Greyline Instruments DFM-6.1 Operating Manual

www.greyline.com

USER'S GUIDE

Installation & Operation

Instructions

Doppler Flow Meter

Model DFM 6.1

Manual Series A.1

Note: This page has been left blank intentionally.

DFM 6.1 Doppler Flow Meter

INDEX |

|

CONNECTIONS ................................................................................................................ |

4 |

KEYPAD SYSTEM............................................................................................................ |

6 |

CALIBRATION MENU..................................................................................................... |

7 |

ICONS................................................................................................................................. |

8 |

MESSAGE ICON............................................................................................................... |

9 |

STATUS ............................................................................................................................. |

9 |

PASSWORD..................................................................................................................... |

10 |

MENU SELECTIONS...................................................................................................... |

10 |

UNITS/MODE.................................................................................................................. |

11 |

CALIBRATION................................................................................................................ |

12 |

RELAY PARAMETERS.................................................................................................. |

13 |

DATA LOGGING............................................................................................................ |

14 |

COMMUNICATION (OPTIONAL)................................................................................ |

16 |

SPECIAL FUNCTIONS................................................................................................... |

18 |

SENSOR MOUNTING..................................................................................................... |

21 |

ENCLOSURE INSTALLATION..................................................................................... |

25 |

FIELD TROUBLESHOOTING ....................................................................................... |

26 |

COMMON QUESTIONS AND ANSWERS ................................................................... |

29 |

APPLICATIONS HOTLINE............................................................................................ |

31 |

PRODUCT RETURN PROCEDURE.............................................................................. |

31 |

OPTIONS.......................................................................................................................... |

33 |

MODBUS® COMMUNICATION................................................................................... |

39 |

HART® COMMUNICATION......................................................................................... |

50 |

SPECIFICATIONS........................................................................................................... |

62 |

PIPE CHARTS.................................................................................................................. |

64 |

IMPORTANT NOTE: This instrument is manufactured and calibrated to meet product specifications. Please read this manual carefully before installation and operation. Any unauthorized repairs or modifications may result in a suspension of the warranty.

If this product is not used as specified by the manufacturer, protection may be impaired.

Available in Adobe Acrobat pdf format

Page 3

DFM 6.1 Doppler Flow Meter

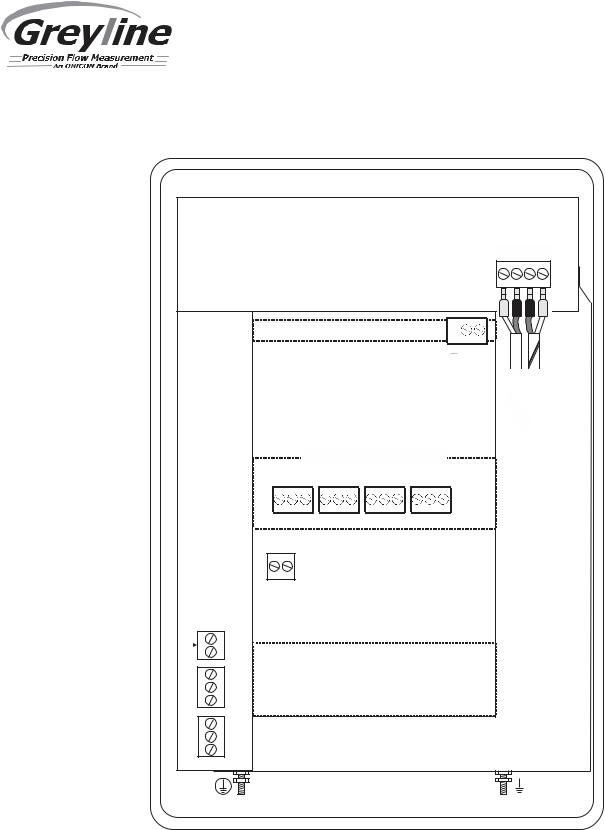

CONNECTIONS:

POWER INPUT: The standard model requires AC power input between 100 to 240 VAC 50/60Hz. No adjustments are necessary for voltages within this range. Connect L (Live) N (Neutral) and AC Ground.

Optional DC input model requires 9-32 VDC/10 Watts. Connect to + and - terminals.

Optional Thermostat and Heater modules are available rated for 115 VAC or 230 VAC.

