Page 1

✩

✩ IMPORTANT INFORMATION

IMPORTANT INFORMATION ✩✩✩✩ KEEP FOR OPERATOR

✩ ✩

IMPORTANT INFORMATION IMPORTANT INFORMATION

KEEP FOR OPERATOR ✩✩✩✩ IMPORTANT INFORMATION

KEEP FOR OPERATOR KEEP FOR OPERATOR

IMPORTANT INFORMATION ✩✩✩✩

IMPORTANT INFORMATION IMPORTANT INFORMATION

OPERATOR MANUAL OM-HY-5G

Part Number 138486 Rev B DOMESTIC

MODELS: HY-5G, (2)HY-5G

HyPerSteam™

Atmospheric Convection

Steamer

Self-Contained

Gas Heated

Capacity: 5 Steamer Pans [per cavity] (HY-5G)

(12" x 20" x 2½”)

HY-5G

(2)HY-5GF

THIS MANUAL MUST BE RETAINED FOR FUTURE REFERENCE. READ,

UNDERSTAND AND FOLLOW THE INSTRUCTIONS AND WARNINGS

CONTAINE D IN THIS MANUAL.

FOR YOUR SAFETY

DO NOT STORE OR USE GASOLINE OR OTHER FLAMMABLE VAPORS A ND

LIQUIDS IN THE VICINITY OF THIS OR ANY OTHER APPLIANCE

.

POST IN A PROMINENT LOCATION

INSTRUCTIONS TO BE FOLLOWED IN THE EVENT USER SMELLS GAS. T HIS

INFORMATION SHALL BE OBTAINED BY CONSULTING YOUR LOCAL GAS

SUPPLIER. AS A MINIMUM, TURN OFF GAS AND CALL YOUR GAS

COMPANY AND YOUR AUTHORIZED SERVICE AGENT. EVACUATE ALL

PERSONNEL FROM THE AREA.

WARNING

IMPROPER INSTALLATION, ADJUSTMENT, ALTERATION, SERVICE OR

MAINTENANCE CAN CAUSE PROPERTY DAMAGE, INJURY OR DEATH.

READ THE INST ALLATION, OPERATING AND MAINTENANCE INSTRUCTIONS

THOROUGHLY BEFORE INSTALLING OR SERVICING THIS EQUIPMENT.

Page 2

OM-HY-5G

IMPORTANT — READ FIRST — IMPORTANT

WARNING: THE UNIT MUST BE INSTALLED BY PERSONNEL QUALIFIED TO WORK WITH ELECTRICITY

AND PLUMBING. IMPROPER INSTALLATION CA N CAUSE INJURY TO PERSONNEL AND/OR

DAMAGE TO THE EQUIPMENT. THE UNIT MUST BE INSTALLED IN ACCORDANCE WITH

APPLICABLE CODES.

CAUTION: SHIPPING STRAPS ARE UNDER TENSION AND CAN SNAP BACK WHEN CUT.

CAUTION: DO NOT INSTALL THE UNIT IN ANY WAY WHICH WILL BLOCK THE SIDE VENTS, OR WITHIN

12 INCHES OF A HEAT SOURCE SUCH AS A BRAISING PAN, DEEP FRYER, CHAR BROILER

OR KETTLE.

CAUTION: LEVEL THE UNIT FRONT TO BACK, OR PITCH IT SLIGHTLY TO THE REAR, TO AVOID

DRAINAGE PROBLEMS.

WARNING: FOLLOW THE WIRING DIAGRAM EXACTLY WHEN CONNECTING A UNIT TO AVOID

DAMAGE OR INJURY. WIRING DIAGRAM IS LOCATED ON THE INSIDE OF THE RIGHT

PANEL.

CAUTION: DO NOT USE PLASTIC PIPE. DRAIN MUST BE RATED FOR BOILING WATER.

WARNING: DO NOT CONNECT THE DRAIN DIRECTLY TO A BUILDING DRAIN.

WARNING: BLOCKING THE DRAIN IS HAZARDOUS.

Important: Improper drain connection will void warranty.

Important: Do not allow any water traps in the line. A trap can cause pressure to build up inside the

cavity during steaming, which will make the door gasket leak.

WARNING: WHEN YOU OPEN THE DOOR, STAY AWAY FROM STEAM COMING OUT OF THE UNIT.

STEAM CAN CAUSE BURNS.

WARNING: BEFORE CLEANING THE OUTSIDE OF THE STEAMER, DISCONNECT THE ELECTRIC

POWER SUPPLY. KEEP WATER AND CLEANING SOLUTIONS OUT OF CONTROLS AND

ELECTRICAL COMPONENTS. NEVER HOSE OR STEAM CLEAN ANY PART OF THE UNIT.

WARNING: ALLOW COOKING CHAMBER TO COOL BEFORE CLEANING.

WARNING: CAREFULLY REA D THE WARNINGS AND FOLLOW THE DIRECTIONS ON THE LABEL OF

EACH CLEANING AGENT.

RECOMMENDED BY DELIMING AGENT MANUFA CTURER.

WARNING: DO NOT MIX DE-LIMING AGENTS (ACID) AND DE-GREASERS (ALKALI).

WARNING: DO NOT PUT HANDS OR TOOLS INTO THE COOKING CHAMBER UNTIL THE FAN HAS

STOPPED TURNING.

WARNING: DO NOT OPERATE THE UNIT UNLESS THE REMOVABLE RIGHT SIDE PANEL HAS BEEN

RETURNED TO ITS PROPER LOCATION.

NOTICE: DO NOT USE A CLEANING OR DE-LIMING AGENT THAT CONTAINS ANY SULFAMIC ACID,

OR ANY CHLORIDE, INCLUDING HYDROCHLORIC ACID. IF THE CHLORIDE CONTENT OF

ANY PRODUCT IS UNCLEAR, CONSULT THE MANUFACTURER.

OR DE-LIMING AGENT THAT CONTAINS MORE THAN 30% PHOSPHORIC ACID.

NOTICE: DO NOT USE ANY DE-GREASER THAT CONTA I NS POTASSIUM HYDROXIDE OR SODIUM

HYDROXIDE OR THAT IS ALKALINE.

WARNING: USE OF ANY REPLACEMENT PARTS OTHER THAN THOSE SUPPLIED BY GROEN OR THEIR

AUTHORIZED DISTRIBUTOR VOIDS ALL WARRANTIES AND CAN RESULT IN BODILY

INJURY TO THE OPERATOR AND DAMAGE THE EQUIPMENT. SERVICE BY OTHER THAN

FACTORY-AUTHORIZED PERSONNEL WILL VOID ALL WARRANTIES.

USE SAFETY GLASSES AND RUBBER GLOVES AS

DO NOT USE A CLEANING

WARNING: HIGH VOLTAGE EXISTS INSIDE CONTROL COMPARTMENTS. DISCONNECT FROM BRANCH

CIRCUIT BEFORE SERVICING. FAILURE TO DO SO CAN RESULT IN SERIOUS INJURY OR

DEATH.

