Page 1

ROOM AIR CONDITIONER

INSTALLATION MANUAL

1U09MADFRA

1U12MADFRA

1U18WADFRA

1U24WADFRA

1U26MADFRA

1U35MADFRA

1U53WADFRA

1U71WADFRA

Please read this manual carefully before installation.

•

This appliance is filled with R32.

Keep this operation manual for future reference.

0011518288

111111

U

11111111111

Page 2

Contents

Warning .................................................................................................................................1

Loading and Unloading/Transporting Management/Storage Requirements.............................3

Installation Instructions.............................................................................................................3

Relocation Procedures.............................................................................................................7

Maintenance Instructions..........................................................................................................7

Scrapping and Recovery..........................................................................................................10

Indoor/Outdoor Unit Installion Drawings............... ................................................................... 12

Safety Precautions .............................................................................................. .....................13

Read Before Installation ....................................... ............................................... .....................17

Installation Procedure........................................... ............................................... .....................20

Outdoor Unit Troubleshooting...................................................................................................25

Page 3

Read the precautions in this manual

w

Keep this manual where the user can easily find it.

carefully before operating the unit.

This appliance is filled with R32.

WARNING:

Ask your dealer or qualified personnel to carry out installation work.Do not attempt to install

the air conditioner yourself. Improper Installation may result in water leakage, electric shocks,

fire or explosion.

Install the air conditioner in accordance with the instructions in this installation manual

Be sure to use only the specified accessories and parts for installation work.

Install the air conditioner on a foundation strong enough to withstand the weight of the unit.

Electrical work must be performed in accordance with relevant local and national regulations

and with instructions in this installation manual,Be sure to use a dedicated power supply circuit

.

only. The wiring method should be in line with the local wiring standard.The type of connecting

wire is H07RN-F.

Use a cable of suitable length,Do not use tapped wires or an extension lead as this may cause

overheating, electric shocks, fire or explosion.

All the cables shall have got the local authentication certificate. During installation, when the

connecting cables break off, it must be assured that the grouding wire is the last one to be broken off.

If refrigerant gas leaks during installation, ventilate the area immediately.oxic gas may be produced

if the refrigerant comes into contact with fire,and explosion may be happen.

After completing installation, check for refrigerant gas leakage

When installing or relocating the air conditioner, be sure to bleed the refrigerant circuit to ensure

it is free of air, and use only the specified refrigerant (R32).

Make sure ground connection is correct and reliable.Do not earth the unit to a utility pipe, lightning

conductor or telephone earth lead. Imperfect earthing may result in electric shocks.

Be sure to install an earth leakage circuit explosion-proof breaker.

The breaker of the air conditioner should be all-pole switch and explosion-proof. The distance

between its two contacts should not be no less than 3mm. Such means for disconnection must be

incorporated in the wiring.

Do not use means to accelerate the defrosting process or to clean, other than those recommended by

the manufacturer.

The appliance must be stored in a room without continuously operating ignition sources, the radius of

the storage area should be no less than 2.5 m (for example:open flames, an operating gas appliance

or an operating electric heater).

Do not pierce or burn.

Be aware that refrigerants may not contain an odour.

The appliance must be installed, operated and stored in a room with a floor area larger than 3m

The room should be well ventilated.

Comply with national gas regulations.

This appliance is not intended for use by persons (including children) with reduced physical,

sensory or mental capabilities, or lack of experience and knowledge, unless they have been

given supervision or instruction concerning use of the appliance by a person responsible for

their safety. Children should be supervised to ensure that they do not play with the appliance.

Cleaning and user maintenance shall not be made by children.

The air conditioner can not be discarded or scrapped randomly. If neccessary, please contact customer

service.

Connectors can not be reused in a confined space.

1

Page 4

CAUTION:

Model

Factory charge(kg

CO2 Equivalent(t)

Do not install the air conditioner at any place where there is danger of flammable gas leakage.

In the event of a gas leakage, build-up of gas near the air conditioner may cause a fire to break out.

Tighten the flare nut according to the specified method such as with a torque wrench.If the flare nut

is too tight, it may crack after prolonged use, causing refrigerant leakage.

Take adequate steps to prevent the outdoor unit being used as a shelter by small animals.Small animals

making contact with electrical parts can cause malfunctions, smoke or fire.

Please instruct the customer to keep the area around the unit clean

The temperature of refrigerant circuit will be high, please keep the inter-unit wire away from copper pipes

that not thermally insulated.

Only qualified personnel can handle, fill, purge and dispose of the refrigerant.

HOW TO USE DRED APPLIANCE

Please consult your reseller and/or installer to determine if you have a DRED

appliance.

Refer to DRED INSTALLATION INSTRUCTION for installation.

IMPORTANT INFORMATION REGARDING THE REFRIGERANT USED

Contains fluorinated greenhouse gases

covered by the Kyoto Protocol

R32

2

1=

2=

1

1+2=

F E

This product contains fluorinated greenhouse gases covered

by the Kyoto Protocol. Do not vent into the atmosphere.

Refrigerant type: R32

GWP=global warming potential

• 1 the factory refrigerant charge of the product

• 2 the additional refrigerant amount charged

+2

the total refrigerant charge

• 1

3 GWP* value=675

tCO2=(1+2) x 3 /1000

1U26MADFRA 0.80

1U35MADFRA

1U53WADFRA

1U71WADFRA

0.84

1.02

1.1 0.74

)

kg

kg

kg

A

B

C

D

in

0.54

0.57

0.0.69

the field

The filled out label must be adhered in the proximity of the

product

cover).

A contains fluorinated greenhouse gases covered by the

Kyoto

B factory refrigerant charge of the product: see unit name

plate

C additional refrigerant amount charged in the field

D total refrigerant charge

E outdoor unit

F refrigerant cylinder and manifold for charging

charging port (e.g. onto the inside of the stop value

Protocol

2

Page 5

Loading and Unloading/Transporting Management/Storage Requirements

Diameter of the liquid

connecting pipe (mm)

Extra gas amount per meter

after standard length (g)

Notes: The most gas amount should be: initial gas amount + extra gas amount <

• Loading and Unloading Requirements

1) The products shall be carefully handled during loading and unloading.

2) Do not give impact to the indoor and outdoor units, or otherwise product damage may result.

3) Be sure to read the safety cautions before conducting any work.

4) Dry powder extinguishers or other suitable fire extinguishing apparatus .aera gnidaol eht ta deppiuqe eb dluohs

5) Untrained personnel cannot be engaged in loading and unloading of air conditioners with flammable refrigerants.

6)

•

1) The maximum transporting volume of finished products shall be determined as per local regulations.

2) The vehicles used for transporting shall be operated as per local laws and regulations.

3) Dedicated after-sales vehicles shall be used for maintenance transportation, and exposed transporting of

4) A rain cover or similar shield material of the transporting vehicles should have certain flame retardancy.

5) Leakage warning device of flammable refrigerant shall be installed inside the closed-type compartment.

6) Anti-static device shall be equipped inside the compartment of transporting vehicles.

7) Dry powder extinguishers or other suitable fire extinguishing apparatus shall be equipped inside the driver ' s cab.

8)

9)

1) The storage package of equipment used shall be such that no leakage of refrigerant will be caused due to

mechanical damage of the equipment inside.

2) The maximum quantity of the equipment allowed to be stored together shall be determined as per local

regulations.

• Installation Precautions

area specified in the table below, to avoid potential safety problems due to out-of-limit of refrigerant

*

concentration inside the room caused by leakage of refrigerant from refrigeration system of the indoor unit.

affected).

*

installation process and operation instructions.

*

*

*

*

R32 Air Conditioner Adding Extra Gas With Longer Pipe Calculator

Smoking and open fire are not allowed around the air conditioner.

Transporting Management Requirements

refrigerant cylinders and the products to be maintained is not allowed.

The transporting vehicles shall run at a constant speed, and heavy acceleration/deceleration shall be avoided.

High-temperature area shall be avoided during transporting, and necessary radiating measures shall be taken

in case the temperature inside the compartment is too high.

Storage Requirements

The area of the room in which R32 refrigerant air conditioner is installed cannot be less than the minimum

Once the horn mouth of connecting lines is fastened, it may not be used again (the air tightness may be

A whole connector wire shall be used for indoor/outdoor unit as required in the operation specification of

It should be stated in the manual that an entire connection pile should be used.

It should be stated in the manual that it is recommended to place the joint of the connection pipes at the outdoor side,

if can’t be at the outdoor side, the side that cannot be reused (not detachable) must be installed at the indoor side.

When the connection pipe is reused, the horn mouth needs to be reinstalled.

