Haier AW12LC2VHA, AB18SC2VHA, AD12SL2VHA, AW18LC2VHA, AD18SL2VHA Installation Manual

...

Installation Manual

Ductless Split Air Conditioner

Indoor

AW12LC2VHA

AW18LC2VHA

AB12SC2VHA

AB18SC2VHA

AD12SL2VHA

AD18SL2VHA

Outdoor

1U12LC2VHA

1U18LC2VHA

1U12LC2VHA

1U18LC2VHA

1U12LC2VHA

1U18LC2VHA

Table of Contents

Outdoor Unit Installation and Indoor Unit Installation – Wall Mount . . . . . . . . . . . . . . . . . 1-8

Indoor Unit Installation - Cassette

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

9-14

Indoor Unit Installation - Slim Duct. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .15-20

INSTALLATION

24k F

or: 09k

ENGLISH

Required Tools for Installation

• Drill

• Wire Snipper

• Hole Saw 2 3/4”

• Vacuum pump

• Soap-and-water solution or gas leakage

detector

• Torque wrench

• 17mm, 22mm, 26mm

• Tubing cutter

• Flaring tool

• Razor knife

• Measuring tape

• Level

• Micron gauge

• Nitrogen

• Mini-Split AD-87 Adapter (1/4” to 5/16”)

• A - Non-adhesive Tape

• B - Adhesive Tape

• C - Saddle (L.S.) with screws

• D - Electrical wiring

• E - Drain hose (Included)

• F - Insulation

• G - Piping hole cover (Included)

Step 1 - Preparation

Procedure for Selecting the Location

• Choose a place solid enough to bear the

weight and vibration of the unit and where

the operation noise will not be amplified.

• Choose a location where the hot air

discharged from the unit or the operation

noise and will not cause a nuisance to the

neighbors of the user.

• There must be sufficient space for

carrying the unit into and out of the site.

• There must be sufficient space for air

passage and no obstructions around the

air inlet and air outlet.

• The site must be free from the possibility

of flammable gas leakage in a nearby

place.

• Locate the unit to avoid noise and

discharged hot air will not annoy the

neighbors.

• Install units, power cords and inter-unit

cables at least 10ft away from television

and radio sets. This is to prevent

interference to images and sounds.

(Noise may be heard even if they are more

than 10ft away depending on radio wave

conditions.)

• Since drain flows out of the outdoor unit,

do not place anything under the unit that

must be kept away from moisture.

Note:

1) Cannot be installed hanging from ceiling

or stacked.

2) If installing on a high place such as a roof,

with a fence or guard rail around it.

3) If there is a potential for accumulated

snow to block the air inlet or heat exchanger, install the unit on a higher base.

4) R-410A refrigerant is a safe, nontoxic and

nonflammable refrigerant. However, if

there is a concern about a dangerous level

of refrigerant concentration in the case of

refrigerant leakage, add extra ventilation.

5) Avoid installing the outdoor unit where

corrosive gases, such as sulfur oxides, ammonia, and sulfurous gas, are produced. If

unavoidable, consult with an installation

specialist about using a corrosion-proof or

anti-rust additive to protect the unit coils.