2

Page 3

OM-HY-5G

Table of Contents

OPERATOR WARNINGS ....................................................................2

REFERENCES............................................................................. 3

EQUIPMENT DESCRIPTION .................................................................4

INSPECTION AND UNPACKING ..............................................................4

WATER QUALITY AND TREATMENT ..........................................................5

INSTALLATION AND START-UP ..............................................................6

OPERATION ............................................................................. 10

CLEANING...............................................................................12

MAINTENANCE ...........................................................................14

TROUBLESHOOTING......................................................................14

PARTS LIST.............................................................................. 15

ELECTRICAL SCHEMATICS................................................................. 19

SERVICE LOG............................................................................20

WARRANTY.............................................................................. 22

References

CSA International

8501 East Pleasant Valley Road

Cleveland, OH 44131

KLENZADE SALES CENTER

ECOLAB, Inc.

370 Wabasha

St. Paul, Minnesota 55102

800 328-3663 or 612 293-2233

NATIONAL FIRE PROTECTION ASSOCIATION

60 Batterymarch Park

Quincy, Massachusetts 02269

NFPA/70 The National Electrical Code

NATIONAL SANITATION FOUNDATION

3475 Plymouth Road

Ann Arbor, Michigan 48106

3

Page 4

OM-HY-5G

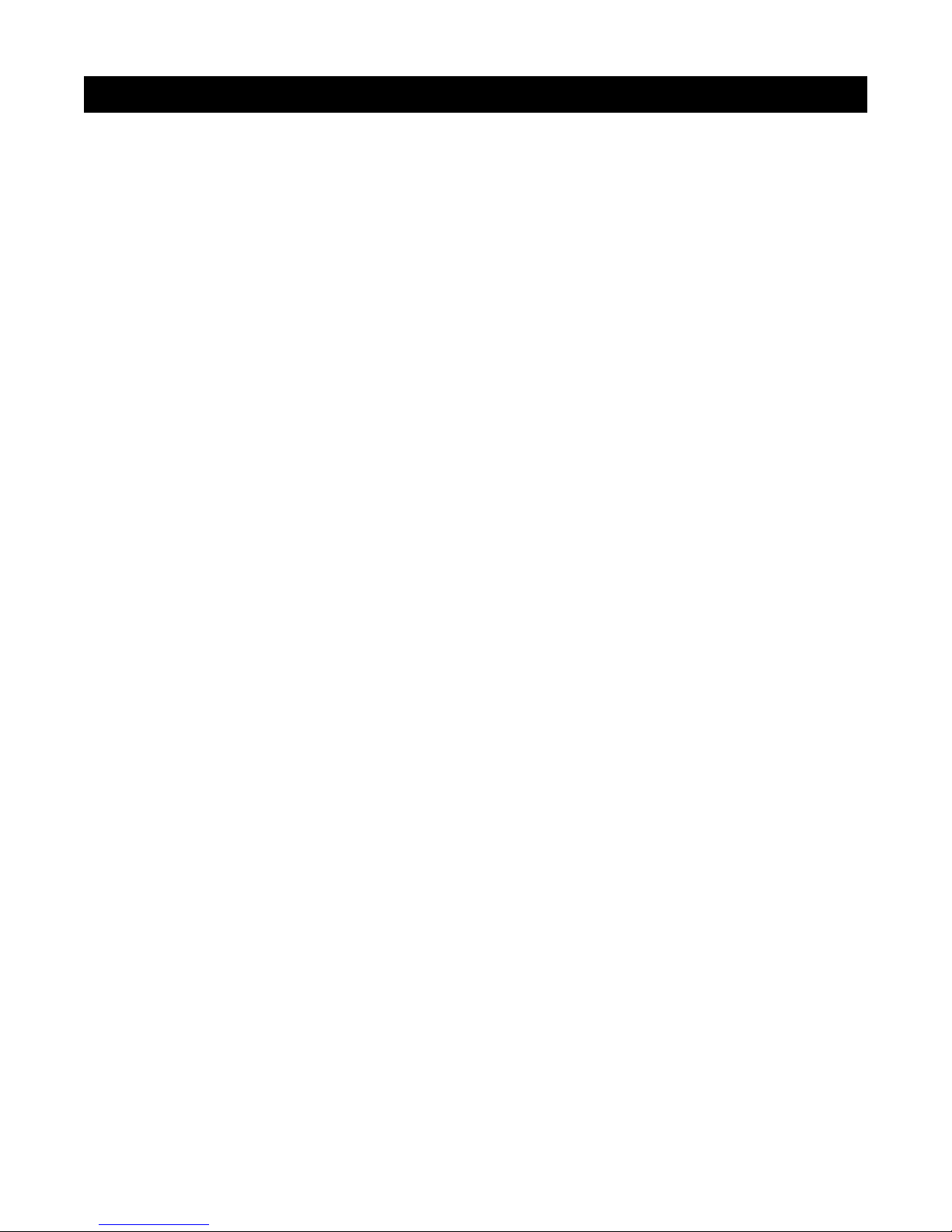

Equipment Description

Your Groen HY-5G or (2)HY-5G HyPerSteam

Convection Steamer is designed to give years of

service. It has a stainless steel cavity (cooking

chamber) which is served by an independent

atmospheric steam generator which is gas-heated. A

powerful blower circulates the steam in the cavity to

increase heating efficiency.

Each cavity holds up to five steam table pans (12" x

20" x 2½" deep). An 18 gauge stainless steel case

encloses the cavity, the steam generator and the

control compartment that houses electrical

components. Door hinges are reversible (the door

may be set to open from the left or right). Operating

Controls are on the front panel.

The HY-5G steamer is equipped with fully electronic

controls and a button-activated, pre-programmed

CLEAN cycle. These units are readily identified by

their unique control panels. The On-Off switch is

operated by touch pad controls, and the distinctive

symbol for steam is integrated into the panel.

The HY-5G steamer holds five standard

12" x 20" x 2½" steamer pans.

The drain system on all models includes a spray

condenser, which helps keep steam from escaping

from the chamber and cools drain water.

BURNER FIRING RATE

Steamer

HY-5G 62,000 62,000

(2)HY-5G 124,000 124,000

Natural Gas at

3.2" W.C.

L.P. Gas at

10.5" W.C.

Inspection and Unpacking

The Steamer will be delivered completely assembled

in a heavy shipping carton strapped to a skid. On

receipt, inspect carton carefully for exterior damage.

CAUTION

SHIPPING STRAPS ARE UNDER TENSION AND

CAN SNAP BACK WHEN CUT.

Carefully cut the straps and detach the s ides of the

carton from the skid. Pull the carton up off the unit. Be

careful to avoid personal injury or equipment damage

from staples which might be left in the carton walls.

The (2)HY-5G holds up to five pans per cavity.

CAUTION

THE HY-5G WEIGHS 203 POUNDS (92 KG). THE

THE (2)HY-5G WEIGHS 460 POUNDS (207 KG ).

YOU SHOULD GET HELP AS NEEDED TO LIFT

THIS WEIGHT SAFELY.

Write down the model number, serial number and

installation date. Keep this information for reference.

Space for these entries is provided at the top of the

Service Log in the back of this manual.

When starting installation, check packing materials to

make sure loose parts such as the condensate drip

tray are not discarded with this material.

4

Page 5

Water Quality and Treatment

It is essential to supply the steam generator with water

that will not form scale. Even though the steam

generator/boiler is engineered to minimize scale

formation, scale development depends on the

hardness of your water and the number of hours you

operate the equipment each day.

Most water supplies contain minerals which form scale.

It is this scale which could lead to an early component

failure.

