Greyline Instruments SLT Operating Manual

www.greyline.com

USER'S GUIDE

Installation & Operation

Instructions

Level & Flow Monitor

Model SLT 5.0

Manual Series A.1.7

Note: This page has been left blank intentionally.

SLT 5.0 Level and Flow Monitor

INDEX

CONNECTIONS: ............................................................................................... 4

KEYPAD SYSTEM ............................................................................................ 6

CALIBRATION MENU ..................................................................................... 7

ICONS ................................................................................................................. 8

MAIN DISPLAY ................................................................................................ 9

MESSAGE ICON ............................................................................................... 9

STATUS ............................................................................................................. 9

PASSWORD ..................................................................................................... 10

UNITS/MODE .................................................................................................. 11

CALIBRATION................................................................................................ 12

CHANNEL SETUP .......................................................................................... 15

RELAY PARAMETERS .................................................................................. 16

SPECIAL FUNCTIONS ................................................................................... 17

SENSOR MOUNTING/LOCATION ............................................................... 19

SENSOR MOUNTING METHODS ................................................................ 21

ERROR/WARNING MESSAGES ................................................................... 26

FIELD TROUBLESHOOTING ....................................................................... 27

APPLICATIONS HOTLINE ............................................................................ 31

PRODUCT RETURN PROCEDURE .............................................................. 32

APPENDIX A - OPTIONS ............................................................................... 34

DATA LOGGING (Optional) ........................................................................... 40

CONVERSION GUIDE ................................................................................... 42

SPECIFICATIONS ........................................................................................... 43

IMPORTANT NOTE: This instrument is manufactured and calibrated to meet product specifications.

Please read this manual carefully before installation and operation. Any unauthorized repairs or

modifications may result in a suspension of the warranty.

Available in Adobe Acrobat pdf format

Page 3

SLT 5.0 Level and Flow Monitor

CONNECTIONS:

POWER INPUT: The standard model requires AC power input between 100 to 240 VAC 50/60Hz . No

adjustments are necessary for voltages within this range.

Optional DC input model requires 9-32 VDC/9 Watts. Connect to + and - terminals.

Optional Thermostat and Heater modules are available rated for 115 VAC or 230 VAC.

IMPORTANT NOTE: To comply with CSA/UL electrical safety standards, AC power input and relay

connection wires must have conduit entry to the instrument enclosure. Installation requires a switch,

overcurrent fuse or circuit breaker in the building (in close proximity to the equipment) that is marked

as the disconnect switch.

Risk of electric shock. Loosen cover screw to access connections. Only qualified personnel should

!

access connections.

Note: Use of instrumentation over 40°C ambient requires special field wiring.

Note: User replaceable fuse is 2 Amp 250V (T2AL250V).

