Page 1

ROOM AIR CONDITIONER

INSTALLATION MANUAL

1U07BS1ERA

1U09BS1ERA

1U12BS1ERA

Contents

Indoor/Outdoor Unit Installion Drawings

Safety Precautions

Read Before Installation

Installation Procedure

Outdoor Unit Troubleshooting

Contenido

1

2

6

9

14

1U18FS1ERA

1U24GS1ERA

Unidad interior y exterior Dibujos de extracción

Precauciones de seguridad 16

Leer antes de realizar la instalación 20

Procedimiento instalación 23

Unidad interior Resolución de problemas

15

28

Indice

Unità esterna/interna Immagini per l'installazione

Precauzioni di sicurezza

Leggere prima dell'installazione

Processo di installazione

Unità esterna Risoluzione dei problemi

29

30

34

37

42

Table des matières

Unité intérieure/extérieure Schémas d'installation

Consignes de sécurité

À lire avant l'installation

Procédure d'installation

Unité extérieure Dépannage

43

44

48

51

56

●

Please read this manual carefully before installtion.

Keep this operation manual for future reference.

NO.0010535386

Page 2

Haier Industrial Park, No.1 Haier Road, Qingdao, P.R.China

EUROPEAN REGULATIONS

CONFORMITY FOR THE MODELS

CE

All the products are in conformity with the following

European provision:

- Low Voltage Directive 73/23/EEC

- Low Voltage Directive 2006/95/EC

-Electomagnetic CompatibilitY 89/336/EEC

-Electomagnetic CompatibilitY 2004/108/EC

ROHS

The products are fulfilled with the requirements in the

directive 2002/95/EEC of the European parliament and of

council on the Restriction of the use of Certain Hazardous

Substances in Electrical and Electronic Equipment (EU

RoHS Directive)

WEEE

In accordance with the directive 2002/96/CE of the European

parliament, herewith we inform the consumer about the disposal requirements of the electrical and electronic products.

DISPOSAL REQUIREMENTS:

Your air conditioning product is marked with this

symbol.This means that electrical and electronic

products shall not be mixed with unsorted

household waste. Do not try to dismantle the

system yourself : the dismantling of the air

conditioning system,treatment of the refrigerant, of oil and of

other part must be done by a qualified installer in

with relevant local and national legislation. Air conditioners

must be treated at a specialized treatment facility for reuse,

recycling and recovery. By ensuring this product is disposed

of correctly, you will help to prevent potential negative consequences for the environment and humen health. Please

contact the installer or local authority for more information.

Battery must be removed from the remote controller and disposed of separately in accordance with relevant local and

nationl legislation.

accordance

IMPORTANT INFORMATION REGARDING THE REFRIGERANT USED

Contains fluorinated greenhouse gases

covered by the Kyoto Protocol

R410A

2

1=

2=

1

1+2=

FE

This product contains fluorinated greenhouse gases covered

by the Kyoto Protocol. Do not vent into the atmosphere.

Refrigerant type:R410A

GWP* value:1975

GWP=global warming potential

Please fill in with indelible ink,

• 1 the factory refrigerant charge of the product

• 2 the additional refrigerant amount charged in the field

and

• 1+2 the total refrigerant charge

on the refrigerant charge label supplied with the product.

The filled out label must be adhered in the proximity of the

product

cover).

A contains fluorinated greenhouse gases covered by the

Kyoto

B factory refrigerant charge of the product: see unit name

plate

C additional refrigerant amount charged in the field

D total refrigerant charge

E outdoor unit

F refrigerant cylinder and manifold for charging

charging port (e.g. onto the inside of the stop value

Protocol

kg

kg

kg

A

B

C

D

Page 3

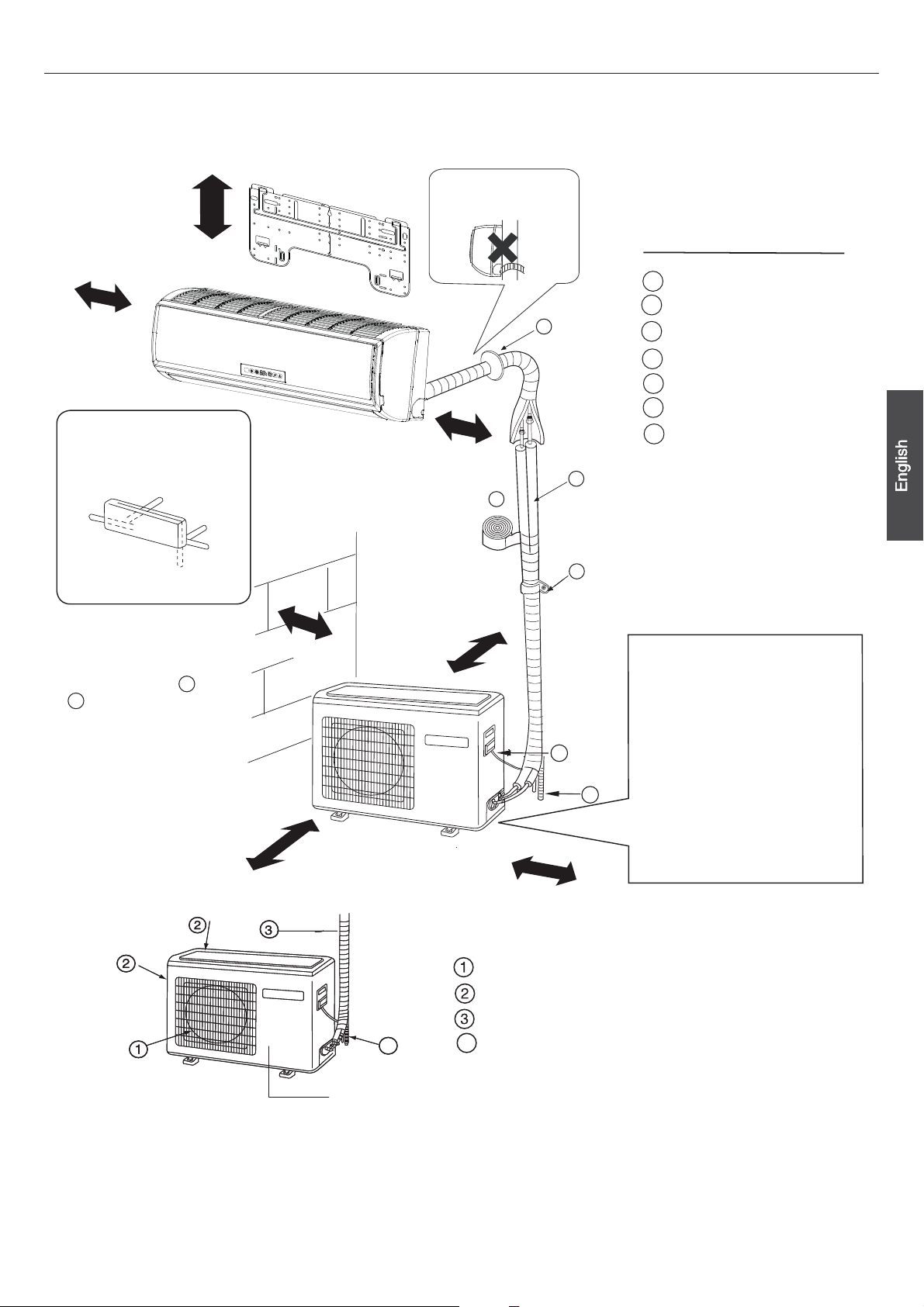

Indoor/Outdoor Unit Installation Drawings

ThemodelsadoptHFCfreerefrigerantR410A.

For installation of the indoor units,refer to the installation manual which was provided with the units.

(The diagram shows a wall-mounted indoor unit.)

Attention must be paid to

more than 15cm

more than

10cm

Arrangement of piping

directions

Rear left

Left

Rear

right

the rising up of drain hose

more than 10cm

A

Optional parts for piping

Non-adhesive tape

A

Adhesive tape

B

G

F

Saddle(L.S)withscrews

C

Connecting electric cable

D

for indoor and outdoor

E

Drain hose

F

Heating insulating material

Piping hole cover

G

Below

The marks from to

ƽ

G

in the figure are the

parts numbers.

Thedistancebetween

ƽ

theindoorunitandthe

floor should be more

than 2m.

more than

Right

more than

20cm

more than 20cm

A

60cm

more than 25cm

C

Fixing of outdoor unit

Fix the unit to concrete or blockƽ

with bolts (10mm) and nuts firmly

and horizontally.

ƽ

When fitting the unit to wall

D

E

surface,rooforrooftop,fix

asupportersurelywithnails

or wires in consideration of

earthquake and strong wind.

ƽ

If vibration may affect the

house, fix the unit by attaching a

vibration-proof mat.

AIR OUTLET

AIR INLET

CONNECTING PIPING AND ELECTRICAL WIRING

DRAIN HOSE

4

Compressor(Inside of Unit)

ƽ

The above indoor and outdoor units’ picture is just for your reference.

Please be subject to the actual product purchased.

1

Page 4

WARNING

CAUTION

2

Page 5

Safety Precautions

WARNING

Have the unit professionally installed.

Improper installation by an unqualified person may result

in water leak, electric shock, or fire.

Place the unit on a stable, level surface that withstands the

weight of the unit to prevent the unit from tipping over or

falling causing injury as a result.

Only use specified cables for wiring. Securely connect each

cable, and make sure that the cables are not straining the

terminals.

Cables not connected securely and properly may generate

heat and cause fire.

Take necessary safety measures against typhoons and

earthquakes to prevent the unit from falling over.

Do not make any changes or modifications to the unit. In

case of problems, consult the dealer.

If repairs are not made properly, the unit may leak water

and present a risk of electric shock, or it may produce smoke

or cause fire.

WARNING

Be sure to carefully follow each step in this handbook when

installing the unit.

Improper installation may result in water leak, electric shock,

smoke or fire.

Have all electrical work performed by a licensed electrician

according to the local regulations and the instructions given

in this manual. Secure a circuit designated exclusively to

the unit.

Improper installation or a lack of circuit capacity may cause

the unit to malfunction or present a risk of electric shock,

smoke,and fire.

Securely attach the terminal cover(panel) on the unit.

If installed improperly, dust and/or water may enter the unit

and present a risk of electric shock, smoke or fire.

Only use refrigerant R410A as indicated on the unit when

installing or relocating the unit.

The use of any other refrigerant or an introduction of air into

the unit circuit may cause the unit to run an abnormal cycle

and abnormal cycle and cause the unit to burst.

Do not touch the fins on the heat exchanger with bare hands,

for they are sharp and dangerous.

In the event of a refrigerant gas leak, provide adequate

ventilation to the room.

If leaked refrigerant gas is exposed to a heat source, noxious

gases may form.

With All-Fresh type air conditioners, outdoor air may be

directly blown into the room upon thermo off. Take this into

consideration when installing the unit.

Direct exposure to outdoor air may present a health hazard,

and it may also cause food items to deteriorate.

Do not try to defeat the safety features of the devices, and

do not change the settings.

Defeating the safety features on the unit such as the pressure

switch and temperature switch or using parts other than the

dealer or specialist may result in fire or explosion.

When installing the unit in a small room, safeguard against

hypoxia that results from leaked refrigerant reaching the

threshold level.

Consult the dealer for necessary measures to take.

When relocating the air conditioner, consult the dealer or

a specialist.

Improper installation may result in water leak, electric shock,

or fire.

After completing the service work, check for a refrigerant

gas leak.

If leaked gas refrigerant is exposed to a heat source such

as fan heater,stove,and electric grill, noxious gases may

form.

Only use specified parts.

Have the unit professionally installed. Improper installation

may cause water leak, electric shock,smoke, or fire.

3

Page 6

Safety Precautions

Precautions for Handling Units for Use with R410A

Caution

Do not use the existing refrigerant piping

The old refrigerant and refrigerator oil in the existing piping

contain a large amount of chlorine, which will cause the

refrigerator oil in the new unit to deteriorate.

R410A is a high-pressure refrigerant, and the use of the

existing piping may result in bursting.

Keep the inner and outer surfaces of the pipes clean and

free of contaminants such as sulfur, oxides, dust/dirt shaving

particles,oils,and moisture.

Contaminants inside the refrigerant piping will cause the

refrigerant oil to deteriorate.

Caution

Store the piping to be used during installation indoors, and

keep both ends of the piping sealed until immediately before

brazing.(keep elbows and other joints wrapped in plastic.)

If dust, dirt, or water enters the refrigerant cycle, it may

cause the oil in the unit to deteriorate or may cause the

compressor to malfunction.

Use a small amount of ester oil, ether oil, or alkylbenzene

to coat flares and flange connections.

A large amount of mineral oil will cause the refrigerating

machine oil to deteriorate.