Your local water utility can tell you about the minerals

in your water. The water going to the steam generator

should have between 30 and 40 parts per million (ppm)

total dissolved solids (TDS) and should have a pH

(acidity rating) of 7.0 to 9.0. Please follow these

simple precautions:

1. The best way to prevent scale is to use a Groen

PureSteem™ Water Treatment System which has

been specifically designed for Groen steamers and

combination ovens. Do not rely on unproven

water treatment systems sold for scale

prevention and removal. They are not

specifically designed to work with Groen

steamers and combination ovens.

OM-HY-5G

HY-5G

2. A well-maintained water treatment system and a

regular cartridge replacement schedule is

essential.

3. Using a Groen PureSteem™ Water Treatment

System will provide longer steam generator/boiler

life, higher steam capacity, and reduce

maintenance requirements.

4. If you notice a slowdown in steam production or an

increase in deliming, have the steamer checked for

scale build-up. This could be an indication that the

water treatment cartridges need replacing. Heavy

scale reduces the unit’s ability to boil water, and

can even cause component failure.

MINIMIZE SCALE PROBLEMS BY INSTALLING

AND MAINTA INING A GROEN PureSteem™

WATER TREATMENT SYSTEM AND BY DELIMING

THE STEAMER REGULARLY.

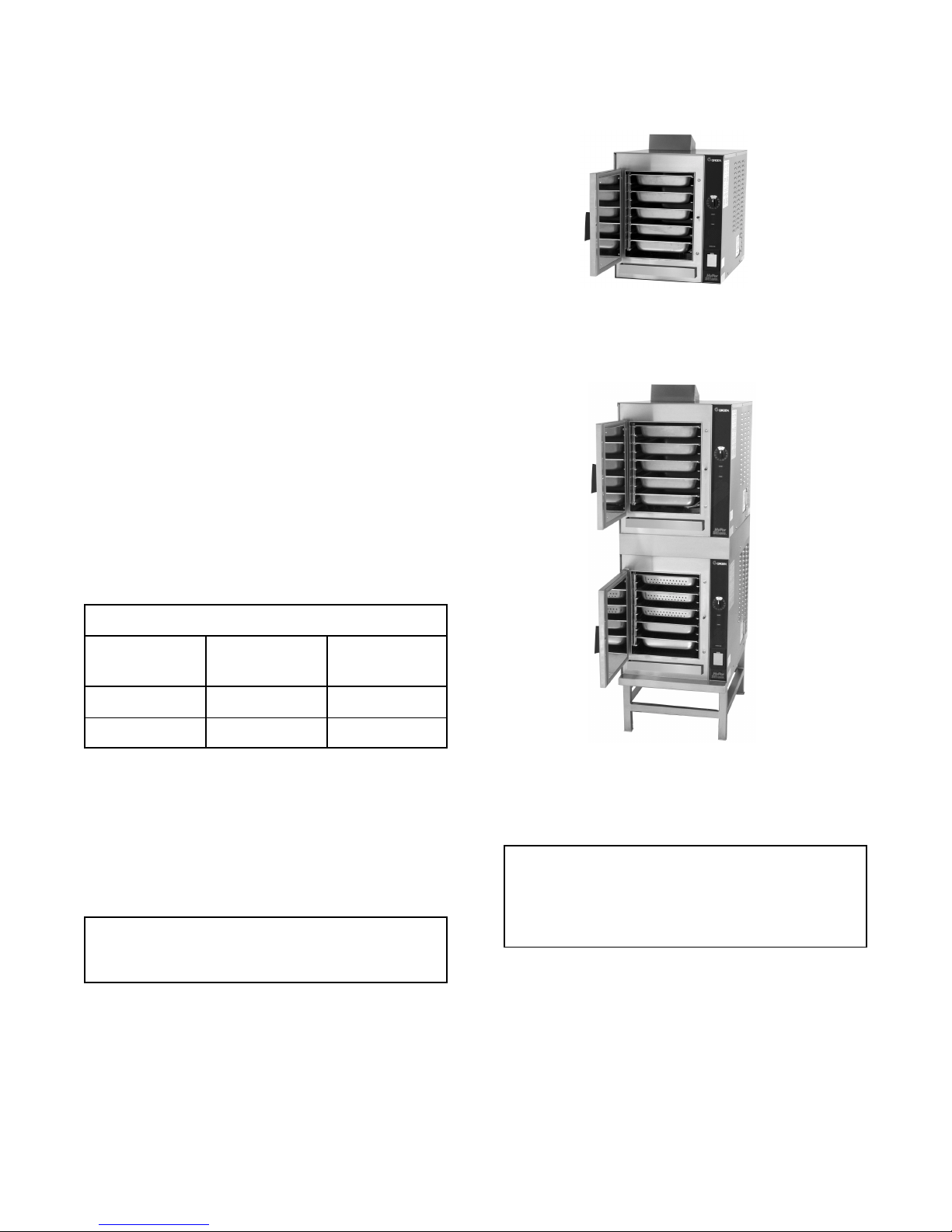

The Groen HY-5G Steamer features two separate

water inlets — one for the steam generator/boiler

(treated water), the other for the spray condenser

(untreated water). The second intake will reduce

treatment requirements resulting in significant savings.

The dual water connections are side by side on the

rear of the unit. When seen from the back of the unit,

the treated water intake is on the left.

(2)HY-5GF

The second water connection can reduce treated

water requirements.

5

Page 6

OM-HY-5G

Installation and Start-Up

WARNING

THE UNIT MUST BE INSTALLED BY PERSONNEL WHO ARE QUALIFIED TO WORK WITH GAS,

ELECTRI CITY AND PLUMBING. IMPROPER INSTALLATION CAN CA USE INJURY TO PERSONNEL AND/OR

DAMAGE TO THE EQUIPMENT. THE UNIT MUST BE INSTALLED IN ACCORDANCE WITH APPLICABLE

CODES

DO NOT INSTALL THE UNIT WITH THE RIGHT OR LEFT SIDE VENTS BLOCKED OR WITHIN 12 INCHES OF

A HEAT SOURCE (SUCH AS A BRAISING PAN, DEEP FAT FRYER, CHARBROILER OR KETTLE).

TO AVOID DRAINAGE PROBLEMS, LEVEL THE UNIT FRONT TO BACK, OR PITCH IT SLIGHTLY TO THE

REAR.

.

CAUTION

A. Installation

The HY-5G steamer is suitable for installation on or

near both combustible and noncombustible surfaces.

Minimum installation clearances are:

Right Side 2 inches

Left Side 2 inches

Rear 6 inches

However, for easy service at least 12 inches

clearance is required for the right side of the unit,

and it may not be installed within 12 inches of a

heat source, as stated in the Caution above.

The unit must be installed in a well-ventilated room

with an adequate air supply. The steamer must be

installed beneath a ventilation hood, since gas

combustion products exit the appliance.

Any item which might obstruct or restrict the flow of

air for combustion and ventilation must be removed.

Do not obstruct the flue cover or any front, side, rear,

or top vents after installation.

The area directly around the appliance must be

cleared of all combustible material. The installation

must conform with local codes or, in the absence of

local codes, with the National Fuel Gas Code, ANSI

Z223.1, latest edition, including the following:

Electrical Code should be observed in

accordance with ANSI/NFPA 70-1987 (or latest

edition). AN ELECTRICAL GROUND IS RE-

QUIRED. The electrical schematic is located in

the service compartment and in this manual.

Maximum load is 2½ AMPs. In Canada, provide

electrical service in accordance with the

Canadian Electrical Code, CSA C22.1 Part 1

and/or local codes.

