Page 1

USER’S GUIDE

Installation & Operation

Instructions

Tank Farm Transmitter

Model TFT 32

Series 2.4

Pressure Sensor Input (-B-)

Page 2

Note: This page has been left blank intentionally.

Page 3

TFT32 Tank Farm Transmitter

Manual Series 2.4

INDEX

Bench Test and Connections·····································4

Calibration System ············································7

Calibration Menu ·············································8

Calibration Units Selection······································9

Output Span Calibration ········································10

Level Calibration ·············································11

Relay Calibration ·············································15

Damping ····················································16

Transmitter/Tank Address ······································16

Baud Rate ···················································17

Output Simulation·············································17

Store/Save Calibration ·········································17

Enclosure Installation ··········································19

Sensor Installation·············································20

Error/Warning Messages ·······································21

Communication Protocol ·······································22

Fuse Replacement ·············································24

Applications Hotline ···········································25

Product Return Procedure ·······································26

Warranty ···················································27

Conversion Tables ············································30

Specifications ················································31

IMPORTANT NOTE: This instrument is manufactured and calibrated to meet product specifications.

Please read this manual carefully before installation and operation. Any unauthorized repairs or

modifications may result in a suspension of the warranty.

Available in Adobe Acrobat pdf format

Page 3

Page 4

TFT32 Tank Farm Transmitter

Manual Series 2.4

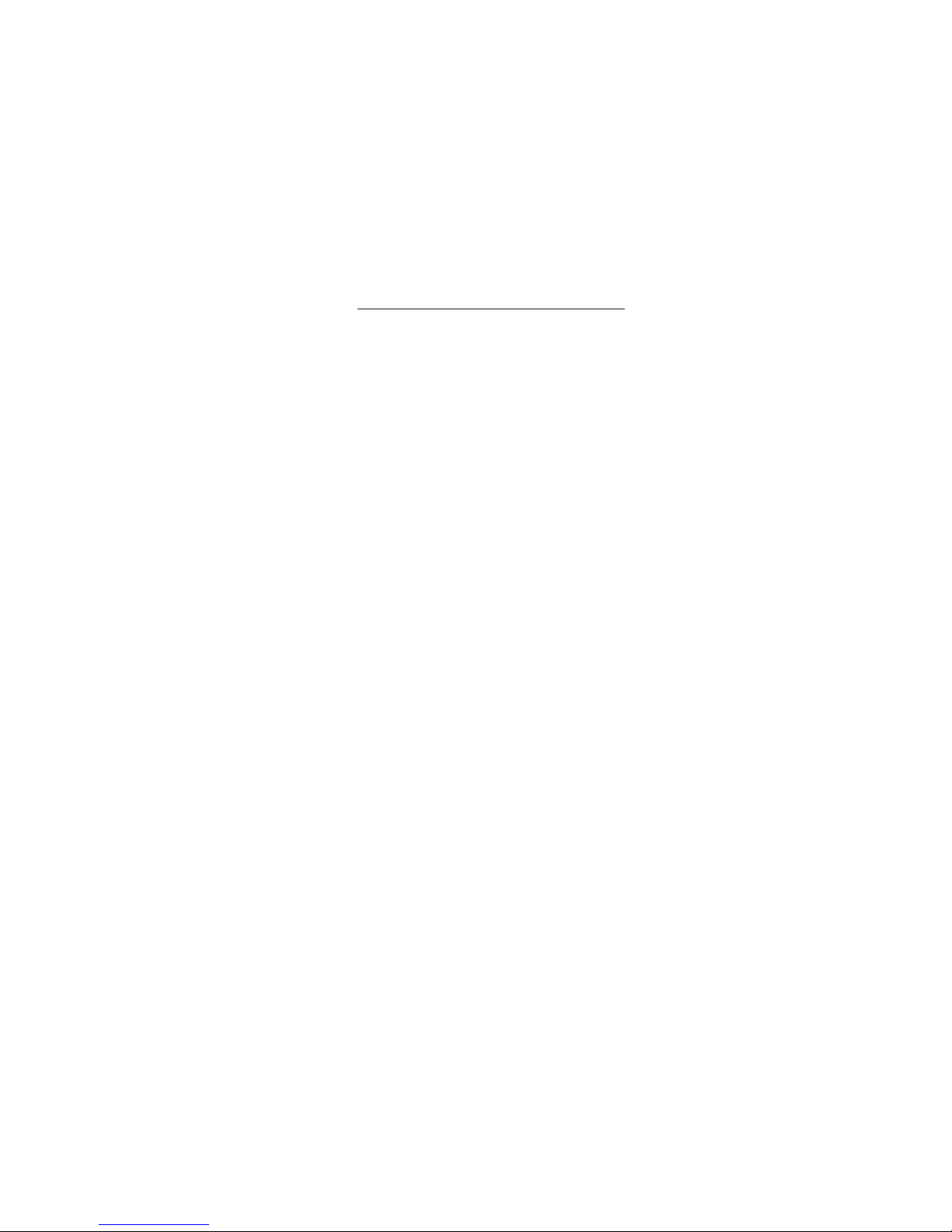

QUICK BENCH TEST (PRESSURE INPUT):

Connect Sensor as shown below, then apply Power. When properly connected figures will be shown on

the LCD display. Test operation of the TFT32 by applying pressure to the sensor or 4-20mA input. The

TFT32 will now display level in inches or cm.

CONNECTIONS:

POWER INPUT: The standard model requires DC power input between 15 to 24VDC with current

consumption of 120mA maximum. Power GND must be connected to a good “earth” ground for surge

protection.

RS485 NETWORK: Connections from the 485 network (other TFT32’s and the PC computer) are:

Data - (D*), Data + (D) and signal/shield ground (S.G.)

IMPORTANT NOTE: To comply with CSA/NRTL standards, power input and relay connection wires

must have a water tight fitting conduit entry to the instrument enclosure.

14 AWG MAX

24VDC

–

+

GND

IMPORTANT:

MUST CONNECT TO A

GOOD GROUND (<1 Ohm)

WITH 14 AWG CONDUCTOR

RELAY

(1 AMP)