Page 4

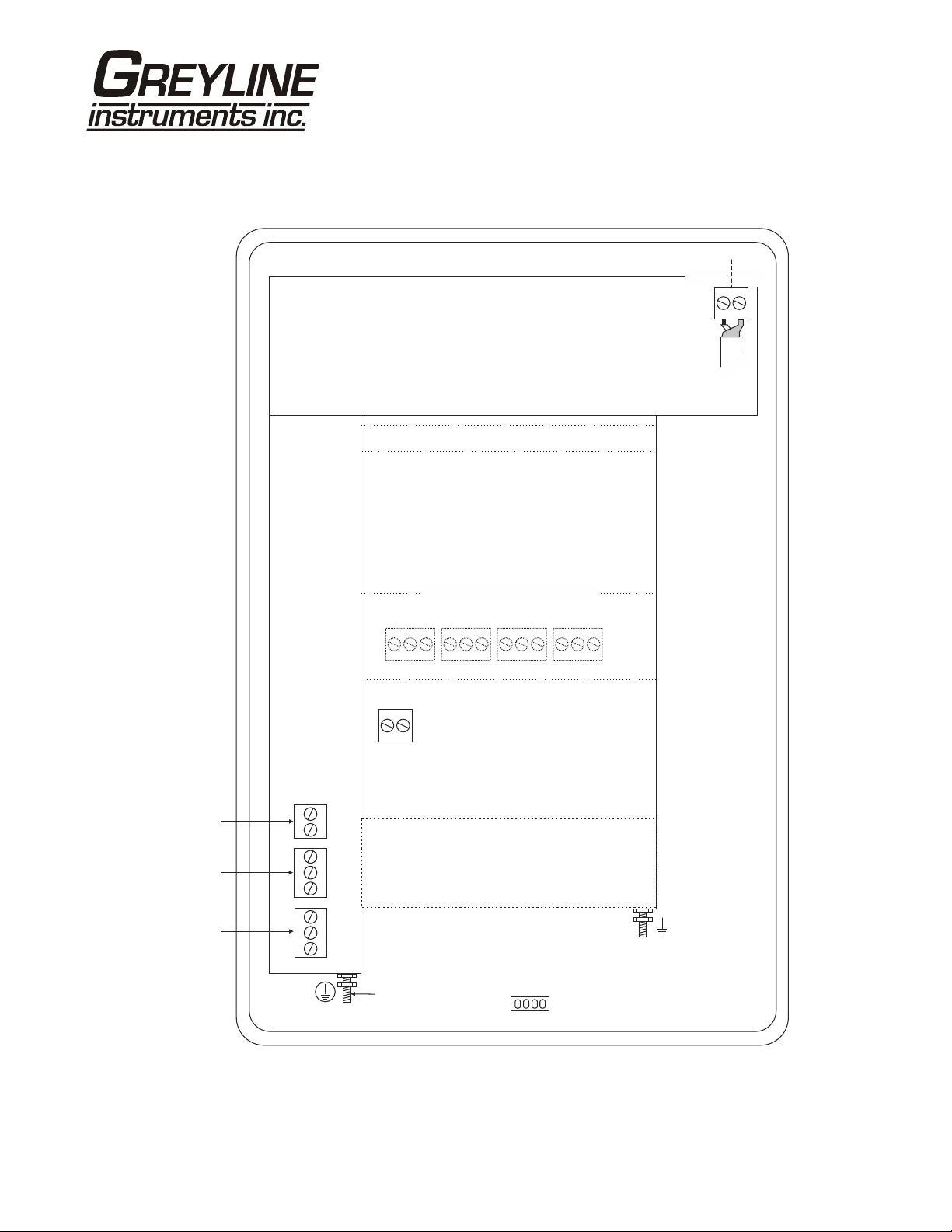

CONNECTIONS

DATA LOGGER OPTION

SLT 5.0 Level and Flow Monitor

SENSOR

SHLD

CORE

GRN

WHT

4-20mA

RLY2

RLY1

–

+

NO

C

NC

NO

C

NC

EXTRA RELAYS OPTION

NC

RLY3

AC

LN

AC

GND

NC

C

POWER

INPUT

C

NO

NO

RLY4

HEATER OPTION

USB HARNESS

CONNECTOR

NC

C

RLY5

NC

NO

RLY6

SENSOR

C

NO

GND

Page 5

SLT 5.0 Level and Flow Monitor

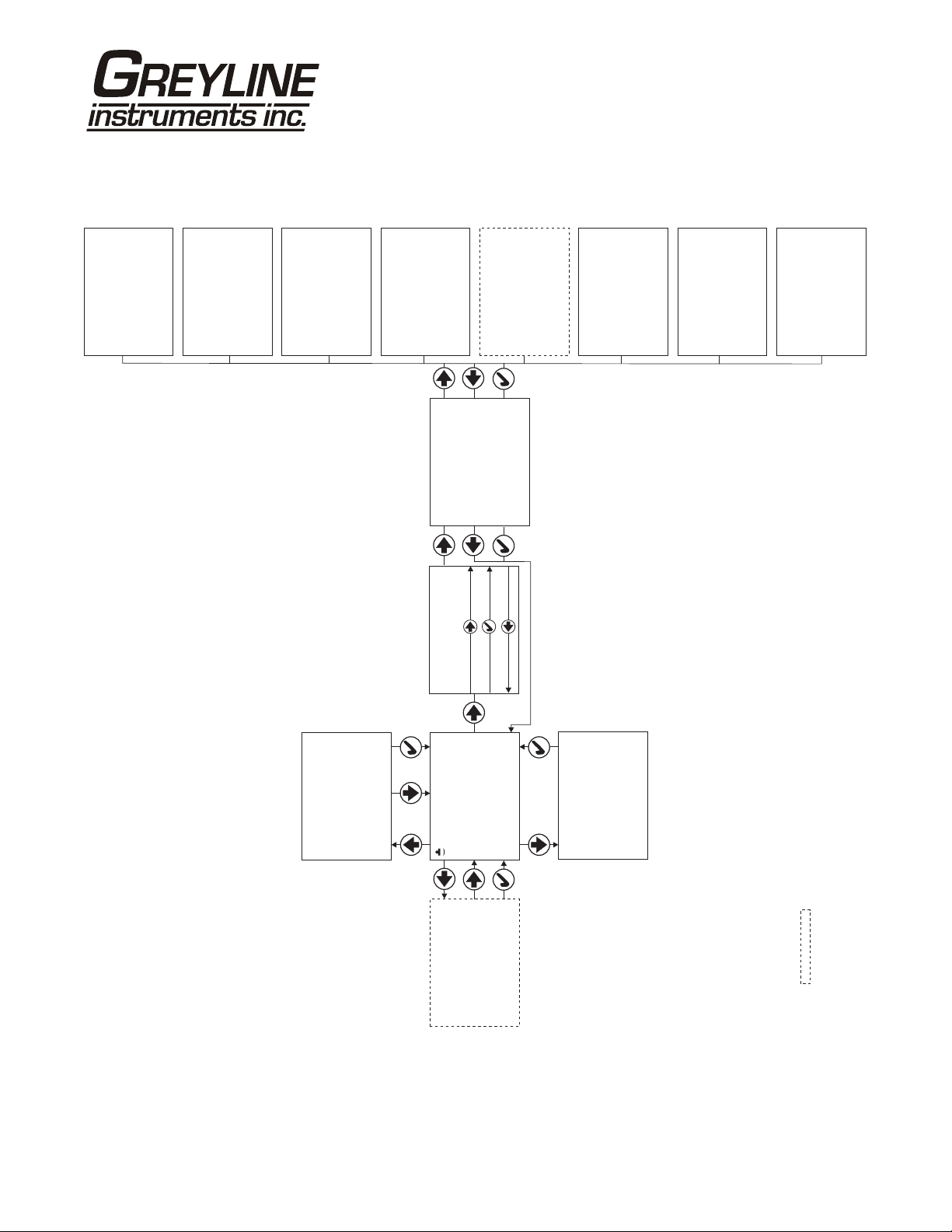

