MODEL G1053/G1054

DIVIDING HEAD

OWNER'S MANUAL

COPYRIGHT © MAY, 2009 BY GRIZZLY INDUSTRIAL, INC., REVISED JULY, 2009 (TS)

WARNING: NO PORTION OF THIS MANUAL MAY BE REPRODUCED IN ANY SHAPE

OR FORM WITHOUT THE WRITTEN APPROVAL OF GRIZZLY INDUSTRIAL, INC.

(FOR MODELS MANUFACTURED SINCE 1/09) #DDTS11699 PRINTED IN TAI WAN

This manual provides critical safety instructions on the proper setup,

operation, maintenance, and service of this machine/tool. Save this

document, refer to it often, and use it to instruct other operators.

Failure to read, understand and follow the instructions in this manual

may result in fire or serious personal injury—including amputation,

electrocution, or death.

The owner of this machine/tool is solely responsible for its safe use.

This responsibility includes but is not limited to proper installation in

a safe environment, personnel training and usage authorization,

proper inspection and maintenance, manual availability and comprehension, application of safety devices, cutting/sanding/grinding tool

integrity, and the usage of personal protective equipment.

The manufacturer will not be held liable for injury or property damage

from negligence, improper training, machine modifications or misuse.

Some dust created by power sanding, sawing, grinding, drilling, and

other construction activities contains chemicals known to the State

of California to cause cancer, birth defects or other reproductive

harm. Some examples of these chemicals are:

• Lead from lead-based paints.

• Crystalline silica from bricks, cement and other masonry products.

• Arsenic and chromium from chemically-treated lumber.

Your risk from these exposures varies, depending on how often you

do this type of work. To reduce your exposure to these chemicals:

Work in a well ventilated area, and work with approved safety equipment, such as those dust masks that are specially designed to filter

out microscopic particles.

Table of Contents

INTRODUCTION ............................................................................................................................... 2

Manual Accuracy ........................................................................................................................ 2

Contact Info ................................................................................................................................ 2

Functional Description ................................................................................................................ 2

Identification ............................................................................................................................... 3

Specifications ............................................................................................................................. 4

SECTION 1: SAFETY ....................................................................................................................... 5

Safety Instructions for Machinery ............................................................................................... 5

SECTION 2: SETUP ......................................................................................................................... 7

Needed for Setup ....................................................................................................................... 7

Unpacking .................................................................................................................................. 7

Inventory ..................................................................................................................................... 8

Clean Up .................................................................................................................................... 8

Installation .................................................................................................................................. 9

Centering Spindle ..................................................................................................................... 10

Tailstock Center Height ............................................................................................................ 11

SECTION 3: OPERATIONS ........................................................................................................... 12

Basic Controls .......................................................................................................................... 12

Changing Dividing Plates ......................................................................................................... 13

Tilting Spindle ........................................................................................................................... 14

Spindle Center.......................................................................................................................... 14

Center Dog ............................................................................................................................... 15

Chuck Backing Plate ................................................................................................................ 15

Setting Index Pin ...................................................................................................................... 16

Using Dividing Plates ............................................................................................................... 16

Disengaging Worm ................................................................................................................... 20

Cutting Angles .......................................................................................................................... 21

SECTION 4: ACCESSORIES ......................................................................................................... 22

SECTION 5: MAINTENANCE......................................................................................................... 23

Schedule .................................................................................................................................. 23

Cleaning ................................................................................................................................... 23

Lubrication ................................................................................................................................ 23

Surface Care ............................................................................................................................ 24

Bearing Preload........................................................................................................................ 25

SECTION 6: PARTS ....................................................................................................................... 26

G1053/G1054 Main .................................................................................................................. 26

G1053 Parts List ...................................................................................................................... 27

G1054 Parts List ...................................................................................................................... 28

WARRANTY AND RETURNS ........................................................................................................ 33

INTRODUCTION

Manual Accuracy

We are proud to offer this manual with your new

dividing head! We've made every effort to be exact

with the instructions, specifications, drawings, and

photographs of the dividing head we used when

writing this manual. However, sometimes errors

do happen and we apologize for them.

Also, owing to our policy of continuous improvement, your dividing head may not exactly

match the manual. If you find this to be the case,

and the difference between the manual and dividing head leaves you in doubt, check our website

for the latest manual update or call technical support for help.

For your convenience, we post all available manuals and manual updates for free on our website at

www.grizzly.com. Any updates to your model of

dividing head will be reflected in these documents

as soon as they are complete.

Contact Info

We stand behind our machines. If you have any

service questions, parts requests or general questions about the dividing head, please call or write

us at the location listed below.

Grizzly Industrial, Inc.

1203 Lycoming Mall Circle

Muncy, PA 17756

Phone: (570) 546-9663

Fax: (800) 438-5901

E-Mail: techsupport@grizzly.com

If you have any comments regarding this manual,

please write to us at the address below:

C

/O Technical Documentation Manager

Grizzly Industrial, Inc.

P.O. Box 2069

Bellingham, WA 98227-2069

Email: manuals@grizzly.com

Functional

Description

The Model G1053/G1054 Dividing Head offers

precision rotary positioning of the workpiece for

machining various spacing patterns.

A pattern of drilled holes radially or on the face

of the workpiece may be produced with exact

spacing. Other typical operations include milling

of spur gears, sprockets, cogs, and circular slots,

as well as, grinding punches or other hardened

materials. These tasks would be difficult to perform without the use of a dividing head.

This dividing head is supplied with a 24-hole

direct indexing plate and index system that allows

divisions of 2, 3, 4, 6, 8, 12, and 24.

-2-

Model G1053/G1054 (Mfg. 1/09+)

Scale Index

Dividing Plate

Sector Arms

Sector Spring

Crank Handle

Identification

Head Tilt Scale

Threaded Spindle

Degree Index Pointer

Direct Indexing Plate

Dead Center

Mounting

Base

Degree Scale

Direct Indexing Lever

Spindle Lock Lever

Head Tilt

Locking Hex Nuts

Figure 1. Model G1053/G1054 identification.

Model G1053/G1054 (Mfg. 1/09+)

-3-

Specifications

Description G1053 G1054

Overall Length 7.72 " 9.96"

Overall Width 7. 25 " 8.5"

Overall Height 6.61" 8.66"

Center Height 3.94" 5.04"

Spindle Taper Brown & Sharpe #7 Brown & Sharpe #9

Spindle Bore 0.63" .078"

Tailstock Length 7.17 " 7.17 "

Tailstock Width 3.23" 3.23"

Tailstock Height 4.84" 5.24"

Spindle Thread 1

Shipping Weight 41 lb s . 69 lbs.

No. of Dividing Plates 3 3

Country of Origin Taiwan Taiwan

1

⁄2 "-8 1 1⁄2 "-8

-4-

Model G1053/G1054 (Mfg. 1/09+)

SECTION 1: SAFETY

For Your Own Safety, Read Instruction

Manual Before Operating This Machine

The purpose of safety symbols is to attract your attention to possible hazardous conditions.

This manual uses a series of symbols and signal words intended to convey the level of importance of the safety messages. The progression of symbols is described below. Remember that

safety messages by themselves do not eliminate danger and are not a substitute for proper

accident prevention measures. Always use common sense and good judgment.

Indicates an imminently hazardous situation which, if not avoided,

WILL result in death or serious injury.

Indicates a potentially hazardous situation which, if not avoided,

COULD result in death or serious injury.

Indicates a potentially hazardous situation which, if not avoided,

MAY result in minor or moderate injury. It may also be used to alert

against unsafe practices.

This symbol is used to alert the user to useful information about

NOTICE

proper operation of the machine.

Safety Instructions for Machinery

OWNER’S MANUAL. Read and understand this

owner’s manual BEFORE using machine.

TRAINED OPERATORS ONLY. Untrained operators have a higher risk of being hurt or killed.

Only allow trained/supervised people to use this

machine. When machine is not being used, disconnect power, remove switch keys, or lock-out

machine to prevent unauthorized use—especially

around children. Make workshop kid proof!

DANGEROUS ENVIRONMENTS. Do not use

machinery in areas that are wet, cluttered, or have

poor lighting. Operating machinery in these areas

greatly increases the risk of accidents and injury.

MENTAL ALERTNESS REQUIRED. Full mental

alertness is required for safe operation of machinery. Never operate under the influence of drugs or

alcohol, when tired, or when distracted.

ELECTRICAL EQUIPMENT INJURY RISKS. You

can be shocked, burned, or killed by touching live

electrical components or improperly grounded

machinery. To reduce this risk, only allow qualified

service personnel to do electrical installation or

repair work, and always disconnect power before

accessing or exposing electrical equipment.

DISCONNECT POWER FIRST.

nect machine from power supply BEFORE making

adjustments, changing tooling, or servicing machine.

This prevents an injury risk from unintended startup

or contact with live electrical components.

EYE PROTECTION. Always wear ANSI-approved

safety glasses or a face shield when operating or

observing machinery to reduce the risk of eye

injury or blindness from flying particles. Everyday

eyeglasses are not approved safety glasses.

Always discon-

Model G1053/G1054 (Mfg. 1/09+)

-5-

WEARING PROPER APPAREL. Do not wear

clothing, apparel or jewelry that can become

entangled in moving parts. Always tie back or

coverlong hair.Wear non-slipfootwear toavoid

accidentalslips,whichcouldcauseloss ofworkpiececontrol.

hAzARdOus dusT. Dust created while using

machinery may cause cancer, birth defects, or

long-term respiratory damage. Be aware ofdust

hazardsassociatedwitheachworkpiecematerial,

andalwayswearaNIOSH-approvedrespiratorto

reduceyourrisk.

hEARING PROTECTION. Always wear hearing protection when operating or observing loud

machinery. Extended exposure to this noise

withouthearing protection cancause permanent

hearingloss.

REMOVE AdJusTING TOOLs. Tools left on

machinery can become dangerous projectiles

uponstartup.Neverleavechuckkeys,wrenches,

or any other tools on machine. Always verify

removalbeforestarting!