CONNECT

TO RS485

NETWORK

CABLE

RS485

D

TO RS485

NETWORK

INPUT

*

18 - 22 AWG RECOMMENDED

mA

D

S.G

+-

BLK

RED

SENSOR

6 - CONDUCTOR SHIELDED

Page 4

Page 5

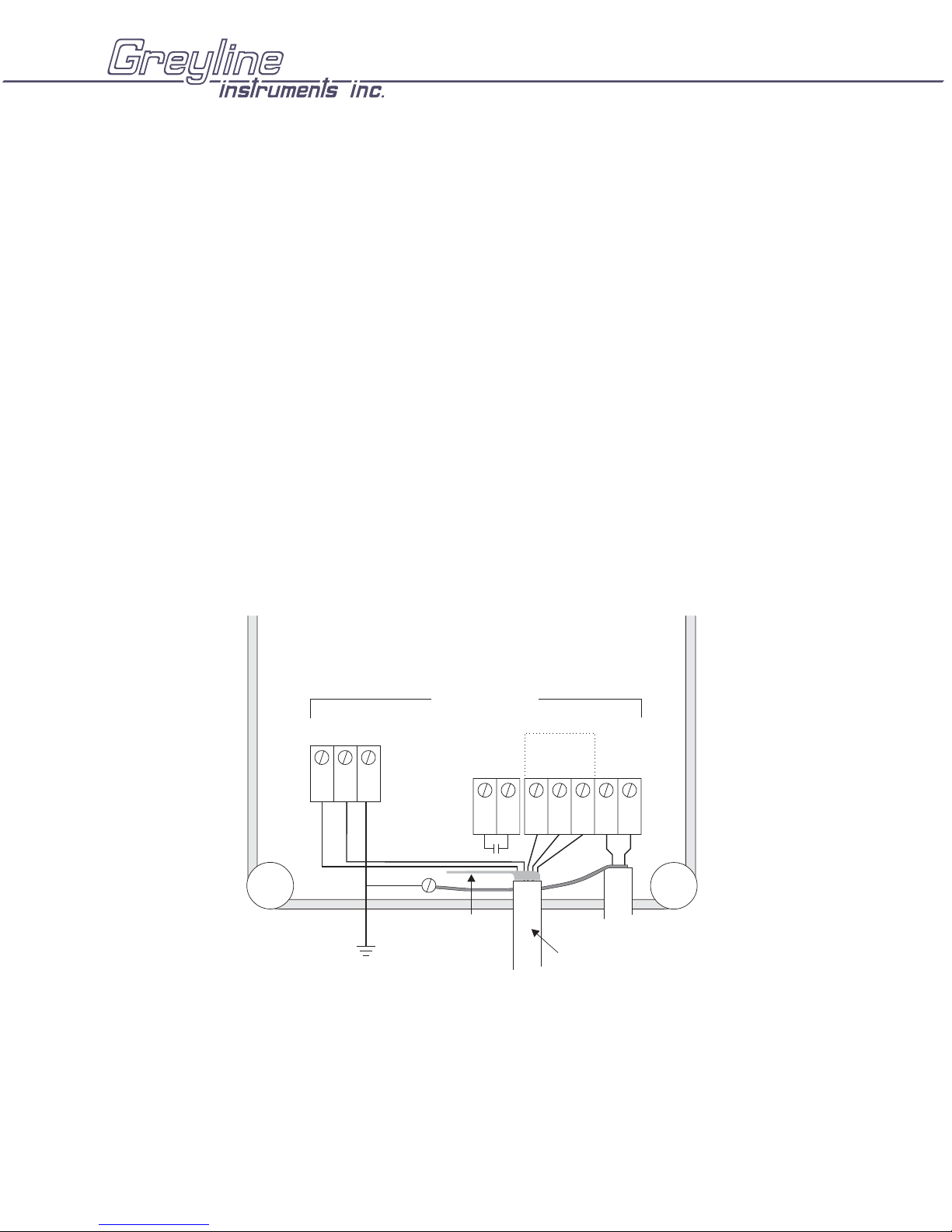

LOCAL NETWORK CONNECTIONS

LAST (FURTHEST) TFT IN THE NETWORK

TFT32 Tank Farm Transmitter

Manual Series 2.4

24VDC

–

+

GND

120 ohm

TERMINATOR

IMPORTANT:

MUST CONNECT TO A

GOOD GROUND (<1 Ohm)

WITH 14 AWG CONDUCTOR

(supplied)

RELAY

(1 AMP)

TO RS485

NETWORK

INPUT

RS485

MORE

TFT'S

mA

*

+-

D

D

S.G

BLK

RED

DO NOT

CONNECT SHIELD

6 - CONDUCTOR SHIELDED

18 - 22 AWG RECOMMENDED

IMPORTANT:

MUST CONNECT TO A

GOOD GROUND (<1 Ohm)

WITH 14 AWG CONDUCTOR

SENSOR

24VDC

+

RELAY

–

GND

(1 AMP)

RS485

*

D

D

S.G

INPUT

mA

+-

RED

BLK

SENSOR

6 - CONDUCTOR SHIELDED

18 - 22 AWG RECOMMENDED

TO RS485

NETWORK

MORE

TFT'S

24VDC

+

RS485

*

D

INPUT

mA

D

S.G

+-

RELAY

–

GND

(1 AMP)

To

RS232

Port

485OI9TB-12V

DB9F

RS232

RS485

RS485/232

CONVERTER

D–

D+

GND

12V

DO NOT

CONNECT

SHIELD

IMPORTANT:

MUST CONNECT TO A

GOOD GROUND (<1 Ohm)

WITH 14 AWG CONDUCTOR

PS150 POWER SUPPLY

S+

V+

V+

V+

V-

V-

NL

115VAC

S-

V-

BLK

RED

SENSOR

6 - CONDUCTOR SHIELDED

18 - 22 AWG RECOMMENDED

TO RS485

NETWORK

D*

D

GND

24V+

24V-

SHIELD

Page 5

Page 6

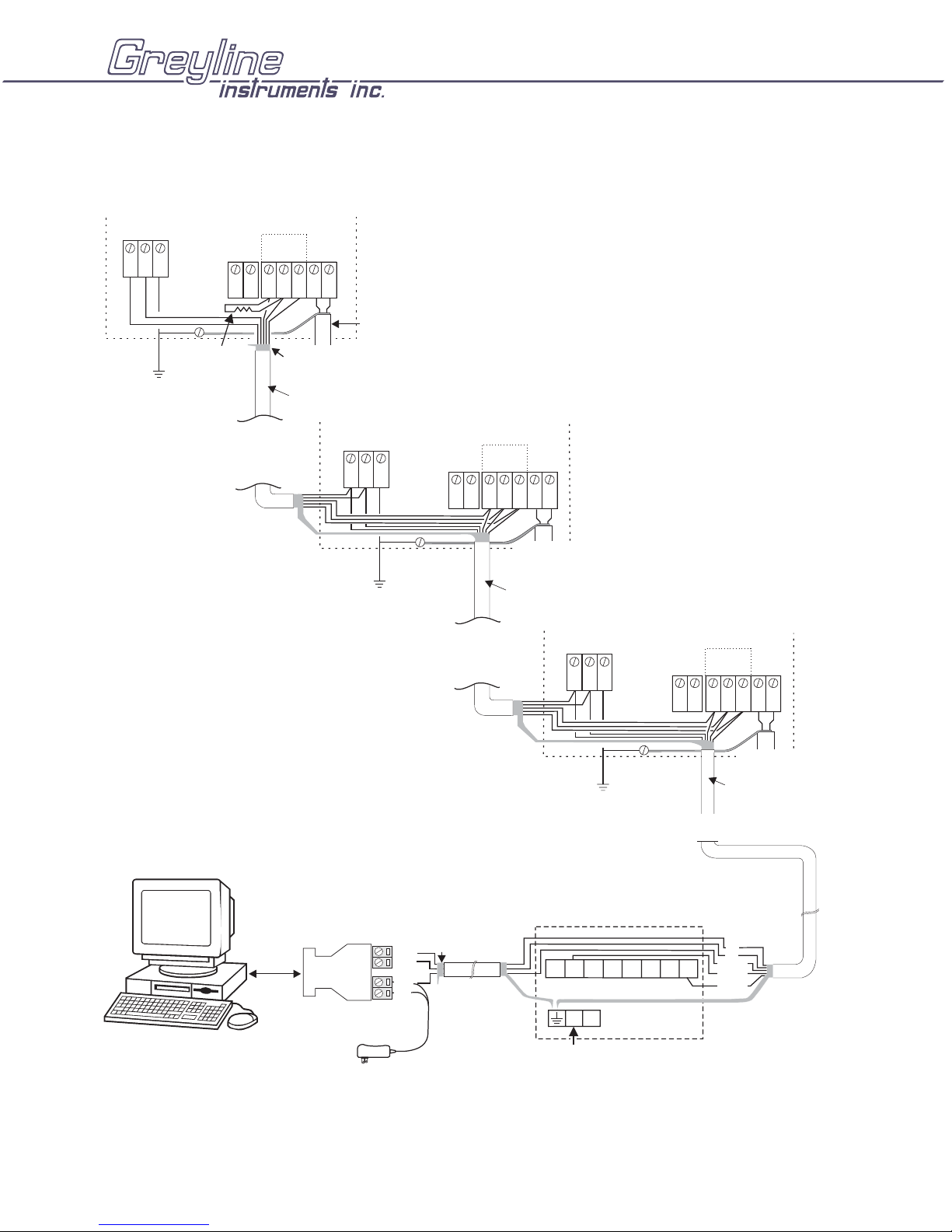

DIAL-UP LOCATION CONNECTIONS

LAST(FURTHEST)TFT IN THE NETWORK

TFT32 Tank Farm Transmitter

Manual Series 2.4

24VDC

–

+

GND

120 ohm

TERMINATOR

IMPORTANT:

(supplied)

MUST CONNECT TO A

GOOD GROUND (<1 Ohm)

WITH 14 AWG CONDUCTOR

RELAY

(1 AMP)

TO RS485

NETWORK

RS485

INPUT

mA

*

+-

D

D

S.G

BLK

RED

DO NOT

CONNECT SHIELD

6 - CONDUCTOR SHIELDED

18 - 22 AWG RECOMMENDED

MORE

TFT'S

IMPORTANT:

MUST CONNECT TO A

GOOD GROUND (<1 Ohm)

WITH 14 AWG CONDUCTOR

24VDC

–

+

SENSOR

GND

RELAY

(1 AMP)

TO RS485

NETWORK

MORE

TFT'S

INPUT

RS485

D

mA

*

+-

D

S.G

BLK

RED

SENSOR

6 - CONDUCTOR SHIELDED

18 - 22 AWG RECOMMENDED

MODEM

DB25M

NULL

MODEM

485OI9TB-12V

DB9M

DB9F

RS232

CONVERTER

RS485

RS485/232

D–

D+

GND

12V

DO NOT

CONNECT

SHIELD

PS150 POWER SUPPLY

S+

V+

V+

V+

V-

V-

V-

NL

115VAC

D*

D

GND

S-

24V+

24V-

SHIELD

Page 6

Page 7

TFT32 Tank Farm Transmitter

Manual Series 2.4

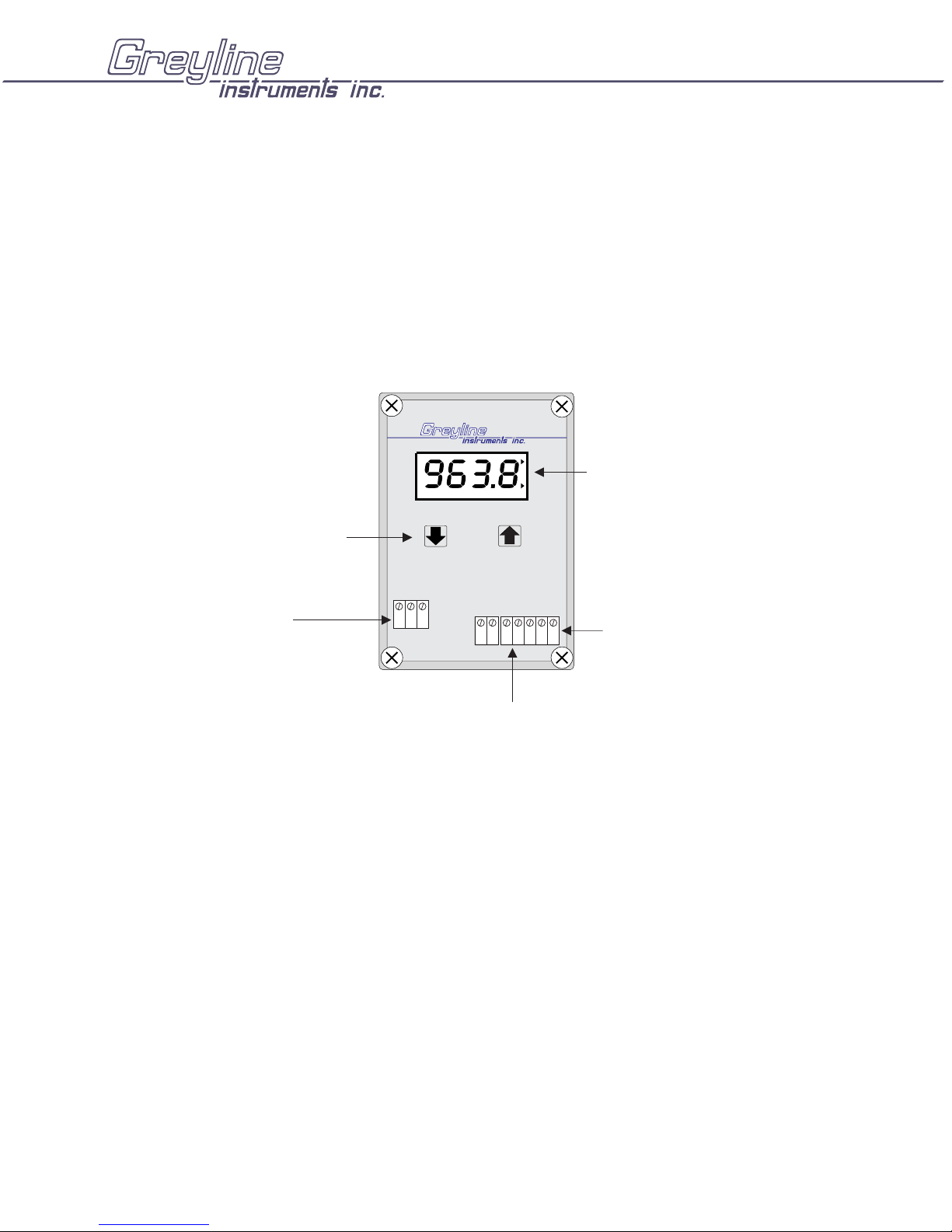

KEYPAD SYSTEM

The TFT32 has a simple 2-key calibration system. Operating and calibration modes are shown on the 4

digit display. The keys are used to calibrate the TFT32, and to view operating mode and functions. If the

keys are not used for 10 minutes, the TFT32 will automatically go to NORMAL MODE. Except in

OUTPUT SIMULATION mode, the Relay and RS485 serial output are not affected by use of the keys

until your calibration is stored.