Installation Instructions

WARNING!

∅6/∅6.35 20g

∅9/∅9.52 50g

permitted gas by safety standard.

Minimum Room Area

Type

R32 0.306

The maximum refrigerant charge amount (M)

Indoor unit Outdoor unit M kg

AS26PBDHRA 1U26MADFRA 1

AS35PBDHRA 1U35MADFRA 1.04

AS53PDDHRA 1U53WADFRA 1.22

3

AS71PDDHRA 1U71WADFRA 1.3

LFL

kg/m3

hv

m

0.6

1.0

1.8

2.2

4 7 10 15 20 30 50

0.68

1.14

2.05

2.50

Total Mass Charged/kg

Minimum Room Area/m

0.90

1.51

2.71

3.31 3.96 4.85 5.60

1.08 1.32

1.80

3.24

2.20

3.97

2

1.53

2.54

4.58

1.87

3.12 4.02

5.61 7.24

6.86 8.85

2.41

Page 6

• Safety Awareness

1. Procedures: operation shall be made as per controlled procedures to minimize the probability of risks.

2. Area: area shall be divided and isolated appropriately, and operation in an enclosed space shall be avoided.

Before the refrigeration system is started or before hot working, ventilation or opening of the area shall be

guaranteed.

3. Site inspection: the refrigerant shall be checked.

4. Fire control: the fire extinguisher shall be placed nearby, and fire source or high temperature is not allowed;

the sign of “No smoking” shall be arranged.

• Unpacking Inspection

1. Indoor unit: nitrogen is sealed during the delivery of indoor units (inside the evaporator), and the red sign at

the top of the green plastic seal cap on the evaporator air pipes of the indoor unit shall be checked first after

unpacking. In case the sign is raised, the nitrogen sealed still exists. Afterwards, the black plastic seal cap at the

joint of evaporator liquid pipes of the indoor unit shall be pressed, to check whether nitrogen still exists. In case

no nitrogen is sprayed out, the indoor unit is subject to leakage, and installation is not allowed.

2. Outdoor unit: the leak detection equipment shall be extended into the packing box of the outdoor unit, to

check whether the refrigerant is leaking. If the refrigerant leakage is identified, installation is not allowed, and the

outdoor unit shall be delivered to the maintenance department.

• Inspection on Installation Environment

1. The room area checked cannot be less than the area specified on the warning sign of the indoor unit.

2. Inspection on the surrounding environment of place of installation: the outdoor unit of flammable

refrigerants air conditioner cannot be installed inside an enclosed room reserved.

3. Power supply, switches or other high-temperature articles such as the fire source and oil heater shall be

avoided below the indoor unit.

4. The power supply shall be provided with earthing wire and be reliably earthed.

5. While punching the wall with an electric drill, whether embedded water/electricity/gas pipelines are

designed at the hole preset by the user shall be verified in advance. It is recommended that the through-wall holes

reserved shall be used as much as possible.

• Safety Principles of Installation

1. Favorable ventilation shall be maintained at the place of installation (doors and windows are opened).

'C

2. Open fire or high-temperature heat source (including welding, smoking and oven) higher than 548

allowed within the scope of flammable refrigerant.

3. Anti-static measures shall be taken, such as the wearing of cotton clothes and cotton gloves.

4. The place of installation shall be convenient for installation or maintenance, and cannot be adjacent to heat

source and flammable and combustible environment.

5. In case of refrigerant leakage of the indoor unit during installation, the valve of the outdoor unit shall be

closed immediately, and windows shall be opened, and all the personnel shall be evacuated. After the leakage of

refrigerant is handled, the indoor environment shall be subject to concentration detection. Further handling is not

allowed until the safety level is reached.

6. In case the product is damaged, it must be delivered to the maintenance point. Welding of refrigerant

pipelines at the user’s site is not allowed.

7. The installation position of air conditioner shall be convenient for installation or maintenance. Barriers shall

be avoided around the air inlet/outlet of the indoor/outdoor unit, and the electrical appliance, power switches,

sockets, valuables and high-temperature products within the scope of both sidelines of the indoor unit shall be

avoided.

is not

0

No fire source around the

place of installation

w

Read operator’ manual

Cotton clothes Anti-static gloves

Read technical manual

Operator’ manual;operating instructions

BEWARE

ELECTROSTATICS

mJ

•

Goggles

4

Page 7

• Electrical Safety Requirements

Note:

1. The surrounding conditions (ambient temperature, direct sunlight and rainwater) shall be noticed during

electrical wiring, with effective protective measures being taken.

2. Copper wire cable in line with local standards shall be used as the power line and connector wire.

3. Both the indoor unit and outdoor unit shall be reliably earthed.

4. Wiring for the outdoor unit shall be made first and then the indoor unit. The air conditioner can only be

powered on after wiring and pipe connection.

5. The dedicated branch circuit must be used, and leakage protector with sufficient capacity must be installed.

• Qualification Requirements of Installer

Relevant qualification certificate must be obtained as per national laws and regulations.

• Indoor Unit In

stallation

1. Fixation of wall panel and piping layout

In case of left/right water pipe connection for the indoor unit, or in case the evaporator interface of the indoor

unit and the horn mouth of the connecting piping cannot be extended to the outdoor side for installation, the

connector pipes shall be connected to the evaporator piping interface of the indoor unit in the process of horn

mouth.

2. Piping layout

During layout of connecting pipes, drain hose and connector wires, the drain hose and connecting wire shall

be placed at the bottom and top respectively. The power line cannot be twined with the connector wire. The drain

pipes (especially inside the room and mach

ine) must be ventilated with thermal insulation materials.

3. Nitrogen charging for pressure maintaining and leak detection

After the evaporator of the indoor unit is connected to the connector pipe (after welding), nitrogen more than

4.0MPa shall be charged inside the evaporator and the piping connected to evaporator with a nitrogen cylinder

(adjusted by a reducing valve). Afterwards, the valve of the nitrogen cylinder shall be closed, for leak detection

with soapy water or leak detecting solution. The pressure shall be maintained for more than 5 minutes, and then

whether the system pressure is reduced or not shall be observed. In case the pressure is reduced, leakage can be

identifie

d. After the leak point is handled, the steps above shall be repeated.

After the evaporator of the indoor unit is connected to connecting piping, nitrogen shall be charged for

pressure maintaining and leak detection. Afterwards, the evaporator shall be connected to the two-way stop valve

and three-way stop valve of the outdoor unit. After the copper cap of the connecting piping is fastened, nitrogen

more than 4.0MPa shall be charged at the access hole of the three-way stop valve with a charging hose. The valve

of the nitrogen cylinder shall be closed, for leak detection with soapy water or leak detecting solution. The

re shall be maintained for more than 5 minutes, and then whether the system pressure is reduced or not shall

pressu

be observed. In case the pressure is reduced, leakage can be identified. After the leak point is handled, the steps

above shall be repeated.

The operation above can also be completed after the indoor unit is connected to the connecting pipelines and

the two-way stop valve and three-way stop valve of the outdoor unit, after the access hole of the outdoor unit is

connected to the nitrogen cylinder and pressure gauge and after more than 4.0MPa nitrogen is charged. No leak

points are identified in the leak detection at the joint/welding junction of the indoor unit and at the join

t of

connecting pipelines of the two-way stop valve and three-way stop valve of the outdoor unit. It must be

guaranteed that each joint is available for leak detection during installation.

The next step (vacuumizing with a vacuum pump) can only be continued after the installation steps (nitrogen

charging for pressure maintaining and leak detection normal) are completed.

• Outdoor Unit Installation

1. Fixation and connection

Note:

a) Fire source shall be avoided within 3m around the place of installation.

b) The leak detection equipment of refrigerant shall be placed at a low position in the

outdoor, and shall be opened.

5

Page 8

1) Fixation

The support of the outdoor unit shall be fixed onto the wall surface, and then the outdoor unit shall be fixed onto

the support horizontally. In case the outdoor unit is wall-mounted or roof-mounted, the support shall be firmly

fixed, to avoid the damage of strong wind.

2) Installation of connecting pipes

The cone of the connecting pipes shall be aligned with the conical surface of corresponding valve connector.

The nut of connecting pipes shall be installed at a proper position and then be tightened with a spanner. Excessive

tightening torque shall be avoided, or otherwise the nut may be damaged.

• Vacuumizing

A digital vacuum gauge shall be connected for vacuumizing. The duration of vacuumizing shall be at least 15

minutes, and the pressure of

the vacuum gauge shall be below 60Pa.Afterwards, the vacuumizing equipment shall

be closed, and whether the reading of the digital vacuum gauge is increased or not shall be observed after the

pressure is maintained for 5 minutes. In case no leakage is identified, the two-way stop valve and three-way stop

valve of the outdoor unit may be opened. Finally, the vacuumizing hose connected to the outdoor unit can be

disassembled.

