GW Instek GPT-10000 Series, GPT-12000 Series, GPT-12001, GPT-12004, GPT-12002 User Manual

...

Electrical Safety Analyzer

GPT-10000 Series

USER MANUAL

ISO-9001 CERTIFIED MANUFACTURER

This manual contains proprietary information, which is protected by

copyright. All rights are reserved. No part of this manual may be

photocopied, reproduced or translated to another language without

prior written consent of Good Will company.

The information in this manual was correct at the time of printing.

However, Good Will continues to improve products and reserves the

rights to change specification, equipment, and maintenance

procedures at any time without notice.

Good Will Instrument Co., Ltd.

No. 7-1, Jhongsing Rd., Tucheng Dist., New Taipei City 236, Taiwan.

Table of Contents

Table of Contents

SAFETY INSTRUCTIONS .................................................. 5

GETTING STARTED .......................................................... 9

GPT-12000 Series Overview ................. 10

Front Panel Overview ........................... 14

Rear Panel Overview ............................ 18

Set Up .................................................. 21

OPERATION .................................................................. 28

Menu Tree ............................................ 30

Test Lead Connection ........................... 35

Manual Tests ....................................... 38

Special MANU Test Mode (000) ........... 87

Sweep Function.................................... 89

Automatic Tests ................................... 92

System Settings ................................. 116

EXTERNAL CONTROL ................................................... 144

External Control Overview .................. 145

REMOTE CONTROL ...................................................... 151

Interface Configuration ...................... 152

Command Syntax ............................... 156

Command List ................................... 159

Error Messages .................................. 208

FAQ .............................................................................. 209

APPENDIX .................................................................... 211

Fuse Replacement .............................. 211

Test Errors ......................................... 212

3

GPT-10000 Series User Manual

GPT-12000 Specifications .................. 214

GPT-12001/12002/12003 Dimensions 220

GPT-12004 Dimensions ...................... 221

Declaration of Conformity .................. 222

INDEX .......................................................................... 223

4

SAFETY INSTRUCTIONS

WARNING

Warning: Identifies conditions or practices that

could result in injury or loss of life.

CAUTION

Caution: Identifies conditions or practices that

could result in damage to the instrument or to

other properties.

DANGER High Voltage

Attention Refer to the Manual

Protective Conductor Terminal

Frame or Chassis Terminal

Earth (ground) Terminal

SAFETY INSTRUCTIONS

This chapter contains important safety

instructions that you must follow during

operation and storage. Read the following before

any operation to ensure your safety and to keep

the instrument in the best possible condition.

Safety Symbols

These safety symbols may appear in this manual or on the

instrument.

5

GPT-10000 Series User Manual

Do not dispose electronic equipment as unsorted

municipal waste. Please use a separate collection

facility or contact the supplier from which this

instrument was purchased.

General

Guideline

CAUTION

Do not place any heavy object on the

instrument.

Avoid severe impact or rough handling that

leads to damaging the instrument.

Do not discharge static electricity to the

instrument.

Use only mating connectors, not bare wires, for

the terminals.

Do not block the cooling fan opening.

Do not disassemble the GPT-10000 unless you

are qualified.

Position

Guideline

WARNING

The rear position of the GPT-10000 should be

placed in an area with easy accessible for power

disconnection, that is, unplugging the power

cord with ease.

Keep away from the device under test which

connects with the GPT-10000 when test is

underway. In addition, while test is ongoing,

never touch the device under test, the GPT10000 as well as other relevant units.

Any inappropriate manner that is unspecified

by the manufacturer may result in irreversible

harms or impaired protection by the GPT-10000.

Safety Guidelines

6

SAFETY INSTRUCTIONS

(Measurement categories) EN 61010-1:2010 specifies the

measurement categories and their requirements as follows. The

GPT-10000 does not fall under category II, III or IV.

Measurement category IV is for measurement performed at the

source of low-voltage installation.

Measurement category III is for measurement performed in the

building installation.

Measurement category II is for measurement performed on the

circuits directly connected to the low voltage installation.

Power Supply

WARNING

AC Input voltage range:

AC 100V – 240V ± 10%

Frequency: 50Hz/60Hz

To avoid electrical shock connect the protective

grounding conductor of the AC power cord to

an earth ground.

Cleaning the

GPT-10000

Disconnect the power cord before cleaning.

Use a soft cloth dampened in a solution of mild

detergent and water. Do not spray any liquid.

Do not use chemicals containing harsh material

such as benzene, toluene, xylene, and acetone.

Operation

Environment

Location: Indoor, no direct sunlight, dust free,

almost non-conductive pollution (Note below)

Relative Humidity: ≤ 70% (no condensation)

Altitude: < 2000m

Temperature: 0˚C~40˚C

7

GPT-10000 Series User Manual

(Pollution Degree) EN 61010-1:2010 specifies the pollution degrees

and their requirements as follows. The GPT-10000 falls under

degree 2.

Pollution refers to “addition of foreign matter, solid, liquid, or

gaseous (ionized gases), that may produce a reduction of dielectric

strength or surface resistivity”.

Pollution degree 1: No pollution or only dry, non-conductive

pollution occurs. The pollution has no influence.

Pollution degree 2: Normally only non-conductive pollution

occurs. Occasionally, however, a temporary conductivity caused

by condensation must be expected.

Pollution degree 3: Conductive pollution occurs, or dry, non-

conductive pollution occurs which becomes conductive due to

condensation which is expected. In such conditions, equipment

is normally protected against exposure to direct sunlight,

precipitation, and full wind pressure, but neither temperature

nor humidity is controlled.

Storage

environment

Location: Indoor

Temperature: -10°C to 70°C

Relative Humidity: ≤ 85% (no condensation)

Disposal

Do not dispose this instrument as unsorted

municipal waste. Please use a separate collection

facility or contact the supplier from which this

instrument was purchased. Please make sure

discarded electrical waste is properly recycled to

reduce environmental impact.

8

GETTING STARTED

GPT-12000 Series Overview ............................................ 10

Series lineup ..............................................................................................10

Lineup Overview......................................................................................11

Main Features ...........................................................................................11

Accessories ................................................................................................12

Package Contents .....................................................................................13

Front Panel Overview ..................................................... 14

GPT-12001/12002/12003/12004 ............................................................14

Rear Panel Overview ...................................................... 18

GPT-12001/12002/12003/12004 ............................................................18

Set Up ........................................................................... 21

Tilting the Stand .......................................................................................21

Line Voltage Connection and Power Up ..............................................22

Installing the Optional GPIB Card .........................................................23

Workplace Precautions ............................................................................24

Operating Precautions .............................................................................25

Basic Safety Checks ..................................................................................27

GETTING STARTED

This chapter describes the safety analyzer in a

nutshell, including its main features and front /

rear panel introduction. After going through the

overview, please read the safety considerations in

the Set Up chapter.

9

GPT-10000 Series User Manual

GPT-12000 Series Overview

Series lineup

The GPT-12000 Series Safety Analyzers are AC/DC withstanding

voltage, insulation resistance, ground bond and continuity safety

analyzers.

The GPT-12001 is AC withstanding voltage and continuity tester,

the GPT-12002 is AC/DC withstanding voltage and continuity

tester and the GPT-12003 is AC/DC withstanding voltage,

insulation resistance and continuity tester. The GPT-12004 includes

all the test functions of the previous models, plus the ground bond

testing. Also, for the all the models, the testing terminals are also

mirrored on the rear panel for added safety and for more

permanent safety testing environments.

