Page 1

IMPORTANT INFORMATION

IMPORTANT INFORMATION KEEP FOR OPERATOR

IMPORTANT INFORMATION IMPORTANT INFORMATION

KEEP FOR OPERATOR IMPORTANT INFORMATION

KEEP FOR OPERATOR KEEP FOR OPERATOR

IMPORTANT INFORMATION

IMPORTANT INFORMATION IMPORTANT INFORMATION

E-CC-MOLAUNAM ROTAREPO

Part Number 121015 Rev. A DOMESTIC

MODEL: CC-E

CONVECTION COMBO™

Combination Steamer-Oven

CC10-E

CC20-EF

THIS MANUAL MUST BE RETAINED FOR FUTURE REFERENCE. READ,

UNDERSTAND AND FOLLOW THE INSTRUCTIONS AND WARNINGS

CONTAINED IN THIS MANUAL.

FOR YOUR SAFETY

DO NOT STORE OR USE GASOLINE OR OTHER FLAMMABLE VAPORS AND

LIQUIDS IN THE VICINITY OF THIS OR ANY OTHER APPLIANCE

.

Information contained in this document is

known to be current and accurate at the time

of printing/creation. Unified Brands recommends referencing our product line websites,

unifiedbrands.net, for the most updated

product information and specifications.

Page 2

OM-CC-E

IMPORT ANT — READ FIRST — IMPORTANT

WARNING:

CAUTION: SHIPPING STRAPS ARE UNDER TENSION AND CAN SNAP BACK WHEN CUT.

CAUTION:

CAUTION:

WARNING: TO AVOID DAMAGE OR INJURY, FOLLOW THE WIRING DIAGRAM EXACTLY WHEN

CAUTION:

WARNING:

WARNING:

IMPORTANT:

IMPORTANT:

WARNING:

THE UN IT MUST BE INSTALLED BY PERSONN EL QUALIFIED TO WORK WITH ELECTRICITY

AND PLUMBING. IMPROPER INSTALLATION CAN CAUSE INJURY TO PERSONNEL AND/OR

DAMAGE TO THE EQU IPMENT. THE UNIT MUST BE INSTALLED IN A CCORDANCE WITH

APPLICABLE CODES.

DO NOT INSTALL THE UNIT IN ANY WAY WHICH WILL BLOCK THE RIGHT SIDE VENTS,

OR WI THIN 12 I NCH ES O F A H EAT SOURCE SUCH A S A BRAISIN G PAN , DEEP FRYER,

CHAR BROILER OR KETTLE.

LEVEL THE UNIT FRONT TO BACK, OR PITCH IT SLIGHTLY TO TH E REA R, TO A VOID

DRAINAGE PROBLEMS.

CONNECTING A UNIT.

DO NOT USE PLASTIC PIPE. DRAIN MUST BE RATED FOR BOILING WATER.

DO NOT CONNECT THE DRAIN DIRECTLY TO A BUILDING DRAIN.

BLOCKING THE DRAIN IS HAZARDOUS.

Improper drain connection will void warranty.

Do not al low any wat er traps in t he line. A t rap can cause pressure t o build up inside t he

cavit y during steaming, which will make the door gasket leak.

WHEN YOU OPEN THE DOOR, STAY AW AY FROM STEAM COMI NG OUT OF THE UNIT.

STEAM CAN CAUSE BURNS.

WARNING: BEFORE CLEANING THE OUTSIDE OF THE STEAMER, DISCONNECT THE ELECTRIC POWER

SUPPLY. KEEP WATER AND CLEANING SOLUTIONS OU T OF CON TROLS AN D ELECTRICAL

COMPONEN TS. NEVER HOSE OR STEAM CLEAN ANY PART OF THE UNIT.

WARNING:

WARNING:

WARNING:

WARNING: DO NOT PUT HANDS OR TOOLS INTO THE COOKING CHAMBER UNTIL THE FAN HAS

WARNING:

NOTICE:

NOTICE:

WARNING:

ALLOW COOKING CHAMBER TO COOL BEFORE CLEANING.

CAREFULLY READ THE WARNINGS AND FOLLOW THE DIRECTIONS ON THE LABEL OF EACH

CLEANING AGENT.

DELIMING AGENT MANUFACTURER.

DO NOT MIX DE-LIMING AGENTS (ACID) AND DE-GREASERS (ALKALI).

STOPPED TURNING.

DO NOT OPER ATE THE UNIT UNLESS THE R EMOVA BLE RIG HT SIDE PANEL H AS BEEN

RETURNED TO ITS PROPER LOCATION.

DO NOT USE A CLEANING OR DE-LIMING AGENT THAT CONTAINS ANY SULFAMIC ACID

OR ANY CHLORIDE, INCLUDING HYDROCHLORIC ACID. IF THE CHLORIDE CONTENT OF

ANY PRODUCT IS UNCLEAR, CONSULT THE MANUFACTURER.

DO NOT USE ANY DE-GREASER THAT CONTAINS POTASSIUM HYDROXIDE OR SODIUM

HYDROXIDE OR THAT IS ALKALINE.

USE OF ANY REPLACEMENT PARTS OTHER THAN THOSE SUPPLIED BY GROEN OR THEIR

AUTHORIZED DISTRIBUTOR VOIDS ALL WARRANTIES AND CAN RESULT IN BODILY INJURY

TO THE OPERATOR AND DAMAGE THE EQUIPMENT. SERVICE BY OTHER THAN FACTORYAUTHORIZED PERSONNEL WILL VOID ALL WARRANTIES.

USE SAFETY GLASSES A ND R UBBER GLOVES AS RECOMMENDED BY

WARNING:

HIGH VOLTAGE EXISTS INSIDE CONTROL COMPARTMENTS. DISCONNECT FROM BRANCH

BEFORE SERVICING. FAILURE TO DO SO CAN RESULT IN SERIOUS INJURY OR DEATH.

2

Page 3

Table of Contents

OM-CC-E

OPERATOR W ARNINGS

REFERENCES ..........................................................3

EQUIPMENT DESCRIPTION

INSPECTION AND UNPACKING

WATER CONDITIONING/REQUIREMENTS .....................................6

INSTALLATION AND START-UP INSTRUCTIONS

OPERATING INSTRUCTIONS

CLEANING ............................................................21

MA I NT ENA NCE

TROUBLESHOOTING

SERVICE LOG..........................................................30

........................................................

...................................................

................................................

.............................................

................................

..............................................

....................................................

2

4

5

7

13

24

25

WARRANTY PROTECTION

UNDERWRITERS LABORATORIES, INC.

333 Pfingst en Road

Northbrook, Illinois 60062

KLENZADE SALES CENTER

ECOLAB, Inc.

370 Wabasha

St. Paul , Minnesota 55102

800 328-3663 or 612 293-2233

................................................

31

References

NATIONAL FIRE PROTECTION

ASSOCIATION

60 Battery March Park

Quincy, Massac husetts 02269

NFPA/70 The National Electrical Code

NATIONAL SANITATION FO UNDATION

3475 Pl y m outh Road

Ann Arbor, Michigan 48106

3

Page 4

OM-CC-E

Equi p ment D escr i p ti o n

Your Groen Convection Combo™ has a stainless

steel cooking ch amber , a n a ir hea ting compa rtment

with electri c hea ting elements an d fan, a steam

generator with electric h eat ing elements, an d a

control compartment which houses other electrical

component s.

All m ajor compon ents of the Conv ection Combo™

are encased in a 16 gauge stainless st eel ca binet.

Glass fiber insulation, lines the cabinet at a thickness

of 1½ to 2 i nch es (4 to 5 cm ). A remov able drip tray

is locat ed benea th the door.

Door hinges are reversible so that doors ma y open

from t he left or r ight side. Operator controls are

located on the ri ght side of th e front panel.

Standard cont rols l et you to opera te the Con vection

Combo in a ny one of three cooking modes:

1. As a conv ection oven

2. As a self-contained, pressureless steamer

3. As a combination oven-steamer

Models CC10- E an d C C 20-E differ in cooking

chamber size and capacity:

CC10-E: 4 steam t able pans (12x20x2½”), or

7 half- size (13x18" ) U S bak ing pans

CC20-E: 10 steam t able pans (12x20x2½”), or

9 ful l-si ze (18x26") US baking pan s

The smaller Conv ection Combo™ is ava ilable as a

table- top unit (the single CC10-E ). These units a re

also supplied on a stain less steel stand as models

CC10-EF an d (2)CC 10-EF. The larger Con vection

Combo™ is alw a y s supplied with a stand as the

single CC20-EF or the double-stacked (2)CC 20-EF.