Use a vacuum pump with a reverse-flow check valve.

If other types of valves are used, the vacuum pump oil will

flow back into the refrigerant cycle and cause the refrigerator

oil to deteriorate.

Do not use the following tools that have been used with the

conventional refrigerants. Prepare tools that are for exclusive

use with R410A.

(Gauge manifold, charging hose, gas leak detector,

reverse-flow check valve, refrigerant charge base,vacuum

gauge, and refrigerant recovery equipment.)

If refrigerant and/or refrigerant oil left on these tools are

mixed in with R410, or if water is mixed with R410A, it will

cause the refrigerant to deteriorate.

Since R410A does not contain chlorine, gas-leak detectors

for conventional refrigerators will not work.

Do not use a charging cylinder.

The use of charging cylinder will change the composition

of the refrigerant and lead to power loss.

Exercise special care when handling the tools.

An introduction of foreign objects such as dust, dirt or

water into the refrigerant cycle will cause the refrigerating

machine oil to deteriorate.

Use liquid refrigerant to charge the system.

Charge the unit with gas refrigerant will cause the refrigerant

in the cylinder to change its composition and will lead to

a drop in performance

Before Installing the Unit

Caution

Do not install the unit in a place where there is a possibility

of flammable gas leak.

Leaked gas accumulated around the unit may start a fire.

Do not use the unit to preserve food, animals, plants, artifacts,

or for other special purposes.

The unit is not designed to provide adepuate conditions

to preserve the quality of these items.

Do not use the unit in an unusual environment

The use of the unit in the presence of a large amount of

oil, steam, acid, alkaline solvents or special types of sprays

may lead to a remarkable drop in performance and/or

malfunction and presents a risk of electric shock, smoke,

or fire.

The presence of organic solvents, corroded gas (such as

ammonia,sulfur compounds,and acid may cause gas or

water leak.)

Only use R410A refrigerant.

The use of refrigerants containing chlorine(i.e. R22) will

cause the refrigerant to deteriorate.

When installing the unit in a hospital, take necessary measures

against noise.

High-frequency medical equipment may interfere with the

normal operation of the air conditioning unit or the air

conditioning unit may interfere with the normal operation

of the medical equipment

Do not place the unit on or over things that may not get wet.

When humidity level exceeds 80% or when the drainage

system is clogged, indoor units may drip water.

Installation of a centralized drainage system for the outdoor

unit may also need to be considered to prevent water drips

from the outdoor units.

4

Page 7

Safety Precautions

Before Installing (Relocating) the Unit or Performing Electric Work

Caution

Ground the unit.

Do not connect the grounding on the unit to gas pipes,water

pipes, lightning rods, or the grounding terminals of

telephones. Improper grounding presents a risk of electric

shock, smoke, fire, or the noise caused by improper

grounding may cause the unit to malfunction.

Make sure the wires are not subject to tension.

If the wires are too taut, they may break or generate heat

and/or smoke and cause fire.

Install a breaker for current leakage at the power source

to avoid the risk of electric shock.

Without a breaker for current leakage, there is a risk of

electric shock, smoke or fire.

Use breakers and fuses (electrical current breaker, remote

switch<switch+Type-B fuse>,molded case circuit breaker)

with a proper current capacity.

The use of large-capacity fuses, steel wire, or copper wire

may damage the unit or cause smoke or fire.

Before the Test Run

Do not spray water on the air conditioners or immerse the

air conditioners in water.

Water on the unit presents a risk of electric shock.

Periodically check the platform on which is placed for damage

to prevent the unit from falling.

If the unit is left on a damaged plarform, it may topple over,

causing injury.

When installing draining pipes, follow the instructions in the

manual, and make sure that they properly drain water so as

to avoid dew condensation.

If not installed properly, they may cause water leaks and

damage the furnishings.

Properly dispose of the packing materials.

Things such as nails may be included in the package.

Dispose of them properly to prevent injury.

Plastic bags present a choking hazard to children. Tear

up the plastic bags before disposing of them to prevent

accidents.

Caution

Do not operate switches with wet hands to avoid electric.

Do not touch the refrigerant pipes with bare hands during

and immediately after operation.

Depending on the state of the refrigerant in the system,

certain parts of the unit such as the pipes and compressor

may become very cold or hot and may subject the person

to frost bites or burning.

Do not operated the unit without panels and safety guards

in their proper places.

They are there to keep the users from injury from

accidentally touching rotating, high-tempreture or highvoltage parts.

Do not turn off the power immediately after stopping the unit.

Allow for at least five minutes before turning off the unit,

otherwise the unit may leak water or experience other

problems.

Do not operate the unit without air filters.

Dust particles in the air may clog the system and cause

malfunction.

5

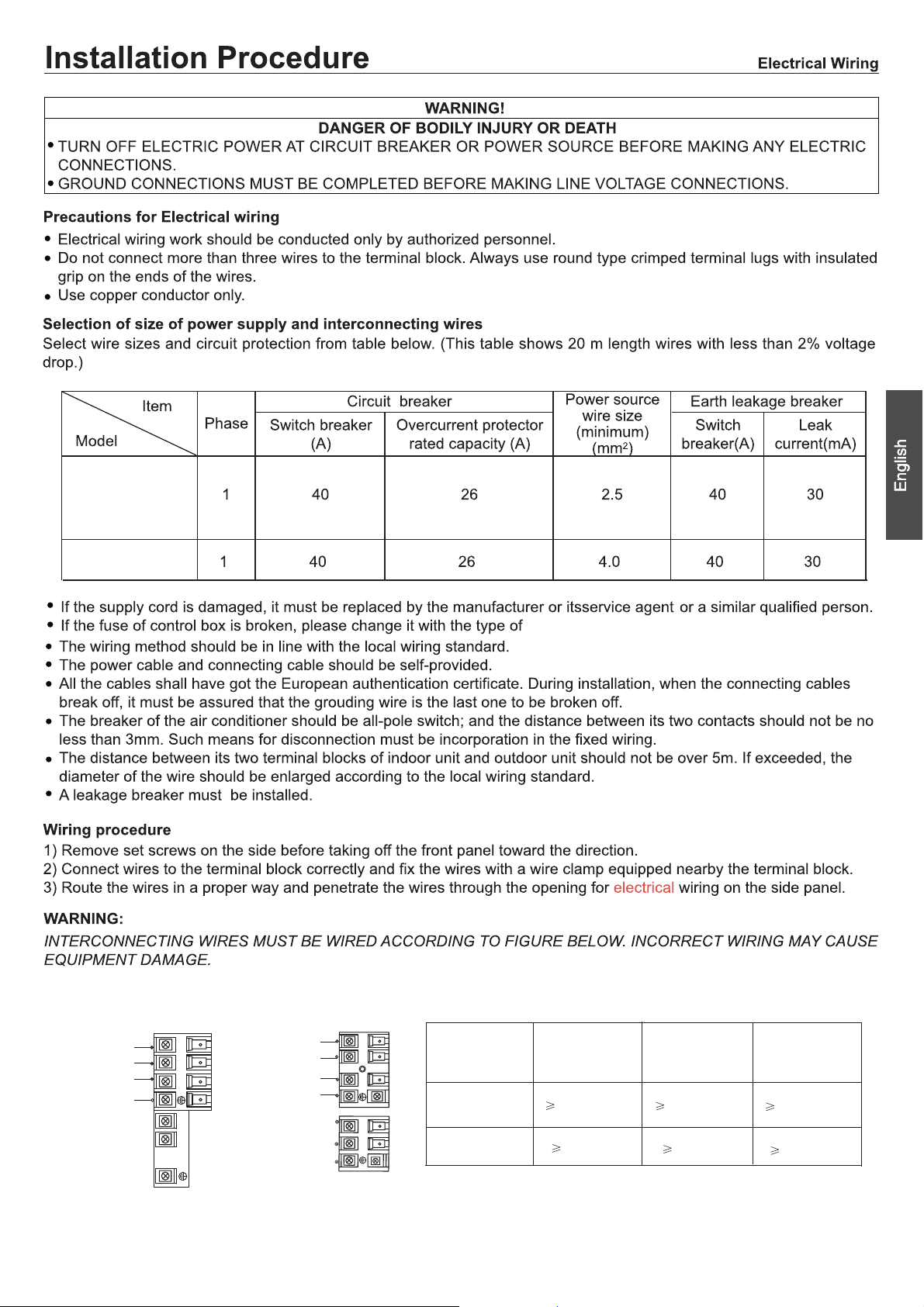

Page 8

Read Before Installation

Items to Be Checked

(1). Verify the type of refrigerant used by the unit to be serviced. Refrigerant Type: R410A

(2). Check the symptom exhibited by the unit to be serviced. Look in this service handbook for symptoms relating to the

refrigerant cycle.

(3). Be sure to carefully read the safety precautions at the beginning of this document.

(4). If there is a gas leak or if the remaining refrigerant is exposed to an open flame, a noxious gas hydrofluoric acid may

form. Keep workplace well ventilated.

CAUTION

Install new pipes immediately after removing old ones to keep moisture out of the refrigerant circuit.

Chloride in some types of refrigerants such as R22 will cause the refrigerating machine oil to deteriorate.

Necessary Tools and Materials

Prepare the following tools and materials necessary for installing and servicing the unit.

Necessary tools for use with R410A(Adaptability of tools that are for use with R22 and R407C).

1. To be used exclusively with R410A ( Not to be used if used with R22 or R407C )

Tools/Materials Use Notes

Gauge Manifold Evacuating,refrigerant charging 5.09MPa on the High-pressure side.

Charging Hose Evacuating, refrigerant charging Hose diameter larger than the concentional ones.

Refrigerant Recovery Equipment Refrigerant recovery

Refrigerant Cylinder Refrigerant charging Write down the refrigerant type. Pink in color at the top of the cylinder.

Refrigerant Cylinder Charging Port Refrigerant charging Hose diameter larger than the conventional ones.

Flare Nut Connecting the unit to piping Use Type-2 Flare nuts.

2. Tools and materials that may be used with R410 with some restrictions

Tools/Materials Use Notes

Gas leak detector Detection of gas leaks The ones for HFC type refrigerant may be used.

Vacuum Pump Vacuum drying May be used if a reverse flow check adaptor is attached.

Flare Tool Flare machining of piping Chages have been made in the flare machining dimension.Refer to the next page.

Refrigerant Recovery Equipment Recovery of refrigerant May be used if designed for use with R410A.

3. Tools and materials that are used with R22 or R407C that can also be used with R410A

Tools/Materials Use Notes

Vacuum Pump with a Check Valve Vacuum drying

Bender Bending pipes

Torque Wrench Tightening flare nuts Only 12.70 (1/2'') and 15.88(5/8'') have a larger flare machining dimension.

Pipe Cutter Cutting pipes

Welder and Nitrogen Cylinder Welding pipes

Refrigerant Charging Meter Refrigerant charging

Vacuum Gauze Checking vacuum degree

4. Tool and materials that must not used with R410A

Tools/Materials Use Notes

Charging Cylinder Refrigerant Charging Must not be used with R410-type units.

Tools for R410A must be handled with special care, and keep moisture and dust from entering the cycle.

6

Page 9

Read Before Installation

Piping Materials

Types of Copper Pipes (Reference)

Maximum Operation Pressure Applicable Refrigerants

3.4MPa R22, R407C

4.15MPa R410A

Use pipes that meet the local standards.

