Page 1

Installation Instructions for

Type TBC, TDC, TEBC, TEBH, TEDH Duct Fans

OPERATION AND MAINTENANCE INSTRUCTIONS -- REVERSE SIDE

1. Pre-Installation Check of Fan. Before

installation of an American Coolair fan, a

careful check should be made for shipping

damage which may affect operation of the

unit. If damage is found, file a claim

immediately with delivering carrier. On

belt drive units, pulley alignment and belt

tension should be checked (see paragraph

2 under Operation and Maintenance).

Before connecting to power source, make

sure propeller turns freely without striking

duct or any foreign object. Check motor

nameplate to be sure correct phase and

voltage are being used. Check wiring

diagram to make sure proper connection

are made for the electrical service being

applied. Note direction arrow adjacent to

propeller and make sure rotation is correct

when power is connected.

2. Installation Procedures.

(a) Duct Connections. The American

Coolair duct fan has flanged ends for

convenient mounting directly to the

duct work. Flexible connections or

transition pieces my be utilized.

(b) Motor Position and Wiring. From an

operating standpoint, the American

Coolair duct fan and motor may be

mounted in any position. For

convenience in wiring and service, the

motor should be readily accessible.

(c) Mounting Feet (Optional Accessory).

If duct fan is not adequately supported

by duct work or otherwise, mounting

feet should be utilized. Type and

location of mounts furnished will be

based on customer’s information as to

type of support (floor or ceiling)

available.

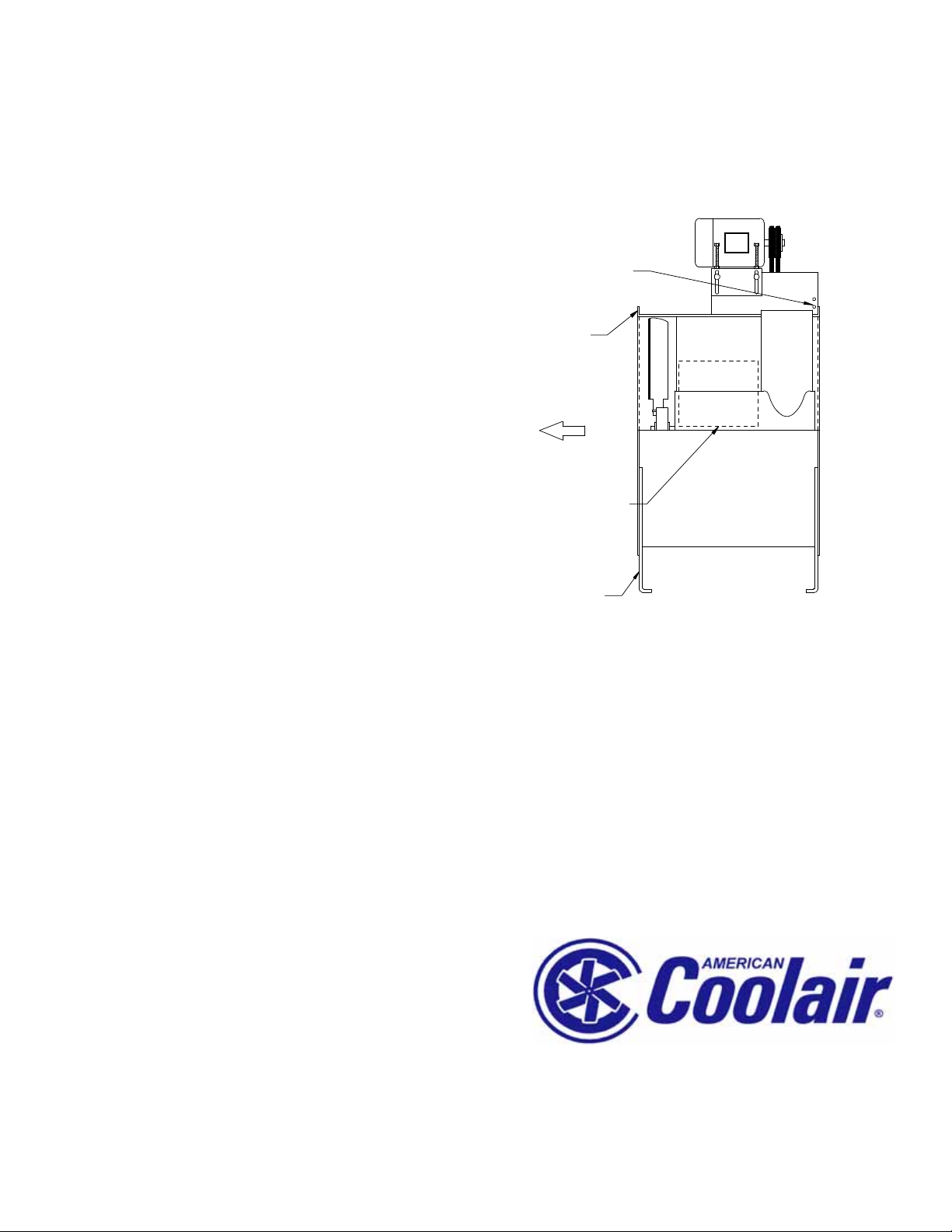

Grease Fittings

(Optional)

Mounting

Flange

Access Panel

(Optional)

Mounting Feet

(Optional)

TYPE TB DUCT FAN

(Cutaway View)

NOTE: All local, state and federal

codes should be checked to make sure all

wiring, guarding and intended usage of the

fan unit(s) comply with all applicable codes.

