Page 1

7'' X 12'' METAL-CUTTING BANDSAW

MODEL G1011Z

INSTRUCTION MANUAL

COPYRIGHT © 1999 BY GRIZZLY INDUSTRIAL, INC.

WARNING: NO PORTION OF THIS MANUAL MAY BE REPRODUCED IN ANY SHAPE

OR FORM WITHOUT THE WRITTEN APPROVAL OF GRIZZLY INDUSTRIAL, INC.

MAY, 1999 PRINTED IN U.S.A.

Page 2

TABLE OF CONTENTS

1. SAFETY RULES

SAFETY INSTRUCTIONS FOR POWER TOOLS ..................................................

SAFETY INSTRUCTIONS FOR METAL-CUTTING BANDSAWS ..............................

2. CIRCUIT REQUIREMENTS

110V OPERATION ......................................................................................................5

FUSING .......................................................................................................................

EXTENSION CORDS ..................................................................................................

GROUNDING ..............................................................................................................

3. GENERAL INFORMATION

COMMENTARY ..........................................................................................................6

UNPACKING ...............................................................................................................

CLEAN UP ..................................................................................................................

SITE CONSIDERATIONS ...........................................................................................

4. ADJUSTMENTS

CONTROLS ................................................................................................................

HEAD PRESSURE ....................................................................................................

TENSION / TRACKING .............................................................................................

BLADE GUIDES ........................................................................................................

HORIZONTAL STOP SCREW .................................................................................

AUTO SHUT-OFF ....................................................................................................

PAGE

2-3

10

11

12

13

13

4

5

5

5

7

7

8

9

5. OPERATIONS

PRE-RUN CHECK ................................................................................................... 14

BLADE SELECTION ................................................................................................

CHANGING BLADES ...............................................................................................

CUTTING SPEED ....................................................................................................

ADJUSTING FEED RATE ........................................................................................

COOLANT ................................................................................................................

GUIDE ADJUSTMENT .............................................................................................

VISE AND STOP ......................................................................................................

6. MAINTENANCE

TABLE ...................................................................................................................... 20

V-BELT .....................................................................................................................

LUBRICATION .........................................................................................................

COOLANT SYSTEM ................................................................................................

MISCELLANEOUS ...................................................................................................

7. CLOSURE ......................................................................................................................

MACHINE DATA ................................................................................................................

TROUBLESHOOTING ..................................................................................................24-25

WIRING DIAGRAMS ....................................................................................................

PARTS LIST .................................................................................................................

PARTS DIAGRAMS ......................................................................................................

WARRANTY AND RETURNS ........................................................................................... 38

15

16

17

18

18

19

19

20

21

21

21

22

23

26-27

28-29

29-36

G1011 7" x 12'' Bandsaw -1-

Page 3

SECTION 1: SAFETY

For Your Own Safety Read Instruction

Manual Before Operating This Equipment

The purpose of safety symbols is to attract your attention to possible hazardous conditions. This

manual uses a series of symbols and signal words which are intended to convey the level of

importance of the safety messages. The progression of symbols is described below. Remember

that safety messages by themselves do not eliminate danger and are not a substitute for proper

accident prevention measures.

Indicates an imminently hazardous situation which, if not

avoided, WILL result in death or serious injury.

Indicates a potentially hazardous situation which, if not avoided, COULD result in death or serious injury.

Indicates a potentially hazardous situation which, if not avoided, MAY result in minor or moderate injury. It may also be

used to alert against unsafe practices.

This symbol is used to alert the user to useful information

NOTICE

about proper operation of the equipment.

Safety Instructions For Power Tools

1. KEEP GUARDS IN PLACE and in working

order.

2. REMOVE ADJUSTING KEYS AND

WRENCHES. Form habit of checking to

see that keys and adjusting wrenches are

removed from tool before turning on

3. KEEP WORK AREA CLEAN. Cluttered

areas and benches invite accidents.

4. DON’T USE IN DANGEROUS

ENVIRONMENT. Don’t use power tools in

damp or wet locations, or where any flam

mable or noxious fumes may exist. Keep

work area well lighted.

.

5. KEEP CHILDREN AND VISITORS AWAY.

All children and visitors should be kept a

safe distance from work area.

6. MAKE WORK SHOP CHILD PROOF with

padlocks, master switches, or by removing

starter keys.

7. DON’T FORCE TOOL. It will do the job

better and safer at the rate for which it was

designed.

8. USE RIGHT TOOL. Don’t force tool or

-

attachment to do a job for which it was not

designed.

-2- G1011 7" x 12'' Bandsaw

Page 4

Safety Instructions For Power Tools

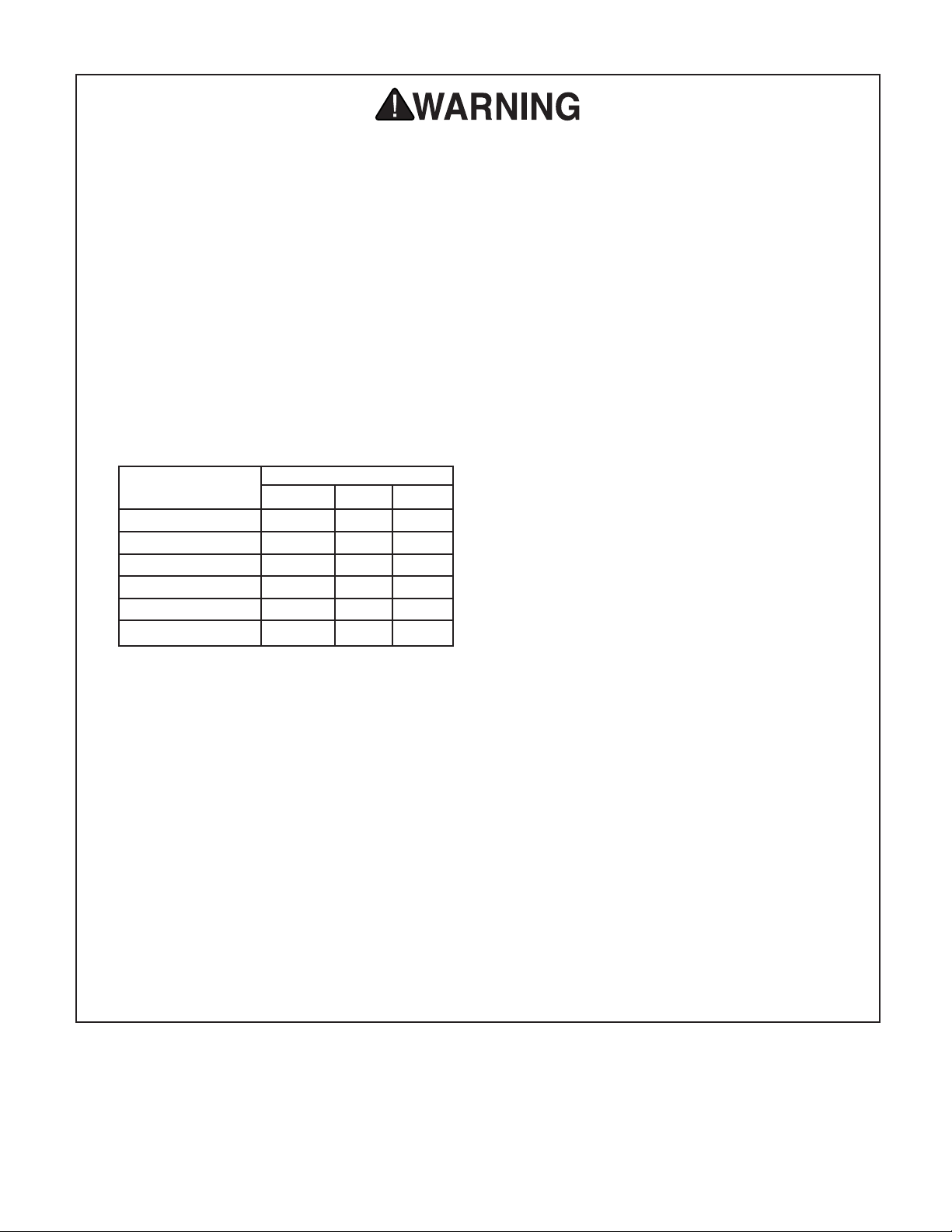

9. USE PROPER EXTENSION CORD. Make

sure your extension cord is in good condi

tion. Conductor size should be in accor

dance with the chart below. The amperage

rating should be listed on the motor or tool

nameplate. An undersized cord will cause

a drop in line voltage resulting in loss of

power and overheating. Your extension

cord must also contain a ground wire and

plug pin. Always repair or replace exten

sion cords if they become damaged.

Minimum Gauge for Extension Cords

LENGTH

AMP RATING 25ft 50ft 100ft

0-6 18 16 16

7-10 18 16 14

11-12 16 16 14

13-16 14 12 12

17-20 12 12 10

21-30 10 10 No

10. WEAR PROPER APPAREL. Do not wear

loose clothing, gloves, neckties, rings,

bracelets, or other jewelry which may get

caught in moving parts. Non-slip footwear

is recommended. Wear protective hair cov

ering to contain long hair.

11. ALWAYS USE SAFETY GLASSES. Also

use face or dust mask if cutting operation

is dusty. Everyday eyeglasses only have

impact resistant lenses, they are NOT

safety glasses.

12. SECURE WORK. Use clamps or a vise to

hold work when practical. It’s safer than

using your hand and frees both hands to

operate tool.

13. DON’T OVERREACH. Keep proper foot-

-

-

-

-

ing and balance at all times.

14. MAINTAIN TOOLS WITH CARE. Keep

tools sharp and clean for best and safest

performance. Follow instructions for lubricating and changing accessories.

15. DISCONNECT TOOLS before servicing

and changing accessories, such as blades,

bits, cutters, and the like.

16. REDUCE THE RISK OF UNINTENTIONAL

STARTING. Make sure switch is in off

position before plugging in.

17. USE RECOMMENDED ACCESSORIES.

Consult the owner’s manual for recom

mended accessories. The use of improper

accessories may cause risk of injury.

18. CHECK DAMAGED PARTS. Before fur

ther use of the tool, a guard or other

part that is damaged should be carefully

checked to determine that it will operate

properly and perform its intended func

tion. Check for alignment of moving parts,

binding of moving parts, breakage of parts,

mounting, and any other conditions that

may affect its operation. A guard or other

part that is damaged should be properly

repaired or replaced.

19. NEVER LEAVE TOOL RUNNING

UNATTENDED. TURN POWER OFF.

Don’t leave tool until it comes to a com

plete stop.