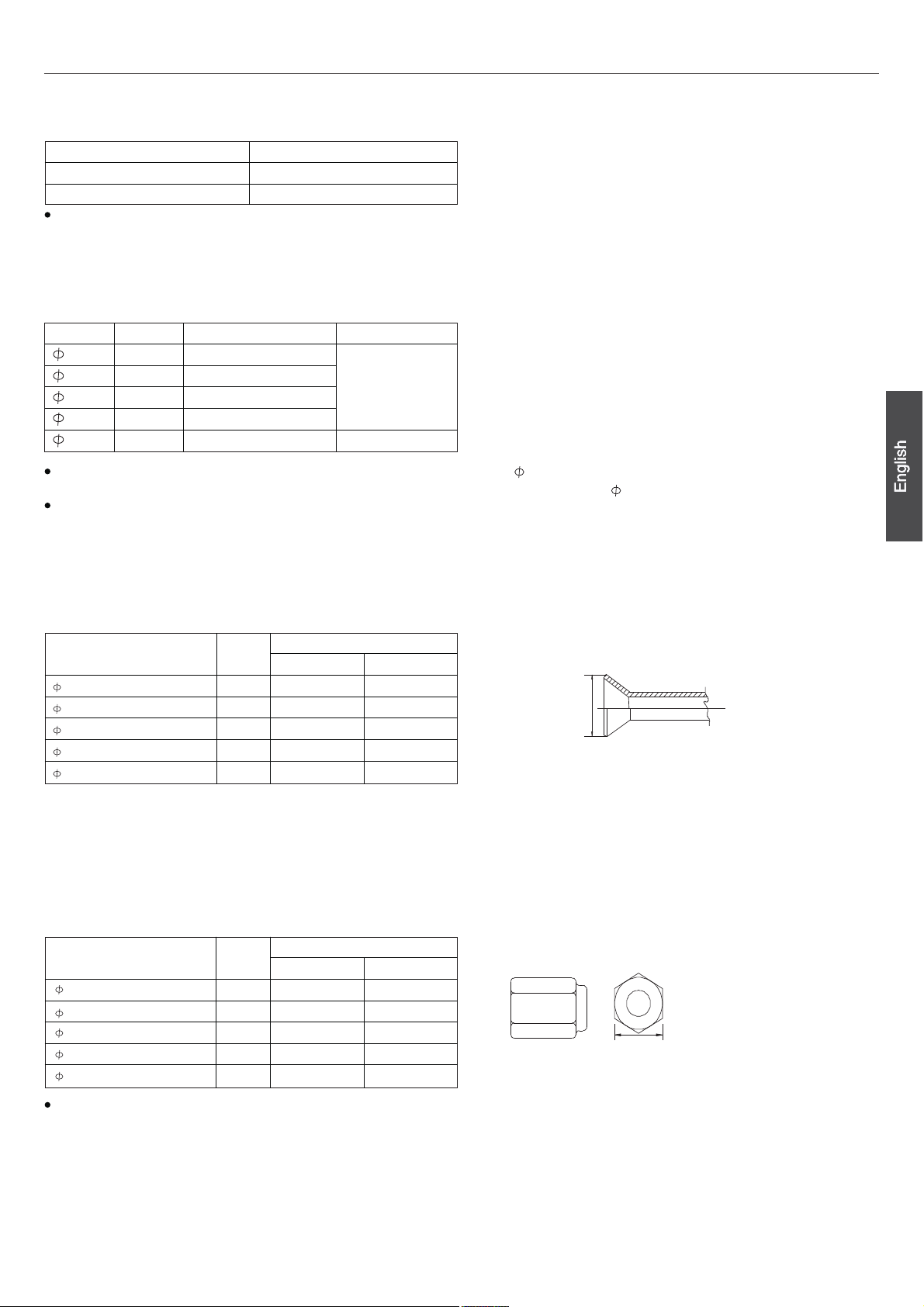

Piping Materials/Radial Thickness

Use pipes made of phosphorus deoxidized copper.

Since the operation pressure of the units that use R410A is higher than that of the units for use with R22, use pipes with

at least the radial thickness specified in the chart below. (Pipes with a radial thickness of 0.7mm or less may not be used.)

Size(mm) Radial Thickness(mm)Size(inch)

6.35

9.52

12.7

15.88

19.05 3/4'' 1.0t

1/4''

3/8''

1/2''

5/8''

0.8t

0.8t

0.8t

1.0t

Although it was possible to use type-O for pipes with a size of up to

1/2H pipes for units that use R410A.(Type-O pipes may be used if the pipe size is

Type

Type-O pipes

Type-1/2H or Hpipes

19.05(3/4") with conventional refrigerants, use type-

19.05 and the radial thickness is 1.2t.)

The table shows the standards in Japan. Using this table as a reference, choose pipes that meet the local standards.

Flare Machining (type-O and OL only)

The flare machining dimensions for units that use R410A is larger than those for units that use R22 in order to increase

air tightness.

Flare Machining Dimension(mm)

External dimension of pipes

6.35

9.52

12.7

15.88

19.05

Size

1/4"

3/8"

1/2"

5/8"

3/4"

Dimension A

R410A R22

9.1

13.2

16.6

19.7

24.0

9.0

13.0

16.2

19.4

23.3

Dimension A

If a clutch type flare tool is used to machine flares on units that use R410A, make the protruding part of the pipe between

1.0 and 1.5mm. Copper pipe gauge for adjusting the length of pipe protrusion is useful.

Flare Nut

Type-2 flare nuts instead of type-1 nuts are used to increase the strength. The size of some of the flare nuts have also

been changed.

Flare nut dimension(mm)

External dimension of pipes Size

6.35

9.52

12.7

15.88

19.05

1/4"

3/8"

1/2"

5/8"

3/4"

R410A(Type2) R22(Type1)

Dimension B

17.0

22.0

26.0

29.0

36.0

17.0

22.0

24.0

27.0

36.0

Dimension B

The table shows the standards in Japan. Using this table as a reference, choose pipes that meet the local standards.

7

Page 10

8

Page 11

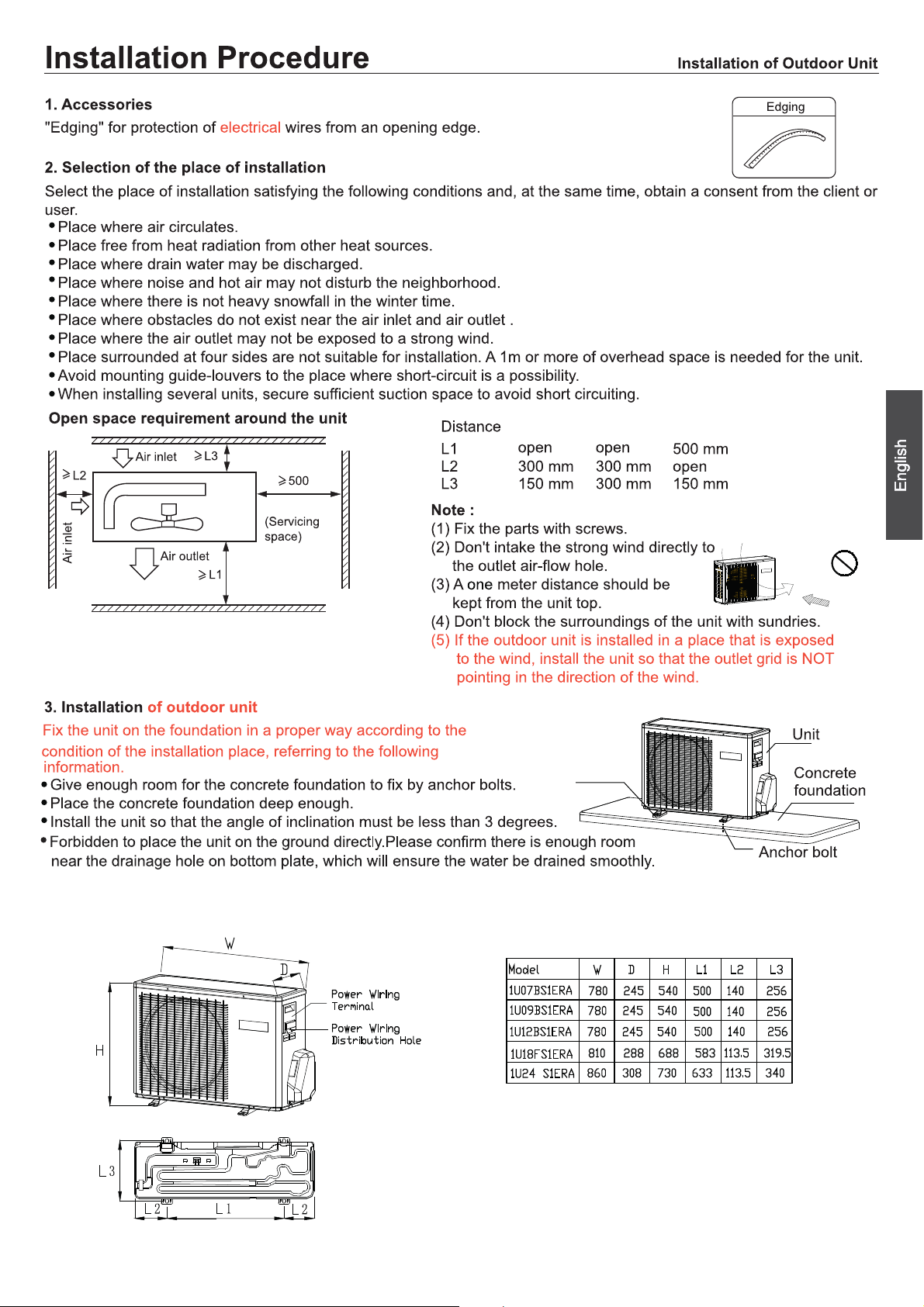

4.Installation dimension(Unit:mm)

NO

Air outlet

Wind direction

Cushion rubber

*

9

Page 12

1.

1U07BS1ERA

1U12BS1ERA

1U18FS1ERA

1U24GS1ERA

2.

Connection of pipes

ƽ

Tobend a pipe,givetheroundnessaslargeaspossiblenottocrushthepipe,

andthebendingradiusshouldbe30to40

ƽ

Connecting the pipe of gas side first makes working easier.

1U09BS1ERA

mm or longer.

TheconnectionpipeisspecializedforR410A.ƽ

Half union

Flare nut

Forced fastening without careful centering may

damagethethreadsandcause a leakageofgas.

Pipe Diameter(ǿ) Fastening torque

Liquid side6.35mm(1/4") 18N.m

Liquid/Gas side9.52mm(3/8") 42 N.m

Gasside12.7mm(1/2") 55N.m

Spanner

Torque wrench

Gasside15.88mm(5/8") 60N.m

Be careful that matters, such as wastes of sand

s,water,

,etc.shallnotenterthepipe.

CAUTION

ThestandardpipelengthisC m.IfitisoverDm,thefunctionoftheunitwillbeaffected.Ifthepipe

to be lengthened, the refrigerant should be charged,

must

beconductedbyprofes

perform

air

purgingfromtherefrigerantpipesandindoorunitusing a vacuum pump,then

sionalairconditionerengineer.Beforeaddingadditionalrefrigerant,

additional refrigerant.

Outdoor unit

Indoor unit

Outdoor unit

Outdoor unit

B

A

Max.Elevation:

●

●

In case the elevation A is more

than 5m, oil trap shoud be

installed every 5~7

Max. Length:

Oil trap

B

A

Indoor unit

●

In case the pipe length B is●

more thanDm, the refrigerant

should be charged, according

to E g/m.

A

B

Indoor unit

Amax

Bmax

according to E g/m. But the charge of refrigerant

charge

has

10

Page 13

11

Page 14

(e.g.1U18FS1ERA)

12

Page 15

1U07BS1ERA

1U09BS1ERA

1U12BS1ERA

1U18FS1ERA

1U24GS1ERA

T 25A/250V.

To Indoor unit

POWER

FOR 07K 09K 12K

Outdoor unit

1

(

N

)

2

L

)(

3

C

)(

1

(

N

)

2

(

L

)

3

(

C

)

^

To Indoor unit

POWER

FOR 18K 24K

Outdoor unit

1

(

N

)

2

(

)

3

C(L

)