2. Gas Supply Connection

Connection to the gas supply can be completed

with ½” NPT pipe or approved equivalent.

Although the immediate connection to the

appliance is ½” NPT, gas supply piping must be

large enough to provide 62,000 BTU/hr/cavity.

Supply pressure must be at least 4.5” W.C.

(maximum 14” W.C.) for natural gas or 12” W.C.

(maximum 14” W.C.) for LP gas. In Canada, the

installation must conform to the Canadian Gas

Code, CAN 1-B149, Installation Codes for Gas

Burning Appliances and Equipment and/or local

codes. Check all gas connections for leaks prior

to unit operation.

The unit and its individual shutoff valve must be

disconnected from the gas supply system during

any pressure testing of that system at test pressures

in excess of ½ PSI (3.45 kPa). It must be isolated

from the gas supply piping system by closing its

individual manual shutoff valve during any pressure

testing of the gas supply piping system at test

pressures equal to or less than ½ PSI (3.45 kPa).

1. Electrical Supply Connection

Provide 115 VAC, 60 HZ, 1 PH, 15 AMP service.

Bring wire in through hole on the lower left back

panel. Each cavity requires a separate cord for

connections. Local codes and/or the National

6

Page 7

After the unit has been connected to the gas

supply, all gas joints must be checked for leaks.

No flame should be used when checking for

leaks. A thick soap solution or other suitable

leak detector should be used.

OM-HY-5G

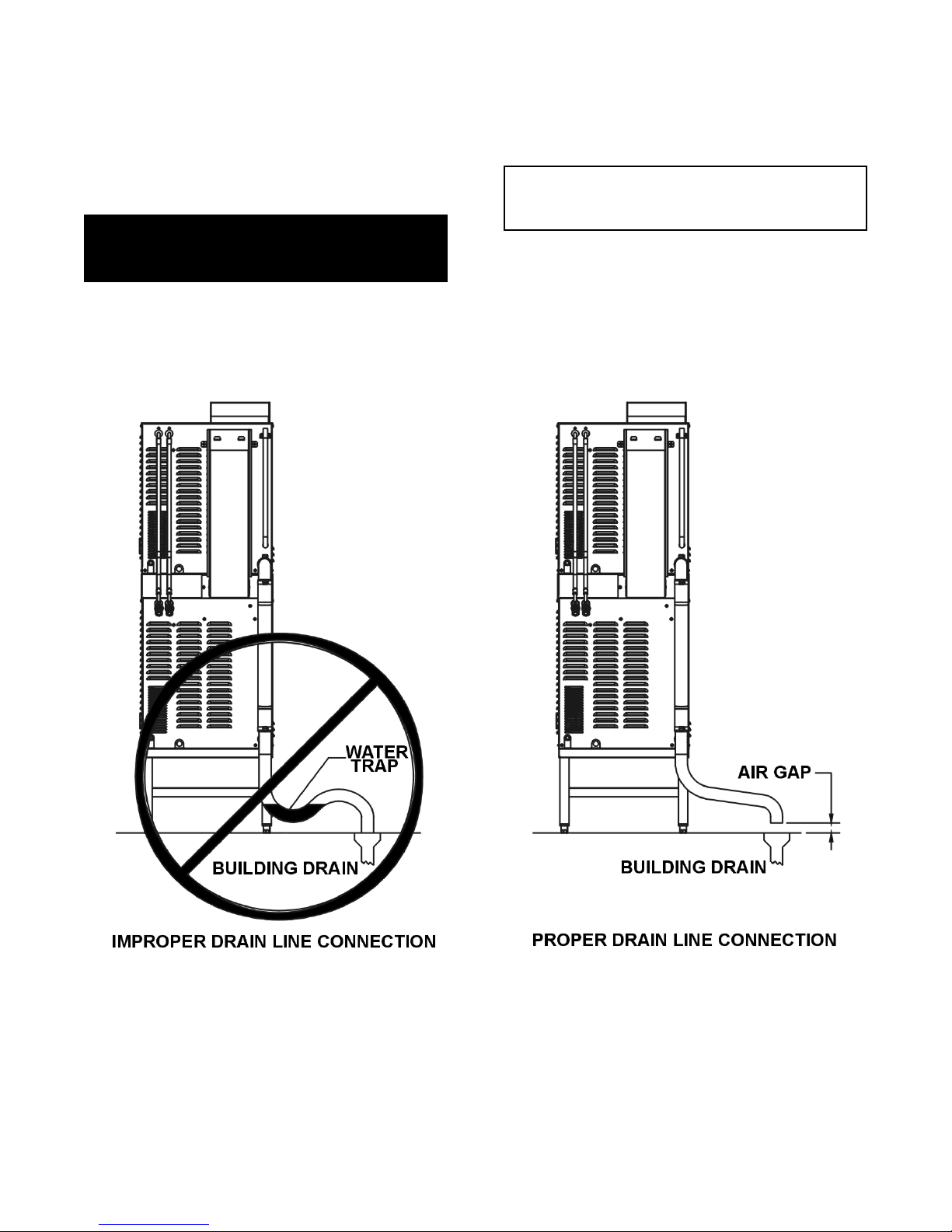

There must be a free air gap between the end of the

hose and the building drain. The free air gap should

be as close as possible to the unit drain. There must

also be no other elbows or other restrictions between

the unit drain and the free air gap.

For a unit on casters, complete connection to the

gas supply with connectors that comply with the

standard for connectors for moveable gas

appliances, ANSI Z21.69 — latest edition.

Restrain movement of the unit by attaching a

cable or chain to the eyelet (provided at the back

of the frame) and anchoring the cable or chain to

the wall or floor. Make the length and location of

the cable such that the unit cannot pull on the

gas connection while the cable is connected.

2. Water Connection(s)

Install a check valve to prevent back flow in the

incoming cold water line, as required by local

plumbing codes. Water pressure in the line

should be between 30 and 60 PSIG and must

deliver a flow rate of 1.5 to 3.0 gallons per

minute. If pressure is above 60 PSIG, a

pressure regulator will be needed.

¾ inch female NH connectors (garden hose

type) are used to attach the water supply to the

inlet valves. One connector is for the steam

generator (treated), the other is for the spray

condenser (untreated). Minimum inside

diameter of the water feed line is ½ inch. Use

a washer in the hose connection. Do not allow

the connection to leak, no matter how slowly. Do

not over tighten hose connections. Treated

(softened) water goes to the right (seen from the

rear of the unit), and untreated water to the left.

Connections for both are made as shown on

Page 5. Though not recommended, an adapter

to use a single water intake is available, P/N

138473.

3. Drain Connection

Level the steamer front to back, or pitch it slightly

to the rear (maximum ¼ inch) by adjusting the

optional legs or bullet feet on optional stand.

A 2 inch ID hose may be attached to the drain

pipe (supplied).

WARNING:

DO NOT CONNECT THE DRAIN DIRECTLY TO A

BUILDING DRAIN. BLOCKING THE DRAIN IS

HAZARDOUS.

CAUTION

DO NOT USE PLASTIC PIPE. DRAIN MUST BE

RATED FOR VERY HOT WATER.

Install the drain line with a constant downward pitch.

IMPORTANT: Do not allow water traps in the

line. A trap can cause pressure build-up in the

cavity, which may cause the door gasket to leak.