-

-

-

-

G1011 7" x 12'' Bandsaw -3-

Page 5

Additional Safety Instructions For The

Metal-Cutting Bandsaw

1. Do not operate your bandsaw with dull

or badly worn blades. Dull blades require

more effort to use and are difficult to con

trol. Inspect blades before each use.

2. Make sure the blade has been properly

tensioned and is tracking on the center of

the wheels

3. Always support stock in the vise and make

certain it is firmly secured. Never attempt

to hold material by hand while sawing.

4. Keep belt guard and bandsaw wheel cov-

ers in place when operating the machine.

5. Never force the saw through the cut. Allow

the feed cylinder to control the rate of cut

ting. If the saw blade binds or stalls turn

the power of immediately.

6. Never position fingers or thumbs in line

with the cut. Serious injury could occur.

-

7. Periodically check the horizontal stop

screw and the automatic shutoff limit

switch to make sure they are properly

adjusted.

8. Exercise great caution when replacing

blades. Wear protective gloves and safety

glasses when handling the blade

9. Support long or heavy workpieces which

extend from the machine bed with a roller

stand or other support device.

10. Habits – good and bad – are hard to

-

break. Develop good habits in your shop

and safety will become second-nature to

you.

Operating this equipment has the poten

tial to propel debris into the air which can

cause eye injury. Always wear safety glass

es or goggles when operating equipment.

Everyday glasses or reading glasses only

have impact resistant lenses, they are not

safety glasses. Be certain the safety glasses

you wear meet the appropriate standards of

the American National Standards Institute

(ANSI).

-4- G1011 7" x 12'' Bandsaw

-

-

Like all power tools, there is danger associated with the Model G1011 Bandsaw.

Accidents are frequently caused by lack

of familiarity or failure to pay attention.

Use this tool with respect and caution to

lessen the possibility of operator injury. If

normal safety precautions are overlooked

or ignored, serious personal injury may

occur.

No list of safety guidelines can be com

plete. Every shop environment is different.

Always consider safety first, as it applies

to your individual working conditions. Use

this and other machinery with caution and

respect. Failure to do so could result in serious personal injury, damage to equipment

or poor work results.

-

Page 6

SECTION 2: CIRCUIT REQUIREMENTS

110V Operation

The Model G1011Z is wired for 110V, single phase

operation only. The 1 HP motor will safely draw

16 amps at 110V. A complete Wiring Diagram for

the motor and switches is provided near the back

of this manual for more information.

Fusing

A 20-amp slow-blow fuse or circuit breaker

should be used on the 110V circuit this bandsaw

is connected to. Circuits rated any higher are

not adequate to protect the motor from power

surges. If you operate this bandsaw on any circuit

that is already close to its capacity, it might blow

a fuse or trip a circuit breaker. However, if an

unusual load does not exist and a power failure

still occurs, contact a qualified electrician or our

service department.

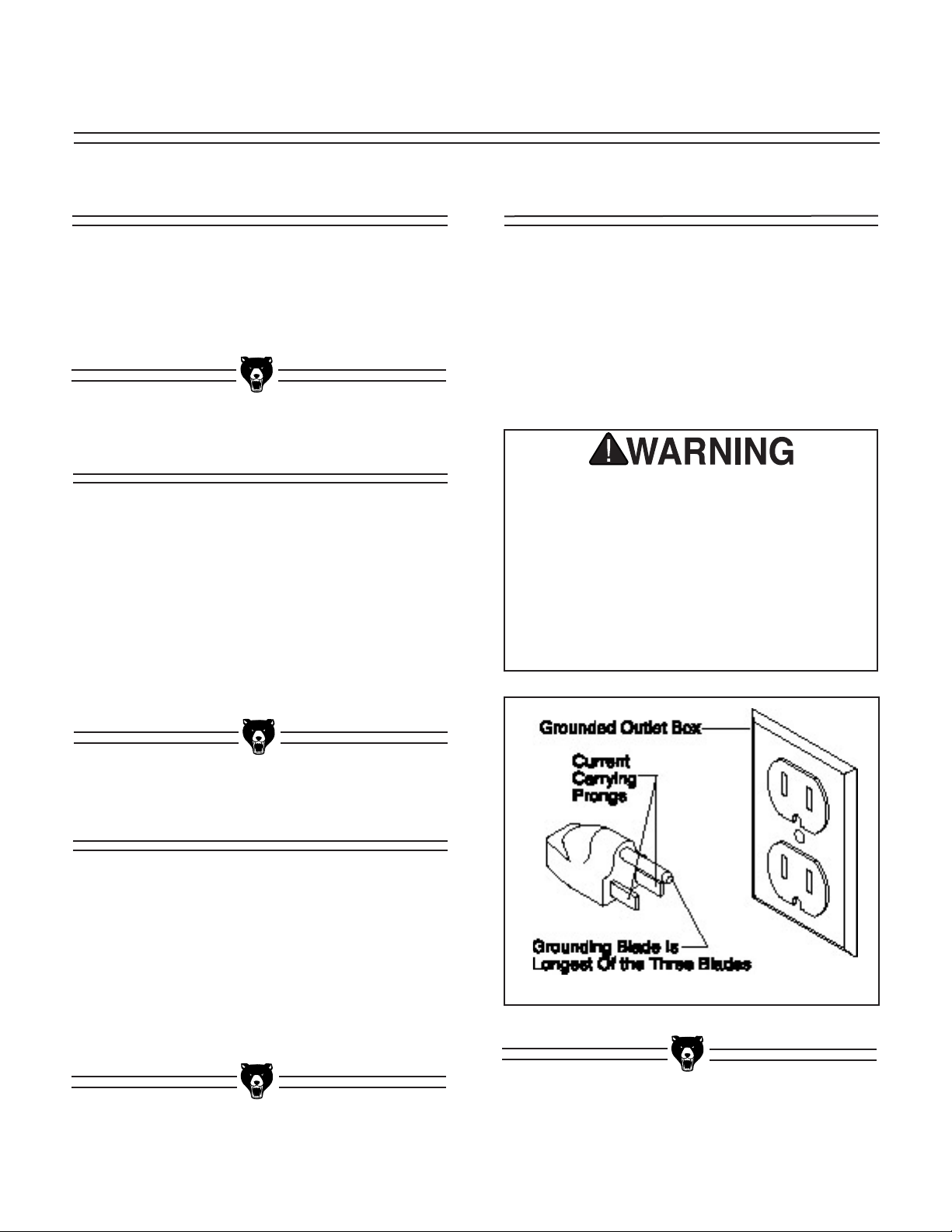

Grounding

In the event of an electrical short, grounding

reduces the risk of electric shock by providing

a path of least resistance to disperse electric

current. This tool is equipped with a power cord

having an equipment-grounding conductor. See

Figure 1. The outlet must be properly installed

and grounded in accordance with all local codes

and ordinances.

This equipment must be grounded. Verify

that any existing electrical outlet and circuit

you intend to plug into is actually ground

ed. If it is not, it will be necessary to run a

separate 12 A.W.G. copper grounding wire

from the outlet to a known ground. Under

no circumstances should the grounding pin

from any three-pronged plug be removed.

Serious injury may occur.

-

Extension Cords

If you find it necessary to use an extension cord

with the Model G1011Z, make sure the cord is

rated Hard Service (grade S) or better. Refer

to the chart in the standard safety instructions

to determine the minimum gauge for the exten

sion cord. The extension cord must also contain

a ground wire and plug pin. Always repair or

replace extension cords when they become worn

or damaged.

G1011 7" x 12'' Bandsaw -5-

-

Figure 1. Grounded plug configuration.

Page 7

SECTION 3: GENERAL INFORMATION

Commentary

Grizzly Industrial, Inc. is proud to offer the Model

G1011Z 7" x 12'' Metal-Cutting Bandsaw. This

saw is a part of Grizzly’s growing family of fine

metalworking machinery. When used according

to the guidelines set forth in this manual, you can

expect years of trouble-free, enjoyable operation,

and proof of Grizzly’s commitment to customer

satisfaction.

The G1011Z features a fully adjustable down

feed, recirculating coolant pump, quick-release

vise, centralized control panel and a 1 HP motor.

The saw comes prewired and ready to operate

at 110V.

We are also pleased to provide this manual with

the G1011Z. It was written to guide you through

assembly, review safety considerations, and

cover general operating procedures. It represents

our latest effort to produce the best documenta

tion possible. If you have any criticisms that you

feel we should pay attention to in our next print

ing, please write to us at the address below:

The specifications, drawings, and photographs

illustrated in this manual represent the Model

G1011Z as supplied when the manual was

prepared. However, owing to Grizzly’s policy

of continuous improvement, changes may be

made at any time with no obligation on the part

of Grizzly. Whenever possible, though, we send

manual updates to all owners of a particular tool

or machine. Should you receive one, we urge

you to insert the new information with the old and

keep it for reference.

-

To operate this or any power tool safely and

efficiently, it is essential to become as famil

iar with it as possible. The time you invest

before you begin to use your Model G1011Z

will be time well spent. DO NOT operate this

machine until you are completely familiar

with the contents of this manual. Serious

personal injury may occur.

-

-

-

Grizzly Industrial, Inc.

C/O Technical Documentation

P.O. Box 2069

Bellingham, WA 98227-2069

Most importantly, we stand behind our machines.

If you have any service questions or parts

requests, please call or write us at the location

listed below.

Grizzly Industrial, Inc.

2406 Reach Road

Williamsport, PA 17701

Phone: (570) 326-3806

Fax: (800) 438-5901

E-Mail: techsupport@grizzlyindustrial.com

Web Site: http://www.grizzlyindustrial.com

-6- G1011 7" x 12'' Bandsaw

Page 8

Unpacking

Clean Up

The bandsaw is shipped from the factory in a

carefully packed crate. If you find the machine

to be damaged after you’ve signed for delivery

and the truck and driver are already gone, you

will need to file a freight claim with the carrier.

Save the containers and all packing materials for

inspection by the carrier or their agent. Without

the packing materials, filing a freight claim can be

difficult. If you need advice regarding this situa

tion, please call us.

The G1011Z is a very heavy machine (626

lbs. shipping weight). DO NOT over-exert

yourself while unpacking or moving your

machine – get assistance. In the event that

your machine must be moved up or down

a flight of stairs, be sure that the stairs are

capable of supporting the combined weight

of people and the machine. Serious per

sonal injury may occur.

-

The unpainted surfaces are coated with a waxy

oil to protect them from corrosion during ship

ment. Remove this protective coating with a

solvent cleaner or citrus-based degreaser. Avoid

chlorine-based solvents as they may damage

painted surfaces should they come in contact.

