Page 1

CS Espresso Machine

CS1-110, CS1-220, CS2-220, CS3-220

Operator Manual

Grindmaster-Cecilware

4003 Collins Lane, Louisville, KY 40245 USA

Phone: 502.425.4776 Toll Free: 800.695.4500

Fax: 502.425.4664

Web: gmcw.com Email: info@gmcw.com

Safety Information..................2

Specifications...........................3

Overview..................................4

Installation...............................6

Programming ..........................6

Operation ................................7

Cleaning...................................8

Adjustments ..........................10

Draining.................................11

Troubleshooting....................11

Parts Diagram........................12

Wiring Diagram.....................26

Thank you for purchasing this quality espresso machine. For your safety and the safety of others, read all warnings

and the operator manual before installing or using the product. Properly instruct all operators. Keep training

records. For future reference, record serial number here:

Table of Contents

©2018 Grindmaster-Cecilware

Printed in Taiwan

0318 Form # CW-345-02

Part # 390-00119

Grindmaster-Cecilware provides the

industry’s BEST warranty. Visit gmcw.com

for warranty terms and conditions.

Model CS2-220

Activate your warranty now at

http://gmcw.com/warranty-registration

Page 2

GB Series Cecilware

®

2

For safe and proper operation the appliance must be placed in a stable, vertical position.

To reduce risk of serious burns or scalding, do not place hand or other body parts under dispenser while product

is brewing.

Always unplug unit from power supply before servicing.

Surfaces are hot and can cause burns. Use caution especially in the areas of the steam wand, hot water wand,

and brewing group.

Packaging material, including plastic bag and Styrofoam, can be dangerous and should be kept out of reach of

children.

To reduce risk of electrical shock, do not touch machine with wet hands or feet.

CAUTION

To reduce risk of electrical shock, do not remove or open cover. No user-serviceable parts inside. Repair should

be done by authorized service personnel only.

The appliance is not intended for outdoor use. Do not expose to rain or direct sunlight.

Do not clean with pressurized water or use in an area where pressurized water may be used.

Cleaning and maintenance shall be made only by properly trained persons with supervision.

This appliance is not intended for use by persons with reduced physical, sensory, or mental capabilities, or lack

of experience and knowledge, unless they have been given supervision or instruction concerning use of the

appliance by a person responsible for their safety.

Children should be supervised to ensure that they do not play with the appliance.

Do not alter or deform the power cord or plug in any way! Altering or deforming the plug may cause electrical

shock, damage unit, and will void warranty.

To reduce risk of explosion or fire, do not use near combustibles.

WARNING

Safety Information

2 Grindmaster

®

CS Espresso Machine

Important Safety Information

This is the safety alert symbol. It is used to alert you to potential personal injury hazards. Obey all safety messages

that follow this symbol to avoid possible injury or death.

For your safety and the safety of others, read all warnings and the operator manual before installing or using

the product.

DANGER: This term warns the user of imminent hazard that will result in serious injury or death.

WARNING: This term refers to a potential hazard or unsafe practice, which could result in serious injury or death.

CAUTION: This term refers to a potential hazard or unsafe practice, which could result in minor or moderate

injury.

NOTICE: This term refers to information that needs special attention or must be fully understood.

Observe machine voltage configuration. Do not apply improper voltage to machine or damage to machine may

occur. For use on individual dedicated branch circuit only. Do not use extension cord.

Follow national and local electrical codes.

Do not use the machine and turn off the power during water outage.

This equipment must be installed in compliance with applicable Federal, State, and/or Local plumbing codes

having jurisdiction. This product requires an approved back flow prevention water device, such as a double

check valve, to be installed between the machine and the water supply.

Please follow maintenance and cleaning instructions specified in this manual to ensure the best operation

efficiency of machine.

NOTICE

Page 3

CS Espresso Machine Grindmaster

®®

3

Rough-In Drawing

24.8”

(63 cm)

20.5”

(52 cm)

37.4”

(95.0 cm)

27.8”

(70.5 cm)

18.9”

(48 cm)

Specifications

Identification Label

Every machine has an identification label placed on the front of the machine as illustrated below. The label

includes information of model number, voltage, serial number, wattage, and its certificate. Do not remove this

label.

Figure A

Figure B

Page 4

4 Grindmaster

®

CS Espresso Machine

Specifications (continued)

Specification Table

Overview

CS1

CS2

Figure C

Figure D

Model Number of Heads Boiler Capacity Electrical

CS1-110 1 Group 6 quarts / 6 L 110/120V / 1Ph / 50/60 Hz / 18 A / 2 kW

CS1-220 1 Group 6 quarts / 6 L 220/240V / 1Ph / 50/60 Hz / 10 A / 2000 W

CS2-220 2 Groups 13 quarts / 6 L 220/240V / 1Ph / 50/60 Hz / 20 A / 4700 W

CS3-220 3 Groups 19 quarts / 18 L 220/240V / 1Ph / 50/60 Hz / 27 A / 6500 W

Side Clearance required - 4" (10.2 cm)

Rear Clearance required - 4" (10.2 cm) for water and electrical connections

Water connection size - 3/4" GHT, 1/2" water line required

Water pressure between 20 PSI and 120 PSI (138 kPa - 827 kPa). Use regulator if higher pressure.

Page 5

CS Espresso Machine Grindmaster

®®

5

Overview continued

CS3

Control Panel

Figure E

Figure F

Figure G

1 Espresso brewing unit control panel 11 Cup rack

4 Hot water wand 12 Sight glass (Boiler level check window)

5 Steam knob 14 Steam boilder pressure gauge

6 Steam wand 15 Pump pressure gauge

7 Main switch 17 Drain tray

8 Brewing group 18 Leg

9 Porta Filter 20 Hot water knob

Small single portion

Small double portion

Large single portion

Large double portion

Continuous Flow Button

Page 6

6 Grindmaster

®

CS Espresso Machine

Unpacking Instructions

Carefully unpack the machine and inspect immediately

for shipping damage. The packaging may contain

unattached parts. Your machine was shipped in a carton

designed to give it maximum protection in normal

handling. It was thoroughly inspected before leaving

the factory. In case of damage, contact the shipper, not

Grindmaster-Cecilware.

NOTICE:

This equipment must be installed in

compliance with applicable Federal, State, and/or Local

plumbing codes having jurisdiction. This product requires

an approved back flow prevention water device, such as

a double check valve, to be installed between the

appliance and the water supply. If a check valve type

backflow preventer is used for water supply protection,

a screen of at least 100 mesh (100 strands per 1.0 in [25

mm]) shall be installed immediately upstream. The screen

shall be accessible and removable for cleaning or

replacement. (Required for NSF approved water hookup.)

Incoming pressure should be greater than 20 psi and not

more than 90 psi.

• A filtering system is recommended to remove odors

and inhibit lime and scale build up in the unit.

• In areas with extremely hard water, a water softener

must be installed in order to prevent a malfunctioning

of the equipment and in order not to void the warranty.

Unsoftened water will decompose dissolvable minerals

and turn to limescale after boiling. The limescale will

reduce the machine’s thermal efficiency and machine’s

lifetime.

NOTICE: Do not use extension cords. Make sure that the

outlet the unit plugs into is grounded.

Check rating

marking on nameplate to be sure electric lines match

voltage, phase, and amperage requirements of

appliance.

Connections

1. When operating the machine for the first time or

replacing water softener and filtration system,

remove the water inlet tube and allow it to drain

for about one minute in order to get rid of

impurities from the water.

2. Connect a 1/2" diameter water line to the water

supply connection.

3. Open the water shut-off valve and check

connections for leaks. DO NOT over-tighten. Verify

water supply.

4. Connect 18mm diameter drain line to bottom,

center of machine.

5. Attach appropriate plug to cord. Power source

corresponds to the electrical rating shown on the

serial tag on unit. Plug the CS Espresso machine into

a dedicated power supply outlet.

6. Activate the Power Switch on front of unit (see

Figure H). The tank will fill in approximately 3-4

minutes.

7. Press continuous flow button on each control panel

(right button) to verify water flow.

8. After installing the machine, verify that during

water intake the steam boiler pressure gauge

indicator is within the green zone (1~1.4bar) and

the pump pressure gauge indicator, when using the

continuous flow button, is also within the green

zone (8~10bar). In case of need to adjust the

pressure, refer to Adjustments section.

Programming

Control Panel

There are two identical control panels on two-cup

models and three identical control panels on 3-cup

models. No default coffee output setting is provided.

Settings must be made manually during set-up. If you

are using a multi-cup machine, settings made on the

farthest right hand side control panel will serve as the

default for the others. Therefore, to set different values

for different cup compartments, begin set up from the

right and work your way to the left, to prevent the

previous setting from being overwritten.

WARNING: ELECTRIC SHOCK HAZARD!

Installation of this appliance should be performed by

qualified service personnel only. Improper installation

could result in electrocution.

CAUTION: BURN HAZARD

Steam wand, hot water wand, and brewing unit are

very hot. Use caution when operating unit to prevent

burns.