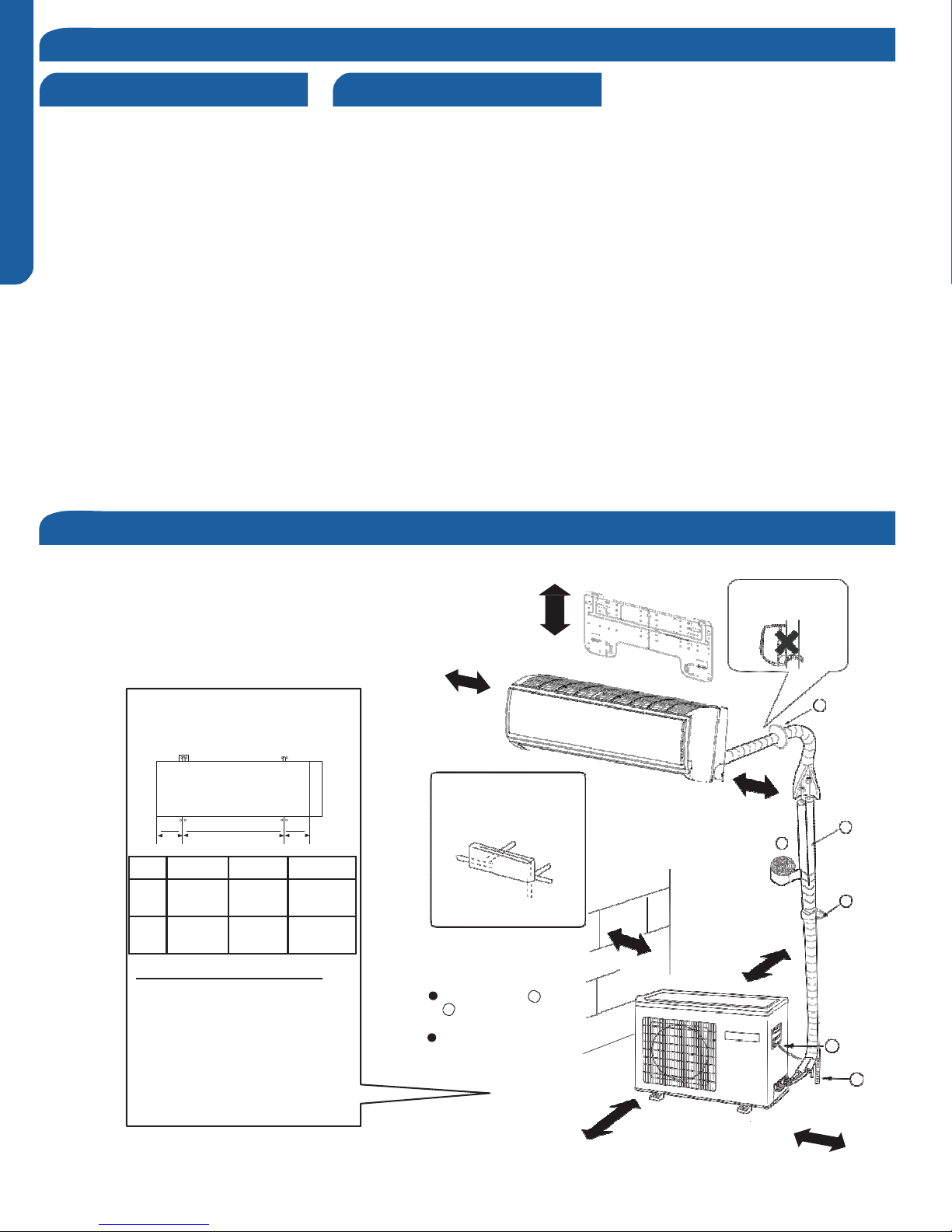

This picture is for reference only. Your product may look

different. Read this manual before installation. Explain the

operation of the unit to the user according to this manual.

Outdoor unit mounting

dimensions (Unit: mm/inch)

For:

12k 18k

X

Y

X

5 1/2”

12k

140

4 7/16”

18k

113.5

Mounting the Outdoor Unit

•

Mount the unit to concrete or a block

with bolts (10mm) and nuts firmly and

horizontally.

•

When mounting the unit to a wall or

roof, take strong winds and other

environmental conditions into

consideration when securing.

•

If vibrations effect the house, mount

the unit using a vibration-proof mat.

mm

mm

19 11/16”

500

22 15/16”

583

Clearances of Indoor and Outdoor Units

The models adopt HFC free refrigerant R410A

Y

mm

mm

Z

X

Z

10 1/16”

256

mm

12 9/16”

319.5

mm

more than 4 in.

more than

4 in.

