Page 1

DOC023.97.80281

AF7000 SCM

09/2014, Edition 4

Basic User Manual

Page 2

Page 3

Table of Contents

Specifications on page 3 Startup on page 15

General information on page 4 Operation on page 15

Installation on page 7 Maintenance on page 16

User interface on page 13

Additional information

Additional information is available on the manufacturer's website.

Specifications

Specifications are subject to change without notice.

General specifications

Specification Details

Dimensions (W x H x D) 320 x 750 x 250 mm (12.6 x 29.5 x 10 in.)

Sample contact components Stainless Steel, UHMW, Epoxy

Weight 21.5 kg (47.4 lb) standard option

Pollution degree 2

Installation category II

Protection class I

Power requirement options 230 VAC, 50 Hz at 1.6 A ; 115 VAC, 50 Hz at 3.2 A

120 VAC 60 Hz at 3.2 A

Operating temperature 0 to 50 °C (32 to 122 °F)

Maximum relative humidity 95% for temperatures up to 50 °C (122 °F)

Storage temperature –20 to 70 °C (–4 to 158 °F) 95% relative humidity, non-condensing

Speed of response 1 second to 1 minute, adjustable average

Sample flow rate > 1 L/min, 2–4 L/min recommended

Sample temperature 7 to 35 °C (45 to 95 °F)

Plumbing connection ½-in. BSP

Communications RS485 electrically isolated; data rate: 1200 to 9600 baud

Outputs (optional) 4–20 mA card: Two 4–20 mA outputs; maximum load 500 Ω, electrically isolated

Alarm relay card: Two relays; SPST, NO and NC terminals, maximum 16 VAC

(35 VDC), 5 A (resistive loads only)

Digital inputs (optional) Two dual digital; optically isolated; switch input or 5 to 24 V input

Certifications CE, cETLus (UL and CSA 61010-1 safety standards)

Warranty 1 year

English 3

Page 4

Automatic flush specifications

Specification Details

Water connection ½-in. BSP

Water pressure 10 bar (145 psi) maximum; 1–5 bar (14.5–72.5 psi) recommended

Auto flush options Interval: 1 minute to 48 hours

Duration: 1 second to 4 minutes

Reading hold: 0 seconds to 4 minutes

General information

In no event will the manufacturer be liable for direct, indirect, special, incidental or consequential

damages resulting from any defect or omission in this manual. The manufacturer reserves the right to

make changes in this manual and the products it describes at any time, without notice or obligation.

Revised editions are found on the manufacturer’s website.

Safety information

N O T I C E

The manufacturer is not responsible for any damages due to misapplication or misuse of this product including,

without limitation, direct, incidental and consequential damages, and disclaims such damages to the full extent

permitted under applicable law. The user is solely responsible to identify critical application risks and install

appropriate mechanisms to protect processes during a possible equipment malfunction.

Please read this entire manual before unpacking, setting up or operating this equipment. Pay

attention to all danger and caution statements. Failure to do so could result in serious injury to the

operator or damage to the equipment.

Make sure that the protection provided by this equipment is not impaired. Do not use or install this

equipment in any manner other than that specified in this manual.

Use of hazard information

D A N G E R

Indicates a potentially or imminently hazardous situation which, if not avoided, will result in death or serious injury.

W A R N I N G

Indicates a potentially or imminently hazardous situation which, if not avoided, could result in death or serious

injury.

C A U T I O N

Indicates a potentially hazardous situation that may result in minor or moderate injury.

N O T I C E

Indicates a situation which, if not avoided, may cause damage to the instrument. Information that requires special

emphasis.

Precautionary labels

Read all labels and tags attached to the instrument. Personal injury or damage to the instrument

could occur if not observed. A symbol, if noted on the instrument, will be included with a danger or

caution statement in the manual.

4

English

Page 5

This is the safety alert symbol. Obey all safety messages that follow this symbol to avoid potential

injury. If on the instrument, refer to the instruction manual for operation or safety information.

This symbol indicates that a risk of electrical shock and/or electrocution exists.

This symbol indicates that the marked item can be hot and should not be touched without care.

This symbol indicates the need for protective eye wear.

This symbol identifies a risk of chemical harm and indicates that only individuals qualified and trained

to work with chemicals should handle chemicals or perform maintenance on chemical delivery

systems associated with the equipment.

This symbol indicates that a risk of fire is present.

