Haier HP200M2, HP250M2, HP250CM2 Installation And Service Manual

Heat Pump Water Heater

Installation and Service Manual

Model

HP200M2

HP250M2

HP250CM2

Please read this manual carefully prior to your use of this water heater.

The appearance of the water heater given in this manual is for reference only.

2

Contents

1. Product safety statement.......................................................................................................... 3

2. Functionings & principles .................................................................................................... 4

3. Technical parameters ............................................................................................................ 5

4. Description of parts and components ................................................................................. 6

5. Installation introduction ........................................................................................................11

6. Operating and settings.............................................................................................................. 22

7. Faults and protection .................................................. ................................................ ............. 25

8. Faults and protection .................................................. ................................................ ...............26

9. The method of dismantling products ........................................................................................33

10. Repairs common tools ............................................................................................................38

3

1. Product safety statement

1. This appliance can be used by children aged from 8 years and above and persons with reduced

physical, sensory or mental capabilities or lack of experience and knowledge if they have been

given supervision or instruction concerning use of the appliance in a safe way and understand the

hazards involved. Children shall not play with the appliance. Cleaning and user maintenance shall

not be made by children without supervision.

2. Children shall be closely supervised to make sure they stay away from this product.

3. The method of installing safety valve please refer to Page 16.

4. The water may drip from the discharge pipe of the pressure relief device and this pipe must be

left open to the atmosphere.

5. The water heater is to be drained according to the instructions specifi ed on pa ge 27 .

Safety instructions (to be followed at any time)

Refrigerant: R134a; When handling product, you should

- No smoking

- Prevent the accumulation of electrostatic charges

- Work in a well ventilated place.