Always follow the usage instructions on the prod

uct you choose for clean up.

-

Many of the solvents commonly used to

clean machinery can be highly flamma

ble, and toxic when inhaled or ingested.

Always work in well-ventilated areas far

from potential ignition sources when deal

ing with solvents. Use care when dispos

ing of waste rags and towels to be sure

they do not create fire or environmental

hazards. Keep children and animals safely

away when cleaning and assembling this

machine.

-

-

-

-

-

NOTICE

Please keep all packaging materials until

you are satisfied that the machine is in

good condition. Should you need to file a

freight claim, the carrier’s agent will require

inspection of those materials. Settling a

claim can be difficult if packaging is not

available.

When you are completely satisfied with the condition of your shipment, you should inventory its

parts.

Do not use gasoline or other petroleumbased solvents to remove this protective

coating. These products generally have low

flash points which makes them extremely

flammable. A risk of explosion and burning

exists if these products are used. Serious

personal injury may occur.

All die-cut metal parts have a sharp edge

(called “flashing”) on them after they are

formed. This is generally removed at the

factory. Sometimes a bit of flashing might

escape inspection, and the sharp edge may

cause cuts or lacerations when handled.

Please examine the edges of all die-cut

metal parts and file or sand the edge to

remove the flashing before handling.

G1011 7" x 12'' Bandsaw -7-

Page 9

Site Considerations

FLOOR LOAD

Your G1011Z Bandsaw represents a large weight

load in a small footprint. Most commercial or resi

dential shop floors should be sufficient to carry the

weight of the machine. If you have any question

about the floor structure being able to support the

weight, contact your local city building inspector

or a qualified civil engineer or contractor.

WORKING CLEARANCES

Working clearances can be thought of as the

distances between machines and obstacles that

allow safe operation of every machine with

out limitation. Consider existing and anticipated

machine needs, size of material to be processed

through each machine, and space for auxiliary

stands and/or work tables. Also consider the rela

tive position of each machine to one another for

efficient material handling. Be sure to allow your

self sufficient room to safely run your machines

in any foreseeable operation.

Notes

-

-

-

-

LIGHTING AND OUTLETS

Lighting should be bright enough to eliminate

shadow and prevent eye strain. Electrical circuits

should be dedicated or large enough to handle

combined motor amp loads. Outlets should be

located near each machine so power or exten

sion cords are not obstructing high-traffic areas.

Be sure to observe local electrical codes for

proper installation of new lighting, outlets, or

circuits.

Make your shop “child safe”. Ensure that

your workplace is inaccessible to young

sters by closing and locking all entrances

when you are away. Never allow visitors in

your shop when assembling, adjusting or

operating equipment.

-

-

-8- G1011 7" x 12'' Bandsaw

Page 10

SECTION 4: ADJUSTMENTS

Controls

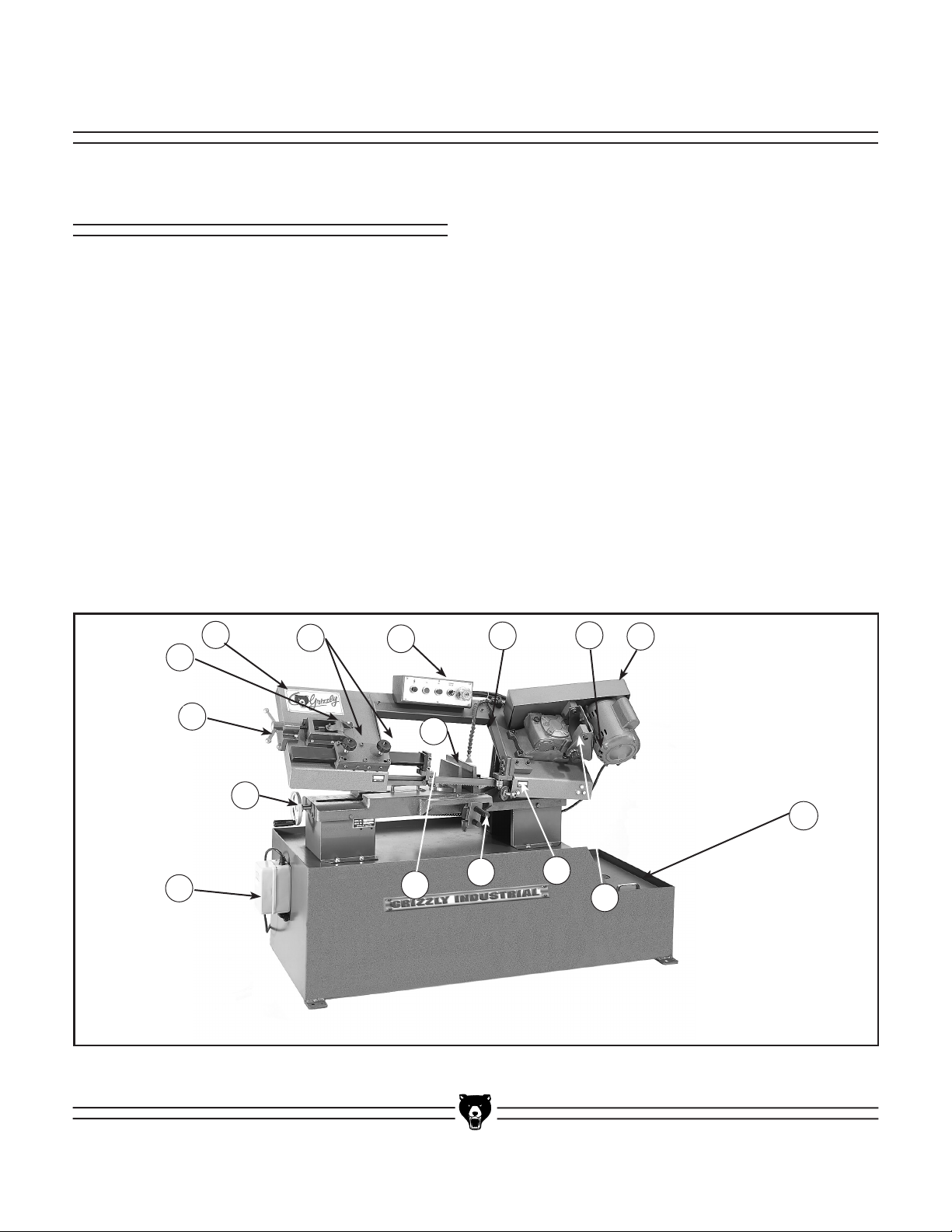

The controls and major components for the

G1011Z metal-cutting bandsaw are shown below

in Figure 2. Please use this drawing for refer-

ence when reviewing the following sections.

A. Saw Bow.

B. Blade Guide Locking Knobs.

C. Control Panel - Contains On/Off buttons,

Power-On indicator light, Coolant On/Off

switch, and the Feed Rate valve.

D. Flexible Coolant Line.

E. Motor Mount (E1) and Belt Guard (E2).

F. Coolant Tank.

G. Gear Box.

H. Stationary Blade Guide.

I. Material Stop Assembly.

J. Moveable Blade Guide.

K. Vise Movable Jaw (K1) and Vise Lead

Screw (K2).

L. Magnetic Starter Switch Box.

M. Blade Tensioning Adjustment Handle.

N. Blade Tracking Adjustment Setscrew.

A

N

M

K2

B

C

K1

D

E1

E2

F

L

Figure 2. Controls

J

I

and key components.

H

G

G1011 7" x 12'' Bandsaw -9-

Page 11

Saw Pressure

The pressure or force which the saw exerts when

pushing through the workpiece is the result of

the weight of the bow assembly counterbalanced

by the amount of spring tension applied through

the large coil spring on the back of the machine

base. This should be set so there is a moderate

amount of pressure. Harder or softer materials

may require adjusting the head pressure for spe

cific operations. See Adjusting Feed Rate in the

Operations Section.

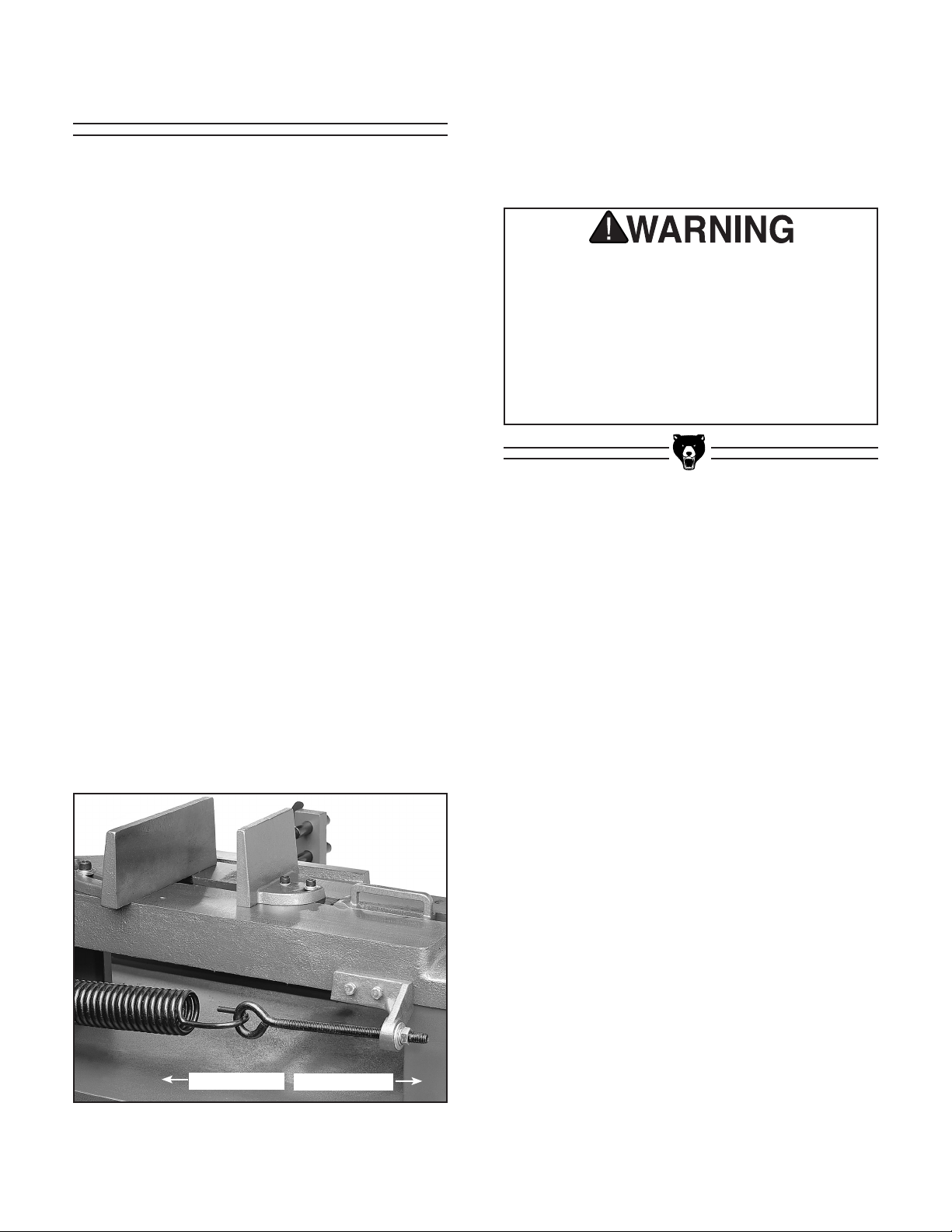

Spring adjustment is performed in the following

sequence:

1. Raise saw bow to the open position, with

the bow at the top of its travel.