• Leak Detection

The joint of connecting pipes for the outdoor unit shall be subject to leak detection with soap bubble or

dedicated leak detection equipment.

• Post-installation Inspection Items and Test Run

Post-installation Inspection Items

qesnoC dekcehC eB ot smetI uence of Improper Installation

Whether the installation is firm or not The unit may fall, vibrate or make a noise

Whether the inspection on air leakage is completed The refrigerating capacity (heating capacity) may be

insufficient

Whether the unit is fully insulated Condensation or drip may occur

Whether the drainage is smooth or not Condensation or drip may occur

Whether the power voltage is identical to that

Failure may occur or the parts may be burned

marked on the nameplate

Whether the circuit and pipeline are installed

Failure may occur or the parts may be burned

correctly

Whether the unit is safely earthed Electric leakage may occur

Whether the type of wire is in line with relevant

Failure may occur or the parts may be burned

regulations

Whether barriers are identified at the air inlet/outlet

of the indoor/outdoor unit

Whether the length of refrigerant pipes and the

The refrigerating capacity (heating capacity) may be

insufficient

The refrigerant amount charged cannot be confirmed

refrigerant amount charged are recorded

Test Run

1. Preparations

(1) Power on is not allowed before all the installation operations are completed and before the leak

detection is proven qualified.

(2) The control circuit shall be connected correctly and all the wires shall be firmly connected.

(3) The two-way stop valve and three-way stop valve shall be opened.

(4) All the scattered articles (especially the metal filing and thread residue) shall be removed from the unit

body.

2. Method

(1) Switch

s

on the power supply and press the “ON/OFF” on the remote controller, after which the air

conditioner will start operating.

(2) Press “Mode” to select refrigeration, heating and sweeping wind, and observe whether the air

conditioner is under normal operation.

6

Page 9

Relocation Procedures

Inspection on system

leakage prior to

disassembly

Inspection on

operational state

Refrigerant recovery

by the system

Cleaning

the indoor

unit

of

and connecting pipes with

inert gas

Disassembly

Safety discharge

of

refrigerant

Safety discharge

of

refrigerant

Installation as required

in

standards

Note: in case relocation is required, the joint of evaporator gas/liquid pipes of the indoor unit shall be cut off with

a cutting knife. Connection is only allowed after re-flaring (the same to the outdoor unit).

Maintenance Instructions

Maintenance Precautions

Precautions

• For all the faults requiring welding the refrigeration pipelines or components inside the refrigeration system

of R32 refrigerant air conditioners, maintenance at the user’s site is never allowed.

• For the faults requiring radical disassembly and bending operation of the heat exchanger, such as the

replacement of the outdoor unit chassis and integral disassembly of the condenser, inspection and maintenance at

the user’s site are never allowed.

• For the faults requiring replacement of the compressor or parts & components of refrigeration system,

maintenance at the user’s site is not allowed.

• For other faults not involved in the refrigerant container, internal refrigeration pipelines and refrigeration

elements, the maintenanc

system requiring no disassembly of refrigeration elements and no welding.

• In case replacement of gas/liquid pipes is required during maintenance, the joint of evaporator gas/liquid

pipes of the indoor unit shall be cut off with a cutting knife. Connection is only allowed after re-flaring (the same

to the outdoor unit).

1. All the operators or the maintenance personnel involved in refrigerating circuits shall be provided with the

effective certificate issued by an industry-accepted assessment institute, to ensure that they are qualified for safety

disposal of refrigerant as required in the assessment regulations.

2. The equipment can only be maintained and repaired as per the method recommended by the manufacturer.

In case the

personnel with qualification certificate involved in flammable refrigerant.

assistance from personnel of other disciplines is required, the assistance shall be supervised by the

e at the user’s site is allowed, including the cleaning and dredging of the refrigeration

Qualification Requirements of Maintenance Personnel

7

Page 10

Inspection on Maintenance Environment

• Before operation, the refrigerant leaked in the room is not allowed.

• The area of the room in which maintenance is made shall be in line with the nameplate.

• Continuous ventilation shall be maintained during maintenance.

• Open fire or high-temperature heat source higher than 548 degree which can easily give birth to open fire is

not allowed inside the room within the maintenance area.

• During maintenance, the phones and the radioactive electronics of all the operators inside the room must be

powered off.

• One dry powder or carbon dioxide extinguisher shall be equipped inside the maintenance area, and the

extinguisher must be working.

Maintenance Site Requirements

• The maintenance site shall be provided with favorable ventilation and must be flat. Arrangement of the

maintena

nce site inside the basement is not allowed.

• Welding zone and non-welding zone shall be divided at the maintenance site, and shall be clearly marked. A

certain safety distance must be guaranteed between the two zones.

• Ventilators shall be installed at the maintenance site, and exhaust fans, fans, ceiling fans, floor fans and

dedicated exhaust duct can be arranged, to meet the requirements of ventilation volume and uniform exhaust, and

to avoid accumulation of refrigerant gas.

• Leak detection equipment for flammable refrigerant shall be equipped, with relevant management system

being established. Whether the leak detection equipment is under available state shall be confirmed before

maintenan

ce.

• Sufficient dedicated vacuum pumps of flammable refrigerant and refrigerant charging equipment shall be

equipped, with relevant management system for maintenance equipment being established. It shall be guaranteed

that the maintenance equipment can only be used for vacuumizing and charging of one type of flammable

refrigerant, and mixed usage is not allowed.

• The master power switch shall be installed outside the maintenance site, with protective (anti-explosive)

device equipped.

• Nitrogen cylinders, acetylene cylinders and oxygen cylinders shall be placed separately. The distance

between the gas cylinders above and the working area involved in open fire shall be at least 6m. The anti-backfire

valve shall be installed for the acetylene cylinders. The color of the acetylene cylinders and oxygen cylinders

installed shall meet the international r

equirements.

• The warning sign of “No Fire” shall be arranged inside the maintenance area.

• Fire control device suitable for electric appliance such as the dry powder extinguisher or carbon dioxide

extinguisher shall be equipped, and shall always be under the available state.

• The ventilator and other electrical equipment at the maintenance site shall be relatively fixed, with

standardized pipe routing. Temporary wires and sockets at the maintenance site are not allowed.

Leak Detection Methods

• The environment in which the refrigerant leakage is checked shall be free from potential ignition source.

Leak detection with halogen probes (or any other detector with open fire) shall be avoided.

• For the system containing flammable refrigerant, leak detecti

on may be realized with electronic leak

detection equipment. During leak detection, the environment in which the leak detection equipment is calibrated

shall be free from refrigerant. It shall be guaranteed that the leak detection equipment will not become potential

ignition source, and is applicable to the refrigerant to be detected. Leak detection equipment shall be set at a

percentage of the LFL of the refrigerant and shall be calibrated to the refrigerant employed, and the appropriate

percentage of gas (25 % maximum) is confirmed.

• The fluid used for leak detection shall be applicable to most of the refrigerant. The use of chlorinecont

aining solvent shall be avoided, to avoid chemical reaction between chlorine and refrigerant and corrosion to

copper pipelines.

• In case leakage is suspected, the open fire at the site shall be evacuated or be put out.

• In case welding is required at the leakage position, all the refrigerants shall be recovered, or be isolated at a

position far from the leak point with a stop valve. Before and during welding, the whole system shall be purified

with OFN.

8

Page 11

Maintenance Items

Maintenance Requirements

• Before the refrigeration system is operated, the circulating system shall be cleaned with nitrogen. Afterwards,

the outdoor unit shall be vacuumized, the duration of which cannot be less than 30 minutes. Finally, 1.5~2.0MPa

OFN shall be used for nitrogen flushing (30 seconds~1 minute), to confirm the position requiring treatment.

Maintenance of the refrigeration system is only allowed after the residual gas of flammable refrigerant is removed.

• During the use of refrigerant charging tools, cross contamination of different refrigerants shall be avoided.

The total length (including the refrigerant pipelines) shall be shortened as much as possible, to reduce the residual

of refrigerant inside.

• The cylinders of refrigerant shall be kept upright, and be fixed.

• Before refrigerant charging, the refrigeration system shall be earthed.

• The refrigerant charged shall be of the type and volume specified on the nameplate. Excessive charging is

not allowed.

• After maintenance of the refrigeration system, the system shall be sealed with a safe manner.

• The maintenance in progress shall not damage or lower the original class of safety protection of the system.