- Avoid contact with the skin and eyes

- Do not inhale the vapours

- Evacuate the hazardous area

- Stop the leakage

4

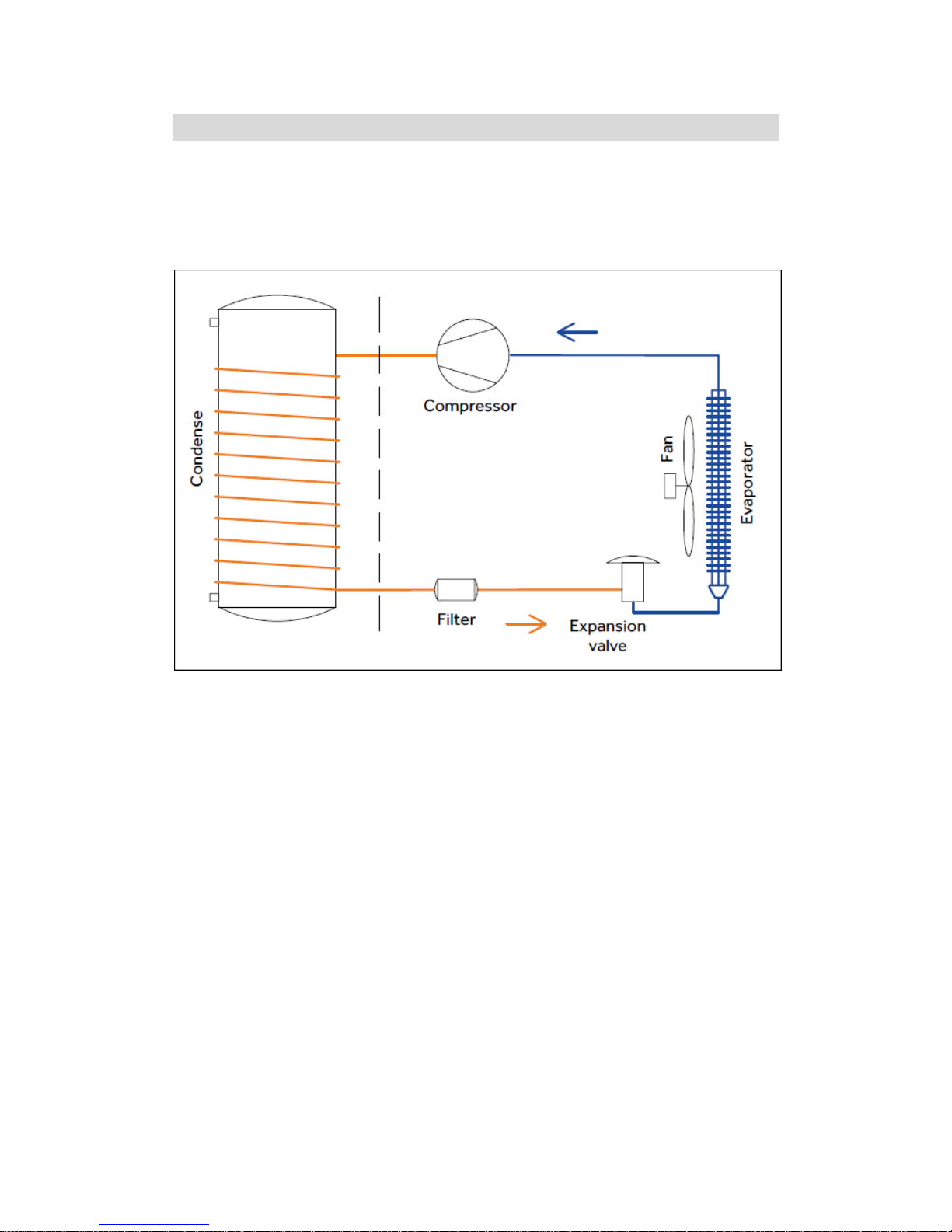

2. Functionings & principles

A low-pressure liquid refrigerant is vaporized in the heat pump's evaporator and passed into the

compressor. As the pressure of the refrigerant increases, so does its temperature. The heated

refrigerant runs through a condenser coil within the storage tank, transferring heat to the water

stored there. As the refrigerant delivers its heat to the water, it cools and condenses, and then

passes through an expansion valve where the pressure is reduced and the cycle starts over.