The GPT-12000 Series can store up to 100 manual tests, as well as

run up to 10 manual tests sequentially as an automatic test,

allowing the safety analyzers to accommodate any number of

safety standards, including IEC, EN, UL, CSA, GB, JIS and others.

Note: Throughout this user manual, the terms ACW, DCW, IR, GB

and CONT refer to AC Withstanding, DC Withstanding, Insulation

Resistance, Ground Bond and Continuity testing, respectively.

10

GETTING STARTED

Model name

ACW

DCW

IR

GB

CONT

GPT-12001

GPT-12002

GPT-12003

GPT-12004

Performance

ACW: 5kVAC

DCW: 6kVDC

IR: 50V~1200V (50V steps)*

GB: 3A~30A

CONT: 100mA

Features

Ramp up time control

Ramp down time control

Safety discharge

100 test conditions (MANU mode)

100 automatic tests (AUTO mode)

Over temperature, voltage and current

protection

Pass, Fail, Test, High Voltage and Ready

indicators

PWM output (90% efficiency, increased

reliability)

Interlock (configurable)

Rear panel output

Lineup Overview

Main Features

11

Interface

Remote control start/stop interface terminal

RS232/USB interface for programming

Optional GPIB interface for programming

Signal I/O port for pass/fail/test monitoring

and start/stop control/interlock

Accessories

Standard

Accessories

Part number

Description

GHT-115x1

Te st lead

Region dependent

Power cord

GTL-215x1

GB test lead

(GPT-12004 only)

GHT-119

Remote terminal cable

N/A

Interlock key

Optional

Accessories

Part number

Description

GHT-205

High Voltage Test Probe

GHT-113

High Voltage Test Pistol

GTL-232

RS232C cable

GTL-248

GPIB cable

GTL-246

USB cable (A to B type)

Options

Part number

Description

Opt.01 GPIB Interface

GPIB module

GPT-10000 Series User Manual

12

GETTING STARTED

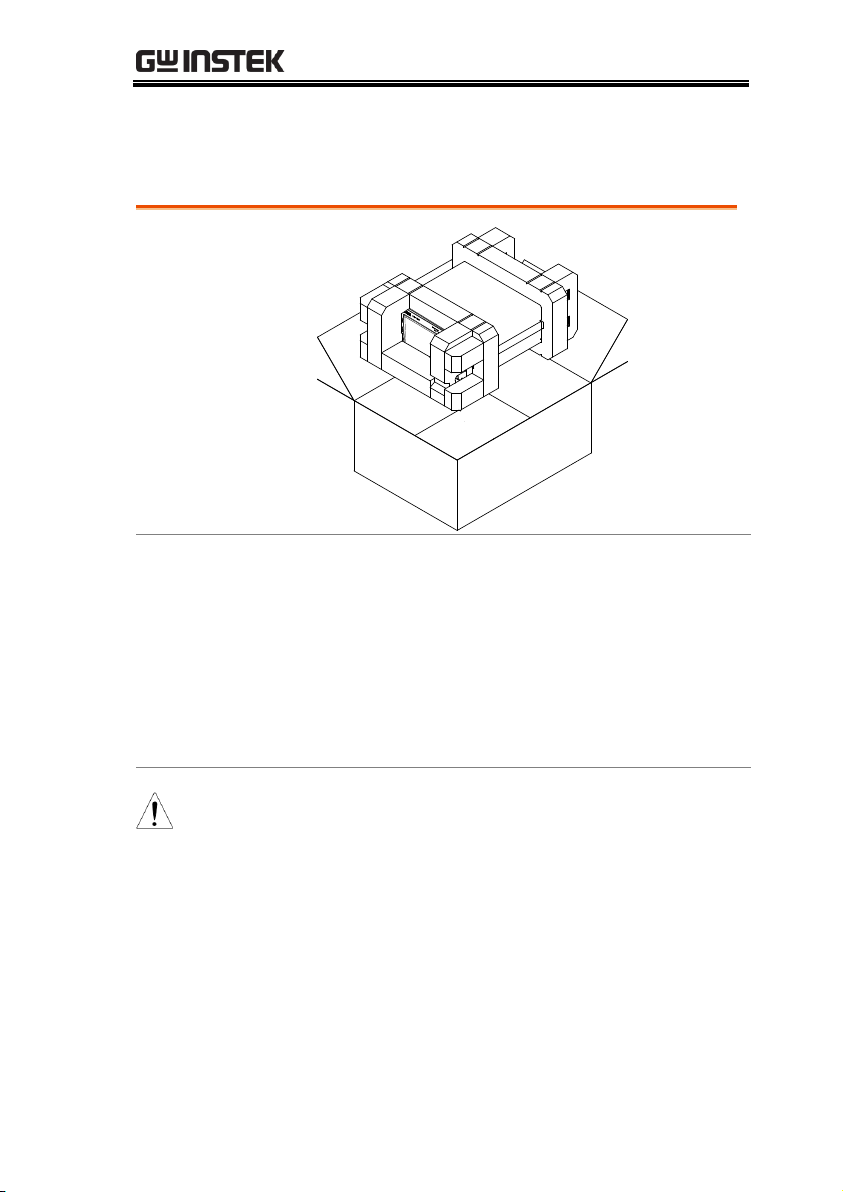

Opening the box

Contents

(single unit)

GPT-12000 unit

Quick Start Guide

User manual CD

CTC (Calibration

Traceable Certificate)

Power cord x1 (region

dependent)

GHT-115 test leads x1

GTL-215 GB test leads

x1 (GPT-12004)

GHT-119 Remote

terminal cable

Interlock key

Note

Keep the packaging, including the box, polystyrene

foam and plastic envelopes should the need arise

to return the unit to GW Instek.

Package Contents

Check the contents before using the GPT-12000 series.