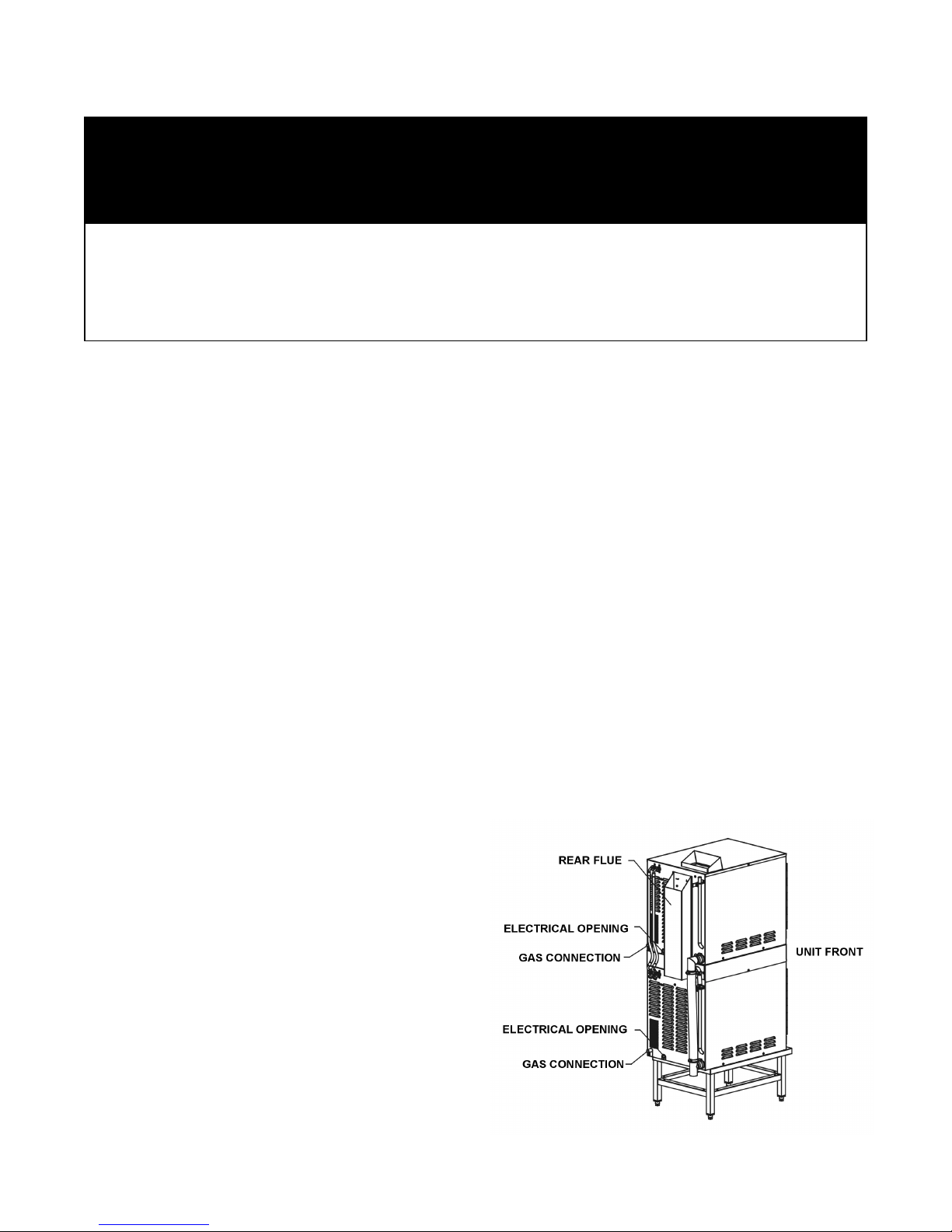

4. Factory Stacked Units

This section is applicable only if you are installing

factory-stacked units. If you plan to stack steamers

yourself, whether purchasing a new one for stacking

or a kit to stack two units you already own, you will

require OM-HY-5G(S), RETROFIT SUPPLEMENT

(Part Number 121087).

Installing stacked steamers is similar to installing a

single unit. The steamers are stacked and

assembled at the factory and delivered with the

water connections and drain hoses required for a

single point connection.

A. Water Connection

The same water supply connection is used for

both units. At the water inlet valves, ¾ inch

female NH connectors (garden hose type) are

used for the water supplies. There are two

connections to be made. Treated water

(softened) is connected to the right valve fitting

(looking from the rear of the unit) and untreated

water to the left fitting.

B. Electrical Supply Connection

Separate, individual electrical connections

will be required for each steamer in the stack.

Each Steamer must have its own branch

circuit protection.

C. Gas Connection

Separate gas connections are required for each

steamer in the stack. Gas supply must be

adequate under all conditions as listed on

page 6.

7

Page 8

OM-HY-5G

D. Drain Connection

Steamers must be leveled front to back, or

pitched to the rear (maximum ¼ inch) by

adjusting the bullet feet on the stand.

Ensure that there is a free air gap between the end

of the unit drain and the building drain. This gap

should be as close as possible to the unit drain. Do

not allow elbows or restrictions between the unit and

the free air gap.

A 2 inch ID hose may be attached to the unit

drain. It must be rated for very hot water.

WARNING

DO NOT CONNECT THE UNIT DRAIN DIRECTLY

TO THE BUILDING DRAIN.

CAUTION

DO NOT USE PLASTIC PIPE. DRAIN MUST BE

RATED FOR VERY HOT WATER.

Install the line with a constant downward pitch.

Proper Drain Line Connection - Drain Line must have a constant downward pitch of at least 1/4" per foot.

(2)HY-5G shown.

8

Page 9

Initial Start-Up

OM-HY-5G

After the HY-5G Steamer has been installed, test it

to ensure that the unit is operating correctly.

1. Remove all literature and packing materials

from the interior and exterior of the unit.

2. Make sure the water supply line is open.

3. Make sure that the gas supply line is open

and that the manual knob on the main gas

valve is turned to the “on” position. This

valve is located behind the front access

panel on the right side of the unit.

4. Turn on electrical service to the unit. The

HY-5G will not operate without electrical

power. Do not attempt to operate the unit

during a power failure.

5. The steamer will not operate until the pilot

burner has been ignited. To light the pilot

burner, activate the pilot switch located

behind the sliding door located on the right

cover panel. When the pilot ignition

sequence has been successfully completed,

a green light - on the pilot switch will glow.

6. The “trial for ignition” period is roughly 90

seconds. If the pilot burner does not light

within about 90 seconds after the switch is

activated, the ignition system automatically

stops gas flow to the pilot burner and stops

the ignition trial. If this happens, turn off the

pilot switch and repeat the trial for ignition.

During the initial start-up, the pilot may

require several trials for ignition until all the

air is bled from the gas piping. Subsequent

start-ups should require only about 5

seconds to achieve pilot ignition.

NOTE: See Automatic Operation of Pilot at

the end of this section.

7. Once the pilot burner flame has been

established (the green light on the pilot

switch is on ), press the “ON” switch for the

desired steamer cavity. The steam

generator will fill with water.

NOTE: The door MUST be closed for the

main (high) burner to work.

water has reached its standby temperature.

When the READY light is displayed, you

may take any one of the following steps:

a. Set the timer to the desired time for

timed steaming.

b. Turn the timer knob to the manual ON

position for continuous steam.

c. Let the unit stay at standby temperature.