5

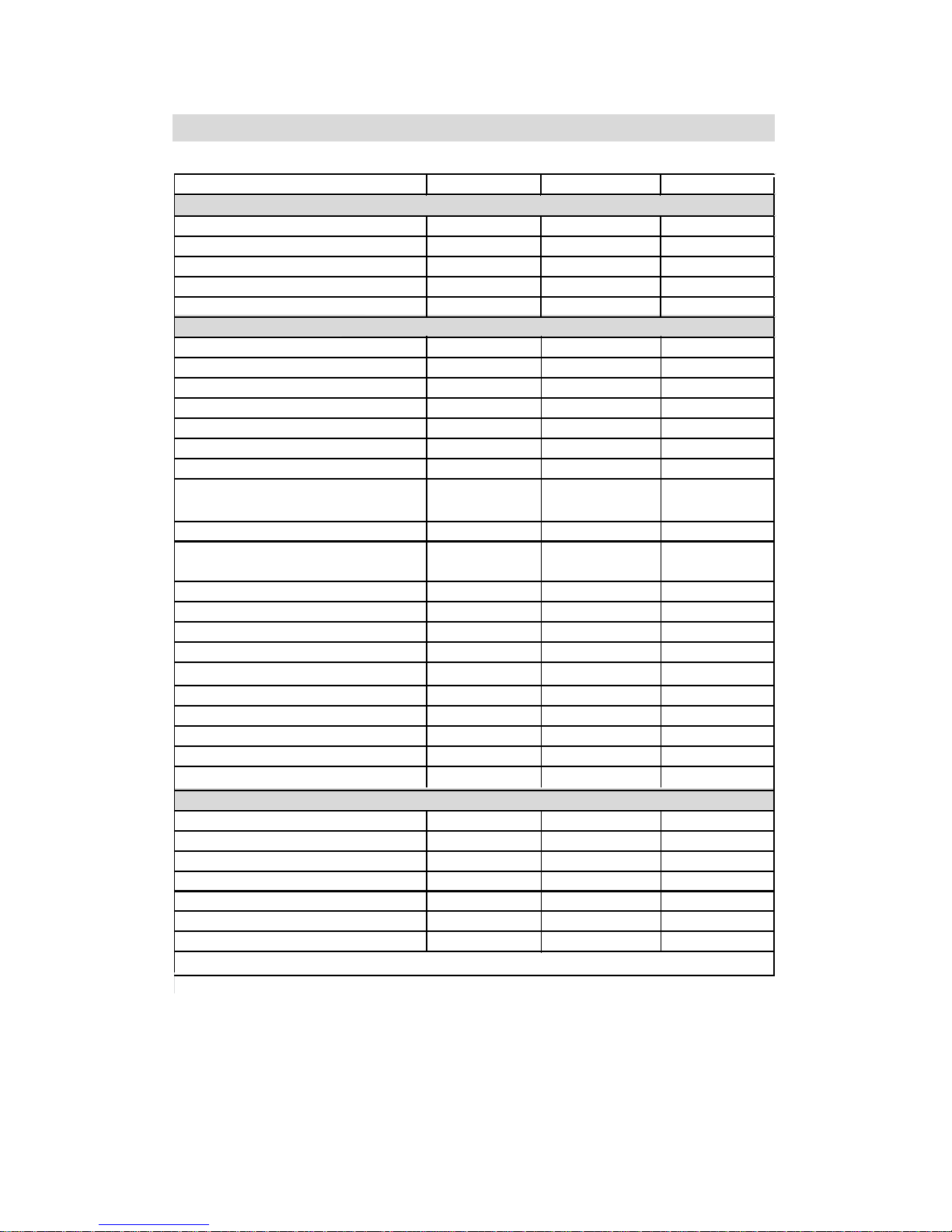

3. Technical parameters

Model HP200M2 HP250M2 HP250CM2

Tank volume 200L 250L 245L

Rated voltage/ frequency 230V/50Hz 230V/50Hz 230V/50Hz

Tank rated pressure 0.85MPa 0.85MPa 0.85MPa

Corrosion protection Magnesium rod Magnesium rod Magnesium rod

Water proof grade IPX4 IPX4 IPX4

Type of extraction Ambient / Exterior Ambient / Exterior Ambient / Exterior

COP@7

℃

/ EN16147 2.5

2.5

2.5

COP@15

℃

/ EN16147 2.9 2.9 2.9

Tapping cycle L L L

Electric heater power 2150W 2150W 2150W

Average

input - heat pump only 665W 665W 665W

Maximum input- heat pump only 850W 850W 850W

Maximum total power input of the

appliance

3000W 3000W 3000W

Standby power input/ Pes 33W 33W 33W

Max volume of usable hot water at 40

℃

setting at 55

℃

230L 300L 275L

Heating up time (7

℃

) 6.5h 8.5h 8.2h

Heating up time (15

℃

) 5.0h 6.8h 6.7h

Default temperature setting 55

℃

55

℃

55

℃

Temperature setting range- with heater 35℃-75

℃

35℃-75

℃