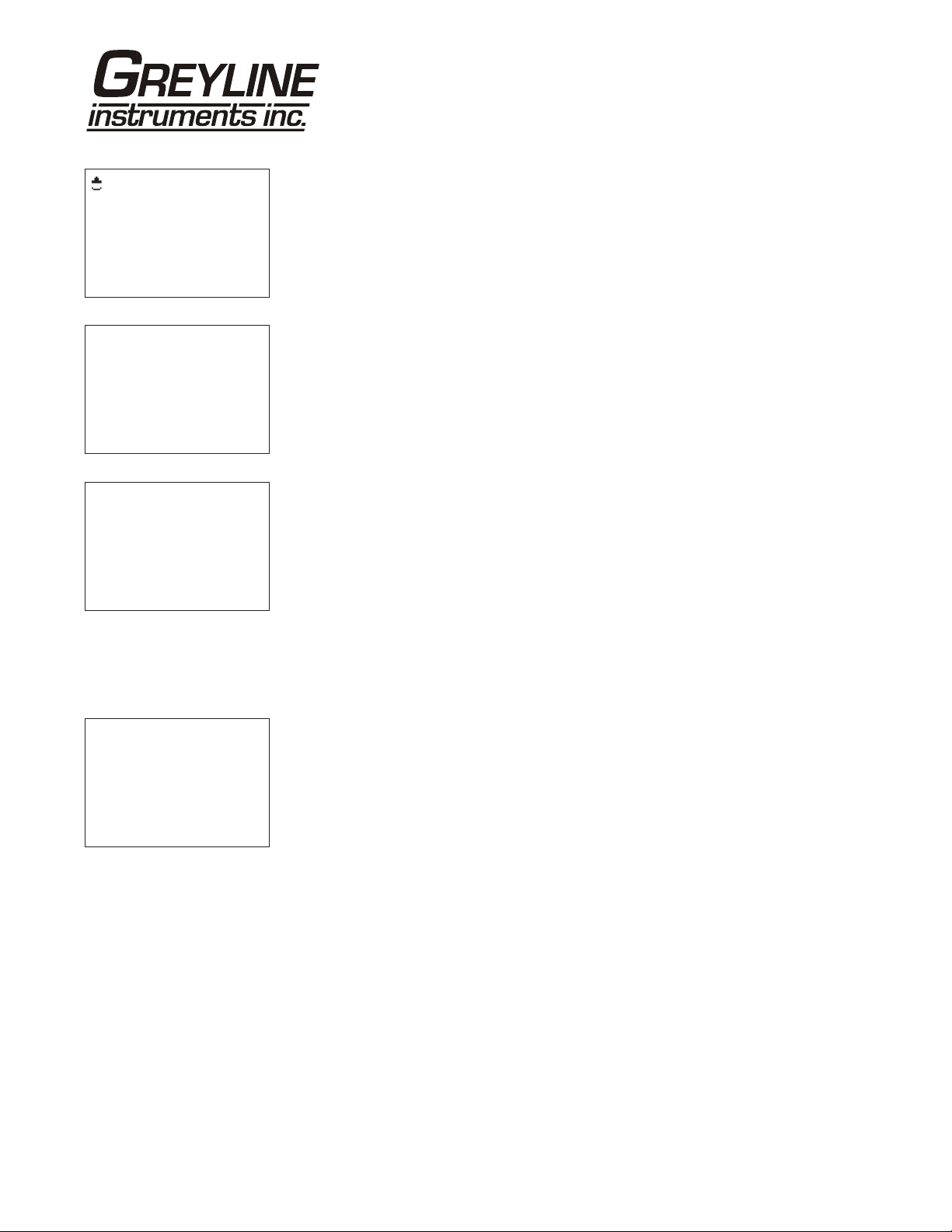

KEYPAD SYSTEM

The following diagram shows the SLT 5.0 menu system. Arrows show the four directions to leave a

menu box. Pressing a corresponding keypad arrow will move to the next item in the direction shown.

Move the cursor (highlighted) under numerals and increase or decrease numerals with the and

keys.

To store calibration values permanently (even through power interruptions), press the .