INTENdEd usAGE. Only use machine for its

intendedpurposeand nevermakemodifications

not approved by Grizzly. Modifying machine or

using it differently than intended may result in

malfunctionormechanicalfailurethatcanleadto

seriouspersonalinjuryordeath!

AWKWARd POsITIONs. Keep proper footing

andbalanceatalltimeswhenoperatingmachine.

Donotoverreach!Avoidawkwardhandpositions

that make workpiece control difficult or increase

riskofaccidentalinjury.

the

ChILdREN & BYsTANdERs. Keepchildrenand

bystandersatasafedistancefromtheworkarea.

Stopusingmachineiftheybecomeadistraction.

FORCING MAChINERY.Donot forcemachine.

Itwill do the jobsafer and betterat the rate for

whichitwasdesigned.

NEVER sTANd ON MAChINE. Serious injury

may occur if machine is tipped or if the cutting

toolisunintentionallycontacted.

sTABLE MAChINE. Unexpectedmovementduring operation greatly increases risk of injury or

lossofcontrol.Beforestarting,verifymachineis

stableandmobilebase(ifused)islocked.

usE RECOMMENdEd ACCEssORIEs.Consult

thisowner’smanualorthemanufacturerforrecommended accessories. Using improper accessorieswillincreasetheriskofseriousinjury.

uNATTENdEd OPERATION. To reduce the

risk of accidental injury, turn machine off and

ensure all moving parts completely stop before

walking away. Never leave machine running

whileunattended.

MAINTAIN WITh CARE.Followallmaintenance

instructions and lubrication schedules to keep

machine in good working condition. A machine

that is improperly maintained could malfunction,

leading

ChECK dAMAGEd PARTs. Regularly inspect

machine for any condition that may affect safe

operation.Immediatelyrepairorreplacedamaged

ormis-adjustedpartsbeforeoperatingmachine.

MAINTAIN POWER CORds. Whendisconnecting cord-connected machines from power, grab

andpulltheplug—NOTthecord.Pullingthecord

may damage the wires inside. Do not handle

cord/plugwithwethands. Avoidcorddamageby

keepingitawayfromheatedsurfaces,hightraffic

areas,harshchemicals,andwet/damplocations.

toseriouspersonalinjuryordeath.

GuARds & COVERs.Guardsandcoversreduce

accidental contact with moving parts or flying

debris. Make sure they are properly installed,

undamaged,andworkingcorrectly.

-6-

EXPERIENCING dIFFICuLTI Es. If at any time

youexperiencedifficulties performingtheintendedoperation,stopusingthemachine!Contactour

TechnicalSupportat(570)546-9663.

Model G1053/G1054 (Mfg. 1/09+)

SECTION 2: SETUP

Needed for Setup

This tool presents serious injury hazards to

untrained users. Read

through this entire manual to become familiar

with the controls and

operations before starting the operation!

Wear safety glasses during the entire setup process!

The dividing head is very

heavy. Get lifting help

and use proper lifting

methods to avoid serious

personal injury.

The following are needed to complete the setup

process, but are not included with your dividing

head.

Description Qty

• Safety Glasses ........................................... 1

• Cleaner/Degreaser (Page 8) ...... As Needed

• Shop Rags .................................. As Needed

• Another Person .......................................... 1

• Precision Square ........................................ 1

• Test Indicator* ............................................. 1

• Edge Finder* .............................................. 1

• Clamping Hardware* .................. As Needed

*Refer to the Accessories section on Page 22 for

options from Grizzly.

Unpacking

Your dividing head was carefully packaged for

safe transportation. Remove the packaging materials from around your dividing head and inspect

it. If you discover the dividing head is damaged,

please immediately call Customer Service at

(570) 546-9663 for advice.

Save the containers and all packing materials for

possible inspection by the carrier or its agent.

Otherwise, filing a freight claim can be difficult.

When you are completely satisfied with the condition of your shipment, inventory the contents.

Model G1053/G1054 (Mfg. 1/09+)

-7-

Inventory

Clean Up

The following is a description of the main components shipped with your dividing head. Lay the

components out to inventory them.

Note: If you can't find an item on this list,

check the mounting location on the dividing head

or examine the packaging materials carefully.

Occasionally we pre-install certain components

for shipping purposes.

Inventory: (Figure 2) Qty

A. Dividing Plates ............................................ 3

B. Dividing Head ............................................. 1

C. Tail sto c k ...................................................... 1

D. Dead Center ............................................... 1

E. Center Dog ................................................. 1

F. Crank Handle ............................................. 1

G. Chuck Backing Plate .................................. 1

H. Hardware Bag (not shown)

— Cap Screw M6-1 x 12 (Crank) ................ 1

— Flat Washer 6mm (Crank) ....................... 1

The unpainted surfaces are coated with a waxy

oil to prevent corrosion during shipment. Remove

this protective coating with a solvent cleaner or

degreaser, such as shown in Figure 3. For thorough cleaning, some parts must be removed.

For optimum performance, clean all moving

parts or sliding contact surfaces. Avoid chlo-

rine-based solvents, such as acetone or brake

parts cleaner that may damage painted surfaces. Always follow the manufacturer’s instructions

when using any type of cleaning product.

Gasoline and petroleum

products have low flash

points and can explode

or cause fire if used to

clean machinery. DO

NOT use these products

to clean the machinery.

B

C

A

D

G

F

E

Figure 2. Model G1053/G1054 inventory.

If any nonproprietary parts are missing (e.g. a

nut or a washer), we will gladly replace them; or

for the sake of expediency, replacements can be

obtained at your local hardware store.

Many cleaning solvents

are toxic if inhaled.

Minimize your risk by only

using these products in a

well ventilated area.

G2544—Solvent Cleaner & Degreaser

H9692—Orange Power Degreaser

Great products for removing shipping grease.

-8-

Figure 3. Cleaner/degreasers available from

Grizzly.

Model G1053/G1054 (Mfg. 1/09+)

Installation

Before installing the dividing head or tailstock,

make sure that your mill table and spindle are

properly aligned as instructed in the owner's

manual for your mill. Remove any surface burrs

or scratches from the mating surfaces of the mill

table, the dividing head, and the tailstock by "stoning" them, then thoroughly wipe them clean and

dry (refer to the Surface Care section on Page 24

for detailed instructions).

3. While aligning the keys with the center T-slot

of the table, place the dividing head on the

table with the spindle facing to the right, then

secure it with the appropriate clamping hardware (see Figure 5).

The dividing head and tailstock have keyways

machined into the bottom of their mounting bases,

which measure 16mm or approximately 0.6299".

Making alignment keys that fit these keyways and

the T-slot of the mill table provides a convenient

and efficient way to ensure alignment of the dividing head and tailstock with the mill table X-axis.

Note: The dividing head and tailstock install in the

same manner.

Installing with Alignment Keys

1. DISCONNECT MILL FROM POWER!

2. Install the alignment keys into the base of the

dividing head, as shown in Figure 4.

x 2

Spindle

Figure 5. Tool installed on the mill table.

Installing Without Alignment Keys

1. DISCONNECT MILL FROM POWER!

2. Place the dividing head in the center of the

mill table with the spindle facing to the right.

3. Mount a test indicator into the mill spindle

with the indicator tip touching the front face

of the dividing head, as shown in Figure 6.

Alignment Key

Figure 4. Alignment key installed.

Model G1053/G1054 (Mfg. 1/09+)

Figure 6. Indicating the front face of the tool.

4. Adjust the position of the dividing head while

moving the mill table back-and-forth along

the X-axis until the indicator reads zero deviation across the face, then clamp the head in

place.

-9-

Centering Spindle

6. Use a caliper to measure the diameter of the

dividing head center where the edge finder

made correct contact.

Whether the spindle of the dividing head is

mounted horizontally or vertically, you must center

the dividing head spindle with the mill spindle to

achieve the most precise results.

We have included two methods to center the spindles below, one for each orientation. However,

there are many ways to center the spindles, and

it is up to the machinist to know their capabilities

and to decide which approach is best.

Horizontal Spindle

1. Make sure the dividing head is properly

aligned with the mill table and firmly secured

in position.

