Groen HY-6GCE Service Manual

OPERATOR MANUAL &

SERVICE MANUAL

IMPORTANT INFORMATION, KEEP FOR OPERATOR

This manual provides information for:

HY-6G(CE) HYPERSTEAM

™

ATMOSPHERIC CONVECTION

STEAMER INTERNATIONAL

· Self-Contained

· Gas Heated

· Capacity: 6 Steamer Pans (305 x 508 x 64mm)

THIS MANUAL MUST BE RETAINED FOR FUTURE REFERENCE.

READ, UNDERSTAND AND FOLLOW THE INSTRUCTIONS AND

WARNINGS CONTAINED IN THIS MANUAL.

NOTIFY CARRIER OF DAMAGE AT ONCE

It is the responsibility of the consignee to inspect the container upon receipt of

same and to determine the possibility of any damage, including concealed dam

age. Unified Brands suggests that if you are suspicious of damage to make a

notation on the delivery receipt. It will be the responsibility of the consignee to file

a claim with the carrier. We recommend that you do so at once.

Manufacture Service/Questions 888-994-7636.

PART NUMBER 128805, REV. E (1/09)

PART NUMBER 128805, REV. C (4/06)

-

1055 Mendell Davis Drive

Jackson, MS 39272

888-994-7636, fax 888-864-7636

unifiedbrands.net

2 OM/SM-HY-6G(CE)

IMPORTANT — READ FIRST — IMPORTANT

IT IS MOST IMPORTANT THAT THESE INSTRUCTIONS AND THE OPERATOR AND SERVICE MANUALS BE

CONSULTED BEFORE INSTALLING AND COMMISSIONING THE APPLIANCE. FAILURE TO COMPLY WITH

SPECIFIED PROCEDURES MAY RESULT IN DAMAGE OR THE NEED FOR A SERVICE CALL.

THESE APPLIANCES HAVE BEEN CE MARKED ON THE BASIS OF COMPLIANCE WITH THE GAS

APPLIANCE DIRECTIVE, EMC AND LOW VOLTAGE DIRECTIVE FOR THE COUNTRIES, GAS TYPES AND

PRESSURES AS STATED ON THE DATA PLATE.

THESE APPLIANCES MUST BE INSTALLED BY A COMPETENT PERSON IN CONFORMITY WITH THE

INSTALLATION AND SERVICING INSTRUCTIONS AND NATIONAL REGULATIONS IN FORCE AT THE TIME.

PARTICULAR ATTENTION MUST BE PAID TO THE FOLLOWING:

I. E. E. REGULATIONS FOR ELECTRICAL INSTALLATIONS

ELECTRICITY AT WORK REGULATIONS

GAS SAFETY (INSTALLATION AND USE) REGULATIONS

HEALTH AND SAFETY AT WORK ACT

LOCAL AND NATIONAL BUILDING REGULATIONS

FIRE PRECAUTIONS ACT

DETAILED RECOMMENDATIONS ARE CONTAINED IN INSTITUTE OF GAS ENGINEERS PUBLISHED

DOCUMENTS: IGE/UP/1, IGE/UP/2, BS6173 AND BE5440.

FURTHERMORE, IS A NEED ARISES TO CONVERT THE APPLIANCE FOR USE WITH ANOTHETR GAS, A

COMPETENT PERSON MUST BE CONSULTED. THOSE PARTS WHICH HAVE BEEN PROTECTED BY THE

MANUFACTURER MUST NOT BE ADJUSTED BY THE USER.

USERS SHOULD BE CONVERSANT WITH THE APPROPRIATE PROVISIONS OF THE FIRE PRECAUTIONS

ACT AND THE REQUIREMENTS OF THE GAS SAFETY REGULATIONS. IN PARTICULAR THEY SHOULD BE

AWARE OF THE NEED FOR REGULAR SERVICING BY A COMPETENT PERSON TO ENSURE THE

CONTINUED SAFE AND EFFICIENT PERFORMANCE OF THE APPLIANCE.

WARNING: TO PREVENT SHOCKS, ALL APPLIANCES GAS OR ELECTRIC, MUST BE EARTHED.

UPON COMPLETION OF THE INSTALLATION, THE OWNERS MANUAL SHOULD BE HANDED TO THE

USERS AND THE INSTALLER SHOULD INSTRUCT THE RESPONSIBLE PERSON(S) IN THE CORRECT

OPERATION AND MAINTENANCE OF THE APPLIANCE.

THIS EQUIPMENT IS ONLY FOR PROFESSIONAL USE, AND SHALL BE OPERATED BY QUALIFIED

PERSONS. IT IS THE RESPONSIBILITY OF THE SUPERVISOR OR EQUIVALENT TO ENSURE THAT USERS

WEAR SUITABLE PROTECTIVE CLOTHING AND TO DRAW ATTENTION TO THE FACT THAT, SOME PARTS

WILL, BY NECESSITY, BECOME VERY HOT AND WILL CAUSE BURNS IF TOUCHED ACCIDENTALLY.

WARNING: BEFORE REMOVING ANY PARTITION OR PANEL, ALWAYS TURN OFF THE ELECTRIC

POWER AND ALLOW THE FAN TO STOP ROTATING. BEFORE WORKING ON ANY

ELECTRICAL COMPONENT, DISCONNECT THE POWER SOURCE FROM THE UNIT.

