Haier Hg80b03508a, Hg80b11520a Owner's Manual

Installation, Operation and Maintenance

MODEL HG80 035 HG80 050

B

HG80 085BHG80 100

HG80 135

B

B

B

HG80 070

HG80 115

B

B

CATEGORY I NATURAL GAS AND LP GAS

MID EFFICIENCY WARM AIR FURNACE

TABLE OF CONTENTS

INTRODUCTION . . . . . . . . . . . . . . . . . . . . . . .1

SAFETY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1

CODES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2

FURNACE SIZING . . . . . . . . . . . . . . . . . . . . . .3

LOCATION of UNIT . . . . . . . . . . . . . . . . . . . .3

INSTALLATION POSITIONS . . . . . . . . . . . . . . .4

AIR CONDITIONING . . . . . . . . . . . . . . . . . . . .4

INSPECTION/ACCESS PANEL . . . . . . . . . . . . .4

CLEARANCES . . . . . . . . . . . . . . . . . . . . . . . . .5

DIMENSIONS . . . . . . . . . . . . . . . . . . . . . . . . .5

DUCTWORK . . . . . . . . . . . . . . . . . . . . . . . . . .6

DETERMING COMBUSTION AIR . . . . . . . . . .7

FURNACE VENTING . . . . . . . . . . . . . . . . . . . .8

GAS SUPPLY . . . . . . . . . . . . . . . . . . . . . . . . .13

CONVERSIONS . . . . . . . . . . . . . . . . . . . . . . .14

HIGH ALTITUDE & AIRFLOW

SPECIFICATION TABLES . . . . . . . . . . . . . . . .15

ELECTRICAL SPECIFICATIONS . . . . . . . . . . .16

START UP PROCEDURES/

SEQUENCE OF OPERATION . . . . . . . . . . . . .18

AIR FLOW . . . . . . . . . . . . . . . . . . . . . . . . . . .20

ADJUSTING BLOWER SPEEDS . . . . . . . . . . .20

MAINTENANCE

TROUBLESHOOTING . . . . . . . . . . . . . . . . . .22

WIRING DIAGRAM . . . . . . . . . . . . . . . . . . . .26

. . . . . . . . . . . . . . . . . . . . . .

21

For future reference write down the model, serial

number, and date of purchase. Use these numbers in

any correspondence or service calls concerning your

furnace.

Model

Serial Number

Date of Purchase

Keep these instructions for future reference.

Please read the operating instructions and safety

precautions carefully and thoroughly before installing

and operating your furnace. Keep this manual in a

safe place for future reference.

USER’S INSTRUCTION GUIDE

LOCATED AFTER PAGE 266 OF THIS

INSTALLATION, OPERATION AND

MAINTENANCE MANUAL

NTRODUCTION

I

This gas fired midefficiency (non-condensing) furnace is an

p flow, counterflow or horizontal flow warm air furnace

u

suitable for residential and light commercial heating

applications from 35,000 to 135,000 BTU/Hr.

his appliance is a CGA / AGA design certified as a Category I

T

chimney vent central forced air furnace with all combustion

air supplied from the ambient air around the furnace.

urnace models HG80B050, HG80B070, HG80B085,

F

HG80B100,HG80B115 and HG80B135 may be field

converted from natural gas to LP gas using Kit , or may be

field converted from LP gas to natural gas using Kit .

Contact manufacturer for conversion kit availability.

urnace

F

*

LP, and is not approved for conversion.

The furnace is shipped completely assembled. Please inspect

for damage, as the furnace is unpacked.

model HG80B035 cannot be converted to

SAFETY

Throughout the manual, symbols and words are used to

draw attention to potentially hazardous conditions.

DANGER

THIS INDICATES AN IMMINENTLY HAZARDOUS

SITUATION WHICH, IF NOT AVOIDED, WILL RESULT IN

DEATH OR SERIOUS INJURY.

WARNING

THIS INDICATES A POTENTIALLY HAZARDOUS

SITUATION WHICH, IF NOT AVOIDED, COULD RESULT IN

DEATH OR SERIOUS INJURY.

CAUTION

THIS INDICATES A POTENTIALLY HAZARDOUS

SITUATION, WHICH, IF NOT AVOIDED, MAY RESULT IN

MINOR OR MODERATE INJURY.

. Always install furnace to operate within the furnace’s

6

intended temperature rise range with a duct system

which has an external static pressure within the

allowable range, as specified in the Furnace Sizing

section on page 3, the Ductwork section on page 6, and

he Airflow section on page 20 of these instructions

t

7. When a furnace is installed so that the supply ducts carry

air circulated by the furnace to areas outside the space

ontaining the furnace, the return air shall also be

c

handled by duct(s) sealed to the furnace casing and

terminating outside the space containing the furnace.

(Furnace for heating the home located in the attached

arage, for example).

g

8. A gas fired furnace for installation in a residential

garage must be installed so that the burners and ignitor

are no less than 18 inches above the floor. The furnace

must be located, or protected to avoid physical damage

by vehicles.

THIS FURNACE IS NOT TO BE USED FOR TEMPORARY

9.

HEATING FOR BUILDINGS UNDER CONSTRUCTION.

10. Nox Baffles are factory installed in the heat exchanger

tubes of this furnace, and must remain installed

regardless of fuel being used.

DANGER

DO NOT INSTALL THIS FURNACE IN A MOBILE HOME!

THIS FURNACE IS NOT APPROVED FOR INSTALLATION IN

A MOBILE HOME. DOING SO COULD CAUSE FIRE,

PROPERTY DAMAGE, PERSONAL INJURY OR LOSS OF

LIFE.

WARNING

THE FURNACE CONTAINS FOIL COVERED FIBERGLASS

INSULATION. INHALATION OF FIBERGLASS PARTICLES IS

ASSOCIATED WITH RESPIRATORY DISEASE INCLUDING

CANCER.

SAFETY RULES:

1. Use this furnace only with type of gas approved for this

furnace. Refer to the furnace rating plate.

2. Install this furnace only in dry indoor locations

(protected from weather).

3. Provide adequate combustion and ventilation air to the

furnace space as specified in the Determining

Combustion Air section on page 7 of these instructions.

4. Combustion products must be discharged outdoors.

Connect this furnace to an approved vent system only, as

specified in the Furnace Venting section on page 8 of

these instructions.

5. Never test for gas leaks with an open flame. Use a

commercially available soap solution made specifically

for the detection of leaks to check all connections as

specified in the Gas Supply section on page 13 of these

instructions.

WARNING

THE FUEL SUPPLIER NORMALL

GAS AND PROP

MAY NOT BE PERCEIVABLE. INSTALLATION OF UL AND

CUL RECOGNIZED FUEL GAS DETECTORS INSTALLED IN

ACCORDANCE WITH THEIR MANUFACTURER’S

INSTRUCTIONS IS RECOMMENDED AS AN ADDITIONAL

MARGIN OF SAFETY

ANE. IN SOME CASES, THE ODORANT

.

Y ODORIZES NATURAL

DANGER

FIRE OR EXPLOSION HAZARD

If the information in these instructions is not followed

exactly, a fire or explosion may result, causing property

damage, personal injury or loss of life.

CAUTION

MAKE SURE TO REMOVE FOAM BLOWER HOUSING

SHIPPING SUPPORTS BEFORE OPERATING FURNACE.

SHIPPING SUPPORTS ARE LOCATED ON THE BOTTOM

RIGHT AND BOTTOM LEFT SIDES OF BLOWER HOUSING.

