Page 1

Modular Equipment

Description

Unit shall be a Groen Model (2)CTDC/3-20-SG, with two

20 quart stainless steel tilting steam jacketed kettles, with

cabinet mounted gas steam boiler, per Bulletin 34Hd and

as follows:

Construction

Kettles shall be Type 304 stainless steel with solid onepiece welded construction, with tubular stainless steel

support arms. Rim shall be triple reinforced to resist

abuse, with a welded “Butterfly” shaped lip, for easy

pouring. Kettles shall have two operating handle lugs so

that handle can be attached on right or left side.

36” wide cabinet base shall have stainless steel frame,

top deck, double panel access doors, side and rear panels

and 6” legs. Front legs shall be adjustable bullet feet while

back legs shall have adjustable flanged feet. Cabinet

design and trim shall match other HyPLUS™ modular

equipment.

Finish

Cabinet base shall be finished to a #3 uniform finish.

Kettle exteriors shall be polished to a bright high buff

finish. Accent strip shall be matt finish polyester film

ensuring maximum ease in cleaning and maintaining an

attractive appearance.

ASME Code & UL Approval

Cabinet mounted steam generator shall be ASME Code

constructed and National Board registered for operation

up to 15 PSI. Kettles shall be coded and registered

for operation up to 55 PSI. Gas boiler is AGA design

certified.

Sanitation

Unit shall be designed and manufactured to meet NSF

known health department and sanitation codes and be

NSF listed.

Sinks/Faucet

Unit shall have one large flush mounted pouring sink

mounted in front of both kettles. Sink shall be piped to

common drain and provided with a removable anti-splash

screen. Unit comes standard with hot and cold water

faucet with swing spout.

Controls

Gas pressure boiler shall be provided with a gas control

valve, power-ON switch, reset light, start switch, exterior

mounted pressure gauge, water level sight glass, low

water sensor and pop safety valve. Kettle steam control

valves and hot and cold water faucets are front mounted

for easy access.

Performance Features

Unit will shut off if water level is too low or unit builds too

much pressure. When power switch is turned “off,” the

boiler automatically drains to reduce sediment build-up,

after water has cooled to 170ºF. Kettles shall operate

dependably at any steam pressure between 5 and 55

PSI.

Cabinet Base Steam Source

Unit shall have a gas heated cabinet mounted steam

boiler to provide approximately 10 PSI steam to the

model (2)CTDC/3-20-SG

kettles. ASME Code constructed and National Board

registered for operation up to 15 PSI. 200,000 BTU boiler

delivers to 120,000 BTU/hr into the product, is 60% efficient

and delivers 3.7 boiler horsepower. Unit comes with

standing pilot. Electronic ignition is available as an option.

Auxiliary manual drain valve to simplify maintenance is

also included.

Installation

Unit requires gas service via 1/2” NPT pipe or approved

equivalent. Unit requires 3/8” NPT hot and 1/2” NPT cold

water supply lines. Requires single free venting 11/4”

NPT drain for automatic and manual drain for kettles and

sink, and 115 Volt, 60 HZ single phase. 15 AMP electrical

service. Kettles are completely pre-piped to gas boiler.

Options

Electronic ignition for gas boiler

Lift-off covers for kettles

Basket insert for kettles

Basket inserts and brush kits for kettles.

Steam Source for Other Equipment

If additional equipment (steam kettle, etc.) is to be powered

by boiler, a power take-off valve is provided. To ensure

proper performance, boiler must be properly sized to meet

boiler horsepower requirements of kettles AND additional

equipment.

Water Supply Requirements

All water boiler systems are subject to contamination and

failure due to mineral content found in most water supplies.

To minimize service problems, a water treatment (softening)

system is recommended when water quality is found to

exceed limits stated below and in operator manual.

Recommended MINIMUM water quality standards are: total

dissolved solids (TDS) content should not exceed 30 parts

per million; and the water pH should be 7.0 or higher.

