Page 1

Catalog Number 8990

Sigma 900 MAX Refrigerated Sampler

INSTRUMENT MANUAL

07/03 4ed

Page 2

Page 3

Catalog Number 8990

Sigma 900 MAX Refrigerated Sampler

INSTRUMENT MANUAL

© Hach Company, 2002, 2003. All rights reserved. Printed in the U.S.A.

eac 07/03 4ed

Page 4

Visit http: //www.hach.com

Page 5

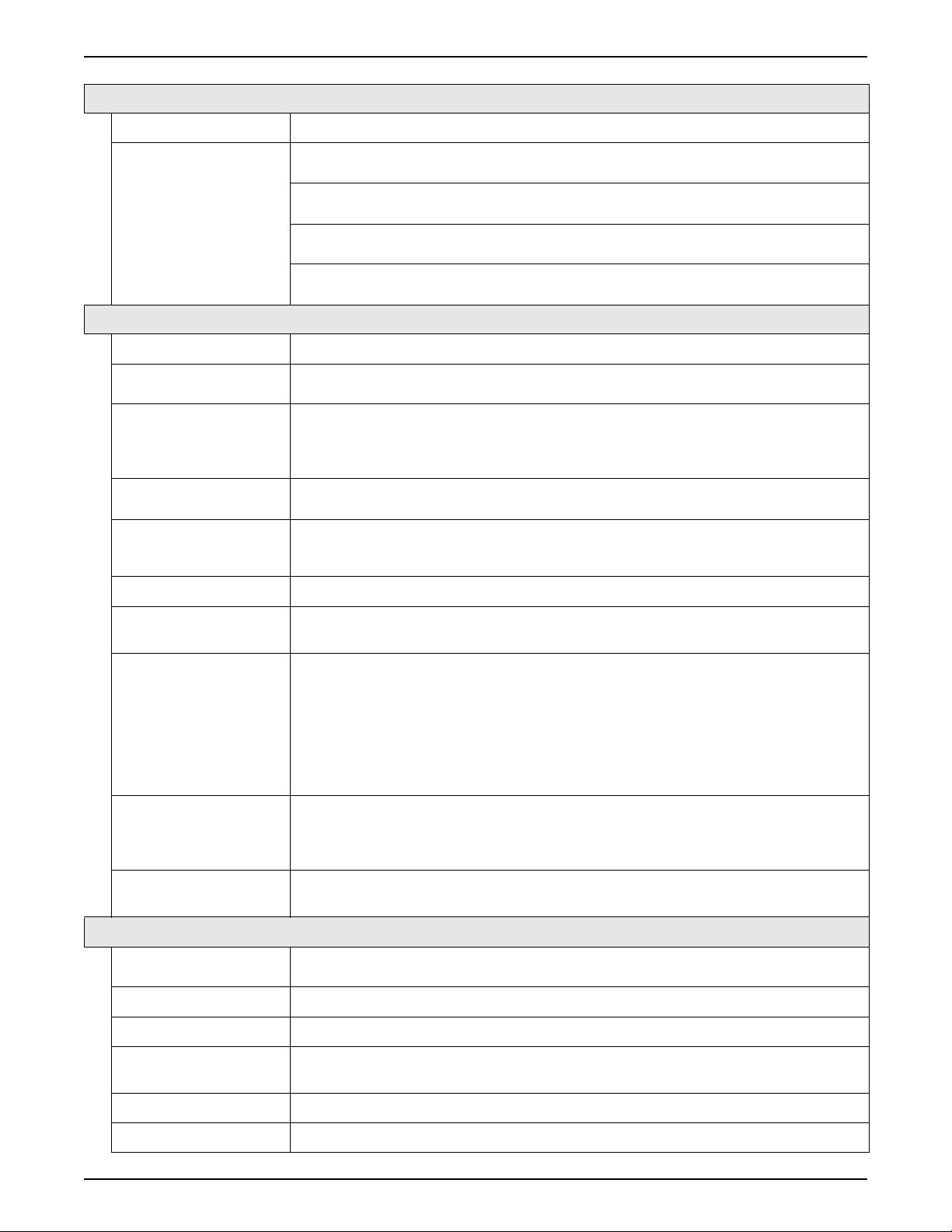

Table of Contents

Safety Precautions .................................................................................................................................................... 7

Specifications ............................................................................................................................................................ 9

Section 1 Introduction ...................................................................................................................................... 15

1.1 Controller Cover ................................................................................................................................................ 15

1.2 Front Panel........................................................................................................................................................ 15

1.2.1 Keypad Description.................................................................................................................................. 16

1.2.2 Liquid Crystal Display.............................................................................................................................. 16

1.2.3 Internal Humidity Indicator....................................................................................................................... 17

1.3 Interface Connectors......................................................................................................................................... 18

1.3.1 Receptacle Caps ..................................................................................................................................... 18

1.4 Principle of Operation ....................................................................................................................................... 19

1.4.1 Liquid Sensing ......................................................................................................................................... 19

INSTALLATION.................................................................................................................................................... 21

Section 2 Installation......................................................................................................................................... 23

2.1 Unpacking the Instrument ................................................................................................................................. 23

2.2 Selecting the Installation Site ............................................................................................................................ 23

2.3 Installing the Pump Tube in the Sensor Body ................................................................................................... 24

2.3.1 Attaching the Intake Line ......................................................................................................................... 25

2.3.1.1 Attaching the Vinyl Tubing .......................................................................................................... 25

2.3.1.2 Attaching the Teflon®-Lined Tubing ........................................................................................... 25

2.3.2 Setting Up the Intake Line and Strainer................................................................................................... 26

2.4 Choosing Bottle and Retainer Configurations ................................................................................................... 26

2.5 Setting Up the Bottles ....................................................................................................................................... 27

2.5.1 One-Bottle Sampling ............................................................................................................................... 27

2.5.2 Two- and Four-bottle Sampling................................................................................................................ 27

2.5.3 Eight-, 12-, or 24-bottle Sampling ............................................................................................................ 28

2.6 Installing the Distributor (Multiple Bottle Operation).......................................................................................... 29

2.6.1 Distributor Arm Alignment........................................................................................................................ 30

2.7 Installing the Full-Bottle Shut-Off Device (Single Bottle Operation) .................................................................. 31

2.8 Power Connections ........................................................................................................................................... 31

2.9 Auxiliary Receptacle Pin Identification .............................................................................................................. 32

2.9.1 Splitter Interface....................................................................................................................................... 33

OPERATION......................................................................................................................................................... 35

Section 3 Basic Programming Setup............................................................................................................ 37

3.1 Initial Power-Up of Sampler............................................................................................................................... 37

3.2 Basic Programming Setup ................................................................................................................................ 37

3.3 Advanced Sampling .......................................................................................................................................... 49

Section 4 Sensor Setup.................................................................................................................................... 61

4.1 Downlook Ultrasonic Sensor ............................................................................................................................. 61

4.1.1 Downlook Ultrasonic Sensor Connection ................................................................................................ 61

4.1.2 Downlook Ultrasonic Sensor Programming ............................................................................................. 61

Page 3

8990TOC.fm Table of Contents

Page 6

Table of Contents

4.1.3 Downlook Ultrasonic Sensor Calibration ................................................................................................. 61

4.1.3.1 Liquid Depth................................................................................................................................ 61

4.1.3.2 Sensor Height ............................................................................................................................. 62

4.1.3.3 Setting the Invisible Range ......................................................................................................... 62

4.2 Submerged Area/Velocity Sensor ..................................................................................................................... 63

4.2.1 Submerged Area/Velocity Sensor Connection......................................................................................... 63

4.2.2 Submerged Area/Velocity Sensor Programming ..................................................................................... 63

4.2.3 Submerged Area/Velocity Submerged Area/Velocity Sensor Calibration ................................................ 64

4.3 Submerged Pressure Sensor............................................................................................................................ 65

4.3.1 Submerged Pressure Sensor Connection ............................................................................................... 65

4.3.2 Submerged Pressure Sensor Programming............................................................................................ 66

4.3.3 Submerged Pressure Sensor Calibration ................................................................................................ 66

Section 5 Optional Device Installation.......................................................................................................... 69

5.1 Rain Gauge ....................................................................................................................................................... 69

5.1.1 Rain Gauge Programming ....................................................................................................................... 70

5.2 pH Probe........................................................................................................................................................... 70

5.2.1 pH Probe Connection .............................................................................................................................. 70

5.2.2 pH Probe Programming ........................................................................................................................... 71

5.2.3 pH Probe Calibration ............................................................................................................................... 71

5.3 ORP Probe........................................................................................................................................................ 72

5.3.1 ORP Probe Connection ........................................................................................................................... 72

5.3.2 ORP Probe Programming........................................................................................................................ 73

5.3.3 ORP Probe Calibration ............................................................................................................................ 73

5.3.3.1 ORP Preamplifier/Junction Box Calibration ................................................................................ 73

5.4 Dissolved Oxygen Probe................................................................................................................................... 74

5.4.1 Dissolved Oxygen Probe Connection ...................................................................................................... 74

5.4.2 Dissolved Oxygen Probe Programming................................................................................................... 74

5.4.3 Dissolved Oxygen Probe Temperature Programming ............................................................................. 75

5.4.4 Dissolved Oxygen Probe Calibration ....................................................................................................... 75

5.5 Conductivity Probe ............................................................................................................................................ 76

5.5.1 Conductivity Probe Connection ............................................................................................................... 76

5.5.2 Conductivity Probe Programming ............................................................................................................ 76

5.5.3 Conductivity Temperature Programming ................................................................................................. 76

5.5.4 Conductivity Probe Calibration ................................................................................................................ 77

Section 6 Communication Setup.................................................................................................................... 79

6.1 RS232 Cable..................................................................................................................................................... 79

6.1.1 RS232 Connection .................................................................................................................................. 79

6.1.2 RS232 Programming ............................................................................................................................... 79

6.2 Modem .............................................................................................................................................................. 80

6.2.1 Modem Connection ................................................................................................................................. 80

6.2.2 Modem Programming .............................................................................................................................. 80

6.2.2.1 Cellular Communication Option .................................................................................................. 81

6.2.2.2 Reliable Communications ........................................................................................................... 82

6.2.2.3 Cellular Modem Scheduling........................................................................................................ 82

6.2.2.4 Cellular Modem Scheduling Basis .............................................................................................. 83

6.2.2.5 Cellular Modem Triggering ......................................................................................................... 84

6.2.2.6 Pager Option............................................................................................................................... 84

6.2.2.7 Reporting Devices ...................................................................................................................... 85

Page 4

Table of Contents

8990TOC.fm

Page 7

Table of Contents

6.3 4–20 mA Option ................................................................................................................................................ 87

6.3.1 4–20 mA Connection ............................................................................................................................... 87

6.3.2 4–20 mA Programming............................................................................................................................ 87

6.3.3 4–20 mA Calibration ................................................................................................................................ 88

6.4 Alarm Relays..................................................................................................................................................... 89

6.4.1 Alarm Relays Connection ........................................................................................................................ 90

6.4.2 Alarm Relays Programming..................................................................................................................... 91

6.4.2.1 Trouble Alarms ........................................................................................................................... 91

6.4.2.2 Set Point Alarms ......................................................................................................................... 91

6.5 Analog Inputs .................................................................................................................................................... 93

6.5.1 Analog Inputs Connection ....................................................................................................................... 93

6.5.2 Analog Inputs Programming .................................................................................................................... 94

MAINTENANCE................................................................................................................................................... 95

Section 7 Maintenance ..................................................................................................................................... 97

7.1 Cleaning the Sampler ....................................................................................................................................... 97

7.1.1 Cleaning the Sampler Cabinet................................................................................................................. 97

7.1.2 Cleaning the Sample Bottles ................................................................................................................... 97

7.1.3 Cleaning the Intake Tubing and Pump Tubing ......................................................................................... 97

7.1.4 No Lubrication Required .......................................................................................................................... 97

7.2 Pump Tubing Maintenance................................................................................................................................ 97

7.2.1 Tubing Life Estimates............................................................................................................................... 97

7.2.2 Replacing Pump Tubing........................................................................................................................... 98

7.3 Upgrades, Repairs, General Maintenance ........................................................................................................ 98

Electrostatic Discharge (ESD) Considerations ................................................................................................. 99

7.4 Internal Maintenance Items............................................................................................................................... 99

7.5 Removing and Opening the Controller.............................................................................................................. 99

7.6 Re-installing the Bottom Panel........................................................................................................................ 100

7.7 Circuit Board Identification .............................................................................................................................. 101

7.8 Replacing the Fuse ......................................................................................................................................... 103

7.9 Motor/Gear Box............................................................................................................................................... 103

7.10 Internal Desiccant Module ............................................................................................................................ 103

7.10.1 Replacing the Desiccant...................................................................................................................... 103

7.11 Memory Battery ............................................................................................................................................ 104

Appendix A Quick Start Guides ......................................................................................................................... 105

Sigma 900 MAX Refrigerated Sampler Main Menu Flow Chart ..................................................................... 105

Sigma 900 MAX Refrigerated Sampler Setup Flow Chart.............................................................................. 106

Sigma 900 MAX Refrigerated Sampler Options Flow Chart........................................................................... 107

Sigma 900 MAX Refrigerated Sampler Advanced Sampling Flow Chart ....................................................... 108

Sigma 900 MAX Refrigerated Sampler Alarms Flow Chart ............................................................................ 109

Sigma 900 MAX Refrigerated Sampler Calibration Flow Chart (1 of 2) ......................................................... 110

Sigma 900 MAX Refrigerated Sampler Calibration Flow Chart (2 of 2) ......................................................... 111

Appendix B Programming Features .................................................................................................................. 113

Review All Items ............................................................................................................................................. 113

Running a Program ........................................................................................................................................ 113

Displaying Data .............................................................................................................................................. 113

Page 5

8990TOC.fm Table of Contents

Page 8

Table of Contents

Selecting the Channel .................................................................................................................................... 114

Tabular or Graph Format ................................................................................................................................ 114

Graph Manipulation ........................................................................................................................................ 115

Graphic Display Averaging ............................................................................................................................. 115

Sample History ............................................................................................................................................... 115

Options Menu Features .................................................................................................................................. 116

Setting the Time and Date.............................................................................................................................. 116

Volume Calibration ......................................................................................................................................... 116

Data Log ......................................................................................................................................................... 119

Logging Intervals ............................................................................................................................................ 119

Dynamic Memory Allocation ........................................................................................................................... 120

Data Logging Configuration ............................................................................................................................ 121

Diagnostics ..................................................................................................................................................... 121

Load Program................................................................................................................................................. 124

Screen Saver Mode ........................................................................................................................................ 124

Flow Totalizer ................................................................................................................................................. 125

Appendix C Troubleshooting and Error Messages............................................................................................ 127

Error Messages .............................................................................................................................................. 127

Trouble Alarm Conditions, Causes, and Solutions ......................................................................................... 129

Downlook Ultrasonic Sensor Troubleshooting................................................................................................ 130

pH Troubleshooting ........................................................................................................................................ 131

Sigma 900 MAX Refrigerated Sampler Troubleshooting Issues .................................................................... 132

Appendix D How to Calculate Pulses/Counts.................................................................................................... 133

Appendix E Exploded Drawings ........................................................................................................................ 137

Sigma 900 MAX Refrigerated Sampler Assembly Drawing (1 of 3) ............................................................... 137

Sigma 900 MAX Refrigerated Sampler Assembly Drawing (2 of 3) ............................................................... 138

Sigma 900 MAX Refrigerated Sampler Assembly Drawing (3 of 3) ............................................................... 139

Sigma 900 MAX Refrigerated Composite Sampler Assembly........................................................................ 140

Sigma 900 Composite Refrigerator Assembly................................................................................................ 141

Sigma 900 MAX Refrigerated Discrete Sampler Assembly............................................................................ 142

Sigma 900 Discrete Refrigerator Assembly.................................................................................................... 143

Transition Tray Assembly ............................................................................................................................... 144

Sigma 900 MAX Refrigerated Sampler Reference Dimensions ..................................................................... 145

GENERAL INFORMATION .............................................................................................................................. 147

Parts and Accessories .......................................................................................................................................... 149

Contact Information for U.S.A. and Outside Europe ............................................................................................. 153

Contact Information for Europe............................................................................................................................. 154

Warranty ............................................................................................................................................................... 155

Page 6

Table of Contents

8990TOC.fm

Page 9

Safety Precautions

Please read this entire manual before unpacking, setting up, or operating this instrument.