WARNING

WHEN YOU OPEN THE DOOR, STAY AWAY

FROM STE AM C OMING OU T OF TH E UN IT. THE

STEAM CAN CAUSE BURNS.

9. To shut down the unit, press the ON switch

into the off position. The steam generator will

then drain. You may also switch off the pilot

switch to conserve energy.

10. If the HY-5G Steamer behaves as described,

the unit is functioning correctly and ready for

use.

Automatic Operation of Pilot

Once the pilot burner is lit, it essentially functions as

a standing pilot. In this state, if the pilot is

accidentally extinguished (by a very strong gust of

wind for example), it will re-ignite automatically. The

unit will completely shut down for a few seconds

while the pilot is re-ignited. Then the unit will come

back on and resume operation in the mode and with

the (running) timer value existing just prior to

shutdown. The pilot switch may be turned off during

“off hours” to conserve energy.

After the unit has been running, if the pilot burner

ever fails to re-ignite automatically within 90

seconds, wait 5 minutes before you attempt to

reactivate it. In the unlikely event that ignition

problems persist, contact your authorized Groen

Service Agency.

8. When the steam generator has filled with

water, the low and main burners will ignite

automatically. Within 8-10 minutes the

READY light will come on, indicating that the

NOTE: For operation at high altitudes (2000 feet and

above) please consult the Groen Food Service

Engineering Department.

9

Page 10

OM-HY-5G

Operation

WARNING

ANY POTENTIAL USER OF THE EQUIPM ENT M UST BE TRAINED IN SAFE AND CORRECT OPERATING

PROCEDURES.

A. Controls

Operator controls are on the front right of the unit.

The HY-5G control panel has the following touch

pads and indicator lights:

! The ON/OFF touch pad gets the

HyPerSteam ready for use, or shuts it off.

! The READY indicator light shows that the

steam generator is at standby temperature

and the cavity is hot enough to begin

steaming.

! The CLEANING indicator light is lit when the

unit is operating in the cleaning mode.

! The SERVICE indicator light shows when

the water level probes have stopped

working, and need to be cleaned (normally

an indication of lime deposits).

When one probe fails, the SERVICE light

flashes briefly every few seconds, but the

unit will continue to operate. De-lime the unit

as soon as possible.

If the problem continues, both probes may

fail. Then the steamer stops working, the

light will flash repeatedly and the beeper will

sound. At this point you must turn off the

power and contact an Authorized Groen

Service Representative for repair.

! The HI TEMP indicator light comes on when

the steam generator is too hot.

The unit will automatically shut off, and

cannot be turned on again until the steam

generator cools and the HI TEMP indicator

light goes out.

! The TIMING indicator light stays on when

the timer is running.

! The CLEAN touch pad is used to start the

automatic 50 minute cleaning cycle.

10

Page 11

The timer is used in three ways:

1 In the OFF position the steam generator

stays at a low boil or “holding” temperature.

2 When a cook time is set, the unit steams

until the timer runs down to OFF. At that

time steaming stops, a red light comes on

and a beeper sounds.

3 With the timer turned to the ON position, the

unit steams continuously. The green light

stays lit. The steamer will not time down.

B. Operating Procedure

1. Press the ON/OFF touch pad for the steamer.

The steam generator will fill, and heat until the

READY light comes on. (About 8-10 minutes.)

2. Load food into pans in uniform layers. Pans

should be filled to about the same levels, and

should be even on top.

3. Open the door and slide the pans onto the

supports. If you will only be steaming one pan,

put it in the middle position.

OM-HY-5G

! If you want to steam continuously, turn the

timer to the manual ON position. A green

light will come on. The unit will continue

steaming until you stop it by turning the timer

to OFF. When steaming continuously YOU

MUST CONTROL STEAMING TIME.

WARNING

WHEN YOU OPEN THE DOOR, STAY AWAY

FROM THE STEAM COMING OUT OF THE UNIT.

THE STEAM CAN CAUSE BURNS.

5. Open the door. Remove the pans from the

steamer, using hot pads or oven mitts to protect

your hands from the hot pans.

6. To shut down the unit, press the ON/OFF touch

pad to OFF. The steam generator will

automatically drain.

4. Close the door. With the READY indicator lit,

take one of the following steps:

! If you want to steam the food for a certain

length of time, set the timer for that period.

The timer will automatically run the steamer

for the set time and then turn it off. A red

light will come on and a beeper will sound.

Steam production stops.

11

Page 12

OM-HY-5G

Cleaning

To keep your HY-5G Steamer in proper working condition, use the following procedure to clean the unit. This

regular cleaning will reduce the effort required to clean the steam generator and cavity.

A. Suggested Tools

1. Mild detergent

2. Stainless steel exterior cleaner such as

Zepper®

3. Steam generator de-liming agent, such as

Groen Delimer Descaler (Part Number

114800), commercial

store brand for residential use) or an equivalent.

A liquid de-liming agent will be easier to use than

crystals or powders. See the warning about

chlorides, below

4. De-greaser, such as EncompasS®, Malone 34®,

Puritan Puribrute®, or Con-Lie®

5. Cloth or sponge

6. Plastic wool or a brush with soft bristles

7. Spray bottle

8. Measuring cup

9. Nylon pad

10. Towels

11. Plastic disposable gloves

12. Funnel

B. Procedure

1. Exterior Cleaning

a. Prepare a warm solution of the mild detergent

as instructed by the supplier. Wet a cloth with

this solution and wring it out. Use the moist

cloth to clean the outside of the unit. Do not

allow freely running liquid to touch the

controls, the control panel, any electrical part,

or any louver on the side or rear panels.

b. To remove material which may be stuck to the

unit, use plastic wool, a fiber brush, or a plastic

or rubber scraper with a detergent solution.

c. Stainless steel surfaces may be polished with a

recognized stainless steel cleaner such as

Zepper®.

Lime-Away® (not the

WARNING

DISCONNECT THE POWER SUPPLY

BEFORE CLEANING THE OUTSIDE OF

THE STEAMER.

KEEP WATER AND CLEANING

SOLUTIONS OUT OF CONTROLS AND

ELECTRICAL COMPONENTS. NEVER

HOSE OR STEAM CLEAN ANY PART OF

THE UNIT.

DON’T MIX DE-LIMING AGENTS (ACID)

WITH DE-GREASERS (ALKALI)

ANYWHERE IN THE UNIT

AVOID CONTACT WITH ANY

CLEANERS, DE-LIMING AGENT OR DEGREASER A S RECOMMENDED BY THE

SUPPLIER. MANY ARE HARMFUL.

READ THE WARNINGS AND FOLLOW

THE DIRECTIONS!

EVEN WHEN THE UNIT HAS BEEN SHUT

OFF, DON’T PUT HANDS OR TOOLS

INTO THE COOKING CHAMBER UNTIL

THE FAN HAS STOPPED TURNING.

DON’T OPERATE THE UNIT UNLESS

THE REMOVABLE PARTITION HAS

BEEN PUT BACK IN ITS PROPER

LOCATION.

DON’T USE ANY CLEANING OR DELIMI NG AG ENT T HAT C ONT AINS ANY

SULFAMIC AGENT, OR ANY CHLORIDE,

INCLUDING HYDROCHLORIC ACID

(HCl). TO CHECK FOR CHLORIDE

CONTENT SEE ANY MATERIAL SAFETY

DATA SHEETS PROVIDED BY THE

CLEANING AGENT MANUFACTURER.