PERCENT INCHES CM

mA

RELAY

4-DIGIT LCD DISPLAY

CALIBRATION KEYS

TFT32

Tank Farm Level Transmitter

POWER

CONNECTION

+ –

GND

SENSOR

CONNECTION

RS485 NETWORK

CONNECTION

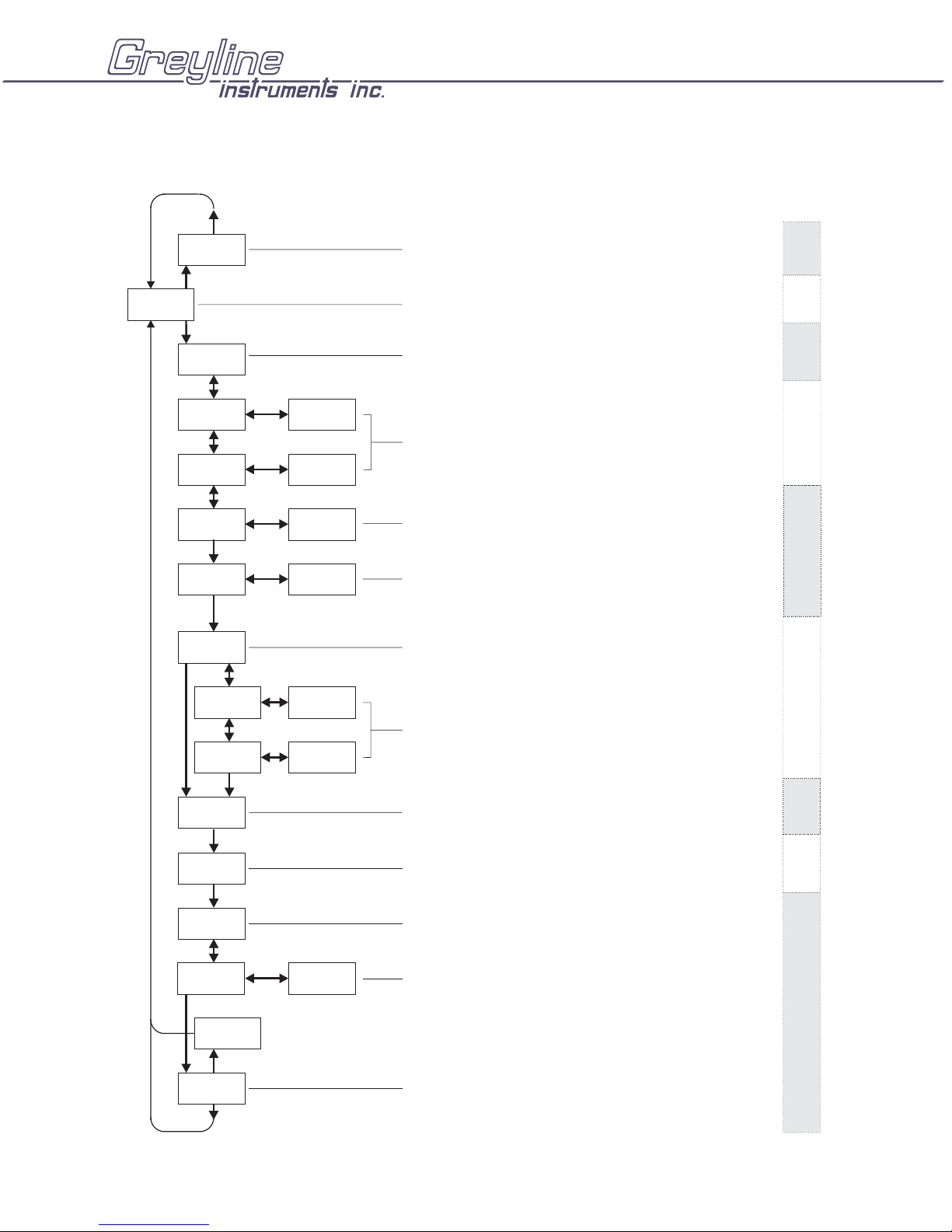

MENU - FLOW CHART

The following diagram shows the TFT32 Menu system. Arrows show the directions to leave a box.

Pressing a corresponding key will move to the next box in the direction shown. Numeric values are

changed by pressing and holding the Ç or È keys.

At the bottom of Menu is a YES? prompt. To store the calibration values permanently (even through

power failure), press the Ç key. If the È key is pressed from the YES? prompt no changes will be

stored and the system will return to NORMAL mode.

Page 7

Page 8

TFT32 CALIBRATION MENU

PRESSURE SENSOR INPUT

TFT32 Tank Farm Transmitter

Manual Series 2.4

See Page

#

20.0

123.4

LEVEL CM

CALU

PERCENT INCHES CM

0=

100= 999.9

LO 1056

HI 1.000

roc1

3,4,5, 6 1,2

ro FF

PERCENT

PERCENT

ron

0.0

CM

CM

CM

CM

100.0

CM

98.0

CM

mA DISPLAY

Displays mA signal as received from sensor

NORMAL MODE

CALIBRATION UNITS SELECTION

Press to select inches, cm, percent or blank (other units)

Ç

OUTPUT SPAN CALIBRATION

"0=" Enter minimum reading to be displayed by the TFT32

"100=" Enter maximum reading to be displayed by the TFT32

Wait for the numeric value then press

decrease.

IN-SITU CALIBRATION

Simulate 4mA with 4-20mA input device and enter the minimum

value of input device.

With level 70% of tank enter the current level.

Simulate 20mA with 4-20mA input device and enter the

maximum value from the input device.

RELAY OPERATION CHOICE.

Press to select: 3 = Signal Loss Only

RELAY SET POINTS

Wait for numeric value and press and to adjust Set Points

(in percentage of Span)

>

Ç

1 = Level Alarm 4 = Always ON

2 = Level + Signal Loss 5 = Always OFF

or to increase or

ÇÈ

ÇÈ

18

9

9

10

11

15

dp10

Ad 1

bd19

100.0OPSL

-C.S-

YES

YES?

NO

DAMPING (0-15 secs)

Press to adjust

Ç

TRANSMITTER/TANK ADDRESS

Press to select 1-32

Ç

SERIAL OUTPUT BAUD RATE

Press to select 19 = 19200 4 = 4800

Ç

OUTPUT SIMULATION

CM

Wait for numeric value and press and to increase or

decrease Simulated Output (Automatically returns to NORMAL

mode in 10 minutes)

STORE YES?

Press to store Calibration (displays -C.S-)