Pay particular attention to all danger and caution statements. Failure to do so could result in serious injury to the

operator or damage to the equipment.

To ensure the protection provided by this equipment is not impaired, do not use or install this equipment in any

manner other than that which is specified in this manual.

Use of Hazard Information

If multiple hazards exist, this manual will use the signal word (Danger, Caution, Note) corresponding to the

greatest hazard.

DANGER

Indicates a potentially or imminently hazardous situation which, if not avoided, could result in

death or serious injury.

CAUTION

Indicates a potentially hazardous situation that may result in minor or moderate injury.

NOTE

Information that requires special emphasis.

Precautionary Labels

Read all labels and tags attached to the instrument. Personal injury or damage to the instrument could occur if

not observed.

This symbol, if noted on the instrument, references the instruction manual for operation

and/or safety information.

This symbol, when noted on a product enclosure or barrier, indicates that a risk of electrical shock

and/or electrocution exists and indicates that only individuals qualified to work with hazardous voltages

should open the enclosure or remove the barrier.

This symbol, when noted on the product, identifies the location of a fuse or current limiting device.

This symbol, when noted on the product, indicates that the marked item can be hot and should not be

touched without care.

This symbol, when noted on the product, indicates the presence of devices sensitive to Electro-static

Discharge and indicates that care must be taken to prevent damage to them.

This symbol, when noted on the product, identifies a risk of chemical harm and indicates that only

individuals qualified and trained to work with chemicals should handle chemicals or perform

maintenance on chemical delivery systems associated with the equipment.

This symbol, if noted on the product, indicates the need for protective eye wear.

This symbol, when noted on the product, identifies the location of the connection for Protective Earth

(ground).

Page 7

8990saf.fm Safety Precautions

Page 10

Safety Precautions

Hazardous Locations

The Sigma 900 MAX Refrigerated Sampler is not approved for use in

hazardous locations as defined in the National Electrical Code.

DANGER

Although some Sigma products

are designed and certified for

installation in hazardous

locations as defined by the

National Electrical Code, many

Sigma products are not suitable

for use in hazardous locations. It

is the responsibility of the

individuals who are installing the

products in hazardous locations

to determine the acceptability of

the product for the environment.

Additionally, to ensure safety, the

installation of instrumentation in

hazardous locations must be per

the manufacturer's control

drawing specifications. Any

modification to the

instrumentation or the

installation is not recommended

and may result in life threatening

injury and/or damage to facilities.

Confined Space Entry

DANGER

Bien que certains produits Sigma soient conçus et certifiés pour être installés

dans des endroits dangereux tels que définis par le National Electric Code, de

nombreux produits Sigma ne conviennent pas pour de tels endroits. Il relève de

la responsabilité des personnes qui placent les produits dans des endroits

dangereux de déterminer s'ils sont adaptés à cet environnement. En outre, à des

fins de sécurité, le placement de machines dans des endroits dangereux doit

s'effectuer dans le respect des consignes des schémas de contrôle du fabricant.

Toute modification apportée aux machines ou tout déplacement de celles-ci est

déconseillé, car susceptible de provoquer des accidents matériels et/ou

corporels.

Important Note: The following

information is provided to guide

users of samplers on the dangers

and risks associated with entry into

confined spaces.

On April 15, 1993, OSHA's final ruling on CFR 1910.146, Permit Required

Confined Spaces, became law. This new standard directly affects more than

250,000 industrial sites in the United States and was created to protect the

health and safety of workers in confined spaces.

Definition of Confined Space

A Confined Space is any location or enclosure that presents or has the

immediate potential to present one or more of the following conditions:

• An atmosphere with less than 19.5% or greater than 23.5% oxygen

and/or more than 10 ppm Hydrogen Sulfide (H

• An atmosphere that may be flammable or explosive due to gases, vapors,

mists, dusts, or fibers

• Toxic materials which upon contact or inhalation, could result in injury,

impairment of health, or death

Confined spaces are not designed for human occupancy. They have restricted

entry and contain known or potential hazards. Examples of confined spaces

include manholes, stacks, pipes, vats, switch vaults, and other similar

locations.

Standard safety procedures must always be followed prior to entry into

confined spaces and/or locations where hazardous gases, vapors, mists,

dusts, or fibers may be present. Before entering any confined space check

with your employer for procedures related to confined space entry

S)

2

Page 8

Safety Precautions

8990saf.fm

Page 11

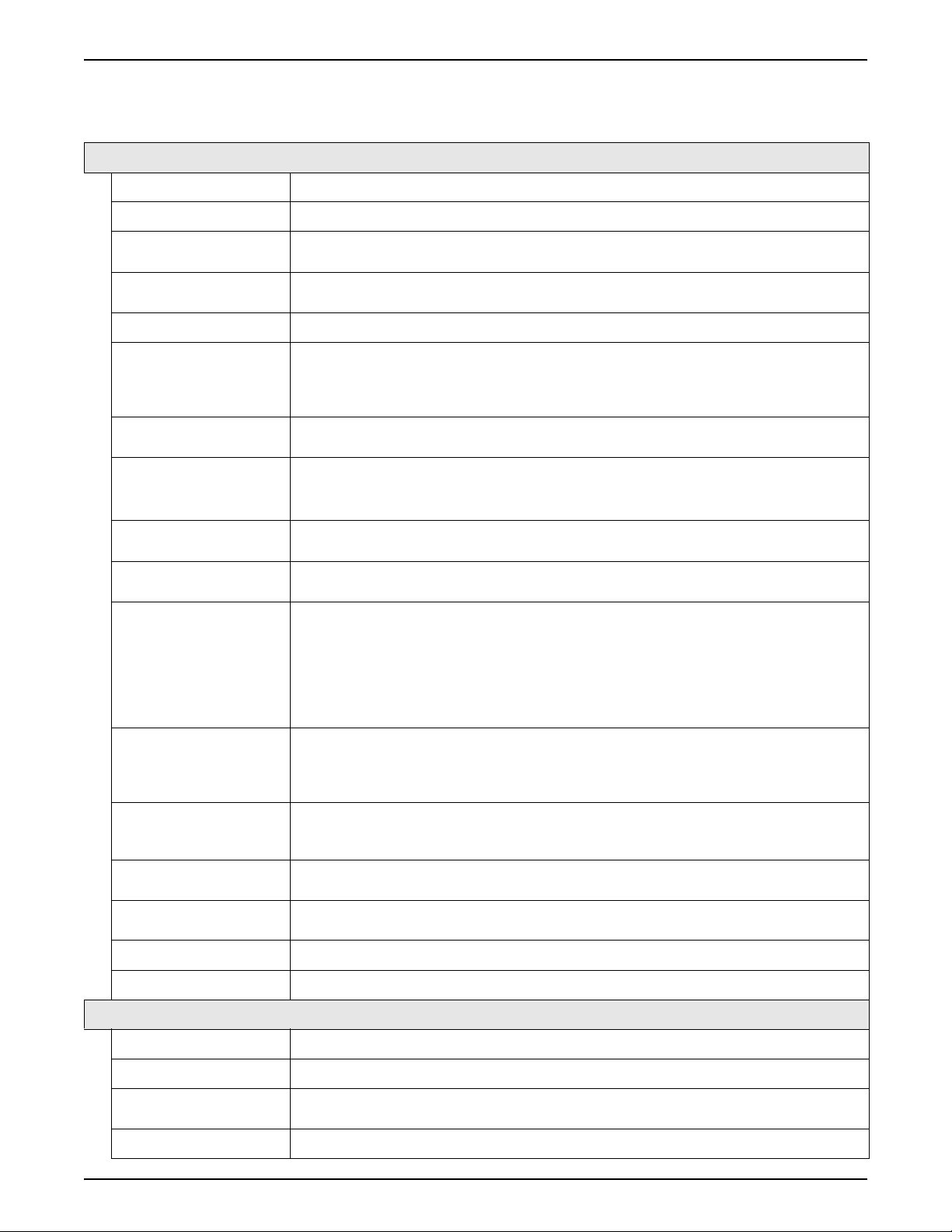

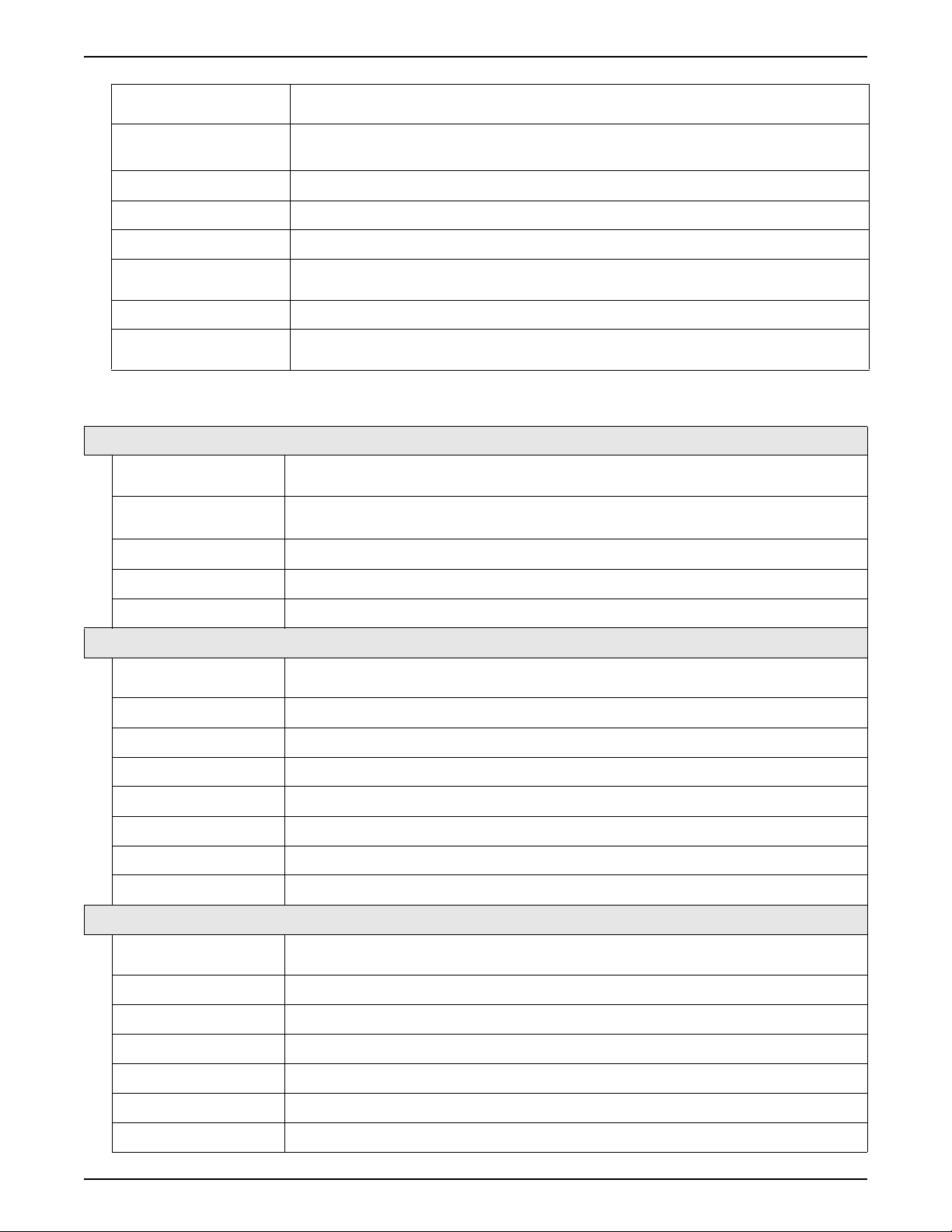

Specifications

Specifications are subject to change without notice.

General

Dimensions Width 61 cm (24 in.), Depth 61 cm (24 in.), Height 110 cm (43.5 in.), Weight 63.3 kg (140 lb)

Cabinet Fiberglass reinforced plastic with beige UV inhibited polymer laminate.

Temperature Range

Recovery Time

Pull-Down Time From 24 °C (75 °F) to 4 °C (39 °F), 15 minutes.

Thermal System

Power Requirements

Optional ac

Power Backup

(Pump Controller Only)

Internal Battery

Control Panel

Data Logging

Set Point Sample Trigger

Sampling Modes

Program Delay

Overload Protection

Diagnostics Tests keypad, display, ROM, pump, liquid sensors, velocity signal, and distributor.

-29 to +50 °C (-20 to 122 °F); With optional controller compartment heater, -40 to +50 °C

(-40 to 122 °F).

With door open one minute in 24 °C (75 °F) ambient and 4 °C sample temperature, 5

minutes.

Top mounted compressor/condenser with fan forced air cooled condenser; three-sided

wrap-around evaporator plate; 2 in. rigid foam insulation; microprocessor controlled

thermostat maintains sample liquid at 4 °C (±1 °C); frost free; compression gasket door seal;

refrigeration components and plumbing are corrosion protected with conformal coating.

115 V ac, 60 Hz (230 and 100 V ac optional); Compressor Running Amperage 1.5–2.0 A.

Locked rotor current 12 amps. Installation Category II.

Pump/Controller Only: Rechargeable 6 amp-hour gel lead acid battery takes over

automatically with ac line power failure. Integral trickle charger maintains battery at full

charge (factory installed option).