13

GPT-10000 Series User Manual

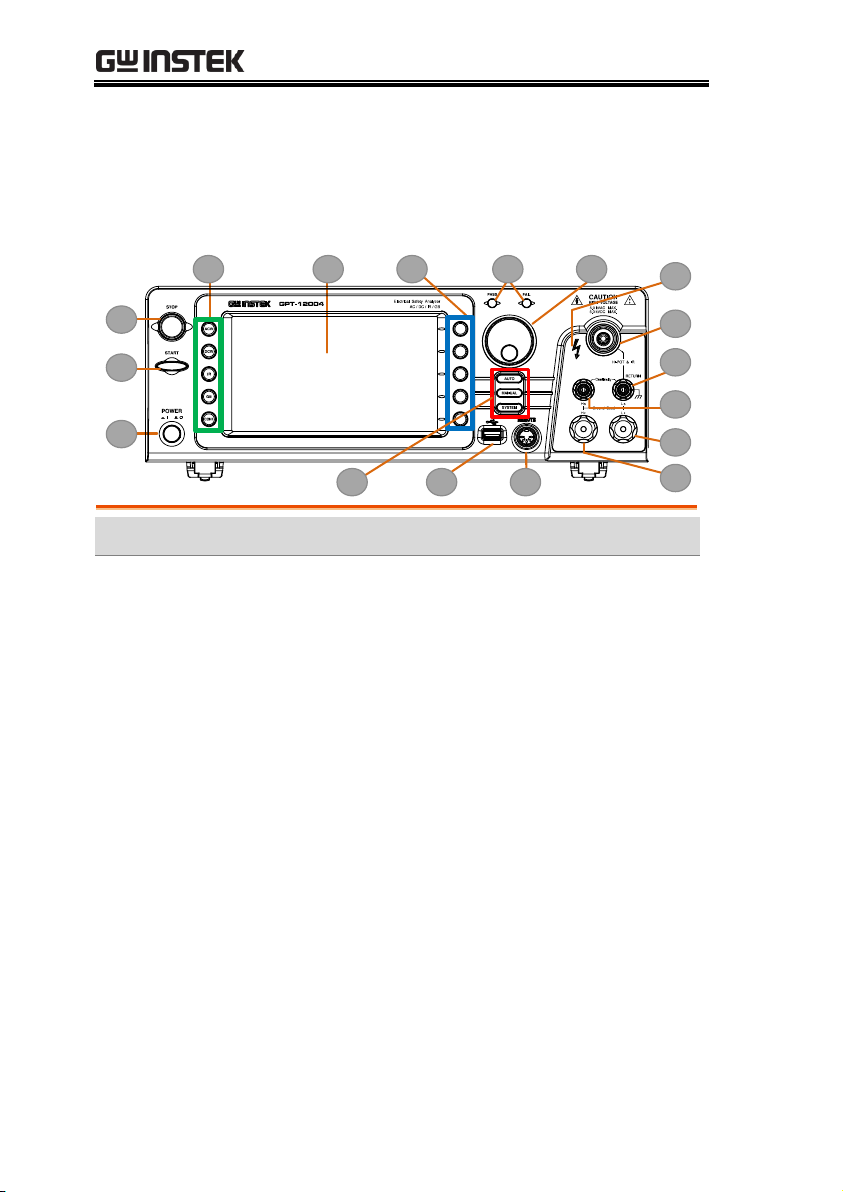

1

2

3

4 5

6

7

8

9

0

A

B

C

D

E

F

G

Item

Description

1

STOP Button

2

START Button

3

POWER Switch

4

Test Function Keys (Green Zone)

5

Display

6

Mode Keys (AUTO, MANUAL, SYSTEM in Red Zone)

7

Soft Keys (Blue Zone)

8

USB A-Type Host Port

9

PASS/FAIL Indicators

0

REMOTE Terminal

A

Scroll Wheel

B

HIGH VOLTAGE Indicator

C

HIGH VOLTAGE Output Terminal

D

SENSE L & RETURN Terminal

E

SENSE H & Output Terminal

F

SOURCE L (GPT-12004 only)

G

SOURCE H (GPT-12004 only)

Front Panel Overview

GPT-12001/12002/12003/12004

14

GETTING STARTED

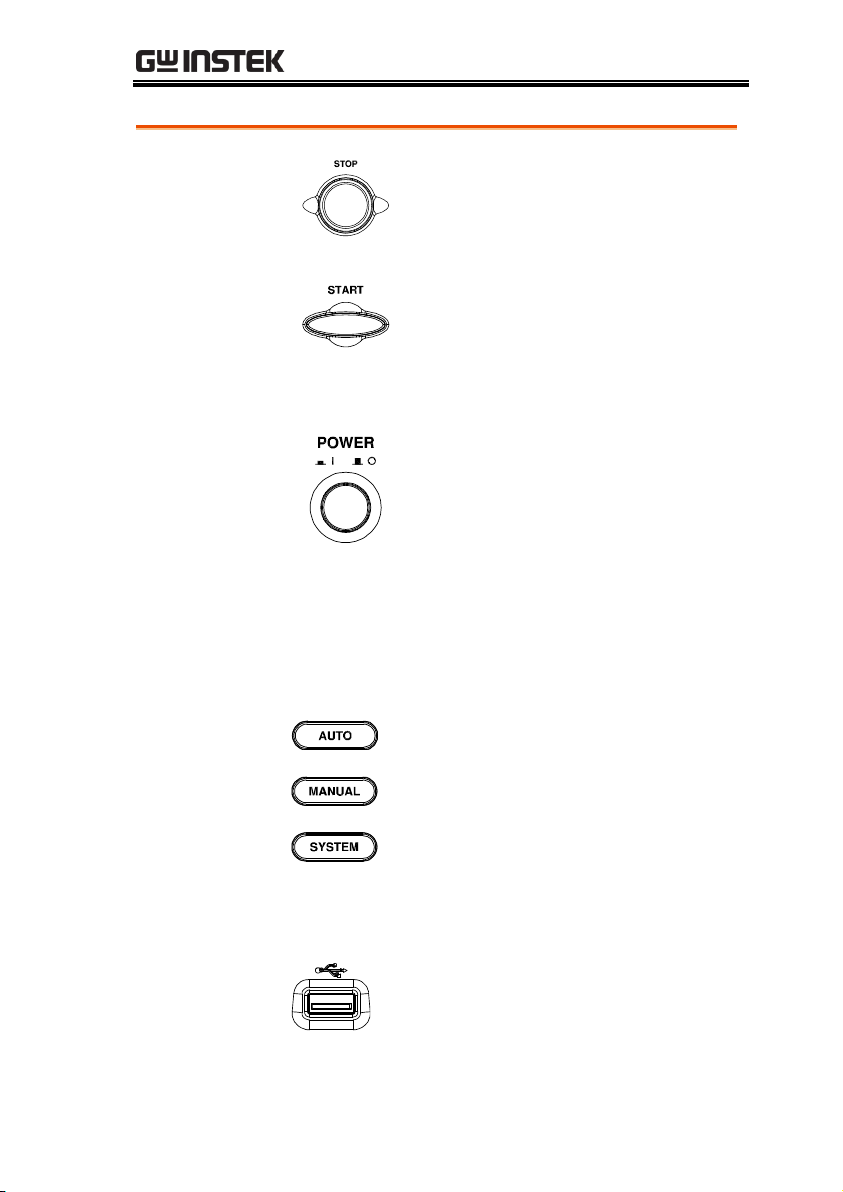

STOP button

The STOP button is used to

stop/cancel tests. The STOP button

will also put the safety analyzer in the

READY status to begin testing.

START button

The START button is used to start tests.

The START button can be used to start

tests when the tester is in the READY

status. Pressing the START button will

put the tester in the TEST status.

POWER switch

Turns the power on. The safety

analyzer will always start up with the

last test setting from when the

instrument was last powered down.

Test Function

Keys

The keys indicate the 5 testing functions including

ACW, DCW, IR, GB and CONT. Pressing one of

the keys enters the function settings.

Display

7” Color TFT LCD display in 800 X 480 resolution

AUTO button

Press to enter the AUTO test mode.

MANUAL button

Press to enter the MANUAL test mode.

SYSTEM button

Press to enter the SYSTEM mode.

Soft Keys

The Soft keys correspond to the menu keys directly

above on the main display.

USB Host Port

It can connect with USB flash drive

for data storage.