NOTE: IT IS IMPORTANT THAT THE END-USER ROUTINELY EXAMINE THE FLUE OUTLET ON A

REGULAR BASIS. DEBRIS COVERING THE FLUE OUTLET CAN CAUSE A POTENTIALLY

HAZARDOUS CONDITION. REMOVE ANY FOREIGN MATERIAL BEFORE USING THIS PIECE

OF EQUIPMENT.

WARNINGS AND CAUTIONS PROVIDED IN THE BASIC OPERATOR AND SERVICE MANUALS (OM-HY-6G

AND GROEN HYPERSTEAM SERVICE MANUAL) MUST BE COMPLIED WITH.

OM/SM-HY-6G(CE) 3

Table of Contents

1.0 EQUIPMENT DESCRIPTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

2.0 INSPECTION AND UNPACKING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4

3.0 WATER CONDITIONING/REQUIREMENTS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5

4.0 INSTALLATION, START-UP AND CONVERSION INSTRUCTIONS . . . . . . . . . . . . . . .

6

5.0 OPERATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

6.0 CLEANING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

7.0 MAINTENANCE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

8.0 TROUBLESHOOTING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

9.0 PARTS LIST . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

10.0 SERVICE PROCEDURES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

11.0 SCHEMATIC . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

12.0 SERVICE LOG . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

WARRANTY PROTECTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

References

UNDERWRITERS LABORATORIES, INC.

333 Pfingsten Road

Northbrook, Illinois 60062

KLENZADE SALES CENTER

ECOLAB, Inc.

370 Wabasha

St. Paul, Minnesota 55102

800 328-3663 or 612 293-2233

NATIONAL FIRE PROTECTION ASSOCIATION

60 Battery March Park

Quincy, Massachusetts 02269

NFPA/70 The National Electrical Code

NATIONAL SANITATION FOUNDATION

3475 Plymouth Road

Ann Arbor, Michigan 48106

NSF INTERNATIONAL

789 N. Dixboro Rd.

P.O. Box 130140

Ann Arbor, Michigan 48113-0140

4 OM/SM-HY-6G(CE)

The HY-6G (CE) has two independent

cavities, each with its own base-mounted

steam generator.

The unit will be delivered in a heavy carton,

strapped to a wooden skid.

1.0 - Equipment Description

Your Groen HY-6G (CE) HyPerSteam Convection

Steamer is designed to give years of service. It has

two stainless steel cavities (cooking chambers) which

are served by twin, independent atmospheric steam

generators which are gas-heated. A powerful blower

circulates the steam in each cavity to increase heating

efficiency.

Each cavity holds up to three steam table pans (305 x

508 x 64 mm). A 1.5 mm stainless steel case

encloses the cavities, the steam generators and the

control compartment that houses electrical

components. Door hinges are reversible (the doors

may be set to open from the left or right). Operating

Controls are on the front panel.

HY-6G (CE) steamers are equipped with fully

electronic controls and a button-activated,

preprogrammed CLEAN cycle.

The drain system includes a spray condenser, which

helps keep steam from escaping down the

condensate drain.

2.0 - Inspection and Unpacking

Your HY-6G HyPerSteam will be delivered completely

assembled in a heavy shipping carton and attached to

a skid. On receipt, inspect the carton carefully for

exterior damage.

CAUTION

SHIPPING STRAPS ARE UNDER TENSION AND

CAN SNAP BACK WHEN CUT.

Carefully cut the straps around the carton and detach

the sides of the carton from the skid. Be careful to

avoid personal injury. Strap edges may be very

sharp, particularly where cut. Write down the model

number, serial number and installation date. Space

for these entries is provided in the Service Log at the

back of this manual. Keep the manual near the

equipment for reference and update as needed.

CAUTION

THIS UNIT WEIGHS 550 LBS. (250 KG). GET

HELP AS NEEDED AND USE MATERIAL

HANDLING EQUIPMENT TO MOVE IT.

When installing, use material handling equipment to

lift the unit straight up from the skid. Check packing

materials for any loose parts.

