Page 1

USER'S GUIDE

Installation & Operation

Instructions

Open Channel Flow Monitor

Model OCF 5.0

www.greyline.com

Manual Series A.1.8

Page 2

Note: This page has been left blank intentionally.

Page 3

OCF 5.0 Open Channel Flow Monitor

INDEX

CONNECTIONS ................................................................................................4

KEYPAD SYSTEM............................................................................................6

CALIBRATION MENU.....................................................................................7

ICONS.................................................................................................................8

MAIN DISPLAY................................................................................................9

MESSAGE ICON...............................................................................................9

STATUS..............................................................................................................9

PASSWORD.....................................................................................................10

UNITS/MODE..................................................................................................11

CALIBRATION................................................................................................12

CHANNEL SETUP..........................................................................................14

RELAY PARAMETERS..................................................................................15

DATA LOGGING............................................................................................16

SPECIAL FUNCTIONS...................................................................................18

SENSOR MOUNTING METHODS................................................................20

ERROR/WARNING MESSAGES...................................................................25

FIELD TROUBLESHOOTING .......................................................................26

APPLICATIONS HOTLINE............................................................................30

PRODUCT RETURN PROCEDURE..............................................................30

APPENDIX A - OPTIONS...............................................................................32

CONVERSION GUIDE ...................................................................................38

SPECIFICATIONS...........................................................................................39

IMPORTANT NOTE: This instrument is manufactured and calibrated to meet product specifications.

Please read this manual carefully before installation and operation. Any unauthorized repairs or

modifications may result in a suspension of the warranty.

Available in Adobe Acrobat pdf format

Page 3

Page 4

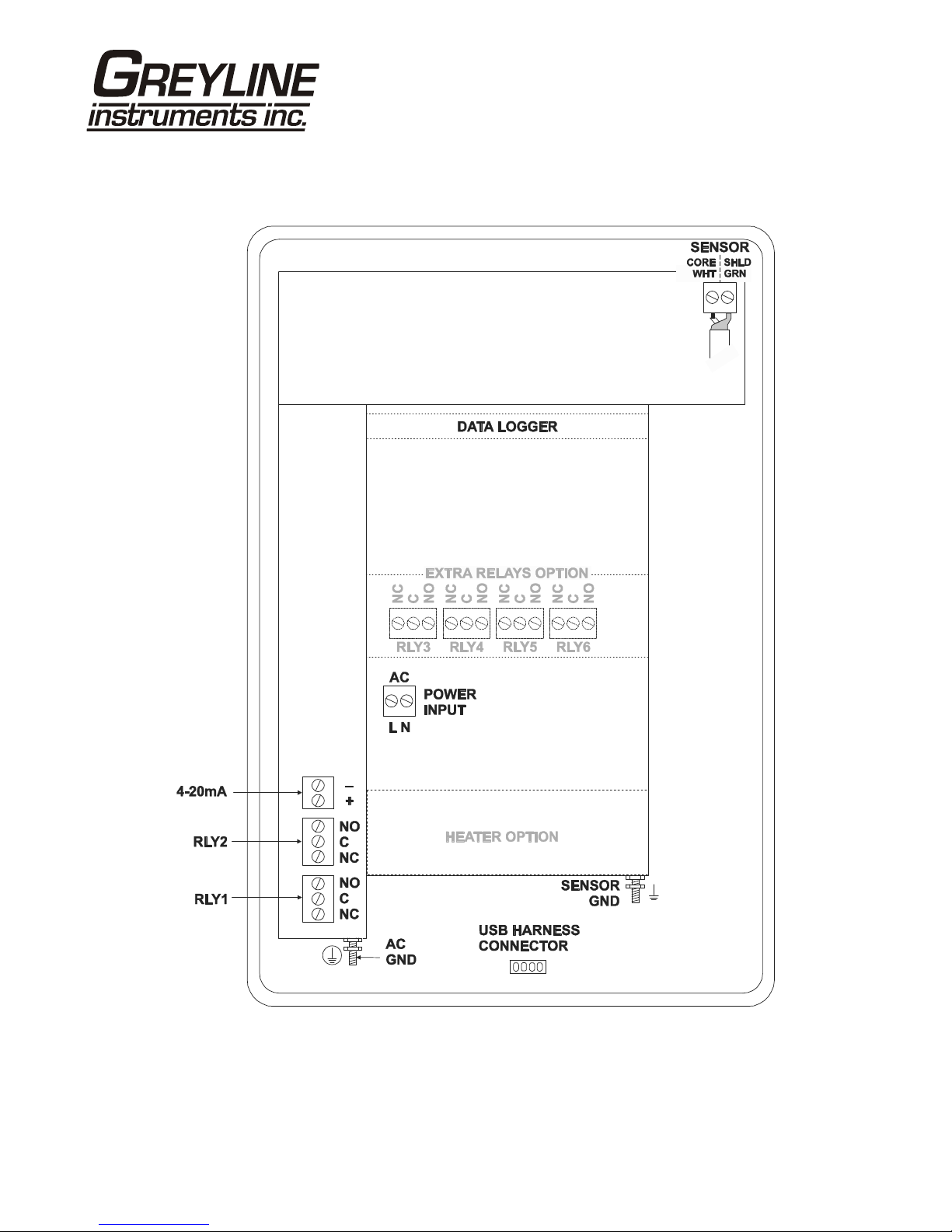

OCF 5.0 Open Channel Flow Monitor

CONNECTIONS:

POWER INPUT: The standard model requires AC power input between 100 to 240 VAC 50/60Hz. No

adjustments are necessary for voltages within this range.

Optional DC: 9-32 VDC. Connect to + and - terminals.

Optional Thermostat and Heater modules are available rated for 115 VAC or 230 VAC.

IMPORTANT NOTE: To comply with CSA/UL electrical safety standards, AC power input and relay

connection wires must have conduit entry to the instrument enclosure. Installation requires a switch,

overcurrent fuse or circuit breaker in the building (in close proximity to the equipment) that is marked

as the disconnect switch.

Risk of electric shock. Loosen cover screw to access connections. Only qualified personnel

should access connections.

Note: Use of instrumentation over 40°C ambient requires special field wiring.

Note: User replaceable fuse is 2 Amp 250V (T2AL250V).

Page 4

Page 5

CONNECTIONS

OCF 5.0 Open Channel Flow Monitor

Page 5

Page 6

OCF 5.0 Open Channel Flow Monitor

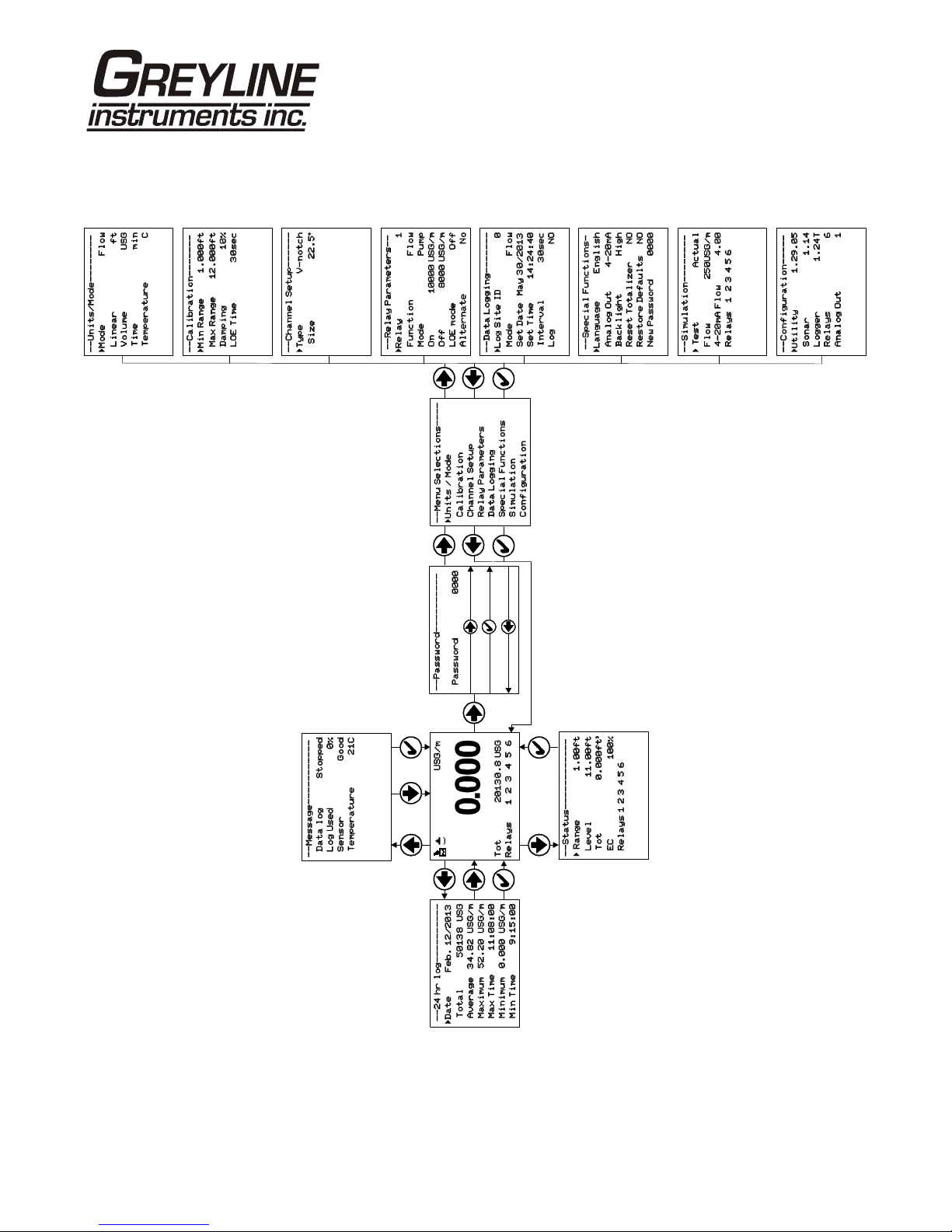

KEYPAD SYSTEM

The OCF 5.0 uses a menu system. Arrows show the four directions to leave a menu box. Press a key to

move to the next item in the direction shown. Move the cursor (highlighted) under numerals and

increase or decrease numerals with the and keys.

To store calibration values permanently (even through power interruptions), press .