Maintenance of Electrical Components

• Partial of the electrical component under maintenance shall be subject to inspection on refrigerant leakage

with dedicated leak detection equipment.

• After the maintenance, the components with safety protection functions cannot be disassembled or removed.

• During the maintenance of sealing elements, before op

powered off first. When power supply is required, continuous leak detection shall be carried out at the most

dangerous position, to avoid potential risks.

• During maintenance of electrical components, the replacement of enclosures shall not affect the level of

protection.

• After maintenance, it shall be guaranteed that the sealing functions will not be damaged or the sealing

materials will not lose the function of preventing the entry of flammable gas due to aging. The substitute

components shall meet the recommended requirements of the air conditioner manufacturer.

ening the seal cover, the air conditioner shall be

Maintenance of

Intrinsically Safe Elements

The intrinsically safe element refers to the components working continuously inside flammable gas without any

risks.

• Before any maintenance, leak detection and inspection on earthing reliability of the air conditioner must be

carried out, to ensure no leakage and reliable earthing.

• In case the allowable voltage and current limit may be surpassed during the service of the air conditioner,

any inductance or capacitance cannot be added in the circuit.

• Only the elements appointed by the air conditioner manufacturer can be used as the parts and components

replaced, or otherwise a fire may be triggered in case of refrigerant leakage.

• If maintenance work does not involve system pipelines, the system pipelines shall be well protected, to ensure

that the maintenance will not cause any leakage.

• After maintenance and before test run, the air conditioner must be subject to leak detection and inspection on

earthing reliability with leak detection equipment or leak detecting

solution. It shall be guaranteed that the startup

inspection is carried out without leakage and under reliable earthing.

9

Page 12

Removal and Vacuumizing

The maintenance or other operations of the refrigeration circuit shall be made as per conventional procedures.

Moreover, the flammability of refrigerant shall also be mainly considered. The following procedures shall be

followed:

• Refrigerant clearing;

• Pipeline purification with inert gas;

• Vacuumizing;

• Pipeline purification again with inert gas;

• Pipeline cutting or welding. The refrigerant shall be recovered to a proper cylinder. The system shall be

purged with OFN, to ensure safety. The step above may need to be repeated for several times. Compressed air or

oxygen cannot be used for purging.

In the course of purging, OFN shall be charged inside the refrigeration system under vacuum state, to reach

the operating pressure. Afterwards, the OFN shall be discharged to the atmosphere. Finally, the system shall be

vacuumized. The step above shall be repeated until all the refrigerants in the system are cleared. The OFN charged

for the last time shall be discharged to the atmosphere. Afterwards, the system can be welded. The operation

above is neces

sary in case of pipeline welding.

It shall be guaranteed that no alight fire source is around the outlet of the vacuum pump and the ventilation is

favorable.

Welding

• Favorable ventilation must be guaranteed in the maintenance area. After the maintenance machine is subject

to the vacuumizing above, the system refrigerant can be discharged on the outdoor unit side.

• Before the outdoor unit is welded, it must be guaranteed that no refrigerant is inside the outdoor unit and the

system refrigerant has been discharged and cleared.

• The refrigeration pipelines cannot be cut with a welding gun under any circumstance. The refrigeration

pipelines must be disassembled with a pipe cutter, and the disassembly must be carried out around a ventilation

opening.

Refrigerant Charging Procedures

The following requirements are added as the supplementation of conventional procedures:

• During the

use of refrigerant charging tools, cross contamination of different refrigerants shall be avoided.

The total length (including the refrigerant pipelines) shall be shortened as much as possible, to reduce the residual

of refrigerant inside;

• The cylinders of refrigerant shall be kept upright;

• Before refrigerant charging, the refrigeration system shall be earthed;

• A label must be pasted on the refrigeration system after refrigerant charging;

• Excessive charging is not allowed; the refrigerant shall be charged slowly;

• In case system leakage is identified, refrigerant charging is not allowed unless the leak point is plugged;

• During refrigerant charging, the charging amount shall be measured with an electronic scale or a spring

scale. The connecting hose between the refrigerant cylinder and the charging equipment shall be relaxed

appropriately, to avoid impact on the measuring accuracy due to stress.

Requirements on storage site of refrigerant

• The cylinder of refrigerant shall be placed in a -10~50°C environment with favorable ventilation, and

warning labels shall

be pasted;

• The maintenance tool in contact with the refrigerant shall be stored and used separately, and the

maintenance tool of different refrigerants cannot be mixed.

Scrapping and Recovery

Scrapping

Before scrapping, the technician shall be completely familiar with the equipment and all its features. The safe

recovery of refrigerant is recommended. In case the refrigerant recovered needs to be reused, before which the

sample of refrigerant and oil shall be analyzed. The power supply required shall be guaranteed before tests.

(1) The equipment and operation shall be well known;

(2) Power supply shall be switched off;

(3) The followings shall be guaranteed before scrapping:

• The mechanical equipment shall be convenient for operation on the cylinder of refrigerant (if necessary);

• All personal protective equipment is available and being used correctly;

• The whole course of recovery shall be guided by qualified personnel;

• The recovery equipment and cylinders shall be in line with corresponding standards.

(4) The refrigeration system shall be vacuumized if possible;

10

Page 13

(5) In case the vacuum state cannot be reached, vacuumizing shall be carried out from numerous positions, to

pump the refrigerant in each part of the system out;

(6) It shall be guaranteed that the capacity of cylinders is sufficient before recovery;

(7) The recovery equipment shall be started and operated as per the operation instructions of the manufacturer;

(8) The cylinder cannot be charged too full. (The refrigerant charged cannot exceed 80% of the capacity of

cylinders)

(9) The maximum operating pressure of cylinders cannot be surpassed, not even for a short term;

(10) After refrigerant charging is completed, the cylinder and equipment must be evacuated rapidly, and all the

stop valves on the equipment must be closed;

(11) Before purification and tests, the refrigerant recovered cannot be charged into another refrigeration system.

Note:

The air conditioner

shall be marked (with dates and signature) after being scrapped and the refrigerant is

discharged. It shall be guaranteed that the sign on the air conditioner can reflect the flammable refrigerant

charged inside.

Recovery

During maintenance or scrapping, the refrigerant inside the refrigeration system needs to be cleared. It is

recommended that the refrigerant be cleared thoroughly.

The refrigerant can only be charged into a dedicated cylinder, the capacity of which shall match with the

refrigerant amount charged in the whole refrigeration system. All cylinders to be used are designated for the

recovered refrigerant and labeled for that refrigerant (Dedicated Cylinder for Refrigerant Recovery). The cylinders

shall be equipped with pressure relief valves and stop valves under favorable state. The empty cylinder shall be

vacuumized before usage and be kept under normal temperature if possible.

The recovery equipment shall always be under favorable working state, and be equipped with operation

instruc

tions, to facilitate information search. The recovery equipment shall be applicable to the recovery of

flammable refrigerant. Moreover, weighing apparatus under available state with measurement certificates shall be

equipped. In addition, removable attachment joints free from leakage shall be used as the hose, and shall always

be under favorable state. Whether the recovery equipment is under favorable state and is properly maintained and

whether all the electrical components are sealed shall be checked before usage, to avoid fire in case of refrigerant

leakage. If you have any question, please contact your local dealer or qualified personnel.

The refrigerant recovered shall be delivered back to the manufacturer in appropriate cylinders, with

transporting instructions being attached. Mixing of refrigerant in recovery equipment (especially the cylinders) is

not allowed.

During transporting, the space in which the flammable refrigerant air conditioners are loaded cannot be

sealed. Anti-static measures shall be taken for the transporting vehicles if necessary. Meanwhile, during the

transporting, loading and unloading of air conditioners, necessary protective measures shall be taken, to protect

the air conditioner from being damaged.

During removal of the compressor or clearing of the compressor oil, it shall be guaranteed that the

compressor is vacuumized to a proper level, to ensure no residual flammable refrigerant is left inside the

lubricating oil. The vacuumizing shall be completed before the compressor is delivered back to the manufacturer.

vacuumizing can only be accelerated by heating the compressor housing through electrical heating. Safety

The

shall be guaranteed when the oil is discharged from the system.