2. Open the hydraulic feed rate valve all the

way by turning it counterclockwise.

5. If it is easy to stop the travel, or if the

saw bow wants to reverse direction, then

the spring tension is too strong. Turn the

adjusting nut clockwise so more of the eye

bolt threads extend beyond the bracket.

Use caution when adjusting the saw bow.

-

Keep hands and arms clear of the cutting

area when releasing the cylinder pressure

to lower the saw. Even with the saw off,

the weight of the bow can severely lacer

ate or break a hand or arm which might

get trapped between the saw and the bed.

Serious personal injury may result.

-

3. The saw bow should come down at a slow

steady rate. You should be able to stop its

travel with a light upward force from one or

two fingers.

4. If it is hard to stop the travel, then the spring

tension is too weak. Turn the adjusting nut

on the spring’s eye bolt (See Figure 3)

counterclockwise so there is less of the eye

bolt threads extending beyond the bracket.

Less Pressure

More Pressure

Figure 3. Adjusting spring tension.

-10- G1011 7" x 12'' Bandsaw

Page 12

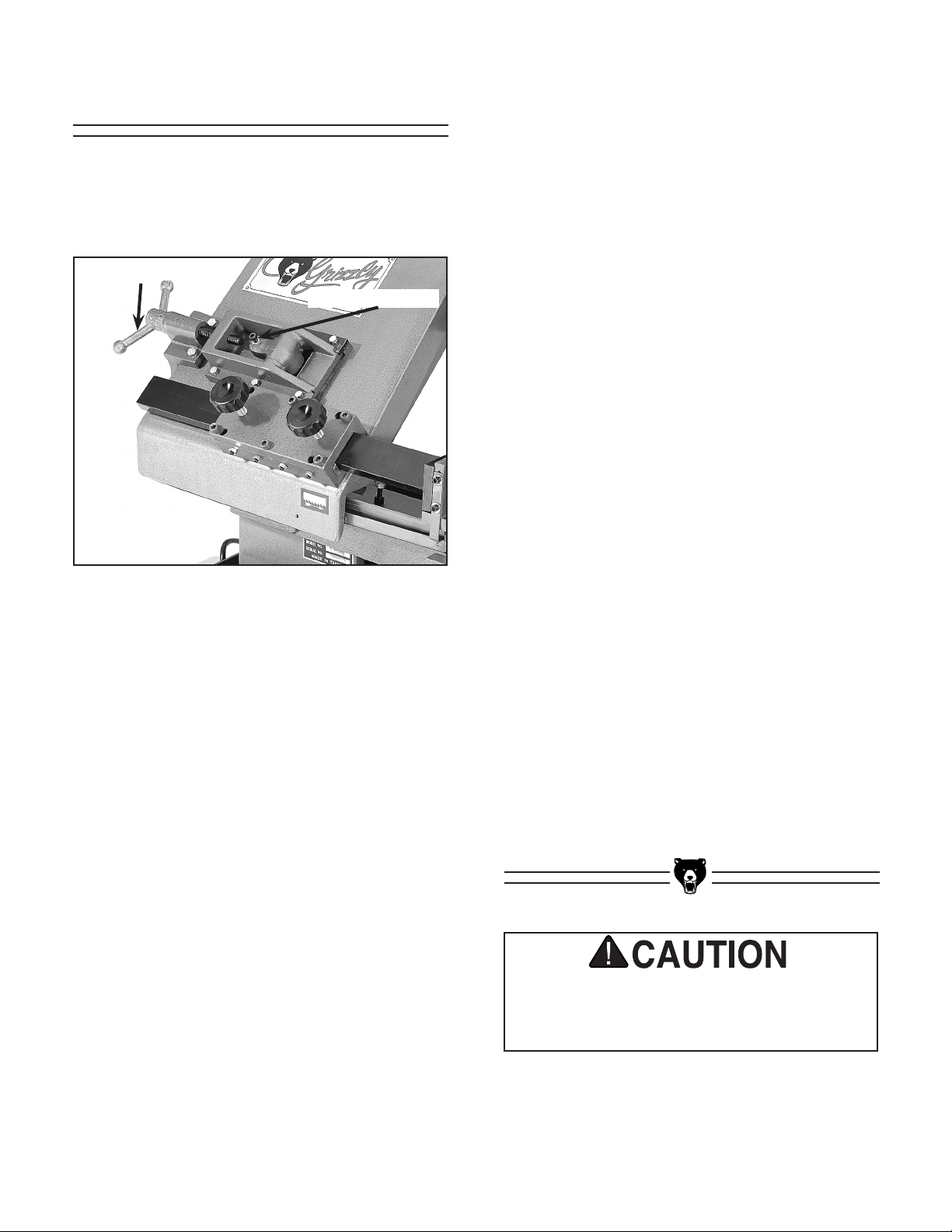

Tension/Tracking

Proper blade tension and tracking are important

for optimum bandsaw performance. See Figure

4 for bandsaw tension and tracking control locations.

Tension Control

Tracking Control

Figure 4. Tension and tracking controls.

TENSION

If the tension seems correct, make the other

adjustments to the saw (aligning guides, tracking

and speed) and test run it on a scrap piece of

material. If the blade is not cutting properly, the

tension may be incorrect and you’ll need to read

just the tension. Remember to reduce the blade

tension when the saw will not be in use, this will

help to prevent premature wear or breakage of

the blade.

TRACKING

To adjust tracking, disconnect the bandsaw from

the power source. Raise the saw bow as high

as possible and remove the cap screw from the

hinged wheel cover. This will allow you to see the

bandsaw wheel which has a machined step and

a groove on it.

The socket head cap screw and lock nut on the

top of the saw bow changes the plane of rotation

of this wheel. Turn the wheel by hand (remove

the belt guard and turn the motor pulley) for a

few revolutions and observe whether the edge of

the blade stays snug against the machined step.

If it does not, adjust the cap screw until the blade

stays against that step through several complete

revolutions of the blade.

-

Since a number of blade metal types and tooth

configurations will work in this saw, proper blade

tension is dependent upon the type of blade and

the material to be cut. Too much tension will

result in blade breakage. A properly tensioned

blade will track the cutting line accurately and the

cut will be smoother.

Initially proper blade tension can best be achieved

by determining the amount of blade deflection:

1. Ensure that the power is off and the saw is

unplugged. Slide the blade guide assembly

all the way to the left so the blade is fully

exposed.

2. Press, with moderate pressure, on the face

of the blade with your thumb.

3. Turn the tensioning knob at the top of the

machine to change the amount of tension.

The blade should flex no more than

1

/4".

Once it stays centered when rotated by hand,

lock the cap screw in place with the locking nut.

Reconnect the machine to power and turn the

machine on for just a few seconds. Observe the

action of the blade and the wheel during this test,

being sure to maintain a safe distance should

the blade become disengaged. If the blade stays

snug to the step, close the cover and secure with

the cap screw.

The saw blade is dangerously sharp. Use

extra care when handling the blade, or work

ing near it. Serious injury is possible.