1

WARM AIR FURNACE

DANGER

WHAT TO DO IF YOU SMELL GAS:

• DO NOT TRY TO LIGHT ANY APPLIANCE

• DO NOT TOUCH ANY ELECTRICAL SWITCH; DO NOT

USE ANY PHONE IN YOUR BUILDING

IMMEDIATELY CALL YOUR GAS SUPPLIER FROM A

•

EIGHBOR’S PHONE, OR A CELLULAR PHONE FROM A

N

LOCATION WELL AWAY FROM THE BUILDING.

FOLLOW THE GAS SUPPLIER’S INSTRUCTIONS.

IF YOU CANNOT REACH YOUR GAS SUPPLIER, CALL

•

THE FIRE DEPARTMENT

• DO NOT ENTER THE BUILDING UNTIL AUTHORIZED TO

DO SO BY THE GAS SUPPLIER OR THE FIRE

DEPARTMENT

IMPROPER INSTALLATION, OPERATION, ADJUSTMENT,

ALTERATION, SERVICE OR MAINTENANCE CAN CAUSE

INJURY, PROPERTY DAMAGE OR LOSS OF LIFE. REFER TO

THIS MANUAL FOR PROPER INSTALLATION, OPERATION,

VICE, AND MAINTENANCE INSTRUCTIONS.

SER

A QUALIFIED INSTALLER, SERVICE AGENCY OR

THE GAS SUPPLIER MUST PERFORM

INSTALLATION AND SERVICE.

DO NOT DESTROY THIS MANUAL

PLEASE READ CAREFULLY AND KEEP IN A SAFE PLACE

FOR FUTURE REFERENCE BY A SERVICE TECHNICIAN.

WARNING

THESE INSTRUCTIONS ARE INTENDED AS AN AID TO

QUALIFIED SERVICE PERSONNEL FOR PROPER

INSTALLATION, ADJUSTMENT AND OPERATION OF THIS

FURNACE. READ THESE INSTRUCTIONS THOROUGHLY

BEFORE ATTEMPTING INSTALLATION OR OPERATION.

FAILURE TO FOLLOW THESE INSTRUCTIONS MAY RESULT

IN IMPROPER INSTALLATION, ADJUSTMENT, SERVICE OR

MAINTENANCE, POSSIBLY RESULTING IN FIRE,

ELECTRICAL SHOCK, CARBON MONOXIDE POISONING,

EXPLOSION, PROPERTY DAMAGE, PERSONAL INJURY OR

DEATH.

DO NOT STORE OR USE GASOLINE OR OTHER

FLAMMABLE VAPORS AND LIQUIDS, OR OTHER

COMBUSTIBLE MATERIALS IN THE VICINITY OF THIS OR

ANY OTHER APPLIANCE.

WARNING

THE EXHAUST GASES FROM THIS FURNACE CONTAIN

CHEMICALS, WHICH ON SOME OCCASIONS MAY

INCLUDE CARBON MONOXIDE (CO). CARBON

MONOXIDE IS AN ODORLESS, TASTELESS, CLEAR

COLORLESS GAS, WHICH IS HIGHL

CONCENTRA

DEFECTS AND OTHER REPRODUCTIVE HARM.

UL AND CUL RECOGNIZED CO DETECTORS ARE

RECOMMENDED FOR ALL BUILDINGS EQUIPPED WITH

FOSSIL FUEL BURNING APPLIANCES. ALL CO DETECTORS

SHOULD BE INST

MANUFACTURER’S INSTRUCTIONS AND APPLICABLE

LOCAL BUILDING CODES.

TIONS ARE SUSPECTED OF CAUSING BIR

ALLED IN ACCORDANCE WITH THEIR

Y TOXIC. EVEN LOW

TH

DANGER

HEN THIS FURNACE IS INSTALLED IN A RESIDENTIAL

W

GARAGE, IT MUST BE INSTALLED SO THE BURNERS AND

IGNITION SOURCE ARE LOCATED NO LESS THAN 18

INCHES ABOVE THE FLOOR TO PREVENT THE RISK OF

IGNITING FLAMMABLE VAPORS WHICH MAY BE

RESENT IN THE GARAGE.

P

THE FURNACE MUST BE LOCATED OR PROTECTED TO

AVOID PHYSICAL DAMAGE BY VEHICLES.

FAILURE TO HEED THESE WARNINGS CAN CAUSE A FIRE

OR EXPLOSION, RESULTING IN PROPERTY DAMAGE,

PERSONAL INJURY OR LOSS OF LIFE.

CODES:

This furnace must be installed:

• In accordance with all local codes, bylaws and

regulations by those authorities having jurisdiction

• In the United States, this furnace must be installed in

accordance with the current ANSI Z223.1 (NFPA 54)

National Fuel Gas Code

• In Canada, this furnace must be installed in

accordance with the current CAN/CGA -B149

Installation Code for Fuel Burning Appliances

Electrical connections must be made in accordance

with:

• Any applicable local codes, bylaws and regulations

• Canada: current edition of CAN/CSA C22.1, Canadian

Electrical Code (Part 1)

• United States: current edition of ANSI/NFPA 70,

National Electrical Code

Codes and additional information may be obtained

from:

•

American Gas Association

1515 Wilson Boulevard

Arlington, VA, 22209

703-841-8400

National Fire Protection Association

•

1 Batterymarch Park

Quincy, MA, 02269-9101

617-770-3000

•

Canadian Gas Association

Suite 1, 243 Consumers Road

North York, ON, M2J 5E3

416-498-1994

2

URNACE SIZING

TABLE 1A

FURNACE TEMPERATURE RISE

Fur nac e Mod

Model

el Tem per atu re

Rise

35 – 65 F

30 – 60 F

35 – 65 F

30 – 60 F

35 – 65 F

30 – 60 F

30 – 65 F

TAB

LE 1B

TYPICAL A IR FLOW

CF M Re qu ired for a T of:

35 45

55 65

03508A

05012A

07012A

07016A

08512A

08516A

10012A

10016A

10020A

11520A

737 574 469 397

1053 819 670 567

1433 1114 912 771

1433 1114 912 771

1791 1393 1140 964

1791 1393 1140 964

2107 1639 1341 1134

2107 1639 1341 1134

2107 1639 1341 1134

2423 1884 1542 1305

13520A

2844 2212 1810 1532

03508A

05012A

07012A

07016A

08512A

08516A

10012A

10016A

10020A

11520A

13520A

F

The maximum hourly heat loss for each heated space shall

e calculated in accordance with the procedures described

b

in Manual J titled, "Load Calculation" published by the Air

Conditioning Contractors of America, or by any other

method which is suitable for local conditions, provided the

esults obtained are in substantial agreement with, and not

r

less than those obtained using the procedure described in

their manual.

n Canada, the maximum hourly heat loss for each heated

I

space shall be calculated in accordance with the procedures

described in the manuals of the Heating, Refrigeration and

Air Conditioning Institute of Canada (HRAI), or by any other

method which is suitable for local conditions, provided the

results obtained are in substantial agreement with, and not

less than those obtained using the procedure described in

their manuals.

If the installation is a retrofit application, do not rely on the

capacity of the existing heating equipment as a method to

size the new furnace. Many of the heat transfer multiples

listed in earlier versions of load calculation manuals were

much higher than those listed in more recent editions. It is

possible that energy saving measures have been completed

since the installation of the existing furnace. This might

include additional insulation in the attic or walls, the

application of sprayed foam insulation, the addition of

storm windows and doors, weather stripping, caulking, etc.