L

N

{

Model

Connecting wiring

Power cable

13

1U07BS1ERA

1U09BS1ERA

1U12BS1ERA

4G0.75mm

3G1.5mm

1U18FS1ERA 1U24GS1ERA

2

2

4G0.75mm

3G2.5mm

2

2

4G0.75mm

3G4.0mm

2

2

Page 16

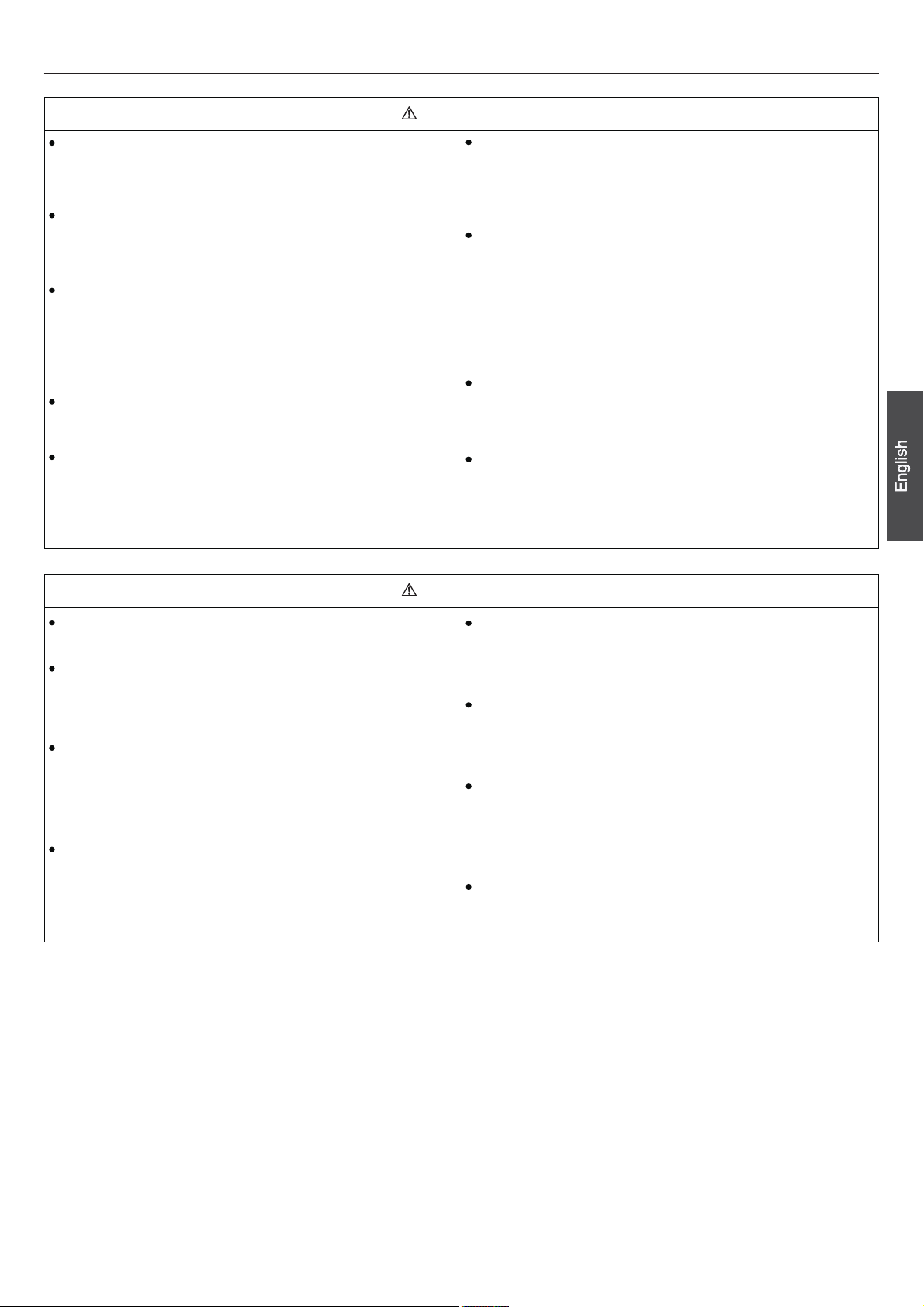

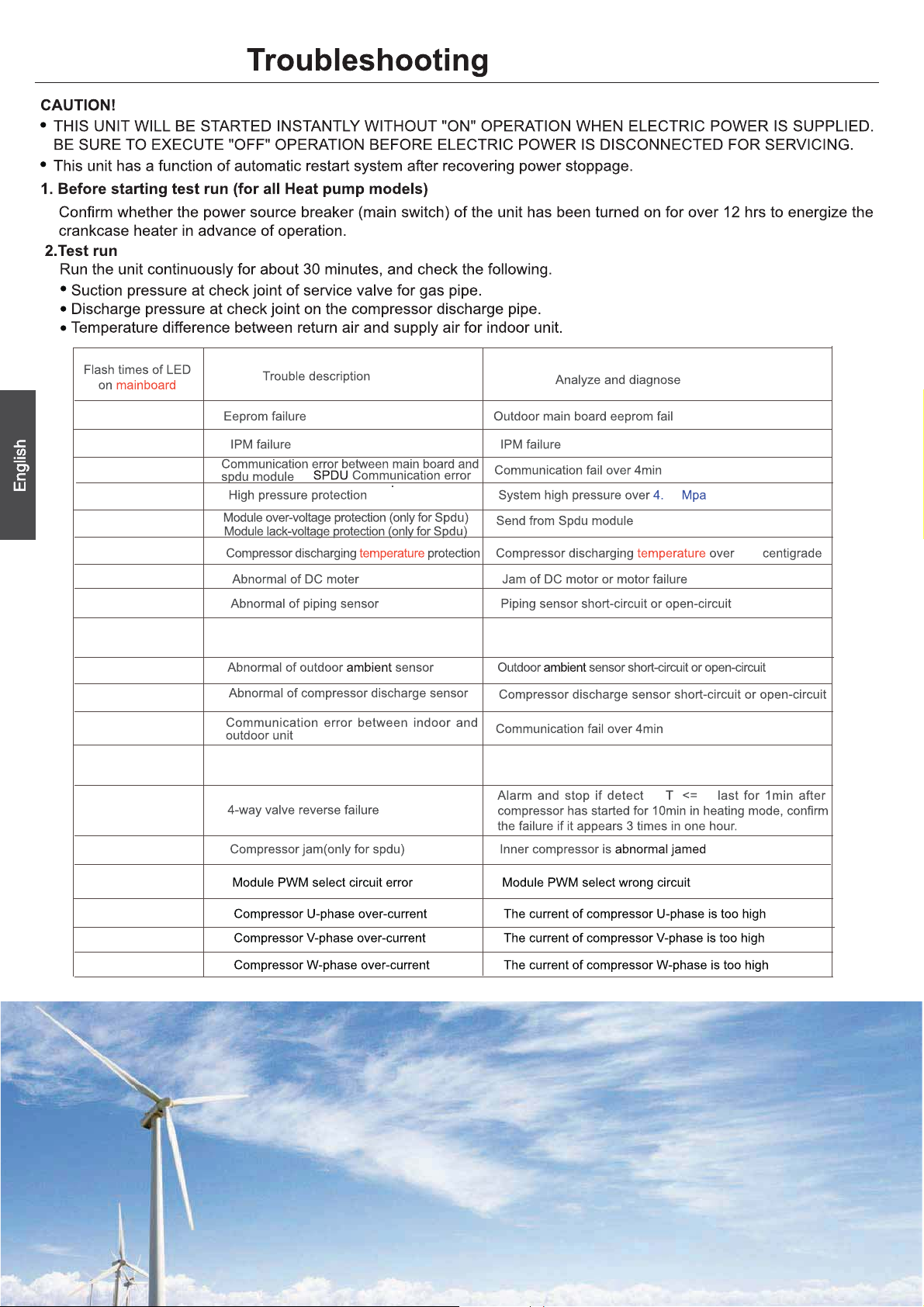

Outdoor Unit

1

2

4

5

15

6

8

10

11

12

13

15

16

17

18

19

25

25

25

110

9

Suction temperature sensor failure

Lack of refrigerant

When the The wiring of compressor is wrong or

the connection is poor

Check if there is leakage in the unit.

m

15

Haier Group

Address:No.1 Haier Road,Hi-tech Zone,Qingdao 266101 P.R.ChiQD

Contacts: TEL +86-532-8893-6943;FAX +86-532-8893-1010

Website: www.haier.com

14

Page 17

Haier Industrial Park, No.1 Haier Road, Qingdao, República Popular China

CONFORMIDAD DE LOS MODELOS

SEGÚN LAS NORMATIVAS EUROPEAS

CE

Todos los productos satisfacen los requisitos de las siguientes

normas europeas:

- Directiva de baja tensión, 73/23/CEE

- Directiva de baja tensión, 2006/95/CE

- Compatibilidad electromagnética 89/336/CEE

- Compatibilidad electromagnética 2004/108/CE

ROHS

Los productos satisfacen los requisitos de la directiva 2002/95/

CEE establecida por el Parlamento Europeo y el Consejo sobre

restricciones a la utilización de determinadas sustancias peligrosas

en aparatos eléctricos y electrónicos (Directiva RoHS UE).

WEEE

De acuerdo con la directiva 2002/96/CE del Parlamento Europeo,

se informa al consumidor acerca de los requisitos de eliminación

de productos eléctricos y electrónicos.

REQUISITOS DE ELIMINACIÓN:

Su aparato de aire acondicionado ha sido

marcado con este símbolo, el cual significa que

los productos de tipo eléctrico y electrónico

no deben mezclarse con residuos domésticos

sin clasificar. No intente desmontar el sistema

personalmente: tanto el desmontaje del sistema de aire

acondicionado como la manipulación del refrigerante, el

aceite y cualquier otro componente deben ser llevados

a cabo por un instalador capacitado, de acuerdo con la

legislación local y nacional al efecto. Los aparatos de aire

acondicionado deben ser manipulados en instalaciones de

manipulación especializadas y aptas para su reutilización,

reciclado y recuperación. Al garantizar la correcta

eliminación de este producto, usted contribuirá a evitar las

posibles consecuencias negativas que podría provocar

sobre el medioambiente y la salud humana. Póngase en

contacto con el instalador o la autoridad local pertinente

si desea obtener más información. Las pilas deben ser

extraídas del mando a distancia y eliminadas de forma

independiente, de acuerdo con la legislación local y nacional

al efecto.

INFORMACIÓN IMPORTANTE ACERCA DEL REFRIGERANTE UTILIZADO

Contiene gases fluorados de efecto invernadero

regulados por el Protocolo de Kioto.

R410A

2

1=

2=

1

1+2=

FE

Este producto contiene gases fluorados de efecto invernadero

regulados por el Protocolo de Kioto. No los libere libremente a la

atmósfera.

Tipo de refrigerante: R410A

Valor GWP*: 1975

GWP = Potencial de contribución al calentamiento global

Escriba con tinta indeleble:

• 1 la carga de refrigerante que contiene el producto de fábrica

• 2 la cantidad de refrigerante adicional cargada durante la

instalación y

• 1+2 la carga total de refrigerante

en la etiqueta de carga de refrigerante suministrada con el

producto.

Una vez escritos los datos correspondientes, la etiqueta deberá

adherirse cerca de la conexión de carga del producto (por ejemplo,

sobre la parte interna de la cubierta de la válvula de retención).

A Contiene gases fluorados de efecto invernadero regulados por el

Protocolo de Kioto.

B Carga de refrigerante que contiene el producto de fábrica:

consulte la placa de características de la unidad.

C Cantidad de refrigerante adicional cargada durante la instalación.

D Carga total de refrigerante.

E Unidad exterior.

F Botella de refrigerante y colector de carga.

kg

kg

kg

A

B

C

D

Page 18

Page 19

Dibujos de instalación de las unidades interior y exterior

Los modelos cumplen la norma R410A sobre refrigerantes libres de HFC.

Para obtener información sobre la instalación de las unidades interiores, consulte el manual de instalación proporcionado

con las mismas.

(El diagrama muestra una unidad interior montada en pared.)

Debe prestarse atención

más de 15 cm

más de

10 cm

Organización de la

dirección de los tubos

Izquierda

Izquierda trasera

más de 10 cm

Derecha

trasera

a la pendiente del

manguito de drenaje

A

Componentes opcionales para

la instalación de los tubos

Cinta no adhesiva

A

B

Cinta adhesiva

G

F

C

Soporte (L.S) con tornillos

Conexión de cable eléctrico para inte-

D

rior y exterior

E

Manguito de drenaje

F

Material aislante de calor

G

Cubierta

de orificio de entubación

Derecha

Inferior

● Las marcas comprendidas

● La distancia entre la

A

entre

ilustración corresponden

a los números de las

piezas.

unidad interior y el suelo

debe ser superior a 2 m.

y G en la

más de 60 cm

más de 20 cm

C

más de

20 cm

Fijación de la unidad exterior

● Fije la unidad a un bloque de

cemento con pernos (10 mm) y

tuercas firme y horizontalmente.

● Si instala la unidad sobre una

D

E

más de 25 cm

pared, techo o tejado, instale un

soporte con clavos o cables considerando la posibilidad de terremotos o viento fuerte.

● Si la vibración afectase a la casa,

fije la unidad instalando una alfombra de absorción de vibraciones.

SALIDA DE AIRE

ENTRADA DE AIRE

TUBOS DE CONEXIÓN Y CABLEADO ELÉCTRICO

4 MANGUITO DE DRENAJE

4

Compresor (dentro de la unidad)

● La imagen anterior de las unidades interior y exterior solamente sirve de referencia.

Remítase al producto real adquirido.

15

Page 20

Precauciones de seguridad

Lea detenidamente la siguiente información para poner en funcionamiento el aire acondicionado de forma correcta.

A continuación se enumeran tres tipos de precauciones de seguridad y sugerencias.

ADVERTENCIA Si realiza operaciones de forma incorrecta, pueden producirse graves consecuencias, como

PRECAUCIÓN Si realiza operaciones de forma incorrecta, pueden producirse lesiones o daños en la

INSTRUCCIÓN: Esta información puede asegurar el correcto funcionamiento de la máquina.

Símbolos utilizados en las ilustraciones

: indica una acción que se debe evitar.

: indica que es obligatorio seguir las instrucciones importantes.

: indica un componente que se debe conectar a tierra.

: atención a las descargas eléctricas (este símbolo se muestra en la etiqueta de la unidad principal.)