This symbol identifies the presence of a strong corrosive or other hazardous substance and a risk of

chemical harm. Only individuals qualified and trained to work with chemicals should handle chemicals

or perform maintenance on chemical delivery systems associated with the equipment.

This symbol indicates the presence of a biohazard.

This symbol indicates that the marked item requires a protective earth connection. If the instrument is

not supplied with a ground plug on a cord, make the protective earth connection to the protective

conductor terminal.

This symbol, when noted on the product, identifies the location of a fuse or current limiting device.

This symbol indicates the presence of devices sensitive to Electro-static Discharge (ESD) and

indicates that care must be taken to prevent damage with the equipment.

Electrical equipment marked with this symbol may not be disposed of in European domestic or public

disposal systems. Return old or end-of-life equipment to the manufacturer for disposal at no charge to

the user.

Certification

Canadian Radio Interference-Causing Equipment Regulation, IECS-003, Class A:

Supporting test records reside with the manufacturer.

This Class A digital apparatus meets all requirements of the Canadian Interference-Causing

Equipment Regulations.

English

5

Page 6

Cet appareil numérique de classe A répond à toutes les exigences de la réglementation canadienne

sur les équipements provoquant des interférences.

FCC Part 15, Class "A" Limits

Supporting test records reside with the manufacturer. The device complies with Part 15 of the FCC

Rules. Operation is subject to the following conditions:

1. The equipment may not cause harmful interference.

2. The equipment must accept any interference received, including interference that may cause

undesired operation.

Changes or modifications to this equipment not expressly approved by the party responsible for

compliance could void the user's authority to operate the equipment. This equipment has been tested

and found to comply with the limits for a Class A digital device, pursuant to Part 15 of the FCC rules.

These limits are designed to provide reasonable protection against harmful interference when the

equipment is operated in a commercial environment. This equipment generates, uses and can

radiate radio frequency energy and, if not installed and used in accordance with the instruction

manual, may cause harmful interference to radio communications. Operation of this equipment in a

residential area is likely to cause harmful interference, in which case the user will be required to

correct the interference at their expense. The following techniques can be used to reduce

interference problems:

1. Disconnect the equipment from its power source to verify that it is or is not the source of the

interference.

2. If the equipment is connected to the same outlet as the device experiencing interference, connect

the equipment to a different outlet.

3. Move the equipment away from the device receiving the interference.

4. Reposition the receiving antenna for the device receiving the interference.

5. Try combinations of the above.

Product overview

D A N G E R

Chemical or biological hazards. If this instrument is used to monitor a treatment process and/or

chemical feed system for which there are regulatory limits and monitoring requirements related to

public health, public safety, food or beverage manufacture or processing, it is the responsibility of the

user of this instrument to know and abide by any applicable regulation and to have sufficient and

appropriate mechanisms in place for compliance with applicable regulations in the event of malfunction

of the instrument.

C A U T I O N

Fire hazard. This product is not designed for use with flammable liquids.

This instrument measures an electrical current (streaming current) from suspended particles in the

sample as the sample flows through the instrument. This current is typically used to monitor the

amount of coagulant that is added to water treatment systems. Good coagulation occurs when the

surface charges on the particles are neutralized by the coagulant. An optional PID controller card can

automatically adjust the coagulant dose to keep the dosage at the optimum level.

Applications include drinking water, wastewater and industrial waters (e.g. pulp and paper). The

instrument can also be used to monitor changes in the source water. A typical setup is shown in

Figure 1.

6

English

Page 7

Figure 1 Instrument overview

1 Wiring access cover 6 Sample chamber 11 Grit filter

2 Cable access cover 7 Sample outlet 12 Manual isolation valve for inlet

3 Head height indicator pipe 8 Sensor 13 Motor

4 Directional valve 9 Clean water in (for optional

flush)

14 Reset switch for motor

5 Overflow port (2x) 10 Optional flush valve 15 Gearbox

Installation

D A N G E R

Multiple hazards. Only qualified personnel must conduct the tasks described in this section of the

document.

English 7

Page 8

Installation guidelines

This instrument is rated for an altitude of 2000 m (6562 ft) maximum. Use of this instrument at an

altitude higher than 2000 m can slightly increase the potential for the insulation to breakdown, which

can result in an electric shock hazard. The manufacturer recommends that users with concerns

contact technical support.

• For best results, the pH of the sample must be reasonably constant or controlled before

coagulation.