15

GPT-10000 Series User Manual

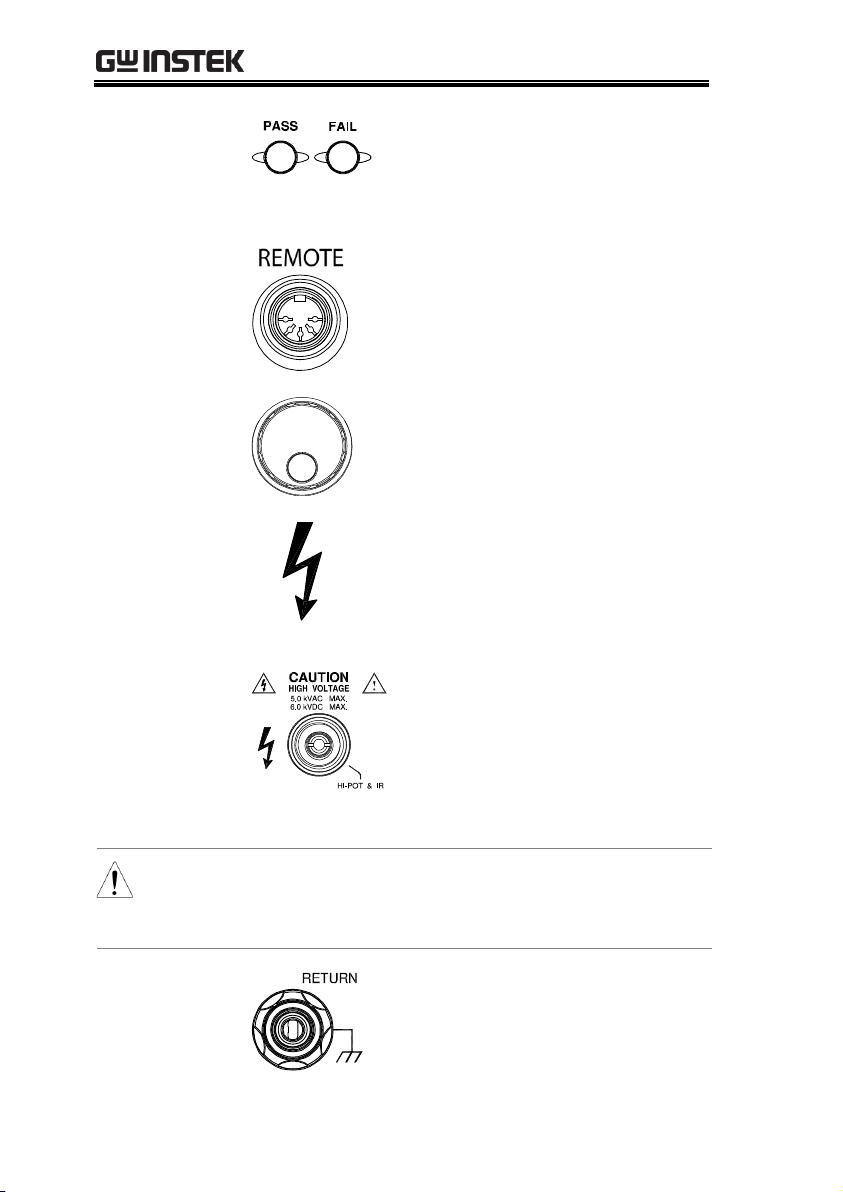

Pass/Fail

indicators

The PASS and FAIL indicators

light up upon a PASS or FAIL test

result at the end of a manual test

or automatic test.

REMOTE

terminal

The REMOTE terminal is used to

connect to a remote controller.

Scroll wheel

The scroll wheel is used to edit

parameter values.

HIGH VOLTAGE

indicator

The HIGH VOLTAGE indicator

will light up red when an output

terminal is active. Only after the

test has finished or stopped will

the indicator turn off.

HIGH VOLTAGE

output terminal

The HIGH VOLTAGE terminal

output is used for outputting the

testing voltage in ACW, DCW and

IR tests. The terminal is recessed

for safety. This terminal is used in

conjunction with the RETURN

terminal.

WARNING

USE EXTREME CAUTION.

Do not touch the HIGH VOLTAGE terminal

during testing.

RETURN

terminal

The RETURN terminal is used

for ACW, DCW, IR and CONT

tests.

16

GETTING STARTED

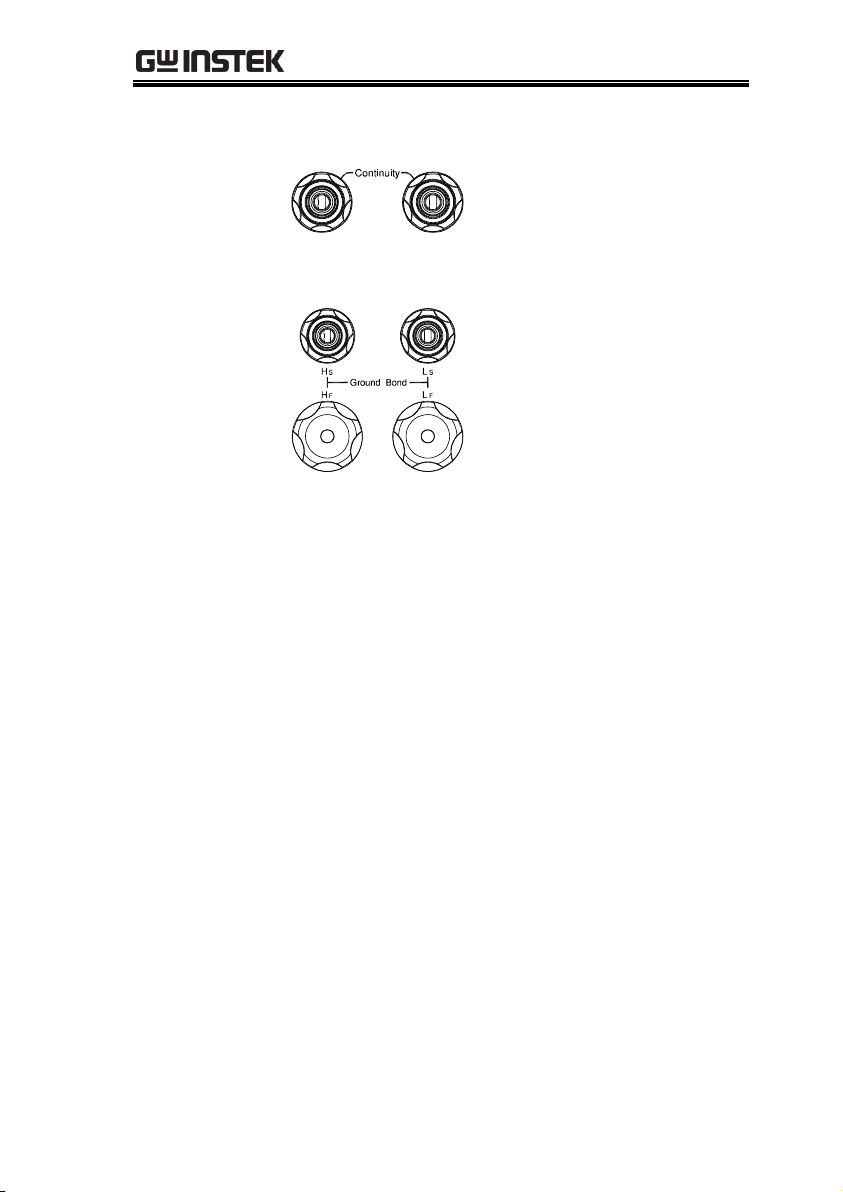

OUTPUT and

RETURN

terminals

All models

The OUTPUT terminal (red)

and RETURN terminal (black)

are used for CONT

(Continuity) test.

SENSE H/L and

SOURCE H/L

terminals

GPT-12004 only

The SENSE H, SENSE L,

SOURCE H and SOURCE L,

terminals are used for GB

(Ground Bond) test.