The proper type, class of fan and motor

should be used for air being handled, such as

explosive or hazardous air mixtures.

P.O. Box 2300 ~ Jacksonville, Florida 32203

Phone: (904) 389-3646

Fax: (904) 387-3449 or (904) 381-7560

E-mail: fans@coolair.com

Form No. 410-40-4 (5-09) Printed in U.S.A.

© American Coolair Corporation 2009

Page 2

Operation and Maintenance Instructions for

Type TBC, TDC, TEBC, TEBH, TEDH Duct Fans

INSTALLATION INSTRUCTIONS -- REVERSE SIDE

1. Fan Cleaning and Adjustment. The entire fan

assembly should be cleaned as necessary to

remove accumulated dust, dirt and other foreign

matter, which may collect on the blades or other

parts. Access to fan through duct work is essential

for proper cleaning. An optional access panel on

fan may be furnished. If so, removal of this panel

allows limited access to fan for inspection, cleaning

and lubrication of motor on direct drive models. On

belt drive models, belt(s) should be inspected and

tension adjusted (see below). Belt alignment should

also be checked to avoid excessive wear and

premature failure. This same inspection of belts and

adjustment of tension should be made after the first

24-48 hours of usage following installation. If rust or

corrosion is found anywhere on the fan, the affected

area should be thoroughly cleaned and refinished.

2. Belt Replacement, Tension and Adjustment.

(a)To change belt(s), loosen motor bracket bolts

and tension adjustment bolts and remove belt(s)

from motor and fan pulleys. Install new belt(s)

and adjust as indicated below. When rep lacing

belt(s), do not roll new belts(s) over pulleys under

tension. This practice can damage the belt(s)

severely.

(b)To tension belt(s), place a finger midway

between the motor pulley and fan pulley and

push belt(s) inward about 1/2” (at approximately

5 lb. force) for proper tension. To adjust tension,

loosen motor bracket bolts and use t ens io n

adjustments bolts to obtain correct belt tension.

Be sure to retighten motor bracket bolts to

maintain proper belt tension. Recheck alignment

of belts between motor pulley and fan pulley.

CAUTION: Use of tension adjustments bolts

makes it easy to over tighten belt(s). When this

occurs, belt(s), motor and fan bearings will soon

fail. Do not over tension.

3. Blade Pitch Adjustment. AMERICAN COOLAIR

DOES NOT RECOMMEND FIELD ADJUSTMENT

OF BLADE PITCH ON TYPE T FANS. Blade pitch

is fixed on TEDH/TEBH fans. Blade pitch is factory

set for specified performance with standard motor

fully loaded on TDC,TBC,TEBC fans. Air volume

may be adjusted through a change in blade pitch.

Any change in blade pitch will affect motor load.

Contact your American Coolair representative

before making any field adjustment of the blade

pitch on these propellers.

4. Adjustment of Fan Speed and Air Volume. On

belt drive models with a variable pitch motor pulley,

fan speed and air flow are easily regulated. Motor

capacity must be carefully checked before any

increase in fan speed is made. Motor capacity

must be carefully checked before any increase in

fan speed is made.

5. Lubrication. Fan bearings on belt drive models

are factory lubricated for extended service.

External grease fittings for fan bearings are

standard on all belt drive models. Relubrication

annually or more frequently is recommended. For

best results, use Shell Alvania No. 3 lubricant or

equivalent. For lubrication of electric motors, see

instructions supplied by motor manufacturer.

6. Repair Parts.

(a) Belts. Replacement belts for belt drive units

are standard V-belts used on industrial

machines. Replacements may be obtained

through local industrial supply houses. If more

than one belt is used on the fan, be sure to

replace with matched sets. To install belt(s),

see instructions above for belt replacement.

(b) Blades. If one or more propeller blades are

damaged, it is recommended that the entire

propeller be replaced or removed and returned

to the factory for repairs. If an unbalanced

condition develops, thoroughly clean blades to

remove dirt or other foreign matter. If

unbalance still exists, treat as blade damage

and replace or return to factory for repairs.

(c) Bearings. Replacement pillow block bearings

may be obtained through local industrial supply

houses.

(d) Motor. Motor repairs should be performed

only by an authorized motor repair station.

Contact the motor manufacturer or American

Coolair for location of repair station.

Caution: Do not return damaged or defective

parts to American Coolair without prior

authorization. If repairs under warranty are

claimed, see warranty terms in American Coolair

catalog or contact the factory in Jacksonville,

Florida. Claims for warranty repairs to electric

motors should be made direct to the motor

manufacturer.

P.O. Box 2300 ~ Jacksonville, Florida 32203

Phone: (904) 389-3646

Fax: (904) 387-3449 or (904) 381-7560

E-mail: fans@coolair.com

Loading...

Loading...