OM/SM-HY-6G(CE) 5

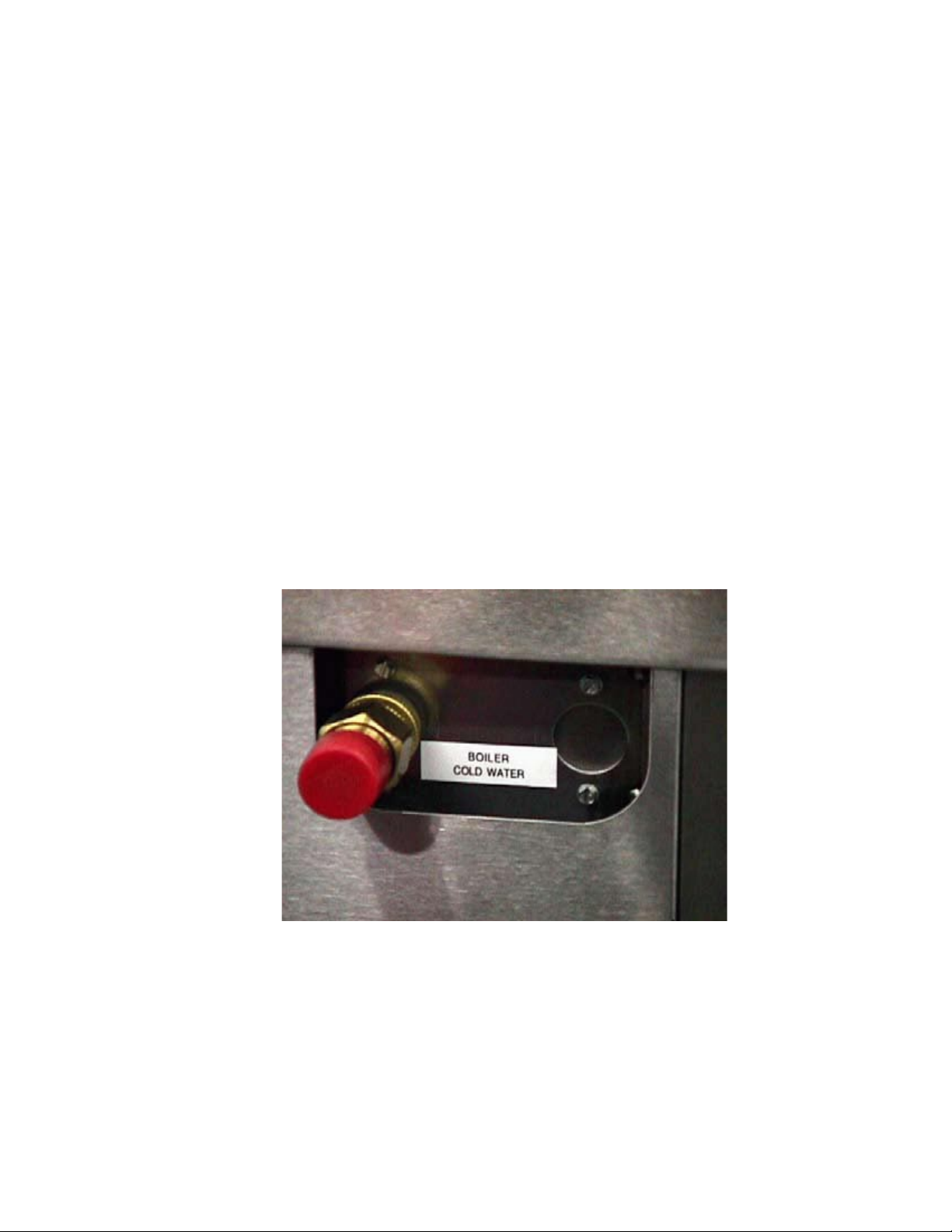

The BPST Connection on the right rear side of the steamer.

3.0 - Water Conditioning

It is essential to supply the steam generator with

water that will not form scale. Even though the steam

generator is engineered to minimize scale formation,

scale development depends on the hardness of your

water and the number of hours the equipment

operates.

In some areas of the country, water is low enough in

minerals to avoid scale formation. But most water

supplies are full of minerals which form scale. It is

this scale which could lead to an early component

failure.

Your water utility can tell you about the minerals in

your water. The water going to the steam generator

should have between 10 and 30 parts per million

(ppm) total dissolved solids (TDS) and should have a

pH (acidity rating) of 7.0 or higher. Please follow these

simple precautions:

3.1 Do not rely on unproven water treatments

which are sold as scale prevention or scale

removers. They don’t always work. The best

way to prevent scale is to supply the purest

possible water (10 - 30 ppm TDS).

3.2 If your water contains scale-forming minerals, as

most water does, use a well-maintained water

softener. Whether an exchangeable softener

cartridge or a regenerating system is chosen, a

regular exchange system is essential.

3.3 Installing a water meter between the softener and

the steamer will provide an accurate gauge of

water use, and will help determine when to

exchange cartridges or regenerate the softener.

Using a water softener will provide longer

generator life, higher steam capacity, and reduce

maintenance requirements.

3.4 If you notice a slowdown in steam production,

check the unit for scale build-up. Heavy scale

reduces the unit’s ability to boil water, and can

even cause heating elements in the steam

generator to overheat and burn out.

MINIMIZE SCALE PROBLEMS BY USING AND

MAINTAINING A SOFTENER, AND BY CLEANING

THE STEAMER REGULARLY.

6 OM/SM-HY-6G(CE)

4.0 - Installation, Start-Up and Conversion

WARNING

THE UNIT MUST BE INSTALLED BY PERSONNEL WHO ARE QUALIFIED TO WORK WITH ELECTRICITY AND

PLUMBING. IMPROPER INSTALLATION CAN CAUSE INJURY TO PERSONNEL AND/OR DAMAGE TO THE

EQUIPMENT. THE UNIT MUST BE INSTALLED IN ACCORDANCE WITH APPLICABLE CODES.

CAUTION

DO NOT INSTALL THE UNIT WITH THE RIGHT SIDE VENTS BLOCKED OR WITHIN 30 CENTIMETERS OF

A HEAT SOURCE (SUCH AS A BRAISING PAN, DEEP FRYER, CHAR BROILER, OR KETTLE).