Figure H

CAUTION: BURN HAZARD

Unit is very hot. Use caution when turning on

programming switch to prevent burns.

Installation

Page 7

CS Espresso Machine Grindmaster

®®

7

1. Turn on the programming switch. (see Figure I)

2. The LED of buttons 1 - 4 on the control panel will

be lit, and the fifth LED will flicker. This indicates

programming mode for setting up the amount of

continuous output. (See Figure J)

3. Place measuring cup under the brewing group.

Hold down the first button until reaching the

required amount of water. Do not otherwise touch

the panel. Meanwhile the first button’s light will be

off, the other three buttons still lit, and the fifth

button flickers (see Figure K). It means the first

button is programmed. Continue programming

other buttons. Turn programming switch to OFF

when completed. Each time the programming

switch is turned ON, it will reset the buttons.

NOTICE: To avoid overheating, electric wires should

be kept untangled and free of obstructions. Don’t block

air intake or outlet vents on the machine. Never cover

or otherwise prevent the free flow of air across the cup

warmer.

NOTICE: Do not use cleansers, bleach liquids, powders

or any other substance containing chlorine. These

products promote corrosion and will pit the stainless

steel. USE OF THESE PRODUCTS WILL VOID THE

WARRANTY.

1. Place an appropriate quantity of ground coffee in

the Porta Filter and tamp the ground coffee firmly.

Clean all residual coffee from the rim and sides of

the filter. This is to ensure a good seal and full

pressure when brewing coffee, and prolong the

lifetime of the gasket. Attach the Porta Filter to the

machine by rotating until it locks in place.

2. Place cup(s) or glass(es) under spout(s).

3. Either press desired portion button or press and

hold the continuous flow button until desired

portion is dispensed. To stop flow at any time, press

and release continuous flow button. (See Figure L)

4. Move cup(s) or glass(es) to side and remove Porta

Filter. Dump grinds. Carefully hold Porta Filter near

group head and rinse using the continuous flow

button water. Use extreme caution to avoid burns.

Then, fit empty Porta Filter to the brewing group

to store and keep warm.

Steam Wand:

This can be used by turning the knob counterclockwise,

which allows for a varied amount of steam or by pulling

out the handle which will dispense the maximum

amount of steam.

Programming (continued) Operation

CAUTION: BURN HAZARD

Steam wand, hot water wand, and brewing unit are

very hot. Use caution when operating unit to prevent

burns.

Figure I

Figure J

Figure K

Figure L

Page 8

8 Grindmaster

®

CS Espresso Machine

Steam Wand (continued)

1. To drain condensate, ensure steam wand is pointed

toward the drain grid and pull handle out briefly to

dispense a small amount of steam.

2. Pour cold milk in a pitcher and place steam arm into

pitcher. Hold pitcher with one hand and turn on

steam, either by twisting to add a controlled

amount or pulling knob out to add steam at full

pressure.

3. Remove pitcher.

4. Wipe arm and nipple clean with soft cloth

moistened with sanitizer solution after each use.

After wiping, pull steam knob to release a steam

burst through the tube to remove any residual milk

remaining in the nozzle.

NOTICE: Remove the pitcher from the steam tube

after foaming milk. Failure to do so may draw liquid

from the pitcher into the steam tube, risking machine

component contamination.

Hot Water

1. Turn the hot water knob counterclockwise to obtain

hot water through hot water wand. Hot water

output will increase the further the hot water knob

is turned. Turn the knob clockwise to reduce/stop

hot water output.

2. You can also pull the knob straight out in order to

obtain hot water.

Cleaning

NOTICE: All sanitizing agents in the food zone must

comply with 21 CFR 178.1010. Sanitize all food

dispensing units periodically. All parts to be sanitized

must be cleaned first. Cleaning and sanitizing frequency

must follow state and local health department

regulations.

NOTICE: Wipe the accessories with a soft cloth or

specific detergent powder. Don’t use scrub sponge or

wire brushes.

After each brewing

1. Carefully hold Porta Filter near group head and

rinse Porta Filter using the continuous flow button

water. Water is hot - use extreme caution.

2. Wipe arm and nipple clean with soft cloth

moistened with sanitizer solution after each use.

After wiping, pull steam knob to release a steam

burst through the tube to remove any residual milk

remaining in the nozzle.

Daily

Exterior:

Wipe the machine exterior with soft, slight

dampened cloth daily before starting operations. If

necessary, a mild, non-corrosive cleaning agent may

be applied to the cloth.

NOTICE: Do not spray cleaning fluid directly on the

espresso machine to avoid corrosion or possible

electrical damage.

Back flushing:

1. Remove screw (E), shower screen (D), and plate (C)

from the group head (be careful, metal components

may be hot). (see Figure M)

2. Place the rubber disc in Porta Filter (see Figure N),

and apply about 2-3 grams of espresso machine

detergent/sanitizer on top of rubber disc. Attach

the Porta Filter to the group head and check for

tightness.

3. Press first and fifth buttons simultaneously to start

automatic back flushing function. The first and fifth

button will be off, and middle three buttons will be

lit. This auto back flushing system will complete 10

cleaning cycles. (see Figure O)

NOTE: If you want to discontinue the cleaning, press 3rd

button to stop.

Figure M

Operation (continued)

CAUTION: BURN HAZARD

Steam wand, hot water wand, and brewing unit are

very hot. Use caution when operating unit to prevent

burns.

Figure N

Page 9

CS Espresso Machine Grindmaster

®®

9

Cleaning (continued)

4. After automatic back flushing cycle is complete,

rinse Porta Filter and rubber disc with water from

the continuous flow button until water in Porta

Filter appears clean.

5. Replace rubber disc on Porta Filter, then place Porta

Filter on the group head and press first and fifth

buttons simultaneously to start automatic back

flushing function to rinse. The first and fifth button

will be off, and middle three buttons will be lit. This

auto back flushing system will complete 10 cleaning

cycles.

NOTE: If you want to discontinue the cleaning, press 3rd

button to stop.

6. Screw (E), shower screen (D), and plate (C) should

be cleaned and sanitized with the Porta Filter, steam

wand nipple and hot water wand sprayer.

Cleaning and sanitizing portafilter:

Notice: To avoid damage, do not immerse espresso

Porta Filter handle in water. Do not put group gasket

(item B from Figure M) in water or any liquid

detergent.

1. Disassemble Porta Filter. (see Figure P)

2. Remove sprayer from hot water wand.

3. Remove nipple from steam arm.

4. Add loose group head parts [screw (E), shower

screen (D), and plate(C) from Figure M].

5. Use brush to clean and wash parts in detergent or

espresso urn cleaner/sanitiser. DO NOT immerse

Porta Filter handle. (see Figure Q)

6. Rinse parts.

7. Prepare a sanitizing solution in accordance with

local health department regulations. You may also

refer to the US Food and Drug Administration

regulation 21 CFR 178.1010 “Sanitizing Solutions”

and US Environmental Protection Agency 40 CFR

18.940 “Tolerance exemptions for active and inert

ingredients for use in antimicrobial formulations

(Food-contact surface sanitizing solutions)”.

8. Follow the instructions provided with the sanitizing

agent.

9. Let all sanitized parts drain and dry naturally. DO

NOT WIPE THEM DRY.

10. Reassemble parts.

Drain Tray and Discharge Trough:

1. Remove and wash the drain tray after stopping use.

(see Figure R)

2. Wipe and remove sediments in the discharge

trough with a wet cloth and wash with hot water

to clear the discharge tube.

3. If water does not discharge properly, place a

Figure O

Figure P

CAUTION: BURN HAZARD

Steam wand, hot water wand, and brewing unit are

very hot. Use caution when cleaning unit to prevent

burns.

Handle

Do not immerse

Liquid

Figure Q

Figure R

Page 10

10 Grindmaster

®

CS Espresso Machine

Cleaning (continued)

teaspoon of detergent into the discharge trough

and flush with hot water to dissolve residual oils in

the tube.

4. Reassemble after the water tray has dried.

Adjustments

NOTICE: Please contact your authorized service

representative to undertake these procedures.

The rest of this manual contains information to aid the

service technician who is maintaining this equipment.

This section has information on performing common

service tasks.

Pump Pressure Adjustment

The pump pressure has been factory adjusted to 9 bar

(the recommended pressure). After machine starts up

and water refills, press continuous flow button and read

pressure on pressure gauge if the indicator is on green

zone (8-10 bar) as shown in Figure S.

If the pressure is not in the green zone, adjust pressure

as shown below:

1. Remove left side panel

2. Attach Porta Filter into the brewing group with

filled ground coffee.

3. Press continuous flow button. Turn screw clockwise

as shown in Figure T to increase pressure; turn

counterclockwise to reduce pressure.

Steam Boiler Pressure Calibration

Steam boiler pressure is controlled by pressure switch.

The pressure inside the boiler continues to rise as the

water is heated by the heating elements. Reducing

pressure will reduce temperature, while increasing

pressure will increase temperature. The steam boiler has

been factory adjusted to 1.2bar, (the recommended

pressure). Please check if your pressure on the pressure

switch is 1.2bar or on the green zone (1-1.4bar) (see

Figure U). if so, you don’t need to adjust the pressure.