Two C cell alkaline batteries; maintains program logic and real time clock for five years.

Internal battery current draws less than 40 micro amps.

21 key membrane switch keypad with 4 multiple function soft keys; 8 line x 40 character

alphanumeric, back lit liquid crystal graphics display. Self prompting/menu driven program.

Records program start time and date, stores up to 400 sample collection times/dates, all

program entries, operational status including number of minutes or pulses to next sample,

bottle number, number of samples collected, number remaining, sample identification

number, and all logged data (i.e. level, flow, pH, stream temperature, refrigerated

compartment sample temperature, ORP, rainfall, and any externally logged data - up to 7

external channels). Also, up to 200 events are logged, including alarm conditions, program

run/stop events, etc.

When equipped with integral flow meter, pH/temperature/ORP meter, conductivity, and/or

D.O. monitoring options, sampling can be triggered upon an upset condition when field

selectable limits are exceeded. Concurrent with normal sampling routine, sample liquid is

deposited in designated “trouble bottle(s)”.

Multiple Bottle Time, Multiple Bottle Flow, Composite Multiple Bottle Time, Composite

Multiple Bottle Flow, Composite Time, Composite Flow, Flow with Time Override, Variable

Interval, Start/Stop, and Level Actuation.

Three formats: (1) 1-9,999 minutes or flow pulses in one unit increments (2) programmable

sampler start time/date, and (3) programmable time/day of week.

Controller: 5 amp dc line fuse. Compressor: Thermal overload relay opens at

110 °C (230 °F).

Program Lock Access code protection precludes tampering.

Communications

EPROM Flash Memory Via RS232. Permits embedded software upgrades in the field.

Serial Interface RS232 compatible; allows on-site collection of stored data.

Modem (optional)

Pager Alarm codes sent to up to three separate pagers’ telephone numbers.

8990spc.fm Specifications

14400, V.32 bis, V.42, MNP2-4 error correction. V.42 bis MNP5 data compression.

MNP10-EC Cellular Protocol.

Page 9

Page 12

Specifications

Sample Bottle Capacity

Single Bottle Mode 6 gal polyethylene (with polypropylene cap)

Two Bottle Sampling: Set of two 2.5 gal glass (with Teflon®-lined lid) or

3 gal polyethylene bottle (with polypropylene cap)

Four Bottle Sampling: Set of four 2.5 gal glass (with Teflon-lined lid) or

Multiple Bottle Mode

Sampling Features

Multiple Programs Stores up to five separate sampling programs.

3 gal polyethylene bottles (with polypropylene cap)

Eight Bottle Sampling: Set of eight 1.9 liter glass bottles (with Teflon-lined lid) or

2.3 L polyethylene bottles (with polypropylene cap)

Twenty-four Bottle Sampling: Set of twenty-four 350 mL glass bottles (with Teflon-lined lid) or

1000 mL polyethylene bottles (with polypropylene cap)

Cascade

Allows using two samplers in combination where the first sampler at the completion of the

program initiates the second.

When equipped with integral flow meter, pH/temperature/ORP meter, conductivity, and/or

Upset Sampling

D.O. monitoring options, sampling can be triggered upon an upset condition when field

selectable limits are exceeded, concurrent with normal sampling routine, sample liquid is

deposited in designated “trouble bottle(s)”. Can also be triggered from an external trigger.

Status Output

Alerts operator to low main battery, low memory power, plugged intake, jammed distributor

arm, sample collected, and purge failure.

Multiple Bottle Mode: After complete revolution of distributor arm (unless Continuous Mode

Automatic Shutdown

selected). Composite Mode: After preset number of samples have been delivered to

composite container, from 1–999 samples, or upon full container.

Sample Volume Programmed in milliliters, in one mL increments from 10 to 9999 mL.

Sample Volume

Repeatability

±5% typical

Time Proportional Sampling: Selectable in single increments from 1 to 9999 minutes in one

minute increments.

Flow Proportional Sampling: Continuous Volume, Variable Time (CVVT): 1 to 9999 “units” of

Sampling Interval

flow volume, where “units” are whatever is set up for in the integral flow option or -1 to 9999

external-meter flow pulses: (momentary contact closure 25 msec. Or 5–12 V dc pulse;

4–20 mA interface optional)

Flow Proportional Sampling: Constant Time, Variable Volume (CTVV):

Format: 999: 00 hrs:min. Selectable in 1-minute increments of 1 to 59,940 minutes.

Selectable in single increments form 1 to 9,999 flow pulses (momentary contact closure

Interval Between

Samples

25 msec. or 5–10 V dc pulse; 4–20 mA interface optional), or 1 to 9,999 minutes in one

minute increments, or 1 to 9,999,999 “units” of volume, where “units” are whatever is set up

for the integral flow option.

Multiplex (Multiple Bottle

Mode)

Multiple Bottle Mode: Programming allows multiple samples per bottle and/or multiple bottles

per sample collection.

Sample Pump and Strainer

Sample Pump

Pump Body

High speed peristaltic, dual roller, with

pump tube.

Impact/corrosion resistant, glass reinforced Delrin®

3

/8 in. ID by 5/8 in. OD medical grade silicone rubber

Vertical Lift 27 ft maximum (Remote Pump Option recommended for lifts from 22 to 35 ft).

Sample Transport

Velocity

2 fps minimum, at 15 ft vertical lift in a

Pump Flow Rate 60 mL/sec at 3 ft vertical lift in a

3

/8 in. ID intake tube.

3

/8 in. ID intake line.

Liquid Sensor Non-wetted, non-contact, ultrasonic.

Page 10

Specifications

8990spc.fm

Page 13

Specifications

Intake Purge

Pump/Controller

Housing

Internal Clock Indicates real time and date; 0.007% time base accuracy.

Manual Sample Initiates a sample collection independent of program in progress.

Intake Rinse Intake line automatically rinsed with source liquid prior to each sample, from 0 to 3 rinses.

Intake Retries

Intake Tubing ¼ in. and 3/8 in. ID vinyl or 3/8 in. ID Teflon* lined polyethylene with protective outer cover.

Intake Strainers

Air purged automatically before and after each sample; duration automatically compensates

for varying intake line lengths.

High impact injection molded ABS; submersible, watertight, dust tight, corrosion & ice

resistant; NEMA 4X,6.

Sample collection cycle automatically repeated from 0 to 3 times if sample is not obtained on

initial attempt.

®

Choice of Teflon

and low profile for shallow depth applications.

and 316 stainless construction, and all 316 stainless steel in standard size

Factory Installed Options

pH/Temperature/ORP Meter

Control/Logging

pH/Temperature Sensor

Measurement Range 0 to 14 pH, -10 to 105 °C

Field selectable to log pH/temperature or ORP independent of sample operation or to control

sample collection in response to volume exceeding low/high setpoints.

Temperature compensated; impact resistant ABS plastic body

Combination electrode with porous Teflon junction

Operating Temperature -18 to 80 °C (0 to 176 °F)

Dimensions 1.9 cm dia. × 15.2 cm long (0.75 in. × 6 in.) with 1.9 cm (0.75 in.) mpt cable end

Dissolved Oxygen Meter

Control/Logging

Measurement Method Galvanic

Sensor Temperature compensated; impact resistant polypropylene body

Measurement Range 0 to 20 mg/L

Resolution 0.01 mg/L

Accuracy ±3% of reading or 0.1 mg/L

Operating Temperature 0 to 50 °C (32 to 122 °F)

Dimensions 1.7 mm diameter × 15.7 cm long (0.65 in. × 6.25 in.) with 1.9 cm (0.75 in.)

Conductivity Meter

Control/Logging

Sensor Temperature compensated; impact resistant polypropylene body

Measurement Range 0 to 20 mS/cm

Field selectable to log dissolved oxygen independent of sampler operation or to control

sample collection in response to volume exceeding low/high setpoints.

Field selectable to log conductivity independent of sampler connection or to control sample

collection in response to volume exceeding low/high setpoints.

Resolution 0.01 mS/cm or 1 mS/cm

Accuracy ±2% of reading or 0.01 mS

Operating Temperature 0 to 50 °C (32 to 122 °F)

Dimensions 1.7 cm diameter × 15.2 cm long (0.67 in. x 6 in.) with 1.9 cm (0.75 in.) mpt cable end

Page 11

8990spc.fm Specifications

Page 14

Specifications

Rain Gauge Input

For use with the Tipping Bucket Rain Gauge.

General Information

Analog Input Channels

General Information

4–20 mA Output

General Information

Maximum Resistive

Load

Output Voltage 24 V dc–no load

The Sampler Program can be initiated upon field selectable rate of rain.

Sampler records rainfall data.

Each tip = 0.25 mm (0.01in.) of rain.

Up to 3 additional data logging channels record data from external source(s)

Field assignable units

-4.0 to +4.0 V dc and 0 to 20 mA

Up to 2 output signals available.

User assignable

600 ohms

Insulation Voltage

Alarm Relays

General Information

Downlook Ultrasonic Sensor 40 kHz

Accuracy 0.003 m (±0.01 ft)

Maximum Range 3.35 m (11 ft) with a 3.05 m (10 ft) span

Deadband 38 cm (15 in.) maximum, self-minimizing

Material PVC housing with Buna-N acoustic window

Cable 4 conductor with integral stainless steel support cable

Submerged Pressure Transducer

Material Epoxy body with stainless steel diaphragm.

Cable Polyurethane sensor cable with air vent.

Cable Length 7.6 m (25 ft) standard; 76 m (250 ft) maximum

Between flow meter and 4–20 mA output—2500 V ac

Between the two 4–20 mA outputs—1500 V ac

(4) 10 amp/120 V ac or 5 amp/220 V ac form C relays

±0.1% FS Error

User assignable for any internal or external data channel or event.

Sensor Dimensions 2 cm H x 3.8 cm W x 12.7 cm L (0.8 in. x 1.5 in. x 5 in.)

Maximum Range

Maximum Allowable

Level

Operating Temperature

Range

Compensated

Temperature Range

Air Intake Atmospheric pressure reference is desiccant protected.

Page 12

Specifications

5 psi, 0.063 to 3.5 mm (0.018 to 11.5 ft)

15 psi, 0.063 m to 10.5 m (0.018 to 34.6 ft)

3x over pressure

0 to 71 °C (32 to 160 °F)

0 to 30 °C (32 to 86 °F)

8990spc.fm

Page 15

Submerged Area/Velocity Probe

Method Doppler Principle/Pressure Transducer.

Material Polymer body, 316 series stainless steel diaphragm.

Cable 8-conductor urethane sensor cable with air vent.

Cable Length 7.6 m (25 ft) standard

Length: 12.7 cm (5 in.)

Sensor Dimension

Velocity

Depth

Width: 3.8 cm (1.5 in.)

Height: 2 cm (0.8 in.)

Velocity accuracy: 2% of reading; Zero Stability: <0.015 mps (<0.05 fps).

Response time: 4.8 seconds.

Profile Time: 4.8 seconds.

Range: -1.52 to 6.1 mps (-5 to +20 fps).

Resolution: 0.3 cm (0.01 fps).

Depth Accuracy: 0–3.35 m (0–11 ft) 1.37 mm (±0.054 in.)

0–10.06 m (0–33 ft) 4.09 mm (±0.161 in.)

Maximum Allowable Level: 3x over pressure.

Operating Temperature Range: 0 to 71 °C (32 to 160 °F).

Compensated Temperature Range: 0 to 30 °C (32 to 86 °F).

Temperature Error:

0.005 to 3.5 m ±0.0022 m/°C (0.018 to 11.5 ft ±0.004 ft/°F)

0.005 to 10.5 m ±0.006 m/°C (0.018 to 34.6 ft ±0.012 ft/°F)

(maximum error w/in compensated temperature range - per degree of change)

Velocity Induced Error on Depth (patent pending):

0 to 3.05 mps (0 to 10 fps) = 0.085% of reading.

Air Intake: Atmospheric pressure reference is desiccant protected.

Specifications

Page 13

8990spc.fm Specifications

Page 16

Visit http: //www.hach.com

Page 17

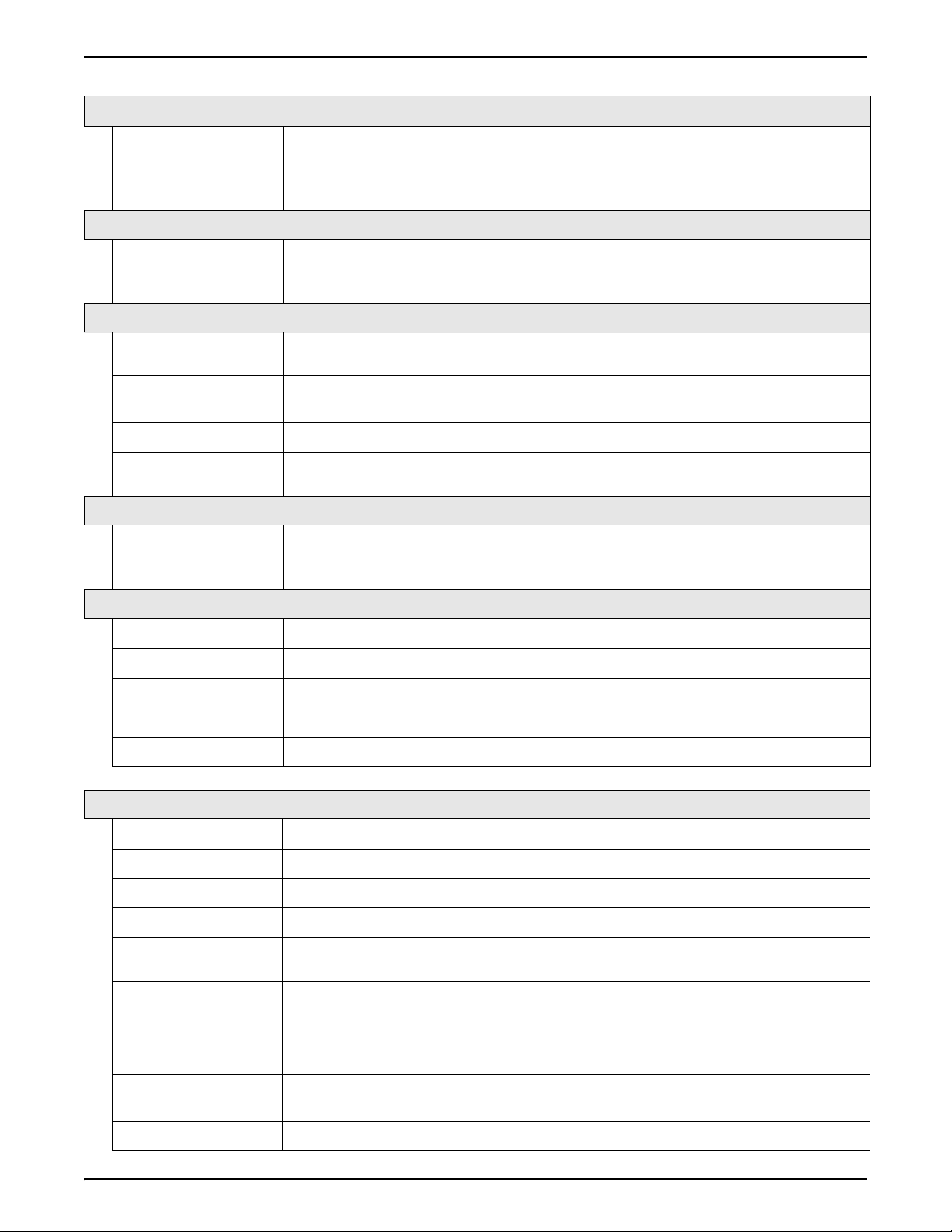

Section 1 Introduction

1.1 Controller Cover

The controller is mounted on top of a specially designed refrigerator. The

sample line passes through the top of the refrigerator and into the refrigerated

compartment where the sample containter(s) are located. The compartment

is surrounded by rigid foam insulation and utilizes a 120 CFM condenser fan.