Page 6

Page 7

CALIBRATION MENU

OCF 5.0 Open Channel Flow Monitor

Page 7

Page 8

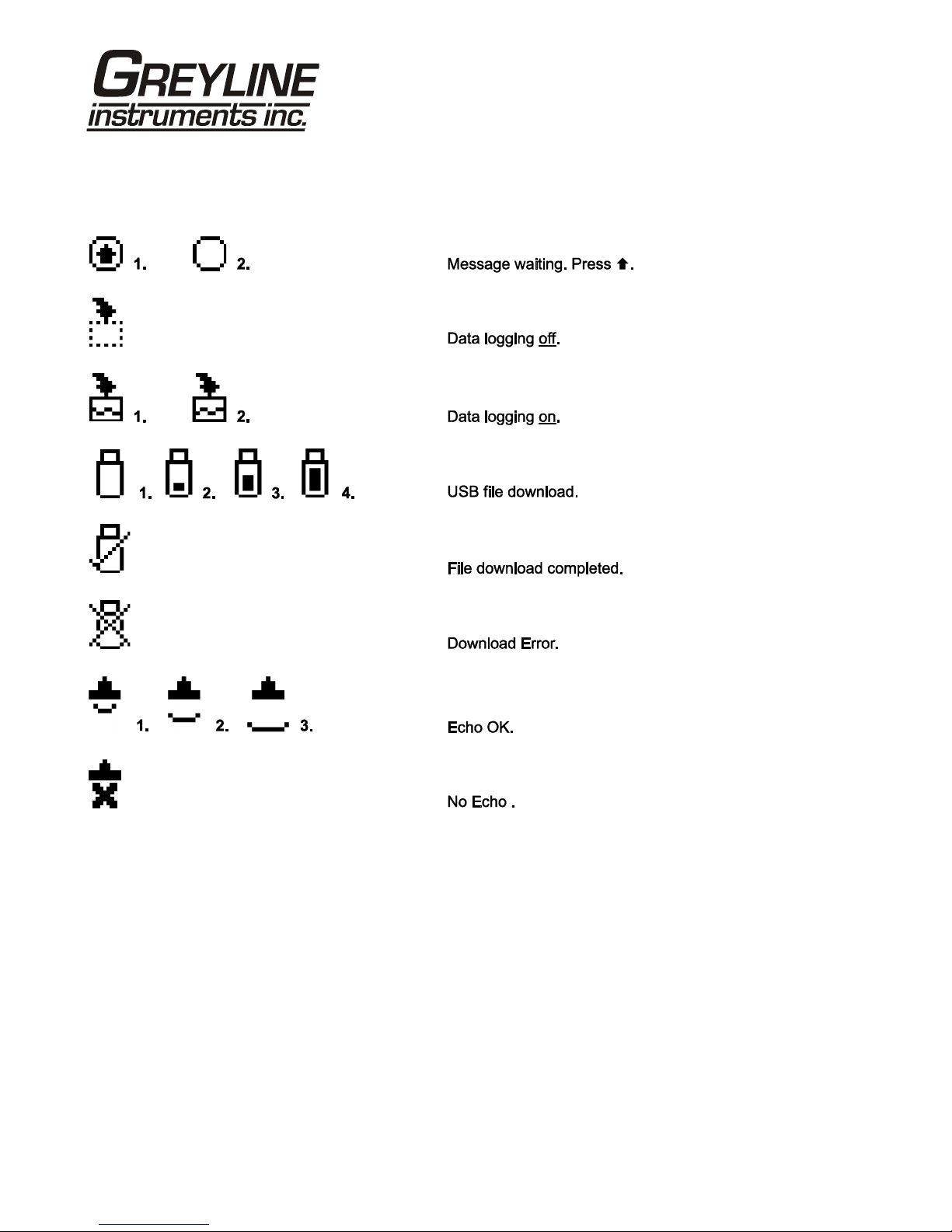

ICONS

OCF 5.0 Open Channel Flow Monitor

Page 8

Page 9

OCF 5.0 Open Channel Flow Monitor

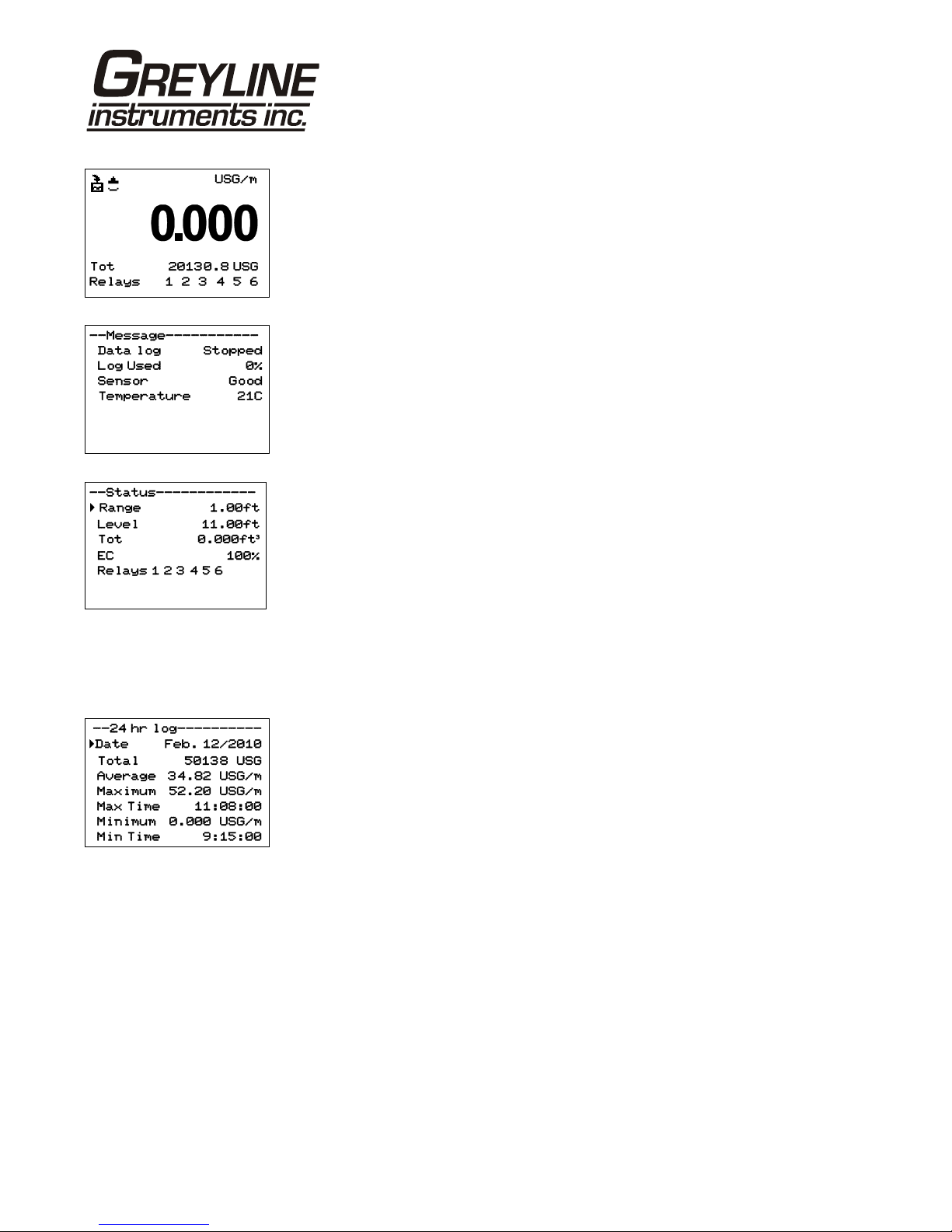

MAIN DISPLAY

The main display shows the units selected from the Units/Mode menu, Level,

Range, Flow, HRT, and Volume rate being measured, TOTALIZER and RELAY

states. The OCF 5.0 will start-up with this display.

MESSAGE ICON

Press from the main display to view status of the data logger and error/warning

messages provided by the instrument. The Message Icon will appear on the main

display if error messages are being generated by the instrument. Refer to the

manual section Error/Warning Messages for a description. Press to return to the

main display.

STATUS

Press from the main display to view instrument status. Range will be displayed

in linear units.

Tot Displays the current totalizer reading.

EC Displays echo confidence.

Relays Energized relays will display as a white character on a black

background.

24 HR LOG

Press from the main display to view a formatted flow report from instruments

with a built-in data logger. Press to scroll down one day or repeatedly to scroll

to a specific date. Up to 365 days can be stored. Newest date will overwrite the

oldest. Press to return to the main display.

