Page 1

Page 2

TA1100/TA1600

Signal-to-Noise: >102dB below rated output “A” weighted

CMRR: >65dB at 1kHz

Input Impedance: 47kΩ per phase balanced

47kΩ unbalanced

Gain: 29dB maximum

Damping Factor: 350 (to 1kHz); 150 (to 10kHz); 18 (to 100kHz)

Controls & Switches: Front Panel: Power Switch and Level Controls

Indicators: Power Lamp, Clip/Thermal/Protect LEDs

Connectors: Input: Balanced:

1

/4” Tip Ring Sleeve

Unbalanced RCA

Output:

1

/4” Phone, Spring Clip

Headphone:

1

/4”

Power: IEC 320

Dimensions: 19”W x 8 1/2”D x 3 1/2”H (2 rack space)

(48cm x 25cm x 8.9cm)

Net Weight: 22 lbs

(9.98kg)

TA 1100

Power Rating: 1kHz, 0.1% THD

50 wpc into 4Ω

40 wpc into 8Ω

Frequency Response: ± 0.1dB, 20Hz to 20kHz

+0/-3dB, 1.0Hz to 100kHz

Slew Rate: 20V/µs

Input Sensitivity for rated output power:

Unbalanced: 0.640V RMS (8Ω), 0.510V (4Ω)

Balanced: 0.320V (8Ω), 0.250V (4Ω) per phase

Power Consumption: 40VA quiescent

TA 1600

Power Rating: 1kHz, 0.1% THD

75 wpc into 4Ω

60 wpc into 8Ω

Frequency Response: ± 0.1dB, 20Hz to 20kHz

+0/-3dB, 1.0Hz to 300kHz

Slew Rate: 100V/µs

Input Sensitivity for rated output power:

Unbalanced: 0.780V RMS (8Ω), 0.620V (4Ω)

Balanced: 0.390V (8Ω), 0.310V (4Ω) per phase

Power Consumption: 60VA quiescent

– i –

Specifications

Page 3

ii

NOTICE - IMPORTANT SAFETY INFORMATION

1. Read Instructions

All the safety and operating instructions of your Hafler equipment should be read before power is applied to the equipment.

2. Retain Owner's Manual

These safety and operating instructions should be retained for

future reference.

3. HEED WARNINGS

All warnings on the equipment and in the operating instructions are important and should be followed.

4. FOLLOW INSTRUCTIONS

All operating and use instructions are important and should be

followed.

5. HEAT

The equipment should be kept away from areas of high temperature, i.e., heater vents, radiators, stoves/ovens, fireplaces,

etc.

6. VENTILATION

The equipment should be used in an area suitable for proper

ventilation. Care should be taken not to impede airflow in and

around the cabinet. Do not mount on a carpeted shelf or in a

sealed enclosure. Allow for proper clearance above the equipment.

7. WATER AND MOISTURE

The equipment should not be used in or around water, such as

a bathtub, sink, or swimming area. Also, the equipment should

not be used in areas prone to flooding, such as a basement.

8. POWER SOURCES

The equipment should be connected only to a power source of

the same voltage and frequency as that listed on the rear panel

above the power cord entry point.

9. POWER CORD PROTECTION

Power cords should be arranged so they do not interfere with

the movement of objects in the room: people, fan blades, utility carts, etc. Also, care should be taken that the cord is not

pinched or cut, and placed so it is not in danger of being

pinched or cut, as in under a rug, around a tight corner, etc.

10. POWER CORD GROUNDING

The power supply cord is of a three wire grounded type,

designed to reduce the risk of electric shock sustained from a

live cabinet. It is assumed to be of suitable length for most uses

of the equipment. The use of extension cords and power strips

is discouraged unless they are of suitable rating to deliver the

required total current for safe operation of all connected

equipment. Furthermore, extension cords or power strips must

provide the same three wire grounded connection. It is important that the blades of the equipment’s plug be able to fully insert

into the mating receptacle.