An optional controller cover locks and protects the controller from damage

and unauthorized users.

Sample temperature is controlled by an adjustable air sensing thermostat

maintaining samples at 4 °C (39 °F) in ambients up to 50 °C (120 °F). The unit

has a magnetic door seal and does not require rear ventilation. The

refrigerator interior is food grade plastic and the exterior is coated galvanized

steel (304 stainless steel is optional). As a further barrier against corrosion,

the refrigeration components and copper plumbing are treated with phenolic

resin coating.

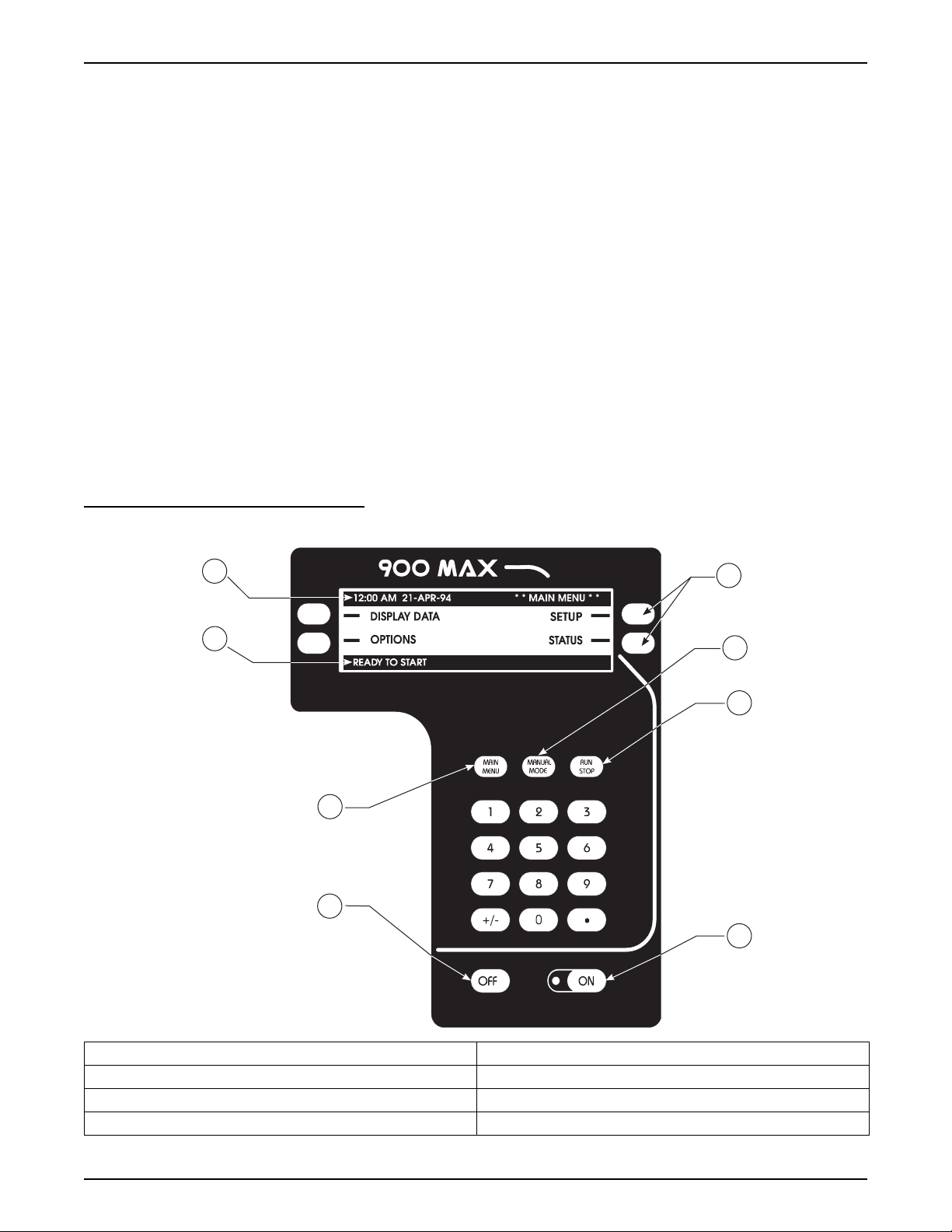

1.2 Front Panel

The front panel (Figure 1) of the sampler consists of the keypad, liquid crystal

display, and the internal case humidity indicator.

Figure 1 Front Panel

8

7

1

2

3

6

5

4

1. Soft Keys 5. Power OFF Key

2. Manual Mode Key 6. Main Menu Key

3. Run/Stop Key 7. Status Bar

4. Power ON Key 8. Menu Bar

Page 15

8990int.fm Introduction

Page 18

Section 1

1.2.1 Keypad Description

The keypad includes the numeric keypad, soft keys, and function keys.

Numeric Keypad

The numeric keypad consists digits 0 through 9, a +/- key, and a decimal key.

“Soft” Keys

Soft keys are blank, white keys located to the left and right of the display. If no

function is shown for a specific key, that key is not currently active. The soft

key labels appear on the display and indicates (with a straight line) the proper

soft key to push for that action.

In some cases during a programming step an item from a list needs to be

selected. The soft keys on the right side of the display will change to display

UP and DOWN arrows. Scroll through the list of choices.

Power ON/OFF Key

To turn the instrument on, press the

on, a green light located next to the

sampler power is turned on. To turn the instrument off, press the

ON key. When the instrument is turned

ON key flashes to indicate that the

OFF key.

Function Keys

Three white function keys (Tab l e 1 ) are located just above the numeric keypad

re used often while operating the sampler. These functions are dedicated

keys to allow quick access.

Table 1Function Key Descriptions

Function Key Description

Main Menu

This is the starting point to get to any other point in the program. Press the Main Menu key at any time

during programming to return to the Main Menu Screen. The current action is cancelled if changes are not

yet accepted.

Manual Mode

Manually controls the operation of the sample pump and the distributor arm.

ADVANCED DISTRIBUTOR soft key: Moves the distributor arm to the user selected bottle. Used to verify the

operation of the distributor or when repositioning the arm if it was moved by hand.

GRAB SAMPLE soft key: Takes a sample in the same manner as when a program is running. Includes all

pre-rinses and sample retries, if programmed.

PUMP OPERATION soft key: Allows manual control of the pump in both forward and reverse directions. Once

started, the pump is stopped by pressing any key.

Run/Stop

Runs (or resumes) a program and stops a currently running program.

1.2.2 Liquid Crystal Display

The liquid crystal display (LCD) works in conjunction with the four soft keys.

When a soft key changes function, the display shows the new function.

Page 16

Front Panel

Menu Bar

The Menu Bar appears in a black band on the top edge of the display.

The upper left corner of the menu bar shows the time and date. The upper

right corner shows the name of the current menu (Figure 1).

8990int.fm

Page 19

Status Bar

The Status Bar appears along the bottom edge of the display.

The appearance of the status bar changes depending upon the

function performed (Figure 1). The lower left corner of the Status Bar

indicates whether a program is Complete, Running, Halted, or Ready To Start.

If it is not needed during a programming step, it disappears.

The lower right corner displays system alarm conditions, such as low memory

battery, jammed distributor etc. For a list of possible alarms refer to

section 6.4 on page 89. The status bar also lists the valid choices when

entering certain programming information.

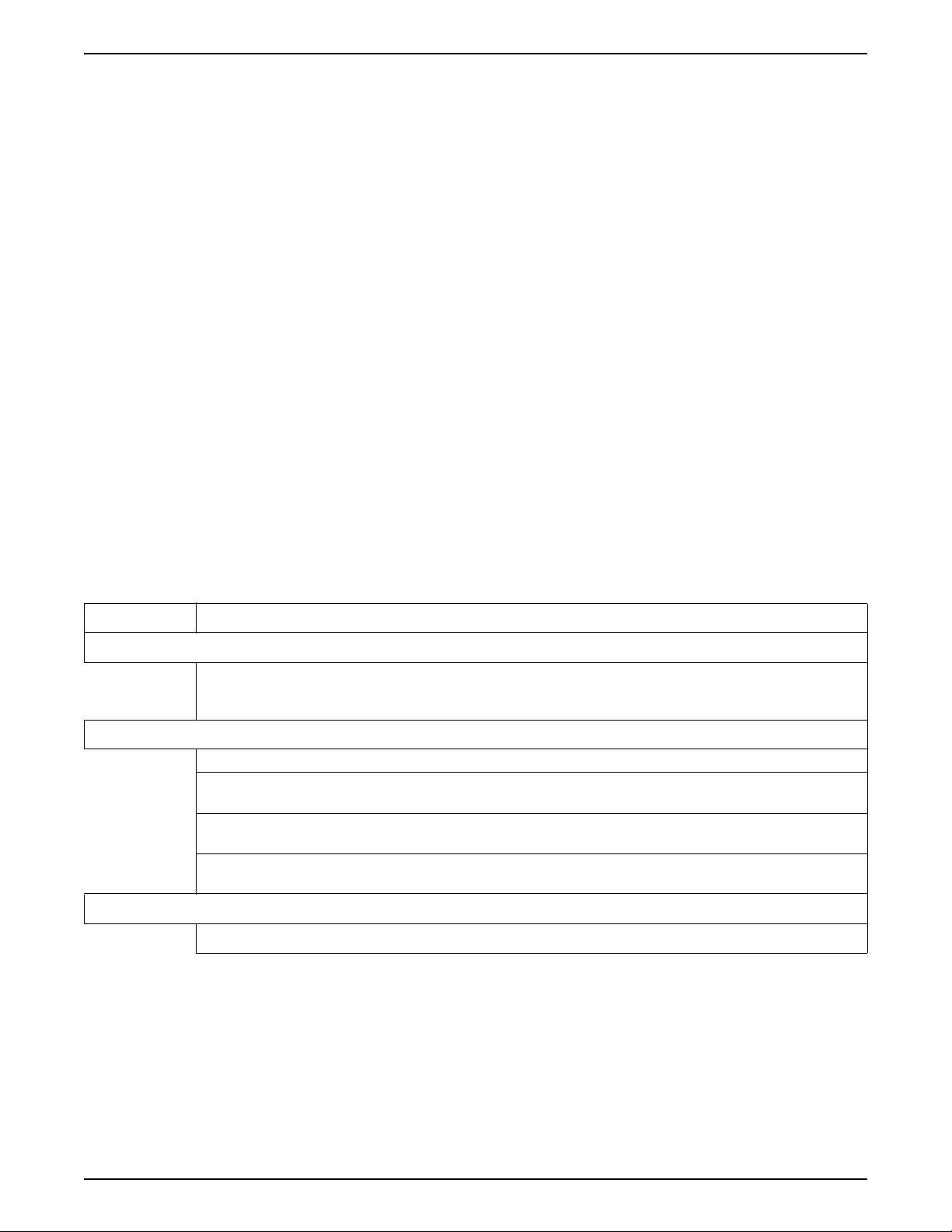

1.2.3 Internal Humidity Indicator

The round window of the internal case humidity indicator (Cat. No. 2660)

turns pink when the internal case humidity exceeds 60 percent.

The sampler is equipped with an internal desiccant module (Cat. No. 8849) to

absorb any humidity that may have been trapped in the case during final

assembly. Under normal operating conditions, this desiccant provides longterm protection against condensed moisture inside the case.

Replacement of the internal desiccant module is only necessary if the

indicator turns pink. (Refer to section 7.10 on page 103 for details on

replacing the internal desiccant.)