Ç

Press Calibration Not Stored

È

9 = 9600 2 = 2400

ÇÈ

16

16

17

Page 8

Page 9

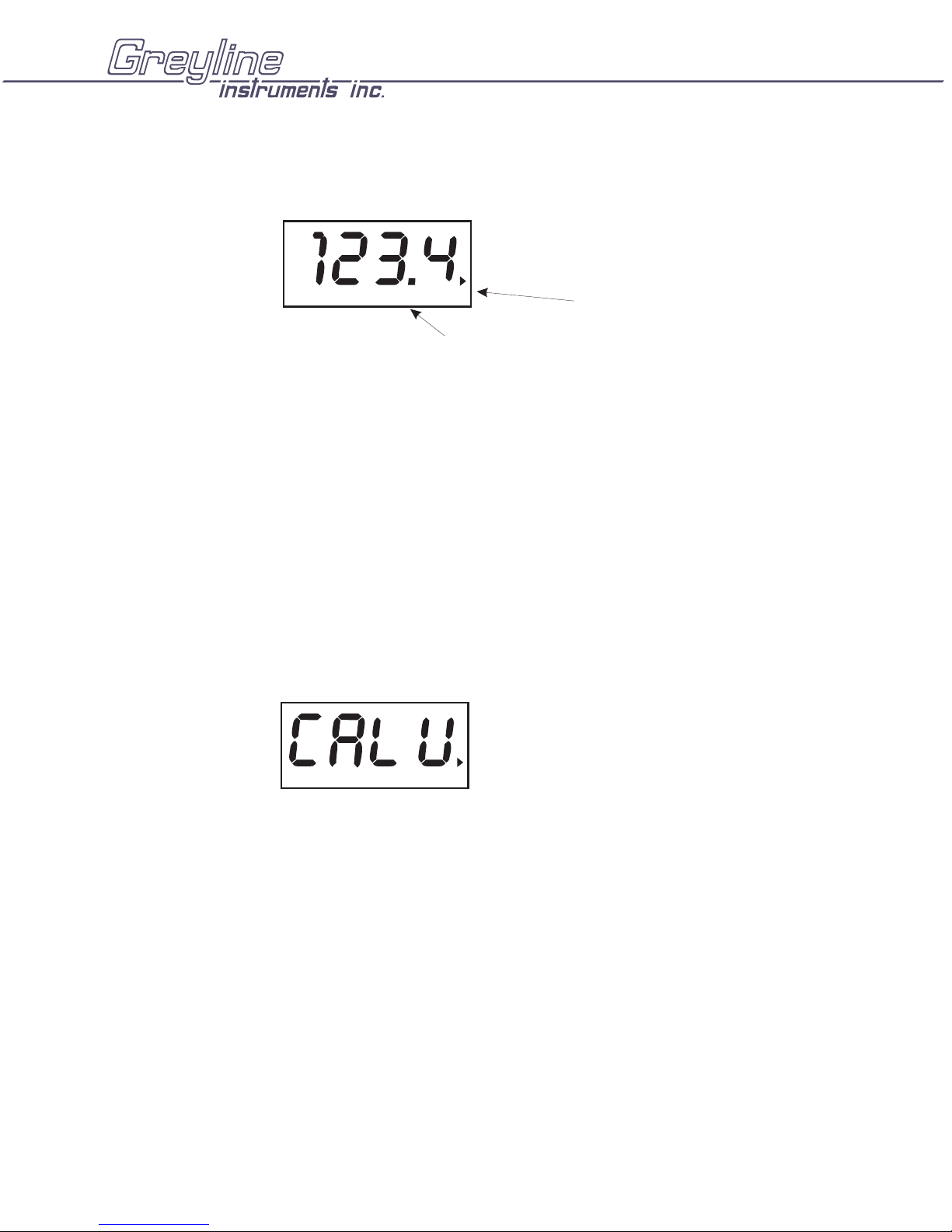

NORMAL MODE

TFT32 Tank Farm Transmitter

Manual Series 2.4

mA

LEVEL CM

The TFT32 Normal Mode

is always Level

CALIBRATION UNITS SELECTION

Press È from NORMAL mode, display will show:

RELAY

ON - Relay energized

OFF - Relay de-energized

PERCENT INCHES CM

È

LEVEL

CALIBRATION

Ç

INCHES

Ç

PERCENT

Ç

BLANK

Ç

CM

Page 9

(Any Units)

Page 10

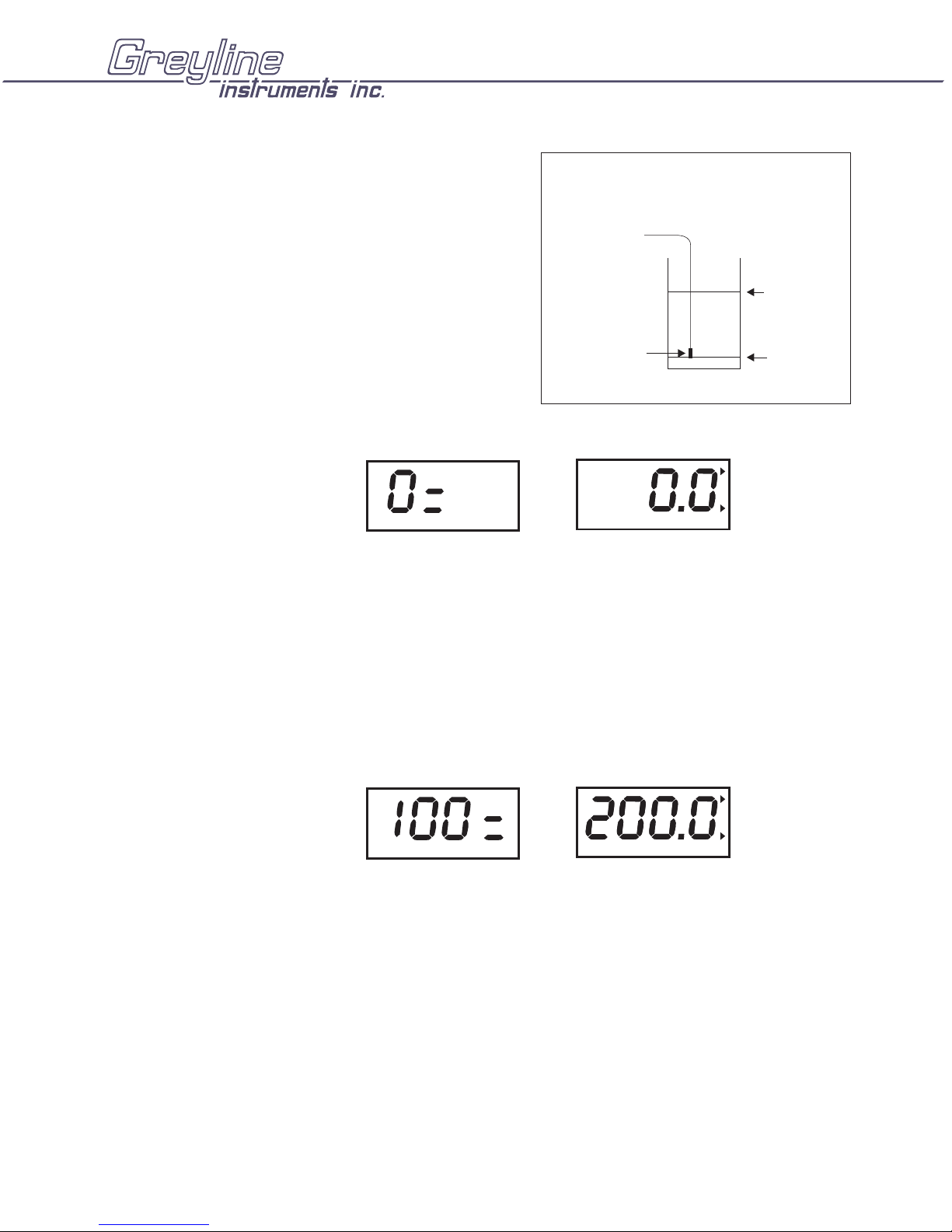

OUTPUT SPAN CALIBRATION

.

.

TFT32 Tank Farm Transmitter

Manual Series 2.4

LEVEL

(Pressure Sensor)

100=

Max Level

The Display will alternate between

È

100=

and

Pressure

Sensor

È

1524

È

1523

È

1522

CM

Ç

0.1

Ç

0.2

Ç

0.3

0=

Zero Level

every 3 seconds

Wait for the numeric value and press Ç to enter the zero level, or minimum level of the tank. With

display on 0 = press È

The Display will alternate between

Wait for the numeric value and press Ç to enter the maximum level of the tank. With display on 100 =

press È.

È

LO

Page 10

and

È

199.9

È

199.8

È

199.7

every 3 seconds

CM

Ç

200.1

Ç

200.2

Ç

200.3

Page 11

LOW LEVEL CALIBRATION (IN-TANK)

.

TFT32 Tank Farm Transmitter

Manual Series 2.4

The Display will alternate between

È

HI

and

È

208.9

È

208.8

È

208.7

every 3 seconds

CM

Ç

209.1

Ç

209.2

Ç

209.3

With tank level <30% of maximum level (100=) wait for the numeric value and press Ç to enter the

current tank level.

HIGH LEVEL CALIBRATION (IN-TANK)

and

CM

every 3 seconds.The Display will alternate between

È

roc 1

È

798.9

È

798.8

È

798.7

Ç

799.1

Ç

799.2

Ç

799.3

With tank level >70% of maximum level (100=) wait for the numeric value and press Ç to enter the

current tank level.

Note: the greater the range between LO and HI levels for this procedure, the better the accuracy of your

calibration. (eg: LO at 10% and HI at 90% will produce a more accurate calibration than LO at 40% and

HI at 60%).

Note: If only one value is changed during a calibration then the second calibration point remains the

unchanged value from the last calibration (ie. You can perform a single point calibration to improve

upon the previous calibration).

Note: Sensor input difference between HI and LO must be greater than 2mA.

Page 11

Page 12

SETUP EXAMPLE: PS11 Sensor in a 70” Tank

TFT32 Tank Farm Transmitter

Manual Series 2.4

Page 12

Page 13

LOW LEVEL CALIBRATION (BENCH)

.