The Convection Combo™ Fam ily: 1. Model (2)CC20-EF (Full- sized double-stacked uni t on rigi d stand),

2. Model CC-20-EF ( Full-sized si ngle unit on a convenient stand), 3. Model (2)CC10-EF (Double-stacked,

stand- m ounted, half- pan C om bo, 4. Model CC10-EL singl e four inch l eg-mounted. (Also availabl e in

tabl etop (CC10-E) and stand-mounted (CC10-EF) versi ons.

4

Page 5

Insp ecti o n an d U n p acki n g

OM-CC-E

Your Convection Combo™ will be completely

assembled in a hea vy shipping car ton or w ooden

crate, and attach ed to a skid. On receipt, inspect

the carton or crate carefully for exter ior damage.

CAUTION

SHIPPING ST RAPS ARE UNDER TENS ION AND

CAN SN AP BA CK WHEN CUT.

Carefully cut the straps around the carton and detach

the sides of the carton from the skid. Pull the carton

up off the unit. Be careful to avoid personal injury or

equipm e nt d amage from staples which might be left in

the carton w alls.

Water Conditioning

It is essential to supply the steam generator with

water that will n ot form scale. Even though the

steam gen erator is engineered to minimize sca le

formati on, scal e development depends on the

hardness of your water and the number of hours you

operate t he equ ipmen t.

In some areas, water is low enough in mi ner al

content to avoid scale formation. But most water

supplies are full of minera ls which form scale. It is

this scale which could lead to an early component

failure.

Your water utility can tell you about the minerals in

your wa ter. The water going to the steam gen era tor

should h a v e between 30 and 40 parts per million

(ppm) total dissol ved solids (TDS) a nd sh ould ha ve a

pH (acidity rating) of 7. 0 to 9.0. Please follow t hese

simple precautions:

Do not rel y on unproven water treat m ents

1.

which a re sold for scale prevention or scale

removal. They don’t always work. The best

way to preven t scale is to supply the purest

possible water (30 - 40 ppm TD S).

Write down the model number, serial number and

installation date and keep this information for future

reference. Space for these entries is provided at the

top of the Ser vice Log in the back of this manual.

CAUTION

THI S UNIT IS VERY HEAVY. YOU SHOULD GET

HELP AS NEEDED TO LIFT THIS WEIGHT

SAFELY.

When starting installation, lift the unit stra ight up off

the skid. Check pa cking materials to make sure

loose part s ar e not discarded w ith the material.

softener will provide longer generator life, higher

steam capacity, and reduce maintenance

requirements.

If you notice a slowdown in steam pr oduction,

3.

hav e the un it checked for scale build-up. H eav y

scale reduces the unit’s ability to boil water, and

can even cause hea ting elements in the steam

generator to overheat an d burn ou t.

MINIMIZE SCALE PROBLEMS, BY USING AND

MA INTAINING A SOFTENER , AND BY CLEANING

THE STEAM GENERATOR REGULARLY.

Groen Con vection C om bo™ ovens are also ava ilable

with an option for two separate water conn ections —

one for the stea m gener ator (soft water ), the other

for the spra y condenser (untreated wa ter). The

steam gen erator only uses 14 to 31% of a

combination oven’s water.

Since softener systems are typically sized by total

GPH (gallons per hour), the second connection could

reduce tr eat m ent requirements by u p to 80%,

resulting in significant sa v in gs.

2. If your water contains scale-forming minerals, as

most wa ter does, use a well -ma inta ined water

soften er. Wh ether an ex changeable soft ener

cartridge or a regener ating system is chosen, a

regular exchange schedule is essential.

Insta llin g a wa ter meter between the softener and

the steamer will provide an a ccurate gauge of water

use, and will help determine when to exchange

cartr idges or regenera te the softener. Using a water

5

Page 6

OM-CC-E

Installation and Start-Up

WARNING

THE UNIT MUST BE INSTALLED BY PERSONNEL WHO ARE QUALIFIED TO WORK WITH ELECTRICITY AND

PLUM B ING. IMPROPER INSTALLATION CAN CAUSE INJURY TO PERSONNEL AND/OR DAMAGE TO T HE

EQUIPMENT. THE UNIT MUST BE INSTALLED IN A CCO RDA NCE WITH APPLICABLE CODES.

CAUTION

DO NOT INSTALL THE UNIT WITH THE RIGHT SIDE VENTS BLOCKED OR WITHIN 12 INCHES OF A HEAT

SOURCE (SUCH AS A BRAISING PAN, DEEP FRYER, CHAR BRO IL ER O R K ET TL E) . D O NO T INS T AL L T O

THE LEFT OF ANY O PEN-FLAME EQUI PMEN T.

TO AVOID DRAINAGE PROBLEMS, LEVEL THE UNIT FRONT TO BACK.

A.MODEL CC10-E

Terminal block

1. M ounting

d.

If you wish t o install a Con vection C om bo™ on

top of a nother, you shoul d obta in a double

stacked un it fr om the factory.

If the unit does not have a factory-installed stand,

the install er must pr ovide a table, stan d or

counter w hich is strong enough to support th e

unit. Use of casters is not recommended.

To avoid drainage problems, level the unit fron t

to rea r, or provide a slight pitch to the rear.

Bolt the unit to the table, stand or coun ter top,

using the mounting holes in its base.

2. Electrical Supply Connections

Panel Removal

a.

The right si de panel must be removed to gain

access to the w iring and control

compartment. Remove the two screws at

the bott om of t he panel . Slide the panel

toward the front of the unit, lift it and set it

aside.

Supply Vol tage

b.

The CC10-E must oper ate at th e rated

nameplate voltage, plus or minus 10%.

Phase Select Plug (Units manufactured

c.

before 1996)

Locate the phase select plug assem bly on

the wiring harn ess from the relay board.

This assembly is black, blue and red. Refer

to t he labels located below the mot or and

above the distri bution block for the correct

phase connection.

The terminal block for incom ing power is

located at t he back of t he control

compartment.

WARNING

WHEN CONNECTING FOR SINGLE PHASE

OP ERATI ON, D O NO T C ONNE C T ANY WI R E TO

LINE 3 (THE TERMINAL FARTHEST LEFT). THIS

WILL CAUSE A SHORT CIRCUIT.

The ground terminal is found on the relay

bracket below the terminal block. The

Convection C om bo™ m ust have a separate

ground wire for safe operatio n. The ground

wire must be at least 10 AWG (2.6 mm).

e. Supply Wire

The type of wir e needed is determined by

fin ding the operating voltage and phase from

the unit’s back data plate an d (on pre-1996

models) phase select connector. Re fer to

the “Elect rical Supply Connection” label on

the back of the unit for correct wire size and

insulation temperatu re rating.

The specified w ire m ust be used to com ply

with U nderwr iters Laboratories and National

Elect ric Code requirements.

The knockout hole i s sized for a ¾ inch (19

mm) conduit fitting.