35℃-75

℃

Pressure drop in air circuit 25Pa 25Pa 25Pa

Max working pressure of refrigerant 0.8/2

.8MPa 0.8/2.8MPa 0.8/2.8MPa

Refrigerant type / weight R134a/0.9kg R134a/0.9kg R134a/0.9kg

Noise pressure level (2m) 40dB 40dB 40dB

Ambient temperature for use of product -5~35

℃

-5~35

℃

-5~35

℃

Operating temperature of heat pump -5~35

℃

-5~35

℃

-5~35

℃

Water inlet and outlet connection G3/4"F G3/4"F G3/4"F

Safety valve connection G3/4"F G3/4"F G3/4"F

Drain & Water intlet connection G3/4"F G3/4"F G3/4"F

Product Dimensions

600*629*1692mm 600*629*1987 mm 600*629*1987 mm

Packing dimension without pallet

736*695*1810 mm 736*695*2120 mm 736*695*2120 mm

Packing dimension with pallet

736*695*1940 mm 736*695*2250 mm 736*695*2250 mm

Net/Gross weight 104/118kg 117/131kg 136/150kg

* The COP and noise level data was tested in Haier lab

Tank

Performances

Dimension and connections

6

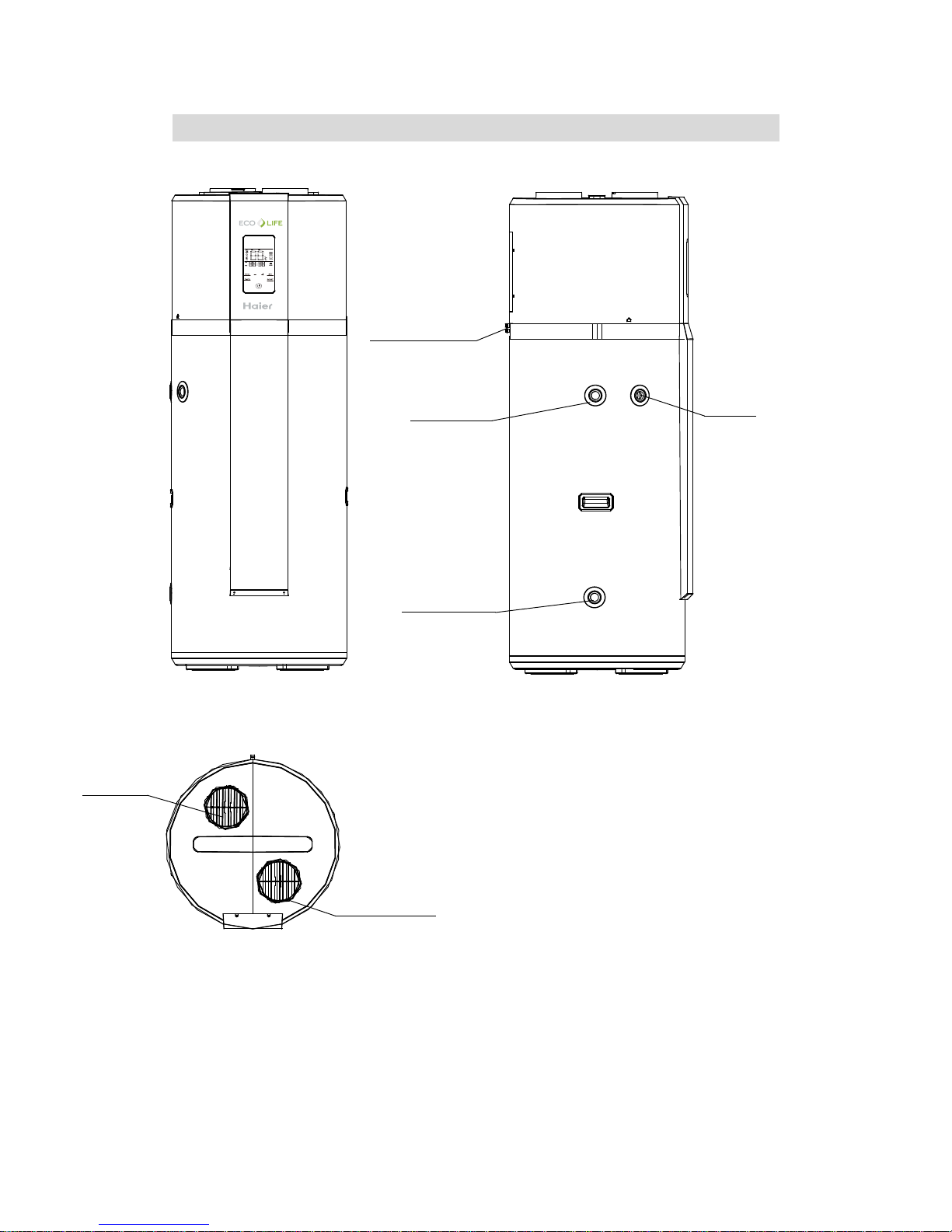

4. Description of parts and components