Many of the older furnaces were equipped with large belt

drive blower systems, operating at low RPMs. If replacing an

existing furnace, be sure that the existing ductwork can

handle the amount of airflow necessary for a reasonable

temperature rise. Most older gas furnaces operated with a

system temperature rise of 70 - 100°F. This series furnace has

been designed for operation with a system temperature rise

(DT) of 35 - 65°F or 30 – 60°F depending on which model is

being installed. See Table 1A below. If the furnace selected

has an identical output capacity as the original furnace, a

substantial increase in system airflow will be required. See

able 1B below

T

Existing ductwork should be assessed for its air handling

capabilities. For residential applications, the recommended

air velocity of a supply air trunk duct is 700 feet per minute

(fpm), and should not exceed 900 fpm. The recommended

air velocity of a supply air branch run is 600 fpm, and should

not exceed 900 fpm. These values are slightly lower for

flexible ducting. The recommended air velocity of a return

air trunk duct is 600 fpm, and should not exceed 700 fpm.

The recommended and maximum air velocity of a return air

branch is 600 fpm.

.

he equal friction chart, as published by ASHRAE and HRAI,

T

is the basis for the various air duct calculators available

through heating supply companies.

NOTE: The return air system is equally as important as the

supply air system. An undersized return air system will

prevent sufficient quantities of air from reaching the supply

air system, properly sized or otherwise, and will

consequently reduce the service life of the furnace and its

components.

LOCATION of UNIT

GENERAL:

1. The furnace is not weatherized. Select a dry indoor

location.

2. Select a location where the furnace venting can be

routed between the furnace and the chimney or B-Vent

with a minimum of lengths and fittings. Be sure to

check that the proposed routing will meet code

requirements with respect to minimum clearances.

3. Select a location as near as possible to the existing or

proposed duct system.

4. The furnace location must permit access for servicing,

and be within the clearance to combustibles guidelines

as marked on the appliance rating plate.

5. The furnace should be installed on a firm base when

installed in the upflow position. This is typically a

concrete floor if installing the furnace in a basement.

6. If the furnace is being installed so that the return air

will enter through the bottom, the perimeter of the

furnace must be properly supported.

7. When installed in the horizontal position, the furnace

may be supported from the bottom, or suspended.

8. When installed in the down flow position on a

combustible floor, subbase kit is required

(contact manufacturer for availability).

OTHER CONSIDERATIONS:

• This furnace is not to be used for temporary heating of

buildings or structures under construction.

• If this furnace is to be used with air conditioning and is

to be installed in an area over a finished ceiling or

living area, install a field fabricated auxiliary drain pan

under the furnace to protect that area from accidental

condensate spills. The auxiliary pan should be large

enough to collect accidentally spilled condensate from

the air conditioning evaporator coil assembly if

applicable. Follow local codes.

These furnaces are approved for installation in attics,

•

alcoves, utility rooms, closets and crawlspaces. If this

furnace is to be installed in a utility room, be sure that

it is located in such a way as to allow access for

servicing or the removal of any other appliance, (hot

water heater, for example).

If the furnace is to be installed in a garage, the burners

•

must be a minimum of 18 inches (460 mm) above the

floor.

If the furnace is to be installed in a commercial (repair)

•

garage, the burners must be a minimum of 4.5 feet

(1375 mm) above the floor.

The furnace must be protected from physical damage

•

by metal barriers or other acceptable means.

3

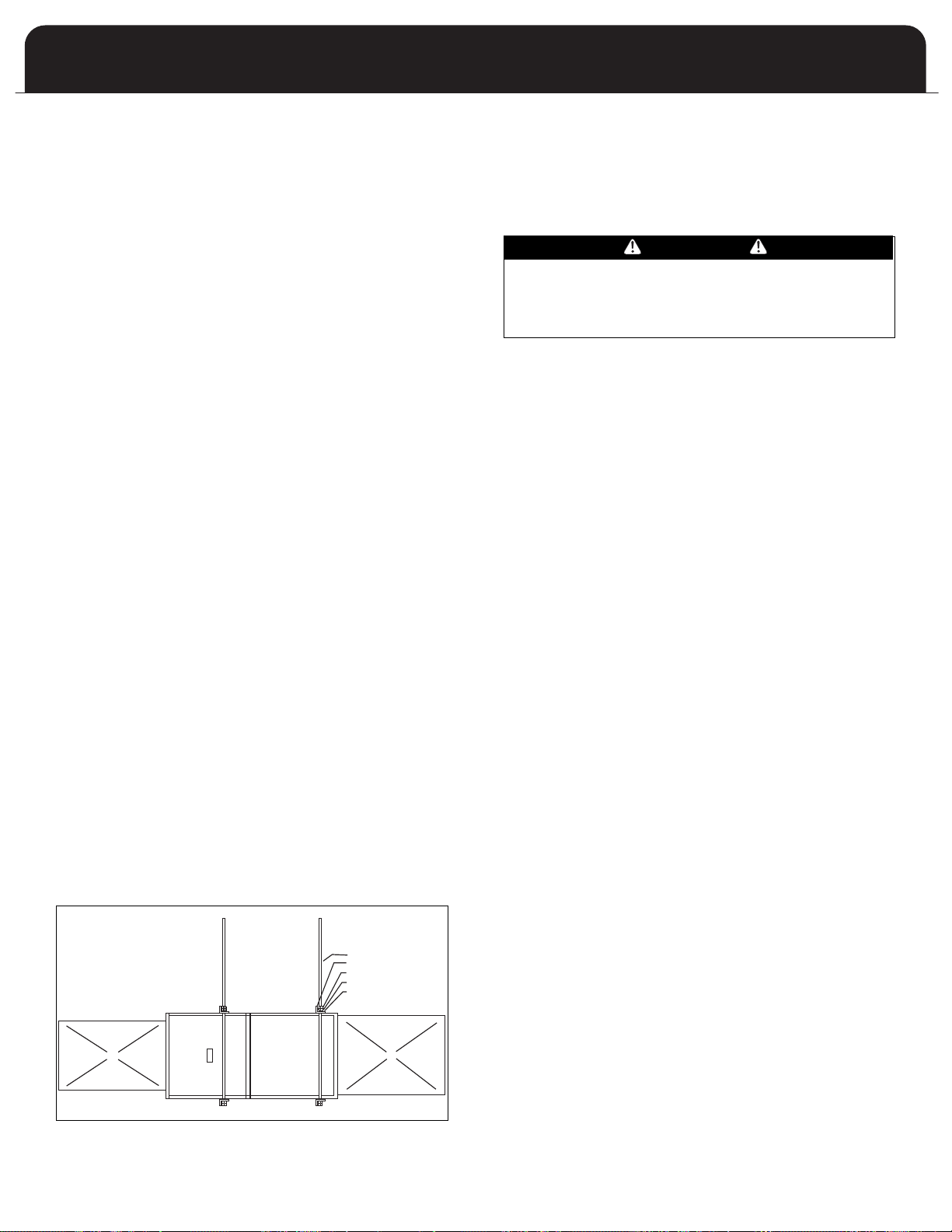

SUGGESTED METHOD FOR

SUSPENDING HORIZONTAL FURNACE

ALLOW ENOUGH ANGLE

IRON OVERHANG TO

PERMIT OPENING THE

BLOWER DOOR

3/8 INCH THREADED ROD

2 INCH ANGLE IRON

JAM NUTS

LOCK WASHER

FLATWASHER

SUPPLY AIR PLENUM

RETURN AIR PLENUM

If the furnace is to be located in an area where the

•

combustion air is laden with chemical compounds such

as bromine, chlorine or fluorine, as may be found in

swimming pool chemicals, laundry detergents, etc., use

outdoor air for combustion. These compounds when

xposed to flame, form acids, which attack the heat

e

exchanger and other components.