11

Page 14

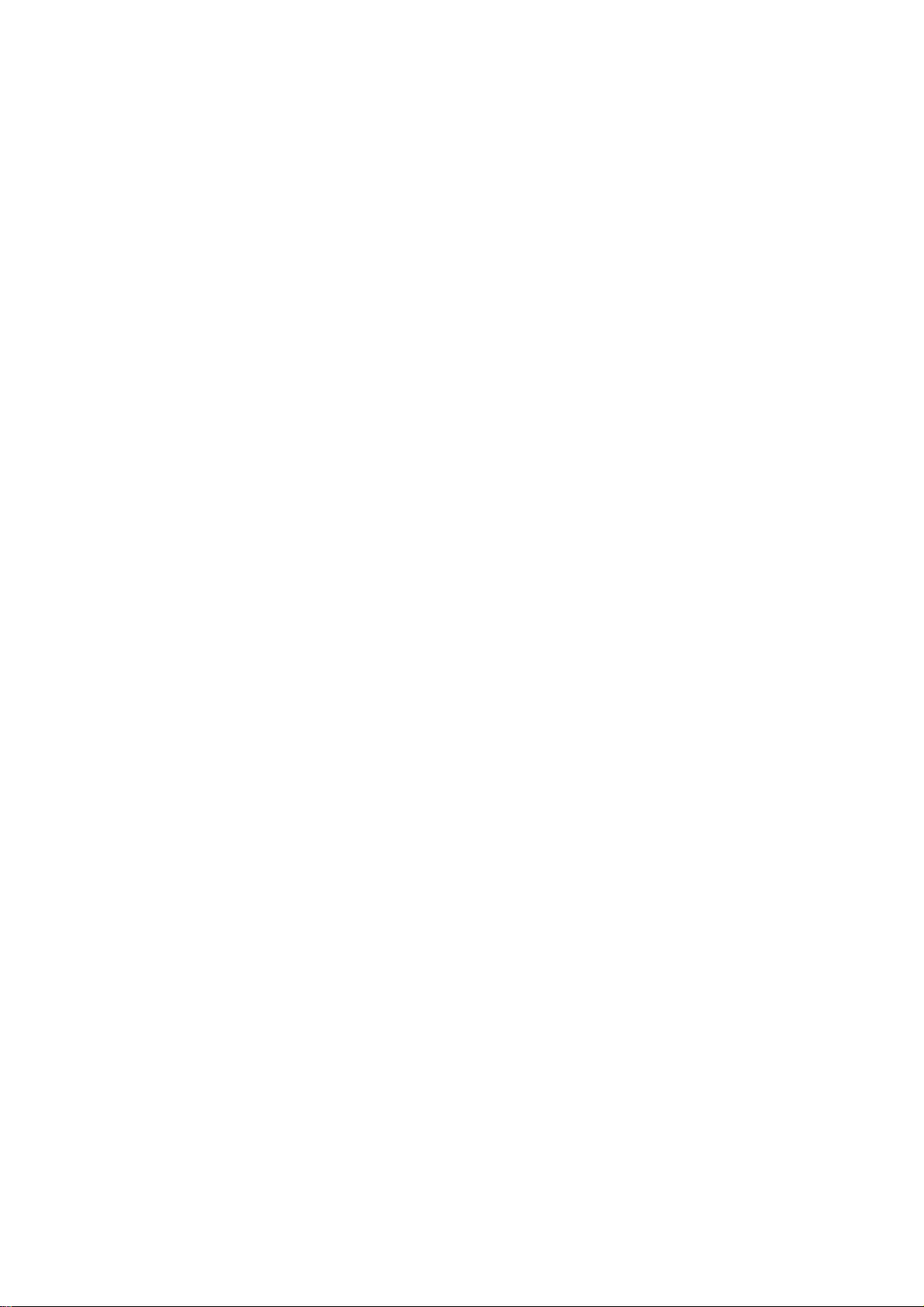

Indoor/Outdoor Unit Installation Drawings

The models adopt HFC free refrigerant R32.

For installation of the indoor units,refer to the installation manual which was provided with the

units.(The diagram shows a wall-mounted indoor unit.)

Attention must be paid to

more than 20cm

the rising up of drain hose

t

more than

10cm

Arrangement of piping

directions

Rear left

Left

Below

The marks from to

•

B

in the

0

parts numbers.

The indoor unit should

•

be installed at the

recommended

height(1.8m).

A

0

figure are the

more than

Rear

right

Right

more than 10cm

60cm

more than 10cm

more than 60cm

A

0

more than

10cm

B

Optional parts for piping

Non-adhesive tape

A

0

Piping hole cover

F

0

C

D

E

B

0

le (L.S) with screws

Sadd

C

0

Connecting electric cable

D

0

for indoor and outdoor

Drain hose

E

0

Heating insulating material

F

0

Fixing of outdoor unit

Fix the unit to concrete or block

•

with bolts (10mm) and nuts

firmly and horizontally.

When fitting the unit to wall

•

surface, roof or roofto

a supporter surely with nails or

wires in consideration of

earthquake and strong wind.

If vibration may affect the

•

house, the unit by attaching a

fix

vibration-proof mat.

p,fix

more than 30cm

AIR OUTLET

G)

AIR INLET

®

CONNECTING PIPING AND ELECTRICAL WIRING

®

4

Compressor(Inside of Unit)

1.When installing the unit to wall, roof or rooftop, fix a supporter

surely with nails or wires in preparation of earthquake and strong wind.

2.Air conditioner mounted not above and one meter away from electric

equipment such as television.

Please be subjected to the actual product purchased.

DRAIN HOSE

©

12

Page 15

3

Safety Precautions

~

WARNING

• Have the unit professionally installed.

Improper installation by

in

water leak, electric shock,

• Place the unit

weight

falling causing injury as a result.

• Only use specified cables for wiring. Securely connect each

cable, and make sure that the cables are not straining the

terminals.

Cables not connected securely and properly may generate

heat and cause fire.

• Take necessary safety measures against typhoons and

earthquakes to prevent the unit from falling over.

Do

•

case

If repairs are not made properly, the unit may leak water

and present a risk

or cause fire.

of

not make any changes or modifications to the unit.

of

on

the unit to prevent the unit from tipping over or

problems, consult the dealer.

an

unqualified person may result

or

fire.

a stable, level surface that withstands the

In

of

electric shock, or it may produce smoke

~

WARNING

• Be sure to carefully follow each step

installing the unit.

Improper installation may result

in

this handbook when

in

water leak, electric shock,

fire or explosion.

• Have all electrical work performed by a licensed electrician

according to the local regulations and the instructions given

in

this manual. Secure a circuit designated exclusively to

the unit.

Improper installation or a lack of circuit capacity may cause

the unit to malfunction or present a risk

of

electric shock,

fire or explosion.

• Securely attach the terminal cover(panel) on the unit.

If installed improperly, dust and/or water may enter the unit

and present a risk

• Only use refrigerant R as indicated

installing or relocating the unit.

The use of any other refrigerant or

the unit circuit may cause the unit to

and abnormal cycle and cause the unit to burst.

of

electric shock, smoke or fire.

32

on

the unit when

an

introduction of air into

run

an

abnormal cycle

•

Do

not touch the fins

for they are sharp and dangerous. hypoxia that results from leaked refrigerant reaching the

In

the event

•

ventilation to the room.

If leaked refrigerant gas

gases a specialist.

•

Do

not try to defeat the safety features

do not change the settings.

Defeating the safety features

switch and temperature switch or using parts other than the

dealer or specialist may result

of

, fire or explosion will be caused.

on

the heat exchanger with bare hands, • When installing the unit

a refrigerant gas leak, provide adequate

is

exposed to a heat source, noxious • When relocating the air conditioner, consult the dealer

of

the devices, and

on

the unit such as the pressure

in

fire

or

explosion.

in

a small room, safeguard against

threshold level.

Consult the dealer for necessary measures to take.

Improper installation may result

in

water leak, electric shock,

fire or explosion.

• After completing the service work, check for a refrigerant

gas leak.

If leaked gas refrigerant is exposed to a heat source such

as fan heater,stove,and electric grill, noxious gases

, fire

or explosion.

• Only use specified parts.

Have the unit professionally installed. Improper installation

may cause water leak, electric shock.smoke

,fire,explosion.

or

13

Page 16

Safety Precautions

Precautions for Handling Units for Use with

Do not use the existing refrigerant piping

• The old refrigerant and refrigerator oil

contain a large amount

refrigerator oil

• is a high-pressure refrigerant, and the use

23R 23R

existing piping may result

Keep the inner and outer surfaces

of

free

Store the piping to be used during installation indoors, and Do not use a charging cylinder.

to coat flares and flange connections.

contaminants such as sulfur, oxides, dust/dirt shaving

particles,oils,and moisture.

• Contaminants inside the refrigerant piping will cause the

refrigerant oil to deteriorate.

keep both ends of the piping sealed until immediately before • The use

brazing.(keep elbows and other joints wrapped

• If dust, dirt,

cause the oil

compressor to malfunction.