DON’T USE ANY CLEANING OR DELIMING AGENT THAT CONTAINS MORE

THAN 30% PHOSPHORIC ACID.

DO NOT USE ANY METAL MATERIAL (SUCH AS META L SPONGES) OR METAL IMPLEMENTS (SUCH AS

A SPOON, SCRAPER OR WIRE BRUSH) THAT MIGHT SCRATCH ANY STAINLESS STEEL SURFACE.

SCRATCHES MAKE THE SURFACE HARD TO CLEA N AND PROVIDE PLA CES FOR BA CTERIA TO GROW.

DO NOT USE STEEL WOOL, WHICH MAY LEAVE PA RTICLES IMBEDDED IN THE SURFACE WHICH COULD

EVENTUALLY CAUSE CORROSION AND PITTING.

IMPORTANT

12

Page 13

OM-HY-5G

Steam Generator and Cooking Chamber

On a regularly scheduled basis, or if the SERVICE

light is on, follow the simple de-liming instructions

below. This procedure should be followed for each

cavity. REMEMBER: DON’T ALLOW DE-LIMING

AGENTS TO MIX WITH DE-GREASERS.

a. Ensure that the unit is turned on.

b. Set the timer to “OFF”.

c. Using a glove or towel for hand protection,

carefully open the deliming port. The port may

be hot, and a small amount of pressureless

steam may escape as you open the port.

d. Add two cups of de-liming agent.

e. Close the deliming port cover.

f. Holding in the “CLEAN” button, press and

release the ON button.

g. The clean cycle will start, and take approximately

30 minutes.

h. When the cleaning cycle is complete, the

CLEANING light will flash and the unit will beep.

NOTES:

1. If the clean cycle ends abruptly, the CLEANING

light will flash five times per second. This

indicates that the clean cycle was aborted.

WARNING

SHOULD A CLEA N CYCLE BE INTERRUPTED, IT

IS POSSIBLE THAT SOME CLEANING

SOLUTION IS ST ILL PRESENT I N THE STEAM

GENERATOR. RE-RUN THE CLEAN CYCLE

AND CONFIRM THAT THE WATER IS DRA INING.

2. In the event of a power outage during a clean

cycle, rerun the clean cycle when the power is

restored.

3. To abort a clean cycle, turn the “ON” switch off

for one second and turn it back on.

REMEMBER, DE-LIMING AGENT MAY STILL

BE PRESENT IN THE STEAM GENERATOR.

If the SERVICE light is on:

i. Wipe out the inside of the steamer cavity.

j. If the steamer is to be used, turn the “ON” switch

on. When READY light turns on, the steamer is

ready for operation, set the timer to the “ON”

position.

1. Take the actions listed in Troubleshooting

Section of this manual. Turn the steamer off for

10 seconds and then re-start.

2. Repeat steam generator cleaning cycle.

13

Page 14

OM-HY-5G

Maintenance

The HY-5G Steamer is designed for minimum

maintenance, and no user adjustments should be

necessary. Certain parts may need replacement

after prolonged use. If there is a need for service,

only authorized Groen representatives should

perform the work.

Always supply water with a low mineral count that

meets the standards outlined in the Water Quality

and Treatment section of this manual.

If steam or condensate is seen leaking from around

the door, take the following steps:

1. Check the door gasket. Replace it if it is cracked

or split.

2. Inspect the cooking chamber drain to be sure it

is not blocked.

3. Adjust the door latch pin to allow for changes

that might occur as the gasket ages.

a. Loosen the lock nut at the base of the latch

pin, then turn the latch pin ¼ turn clockwise,

and tighten the lock nut.

b. After adjustment, run the unit to test for

further steam leakage.

c. If there is still leakage, repeat the

adjustment.

d. Continue adjusting the pin clockwise until the

door fits tightly enough to prevent leakage.

The hinge may also be adjusted.

Troubleshooting

This Groen Steamer is designed to operate smoothly and efficiently if properly maintained. However, the following

is a list of checks to make in the event of a problem. Wiring diagrams are furnished inside the service panel. If an

item on the check list is marked with (x), it means that the work should be done by a factory-authorized service

representative.

SYMPTOM WHO

Pilot will not light User a. Are electrical connections made with a ground?

Auth Service

Rep Only

Steam generator does not fill with

water.

No steam. User a. Is the ON switch depressed?

Service light comes on after four

minutes.

Excessive steam escaping from rear

of unit

User a. Is the ON switch depressed?

User a. Is the water supply connected?

User a. Is the water spray hose kinked or obstructed?

Auth Service

Rep Only

(If item is marked X, work should be done by a factory authorized service rep)

b. Is gas supply connection made?

c. Is pilot ignition switch on?

d. Is gas valve turned on?

e. Are building fuses or circuit breakers all right?

f. Are there drafts which could blow out the pilot?

g. Is spark ignition cable connected to module? (X)

b. Is the water supply connected?

c. Is the water turned on?

d. Check for low water pressure (less than 30 PSI or

210 kPa).

e. Is the screen at the water connection clogged?

f. Has the steam generator been delimed?

b. Is the water supply connected?

c. Is the water turned on?

d. Are steamer doors open?

e. Is the steam generator limed up?

b. Is the water turned on?

c. Has the unit been delimed? (Refer to Cleaning

Section)

b. Is the water spray solenoid connected?(X)

c. Is the drain properly vented? (X)

WHAT TO CHECK

14

Page 15

OM-HY-5G

Parts List - HY-5G

To order parts, contact your authorized Groen Service Agency. Supply the model designation, serial number, part

description, part number, quantity, and when applicable, voltage and phase.

Key Description New Key Description New

1 Right Side Panel 138532 13 Funnel, Delime 106624

2 Door Assy, Complete 125922 14 Back Panel 138530

3 Door Handle 129723 15 Optional Table 100913

4 Door Gasket 125907 16 Drip Tray 094151

5 Left Pan Rack 125901 17 Timer Fastener Nut 101145

6 Blower Cover/Rack (fan baffle) 125902 18 Drain Tube 138546

7 Door Latch Pin 078914 19 Water Valve Single 071235

8 Door Pin Lock Nut 003823 20 Water Valve Double 100934

9 Left Side Panel 138534 x Motor Shaft Seal 096868

10 Timer Knob 123100 x Optional Legs 041121

11 Front Panel Overlay 138424 x Groen De-limer/De-scaler 114800

12 Top Panel 138536 x Cavity Fan 096790

x - Item not depicted/called out in drawings

15

Page 16

OM-HY-5G

Parts List - (2) HY-5G

To order parts, contact your authorized Groen Service Agency. Supply the model designation, serial number, part

description, part number, quantity, and when applicable, voltage and phase.

Parts listed below only apply to model (2) HY-5G. Common parts are listed on page 15.

Key Description Part No. Key Description Part No.

1 Table 138579 8 Hose Vent 138463

2 Spacer 138594 9 Drain T-Connector 126003

3 Flue, Inside 138406 10 Hose Drain 138471

4 Flue, Vertical 138401 11 Clamp, Hose 9/16" - 1 1/16" DIA 099284

5 Drain and Vent Pipe 138458 12 Bullet Foot 042505

6 Hose 2" ID x 2" Lg 090742 13 Water Hose 138470

7 Clamp, Hose 1 3/4" - 2 1/2" DIA 015663 14 Hose Connector 101189

16

Page 17

OM-HY-5G

Electrical Parts List - HY -5G

To order parts, contact your authorized Groen Service Agency. Supply the model designation, serial number, part

description, part number, quantity, and when applicable, voltage and phase.