TFT32 Tank Farm Transmitter

Manual Series 2.4

È

HI

and

È

208.9

È

208.8

È

208.7

CM

Ç

209.1

Ç

209.2

Ç

209.3

every 3 seconds.The Display will alternate between

With sensor input OPEN (sensor not connected) wait for the numeric value and press Ç to enter the

level of the sensor in the tank. (eg. If sensor will be mounted at a level of 6 inches then LO = 6.0 inches)

HIGH LEVEL CALIBRATION (BENCH)

The Display will alternate between

and

every 3 seconds

CM

È

roc 1

È

798.9

È

798.8

È

798.7

Ç

799.1

Ç

799.2

Ç

799.3

With sensor input OPEN (sensor not connected) wait for the numeric value and press Ç to enter the high

level:

HI = [20mA Level]

+ LO

Specific Gravity

Where [20mA level] is to be read from the “Pressure Sensor Conversion Chart” (Page 10). The

“Specific Gravity” is the specific gravity of your fluid (=1 for water). “LO” is the Low Level

Calibration value entered above.

Note: See page 12 for samples of bench calibration calculations.

Page 13

Page 14

TFT32 Tank Farm Transmitter

PRESSURE SENSOR CONVERSION CHART (Bench Calibration)

Manual Series 2.4

Examples of “Bench Calibration” Calculations

Example 1 - PS11 sensor

- Specific gravity of tank contents is 1.5

- Sensor is mounted at a level of 6 inches

- Calibration units (CALU) are in inches

LO = 6.0

[20mA Level] = 138.6 inches

HI = [20mA Level]

+ LO = 138.6 + 6.0 = 98.4

Specific Gravity 1.5

Example 2 - PS11 sensor

- Specific gravity of tank contents is 1.0

- Sensor is mounted at a level of 15

- Calibration units (CALU) are in cm

LO = 15.0

[20mA Level] = 352.0 cm

HI = [20mA Level]

+ LO = 352.0 + 15.0 = 367.0

Specific Gravity 1.0

cm

Page 14

Page 15

RELAY OPERATION CHOICE

The TFT32’s Signal Relay can be configured to operate as:

ROC1 = Level Alarm

ROC2 = Level + Signal Loss Alarm

ROC3 = Signal Loss Alarm only

ROC4 = Always ON

ROC5 = OFF (de-energized) at all times

Press Ç to select the ROC.

RELAY CALIBRATION

TFT32 Tank Farm Transmitter

Manual Series 2.4

È

roc = 3,5,6 roc =

ÈÈ

È

1,2,4

Ç

roc2

Ç

roc3

Ç

roc4

ROC1 (Level Alarm)

ROC2 (Level + Echo Loss Alarm) - Relay will be energized when the Relay ON set point is

reached.

or if the signal is lost (e.g. sensor wires short or open).

NOTE: The Set Points are displayed in percentage of span (LEVEL). Two different Set Points (ronand

roFF) allows a Relay “deadband” for Pump Control and to avoid Relay chatter.

Page 15

Page 16

TFT32 Tank Farm Transmitter

4

Manual Series 2.4

Example of Relay Calibration

Span (Max Level) = 184 inches

ron in percent =150/184 = 81.5%

roFF in percent = 30/184 = 16.3%

DAMPING

Normal Setting: dP10

Fast Response (up to ½ inch /13 mm level

change per second): dP5 or less

Slow Response (turbulence) dP15

RON

R OFF

È

30"

150"

Ç

dP11

Ç

dP12

rAn2 = 18

SPAN = 184"

15 SECS.

MAXIMUM

TRANSMITTER/TANK ADDRESS

Select transmitter address 1 to 32 taking into

consideration the following:

1) Each transmitter must have a different address.

2) The address number is also the tank position on the

page when running the TFS Tank Farm Supervisor

PC software.

Page 16

Page 17

BAUD RATE

Select the highest Baud Rate whenever

possible. All Transmitters connected to

the network must have the same Baud

Rate.

OUTPUT SIMULATION MODE

È

Ç

bd 2

Ç

bd 4

TFT32 Tank Farm Transmitter

Manual Series 2.4

bd 19 = 19200

bd 9 = 9600

bd 4 = 4800

bd 2 = 2400

Output Simulation controls the RS485 serial output, digital display and signal relay. Use it to test

Transmitter Communication to the remote PC running TFS software and to test Relay set-points.

Simulation values are in percentage of Span.

TO STORE (SAVE) CALIBRATION

Press Ç to Store calibration (TFT will display -C.S-).

Calibration is stored in non-volatile memory (even through power interruptions).

Press È to return to NORMAL mode without storing any changes.

Page 17

Page 18

mA DISPLAY

e

TFT32 Tank Farm Transmitter

Manual Series 2.4

From Normal Mode press Ç

Displays mA input signal as received from pressure sensor

or 4-20mA transmitter.

mA

Ç

Return to

Normal Mod

Page 18

Page 19

TFT32 Tank Farm Transmitter

Manual Series 2.4

ENCLOSURE INSTALLATION

Locate the enclosure within 10,000 ft (3,000 m) of the pressure sensor. It can be wall mounted with four

mounting screws (supplied) or panel mounted with Option PM Panel Mounting Kit from Greyline

Instruments. Avoid mounting the enclosure in direct sunlight to protect the electronics from damage due

to overheating and condensation. Seal conduit entries to prevent moisture from entering enclosure.

NEMA4X (IP66) WITH CLEAR COVER

COVER

ENCLOSURE

MOUNTING

HOLES

1. Remove enclosure cover.

2. Insert #6 screws through the four enclosure mounting holes to secure

enclosure to wall or mounting stand.

ENCLOSURE

END VIEW

3. Replace Cover

An additional conduit hole can be cut in the end of the enclosure if

required. Use a hole saw or Greenlee-type hole cutter to cut the required

holes.

Note:

1 This non-metallic enclosure does not automatically provide grounding between conduit connections.

Grounding must be provided as part of the installation. Ground in accordance with the requirements

of the National Electrical Code. System grounding is provided by connecting grounding wires from

all conduit entries to the steel mounting plate or another point which provides continuity.

2

Water tight “O” ring seals must be used if cable strain-reliefs are used.

Page 19

Page 20

PST THREADED PRESSURE SENSOR INSTALLATION

R

MAX LEVEL

1/4" NIPPLE

STAINLESS STEEL

CONDUIT

2ft/60cm

MIN LEVEL

PST PRESSURE

SENSOR

TFT32 Tank Farm Transmitter

Manual Series 2.4

RED

BLK

SHIELD

NEMA4 ENCLOSURE

VENTED TUBE MUST

NOT COME IN CONTACT

WITH ANY LIQUID

SHIELDED PAI

TO TFT32

TRANSMITTER

SUBMERSIBLE PRESSURE SENSOR INSTALLATION

SHIELDED PAIR

TO TFT32

TRANSMITTER

To

Transmitter

MAX LEVEL

VENTED TUBE MUST

NOTCOMEINCONTACT

WITH ANY LIQUID

NEMA4 ENCLOSURE

SHIELD

BLK

RED

CONDUIT

MIN LEVEL

Page 20

Page 21

ERROR / WARNING MESSAGES

t

Instrument has detected Sensor connections/cable open

or signal from sensor is too low (0.25mA)

Instrument has detected Sensor connections/cable short

or signal from sensor is too high (23.0mA)

Indicates that the TFT32 has experienced electrical interference strong enough to corrup

the memory. The TFT32 must be reset and recalibrated.

Reset Procedure 1:

procedure: Press and Hold and until the TFT32 displays .

