Page 1

COOKER/MIXERS

PROJECT NAME:

LOCATION:

ITEM NO:

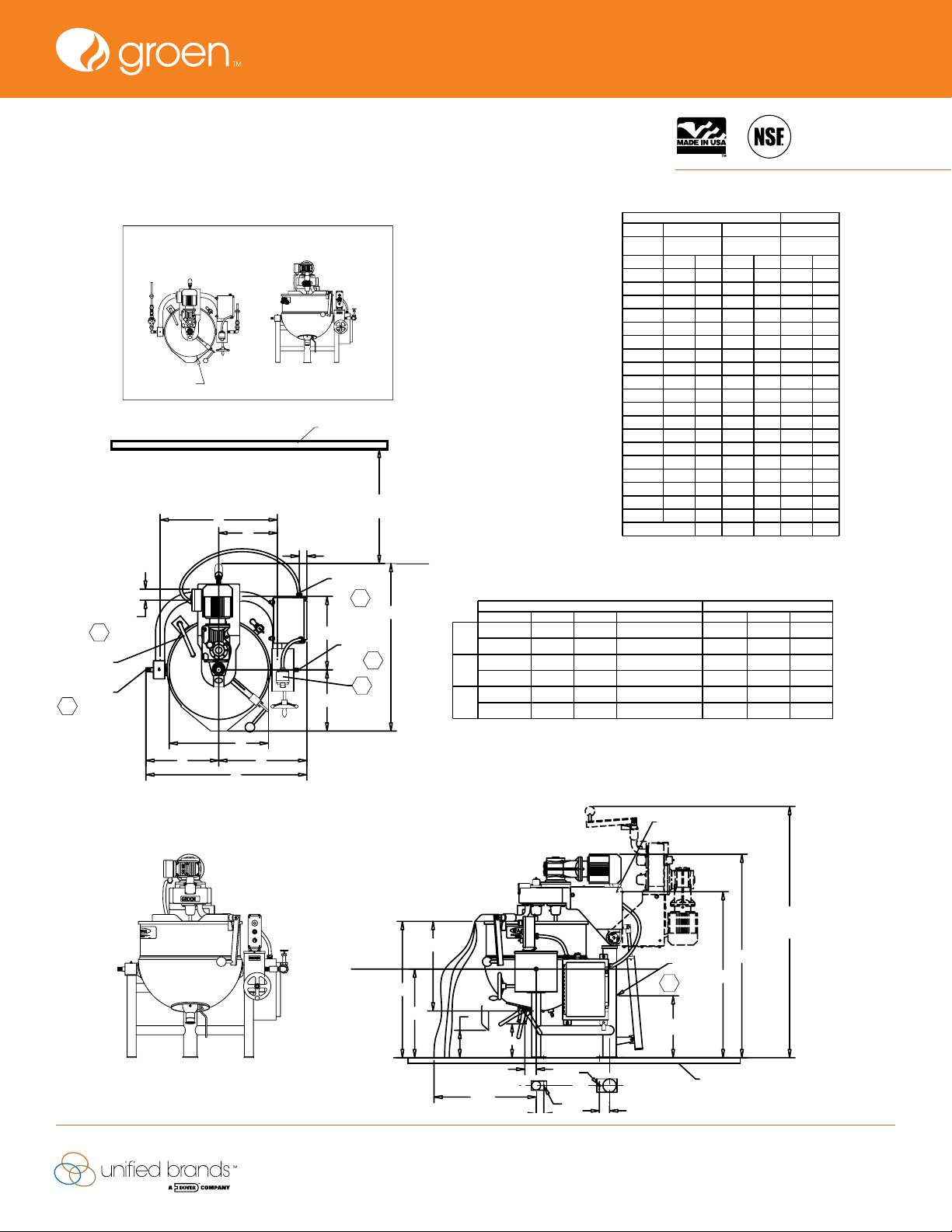

FLOOR MOUNTED TWIN SHAFT AGITATOR DIRECT STEAM MODEL DL

Cooker Mixer Kettle shall be a Groen Model DL-40, 60, 80, TA/3 (Specify 40-, 60- or 80- gallon) stainless steel

2/3 steam jacketed unit operating from a direct steam source and complete with console-mounted tilt-out twin

shaft scraper mixer.