Never remove the round grounding

pin on the plug in an attempt to mate to a two wire ungrounded receptacle:

use a grounding adapter with the grounding tab or

wire suitably connected to earth ground.

11. NON-USE PERIODS

During periods of extended non-use, the power cord should be

unplugged from the power source.

12. CLEANING

The equipment should be cleaned only as detailed in the operating instructions.

13. OBJECT AND LIQUID ENTRY

Care should be taken so that objects and/or liquids, such as

cleaning fluids or beverages, are not spilled into the enclosure of

the equipment.

14. DAMAGE REQUIRING SERVICE

Hafler equipment should be serviced by qualified service personnel when:

A. The power supply cord or plug has been damaged, or

B. Objects have fallen, or liquid has been spilled into the

equipment, or

C. The equipment has been exposed to rain, or

D. The equipment does not appear to operate normally or

exhibits a marked change in performance, or

E. The equipment has been dropped, or the enclosure has

been damaged.

15. SERVICING

The user should not attempt to service the equipment beyond

that which is described in the operating instructions. All other service should be referred to qualified service personnel.

16. CARTS AND STANDS

The equipment should be used with carts or stands only of

sufficient strength and stability for the use intended.

An equipment and cart combination should be moved with

care. Quick stops and starts, excessive force, and uneven sur

faces.

The lightning flash with arrowhead symbol within an equilateral triangle

is intended to alert the user to the presence of uninsulated "dangerous voltage" within the product's enclosure, that may be of sufficient magnitude

to constitute a risk of electric shock to persons.

The exclamation point within an equilateral triangle is intended to alert

the user of the presence of important operating and maintenance (servicing) instructions in the literature accompanying the appliance.

CAUTION

RISK OF ELECTRIC SHOCK

DO NOT OPEN

WARNING:

DO NOT EXPOSE THIS EQUIPMENT TO RAIN OR MOISTURE.

TO PREVENT FIRE OR SHOCK HAZARD

!

Page 4

1. LEA LAS INSTRUCCIONES

Todas las instrucciones de seguidad y operación de su equipo

Hafler, deben ser leídas antes de que el equipo sea conectado

dléctricamente.

2. CONSERVE EL MANUAL DEL PROPIETARIO

Estas instrucciones de seguridad y operación, deben ser conservadas para futuras referencias.

3. CUADROS DE ADVERTENCIAS

Todas las advertencias en el equipo y en las instrucciones de

operación, son importantes y deben ser seguidas.

4. SIGA LAS INSTRUCCIONES

Todas las instrucciones de uso y operación son importantes y

deben ser seguidas.

5. CALOR

El equipo debe ser mantenido lejos de areas de alta temperatura,

como por ejemplo: ventilaciones de calentadores, radiadores, estufas/hornos, hogueras, etc.

6. VENTILACION

El equip debe ser usado en áreas con ventilación adecuada.

Deben er tornadas las precauciones necesarias para no impedir

el flujo de aire dentro y alrededor del aparato.

7. AGUA Y HUMEDAD

El equipo no debe ser usado en el agua ó alrededor de ésta, tales

como en una bañera, tanque o áreas de nado. También, el

equipo no debe ser usado en áreas propensas a inundaciones,

tales como en un sótano.

8. FUENTES DE PODER

El equipo debe ser conectado a una fuente de poder del mismo

voltaje y frecuencia que el indicado en el panel trasero sobre el

punto de entrada del cable de corriente.

9. PROTECCION DEL CABLE DE CORRIENTE

Los cables de corriente deben ser dispuestos de forma tal que no

interfieran con el movimiento de objetos en la sala: personas,

aspas de ventilación, carretillas, etc. También, es necesario tener

cuidado de que el cable no esté punzado o cortado, y debe estar

ubicado de forma tal que esto no ocurra, como podría suceder

debajo de una alfombra o al pasar el cable por una esquina

aguda, etc.