Origin of Manufacture

Kettle and cabinet mounted electric steam boiler shall be

made in the United States.

Stainless Steel

2/3 Steam Jacketed

Tilting Kettles

Cabinet Mounted

With Gas Boiler

Short Form

Unit shall be a Groen HyPLUS™

style cabinet base with two 20

quart tilting steam jacketed

kettles and gas steam boiler

per bulletin 34Hd. Kettles have

one piece welded construction

of Type 304 stainless steel

with reinforced bar rim and

butterfly shaped pouring lip.

Stainless steel support arms,

and two lugs for right or left

hand tilt standard. Cabinet

base has stainless steel frame

and exterior, removable double

panel doors, large sink flush

mounted in front of kettles,

hot and cold water fill faucet,

and 6” adjustable legs. Boiler

ASME code constructed for

15 PSI maximum. AGA design

certified and standard with

automatic blow down. Hot

and cold water connections,

condensate drain and electric power and gas connection

required, (See reverse side).

Made in USA.

Applications

Fresh and Frozen

Vegetables

Gravies

Sauces

Soup

Puddings

Pie Fillings

Pasta

Open Kitchen Display

Cooking

1055 Mendell Davis Drive, Jackson, MS 39272

888-994-7636, unifiedbrands.net

Please reference our website for the most

updated product information and specifications.