2. Mount the included dead center into the dividing head spindle and an edge finder into the

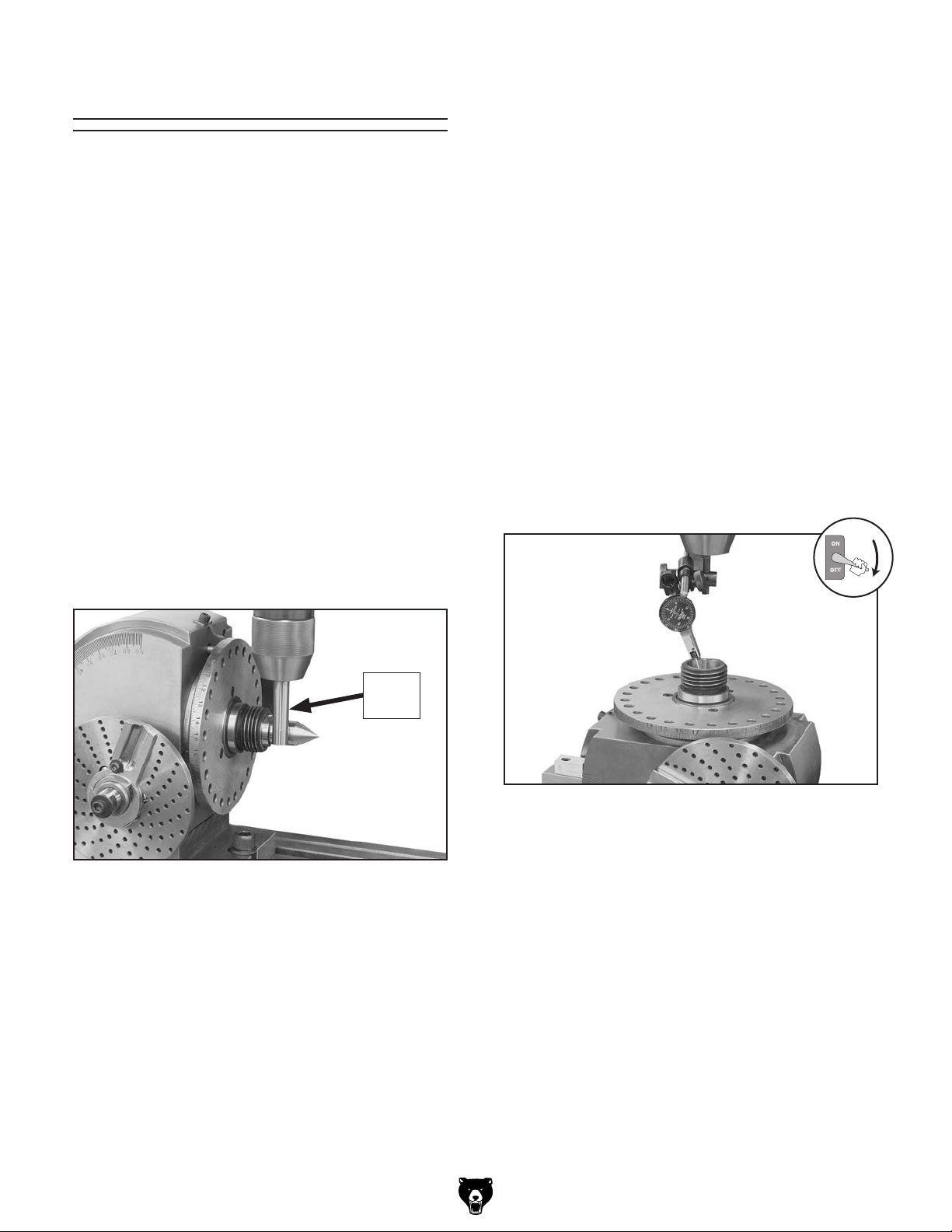

mill spindle, then move the mill table to position the edge finder in front of the center, as

shown in Figure 7.

7. Add half the diameter of the center and half

the diameter of the edge finder together,

then move the mill table in toward the mill an

additional distance equal to the calculated

number above.

Vertical Spindle

1. DISCONNECT MILL FROM POWER!

2. Make sure the dividing head is properly

aligned with the mill table and firmly secured

in position.

3. Mount a test indicator in the mill spindle and

position the indicator tip against the inside

wall of the dividing head spindle bore, as

shown in Figure 8.

Edge

Finder

Figure 7. Aligning the spindles using an edge

finder.

3. Set the mill for the slowest spindle speed,

then turn the mill ON.

4. Carefully and slowly move the table in-andout along the Y-axis until you find the edge of

the dividing head center.

5. Note the Y-axis position of the mill table.

Note: When recording the mill table position,

take into account the backlash that is usually

present in the leadscrew.

Figure 8. Indicating the spindle bore.

4. Slowly rotate the mill spindle by hand and

watch the test indicator dial.

Note: For best results, turn the spindle in only

one direction.

Tip: Use a mirror to view the indicator dial as

it turns away from you.

5. Slowly adjust the mill table to adjust for the

runout as shown on the indicator.

6. The spindles of the dividing head and mill

are centered with one another when the test

indicator shows zero runout when rotated a

full 360°.

-10 -

Model G1053/G1054 (Mfg. 1/09+)

Tailstock Center

Height

When supporting a workpiece between centers, it

is necessary to set the height of the tailstock center so that it is even and parallel with the center

line of the dividing head spindle. One method for

accomplishing this is listed below.

Tools Needed Qty

Wrench or Socket 14mm ................................... 1

To properly adjust the tailstock center height:

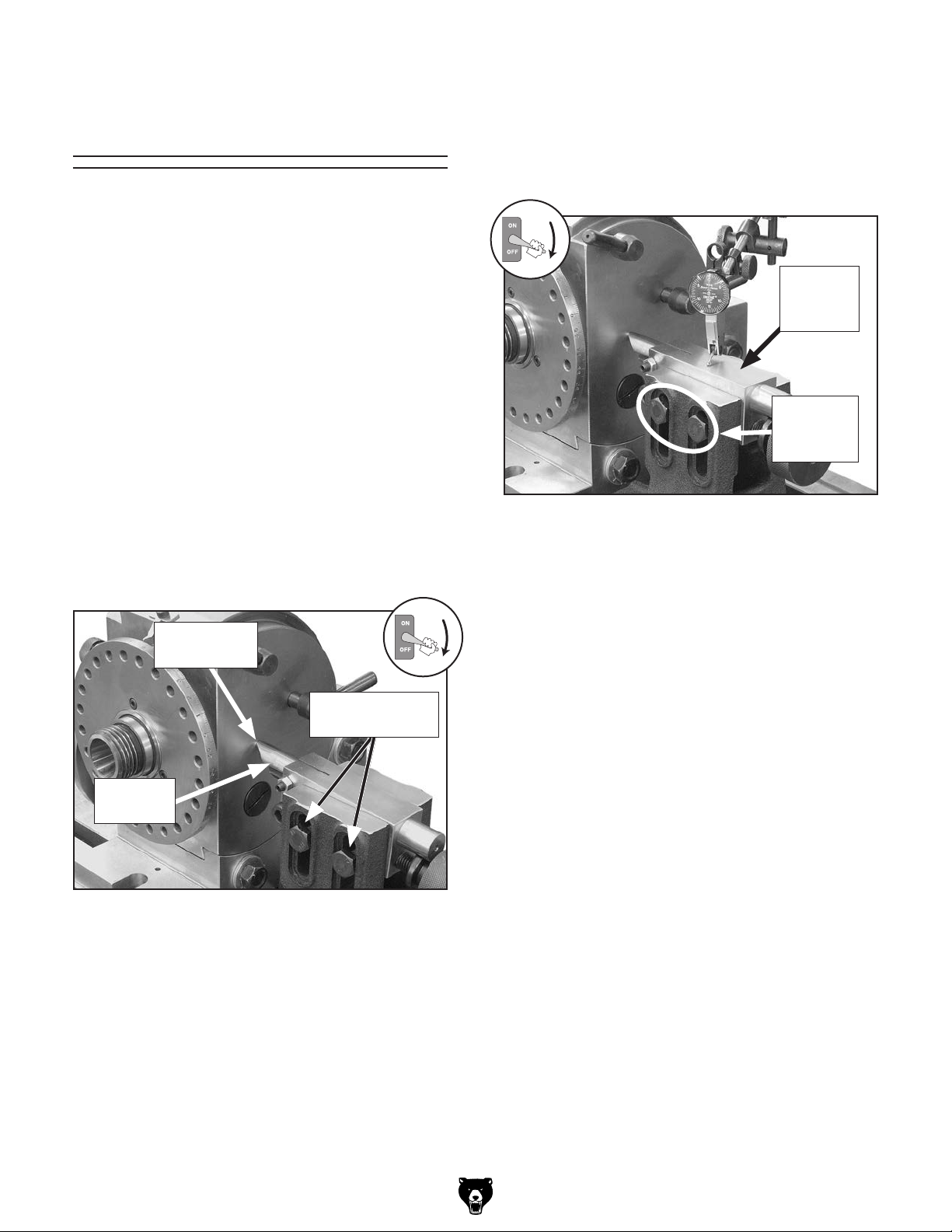

4. Loosen the hex nuts on the tailstock center

support lock bolts (see Figure 10), adjust the

tailstock center so that the tip is in the center

hole of the head and is approximately level,

then snug one of the hex nuts to hold it in

place.

Tailstock

Center

Support

1. DISCONNECT MILL FROM POWER!

2. Place the dividing head on the table and posi-

tion it so that the spindle faces toward the

operator.

3. Install the tailstock so that its center is aligned

with the center hole in the side of the dividing

head, as shown in Figure 9.

Center Hole

in Head

Center Support

Lock Bolts

Tailstock

Center

Center

Support

Lock Bolts

Figure 10. Indicating the tailstock center support.

5. Mount a test indicator into the mill spindle

with the tip resting on the top of the tailstock

center support, as shown in Figure 10.

6. Move the mill table back-and-forth along its

X-axis so that the full length of the center

support is indicated.

7. Make adjustments to the height of the center

support until there is zero deviation indicated

along the full length of the center support,

then completely tighten the lock bolt hex

nuts.

8. Indicate the full length of the center support

again and make any necessary corrections.

Figure 9. Tailstock center contacting the center

hole of the dividing head.

Model G1053/G1054 (Mfg. 1/09+)

-11-

SECTION 3: OPERATIONS

To reduce the risk of

serious injury when

using this tool, read and

understand this entire

manual before beginning

any operations.

Damage to your eyes and lungs could result

from using this tool without proper protective gear. Always wear safety glasses and a

respirator when operating this tool.

Basic Controls

Use Figures 11–12 and the following descriptions

to become familiar with the basic controls of your

dividing head.

D

C

B

E

Loose hair, clothing, or

jewelry could get caught

in machinery and cause

serious personal injury.

Keep these items away

from moving parts at all

times to reduce this risk.

NOTICE

If you have never used this type of equipment before, WE STRONGLY RECOMMEND

that you read books, review industry trade

magazines, or get formal training before

beginning any projects. Regardless of the

content in this section, Grizzly Industrial

will not be held liable for accidents caused

by lack of training.

A

Figure 11. Basic controls, left side.

A. Hand Crank: Rotates the spindle when

turned. Pulling the knob out causes the index

pin to disengage from the dividing plate.

B. Dividing Plate: Provides 6 circles of holes

for indexing (1 of 3 plates).

C. Sector Arms: Sections the dividing plate into

a segment that allows you to keep track of

the fraction of rotation.

D. Head Tilt Scale: Shows the amount of spin-

dle tilt and is calibrated from -10° to +90° in

one degree increments.

E. Threaded Spindle: Provides threaded

mounting for the chuck backing plate or

other precision accessories. The threads are

1

⁄2"-8.

1

-12-

Model G1053/G1054 (Mfg. 1/09+)

F

G

Changing Dividing

Plates

H

The dividing plates can be changed when a specific hole count is required for indirect indexing.