In case there is a need to calibrate the pressure, please

follow below procedure for calibration:

NOTE: Please turn off the machine before undertaking

this operation.

1. Turn off machine.

2. Remove top cover of machine, and locate the

pressure switch on the upper right size.

3. Remove the yellow case from the pressure switch.

Use screw to adjust the pressure as shown in Figure

V. Turn screw clockwise to decrease pressure, or

counterclockwise to increase pressure. A complete

screw turn results in 0.1 bar variation.

Figure S

Figure T

Figure U

Figure V

WARNING: SHOCK HAZARD

Disconnect power before adjusting steam boiler

pressure.

CAUTION: BURN HAZARD

Steam wand, hot water wand, and brewing unit are

very hot. Use caution when adjusting unit to prevent

burns.

Page 11

CS Espresso Machine Grindmaster

®®

11

If espresso machine will not be used for an extended

period, will be stored, or transported, drain tank to

prolong life and prevent damage from freezing.

1. Turn off the machine, and release all the pressure

from boiler by turning on the steam knob(s).

2. After the steam is completely released and the

pressure on steam boiler pressure gauge reads “0”,

remove drain tray and locate drain valve under

drain tray. Turn on drain valve to drain water out of

boiler. Drain valve is on when it is parallel to pipe.

NOTE: Please DO NOT turn off the steam knob after the

steam is released for storage. Keep the steam knob on.

When you re-start the machine, do not turn off the

steam knob until you see water drop from the steam

wand. This is to balance the boiler pressure.

3. Turn off drain valve when water stops flowing into

waste cup. Drain valve is off when it is

perpendicular to pipe.

CAUTION: BURN HAZARD

Dispenser surfaces and water inside dispenser are very

hot. Use caution when draining unit to prevent burns.

CAUTION: BURN HAZARD

Never turn on drain valve when there is pressure in

the boiler.

Troubleshooting

Before you call for help, please read the following:

WARNING: To reduce the risk of electrical shock, unplug the dispenser power cord before repairing or

replacing any internal components of the unit. Before any attempt to replace a component, be sure to check all

electrical connections for proper contact. Only a qualified service technician should perform electrical and

mechanical adjustments or repairs.

Note: Wait at least 3 seconds to restart the machine after turning it off to ensure previous error stored in memory

is cleared.

If you need help, call Grindmaster-Cecilware Technical Service Department, (502) 425-4776 or (800) 695-4500 (USA

& Canada only) (Monday through Friday 8 AM - 6 PM EST). Please have the model and serial number ready so

that accurate information can be given.

Prior authorization must be obtained from Grindmaster-Cecilware for all warranty claims.

Grindmaster-Cecilware provides the industry’s BEST warranty. Visit our website at gmcw.com for

warranty terms and conditions.

INDICATION PROBABLE CAUSE SOLUTION

All lights on control •

Aer two minutes of •Water level probe not

•

Make sure that the water

panel turn on water input, indicator

funconing properly.

valve is turned on and

still does not show a there is water flowing

rise in machine water into machine.

level. It will take more •

Water intake solenoid is

• Turn off machine. Restart

than two minutes to

out of order.

after 3 seconds.

replenish water when •

Input water flow has been

• Turn water supply on.

the machine is used

interrupted.

for the first time.

All lights on ONE • No water output • Coffee grounds are too • Adjust fineness of coffee

control panel flash from brewing group. fine. grinds.

• Brewing for a long • Water intake solenoid is • Turn off machine. Restart

time without reaching out of order. after 3 seconds.

setup value. • Flow meter is out of order. • Press any key to eliminate

the breakdown signal,

and notify qualified service

technician.

Draining

Page 12

12 Grindmaster

®

CS Espresso Machine

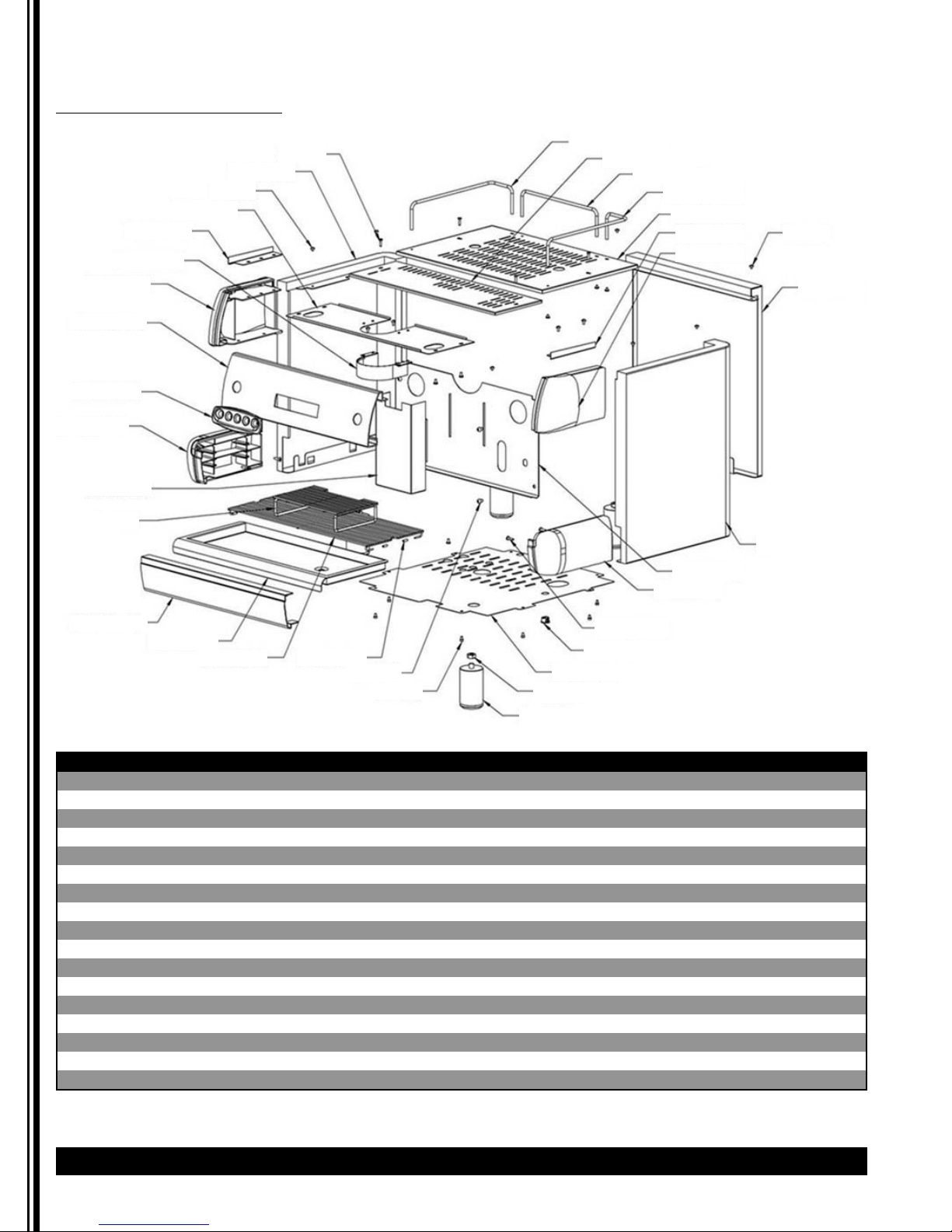

Parts Diagram

Body Parts CS1-110, CS1-220

Item Part # Descripon Item Part # Descripon

1 SCREW M4*16 18 SCREW M4*5 (SUS)

2 LEFT SIDE PANEL(BLACK) 19 410-00482 FOOT

3 SCREW M4*5 20 NUT M10

4 CABLE COVER 21 BOTTOM METAL COVER (ETL)

5 TOP RIGHT SIDE PANEL SUPPORT 22 CABLE PROTECTION RING (ETL)

6 SURROUND STEEL 23 SCREW ( 4mm*15 )

7 TOP LEFT SIDE PANEL 24 DOWN RIGHT SIDE PANEL

8 BASE FRONT PANEL 25 S.STEEL BOILER COVER

9 410-00483 OPERATE FACEPLATE 26 RIGHT SIDE PANEL (BLACK)