Arrangement of piping

directions

Rear left

Left

The marks from A to

G

in the figure are the

parts numbers.

The distance between

the indoor unit and the

floor should be more

than 6.5 ft.

Below

more than

Rear

right

Right

more than 8 in.

24 in.

Attention must be paid to

the rising up of drain hose

more than 4 in.

A

more than

6 in.

more than 10 in.

G

F

C

D

E

INSTALLATION

P

AGE

3

Step 2.5A

ENGLISH

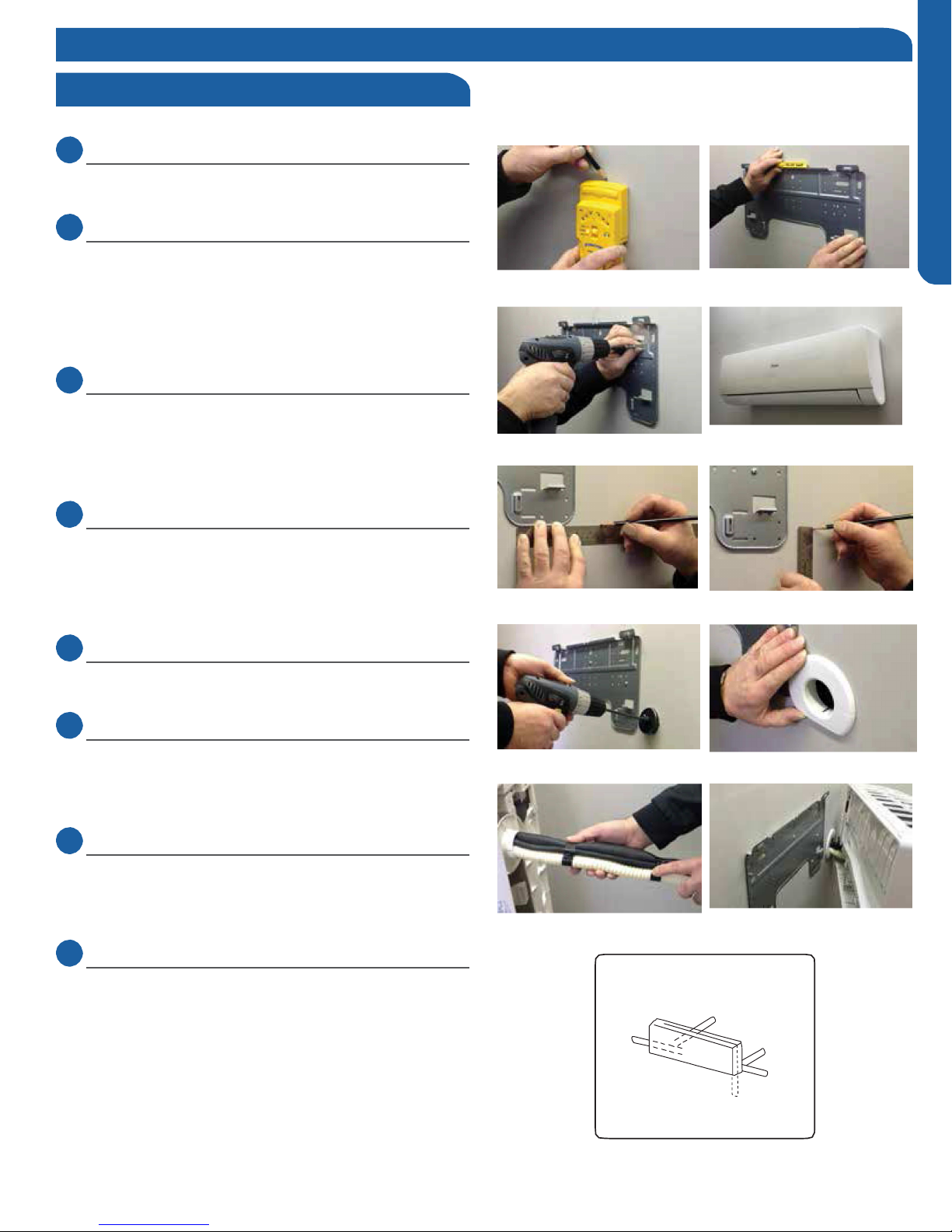

Step 2 - Installation of the Indoor Unit

Attaching the Mounting Plate to the Wall

2.1

Step 2.1

Using a stud sensor, locate and mark the stud positions in the

wall where the indoor unit is to be mounted.