TO AVOID DRAINAGE PROBLEMS, LEVEL THE UNIT FRONT TO BACK, OR PITCH IT SLIGHTLY TO THE

REAR.

4.1 General

4.1.1 Model Number and Dimensions

MODEL

WIDTH

mm (in.)

DEPTH

mm (in,)

HEIGHT

mm (in.)

WEIGHT

Kg (lbs)

HY-6G(CE)

549

(21.6)

894

(35.2)

1464

(57.6)

193

(425)

4.1.2 Siting and Clearances

The HY-6G(CE) steamer is suitable for installation in

combustible and noncombustible locations.

Minimum clearances for installation are:

Right Side 300 mm (12 inches)

Left Side 0 mm (0 inches)

Rear of Flue 150 mm (6 inches)

However, for easy service at least 300 mm (12

inches) clearance is required for the right side of

the unit, and it may not be installed within 300 mm

(12 inches) of a heat source, as stated in the

Caution above.

The unit must be installed in a well-ventilated room

with an adequate air supply. The steamer must be

installed beneath a ventilation hood, since gas

combustion products exit the appliance.

Any item which might obstruct or restrict the flow of

air for combustion and ventilation must be removed.

Do not obstruct the flue cover or any front, side, rear,

or top vents after installation.

The area directly around the appliance must be

cleared of all combustible material. The installation

must conform with local codes or, in the absence of

local codes, with the National Fuel Gas Code, ANSI

Z223.1, latest edition, including the following:

The unit and its individual shutoff valve must be

disconnected from the gas supply system during

any pressure testing of that system at test pressures

in excess of ½ PSI (3.45 kPa). It must be isolated

from the gas supply piping system by closing its

individual manual shutoff valve during any pressure

testing of the gas supply piping system at test

pressures equal to or less than ½ PSI (3.45 kPa).

4.2 Electrical Supply Connection

The unit is designed for connection to fixed wiring. A

suitably rated isolating switch with contact separation

of at least 3 mm on both poles must be fitted to the

installation.

Wiring must be executed in accordance

with the regulations listed on page 2 of this manual.

Cable entry is at the bottom rear right side of the

appliance. To gain access the panel must be

removed. Open the lower front panel by removing its

screws. Lift the panel and swing its bottom toward

you. Set the panel aside.

Provide 230 Volt, 50 Hz, Single Phase, 15 Ampere

service. Maximum load is 2½ amps. The electrical

schematic is located in the service compartment. A

copy is also printed at the rear of this manual.

CAUTION

THE UNIT MUST HAVE

A SEPARATE EARTHING

WIRE FOR SAFE OPERATION.

4.3 Gas Supply Connection

Incoming service must be of sufficient size to supply

full rate without excessive pressure drop. A gas

meter is connected to the service pipe by the Gas

Supplier. Any existing meter should be checked out

by the Gas Supplier to ensure that it has adequate

capacity to provide the required rate of gas to the

steamer, in addition to any other equipment.

OM/SM-HY-6G(CE) 7

Gas input is through a ½ inch B.S.P.T connection

at the left rear of the unit.