Tools Needed Qty

J

I

Phillips Screwdriver #2 ...................................... 1

Hex Wrenches 3, 5mm ............................. 1 Each

To change the dividing plate:

Figure 12. Basic controls, right side.

F. Direct Indexing Plate: Provides 24 evenly

spaced holes for indexing 2, 3, 4, 6, 8, 12, or

24 locations.

G. Direct Indexing Lever: Engages the index-

ing pin with the direct indexing plate holes.

H. Spindle Lock: Locks the spindle in place to

ensure rigidity and accuracy.

I. Head Tilting Hex Nuts: When loosened,

allows the head to be tilted.

J. Mounting Base: Precision ground base with

slots for mounting to the mill table.

1. Remove the cap screw and flat washer that

secure the hand crank, then remove the

crank (see Figure 13).

Sector Arm Spring

Phillips

Head

Screw

Crank Handle

Figure 13. Dividing plate components.

2. Loosen the sector arm cap screw, then

remove the sector arm spring and the sector

arms.

Sector Arm

Cap Screw

Model G1053/G1054 (Mfg. 1/09+)

3. Replace the dividing plate, then re-install the

parts in the reverse order that you removed

them.

Note: Before storing or installing a dividing

plate, thoroughly clean it with mineral spirits,

then apply a thin coat of light machine oil to

the surfaces to prevent corrosion.

-13-

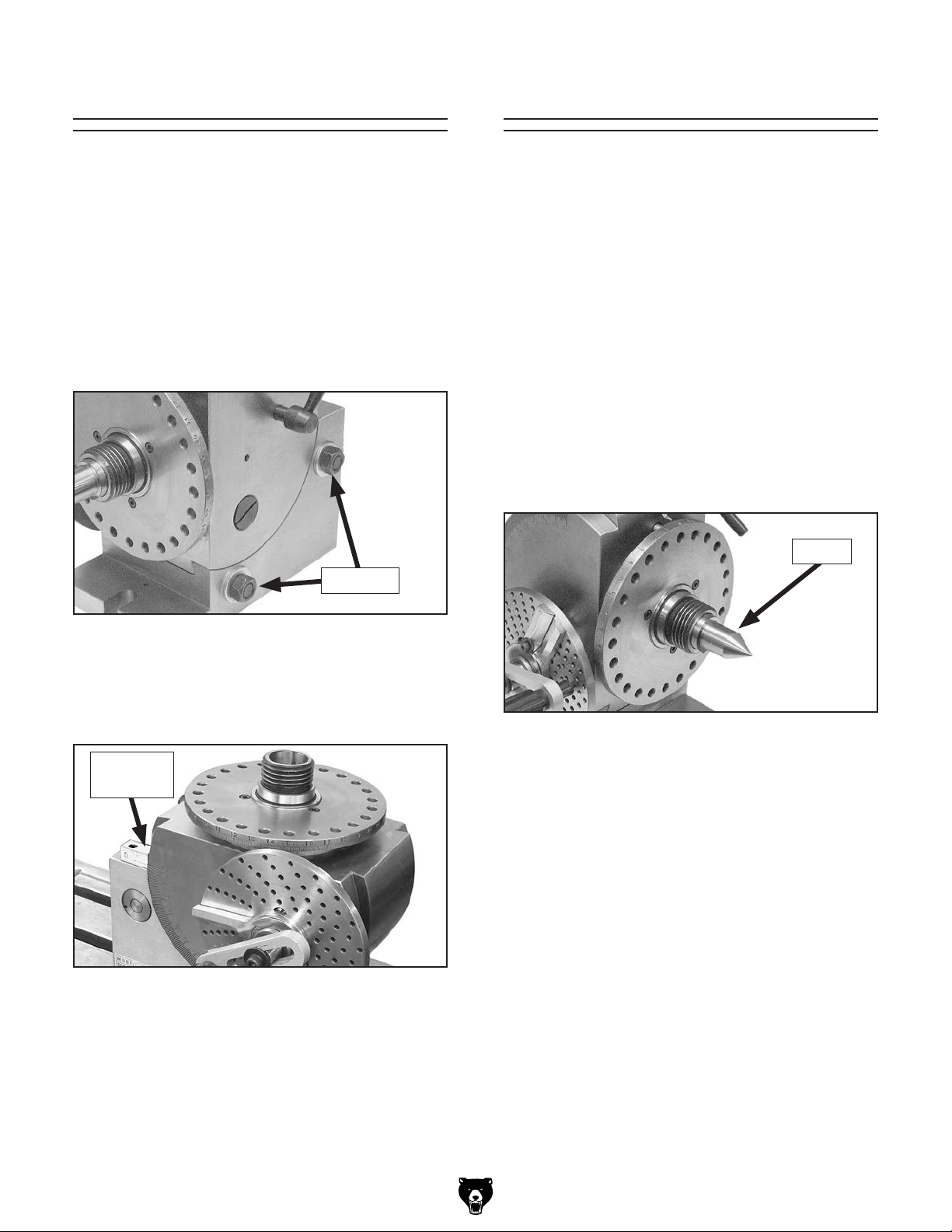

Tilting Spindle

Spindle Center

The spindle of your dividing head tilts from -10° to

+90° out of parallel from the bottom of the mounting base.

Tools Needed Qty

Wrench or Socket 19mm ................................... 1

To tilt the spindle:

1. Loosen the two tilt locking hex nuts on the

rear of the dividing head (see Figure 14).

Hex Nuts

Your dividing head includes a dead center for use

in the spindle. The spindle bore and the shank of

the center are a Brown & Sharpe taper #7 for the

Model G1053 and a #9 for the Model G1054.

To install the dead center:

1. Thoroughly clean the spindle bore and the

center shank. Inspect these surfaces for

scratches or nicks. If necessary, dress or

"stone" them (refer to Surface Care on Page

24 for detailed instructions).

2. Insert the center into the spindle bore to

within

center rapidly into the bore the rest of the way

to ensure the tapers lock (see Figure 16).

1

⁄2" of being fully seated, then thrust the

Center

Figure 14. Tilt locking hex nuts.

2. Tilt the spindle to the desired angle as dis-

played on the tilt scale, then re-tighten the

hex nuts (see Figure 15).

Tilt Scale

& Index

Figure 15. Spindle tilted vertical.

Note: It may be necessary to tap on the

hex nuts with a dead blow hammer to break

the locking bolts loose before the head will

move.

Figure 16. Dead center installed.

3. Test the taper lock by grasping the protruding

portion of the center and attempt to twist it out

of the bore.

— If the center comes out of the spindle bore,

repeat Steps 1–2 until it does not.

Removing Spindle Center

Tools Needed Qty

Brass or Aluminum Rod

Approx.

To remove the dead center:

1. Use a gloved hand or shop rags to hold the

5

⁄8" Diameter x 12"–16" Long ................ 1

center.

-14-

2. Insert the rod into the rear of the spindle bore

and tap the center until it releases.

Model G1053/G1054 (Mfg. 1/09+)

Center Dog

Chuck Backing Plate

When supporting the workpiece between centers,

it is necessary to use the center dog (sometimes

referred to as a drive bracket). The center dog that

is supplied with your dividing head is designed

to mount onto the included dead center and will

require the use of a bent-tail lathe dog (not provided) installed onto the workpiece.

To mount a workpiece between centers:

1. DISCONNECT MILL FROM POWER!

2. Loosen the middle hex nut on the center dog

until it clears the bore, slide it onto the dead

center, then re-tighten the hex bolt to secure

it in place, as shown in Figure 17.

A chuck backing plate is included with your dividing head for mounting a lathe chuck, as shown in

Figure 18.

Run True

Set Screw

Figure 18. Model G9856 6-jaw run true chuck

installed (Model G1054 only).

Follow these rules when mounting a chuck

onto your dividing head:

Figure 17. Workpiece installed between centers.

3. Install the lathe dog onto the workpiece with

the tail extending beyond the end of it.

4. Align the lathe dog tail with a side slot of

the center dog, then properly mount the

workpiece between the centers.

5. Tighten the two hex bolts on the center dog

so that they firmly hold the lathe dog tail.

Note: It may be necessary to alter the lathe

dog tail so that the hex bolts make contact

with two flat surfaces.

6. Make adjustments as necessary to ensure

that the workpiece does not rotate independently of the dead center.

• The backing plate must be mounted on a

lathe with a threaded mandrel, then faced

and shouldered.

• Make the new shoulder a "press fit" with the

chuck to maximize accuracy.

• Correctly drill holes into the backing plate to

accept the mounting of the chuck.

• For maximum accuracy when using the Model

G1054, a run true chuck should be used,

such as the Grizzly G9856 shown in Figure

18. This chuck has four set screws that allow

the center line of the chuck to be correctly

aligned with the center line of the dividing

head spindle.

Note: If you are using a run true chuck, a

press fit is not necessary.

Model G1053/G1054 (Mfg. 1/09+)

-15-

Setting Index Pin

The index pin on the end of the hand crank can

be repositioned to any of the six hole circles on

the dividing plate (see Figure 19). The index pin

is spring loaded so that it will stay engaged with

the current hole.

Numbered

Row

Hole Circle

(1 of 6)

Figure 19. Dividing plate.

2. Slightly loosen the crank cap screw, adjust

the crank arm on the shaft until the index pin

is aligned with the required hole circle on the

dividing plate, then re-tighten the cap screw.

Note: Because the index pin is spring loaded,

it will tend to push the crank arm out when the

cap screw is not tightened. As you re-tighten

the cap screw, push in on the crank arm so

that it stays flat against the shaft shoulder.

Using Dividing

Plates

Your dividing head includes three dividing plates,

each having six hole circles in the following patterns:

Plate Number of Holes Per Circle

Plate A ................................ 15, 16, 17, 18, 19, 20

Plate B ................................ 21, 23, 27, 29, 31, 33

Plate C ................................ 37, 39, 41, 43, 47, 49

Tools Needed Qty

Hex Wrench 5mm .............................................. 1

To set the index pin:

1. Pull the crank handle out to disengage the

index pin, then rotate the crank until it is

aligned with the numbered row on the dividing plate (see Figure 20).