• Install the instrument as near to the sample mixer as possible. The sample measurement must

occur within 30 seconds after the coagulant is fully mixed with the sample at all expected flow

rates.

• Install the instrument as near to the point of chemical addition (coagulant and pH adjustment) as

possible and make sure that the sample is well-mixed when measured. Typically, this means that

the instrument is installed in a location where the sample will reach the instrument within

30 seconds of chemical addition at all expected flow rates.

• Installation of the instrument indoors is recommended. Install the instrument in a relatively dust-

free location away from direct sunlight.

• If the instrument is installed in an outdoor environment, put the instrument in an enclosure that

supplies protection from precipitation and direct sunlight. The enclosure must also supply good

ventilation and temperature control.

• Make sure that there is sufficient drainage for any sample that flows through the overflow ports.

• Make sure that sufficient airflow is supplied around the motor so that the motor does not become

too hot.

• Make sure that the sample flow is more than 1 L/minute. A flow rate of 2–4 L/min is recommended.

A sample flow more than 4 L/min will cause water to leak from the weep hole in the piston shaft.

• If the sample water contains sand or fibrous material, install an inlet filter (Y-strainer). A 40-mesh

strainer is sufficient for most applications.

Mechanical installation

Attach the instrument to a wall

W A R N I N G

Personal injury hazard. Instruments or components are heavy. Use assistance to install or move.

Attach the instrument vertically to a wall or structure that is able to hold at least 86 kg (190 lb) of

downward force. Make sure that there is sufficient airflow around the motor.

User-supplied hardware:

• Four bolts, 10 × 40 mm (7/16 × 1.5 in.)

Figure 2 shows the installation dimensions.

8

English

Page 9

Figure 2 Installation dimensions

Plumb the instrument

N O T I C E

Supply ½-in. NPT plumbing for both the sample inlet and the sample outlet. Outlet fittings smaller in diameter than

½-in. NPT can cause unwanted back pressure into the instrument and result in instrument damage.

Plumb the sample to the instrument as shown in Figure 1 on page 7. Plumbing guidelines:

• Install a manual flow isolation valve at the inlet.

• Keep the sample flow within the specified flow rate of 2–4 L/min.

• Use Teflon tape on the pipe threads.

• The inlet piping and outlet piping must be ½-in. NPT.

• Use ½-in. NPT fittings for the inlet piping.

English

9

Page 10

• Use ½-in. or larger NPT fittings for the outlet piping.

• If the water connections are user-supplied, install an elbow after the sensor to keep a 25–133 mm

(1–5.25 in.) head of water above the sensor (in the head height indicator pipe). Refer to Figure 1

on page 7.

• If the automatic flush mechanism is used, plumb a clean water supply at 1–5 bar (14.5 to 72.5 psi),

10 bar (145 psi) maximum.

Note: The direction of sample flow can be in either direction through the sensor.

Electrical installation

Wiring safety information

D A N G E R

Multiple hazards. Only qualified personnel must conduct the tasks described in this section of the

document.

D A N G E R

Electrocution hazard. Always remove power to the instrument before making electrical connections.

D A N G E R

Electrocution hazard. If this equipment is used outdoors or in potentially wet locations, a Ground Fault

Circuit Interrupt (GFCI/GFI) device must be used for connecting the equipment to its main power

source.

Electrostatic discharge (ESD) considerations

N O T I C E

Potential Instrument Damage. Delicate internal electronic components can be damaged by static

electricity, resulting in degraded performance or eventual failure.

Refer to the steps in this procedure to prevent ESD damage to the instrument:

• Touch an earth-grounded metal surface such as the chassis of an instrument, a metal conduit or

pipe to discharge static electricity from the body.

• Avoid excessive movement. Transport static-sensitive components in anti-static containers or

packages.

• Wear a wrist strap connected by a wire to earth ground.

• Work in a static-safe area with anti-static floor pads and work bench pads.

Wiring overview

Figure 3 shows all of the possible connections for optional devices and communications.

10

English

Page 11

Figure 3 Optional connections

1 Modbus (RS485) card or alarm relay card (optional) 4 Autoflush card (optional)

2 4–20 mA PID controller card or alarm relay card

(optional)

5 High voltage barrier

3 4–20 mA Process Output controller card or digital

input card (optional)

Connect to devices

W A R N I N G

Electrical shock hazard. Externally connected equipment must have an applicable country safety

standard assessment.