IMPORTANT NOTE: To comply with CSA/UL electrical safety standards, AC power input and relay connection wires must have conduit entry to the instrument enclosure. Installation requires a switch, overcurrent fuse or circuit breaker in the building (in close proximity to the equipment) that is marked as the disconnect switch.

!Risk of electric shock. Loosen cover screw to access connections. Only qualified personnel should access connections.

Note: Use of instrumentation over 40°C ambient requires special field wiring.

Page 4

DFM 6.1 Doppler Flow Meter

CONNECTIONS

SENSOR

TMTR

GND

GND

RCVR

SERIAL COMMUNICATION OPTION

+ G

RS-485 Output

EXTRA RELAYS OPTION

NC C NO |

NC C NO NC C NO NC C NO |

RLY3 |

RLY4 RLY5 RLY6 |

AC

POWER

INPUT

L N

4-20mA |

– |

|

+ |

||

|

NO

RLY2 C HEATER OPTION

C HEATER OPTION

NC

NO

RLY1 C

C

NC

AC |

SENSOR |

GND |

GND |

Page 5

DFM 6.1 Doppler Flow Meter

KEYPAD SYSTEM

The diagram on page 7 shows the DFM 6.1 menu system. Arrows show the four directions to leave a menu box. Pressing a corresponding keypad arrow will move to the next item in the direction shown. Move the cursor (highlighted) under numerals and increase or decrease numerals with the and keys.

To store calibration values permanently (even through power interruptions), press the button.

Page 6

CALIBRATION MENU

------------Messages |

|

Data Log |

Logging |

Log Used |

0.00000 % |

Sensor |

Good |

|

|

--24 hr log---------- |

|

USG/m |

|||

Date |

Feb. 12/2010 |

0.000 |

|||

Total |

50138 USG |

||||

Average 34.82 USG/m |

|||||

Maximum |

52.20 USG/m |

||||

Max Time |

11:08:00 |

Tot |

20130.8 USG |

||

Minimum |

0.000 USG/m |

||||

Relays |

1 2 3 4 5 6 |

||||

Min Time |

9:15:00 |

||||

|

|

|

|||

|

|

--Status------------ |

|||

|

|

Velocity |

0.00ft/s |

||

|

|

Flow |

0.00 USG/M |

||

|

|

Min Flow |

0.00USG/M |

||

|

|

Signal Strength |

0% |

||

|

|

Signal Cutoff |

10% |

||

--*Password----------

Password 0000

OPTIONAL FEATURES

*Menu only appears if "New Password" has been changed from 0000 in "Special Functions" menu.

DFM 6.1 Doppler Flow Meter

--Menu--------------

Units / Mode

Calibration

Relay Parameters Data Logging

Communication Special Functions

Simulation Configuration

--Units/Mode-------- |

|||

Mode |

|

Flow |

|

Linear |

|

|

in |

Volume |

|

|

USG |

Multiplier |

|

x1 |

|

Velocity |

ft/s |

||

Flow |

|

USG/m |

|

--Calibration------- |

|||

Mode |

|

Flow |

|

20mA |

2500.0 USG/m |

||

4mA |

0.000 USG/m |

||

Pipe ID |

|

12.00in |

|

Min Flow |

0.00 USG/m |

||

Signal Cutoff |

10% |

||

Damping |

|

|

10% |

Cal Constant |

1.000 |

||

--Relay Parameters-- |

|||

Relay |

|

|

1 |

Function |

Flow |

||

On |

1000 USG/m |

||

Off |

0.000 USG/m |

||

--Data Logging------- |

|||

Log Site ID |

|

0 |

|

Mode |

|

Flow |

|

File Format |

.LG2 |

||

Date |

May 18/2018 |

||

Time |

11:27:40 |

||

Interval |

10sec |

||

Data Log |

|

Logging |

|

--Communication----- |

|||

Protocol |

Modbus |

||

Address |

|

|

001 |

BPS |

|

9600 |

|

Parity |

|

Even |

|

Stop Bits |

|

1 |

|

--Special Functions- |

|||

Language |

English |

||

Analog Out |

4-20mA |

||

Backlight |

High |

||

Reset Totalizer |

NO |

||

Neg. Totals |

|

No |

|

Rev. Flow |

|

Off |

|

Capture WF |

|

No |

|

Restore Defaults |

No |

||

New Password |

0000 |

||

--Simulation-------- |

|

|

|

Test |

|

Actual |

|

Flow |

250USG/m |

||

4-20mA Flow |

5.60 |

||

Relays |

1 2 3 4 5 6 |

||

--Configuration-----

Serial# 12345

Utility 1.22.0.5

Doppler 1.16.1

CommBoard |

1.18.0 |

Relays |

6 |

Analog Out |

1 |

Page 7

DFM 6.1 Doppler Flow Meter

ICONS

1. |

2. |

Message waiting. Press . |

Data logging off.