2.2

Step 2.2

Place the mounting plate on the wall in the desired location

taking into account the minimum clearances necessary for

proper operation.

Using a level, verify the mounting plate is horizontal and mark

the screw locations.

2.3

Step 2.3

Screw the mounting plate to the wall.

The piping for the indoor unit may be routed to the unit from

one of several directions. Left, Left Rear, Right, Right Rear, or

Below (Illustration 1).

2.4

Step 2.4

Knockouts are provided on the case for Left, Right, and Right

Below.

Drilling the hole through the wall for left rear or right rear

installation

2.5

Step 2.5A & 2.5B

Measure and mark the location where the piping hole is to be

drilled.

2.6

Step 2.6

Drill the piping hole using a hole saw of the correct diameter.

Angle the drill with a downward pitch to the outside wall so

that the outside hole will be ¼” lower than the inside hole,

giving the hole the proper angle for condensate drainage.

2.7

Step 2.7

Install the piping hole cover flange at the hole opening on the

inside wall.

NOTE: The cover flange may require modification to fit

properly behind the wall unit housing.

2.8

Step 2.8A & 2.8B

Bundle the refrigerant piping, drain piping and wiring with

tape and pass the bundle through the piping hole.

NOTE: When bundling the power cable, leave sufficient length

available in the indoor unit to make the connections to the

terminal block.

Step 2.1

Step 2.2

Step 2.3

Step 2.4

Step 2.5B

Step 2.6

Step 2.7

Step 2.8A

Piping Exit Options

Step 2.8B

Rear left

Left

Rear

right

Right

Below

Illustration 1

INSTALLATION

Step 2.9

ENGLISH

Mounting the Indoor Unit Onto the Wall Plate

2.9

Step 2.9

With the top of the indoor unit closer to the wall, hang the

indoor unit on the upper hooks of the mounting plate. Slide

the unit slightly side to side to verify proper placement of the

indoor unit on the mounting plate. Rotate the lower portion

of the indoor unit to the mounting plate, and lower the unit

onto the lower hooks of the mounting plate. (Illustration 2)

Verify the unit is secure.

2.10

Step - 2.10

Slightly raise the entire unit vertically, pull the lower portion

of the unit off the lower hooks of the mounting plate and

away from the wall, then lift the upper portion of the unit off

the upper hooks of the wall plate.

Electrical Connections for the Indoor Unit

2.11

Step - 2.11A & 2.11B

To make the electrical connections for the indoor unit, two

cover plates must be removed. Raise the front cover to

access the screws to remove these covers.

2.13

Step - 2.13

Access the four conductor cable through the cover plate

opening and make the wiring connections noting the wire

color used on each terminal. The color of each wire must

match the same positions on the terminal block of the

outdoor unit. (Illustration 3)

Failure to wire the system correctly may lead to improper

operation or component damage.

2.14

Step - 2.14A & 2.14B

After the terminal block wiring is completed, replace both

cover plates.

Attaching Drain Elbow to Outdoor Unit

(Heat Pump models only)

3.1

Step - 3.1

If attaching the supplied drain elbow to the outdoor unit,

do so prior to attaching the refrigerant lines and wiring.

Extension piping to attach to this fitting is field supplied.