6

Page 7

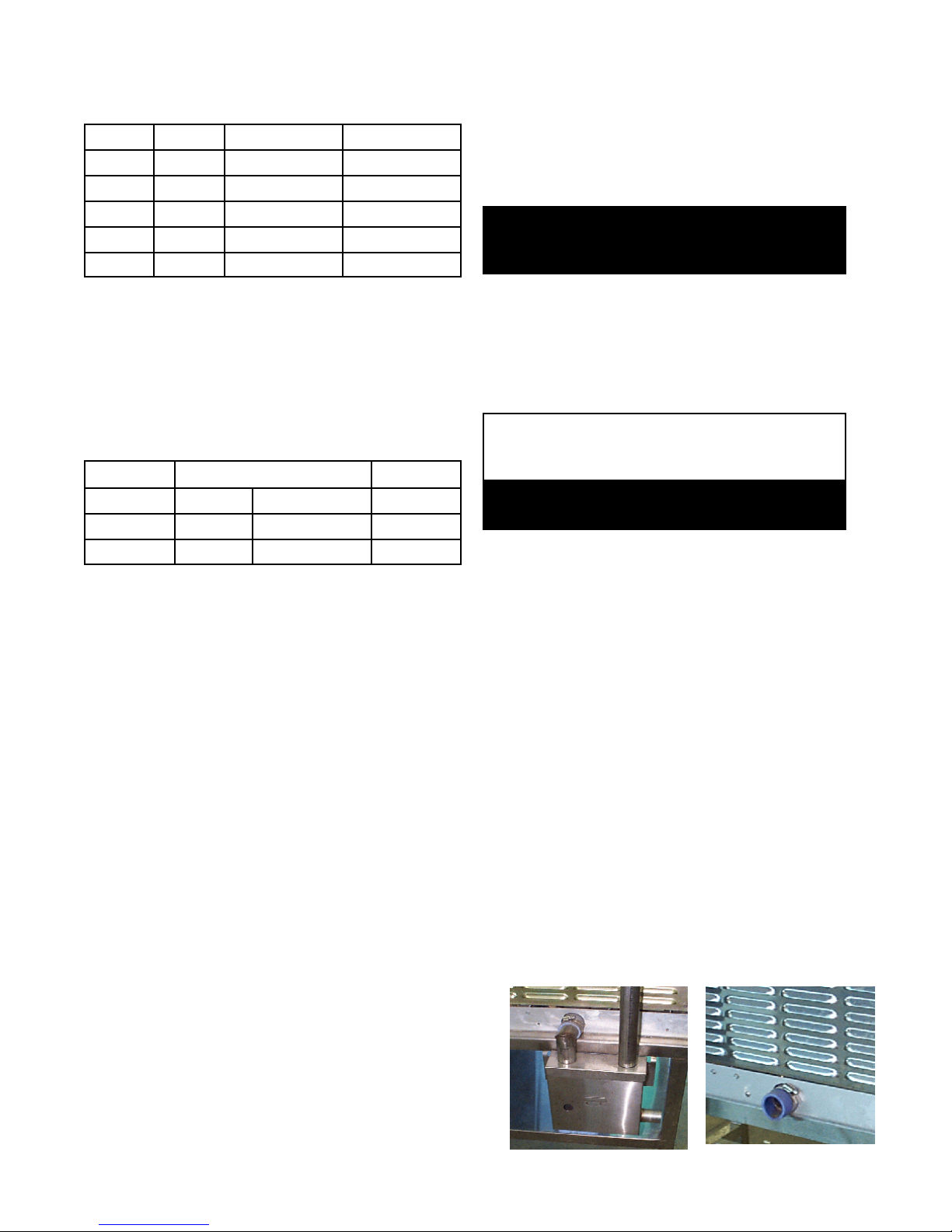

CC10-E ELECTRICAL SUPPLY CO NNECTION

(Al l w ires copper only.

Reference: National Electri cal Code)

4. Drain Co nnectio n

CC10-E Without Drai n Tank (tabletop model)

a.

OM-CC-E

Volt age Phase Wire Size Insul ation

208 1 6AWG (4.1m m ) 75

208 1 8AWG (3.3m m ) 90

208 3 8AWG (3.3m m ) 75

240 1 8AWG (3.3m m ) 75

240 3 8AWG (3.3m m ) 75

Branch Circuit Protection

f.

o

C

o

C

o

C

o

C

o

C

Groen strong ly recommends tha t each

Convection Co mbo™ have its own branch

cir cuit protecti on. A double sta cked u nit should

have separat e protection for the upper and

lower steamer-ovens.

CURRENT DEMAND

Voltage Current Power

1 Phase 3 Ph., per Line

208 44.7 A 27.5 A 9.3 KW

240 38.8 A 24.1 A 9.3 KW

Each current-carrying conductor must have

overcurrent protect ion. Refer to the label on

the back of the unit for pr oper w ire size an d

type. Watertight connections are required.

3. Water Supply Connection

A check val ve (back siph onage devi ce) mu st be

installed in th e incoming cold water line in keeping

with local plum bing codes. Wat er li ne pressur e

should be between 30 and 60 PSI ( 210 and 410

kPa). A pressure regulator is requir ed above 60

PSI (410 kPa).

A ¾ inch (19 mm) N H (gar den hose ty pe)

connector is required t o connect t he water supply

to t he wat er inlet valve. The w ater feed line

diameter ma y not be less that ½ inch (13 mm) .

Use a washer (or if necessary, tw o washers) in the

hose connection. Do not allow the connection to

have any leak, no matter how small.

A 1½ inch (4 cm) hose ma y be attached to the

provided dr ain elbow wit h a cla m p. Do not use

plastic pipe. The drain must withstand boiling

water.

WARNING:

DO NO T C O NNECT THE DRAIN DI RE CT LY TO A

BUILDING DRAIN.

There mu st be a free air gap between the end

of th e hose and t he building drain. The free air

gap shou ld be as close as possible t o th e unit’s

drain. There must also be no other elbows or

other restrictions between the unit drain and the

two inch free air gap.

CAUTION

DO NOT USE PL AST IC PIPE. DRAIN MUST BE

RATED FOR BOILING WATER.

WARNING

BLOCKING THE DRAIN IS HAZARDOUS.

Install the drain line with a constant downward

pitch.

IMPORTA NT: Do not allow any water traps in the

li ne. A trap can cause pressure to build up inside

the cavi ty during st eam ing, which will make the

door gasket leak.

NOTE: Improper drain connection will void the w a r ra n ty .

b. CC10-E With Drain Tank

A 1½ inch (4 cm) ID hose may be atta ched to

the supplied dr ain elbow wit h a cla m p. The

hose may be connected directly to a building

drain since the drain tank has an air vent, which

elim inates th e need for a fr ee air gap at the

building drain. Do not block the air vent in any

way. Do not attach anything to the vent tu be or

reduce it s size .

Do NO T use plastic pipe i n the drain line,

because the drain must withstand boiling w a ter.

If you r CC10-E is equipped with the optional split

water su pply, the supply for each steam gen era tor

must be able to fill the generator with 1½ gallons

(5.7 liters) or water in 1½ minutes. The make-up

water rate is 0.06 gall ons per min ute (0.2 lit ers per

minute). Condensate spray water rate is 0.34

gallons per minute (1.3 l iters per minute) at 30 PSI

(210 kPa).

7

Drain Tank

Tabletop Model

Page 8

OM-CC-E

Proper Drain Line Connections

8

Page 9

B.MODEL CC20-E

Mounting

1.

If you wish t o install one Con vection C om bo™

above another , obtain a double-stacked unit from

the fact ory.

CAUTION

DO NOT INS T AL L A CC 20 -E IN AN Y L O CATI ON

WHERE RIGHT SIDE VENTS ARE BLOCKED, OR

WIT HIN 12 INC HE S O F A HEAT S OURCE SUCH

AS A BRAISING PAN, DEEP FRYER, CHAR

BROI LER OR KETTLE.

DO NOT INSTALL THE UNIT TO THE LEFT OF

ANY OPEN FLAME EQU IPMENT.

OM-CC-E

breaker or 10 AWG ( 2.6 mm) for a 40 to 60

amp brea ker.

d. Supply Wire

The type of wir e needed is determined by

fin ding the operating voltage and phase from

the unit’s back data plate and phase select

conn ector. Refer to the “Electrical Supply

Connection” label on the back of the unit for

correct wire size and insulation temperature

rating.

The specified w ire m ust be used to com ply

with U nderwr iters Laboratories and National

Elect ric Code requirements.

To avoid drainage problems, level the unit fron tto-rear , or provide a slight pitch to the rear.

WARNING

THE UNIT MUST BE INSTALLED BY

PERSONNEL QUALIFIED TO WORK WITH

ELECTRICITY AND PLUMBING. IMPROPER

INSTALLATION CAN CAUSE INJURY TO

PERSONNEL AND/OR DAMAGE TO

EQUIPMENT.

CAUTION

INSTALLATION MUST BE IN ACCORDANCE

WITH ALL APPLICABLE CODES.

Elect ri cal Supply Connections

2.

a. Panel Removal

The right si de panel must be removed to gain

access to the w iring and control

compartment. Remove the screw a t th e

back of the panel. Sli de th e panel toward

the front of the u n it, lift it and set it a side.

b. Supply Voltage

The CC20-E must oper ate at th e rated

nameplate voltage, plus or minus 10%.

c. Termi nal block

The terminal block for incom ing power is

located at t he back of t he control

compartment.

The knockout hole i s sized for a one in ch

(25.4 mm) conduit fitting.

CC20-E ELECTRICAL SUPPLY CO NNECTION

(Al l w ires copper only.

Reference: National Electri cal Code)

o

Voltage

208 4 AWG (5.2 m m ) 6 AWG (4.1 m m )

240 4 AWG (5.2 m m ) 6 AWG (4.1 m m )

480 8 AWG (3.3 m m ) 8 AWG (3.3 m m )

e. Branch Circuit Protection

Voltage

Size for 75

(THWN)

Groen strong ly recommends tha t each

Convection Co mbo™ have its own branch

cir cuit protecti on. A double stacked unit

should have separate protecti on for the

upper and lower steam er-ovens.

CURRENT DEMAND

208 65.4 A 21 KW

240 56.7 A 21 KW

480 28.3 A 21 KW

Each current-carrying conductor must have

overcurrent protect ion. Refer to the label on

the back of the unit for pr oper w ire size an d

type. Watertight connections are required.

