance can be used by children aged from 8 years and above and persons with reduced

physical, sensory or mental capabilities or lack of experience and knowledge if they have been

given supervision or instruction concerning use of the appliance in a safe way and understand the

hazards involved. Children shall not play with the appliance. Cleaning and user maintenance shall

not be made by children without supervision.

2. Children shall be closely supervised to make sure they stay away from this product.

3. The method of installing safety valve please refer to Page 16.

4. The water may drip from the discharge pipe of the pressure relief device and this pipe must be

left open to the atmosphere.

5. The water heater is to be drained according to the instructions specified on page 27.

Safety instructions (to be followed at any time)

Refrigerant: R134a; When handling product, you should

- No smoking

- Prevent the accumulation of electrostatic charges

- Work in a well ventilated place.

- Avoid contact with the skin and eyes

- Do not inhale the vapours

- Evacuate the hazardous area

- Stop the leakage

3

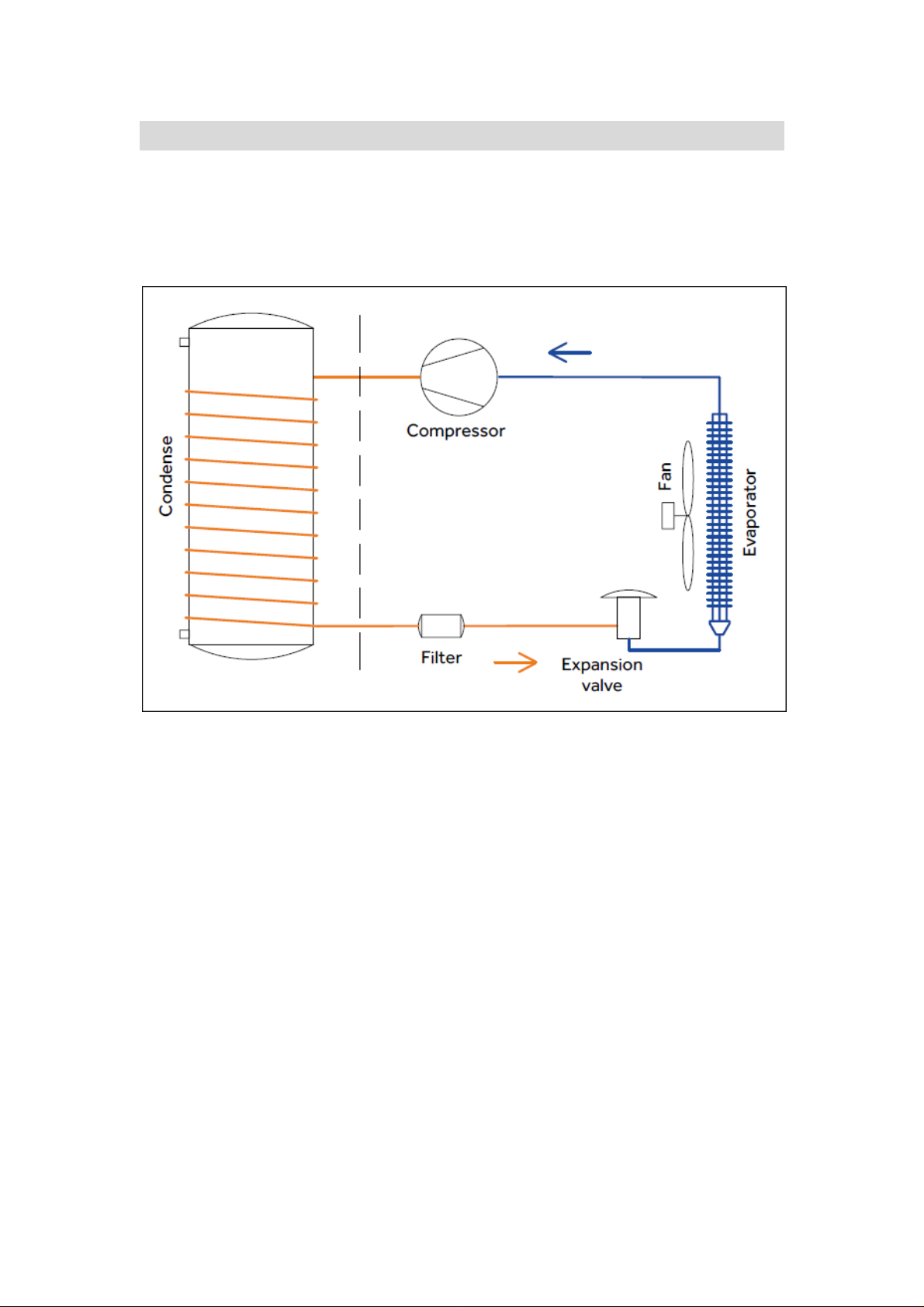

2. Functionings & principles

A low-pressure liquid refrigerant is vaporized in the heat pump's evaporator and passed into the