Step 3 - Installation of the Outdoor Unit

Step 2.10

mounting plate

Illustration 2

Step 2.11A

Step 2.11B

Step 2.12

Indoor unit

Step 2.13A

3wire 14AW G

Control Wiring

Step 2.13B

Illustration 3

Step 3.1

Step 3.2

Outdoor unit

1

(

N

)

2

(L)

3

(

C

Power

Wiring

)

1

(

N

)

2

(

L)

3

(C)

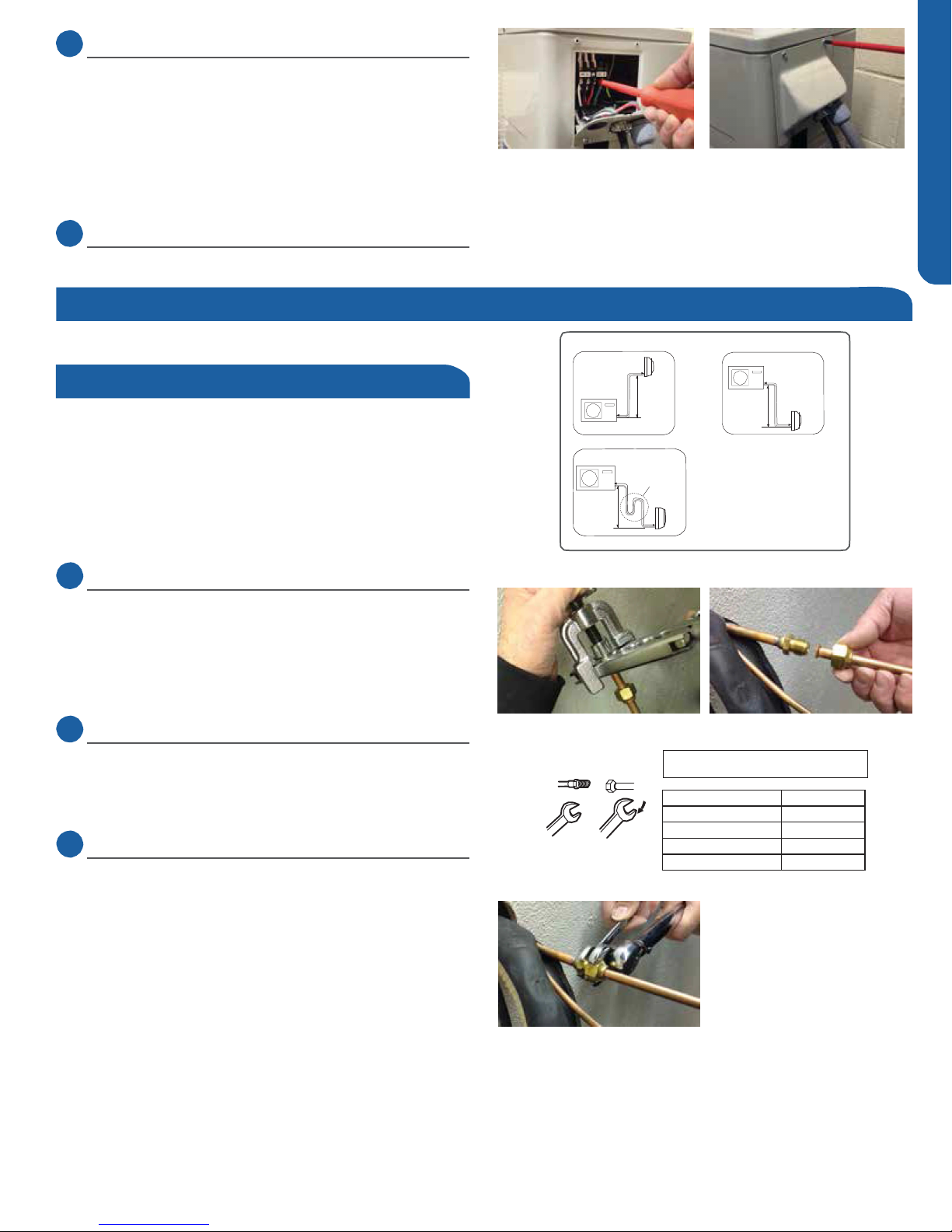

Electrical Connections for the Outdoor Unit

3.2

Step - 3.2

Remove the cover plate of the outdoor unit to expose the

terminal block connections.