Reset will clear all memory. TFT32 will need recalibration after this

TFT32 Tank Farm Transmitter

Manual Series 2.4

Illegal Span:

Distance between and must be greater

0= 100=

than 2"(5cm).

Distance for (Max Level) must be greater than

(Min Level).

0=

100=

ÈÇ ----

Page 21

Page 22

TFT32 Tank Farm Transmitter

>

3

(

)

Manual Series 2.4

TFT32 COMMUNICATION PROTOCOL

Greyline TFS Tank Farm Supervisor software manages communications with TFT32 Transmitters

automatically. The following Communication Protocol information is supplied for programmers who are

not using the Greyline TFS Tank Farm Supervisor program. Programmers can create their own drivers

to address TFT32 Transmitters through other software programs on PC computers or PLC’s.

The TFT32 uses an ASCII format command/response protocol. The TFT transmits an answer only when

polled with a valid command and address. The Host computer always initiates the command/response

sequence.

Example of command/response sequence:

Command: #%1RA<CR>

Response: *%1RA+959.3000210AA<CR>

COMMAND STRUCTURE:

RESPONSE STRUCTURE:

*%1RA +959.3 0 0 XXX 0 AA <CR>

RESPONSE

PROMPT

#% 1 RA <CR

COMMAND

PROMPT

FOR TFT32

ADDRESS

A-W = 10-

TFT DATA

(SEE TEXT)

COMMAND

(MUST BE

CAPITAL

LETTERS)

TANK/T FT

1-9 = 1-9

0=LEVEL

CARRIAGE

RETURN

2

MODE

RELAY

STATUS

0=OFF

1=ON

CARRIAGE

RETURN

UNITS

0=cm

TEMP

IN °C

XXX

N/A

CHECKSUM

IN HEX

Page 22

Page 23

COMMAND SET

>

TFT32 Tank Farm Transmitter

Manual Series 2.4

COMMAND DEFINITION COMMAND MESSAGE

(Address 1)

RA Read all

parameters

RS Read Span

(Max Level)

NBxx New Baud Rate

xx = 00 = 38400

01 = 19200

02 = 9600

03 = 4800

04 = 2400

RR Remote Reset

!RR Broadcast Reset

#%1RA<CR> *%1RA+959.300X

#%1RS<CR> *%1RS+999.900X

#%1NBxx<CR>

(TFT will change to new

Baud Rate only after

reset)

#%1RR<CR>

#%!RR<CR>

(All units in the Network

will reset)

TFT RESPONSE:

TFT Data: Valid analog Data Range is + 000.0 to + 6550.

Values with (-) sign represent error messages

TYPICAL RESPONSE

X

X0AA<

X0BF<CR

X

*%1NB02

*1RR

(No Response)

CR>

- 100.0 = “Not Ready Please Wait”

- 101.0 = “Signal Lost”

- 102.0 = “Sensor Short”

- 103.0 = N/A

- 104.0 = “Sensor Open”

- 105.0 = N/A

- 106.0 = N/A

- 107.0 = N/A

Units and mode: Always cm and Level.

Page 23

Page 24

FUSE REPLACEMENT

P

REMOVE

TFT32

Tank Farm Transmitter

TFT32 Tank Farm Transmitter

Manual Series 2.4

1. Disconnect Power

2. Remove 2 top screws

3. Pull and flip chassis

4. Remove 0.5 amp fuse with long nose pliers

5. Install new fuse

(Replacement Greyline Part #1/2 Amp PCC))

PULL AND

FLIP

0.5 AMP

FUSE

RELAY

SOFTWARE CHI

Page 24

Page 25

TFT32 Tank Farm Transmitter

Manual Series 2.4

APPLICATIONS HOTLINE

For applications assistance, advice or information on any Greyline Instrument contact your Sales

Representative, write to Greyline or phone the Applications Hotline below:

United States: Tel: 315-788-9500 Fax: 315-764-0419

Canada: Tel: 613-938-8956 Fax: 613-938-4857

Toll Free: 888-473-9546

Email: info@greyline.com

Web Site: www.greyline.com

Greyline Instruments Inc.

Canada USA:

16456 Sixsmith Drive 105 Water Street

Long Sault, Ont. K0C 1P0 Massena, NY 13662

Page 25

Page 26

TFT32 Tank Farm Transmitter

Manual Series 2.4

PRODUCT RETURN PROCEDURE

Instruments may be returned to Greyline for service or warranty repair.

Obtain an RMA Number from Greyline -

1

Before shipping a product to the factory please contact Greyline by telephone, fax or email to obtain

an RMA number (Returned Merchandise Authorization). This ensures fast service and correct billing

or credit.

When you contact Greyline please have the following information available:

1. Model number / Software Version

2. Serial number

3. Date of Purchase

4. Reason for return (description of fault or modification required)

5. Your name, company name, address and phone number

Clean the Sensor/Product -

2

Important

1. Rinse sensor and cable to remove debris.

2. If the sensor has been exposed to sewage, immerse both sensor and cable in a solution of 1 part

household bleach (Javex, Clorox etc.) to 20 parts water for 5 minutes. Important: do not immerse open

end of sensor cable.

3. Dry with paper towels and pack sensor and cable in a sealed plastic bag.

4. Wipe the outside of the enclosure to remove dirt or deposits.

5. Return to Greyline for service.

3

Ship to Greyline After obtaining an RMA number please ship the product to the appropriate address below:

: unclean products will not be serviced and will be returned to the sender at their expense.

Canadian and International USA

Customers: Customers:

Greyline Instruments Inc. Greyline Instruments Inc.

16456 Sixsmith Drive 105 Water Street

Long Sault, Ont. K0C 1P0 Massena, NY 13662

RMA# RMA#

Page 26

Page 27

TFT32 Tank Farm Transmitter

LIMITED WARRANTY

______________________

Greyline Instruments warrants, to the original purchaser, its

products to be free from defects in material and workmanship for

a period of one year from date of invoice. Greyline will replace

or repair, free of charge, any Greyline product if it has been

proven to be defective within the warranty period. This warranty

does not cover any expenses incurred in the removal and

re-installation of the product.

Manual Series 2.4

If a product manufactured by Greyline should prove defective

within the first year, return it freight prepaid to Greyline

Instruments along with a copy of your invoice.

This warranty does not cover damages due to improper

installation or handling, acts of nature, or unauthorized service.

Modifications to or tampering with any part shall void this

warranty. This warranty does not cover any equipment used in

connection with the product or consequential damages due to a

defect in the product.

All implied warranties are limited to the duration of this

warranty. This is the complete warranty by Greyline and no

other warranty is valid against Greyline. Some states do not

allow limitations on how long an implied warranty lasts or

limitation of incidental or consequential damages, so the above

limitations or exclusions may not apply to you.

This warranty gives you specific legal rights, and you may also

have other rights which vary from state to state.

Greyline Instruments Inc.

Page 27

Page 28

PS150 POWER SUPPLY

O

150 Watt Power Supply for TFT32 Tank Farm System

Powers up to 32 Greyline TFT32 Transmitters + 6 RB12 Relay Boards

TFT32 Tank Farm Transmitter

Manual Series 2.4

CONDUIT

ENTRY

LOCATION

SIDE VIEW

SPECIFICATIONS PS150 POWER SUPPLY

Power Input: PS150-AI: 90-132VAC, 47-63Hz

PS150-EI: 180-264VAC, 47-63Hz

AC Input Current: PS150-AI: 4A maximum

PS150-EI: 2A maximum

Fuse: 4A, 250V

Operating Temperature: 32 to 122°F(0to50°C)

Storage Temperature: -13 to 185°F (-25 to 85°C)

Enclosure: Watertight, dust tight NEMA4X (IP 66) fiberglass

Safety Approvals: UL 1950

CSA 22.2 1402C Level 3

TUV EN 60950 (IEC 950)

-V

24 VDC

L

-V

115VAC

CATION

+V +V

CONDUIT ENTRY

L

N

Page 28

Page 29

TFT32 Tank Farm Transmitter

Manual Series 2.4

MODEL 485OI9TB-24V

RS232/RS485 Converter

Converts RS485 signals from a TFT32 Transmitter to RS232 for connection to a PC Computer or

Modem.