1. |

2. |

Data logging on. |

1. |

2. |

3. |

4. |

USB file download. |

File download completed.

Download Error.

Page 8

USG/m

0.000

Tot |

20130.8 USG |

Relays |

1 2 |

|

|

|

|

--Messages---------- |

|

Data Log |

Logging |

Log Used |

0.00000 % |

Sensor |

Good |

|

|

--------------Status |

|

|

Velocity |

0.00ft/s |

|

Flow |

0.00 USG/m |

|

Min Flow |

0.00USG/m |

|

Signal Strength |

0% |

|

Signal Cutoff |

10% |

|

|

|

|

DFM 6.1 Doppler Flow Meter

MAIN DISPLAY

The main display shows the units selected from the Units/Mode menu, flow or velocity rate being measured, totalizer and relay states. The DFM 6.1 will start-up with this display.

MESSAGE ICON

Press from the main display to view status of the data logger and error/warning messages provided by the instrument. The Message Icon will appear on the main display if error messages are being generated by the instrument. Press to return to the main display.

STATUS

Press from the main display to view instrument status. Velocity will be displayed in ft/sec or m/sec.

Velocity

Flow

Min Flow

Displays the measured flow velocity in units selected in the Units/Mode menu.

Displays the measured flow rate in units selected in the Units/Mode menu.

Displays the minimum flow rate setting. This value is read-only. The Min Flow can be changed in the Calibration programming menu. A measured Flow value below the Min Flow value will display as 0 flow on the meter’s LCD display.

Signal

Strength

Signal Cutoff

Displays the strength of the received Doppler signal on a 0-100% scale.

Displays the signal cutoff. This value is read-only. The Signal Cutoff can be changed in the Calibration programming menu. If Signal Strength is less than Signal Cutoff, the meter will report 0 velocity and flow on the LCD display. Setting may need to be adjusted in the case of unstable flow near zero, or when high levels of industrial noise are present.

Page 9

------------24 hr log |

|

|

Date |

Feb. 12/2010 |

|

Total |

50138 USG |

|

Average |

34.82 |

USG/m |

Maximum |

52.20 |

USG/m |

Max Time |

11:08:00 |

|

Minimum |

0.000 |

USG/m |

Min Time |

9:15:00 |

|

|

|

|

|

|

|

--Password---------- |

|

|

Password |

|

0000 |

|

|

|

--Menu--------------

Units / Mode

Calibration Relay Parameters Data Logging Communication Special Functions Simulation Configuration

DFM 6.1 Doppler Flow Meter

24 HR LOG (Data Logging option only)

Press from the main display to view a formatted flow report from instruments with a built-in data logger. Press to scroll down one day or repeatedly to scroll to a specific date. Up to 365 days can be stored. Newest date will overwrite the oldest. Press to return to the main display.

PASSWORD

The Password (a number from 0000 to 9999) prevents unauthorized access to the Calibration menu.

From the Main Display press the key to get to Password. Factory default password is 0000 and if it has not been changed, this screen will be bypassed completely.

A new password can be stored by going to the Special Functions New Password menu.

If a user password is required, press to place the cursor under the first digit and or to set the number, then to the second digit, etc. Press or to proceed to the Menu Selections screen.

MENU SELECTIONS

The Menu selections page is used to navigate to specific menus which are described in more detail on the following pages.

Press or to navigate to different menus, and to enter the selected menu.

Page 10

DFM 6.1 Doppler Flow Meter

----------Units/Mode |

|

Mode |

Flow |

Linear |

in |

Volume |

USG |

Multiplier |

x1 |

Velocity |

ft/s |

Flow |

USG/m |

|

|

UNITS/MODE

At Mode, press the and then the or to select Flow or Velocity. Flow mode displays the flow rate in engineering units (e.g. gpm, litres/sec, etc.) Press the to store your selection then the to the next menu item.