C

Current per l ine

(Three Phase)

Size for 90oC (THHN)

Power

The ground termina l is fou nd below the

ter m inal block. The Convection Combo™

must h ave a separate ground wir e for safe

operati on. The ground wire must be at least

8 AWG (3.3 m m ) for a 100 am p circuit

W ater Supply Connect ion

3.

A check val ve (back siph onage devi ce) mu st be

installed in th e incoming cold water line in

keeping with local plumbing codes. Water line

pressure should be between 30 and 60 PSI (210

9

Page 10

OM-CC-E

and 410 kP a). A pressure regu lator i s requ ired

above 60 PSI (410 kPa ).

A ¾ inch (19 mm) N H (gar den hose ty pe)

connector is required t o connect t he water supply

to t he wat er inlet valve. The w ater feed line

diameter ma y not be less that ½ inch (13 mm) .

Use a washer (or if necessary, tw o washers) in

the hose connection. Do not allow the

connection to have any leak, no matter how

small.

Drain Connect ion

4.

CAUTION

DO NOT USE PLAST IC PIPE. DRAIN MUST BE

RATED FOR BOILING WATER.

WARNING

BLOCKING THE DRAIN IS HAZARDOUS.

IMPORTA NT: Do not allow any water traps in the

li ne. A trap can cause pressure to build up

insi de the cavity during steam ing, which will

make the door gasket leak.

NOTE: Improper drain connection will void the

warranty.

CC20-E With Drain Tank

A two inch (51 cm) ID hose may be attached to

the supplied dr ain elbow wit h a cla m p. Th e hose

may be connected dir ectly to a building drain

since the drain tank has an air vent, which

elim inates th e need for a fr ee air gap at the

building drain.

Do not block th e air vent in an y w a y . Do not

attach anythin g to the vent or reduce its size.

Do NO T use plastic pipe i n the drain line,

because the drain must withstand boiling w a ter.

10

Page 11

OM-CC-E

Initial Start-Up

WARNING

ANY P OTE NT IAL US ER O F THE EQ UIP M E NT SHO UL D B E TRAIN E D I N SAF E AND C ORRE CT O PE RAT ING

PROCEDURES.

After the Convection Combo™ has been installed,

test it to ensure th at it i s opera ting correctly.

Remove all literature and packing materials from

1.

the interior an d exterior of the unit.

2. Check tha t the cold water supply line is open and

that none of the fittings are leaking.

Turn on electrical service to the unit.

3.

High Altitude Operat ion. At altitudes above

4.

5,000 feet (1524m), the u nit will n ot operate in

the Steamer or Combo Modes unless the altitude

is set. You can program the altitude as follows:

a. If the unit is on, turn it off by pressing the ON

touch pad.

b. Press and hold the STEAM touch pad while

turning the unit on by pressing the ON touch

pad. The Timer Display will show the letters

AL and a number representing the altit ude in

thousands of feet. If the altitude has not

been set for y our unit , the displ ay will be 0.

c. Enter an altitude value between 0 and 15,

usi ng the numbered touch pads. For

example, if the unit will be operating at 7,000

feet, enter 7.

For CC20-E onl y: Check Fan

5.

Rotation — IMPORTANT! As

seen fr om inside the oven cavi ty,

the fan should be turnin g in a

counterclockw ise dir e ction. If the

fan is running backwards

(clockwise), have a qualified

elect rici an turn off th e m ain pow er and switch

any tw o incom ing power lea ds on the di stri bution

block. An incorrectly turn ing fan will eventually

shut the oven down.

Select Farenhei t or

6.

Celsius

Temperatures. The

Convection Com bo™

is delivered w ith the

Farenheit scale as

default. To change

the current

temperature scale,

holding the 5 key in,

press ON. The Tim er

Display will either

show dEG°F or

dEG°C. Press the 5

key again to change

from one to t he other . Press STA RT to a ccept

the change.

d. Press the START touch pad.

Alti tude Metri c C onversion

Altitude

Feet Meters

5000 1524 5

6000 1830 6

7000 2133 7

8000 2438 8

9000 2745 9

10000 3048 10

11000 3353 11

12000 3658 12

13000 3962 13

14000 4267 14

15000 4572 15

Setting

11

To Test S teamer Mode Operation, tu rn on the

7.

unit. ( For details of opera ting procedure, see the

Operation section of this manual.) Clear time

from the time display. Press the STEAM touch

pad. (If the HOT light is on, see the Fast Cool

instructions in th e Opera tion section.)

The WAIT ligh t will stay on while the steam

gen erator fills with a nd heats the water. The

WAIT ligh t should turn off within three minutes,

and the READY light should come on. This

indicates that the water is at its stan dby

temperature. The timer only controls operati ons

in the Steamer Mode. Enter a ti m e and press

START. (“Time” is set in minutes and hours

only. Seconds are not displayed).

Examples: 2 minutes = 00:02

(Just pr ess 2).

1 hour and 30 minutes = 01:30

(Press 1, 3, and 0, or press 9,0

the timer w ill ch ange to 1:30)

Page 12

OM-CC-E

The colon [:] between the numbers on the time

display w ill blink a n d the genera tor will begin to

produce steam. The time will n ot count down

unless the READY light is lit.

NOTE: You cannot change modes i f the timer is

running.

8. To Test C om bo Mode Operation, turn on the

power and clear any t ime from the timer display.

Press the COMBO touch pad. Set the COOK

temperature to 300

will come on. It will rema in on wh ile (1) the

steam generator fills with water and heats it to

its standby temperature and (2) the air heater

raises t he air temperatur e to 300

actions should be completed in about five

minutes, starting with a cold unit. When the set

temperature is att ained, the WAIT light will go

off, and the READY light will come on.

NOTE: The timer does not control the oven in

eit her the C om bo or Oven Modes.

o

F (150oC). The WAIT light

o

F. Both

To Test O ven Mode Operation, turn on the

9.

power and clear the timer display. Press the

OVEN touch pad. Set the cook temperature to

o

F (175oC). The WAIT light will come on.

350

With in six minutes from a cold start, the WAIT

lig ht shou ld go out and the READY light shou ld

come on. When that happens, t urn the COOK

o

temperature setting down to 320

F (160oC). The

HOT light will come on.The heat-up times

provided above may vary sli ghtly as a resu lt of

voltage or wa ter pressure differences.

To shut down the unit, first clear the timer. Next,

10.

press t he mode pad for the mode in wh ich the

unit is oper ating. Finally, switch off the power.

11. If y our Convecti on Combo™ behaves as

descri bed, the u nit is fu nctioning correctly, an d is

ready for use.

12

Page 13

OM-CC-E

Operation

WARNING

ANY P OTE NT IAL US ER O F THE EQ UIP M E NT SHO UL D B E TRAIN E D I N SAF E AND C ORRE CT O PE RAT ING

PROCEDURES.

Controls and Indicators

A.

Operator controls feat ures ar e on the right front si de

of th e unit. Their use is described below:

1. Time Section

In Oven and Combo M odes, the timer

functions only as a “cooking time minute

minder” and does not turn th e unit on or off.

In t he Steamer Mode, h owever, it controls

the steaming function.

a. Displ ay Window — Show s opera ting

ti m e rema ining in the Stea mer, Oven or

Combo Mode. The ti m er counts down.

If the unit is equipped with, and opera ting

in the opti onal H old M ode, the timer will

count up, and will show the total

accumulated t ime that t he product has

been holding. The window shows

operati ng time in “hou rs:minutes” format.

For example, en tering 9 and 0 will result

in a display of 01: 30. (On some older

units numbers higher than 59 will not be

accepted - i n these cases, convert the

time to hours and minutes. 90 minutes

would be entered 1,3, 0.

beeper will sound and the SERVICE light

will be on when you switch on th e power.

The unit may cont inue to operate,

depending on the type of probl em .

Refer t o the Troubleshooting section to

deter m ine the natu re of the probl em .

b. Time t ouch pads — used to enter time

values.

c. CLEAR — Pressing this touch pad once

stops t he beeper an d resets t he timer to

the time tha t was last set. Pressing

twice cl ears it to 00:00. At the en d of a

cooki ng period, opening the door is the

sam e as pressing CLEAR once.

d. START — Press th is touch pad to start

the ti m er. If the unit is in Steam er M ode,

it will also cause steaming to begin.

2. Stat us Lights

a. HOT — Indicates chamber tempera ture

is more than 15

temperature. (See Para graph 5 in this

section)

b. SERVICE — Indicates that there is a

probl em which might require a service

call. If t here is such a problem th e

o

F (8oC) over the set

13

Page 14

OM-CC-E

c. WAIT — Indicates the u n it is either

d. READY — Indicates the unit is ready for

Cooking Mode Select ion

3.

a. STEAM — Selects st eamer operation

b. COMBO — Selects superheated st eam

c. OVEN — Sel ects con vection oven

4. Power

The ON touch pad turns th e unit on or off.