compressor. As the pressure of the refrigerant increases, so does its temperature. The heated

refrigerant runs through a condenser coil within the storage tank, transferring heat to the water

stored there. As the refrigerant delivers its heat to the water, it cools and condenses, and then

passes through an expansion valve where the pressure is reduced and the cycle starts over.

4

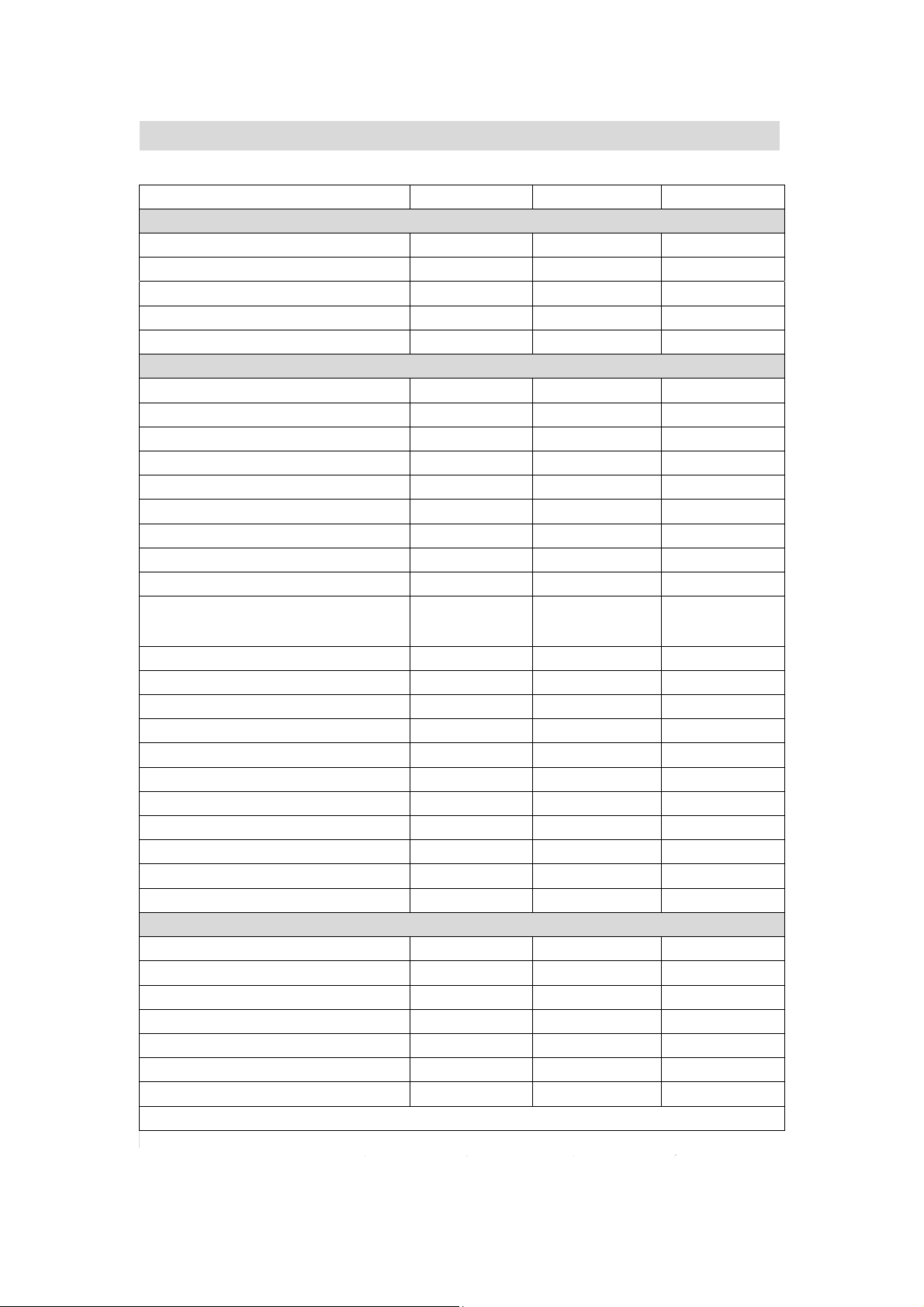

3. Technical parameters

Model HP200M3

HP250M3

HP250M3C

Tank

Tank volume 195L

246L

240L

Rated voltage/ frequency

220V~240V/50Hz

220V~240V/50Hz

220V~240V/50Hz

Tank rated pressure

0.7MPa

0.7MPa

0.7MPa

Corrosion protection

Magnesium rod

Magnesium rod

Magnesium rod

Water proof grade

IPX4 IPX4

IPX4

Performances

Type of extraction

Ambient / Exterior

Ambient / Exterior

Ambient / Exterior

COP@7℃/EN16147

3.04

3.02

3.10

COP@14℃/EN16147

3.39 3.41 3.56

Tapping cycle L L L

Power input by electric backup

1500W

1500W

1500W

Rated power input by heat pump

495W

495W

495W

Maximum power input by heat pump

865W

865W

865W

Maximum power input

2365W

2365W

2365W

Standby power input/ Pes

27W 27W

27W

Max volume of usable hot water at 40℃

setting at 55℃

224L

311L 332L

Heating up time (7℃)

5.5 h 7.35h

6.92h

Heating up time (14℃)