All divisions from 1 to 50 can be made with one

of the three plates provided. However, not all of

the divisions from 51 to 100 are capable with your

dividing head, as noted with a "—" in the charts

on the next page.

The dividing charts on Page 17 are set up with

three rows and one column for each division.

Refer to the charts and the following descriptions

to understand the numbers in the rows.

D – Division: The number of stops required for

the machining operation.

H – Hole Circle: The number of the hole circle on

the dividing plate required for the division.

R – Rotations of the Crank Handle: The num-

ber of crank handle rotations required for the

division.

Figure 20. Adjusting the position of the crank

index pin.

-16 -

Model G1053/G1054 (Mfg. 1/09+)

indexing charts

Dividing Charts

D

H

R

D

H

R

D

H

R

D

H

R

D

H

T

1 2 3 4 5 6 7 8 9 10

Any 33 Any Any 33 49 Any 18 Any

11

20 13

⁄33 10 8 6 22⁄33 5 35⁄49 5 4 8⁄18 4

11 12 13 14 15 16 17 18 19 20

33 33 39 49 33 20 17 18 19 Any

21

⁄33 3 11⁄33 3 3⁄39 2 42⁄49 2 22⁄33 2 10⁄20 2 6⁄17 2 4⁄18 2 2⁄19 2

3

21 22 23 24 25 26 27 28 29 30

21 33 23 33 20 39 27 49 29 33

19

⁄21 1 27⁄33 1 17⁄23 1 22⁄33 1 12⁄20 1 21⁄39 1 13⁄27 1 21⁄49 1 11⁄29 1 11⁄33

1

31 32 33 34 35 36 37 38 39 40

31 20 33 17 49 18 37 19 39 Any

1

9

⁄31

1

5

⁄20

1

7

⁄33

1

3

⁄17

1

7

⁄49

1

2

⁄18

1

3

⁄37

1

1

⁄19

1

1

⁄39

41 42 43 44 45 46 47 48 49 50

41 21 43 33 18 23 47 18 49 20

40

⁄41

20

⁄21

40

⁄43

30

⁄33

16

⁄18

20

⁄23

40

⁄47

15

⁄18

40

⁄49

1

16

⁄20

D

H

R

D

H

R

D

H

R

D

H

R

D

H

R

51 52 53 54 55 56 57 58 59 60

— 39 — 27 33 49 — 29 — 33

30

⁄39

20

⁄27

24

⁄33

35

⁄49

20

⁄29

22

⁄33

61 62 63 64 65 66 67 68 69 70

— 31 — 16 39 33 — 17 — 49

20

⁄31

10

⁄16

24

⁄39

20

⁄33

10

⁄17

28

⁄49

71 72 73 74 75 76 77 78 79 80

— 18 — 37 15 19 — 39 — 20

10

⁄18

20

⁄37

8

⁄15

10

⁄19

20

⁄39

10

⁄20

81 82 83 84 85 86 87 88 89 90

— 41 — 21 17 43 — 33 — 18

20

⁄41

10

⁄21

8

⁄17

20

⁄43

15

⁄33

8

⁄18

91 92 93 94 95 96 97 98 99 100

— 23 — 47 19 — — 49 — 20

10

⁄23

20

⁄47

8

⁄19

20

⁄49

8

⁄20

Legend:

D – Divisions

H – Hole Circle

R – Rotations of the Crank Handle

Model G1053/G1054 (Mfg. 1/09+)

-17-

Example

To better understand how to properly use the

dividing plates, perform the instructions in the

example below.

In this example, you will set up the dividing

head for 18 divisions:

6. Position the left sector arm up against the

index pin.

7. Move the right sector arm clockwise so that

there are four holes showing in the 18 hole

circle between the arms, as shown in Figure

22.

1. Locate division 18 in the charts on the pre-

vious page, then note the number directly

below it, which is the required hole circle. In

this case, the hole circle is 18.

2. Install the dividing plate with the 18 hole

circle on the dividing plate, as instructed in

the Changing Dividing Plates section on

Page 13.

3. Loosen the sector arm cap screw, spread the

sector arms apart so that you can position

the index pin of the crank handle between

the sector arms and in a hole of the 18 hole

circle, as shown in Figure 21.

Note: Do not count the hole that the index pin

is in.

Figure 22. Sector arms correctly spread apart

four holes on the 18 hole circle.

8. Tighten the sector arm cap screw to secure

the arms in place and to preserve the correct

4-hole spacing.

Figure 21. Index pin between the sector arms

and seated in the 18 hole circle.

4. Make sure the crank cap screw is fully tightened to firmly secure the crank on the shaft.

5. Look at the division 18 column of the chart

again and note the number in the third row

4

below it. In this case the number is 2

⁄18,

which means the crank handle will be rotated

4

two full turns and

⁄18, or 4 holes, of the third

rotation for each machining cycle after the

first one.

9. Eliminate the backlash in the crank by pulling

the crank handle out to disengage the index

1

pin, rotating the crank

⁄2 counterclockwise

turn, then turning it clockwise and engaging

the index pin with the hole it was in before.

Note: To ensure accurate indexing, it is

imperative that the crank index pin does not

make contact with the sector arms as you

rotate the crank so that the sector arms do

not move from their correct locations.

-18-

Model G1053/G1054 (Mfg. 1/09+)

10. Lock the spindle in place and perform the

machining operation.

11. Without moving the sector arms, pull the

crank handle out to disengage the index pin

and carefully rotate the crank two full turns

clockwise back to the position it started in.

Divisions Beyond 100

In the event that divisions beyond 100 are required,

you can usually find the correct hole circle number

to use by dividing the number of divisions by the

number of the hole circles available on the dividing plates until the answer is a whole number

(without a fraction or decimal).

12. Continue to rotate the crank clockwise until

you can engage the index pin into the hole

that is next to the right sector arm. You have

now rotated the crank handle the required

4

⁄18 turns, as shown in Figure 23.

2

Note: If you move the crank index pin beyond

the final hole, it is crucial to the operation that

you eliminate the crank backlash again, as

explained in Step 9.

Figure 23. Crank position after 2 4⁄18 rotations.

13. While keeping the sector arm cap screw tight,

rotate the sector arms clockwise so that the

left sector arm is up against the crank index

pin and the right arm has moved an additional

4 holes.

Note: If the sector arm cap screw is loos-

ened, the arms will move independently from

one another and the 4-hole spacing will be

changed.

For example, for a division of 115, dividing the

number 23 into 115 gives the answer of 5, a whole

number. This means that the dividing plate with

the 23 hole circle can be used.

The rotation of the crank for each division will

always be less than one full turn for divisions

beyond 40. The amount of holes on the required

hole circle that the crank must be moved can be

found with the following formula:

R = (H x 40) / D

where R is the number of holes between the sector arms, H is the number of the required hole

circle, 40 is a constant that represents the number

of full crank rotations necessary to complete one

revolution of the spindle, and D is the number of

divisions required for the operation.

To continue the example given above, if the number of divisions needed is 115 and the number of

the dividing plate hole circle is 23, then the number of holes that the sector arms must be separated per division is 8, as calculated below:

R = (23 x 40) / 115

R = 920 / 115

R = 8

Note: As in the divisions between 50 and 100,

not all divisions beyond 100 are possible with your

dividing head.

14. Repeat Steps 9–13 until the dividing spindle

and workpiece have made one full revolution.

Model G1053/G1054 (Mfg. 1/09+)

-19 -

Use the following tips to help ensure a trouble-free dividing head operation:

Disengaging Worm

• Because the scale on the direct indexing

plate mounted on the dividing head spindle

is oriented clockwise, always rotate the crank

clockwise to make it easier to keep track of

the spindle orientation during the operation.

• Take the time to create a quick-reference

chart when divisions are complex. Using this

chart to compare with the degree scale and

check off as you change locations will reduce

unnecessary mistakes.

• As in most operations, it is a good idea to

perform a test-run before actually making the

cuts, especially before machining an expensive part. Test your dividing setup by running

the complete progression of settings and

turns without actually machining the part.

For example, when performing a test-run for

the previous example, the spindle should

return to its original position after running

the 18 positions. This can be verified by noting the location of the spindle on the degree

scale before and after the test-run. Also, you

can score the part at each division stop to

make sure the cuts will be in the required

locations, as shown in Figure 24.

The worm gear and wheel drive the spindle when

the crank is rotated and these gears are engaged.

They can be disengaged to rotate the spindle by

hand for quick direct indexing.

Tools Needed Qty

Hex Wrenches 3, 4, 5mm ......................... 1 Each

Phillips Screwdriver #2 ...................................... 1

To disengage the worm gear and wheel:

1. Remove the crank handle, sector spring, sec-

tor arms, and dividing plate.

2. Loosen the two cap screws that secure the

worm gear hub, rotate it counterclockwise

until you can turn the spindle by hand, then

re-tighten the cap screws (see Figure 25).

Worm Gear Hub

Figure 24. Scoring the part during a test run.

-20-

Figure 25. Disengaging worm gear and wheel.

To re-engage the worm gear and wheel:

1. Rotate the worm gear hub clockwise until you

feel resistance, then tighten the cap screws.

2. Check the rotation of the spindle with the

crank before reassembling the rest of the

parts. If necessary, re-adjust the rotation of

the worm gear hub so that the crank rotates

freely without excess backlash.

Model G1053/G1054 (Mfg. 1/09+)

Cutting Angles

The dividing head can be used for cutting a specific angle or producing a series of angles, such

as in faceting. Perform the example below to learn

how to use your dividing head for angled cuts.

To produce a hex shape (6-sided) with the

dividing head:

1. Disengage the worm gear and wheel so that

the spindle can be rotated by hand.

2. Rotate the spindle by hand until the zero

point of the degree scale is aligned with the

pointer, as shown in Figure 26.

Note: In the next step, keep in mind that the

direct indexing plate mounted on the spindle

has 24 holes, which is evenly divisible by

6. Each index stop will require that 4 holes

pass by the index pin—i.e., the index pin will

engage the 5

was.

3. Use the direct indexing lever to engage the

pin into the plate hole.