Page 9

Page 10

OCF 5.0 Open Channel Flow Monitor

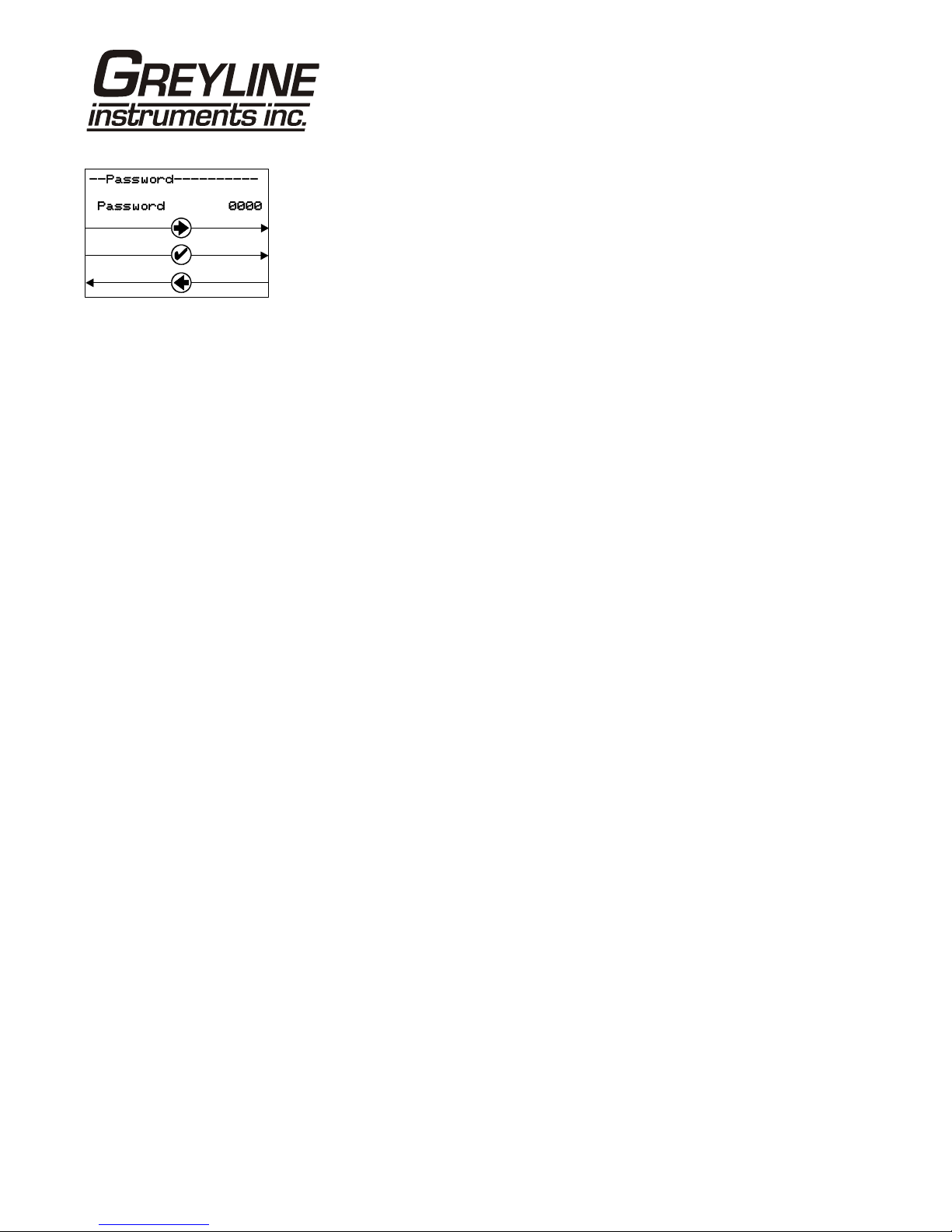

PASSWORD

The Password (a number from 0000 to 9999) prevents unauthorized access to

the Calibration menu.

From the Main display press to get to Password. Factory default password is

0000 and if it has not been changed press the to proceed to the Menu

Selections screen.

If a password is required, press to place the cursor under the first digit and or

to set the number, then to the second digit, etc. Press or to proceed to

the Menu Selections screen.

A new password can be stored by going to Special Functions/New Password.