When power is on, the ON light just above

the touch pad is lit. U se of t his pad does n ot

reset the con trols. The unit will always come

on in the same mode it was in when shut

down.

heating or cooli ng toward the set

temperature. The HOT and WAIT lights

will both be on if the chamber is more

than 15

o

F (8oC) above the set point.

use.

only.

and con vection oven operation.

operati on only .

5. Temperature (TEMP) Section

a. The Tempera ture Display Win dow shows

the select ed temperatur e in either Oven

or Combo Mode. It is bl ank i n the

Steamer Mode or when th e optional Hold

Mode is operational.

b. Turning the Temperatu re Control Knob

select s the cooking tem peratu res in 5

increments. The control ranges a re:

o

Oven Mode 200-575

Combo Mode 220-575

Optional HOLD Section

6.

F (95- 300oC)

o

F (105- 300oC)

This optional feature permits l ow

temperature holding or (on m odels built

before November 1996) proofin g with

controlled humidity, when the unit has

already been set in the O ven or Combo

Mode. Whet her Oven or Combo Mode has

been selected has no effect on this optional

feat ure’s operation. H old M ode controls are

located at t he bottom of the control panel.

o

F

a. The upper window shows the sel ected

holding temperature. This display is

blank w hen th e Hold Mode has been

turned off.

14

Page 15

b. Turning the Hold Cont rol Knob clockw ise

activates the H old M ode and sets

temperatures in 5

range of 90

o

The OVEN or COMBO mode light m ust

be on befor e Hold Mode can opera te.

c. On units with the Hold Option which

were manufactured before November

1996, t here is a lower w indow which

displays the selected humidity. If the

Hold M ode is turned off, it will be blank.

d. Pressi ng the hum idit y set touch pad on

these units selects the relative humidity

Available choices for hum idity setti ngs

are LO; 45, 50, 55, 60, 65, 70, or 80%;

and HI.

Operati ng Instructio ns

B.

1. Steamer Mode

a. If the unit is off, switch on the electric

power by pressing the ON touch pad. (If

the SERVICE light comes on when you

turn on the power, see the

Troubleshooti ng section).

o

F increments within a

F to 200oF (30 t o 95oC).

OM-CC-E

WARNING

WHEN YOU OPEN THE DO OR STAY AWAY

FROM ANY STEAM COMI NG OUT OF THE

UNIT. STEAM CAN CAUSE BURNS.

e. The WAIT ligh t will be on un til th e water

reaches 200

off a nd the READY light will come on.

You are n o w ready to st eam foods in

your Convection Combo™.

f. Load the food in to pans in a n even,

o

F (93oC). It w ill th en turn

b. If the power is already on, an d th ere is a

number in the time display window,

press t he CLEAR t ouch pad one or more

times to reset the time to zero.

NOTE: You cannot change operating

modes w hile the ti m er is running

c. The unit will power up in th e mode of

operati on in which it was la st used.

Because of this, the indicator light for

that mode w ill be lit. If the unit is not

already in the S team er M ode, press the

STEAM touch pad. The STEAM light

will come on and the Temperature

Window will go blank.

d. If the unit was recentl y used in O ven or

Combo Mode, t he HOT li ght may come

on, indicati ng that t he cookin g chamber

is too hot for use as a steamer. The unit

can be cooled quickly to the steam ing

temperature range by leav ing the door

open or following the Fast Cool

procedure described near the end of this

secti on (Par agraph 5). With the door

open the generator can fill a n d heat the

water to 200

o

F, but it cannot produce

steam.

uniform layer.

g. Carefully open the door and slide the

pan or pan s onto the pan ra cks in the

cooki ng chamber. If y ou are on ly using

one pan , place it in the m iddle posi tion.

Close t he door.

h. Press the nu m bered touch pads to set

the cooking time. The time will appear in

the Time Display Window . If you enter

the wron g number, press the CLEAR

touch pad to erase the time from the

display, an d enter the time again.

i. When the correct cooking time has been

entered, press the START pad. The

colon in th e display w ill blink a n d the time

will count down the cooking time. (The

unit must be READY before the ti m er

can count down.

j. If you open the door during the cooking

period, steaming and the timer will stop

(but will not reset). When y ou close the

door, steam in g and tim ing will continue.

15

Page 16

OM-CC-E

WARNING

WHEN YOU OPEN THE DOOR STAY AWAY

FROM ANY S TE AM C O MING O UT O F T HE UNIT.

STEAM CAN CAUSE BURNS.

number keys when you first use set that

time.

n. After the display has counted down to

zero you can reset the time to zero by

eit her (1) opening the door and pressing

CLEAR or pressing CLEAR twice. A

new cookin g time m ay th en be set by

usi ng the number keys.

2. Oven Mode

a. To use the Convection Combo™ as a

conv ection oven, first switch on the

elect ric power by pu shing the ON touch

pad. (If the SERVICE light comes on

when you turn on the power, see the

Troubleshooti ng section). If the door is

closed and the cooking tem perature is

above 200

o

F (93oC) the fan w ill begin to

operate.

b. If the power is already on, an d th ere is a

number in the time display window,

press t he CLEAR t ouch pad one or more

times to reset the time to zero.

Wh en the timer reaches zero, it stops steam

k.

generation and sounds a beeper alarm . Water in

the steam gen era tor stays at its stan dby

temperature (200

o

F - 93oC). On some older

models, the beeper will continue to sound until

the door i s opened or the CLEAR pad i s

pressed.

l. Careful ly open the door. If th e food i s

cooked, remove the pa ns using hot pads

or oven mitts to protect your hands from

the hot pans.

m. After the display h as counted dow n to

zero opening the door or pressing

CLEAR once

will reset the display to the

time that was last used. Pressing

START will repeat the cook cycle. If the

NOTE: You cannot change operating

modes w hile the ti m er is running

c. The unit will power up in th e mode of

operati on in which it was la st used.

Because of this, the indicator light for

that mode w ill be lit. If the unit is not

already in the O ven Mode, press t he

OVEN touch pad. The OVEN light will

come on and the oven fan will operate.

d. Use the Tem perature Con trol Knob to

set t he desired cooking temperatur e,

which will appear in th e temperature

displ ay wi ndow. Unless the cookin g

chamber is already at or above the

selected temperatu re, the unit will begin

heating and the WAIT ligh t will come on.

same cooking time will be used

repeatedl y, you only n eed to press the

16

Page 17

e. If the unit was recently used at a

temperature more than 15

o

F (8oC) higher

than the temperature selected, the HOT

and WAIT lights will turn on. The unit can

be cooled quick ly to the desired cooking

temperature by leaving the door open or

following the Fast Cool procedure

descri bed near t he end of this secti on

(Paragraph 5).

f. The READY light will indicate when the

oven is at the desired t em peratu re.

OM-CC-E

k.

To stop cooking, t ake th e pans out of the

oven using hot pads or oven mit ts to

protect your hands from the hot pans.

The unit will con tin u e heating to keep th e

chamber at the set temperature until the

temperature control is r eset, or the pow er

is shut off.

g. Load the food i nto the pan or pa ns in a

uniform layer.

h. The Convection Combo™ will operate i n

Oven Mode with the timer either on or off.

If you wan t to time the cooking, press th e

number ed pads in the TIM E portion of t he

control panel to set the cooking time. The

time will appear in the Time Display

Window. If you enter the wrong number,

press t he CLEAR t ouch pad t o erase the

time from the display, and enter the time

again. Remember that the timer does not

control the unit in the O ven Mode.

i. Open the door a nd slide the pan or pan s

onto the pan rack s in the cooking ch amber.

If you are only u sing one pa n, place it i n

the middle posit ion. Close the door.

j. If the correct ti m e has been set on the

timer, press the START pad. The colon [:]

between the numbers in the display will

blink and the time will count down the

cooking time. When the timer ha s counted

dow n to zero, it will sou n d a beeper . This

sou n d will continue until the door i s opened

or t he CLEAR pad is pr essed.

WARNING

PANS AND INTERNAL PARTS OF THE OVEN

WILL BE VERY HOT. AVOID CONTACT WITH

HOT SURFACES.

l. Opening the door du ring operation shu ts

off power to the heaters and fan and

stops the timer, but it has no other affect

on the controls. When the door is cl osed,

operati on conti nues. Note t hat cook in g

time will be extended by the period the

door was open.