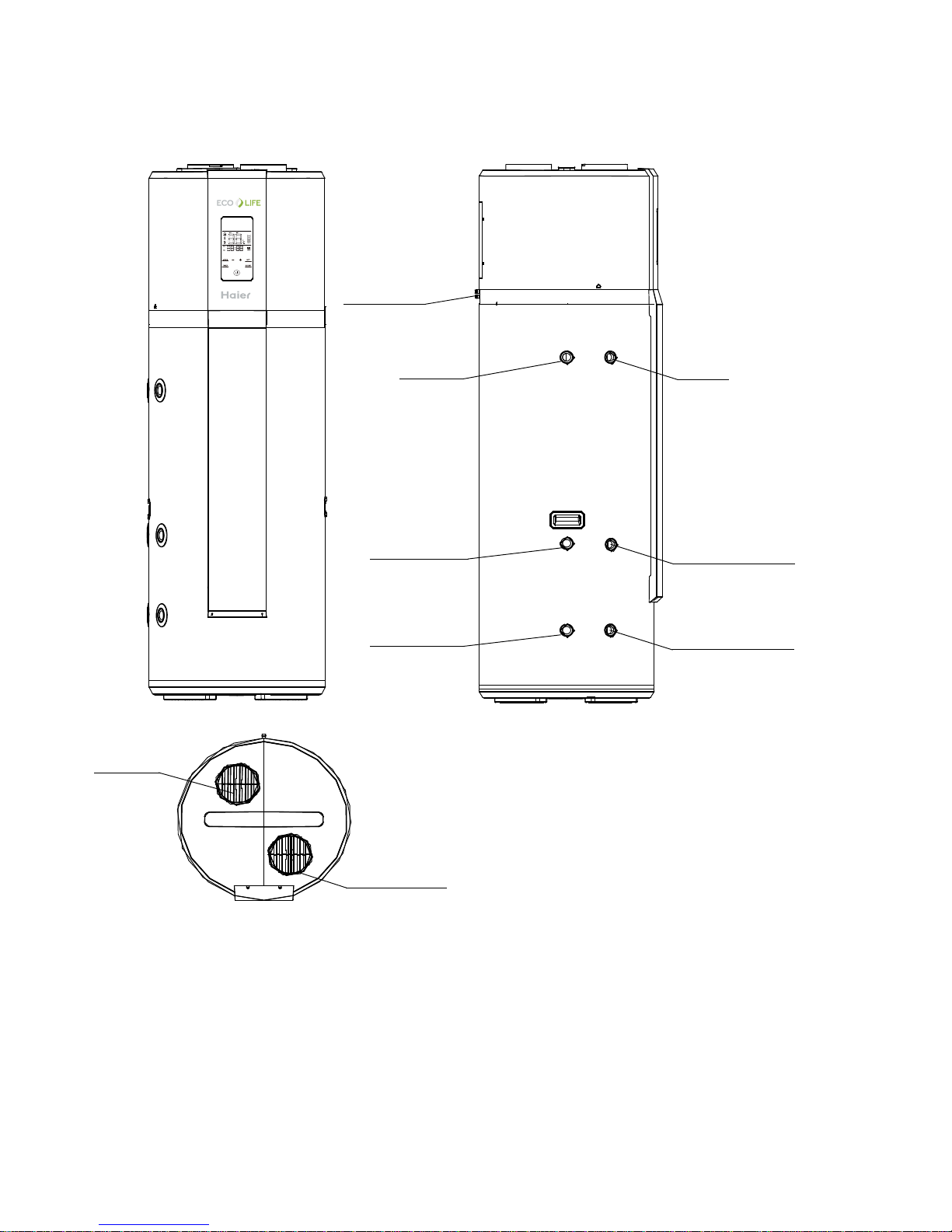

Heat pump structure(HP200M2/HP250M2)

Safety

valve

Outlet of

condensation water

Air inlet

Inlet for cold

water/drain

outlet

Hot water

outlet

Air outlet

7

Heat pump structure(HP250CM2)

Safety

valve

Outlet of

condensation water

Air inlet

Inlet for cold

water/drain

outlet

Hot water

outlet

Air outlet

HP250CM2

Circulating

entrance

Circulating

exit

Sensor pocket

8

Exploded view

Heat pump system components

1. Compressor

The compressor is to effect a low-temperature low-pressure evaporator refrigerant vapor sucked

and compressed into high temperature and pressure of the superheated vapor, and then discharged

to the condenser heat exchanger.

Inspiratory pipe

Exhaust pipe

Wiring box

5

6

7

9

10

13

12

11

12

3

4

1

4

15

8

Boiler signal wire

(HP250CM2 only)

(2*0.75mm2,White wire)

Power cable (3*1.5mm2)

Off-peak power

signal wire

(2*0.75mm2 ,Black wire)

Solar or boiler sensor

(HP250CM2 only)

(From heat pump)