Page 10

Page 11

OCF 5.0 Open Channel Flow Monitor

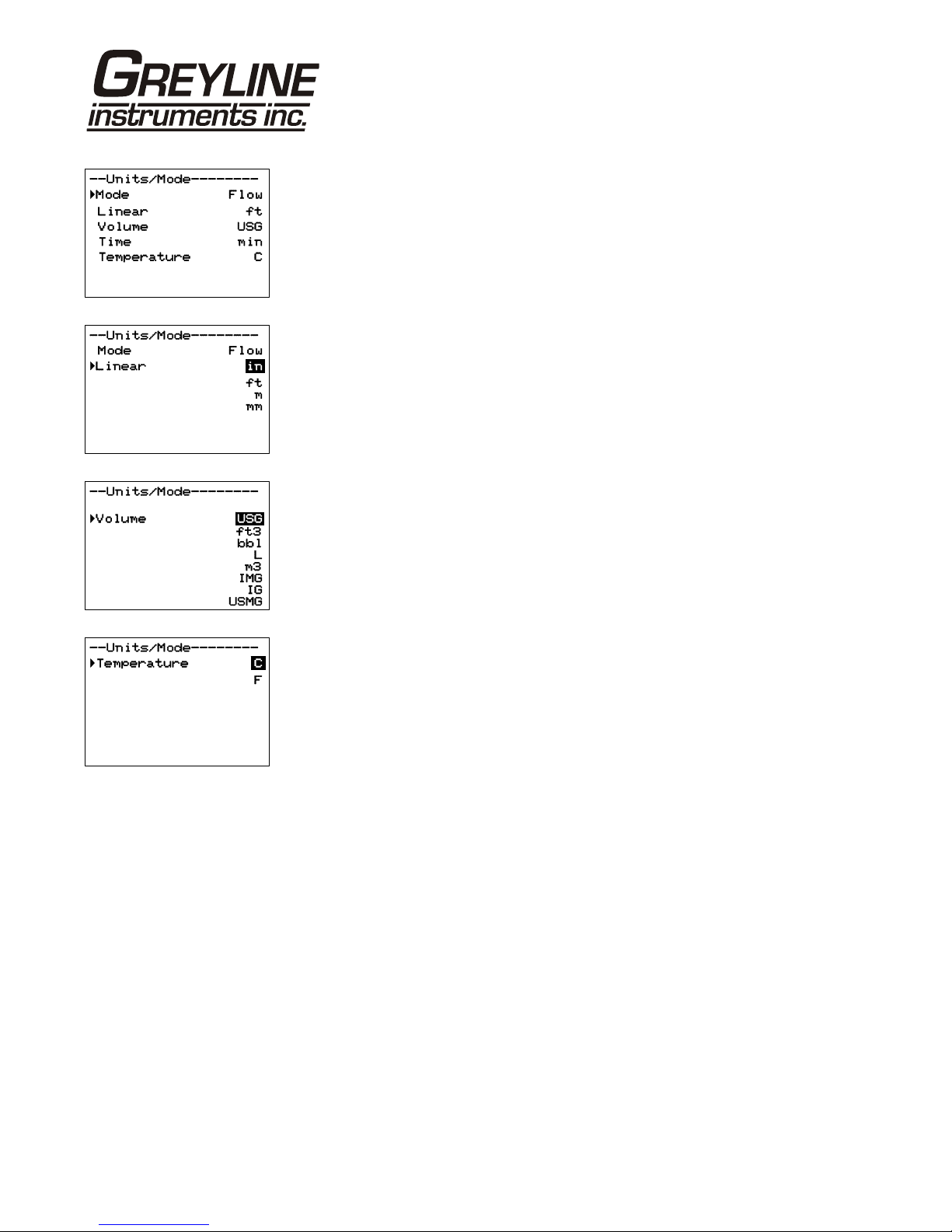

UNITS/MODE

From Mode press the and then the or to select Level, Range, Flow,

HRT or Volume.

Range displays distance from the sensor to the target or liquid surface like a

tape measure. Range mode is useful to measure the exact distance

from the sensor to the zero level during calibration.

Level used to measure tank level in linear units, or "Head" in an open

channel for comparison with flow tables.

Volume displays tank inventory in engineering units.

HRT select Horizontal Round Tank mode to calculate and display volume

units in a horizontal round tank.

Flow calculates open channel flow through a flume or weir.

Volume, HRT or Flow gives the additional choice of volumetric units:

ft3 - cubic feet

USG - US gallons

USMG - US million gallons (FLOW only)

IG - Imperial gallons

IMG - Imperial million gallons (FLOW only)

m3 - cubic meters

L - liters

bbl - U.S. oil barrel

Press to store the selection, then to the next menu item and to enter.

Linear press and then or to select units of measurement.

Press to store the selection.

Time press and then or to select day, hr, min or sec.

Temperature press and then or to select C or F (Centigrade or

Fahrenheit).

Press or to return to the Menu Selections screen.