10 DOWN LEFT SIDE PANEL 27 BACK PANEL(BLACK)

11 VALVE COVER 28 TOP RIGHT SIDE PANEL

12 410-00484 CUP RACK 29 TOP LEFT SIDE PANEL SUPPORT

13 BASE FRONT PANEL 30 UPPER STAINLESS STEEL GRILL

14 410-00485 DRAIN PAN 31 CUP FENCE-RIGHT

15 410-00486 LOWER DRAIN PAN 32 CUP FENCE -REAR

16 DRAIN TUBE 5/8" HIGH TEMP 33 GROUP COVER

17 SCREW M6*8 34 CUP FENCE-LEFT

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

26

25

24

23

22

21

20

19

34

33

32

31

30

29

28

3

27

Page 13

CS Espresso Machine Grindmaster

®®

13

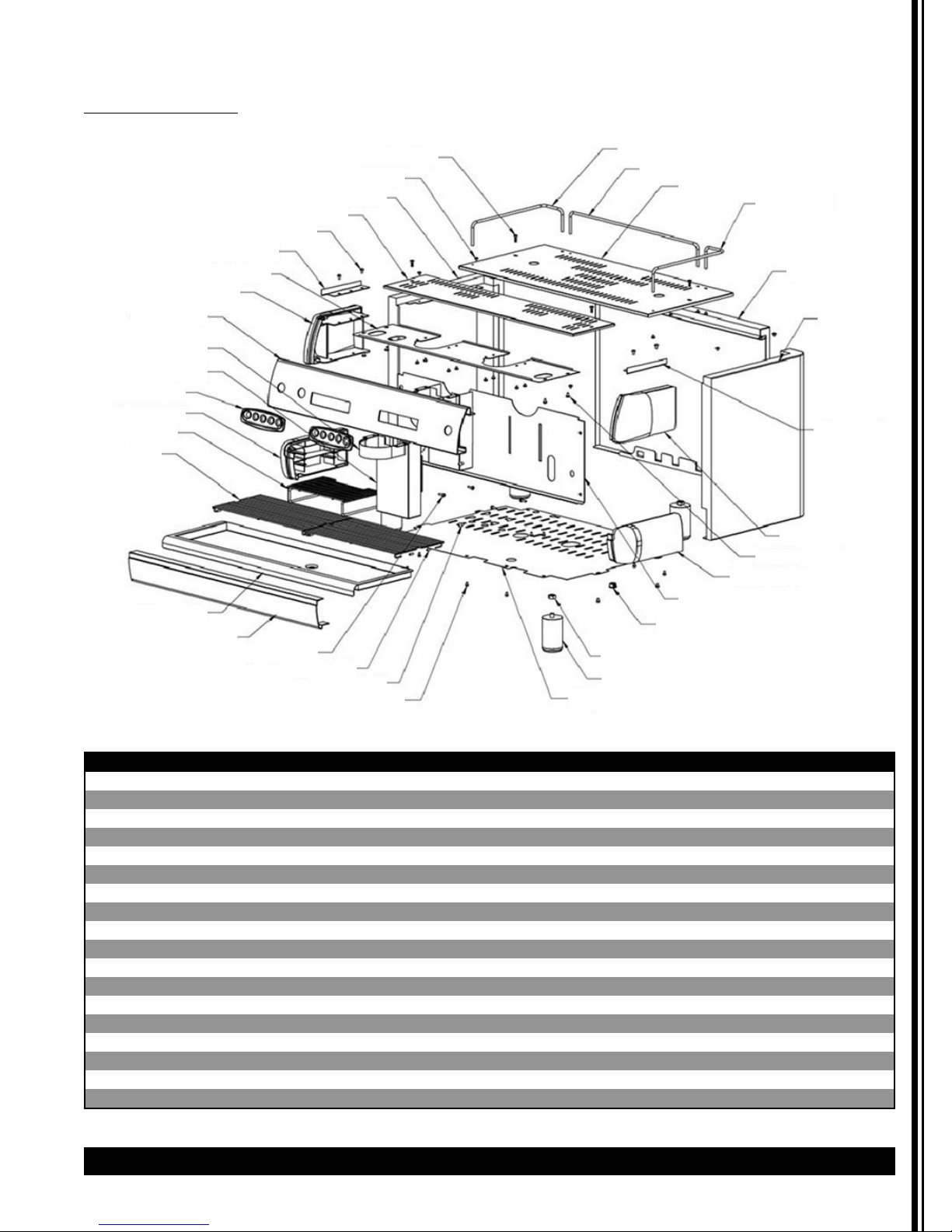

Parts Diagram (continued)

Body Parts CS2-220

Item Part # Descripon Item Part # Descripon

1 SCREW M4*16 19 DRAIN TUBE 5/8" HIGH TEMP

2 SCREW M4*5 20 SCREW M6*8

3 LEFT SIDE PANEL(BLACK) 21 SCREW M4*6

4 GROUP COVER 22 BOTTOM METAL COVER (ETL)

5 SCREW M4*8 (SUS) 23 410-00482 FOOT

6 TOP RIGHT SIDE PANEL SUPPORT 24 NUT M10

7 CABLE COVER 25 CABLE PROTECTION RING (ETL)

8 TOP LEFT SIDE PANEL 26 S.STEEL BOILER COVER

9 OPERATION PANEL 27 DOWN RIGHT SIDE PANEL

10 SURROUND STEEL 28 TOP RIGHT SIDE PANEL

11 VALVE COVER 29 TOP LEFT SIDE PANEL SUPPORT

12 410-00483 OPERATE FACEPLATE 30 RIGHT SIDE PANEL (BLACK)

13 DOWN LEFT SIDE PANEL 31 BACK PANEL(BLACK)

14 410-00484 CUP RACK 32 CUP FENCE-RIGHT

15 410-00488 LOWER DRAIN PAN 33 UPPER STAINLESS STEEL GRILL

16 410-00487 DRAIN PAN 34 CUP FENCE-REAR

17 BASE SURROUND FRONT 35 CUP FENCE-LEFT

18 SCREW ( 4mm*15 )

1

35

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

34

33

32

31

30

29

28

5

27

26

25

24

23

22

Page 14

14 Grindmaster

®

CS Espresso Machine

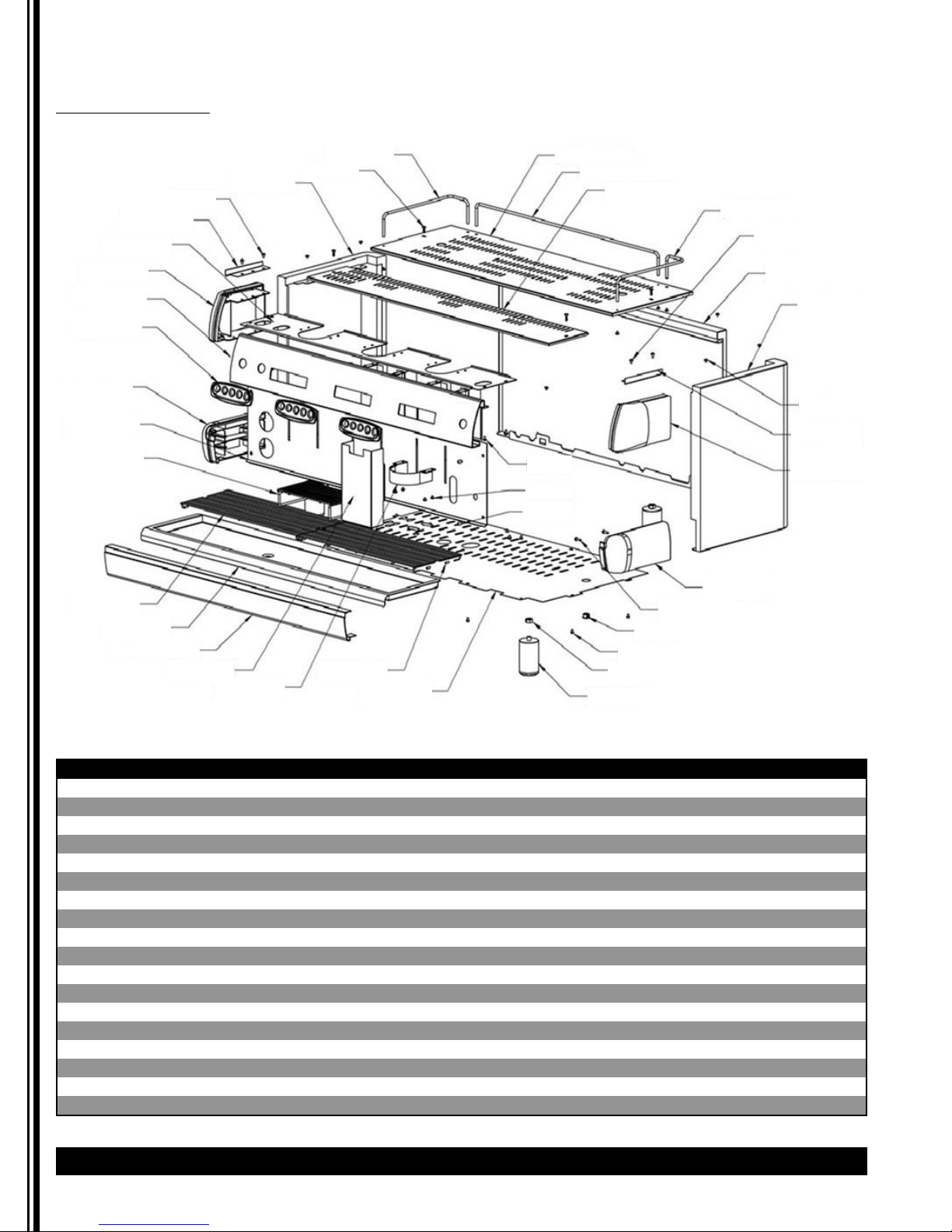

Parts Diagram (continued)