A partial list of these contaminants includes:

- Aerosols, particularly CFC based aerosols

Air fresheners

-

- “Airplane” glue and similar cements

- Ammonia, as is commonly found in permanent wave

solutions used in women’s hair dressing salons

- Anti-static fabric softeners used in clothes dryers

- Carbon tetrachloride

- Chlorinated cleaners and waxes

- Chlorine and bromine based swimming pool chemicals

and treatments

- Deicing salts or chemicals, rock salt, etc.

- Dry cleaning solutions such as perchloroethylene

- Halogen based refrigerants including R-12 and R-22

- Hydrochloric acid, muriatic acid, or other acid based

masonry washing compounds

- Polyurethane and similar derivatives fumes

- Printer’s inks, paint removers, furniture strippers,

varnishes, varsol, toluene, etc.

- Water softener salts and chemicals

INSTALLATION POSITIONS

NONSUSPENDED INSTALLATION

Maintain clearances to combustibles as outlined in Table 2

on page 5. The furnace must be supported in such a way as

to not allow twisting or sagging of the cabinet.

SUSPENDED INSTALLATION

Refer to Figure 1 (below). Maintain clearances to

combustibles as outlined in Table 2 on page 5. The furnace

may be suspended by field fabricating a cradle of angle iron

and threaded rod. Secure the furnace with 2 inch minimum

slotted angle or equivalent, as shown in Figure 1 (below).

The furnace must be supported in such a way as not to

allow twisting or sagging of the cabinet. Position the

supports so as not to interfere with accessing the burner

and blower compartments.

FIGURE 1: SUSPENDED INST

ALLATION

WARM AIR FURNACE

PFLOW INSTALLATION

U

This furnace comes assembled for installation in the upflow

osition and ready for vertical venting. In the event that the

p

furnace will be installed in another position, the following

guidelines should be followed.

COUNTERFLOW INSTALLATION

WARNING

HEN INSTALLED IN THE COUNTERFLOW POSITION ON

W

A COMBUSTIBLE FLOOR, SUBBASE KIT IS

REQUIRED. FAILURE TO INSTALL SUBBASE KIT COULD

RESULT IN FIRE, DEATH OR SERIOUS INJURY.

The opening in the floor must provide adequate clearances

to the combustible material.

According to the Clearances to Combustibles Table 2 on

page 5, 1/2 inches clearance will be required between the

plenum and the combustible material. If installed on a

non-combustible material, zero clearance is required.

Inducer position changes required shall be performed in

accordance with the inducer rotation instructions in the

Furnace Venting section on page 8 of this manual. In the

counterflow installation, this furnace can only vent through

the left or right side of the furnace.

HORIZONTAL INSTALLATION

Inducer position changes required shall be performed in

accordance with the inducer rotation instructions in the

Furnace Venting section on page 8 of this manual. In the

horizontal installation, it is not permissible to vent

downwards. Therefore the orientation of left or right

horizontal position will determine the inducer orientation.

NOTE: It is not permissable to use a rear return on this

furnace although side and end returns may be used.

AIR CONDITIONING

This furnace may be used as part of an air conditioning

system. The furnace wiring and control system are “air

conditioning ready”. There are the following factors to

consider:

• The air conditioning evaporator coil must be

downstream of the heat exchanger. The cooled air

passing over the warm ambient air inside the heat

exchanger tubes can cause condensation inside the

tubes, resulting in corrosion and premature failure.

A parallel duct system can be installed to direct the air

•

from the furnace through the evaporator coil only. Use

dampers or other means to bypass the heat exchanger.

If [summer/winter] dampers are used, they should be

interlocked to prevent system operation unless the

dampers are in the full open or full closed position.

INSPECTION / ACCESS PANEL

If an air conditioning coil is not to be used in the supply air

plenum, it is recommended that the outlet duct be provided

with a removable access panel, which is accessible when

installed so the heat exchanger may be viewed for possible

openings using light assistance or a probe that can be

inserted for sampling the air stream. The access cover must

be fabricated in such a manner as to prevent leaks.