Page 11

Page 12

OCF 5.0 Open Channel Flow Monitor

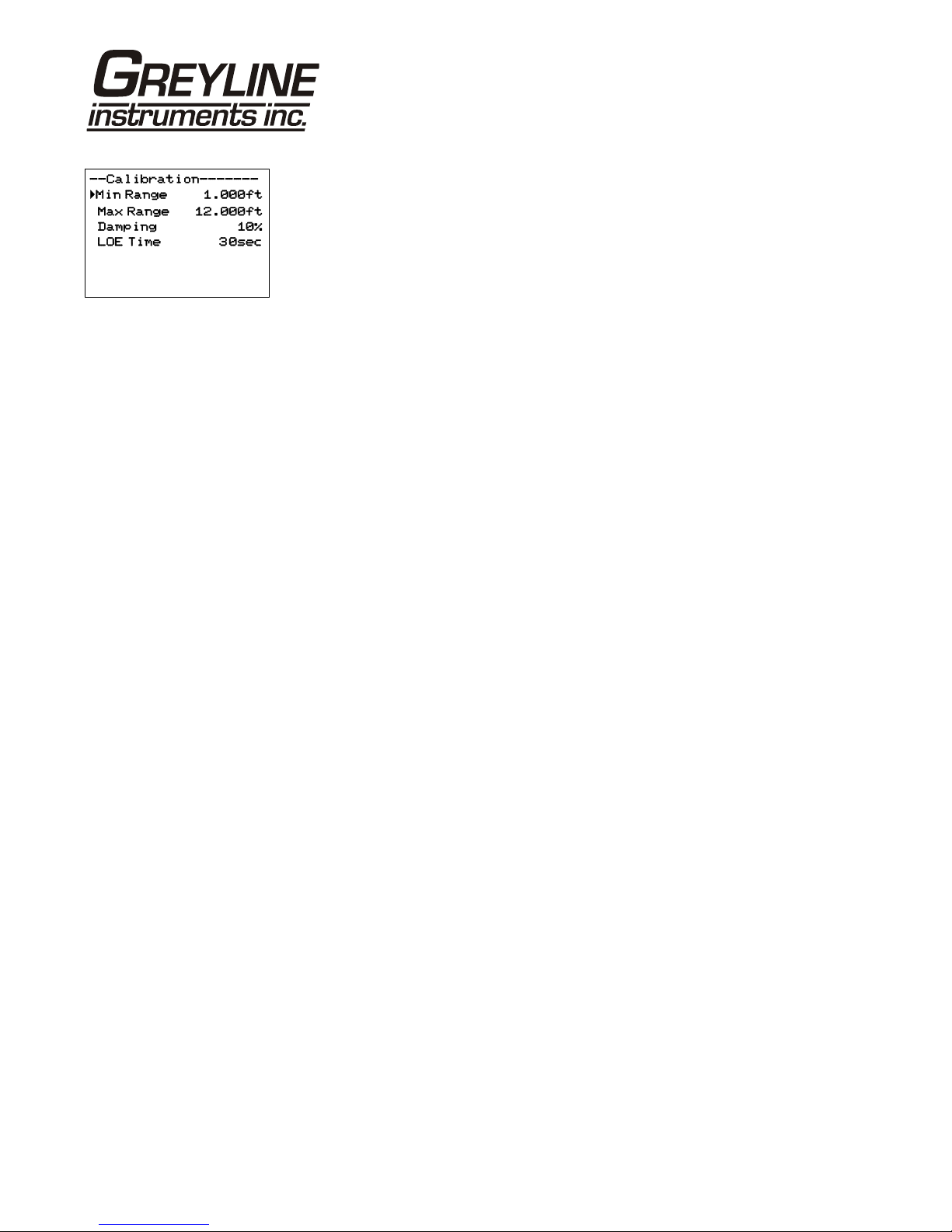

CALIBRATION

Press to Calibration and to enter. Use or to position before each

menu item and to enter. When settings are completed press to store and

return to the Calibration menu.

Min Range Distance from the sensor face to highest expected level.

Max Range Distance from sensor to Zero level.

MaxVol For Volume and HRT mode only. Enter the maximum volume of

the vertical or horizontal tank.

Damping Minimum damping allows fast response to level changes.

Increasing damping slows the OCF 5.0's response to level changes

and is ideal to smooth the display and outputs in turbulent

conditions. Damping value is shown in percent (0-99%). Some

experimentation may be required to select the optimum damping

value. A value of 1% is recommended for most applications and for

fast level changes (up to ½ inch/sec - 13 mm/sec).

LOE Time Press and or to change the number of seconds without

receiving an echo before the OCF 5.0 displays ECHO LOSS, and

Control relays change state as calibrated under Relay Parameters.

Factory default is 30 seconds and is recommended for most

applications, Minimum is 1 second and maximum is 99 seconds.

Press to return to Menu Selections.