Note: If necessary, rock the plate by hand

until the pin engages the hole, then loosen

the pointer cap screw, adjust it to the zero

mark on the degree scale, and re-tighten the

cap screw to secure it in place.

4. Properly mount the workpiece onto the dividing head.

th

hole from where it originally

Pointer

Degree

Scale

Figure 26. Direct indexing plate.

Direct

Indexing Plate

5. Lock the spindle and machine the part.

6. Unlock the spindle, use the lever to disen-

gage the pin, rotate the plate clockwise by

hand until the pin is aligned with the 5

from where it originally was, then re-engage

the pin with the plate.

Note: The pointer will be aligned at the 60°

mark on the degree scale.

7. Repeat Steps 5–6 until the spindle and

workpiece have completed one full revolution.

th

hole

Model G1053/G1054 (Mfg. 1/09+)

-21-

ACCESSORIES

SECTION 4: ACCESSORIES

G9610—Test Indicator

0.03" Range/0.001" Resolution

G9611—Test Indicator

0.008" Range/0.0001" Resolution

G9612—Test Indicator

0.030" Range/0.0005" Resolution

These test indicators have an easy to read dial

and a pivoting stylus that moves at right angles to

the dial face.

1

G1075—52-PC. Clamping Kit

G1076—52-PC. Clamping Kit

⁄2" T-Nut

5

⁄8" T-Nut

This clamping kit includes 24 studs, 6 step block

pairs, 6 T-nuts, 6 flange nuts, 4 coupling nuts, and

6 end hold-downs. The rack is slotted so it can be

mounted close to the machine for easy access.

Figure 27. Test Indicator.

H2939—4 Piece Edge Finder Set

Four different styles to cover any setup problem!

Set includes one each: a

3

point, a combination

a 0.200" shoulder, a

⁄8" diameter with a point and

1

shoulder, and a combination

3

⁄8" diameter with a

⁄2 " diameter with a 0.200"

1

⁄2 " diameter with a

0.200" shoulder and a 0.500" shoulder.

Figure 29. 52-PC. Clamping Kit.

G9856—6-Jaw Precision Run True Chuck

When used with your dividing head, this chuck

offers maximum holding power on delicate parts

and absolute positioning using the 4 adjustment

screws.

Figure 30. G9856 6-Jaw Chuck.

Figure 28. H2939 4-Pc. Edge Finder Set.

-22-

Model G1053/G1054 (Mfg. 1/09+)

SECTION 5: MAINTENANCE

Schedule

For optimum performance from your dividing

head, follow this maintenance schedule and refer

to any specific instructions given in this section.

Every 8 Hours of Use:

• Clean and lubricate the tool.

• Dress the surfaces of the tool (Page 24).

• Check/resolve any unsafe condition.

Every 160 Hours of Use:

• Disassemble, clean, and lubricate the worm

gear and wheel (Page 24).

Cleaning

To ensure smooth operation and long life of your

dividing head, it is essential that it is cleaned after

every use and a thin coat of light machine oil is

applied to the surfaces to prevent corrosion.

DO NOT use compressed air to clean your dividing head. This could force chips and swarf to

become lodged between the moving parts and

reduce the life and accuracy of the tool. Instead,

use a stiff-bristled brush to remove the chips and

swarf, then wipe down the surfaces with a clean

shop rag.

Lubrication

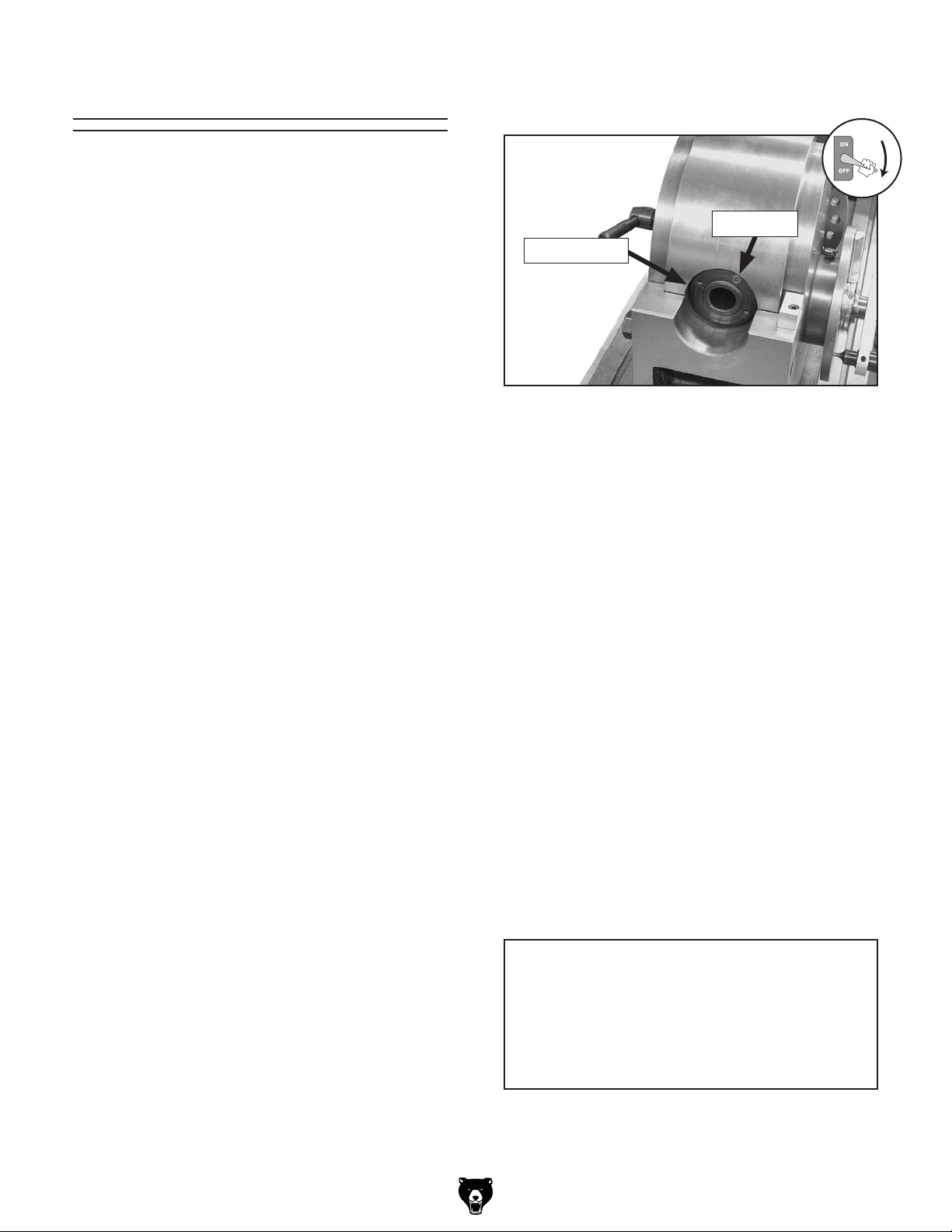

Ball Oiler & Oil Port

Wipe off the ball oiler on the head shown in

Figure 31, then use the tip of an oil can to add

one squirt of 30W non-detergent oil to the oiler.

Ball Oiler

Figure 31. Ball oiler on the head.

Open the lid of the oil port on the worm gear hub

shown in Figure 32, then add one squirt of 30W

non-detergent oil to the port. Make sure to close

the lid to keep debris out.

Oil Port

Model G1053/G1054 (Mfg. 1/09+)

Figure 32. Worm gear oil port.

-23-

Worm Gear & Wheel

Tools Needed Qty

Hex Wrenches 3, 4, 5mm ......................... 1 Each

Phillips Screwdriver #2 ...................................... 1

To lubricate the worm gear and wheel:

1. Remove the crank handle, sector spring, sec-

tor arms, and dividing plate.

2. Remove the two cap screws that secure the

worm gear hub, then remove the hub from

the worm gear shaft, as shown in Figure 33.

Surface Care

Nicks, dings, and scratches on the surfaces of

the dividing head and mill table can have an

adverse effect on accuracy and may damage the

workpiece or mill table.

Prior to use, dress or "stone" these surfaces with

a fine sharpening stone until they are smooth. A

few strokes of the stone on the mill table surface

and the machined surfaces of the dividing head

will help to ensure machining accuracy.

Worm

Wheel

Worm Gear

Worm Gear Hub

Figure 33. Worm gear removed to expose the

worm wheel.

3. Use a stiff-bristled brush, shop rags, and

mineral spirits to clean away the old grease

and grime. When dry, apply a light coat of

medium bearing grease, then re-install the

parts.

Make sure to thoroughly wipe these surfaces

clean to remove any dust generated from the process, then re-apply a thin coat of light machine oil

to prevent corrosion.

-24-

Model G1053/G1054 (Mfg. 1/09+)

Bearing Preload

The spindle in the dividing head is mounted

with tapered roller bearings. The preload on

these bearings was set at the factory and should

never need adjusting. However, if you experience

excess play in the spindle, you can adjust the

spindle bearing preload.

Testing Spindle Play

1. DISCONNECT MILL FROM POWER!

2. Firmly mount the dividing head to the mill

table.

4. Loosen the set screw on the spanner nut

shown in Figure 34.

Set Screw

Spanner Nut

Figure 34. Spanner nut and set screw.

3. Mount a test indicator in the mill spindle and

rest the indicator tip on the top of the spindle

nose.

4. While watching the indicator dial, attempt to

lift the spindle up.

— If the test indicator shows zero deviation

as you attempt to lift the spindle up, there

is no spindle play and the bearing preload

is sufficient.

— If the indicator shows a deviation when you

attempt to lift the spindle up, there is not

enough bearing preload. Continue to the

next subsection to adjust the preload.

Adjusting Bearing Preload

Tools Needed Qty

Hex Wrench 3mm .............................................. 1

Hammer & Punch ..................................... 1 Each

Dead Blow Hammer .......................................... 1

To adjust the bearing preload:

5. Rotate the spanner nut counterclockwise one

full turn, then tap on it with the dead blow

hammer to release the bearing preload.