4

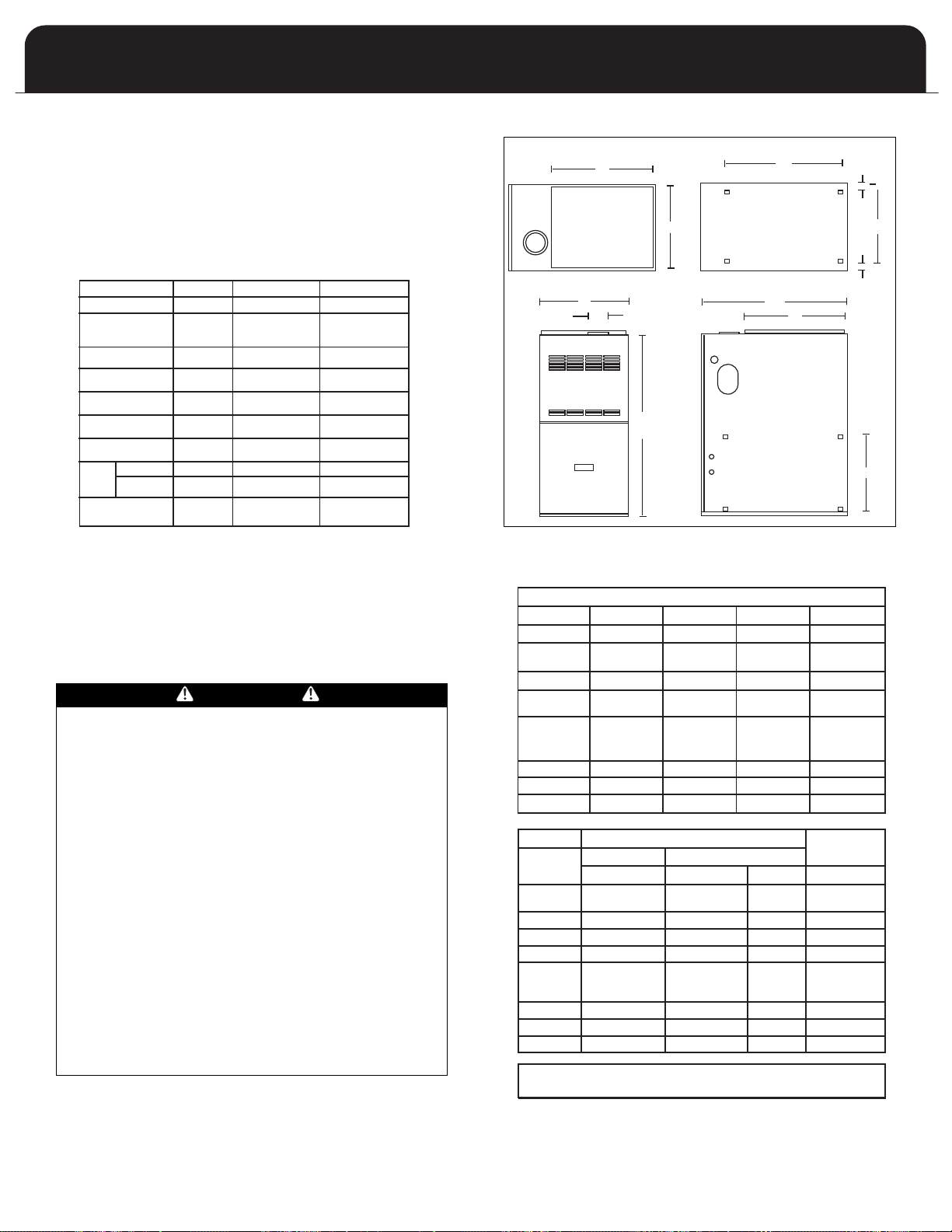

DIMENSIONS (Inche

MODEL WI DTH DEPTH HEIGHT SUPPLY

A

35-2 14-1/2 29 35 13-1/2 x 19

50-3 14-1/2 29 35 13-1/2 x 19

70-3 16 29 35 15 x 19

70-4 17-1/2 29 35 16-1/2 x 19

85-3 17-1/2 29 35 16-1/2 x 19

85-4

4100- 20-1/2 29 35 19-1/2 x 19

100-5 20-1/2 29 35 19-1/2 x 19

115-5 22 29 35 21 x 19

MODEL RETURN

S

35-2 14 x 22 13-1/2 x 22 1/2 3

1

50-3 14 x 22 13-1/2 x 22 1/2 3

1

70-3 14 x 22 14-1/2 x 22 3/4 4

70-4 14 x 22

2

85-3 14 x 22 14-1/2 x 22 1-1/2 4

85-4

4100- 14 x 22 16 x 22 2-1/4 4

100-5 14 x 22

2

115-5 14 x 22

2

1

Vent outlet 4” -

2

Two return air openings required

G

A

H

C

G

B

F

D

J

L

L

K

LEARANCES

UPFLOW

COUNTERFLOW

HORIZONTAL

1" 0" 2"

1" 1" 2.5"

.5" .5" .5"

3.5"* 3.5"* 3.5"*

0" 0" 0"

0" 0" 1"**

0"*** 0"**** 0"

6" 6" 6"

1" 1" 1"

CLOSET

CABINET

CLOSET

CABINET

CLOSET

CABINET

UNIT TOP

PLENUM

TOP/BOTTOM

PLENUM SIDES

UNIT FRONT

UNIT BACK

UNIT SIDES

ENCLOSURE

UNIT BASE

FLUE

PIPE

C VENT

B VENT

03508A

05012A

07012A

07016A

08512A

08516A

10012A

10016A

10020A

11520A

13520A

03508A

05012A

07012A

07016A

08512A

08516A

10012A

10016A

10020A

11520A

13520A

C

Table 2 (below) provides the certified clearances to

ombustibles.

c

MPORTANT:

I

This furnace requires a minimum of 24-inches of front

clearance for service purposes. For this purpose, service

clearance takes precedence over clearance to combustibles.

TABLE 2: CLEARANCES TO COMBUSTIBLES

* 24 inches required for service

** Supply air end 1 inch / return air end 0 inches

*** Certified for closet installation on combustible flooring

**** Certified for installation on combustible flooring

See the appliance rating plate affixed to the furnace

for specific model number, serial number and

clearance to combustibles information.

COMBUSTIBLE MATERIAL MUST NOT BE PLACED ON OR

AGAINST THE FURNACE JACKET.

THE AREA AROUND THE FURNACE MUST BE KEPT CLEAR

AND FREE OF ALL COMBUSTIBLE MATERIALS INCLUDING

GASOLINE AND OTHER FLAMMABLE VAPORS AND

LIQUIDS.

PLACEMENT OF COMBUSTIBLE MATERIALS ON, AGAINST

OR AROUND THE FURNACE JACKET CAN CAUSE AN

EXPLOSION OR FIRE RESULTING IN PROPERTY DAMAGE,

PERSONAL INJUR

THE HOMEOWNER SHOULD BE CAUTIONED THA

FURNACE AREA MUST NOT BE USED AS A BROOM

CLOSET OR FOR ANY OTHER STORAGE PURPOSE.

UPFLOW FURNACES ARE DESIGN CERTIFIED FOR

INSTALLATION ON COMBUSTIBLE FLOORS. THIS SHALL

BE INTERPRETED AS A WOOD FLOOR ONLY

THE FURNACE MUST NOT BE INSTALLED DIRECTLY ON

CARPETING, VINYL TILE, OR OTHER COMBUSTIBLE

MATERIAL EXCEPT WOOD. INSTALLATION ON

COMBUSTIBLE MATERIAL CAN RESULT IN FIRE, CAUSING

PROPER

only when installed on special base .

DANGER

TY DAMAGE, PERSONAL INJUR

Y OR LOSS OF LIFE.

.

Y OR DEA

IGURE 2: DIMENSIONS

F

TABLE 3: DIMENSIONS

DIMENSIONS (Inches)

MODEL WIDTH DEPTH HEIGHT SUPPLY

T THE

TH.

5

MODEL RETURN

1

Vent outlet 4” - Use reducer fittings.

2

Two return air openings required

ABCFx G

14-1/2 29 35 13-1/2 x 19

16 29 35 15 x 19

17-1/2 29 35 16-1/2 x 19

20-1/2 29 35 19-1/2 x 19

20-1/2 29 35 19-1/2 x 19

22 29 35 21 x 19

22 29 35 21 x 19

SIDE BOTTOM

VENT

D x E J x K L H

14 x 22 13-1/2 x 22 1/2 3

14 x 22 14-1/2 x 22 3/4 4

2

14 x 22

14-1/2 x 22 1-1/2 4

1

14 x 22 14-1/2 x 22 1-1/2 4

14 x 22 16 x 22 2-1/4 4

2

14 x 22

14 x 22

14 x 22

2

2

16 x 22 2-1/4 4

19 x 22 1-1/2 5

19 x 22 1-1/2 5

1

1

WARM AIR FURNACE

UCTWORK

D

Proper airflow is required for the correct operation of this

urnace. Insufficient airflow may cause erratic operation,

f

could cause the furnace to cycle on the high temperature

limit, and may damage the heat exchanger. Excessive

airflow may result in an excessively noisy duct system and

may result in undesirable consequences such as creating

ncomfortable drafts and causing drapes or curtains to

u

blow around.

If air conditioning is to be used with the furnace, the duct

ystem must be capable of delivering the correct amount of

s

airflow for each system.

The ductwork should be sized and constructed in

accordance with accepted industry standards. Duct sizing

and construction information may be obtained from:

• A.C.C.A. (Air Conditioning Contractors of America)

• A.S.H.R.A.E. (American Society of Heating,

Refrigeration and Air Conditioning Engineers)

• H.R.A.I. (Heating, Refrigerating and Air Conditioning

Institute (Canada)

• S.M.A.C.N.A. (Sheet Metal and Air Conditioning

Contractors’ National Association (United States)

All of the above professional organizations have duct sizing

manuals available.

The total static pressure drop of the air distribution system

should not exceed 0.5 inches water column.

NOTE:

UNITS 07016A,10020A,11520A AND 13520A MUST HAVE

DUAL RETURN AIR INLETS FOR OPTIMAL AIRFLOW AND

AIR FILTRATION. IF NOT SPECIFICALLY STATED BY THE

FILTER MANUFACTURER, FOR EFFECTIVE AIR FILTRATION,

ASSUME A MAXIMUM VELOCITY OF 300 FPM FOR DISPOSABLE

TYPE FILTERS, OR 600 FPM FOR PERMANENT TYPE FILTERS.