Section 1

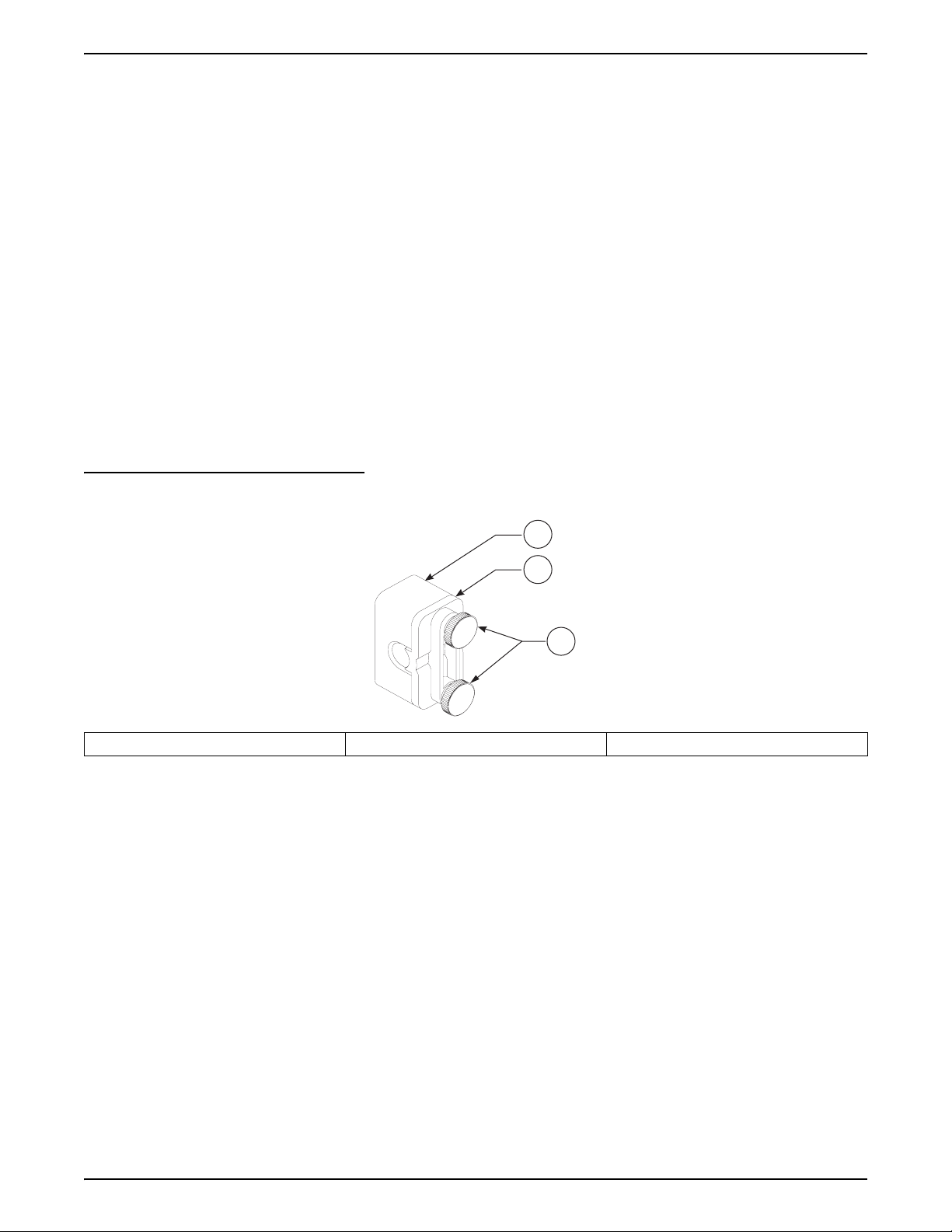

Figure 2 Humidity Indicator

Internal Humidity

Replace

Desiccant

When

Pink

Page 17

8990int.fm Front Panel

Page 20

Section 1

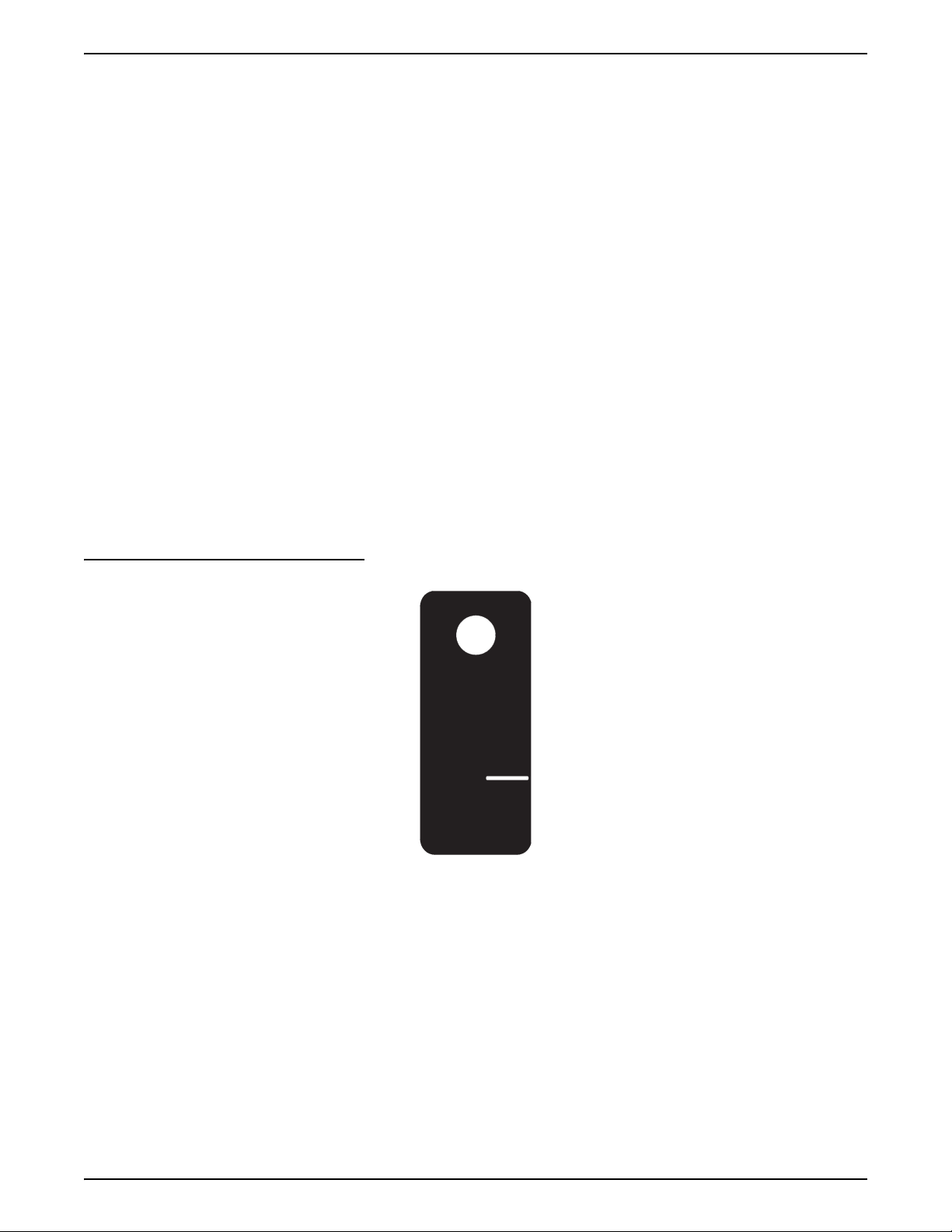

1.3 Interface Connectors

1

2

3

Interface connectors are located on the left side of the controller housing. An

optional weather tight terminal box located on the back of the sampler

provides conduit termination for all input/output lines.

1. 12 V dc 2. RS232 3. Auxiliary

The sampler comes standard with two interface receptacles.

• 12 V dc (Power Input)

• Auxiliary (Multi-purpose input/output port)

• RS232 (Serial communications port)

• Thermal (Control port for heating and cooling system)

In addition, the sampler can be used with a wide variety of optional devices:

• Level and Flow Monitoring

(Sensors)

• pH/ORP • 4–20 mA Current Loop Output

• Conductivity • Modem

• Dissolved Oxygen • Rain Gauge

• Temperature

Three additional analog inputs of

4–20 mA or -4.0 V dc to +4.0 V dc

1.3.1 Receptacle Caps

Page 18

Interface Connectors

Interface receptacles are covered with push-on receptacle caps. These caps

protect the connector pins from dirt and moisture and should be attached to

any receptacle not in use.

8990int.fm

Page 21

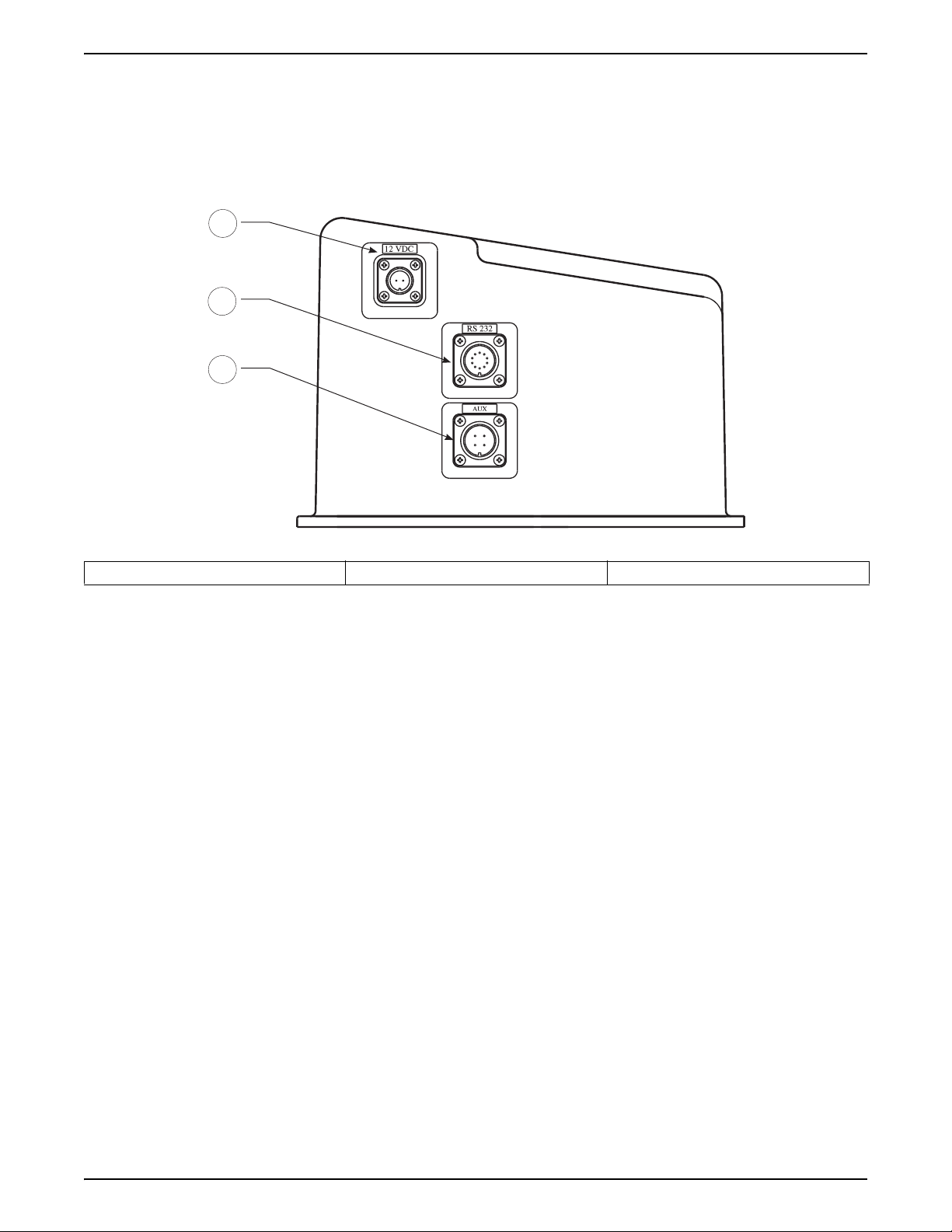

1.4 Principle of Operation

1.4.1 Liquid Sensing

The sampler is designed for indoor, permanent installation. All controls are

located on the front panel. Capped, watertight connectors for interfacing to

external devices are located along the left side of the controller.

The sampler uses a liquid sensing system to detect the absence or presence

of liquid at the peristaltic pump intake. The liquid sensor (Figure 3) is located

on the front of the control housing.

The liquid sensing system provides three primary benefits:

• Accurate, repeatable sample volumes

• Intake tube prerinse

• Sample retry

Figure 3 Liquid Sensor

Section 1

1

2

3

1. Sensor Body 2. Sensor Cover 3. Knobs (turn to remove)

Accurate, Repeatable Sample Volumes

The liquid sensor detects the presence and velocity of the incoming sample.

This information allows the sampler to automatically dispense the correct

amount of liquid into the sample bottle.

The liquid sensing system allows the sampler to deliver repeatable sample

volumes even with changing suction lifts. Each time the peristaltic pump pulls

a sample, the microprocessor determines the time required for liquid to travel

to the liquid sensor. If the suction lift increases due to a drop in level at the

sample source, the time required for liquid to reach the sensor will increase.

The microprocessor automatically compensates for this change by allowing

the peristaltic pump to deliver sample liquid for a corresponding longer period

of time. Conversely, if suction lift decreases due to an increase in level at the

sample source, the time required for liquid to the sensor will decrease. Again,

the microprocessor automatically compensates for this change by decreasing

the sample delivery time.

Page 19

8990int.fm Principle of Operation

Page 22

Section 1

Intake Tube Pre-Rinse

The liquid sensor also rinses the intake tubing with the liquid from the sample

source before taking each sample.

Upon sample initiation, the pump purges the intake line. The pump then

reverses, pulling liquid through the tubing, until it reaches the liquid sensor.

When the sensor detects liquid, the pump purges back to the source, and

then draws a sample. After the desired sample is collected, the pump purges

the intake line and awaits the next sample cycle. The sampler can be

programmed for up to 3 rinses before each sample.

Sample Retry

The liquid sensing system permits the sampler to repeat a collection cycle if a

sample is not obtained during the regular cycle.

The intake line length is user-programmed into the sampler memory. For a

line length of 3 to 99 feet, the sampler has a built-in “look up” table that

detects the maximum time required for liquid to reach the sensor. If liquid

does not reach the sensor within the defined time period, the pump will

automatically purge the intake line and initiate another sample cycle. The

sampler may be programmed for up to three repeated attempts. If a sample is

not obtained, the sampler retains in memory the time, date and reason for the

missed sample.

Page 20

Principle of Operation

8990int.fm

Page 23

INSTALLATION

DANGER

Some of the following manual sections contain information in the form of warnings, cautions and notes

that require special attention. Read and follow these instructions carefully to avoid personal injury and

damage to the instrument. Only personnel qualified to do so, should conduct the installation/maintenance

tasks described in this portion of the manual.

DANGER

Certains des chapitres suivants de ce mode d’emploi contiennent des informations sous la forme

d’avertissements, messages de prudence et notes qui demandent une attention particulière. Lire et suivre

ces instructions attentivement pour éviter les risques de blessures des personnes et de détérioration de

l’appareil. Les tâches d’installation et d’entretien décrites dans cette partie du mode d’emploi doivent être

seulement effectuées par le personnel qualifié pour le faire.

PELIGRO

Algunos de los capítulos del manual que presentamos contienen información muy importante en forma de

alertas, notas y precauciones a tomar. Lea y siga cuidadosamente estas instrucciones a fin de evitar

accidentes personales y daños al instrumento. Las tareas de instalación y mantenimiento descritas en la

presente sección deberán ser efectuadas únicamente por personas debidamente cualificadas.

GEFAHR

Einige der folgenden Abschnitte dieses Handbuchs enthalten Informationen in Form von Warnungen,

Vorsichtsmaßnahmen oder Anmerkungen, die besonders beachtet werden müssen. Lesen und befolgen

Sie diese Instruktionen aufmerksam, um Verletzungen von Personen oder Schäden am Gerät zu

vermeiden. In diesem Abschnitt beschriebene Installations- und Wartungsaufgaben dürfen nur von

qualifiziertem Personal durchgeführt werden.

PERICOLO

Alcune parti di questo manuale contengono informazioni sotto forma d’avvertimenti, di precauzioni e di

osservazioni le quali richiedono una particolare attenzione. La preghiamo di leggere attentivamente e di

rispettare quelle istruzioni per evitare ogni ferita corporale e danneggiamento della macchina. Solo gli

operatori qualificati per l’uso di questa macchina sono autorizzati ad effettuare le operazioni di

manutenzione descritte in questa parte del manuale.