17

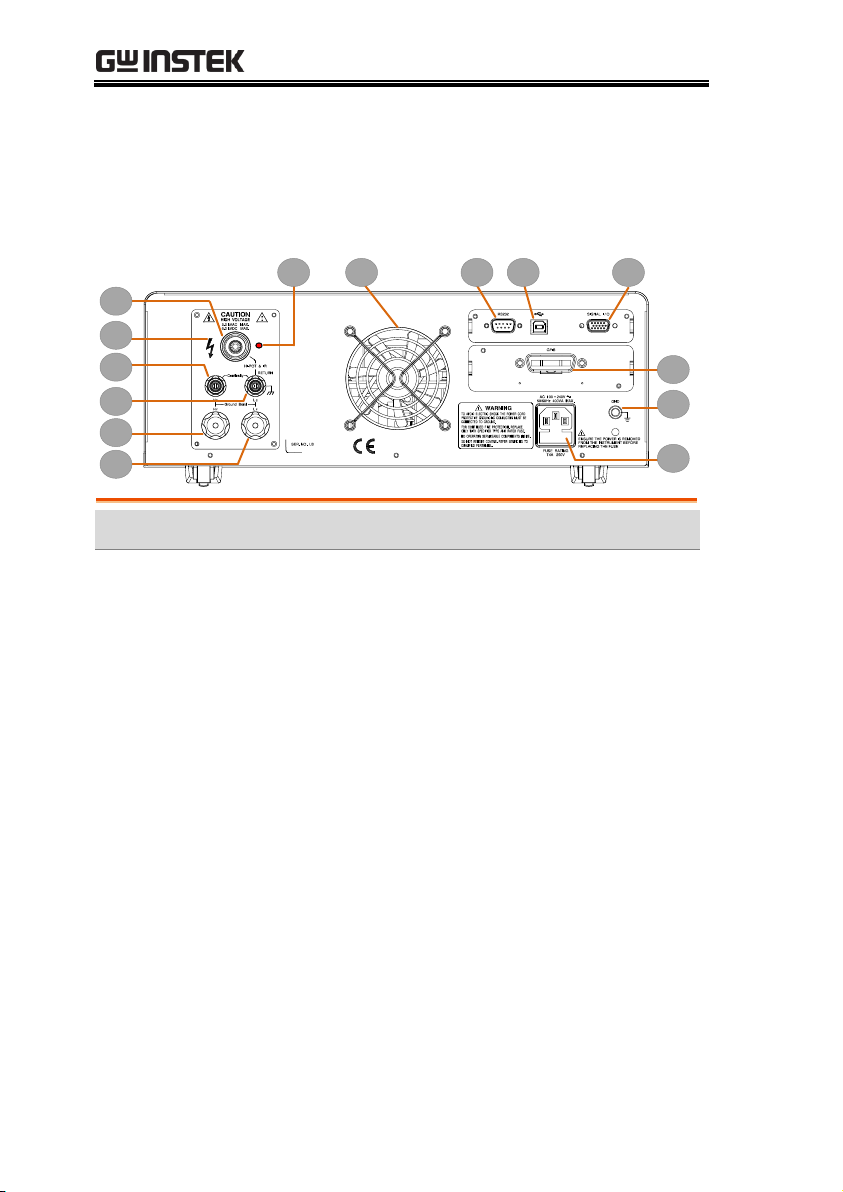

GPT-10000 Series User Manual

1

3

7 8 9 A

B

C

D

2

4

5

6

E

Item

Description

1

HIGH VOLTAGE Output Terminal

2

HIGH VOLTAGE Indicator

3

SENSE H & Output Terminal

4

SENSE L & RETURN Terminal

5

SOURCE H (GPT-12004 only)

6

SOURCE L (GPT-12004 only)

7

Fan 8 RS-232 Port

9

USB B-Type Interface Port

A

Signal I/O Port

B

GPIB Port (Optional)

C

GND

D

AC Mains Input (Power Cord Socket)

E

HIGH VOLTAGE pilot lamp

Rear Panel Overview

GPT-12001/12002/12003/12004

18

GETTING STARTED

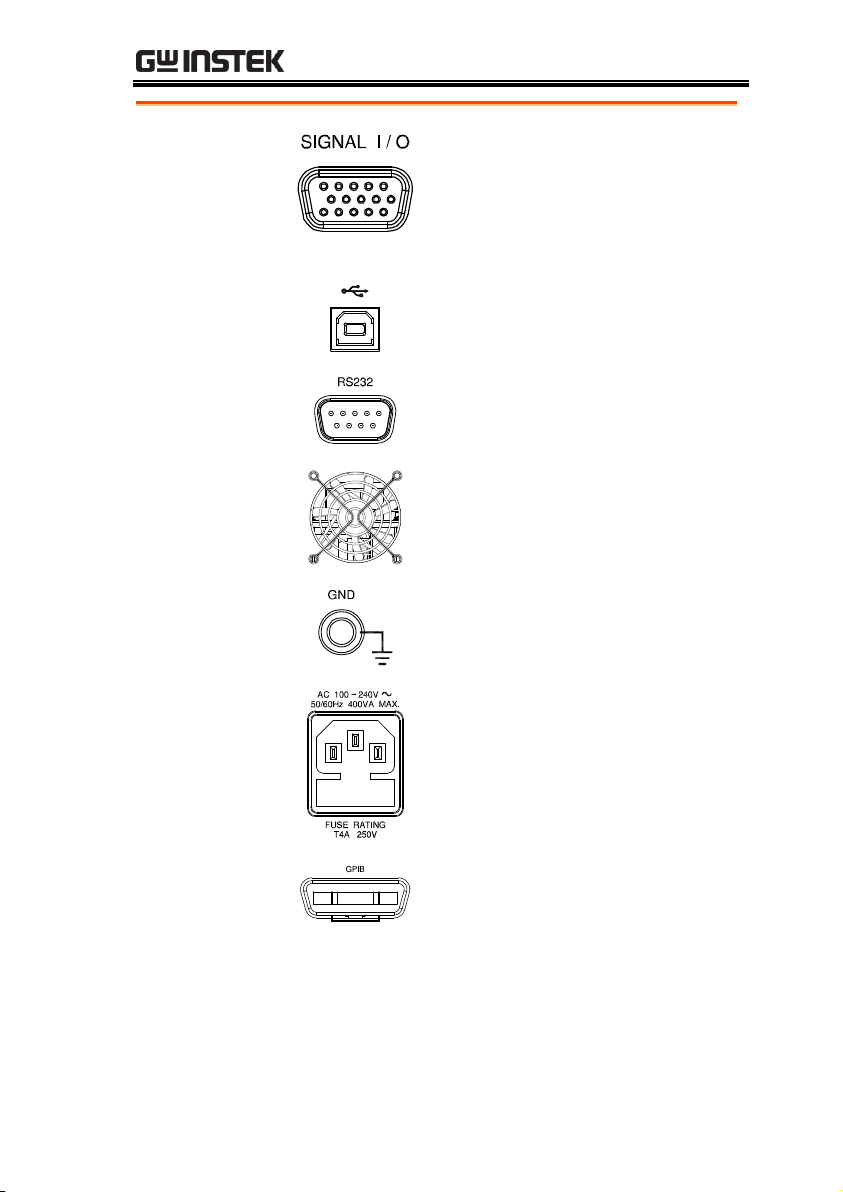

SIGNAL I/O port

The SIGNAL I/O port is used to

monitor the tester status (PASS,

FAIL, TEST) and input (START/

STOP signals). It is also used with

the Interlock key.