10. ATERRAMIENTO DEL CABLE DE CORRIENTE

El cable de corriente es del tipo aterrado de tres hilos, diseñado

para reducir el riesgo de una descarga eléctrica procendent de un

chasis energizado. Se asume que su longitud es suficiente para la

mayoría de usos del equipo. El uso de extensiones y multienchufes no es recomendado, a menos que tengan el amperaje

adecuado para poder suministrar la corrioente requerida pra la

operación segura de todo el equipo conectado. Aun más, las

extensiones deben proveer de la misma conección aterrada de

tres hiles. Es importante que el enchufe se pueda introducir completamente en el receptáculo.

Nunca remeva el pin de aterramiento en un intento por conectar el cable en un receptáculo

de dos hilos no aterrado:

use un adaptador de aterramiento que

esté adecuadamente conectado a un punto de tierra.

11. PERIODOS SIN USO

Durante períodos prolongados sin uso del equipo, el cable de

corriente debe ser desconectado de la fuente de electrixidad.

12. LIMPIEZA

El equip debe ser limpiado solo en la forma que se detalla en las

instruccione opera`Å+˘ción.

13. INTRODUCCIÓN DE OBJETOS Y LIQUIDO

Deben ser tornadas precauciones con el fin de que objetos y/ó

líquidos, tales como fluidos de limpieza y gaseosas, no sean derramados dentro del chassis del aparato.

14. DAÑOS QUE REQUIEREN DE SERVICIO

Los equipos Hafler deben ser llevados a servicio por personal

calificado cuando:

A. El cable de corriente ó el enchufe haya sido dañado, ó

B. Objetos ó líquido hayan sido introducidos ó derramado en

el equipo, ó

C. El equipo haya sido expuesto a lluvia, ó

D. El equipo aparenta no operar normalmente ó exhibe un

marcado cambio en su desempeño, ó

E. El equipo se ha caído, o el chassis ha sido golpeado.

15. SERVICIO

El usuario no deberá intentar darle servicio al equipo más allá de

lo que está descrito en el instructivo de operación. Todo lo

demás, deberá ser referido a servicio por personal calificado.

16. CARRETILLAS Y SOPORTES

El equipo podrá ser usado con carretillas y soportes que tengan la

fortaleza y estabilidad suficiente para el uso previsto.

La combinación equipo/carretilla deberá ser movida con cuidado. Rápidas paradas y arranques, excesiva fuerza y superficies

imparejas, pueden causar el volcamiento del conjunto de carretilla/equipo.

ADVERTENCIA – INFORMACION DE SEGURIDAD IMPORTANTE

El símbolo de flecha relámpago dentro de un triángulo equilátero, es para alertar al usario de la presencia de “voltajes peligrosos” no aislados en el interior del aparato, los cuales pueden

ser de suficiente magnitud para constituir un riesgo de choque

eléctrico a las personas.

El símbolo de exclamación dentro de un triángulo equilátero, es

para alertar al usuario de la presencia de instrucciones importantes de operación y mantenimiento (servicio) en la documentación que acompaña al equipo.

iii

P E L I G R O

RIESGO DE DESCARGA

´

ELECTRICA NO ABRIR.

PRECAUCIONS:

Para Prevenir el incendio o la descarga electrica, no

exponer este equipo a la lluvia o a la humedad

´

´

!