1 Electric heater

2 Electric cover

3 Front cover - down

4 Display panel

5 Front cover - up

6 Control box

7

Compressor

8 Air grille

9 Air channel - up

Air channel - down

10 Fan

11 Four-way valve

12

Top cover

Tank case

13

14

15 Handle

S/N Description

2. E

v

Eva

p

3. C

A c

o

con

d

4. T

h

The

pres

the

t

5. F

i

It’s

i

can

v

aporator

orator effec

t

ondenser

ndenser: hi

g

ensation, th

e

ermal expa

n

refrigerant

p

sure is redu

c

hrottling pro

lter

nterior has a

filter out im

p

s: it makes t

h

h-temperat

u

refrigerant

v

sion valve:

asses throu

g

ed to the ev

a

cess.

filter and de

urities in the

e liquid refr

i

re high-pres

s

apor discha

r

h the ther

m

poration pr

e

siccant, the

d

refrigerant.

9

gerant abso

r

ure refriger

a

ge heat, the

h

al expansio

n

ssure, part

o

esiccant abs

o

bs heat and i

s

nt vapor is

eat is absor

b

valve, the

p

f the refrige

r

rbs moistur

e

evaporated

condensed i

n

ed by the he

a

p

ressure fro

m

ant will eva

p

from the re

f

into steam.

to liquid, d

u

ting mediu

m

the conde

n

p

orate into

g

rigerant, the

ring

.

sing

as in

filte

r

6.

H

Hig

h

syst

e

7. S

e

Ser

v

nee

d

8. F

a

It f

o

effi

c

igh Voltage

S

-voltage sw

i

m compone

n

rvice valve

ice valve is

le, sales sta

ff

n

rced air thr

o

iency of the

witchgear

tch is to pr

e

ts, high-pre

s

mainly use

d

can vacuu

m

ugh the duc

t

heat exchan

g

vent excessi

v

sure of the

h

for filling

r

infusion re

fr

, and then f

l

er.

Se

r

nuts

10

e pressure

i

igh-voltage

s

efrigerant, a

f

igerant fro

m

ows through

vice valve

n the syste

m

witch is 2.8

M

ter removin

g

here.

a heat exch

a

, thus affect

i

Pa.

the nuts, i

t

nger to imp

r

ng the life

o

contains a

v

r

ove heat tr

a

f the

alve

nsfer

9.

R

Hea

t

can

s

5.

I

a. I

- D

o

- In

s

con

d

- N

o

- M

a

- T

h

- T

h

of t

h

- T

h

- I

will

- It

s

- T

h

- In

s

- Te

efrigerant

pump refri

g

appearance

nstalla

t

nstallatio

n

not install t

h

tall the appl

i

ensate wate

r

ise due to o

p

ke sure ther

e

ere is no stro

ere is no sul

f

e machine a

n

e water pipe

t shall not b

e

not be affec

t

hall not be s

e

e air taken i

n

tall the appl

i

mperature o

f

erant is R13

4

is as follows

:

ion intr

o

precauti

e water heat

ance on a fl

a

can be drai

n

erating and

a

is sufficien

t

ng electrom

a

ur gas or mi

n

d the fitting

s

for the wate

r

set in roo

m

ed.

t inside a to

t

must in no

e

ance in a dr

y

the ambien

t

a, ODP val

u

ductio

n

on

er in the pos

i

t, solid surf

a

ed freely.

ir flow do n

o

space left f

o

gnetic interf

e

eral oil exis

t

.

heater used

a

s where a h

e

ally-enclose

d

vent be dust

y

, frost-free r

o

air or of t

h

11

e is 0, no d

a

tion where e

x

ce. The surf

a

t bother nei

g

r installation

rence aroun

d

ing at the in

s

t temperatu

r

ating syste

m

space.

.

om.

e air taken i

mage to the

posed to ga

s

ce can supp

o

hbors.

and mainte

n

that may a

ff

tallation pla

c

es below 0°

C

is used so t

h

n by the he

a

ozone layer.

, vapours or

rt the machi

ance.

ect control

f

e, which m

a

shall not fr

e

at heating s

u

t pump for

o

R134a refri

g

dust.

ne weight a

n

unctions.

y cause corr

o

eze.

pply to the

r

ptimum run

n

erant

d the

sion

oom

n

ing:

12

from 10 to 35°C.

Keep an adequate distance between the working heat-pump and the resting places.

b. Installation dimensions (mm)

HP200M2/HP250M2

HP250CM2

Loading...

Loading...