6. Position a test indicator so that the indicator

tip is touching the front end of the spindle.

7. While watching the test indicator, rotate the

spanner nut clockwise until the indicator dial

stops moving.

Note: By accurately performing this step, you

have reached the zero preload point, which

means that all of the slack has been taken up

between the bearings, seats, and spindle.

8. Tighten the spanner nut clockwise an addi-

9. Test the spindle play. If necessary, repeat

1

tional

er amount of bearing preload, then re-tighten

the set screw.

this procedure until you have achieved the

proper amount of bearing preload.

⁄16 of its circumference to set the prop-

1. DISCONNECT MILL FROM POWER!

2. Firmly mount the dividing head to the mill

table.

3. Use the spindle lock lever to hold the spindle

in place.

Model G1053/G1054 (Mfg. 1/09+)

NOTICE

Spindle bearing life will be greatly reduced

if the preload is either too loose or too tight.

Disengage the worm gear and wheel and

rotate the spindle by hand to make sure it

turns easily without any play.

-25-

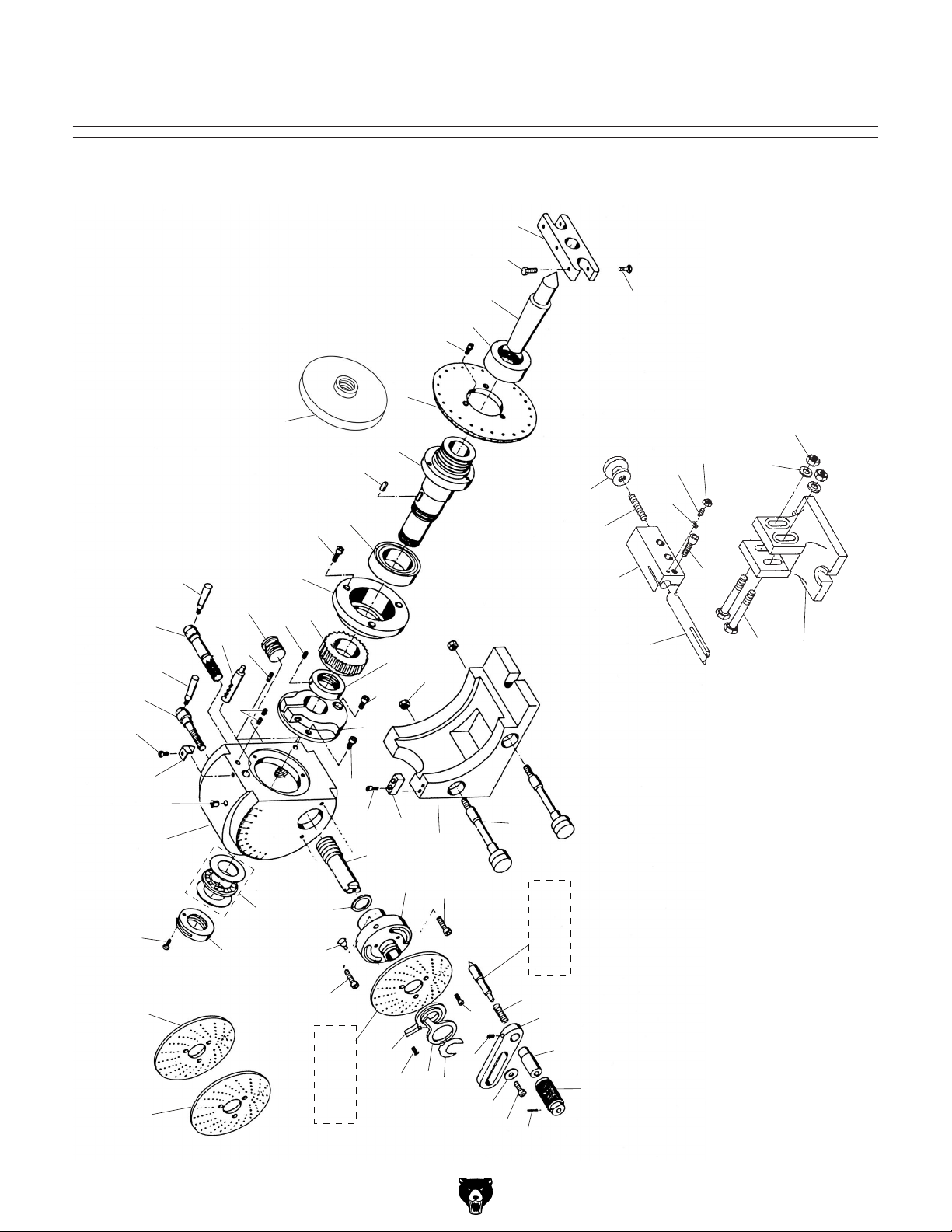

SECTION 6: PARTS

G1053/G1054 Main Breakdown

1

2

22

20

18

17

17

19

13

15

16

113

13

10

11

73

3

4

5

6

7

8

9

12

56

36

54

107

106

102

2

103

105

104

108

109

111

112

110

101

-26-

27

35A

21

24

35B

23

26

25

53

52

40

39

38

36

35 (G1054)

35C (G1053)

34

22

30

29

48

45

28

46 (G1054)

46A (G1053)

44

43

42

51

50

37

36

33

31

32

4

Model G1053/G1054 (Mfg. 1/09+)