GUIDE:

Filter free area (in2) = 144 x (CFM / desired velocity (fpm))

IMPORTANT: Some high efficiency filters have a greater

than normal resistance to airflow. This can adversely affect

furnace operation. Ensure to check the airflow when using

any filter.

ARNING

W

DO NOT, UNDER ANY CIRCUMSTANCES, CONNECT

RETURN OR SUPPL

OTHER HEA

INSERT, STOVE, ETC. DOING SO MAY RESULT IN FIRE,

CARBON MONOXIDE POISONING, EXPLOSION,

PERSONAL INJURY, LOSS OF LIFE, OR PROPERTY

DAMAGE.

Y AIR DUCTWORK TO OR FROM ANY

-PRODUCING DEVICE SUCH AS A FIREPLACE

T

6

UCTWORK STEPS:

D

1. Position the furnace to minimize ductwork length and

fittings.

. Cut open a return air inlet. The choices are:

2

a) either side

b) furnace bottom

) any combination, i.e. two sides or a side and the

c

bottom. Note: 2 return openings required for

07016A, 10020A, 11520A and 13520A.

CAUTION

O NOT USE THE REAR PANEL AS A RETURN AIR INLET.

D

THERE IS INSUFFICIENT ROOM TO PERMIT ADEQUATE

AIRFLOW.

In all cases, cut the inlet air opening the full width of

the knockouts.

NOTE: When two return air inlets are used, both must

be equipped with filters.

3. Install the filter rack(s) (field supplied).

4. Connect the return air duct or fitting to the furnace. The

connection should be as air tight as possible to prevent

entraining combustion gases from an adjacent fuel

burning appliance, or entraining combustion air for this

furnace .

5. Ensure that there is adequate space and accessibility for

the air filter.

6. If an air conditioning evaporator coil is required,

position it on the top of the furnace. Ensure that no air

can bypass the evaporator coil.

7. Connect the supply air plenum to the supply air outlet.

Flexible duct connectors are an effective device to

prevent the telegraphing of mechanical noise from the

furnace to other parts of the home via the ductwork. If

using flexible connectors, ensure that the adjoining

duct is independently supported.

Adequate provisions for combustion and ventilation air

must be in accordance with ANSI Z223.1 (NFPA 54), section

5.3 "Air for Combustion and Ventilation" in the United

States, and CAN/CGA B149 in Canada. Check with local

authorities for any additional building codes, bylaws or

regulations.

WARNING

NEVER ALLOW THE PRODUCTS OF COMBUSTION FROM

THE FLUE TO ENTER THE RETURN AIR OR SUPPLY AIR

DUCTWORK.

ALL RETURN AIR DUCTWORK MUST BE ADEQUA

SEALED AND SECURED TO THE FURNACE WITH SHEET

METAL SCREWS. TAPE THE SHEET METAL SEAMS IN THE

VICINITY OF THE FURNACE WITH DUCT TAPE OR

SIMILAR MA

WHEN THE FURNACE IS MOUNTED ON A PLATFORM

WITH RETURN AIR THROUGH THE BOTTOM, IT MUST BE

SEALED AIR TIGHT BETWEEN THE FURNACE AND THE

RETURN AIR PLENUM. THE FLOOR OR PLA

PROVIDE SOUND PHYSICAL SUPPORT OF THE FURNACE

WITHOUT SAGGING, CRACKS OR GAPS AROUND THE

BASE, PROVIDING A SEAL BETWEEN THE SUPPORT AND

THE BASE.

AILURE TO PREVENT PRODUCTS OF COMBUSTION

F

FROM BEING CIRCULATED INTO THE LIVING SPACE CAN

CREATE POTENTIALLY HAZARDOUS CONDITIONS,

INCLUDING CARBON MONOXIDE POISONING THA

COULD RESULT IN PERSONAL INJURY OR DEATH.

TERIAL.

TFORM MUST

TELY

T

ETERMING COMBUSTION AIR

D

ANGER

D

READ, UNDERSTAND AND FOLLOW ALL INSTRUCTIONS

IN THIS SECTION. FAILURE TO PROPERLY VENT OR

SUPPLY COMBUSTION AIR TO THIS FURNACE CAN

CAUSE CARBON MONOXIDE POISONING, OR AN

EXPLOSION OR FIRE, RESULTING IN PROPERTY DAMAGE,

PERSONAL INJURY OR LOSS OF LIFE.

DANGER

THIS FURNACE AND ANY OTHER FUEL BURNING

APPLIANCE MUST BE PROVIDED WITH ENOUGH FRESH

AIR FOR PROPER COMBUSTION AND VENTILATION OF

THE FLUE GASES. MOST HOMES WILL REQUIRE THAT

OUTSIDE AIR BE BROUGHT TO THE FURNACE AREA.

FAILURE TO DO SO CAN CAUSE PERSONAL INJURY OR

DEATH FROM CARBON MONOXIDE POISONING.

CASE 1:

FURNACE LOCATED IN AN UNCONFINED SPACE

Unconfined space does not necessarily mean that

combustion and ventilation will not have to be introduced

from the outdoors, particularly in airtight homes. Refer to

the appropriate installation code requirements regarding

the minimum combustion air required for all fuel burning

appliances located within the unconfined area.

If the amount of combustion and ventilation air is

insufficient to properly operate the furnace and other fuel

burning appliances within the unconfined area, it will be

necessary to supply it from the outdoors based on the

criteria used when calculating the air supply for a confined

space.

NOTE: If planning to use the inside air of an unconfined

space, remember to test for proper furnace operation (as

well as other fuel burning appliances located within the

unconfined space) with respect to adequate combustion

and ventilation air with fireplace dampers open, clothes

dryer running, bathroom exhaust fans on, kitchen range

hood on, etc.

CASE 2:

FURNACE LOCATED IN A CONFINED SPACE

A confined space, (any space smaller than the minimums

discussed in CASE 1), must have two air openings one within

12 inches of the ceiling and the other within 12 inches of

the floor

the combustion and ventilation air is being taken from

indoors or outdoors, the method outdoor air (if used) is

introduced, and taking into account any other fuel burning

appliances in the confined space.

If sufficient indoor combustion and ventilation air is

available for the furnace and all other fuel burning

appliances, even when clothes dryers, bathroom fans, range

hoods, etc. are running, size each opening according to the

appropriate installation codes.

. The air openings must be sized based on whether

OTE: If using grilles to cover the two openings, factor in

N

the free area of the grille. Typically, a grille will have a free

area approximately 50% of its nominal size. Consequently,

if the required opening is 10 inches x 10 inches , it will have

to be doubled if using a sidewall grille with 50% free area.

IMPORTANT: If an exhaust fan, fireplace, clothes dryer or

any similar device is present in the indoor area from which

the combustion and ventilation air will be drawn, negative

ressure could be a problem if natural infiltration from the

p

outdoors does not match the rate at which air is exhausted.

CASE 3:

FURNACE LOCATED IN A CONFINED SPACE, OUTDOOR

AIR FROM ATTIC OR CRAWL SPACE

In this circumstance, refer to the appropriate installation

code for the free area of the combustion and ventilation air

openings. If other fuel burning appliances are present, their

combustion air and ventilation air requirements must be

added to those of the furnace.

CASE 4:

FURNACE LOCATED IN A CONFINED SPACE, OUTDOOR

AIR DUCTED HORIZONTALLY

Similar to CASE 3, outdoor air for combustion and

ventilation may be drawn through horizontal ducting.