Page 6

CALIBRATION MENU

FlowFunction

8000 USG/mOff

10000 USG/mOn

May 30 13Set Date /20

SLT 5.0 Level and Flow Monitor

6Relays

24Logger 1. T

1.} 25.01

Mode} Flow

Linear ft

Volume USG

Time min

--Units/Mode--------

Temperature C

--Calibration-------

Min Range 1.000ft}

Max Range 12.000ft

Damping 10%

LOE Time 30sec

Size 22.5°

Type V-notch}

-- ----Channel Setup--

Relay 1}

Mode Pump

LOE mode Off

--Relay Parameters--

Alternate No

--Data Logging-------

SetupChannel

Units / Mode}

Calibration

Relay Parameters

--Menu Selections----

Password 0000

--Password----------

USG/m

Log Site ID 0}

Mode Flow

Set Time 14:24:40

Interval 30sec

Log NO

Data Logging

Special Functions

Simulation

Configuration

Language English}

Analog Out 4-20mA

Backlight High

Reset Totalizer NO

Restore Defaults NO

--Special Functions-

New Password 0000

--Simulation--------

Flow 250USG/m

4-20mA Flow 4.00

Relays 1 2 3 4 5 6

}Test Actual

Utility

Sonar 1.15

--Configuration-----

Analog Out 1

0.000

Data log Stopped

Log Used 0%

Sensor Good

Temperature 21C

--Message-----------

Date Feb. 12/20} 13

--24 hr log----------

Page 7

Tot 20130.8 USG

Relays 1 2 3 4 5 6

9:15:00Min Time

11:08:00Max Time

50138 USGTotal

52.20 USG/mMaximum

0.000 USG/mMinimum

34.82 USG/mAverage

Range 1.00ft}

Tot 0.000ft³

EC 100%

Relays 1 2 3 4 5 6

--Status------------

OPTIONAL FEATURES

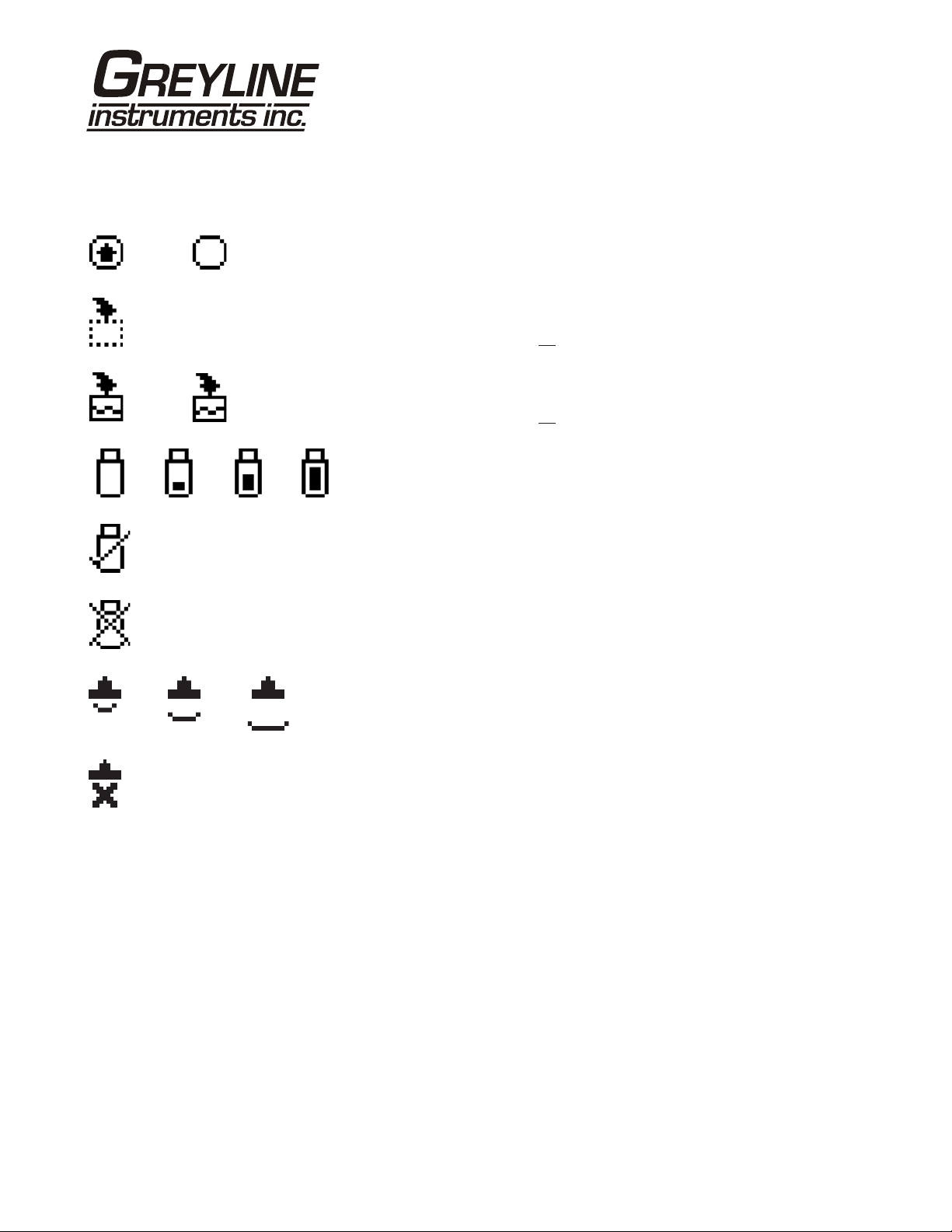

ICONS

SLT 5.0 Level and Flow Monitor

1. 2.