Use a small amount

• A large amount

machine oil to deteriorate.

in

or

water enters the refrigerant cycle, it may

in

the unit to deteriorate or may cause the

of

of

chlorine, which will cause the

the new unit to deteriorate.

in

bursting.

of

ester oil, ether oil,

mineral oil will cause the refrigerating

in

of

the pipes clean and

R32

~

Caution

the existing piping

of

the

~

Caution

in

plastic.)

or

alkylbenzene

Use a vacuum pump with a reverse-flow check valve.

• If other types of valves are used, the vacuum pump oil will

flow back into the refrigerant cycle

oil to deteriorate.

Do not use the following tools that have been used with the

conventional refrigerants. Prepare tools that are for exclusive

use with

(Gauge manifold, charging hose, gas leak detector,

reverse-flow check valve, refrigerant charge base,vacuum

gauge, and refrigerant recovery equipment.)

• If refrigerant and/or refrigerant oil left

mixed

cause the refrigerant to deteriorate.

• Since does not contain chlorine, gas-leak detectors

R32

R32

in

with , or if water is mixed with , it will

R32

for conventional HFC refrigerants will not work

of

charging cylinder will change the composition

of

the refrigerant and lead to power loss.

Exercise special care when handling the tools.

• An introduction

water into the refrigerant cycle will cause the refrigerating

machine oil to deteriorate.

of

foreign objects such as dust, dirt

and

cause the refrigerator

on

these tools are

R32

or

Use liquid refrigerant to charge the system.

• Charge the unit with gas refrigerant will cause the refrigerant

in

the cylinder to change its composition and will lead to

a drop

in

performance

Before Installing the Unit

~

Caution

in

Do not install the unit

of

flammable gas leak.

• Leaked gas accumulated around the unit may start a fire.

Do

not use the unit to preserve food, animals, plants, artifacts,

or

for other special purposes.

•The

unit is not designed to provide adepuate conditions

to preserve the quality

Do not use the unit

• The use

oil,

may lead to a remarkable drop

malfunction and presents a risk

or fire.

•The

ammonia,sulfur compounds,and acid may cause gas

water leak.)

of

the unit

steam, acid, alkaline solvents or special types of sprays

presence

of

a place where there is a possibility

of

these items.

in

an

unusual environment

in

the presence

organic solvents, corroded gas (such as

of

a large amount

in

performance and/or

of

electric shock, smoke,

Only use refrigerant.

• The use

cause the refrigerant to deteriorate.

When installing the unit

against noise.

• High-frequency medical equipment may interfere with the

normal operation

conditioning unit may interfere with the normal operation

of

of

Do

• When humidity level exceeds 80%

system is clogged, indoor units may drip water.

• Installation of a centralized drainage system for the outdoor

or

unit may also need to

from the outdoor units.

R32

of

refrigerants containing chlorine(i.e. R22) will

in

of

the air conditioning unit

the medical equipment

not place the unit

on

be

a hospital, take necessary measures

or over things that may not get wet.

or

when the drainage

considered to prevent water drips

or

the air

14

Page 17

Safety Precautions

Carefully read the following information

Below are listed three kinds

.&.

WARNING

.&.

CAUTION

INSTRUCTIONS: These information can ensure the correct operation

Symbols used

(S)

:Indicates

Incorrect operations may result

I Incorrect operations may result

cause serious consequences.

in

the illustrations

an

action that must be avoided.

of

Safety Precautions and Suggestions .

in

order to operate the air conditioner correctly.

in

severe consequences

in

injuries

or

machine damages;

of

death or serious injuries .

in

of

the machine.

some cases may

0 :Indicates that important instructions must be followed.

0 :Indicates a part which must be grounded.

© :Beware

After reading this handbook, hand it over to those who will be using the unit.

The user

relocating the unit. Also, make it available to the new user when the user changes hands.

Be sure to conform with the following important Safety Precautions .

•

1f

any abnormal phenomena is found

(e. g.smell

the power supply immediately, and

contact the dealer to find out the

handling method.

Open the window and well ventilated the room

In

such case, to continue using the condition~r will damage • When need mainten~nce and repairment,

the conditioner, and may cause electrical shock or fire call dealer to handle

hazard.

• After a long time use

the base should be checked for any

damages.

If the damaged base is not repaired, the

unit may fall down and cause accidents.

of

electric shock (This symbol is displayed on the main unit label.)

of

the unit should keep this mamual at hand and make it available to those who will be performing repairs

.&.

WARNING

of

firing), please cut off

of

air-conditioner and fire hazard.

:':'.)

-_

switcti off outdoor unit.

11

I

fil

_:

-e

"'~::-iiiii~;,J

'-=

• Don't dismantle the outlel

The exposure

which may harm human beings.

Incorrect maintenance and repairment

may cause water leak, electrical shock

of

fan is very dangerous

it.

of

the

or

.&.

WARNING

• No goods

placed

falling of goods and people may cause

accidents.

• Don't operate the air-conditioner with

damp hands.Otherwise it will be shocked.

•Only

May not use wire or any other materials

replacing fuse, otherwise it may cause

faults

or

nobody is permitted to

on

or stand

explosion-proof fuse

use

or

fire accidents.

on

outdoor unit.The

•

~

~

~

• Use discharge pipe correctly to ensure efficient discharge.

Incorrect pipe use may cause water leaking.

• installed electrical-leaking circuit breaker.

It easily cause electrical shock without circuit breaker.

• Air-conditioner can't be installed

inflammable gases because the inflammable gases near

air-conditioner may cause fire hazard.

Please let the dealer be responsible for installing the

conditioner. Incorrect installation may cause water leak,

electrical shock and fire hazard.

• Call the dealer to take measures to prevent the refrigerant

from leaking.

If conditioner is installed

every measure

even

in

case

• When conditioner

be responsible for them.

Incorrect installation may cause water leaking, electrical

shock and fire hazard.

• Connect earthing wire.

Earthing wire should not be connected to the gas

pipe, water pipe, lightning

incorrect earthing may cause shock.

in

of

refrigerant leakage.

is

in

order to prevent suffocation accident

installed or reinstalled, the dealer should

in

the environment with

a small room, be sure to take

@

rod

or phone line,

Earthing

15

Page 18

Safety Precautions

Before Installing (Relocating) the Unit or Performing Electric Work

~

Caution

Ground the unit.

on

• Do not connect the grounding

pipes, lightning rods, or the grounding terminals of

telephones. Improper grounding presents a risk

shock, smoke, fire,

grounding may cause the unit to malfunction.

Make sure the wires are not subject to tension.

• If the wires are too taut, they may break or generate heat

and/or smoke and cause fire.

or

the noise caused by improper

the unit to gas pipes,water

of

electric

Install a explosion-proof breaker for current leakage at the

power source to avoid the risk of the electric shock.

Without a breaker for current leakage will cause risks

•

of electric shock, fire or explosion.

Do not use large-capacity fuses,steel wire,or copper wire.

•

Damaging the unit ,fire,smoke or explosion will be

caused otherwise.

Before the Test Run

~

Caution

Do not spray water on the air conditioners

air conditioners

• Water on the unit presents a risk

Periodically check the platform on which

to prevent the unit from falling.

• If the unit

causing injury.

When installing draining pipes, follow the instructions

manual, and make sure that they properly drain water so as

to avoid dew condensation.

• If not installed properly, they may cause water leaks and

damage the furnishings.

Properly dispose

• Things such as nails may be included

Dispose

• Plastic bags present a choking hazard to children. Tear

up the plastic bags before disposing of them to prevent

accidents.

in

water.

of

is

left

on

a damaged plarform, it may topple over,

of

the packing materials .

of

them properly to prevent injury.

or

immerse the

electric shock.

is

placed for damage

in

the package.

in

the

Do not operate switches with wet hands to avoid electric.

Do not touch the refrigerant pipes with bare hands during

and immediately after operation.

of

• Depending on the state

of

certain parts

may become very cold or hot and may subject the person

to frost bites

Do not operated the unit without panels and safety guards

in

their proper places.

• They are there to keep the users from injury from

accidentally touching rotating, high-tempreture or highvoltage parts.

the unit such as the pipes and compressor

or

burning.

the refrigerant

in

the system,

Do not turn off the power immediately after stopping the unit.

• Allow for at least five minutes before turning off the unit,

otherwise the unit may leak water or experience other

problems.

Do not operate the unit without air filters.

• Dust particles

malfunction.

in

the air may clog the system and cause

16

Page 19

Read Before Installation

Items to Be Checked

(1

).