Page 21

8990i_stop.fm INSTALLATION

Page 24

Visit http: //www.hach.com

Page 25

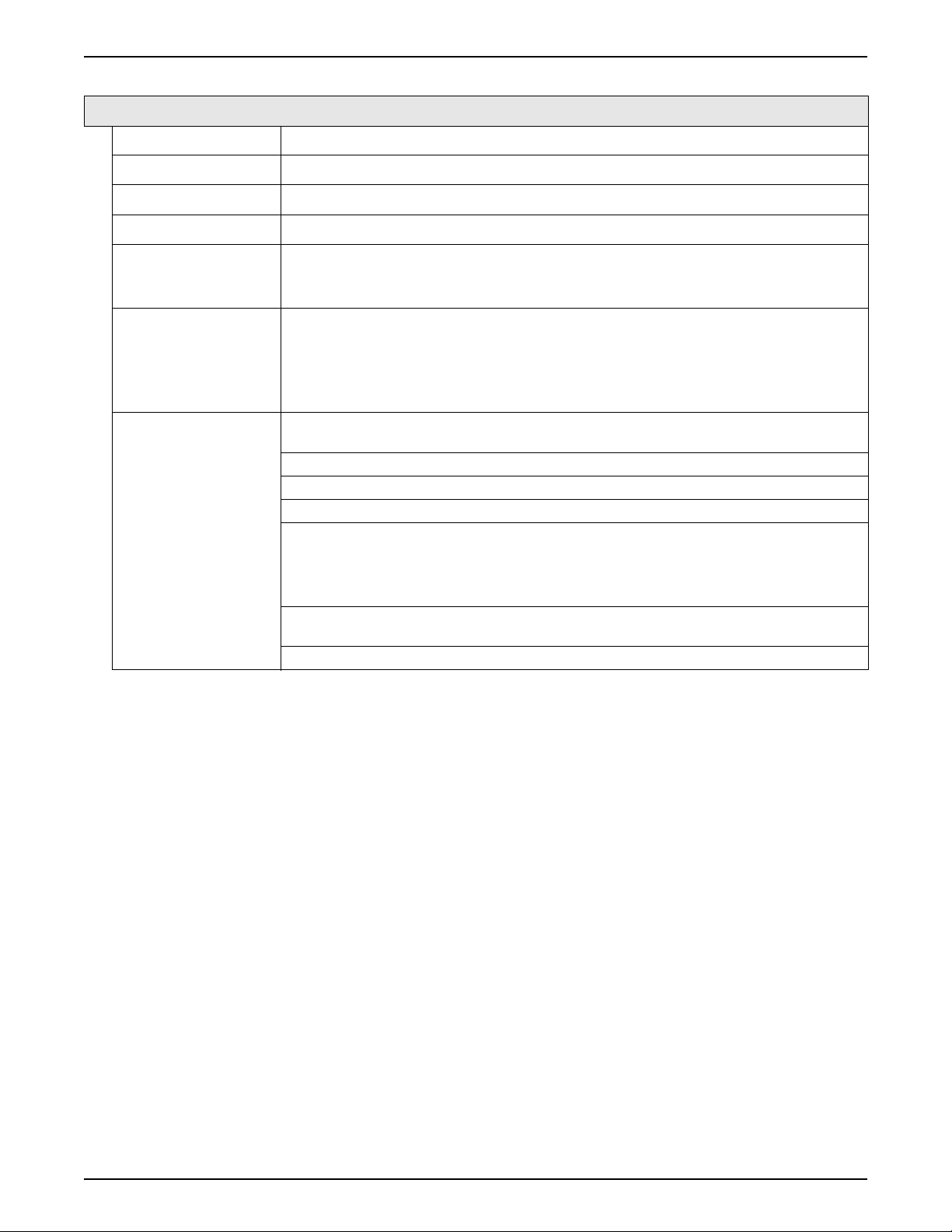

Section 2 Installation

DANGER

This instrument should be

installed by qualified technical

personnel to ensure adherence to

all applicable electrical codes.

DANGER

Cet appareil doit être installé par du personnel technique qualifié, afin d'assurer

le respect de toutes les normes applicables d'électricité.

2.1 Unpacking the Instrument

Remove the sampler from the shipping carton and inspect it for any damage.

Contact Hach Customer Service at 1-800-227-4224 if any items are missing

or damaged.

2.2 Selecting the Installation Site

DANGER

This product is not designed for

hazardous locations where

combustible environments may

exist.

DANGER

Ce produit n'est pas conçu pour des endroits dangereux dans lesquels il peut

exister des environnements combustibles.

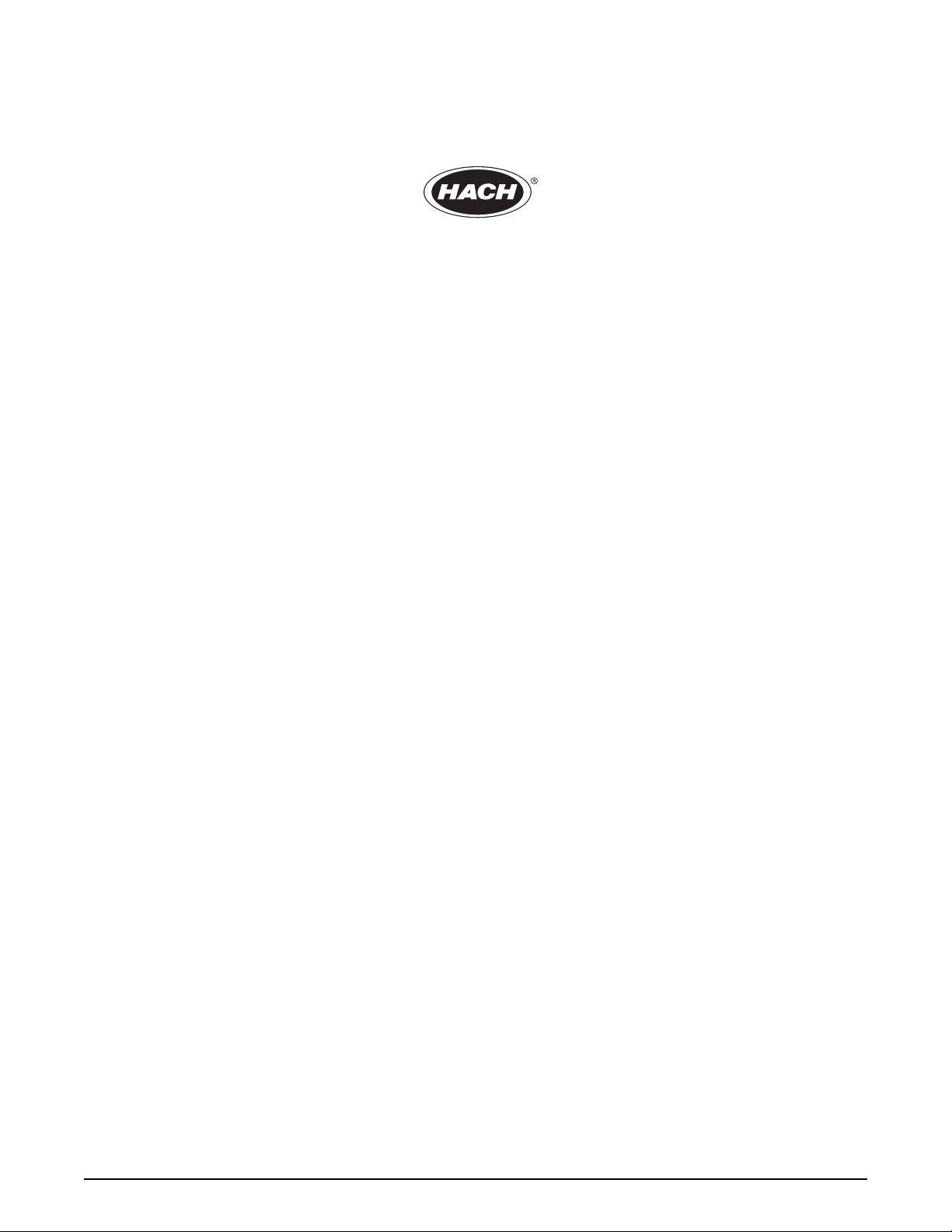

See Figure 4 and follow the simple guidelines below to allow complete

drainage of the intake line and prevent cross-contamination between samples.

• Install the sampler as close to the sample source as site conditions

permit. This will increase pump tube life and optimize overall sampler

performance.

• Install the sampler above the sample source, with the intake tubing

sloping downward to the sample.

• Make sure that the intake tubing is free of kinks or loops.

Figure 4 Setting Up the Instrument

3

1

2

FLOW

1. Slope tubing down to source (no

loops, kinks, or excessive tubing)

8990hrd.fm Installation

2. Place sampler on a level surface. 3. Locate strainer in an area of

turbulent and well mixed flow.

Page 23

Page 26

Section 2

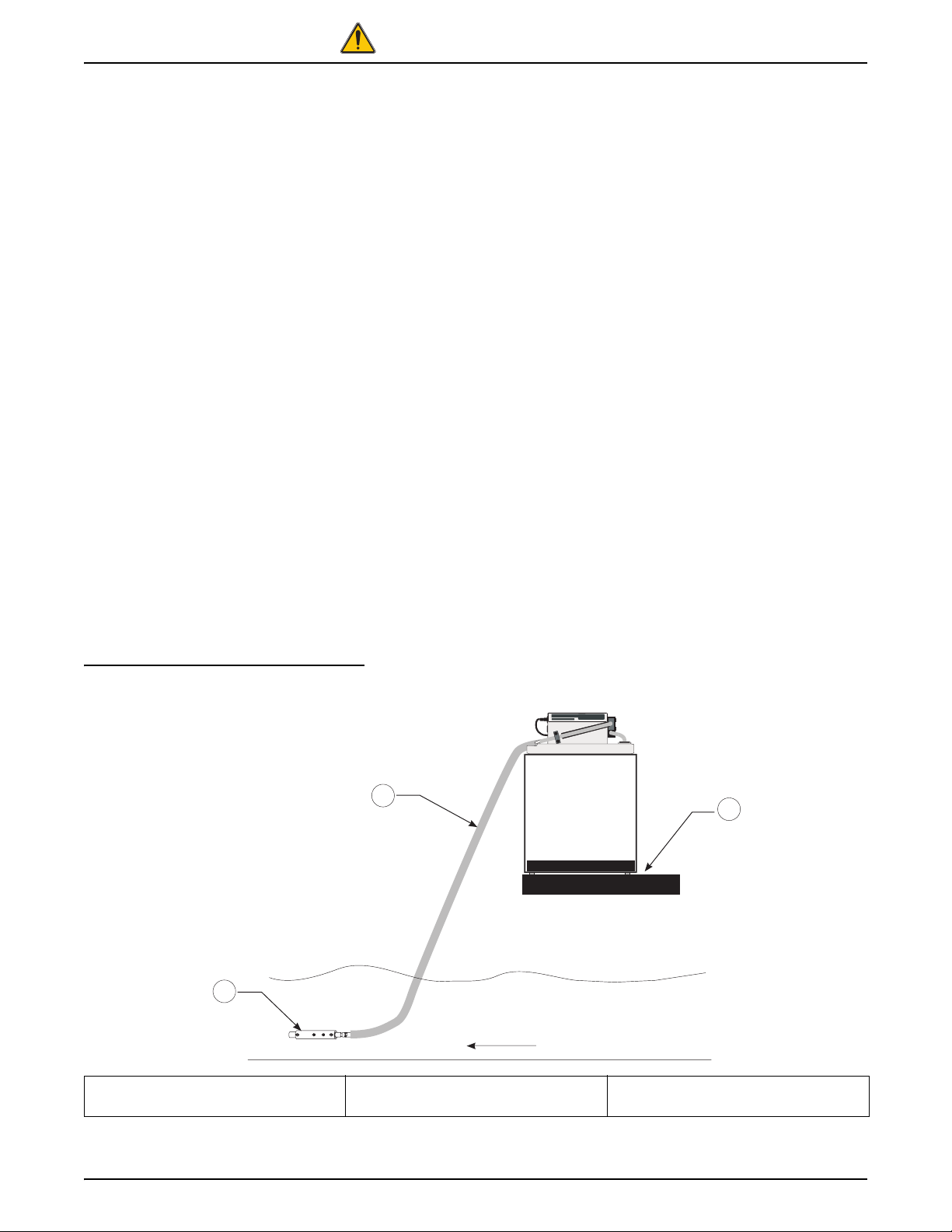

2.3 Installing the Pump Tube in the Sensor Body

1. Remove the four screws on the pump cover (Figure 5).

Note: Do not stretch the tubing in

the sensor body, as this could affect

the ability of the sensor to detect

liquid through the pump tubing.

2. Remove the front cover of the pump housing. Remove the tubing. Locate

the black dots on the tubing. The end of the tube that extends farthest

beyond the black dot attaches to the stainless steel tubing connector.

3. Install the pump tube in the pump housing so the black dots are visible

just outside the pump body.

Note: Use the proper length of

silicone tubing in the pump body. An

improper length can reduce the life

of the tubing and pump rollers. Refer

to Figure 5 for the correct length.

Figure 5 Pump Tube Loading

To Intake Tubing Connector

4. After inserting the new pump tube as shown, reinstall the front cover and

secure it with the four screws until finger tight.

5. Make sure that the tubing extends through the liquid sensor and out of the

controller as shown in Figure 6.

11 5/8 in.