1.

1.

2.

2. 3.

4.

Message waiting. Press .Ç

Data logging .off

Data logging .on

USB file download.

File download completed.

Download Error.

1.

3.2.

Echo OK.

No Echo .

Page 8

SLT 5.0 Level and Flow Monitor

USG/m

0.000

Tot 20130.8 USG

Relays 1 2 3 4 5 6

--Message----------Data log Stopped

Log Used 0%

Sensor Good

Temperature 21C

--Status------------

Range 1.00ft

}

Tot 0.000ft

EC 100%

Relays 1 2 3 4 5 6

--24 hr log---------Date Feb. 12/2010

}

Total 50138 USG

Average 34.82 USG/m

Maximum 52.20 USG/m

Max Time 11:08:00

Minimum 0.000 USG/m

Min Time 9:15:00

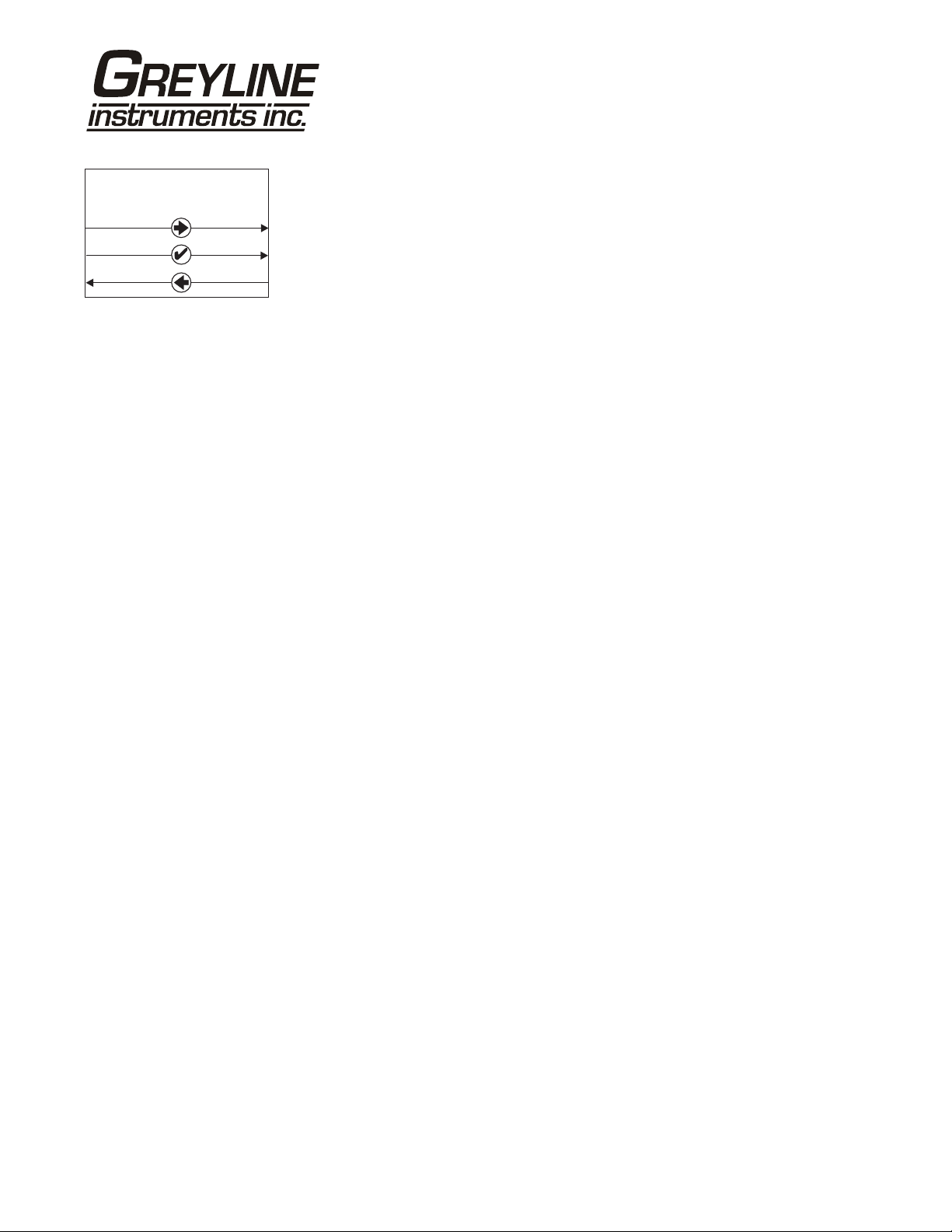

MAIN DISP LAY

The main display shows the units selected from the Units/Mode menu, Level,

Range, Flow, HRT, and Volume rate being measured, TOTALIZER and RELAY

states. The SLT 5.0 will start-up with this display.