USB B-Type port

The USB B-Type port is used for

remote control.

RS232 interface

port

The RS-232 port is used for remote

control and firmware updates.

Fan/Fan Vents

Exhaust fan. Allow enough room

for the fan to vent. Do not block the

fan openings.

GND

Connect the GND (ground)

terminal to the earth ground.

AC Mains Input

AC Mains Input for Power Cord

Socket: 100 – 240 VAC ±10%.

The fuse holder contains the AC

mains fuse. For fuse replacement

details, see page 45.

Optional GPIB

port

Optional GPIB interface for remote

control.

19

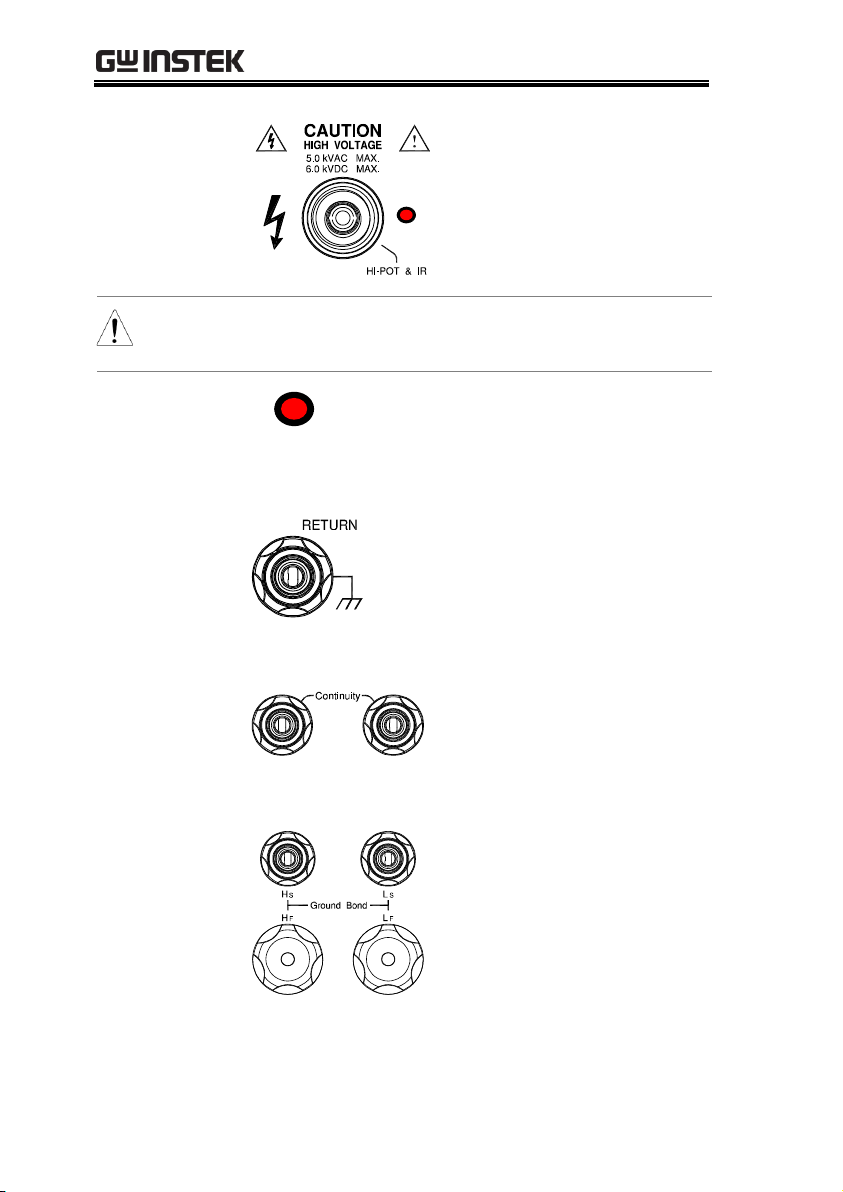

GPT-10000 Series User Manual

HIGH VOLTAGE

output terminal

The HIGH VOLTAGE

terminal output is used for

outputting the testing voltage

in ACW, DCW and IR tests.

The terminal is recessed for

safety and used in conjunction

with the RETURN terminal.

WARNING

USE EXTREME CAUTION. Do not touch the

HIGH VOLTAGE terminal during testing.

HIGH

VOLTAGE pilot

lamp

The HIGH VOLTAGE pilot lamp will

light up red when an output terminal is

active. Only after the test has finished

or stopped will the lamp turn off.

RETURN

terminal

The RETURN terminal is

used for ACW, DCW, IR and

CONT tests.

OUTPUT and

RETURN

terminals

All models

The OUTPUT terminal (red)

and RETURN terminal

(black) are used for CONT

(Continuity) test.

SENSE H/L and

SOURCE H/L

terminals

GPT-12004 only

The SENSE H, SENSE L,

SOURCE H and SOURCE L,

terminals are used for GB

(Ground Bond) test.

20

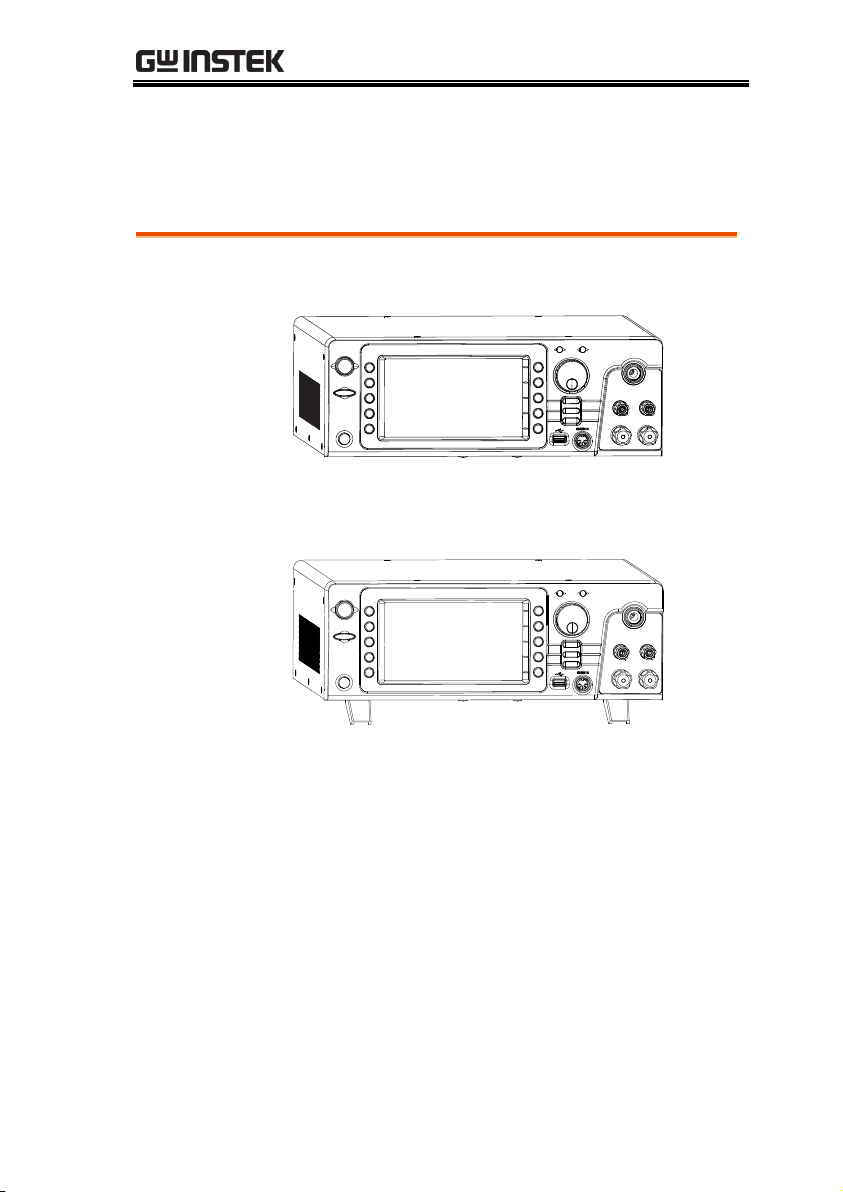

GETTING STARTED

Horizontal

position

Place the unit on a flat surface horizontally.