Groen Modular Equipment, Page 2

160172B

Revised 08/09

Page 2

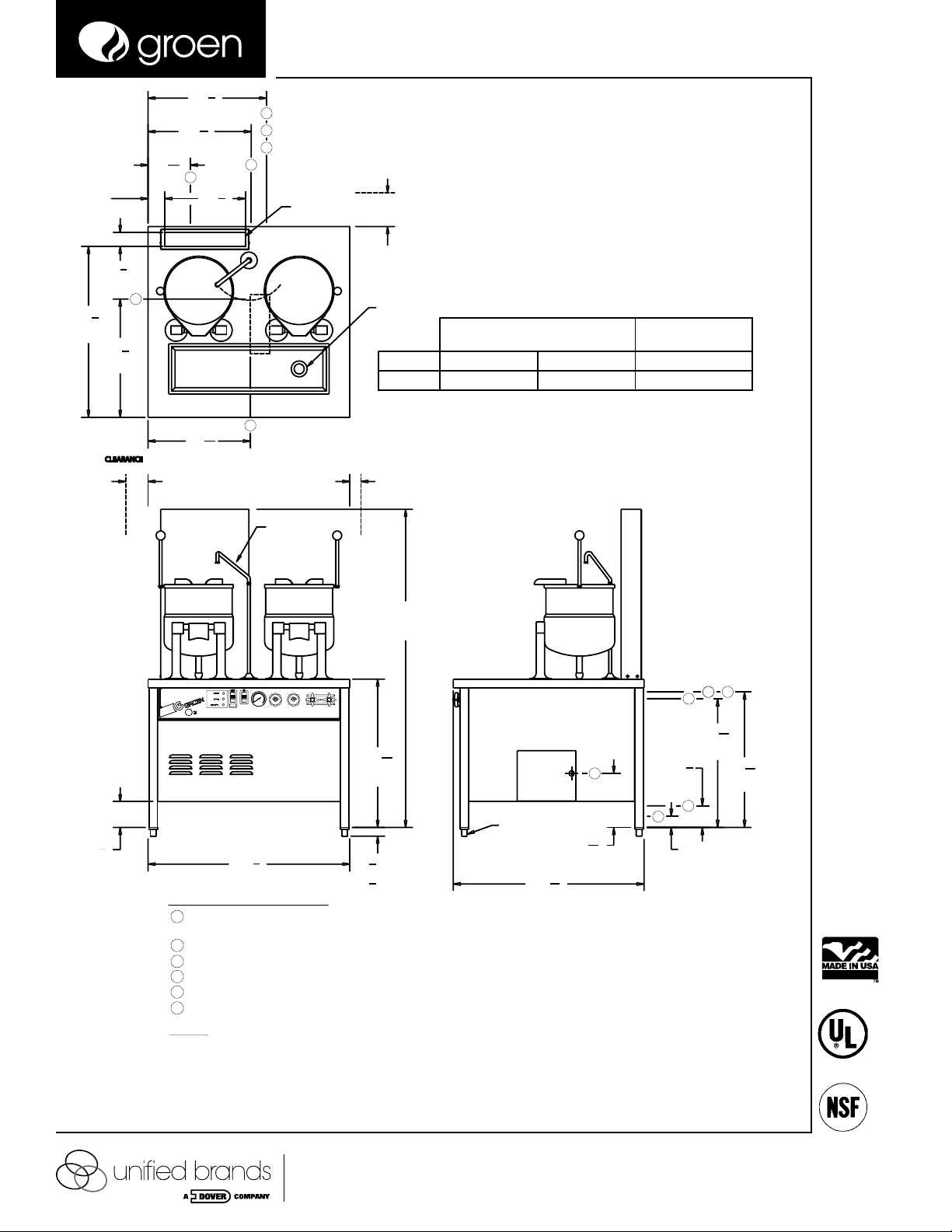

30

(778)

3

(76)

5

8

1

2

2

(64)

3

21

16

(538)

SEE NOTE 1

Model (2)CTDC/3-20-SG

1

21

4

(540)

1

18

2

(470)

9

7

16

1

(192)

14

(365)

4

3

18

16

(462)

2

3

5

6

3

8

FLUE

4

6

(152)

SINK

DRAIN

NATURAL

PROPANE

CLEARANCE

SEE NOTE 1

RECOMMENDED

INCOMING GAS PRESSURE

5" W.C. (MIN.)

11" W.C. (MIN.) 14" W.C. (MAX.)

*

INCHES WATER COLUMN

14" W.C. (MAX.)

INPUT RATE (BTU/HR.): 200,000

*

GAS PRESSURE

OPERATING

10.0" W.C.

OUTPUT RATE (BTU/HR.): 120,000

CLEARANCE

SEE NOTE 1

24

(51)(102)

BOILER HORSEPOWER: 3.7

P/N 121509 REV D

*

3.5" W.C.

4

(117)

SWING

SPOUT

57

(1448)

3

6

2

1

23

16

9

26

16

(675)

ADJUSTABLE

5

8

36

(918)

1

8

SERVICE CONNECTIONS:

DRAIN CONNECTION: 1-1/4" NPT

1

(INCLUDES AUTOMATIC & MANUAL BOILER, KETTLES & SINK)

2

COLD WATER SUPPLY: 1/2" NPT (FOR BOILER & FAUCET)

HOT WATER SUPPLY: 3/8" NPT (FOR FAUCET)

3

4

ELECTRICAL CONNECTION: 7/8" DIA. HOLE (REF. 1/2" CONDUIT KNOCK-OUT)

5

GAS CONNECTION: 1/2" NPT

6

STEAM POWER TAKE-OFF: 1/2" NPT

1

(38) MIN.

1

2

5

(67) MAX.

2

8

BULLET FEET

34

(868)

4

1

11

9

16

(246)

3

16

(586)

7

3

8

(98)

5

2

(51)

24

(618)

5

16

NOTES:

1. MINIMUM CLEARANCE FROM COMBUSTIBLE MATERIALS

RIGHT SIDE 2" (51)

LEFT SIDE 4" (102)

REAR 6" (152)

2. DIMENSIONS IN BRACKETS ( ) ARE MILLIMETERS.

3. SPLASHGUARD SUPPLIED BUT NOT SHOWN.

121509 REV. D

1055 Mendell Davis Drive, Jackson, MS 39272, 888-994-7636, unifiedbrands.net

© 2009 Unified Brands. All Rights Reserved. DOVER® and the DOVER® Logo are registered

trademarks in the United States [and various other countries] of Unified Brands, a

wholly-owned subsidiary of Dover Corporation.

Loading...

Loading...