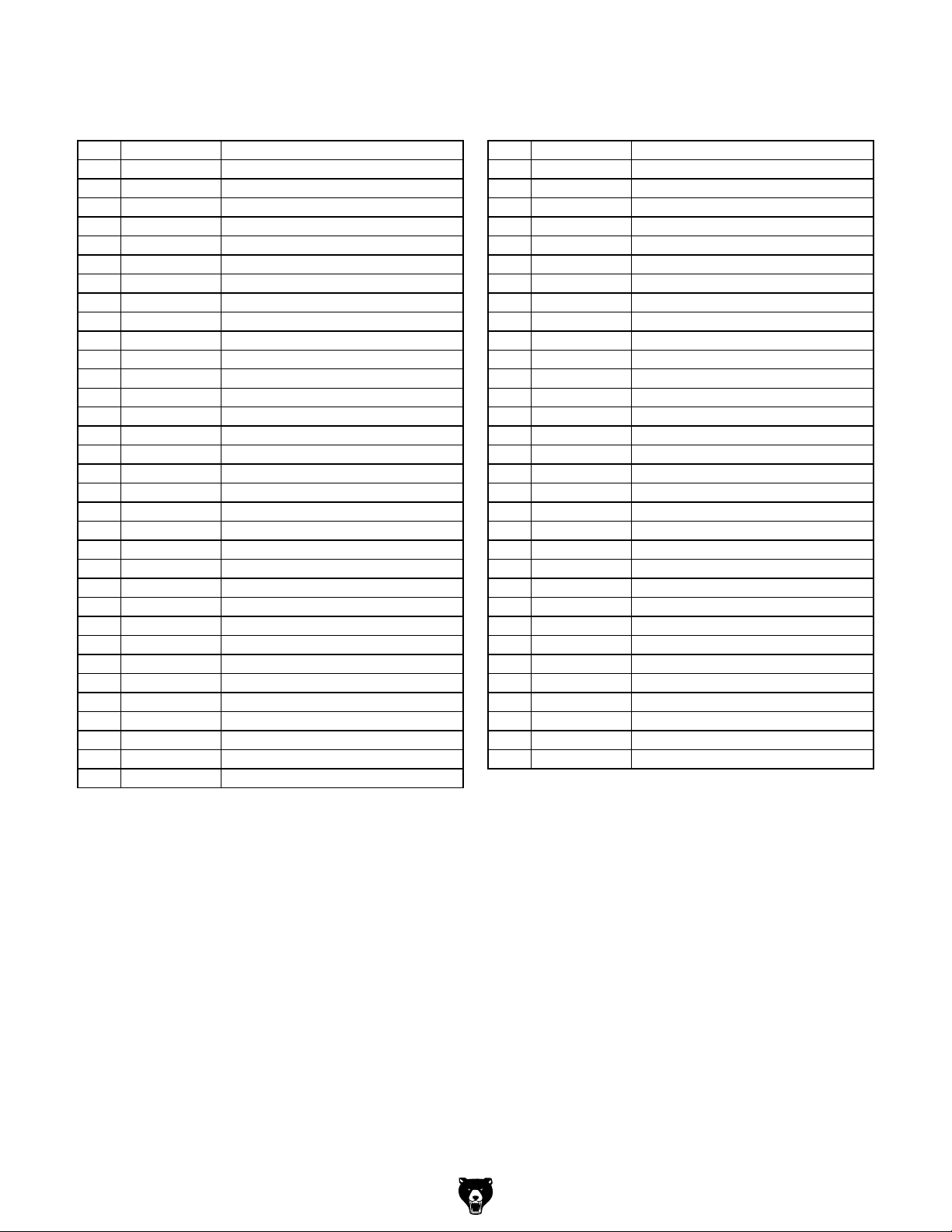

G1053 Parts List

REF PART # DESCRIPTION REF PART # DESCRIPTION

1 P1053001 CENTER DOG 35B P1053035B DIVIDING PLATE 21-33 HOLE

2 PB03M HEX BOLT M8-1.25 X 16 35C P1053035C DIVIDING PLATE 37-49 HOLE

3 P1053003 TAPERED BUSHING 36 PCAP24M CAP SCREW M5-.8 X 16

4 PFH19M FLAT HD SCR M4-.7 X 10 37 P1053037 MOUNTING BRACKET

5 P1053005 DIRECT INDEXING PLATE 38 P1053038 OIL FITTING

6 P1053006 SPINDLE 39 P1053039 SPACER

7 PK08M KEY 5 X 5 X 16 40 P1053040 WORM SHAFT GEAR

8 P32007 TAPERED BEARING 32007 42 P1053046 OUTER HANDLE

9 PCAP23M CAP SCREW M4-.7 X 12 43 P1053046 INNER HANDLE

10 P1053010 FRONT BEARING SEAT 44 P1053044 HANDLE BRACKET

11 P1053011 WORM GEAR 45 P1053046 COMPRESSION SPRING

12 P1053012 RETAINING NUT M30-1.5 46A P1053046A INDEX NEEDLE W/42, 43, 44, 45

13 PSS34M SET SCREW M5-.8 X 16 48 P1053048 THREADED CLAMP SHAFT

15 P1053015 PLUG 50 P1053050 BASE

16 PSS34M SET SCREW M5-.8 X 16 51 P1053051 SCALE INDEX

17 P1053017 HANDLE 52 PCAP16M CAP SCREW M4-.7 X 16

18 P1053018 GEARED HANDLE SHAFT 53 PCAP33M CAP SCREW M5-.8 X 12

19 P1053019 GEARED INDEXING PIN 54 P1053054 LASHING RING

20 P1053020 LOCK SHAFT 56 PN31M HEX NUT M12-1.5

21 P1053021 POINTER 73 P1053073 DEAD CENTER B&S#7

22 PS09M PHLP HD SCR M5-.8 X 10 101 P1053101 TAILSTOCK BASE

23 P1053023 OIL FITTING 1/4" 102 P1053102 CENTER BASE

24 P1053024 MAIN CASTING 103 P1053103 TAILSTOCK CENTER

25 P1053025 NEEDLE THRUST BEARING 25X42X4 104 PK06M KEY 5 X 5 X 10

26 P1053026 SPLIT RETAINING NUT M25-1.5 105 PSS11M ECCENTRIC SET SCREW M6-1 X 16

27 PCAP18M CAP SCREW M4-.7 X 8 106 P1053106 THREADED SHAFT

28 PRP02 ROLL PIN 1/8 X 3/4 107 P1053107 KNURLED KNOB

29 PCAP26M CAP SCREW M6-1 X 12 108 PN01M HEX NUT M6-1

30 PW03M FLAT WASHER 6MM 109 PCAP72M CAP SCREW M10-1.5 X 30

31 PSS07M SET SCREW M5-.8 X 5 110 PN02M HEX NUT M10-1.5

32 P1053032 RETAINING CLIP 111 PW04M FLAT WASHER 10MM

33 P1053033 FRONT SECTOR ARM 112 PB13M HEX BOLT M10-1.5 X 80

34 P1053034 REAR SECTOR ARM 113 P1053113 CHUCK BACKING PLATE

35A P1053035A DIVIDING PLATE 15-20 HOLE

Model G1053/G1054 (Mfg. 1/09+)

-27-

G1054 Parts List

REF PART # DESCRIPTION REF PART # DESCRIPTION

1 P1054001 CENTER DOG 35A P1054035A DIVIDING PLATE 15-20

2 PCAP24M CAP SCREW M5-.8 X 16 35B P1054035B DIVIDING PLATE 21-33

3 P1054003 TAPERED BUSHING 36 PCAP15M CAP SCREW M5-.8 X 20

4 PFH19M FLAT HD SCR M4-.7 X 10 37 P1054037 MOUNTING BRACKET

5 P1054005 DIRECT INDEXING PLATE 38 P1054038 OIL FITTING

6 P1054006 SPINDLE 39 P1054039 SPACER

7 PK08M KEY 5 X 5 X 16 40 P1054040 WORM SHAFT GEAR

8 P1054008 TAPERED BEARING 32009 42 P1054042 OUTER HANDLE

9 PCAP33M CAP SCREW M5-.8 X 12 43 P1054043 INNER HANDLE

10 P1054010 FRONT BEARING SEAT 44 P1054044 HANDLE BRACKET

11 P1054011 WORM GEAR 45 P1054045 COMPRESSION SPRING 10X12X45

12 P1054012 RETAINING NUT M38-1.5 46 P1054046 INDEX NEEDLE

13 PSS34M SET SCREW M5-.8 X 16 48 P1054048 THREADED CLAMP SHAFT

15 P1054015 PLUG 50 P1054050 BASE

16 PSS34M SET SCREW M5-.8 X 16 51 P1054051 SCALE INDEX

17 P1054017 HANDLE 52 PCAP16M CAP SCREW M4-.7 X 16

18 P1054018 GEARED HANDLE SHAFT 53 PCAP33M CAP SCREW M5-.8 X 12

19 P1054019 GEARED INDEXING PIN 54 P1054054 LASHING RING

20 P1054020 LOCK SHAFT 56 PN09M HEX NUT M12-1.75

21 P1054021 POINTER 73 P1054073 DEAD CENTER B&S#9

22 PS09M PHLP HD SCR M5-.8 X 10 101 P1054101 TAILSTOCK BASE

23 P1054023 OIL FITTING 1/4" 102 P1054102 CENTER BASE

24 P1054024 MAIN CASTING 103 P1054103 TAILSTOCK CENTER

25 P1054025 NEEDLE THRUST BEARING 30X47X4 104 P1054104 SPECIAL KEY 3/16 X 3/16 X 3/8

26 P1054026 SPLIT RETAINING NUT M30-1.5 105 P1054105 ECCENTRIC SET SCREW M6-1 X 16

27 PS07M PHLP HD SCR M4-.7 X 8 106 P1054106 THREADED SHAFT

28 PRP02 ROLL PIN 1/8 X 3/4 107 P1054107 KNURLED KNOB

29 PCAP33M CAP SCREW M5-.8 X 12 108 PN01M HEX NUT M6-1

30 PW02M FLAT WASHER 5MM 109 PCAP72M CAP SCREW M10-1.5 X 30

31 PSS07M SET SCREW M5-.8 X 5 110 PN02M HEX NUT M10-1.5

32 P1054032 RETAINING CLIP 111 PW04M FLAT WASHER 10MM

33 P1054033 FRONT SECTOR ARM 112 PB13M HEX BOLT M10-1.5 X 80

34 P1053034 REAR SECTOR ARM 113 P1054113 CHUCK BACKING PLATE

35 P1054035 DIVIDING PLATE 37-49

-28-

Model G1053/G1054 (Mfg. 1/09+)

Notes

WARRANTY CARD

Name _____________________________________________________________________________

Street _____________________________________________________________________________

City _______________________ State _________________________ Zip _____________________

Phone # ____________________ Email _________________________________________________

Model # ____________________ Order # _______________________ Serial # __________________

The following information is given on a voluntary basis. It will be used for marketing purposes to help us develop

better products and services. Of course, all information is strictly confidential.

1. How did you learn about us?

____ Advertisement ____ Friend ____ Catalog

____ Card Deck ____ Website ____ Other:

2. Which of the following magazines do you subscribe to?

____ Cabinetmaker & FDM

____ Family Handyman

____ Hand Loader

____ Handy

____ Home Shop Machinist

____ Journal of Light Cont.

____ Live Steam

____ Model Airplane News

____ Old House Journal

____ Popular Mechanics

3. What is your annual household income?

____ $20,000-$29,000 ____ $30,000-$39,000 ____ $40,000-$49,000

____ $50,000-$59,000 ____ $60,000-$69,000 ____ $70,000+

CUT ALONG DOTTED LINE

4. What is your age group?

____ 20-29 ____ 30-39 ____ 40-49

____ 50-59 ____ 60-69 ____ 70+

5. How long have you been a woodworker/metalworker?

____ 0-2 Years ____ 2-8 Years ____ 8-20 Years ____ 20+ Years

6. How many of your machines or tools are Grizzly?

____ 0-2 ____ 3-5 ____ 6-9 ____10+

____ Popular Science

____ Popular Woodworking

____ Precision Shooter

____ Projects in Metal

____ RC Modeler

____ Rie

____ Shop Notes

____ Shotgun News

____ Today’s Homeowner

____ Wood

____ Wooden Boat

____ Woodshop News

____ Woodsmith

____ Woodwork

____ Woodworker West

____ Woodworker’s Journal

____ Other:

7. Do you think your machine represents a good value? _____ Yes _____No

8. Would you recommend Grizzly Industrial to a friend? _____Yes _____No

9. Would you allow us to use your name as a reference for Grizzly customers in your area?

Note: We never use names more than 3 times. _____ Yes _____No

10. Comments: _____________________________________________________________________

_________________________________________________________________________________

_________________________________________________________________________________

_________________________________________________________________________________

FOLD ALONG DOTTED LINE

FOLD ALONG DOTTED LINE

Place

Stamp

Here

GRIZZLY INDUSTRIAL, INC.

P.O. BOX 2069

BELLINGHAM, WA 98227-2069

Send a Grizzly Catalog to a friend:

Name_______________________________

Street_______________________________

City______________State______Zip______

TAPE ALONG EDGES--PLEASE DO NOT STAPLE

WARRANTY AND RETURNS

We shall in no event be liable for death, injuries to persons or property or for incidental, contingent, special,

WARRANTY AND RETURNS

Grizzly Industrial, Inc. warrants every product it sells for a period of 1 year to the original purchaser from

the date of purchase. This warranty does not apply to defects due directly or indirectly to misuse, abuse,

negligence, accidents, repairs or alterations or lack of maintenance. This is Grizzly’s sole written warranty

and any and all warranties that may be implied by law, including any merchantability or fitness, for any particular purpose, are hereby limited to the duration of this written warranty. We do not warrant or represent

that the merchandise complies with the provisions of any law or acts unless the manufacturer so warrants.

In no event shall Grizzly’s liability under this warranty exceed the purchase price paid for the product and

any legal actions brought against Grizzly shall be tried in the State of Washington, County of Whatcom.

or consequential damages arising from the use of our products.

To take advantage of this warranty, contact us by mail or phone and give us all the details. We will then

issue you a “Return Number,’’ which must be clearly posted on the outside as well as the inside of the

carton. We will not accept any item back without this number. Proof of purchase must accompany the

merchandise.

The manufacturers reserve the right to change specifications at any time because they constantly strive to

achieve better quality equipment. We make every effort to ensure that our products meet high quality and

durability standards and we hope you never need to use this warranty.

Please feel free to write or call us if you have any questions about the machine or the manual.

Thank you again for your business and continued support. We hope to serve you again soon.

Loading...

Loading...