4.68h

6.17h

6h

Default temperature setting

55℃

55℃

55℃

Temperature setting range- with heater

35℃-75℃

35℃-75℃

35℃-75℃

Maximum length of air inlet duct

2.5m 2.5m 2.5m

Maximum length of air outlet duct

2.5m 2.5m 2.5m

Max working pressure of refrigerant

0.8/2.8MPa

0.8/2.8MPa

0.8/2.8MPa

Refrigerant type / weight

R134a/0.9kg

R134a/0.9kg

R134a/0.9kg

Sound power level

57dB 58dB

59dB

Ambient temperature for use of product

-7~35℃

-7~35℃

-7~35℃

Operating temperature of heat pump

-7~35℃

-7~35℃

-7~35℃

Dimension and connections

Water inlet and outlet connection

G3/4"F

G3/4"F

G3/4"F

Safety valve connection

G3/4"F

G3/4"F

G3/4"F

Drain & Water intlet connection

G3/4"F

G3/4"F

G3/4"F

Product Dimensions

600*629*1692mm

600*629*1987 mm

600*629*1987 mm

Packing dimension without pallet

736*695*1810 mm

736*695*2120 mm

736*695*2120 mm

Packing dimension with pallet

736*695*1940 mm

736*695*2250 mm

736*695*2250 mm

Net/Gross weight

91/103kg

102/115kg

119/132kg

* The COP and noise level data was tested in Haier lab

5

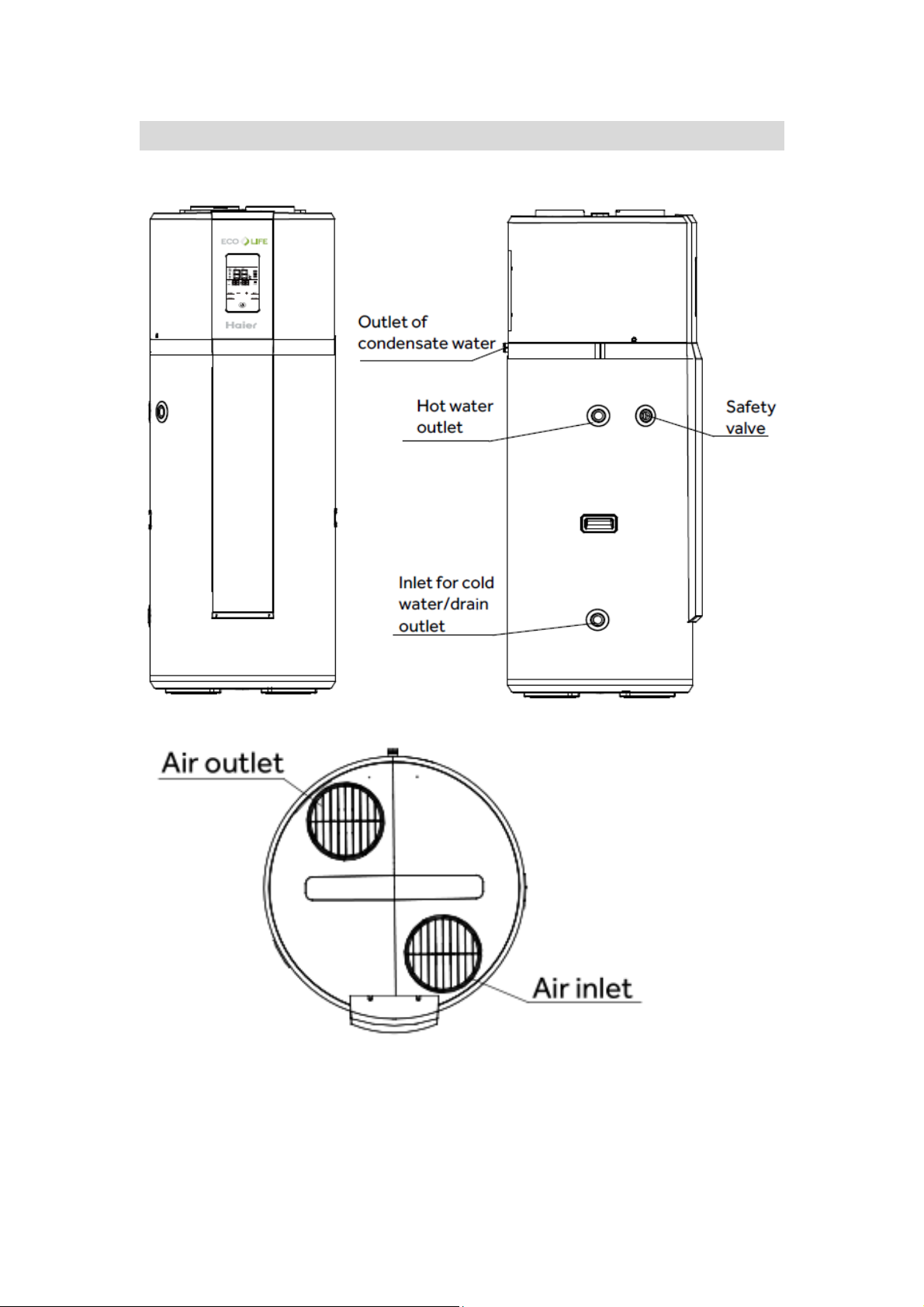

4. Description of parts and components

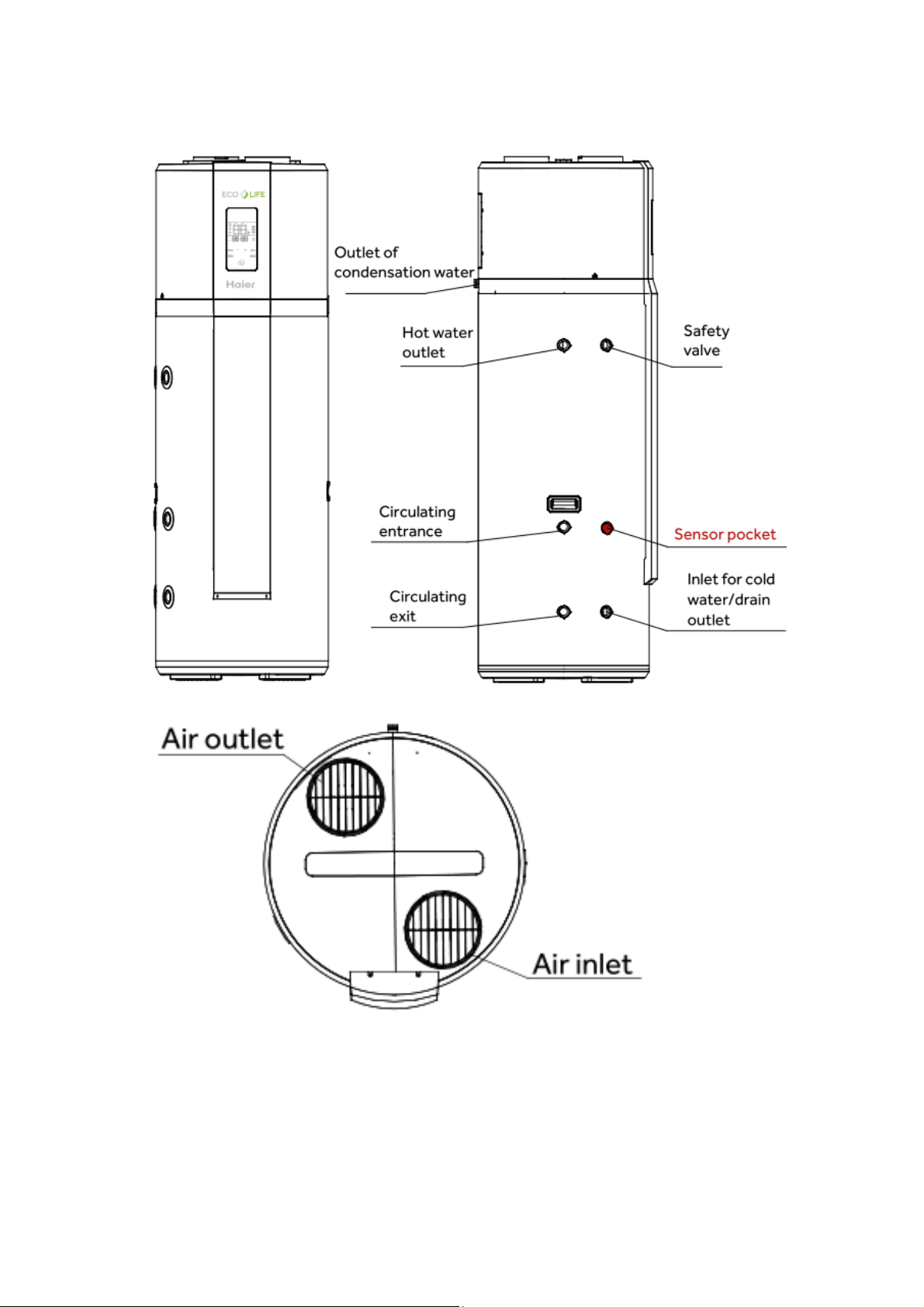

Heat pump structure(HP200M3/HP250M3)

6

Heat pump structure(HP250M3C)