Key Description Part No. Key Description Part No.

1 Fuse, 3 Amp 077853 15 Gas Valve 099906

2 Water Level Probes 070178 16 Control Board 119801

3 Water Valve Single 071235 17 Timer Board 119817

4 Water Valve Double 100934 18 Drain Valve 074594

Transformer 120V Primary /

5

24V Secondary 75VA 20 Motor Assy 146880

Transformer 115/230V Primary /

6

20VAC CT Secondary 22 Timer 096826

7 Relay, 12VDC 119813 23 Pilot Switch 087951

8 Relay, 24VAC 119814 24 Door Switch 096857

9 Relay, 24VDC 138420 x Harness, Power 130397

10 Ignition Module 085153 x Harness, Control 130399

11 Capacitor 096813 x Harness, Drain 130398

12 Fuse Holder 077854 x Harness, Transformer 119871

13 Terminal Block 003887 x Harness, Door + Switch 119878

14 Main Gas Valve 098443

106233

119815

x - Item not depicted/called out in drawings

19 Ready Thermostat 099947

21 Overtemp Sensor 096892

17

Page 18

OM-HY-5G

Parts List - HY-5G

To order parts, contact your authorized Groen Service Agency. Supply the model designation, serial number, part

description, part number, quantity, and when applicable, voltage and phase.

Key Description Part No. Key Description Part No.

1 Steam Generator 138521 13 Gasket 106232

2 Cavity 138549 14 Pressure Relief 132183

3 Manifold Asm - Natural Gas 138585 15 Hose, 10 1/2" Steam Inlet 138445

Manifold Asm - Propane 138586 16 Hose, 7 7/8" Steam Inlet 138446

4 Insulation Steam Generator 138588 17 Trap 106229

5 Drain Hose Steam Generator 138464 18 Hose, Trap 138451

6 Drain Hose 138465 19 Tube, High Fire 138425

7 Hose, Water Fill 138467 20 Tube, Low Fire 138426

8 Hose, Condensate 138468 21 Tube, Pilot 138427

9 Hose, Delime (Single Stack) 138449 22 Hose, Vent 138447

10 Cavity Insulation 096738 23 Delime Tank ASM 138415

11 Water Flow Reducer 112720 x Hose, Delime (Double Stack) 138450

12 Check Valve 138428

x - Item not depicted/called out in drawings

18

Page 19

OM-HY-5G

19

Electrical Schematic - HY-5G

All Voltages

HY-5G Wiring Diagram

P/N 130396 Rev A

Page 20

OM-HY-5G

Service Log

Model No.

Serial No.

Date Purchased

Purchase Order No.

Date Maintenance Performed Performed by

Purchased From

Location

Date Installed

For Service Call

20

Page 21

NOTES:

OM-HY-5G

21

Page 22

OM-HY-5G

LIMITED WARRANTY TO

COMMERCIAL PURCHASERS*

(U.S. & Canadian Sales Only.)

Groen warrants to original commercial purchaser/users that foodservice equipment manufactured by Groen (“Groen

Equipment”) (other than CapKold foodservice equipment) shall be free from defects in material and workmanship for

(12) twelve months from the date of installation or fifteen (15) months from date of shipment from Groen, whichever date

first occurs (the “Warranty Period”), in accordance with the following terms and conditions:

I. This warranty is limited to replacement parts and related labor for Groen Equipment located at its original place

of installation in the United States and Canada.

II. Damage to Groen Equipment that occurs during shipment must be reported to the carrier, and is not covered

under this warranty. The reporting of any damage during shipment is the sole responsibility of the commercial

purchaser/user of such Groen Equipment.

III. For Groen Convection Combo

TM

Steamer-Ovens, HyPerSteamTM Convection Steamers and HyPlus

TM

Pressureless Steam er s, Gro en further warr ants to the original com mercial pur chaser/users of such Gr oen

Equipment that the atmospheric steam generators or boilers contained in such Groen Equipment shall be free

from defects in material and workmanship for twenty-four (24) months from the date of installation or twentyseven (27) months from date of shipment from Groen, whichever date first occurs, provided that: (a) the original

purchaser/user shall have also purchased and installed a Groen PureSteem W ater Treatment System

use in connection with such Groen Convection Combo

or HyPlus

TM

Pressureless Steamer on or before the date such Groen Equipment was installed, (b) the original

TM

Steamer-Oven, HyPerSteamTM Convection Steamer

TM

for

purchaser/user has continuously used such Water Treatment Sy stem in connection with such Groen Equipment

from the date of installation, and (c) the commercial purchaser/user shall have maintained such W ater

Treatment System in accordance with the maintenance and filter cartridge replacement recommendations of

Groen, and otherwise maintained such Oven or Steamer in accordance with all other operational and

maintenance recommendations of Groen.

IV. Groen further warrants to the original commercial purchaser/user s of Gr oen Convec tion Com bo

Ovens that the electronic relay and control board contained in such Groen Convection Combo

TM

TM

Steamer-

Steamer-Oven

shall be free from defects in material and workmanship for twenty-four (24) months from the date of installation

or twenty-seven (27) months from date of shipment from Groen, whichever date first occurs.

V. During the Warranty Period, Groen, directly or through its authorized service representative, will either repair

or replace, at Groen’s sole election, any Groen Equipment determined by Groen to have a defect in material

or workmanship. As to any such warranty service during the Warranty Period, Groen will be responsible for

related reasonable labor and portal to portal transportation ex penses (time & mileage) incurred within the

United States and Canada.

VI. This warranty does not cover boiler maintenance, calibration, periodic adjustments as specified in operating

instructions or manuals, consumable parts (such as scraper blades, gaskets, packing, etc.), and labor costs

incurred for removal of adjacent equipment or objects to gain access to Groen Equipment. This warranty does

not cover defects caused by improper installation, abuse, careless operation, or improper m aintenance of

Groen Equipment. This warranty does not cover damage to Groen Equipment caused by poor water quality

or improper boiler maintenance.

22

Page 23

OM-HY-5G

VII. THIS WARRANTY IS EXCLUSIVE AND IS IN LIEU OF ALL OTHER WARRANTIES, EXPRESSED OR

IMPLIED, INCLUDING ANY IMPLIED WARRANTY OF MERCHANTABILITY OR FITNESS FOR A

PARTICULAR PUR POSE, EACH OF WHICH IS HEREBY EXPRESSLY DISCLAIMED. THE REM EDIES

DESCRIBED ABOVE ARE EXCLUSIVE AND IN NO EVENT SHALL GROEN BE LIABLE FOR SPECIAL,

CONSEQUENTIAL, OR INCIDENTAL DA MAGES FOR THE BREACH OR DELAY IN PERFORMANCE OF

THIS WARRANTY.

VIII. Groen Equipment is for commercial use only. If sold as a component of another (O.E.M.)

manufacturer’s equipment, or if used as a consumer product, such Equipment is sold AS IS and

without any warranty.

* (Covers all Groen Equipment (other than CapKold foodservice equipment) ordered after

September 11, 2001).

23

Page 24

1055 Mendell Davis Drive

Jackson, MS 39272

Telephone 601 372-3903

Fax 601 373-9587

www.groen.com

OM-HY-5G

Revised 10/01

Part Number 138486 Rev B

Loading...

Loading...