Consult the appropriate installation code for the free area

for openings. If other fuel burning appliances are present,

their combustion air and ventilation air requirements must

be added to those of the furnace.

IMPORTANT: The outdoor grilles must be installed in a

location where they will not be obstructed in any manner.

IMPORTANT: If grilles are used on the outside wall, they

must be sized properly. Most sidewall grilles have only 50%

free area, so the grill size opening must be twice the size of

the free air opening requirement.

WARNING

DO NOT ALLOW GAS PIPING TO BE ROUTED THROUGH

JOIST SPACES THAT ARE USED FOR RETURN AIR

PURPOSES. DO NOT USE JOIST SPACES FOR RETURN AIR

PURPOSES IF THE JOIST SPACE ALREADY CONTAINS

PLUMBING STACKS, CHIMNEY COMPONENTS, ETC.

UNLESS THE PORTION USED FOR RETURN AIR PURPOSES

CAN BE COMPLETELY ISOLATED FROM PORTIONS WITH

OTHER USAGES.

7

WARM AIR FURNACE

FURNACE VENTING

DEFINITIONS

"Vent" and "Chimney" refer to open passageways that

convey vent gases from the furnace, or its vent connector, to

he outside. Vents and chimneys usually run vertically or

t

early vertically. When they serve only one gas appliance,

n

they are called "dedicated" vents or chimneys. When they

serve multiple gas appliances, they are called "common"

vents or chimneys.

"Vent Connector" refers to a pipe or duct that connects the

furnace to a vent or chimney. Vent connectors usually run

rom the furnace’s vent collar to the vent or chimney. Vent

f

onnectors may have vertical and horizontal runs.

c

"Venting System" refers to a continuous open passageway

from the vent collar to the outside. Venting systems usually

have a vent connector(s) and a vent or chimney. Venting

systems commonly serve a single furnace, or a single

furnace and a hot water heater. Other multiple appliance

venting systems are less common.

"Fan Assisted Combustion System" refers to an appliance

equipped with an integral mechanical means to either draw

or force products of combustion through the combustion

chamber and/or heat exchanger. This series furnace uses a

draft inducer to draw combustion products through the

heat exchanger and is considered to have a fan assisted

combustion system. Category I furnaces with fan assisted

combustion systems must not be vented into single wall

metal vents.

DESIGN CONSIDERATIONS

The furnace is design certified as a Category I appliance,

which means that the furnace relies on the buoyancy of

combustion products to vent properly. Since buoyancy

decreases proportionately with temperature, the chimney

size and properties are very important. An oversized

chimney, or one that is exposed to the cold will not

maintain the required buoyancy as well as it should, and

may allow excessive condensation to form.

IMPORTANT: Do not common vent the furnace with Category III or IV gas-fired appliances.

The furnace must be vented in accordance with these

instructions, the Venting Tables and rules published in the

current editions of ANSI Z223.1 / NFPA 54, National Fuel Gas

Code in the United States, or B149, Natural Gas and

Propane Installation Code in Canada, and within the

requirements of the codes of the local authority having

jurisdiction.

Refer to section 5.3 of ANSI Z2213.1/NFPA 54 or sections 7.2,

7.3 or 7.4 of CSA B149 for venting requirements.

The furnace is not equipped with a draft hood to introduce

dilution air to the chimney. The products of combustion will

therefore have a higher concentration of water vapor

within them. If the furnace is the only appliance served by

the chimney, a tiled masonry chimney, regardless of tile size,

must not be used without a suitably sized certified chimney

liner and termination. Consider dedicated venting with a B

Vent used as a liner in this case. See Dedicated Venting on

page 12.

Multistory and common venting with other Category I gas

fired appliances is permitted. The venting system must be in

accordance with the National Gas Code, B149 in Canada,

ANSI Z223.1/NFPA 54 in the United States, local codes, and

approved engineering practices.

CAUTION

Combustion air must be free of acid forming chemicals

such as sulphur, fluorine and chlorine. These elements

are found in aerosol sprays, detergents, bleaches,

cleaning solvents, air fresheners, paint and varnish

emovers, refrigerants, and many other commercial and

r

ousehold products.

h

When burned in a gas flame, vapors from these products

form acid compounds. Acid compounds increase the dew

point temperature of the flue products and are highly

orrosive after they condense.

c

Any furnace failure caused by corrosive elements is

excluded from warranty coverage.

The following types of installation sites (but not limited

to the following) will require OUTDOOR AIR for

combustion because of chemical exposures: commercial

buildings, buildings with indoor swimming pools,

furnaces installed in laundry rooms, furnaces in hobby or

craft rooms, furnaces installed near chemical storage

areas.

Exposure to the following substances in the combustion

air supply (but not limited to the following) will also

require OUTDOOR AIR for combustion:

• Aerosols, particularly CFC based or propelled aerosols

• Air fresheners

• Airplane Glue and similar adhesives and cements

• Ammonia, as commonly found in permanent wave

solutions used in hair dressing salons

• Antistatic fabric softeners used in clothes dryers

• Carbon tetrachloride

• Chlorinated cleaners and waxes

• Chlorine and bromine based swimming pool chemicals

• Deicing salts or chemicals, e.g. rock salt, etc.

• Dry cleaning fluids such as perchloroethylene

• Fumes from curing polyurethane and similar

substances

• Halogen based refrigerants including R-12 and R-22

• Hydrochloric acid, muriatic acid and other acid based

masonry washing and curing materials

• Printer’s inks, paint removers, varnishes, varsol,

toluene, etc.

• Water softener salt and chemicals

WARNING

SELECT APPROPRIATE VENTING MATERIALS AND

ENSURE PROPER CLEARANCES TO COMBUSTIBLES.

INADEQUA

PROPER CLEARANCES TO COMBUSTIBLES MAY ALLOW

THE ACCUMULATION OF THE PRODUCTS OF

COMBUSTION WITHIN THE BUILDING RESULTING IN

FIRE, NAUSEA, OR ASPHYXIATION.

DO NOT USE AN UNLINED MASONRY CHIMNEY TO

VENT THIS FURNACE. THE USE OF AN UNLINED

MASONRY CHIMNEY INCREASES THE RISK OF

CONDENSA

CHIMNEY TO DETERIORATE, ALLOWING COMBUSTION

PRODUCTS AND CONDENSATE TO COLLECT IN THE

BUILDING.

TE VENTING OR FAILURE TO MAINTAIN

TE FORMA

TION, WHICH MAY CAUSE THE

8

MPORTANT: THIS FURNACE IS NOT TO BE VENTED IN THE

OFF

ON

C2

C3

C1

OFF

ON

C2

C3

C1

OFF

ON

C2

C3

C1

I

SAME CHIMNEY OR VENTING SYSTEM SERVING A SOLID

UEL APPLIANCE (WOOD OR COAL). IF THE FURNACE IS TO

F

BE VENTED INTO A CHIMNEY THAT NO LONGER SERVES A

FIREPLACE, THE FIREPLACE OPENING IS TO BE

PERMANENTLY SEALED.

The furnace must connect to a listed chimney (B-1 Vent), or

vent complying with a recognized standard, or a suitably

sized, constructed and lined masonry chimney. The chimney

lining method and material must comply with local

requirements. Use corrosion resistant material meeting

nationally recognized standards for vent construction.

Avoid over sizing the furnace for the application. A furnace

selected as close as possible for the actual building heat loss

will have longer firing cycles which will reduce the potential

for damaging condensate formation in the venting system.