AVAILABLE MODELS:

DL-40 TA/3 (40 GALLON)

DL-60 TA/3 (60 GALLON)

DL-80 TA/3 (80 GALLON)

CONSTRUCTION: Kettle interior shall be 316

stainless steel, solid one-piece welded construction.

Kettle jacket shall be 304 stainless steel solid one piece

construction. Unit shall be provided with a heavy-duty

reinforced rim with a heavy-duty butterfly-shaped

pouring lip for maximum sanitation and durability. Unit

includes 10-gallon etch markings, double pantry faucet

and steam regulating system. Kettle to be tilting type

with a positive locking worm and gear tilt mechanism

enclosed in a polished, drip-proof stainless steel housing.

Kettle mounted on a polished, stainless steel tri-leg

stand with stainless steel floor flanges.

AGITATOR ASSEMBLY: Enclosed power transfer

case to be cast aluminum with a 3-to-1 gear ratio. Gear

motor to be completely enclosed type, cast iron housing,

right angle shaft down, helical bevel gearing, variable

speed motor driven through a variable electronic speed

control. See table on back for minimum and maximum

agitator speeds. Main agitator to be anchor-type, shaped

to the contour of the kettle and provided with removable

nylon finger scrapers. The secondary counter rotating

agitator to be centrally located between the center shaft

and the outside arms of the main agitator. Both agitators

are attached with bayonet connections for easy, quick

removal for cleaning or when kettle is to be used as a

without the mixing mechanism. Both agitators are 304

stainless steel and either can be used alone. Agitator

assembly and motor drive can be manually tilted out to

the back of the kettle.

FINISH: Kettle interior shall be polished to a 180

emery grit finish. Kettle exterior shall be finished to a

bright semi-deluxe buff finish to ensure maximum ease

in cleaning and maintaining brilliant appearance.

ASME CODE: Unit shall be ASME shop-

inspected, stamped and registered with the National

Board for operation up to a maximum working

pressure of 50 PSIG.

SANITATION: Unit shall be designed and

constructed to be NSF listed, meeting NSF

requirements.

DRAWOFF: Bottom outlet to be 2” flush mounted,

sanitary, quick opening ball valve.

STEAM PRESSURE: Kettle shall operate

dependably at steam pressure of 50 PSIG or below

(to a minimum of 5 PSIG). Higher working pressure

available. The steam supply shall be injected

directly into the jacket through the trunnion and

the condensate shall be removed through a tube

contained in the jacket and connected to the opposite

trunnion. No exposed steam piping or obstructions

shall be on the kettle body.

CONTROLS: Agitator to be electronic, variable

speed-control type, capable of operating at any RPM

between maximum and minimum settings.

INSTALLATION REQUIREMENTS: 3/4”

NPT steam inlet and condensate connection are

provided. A remote steam source is required. A

steam trap assembly with check valve and globe

valve is provided as standard . Unit requires agitator

power connection, specify 208 Volt (1 or 3-phase is

standard). Other voltages are available.

ORIGIN OF MANUFACTURE: Designed and

manufactured in the United States.

QTY:

MODEL NO:

AIA NO:

SIS NO:

Stainless Steel 2/3 Steam Jacketed

Cooker/Mixer, Floor Mounted, Tilting,

Direct Steam, 40, 60 or 80-Gallon

Capacities With Twin Shaft Agitator.