INSTALLATION

P

AGE

5

3.3

Step -

3.3

may

lead to

improper

operation

or

component

damage.

Step 3.3

Step 3.4

3.4

Step -

3.4

Replace

the cover

plate.

Step 4 -

Int

erconnec

ting

the Indoor

and

Out

door

Units

CAUTION

Outdoor unit

B

Indoor unit

B

A

Indoor unit

A

Outdoor unit

Oil trap

B

Indoor unit

A

●

ENGLISH

Connect the wiring for both the power source and indoor

wiring.

Wire the system according to applicable national / local

codes.

Verify that the wiring connections for the indoor unit match

wire for wire.

(1-1, 2-2, 3-3, Gnd-Gnd). Failure to wire the system correctly

*See Steps 2.11 - 2.13 & 3.2 - 3.4 for connecting the

electrical.

Piping

The standard lineset length is 25ft. If the installation length is

different, adjust the refrigerant charge by .2 oz / ft. for the 9K,

12K, 18K, and 24K model. (Illustration 4)

Cut the lineset to length, flare and attach the piping to the

outdoor unit valves.

Torque the fittings to the specifications shown in the torque

chart.

4.1

Step - 4.1

Refrigerant piping connections for the mini-split system are

made utilizing flare connections. Follow standard practices

for creating pipe flares. When cutting and reaming the tubing,

use caution to prevent dirt or debris from entering the tubing.

Remember to place the nut on the pipe before creating the

flare.

4.2

Step - 4.2

To join the lineset piping together, directly align the piping

flare to the fitting on the other pipe, then slide the nut onto

the fitting and tighten. Misalignment may result in a leaking

connection.

2.17

Step - 4.3

Two wrenches are required to join the flare connections, one

standard wrench, and one torque wrench. See Table 1 for the

specific torque per piping diameter.

Half union

Spanner

Outdoor unit

Step 4.1

Torque wrench

Step 4.3

Flare nut

Max. Elevation: A Max

= 32ft / 10m (09k / 12k)

= 50ft / 15m (18k / 24k)

●

In case the height of A is more than

15ft / 5m, an oil trap should be

installed every 16-23ft /5-7m

●

Max. Length: B Max

= 50ft / 15m (09k / 12k)

= 80ft / 25m (18k / 24k)

Illustration 4

Step 4.2

Forced fastening without careful centering may

damage the threads and cause a leakage of gas.