Page 5

iv

PERFORMANCE SPECIFICATIONS ..................................................................................................................................................i

SAFETY PRECAUTIONS ..................................................................................................................................................................ii

INTRODUCTION ............................................................................................................................................................................1

DESIGN FEATURES ..........................................................................................................................................................................2

INSTALLATION

Location ....................................................................................................................................................................................3

AC Line......................................................................................................................................................................................3

Input..........................................................................................................................................................................................3

Output ......................................................................................................................................................................................3

Hum ..........................................................................................................................................................................................3

OPERATION

Power Switch ............................................................................................................................................................................5

Level Controls............................................................................................................................................................................5

TA1100 ....................................................................................................................................................................................5

TA1600 - Short Circuit Protection ............................................................................................................................................5

Warm Up ..................................................................................................................................................................................5

Cleaning and Maintenance........................................................................................................................................................5

SERVICE POLICY & LIMITED WARRANTY ......................................................................................................................................6

Table of Contents

Page 6

– 1 –

The Hafler TA1100 and TA1600 are two channel, two rack height, convection-cooled, MOSFET power amplifiers suitable

for use in the most demanding applications of critical listening and instrument amplification. These amplifiers offer the

same outstanding sonic quality and reliability that has contributed to Hafler’s enviable reputation within professional

recording studios and broadcast facilities all over the world.

This manual contains information on using the TA1100 and TA1600 amplifiers. It is organized into two main sections.

“Installation” covers the location and connection of the amplifier in the system. Like many precision components, careful

attention to the initial setup can yield dividends in higher performance and trouble-free use. “Operation” covers the controls and features of the amplifiers and how to use them to get the best effect.

The circuitry used in the TA 1600 is the latest refinement of our patented trans•

nova

(TRANSconductance NOdal Voltage

Amplifier, US Patent 4,467,288) circuit. It has been proven to offer sound quality to satisfy the most analytic audiophile or

the most demanding professional. The natural sound and realistic reproduction have made trans•

nova

amplifiers preferred

in many critical installations. Since our pioneering use of MOSFETs in the DH-200 amplifier, they have proven extremely

fault tolerant even in abusive situations. This sturdiness enables the amplifier to drive reactive speaker loads without the

performance and sound penalties imposed by elaborate protection schemes.

The TA1100 trans•

ana

circuitry has been very successful in bringing new levels of clarity and intelligibility to many broad-

cast facilities and headphone monitoring installations. Even at low power levels, the trans•

ana

MOSFET amplifier circuit

imitates the accuracy and warmth of it’s bigger brother, the TA1600 trans•

nova.

Specialized circuits in both amplifiers prevent damage to the amplifiers and speakers, without affecting the audio signal. A

soft start circuit prevents sending potentially destructive turn-on and turn-off transients to the speakers. A thermal sensing

network monitors the heatsink and transformer temperature, and shuts down the amplifier to protect from excessive operating heat. The need for internal fuses has been eliminated; a sensing circuit monitors the output and shuts down operation

when it detects a short in the output load.

The front panel has controls for input level adjustment. In addition, LED indicators give a visual representation of the operating status of each channel. Any type of fault - whether it is clipping, short protection, or thermal standby - will be indicated with a red LED.

Hafler manufactures additional Professional and Home Theatre amplifiers and monitors that offer an extreme level of performance and advanced technology. Visit our website at www.hafler.com for more information.

Introduction

Page 7

2

Design Features

1. Input level control

2. Clip/Thermal/ Protect LED

3. Power switch

4. Headphone jack

1. Balanced 1/4” input

2. Unbalanced RCA input

3. IEC line cord connector

4. Line fuse compartment

5. 1/4” mono speaker output

6. Spring clip output

1 2 4 3 2 1

1

2

4

3 5

6

5 2 1

Page 8

LOCATION

The TA1100 and TA1600 power transformer can generate a substantial magnetic field, so caution should be exercised in

the placement of low level components such as a tape deck, mixer or mic preamp to avoid inducing noise in the low level

circuitry. The amplifiers can also produce considerable heat in normal operation, so the primary consideration when determining a location for the amplifiers is to allow for adequate ventilation. The large heatsinks provide unrestricted airflow, but

care must be taken to keep the slots in the bottom panel and top cover clear. Use the rubber feet if the amplifier is placed

on a flat surface. If the amplifier is mounted in an equipment rack, make sure adjacent equipment does not impede cool air

flow.

We recommend leaving one rack space above and below the amplifier for proper cooling.