MESSAGE ICON

Press from the main display to view status of the data logger and error/warning

messages provided by the instrument. The Message Icon will appear on the main

display if error messages are being generated by the instrument. Refer to the

manual section Error/Warning Messages for a description. Press to return to the

main display.

STATUS

³

Press from the main display to view instrument status. Range will be displayed

in linear units.

Tot Displays the current totalizer reading.

EC Displays echo confidence.

Relays Energized relays will display as a white character on a black

background.

24 HR LOG (Data Logging option only)

Press from the main display to view a formatted flow report from instruments

with a built-in data logger. Press to scroll down one day or repeatedly to scroll

to a specific date. Up to 365 days can be stored. Newest date will overwrite the

oldest. Press to return to the main display.

Page 9

SLT 5.0 Level and Flow Monitor

--Password----------

Password 0000

PASSWORD

The password (a number from 0000 to 9999) prevents unauthorized access to the

Calibration menu.

From the Main display press the key to get to

password is 0000 and if it has not been changed press the to proceed to the

Menu Selections screen.

If a password is required, press to place the cursor under the first digit and or

to set the number, then to the second digit, etc. Press or to proceed to

the Menu Selections screen.

A new password can be stored by going to

Password

.

Password. Factory default

Special Functions/New

Page 10

SLT 5.0 Level and Flow Monitor

--Units/Mode-------Mode Flow

}

Linear ft

Volume USG

Time min

Temperature C

--Units/Mode--------

Mode Flow

Linear} in

--Units/Mode--------

}Volume USG

ft3

bbl

IMG

USMG

--Units/Mode-------Temperature} C

ft

mm

m3

IG

UNITS/MODE

From

Flow, HRT or Volume.

Mode press the and then the or to select Level, Range,

Range mode displays distance from the sensor to the target or liquid surface

like a tape measure. Range mode is useful to measure the exact

distance from the sensor to the zero level during calibration, or to

monitor "outage" or free space in a tank.

Level mode can be used to measure tank level in linear units, or "Head"

m

(height of flow) in an open channel for comparison with a flume

manufacturer's flow tables.

Volume Volume mode displays tank inventory in engineering units like

gallons or liters.

HRT Horizontal Round Tank mode sets the SLT 5.0 to calculate and

display volume units in a horizontal round tank.

L

Flow mode is for open channel flow through a flume or weir.

From

Volume HRT or Flow press to make your selection. (Range or

Level mode will bypass the Volume units selection menu). Volume Hrt or Flow

modes will give you the additional choice of volumetric units:

F

ft3 - cubic feet

USG - US gallons

USMG - US million gallons (FLOW only)

IG - Imperial gallons

IMG - Imperial million gallons (FLOW only)

m3 - cubic meters

L - liters

bbl - U.S. oil barrel

Press the to store your selection then the to the next menu item and to

enter.

Linear

press the key and then the or to select your units

of measurement. Press the to store your selection.

Time

press and then or to select

sec.

or

day, hr, min

Temperature

press and then or to select C or F

(Centigrade or Fahrenheit).

Press or to return to the Menu Selections screen.

Page 11

SLT 5.0 Level and Flow Monitor

--Calibration------Min Range 1.000ft

}

Max Range 12.000ft

Damping 10%

LOE Time 30sec

CALIBRATION

Press the to

Calibration and to enter. Use or to position

before each menu item and to enter. When settings are completed press to

store and return to the Calibration menu.

Min Range Distance from the sensor face to highest expected level.

Max Range Distance from sensor to Zero level.

MaxVol For Volume and HRT mode only. Enter the maximum volume of

the vertical or horizontal tank.

Damping Minimum damping allows fast response to level changes.

Increasing damping slows the SLT 5.0's response to level changes

and is ideal to smooth the display and outputs in turbulent

conditions. Damping value is shown in percent (0-99%). Some

experimentation may be required to select the optimum damping

value. A value of 1% is recommended for most applications. For

fast level changes (up to ½ inch/sec - 13 mm/sec), a Damping

value of 1% is recommended.

LOE Time Press and or to change the number of seconds without

receiving an echo before the SLT 5.0 displays ECHO LOSS, and

Control relays change state as calibrated under Relay Parameters.

Factory default is 30 seconds and is recommended for most

applications, Minimum is 1 second and maximum is 99 seconds.

Press to return to Menu Selections.