(Tubing in Pump)

5 3/4 in. to Sample Fitting

Figure 6 Installing Pump Tube Through the Sensor Body

Page 24

Installing the Pump Tube in the Sensor Body

8990hrd.fm

Page 27

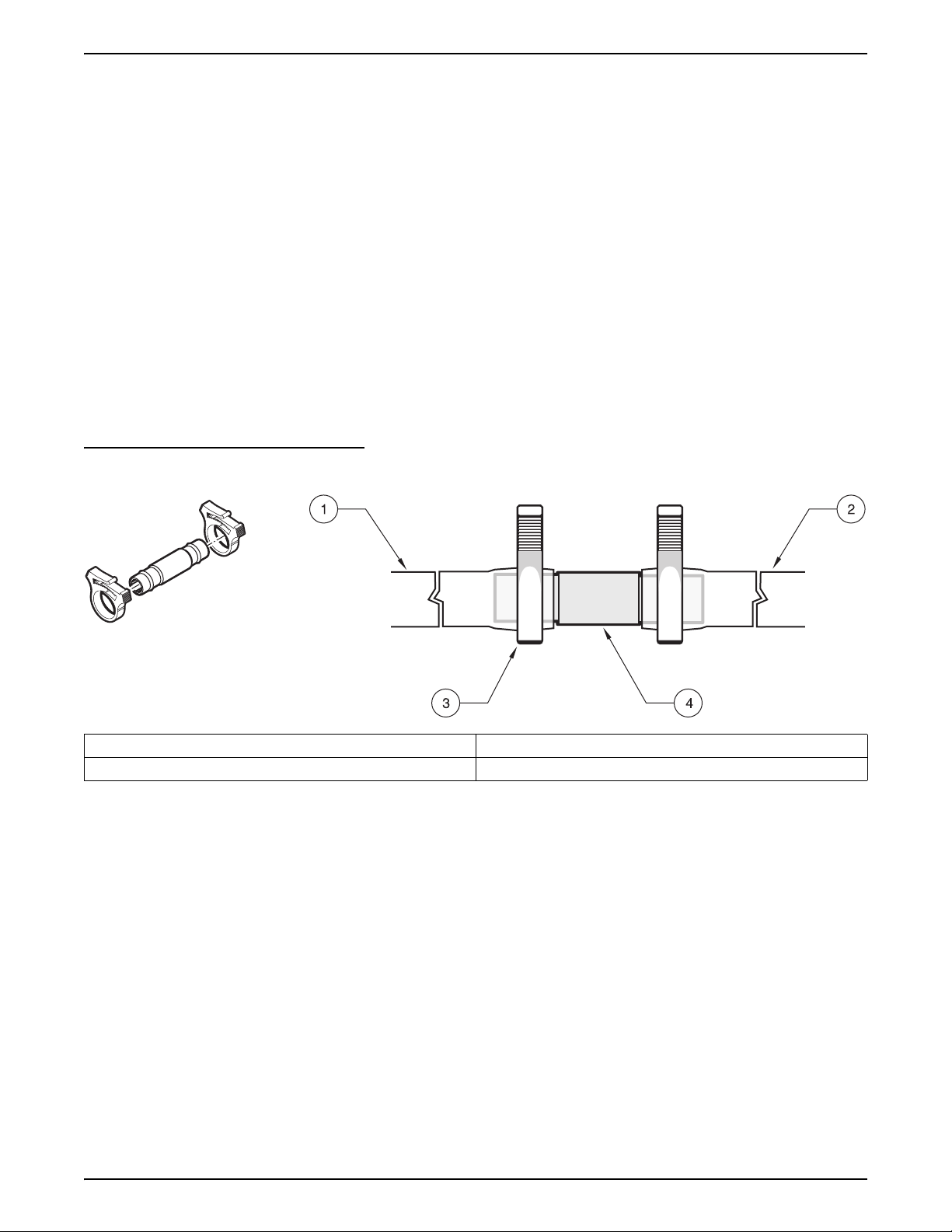

2.3.1 Attaching the Intake Line

2.3.1.1 Attaching the Vinyl Tubing

The connection kit (Cat. No. 2248) contains two identical assemblies, one for

connecting vinyl tubing to the tubing attached to the sampler, and the other for

connecting the vinyl tubing to an intake strainer or remote pump. The kit

contains four hose clamps and two stainless-steel tubing connectors.

1. Push one end of the tubing connector into the vinyl tubing attached to the

controller until the tubing abuts the shoulder of the tubing connector.

Secure with a tubing clamp (Figure 7).

2. Push the other end of the tubing connector into the vinyl tubing until the

tubing abuts the shoulder of the tubing connector and secure with a

tubing clamp (Figure 7).

3. Repeat Step 1 and Step 2 for the fitting that connects the vinyl tubing to

an intake strainer or a remote pump.

Figure 7 3/8” Vinyl Tubing Connector

Section 2

1. Vinyl tubing to controller 3. Tubing clamp (2 required)

2. Vinyl tubing to strainer or pump. 4. Stainless-steel tubing connector

2.3.1.2 Attaching the Teflon®-Lined Tubing

The Connection Kit for Teflon-lined Tubing (Cat. No. 2186) contains two

identical assemblies, one for connecting the Teflon-lined tubing to the

stainless steel tubing connector and the other for connecting the Teflon-lined

tubing to the intake strainer. The kit contains six clamps, two lengths of

silicone tubing, and two stainless-steel barbed fittings.

To connect the Teflon-lined tubing follow the instructions and Figure 8 below:

1. Place the Teflon-lined tubing over the tubing connector nipple until it abuts

the shoulder of the tubing connector and secure with a tubing clamp.

2. Place one end of the silicone tubing over the wide end of the tubing

connector and secure with a tubing clamp.

3. Slide a second tubing clamp over the other end of the silicone tubing.

Push the silicone tubing over the stainless-steel fitting on the intake

strainer and tighten the tubing clamp.

Page 25

8990hrd.fm Installing the Pump Tube in the Sensor Body

Page 28

Section 2

4. Repeat the procedure for the fitting that connects the Teflon-lined tubing

to the silicone pump tubing.

Figure 8

1. Intake strainer 4. Stainless-steel tubing connector

2. Tubing clamp (3 required) 5. Teflon-lined intake tubing

3. Two-inch piece of silicone tubing 6. Wide end of stainless steel tubing connector

3

/8″ ID Teflon-lined Tubing Attached to Intake Strainer and Tubing Connector

2.3.2 Setting Up the Intake Line and Strainer

Note: If site conditions do not permit

the intake to slope downward from

the sampler to the sample source,

disable the liquid sensors by

calibrating the sample volume using

the Timed Calibrate method when

programming the sampler.

For each sampling location, the intake line should be as short as practical,

and be free of any sharp bends, coils, or loops. Install the intake line with a

downward slope from the sampler to the sample source because:

• This will ensure the complete drainage of the intake line when it is

air-purged before and after each sample, and will help to prevent

cross-contamination of the individual samples.

• Complete drainage is important in freezing conditions, as any liquid slugs

that remain could freeze and plug the line and possibly damage the

sampler.

Note: Vertical lift should not exceed

27 ft. If the site requires more lift,

you may purchase the Remote

Pump Option. The remote pump

option is factory installed. Any

remote pump installed outside the

factory will void the warranty.

Place the sample intake and strainer in the mainstream of the sampling

source, in an area of turbulent and well mixed flow.

Also, you must account for the vertical location of the intake. A position too

near the surface may yield excess lighter materials, while a position too near

the bottom may yield excess heavy materials. The constituents of interest

must be considered when positioning the intake strainer.

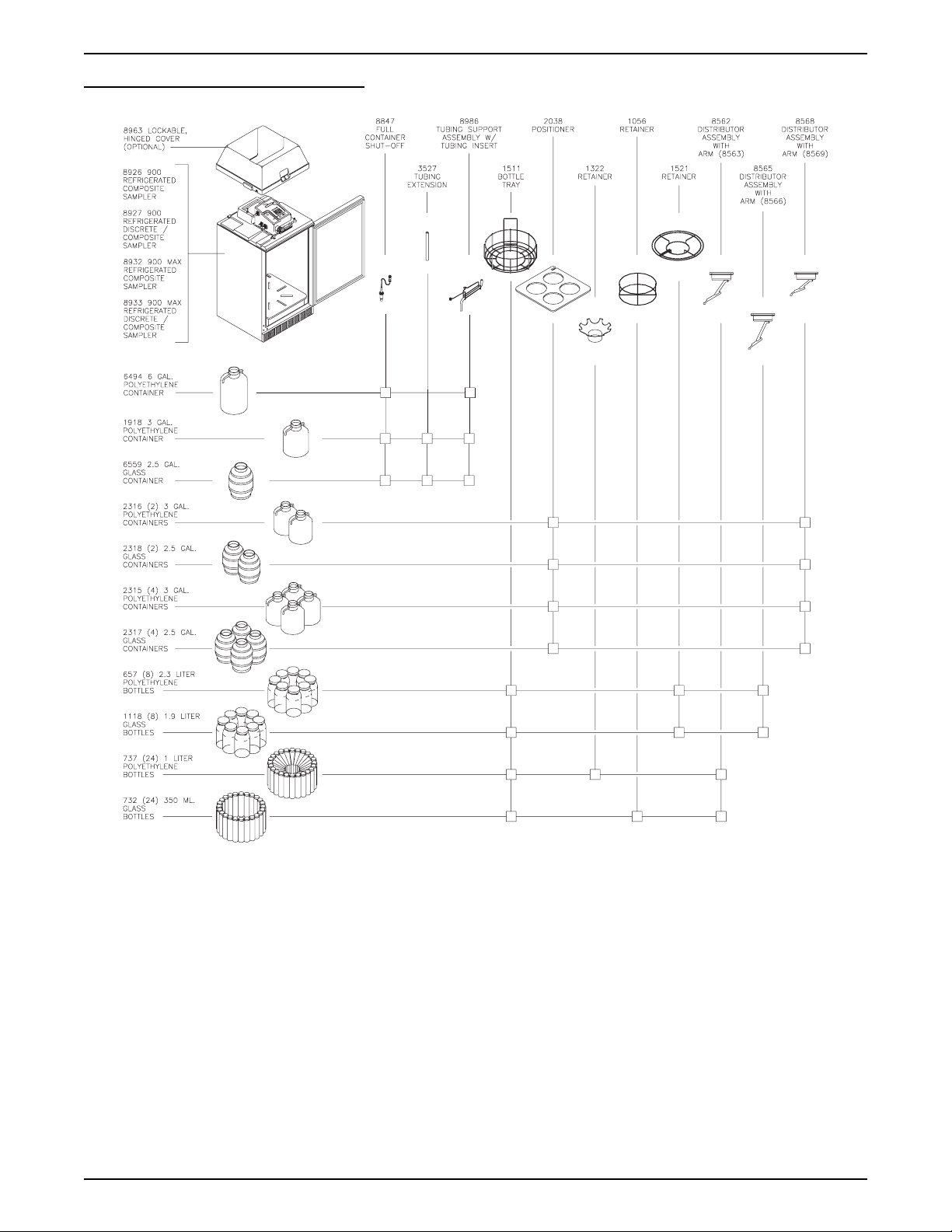

2.4 Choosing Bottle and Retainer Configurations

A broad range of bottle configurations are available for the Sigma 900 MAX

Refrigerated Sampler.

Page 26

Choosing Bottle and Retainer Configurations

8990hrd.fm

Page 29

Figure 9 Bottle Configurations

Section 2

2.5 Setting Up the Bottles

2.5.1 One-Bottle Sampling

For single bottle composite sampling, install the Full Bottle Shut-off (refer to

Section 2.7 on page 31) and place the bottle in the center of the refrigerator

(Figure 15 on page 31). The Full Bottle Shut-off positions the sample tubing

over the bottle mouth.

2.5.2 Two- and Four-bottle Sampling

For two-bottle sampling, install the distributor (refer to Section 2.6.1 on

page 30) and place the bottles in the Bottle #1 and Bottle #2 positions in the

tray as shown in Figure 10.

Page 27

8990hrd.fm Setting Up the Bottles

Page 30

Section 2

For four-bottle sampling, install the distributor and place all four bottles in the

tray as shown in Figure 11.

Figure 10 Two-bottle Locations

2

2

1

3

1

Front

1. Single Bottle Location 2. Two Bottle Location 3. Slots for Wire From Bottle Tray (8 or 24 bottle)

Figure 11 Four-bottle Locations

1

2

1

1. 1, 2, or 4 Bottle Locations 2. Slot for Wire From Bottle Tray (8 or 24 bottles)

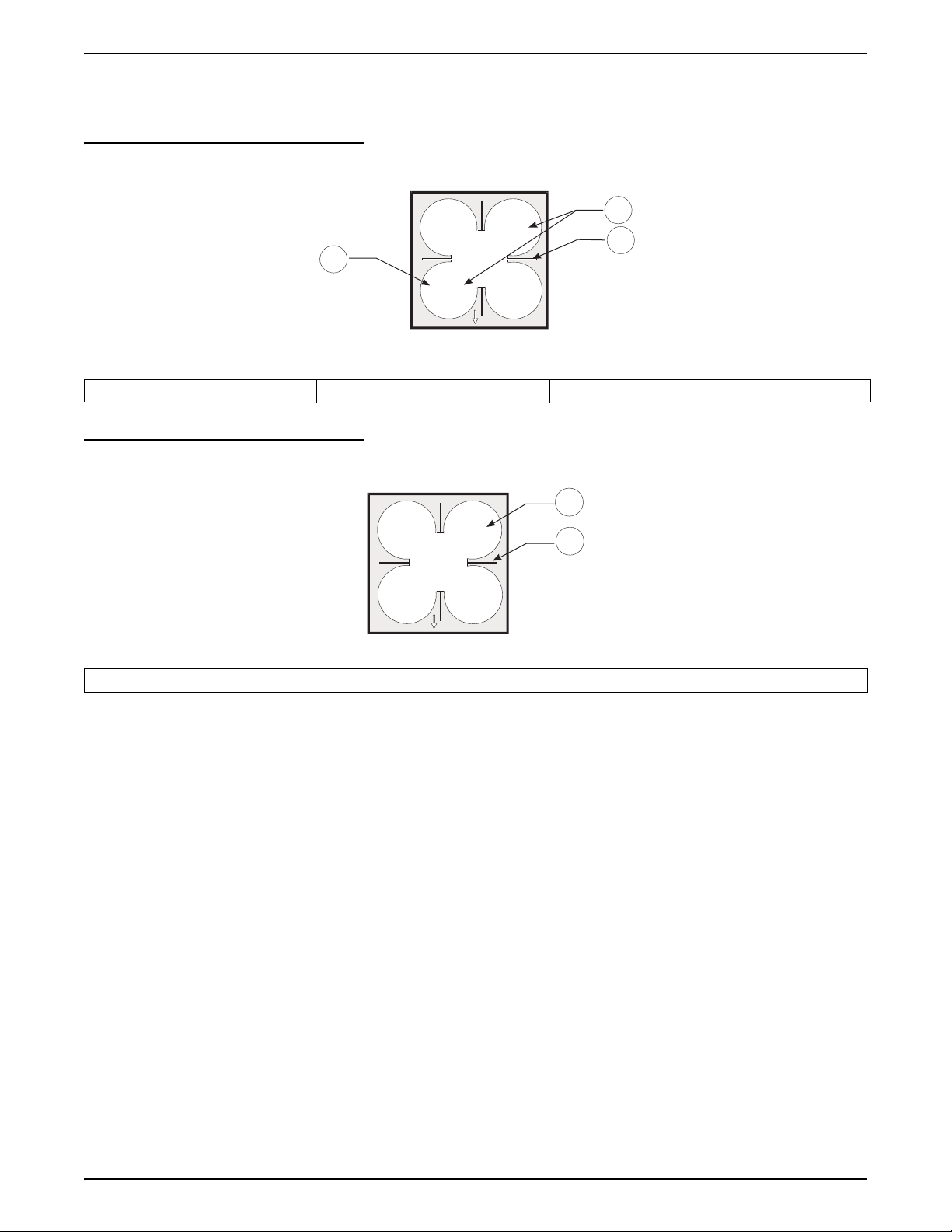

2.5.3 Eight-, 12-, or 24-bottle Sampling

For eight-, 12- or 24-bottle sets, install the distributor (refer to section 2.6.1 on

page 30). Place the bottles in the tray and install the proper bottle retainer

(Figure 12).

Bottle #1 is the first bottle clockwise (looking down on the tray) from the right

side of the tray. Bottle #1 is located on the inside of each bottle tray for all

multiple bottle sets (Figure 12).