Inadequate ventilation can shorten component life, especially when other equipment raises the ambient air temperature, so

circulating fans should be considered in tight quarters.

AC LINE

The TA1100 and TA1600 operate from a 120 volt, 60Hz AC power line. Connection is made by a 16 gauge, IEC Type 320,

grounded line cord. For safety considerations only a properly grounded (earthed) receptacle should be used. If a grounded

circuit is not available do not break off the ground pin; use the proper adapter plug for a two wire receptacle. The line fuse

mounted on the rear panel will interrupt power to the amplifier if an internal fault is detected. If this fuse blows, replace it

with the same type and rating fuse only. The correct replacement fuse value is printed on the rear panel of the amplifier. If

the new fuse blows, this is an indication of a fault with the amplifier. Servicing should be performed only by a qualified

technician.

INPUT

The input jacks on the back of the amplifier will accept either

1

/4” balanced, 1/4” unbalanced, or RCA unbalanced inputs. If

both jacks are used simultaneously, the

1

/4” input will automatically activate internal switches and disconnect the RCA

input, so that only the

1

/4” input remains operational.

OUTPUT

Speakers can be connected to the amplifier with

1

/4” mono plugs, or bare wires into spring clip connectors. Polarity of the

1

/4” connectors is Tip (+) and Sleeve (-).

HUM

It is not unusual to experience objectionable hum in even the simplest audio systems. If you are hearing hum in the

speakers or headphones, here is a very effective test that will help you troubleshoot your system, and eliminate the

problem:

CAUTION: DO NOT PERFORM THIS TEST WITH HEADPHONES . PROTECT YOUR EARS. MONITOR THE

OUTPUT OF YOUR AMPLIFIER AT A SAFE DISTANCE AWAY FROM FULL- RANGE SPEAKERS.

Hum Test:

Step 1:

Turn off the amplifier, turn both level controls all the way down, disconnect all input cables, disconnect head-

phones.

Step 2: Connect a full- range speaker to the output of One CHANNEL of the amplifier.

Step 3: Turn on amplifier. Slowly turn up the level controls and listen for hum. Turn level control back down and turn off

the amplifier. If the hum level was low, then the amplifier is not the source of the hum problem.

Step 4: Repeat this procedure on the remaining channel.