Después de leer este manual, entréguesela a aquellas personas que utilicen a la unidad.

El usuario de esta unidad debe tener este manual a mano y ponerlo a disposición de quienes repararán o reubicarán la unidad. Asimismo,

debe ponerlo a disposición de los nuevos usuarios cuando el producto cambio de manos.

Asegúrese de seguir estas importantes precauciones de seguridad.

la muerte o graves lesiones.

máquina; en algunos casos pueden producirse graves consecuencias.

ADVERTENCIA

● Si se producen fenómenos anormales

(por ejemplo, olor a quemado), corte la

fuente de alimentación inmediatamente,

y póngase en contacto con el distribuidor

para averiguar el método de manipulación.

En dicho caso, si sigue utilizando el aire acondicionado, éste

resultará dañado, y pueden producirse descargas eléctricas o

peligro de incendio.

● Tras un largo período de tiempo sin utilizar

el aparato de aire acondicionado, debe

comprobar la base para ver si se han producido daños.

Si la base dañada no se repara, es posible

que la unidad se caiga y provoque accidentes.

● No se pueden colocar cosas o personas

sobre la unidad exterior. La caída de cosas o

personas puede provocar accidentes.

●

No ponga en funcionamiento el aire acon-

dicionado con las manos mojadas. De lo contrario, se producirán descargas eléctricas.

●

Utilice sólo fusibles del tipo correcto.

No se puede utilizar ningún cable ni otro ma-

terial que sustituya al fusible, de lo contrario,

se producirán fallos o incendio.

●

Utilice el tubo de descarga correctamente

para asegurar la eficacia de la descarga.

Si utiliza el tubo de forma incorrecta podrían

producirse fugas de agua.

●

Interruptor de circuito de fugas eléctricas instalado.

Provoca descargas eléctricas con facilidad sin el interruptor de

circuito.

Desactivar

ADVERTENCIA

● No desmonte la boca de salida de la

unidad exterior.

La exposición del ventilador es muy peli-

grosa, ya que puede provocar lesiones

en las personas.

Cuando necesite mantenimiento y repa-

●

ración, llame al distribuidor para gestionarlo.

Si el mantenimiento y la reparación se

realizan de forma incorrecta podrían

producirse fugas de agua, descargas

eléctricas y peligro de incendio.

El aire acondicionado no puede instalarse en lugares con gases

●

inflamables, ya que podrían provocar peligro de incendio.

El distribuidor es el responsable de la instalación del aparato de

aire acondicionado. Si la instalación se realiza de forma incorrecta podrían producirse fugas de agua, descargas eléctricas y

peligro de incendio.

●

Llame al distribuidor para tomar medidas que eviten fugas de

refrigerante.

Si el aparato de aire acondicionado está instalado en una habita-

ción pequeña, asegúrese de tomar las medidas necesarias para

evitar

asfixia, incluso en caso de fuga de refrigerante.

● Cuando el aire acondicionado se instala o se vuelve a instalar, el

distribuidor en el responsable de dichas tareas.

Si la instalación se realiza de forma incorrecta podrían producir-

se fugas de agua, descargas eléctricas y peligro de incendio.

●

Conecte el cable de conexión a tierra.

El cable de conexión a tierra no debe conectarse al

tubo de gas, tubo de agua, barra pararrayos o línea

telefónica. Si la conexión a tierra se realiza de manera

incorrecta, podrían producirse descargas.

Puesta a

tierra

16

Page 21

Precauciones de seguridad

ADVERTENCIA

● La unidad debe ser instalada por un profesional.

La instalación inadecuada por una persona no cualificada puede

provocar fugas de agua, descargas eléctricas o un incendio.

● Coloque la unidad en una superficie estable y nivelada que

soporte el peso de la misma para impedir que se vuelque o se

caiga, evitando así lesiones personales.

● Utilice solamente los cables especificados para el cableado. Co

necte de forma segura todos los cables y asegúrese de que los

mismos no tensan los terminales.

Los cables que no se conecten de forma correcta y segura, pue

den generar calor y provocar un incendio.

● Tome las medidas de seguridad necesarias contra tifones y terre

motos para evitar que la unidad se caiga.

● No realice ningún cambio o modificación a la unidad. Si surgen

problemas, consultar distribuidor.

Si las reparaciones no se realizan correctamente, se pueden

producir fugas de agua en la unidad, lo que supone un riesgo

de descargas eléctricas. También se puede producir humo o un

incendio.

● Asegúrese de seguir atentamente todos los pasos de este

manual cuando instale la unidad.

La instalación inadecuada puede provocar fugas de agua, de

scargas eléctricas, humo o incendios.

● Encomiende todos los trabajos eléctricos a un electricista pro

fesional de forma que se cumplan las normativas locales y las

instrucciones proporcionadas en este manual. Fije un circuito

designado exclusivamente a la unidad.

La instalación inadecuada o la falta de capacidad de los circuitos

puede hacer que la unidad no funcione correctamente o presente riesgos de descargas eléctricas, humo e incendio.

-

● Acople de forma segura la cubierta de terminales (panel) a la

unidad.

Si se instala incorrectamente, puede entrar polvo y/o agua en la

unidad lo que supone un riesgo de descargas eléctricas, humo o

incendio.

● Utilice únicamente el refrigerante R410A tal y como se indica en

la unidad cuando la instale o reubique.

El uso de cualquier otro refrigerante o la penetración de aire en

el circuito de la unidad puede provocar que ésta funcione en un

ciclo anómalo, lo que puede provocar que se queme.

-

-

ADVERTENCIA

● No toque las aletas del intercambiador de calor con las manos al

descubierto ya que están afiladas y son peligrosas.

● En el caso de que haya una fuga de gas refrigerante, proporcio

ne la ventilación adecuada a la sala.

Si el gas refrigerante fugado queda expuesto a una fuente de

calor, se pueden producir gases nocivos.

● Con

aparatos de aire acondicionado de tipo All-Fresh, el aire ex-

terior se puede dirigir directamente dentro de la sala. Tenga esto

en cuenta cuando instale la unidad.

La

exposición directa al aire de exterior puede suponer un riesgo

para la salud así como causar deterioro en productos alimenticios.

● No pase por alto las instrucciones de seguridad de los dispositi

vos y no cambie la configuración.

Si pasa por alto las instrucciones de seguridad de la unidad,

como por ejemplo el cambio de presión y el cambio de temperatura, o utiliza piezas distintas a las proporcionadas por el proveedor o el especialista, se pueden producir un incendio o explosión.

-

● Cuando instale la unidad en una sala pequeña, protéjase contra

la hipoxia causada por el refrigerante fugado que alcance el nivel

umbral.

-

Consulte al distribuidor para tomar las medidas necesarias.

● Cuando reubique el aparato de aire acondicionado, consulte al

proveedor o a un especialista.

La instalación inadecuada puede provocar fugas de agua, de

scargas eléctricas o incendios.

● Después de completar las tarea de servicio, compruebe si que

dan fugas de gas refrigerante.

Si el gas refrigerante fugado queda expuesto a una fuente de

calor, como por ejemplo un calefactor, una estufa o una parrilla

eléctrica, se pueden producir gases nocivos.

● Utilice solamente las piezas especificadas.

La unidad debe ser instalada por un profesional. La instalación

inadecuada puede provocar fugas de agua, descargas eléctricas,

humo o incendios.

-

-

17

Page 22

Precauciones de seguridad

Precauciones para manipular unidades para utilizarse con R410A

Precaución

No utilizar el tubo refrigerante asistente

● El refrigerante usado y el aceite del refrigerador de los tubos

existentes contiene una gran cantidad de cloro que deteriorará el

aceite del refrigerador de la nueva unidad.

● R410A es un refrigerante de alta presión y el uso de los tubos

existentes puede dar lugar a reventones.

Mantenga las superficies interior y exterior de los tubos limpias y

sin contaminantes como el sulfuro, óxidos, partículas de polvo o

suciedad, aceites y humedad.

● Los contaminantes que se encuentran dentro del tubo refrigeran

te provocarán el deterioro del aceite refrigerante.

Precaución

Almacene los tubos que se van a utilizar durante la instalación de

las unidades interiores y mantenga ambos extremos de los tubos

sellados hasta el preciso instante en el que se suelden. (Mantenga

los ángulos y otras juntas envueltas en plásticos.)

● Si entra polvo, suciedad o agua en el circuito refrigerante, el

aceite de la unidad podría deteriorarse o provocar averías en el

compresor.

Utilice una pequeña cantidad de aceite de ésteres, aceite de éter o

alcalibenceno para recubrir abocinados y uniones de bridas.

● Una gran cantidad de aceite mineral deteriorará el aceite de la

máquina refrigerante.

Utilice refrigerante

● Si carga la unidad con refrigerante gaseoso el refrigerante de

la botella cambiará su composición y provocará una pérdida de

rendimiento.

líquido para cargar el sistema.

Utilice una bomba de vacío con una válvula de comprobación de

flujo inverso.

● Si se utilizan otros tipos de válvula, el aceite de la bomba de

vacío retrocederá al circuito refrigerante y provocará el deterioro

del aceite del refrigerador.

No utilice las siguientes herramientas que hayan sido utilizadas

con los refrigerantes convencionales. Prepare las herramientas que

vaya utilizar exclusivamente con R410A.

(Colector, manguera de carga, detector de fuga de gas, válvula

de comprobación de flujo inverso, base de carga del refrigerante,

calibrador de vacío y equipo de recuperación de refrigerante.)

● Si y el refrigerante y/o el aceite refrigerante residual de estas

herramientas se mezcla con el refrigerante R410A, éste se deteriorará.

-

● Dado que el refrigerante R410A no contiene cloro, los detectores

de fuga de gas para refrigeradores convencionales no funcionarán.

No utilice una botella carga.

● El uso de una botella de carga cambiará la composición del refri

gerante y provocará pérdida de potencia.

Preste especial atención cuando manipule las herramientas.

● Si se introducen objetos extraños como polvo, sociedad o agua

en el circuito refrigerante, el aceite de la máquina refrigerante se

deteriorará.

Utilice solamente refrigerante R410A.

● El uso de refrigerantes que contengan cloro (por ejemplo R22)

deteriorará el refrigerante.

-

Antes de utilizar la unidad

Precaución

No instale la unidad en lugares donde haya riesgo de fuga de gas

inflamable.

● El gas fugado acumulado alrededor de la unidad puede desencadenar un incendio.

No utilice la unidad para conservar comida, animales, plantas, artefactos

o para otras finalidades especiales.

● La unidad no está diseñada para proporcionar condiciones adecuadas para conservar la calidad de estos elementos.

No utilice la unidad en un entorno inusual.

●

El uso de la unidad en presencia de una gran cantidad de aceite,

vapor, ácido, disolventes alcalinos o tipos especiales de espray

puede producir una pérdida considerable de rendimiento y/o averías, además del riesgo existente de descargas eléctricas, humo

o incendio.

●

La presencia de disolventes orgánicos o gas corroído (como

amoniaco, compuestos de azufre y ácido) puede provocar fugas

de agua o gas.)

Cuando instale la unidad en un hospital, tome las medidas

necesarias para eliminar el ruido.

● Los equipos médicos de alta frecuencia pueden interferir en el

funcionamiento normal de la unidad de aire acondicionado o

viceversa.

Lo coloque la unidad sobre objetos que no se puedan mojar.

●

Cuando el nivel de humedad supere el 80% o cuando el sistema

de drenaje se atasque, las unidades interiores pueden gotear

agua.

●

La instalación de un sistema de drenaje centralizado para la uni-

dad exterior también debe tenerse en cuenta para evitar el goteo

de agua de las unidades exteriores.

18

Page 23

Precauciones de seguridad

Antes de instalar (reubicar) la unidad o realizar tareas eléctricas

Precaución

Conecte la unidad a tierra.

● No conecte las tomas de tierra de la unidad a tubos de gas,

tubos de agua, pararrayos o a los terminales de conexión a tierra

de teléfonos. La conexión inadecuada a tierra supone riesgos de

descargas eléctricas, humo, incendio. Además, el ruido causado por una conexión de este tipo puede provocar averías en la

unidad.

Asegúrese de que los cables no están tensos.

● Si los cables están demasiado tirantes, se pueden romper o

generar calor y/o humo, lo que puede provocar un incendio.

Instale un disyuntor para fugas de corriente en la fuente de alimentación para evitar el riesgo de descargas eléctricas.

● Si no cuenta con un disyuntor para fugas de corriente, existe el

riesgo de descargas eléctricas, humo o incendio.

Utilice disyuntores y fusibles (disyuntor de corriente eléctrica,

conmutador remoto <conmutador+fusible de Tipo-B>, disyuntor de

circuito o con carcasa moldeada) con una capacidad de corriente

adecuada.