3. Combo Mode

a. If the unit is off, switch on the electric

power by pressing the ON touch pad. (If

the SERVICE light comes on when you

turn on the power, see the

Troubleshooti ng section). If the door is

closed and the cooking tem perature is

above 200

o

F (93oC) the fan w ill begin to

operate.

b. If the power is already on, an d th ere is a

number in the time display window, pr ess

the CLEAR tou ch pad one or m ore times

to reset the time to zero.

17

NOTE: You cannot change operating

modes w hile the ti m er is running

c. The unit will power up in th e mode of

operati on in which it was la st used.

Because of this, the indicator light for that

mode w ill be lit. If the unit is not already

in the Combo Mode, press the COMBO

touch pad. The COMBO light will come

on an d if th e stea m generat or is not

already fu ll, w a ter will flow into it and

begin heating.

d. Use the Tem perature Con trol Knob to set

the desir ed oven temper ature betw een

220 and 575

o

F (105 t o 300oC). The

temperature will appear in the

temperature displ ay window.

Page 18

OM-CC-E

e. If the unit was recently used at a

temperature more than 15

than the temperature selected, the HOT

and WAIT lights will turn on. The unit can

be cooled quick ly by leaving th e door open

or followin g the Fast Cool procedure

descri bed near t he end of this secti on

(Paragraph 5).

WARNING

WHEN YOU OPEN THE DOOR STAY AWAY

FROM ANY ST EAM CO MING O UT O F T HE UNIT.

STEAM CAN CAUSE BURNS.

f. The WAIT light will be on u n til th e wa ter in

the steam generator reaches the boiling

point and the air in the cooking chamber

reaches the set temperatu re. It will then

turn off and the READY light will come on

indicati ng tha t the oven is at th e desired

temperature.

o

F (-8oC) higher

i. Open the door a nd slide the pan or pan s

onto the pan racks in the cooking

chamber . If you are only usin g one pan,

place it in the m iddle posi tion. Close the

door.

j. If the timer h as been set, press the

START pad. The colon [:] between the

numbers in th e display w ill blink a n d the

time will count down the cooking time.

When the timer has count ed down to

zero, it will sound a beeper . This beeping

will continue until the door is opened or

the CLEAR pad i s pressed.

k. To stop cooking, take the pans out of t he

oven using hot pads or oven mit ts to

protect your hands from the hot pans.

The unit will con tin u e steaming and

heating the oven at the set temperatu re

until the temperature control is reset, or

the power is shut off.

Hold Mode (Cook-n-Hold Option) - (Cook-n-

4.

Hold/Proof ing Option on Models Manu-

g. The unit w ill operate in Combo Mode w ith

the timer either on or off. If you w a n t to

ti m e the cooking, press the n umbered

pads in the TIME portion of the control

panel to set the cooking time. The time

will appear i n the Tim e D isplay Window . If

you enter the wrong num ber, press the

CLEAR touch pad to era se the time fr om

the display, and enter the time again. The

timer does not control the unit in Combo

Mode.

h. Load the food i nto the pan or pa ns in a

uniform layer.

WARNING

WHEN YOU OPEN THE DOOR STAY AWAY F ROM

ANY STEAM COMING OUT OF T HE UNIT . STEAM

CAN CAUSE BURNS.

fact ured Before Novem ber 1996) Items

identi fi ed by an asterisk (*) and/or in italics per tain

to Hum idity Control features on some model s

manufactured prior to November 1996.

18

Page 19

a. If these optiona l feat ures ar e included in

your Convection Combo,™ the controls are

located near the bottom of the Control

Panel. Hold M ode m ay be act ivated when

the oven is ei th er in Combo or O ven Mode,

and works the same in both.

b. If you want your Convection Combo™ to

switch to Hold Mode automa tically when i t

fin ishes cooking, use the foll owing

procedure:

1) Set the unit for Combo or Oven Mode.

2) Set COOK tem peratu re.

OM-CC-E

NOTE: Food will continue to be cooked

by the excess heat as the unit

slow s to the set HOLD

temperature. The am ount of

additi onal cook ing depends on

the food produ ct a nd the initial

COOK temperature.

The oven will opera te at the set HOLD

temperature (and humidity)* u n til it is

chan ged or turned off. If desir ed, you

may check t he time on hold by pressing

START. The u n it w ill count up and

displ ay th e time elapsed since it has been

holding. The maximum that the timer is

able to display is 19 hours and 59

minutes. After that the display will flash

19:59, but the unit will continue to

maintain the HOLD settings.

c. To end manual operation of the Hold

Mode, fir st remove the food from t he uni t.

Then take either of t he following steps:

1) If the timer is not running, turn the

COOK temperature set knob

clockwise until a number appears i n

the COOK temperatur e display. (The

unit will h eat to the COOK setting).

2) If the timer is running, press and hold

in the CLEAR touch pad for at least

two second s.

3) Set the cooking time.

4) Turn the HOLD temper ature set knob

until t he desired hold temperatu re

appears in the HOLD temperature

display.

5) (Press HUMIDITY set touch pad unt il

the desired setting appear s in t he

HUM IDITY displ ay).*

6) After the READY light comes on to

indicate the oven is at the set

temperature, open the door, load food

into t he uni t a nd close the door.

7) Press the START touch pad.

When the set cook time is ended, the unit

will automatically switch to the H old Mode.

The beeper will NOT sound. The timer

will now count UP. The COOK

temperature display w ill be blank and the

temperature of the unit w ill slowly drop to

the HOLD temperature setting.

19

Page 20

OM-CC-E

5. Fast Cool

Shutt ing Down

6.

a. When the HOT indicator is lit and the

ti m er is cl eared, the uni t can be cooled

quickl y by openi ng the door and

pressing START. The fan will

operate, and th e TIME window will

display the word “COOL.” This is the

only time t he fan opera tes with the

door open.

WARNING

DO NOT PUT HANDS OR OTHER OBJECTS

INTO THE COOKING CHAMBER DURING THE

FAS T C OO L OP ERATIO N. T HE RO T AT ING FAN

CAN BE HAZARDOUS.

b. To stop t he Fast Cool operation, press

any tou ch pad or close the door.

a. Press the touch pa d for the mode in w hich

the unit is oper ating.

b. Switch off th e power by pr essing the ON

touch pad.

Leave the door at least partially open, if local

sanitation regulations permit.

20

Page 21

OM-CC-E

Cleaning

To keep your Con vection C om bo™ in proper opera ting condition an d to ma ke the cleanin g process ea sier, clea ning

should be a daily activity.

Suggested Tools and Cl eaners

A.

1. Mild det ergent

2. Stainless steel exterior cleaner such as

Zepper®

3. Steam gen erator de-li m ing agent, such as

Groen Deli m er Descaler, Lime-Away®

or an equivalent. A liquid de- liming agent

will be easier to use than crystals or

powders. See the warning about chlorides

below.

4. De-greaser, such as EncompasS®, Malone

34®, Puritan P uribrute® , or Con-Lie®

5. Clot h or sponge

Plasti c wool or a brush wit h soft bri stles

6.

Spra y bottle

7.

8. Measuring cup

9. Nylon pa d

10. Towels

Plasti c disposable gloves

11.

Procedure

B.

1. Exterior Cleaning

a. Prepare a w arm solu tion of the mild

deter gent as instru cted by the supplier. Wet

a cloth with this solution and wring it out.

Use the m oist cl oth to clean the outside of

the unit. Do not allow freely running liquid to

touch the controls, the control panel, any

elect rical part, or any open louver.

To remove material which may be stu ck to

b.

the unit, use plasti c wool, a fiber br ush, or

a plastic or ru bber scraper with a

deter gent solution.

Stainless steel surfaces may be polished

c.

with a recognized sta inless steel clea ner

such a s Zepper®.

DISCONNECT THE POWER SUPPLY

BEFORE CLEANING THE OUTSIDE OF

THE UNIT.

KEEP WATER AND CLEANING

SOLUTIONS OUT OF CONTROLS AND

ELECTRICAL COMPONEN TS. NEVER

HOSE OR STEAM CLEAN ANY PART

OF THE UNIT.

DON’ T MIX DE-LIMIN G AGENTS (ACID)

WITH DE-GREA SERS (ALKA LI)

ANYWHERE IN THE U NIT

AVOID CONTACT WITH ANY

CLEANERS, DE-LIMING AGENT OR DEGREASER AS RECOMMENDED BY THE

SUPPLIER. MANY ARE HARMFUL.

READ THE WARNINGS AND FOLLOW

THE DIR ECTIONS!

EVEN WHEN THE UN IT HAS BEEN

SHUT OFF, DON’T PUT HANDS OR

TOOLS I NTO THE COOKIN G

CHAMBER UNTIL THE FAN HAS

STOPPED TURNING.