At Linear press the key and then the or to select your units of measurement. The Linear units define what units the pipe dimensions and sensor spacing will be displayed in. Typically inches or mm is selected. Press the to store your selection then the to the next menu item.

At Volume, press the and then the or to select units for volume. Note: “bbl” denotes US oil barrels. Press the to store your selection then the to the next menu item.

At Multiplier, press the and then the or to select the totalizer multiplier. Multipliers are used when resolution down to single digit is not required, or when you don’t want to convert from gallons to thousands of gallons, as an example. Press to store your selection then to the next menu item.

At Velocity, press the and then the or to select the engineering units for flow velocity and sonic velocity of the fluid. Press to store your selection then to the next menu item.

At Flow, press the and then the or to select the engineering units for flow rate. Press to store your selection then to the next menu item.

Available Flow Rate Engineering Units:

Abbreviation |

Description |

Abbreviation |

Description |

|

|

|

liters per day |

USG/d |

US gallons per day |

L/d |

|

USG/h |

US gallons per hour |

L/h |

liters per hour |

USG/m |

US gallons per minute |

L/m |

liters per minute |

USG/s |

US gallons per second |

L/s |

liters per second |

ft3/d |

cubic feet per day |

m3/d |

cubic meters per day |

ft3/h |

cubic feet per hour |

m3/h |

cubic meters per hour |

ft3/m |

cubic feet per minute |

m3/m |

cubic meters per minute |

ft3/s |

cubic feet per second |

m3/s |

cubic meters per second |

bbl/d |

barrels per day (1 bbl = 42 USG) |

IG/d |

Imperial gallons per day |

bbl/h |

barrels per hour (1 bbl = 42 USG) |

IG/d |

Imperial gallons per day |

bbl/m |

barrels per minute (1 bbl = 42 USG) |

IG/d |

Imperial gallons per day |

bbl/d |

barrels per second (1 bbl = 42 USG) |

IG/d |

Imperial gallons per day |

USMG/d |

US million gallons per day |

IMG/d |

Imperial million gallons per day |

USMG/h |

US million gallons per hour |

IMG/h |

Imperial million gallons per hour |

USMG/m |

US million gallons per minute |

IMG/m |

Imperial million gallons per minute |

USMG/s |

US million gallons per second |

IMG/s |

Imperial million gallons per second |

Page 11

---------Calibration |

|

|

Mode |

|

Flow |

20mA |

500 USG/m |

|

4mA |

|

0 USG/m |

Pipe ID |

|

4.03 in |

Min Flow |

5.00 USG/m |

|

Signal Cutoff |

10% |

|

Damping |

|

10% |

Cal Constant |

1.000 |

|

|

|

|

DFM 6.1 Doppler Flow Meter

CALIBRATION

Press or to position curser at Calibration menu, and to enter. Use or to position cursor before each menu item and to enter. When settings are completed press to store and again to return to the Main Menu.

20mA |

Press then or to change the numbers and decimal |

(5V) |

point. Use this menu to set the corresponding flow rate |

|

that will be represented by 20mA analog output. If |

|

maximum flow is unknown, enter an estimated flow rate |

|

and observe actual flow to determine the correct |

|

maximum value. Any velocity or flow rate up to +40 |

|

ft/sec (12.2 m/sec) may be selected. |

4mA |

Press or to set the flow rate corresponding to 4mA |

(0V) |

analog output. This setting may be left at zero flow (or |

velocity or can be raised to any value less than the 20mA setting, or lowered to any velocity or corresponding flow rate down to -40 ft/sec

(-12.2 m/sec).

Pipe ID

Min Flow

Signal

Cutoff

Damping

Cal Constant

Place the cursor under the digits and then or to change the numbers and decimal point. Pipe ID should be entered as the exact inside diameter of the pipe where the sensor is mounted. Refer to the Pipe Charts Appendix in this manual for inside diameter of common pipe types and sizes.

Press and enter a minimum flow cutoff. Forward and reverse flows less than Min Flow will be forced to zero.

Adjust the setting in percent to suppress flow readings at zero flow when fluid swirling or pipe vibration may cause the instrument to continue reading. Example: Signal Cutoff at 5% will force the display and outputs to zero when signal strength drops below 5%.