● El uso de fusibles de gran capacidad, cables de acero o cables

de cobre puede dañar la unidad o provocar humo o un incendio.

No rocíe agua en aparatos de aire acondicionado mi sumerja

dichos aparatos en agua.

● La presencia de agua sobre la unidad supone un riesgo de de

scargas eléctricas.

Compruebe periódicamente la plataforma sobre la que se coloca la

unidad

para ver si existen daños y evitar así que dicha unidad se caiga.

● Si la unidad se deja en una plataforma dañada, puede volcarse y

provocar lesiones personales.

Cuando instale tubos de drenaje, siga las instrucciones del manual

y asegúrese de que desaguan el agua correctamente para evitar

condensación.

● Si la instalación no se realiza correctamente, se pueden producir

fugas de agua y el mobiliario puede resultar dañado.

Deshágase adecuadamente de los materiales de embalaje.

● El embalaje puede incluir objetos como, por ejemplo, clavos.

Deshágase de ellos adecuadamente para evitar lesiones personales.

● Las bolsas de plástico suponen un riesgo de asfixia para los

niños. Despedace las bolsas de plástico antes de deshacerse de

ellas para evitar accidentes.

-

Antes de ejecutar las comprobaciones

Precaución

Para evitar descargas eléctricas, no utilice los conmutadores con

las manos mojadas.

No toque los tubos refrigerantes con las manos al descubierto

mientras el aparato está en funcionamiento o inmediatamente después de haberlo estado.

● Dependiendo del estado del refrigerante del sistema, ciertas par

tes de la unidad como los tubos y el compresor, pueden alcanzar una temperatura muy baja o caliente lo que puede provocar

quemaduras a las personas.

No utilice la unidad sin que los paneles y las protecciones de seguridad estén colocados en sus lugares correctos.

● Están ahí para evitar lesiones a los usuarios producidas por to

car accidentalmente piezas giratorias, con elevada temperatura

o alto voltaje.

No desconecte alimentación inmediatamente después de detener

la unidad.

● Deje que transcurran al menos cinco minutos antes de apagar la

unidad. De lo contrario dicha unidad puede tener fugas de agua

u otros problemas.

-

-

No ponga en funcionamiento la unidad sin los filtros de aire.

● Las partículas de polvo del aire pueden obturar el sistema y cau

sar averías.

-

19

Page 24

Leer antes de realizar la instalación

Elementos que se deben comprobar

(1). Compruebe el tipo de refrigerante utilizado por la unidad que se va a revisar. Tipo de refrigerante: R410A

(2). Compruebe los síntomas que presenta la unidad que se va a revisar. Busque en el manual de servicio los síntomas relacionados con

el circuito refrigerante.

(3). Asegúrese de leer atentamente las precauciones de seguridad que se encuentran al principio de este documento.

(4). Si hay fuga de gas o si el refrigerante restante se expone a una llama viva, se puede formar ácido fluorhídrico. Mantenga el lugar de

trabajo bien ventilado.

PRECAUCIÓN

● Instale los tubos nuevos inmediatamente después de quitar los usados para mantener la humedad fuera del circuito refrigerante.

●

El cloruro en algunos tipos de refrigerantes como el R22 deteriorarán el aceite de la máquina refrigerante.

Herramientas y materiales necesarios

Preparar las siguientes herramientas y materiales para instalar y reparar la unidad.

Herramientas necesarias para utilizar con R410A (disponibilidad de herramientas para utilizar con R22 y R407C).

1. Para utilizarse exclusivamente con R410A (no se deben utilizar con R22 o R407C)

Herramientas y materiales Uso Notas

Colector Evacuación, carga del refrigerante 5,09 MPa en alta presión.

Manguera de carga

Equipo de recuperación del refrigerante Recuperación del refrigerante

Botella de refrigerante Carga de refrigerante Anote el tipo de refrigerante. Color rosa la parte superior de la botella.

Puerto de carga de la botella de

refrigerante

Tuerca cónica Conectar la unidad a los tubos Usar las tuercas cónicas de tipo 2.

Evacuación, carga del refrigerante Diámetro de la manguera mayor que los convencionales.

Carga de refrigerante Diámetro de la manguera mayor que los convencionales.

2. Herramientas y materiales que se pueden utilizar con R410 con algunas restricciones

Herramientas y materiales Uso Notas

Detector de fuga de gas Detección de fugas de gas Se pueden usar los adecuados para el refrigerante de tipo HFC.

Bomba de vacío Secado en vacío Se puede utilizar si se acopla un adaptador de comprobación de flujo inverso.

Herramienta de conicidad Maquinaria de conicidad de tubos Se han realizo cambios en la dimensión de la maquinaria de conicidad. Consulte la página

Equipo de recuperación del refrigerante Recuperación de refrigerante Se puede utilizar si está pensado para utilizarse con R410A.

siguiente.

3. Herramientas y materiales que se van a utilizar con R22 o R407C que también pueden utilizarse con R410A

Herramientas y materiales Uso Notas

Bomba de vacío con válvula de

comprobación

Curvadora Doblar tubos

Llave dinamométrica Apretar tuercas cónicas Solamente

Cortatubos Cortar tubos

Soldador y botella de nitrógeno Soldar tubos

Medidor de carga de refrigerante Carga de refrigerante

Malla de vacío Comprobar el grado de vacío

Secado en vacío

12,70 (1/2'') y 15,88 (5/8'') tienen una dimensión de maquinaria de

conicidad más grande.

4. Herramientas y materiales que no se deben utilizar con R410A

Herramientas y materiales Uso Notas

Botella de carga Carga de refrigerante No se debe utilizar con unidades de tipo R410.

Las herramientas para R410A se deben utilizar con extremo cuidado y se debe impedir que la humedad y el polvo entre en el circuito.

20

Page 25

Leer antes de realizar la instalación

Materiales para tubos

Tipos de tubos de cobre (referencia)

Presión de funcionamiento máxima Refrigerantes aplicables

3,4 MPa R22 y R407C

4,15 MPa R410A

● Usar tubos que cumplen los estándar locales.

Materiales para tubos/Grosor del radio

Utilice tubos fabricados con cobre desoxidado con fósforo.

Dado que la presión de funcionamiento de las unidades que utilizan R410A es superior a la de las unidades que utilizan R22, emplee

tubos con al menos el grosor radial especificado en el gráfico siguiente. (No se deben utilizar tubos con un grosor radial de 0,7 mm o

menos.)

Tamaño (mm) Tamaño (pulgadas) Grosor radial (mm) Tipo

6.35 1/4'' 0,8t

9.52 3/8" 0,8t

12.7 1/2" 0,8t

15.88 5/8" 1,0t

19.05 3/4" 1,0t Tubos de tipo 1/2H o H

● Aunque es posible utilizar el tipo O para tubos con un tamaño de hasta 19,05 (3/4") con refrigerantes convencionales, utilice tubos de

tipo 1/2H para unidades que utilicen R410A. (Se pueden utilizar tubos de tipo-O si el tamaño del tubo es 19.05 y el grosor radial es de

1,2 t.)

● La tabla

muestra los estándares de Japón. Utilice esta tabla como referencia y elija tubos que cumplan los estándares locales.

Tuberías de tipo O

Maquinaria de conicidad (solamente para el tipo O y OL)

Las dimensiones de la máquina de conicidad para unidades que utilizan R410A son mayores que las de las unidades que utilizan R22

para aumentar la hermeticidad del aire.

Dimensiones de la máquina de conicidad (mm)

Dimensiones externas de los

tubos

6.35 1/4'' 9.1 9.0

9.52 3/8" 13.2 13.0

12.7 1/2" 16.6 16.2

15.88 5/8" 19.7 19.4

19.05 3/4" 24.0 23.3

Tamaño

Dimensión A

R410A R22

Dimensión A

Si una herramienta de comicidad de tipo acoplamiento se utiliza para realizar la conicidad en unidades que usan R410A, haga que

la parte que sobresale del tubo tenga un tamaño comprendido entre 1,0 y 1,5 mm. El calibre de tubos de cobre es útil para ajustar la

longitud de la prominencia del tubo.

Tuerca cónica

Se utilizan tuercas cónicas de tipo 2 en lugar de las de tipo 1 para aumentar la fuerza. El tamaño de algunas de las tuercas cónicas

también ha cambiado.

Dimensiones de la máquina de conicidad (mm)

Dimensiones externas de los

tubos

6.35 1/4'' 17.0 17.0

9.52 3/8" 22.0 22.0

12.7 1/2" 26.0 24.0

15.88 5/8" 29.0 27.0

19.05 3/4" 36.0 36.0

Tamaño

R410A (Tipo 2) R22 (Tipo 1)

Dimensión B

Dimensión B

● La tabla muestra los estándares de Japón. Utilice esta tabla como referencia y elija tubos que cumplan los estándares locales.

21

Page 26

Leer antes de realizar la instalación

Prueba de hermeticidad del aire

El método convencional NO cambia. Tenga en cuenta que el detector de fugas de refrigerante para R22 o R407C no puede detectar

fugas de R410A.

Antorcha de haluro

Elementos que se deben tener muy en cuenta:

1. Presurice el equipo con nitrógeno hasta la presión de diseño y, a continuación, evalúe la hermeticidad del aire de dicho equipo

teniendo en cuenta las variaciones de temperatura.

2. Cuando investigue las ubicaciones de las fugas utilizando un refrigerante, asegúrese de usar R410A.

3. Asegúrese de que R410A se encuentran estado líquido cuando lo cargue.

Razones:

1. El uso de oxígeno cómo gas presurizado puede provocar explosiones.

2. La carga con gas R410A cambiará la composición del refrigerante restante de la botella, por lo que no podrá utilizarlo.

Vacío

1. Bomba de vacío con válvula de comprobación

Se necesita una bomba de vacío con válvula de comprobación para evitar que el aceite de dicha bomba retroceda y se introduzca

en el circuito refrigerante cuando la alimentación de la bomba de vacío se apague (error de alimentación). También es posible

acoplar una válvula de comprobación a la bomba de vacío real después.

2. Grado estándar de vacío para la bomba de vacío

Utilice una bomba que alcance 65 Pa o menos después de 5 minutos de funcionamiento.

Además, asegúrese de utilizar una bomba de vacío en la que se hayan realizado todas las tareas de mantenimiento

convenientemente

adecuadas en la bomba de

3. Precisión necesaria del indicador de vacío

Utilice un indicador de vacío que pueda medir hasta 650Pa. No utilice un colector general ya que no puede medir un grado de

vacío de 650 Pa.

4. Tiempo de evacuación

Evacuó el equipo durante 1 hora después de alcanzar 650 Pa.

Después de la evacuación, deje el equipo en reposo durante 1 hora y asegúrese de que el vacío no se pierde.

5. Procedimiento de funcionamiento cuando la bomba de vacío se detiene

Para evitar flujo de retorno del aceite de la bomba de vacío, abra la válvula de seguridad del lado de la bomba de vacío o afloje la

manguera de carga para retraer el aire antes de detener el funcionamiento. Debe utilizar el mismo procedimiento cuando utilice una

bomba de vacío con válvula de comprobación.

y esté engrasada utilizando el aceite especificado. Si no se han realizado las tareas de mantenimiento

vacío, el grado de vacío puede ser demasiado bajo.

Detector de fugas de R22 o R407C

Carga de refrigerante

R410A debe estar en estado líquido durante la carga.

Razones:

R410A es un refrigerante pseudo-azeotrópico (punto de ebullición R32=-52

la misma forma que el R22; sin embargo, asegúrese de rellenar el refrigerante desde el lado del líquido. Si lo hace desde el lado del

gas la composición del refrigerante cambiará en la botella.

Nota

● En el caso la botella con sifón, el R410A líquido se carga sin poner la botella boca abajo. Compruebe el tipo de botella antes de

realizar la carga.

Remedios que se deben tomar en caso de fuga del refrigerante

Si el refrigerante se fuga, debe cargar más refrigerante. (Agregue el refrigerante desde el lado del líquido)

Características de los refrigerantes convencionales y nuevos

● Debido a que el R410A es un refrigerante azeotrópico simulado, se puede manipular prácticamente de la misma manera que un

refrigerante sencillo, como por ejemplo el R22. Sin embargo, si el refrigerante se retira en la fase de gas, la composición del

refrigerante de la botella cambiará.

● Quite el refrigerante en la fase líquida. Si el refrigerante

se fuga, puede agregar más refrigerante.

22

O

C, R125=-49 OC) y se puede manipular más o menos de

Page 27

Procedimiento instalación

Instalación de la unidad exterior

1. Accesorios

"Borde" para proteger los cables

eléctricos de un borde de apertura.