Take the building orientation and the presence of other

buildings or other nearby structures into consideration

when planning the venting system location. Certain

external structures could create air turbulence around the

vent termination leading to downdrafts and similar venting

problems.

If local experience indicates that condensation problems are

probable, provide for drainage and disposal of venting

system condensate.

VENT SIZING

The venting system, taking all appliances to be vented into

consideration, must be sized in accordance with the Venting

Tables and rules published in the current editions of ANSI

Z223.1 / NFPA 54, National Fuel Gas Code in the United

States, or B149, Natural Gas and Propane Installation Code

in Canada. An undersized venting system will not permit

the complete removal of products of combustion, and an

oversized venting system will not heat up quickly enough to

avoid condensation formation.

VENT INSTALLATION

Vents and chimneys usually extend vertically with offsets

not exceeding 45° from vertical. Consider all offsets greater

than 45° from vertical as horizontal runs. Include their

length in the total horizontal run calculation.

Horizontal runs should be as short as practical and not

exceed 75% of the vent height.

The vent height must be a minimum of 5 feet above the

highest appliance in a Category I venting system.

Minimize vent connector horizontal runs to the extent

possible for best performance. Avoid unnecessary fittings.

For example, an offset constructed of 45° elbows is

generally better than one made of 90

Support all horizontal sections of the venting system with

pipe hangers, strap or equivalent at each joint to prevent

sagging. Horizontal segments must slope upward from the

furnace to vent or chimney with a minimum 1/4 inch per

foot.

When the vent tables from ANSI 223.1/NFPA 54 or B149permit more than one pipe diameter for the vent or vent

connector, the smallest size is usually the best choice to help

reduce the potential for condensation formation.

When using manufactured venting (B-1 Vent for example),

follow the vent manufacturer’

venting both flexible and rigid, are suitable venting

materials for the furnace.

The installer must ensure that the venting of the furnace

and all

other gas appliances connected to the vent or

chimney function properly

elbows.

°

s instructions. UL listed B-1

.

NDUCER BLOWER INSTALLATION

I

This furnace can be installed in upflow, counterflow and

orizontal applications. The furnace is capable of being

h

vented vertically through the top panel, left or right through

the side panels. Each furnace is assembled and supplied set up

for vertical venting applications. If the installer chooses to vent

through the side panels such as in horizontal or counterflow

pplications, rotation of the inducer will be required. In

a

addition, the pressure switch will require relocation in the

event of a right hand inducer discharge installation.

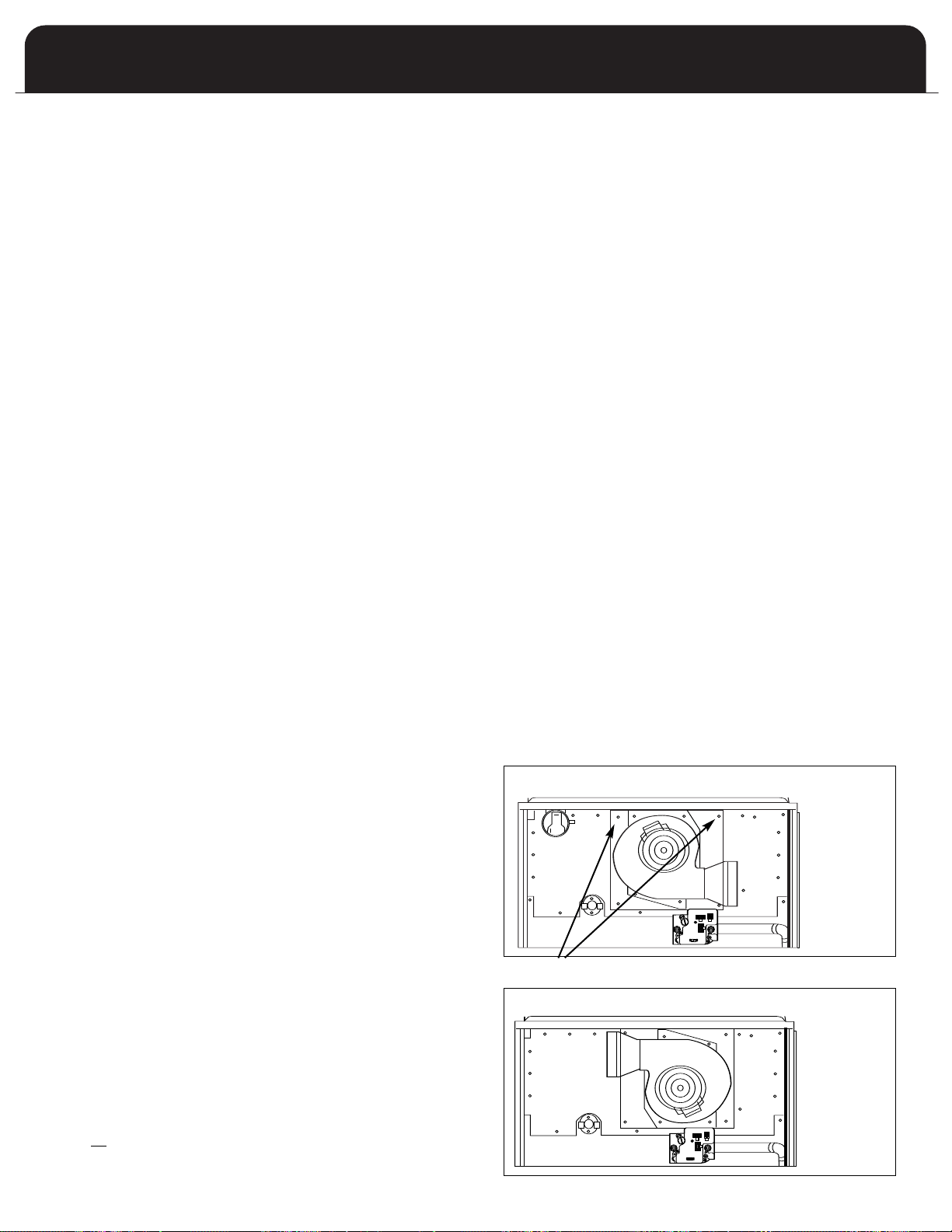

INDUCER ROTATION STEPS ON 07012A, 07016A,

08512A, 08516A,10012A, 10016A, 10020A, 11520A

and 13520A (See Figure 4A below for Right Exhaust,

Figure 4B below for Left exhaust)

1. Ensure all power to the furnace is disconnected.

2. Disconnect inducer wiring and pressure switch tubing.

3. Remove four screws securing inducer plate to flue box

cover plate.

4. Place inducer plate and gasket in desired position and

locate mounting holes required. NOTE: INDUCER PLATE

AND GASKET MUST BOTH BE ROTATED.

NOTE: Any holes not concealed by the inducer gasket

require the use of screws to plug the holes.

5. Secure inducer plate to flue box cover using four screws in

the correct mounting position.

6. Carefully remove side panel knockout corresponding to the

venting application and install knockout underneath top

panel using two screws (field supplied).

7. In the event of a right hand discharge inducer application,

the pressure switch will have to be relocated to the

underside of the top panel (see Figure 4A below ) using

existing holes in top panel. The pressure switch tubing will

have to be cut to the length listed in Table 4 on page 10 if

inducer is mounted in right hand configuration.

8. Connect inducer wiring and pressure switch tubing to the

inducer housing.

FIGURE 4A: RIGHT INDUCER POSITION

Inducer Plate mounting screws (all models except 03508A, 05012A)

FIGURE 4B: LEFT INDUCER POSITION

9

Loading...

Loading...