Tilt stand

position

Gently pull the 2 stands out from the bottom and

the unit will be placed in the tilt stand position.

Set Up

Tilting the Stand

21

GPT-10000 Series User Manual

Background

The GPT-12000 accepts line voltages of

100 - 240V at 50Hz or 60Hz.

Steps

1. Connect the power cord to

the AC Mains Input socket

on the rear panel.

2. If the power cord does not

have an earth ground,

ensure the ground

terminal is connected to an

earth ground.

Warning

Ensure the power cord is connected to an earth

ground. Failure could be harmful to the operator

and instrument.

3. Press the Power button.

4. When the unit is powered up, the display will

show the last time parameters in either MANU

or AUTO test mode as shown below.

Line Voltage Connection and Power Up

22

GETTING STARTED

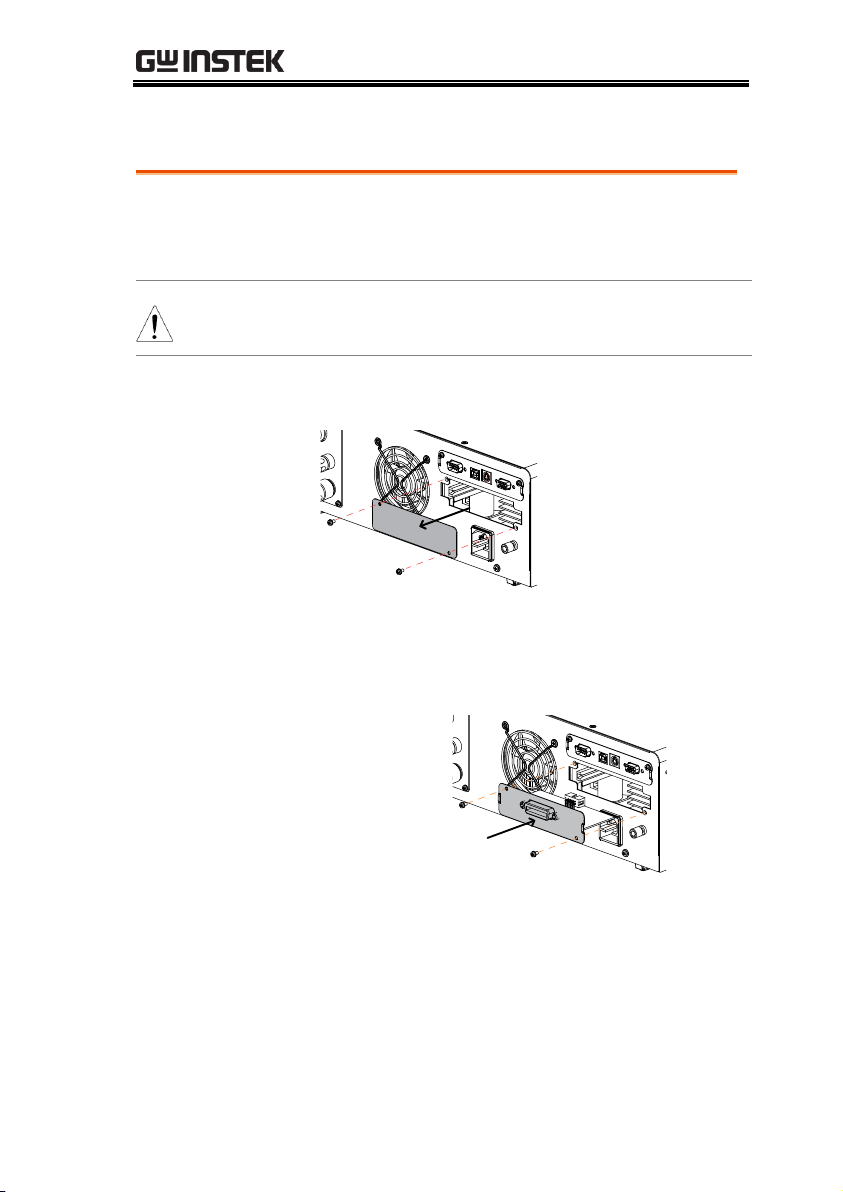

Background

The optional GPIB is a user-installable option.

Follow the instructions below to install the

GPIB card.

WARNING

Before installing optional GPIB card ensure the GPT12000 is turned off and disconnected from power.

Steps

1. Remove screws from the rear panel cover plate.

2. Insert the GPIB card into the opening of rear

panel. Push the card gently until it is fully

inserted followed by fastening the screws.

GPIB Card

Installing the Optional GPIB Card

23

GPT-10000 Series User Manual

Background

The GPT-12000 is a high voltage instrument

that outputs dangerous voltages. The following

section describes precautions and procedures

that must be followed to ensure a safe work

environment.

WARNING

The GPT-12000 generates voltages in excess of

5kVAC or 6kVDC. Follow all safety precautions,

warnings and directions given in the following

section when using the instrument.

1. Only technically qualified personnel should be

allowed to operate the safety analyzer.

2. The operating workplace must be fully isolated,

especially when the instrument is in operation.

The instrument should be clearly labeled with

appropriate warning signage.

3. The operator should not wear any conductive

materials, jewelry, badges, or other items, such

wrist watches.

4. The operator should wear insulation gloves for

high voltage protection.

5. Ensure the earth ground of the line voltage is

properly grounded.

6. Ensure any devices that are adversely affected

by magnetic fields are not placed near the

tester.

Workplace Precautions

24

GETTING STARTED

Background

The GPT-12000 is a high voltage instrument

that outputs dangerous voltages. The following

section describes precautions and procedures

that must be followed to ensure that the tester

is operated in a safe manner.

WARNING

The GPT-12000 generates voltages of up to 5kVAC

or 6kVDC. Follow all safety precautions, warnings

and directions given in the following section when

using the instrument.

1. Never touch the safety analyzer, lead wires,

terminals, probes and other connected

equipment when the tester is testing.

2. Do not turn the safety analyzer on and off

quickly or repeatedly. When turning the power

off, please allow a few moments before turning

the power back on. This will allow the

protection circuits to properly initialize.

Do not turn the power off when a test is

running, unless in an emergency.

3. Only use those test leads supplied with the

instrument. Leads with inappropriate gauges

can be dangerous to both the operator and the

instrument.

For GB testing, never use the Sense leads on the

SOURCE terminals.