Page 12

SLT 5.0 Level and Flow Monitor

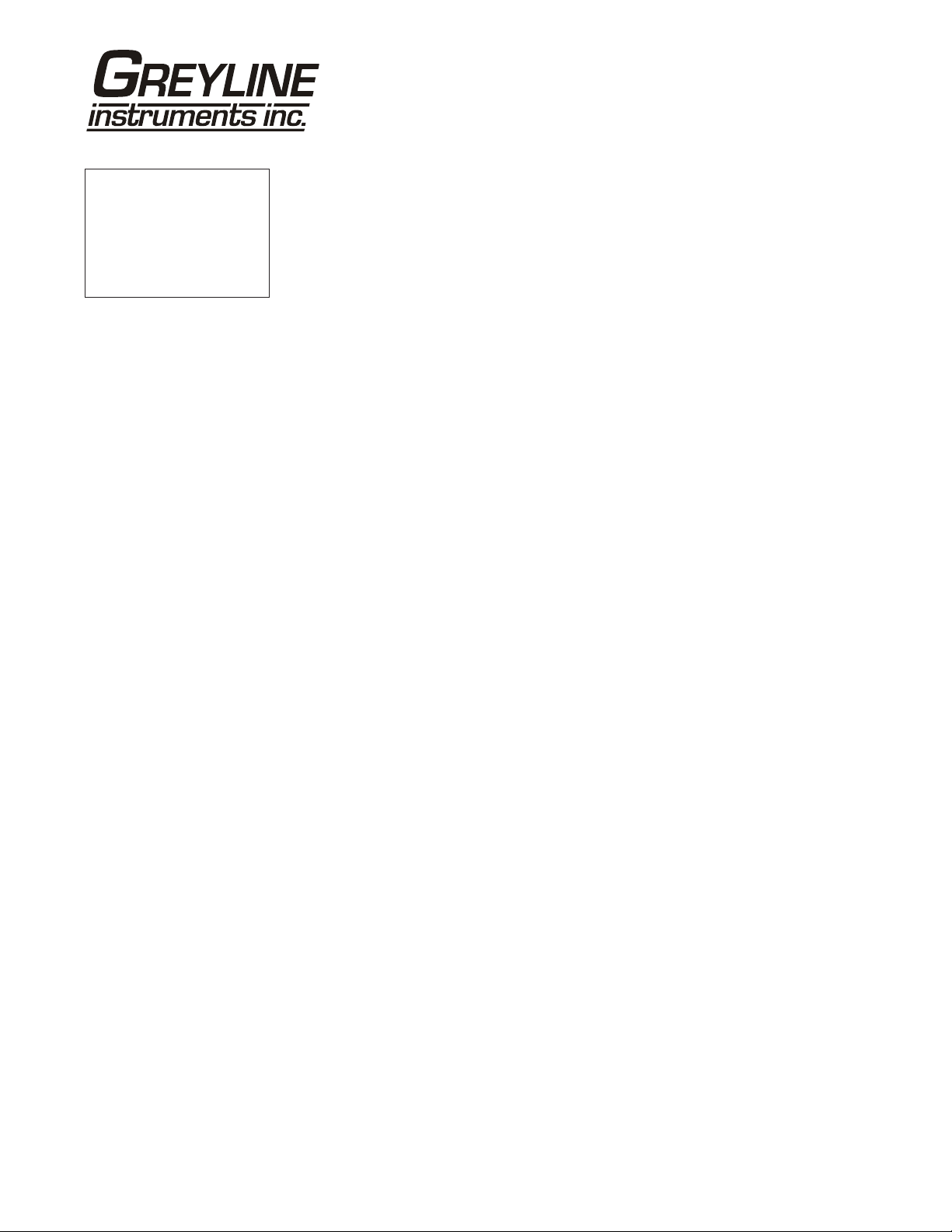

TAN KINVENTORY

LEVEL MODE

SENSOR

MAX RANGE

100%

MIN RANGE

0%

TAN KINVENTORY

RANGE MODE

SENSOR

MAX RANGE

0%

100%

MIN RANGE

TAN KINVENTORY

HORIZONTAL ROUND TANK(HRT)MODE

MIN RANGE

MAX

VOLUME

MAX RANGE

MAX LEVEL

MAX

VOLUME

ZERO LEVEL

MAX LEVEL

ZERO LEVEL

CALIBRATION

- for Level/Inventory Applications

1. Before starting the calibration determine:

a) MAX RANGE = ________________

(Maximum range = distance from Sensor to Zero level)

b) MAX LEVEL = ________________

(Maximum level of product being measured)

c) MIN RANGE = ________________

(Distance from sensor to Max Level)

Minimum range = MAX RANGE - MAX LEVEL

(must be at least 8" / 203 mm depending on sensor model)

2. Check the maximum range with the sensor installed by:

a) When liquid is at zero level press to view the Range reading in the

Status menu. Use this range measured by the SLT 5.0 as the Max Range

setting.

or

b) Carefully measure distance from sensor to zero level with a tape measure,

and use this measurement as the Max Range setting.

MINIMUM RANGE:

At CALIBRATION

- Press to get to Min Range

- Press to move the cursor under the digits

- Use or to set th e minimum range

Note: Min Range must be at least 12" (30.5 cm) for PZ32T sensors, 16" (40.6 cm)

for PZ52T and PZ34 sensors and 8" for PZ15 sensors. For correct tank volume

calculation in Hrt mode Min Range must be the actual distance from the end of

the sensor to the top of the tank.