English 11

Page 12

W A R N I N G

Fire hazard. Relay loads must be resistive. Always limit current to the relays with an external fuse or

breaker. Obey the relay ratings in the Specifications section.

Refer to the illustrated steps in this section to connect the instrument to external devices or to a

communications network. For connection to the wire terminals, refer to Table 1 and Table 2.

Table 1 Optional device wiring

Option Pin name (description) Pin name (description) Pin name (description)

4–20 mA Sh (shield with ground) + (positive) – (neutral)

Modbus (RS485) Sh (shield without ground) Tx (transmit) Rx (receive)

Alarm relays NC (normally closed) Com (common) NO (normally open)

External PID controller Sh (shield) + (positive) – (negative)

Digital input 1 (input 1) 2 (input 2) Com (common)

Table 2 Autoflush card wiring

Pin Description Wire color

P Phase Black—1

N Neutral Black—2

E Protective earth ground Green/yellow

1 2

12 English

Page 13

3

User interface

Figure 4 shows the instrument keypad and display. Table 3 gives the display and keypad

descriptions.

English

13

Page 14

Figure 4 Display and keypad overview

1 Top display 4 UP arrow key 7 Set Zero key

2 Bottom display 5 Enter key 8 Auto/Manual key

3 DOWN arrow key 6 Menu/Cancel key

Table 3 Display and keypad descriptions

Item Name Description

(1) Top display Raw streaming current value (the same value shown in the bottom display) until the

zero point has been set. When the zero point is set, the display shows the deviation

from the raw streaming current value.

• 0 = Optimal amount of coagulant if the user has set the zero point based on the zeta

potential or the jar test

• – XX = The streaming current value is less than the optimum value. Coagulant may

need to be added if the user has set the zero point based on the zeta potential or

the jar test.

• + XX = The streaming current value is more than the optimum value. The coagulant

feed may need to be stopped or reduced if the user has set the zero point based on

the zeta potential or the jar test.

(2) Bottom display Raw streaming current value

Note: "PXX"(e.g., P66) shows when the instrument has a PID controller that is set to manual mode.

Push Auto/Manual to show the raw streaming current value.

"PXX" identifies the percentage at which the PID controller is operating. For example, if the

instrument output signal (4–20 mA) is 4 mA, "P00" shows. If the instrument output signal is 12 mA,

"P50" shows. The percentage shown depends on the user settings.

(3) DOWN arrow key Select a menu or option, set or change a value

To adjust the zero point, push and hold an arrow key for 2 seconds, then push the

applicable arrow key.

• DOWN arrow = increase the zero point

• UP arrow = decrease the zero point

Note: When the optional 4–20 mA PID controller card is installed, the controller must be in manual

mode to adjust the zero point. Push Auto/Manual to go to manual mode.

(4) UP arrow key

(5) Enter key Select a menu item or accept an entry

14 English

Page 15

Table 3 Display and keypad descriptions (continued)

Item Name Description

(6) Menu/Cancel key Show the menu options or exit the menu options.

Push the DOWN arrow to scroll through the menu options.

(7) Set Zero key Set the zero point. The top display changes to "0".

To set the zero point, push and hold Set Zero for 3 seconds. Set the zero point when

the optimum coagulant dose is added and the reading is stable.

Note: Set the zero point again whenever there is a significant change in source water. Significant

changes include seasonal changes such as lake turnover, after a storm or other high turbidity event.

It is important to keep the variation from the zero point very small so that the instrument can make

fine adjustments.

(8) Auto/Manual key When the optional 4–20 mA PID controller card is installed, push Auto/Manual to

switch between automatic and manual controller mode.

Startup

Connect the instrument to power

C A U T I O N

Burn hazard. The motor surface gets hot. Do not touch.

Plug the power cord into an electrical outlet. The instrument starts automatically.

Validate the installation

1. Set the zero point. Refer to Set the zero point on page 15.

2. Increase the coagulant dose by 10%. Make sure that the top and bottom values on the display

increase. Wait 5–10 minutes for the full-scale change to complete.

Note: The instrument shows an approximate half-scale change in 20–40 seconds. A full-scale change occurs in

5–10 minutes.

3. Decrease the coagulant dose by 10% of the optimal dose. Make sure that the top and bottom

values on the display decrease. Wait 5–10 minutes for the full-scale change to complete.