Body Parts CS3-220

Item Part # Descripon Item Part # Descripon

1 CUP FENCE-LEFT 19 BOTTOM METAL COVER (ETL)

2 SCREW M4*16 20 410-00482 FOOT

3 LEFT SIDE PANEL(BLACK) 21 NUT M10

4 SCREW M4*8 (SUS) 22 SCREW M4*6

5 TOP RIGHT SIDE PANEL SUPPORT 23 CABLE PROTECTION RING (ETL)

6 CABLE COVER 24 SCREW ( 4mm*15 )

7 TOP LEFT SIDE PANEL 25 DOWN RIGHT SIDE PANEL

8 OPERATION PANEL 26 SCREW M6*8

9 410-00483 OPERATE FACEPLATE 27 SCREW M4*5

10 DOWN LEFT SIDE PANEL 29 TOP RIGHT SIDE PANEL

11 S.STEEL BOILER COVER 30 TOP LEFT SIDE PANEL SUPPORT

12 410-00484 CUP RACK 30 RIGHT SIDE PANEL (BLACK)

13 410-00490 LOWER DRAIN PAN 31 BACK PANEL(BLACK)

14 410-00489 DRAIN PAN 32 CUP FENCE-RIGHT

15 BASE SURROUND FRONT 33 GROUP COVER

16 VALVE COVER 34 CUP FENCE-REAR

17 SURROUND STEEL 35 UPPER STAINLESS STEEL GRILL

18 DRAIN TUBE 5/8" HIGH TEMP

1

35

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

34

33

32

4

31

30

27

29

28

25

24

23

22

21

20

4

27

26

Page 15

CS Espresso Machine Grindmaster

®®

15

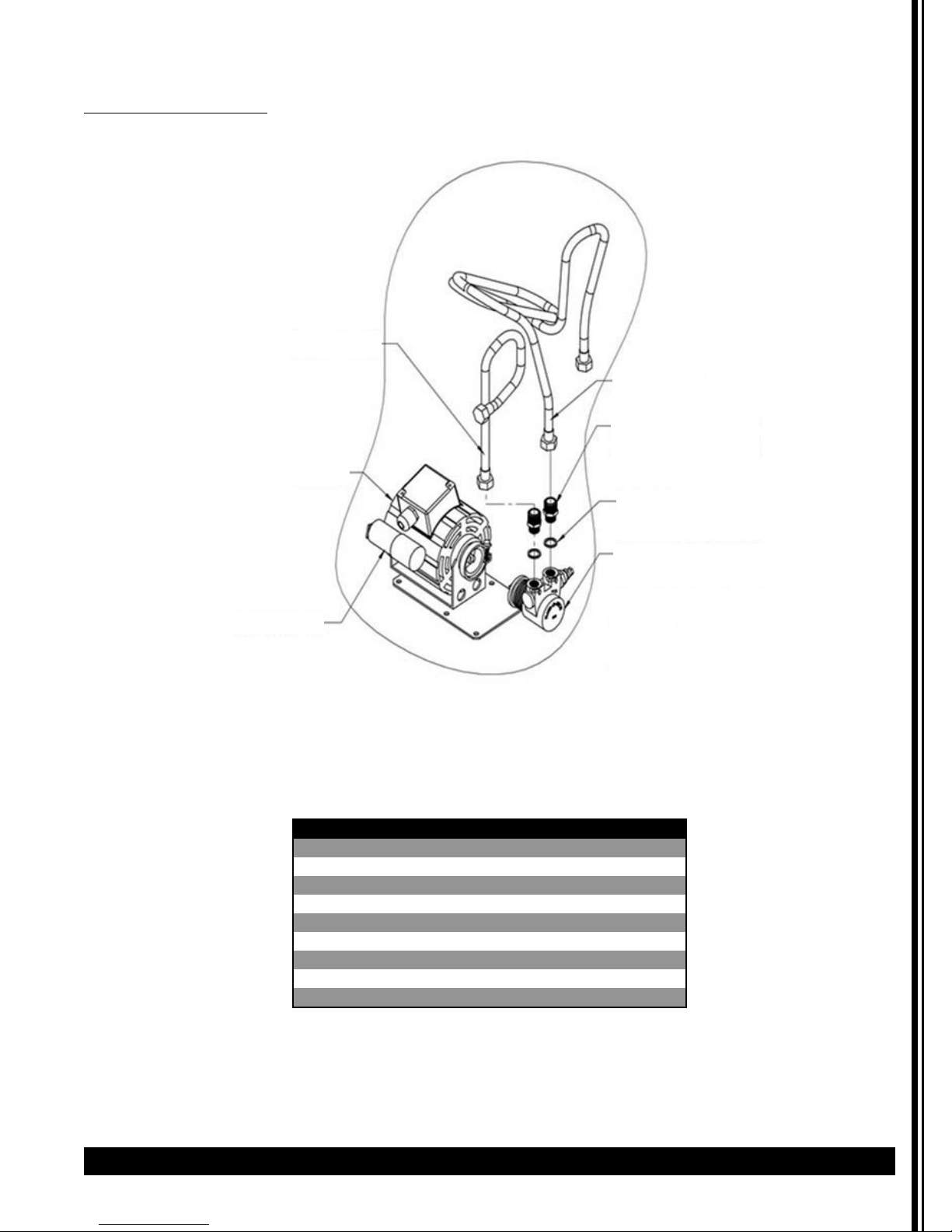

Parts Diagram (continued)

Motor Pump Assembly

Item Part # Descripon

1 S.T. STEEL WIRE PIPE (600mm)

2 01329L MOTOR 220-240V 50/60Hz 1.6A (ETL)

3 410-00491 CAPACITOR 10μF

4 01330L PUMP FOR CS1-220

4 PUMP FOR CS2 & CS3

4 PUMP FOR CS1-110

5 01312L PIPE GASKET TEFLON

6 NPT FITTING NPT3/8"*NPT1/2"

7 S.T. STEEL WIRE PIPE (2400mm)

1

7

6

5

4

2

3

Page 16

16 Grindmaster

®

CS Espresso Machine

Parts Diagram (continued)

Boiler Hydraulic Circuit CS1

Item Part # Descripon Item Part # Descripon

1 01320L LEVEL PROBE ASSEMBLY 27 WATER LEVEL LOWER TUBE

2 01319L ANTI-EDDY VALVE V.A.R. 28 01318L SI-GASKET ELEMENT

3 01322L VALVE GASKET BRASS 29 01316L HEATING ELEMENT 2000W�CE�

4 01371L SAFETY VALVE 29 410-00494 HEATING ELEMENT 1500W�110V)

5 HEAT EXCHANGER OUTLET TUBE 30 410-00495 HEX SCREW (M10*16)

6 WATER LEVEL UPPER TUBE 31 ELBOW BRASS 5/16*1/4

7 HEAT EXCHANGER RETURN TUBE 32 BRASS PLUG

8 STEAM PRESSURE GAUGE TUBE 33 AUT.WATER REFILL TUBE REAR

9 BRASS CONNECTOR 1/2-20UNF*PT1/4 34 PRESSURE GAUGE COPPER TUBE

10 HOT WATER OUTLET TUBE REAR 35 STEAM OUTLET TUBE FRONT RIGHT

11 BOILER 36 01321L VALVE GASKET BRASS

12 AUT.WATER REFILL TUBE 37 BRASS CONNECTOR 1/4"X1/8"

13 HEAT EXCHANGER INLET TUBE 38 01324L SOL. VALVE WATER REFILL ASSY 208~240V 60Hz

14 BRASS FITTING PS/1/4*PS1/4*L33.5 39 BRASS CONNECTOR PT1/4*1/2-20UNF*1/2-20UNF

15 BRASS FITTING PS/1/4*PS1/4*L42 40 BRASS CONNECTOR

16 01325L FLOWMETER DOSER 41 SPHERICAL BRONZE CONICAL FILTER

17 FLOW METER GAUGE 42 01323L NBR O RING

18 ELBOW BRASS PT3/8*3/8 43 LEVEL PROBE BASE

19 FLOWMETER INLET TUBE 44 410-00502 PROBE FIXED SUPPORT

20 410-00492 S.C.N.R.DOSER VALVE 1/2*1/2*1/2 45 PROBE FIXED BOLT

21 BOILER DRAIN TUBE FRONT 46 410-00504 PROBE ( SUS304 /3mm L132 )

22 EXPANSION DRAIN TUBE 47 410-00496 BRASS NUT

23 NUT M8 48 410-00497 TEFLON WASHER

24 SPRING WASHER M8 49 410-00498 SI O-RING

25 410-00493 PRESSURE RELEASE TAP BULK PS1/4xPS1/4 50 410-00499 SHAFT

26 BOILER DRAINTUBE REAR 51 410-00500 ANTI-EDDY VALVE BASE

1

42

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

19

20

18

21

22

40

39

38

37

36

35

34

33

32

31

30

29

28

27

26

25

24

23

31

43

44

45

46

1

47

48

49

50

51

2

41

Page 17

CS Espresso Machine Grindmaster

®®

17

Parts Diagram (continued)