7

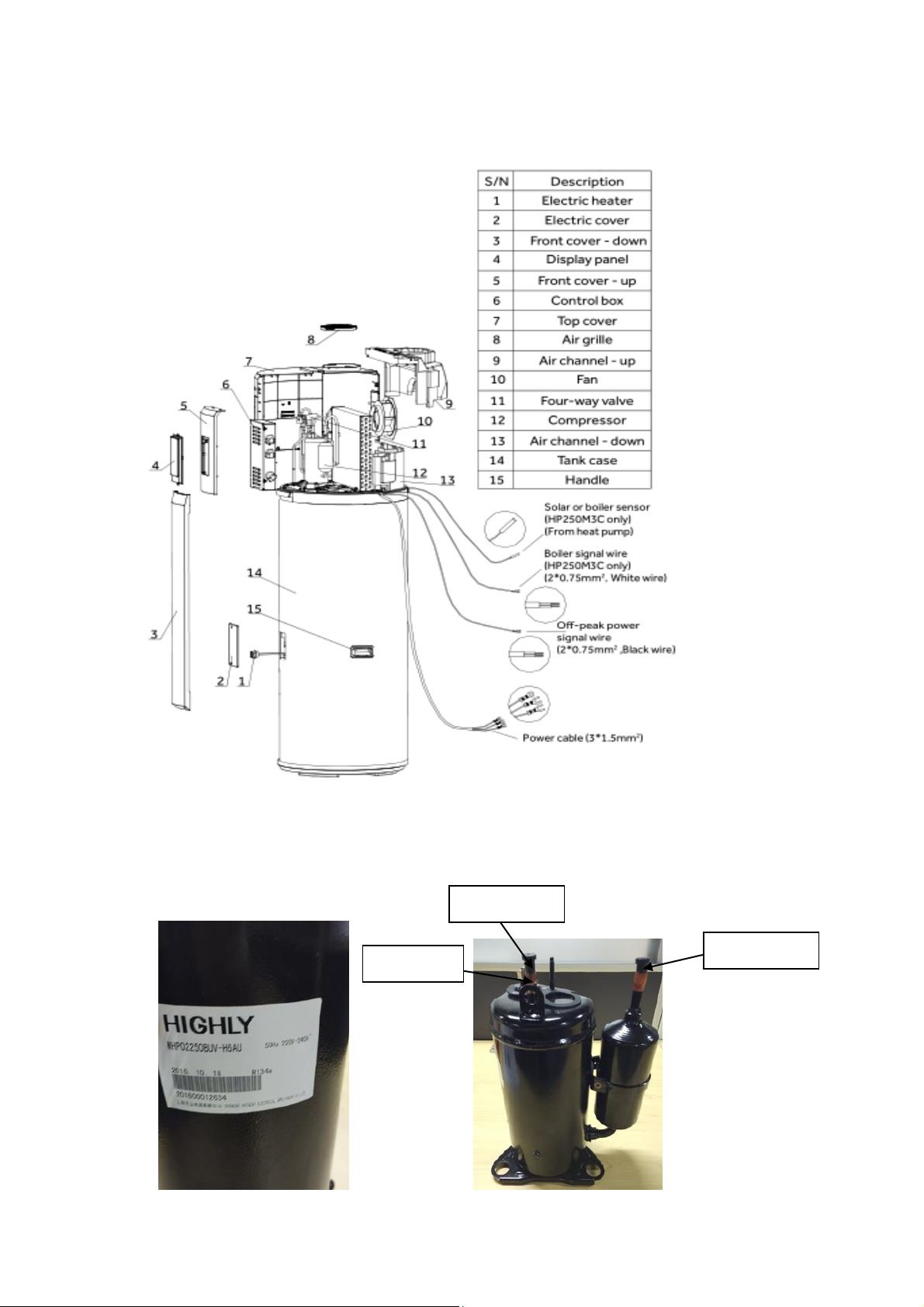

Exploded view

Intake pipe

Exhaust pipe

Wiring box

Heat pump system components

1. Compressor

The compressor is to effect a low-temperature low-pressure evaporator refrigerant vapor sucked

and compressed into high temperature and pressure of the superheated vapor, and then discharged

to the condenser heat exchanger.

8

2. Evaporator

Evaporator effects: it makes the liquid refrigerant absorbs heat and is evaporated into steam.

3. Condenser

A condenser: high-temperature high-pressure refrigerant vapor is condensed into liquid, during

condensation, the refrigerant vapor discharge heat, the heat is absorbed by the heating medium.

4. Electronic expansion valve:

The refrigerant passes through the electric expansion valve, the pressure from the condensing

pressure is reduced to the evaporation pressure, part of the refrigerant will evaporate into gas in

the throttling process.

5. Filter

It’s interior has a filter and desiccant, the desiccant absorbs moisture from the refrigerant, the filter

can filter out impurities in the refrigerant.

9

Service valve

nuts

6. High Voltage Switchgear

High-voltage switch is to prevent excessive pressure in the system, thus affecting the life of the

system components, high-pressure of the high-voltage switch is 2.8MPa.

7. Service valve

Service valve is mainly used for filling refrigerant, after removing the nuts, it contains a valve

needle, sales staff can vacuum infusion refrigerant from here.

8. Fan

It forced air through the duct, and then flows through a heat exchanger to improve heat transfer

efficiency of the heat exchanger.

10

9. Refrigerant

Heat pump refrigerant is R134a, ODP value is 0, no damage to the ozone layer. R134a refrigerant

cans appearance is as follows:

5. Installation introduction

a. Installation precaution

- Do not install the water heater in the position where exposed to gas, vapours or dust.

- Install the appliance on a flat, solid surface. The surface can support the machine weight and the

condensate water can be drained freely.

- Noise due to operating and air flow do not bother neighbors.

- Make sure there is sufficient space left for installation and maintenance.

- There is no strong electromagnetic interference around that may affect control functions.

- There is no sulfur gas or mineral oil existing at the installation place, which may cause corrosion

of the machine and the fittings.

- The water pipe for the water heater used at temperatures below 0°C shall not freeze.

- It shall not be set in rooms where a heating system is used so that heating supply to the room

will not be affected.