Verify the type

(2). Check the symptom exhibited by the unit to be serviced. Look

refrigerant cycle.

(3). Be sure to carefully read the safety precautions at the beginning

(4

).

If there is a gas leak or if the remaining refrigerant is exposed to

form. Keep workplace well ventilated.

CAUTION

• Install new pipes immediately after removing old ones to keep moisture out

• Chloride

in

Necessary Tools and Materials

Prepare the following tools and materials necessary for installing and servicing the unit.

Necessary tools for use with (Adaptability

1.

To

be used exclusively with ( Not to be used if used with R22

Tools/Materials Use Notes

Gauge Manifold Evacuating.refrigerant charging 5.09MPa on the High-pressure side.

Charging Hose Evacuating, refrigerant charging Hose diameter larger than the concentional ones.

Refrigerant Recovery Equipment Refrigerant recovery

Refrigerant Cylinder Refrigerant charging Write down the refrigerant type. Pink

Refrigerant Cylinder Charging Port Refrigerant charging Hose diameter larger than the conventional ones.

Flare Nut Connecting the unit to piping Use Type-2 Flare nuts.

of

refrigerant used by the unit to be serviced. Refrigerant Type:

some types

R32

in

this service handbook for symptoms relating to the

of

this document.

an

open flame, a noxious gas hydrofluoric acid may

of

the refrigerant circuit.

of

refrigerants such as R22 will cause the refrigerating machine oil to deteriorate.

R32

R32

of

tools that are for use with R22 and R407C).

or

R407C )

in

color at the top

of

the cylinder.

2.

Tools and materials that may be used with with some restrictions

Tools/Materials Use Notes

Gas leak detector Detection

Vacuum Pump Vacuum drying May

Flare Tool Flare machining

Refrigerant Recovery Equipment Recovery

3.

Tools and materials that are used with R22 or R407C that can also be used with

Tools/Materials Use Notes

Vacuum Pump with a Check Valve Vacuum drying

Bender Bending pipes

Torque Wrench Tightening flare nuts

Pipe Cutter Cutting pipes

Welder and Nitrogen Cylinder Welding pipes

Refrigerant Charging Meter Refrigerant charging

Vacuum Gauze Checking vacuum degree

4.

Tool

and materials that must not used with

Tools/Materials Use Notes

Charging Cylinder Refrigerant Charging Must not be used with -type units.

Tools for must be handled with special care, and keep moisture and dust from entering the cycle.

R32

R32

of

gas leaks The ones for HFC type refrigerant may be used.

be

used if a reverse flow check adaptor is attached.

of

piping Chages have been made

of

refrigerant May

be

used if designed for use with

in

the flare machining dimension.Refer to the next page.

R32

R32

Only

cj:,12.70

(1/2") and

cj:,

15.88(5/8") have a larger flare machining dimension.

R32

R32

17

Page 20

Read Before Installation

Piping Materials

Types

• Use pipes that meet the local standards.

Piping Materials/Radial Thickness

Use pipes made

Since the operation pressure

at least the radial thickness specified

of

Copper Pipes (Reference)

Maximum Operation Pressure Applicable Refrigerants

3.4MPa

3

4. MPa

of

phosphorus deoxidized copper.

R22,R407C

R32

of

the units that use is

in

the chart below. (Pipes with a radial thickness

R32

hig_her

than that

of

the units for use with R22, use pipes with

of

0.7mm

or

less may not be used.)

Size(mm) Size(inch) Radial Thickness(mm)

cp6.35 1/4" 0.8t

cp9.52 3/8" 0.8t

cp

12.7 1/2" 0.8t

C/)

15.88

C/)

19.05 3/4" 1.0t Type-1/2H

5/8" 1.0t

• Although it was possible to use type-O for pipes with a size

1 /2H pipes for units that use .(Type-O pipes may be used if the pipe size

• The table shows the standards

R32

in

Japan. Using this table as a reference, choose pipes that meet the local standards.

Type

Type-O pipes

or

Hpipes

of

up

to

c/)

19.05(3/4") with conventional refrigerants, use type-

Flare Machining (type-O and OL only)

The flare machining dimensions for units that use

R32

is larger than those for units that use R22

air tightness.

Flare Machining Dimension(mm)

External dimension

<P6.35

<P9.52

<P12.7

<P15.88

<P19.05

of

pipes

Size

1/4"

3/8" 13.2

1/2"

5/8" 19.7

3/4" 24.0

R32

9.1

16.6

Dimension A

R22

9.0

13.0

16.2

19.4

23.3

is

c/)19.05

and the radial thickness is 1.2t.)

in

order to increase

If a clutch type flare tool is used to machine flares

on

units that use , make the protruding part

1.0 and 1.5mm. Copper pipe gauge for adjusting the length

Flare Nut

Type-2 flare nuts instead

of

type-1 nuts are used to increase the strength. The size of some

been changed.

Flare nut dimension(mm)

External dimension

<P6.35

<P9.52

<P12.7

<P15.88

<P19.05

of

pipes Size

1/4" 17.0 17.0

3/8"

1/2" 26.0 24.0

5/8"

3/4" 36.0 36.0

• The table shows the standards

in

Dimension B

(Type2) R22(Type1)

R32

22.0

29.0 27.0

22.0

Japan. Using this table as a reference, choose pipes that meet the local standards.

R32

of

pipe protrusion is useful.

ED~

Dimension B

of

the pipe between

of

the flare nuts have also

18

Page 21

Read Before Installation

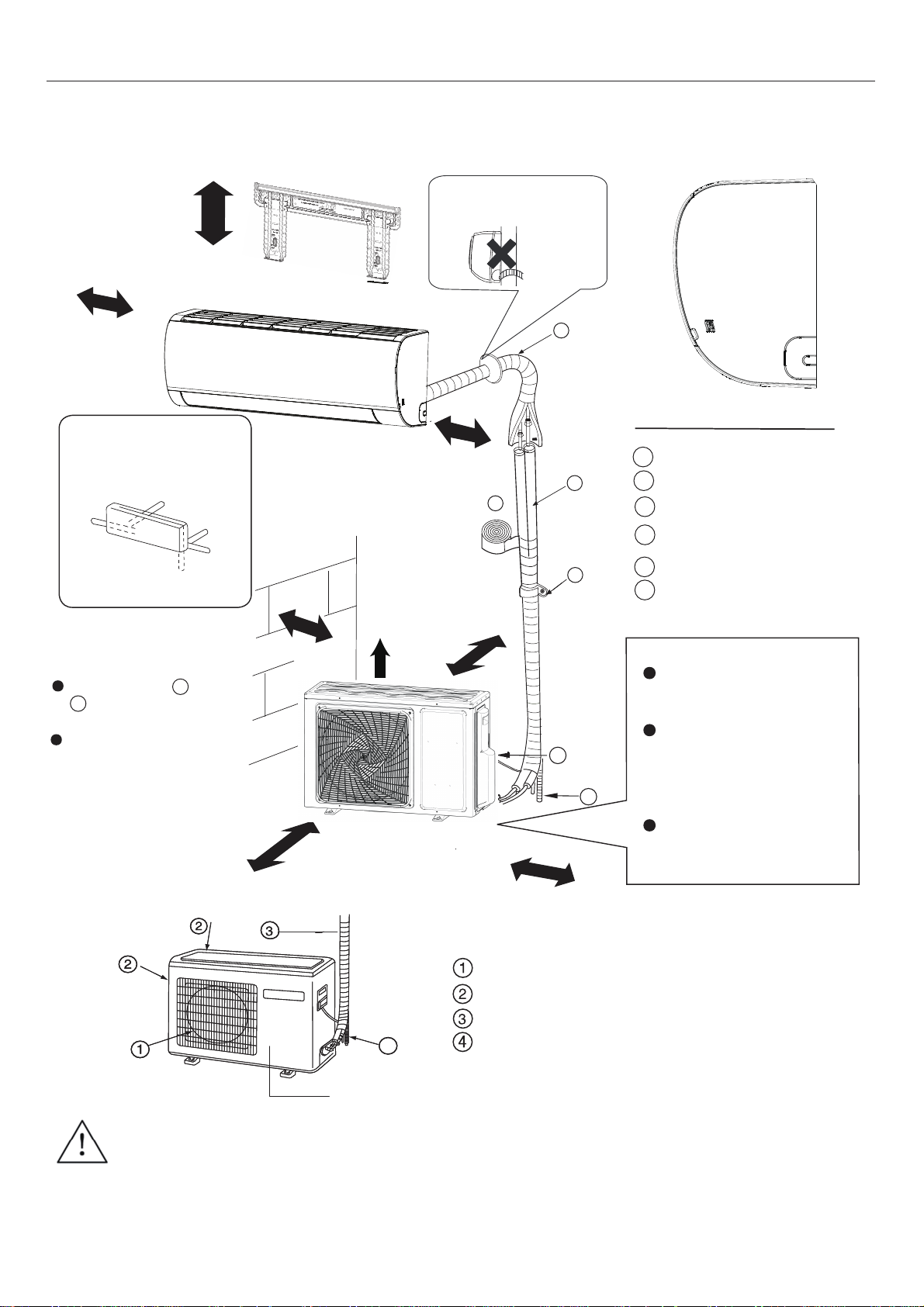

Air Tightness Test

No changes from the conventional method. Note that a refrigerant leakage detector for R22 or

leakage.