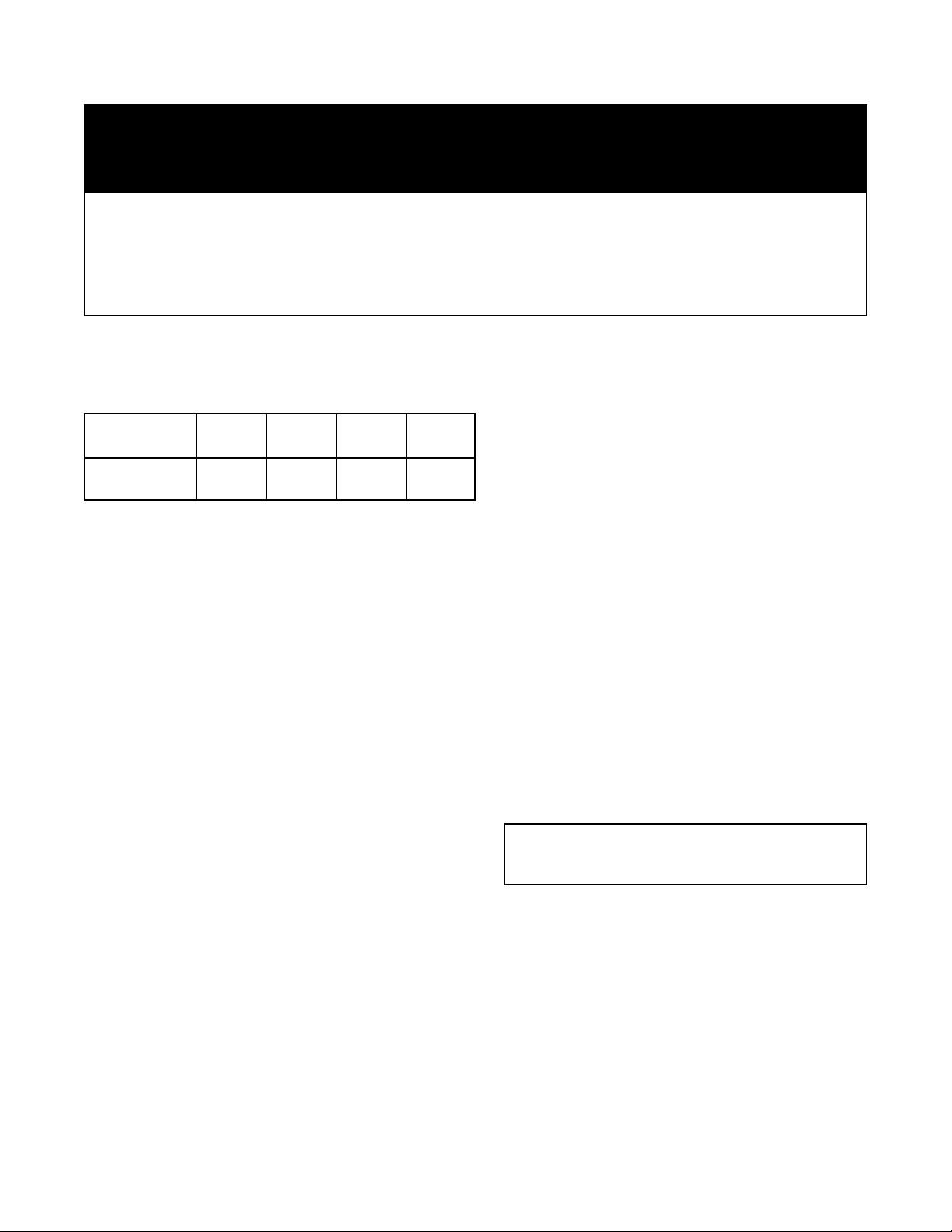

GAS INPUT RATE BTU/HR AND KW

HY-6G(CE)

Natural Gas

9.25 mBar

(3.7 in. W.C)

Propane Gas

26.25 mBar

(10.5 in. W.C.)

Individual

Steamer Cavity

40950 BTU/hr

12 KW

40950 BTU/hr

12 KW

Total

Both Cavities

81900 BTU/hr

24 KW

81900 BTU/hr

24 KW

Installation pipe work must be fitted in accordance with

IGE/UP/2.

The appliance governor is suitable for both natural and

propane gas without conversion. The governor is

incorporated in the gas control valve, which is inside the

control cabinet.

Connection to the gas supply can be completed with ½”

B.S.P.T. pipe. Although the immediate connection to the

appliance is ½” B.S.P.T., gas supply piping must be large

enough to provide 90,000 BTU/hour. Minimum supply

pressure must be 20 mBar for natural gas, or 37 mBar

for propane gas.

An isolating cock must be located close to the appliance

to allow shut down in an emergency, or for servicing.

The installation must be tested for gas soundness and

purged as specified in IGE/UP/1.

4.3.1 Gas Pressure Adjustment

Gas pressure has been set at the factory but should be

checked by connecting a manometer to the pressure tap

on the burner manifold. The adjusted gas pressures is

shown in the table below.

G20 Natural Gas G31 Propane Gas

mBar Inch W.C. mBar Inch W.C.

9.25 3.7 26.25 10.5

If necessary, the gas pressure may be readjusted as

described in the Service Manual.

NOTE:

With reference to gas rate, pressure adjustments

and conversions, this appliance is CE-approved for use

with C20 natural gas and G31 propane gas in Ireland

and the United Kingdom.

Use of the appliance with non-approved gases in a listed

country, or use in other countries, will void CE

certification.

4.3.2 Injector Diameters

Natural Gas Propane Gas

Injector

Dia. (mm)

No. of

Injectors

Injector

Dia. (mm)

No. of

Injectors

Main

Burner

1.49 4 x 2 0.94 4 x 2

Standby

Burner

0.99 1 x 2 0.57 1 x 2

Pilot

Burner

0.60

1 0.25 1

4.3.3 Burner Air Adjustment

The unit is equipped with fixed aeration type burners

which have no provision for air inlet adjustment.

4.3.4 Equipotential Terminal

In accordance with national regulations, each unit is

fitted with an equipotential terminal.

4.4 Water Supply Connection

The HY-6G CE model is fitted for a 3/4 inch B.S.P.T.

cold water connection. The water supply must be

provided at a rate of not less than 2.7 liters (0.70

gallons) per minute. Pressure must be 2.0 to 4.0 Bar

(30 to 60 PSI) maximum.

Water quality minimums require totally dissolved

solids (T.D.S.) of 30 parts per million maximum, and

a water pH of 7.0 or greater. If the available water

supply fails to meet these requirements, water

treatment equipment must be provided to ensure

steamer reliability and operating life.