Boiler Hydraulic Circuit CS2

Item Part # Descripon Item Part # Descripon

1 01321L VALVE GASKET BRASS 28 WATER LEVEL LOWER TUBE

2 01319L ANTI-EDDY VALVE V.A.R. 29 01318L SI-GASKET ELEMENT

3 01322L VALVE GASKET BRASS 30 01315L HEATING ELEMENT 4000W (CE)

4 HEAT EXCHANGER OUTLET TUBE LEFT 31 410-00495 HEX SCREW (M10*16)

5 HOT WATER CONDUCT TUBE IN BOILER 32 AUT.WATER REFILL TUBE REAR

6 STEAM OUTLET TUBE FRONT RIGHT 33 WATER LEVEL UPPER TUBE

7 HOT WATER OUTLET TUBE REAR 34 PRESSURE GAUGE COPPER TUBE

8 STEAM OUTLET TUBE FRONT LEFT 35

BRASS CONNCTR PT1/4*1/2-20UNF*1/2-

9 BOILER 36 BRASS CONNECTOR 1/4"X1/8"

10 AUT.WATER REFILL TUBE 37 01324L

SOL. VALVE WATER REFILL ASSY 208~240V 60Hz

11 HEAT EXCHANGER RETURN TUBE LEFT 38 BRASS CONNECTOR

12 HEAT EXCHANGER RETURN TUBE RIGHT 39 SPHERICAL BRONZE CONICAL FILTER

13 ELBOW BRASS PT3/8*3/8 40 01323L NBR O RING

14 BRASS FITTING PS/1/4*PS1/4*L33.5 41 HEAT EXCHANGER OUTLET TUBE RIGHT

15 BRASS FITTING PS/1/4*PS1/4*L42 42 01371L SAFETY VALVE

16 01325L FLOWMETER DOSER 43 01320L LEVEL PROBE ASSEMBLY

17 FLOW METER GAUGE 44 410-00496 BRASS NUT

18 EXPANSION DRAIN TUBE 45 410-00497 TEFLON WASHER

19 410-00492 S.C.N.R.DOSER VALVE 1/2*1/2*1/2 46 410-00498 SI O-RING

20 FLOWMETER INLET TUBE 47 410-00499 SHAFT

21 HEAT EXCHANGER INLET TUBE 48 410-00500 ANTI-EDDY VALVE BASE

22 BOILER DRAIN TUBE FRONT 49 410-00504 PROBE ( SUS304 /3mm L132 )

23 410-00493

PRESSURE RELEASE TAP BULK UNIT PS1/4xPS1/4

50 PROBE FIXED BOLT

24 BOILER DRAINTUBE REAR 51 410-00502 PROBE FIXED SUPPORT

25 ELBOW BRASS 5/16*1/4 52 LEVEL PROBE BASE

26 NUT M8 53 BRASS CONNECTOR 1/2-20UNF*PT1/4

27 SPRING WASHER M8

1

43

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

42

3

41

40

39

38

37

36

35

34

33

32

44

45

46

47

48

2

31

30

29

28

27

26

25

24

43

49

50

51

52

23

22

53

Page 18

18 Grindmaster

®

CS Espresso Machine

Parts Diagram (continued)

Boiler Hydraulic Circuit CS3

1

48

6

50

2

49

3

4

5

7

8

9

10

11

12

13

14

15

16

17

18

19

22

23

24

25

26

27

20

21

47

46

45

44

43

42

33

41

40

39

38

28

29

30

31

32

33

34

37

36

35

55

56

57

58

59

44

51

52

53

54

47

Page 19

CS Espresso Machine Grindmaster

®®

19

Parts Diagram (continued)

Boiler Hydraulic Circuit CS3

Item Part # Descripon Item Part # Descripon

2 GROUP FILTER ST.STEEL D13.8*d10.5*11.5 32 SPRING WASHER M8

3 01323L NBR O RING 33 ELBOW BRASS 5/16*1/4

4 AUT. WATER REFILL REDUCTION 34 WATER LEVEL LOWER TUBE

6 HOT WATER OUTLET TUBE REAR 35 410-00495 HEX SCREW (M10*16)

7 SHAFT 36 01317L HEATING ELEMENT 6000W (CE)

8 BRASS CONNECTOR 37 01318L SI-GASKET ELEMENT

9 STEAM OUTLET TUBE FRONT LEFT 38 AUT.WATER REFILL TUBE REAR

10 01322L VALVE GASKET BRASS 39

WATER LEVEL UPPER TUBE

11 HOT WATER CONDUCT TUBE IN BOILER 40 BOILER

12 STEAM PRESSURE GAUGE TUBE 41

HEAT EXCHANGER OUTLET TUBE RIGHT

13 HEAT EXCHANGER RETURN TUBE MIDDLE 43 HEAT EXCHANGER OUTLET TUBE MIDDLE

14 HEAT EXCHANGER RETURN TUBE RIGHT 44 01319L ANTI-EDDY VALVE V.A.R.

15 AUT.WATER REFILL TUBE MIDDLE 45 HEAT EXCHANGER OUTLET TUBE LEFT

16 BRASS FITTING PS/1/4*PS1/4*L33.5 46 01321L VALVE GASKET BRASS

17 BRASS FITTING PS/1/4*PS1/4*L42 47 01320L LEVEL PROBE ASSEMBLY

18 01325L FLOWMETER DOSER 48 01371L SAFETY VALVE

19 FLOW METER GAUGE 49 BRASS CONNECTOR 1/4"X1/8"

20 ELBOW BRASS PT3/8*3/8 50 01324L

SOL. VALVE WATER REFILL ASSY 208~240V 60Hz

21 HEAT EXCHANGER INLET TUBE LEFT 51 LEVEL PROBE BASE

22 EXPANSION DRAIN TUBE 52 410-00502 PROBE FIXED SUPPORT

23 410-00492 S.C.N.R.DOSER VALVE 1/2*1/2*1/2 53 PROBE FIXED BOLT

24 BOILER DRAIN TUBE FRONT 54 410-00504 PROBE ( SUS304 /3mm L132 )

25 410-00493

PRESSURE RELEASE TAP BULK UNIT PS1/4xPS1/4

55 410-00496 BRASS NUT

26 HEAT EXCHANGER INLET TUBE MIDDLE 56 410-00497 TEFLON WASHER

27 FLOWMETER INLET TUBE 57 410-00498 SI O-RING

28 HEAT EXCHANGER RETURN TUBE LEFT 58 410-00499

BRASS CONNECTOR PT1/4*1/2-20UNF*1/2-20UNF

29 HEAT EXCHANGER INLET TUBE RIGHT 59 410-00500 ANTI-EDDY VALVE BASE

30 BOILER DRAINTUBE REAR WATER REFILL SET

31 NUT M8 STEAM OUTLET TUBE FRONT RIGHT

Page 20

20 Grindmaster

®

CS Espresso Machine

Parts Diagram (continued)

Water Level Assembly

1

8

2

3

4

5

6

7

2

1

8

13

12

11

10

4

3

9

Item Part # Descripon

1 01375L HEX SCREW (M8*10)

2 01305L

SIGHT GLASS RUBBER GASKET�10.69*ψ 3.5�

3 01306L COPPER SEAL

4 01372L BRASS NUT

5 01373L LEVEL-INDICATING BALL

6 01307L SIGHT GLASS

7 PC PANNEL

8 01374L WASHER (M8*3t)

9 01376L LAVEL CONNECTOR (LOWER)

11 WATER LEVEL ASSEMBLY

12 SIGHT GLASS REAR COVER

13 01370L LEVEL CONNECTOR (UPPER)

LEVEL LABEL

Page 21

CS Espresso Machine Grindmaster

®®

21

Parts Diagram (continued)

Distribution Group Assembly

Item Part # Descripon Item Part # Descripon

1 DISTRIBUTION GROUP CAP 14 410-00506 HEX SCREW M4*12

2 TEFLON GASKET D22*d18*2.0 15 01381L GROUP JET D0.8

3 01382L GROUP FILTER ST.STEEL D13.8*d10.5*11.5 15 01301L

PAEKER GROUP SOLENOID VALVE COIL 208~240V

5 STAINLESS STEEL SCREW M5*10 15 410-00507

PAEKER GROUP SOLENOID VALVE COIL 110V

6 DISTRIBUTION GROUP BODY 16 410-00508 DISTRIBUTION GROUP ASSEMBLY

7 01304A SI_O-RING d47*3.5t 17 BRASS PLUG

8 CHROMED CLAMPING RING 18 WATER INLET CONNECTOR

9 01300L FILTER GROUP GASKET 19 410-00510 GROUP WASHER

10 410-00501 GROUP PLATE 20 PT1/4x5/8-18UNF L_FITTING

11 410-00503 GROUP SHOWER SCREEN 21 WATER RECYCLE CONNECTOR

12 01302L STAINLESS STEEL FLATHEAD SCREW M5*15 22 410-00509 DISTRIBUTION GROUP ASSEMBLY

13 410-00505 PRESSURE RELEASE DRAIN TUBE

1

18

2

3

4

5

6

5

7

8

9

10

11

12

19

18

17

17

16

15

14

13

13

14

15

17

19

17

22

20

21

1

2

3

4

5

6

5

7

8

9

10

11

12

CS1-110, CS1-220

CS2-220, CS3-220

Page 22

22 Grindmaster

®

CS Espresso Machine

Parts Diagram (continued)