- It shall not be set inside a totally-enclosed space.

- The air taken in must in no event be dusty.

- Install the appliance in a dry, frost-free room.

- Temperature of the ambient air or of the air taken in by the heat pump for optimum running:

11

from 10 to 35°C.

Keep an adequate distance between the working heat-pump and the resting places.

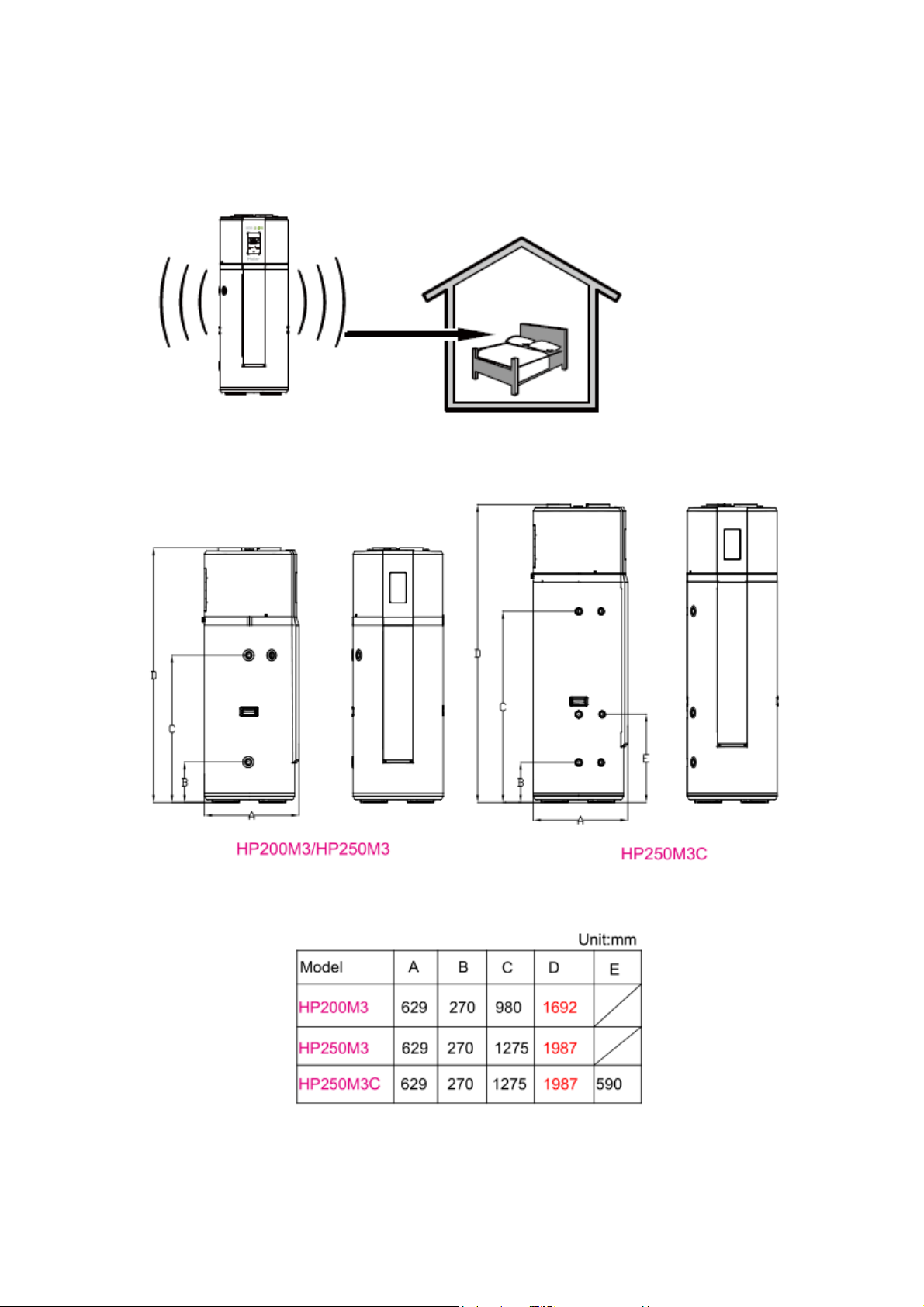

b. Installation dimensions (mm)

12

Loading...

Loading...