-

G1011 7" x 12'' Bandsaw -11-

Page 13

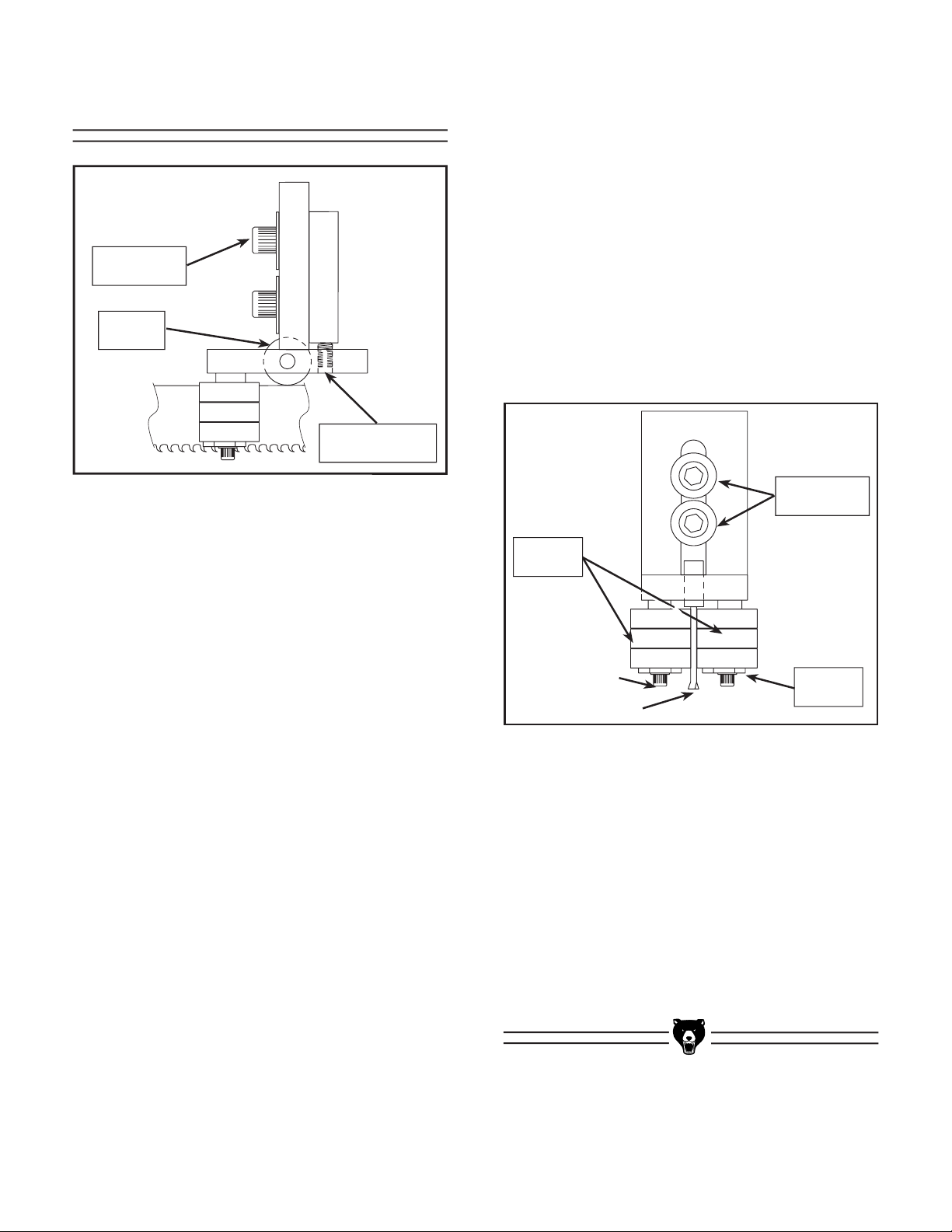

Blade Guides

Securing

Cap Screws

Support

Bearing

Fine Adjustment

Set Screws

2. Guide Bearings - The guide bearings ride

on either side of the blade and ensure that

the blade is not pushed too far laterally. To

adjust the guide bearings, loosen the cap

screw at the bottom of the bearing assem

bly. Use an open end wrench to move the

brass hex nut which is an eccentric bush

ing. Turning the hex nut will move the bear

ing assembly into or away from the blade.

When the bearings are just touching the

blade, tighten the cap screw. Repeat this

procedure for all four guide bearing assem

blies. The bearings should be able to be

rotated by hand while still touching the side

of the blade. See Figure 6

.

-

-

-

-

Figure 5. Support Bearing Adjustments.

Whenever changing a blade or adjusting tension

and tracking, the left and right hand blade support

bearings and guide bearings must be re-adjust

ed. Always adjust the guide bearings away from

the blade before installing a new blade or making

blade tracking adjustments. After blade tension

and tracking are set correctly, re-adjust the left

and right support bearings and guide bearings

into position.

Adjustment of the guides is a three step pro

cedure, consisting of adjustments to both the

support bearings and guide bearings. The adjust

ments are as follows:

1. Support Bearings - The support bearings

guide the back edge of the blade during

the sawing operation. There is one bearing

each on the left and right hand guides.

Figure 5. To adjust the support bearings,

loosen the two cap screws until the blade

guide block can be moved. Move the block

so the bearing just touches the back of the

blade. Tighten the cap screw closest to

the blade, leave the other loose for now.

Use the two fine adjustment set screws to

back the bearing away from the blade until

it is between .003'' and .005'' away from

the edge of the blade. It may help to use a

feeler gauge to check the gap. Be sure to

adjust both the left and right hand sides.

See

Securing

Cap Screws

Guide

-

-

-

Bearings

Eccentric

Bushing

Figure 6. Guide Bearing Adjustments.

3. Blade Square To Table - The blade guide

bearings must also be adjusted to make

sure the blade is perpendicular to the sur

face of the table. Lower the saw bow all the

way down until it contacts the stop screw.

Use a machinist’s square with one edge on

the bed table surface and the other against

the side of the blade. With the upper secur

ing bolt still loose, rotate the guide bearings

assembly block until the blade is square.

Now tighten the upper and lower bolts to

secure this position.

-

-

-12- G1011 7" x 12'' Bandsaw

Page 14

Horizontal Stop Screw

Auto Shut-Off

The horizontal stop screw limits the downward

travel of the saw bow to keep the blade from

running into the cast iron bed. The stop screw is

located on the saw bow just next to the left hand

blade wheel cover. See Figure 7.

Lower the saw bow by opening the feed rate

valve. Stop the bow when the teeth are just

below the top surface of the bed. Adjust the stop

screw so it touches the bed surface. Tighten the

locknut on the stop screw.

1

⁄8''

Locknut

Stop Screw

The motor should shut off immediately after

the blade has cut through the material and just

before the head comes to rest on the horizontal

stop screw. The automatic shut off limit switch is

located near the saw bow pivot point next to the

hydraulic cylinder. See Figure 8.

Turn the saw on (after making sure the blade

tensioning and tracking is correct), and lower

the saw bow slowly. The saw should turn off just

before the saw bow hits the stop screw. If it does

not shut off at the proper point, the limit switch

needs adjustment.

Loosen the two screws holding the limit switch

bracket, and raise or lower the switch until the

proper shut off point is achieved. If the switch is

manually depressed, you will hear a click at the

point the switch is being activated. You can use

this activation point to set the switch in the proper

position without the saw power being on.

After positioning the switch, double check its

operation to make certain it is shutting off the

blade just before contacting the horizontal stop

screw.

Figure 7. Horizontal stop screw.

Figure 8. Automatic shut-off switch.

G1011 7" x 12'' Bandsaw -13-

Page 15

SECTION 5: OPERATIONS

The metal-cutting bandsaw is one of the most

versatile machines in the shop. It can be used

to cut off bar stock and structural steel to length

as well as shaping metal into semifinished and

finished components.

Pre-Run Check

There are many adjustment points and compensating differences to consider when operating

this type of saw. Therefore, cutting results can

be somewhat unpredictable if some or all of the

crucial adjustments are neglected. Here are a few

simple things you can do to increase the predict

ability of your bandsaw’s performance:

1. Blade Type - Is the blade the proper

tooth count and blade configuration for the

material you need to cut? Is it sharp? Is it

installed in the machine so the teeth are

pointing in the right direction, according to

the label on the saw bow.

2. Blade Tensioning - Is the blade tensioned

properly? Is the blade tracking evenly on

the wheels?

3. Blade Guides - Are the blade guides

adjusted so the bearings are just touching

the blade without binding. The movable

blade guide on the left hand side should be

moved as close to the material to be cut as

possible.

4. Speeds and Feeds - Has the proper cut

ting speed been selected for the type of

material to be cut? Has the proper feed rate

for the bow been set for the type of material

to be cut?

6. Coolant - Has the coolant reservoir been

filled with the proper type of coolant solution

to the manufacturer’s mix ratio? Is the cool

ant nozzle directed at the cutting location

and is the pump on?

7. Operator Safety - Is the machine operator

wearing safety goggles and hearing protec

tion? Avoid standing directly in front of the

machine while it is cutting, stand to one side

yet close enough to reach the control panel

if needed.

-

The Model G1011Z Bandsaw is a powerful,

professional-quality machine, designed and

built to provide outstanding results when

used cautiously and with respect. Like any

machine of its type, the Model G1011Z has

some inherent dangers, which, when used

with a lack of care, can result in serious

injury or fatality. Please do not attempt

to use this machine without familiarizing

yourself with the instructions for assembly,

adjustment, and safe operation. Failure to

do so could result in serious personal injury, as well as property damage and damage

-

to the machine.

-

-

5. Vise - Is the material to be cut securely held

in the vise? Is the vise oriented to the blade

properly? Is the material situated in such a

manner that the cutting will not begin on a

sharp corner?

-14- G1011 7" x 12'' Bandsaw

Page 16

Blade Selection

A bandsaw blade is a ribbon of steel subjected

to tremendous strain. Be sure you use qual

ity blades for the various types of cutting opera

tions. The Grizzly G1011Z bandsaw accepts 1'' x

101" blades. Bandsaw blades can be purchased

welded, set, and sharpened ready-for-use from

most saw shops. We also supply tool steel and

variable pitch bi-metal blades for this saw. Please

refer to our current catalog for prices and ordering

information.

There are several key factors to consider in

choosing a blade:

Tooth Pitch - The number of teeth per inch

(TPI) on the blade, also known as tooth

pitch. Select a pitch which will assure that

at least three teeth are contacting the

workpiece while cutting. This helps to dis

tribute the cutting forces and avoids tooth

breakage.

Many conditions can lead to breakage. Blade

breakage is, in some cases, unavoidable, since it

is the natural result of the peculiar stresses that

bandsaw blades are subjected to. Blade break

age is also due to avoidable causes. Avoidable

-

-

-

breakage is most often the result of poor care

or judgement on the part of the operator when

mounting or adjusting the blade or support guides.

The most common causes of blade breakage are:

(1) faulty alignment and adjustment of the guides;

(2) Insufficient number of teeth contacting the cut;

(3) feeding too fast; (4) tooth dullness or absence

of sufficient set; (5) excessive tension; (6) using

a blade with a lumpy or improperly finished weld;

and (7), continuously running the bandsaw when

not in use.

Gullet

-

Tooth Form - There are four common forms

of teeth on the blade: buttress, claw-tooth,

precision and tungsten carbide. Precision is

the most common and is the type supplied

with this saw. See Figure 9. It is the most

versatile and it provides a good surface

finish.

Tooth Set - Set is the degree to which the

teeth are bent away from the blade. Typical

tooth set styles are raker, wave and straight

set. Raker set is the most common with one

tooth offset to the right, the next one to the

left, and the third is straight. A wave set

will have 3-4 teeth bent progressively one

direction, then to the other in a wave-like

pattern. A straight set is alternating teeth

set right, then left.

Always select and use good-quality saw blades

and choose the right blade for the job. Discuss

your cutting requirements with your saw blade

dealer to make sure you are getting the type of

blade which best suits your need. Poor quality

blades and improper use are often the cause of

premature blade failure.

Gullet Line

Figure 9. A precision tooth, raker set blade.

Operating this equipment has the potential to propel debris into the air which can

cause eye injury. Always wear safety glass

es or goggles when operating equipment.

Everyday glasses or reading glasses only

have impact resistant lenses, they are not

safety glasses. Be certain the safety glasses

you wear meet the appropriate standards of

the American National Standards Institute

(ANSI).

-

G1011 7" x 12'' Bandsaw -15-

Page 17

Changing Blades

Use extreme caution when replacing blades.

Teeth are dangerously sharp and coiled

blades are prone to spring when released

from their packaging. Use heavy leather

or welding gloves and safety glasses or

goggles whenever handling blades. Failure

to do so could result in serious personal

injury.

To remove the blade, ensure the power is discon

nected and raise the saw bow as high as it will

go:

1. Loosen tension on the blade by turning the

tension knob.