Water and Steam Assembly

Item Part # Descripon Item Part # Descripon

1 410-00511 TAP BODY 19 EXTERNAL SPRAYER

2 BRASS NUT 20 SILICON GASKET

3 410-00512 WATER/STEAM TAP UNIT 21 HOT WATER SPRINKLE-NOZZLE (UPPER)

4 01336L AS�KNOB 23 HOT WATER TUBE KIT

5 01311L R STEEL CIRCLIP 24 NUT PIPE STEAM FOR SPRING

6 01337L WATER STEAM TAP ASSEMBLY 25 01312L PIPE GASKET TEFLON

7 01333L STEAM KNOB CAP 26 STEAM TAP SPRING

8 01332L HOT WATER KNOB CAP 27 01379L STEAM TAP WASHER

9 01308L SI-GASKET 28 01313L O-RING

10 STEAM HOT WATER A VALVE SHAFT 29 410-00513 KIT HOT WATER TUBE

11 01310L COPPER SEAL 31 EXTERNAL SPRAYER

12 STEAM TAP SPRING 32 410-00514 STEAM TUBE

13 TAP CONNECTOR 33 410-00515 STEAM TUBE KIT

14 01335L CHROMED TAP SHAFT 34 410-00516 ANTISCORCHING CLIP

15 WASHER (SUS 304) 35 O-RING

17 TIGHTING GASKET 36 STEAM SPRAYER

18 HOT WATER SPRINKLE-NOZZLE (UNDER)

6

13

5

17

16

3

15

22

21

20

19

18

14

12

11

10

9

3

2

1

4

23

24

25

26

31

30

29

28

27

36

32

24

28

27

26

25

33

34

7

8

35

Page 23

CS Espresso Machine Grindmaster

®®

23

Parts Diagram (continued)

Portafilter Assembly

Item Part # Descripon

1 01356 2 CUP STAINLESS STEEL FILTER

2 01352 FILTER CLAMP SPRING D1.4

3 01350 FILTER SUPPORT

4 01358 2 CUP BRASS SPOUT

5 01355 2 CUP PORTA FILTER ASSEMBLY

6 01346 FILTER HOLDER KNOB CAP

7 01354 FILTER HOLDER BACK LID

8 01348 1 CUP STAINLESS STEEL FILTER

9 01351 1 CUP BRASS SPOUT

10 01347 1 CUP PORTA FILTER ASSEMBLY

11 01346 SILICA GEL WASHER

4

5

3

2

1

6

7

8

2

3

9

10

6

11

Page 24

24 Grindmaster

®

CS Espresso Machine

Parts Diagram (continued)

Electrical System Assembly

2

1

4

5

6

8

9

10

11

12

13

3

14

27

26

25

23

22

24

21

20

19

18

9

17

16

15

7

Item Part # Descripon Item Part # Descripon

1 LEVEL PROBE CABLE 15 FLOWMETER GAUGE CABLE FOR CS2

2 RADIATOR (ETL) 15 FLOWMETER GAUGE CABLE FOR CS3

3 410-00517

SOLID STATE RELAY 25A GN84131011 /CS1

15 FLOWMETER GAUGE CABLE FOR CS1

3 410-00518

SOLID STATE RELAY 50A GN84137021 /CS2 CS3

16 MAIN SWITCH COVER

3 410-00519

SOLID STATE RELAY 25A GN84131011 /N1 110V

17 BAND/CS3

4 410-00520 FAN FOR SSR (ETL) 17 BAND/CS1 CS2

5 SERIES CABLE PCB<->PANEL 18 SCREW ST3.5*19

6 SERIES CABLE PANEL<->PANEL 19

CONTROL BOX WITHOUT IC BOARD (UP COVER)

7 OPERATE BOX 20 SCREW M4*20

8 KEY BOARD FOR COFFEE 21 410-00526 CONTROL PC-MAINBOARD

9 SCREW 3*8 21 410-00527 110V CONTROL PC-MAINBOARD

10 CONTROL PC-MAINBOARD 22 410-00528 CONTROL BOX WITH IC BOARD

11 410-00521

TIMER / TOUCH PAD(CONTROL PC-MAINBOARD)

23

CONTROL BOX WITHOUT IC BOARD (LOWER COVER)

12 MAIN SWITCH HAND GRIP (CE/AU) 24 CABLE UNIT / CS1

13

MAIN SWITCH HAND GRIP LABEL PLATE 0-1 (ETL)

24 CABLE UNIT / CS3

13

MAIN SWITCH HAND GRIP LABEL PLATE 0-1-2 ( CE )

24 CABLE UNIT / CS2

14 410-00522 MAIN SWITCH ASSEMBLY /N1 N2(ETL)(32A) 25 01338L TEMP. PROTECTION FUSE (ETL)

14 410-00523 MAIN SWITCH ASSEMBLY /N3 (ETL)(63A) 26 01326L

SI_501 CE PRESSURE SWITCH 220V AC 7KW 30A

410-00524 MAIN SWITCH ASSEMBLY FOR CS3 27 410-00529 SELECT SWITCH

410-00525 MAIN SWITCH ASSEMBLY FOR CS1 CS2

Page 25

CS Espresso Machine Grindmaster

®®

25

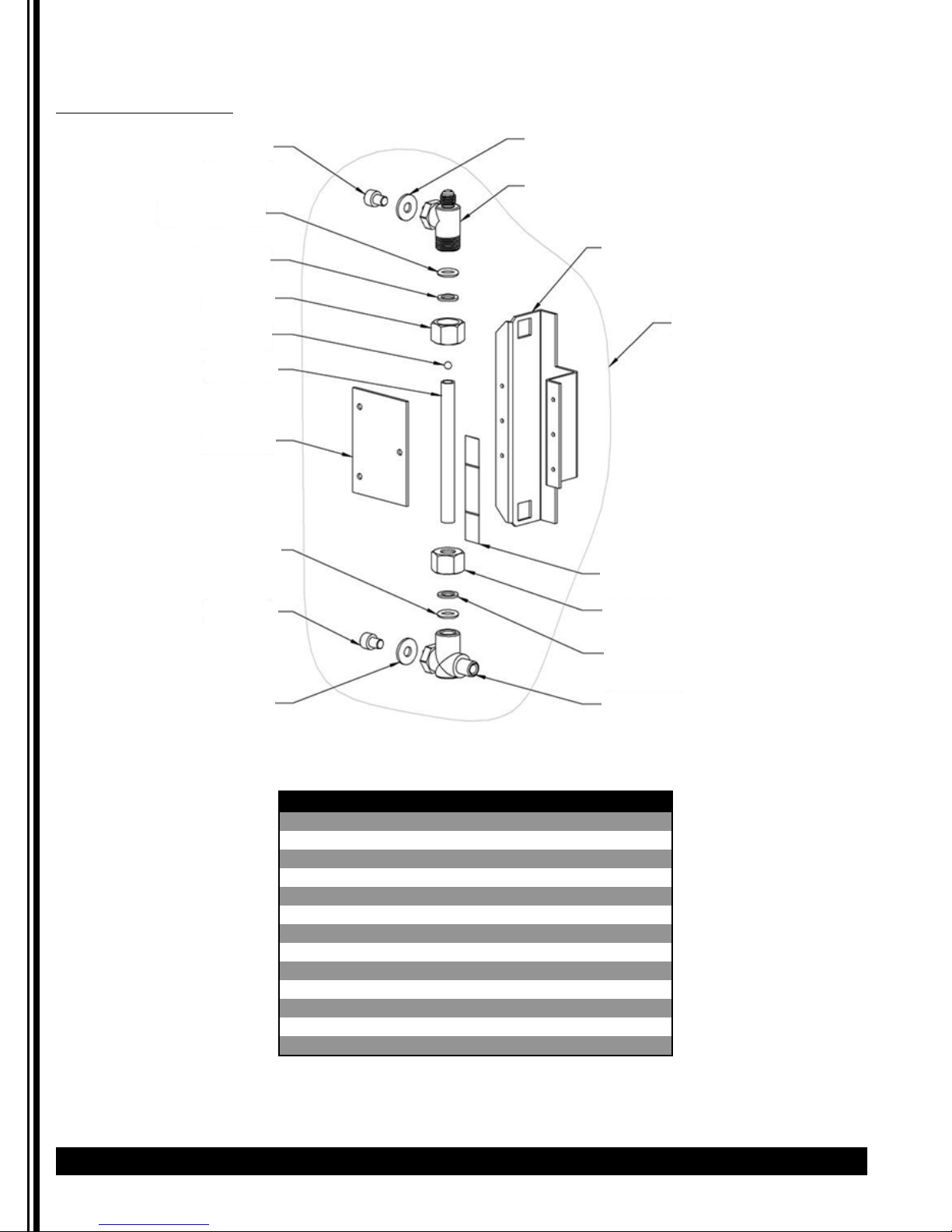

Parts Diagram (continued)