8 OM/SM-HY-6G(CE)

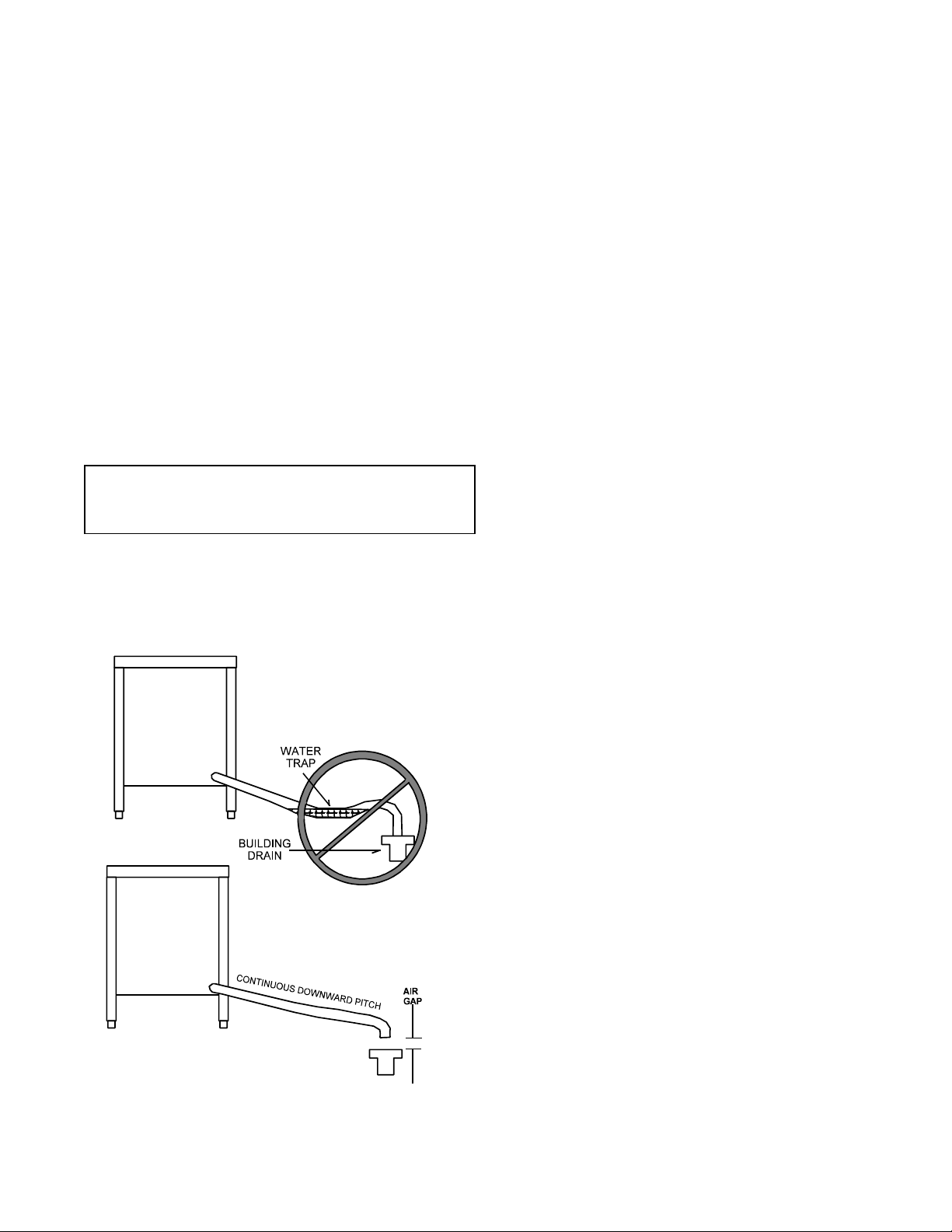

Leave an air gap between the hose and the building

drain, and don’t allow water traps in the hose.

Install a WRAS approved double-check valve or an

equally effective backflow preventive device in the

incoming cold water line at the point of connnection(s)

to the steamer and in compliance with all local plumbing

codes. This installation must be per WRAS-IRN R160

Schedule 2-15(1). For units with the dual water

connection option, a double-check valve shall be

installed on each water line.

Do not allow the connection to have any leak, regardles

s

of how small.

4.

5 Drain Connection

The HY-6G (CE)Steamer must be leveled front to back.

A 38mm (1½ inch) ID hose may be attached to the drain

pipe (supplied) by means of a hose.

DO NOT

CONNECT THE HOSE DIRECTLY TO

A BUILDING

DRAIN

. There must be a free air gap between the end

of the hose and the building drain. The free air gap

should be as close as possible to the unit drain. There

must also be no other elbows or other restrictions

between the unit drain and the free air gap

.

CAUTIO

N

DO NOT USE PLASTIC PIPE. THE DRAIN MUST

WITHSTAND HOT WATER.

Install the drain line with

a constant downward pitch.

IMPORTANT

: Do not allow any water traps in the

line. A trap can cause pressure to build up inside the

cavity during steaming, which will make the doo

r

gasket leak.

4.

6 Initial Start-Up

After the HY-6G(CE) Steamer has been installed,

test it to ensure that the unit is operating correctly

.

4.6.

1 Remove all literature and packing materials

from the interior and exterior of the unit.

4.6.

2 Make sure the water supply line is open.

4.6.

3 Make sure that the gas supply line is open

and that the manual knob on the main gas

valve is turned t

o the “on” position. This

valve is located behind the front access

panel on the righ

t side of the unit.

4.6.

4 Turn on electrical service to the unit. The

HY-6G(CE) will not operate without electrica

l

power. Do not attempt to operate the unit

during

a power failure.

4.6.

5 The steamer will not operate until the pilot

burner has been ignited. To light the pilo

t

burner, activate the pilot switch located at

the lower front, next to the main gas valve.

When the pilot ignition sequence has been

successful, a green light on the pilot switch

will glow

.