2. Open the gap between the blade bearing

guides by loosening the locking screw and

turning the eccentric bushing with an open

end wrench. See Blade Guide Adjustment

section.

3. Remove the cap screws from the cover

plates over both of the bandsaw wheels.

At the outer end of the bow the cover is

hinged, at the other the plate must be com

pletely removed.

4. Slide the blade off both wheels and out of

the blade guides. Use caution, the blades

are sharp!

See Figure 10.

-

-

Figure 10. Outer wheel and cover.

3. Apply tension to the blade by turning the

tension control knob. Refer to blade ten

sioning instructions earlier in this section.

4. Adjust the guide blocks and bearings as

described in the previous section.

5. Close the wheel covers. Install the cap

screws to secure the covers.

-

To replace the blade, ensure that the power is

disconnected and:

1. Position the blade so the teeth are pointing

down and toward the right when you are

facing the front of the machine. There are

blade tooth direction labels on the front of

the saw. If the teeth will not point downward

in any orientation, the blade is inside out.

Twist it until it is right side out.

2. Slip the blade through the left and right hand

guides and mount over the two wheels.

-16- G1011 7" x 12'' Bandsaw

Page 18

Cutting Speed

Blade speed selection should be made according

to the material being cut. In general, the harder

the material the slower the blade speed. The

chart in Figure 12 provides a general reference.

Motor Pulleys

Saw Pulleys

Material

Hard Materials High Speed steels,

stainless and heavy

cross section mat’l

Moderately Hard

- Tool, stainless and

alloy steels, bearing

bronzes

Moderately Soft

- Cast iron, mild

steel, hard brass

and bronze

Soft Materials Plastic, copper, soft

brass, aluminum,

other light materials

Figure 11. Cutting speeds and pulley selection.

The speed is changed by moving the V-belt onto

the different sized pulleys on the motor and the

saw. See Figure 12.

Speed

FPM

63

104

156

206

Pulley Used

Motor

smallest

small

medium

large

Saw

large

medium

small

smallest

Tension Knob

Figure 12. Motor and saw blade pulleys.

DO NOT attempt to assemble, adjust, or

maintain this machine while it is running.

Turn off the switch, disconnect the bandsaw

from its power source and wait for all

moving parts to come to a complete stop

before attempting any adjustments or maintenance. Failure to do so could result in

serious injury.

1. Remove the belt guard.

2. Loosen the motor tension knob.

3. Pull the motor over to relieve the belt

tension. Move the belt to one of the four

desired locations according to the speed

chart. Never cross the belt so it is diagonal

across the pulleys.

4. Tighten the motor tension knob.

5. Replace the belt guard.

G1011 7" x 12'' Bandsaw -17-

Page 19

Adjusting Feed Rate

Coolant

The hydraulic cylinder connected to the saw bow

regulates the rate at which the blade is lowered

into the workpiece. Opening and closing the valve

on the control panel (See Figure 13) controls the

feed rate.

There is a by-pass valve on the side of the

hydraulic cylinder which is preset at the factory.

This by-pass allows the pressure to be relieved

if for some reason the saw bow is forced down

ward. Do not attempt to adjust the by-pass valve

setting.

Regulator Valve

Use of the coolant system is optional and is

dependent upon the type of material being cut

and the quantity. Directing coolant on the cut

keeps the blade and workpiece from overheating,

and it flushes the metal chips away from the tooth

area to keep a good cutting surface.

The coolant tank is at the bottom of the machine

on the right hand side. See Figure 14.

-

the coolant solution to this tank, and locate the

submersible pump so the suction intake is com

pletely submerged. Generally water soluble fluids

will work best. Refer to the specific mixing and

replacement instructions of the coolant manufac

turer. A drain plug is located at the corner of the

tank to allow the easy draining of the coolant.

Turn the coolant pump on at the control panel,

and direct the coolant nozzle directly at the cut.

Add

-

-

Figure 13. Feed regulator on control panel.

Figure 14. Coolant pump.

-18- G1011 7" x 12'' Bandsaw

Page 20

Guide Adjustment

Vise and Stop

The blade will cut best when the blade is supported as close to the workpiece as possible. Once

the material has been secured in the vise, loosen

the two knobs on top of the saw bow and slide the

moveable guide over as close to the material as

possible without interfering with the cut. Tighten

the knobs. See Figure 15.

Figure 15. Moveable blade guide.

The workpiece(s) must always be secured in the

vise for cutting. Never attempt to hold the mate

rial by hand, the cutting forces on a metal-cutting

bandsaw are too strong. The angle of the cut can

be revised by loosening the cap screws securing

the vise jaws to the table and turning them to the

angle desired. Tighten the cap screws.

One side of the vise slides along the bed when

the handle lifts the threads off the lead screw.

See Figure 16. Place the material to be cut

between the sides of the vise jaws, and move the

sliding portion as close to the material as pos

sible. Seat the handle on the lead screw threads.

Then using the handwheel on the left hand side

of the bed, tighten the jaws until the material is

firmly secured. Never release the vise by pulling

up on the handle. Damage to the screw and nut

will occur and may render it unusable.

Just in front of the vise, protruding from beneath

the table, is the material stop bar. This can be set

so that material can be cut to the same length

over a series of cuts. Set the length of cut by

measuring from the plane of the saw blade to the

end of the stop bar. Tighten the thumb screws.

Slide the material so it contacts the stop bar.

Activate the saw and make the cut. Raise the saw

bow and advance the material so it once again

touches the stop bar. This will assure the cuts are

made to the same exact length.

-

-

Fixed Jaw

Movable

Jaw

Release

Handle

Figure 16. Vise components.

G1011 7" x 12'' Bandsaw -19-

Material Stop

Page 21

SECTION 6: MAINTENANCE

Table

The table and other non-painted surfaces on the

Model G1011Z should be protected against rust

and pitting. Wiping the saw clean after every use

helps to ensure that coolant and chips won’t begin

to corrode the working surfaces of the bandsaw.

Protect the table surfaces with a light coating of

oil periodically, especially when the saw will not

be used for a time period.

V-Belt

To ensure optimum power transmission from the

motor to the blade, the V-belt must be in good

condition and must be under the proper tension.

The belt should be checked for cracks, fraying

and wear. Belt integrity should be checked at

least every 3 months; more often if the bandsaw

is used daily.

Make sure the belt is tensioned properly whenev

er speed changes are made Refer to the Cutting

Speed section for more complete detail on the

speeds and moving the belt.

-

Make your workshop “child-safe.” Remove

all safety keys from this and other machin

ery when they’re not in use. Place sharp

tools and blades high enough to discourage

curious fingers. Store lubricants, finishes

and other harmful chemicals where they

can’t be easily reached. Lock your workshop securely when you are away.

Operating this equipment has the potential to propel debris into the air which can

cause eye injury. Always wear safety glass

es or goggles when operating equipment.

Everyday glasses or reading glasses only

have impact resistant lenses, they are not

safety glasses. Be certain the safety glasses

you wear meet the appropriate standards of

the American National Standards Institute

(ANSI).

-

-

-20- G1011 7" x 12'' Bandsaw

Page 22

Lubrication

Miscellaneous

The bearings used in the motor, the wheels and

the blade guides are shielded and pre-lubricated

ball bearings. These require no lubrication for

the life of the bearings. All bearings are standard

sizes and replacements can be purchased from

our parts department or bearing supply store.

The rod on which the saw bow pivots needs

an occasional shot of light oil to keep it moving

smoothly.

The gear box should not need changing unless

the oil becomes contaminated or leaks. To check

the oil, lower the saw bow down all the way and

wait a few minutes for the oil to drain down. Open

the oil cap on top of the gearbox. The gear case

is full when the oil is up to the bottom of the filler

hole. Use 90W gear oil if it becomes necessary to

change or add to the oil.

Always be aware of the condition of your bandsaw

before using it. Routinely check the condition of

the following items and repair or replace as nec

essary.

1. Worn or damaged blade.

2. Worn switches.

3. Loose mounting bolts.

4. Worn or damaged support bearings or

guide bearings.

-

Coolant System

The coolant system must be properly filled with

the proper mix of coolant and water in accor

dance with the coolant manufacturer’s specifi

cations. The coolant will need to be replaced

periodically as the bandsaw is used more. Some

coolant types also breakdown over time, or need

additives to reduce the growth of bacteria or fun

gus in the solution.

There is a filter in the bottom of the coolant pump

which will need periodic cleaning or replacement.

Any time coolant flow does not seem sufficient,

check the coolant sump for level, and check the

pump filter.

-

-

-

G1011 7" x 12'' Bandsaw -21-

Page 23

SECTION 7: CLOSURE

The following pages contain general machine

data, parts diagrams/lists, troubleshooting guide

and Warranty/Return information for your Model

G1011Z Metal-Cutting Bandsaw.

If you need parts or help in assembling your

machine, or if you need operational information, we encourage you to call our Service

Department. Our trained service technicians will

be glad to help you.

If you have comments dealing specifically with

this manual, please write to our Bellingham,

Washington location using the address in Section

3 General Information The specifications, draw

ings, and photographs illustrated in this man

ual represent the Model G1011Z as supplied

when the manual was prepared. However, due

to Grizzly’s policy of continuous improvement,

changes may be made at any time with no obli

gation on the part of Grizzly. Whenever possible,

though, we send manual updates to all owners of

a particular tool or machine. Should you receive

one, add the new information to this manual and

keep it for reference.

We have included some important safety mea

sures that are essential to this machine’s opera

tion. While most safety measures are generally

universal, Grizzly reminds you that each work

shop is different and safety rules should be con

sidered as they apply to your specific situation.

Operating this equipment has the potential

for flying debris to cause eye injury. Always

wear safety glasses or goggles when operat

ing equipment. Everyday glasses or reading

glasses only have impact resistant lenses,

they are not safety glasses. Be certain the

safety glasses you wear meet the appro

priate standards of the American National

Standards Institute (ANSI).

-

-

We recommend you keep a copy of our current catalog for complete information regard

ing Grizzly's warranty and return policy. If you

need additional technical information relating

to this machine, or if you need general assis

tance or replacement parts, please contact the

Service Department listed in Section 3: General

Information.

Additional information sources are necessary to

realize the full potential of this machine. Trade

journals, woodworking magazines, and your local

library are good places to start.

-

-

The Model G1011Z was specifically designed

for metal-cutting operations. DO NOT MODIFY

-

-

-

-

-

AND/OR USE THIS MACHINE FOR ANY

OTHER PURPOSE.

er use of this tool will void the warranty. If you

are confused about any aspect of this machine,

DO NOT use it until you have answered all

your questions. Serious personal injury may

occur.