MAXIMUM R A NGE:

Press to get to Max Range

Enter Max Range determined above.

Page 13

SLT 5.0 Level and Flow Monitor

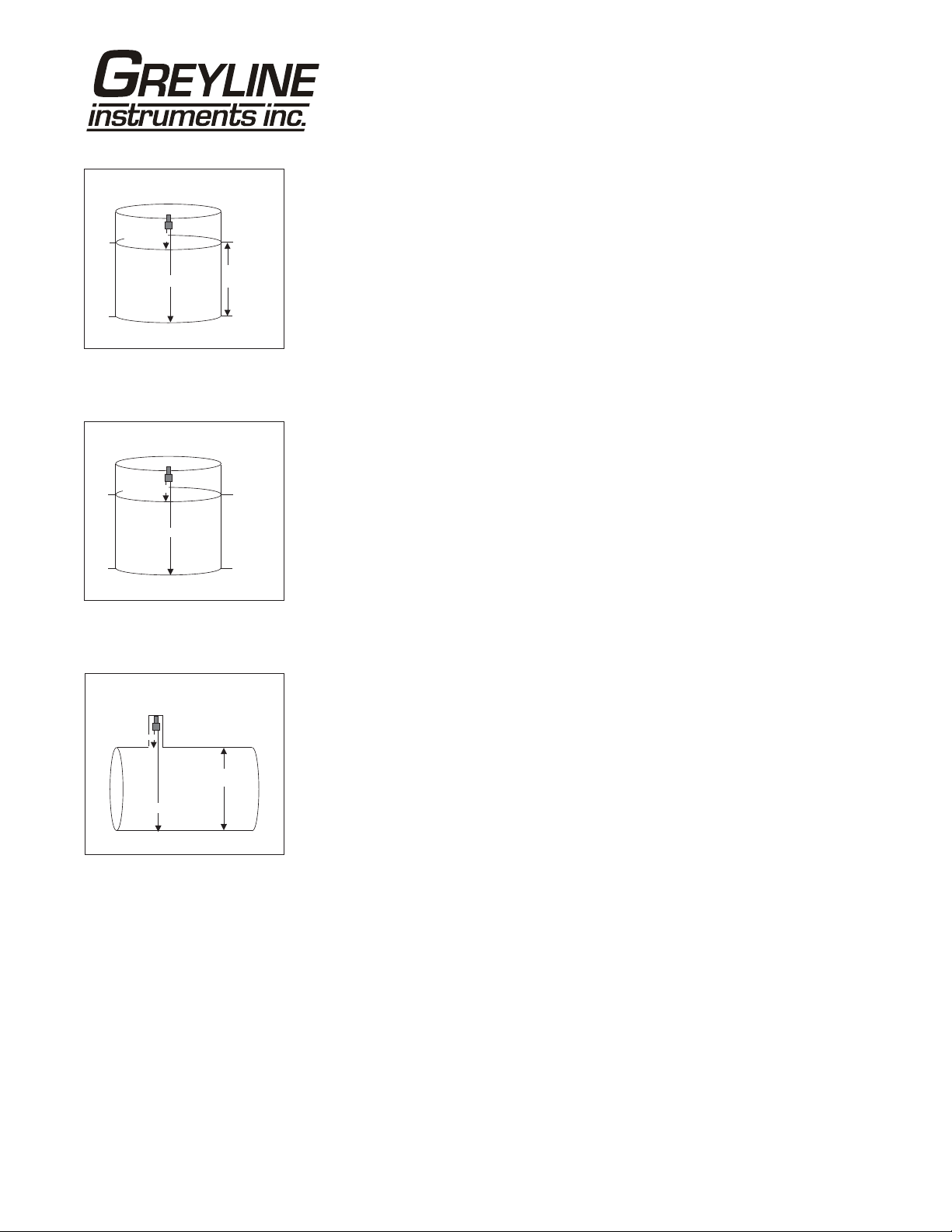

PAL MER BOWLUS

MAX LEVEL

V-NOTCH

ZERO LEVEL

SENSOR

SENSOR

MIN

RANGE

MAX LEVEL

MAX

RANGE

ZERO LEVEL

MIN

RANGE

MAX

RANGE

CALIBRATION

- for Open Channel Flow

1. Before starting the calibration determine:

a) MAX RANGE = ____________________

(Maximum range = distance from the Sensor to Zero flow point)

b) MAX LEVEL = ____________________

(Maximum level of flow through flume or weir)

c) MIN RANGE = __________________

(Distance from sensor to Max Level)

Minimum range = MAX RANGE - MAX LEVEL

(must be at least 8" / 20.3 cm depending on sensor model).

2. Check the maximum range with the sensor installed by:

a) When liquid is at zero level press to view the Range reading in the

Status menu. Use this range measured by the SLT 5.0 as the Max Range

setting.

or

b) Carefully measure distance from sensor to zero level with a tape measure,

and use this measurement as the Max Range setting.

NOTE

: The SLT 5.0 will not detect targets beyond user entered MaxRg.

Page 14

Loading...

Loading...