Pipe Diameter(ǿ) Fastening torque

Liquid side6.35mm(1/4") 18N.m/13.3Ft.lbs

Liquid/Gas side9.52mm(3/8") 42 N.m/30.1Ft.lbs

Gas side 12.7mm(1/2") 55N.m/40.6Ft.lbs

Gas side 15.88mm(5/8") 60 N.m/44.3Ft.lbs

Table 1

INSTALLATION

Step 5.4B Step 5.5A

ENGLISH

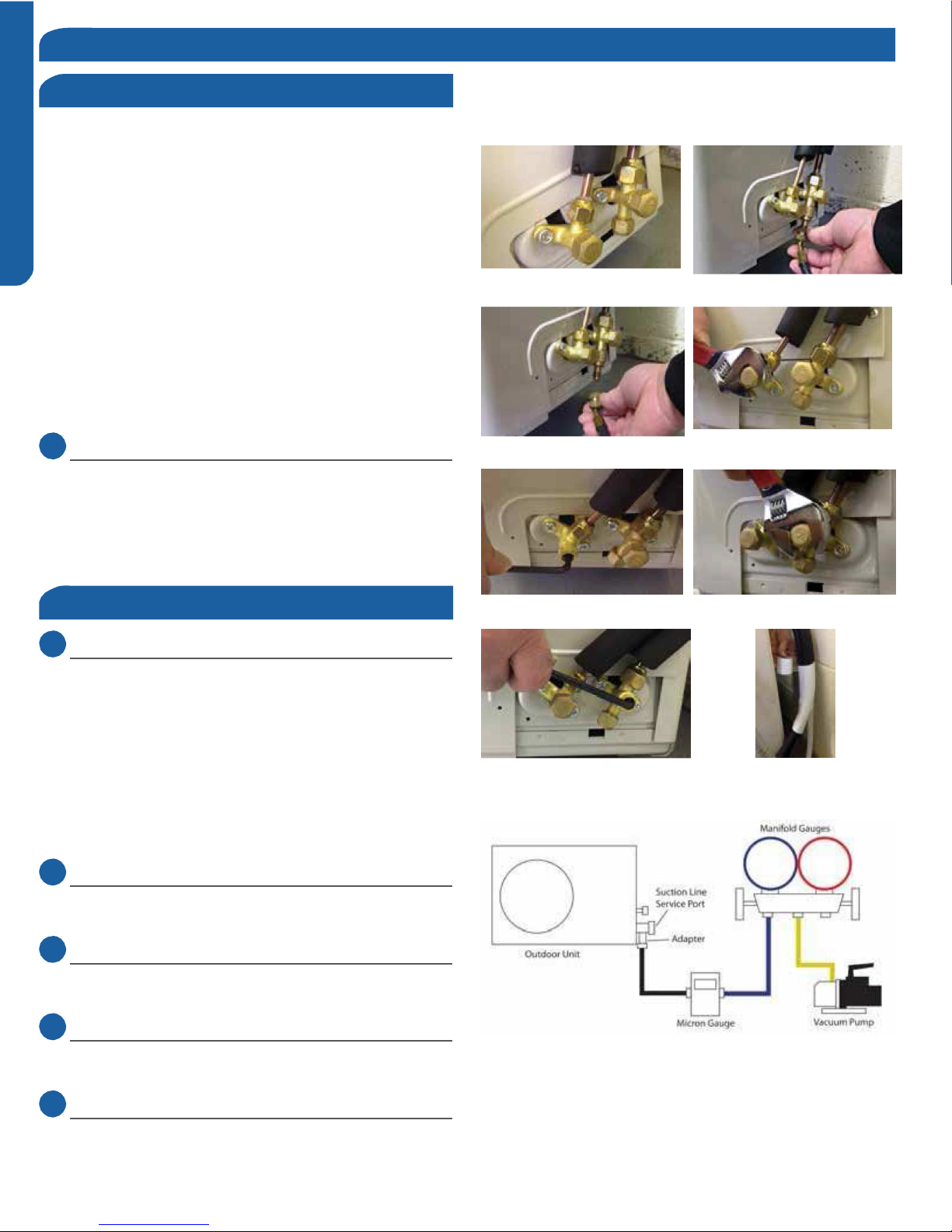

Step 5 - Leak Test and Evacuation

Leak Test

Hazard of Explosion! Never use an open flame to detect gas

leaks. Explosive conditions may occur. Use a leak test solution

or other approved methods for leak testing. Failure to follow

recommended safe leak test procedures could result In death

or serious injury or equipment or property damage.

Use only dry nitrogen with a pressure regulator for

pressurizing unit. Do not use acetylene, oxygen or

compressed air or mixtures containing them for pressure

testing. Do not use mixtures of a hydrogen containing

refrigerant and air above atmospheric pressure for pressure

testing as they may become flammable and could result in

an explosion. Refrigerant, when used as a trace gas should

only be mixed with dry nitrogen for pressurizing units. Failure

to follow these recommendations could result in death or

serious injury or equipment or property damage.

5.1

Step - 5.1

Using a tank of nitrogen with attached regulator, charge the

system with 500 PSIG of dry nitrogen. Use adapter AD-87

(field supplied) to connect to the valve. Check for leaks at the

flare fittings using soap bubbles or other detection methods.