Like all power tools, there is danger associated with the Model G1011Z Metal-Cutting

Bandsaw. Accidents are frequently caused

by lack of familiarity or failure to pay atten

tion. Use this tool with respect and caution

to lessen the possibility of operator injury.

If normal safety precautions are overlooked

or ignored, serious personal injury may

occur.

Modifications or improp-

-

-

-

-22- G1011 7" x 12'' Bandsaw

Page 24

MACHINE DATA

SHEET

Customer Service #: (570) 326-3806 • To Order Call: (800) 523-4777 • Fax #: (800) 438-5901

GRIZZLY MODEL G1011 METAL-CUTTING BANDSAW

Design Type ......................................................................................................Floor Model

Overall Dimensions:

Crate Size ............................................................................ 68" L x 27

Foot Print .........................................................................................................57" x 23"

Angle Cuts .......................................................................................................45° - 90°

Length ...................................................................................................................631⁄4"

Width (front to back) .................................................................................................

Height (head in high position) ...............................................................................

Height (from floor to cutting area) .........................................................................

Weight (shipping) ............................................................................................. 626 lbs.

Weight (Net) ..................................................................................................... 548 lbs.

Capacities:

Maximum Cutting Capacity ..................................................................7" Round Stock

Maximum Cutting Capacity ....................................................... 7" x 11

Bed Size .......................................................................................................

Cuts .................................................................................................................45° - 90°

Blade Size .......................................................................................................1" x 101"

Blade Speeds ........................................................................... 63, 106, 156, 206 FPM

Construction:

Main Body ....................................................................................................... Cast Iron

Stand ............................................................................................ Formed and Welded

Wheels ............................................................................................................ Cast Iron

Gear Box ...................................................................Sealed & Lubricated Worm Gear

Blade Guides ................................................................................ 7 Ball Bearing Guide

Motor:

Type .............................................................................. Capacitor Start Induction Run

Horsepower ........................................................................................................... 1 HP

Phase ⁄ Cycle .............................................................................. Single Phase ⁄ 60 HZ

Voltage ..............................................................................(prewired 110V) 110V⁄220V

Amps .................................................................................................................... 16 ⁄ 8

RPM .............................................................................................................1725 RPM

Bearings ...........................................................Shielded and Lubricated-For-Life ⁄ Ball

Switch ..............................................................................................Automatic Shut Off

Features:

............................................................ Centralized Control Panel on Top of Saw Bow

........................................................................... Heavy-Duty, all steel one-piece base

.......................... Adjustable hydraulic down-feed—dial feed rate on the control panel

............................................................ Worm-gear box has hardened & ground gears

........................................................................Quick release vise for fast job changes

............................ Built in coolant system (tank not removable) uses water soluble oil

1

⁄2" W x 471⁄4" H

27"

661⁄2"

251⁄2"

5

⁄8" Rectangular

81⁄4 x 171⁄2" A n g l e

Specifications, while deemed accurate, are not guaranteed.

REVISED 5/99

G1011 7" x 12'' Bandsaw -23-

Page 25

TROUBLESHOOTING

SYMPTOM

Teeth Breakage

Blade breakage.

Cut not straight.

Blade Twisting.

POSSIBLE CAUSE

1. Too few teeth per inch.

2. Excessive loading of gullets.

3. Excessive feed rate.

4. Work not secured in vise.

1. Teeth too coarse.

2. Misalignment of guides.

3. Dry cutting

4. Excessive speed.

5. Excessive feed

6. Excessive tension.

1. Wheels out of line.

2. Guides out of line.

3. Excessive feed pressure.

4. Insufficient blade tension

5. Work not secured in vise.

1. Blade not aligned with blade

guides.

2. Excessive feed pressure.

3. Excessive feed rate.

CORRECTIVE ACTION

1. Use finer tooth blade (make sure at least three teeth

contact the workpiece).

2. Use coolant or increase coolant flow, or use coarser

tooth blade.

3. Decrease feed rate.

4. Check that vise is tight to the bed and the movable

jaw is tightened.

1. Use a finer tooth blade.

2. Adjust blade support and guide bearings.

3. Use coolant system.

4. Decrease cutting speed

5. Decrease cutting feed rate.

6. Reduce blade tension

1. Adjust blade tracking.

2. Adjust support and guide bearings.

3. Adjust spring tension to reduce feed pressure.

4. Increase blade tension.

5. Check that vise is tight to the bed and the movable

jaw is tight on the material to be cut.

1. Adjust support and guide bearings, check alignment

of blade to table.

2 Adjust spring tension to reduce feed pressure.

3. Reduce feed rate at control panel.

-

Premature tooth wear.

Repetitive ticking noise

when blade is on.

Blade does not run even

ly on wheels or runs off.

Blade does not cut

evenly.

Blade contacting table

surface.

Blade does not stop after

cut is complete.

1. Dry cutting.

2. Blade too coarse.

3. Insufficient feed rate.

4. Excessive speed.

5. Tooth set is uneven.

1. Blade weld contacting support

or guide bearings.

2. Blade weld may be failing.

-

1. Tracking is not adjusted prop

erly.

1. Blade tension is incorrect.

2. Tooth set is uneven.

3. Teeth are sharper on one side

than the other.

1. Horizontal stop screw not

adjusted.

1. Automatic shut-off switch not

adjusted.

1. Use coolant system.

2. Use finer tooth blade.

3. Increase feed rate so that blade does not ride in cut.

4. Reduce cutting speed.

5. Replace blade, or have it professionally sharpened.

1. Use file or stone to smooth and round the back of the

blade.

2. Inspect and replace blade if necessary.

1. Adjust tracking.

-

1. Adjust tension.

2. Replace blade, or have it professionally sharpened.

3. Replace blade, or have it professionally sharpened.

1. Adjust horizontal stop screw.

1. Adjust automatic shut-off switch.

-24- G1011 7" x 12'' Bandsaw

Page 26

TROUBLESHOOTING

SYMPTOM

Motor will not start.

Motor will not start; fuses

or circuit breakers blow.

Motor overheats.

Motor stalls (resulting in

blown fuses or tripped

circuit).

Motor and blade speed

slows when operating.

POSSIBLE CAUSE

1. Low voltage.

2. Open circuit in motor, control

panel or magnetic starter.

1. Short circuit in line cord or

plug.

2. Short circuit in motor or loose

connections.

3. Incorrect fuses or circuit break

ers in power line.

1. Motor overloaded.

2. Air circulation through the motor

restricted.

1. Short circuit in motor or loose

connections.

2. Low voltage.

3. Incorrect fuses or circuit break

ers in power line.

4. Motor overloaded.

1. Excessive feed pressure.

2. Blade is dull.

CORRECTIVE ACTION

1. Check power line for proper voltage.

2. Inspect all lead connections on motor, switch and

starter for loose or open connections.

1. Inspect cord or plug for damaged insulation and

shorted wires.

2. Inspect all connections on motor for loose or shorted

terminals or worn insulation.

-

3. Install correct fuses or circuit breakers.

1. Reduce load on motor.

2. Clean out motor to provide normal air circulation.

1. Inspect connections on motor for loose or shorted

terminals or worn insulation.

2 Correct the low voltage conditions.

3. Install correct fuses or circuit breakers.

-

4. Reduce load on motor.

1. Adjust spring tension to reduce feed pressure.-

2. Replace blade.

G1011 7" x 12'' Bandsaw -25-

Page 27

G1011Z 110 Volt Wiring Diagram

Limit Switch

To Motor

To Pump

Light Start

Stop

Pump

Switch

Switch

Switch

Copyright, Grizzly Industrial Inc.

12

15

18

Ground

Control Panel

110 Volt Power

Magnetic

Starter

-26- G1011 7" x 12'' Bandsaw

Page 28

G1011Z WIRE DIAGRAM

110 VOLT

WHITE (GROUND)

TO 110 VOLT

POWER SUPPLY

NOTE: THE WIRES FROM THE

POWER SUPPLY, BESIDES THE

GREEN GROUND WIRE, ARE

INTERCHANGABLE, THEREFORE

COLORS ARE NOT SPECIFIED.

© Grizzly Industrial, Inc. 1999

1

3

2 4

G1011 7" x 12'' Bandsaw -27-

Page 29

PARTS LIST

REF PART # DESCRIPTION

002 P1011Z002 DOWEL PIN

003 P1011Z003 RAPID NUT

004 P1011Z004 MOVABLE JAW

005 PW01M WASHER 8

006 PSB45M CAP SCR M8-1.25 x 45mm

007 PSB45M CAO SCR M8-1.25 x 45mm

009 P1011Z009 MOVABLE JAW SUBPLATE

010 PSB44M CAP SCR M10-1.5 x 28mm

011 P1011Z011 FIXED JAW

012 P1011Z012 PIVOT SHAFT NUT

013 P1011Z013 NUT

014 PW01 FLAT WASHER

019 PW01M FLAT WASHER 8

020 PB03M HEX BOLT M8-1.25 x 16mm

021 P1011Z021 PIVOT SHAFT

022 P1011Z022 SLEEVE

023 P1011Z023 TORSION SPRING

024 P1011Z024 TABLE

025 P1011Z025 RETAINING PLATE

026 PB07M HEX BOLT M8-1.25 x 25mm

027 PW01M FLAT WASHER 8

028 P1011Z028 FEED SUPPORT BRACKET

029 PB07M HEX BOLT M8-1.25 x 25mm

030 PSB13M CAP SCR M8-1.25 x 30

031 PLW04M LOCK WASHER 8

032 P1011Z032 EYE BOLT

033 P1011Z033 FEED SPRING

034 PW01M FLAT WASHER 8

035 P1011Z035 HOSE CLAMP

036 P1011Z036 SPINDLE BRACKET

038 P1011Z038 GASKET

060 P1011Z060 SETSCREW

061 P1011Z061 WORK STOP ARM

062 P1011Z062 UPPER WORK STOP ROD

063 P1011Z063 LOWER WORK STOP ROD

072 P1011Z072 HAND WHEEL

073 P1011Z073 SETSCREW

074

P1011Z074 CLAMP SPINDLE

079 P1011Z079 PUMP

102 PSB540M CAP SCR M5-.8 x 10mm

103 P1011Z103 BLADE GUARD

mm

1

⁄2"