4. Do not short the HIGH VOLTAGE terminal

with ground. Doing so could charge the chassis

to dangerously high voltages.

Operating Precautions

25

GPT-10000 Series User Manual

5. Ensure the earth ground of the line voltage is

properly grounded.

6. Only connect the test leads to the HIGH

VOLTAGE/SOURCE H/SENSE H terminals

before the start of a test. Keep the test leads

disconnected at all other times.

7. Always press the STOP button when pausing

testing.

8. Do not leave the safety analyzer unattended.

Always turn the power off when leaving the

testing area.

9. When remotely controlling the safety analyzer,

ensure adequate safety measures are in place to

prevent:

Inadvertent output of the test voltage.

Accidental contact with the instrument during

testing. Ensure that the instrument and DUT are

fully isolated when the instrument is remotely

controlled.

10. Ensure an adequate discharge time for the

DUT.

When DCW or IR tests are performed, the DUT,

test leads and probes become highly charged.

The GPT-12000 has discharge circuitry to

discharge the DUT after each test. The time

required for a DUT to discharge depends on the

DUT and test voltage.

Never disconnect the safety analyzer before a

discharge is completed.

26

GETTING STARTED

Background

The GPT-12000 is a high voltage device and as

such, daily safety checks should be made to

ensure safe operation.

1. Ensure all test leads are not broken and are free

from defects such as cracks or splitting.

2. Ensure the safety analyzer is always connected

to an earth ground.

3. Test the safety analyzer operation with a low

voltage/current output:

Ensure the safety analyzer generates a

FAIL judgment when the HIGH

VOLTAGE and RETURN terminals are

shorted (using the lowest voltage/current as

the testing parameters).

WARNING

Do not use high voltages/currents when the HIGH

VOLTAGE and RETURN terminals are shorted. It

may result in damage to the instrument.

Basic Safety Checks

27

GPT-10000 Series User Manual

Menu Tree ...................................................................... 30

Menu Tree Overview ............................................................................... 31

Test Lead Connection ...................................................... 35

ACW, DCW, IR Connection ................................................................... 35

GB Connection .......................................................................................... 36

CONT Connection.................................................................................... 37

Manual Tests .................................................................. 38

Setting the Test Function ......................................................................... 39

Choose/Recall a Manual Test Number ................................................. 40

Creating a MANU Test File Name ......................................................... 41

Setting the Upper and Lower Limits ..................................................... 42

Setting the Test Time ............................................................................... 44

Setting the Ramp Up Time ...................................................................... 46

Setting the Ramp Down Time ................................................................ 48

Setting the Test Voltage or Test Current ............................................... 50

Setting the Test Frequency ...................................................................... 52

Setting a Reference Value ........................................................................ 53

Setting an Initial Voltage ......................................................................... 54

Setting the Wait Time .............................................................................. 56

Setting the ARC Function........................................................................ 58

Setting MAX HOLD ................................................................................. 61

Setting PASS HOLD ................................................................................. 62

Setting IR Mode ........................................................................................ 63

Setting GND OFFSET .............................................................................. 65

Setting GB Contact ................................................................................... 67

Zero Check for the Test Leads ................................................................ 69

Setting the Grounding Mode .................................................................. 72

Running a MANU Test ............................................................................ 76

PASS / FAIL MANU Test ....................................................................... 81

OPERATION

28

OPERATION

Special MANU Test Mode (000) ...................................... 87

Sweep Function .............................................................. 89

Automatic Tests ............................................................. 92

Choose/Recall an AUTO Test ................................................................93

Creating an AUTO Test File Name ........................................................94

Adding a Step to the AUTO Test ...........................................................95

Continuous AUTO Tests .........................................................................97

AUTO Test Page Editing .........................................................................99

Running an Automatic Test ..................................................................104

Automatic Test Results ..........................................................................110

29

GPT-10000 Series User Manual

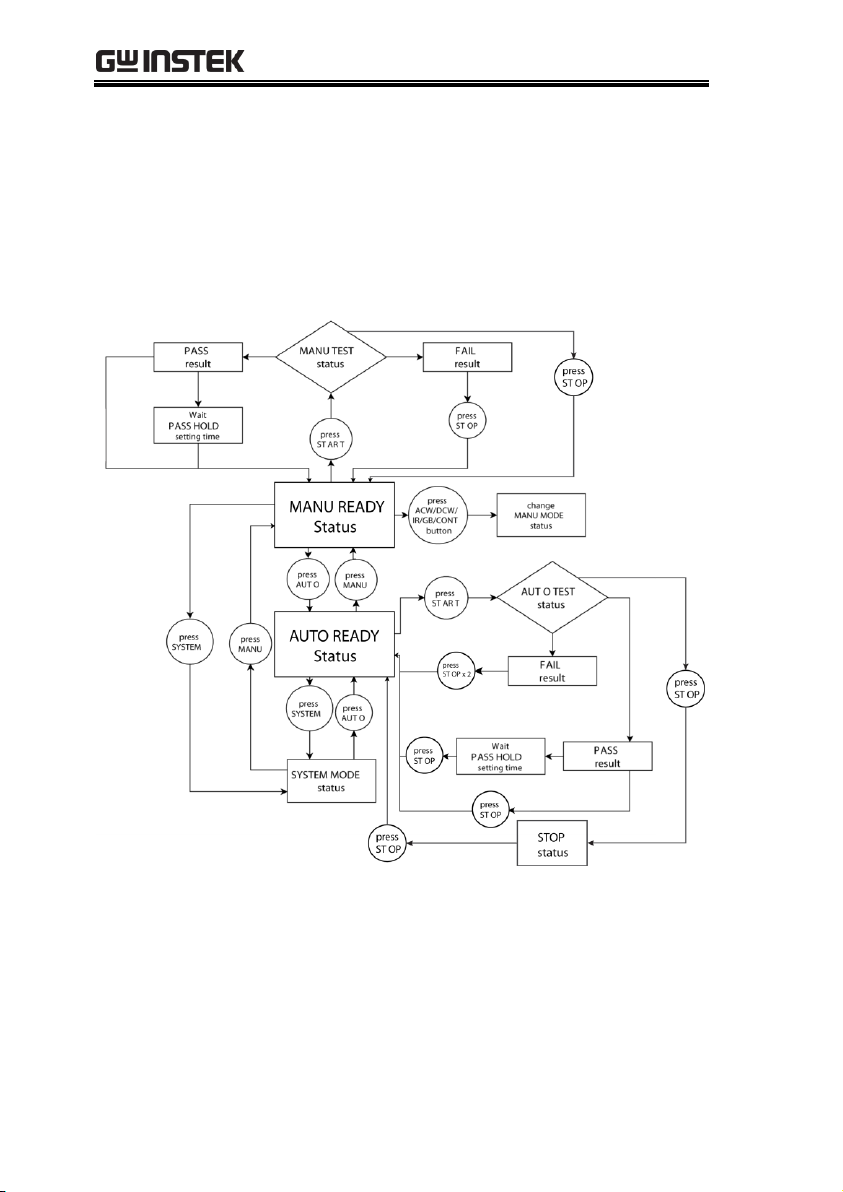

Menu Tree

This section describes the overall structure of the operation statuses

and modes for the GPT-12000 safety analyzers. The testers have

two main testing modes (MANU, AUTO), one system mode

(SYSTEM) and 5 main operation statuses (READY, TEST, PASS,

FAIL and STOP).

30

Loading...

Loading...