4. Set the coagulant dose back to the optimal dose. Wait 5–10 minutes for the full-scale change to

complete.

Operation

Set the zero point

Pre-requisite: Complete a jar test, or take a zeta potential measurement, to find the optimum

coagulant dose. The optimum dose gives the best floc formation and lowest turbidity without excess

coagulant. Set the coagulant pump speed to supply the optimum dose and examine the coagulation.

If necessary, increase or decrease the coagulant pump speed until the optimum dose is supplied.

Push the Set Zero key to set the top display to 0 when the optimum sample-coagulant mixture goes

through the instrument. If the display later shows a positive or negative number, the coagulant

dosage is above or below the optimum setting.

1. Set the optimum coagulant dose in the system.

2. Wait for the dosage change to get to the instrument and a full-scale change to complete through

the instrument (approximately 5–10 minutes).

3. When the reading is stable, push and hold Set Zero for three seconds. The top display shows 0.

English

15

Page 16

Adjust the zero point

The zero point can be changed to increase or decrease the coagulant dosage. Increase the zero

point setting to decrease the coagulant dose. Decrease the zero point setting to increase the

coagulant dose.

1. Put the controller in manual mode.

2. Push and hold the Up or Down key for two seconds.

3. Push the Up or Down key to increase or decrease the zero point setting (top display).

4. Put the controller in automatic mode. The coagulant dose changes until the zero point setting

shows 0.

Maintenance

D A N G E R

Multiple hazards. Only qualified personnel must conduct the tasks described in this section of the

document.

Maintenance schedule

Table 4 shows the recommended schedule of maintenance tasks. Facility requirements and

operating conditions may increase the frequency of some tasks.

Table 4 Maintenance schedule

Task 14 days 1 month 6 months 1 year 5 years

Examine and clean the sensor. Refer to

Clean the sensor on page 17.

X1 (without auto-

flush)

X1 (with grit filter

and auto-flush)

Examine the replaceable parts for wear.

Refer to Examine the replaceable parts

on page 18.

X

Replace the piston.

2

X

Replace the cam rod to piston linkage.

2

X

Replace the linear bearings.

2

X

Replace the sensor.

2

X

1

Do this task also after each high-turbidity event.

2

Refer to the instructions that are supplied with the replacement part.

Clean spills

C A U T I O N

Chemical exposure hazard. Dispose of chemicals and wastes in accordance with local, regional and

national regulations.

1. Obey all facility safety protocols for spill control.

2. Discard the waste according to applicable regulations.

Clean the instrument

Clean the exterior of the instrument with a moist cloth and a mild soap solution and then wipe the

instrument dry.