DON’T USE ANY CLEANING OR DELIMING AGENT THAT CONTAINS ANY

SULFAMIC AGENT OR ANY CHLORIDE,

INCLUDING HYDROCHLORIC ACID

(HCl). TO CHECK FOR CHLORIDE

CONTENT SEE ANY MATERIAL

SAFETY DATA SHEETS PROVIDED BY

THE CLEANING AGENT

MANUFACTURER.

UNIT MA Y BE HOT. TA KE

PRECAUTIONS TO PREVEN T

CONTACT WITH HOT SURFACES.

PRECAUTIONS

WARNING

DO NOT USE ANY METAL MATERIAL (SUCH AS METAL SPONGES) OR METAL IMPLEMENTS (SUCH AS

A SPOON, SCRAPER OR WIRE BRUSH ) THAT MIGHT SCRATCH THE SURFACE. SCRATCHES M AKE THE

SURFACE HARD TO CLEAN AND PROVIDE PLACES FOR BACTERIA TO GROW. DO N O T USE STEEL

WOOL, WHICH MAY LEAVE PARTICLES IMBEDDED IN THE SURFACE WHICH COULD EVENTUALLY

CAUSE CORROSION AND PITTIN G.

IMPORTANT

21

Page 22

OM-CC-E

Interior Cleaning

2.

To exit the Clean Cycle at any time, press and

hold the CLEAR touch pad. Be sure to wash

out al l chemical residues t horoughly before

using t he unit.

UNIT MAY BE HOT. DO NOT TOUCH HOT

SURFACES.

DO NOT PUT HANDS OR OTHER OBJECTS

IN TO COOKING CH AMBER WHILE CONVECTION

CO MB O ™ IS OPE RATING. THE RO TATING F AN

CAN BE HAZARDOUS.

a. Turn off a ll operating modes by stopping the

ti m er, an d pressing the mode t ouch pad( s).

b. Enter 99 on the timer. The display should

show “00:99.”

c. If the HOT light is on, use the Fast Cool

method to reduce the temperatur e

(Paragraph 5, Oper ation, Page 18). If the

HOT light is off, “CI” will be displayed in th e

ti m er w indow, an d you may proceed to the

next step.

Remove all pan racks and clean them in a

d.

sink. To remove the right side rack, lift it up

and to the left.

Remov e the right side of th e cooking

e.

chamber.

Prepare oven degreaser a s direct ed on the

f.

product l abel. Thorou ghly coat a ll i nside

surfaces of the cookin g chamber and both

sides of the right side pan el with the

degreaser.

WARNING

It ma y cause the unit to display false service

messages.

Replace the generator cover an d right side

i.

panel in their normal positions.

Close t he door and press START. The timer

j.

will display “CL:50,” with the colon [:]

between the numbers flashin g. The timer w ill

count down to “CL:26.”

k. When the buzzer sounds and the timer

displays “C2,” open the door.

WARNING

THE UNIT WILL BE HOT ENOUGH TO CAUSE A

BURN. DO NOT TOUCH ANY HOT SURFACE.

l. Remov e the right side panel an d steam

generator cover an d rinse them in the sink.

l. Rinse and wipe down the cooking ch amber

with a cloth and plenty of clean wa ter. Rinse

the clot h often.

n. Add de-l iming agent to the steam generator

as speci fied by the de-li m ing agent label.

o. Put the genera tor cover an d right si de panel

back in place.

p. Close t he door. The timer w ill display

“CL:26" and count down automatically to

“CL:00.”

q. Press the ON switch to turn off the u n it. Let

the unit cool.

Remov e the steam generat or cover.

g.

NOTE:

h. If there are grease deposits in the genera tor,

Add degreaser to the steam gen erator

only if you see grease deposit s.

add ¼ to ½ cup (60 t o 125 m l) of fu ll

str ength degr easer to the genera tor, or

lig htly coat the generator w ith spray

degreaser. Do not use too mu ch degreaser .

22

WARNING

UNIT MAY BE HOT. DO NOT TOUCH HOT

SURFACES.

Remov e the right side panel an d steam

r.

generator cover and rinse them thoroughly in

a sink.

Page 23

Rinse and wipe down the cooking ch amber

s.

with a cloth and plenty of clean wa ter. Rinse

the clot h often.

3. De-liming Only

If you only w ant t o clean har d, w hite deposits out of

the steam gen era tor, it is not necessary t o degrease

the unit.

a. Turn off a ll operating modes by stopping the

ti m er, an d pressing the mode t ouch pad( s).

Enter 99 on the timer. The display should

b.

show “00:99.”

c. If the HOT light is on, use the Fast Cool

method to reduce the temperatur e

(Paragraph 5, Oper ation, Page 18). If the

HOT light is off, “CI” will be displayed in th e

ti m er w indow, an d you may proceed to the

next step.

OM-CC-E

Press the ON switch to turn off the unit. Let

k.

the unit cool.

WARNING

UNIT MAY BE HOT. DO NOT TOUCH HOT

SURFACES.

l. Remov e the right side panel an d steam

generator cover and rinse them thoroughly in

a sink.

m. Rinse and wipe down the cooking chamber

with a cloth and plenty of clean wa ter. Rinse

the clot h often.

n. Re-install the pan racks.

d. Remove all pan racks and clean them in a

sink. To remove the right side rack, lift it up

and to the left.

Pour one pint (two pints for CC-20E) de-

e.

lim ing agent into th e steam generator.

Close t he door and press START. The timer

f.

will display “CL:50,” with the colon [:]

between the numbers flashin g. The timer w ill

count down to “CL:26.”

WARNING

THE UNIT WILL BE HOT ENOUGH TO CAUSE A

BURN. DO NOT TOUCH ANY HOT SURFACE.

g. When the buzzer sounds and the timer

displays “C2,” open the door AND CH EC K

THE STEAM GENERATOR.

NOTE: If the timer stops and the SERVICE light

comes on, it mea ns tha t there have been

errors that prevent the unit from completing

it s Clea n Cycle. Take the following st eps:

1) Perform a reset. With the unit turned off,

press and hold the COMBO touch pad.

Then press the ON touch pad to display any

err or codes.

If the error numbers displayed ar e 1 and 3,

2)

or 2 and 3, press CLEAR, and restart the

Clean C ycle by entering “99" (00:99) on the

ti m er. Add one cup of full strength

degreaser and continue the Cl ean Cycle by

pressing START.

3) If the error numbers ar e 1 and 2, or 6, call

your auth orized Groen Service A gency for

immediate service.

If the error number displayed is 1 or 2, but

4)

not both, t he unit may need more cleaning.

If there are other errors, refer to this manual’s

Troubleshooti ng Section (Page 24)

h. If the generator is fr ee of hard deposits, go

to t he next step. If h ard, w hite deposits are

still visible, add de-liming agent a gain before

proceeding.

i. Put the genera tor cover an d right side panel

back in place.

j. Close t he door. The timer w ill display

“CL:26" and count down automatically to

“CL:00.”

Clean Cycle Counter

The Convection Combo™ keeps track of

completed Clean Cycles. To see this total, turn

off the unit. Press and hold the 0 touch pad while

turning on the unit. The total will show in the

timer window. It cannot be reset.

3. Manual Cleani ng

This procedure may be necessary if r egular cleaning

was not per for m ed.

23

Page 24

OM-CC-E

NOTE:

DO NOT PUT HANDS OR OTHER OBJECTS

INTO THE COOK ING CHAMB E R WHILE THE FAN

IS TURNING.

It is strongly recom m ended tha t the u nit be

run through a Clean Cycle after manual

cleaning. Repea t a s necessary .

WARNING

1. If the unit has been oper ating in the O ven or

Combo Mode, all ow it to cool or use the

Fast Cool procedure descri bed in the

Operations Section (Page 18).

Maintenance

When the unit has cooled en ough to be

2.

cleaned, sw itch it off by pressing th e ON

touch pad.

3. Remov e the right side panel fr om th e cooking

chamber.

®

Using Easy-Off

4.

comparable product, thoroughly coat all

inside surfaces of th e chamber, in cluding the

right side panel. Follow the manufacturer’s

instr uction s on the cleanin g agent label.

5. Inst all the right side panel.

Rinse and wipe down the cooking ch amber

6.

with a cloth and plenty of clean wa ter. Rinse

the clot h often.

Oven Clean er or a

The Groen C onvection Combo™ is designed for

minimum maintenance. Certain parts may need

repl acement after prolonged use. If th ere is a need

for service, only Groen person nel or author ized

Groen representa tives should perform the work.

Always supply water with a low mineral count that

meets the standards outl ined in the Water

Conditioning section of this manual.

If steam or con densate is seen leak ing from arou nd

the door, ta ke the following steps:

Check the door gasket. R eplace if it is cracked

1.

or spl it. Inspect the cooking ch amber drain to be

sure it is not blocked.