4.6.

6 The “trial for ignition” period is roughly 90

seconds. If the pilot burner does not light

wi

thin about 90 seconds after the switch is

activated, the ignition system automatically

stops gas flow to the pilot burner and stops

the ignition trial. If this happens, turn off the

pilot switch and repeat the trial for ignition.

Du

ring the initial start-up, the pilot may

require several trials for ignition until all the

air is bled from the gas piping. Subsequent

start-ups should require only about 5

seconds to achieve pilot ignition. Reinstal

l

panel(s). NOTE: See Automatic Operation of

Pilot at the end of this section.

4.6.7

. Once the pilot burner flame has been

es

tablished (the green light on the electrical

panel is on), press the ON/OFF touch pad

for the desired steamer cavity. The steam

generator will fill with water

.

NOTE: The door MUST be closed for the

main (high) burner

to work.

4.6.

8 When the steam generator has filled with

water, the main and low burners will ignit

e

au

tomatically. Within 6-8 minutes the

READY light will come on, indicating that the

water has reached its standby temperature.

When the READY light is displayed, you ma

y

take any one of the following steps:

OM/SM-HY-6G(CE) 9

OM/SM-HY-6G(CE)

a. Set the timer to the desired time for timed

steaming.

b. Turn the timer knob to the manual ON

position for continuous steam.

c. Let the unit stay at standby temperature.

WARNING

WHEN YOU OPEN THE DOOR, STAY

AWAY FROM

STEAM COMING OUT OF THE UNIT. THE STEAM

CAN CAUSE BURNS.

4.6.9 To shut down the unit, press the ON/OFF touch

pad into the off position. The steam generator

will then drain. You may also switch off the pilot

switch to conserve energy.

4.6.10 If the HY-6G(CE) Steamer behaves as

described, the unit is functioning correctly and

ready for use.

4.6.11 Automatic Operation of Pilot

Once the pilot burner is lit, it essentially functions as a

standing pilot. In this state, if the pilot is accidentally

extinguished (by a very strong gust of wind for example),

it will re-ignite automatically. The unit will completely shut

down for a few seconds while the pilot is re-ignited.

Then the unit will come back on and resume

operation in the mode and with the (running) timer

value existing just prior to shutdown. The pilot

switch may be turned off during “off hours” to

conserve energy.

After the unit has been running, if the pilot burner

ever fails to re-ignite automatically within 90

seconds, wait 5 minutes before you attempt to

reactivate it. In the unlikely event that ignition

problems persist, contact your authorized Groen

Service Agency.

NOTE: For operation at high altitudes (2000 feet and

above) please consult the Groen Food Service

Engineering Department.

4.7 Gas Type Conversion (See Paragraph 4.3.1 for

important information for gas conversion. Verify

the type of gas to be used).

To change the type of gas used (e.g. G20 to/from

G31) change the following:

Burner injector

Pressure setting on Main Gas Valve

Data plate

Gas pressure Regulator Springs

The governor spring does not need to be changed;

only the pressure setting. ALL CONVERSIONS

MUST BE FOR APPROVED GAS IN THE

COUNTRIES LISTED IN PARAGRAPH 4.3.1

10 OM/SM-HY-6G(CE)

OM/SM-HY-6G(CE)

5.0 - Operation

WARNING

ANY POTENTIAL USER OF THE EQUIPMENT SHOULD BE TRAINED IN SAFE AND CORRECT OPERATING

PROCEDURES.

5.1 Controls

Operator controls are on the front right of the unit.

The control panel has the following touch pads and

indicator lights. (Your controls may have either words or

the symbols shown below):

The ON/OFF touch pad gets the

HyPerSteam ready for use, or shuts it off.

The READY indicator light shows that the

steam generator is at standby

temperature and the cavity is hot enough

to begin steaming.

The CLEANING indicator lights when the

unit is operating in the cleaning mode.

The SERVICE indicator light shows when

the water level probes have stopped

working, and need to be cleaned

(normally an indication of lime deposits).

When one probe is not working, the

SERVICE light flashes briefly every few

seconds. When both probes fail, the light

will flash continuously and the beeper will

sound.

The HI TEMP indicator light comes on

when the steam generator is too hot.

The unit will automatically shut off, and

cannot be turned on again until it has

been serviced.

The TIMING indicator light stays on when

the timer is running.

The CLEAN touch pad is used to start the

automatic 50 minute cleaning cycle.

The timer is used in three ways:

1 In the OFF position the steam generator stays at a

low boil or “holding” temperature.

2 When a cook time is set, the unit steams until the

timer reaches OFF. The steaming stops, a red light

comes on and a beeper sounds.

3 With the timer turned to the ON position, the unit

steams continuously. The green light stays lit. The

steamer will not time down.

Gas Lockout Indicator and Reset Control

Should the pilot fail to ignite during start-up, a yellow

indicator on the control panel (see page 11) will light

and the supply of gas to the unit will be halted.

When this occurs, the ignition process may not be

started again for five minutes. After that time, press the

Lockout Reset Switch located behind the front panel

and attempt to start the unit again. If the lockout

continues to occur after three attempts, contact your

Groen Service Agency for assistance.