Other Components

Item Part # Descripon

1 SPRING WASHER M8

2 SCREW M8*25

3 410-00530 PRESSURE GAUGE 0 � 20 BAR

4 410-00531 PRESSURE GAUGE 0 ~ 6 BAR

5 ANTI FOOT VIBRATION

6 SPRING WASHER M6

7 NUT M6

8 410-00532 DRAIN BASIN

9 410-00533 SPRING WASHER M10

10 410-00534 NUT M10

1

8

5

2

3

4

6

7

9

10

Page 26

26 Grindmaster

®

CS Espresso Machine

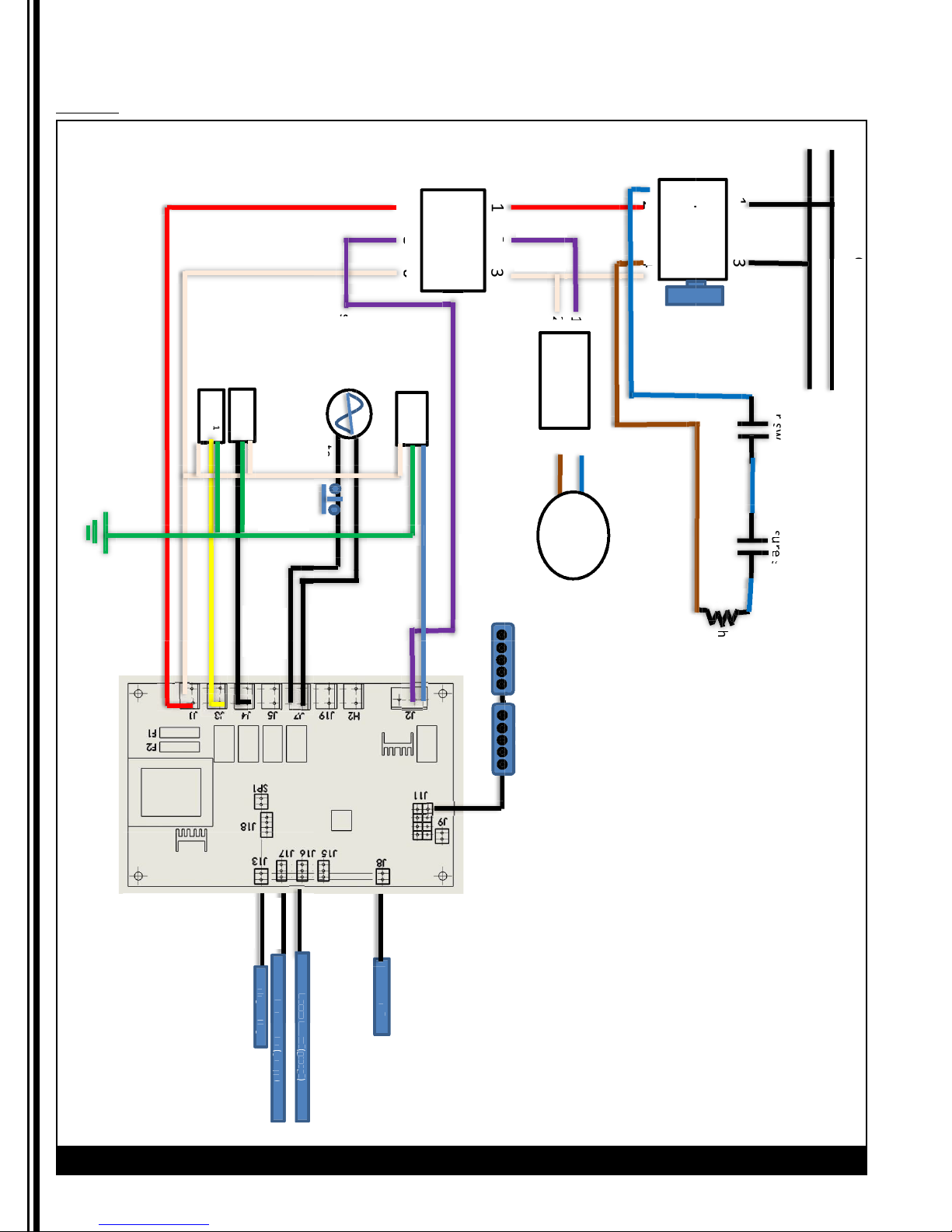

Wiring Diagram

CS1-110

1

%

p

it

w

w

s

s

r

itc

ssr

3

%

s

re

re

u

u

s

h

h

h

s

e

h

c

e

g

g

)

)

puop

g

g

(

g

m

(

t

g

p

2

1

2

1

3

1

lignasssr

tc

t

g

g

Red

White

Blue

Brown

Violet

Yellow

Black

Black

Blue

Brown

Violet

Red

Black

Black

Green

Blue

Black

Black

Black

Black

White

N

L

G

puor

evalv

4

W

erat

evalv

con

cten

o

r

co

roectnn

4

pmpu&

3

rotoM

erwo

hcitsw

reat

Ʋ110

10

H50/60Ɍ 1V

h

srep

itchw

z

1puorg

darobkey

wiring

D

niso

erwoFl

ets

ni

et

1er

r

1

eborperatW

dia

r

am

CV)CS1(110A

Page 27

CS Espresso Machine Grindmaster

®®

27

Wiring Diagram (continued)

CS1-220

%

p

r

e

g

lignasssr

lignasssr

t

Violet

Blue

Black

Black

Yellow

Red

White

Green

White

Red

Violet

White

Blue

Brown

Black

Black

Black

Black

Black

Black

Brown

Blue

am

r

eborperatW

1

uo

r

1er

et

ni

ets

erwoFl

niso

D

CV)CS1(220A

dia

wiring

reat

itchw

srep

darobkey

1puorg

pmpu&

rotoM

tc

z

h

H50/60Ɍ 1V

hcitsw

erwo

10

Ʋ220

L

N

4

3

roectnn

co

erat

W

r

o

cten

con

evalv

4

evalv

puor

G

Page 28

28 Grindmaster

®

CS Espresso Machine

Wiring Diagram (continued)

CS2-220

1

%

p

it

w

w

s

s

r

itc

ssr

3

%

s

re

re

u

u

s

h

h

h

s

e

h

c

e

g

)

)

puop

g

g

(

g

)

)

puop

g

g

(

g

m

(

t

g

m

(

p

2

1

2

1

t

ssr

3

tc

1

m

t

g

g

Black

Black

Black

Black

Black

Black

Black

Black

Black

Black

Yellow

Blue

Brown

White

Red

Violet

Blue

Green

Red

Violet

White

Brown

Blue

puorG

evalv

evalv

G

2puor

N

L

4

con

cten

o

r

lignas

W

erat

evalv

hcitsw

co

roectnn

4

3

rotoM

pmpu&

erwo

Ʋ220

10

H50/60Ɍ 1V

h

srep

itchw

z

2puorg 1puorg

darobkey

reat

wiring

dia

D

Fl

niso

erwo

erwoFl

ets

ni

et

et

2er

1er

r

r

2

1

eborperatW

r

am

CV)CS2(220A

Page 29

CS Espresso Machine Grindmaster

®®

29

Wiring Diagram (continued)

CS3-220

%

p

r

e

g

e

m

m

t

Red

Red

White

Green

Violet

Blue

Black

Orange

Black

Yellow

Black

Brown

Blue

Black

Black

Violet

White

Brown

Blue

Black

Black

Black

Black

Black

Black

Black

am

r

CV)CS3(220A

dia

wiring

reat

itchw

srep

3

uo

r

3er

et

eborperatW

darob

2puorg 1puorg

y

k

3

uo

r

pmpu&

roto

M

erwo

Fl

1

2

uo

uo

r

r

1er

2er

et

et

ni

ets

erwoFl

erwo

niso

Fl

D

z

h

H50/60Ɍ 1V

10

Ʋ220

hcitsw

erwo

L

N

4

3

roectnn

co

r

o

cten

con

erat

W

evalv

4

3puor

evalv

G

lignas

2puor

evalv

puorG

evalv

G

Page 30

30 Grindmaster

®

CS Espresso Machine

Page 31

CS Espresso Machine Grindmaster

®®

31

Page 32

Grindmaster-Cecilware

4003 Collins Lane, Louisville, KY 40245 USA

Phone: 502.425.4776 Toll Free: 800.695.4500

Fax: 502.425.4664

Web: gmcw.com Email: info@gmcw.com

©2018 Grindmaster-Cecilware

Printed in Taiwan

0318 Form # CW-345-02

Part # 390-00119

Loading...

Loading...