mm

mm

mm

mm

REF PART # DESCRIPTION

113 P1011Z113 SAW BOW

114 P1011Z114 TILT ARM

117 P1011Z117 PIN

118 P1011Z118 RETAINING RING

119 P1011Z119 CYLINDER PIVOT BRKT

122 P1011Z122 HYDRAULIC CYLINDER

126 P1011Z126 DRIVE WHEEL COVER

130 P1011Z130 BRACKET

132 P1011Z132 BRUSH SPACER

133 P1011Z133 CHIP BRUSH

134 P1011Z134 SHOULDER SCREW

136 P1011Z136 IDLER WHEEL COVER

144 P1011Z144 COLUMN BLADE COVER

145 P1011Z145 NOZZLE

146 PSB07M CAP SCR M6-1 x 30mm

147 P1011Z147 COOLANT MOUNT

148 P1011Z148 BARB FITTING

150 P1011Z150 HOSE

151 P1011Z151 BLADE

201 PRP03M ROLL PIN M5 x 20mm

202 P1011Z202 HANDLE

203 P1011Z203 THREADED ROD

204 PB07M HEX BOLT M8-1.25 x 25mm

205 P1011Z205 TENSION BLOCK

207 P1011Z207 ROLL PIN

208 PN01M HEX NUT M6-1

209 PSB30M CAP SCREW M6-1 x 45mm

210 P1011Z210 YOKE AND SHAFT ASSY

211 P1011Z211 SLIDE

213 P1011Z213 THRUST BEARING

214 P1011Z214 IDLER WHEEL

215 P1011Z215 BRONZE BEARING

217 P1011Z217 RETAINING RING

218 P1011Z218 SLIDE PLATE

219 PSB01M CAP SCREW M6-1 x 16mm

220 PB26M HEX BOLT M8-1.25 x 30mm

221 PB18M HEX BOLT M6-1 x 15mm

222 P1011Z222 GIB

223 PSB07M CAP SCREW M6-1 x 30mm

-28- G1011 7" x 12'' Bandsaw

Page 30

REF PART # DESCRIPTION

224 PW03M FLAT WASHER

301 P1011Z301 KNOB

302 P1011Z302 GUIDE BAR COVER

303 PSB31M CAP SCR M8-1.25 x 25mm

304 P1011Z304 SETSCREW

305 P1011Z305 GUIDE BAR

308 P1011Z308 DOWEL PIN

309 P1011Z309 BLADE GUIDE BRACKET

310 P1011Z310 STRAIGHT BUSHING

312 P1011Z312 ECCENTRIC BUSHING

313 PSB13M CAP SCR M8-1.25 x 30mm

314 PW01M FLAT WASHER 8mm

316 P1011Z316 BLADE GUIDE SUBPLATE

318 P1011Z318 GUIDE BAR CRADLE

319 PSS12M SETSCREW M6-1 x 25mm

320 PN01M HEX NUT M6-1

321 P1011Z321 GIB

401 P1011Z401 BACK PANEL

402 P1011Z402 DRIVE PULLEY

403 PVM34 V-BELT M34 3L340

404 P1011Z404 BELT GUARD

405 P1011Z405 STUD

406 PW01M FLAT WASHER 8

mm

407 P1011Z407 KNOB-PULLEY COVER

408 P1011Z408 MOTOR PULLEY

409A P1011Z409A MOTOR MOUNT

409B P1011Z409B MOTOR MOUNT

410 P1011Z410 MOTOR MOUNT PLATE

411 P1011Z411 MOTOR 1 HP

412 PLW05M LOCK WASHER 12

mm

413 PSB36M CAP SCR M12-1.75 x 25mm

414 P1011Z414 DRIVE WHEEL

415 P1011Z415 SPEED REDUCER

416 PSB47M CAP SCR M10-1.5 x 30mm

417 PSS05M SETSCREW M5-.8 x 10mm

418 PB31M HEX BOLT M10-1.5 x 40mm

420 PB03M HEX BOLT M8-1.25 x 16mm

421 PLW04M LOCK WASHER 8mm

REF PART # DESCRIPTION

422 PW01M FLAT WASHER 8mm

423 P1011Z423 KNOB-MTR ADJUST PLATE

1

424 PW01 FLAT WASHER

⁄2"

428 PB03M M8-1.25 x 16mm

429 PLW04M LOCK WASHER 8mm

430 PW01M FLAT WASHER 8mm

501 PSB13M CAP SCR M8-1.25 x 30mm

502 PW01M FLAT WASHER 8mm

503 P1011Z503 BLADE GUIDE BRACKET

506 PSB12M CAP SCR M8-1.25 x 40mm

507 P1011Z507 GUIDE BAR

509 P1011Z509 DOWEL PIN

510 PSS24M SETSCREW M5-.8 x 20mm

511 P1011Z511 JAM NUT

512 P1011Z512 ECCENTRIC BUSHING

513 P1011Z513 BEARING

514 P1011Z514 STRAIGHT BUSHING

515 P1011Z515 SOC HD CAP SCREW

516 P1011Z516 BEARING

517 P1011Z517 SPACER

601 P1011Z601 FLOW CONTROL VALVE

602 P1011Z602 90 DEG CONNECTOR

603 P1011Z603 STRAIGHT CONNECTO

R

604 P1011Z604 HYDRAULIC HOSE

605 P1011Z605 HYDRAULIC CYLINDER

606 P1011Z606 CLEVIS

607 P1011Z607 LOCKNUT

608 P1011Z608 PIN

609 P1011Z609 SNAP RING

610 P1011Z610 SNAP RING

611 P1011Z611 SHAFT

G1011 7" x 12'' Bandsaw -29-

Page 31

MAIN BODY

-30- G1011 7" x 12'' Bandsaw

Page 32

SAW BOW ASSEMBLY

G1011 7" x 12'' Bandsaw -31-

Page 33

UPPER WHEEL ASSEMBLY

-32- G1011 7" x 12'' Bandsaw

Page 34

UPPER GUIDE ASSEMBLY

G1011 7" x 12'' Bandsaw -33-

Page 35

GEAR BOX & MOTOR

-34- G1011 7" x 12'' Bandsaw

Page 36

LOWER GUIDE ASSEMBLY

G1011 7" x 12'' Bandsaw -35-

Page 37

HYDRAULICS

-36- G1011 7" x 12'' Bandsaw

Page 38

NOTES

G1011 7" x 12'' Bandsaw -37-

Page 39

WARRANTY AND RETURNS

Grizzly Industrial, Inc. warrants every product it sells for a period of 1 year to the original purchaser from

the date of purchase. This warranty does not apply to defects due directly or indirectly to misuse, abuse,

negligence, accidents, repairs or alterations or lack of maintenance. This is Grizzly’s sole written warranty

and any and all warranties that may be implied by law, including any merchantability or fitness, for any par

ticular purpose, are hereby limited to the duration of this written warranty. We do not warrant or represent

that the merchandise complies with the provisions of any law or acts unless the manufacturer so warrants.

In no event shall Grizzly’s liability under this warranty exceed the purchase price paid for the product and

any legal actions brought against Grizzly shall be tried in the State of Washington, County of Whatcom.

We shall in no event be liable for death, injuries to persons or property or for incidental, contingent, special,

or consequential damages arising from the use of our products.

To take advantage of this warranty, contact us by mail or phone and give us all the details. We will then

issue you a “Return Number’’, which must be clearly posted on the outside as well as the inside of the

carton. We will not accept any item back without this number. Proof of purchase must accompany the

merchandise.

The manufacturers reserve the right to change specifications at any time because they constantly strive to

achieve better quality equipment. We make every effort to ensure that our products meet high quality and

durability standards and we hope you never need to use this warranty.

-

Please feel free to write or call us if you have any questions about the machine or the manual.

Thank you again for your business and continued support. We hope to serve you again soon.

-38- G1011 7" x 12'' Bandsaw

Page 40

WARRANTY CARD

NAME_______________________________________________ PHONE NUMBER___________________

STREET________________________________________________________________________________

CITY_______________________________STATE_________ZIP ___________________________________

MODEL#

The following information is given on a voluntary basis. This information will be used for marketing purposes to

help Grizzly develop better products. Your name will be included in our mailing list

companies. Of course, all information is strictly confidential.

1. How did you find out about us?

__Advertisement __Friend __Other____________________

__Catalog __Machinery Show

2. Do you think your machine represents good value? __YES __NO

3. Would you allow us to use your name as a reference for Grizzly customers in your area? __YES __NO

(Note: Your name will be used a maximum of three times.)

4. To which of the following publications do you subscribe? Check all that apply.

__Home Shop Machinist __Rifle Magazine Other ________________

__Projects in Metal __Hand Loader Magazine

__Modeltec __Precision Shooter

__Live Steam __RC Modeler

__Shotgun News __Model Airplane News

G1011 7" x 12'' Bandsaw INVOICE#_________________

only. It will not be sold to other

5. What is your annual household income?

__$20,000-$30,000 __$50,001-$60,000 __$80,000-$90,000

__$30,001-$40,000 __$60,001-$70,000 __+$90,000

__$40,001-$50,000 __$70,001-$80,000

6. To which age group do you belong?

__20-30 __31-40 __41-50 __51-60 __61-70 __71+

7. Which of the following machines or accessories do you own? Check all that apply.

__Engine Lathe __Abrasive Cutoff __Sheet Metal Machine

__Band Saw (Metal) __Arc Welder __Other _____________________________

__Band Saw (Wood) __Oxy/Ac. Outfit

__Milling Machine __Air Compressor

__Bench Grinder __Drill Press

8. How many of the machines you checked in Question 7 are Grizzly machines? ______________________

9. Which of the following tooling and accessories do you own? Check all that apply.

__Milling Vises __Collet Closer __Digital Readout

__Indexing Head __Taper Attachment __Tool Post Grinder

__Rotary Table __Boring Head __Other _________________________________________

10. In the space below, list three tools you would like Grizzly to carry.

_________________________ ____________________________ ____________________________

CUT ALONG DOTTED LINE

11. Of all the mail order metalworking company’s you have purchased from, how do you rate Grizzly in terms of

overall customer satisfaction?

__The BEST __Above Average __Average __Below Average __The Worst

12. Comments________________________________________________________________________________

_________________________________________________________________________________________

_________________________________________________________________________________________

_________________________________________________________________________________________

_________________________________________________________________________________________

Page 41

FOLD ALONG DOTTED LINE

FOLD ALONG DOTTED LINE

Place

Stamp

Here

GRIZZLY INDUSTRIAL, INC.

P.O. BOX 2069

BELLINGHAM, WA 98227-2069

Send a Grizzly Catalog to a friend:

Name_______________________________

Street_______________________________

City______________State______Zip______

TAPE ALONG EDGES--PLEASE DO NOT STAPLE

Loading...

Loading...