Troubleshooting

Resetti ng the Solid S t at e Controls

A.

(I f problems persist call an authorized Groen

Service Agency)

If the controls stop responding to norm al

operati ons, or the unit is behaving oddly, reset

the control s using the following procedure:

1. Switch off th e power by pr essing the ON

touch pad.

2. While pressi ng the COMBO touch pad,

switch the pow er back on. If no errors are

present the unit will beep and show four

zeroes in the displ ay. If there are er rors, the

unit will not beep, but will display Serv ice

Codes, i n the t imer and cook tempera ture

displ ays. N ote the Service Codes. Press

CLEAR to exit Service Mode and refer to t he

following explanation of service messages.

Adjust the latch pin as follows:

2.

a. Loosen the lock nut a t the base of the latch

pin, and turn the latch pin ¼ turn clockwise.

Re-tighten the lock nut.

b. After adjustment, run the unit to test for

further steam leak s.

c. If there is still leakage, repeat th e

adjustment.

d. Continu e adjusting the pin clockwise un til the

door fits ti ghtly enough t o prevent leaks.

Service Messages

B.

There are two types of service message:

1. Non-critical er ror: signaled by three quick

beeps. The SERVICE ligh t comes on for 15

seconds and th en goes out.

Critical error: signaled by a continuous five

2.

second beep. The SERVICE comes on and

stays on.

If there is a non-critical error you may continue to

operate t he uni t. When possi ble, i nspect th e Service

Code. Turn off th e unit by pressing the ON touch

pad. While pressing the COMBO touch pad, switch

the power ba ck on . N ote the numbers and refer to

the Troubleshooti ng Guide which fol low s. Press

CLEAR to exit the Service Mode. If ther e is a crit ical

error, the un it will not opera te in it s curren t mode, but

may operate in another. Inspect the Service Code

as described above, and call your a uthor ized Groen

Service Agency.

24

Page 25

OM-CC-E

Troubleshooting Guide

If a problem persists after t akin g the actions suggested below , ca ll your author ized Groen serv ice representative.

CODE IN DICATES SUGGESTED ACTION

Try cleaning steam generator to remov e contami nation from the probes.

1 Low water l evel probe

2 High water level probe

Maximum generator fi ll

3

ti m e (90 secon ds) has

been exceeded.

4 Faulty air probe

5*

7*

7A*

*Service Code 5 is not used on units manufactured after March 1, 1997. Service Code 7 indicates Out of

Calibration for units m ade before March 1, 1997. Th ereafter i t indicates Time Between Fills, descri bed in 7A ,

above. These ch anges wer e m ade on units aft er Serial Number C7439MS .

Faulty drain probe

(Units Befor e 3/97 On ly)

6 Fau lty generator probe

Out of Calibration

(Units Befor e 3/97 On ly)

Time Between Fills

(Units After 3/97 Only)

Maximum generator drain

8

time (five minutes) has

been exceeded.

If either code continues call your Gr oen Servi ce Agency.

•

If both codes are displayed the unit will only operate in the Ov en Mode.

•

If only on e code is displ ayed th e unit will operat e in all modes, but water

•

may overflow from the generator into the cooking ch amber dur ing

operati ons in either the Steam or Combo M odes.

Make sure the water supply is fully turned on and that hoses are not kinked

or pi nched.

If the code is still displayed the unit w ill operate in the Ov en Mode onl y.

•

Call your Groen Servi ce Agency

•

• The un it will operate i n Steamer and Clean C ycle Modes only .

• Call your Gr oen Service Agency

The unit will operate i n all m odes.

•

Call your Groen Servi ce Agency

•

• The un it will operate i n Oven Mode only .

• Call your Gr oen Service Agency

The unit will operate i n all m odes.

•

Call your Groen Servi ce Agency

•

Check for a leaky fill valve.

The unit will operate i n Oven Mode only .

•

Call your Groen Servi ce Agency

•

Inspect the drain line and remove any blockage. Make certain that the

drain is free-vented as detailed in the Installation Section of this Manual.

(Paragraph 4, Pa ge 6)

Mode Operation — After a Service Code Occurs

Mode

Steam Yes Yes No Yes Yes NA No Yes No No No

Combo YesYesNoNoYesNANoYesNoNoNo

Oven Yes Yes Yes No Yes NA Yes Yes Yes Yes Yes

Clean Yes Yes No Yes Yes NA No Yes No No No

*Service Code 5 is not used on units manufactured after March 1, 1997. Service Code 7 indicates Out of

Calibration for units m ade before March 1, 1997. Th ereafter i t indicates Time Between Fills. These cha nges

were ma de on uni ts after Ser ial N umber C7439MS.

12345* 5A 6 7* 7A 8 1 & 2

Service Code

25

Page 26

OM-CC-E

Diagrams & Schem atics

CC10-E Control Schematic

CC10-E Heater S chematic

26

Page 27

Diagrams & Schem atics, Continued

OM-CC-E

CC20-E Co ntrol Schematic, 208/240 Volt s

CC20-E Co ntrol Schematic 480 Vo lts

27

Page 28

OM-CC-E

Diagrams & Schem atics, Continued

CC20-E Heater S chematic, 208/ 240 V olts

CC20-E Heater S chematic, 480 Volts

28

Page 29

Diagrams & Schem atics, Continued

OM-CC-E

CC20-E Heater S chematic 208/240 Volts

(Units That Meet Canadian Standards Association Requirements)

29

Page 30

OM-CC-E

Service L o g

Model No.

Serial No.

Date Purchased

Purchase Order No.

Date Maintenance Performed Performed by

Purchased From

Location

Date Installed

For Service Call

30

Page 31

OM-CC-E

LIMITED WARRANTY TO

COMMERCIAL PURCHASERS*

(Continental U.S., Hawaii and Canadian Sales Only)

Groen Foodservice Equipment (“Groen Equ ipmen t”) has been skillfu lly manufactured, carefully inspected, and

packaged to meet rigi d sta ndards of excellence. Groen warrants its Equipment to be free from defects in ma terial

and workmanship for (12) twelve months with the following conditions an subject to the following limitations.

I. This parts and labor w arranty is limited t o G roen Equipment sold to the origi nal commercial

purchaser/users (but not original equipment manufacturers {O.E.M.}), at its original place of installation in

the continental United States, Hawaii and Canada.

II. Dam age during shipment i s to be reported to the carrier, is not covered under th is warra nty, and is the sole

responsibility of the purchaser/user.

III. Gr o e n,, o r an aut horized service r e p resentativ e , will repair or replace, at Groen’s sole election, any Groen

equipmen t, i ncluding but not l imited to, draw -off valv es, sa fet y val ves, gas a nd electric compon ents, found

to be defective during the warr anty period. As to wa rran ty service in the terri tory described above, Groen

will absorb labor and portal to portal transportation costs (time and mileage) for the first twelve (12)

month s fr om date of installati on or fifteen (15) months from date of shipme nt from Groen.

IV. This warranty does not cover boiler main tenance, calibration, periodic adjustments as specified in

operati ng inst ructions or m anuals, and consumable parts such as scraper blades, gaskets, packing, etc.,

or l abor costs incu rred for removal of adj acent equ ipment or objects to gain access to Groen E quipment .

This warranty does not cover defects caused by i m proper installati on, abuse, carel ess opera tion, or

improper maintenance of equipment. This warranty does not cover dama ge caused by poor water quality

or i m proper boiler m aintenance.

V. THIS WARRANTY IS EXCLUSIVE AND IS IN LIEU OF ALL OTHER WARRANTIES, EXPRESS OR

IMPLIED, INCLUDING ANY IMPLIED WARRANTY OF MERCHANTABILITY OR FITNESS FOR A

PARTICULAR PURPOSE, EACH OF WHICH IS HEREBY EXPRESSLY DI SCLAIMED. THE REMEDIES

DESCRIBED ABOVE ARE EXCLUSIVE AND IN N O EVENT SHALL GROEN BE LIABLE FO R SPECIAL,

CONSEQUENTIAL OR INCIDENTAL DAMAGES FOR THE BREACH OR DELAY IN PERFORMANCE

OF THIS WARRANTY.

VI. Groen Equipment is for commercial use only. If sold as a component of another (O.E.M.) Manufacturer’s

equ ipment, or if used as a consumer product, such Equipment is sold AS IS a n d without an y warranty.

*(Covers all Foodservice Equipment Ordered after Oct ober 1, 1995)

31

Page 32

1055 Mendell Davis Drive OM-CC-E (Revised 7/00)

Jackson, MS 39212 Part Number 121015 Rev. A

Telephone 601 372-3903

Fax 601 373-9587

Loading...

Loading...