5.2 Operating Procedure

5.2.1 Press the ON/OFF touch pad for the steamer.

The steam generator will fill, and heat until the

READY light comes on. (About 10 minutes.)

5.2.2 Load food into pans in uniform layers. Pans

should be filled to about the same levels, and

be even on top. The maximum allowable weight

of food is 9.8 kilograms (21.6 lbs.) per pan.

5.2.3 Open the door and slide the pans onto the

supports. If you will only be steaming one pan,

put it in the middle position.

5.2.4 Close the door.

With the READY indicator lit,

take one of the following steps:

• If you want to steam the food for a certain

length of time, set the timer for that period. The

timer will automatically run the steamer for the

set time and then turn it off. A red light will

come on and a beeper will sound. Steam

production stops.

• To steam continuously, turn the timer to the

manual ON position. A green light will come

on. The unit will continue steaming until you

stop it by turning the timer to OFF. When

steaming continuously YOU MUST CONTROL

STEAMING TIME.

WARNING

WHEN YOU OPEN THE DOOR, STAY AWAY FROM

THE STEAM COMING OUT OF THE UNIT. THE

STEAM CAN CAUSE BURNS.

5.2.5 Open the door. Remove the pans from the

steamer, using hot pads or oven mitts to protect

your hands from the hot pans.

5.2.6 To shut down the unit, press the ON/OFF touch

pad OFF. The steam generator will drain.

OM/SM-HY-6G(CE) 11

Upper Portion of HY-6G(CE) Control Panel

12 OM/SM-HY-6G(CE)

6.0 - Cleaning

To keep your HY-6E Steamer in proper working condition/order, use the following procedure to clean the unit.

This regular cleaning will reduce the effort required to clean the steam generators and cavities.

6.1 Suggested Tools

1. Mild detergent

2. Stainless steel exterior cleaner such as Zepper®

3. Steam generator de-liming agent, such as

Groen Delimer Descaler, Lime-Away® or an

equivalent. A liquid de-liming agent will be

easier to use than crystals or powders. See the

warning about chlorides, below

4. De-greaser, such as EncompasS®, Malone 34®,

Puritan Puribrute®, or Con-Lie®

5. Cloth or sponge

6. Plastic wool or a brush with soft bristles

7. Spray bottle

8. Measuring cup

9. Nylon pad

10. Towels

11. Plastic disposable gloves

12. Funnel

6.2 Procedure

6.2.1 Outside of Steamer

1. Prepare a warm solution of the mild

detergent as instructed by the supplier. Wet

a cloth with this solution and wring it out. Use

the moist cloth to clean the outside of the unit.

Do not allow freely running liquid to touch the

controls, the control panel, any electrical part, or

any open louver.

2. To remove material which may be stuck to

the unit, use plastic wool, a fiber brush, or a

plastic or rubber scraper with a detergent

solution.

3. Stainless steel surfaces may be polished

with a recognized stainless steel cleaner such as

Zepper®.

WARNING

DISCONNECT THE POWER SUPPLY

BEFORE CLEANING THE OUTSIDE OF

THE STEAMER.

KEE P W ATER AND CLE A N ING

SOLUTIONS OUT OF CONTROLS AND

ELECTRICAL COMPONENTS. NEVER

HOSE OR STEAM CLEAN ANY PART OF

THE UNIT.

DON’T MIX DE-LIMING AG

ENTS (ACID)

WIT H DE -GREA S E R S ( A L K ALI)

ANYWHERE IN THE UNIT

A V O I D CO N T A C T W I T H A N Y

CLEANERS, DE-LIMING AGENT OR DEGREASER AS RECOMMENDED BY THE

SUPPLIER. MANY ARE HARMFUL.

READ THE WARNINGS

AND FOLLOW

THE DIRECTIONS!

EVEN WHEN THE UNIT HAS BEEN SHUT

OFF, DON’T PUT HANDS OR TOOLS

INTO THE COOKING CHAMBER UNTIL

THE FAN HAS STOPPED TURNING.

DON’T OPERATE THE UNIT UNL

ESS

THE TWO REMOVABLE INTERIOR

PARTITIONS HAVE BEEN PUT BACK IN

THEIR PROPER LOCATIONS.

DON’T USE ANY CLEANING OR DELIMING AGENT THAT CONTAINS ANY

SULFAMIC AGENT OR ANY CHLORIDE,

INCLUDING HYDROCHLORIC ACID

(HCl). TO CHECK FOR CHLORIDE

CONTENT SEE ANY MATERIAL SAFETY

DATA SHEETS PROVIDED BY THE

CLEANING AGENT MANUFACTURER

.

IMPORTANT

DO NOT USE ANY METAL MATERIAL (SUCH AS METAL SPONGES) OR METAL IMPLEMENT (SUCH AS

A

SPOON, SCRAPER OR

WIRE BRUSH) THAT MIGHT SCRATCH THE SURFACE. SCRATCHES MAKE THE

SURFACE HARD TO CLEAN AND PROVIDE PLACES FOR BACTERIA TO GROW . DO NOT USE STEEL

WOOL

, WHICH MAY LEAVE PARTICLES IMBEDDED IN THE SURFACE WHICH COULD EVENTUALLY CAUSE

CORROSION AND PITTING.

Loading...

Loading...