Front

3

4

2

Page 28

Setting Up the Bottles

8990hrd.fm

Page 31

Figure 12 Eight-, 12-, or 24-bottle Configuration

1

2

3

1. Distributor 2. Retainer 3. Bottles and Bottle Tray

Section 2

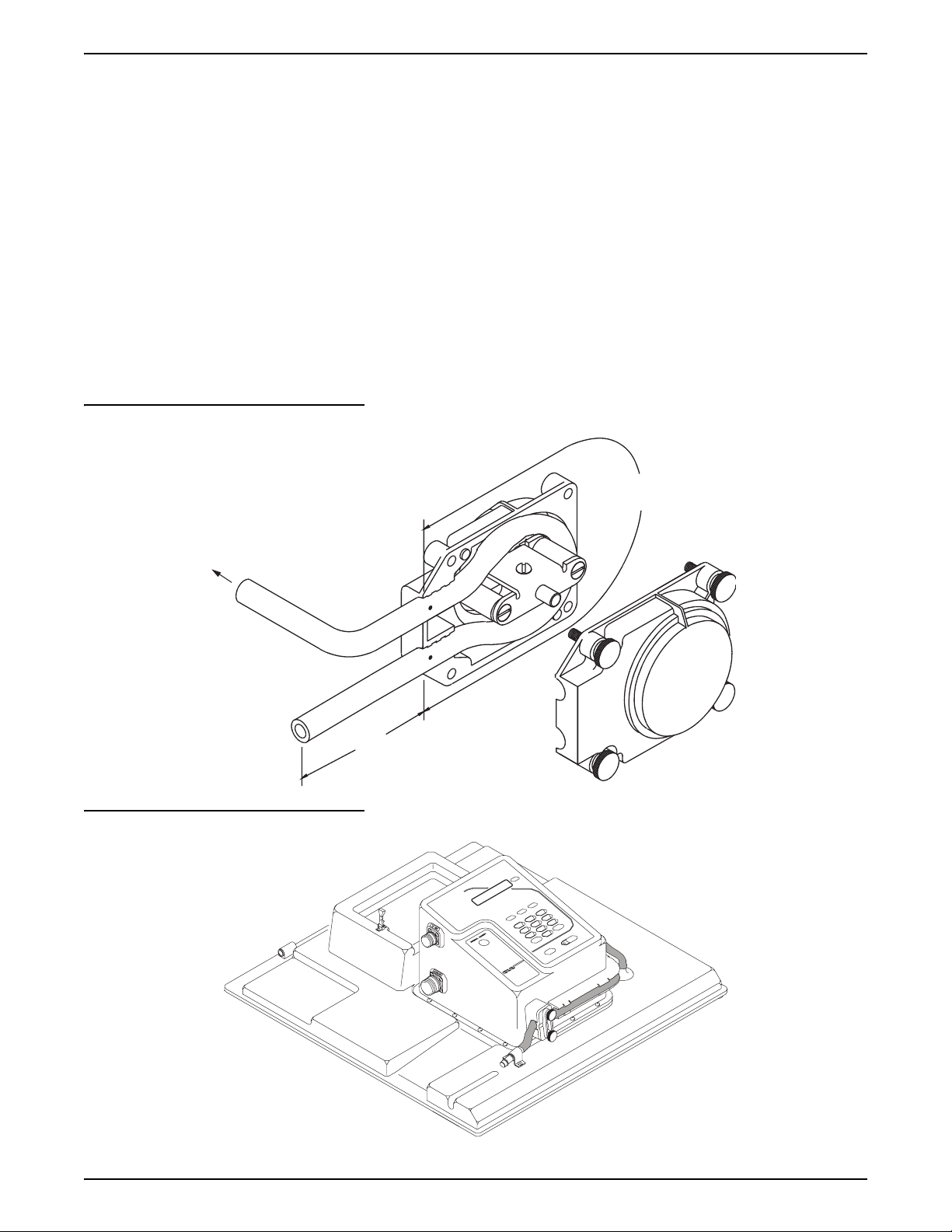

2.6 Installing the Distributor (Multiple Bottle Operation)

Note: Make sure the sampler is

powered off before removing or

installing the distributor.

For multiple bottle sampling, a motorized arm (Distributor) is provided to

automatically position the sample tube over the proper bottle. The

microprocessor-controlled distributor arm can automatically locate two, four,

eight, 12, or 24 discrete bottles.

To install the distributor:

1. Locate the two slots along one edge of the distributor assembly base

plate (Figure 14). Slide the distributor assembly, slots first, under the

shoulder screws located on the top inside surface of the controller

section.

2. When fully seated, hand tighten the knurled thumbscrew to hold the

distributor in place.

3. To ensure the arm has sufficient freedom of movement, hand-rotate the

arm to the opposite end of the Arm Stop.

4. Install the silicone distributor tubing to the sample fitting on the top

underside surface of the controller housing.

Note: Use care not to force the arm past the Arm Stop clip. The Arm Stop keeps the

arm from being rotated more than 360 degrees and keeps the distributor tubing

from kinking.

The distributor tubing should be installed so that the end of the tubing extends

out of the nozzle end of the distributor arm no more than

not let the tubing extend more than

8990hrd.fm Installing the Distributor (Multiple Bottle Operation)

1

/8 in. past the nozzle end of the arm.

1

/8 in. (Figure 13). Do

Page 29

Page 32

Section 2

2.6.1 Distributor Arm Alignment

1. Program the sampler for 24-bottle operation.

2. Press

Bottle #1 position.

3. Place the arm on the distributor shaft and align the rib on the inside wall of

the control housing skirt.

4. Secure the arm to the shaft by tightening the

located on the distributor arm.

Figure 13 Distributor Tubing in Arm

START PROGRAM to set the distributor shaft to the

1

/8 in. hex-head screw,

1

2

1. Distributor Shaft 2. Nozzle End (1/8 in. max)

Figure 14 Distributor Installation

2

3

1

1. Refrigerator 2. Distributor Assembly 3. Distributor Arm

Page 30

Installing the Distributor (Multiple Bottle Operation)

8990hrd.fm

Page 33

Section 2

2.7 Installing the Full-Bottle Shut-Off Device (Single Bottle Operation)

1. Install the rubber grommet into the hole provided in the cap of the

composite bottle.

2. Slide the Full Bottle Shut-Off, float first, into the bottle through the center

of the grommet.

3. Insert the Full Bottle Shut-Off connector into the receptacle (Figure 15)

and securely tighten.

Figure 15 Full Bottle Shut-off Installation

2

1

1. Full Bottle Shut-off 2. Refrigerator

2.8 Power Connections

Note: Install the sampler on its own

circuit to ensure a continuous,

stable source of power.

Use the ac power cords to apply ac power to the controller and

the refrigerator.

The sampler controller operates on a 12 V dc which is supplied by a built-in

ac/dc power converter. The power supply is permanently sealed in the

compartment located behind the transition plate. An ac line fuse is located on

the left side of the controller.

An optional power backup assembly is located on top of the ac power supply.

The ac power backup is designed to power the pump and controller only. Pull

the rubber hold-downs up and over the clips at each end of the ac Power

Backup to hold it in place.

The short, 2-pin cable on the power supply (or battery) connects to the

controller receptacle labeled 12 V dc.

Page 31

8990hrd.fm Installing the Full-Bottle Shut-Off Device (Single Bottle Operation)

Page 34

Section 2

Important: Whenever electricity is present, there is a possibility of electrical

shock. Before connecting the sampler to an ac power source, the following

safety precautions should be taken:

• Check the power source to make sure that it satisfies the ac power

requirements of the sampler.

• Make sure that all electrical installations and connections are in

accordance with national and local electrical codes.

• Before performing any maintenance, disconnect the sampler from the

power source.

• Do not attempt to make any connection or otherwise handle the electrical

components of the sampler when connected to ac line power if the

immediate area is wet, or if hands or clothing are wet.

• If the circuit breaker or fuse in the ac power source is tripped, determine

the cause before restoring power to the sampler.

• Make sure the power circuit is grounded and protected with a Ground

Fault Interrupter (GFI).

2.9 Auxiliary Receptacle Pin Identification

Pin A/White (12 V dc) Powers an external device or flow meter. Must be used in conjunction with Pin B (ground).

Pin B/Blue (Ground) Connected to dc ground and is isolated from the earth ground found in the ac power line.

With the sampler in Flow Proportional mode and connected to an external flow meter, a 5 to

12 V dc input pulse lasting at least 25 milliseconds will cause the sampler to decrement one

Pin C/Yellow (Pulse Input)

Pin D/Black

(Liquid Level Actuator/

Auxiliary Control Input)

count. The 12 V dc line found on Pin A can be used directly with a simple contact closure to

Pin C or an external 5 to 12 V dc pulse may be applied providing the ground side of the

external signal is connected to the sampler ground at Pin B. This count is actuated at the

beginning of the input signal (the leading edge of the pulse).

This line is held at 5 V dc inside the sampler. When shorted to ground (Pin B), a signal is sent

to the microprocessor inside the sampler causing it to “wake up” and begin or resume its

sampling program. It can be used in conjunction with a simple level float to actuate the

sampler when liquid is present or to take over after a second sampler has finished its

program. It may also be used with any device (such as a pH meter) that produces a dry

contact output to control the sampler in response to some user-defined condition (i.e. high or

low pH); must be used in conjunction with Pin B.

Pin E/Red (Special Output) Normally at 0 V dc, this line goes to 12 V dc upon any of the selected events described in.

Normally an open circuit, this line switches to ground for 90 seconds at the conclusion of the

Pin F/Green

(Program Complete Output)

Page 32

Auxiliary Receptacle Pin Identification

sampling program. Used to “wake up” another sampler to take over sampling or to signal an

operator or data logger upon the completion of the sampling program. This pin is also used to

signal the bottle full condition in a single bottle/continuous mode, and will transmit the bottle #

to an 950 Flow Meter if the program complete signal is disabled.

8990hrd.fm

Page 35

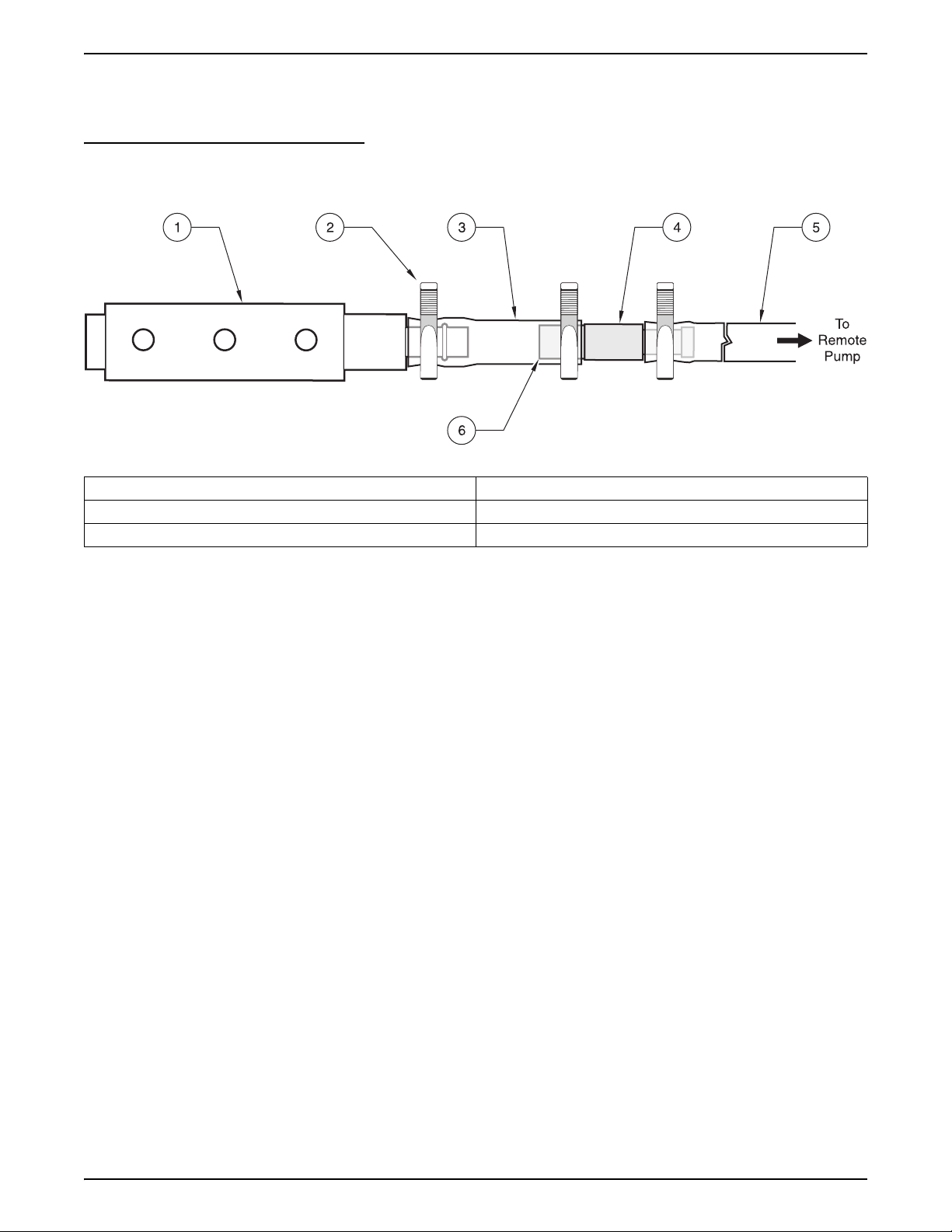

2.9.1 Splitter Interface

Figure 16 Splitter Interface

Section 2

Use the Splitter Interface (Cat. No. 939) when more than one signal is needed

simultaneously. Connecting the interface to the 6-pin connector on the

sampler provides three additional connectors. Two or more interfaces may be

connected in series to allow for additional connections.

Page 33

8990hrd.fm Auxiliary Receptacle Pin Identification

Page 36

Visit http: //www.hach.com

Page 37

OPERATION

DANGER

Handling chemical samples, standards, and reagents can be dangerous. Review the necessary Material

Safety Data Sheets and become familiar with all safety procedures before handling any chemicals.

DANGER

La manipulation des échantillons chimiques, étalons et réactifs peut être dangereuse. Lire les Fiches de

Données de Sécurité des Produits (FDSP) et se familiariser avec toutes les procédures de sécurité avant

de manipuler tous les produits chimiques.

PELIGRO

La manipulación de muestras químicas, estándares y reactivos puede ser peligrosa. Revise las fichas

de seguridad de materiales y familiarícese con los procedimientos de seguridad antes de manipular

productos químicos.

GEFAHR

Das Arbeiten mit chemischen Proben, Standards und Reagenzien ist mit Gefahren verbunden. Es wird dem