Increase damping to stabilize readings under turbulent flow conditions. Decrease for fast response to small changes in flow. Damping is shown in percentage (maximum is 99%). Factory default is 10%.

Scales the velocity reading. Factory value is close to 1.000 for a SE4-A sensor.

Press to return to Menu Selections screen.

Page 12

--Relay Parameters--

Relay |

|

1 |

Function |

|

Flow |

On |

1000 |

USG/m |

Off |

0.000 |

USG/m |

DFM 6.1 Doppler Flow Meter

RELAY PARAMETERS

Press or to position curser at Relay Parameters, and to enter. Use or to position cursor before each menu item and to enter. When settings are completed press to store and again to return to the Main Menu.

Relay

Function

Flow

Pulse

Press and or to select a corresponding relay number (2 relays are standard, 4 additional are optional).

Press or to select Off, On, Pulse or Flow.

On Highlight the numerals and press or to set digits to the required relay On set point.

Off set digits to the required Off set point.

Press and set digits to the flow volume increment required between relay pulses. Use this feature for remote samplers, chlorinators or totalizers. Minimum time between pulses is 2.25 seconds and pulse duration is 350 milliseconds.

|

Return to Relay and change settings for each relay |

|

number. |

|

Press to return to Menu Selections. |

ON |

Sets relay in energized state. |

Page 13

--Data Logging------- |

||

Log Site ID |

0 |

|

Mode |

|

Flow |

File Format |

.LG2 |

|

Date |

May 18/2018 |

|

Time |

|

11:27:40 |

Interval |

|

10sec |

|

|

60min |

|

|

30min |

|

|

15min |

|

|

10min |

|

|

5min |

|

|

2min |

|

|

1min |

|

|

30sec |

Data Log |

|

Stop |

|

|

Start |

|

|

Delete |

|

|

|

DFM 6.1 Doppler Flow Meter

DATA LOGGING

Press or to position curser at Data Logging, and to enter. Use or to position cursor before each menu item and to enter. When settings are completed press to store and again to return to the Main Menu.

Log Site ID Enter a number from 00 to 99. The site ID will become part of the downloaded file name to help distinguish downloads from

|

different instruments. Press to store the setting. |

Mode |

Select Velocity (e.g. ft/sec or m/sec) or Flow (e.g. USGPM or |

|

l/sec). Press to store the setting. |

File Format Choose .LG2 to download data in .lg2 format for viewing on Greyline Logger software. Choose .CSV to download data in

.csv format for import directly to Excel. This menu option can be changed at any time without adversely affecting existing data.

Date |

Press , and or to scroll and select Month, Day and |

|

Year. Press to store the setting. |

Time |

Press , and or to select the current time in Hours, |

|

Minutes and Seconds. Press to store the setting. |

Interval |

Press or to select the logging interval. Press to store |

|

the setting. Greyline recommends choosing an interval which |

|

will give you as much resolution as required and no more. |

|

Choosing too often of an interval for what is required will |

|

result in larger data files, which may take a long time to |

|

download to USB. Reference page 15 for specific download |

|

times. In critical installations, data should be downloaded |

|

often. |

Data Log |

Stop, Start or Delete the log file. Press or to select Delete |

|

and to delete the log file. Press or to select Start and |

|

to start the logger. |

Important Note: You MUST Delete an old log and Start a new log AFTER having made changes to Log Site ID, Mode, Date, Time and/or Interval for those changes to be applied.

Important Note: Changing any of the parameters in the Units/Mode menu will start a new log. It is recommended that you Delete and start a new log after changing any Units/Mode settings.

Page 14

DFM 6.1 Doppler Flow Meter

RETRIEVING LOG FILE

Plug a USB Flash Memory Drive (one is included with the DFM 6.1) into the USB output port on the Panel of the meter. The instrument display will show the data download icon until the log file is transferred to the memory card. The USB flash drive may be removed when the icon for download successful appears.

Download file names will appear in this format:

DFM__00A.LG2 or

DFM__00A.CSV

MODEL TAG DOWNLOAD

Tag is set according to the Log Site ID entered in the instrument Data Logging menu.