3

Installation

Page 9

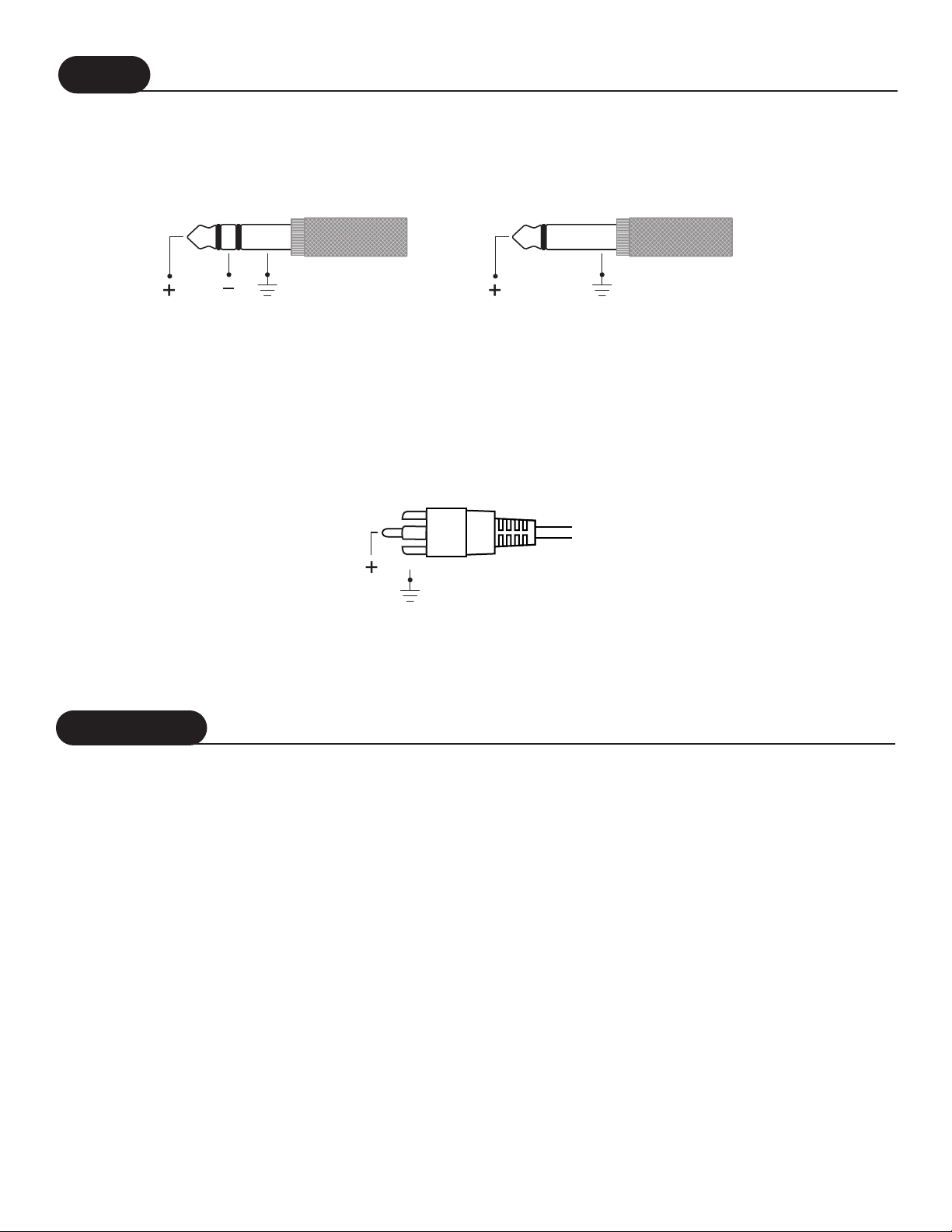

1/4" TRS Balanced Input

Check output of source unit for proper signal polarity

Tip = (+)

Ring = (–)

Sleeve = GND

1/4" TRS Unbalanced Input

Tip

= (+)

Sleeve = GND

4

Operation

RCA Unbalanced Input

Tip = (+)

Shell = GND

Input

Tip

Shell

POWER SWITCH

The POWER switch is located on the front panel of the amplifier. An internal lamp indicates when it is turned on.

Standard practice is to turn the amplifier on last and off first when switching components to prevent sending damaging transients to the speakers.

It is possible to leave the power switch in the on position and switch the amplifier remotely through a power distribution block

or preamp switched outlet. When doing so make sure the switch is rated for the current required by the amplifier.

LEVEL SETUP

The input sensitivity for each channel can be adjusted individually using the Level Controls on the front panel. Set up the

amplifier Level Controls such that the amplifier clipping LED’s light occasionally when the source unit level control is turned

up approximately

2

/

3

to

3

/

4

full on.

Turning up the amplifier level controls any further than this will not make the amplifier any

louder! It will only increase the noise floor (hum and hiss)

TA 1100 - SHORT CIRCUIT PROTECTION

In the event of a short in the speaker load or cables, the protection circuit will automatically shut down the amplifier and

illuminate the red LED. When the short is removed, the red LED will turn off, and the signal will return to normal.

Tip Ring Sleeve Tip Sleeve

1/4" TRS Unbalanced Input1/4" TRS Balanced Input

Page 10

TA 1600 - SHORT CIRCUIT PROTECTION

The TA1600 amplifier circuit has no need for sonically degrading voltage and current limiting circuits. To protect the amplifier from problems which may occur in the speaker line there is an overload detection circuit.