If a leak is detected, repair and recheck. If no leaks are

detected, proceed to evacuate the system.

5.2

Step - 5.2

Attach a manifold gauge, micron gauge, and vacuum pump

to the suction line port using adapter AD-87 (field supplied).

(Illustration 5)

Evacuate the system to 350 microns.

Close the vacuum pump valve and check the micron

gauge. If the gauge rises above 500 microns in 60 seconds,

evacuation is incomplete or there is a leak in the system. If

the gauge does not rise above 500 microns in 60 seconds,

evacuation is complete.

5.3

Step - 5.3

Remove the adapter and hose connection from the suction

line port, and replace the cap.

5.4

Step - 5.4A & 5.4B

Remove the cap from the liquid line valve. Using the hex

wrench, open the valve, then replace and tighten the cap.

5.5

Step - 5.5A & 5.5B

Remove the cap from the suction line valve. Using the hex

wrench, open the valve, then replace and tighten the cap.

5.6

Step - 5.6

Wrap the lineset, drain line, and wiring starting at the bottom

of the bundle with an overlap type wrap, concluding at the

System Evacuation

Step 5.1

Step 5.2

Step 5.3

Step 5.4A

Step 5.5B

Step 5.6

Illustration 5

INSTALLATION

P

AGE

7

piping

hole.

Use a sealant

to

seal the piping

hole opening

(Illustration

6)

Less than

Verify

the condensate

drain

line has a constant

pitch

resulting

in

the f

ailure

of

the condensate

to exit the piping.

It

becomes

The end is

imm-

It

waves.

The gap with

the There is the bad

ground is too small

smell

from a sewer

Illustration

6

Step 6 -

Charging

charging.

The standard

lineset

length

is

25ft.

If

the installation

System Test

Contains

fluorinated

gree

nhouse

gases

R410A

1

1= oz

B

2= oz

C

1+2=

oz

D

F E

ENGLISH

to prevent weather elements from entering the building.

5cm

downward for proper water flow. There should be no kinks

or rises in the tubing which may cause a trapping effect

See Steps 5.2 - 5.5 for evacuating the system prior to

length is different, adjust the refrigerant charge by .2 oz / ft.

for the 9K, 12K, 18K, and 24K model. (Step 4 - Illustration 4)

Refrigerant Charge Label

This product contains fluorinated greenhouse gases covered

by the Kyoto Protocol. Do not vent into the atmosphere.

Refrigerant type: R410A

GWP* value: 1975

GWP = global warming potential

Please fill in with indelible ink,

• 1 the factory refrigerant charge of the product

• 2 the additional refrigerant amount charged in the field and

• 1+2 the total refrigerant charge on the refrigerant charge

label supplied with the product.

The filled out label must be adhered in the proximity of the

product charging port (e.g. onto the inside of the stop valve

cover).

A - contains fluorinated greenhouse gases covered by the

Kyoto Protocol

B - factory refrigerant charge of the product: see unit name

plate

C - additional refrigerant amount charged in the field

D - total refrigerant charge

E - outdoor unit

F - refrigerant cylinder and manifold for charging

high midway.

ersed in water.

Please kindly explain to our customers how to operate

through the instruction manual.

Check Items for Test Run

Put check mark √ in boxes

No gas leak from linesets?

Are the linesets insulated properly?

Are the connecting wirings of indoor and outdoor firmly

inserted to the terminal block?

Is the connecting wiring of indoor and outdoor firmly

fixed?

Is condensate draining correctly?

Is the ground wire securely connected? Is the indoor unit

securely fixed?

Is power source voltage correct according to local code?

Is there any noise?

Is the lamp normally lighting?

Are cooling and heating (when in heat pump) performing

normally?

Is the operation of room temperature sensor normal?

covered by the Kyoto Protocol

2

A

Loading...

Loading...