Download letter will be A for the first download from an instrument. B for the second, then C etc. At the letter Z a - character will appear indicating that the maximum number of downloads for that instrument are on the USB flash drive. Older files can be erased or moved from the flash memory drive or a new memory drive can be used.

Note: Downloading files in .lg2 format will take approximately 35 seconds per 1% of internal log memory used.

Downloading files in .csv format will take approximately 8 minutes per 1% of internal log memory used.

OPENING .LG2 FILES

Install Greyline Logger on your PC or laptop. Select File/Open/Instrument Log (.log) to open the log file from your USB flash drive. Greyline Logger software is available on Greyline’s website, www.greyline.com. Data can also be converted to .CSV via Greyline Logger software.

OPENING .CSV FILES

Use a datasheet program such as Microsoft Excel® to import data in a comma delimited format. Use Excel to manipulate or graph data.

Page 15

--Communication----- |

|

Protocol |

Modbus |

Address |

001 |

BPS |

9600 |

Parity |

Even |

Stop Bits |

1 |

DFM 6.1 Doppler Flow Meter

COMMUNICATION (Optional)

Press or to position curser at Communication, and to enter. Use or to position cursor before each menu item and to enter. When settings are completed press to store and again to return to the Main Menu.

MODBUS Protocol Information:

Transceiver: |

2-wire, half-duplex |

Data format: |

8 Data Bits |

Floating Point Byte Order: ABCD |

|

Termination: |

Jumper JP1 selectable 120Ω resistor. TB1 & TB2 = OFF, |

|

TB2 & TB3 = ON |

Biasing: |

None |

HART® (Highway Addressable Remote Transducer) Protocol Information:

HART Version: |

7.0 |

Device |

DD files allow the user’s handheld HART communicator to |

Description |

fully configure the DFM 6.1 Greyline provides DD files for |

Files: |

the Emerson 475 Communicator. The files are included in the |

|

USB drive provided with your DFM 6.1 meter. You may also |

|

request the files from Greyline by calling or emailing us at |

|

info@greyline.com. Warning: The DFM 6.1 and associated |

|

DDs are pending certification from the Fieldcomm Group. |

Connections: |

HART Protocol uses a digital signal superimposed on the 4- |

|

20mA output. When the 4-20mA output of the DFM 6.1 is |

|

connected with a load resistor (230Ω to 600Ω), the HART |

|

communicator can be connected on the loop in order to |

|

communicate. |

Protocol |

Choose MODBUS or HART. |

Address |

Device address for the DFM. Valid range: 001-247 (Default: |

(Modbus) |

001). This number should be unique across the bus. Press |

|

or to scroll, to select digits, and press to store the |

|

setting. |

|

Page 16 |

|

DFM 6.1 Doppler Flow Meter |

COMMUNICATION (Optional) cont. |

|

BPS |

Baud rate for the MODBUS communications. Press or |

(Modbus) |

to select, and to store the setting. Options: 4800, 9600, |

|

19200, 38400, 57600, 76800, and 115200 (Default: 9600). |

Parity |

Error checking parity for the MODBUS communications. |

(Modbus) |

Press or to select, and to store the setting. Options: |

|

None, Even, and Odd (Default: Even). |

Stop Bits |

Press or to select, and to store the setting. Options: 1 |

(Modbus) |

or 2 (Default: 1). |

Page 17

--Special Functions-

Language |

English |

|

Analog Out |

4-20mA |

|

Backlight |

High |

|

Reset Totalizer |

NO |

|

Neg. Totals |

|

No |

Rev. Flow |

|

No |

Capture WF |

|

No |

Restore Defaults |

No |

|

New Password |

0000 |

|

--Special Functions-

Language English

Backlight High

Medium

Low

Key Hi/Lo

Key High

Key Med

Key Low

Off

DFM 6.1 Doppler Flow Meter

SPECIAL FUNCTIONS

Language

Analog Out

Backlight

Select English, French or Spanish

Select 4-20mA or 0-5V mode for the analog output.

Select High, Medium or Low for continuous backlight.

Select Key Hi/Lo for high backlight for 1 minute after a keypress and then Lo backlight until a key is pressed again.

Select Key High, Med or Low for backlight for 1 minute after a keypress and then backlight off until a key is pressed again.

Reset Totalizer

Neg. Totals

Rev. Flo

Press and select Yes to erase and restart the totalizer at zero.