R4

10A

cannot detect

R32

~

Halide torch R22 or R407C leakage detector

Items to be strictly observed :

1.Pressurize the equipment with nitrogen up to the design pressure and then judge the equipment's air tightness, taking

temperature variations into account.

2.When investigating leakage locations using a refrigerant, be sure to use

3.Ensure that is

Reasons:

1.

Use

of

2.Charging with gas will lead the composition

refrigerant can not be used.

Vacuuming

1.Vacuum pump with check valve

A vacuum pump with a check valve is required to prevent the vacuum pump oil from flowing back into the refrigerant

circuit when the vacuum pump power is turned off (power failure). It is also possible to attach a check valve to the actual

vacuum pump afterwards.

R32

oxygen as the pressurized gas may cause an explosion.

R32

in

a liquid state when charging.

of

the remaining refrigerant

R32

in

the cylinder to change and then this

2.Standard degree

Use a pump which reaches 65Pa or below after 5 minutes

In

addition, be sure to use a vacuum pump that has been properly maintained and oiled using the specified oil. If the

vacuum pump is not properly maintained, the degree

3.Required accuracy

Use a vacuum gauge that can measure up to 650Pa. Do not use a general gauge manifold since it cannot measure a

vacuum

4.Evacuating time

Evacuate the equipment for 1 hour after 650Pa has been reached.

After envacuating, leave the equipment for 1 hour and make sure the that vacuum

5-0perating procedure when the vacuum pump

In

charge hose to drawn

vacuum pump with a check valve.

Charging Refrigerant

R32

Reasons:

R32

however,

the composition

Note

•

In

type

Remedies to be taken

When refrigerant leaks, additional refrigerant may be charged. (Add the refrigerant from the liquid side)

of

650Pa.

order to prevent a backflow

must be

HFC

is a refrigerant (boiling point = -52 °C ) and can roughly be handled

be

sure to fill the refrigerant from the liquid side, for doing so from the gas side will somewhat change

the case

of

cylinder before charging.

of

vacuum for the vacuum pump

of

operation.

of

vacuum may be too low.

of

the vacuum gauge

is

not lost.

is

stopped

of

the vacuum pump oil, open the relief valve on the vacuum pump side or loosen the

in

air before stopping operation.The same operating procedure should be used when using a

in

a liquid state when charging.

in

the same way as R

of

the refrigerant

of

a cylinder with a syphon, liquid is charged without turning the cylinder up side down. Check the

in

case

in

the cylinder.

of

a refrigerant leak

R32

410A

Characteristics

• Because is a simulated azeotropic refrigerant, it can be handled

such as R22. Howerver, if the refrigerant is removed in the vapor phase, the composition

will somewhat change.

• Remove the refrigerant

R32

of

the Conventional and the New Refrigerants

in

the liquid phase. Additional refrigerant may be added

in

almost the same mammer as a single refrigerant

in

case

of

the refrigerant

of

a refrigerant leak.

in

the cylinder

19

Page 22

Installation Procedure

1.

Accessories

"Edging" for protection

2.

Selection

Select the place

user.

• Place where air circulates.

• Place free from heat radiation from other heat sources.

• Place where drain water may be discharged.

• Place where noise and hot air may not disturb the neighborhood.

• Place where there is not heavy snowfall

• Place where obstacles do not exist near the air inlet and air outlet .

• Place where the air outlet may not be exposed to a strong wind.

• Place surrounded at four sides are not suitable for installation. A 1 m or more

• Avoid mounting guide-louvers to the place where short-circuit is a possibility.

• When installing several units, secure sufficient suction space to avoid short circuiting.

Open space requirement around the unit

of

the place

V Air inlet

;;,,

100

Q

u

Q)

E

<(

....

c::J;61

vAiroutlet

of

electrical wires from

of

installation

of

installation satisfying the following conditions and, at the same time, obtain a consent from the client or

;;,,

100

;;,,

300

(Servicing

space)

;;,,

600

an

opening edge.

in

the winter time.

of

overhead space is needed for the unit.

Note:

(1) Fix the parts with screws.

(2) Don't intake the strong wind directly to , t<:\

the outlet air-flow hole.

(3) A one meter distance should be

kept from the unit top.

(4) Don't block the surroundings

(5) If the outdoor unit is installed

to the wind, install the unit so that the outlet grid is NOT

in

pointing

the direction

of

Installation

of

the unit with sundries.

in

a place that is exposed

the wind.

of

Outdoor Unit

Air outlet

\.Y

Wind direction

NO

3.

Installation

Fix the unit on the foundation

condition

information.

• Give enough room for the concrete foundation to fix by anchor bolts.

• Place the concrete foundation deep enough.

• Install the unit so that the angle

• Forbidden to place the unit

near the drainage hole

of

outdoor unit

in

a proper way according to the

of

the installation place, referring to the following

of

inclination must be less than 3 degrees.

on

the ground directly.Please confirm there is enough room

on

bottom plate, which will ensure the water be drained smoothly.

4.Installation dimension(Unit:mm)

313

160

1

I

374

B=

Ø

60mm

43.4mm

A=170mm C=130mm

B=

Ø

60mm

36mm

A=222mm C=165mm

20

~I

Floor fixing dimensions

of the outdoor unit

(Unit:mm)

1U09MADFRA

1U26MADFRA

1U12MADFRA

1U35MADFRA

1U18WADFRA

1U53WADFRA

1U24WADFRA

1U71WADFRA

510

130

r---,,,,---;

130 130

of

(Unil:mm)

------...---1--~

630

the outdoor unit

Cushion rubber

AS26PBDHRA

AS35PBDHRA

AS53PDDHRA

AS71PDDHRA

B=Ø60mm

43.4mm

Ø

60mm

B=

42mm

Page 23

Installation Procedure

1.

Piping size

Piping Connection

AS26PBDHRA/1U26MADFRA

FOR

AS35PBDHRA/1U35MADFRA

AS53PDDHRA/1U53WADFRA

FOR

AS71PDDHRA/1U71WADFRA

2.

Connection of pipes

When bending the pipe, be careful not to crush it. To prevent breaking of the pipe, avoid sharp bends.

•

Bend the pipe with a radius of curvature of 40 mm or over.

Connecting the pipe of gas side

•

The connection pipe is specialized for R32.

Liquid pipe

Gas pipe

Liquid pipe

Gas pipe

rst makes working easier.

fi

cp

6.35x0.8mm

cp

9.52x0.8mm

cp

6.35x0.8mm

cp

12.7x0.8mm

• Install the removed flare nuts to the pipes

to be connected, then flare the pipes .

•

Half union

Spanner

Flare nut

Torque wrench

Forced fastening without careful centering may

damage the threads and cause a leakage of gas.

Pipe Diameter( ) Fastening torque

Liquid side6.35mm(1/4") 18N.m

Liquid/Gas side9.52mm(3/8") 42 N.m

Gas side 12.7mm(1/2") 55N.m

Gas side 15.88mm(5/8") 60 N.m

0

Be careful that matters, such as wastes of sand

s,water,

CAUTION

The standard pipe length is Cm. If the pipe

according to D g/m. But the charge of refrigerant

engineer. Before adding additional refrigerant,

unit using a vacuum pump,then charge additional refrigerant.

Outdoor unit

Indoor unit

B

A

A

Outdoor unit

Outdoor unit

Max.Elevation:

•

In case the elevation A is more

•

than 5m, oil trap shoud be

Oil trap

B

A

Indoor unit

installed every 5~7

Max. Length:

•

M i n. Length:

•

In case the pipe length B is

•

more than Cm, the refrigerant

should be charged, according

to D g/m.

L

to be lengthened, the refrigerant should be charged,

has

must

be conducted by profes

perform air purging from the refrigerant pipes and indoor

B

Indoor unit

Amax

Bmax

B min

, etc. shall not enter the pipe.

sional air conditioner

Outdoor