Borde

2. Selección del lugar de instalación

Seleccione un lugar de instalación que cumpla con las siguientes condiciones y, al mismo tiempo, obtenga un consentimiento del cliente o

del usuario.

● Coloque la unidad en un lugar en el que circule el aire.

● Coloque la unidad en un lugar alejado de radiaciones de calor emitidas por otras fuentes de calor.

● Coloque la unidad en un lugar en el que pueda descargarse el agua de drenaje.

● Coloque la unidad en un lugar en el que el ruido y el aire caliente no molesten a los vecinos.

● Coloque la unidad en un lugar en el que no haya grandes nevadas durante el invierno.

● Coloque la unidad en un lugar en el que no existan obstáculos en la entrada o salida de aire.

● Coloque la unidad en un lugar en el que la salida de aire no esté expuesta a fuertes vientos.

● La instalación no se realizará correctamente si la unidad está rodeada por los cuatro lados. Debe dejar 1 m o más de espacio por

encima de la unidad.

● No monte las lamas en lugar en el que exista la posibilidad de que se produzca un cortocircuito.

● Al instalar varias unidades, compruebe que existe espacio de aspiración suficiente para evitar cortocircuitos.

Requisito de espacio abierto alrededor de la unidad

Distancia Caso I Caso II Caso III

L1 abrir abrir 500 mm

Entrada de aire

L2 300 mm 300 mm abrir

L3 150 mm 300 mm 150 mm

(Espacio para

mantenimiento)

Salida de aire

Entrada de aire

Nota:

(1) Fije las piezas con los tornillos.

(2) No permita que el fuerte viento

entre directamente en el orificio

de flujo de aire de salida.

(3) Debe dejar una distancia de un

Salida de

aire

NO

Dirección del

viento

metro desde la parte superior de la unidad.

(4) No bloquee los alrededores de la unidad con objetos.

(5) Si la unidad exterior se instala en un lugar expuesto al

viento, instálela de forma que la rejilla de salida de aire NO

apunte en la dirección del viento.

3. Instalación de la unidad exterior

Fije la unidad a la base de la forma adecuada en función del estado del

lugar de la instalación. Consulte para ello la siguiente información.

● Deje suficiente espacio para fijar la base de hormigón mediante los

pernos de anclaje.

● Coloque la base de hormigón a una profundidad suficiente.

● Instale la unidad de manera que el ángulo de inclinación sea inferior a 3

grados.

● Prohibido colocar la unidad en el suelo directamente. Asegúrese de que

hay espacio suficiente cerca del orificio de drenaje en la placa inferior, lo

que garantizará que el agua se desagua sin problemas.

4. Dimensiones de instalación (unidad: mm)

Goma amortiguadora

Unidad

Base de

hormigón

Perno de anclaje

Terminal del

cableado de

alimentación

Orificio de

distribución del

cableado de

alimentación

Modelo AN D AL L1 L2 L3

1U07BS1ERA 780 245 540 500 140 256

1U09BS1ERA 780 245 540 500 140 256

1U12BS1ERA 780 245 540 500 140 256

1U18FS1ERA 810 288 688 583 113.5 319.5

1U24GS1ERA 860 308 730 633 113.5 340

23

Page 28

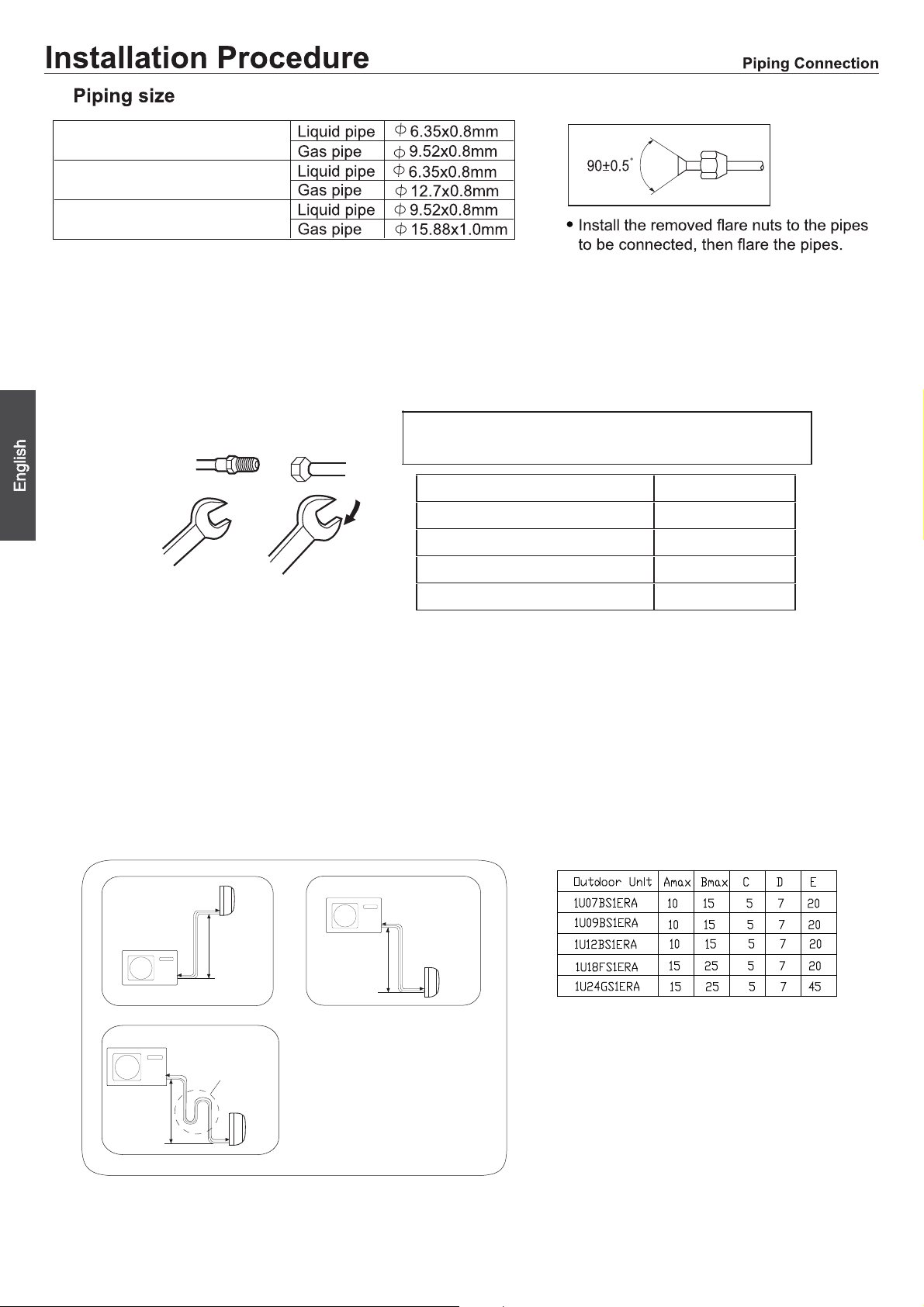

Procedimiento instalación

1. Tamaño de los tubos

Conexión de los tubos

1U07BS1ERA 1U09BS1ERA

1U12BS1ERA

1U18FS1ERA

1U24GS1ERA

2

. Conexión de los tubos

Tubo de líquido

Tubo de gas

Tubo de líquido

Tubo de gas

Tubo de líquido

Tubo de gas

6,35x0,8 mm

9,52x0,8 mm

6,35x0,8 mm

12,7x0,8 mm

9,52x0,8 mm

15,88x1,0 mm

● Inserte las tuercas cónicas retiradas en los tubos que se

van a conectar y, a continuación, abocarde los tubos.

● Para doblar un tubo, intente hacer la curva lo más suave posible para no aplastar el tubo. El radio de doblado

debe ser de entre 30 y 40 mm o superior.

● Será más sencillo conectar en primer lugar el tubo de gas.

● El tubo de conexión es especial para el tipo R410A.

Media unión Tuerca cónica

Si se fuerza la fijación sin aplicar centrado podrían

dañarse los tubos y provocarse una fuga de gas.

Diámetro del tubo (ø) Par de apriete

Lado de líquido 6,35 mm (1/4") 18N.m

Lado de líquido/gas 9,52mm (3/8") 42 N.m

Lado de gas 12,7mm (1/2") 55 N.m

Llave Llave dinamométrica

Lado de gas 15,88 mm (5/8") 60 N.m

Procure que no penetren materiales, como residuos de arena, agua, etc., en el tubo.

PRECAUCIÓN

La longitud del tubo estándar es C m. Si es superior a D m, el funcionamiento de la unidad se verá afectado. Si

es necesario alargar el tubo, deberá cargarse refrigerante adicional a razón de E g/m. No obstante, la carga de

refrigerante deberá ser realizada por un ingeniero profesional en aire acondicionado. Antes de añadir refrigerante adicional, realice una purga de aire desde los tubos refrigerantes y la unidad interior utilizando una bomba de

vacío y cargue después el refrigerante adicional.

Unidad exterior A máx. B máx. C D E

Unidad exterior

Unidad exterior

A

Unidad

B

interior

A

Filtro de aceite

B

Unidad

interior

Unidad exterior

B

Unidad

interior

A

● Elevación máx. A máx.

● En caso de que la elevación A sea

superior a 5 m, el filtro de aceite debe

instalarse cada 5 ~7 m.

● Longitud máx.: B máx.

● En caso de que la longitud del tubo B

sea superior a D m, deberá cargarse

el refrigerante a razón de E g/m.

1U07BS1ERA 10 15 5 7 20

1U09BS1ERA 10 15 5 7 20

1U12BS1ERA 10 15 5 7 20

1U18BS1ERA 15 25 5 7 20

1U24BS1ERA 15 25 5 7 45

24

Page 29

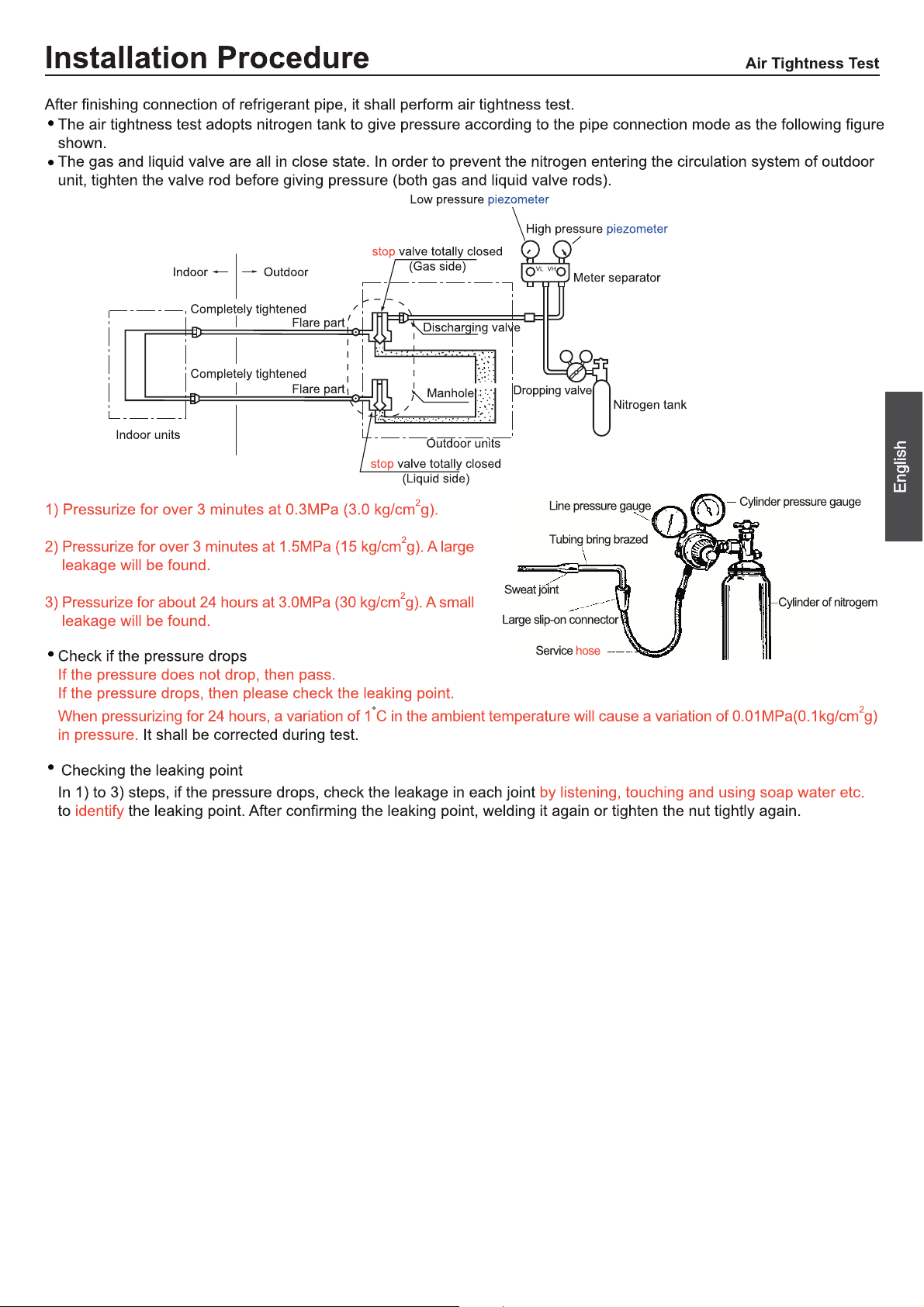

Procedimiento instalación

Prueba de hermeticidad del aire

Tras finalizar la conexión del tubo de refrigerante, debe realizar la prueba de hermetizado.