DB9 RS232 Connector plugs directly into your computer’s

–

COM port

Optically isolates and protects your computer’s RS232 port

–

Terminal block for RS485 connections

–

Operates from 2400 up to 19.2K baud

–

Terminal connections are provided for RS485 D-, D+, 24V

–

and GND

Terminal connections are provided for RS485 Data – (D*), Data + (D),and RS485 power and ground.

The RS485 side of the converter is internally biased and terminated to operate with a RS485 network of

up to 32 devices.

FROM GREYLINE

OR

TFT TRANSMITTERS

IN RS485 NETWORK

D* (D-)

D(D+)

S.G.

TO PC

COM PORT

or MODEM

CABLE

485OI9TB-12V

DB9F

RS232

RS485

D–

D+

GND

12V

FROM GREYLINE

TRANSMITTER

WITH RS485 OUTPUT

(OPTION RS5)

DATA*

DATA

GND

DO NOT CONNECT CABLE SHIELD

Page 29

Page 30

TFT32 Tank Farm Transmitter

CONVERSION

GUIDE

FROM TO MULTIPLY BY

US GALLONS CUBIC FEET 0.1337

US GALLONS IMPERIAL GALS 0.8327

US GALLONS LITRES 3.785

US GALLONS CUBIC METERS 0.003785

LITRES/SEC GPM 15.85

LITRES CUBIC METERS 0.001

BARRELS US GALLONS 42

BARRELS IMPERIAL GALS 34.9726

BARRELS LITRES 158.9886

INCHES MM 25.4

DEGREES F DEGREES C

(°F-32) x 0.556

POUNDS KILOGRAMS 0.453

PSI BAR 0.0676

FOOT² METER² 0.0929

PSIG FEET (H

PSIG METER (H

20) 2.31

20) 0.70

PSIG BAR 0.0666

Manual Series 2.4

VOLUME CALCULATION FOR ROUND TANKS: 3.142 x R² x H

R = TANK RADIUS (½ TANK DIAMETER)

H = TANK HEIGHT

Page 30

Page 31

SPECIFICATIONS:

m

TFT32 Tank Farm Transmitter

Manual Series 2.4

Electronics Enclosure: NEMA4X (IP 67), watertight and dust tight,

fiberglass with clear, shatterproof Lexan cover

Accuracy: 0.25% F.S., Repeatability: 0.1% F.S., Linearity:

0.1%F.S.

Display: ¾” / 19mm high, 4 digit LCD

Programming: 2-button Menu selection. Calibration parameters

are permanent when Stored (even through power

interruptions)

Power Input: 24VDC, 120mA max., 2.9 W (max.)

Optional: 100-130VAC 50/60 Hz, (4.2 W max.)

Optional: 200-260VAC 50/60 Hz, (4.8 W max.)

Fuse: internal, rated 1A

Output: Isolated RS485

Signal Relay: Qty 1, rated 120/240 VAC or 24VDC, 1 ampere

Temperature Compensation: Automatic, temperature probe built in to level

Sensor

Electrical/Surge Protection: Sensor, RS485 and power input

Operating Temperature: -13 to 140°F (-25 to 60°C)

(Electronics)

SUBMERSIBLE PRESSURE SENSOR

Mounting

6.18"

157 mm

Mounting

4.21"

107 mm

TFT32

Tank Farm Level Transmitter

4.92"

125 mm

END VIEW

61.89"

75 m

2.95"

75 mm

Wetted Materials: 303 Stainless steel body with uPVC nose cone

Accuracy: ±0.25% FSO (RSS) includes non-linearity,

hysteresis and non-repeatability

Long term stability: 0.1% / 12 months

Operating Temperature: -13°Fto212°F (-25°Cto100°C)

Compensated Temperature: 14°Fto176°F (-10°Cto80°C)

Output: 4-20mA 2-wire Transmitter

Load Impedance: 1000 ohms max at 24VDC

Proof Pressure: 1.5 times full scale pressure range (or URL)

Burst Pressure: 3 times full scale pressure range (or URL)

Cable: Polyurethane jacketed 4-core with vent tube and strain

wire - rated IP68

Connection: RED = +, BLUE = –, WHITE = SHIELD

MODEL MEASUREMENT RANGE CABLE

LENGTH

PS11S 5 PSIG (11.55 ft) / 0.3 bar (3.15 m) 20 ft / 0.6 m

PS17S 7.5 PSIG (17.33 ft) / 0.5 bar (5.25 m) 23 ft / 7 m

PS23S 10PSIG(23.10ft)/0.67bar(7.04m) 30ft/9m

PS35S 15 PSIG (34.65 ft) / 1.0 bar (10.50 m) 40 ft / 12 m

PS46S 20 PSIG (46.20 ft) / 1.3 bar (13.65 m) 55 ft / 17 m

PS69S 30 PSIG (69.30 ft) / 2.0 bar (21.00 m) 75 ft / 23 m

PS102S 44 PSIG (101.64 ft) / 3.0 bar (31.50 m) 105 ft/ 32 m

PS170S 72 PSIG (166.32 ft) / 5.0 bar (52.50 m) 174 ft / 53 m

5.50"

140 mm

0.985"

25 mm

Page 31

Page 32

THREADED CONNECTION PRESSURE SENSOR

Wetted Materials: 316 and 15-5 PH Stainless steel

Enclosure Material: 316 stainless steel

Accuracy: ±0.25% FSO (RSS) includes non-linearity,

hysteresis and non-repeatability

Operating Temperature: -20°F to 190°F (-29°C to 88°C)

Compensated Temperature: 0°F to 180°F (-18° to 82°C)

Output: 4-20mA 2-wire Transmitter

Load Impedance: 600 ohms max at 24VDC

Proof Pressure: 2 times full scale pressure range (or URL)

Burst Pressure: 5 times full scale pressure range (or URL)

Pressure Response: Less than 5 ms to 90%

Pressure Connection: 1/4" NPT (Female)

Electrical Cable: 2’ (0.6 m) long molded polyrethane jacket,

6-conductor with breather tube

Connection: RED = +, BLACK = –, SHIELD = SHIELD

Model Measurement Range

PS11T 5 PSIG (11.55 ft) / 0.3 bar (3.15 m)

PS17T 7.5 PSIG (17.33 ft) / 0.5 bar (5.25 m)

PS23T 10 PSIG (23.10 ft) / 0.67 bar (7.04 m)

PS35T 15 PSIG (34.65 ft) / 1.0 bar (10.50 m)

PS46T 20 PSIG (46.20 ft) / 1.3 bar (13.65 m)

PS69T 30 PSIG (69.30 ft) / 2.0 bar (21.00 m)

PS115T 50 PSIG (115.50 / 3.45 bar (36.23 m)

PS173T 75 PSIG (173.25 / 5.2 bar (54.60 m)

TFT32 Tank Farm Transmitter

Manual Series 2.4

1/2" NPT

CONDUIT

END

1.25" FLATS

31.75 mm

3.471"

0.380"

9.65 mm

(FEMALE)

88.16 mm

1/4" NPT

1.250"

31.8 mm

1.50"

37.65 mm

Page 32

Loading...

Loading...