OPTIONS/ACCESSORIES:

240, 480 Volt Power Supply

(For agitator motor)

Kettle Brush Kit

Pan Carrier

Wall Mount With In Wall Carrier

Gallon Master

Basket Insert

Cold Water Cooling

Working Pressure (higher or

lower than 50 PSIG)

Lip strainers

Contour measuring strips

Cooker/Mixers

146764 RevC

Revised 04/12

Page 2

2.66

5

DOUBLE PANTRY

FAUCET

3/4" CONDENSATE

OUTLET

4

2-5/8

PLAN VIEW 1=2

ÿ13.00

D-40 TA/3

P

DL

P/N 141239 REV B

TABLE OF DIMENSIONS

D-40 TA/3 D-60 TA/3 D-80 TA/3

NOTES:

(DIM) ARE IN MM.

STEAM PIPING SHOWN ON PRINT

ARE FOR REFERENCE ONLY. UNIT

WILL BE SHIPPED WITHOUT PIPING INSTALLED.

SERVICE CONNECTIONS:

1: ELECTRICAL POWER CONNECTION, AGITAIOR

ELEVATION 1=2

1-3/4" DIAMETER HOLE

2: AGITAT OR MOTOR SPEED SWITCH.

WALL

3. STEAM INLET CONNECTION.

4. STEAM OUTLET CONNECTION.

5. COLD WATER & HOT WATER SUPPLY

30" BACK CLERANCE

FOR TILTING

Q

3-3/4

ELECTRICAL

CONNECTION

R

S

1

3/4" STEAM

INLET

2

C

GAL

3

GAL

GAL

AGITATOR MOTOR DATA SPECIFICATIONS

MAXIMUM

40

MINIMUM

MAXIMUM

60

MINIMUM

MAXIMUM

80

MINIMUM

RPM MAIN

H.P.

1-1/2 150

3/4

2 120

1

2

1

MODEL

CAPACITY

RPM SECONDARY 240V 3PH

54

27

46

23

46

23

B

D

E

F

G 22

H

J

K

L

M

N

P

Q

R

S

T

U

APPROX. WEIGHT

75

60

120

60

40 GAL.

INCH

26A

43.5

1105

42C

1067

7-1/2

4

10-1/2

36

1372

54

1803

71

23-1/4

22-3/8

19-5/8

30-3/4

15-3/8

19-1/4

16

24 27

38-3/4

762

1207

1118

178

102

292

635

1016

1500

2032

641

629

524

883

441

591

457

686

1086

4.55 A

5.7 A

80 GAL.

INCH

34

864

51.5

1308

46

1168

4-1/2

4

10

27

40-1/2

1029

59

1500

81

2057

24-3/4

26-1/8

22-7/8

38-1/4

19.1/8

23-1/8

20

29

43-1/4

1099

480V 3PH

2.28 A

2.83 A

6 A

3 A

4 A

2 A

6 A

3 A

4 A

2 A

60 GAL.

MMDIM.

INCH30MM

660

47.5

44

7

191

4

102

11-1/2

267

25

559

40

914

59

80

25-1/4

591

24-3/4

568

20-5/8

498

34-3/4

781

17-3/8

391

23-1/4

489

18

406

610

42-3/4

988

615 670 740

ELEC. LOAD RATING

208V 3PH

5 A

6.3 A

6.8 A

4.7 A

6.8 A

4.7 A

MM

114

102

254

686

629

664

581

972

486

587

508

737

A

N

M

B

ELECTRICAL

CONNECTION

K

CLERANCE INCLUDING

G

ELECTRICAL

CONNECTION

H

VALVE

L

F

T

POUR

PATH

OPEN

VALVE

L

CLOSE

E

ÿ.56

C

L

ÿ.56

1

17-1/8

FLOOR

HANDLE & LATCH DEVICE

J

U

1055 Mendell Davis Drive, Jackson, MS 39272, 888-994-7636, unifiedbrands.net

© 2013 Unified Brands. All Rights Reserved. Unified Brands is a wholly-owned subsidiary of Dover Corporation.

Loading...

Loading...