●

La prueba de hermetizado utiliza el depósito de nitrógeno para dar presión según el modo de conexión del tubo tal y como

se muestra en la siguiente figura.

●

Las válvulas de gas y líquido están cerradas. Para evitar que el nitrógeno entre en el sistema de circulación de la unidad

exterior, apriete el vástago de la válvula antes de dar presión (ambos vástagos de las válvulas de gas y líquido).

Piezómetro de baja

presión

ExteriorInterior

Completamente apretado

Completamente apretado

Unidades interiores

Pieza cónica

Pieza cónica

1) Presurice durante más de 3 minutos a 0,3 MPa (3,0 kg/cm2g)

2

2) Presurice durante más de 3 minutos a 1,5 MPa (15 kg/cm

g) Se encontrarán las fugas más importantes.

3) Presurice durante aproximadamente 24 horas a 3,0 MPa (30 kg/cm

Junta estañosoldada

● Compruebe si la presión disminuye

Conector de protección grande

Si la presión no disminuye, la comprobación se da por buena.

La presión disminuye, compruebe el punto de fuga.

Cuando se presurice durante 24 horas, una variación de 1

kg/cm2 g) en la presión.

Debe corregirse durante la prueba.

O

C en la temperatura ambiente provocará una variación de 0,01 MPa (0,1

Válvula de

totalmente cerrada

Válvula de retención totalmente

Manómetro de presión de

línea

Tubos cobresoldados

2

g) Se encontrarán las fugas más pequeñas.

Manguera de

mantenimiento

retención

(lado del gas)

Válvula de descarga

Registro

Unidades exteriores

cerrada (lado del líquido)

Piezómetro de alta presión

Separador

Válvula de

goteo

Depósito de nitrógeno

Manómetro de presión la

botella

Botella de nitrógeno

Comprobación del punto de fuga

●

En los pasos 1) a 3), si la presión disminuye, compruebe la fuga en cada junta

identificar

el punto de fuga. Tras comprobar el punto de fuga, vuelva a soldarlo o vuelva a apretar firmemente la tuerca.

25

escuchando, tocando, utilizando agua de jabón, etc. para

Page 30

Procedimiento instalación

Vacío

Método de vacío de los tubos: utilizar

una bomba de vacío

(por ejemplo 1U18FS1ERA)

1. Retire el tapón del puerto de mantenimiento de la válvula de 3 vías, el tapón del

vástago de la válvula de 2 vías y 3 vías, y conecte el puerto de mantenimiento a

la manguera de proyección de carga (inferior) del colector. Conecte entonces la

manguera de proyección de carga (central) del colector a la bomba de vacío.

2. ed rodacidni le iS .oícav ed abmob al enoicca y rotceloc led roirefni atipse al arbA

la escala (inferior) alcanza la condición de vacío por un momento, compruebe de

nuevo el paso 1.

3. Succione durante 15 minutos. Compruebe el nivel medido, que deberá ser de

-0,1 Mpa (-76cm Hg) en el lado de baja presión. Tras finalizar la succión, cierre el

mando de baja de la bomba de vacío. Compruebe el funcionamiento de las escala

y manténgala durante 1-2 min. Si la escala retrocede a pesar de ajustarse, realice

de nuevo los trabajos de conicidad y vuelva al punto 3.

4. 6

segundos, cierre la válvula de 2 vías e inspeccione si existen fugas de gas.

Válvula de 2 vías

Válvula de 3 vías

ed séupseD .adreiuqzi al aicah sodarg 09 saív 2 ed aluvláv al ed ogatsáv le arbA

Válvula de 2 vías

Válvula de 3 vías

Abrir

Cerrar

Válvula de 2 vías

Válvula de retención de líquido

Válvula de retención de gas

Colector (R410A)

Bomba de vacío (R410A)

Válvula de 3 vías

Puerto de mantenimiento

90 para 6 s

5. ¿No existen fugas de gas? En caso de que exista una fuga de gas, apriete las conexiones de los tubos. Si la fuga se detiene, siga

con el paso 6. Si la fuga de gas no se detiene, descargue todo el refrigerante a través del puerto de mantenimiento. Después de

realizar de nuevo la operación de conicidad y succión, rellene con el refrigerante especificado desde la botella de gas.

Válvula de 2 vías

6. Desconecte la manguera de carga del puerto de mantenimiento y abra las válvulas de 2

Válvula de 3 vías

y 3 vías. Gire el vástago de la válvula hacia la izquierda hasta que golpee ligeramente.

7. Para evitar fugas de gas, gire el tapón del puerto de mantenimiento y el tapón del

vástago de las válvulas de 2 y 3 vías un poco por encima del punto en el que la torsión

aumenta súbitamente.

Válvula de 2 vías

Válvula de 3 vías

Tapa del vástago de válvula

Tapa del vástago de válvula

Tapa del puerto de mantenimiento

PRECAUCIÓN:

Si existen fugas de refrigerante en el aire acondicionado, será necesario descargar todo el refrigerante. Haga el vacío primero, y

cargue líquido refrigerante en el acondicionador de aire de acuerdo con la cantidad marcada en la placa de valores nominales.

26

Page 31

Procedimiento instalación

Cableado eléctrico

¡ADVERTENCIA!

PELIGRO DE LESIONES PERSONALES O MUERTE

● DESCONECTE LA ENERGÍA ELÉCTRICA EN EL INTERRUPTOR DE CIRCUITO O LA FUENTE DE ALIMENTACIÓN ANTES DE

REALIZAR CONEXIONES ELÉCTRICAS.

● LAS CONEXIONES A TIERRA DEBEN COMPLETARSE ANTES DE REALIZAR CONEXIONES DE TENSIÓN DE LÍNEA.

Precauciones para el cableado eléctrico

● El trabajo de cableado eléctrico sólo debe realizarlo el personal autorizado para dicha tarea.

● No conecte más de tres cables al bloque de terminales. Utilice siempre orejetas de terminales en rizo de tipo redondo con agarre con

funda en los extremos de los cables.

● Utilice exclusivamente conductores de cobre.

Selección del tamaño de la fuente de alimentación y los cables de interconexión

Seleccione los tamaños del cable y la protección de circuito en la siguiente tabla. (Esta tabla muestra cables de 20 m con una caída de

tensión inferior al 2%.)

Interruptor de fugas de masa

Interruptor (A)

Corriente de

fuga (mA)

Modelo

Elemento

Fase

Interruptor de circuito Tamaño del cable

Interruptor

(A)

Capacidad nominal del

protector de sobrecarga

de corriente (A)

de la fuente de

alimentación

(mínimo)

2

)

(mm

1U07BS1ERA

1U09BS1ERA

1U12BS1ERA

1 40 26 2.5 40 30

1U18BS1ERA

1U24GS1ERA 1 40 26 4.0 40 30

● Si el cable de alimentación está dañado deberá ser reemplazado por el fabricante, agente de servicio o profesional cualificado.

● Si el fusible de la caja de control se funde, cámbielo por otro de tipo T 25 A/250 V.

● El método de cableado debe satisfacer los requisitos de las normas locales de cableado.

● El cable de alimentación y el cable de conexión deben estar incluidos.

● Todos los cables deben contar con el certificado de autentificación europeo. Durante la instalación, cuando quite los cables de conexión,

debe asegurarse de que el hilo de tierra es el último en quitarse.

● El interruptor del aire acondicionado debe estar conectado a todos los polos y la distancia entre los dos contactos del interruptor no

debe ser inferior a 3 mm. Dicho método de desconexión debe instalarse en el cableado fijo.

● La distancia entre los dos bloques de terminales de la unidad interior y la unidad exterior no debe ser superior a 5 m. Si es superior, el

diámetro del hilo se debe aumentar conforme al estándar de cableado local.

● Se debe instalar un interruptor de fugas.

Procedimiento de cableado

1) Extraiga los tornillos del lateral

antes de tirar el panel delantero hacia la dirección que se muestra en la figura.

2) Conecte los cables al bloque de terminales de forma correcta y fije los cables con una pinza del cable situada junto al bloque de

terminales.

3) Coloque los cables de forma adecuada e introdúzcalos por la apertura del cableado

eléctrico del panel lateral.

ADVERTENCIA:

LOS CABLES DE INTERCONEXIÓN DEBEN CONECTARSE SEGÚN LA FIGURA SIGUIENTE. SI REALIZA EL CABLEADO DE FORMA

INCORRECTA PUEDEN PRODUCIRSE DAÑOS EN EL EQUIPO.

PARA 18K 24K

Unidad exterior

1

(

N

)

2

)

3

C(L(

)

L

N

{

Modelo

1U09BS1ERA

1U12BS1ERA

1U07BS1ERA

Cableado de conexión

4G 0,75 mm

Cable de alimentación 3G 1,5 mm

1U18BS1ERA 1U24GS1ERA

2

2

4G 0,75 mm

3G 2,5 mm

2

2

4G 0,75 mm

3G 4,0 mm

2

2

A la unidad interior

INTENSO

PARA 07K 09K 12K

Unidad exterior

1

(

N

)

2

L

)(

3

C

)(

1

(

N

)

2

(

L

)

3

(

C

)

A la unidad interior

INTENSO

27

Page 32

Resolución de problemas en la unidad exterior

¡PRECAUCIÓN!

● ESTA UNIDAD SE PONDRÁ EN FUNCIONAMIENTO DE FORMA INSTANTÁNEA SIN ACTIVARLA CUANDO SE SUMINISTRE LA

ENERGÍA ELÉCTRICA. ASEGÚRESE DE DESACTIVARLA ANTES DE DESCONECTAR LA ENERGÍA ELÉCTRICA PARA REALIZAR

EL MANTENIMIENTO.

● Esta unidad cuenta con una función de sistema de reinicio automático que se activa al finalizar la interrupción de la energía.

1. Antes de iniciar el funcionamiento de prueba (para los modelos de bomba de calor)

Compruebe si el interruptor de la fuente de alimentación (interruptor principal) de la unidad se ha activado durante más de 12 horas

para energizar el calentador del cárter en previsión de la puesta en marcha.

2. Funcionamiento de prueba

Ponga la unidad en funcionamiento de forma continua durante 30 minutos y compruebe lo siguiente.

● La presión de aspiración en la junta de comprobación de la válvula de servicio del tubo de gas.

● La presión de descarga de la junta de comprobación del tubo de descarga del compresor.

● La diferencia de temperatura entre el aire de retorno y el aire de suministro de la unidad interior.

Destellos del LED

en la

placa principal

1 Error en la memoria EEPROM Error en la memoria EEPROM de la placa principal externa

2 Error de IPM Error de IPM

4

5 Protección de alta presión Presión alta del sistema superior a

6

8

9 Anomalía en el motor de CC Obstrucción del motor de CC o error del motor

10 Anomalía en el sensor de tubos Cortocircuito o circuito abierto en el sensor de tubos

11 Error en el sensor de temperatura de succión

12

13

15

16

17 Error de inversión de la válvula de cuatro vías

18 Compresor obturado (solamente para SPUD) El compresor interno tiene una obstrucción anómala

19 Error en el circuito de selección PWM del módulo Circuito erróneo de selección PWM del módulo

25 Exceso de corriente en la fase U del compresor La corriente de la fase U del compresor es demasiado alta

25 Exceso de corriente en la fase V del compresor La corriente de la fase V del compresor es demasiado alta

25 Exceso de corriente en la fase W del compresor La corriente de la fase W del compresor es demasiado alta

Descripción del problema Analizar y diagnosticar

Error de comunicación entre la placa principal y

el módulo SPDU Error de comunicación SPDU

Protección contra exceso de voltaje del módulo

(solamente para SPUD)

Protección contra ausencia de voltaje del módulo

(solamente para SPUD)

Protección contra

compresor

Anomalía en el sensor de temperatura ambiente

exterior

Anomalía en el sensor de descarga del

compresor

Error de comunicación entre las unidades interior

y exterior