In the event of a short in the speaker load or cables, the speaker detection circuit will shut down that channel and light

the red front panel indicator. If this happens, correct the fault and turn the amplifier off, then back on. This will reset

the amplifier.

WARM UP

In order to achieve the best sonic performance from the amplifier, we recommend letting it warm up for 1 hour before beginning any critical listening. The amplifier may not deliver its full potential sound quality before this time has passed. Many users

leave Hafler amplifiers on indefinitely to ensure the best operation without delay.

CLEANING AND MAINTENANCE

There is no requirement for regular maintenance on the electronic components of the amplifier. If the case becomes soiled it

can be cleaned using a soft cloth and a mild detergent, such as spray window or glass cleaner. If the amplifier is located in a

particularly dusty environment cleaning the inside with compressed air or vacuuming every 18 to 24 months is sufficient.

Troubleshooting

No Sound

Adjust the system headroom. First, turn the

source unit level control up to

3

/

4

maximum. Next, turn the amplifier level

controls down until the clip LED activates

occasional, only during peak audio events.

SYMPTOM DIAGNOSIS REMEDY

No Power

Check the line fuse on the back panel, line

cord connections, power strip switch, wall

receptacle switch, and breaker.

Check connections, substitute with known

working source and cables and repair or

replace as

necessary.

Disconnect existing speakers and wires and

replace with known working speakers and

wires. If amplifier works, check and repair

wiring and speakers as needed.

Line voltage not present

RCA or

1

/

4

” input from

source unit is not connected

or not functioning properly

Speaker leads are shorted, or

speakers are blown

Too much system Gain

Protection circuit has

activated

Reset the amplifier by turning the power

off, then back on again. If protection

activates again, check for shorted speaker

wires or blown speakers.

No Sound - Red LED on

TA1600

Hum in Speakers or

Headphones

Ground Loop

(Balanced Input Only)

Try disconnecting the ground wire on both

1

/

4

”balanced cables

5

Page 11

Please contact Hafler for any Warranty issues.

Hafler offers the following limited warranty on Hafler products.

• Length of Warranty

1 year on TA1100 and TA1600

90 days on all B-Stock electronics (receipts are required)

• What is Covered

This warranty applies only to products sold to the original owner (non-transferable). This only applies to units sold in the

Continental United States. You are required to have a copy of the receipt stating the customer's name, dealer name, product purchased and date of purchase.

• Products found to be defective during the warranty period will be repaired or replaced (with product deemed to be

equivalent) at Hafler's discretion.

• What is NOT Covered

1. Damage caused by accident, abuse, improper operation, water, theft

2. Service performed by anyone other than Hafler or an Authorized Hafler service center

3. Any product purchased outside the United States (please contact your local dealer)

4. Shipping charges to get the unit to Hafler

5. Any product which has had the serial number defaced, altered, or removed

• Limit on Implied Warranties

Any implied warranties including warranties of fitness for use and merchantability are limited in duration to the period

of the express warranty set forth above. Some states do not allow limitations on the length of an implied warranty, so

this limitation may not apply. No person is authorized to assume for Hafler any other liability in connection with the

sale of the product.

•

How to obtain service or technical support

Please call 1-800-669-9899 for Rockford/Hafler support. You must obtain an RA # (return authorization number) to

return any products to Hafler. You are responsible for shipment of product to Hafler.Always include proof of purchase.

Mark RA# on outside of shipping carton.

Rockford Corporation

Hafler Division - receiving amps.

2055 E. 5th Street

Tempe, Arizona 85281

6

Service Policy & Limited Warranty

Page 12

®

HAFLER

A DIVISION OF

ROCKFORD CORPROATION

546 SOUTH ROCKFORD DRIVE

TEMPE, ARIZONA 85281 U.S.A.

480-967-3565 / 1-888-HAFLER1

WWW.HAFLER.COM

M.J.T. 6/00

MADE IN TAIWAN

Loading...

Loading...