Select Yes to have reverse flow readings deducted from the totalizer. Select No to totalize forward flow only and ignore reverse flow.

Select On to enable flow direction measurement. Select Off to disable flow direction measurement. Select Invert to invert the sense of the flow measurement.

Capture WF

Restore Defaults

This function should only be used when instructed by a Greyline representative to do so. The function captures the ultrasonic signal so that it can be evaluated by Greyline.

Select Yes to start the waveform download process. After pressing Yes , the screen will flash Working for approximately 20 seconds, until the message Done appears. When Done is on the screen, connect a flash drive to the USB port on the front of the meter. The screen will flash Saving for a couple seconds, and then return to No . The waveform is now stored on your flash drive and ready to be sent to Greyline.

Select Yes and press to erase all user settings and return the instrument to factory default settings.

Page 18

|

DFM 6.1 Doppler Flow Meter |

SPECIAL FUNCTIONS (cont.) |

|

New Password |

Select any number from 0000 to 9999 and press . |

|

Default setting of 0000 will allow direct access to |

|

the calibration menus. Setting of any password |

greater than 0000 will require the password to be entered to access the calibration menus.

Press to return to Menu Selections.

Page 19

--Simulation |

-------- |

|

Test |

|

Actual |

Flow |

|

250USG/m |

4-20mA Flow |

5.60 |

|

Relays |

1 2 3 4 5 6 |

|

|

|

|

DFM 6.1 Doppler Flow Meter

SIMULATION

Press or to position curser at Simulation, and to enter. Use or to position cursor before each menu item and to enter. When settings are completed press to store and again to return to the Main Menu.

Changes made in the Simulation menu exercise the 4-20mA output, digital display and control relays.

Simulate a Flow /Velocity reading. Press and then or to change the simulated output. Press to begin simulation. The 4-20mA output and relay states will be displayed on the screen below.

Press the to terminate simulation and return to the Menu Selections screen.

Page 20

DFM 6.1 Doppler Flow Meter

SENSOR MOUNTING LOCATION

The position of the sensor is one of the most important considerations for accurate flow measurement. The same location guidelines apply to Doppler as most other types of flow meters.

VERTICAL OR HORIZONTAL PIPE - Vertical pipe runs generally provide evenly distributed flow. On Horizontal pipes and liquids with high concentrations of gas or solids, the sensor should be mounted on the side (3 or 9 o’clock position) to avoid concentrations of gas at the top of the pipe, or solids at the bottom. For liquids with minimal gas bubbles (e.g. potable water) the sensor should be mounted on the top of a horizontal pipe (12 o’clock position) to obtain the best signal strength.

12 O'CLOCK POSITION WITH LOW GAS CONTENT

3 O'CLOCK POSITION WITH HIGH GAS OR SOLIDS CONTENT

VERTICAL PIPE USUALLY

HAS EVENLY DISTRIBUTED FLOW

5 Dia

5 Dia

10 Dia

10 Dia

FLOW

STRAIGHT RUN REQUIREMENTS – For best results, the transducers must be installed on a straight run of pipe, free of bends, tees, valves, transitions, insertion probes and obstructions of any kind. For most installations, ten straight unobstructed pipe diameters upstream and five diameters downstream of the transducers is the minimum recommended distance for proper operation.

Additional considerations are outlined below.

•Do not, if possible, install the transducers downstream from a throttling valve, a mixing tank, the discharge of a positive displacement pump or any other equipment that could possibly aerate the liquid. The best location will be as free as possible from flow disturbances, vibration, sources of heat, noise, or radiated energy.

•Avoid mounting the transducers on a section of pipe with any external scale. Remove all scale, rust, loose paint, etc., from the location prior to mounting the transducers.

•Do not mount the transducers on a surface aberration (pipe seam, etc.).

•Do not mount transducers from different ultrasonic flow meters on the same pipe.

•Do not run the transducer triaxial cables in common bundles with cables from other instrumentation. You can run these cables through a common conduit ONLY if they originate at the same flow meter.

•Never mount transducers under water.

IMPORTANT NOTE: In some cases, longer straight runs may be necessary where the transducers are placed downstream from devices which cause unusual flow profile disruptions or swirl. For example: modulating valves, or two elbows in close proximity and out of plane.

Page 21

Loading...

Loading...