16

English

Page 17

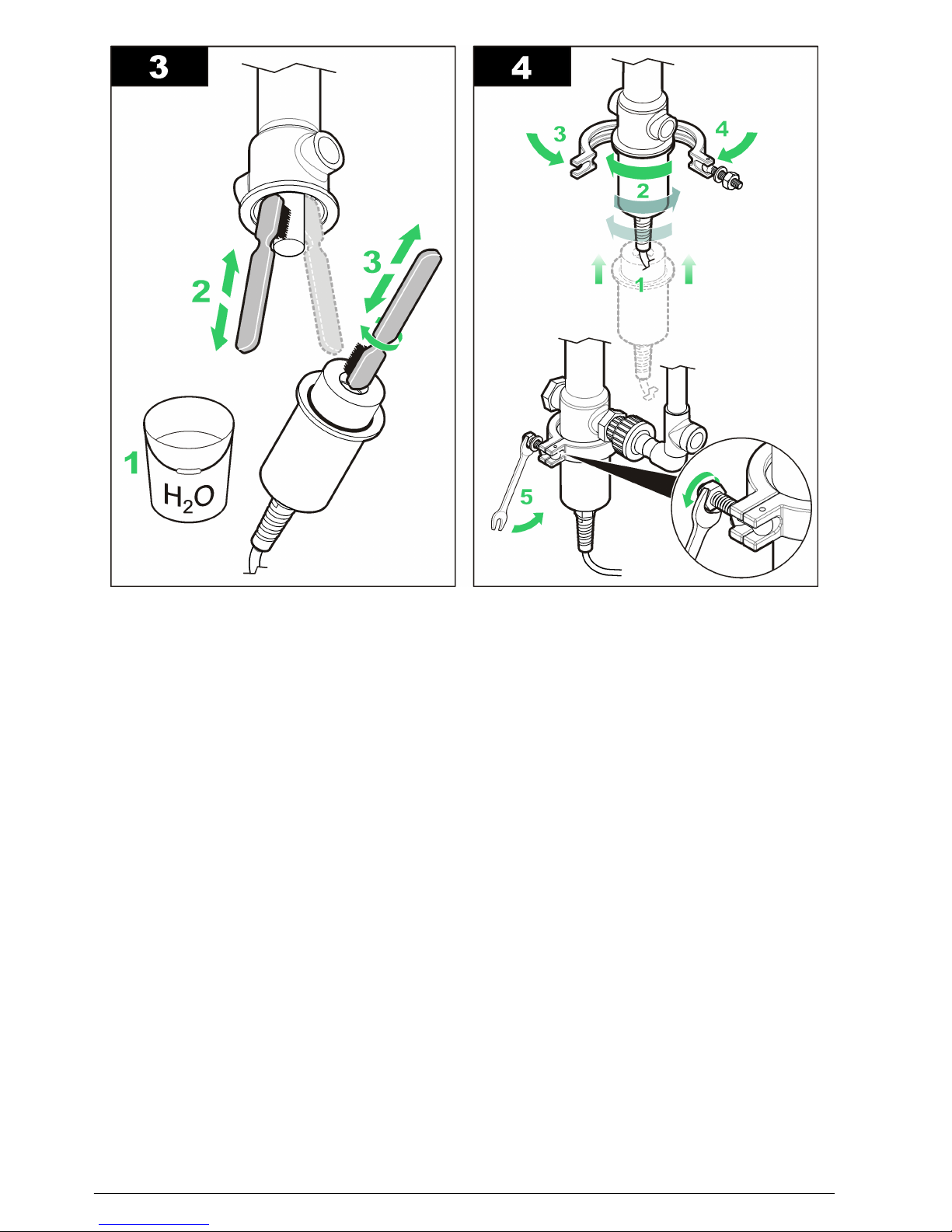

Clean the sensor

N O T I C E

Do not use abrasive cleaners. Always use gloves to handle the piston or the sensor. Oil from hands will increase

the stabilization time.

Pre-requisites:

1. Put the controller in manual mode.

2. Disconnect power to the instrument.

Required items:

• Soft toothbrush or soft cloth

• Clean sample water

Procedure:

The frequency and cleaning method changes with conditions in the process water. The streaming

current is very sensitive to the surface condition of the piston. After the sensor is cleaned, the

stabilization time can be up to 30 minutes. Refer to the illustrated steps to clean the sensor.

English 17

Page 18

Post-requisites:

1. Apply power to the instrument.

2. Let the reading become stable.

3. Set the zero point.

Examine the replaceable parts

Worn parts can cause poor sensitivity and frequent drifts in the zero point. To examine the parts,

refer to Clean the sensor on page 17 and the illustrated steps that follow. Look for signs of wear:

• Piston—deep scratches or scores.

• Cam rod to piston linkage—too much movement when the piston is pushed up and down.

• Linear bearings—too much movement when the piston is pushed side to side.

• Sensor—deep scratches or scores.

18

English

Page 19

Replace the fuses

D A N G E R

Fire hazard. Use the same type and current rating to replace fuses.

The instrument has fuses in two locations. Figure 5 shows the location of the 5 A fuses. Figure 6

shows the location of the 8 A fuses.

Figure 5 Fuse location, 5 A

English 19

Page 20

Figure 6 Fuse location, 8 A

20 English

Page 21

Page 22

HACH COMPANY World Headquarters

P.O. Box 389, Loveland, CO 80539-0389 U.S.A.

Tel. (970) 669-3050

(800) 227-4224 (U.S.A. only)

Fax (970) 669-2932

orders@hach.com

www.hach.com

HACH LANGE GMBH

Willstätterstraße 11

D-40549 Düsseldorf, Germany

Tel. +49 (0) 2 11 52 88-320

Fax +49 (0) 2 11 52 88-210

info@hach-lange.de

www.hach-lange.de

HACH LANGE Sàrl

6, route de Compois

1222 Vésenaz

SWITZERLAND

Tel. +41 22 594 6400

Fax +41 22 594 6499

©

Hach Company/Hach Lange GmbH, 2012-2014.

All rights reserved. Printed in New Zealand.

Loading...

Loading...