Page 1

HYPERSTEAM PRESSURELESS STEAMER

PROJECT NAME:

LOCATION:

ITEM NO:

MODEL HY-6SM

Steamer shall be a direct steam powered Groen HyPLUS Model HY-6SM, stainless steel twin cavity, 6 pan

cabinet mounted pressureless steamer, per Bulletin 76Ca and as follows.

CONSTRUCTION: Steamer cavities and cabinet

base shall be all stainless steel construction. Steamer unit

shall have a unitized body with removable right side panel

providing access to internal components. Steamer doors are

all stainless steel with strong continuous hinge and are field

reversible for left or right swing. Doors shall be insulated

and provided with a one piece, replaceable seal. Easy

open handle and latch shall provide positive lock and seal

when door is pushed or slammed shut. Hidden magnetic

door switch cuts power to blower and steam flow to that

cavity, when the door is opened. Pan support racks shall be

polished stainless steel and removable for easy cleaning.

Wide drip sink with condensate drain is positioned under

cavity doors. 24” wide cabinet base shall have stainless steel

frame with all stainless steel top deck, removable access

door, with side and rear panels standard. Front and rear legs

shall have adjustable bullet feet.

FINISH: Cabinet exterior including doors shall be finished

to a #3 uniform finish. Cavity interiors are polished stainless

steel. Control panel face plates shall be smudge resistant

polyester film, ensuring maximum ease in cleaning and

maintaining an attractive appearance.

UL LISTED: Steamer units shall be UL listed.

SANITATION: Unit shall be designed and constructed

to meet NSF and known health department and sanitation

codes, and be NSF listed.

CONTROLS: Steamer cavity controls shall be mounted

on the front panel for easy replacement or repair and will

include a separate ON-OFF/60 minute timer control with

constant steam setting, for each cavity. Cabinet mounted

power-ON switch shall activate steamer electronics.

PERFORMANCE FEATURES: Each steamer

cavity shall have a powerful side mounted blower, which

increases steam velocity and provides efficient steam

distribution throughout cavity and between loaded pans.

REMOTE STEAM SOURCE: HY-6SM requires

food safe steam delivered at a minimum of 52 lbs. per

hr., at a maximum working pressure of 15 PSI. Operator

must verify steam doesn’t contain caustic boiler cleaning

compounds or contaminants unsuitable for direct contact

with food.

PAN CAPACITY

Pan Size/Type Per cavity Total

12 x 20 x 1” 6 12

12 x 20 x 2 1/2” 3 6

12 x 20 x 4” 2 4

INSTALLATION: Unit requires steam connection

via 1/2” NPT pipe. Unit requires 3/8” NPT cold water

supply line, 1 1/4” NPT free venting drain; and 115 volt,

single phase, 60 cycle 15 AMP electric service, 4 AMP

maximum load.

WATER SUPPLY REQUIREMENTS:

To minimize service problems, a water treatment

(softening) system is recommended when water quality

is found to exceed limits stated below and in operator

manual. Recommended MINIMUM water quality

standards are: Total dissolved solids (TDS) content should

not exceed 30 parts per million, and the water pH should

be 7.0 or higher.

ORIGIN OF MANUFACTURE: Designed and

manufactured in the United States.

QTY:

MODEL NO:

AIA NO:

SIS NO:

6-Pan capacity stainless steal

pressureless steamer, direct steam

powered (remote source) on cabinet

base. (model HY-6SM shown)

OPTIONS/ACCESSORIES:

Flanged mounting feet

HyPerSteam

160176 RevB

Revised 04/11

Page 2

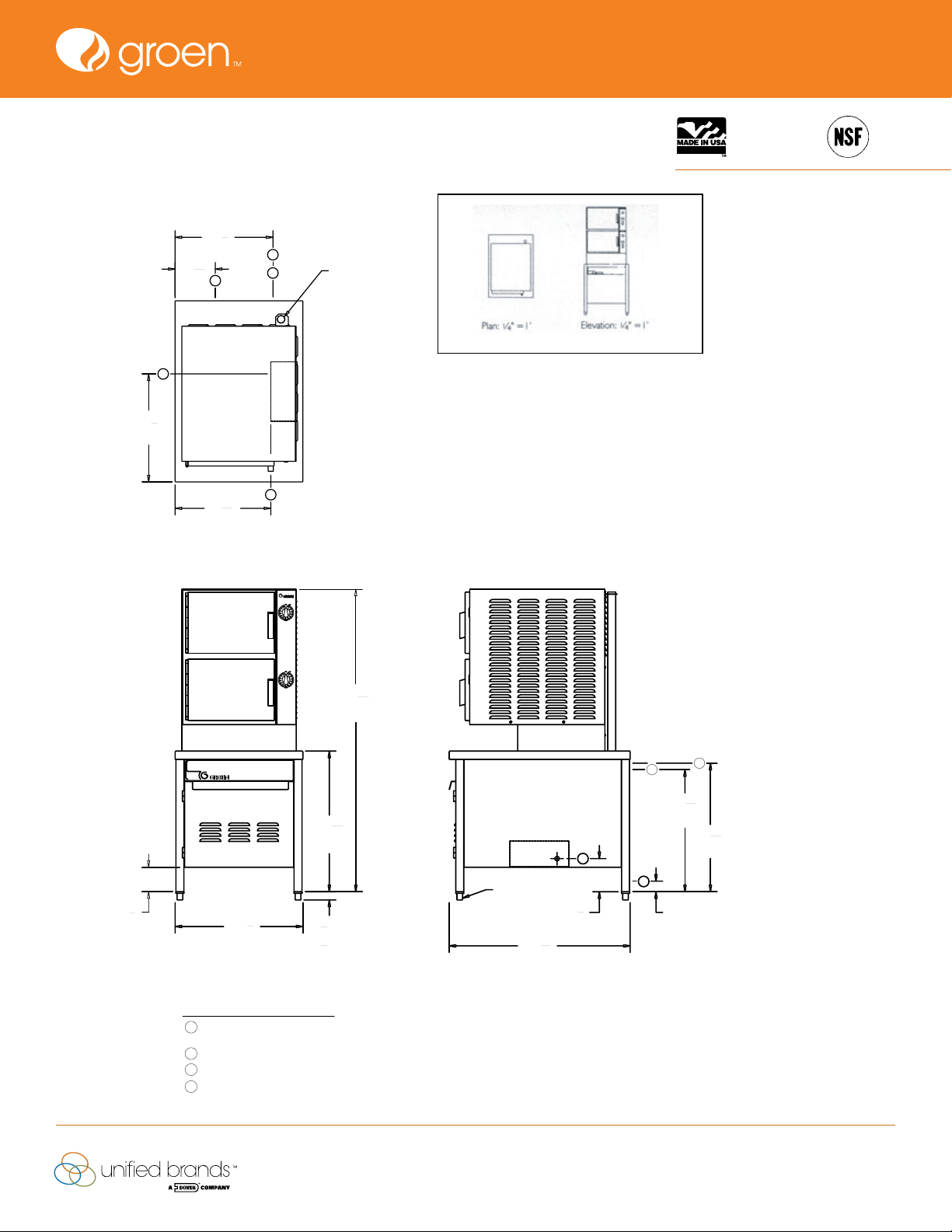

20

Groen AutoCAD Library Plot

(518)

HY-6SM

P/N C-9390-191/3

1

18

2

(470)

9

7

16

1

(192)

3

3

8

1

18

16

(459)

2

4

CONDENSATE

DRAIN VENT

3

4

(117)

3

57

16

(1453)

(51)

23

2

(586)

4

1

16

5

24

16

(618)

2

9

26

16

(675)

3

ADJUSTABLE

5

8

24

(613)

1

8

1

2

1

2

5

8

(38) MIN.

(67) MAX.

BULLET FEET

34

(868)

1

6

4

(159)

3

16

DIMENSIONS: INCHES (MILLIMETERS)

1

SERVICE CONNECTIONS:

DRAIN CONNECTION: 1-1/4" NPT

1

(INCLUDES STEAMERS, & CONDENSATE SPRAY)

2

COLD WATER SUPPLY: 3/8" NPT (FOR CONDENSATE SPRAY)

ELECTRICAL CONNECTION: 7/8" DIA. HOLE (REF. 1/2" CONDUIT KNOCK-OUT)

3

STEAM CONNECTION: 1/2" NPT - 52 LBS/HR (MIN.) @ 15 PSI (MAX.)

4

NOTE: STEAM MUST BE "CLEAN" AND SUITABLE FOR FOOD CONTACT.

1055 Mendell Davis Drive, Jackson, MS 39272, 888-994-7636, unifiedbrands.net

© 2013 Unified Brands. All Rights Reserved. Unified Brands is a wholly-owned subsidiary of Dover Corporation.

Loading...

Loading...