Page 12

Page 13

OCF 5.0 Open Channel Flow Monitor

CALIBRATION

- for Open Channel Flow

1. Before starting the calibration determine:

a) MAX RANGE = ____________________

(Maximum range = distance from the Sensor to Zero flow point)

b) MAX LEVEL = ____________________

(Maximum level of flow through flume or weir)

c) MIN RANGE = __________________

(Distance from sensor to Max Level)

Minimum range = MAX RANGE - MAX LEVEL

(must be at least 8" / 20.3 cm depending on sensor model).

2. Check the maximum range with the sensor installed by:

a) When liquid is at zero level press to view the Range reading in the

Status menu. Use this range measured by the OCF 5.0 as the Max Range

setting.

or

b) Carefully measure distance from sensor to zero level with a tape measure,

and use this measurement as the Max Range setting.

NOTE: The OCF 5.0 will not detect targets beyond user entered Max Range.

Page 13

Page 14

CHANNEL SETUP

OCF 5.0 Open Channel Flow Monitor

Page 14

Page 15

OCF 5.0 Open Channel Flow Monitor

RELAY PARAMETERS

Relay Press and or to select a relay (2 relays are standard, 4

additional are optional).

Function Press or to select Off, Temperature, Pulse or Flow.

Temperature Air temperature at the sensor location.

Press and and set the relay On and

Off for specific temperatures.

Pulse Press and set digits to the flow volume

increment required between relay pulses.

Use this feature for remote samplers,

chlorinators or totalizers. Minimum time

between pulses is 2.25 seconds and pulse

duration is 350 milliseconds.

Flow Press to Mode and to select

Pump, Low Alarm or Hi Alarm.

Note: Function setting Flow will change according to selections made under

Units /Mode eg Level, Range, Volume or HRT.

Press to return to Menu Selections.

LOE Set relay state for ‘echo loss’ event (On, Off or Hold)

Alternate Pumps can be set to alternate when in pump mode.

Page 15

Page 16

OCF 5.0 Open Channel Flow Monitor

Note:

DATA LOGGING

Setup

Select Data Logging from Menu Selections.

Log Site ID

Mode

Set Date

Set Time

Interval

Log

You MUST delete old log and start a new log AFTER having set

changes to Log Site ID, Mode and/or Interval for those changes to be

applied to the log file.

Enter a number from 00 to 99. The site ID will

become part of the downloaded file name to help

distinguish downloads from different instruments.

Press to store the setting.

Select Level, Range, Flow, HRT and Volume.

Flow (e.g. USGPM or l/sec).

Press to store the setting.

Pressorto scroll and select Month, Day and Year.

Press to store the setting.

Pressorto select the current time in Hours, Minutes

and Seconds. Press to store the setting.

Pressorto select the logging interval.

Press to store the setting.

Stop, Start or Delete the log file.

Press or to Delete and to delete the log file.

Press or to Start and to start the logger.

RETRIEVE LOG FILE

Plug a USB Flash Memory Drive (not supplied by Greyline) into the USB output

cable from the instrument. The instrument display will show the USB file

download icon until the log file is transferred to the memory card and then display

file download completed icon. The USB flash drive may be removed.

Download file names will appear in this format:

Tag is set according to the Log Site ID entered in the instrument Data Logging

menu.

Page 16

Page 17

OCF 5.0 Open Channel Flow Monitor

Download letter will be A for the first download from an instrument. B for the

second, then C etc. At the letter Z a - character will appear indicating that the

maximum number of downloads for that instrument are on the USB flash drive.

Older files can be erased or moved from the flash memory drive or a new memory

drive can be used.

OPENING LOG FILES

Install Greyline Logger on your PC or laptop. Refer to the Help menu in the

program for detailed instructions.

Select File/Open/Instrument Log (.log) to open the log file from your USB flash

drive.

Page 17

Page 18

OCF 5.0 Open Channel Flow Monitor

SPECIAL FUNCTIONS

Language Select English, French or Spanish and press .

Analog Out Select 4-20mA or 0-5V mode for the analog output.

Backlight Select High, Medium or Low for continuous

backlight.

Select Key Hi/Lo for high backlight (for 1 minute)

after a keypress and then Lo backlight until a key is

pressed again.

Select Key High, Med or Low for backlight after

a keypress and then backlight off until a key is pressed

again.

Reset Totalizer Press and select Yes to erase and restart the

totalizer at zero.

Restore Defaults Select Yes and press to erase all user settings and return

the instrument to factory default settings

New Password Select any number from 0000 to 9999 and press .

Default setting of 0000 will allow direct access to the

calibration menus. Setting of any password greater

than 0000 will require the password to be entered to

access the calibration menus.

Press to return to Menu Selections.

Page 18

Page 19

OCF 5.0 Open Channel Flow Monitor

SIMULATION

Exercises the 4-20mA (0-5V) output, digital display and control relays.

Test Select Maximum and press to simulate maximum Flow, Range or

Level and to output 20mA (5V) to the analog channel.

Select Minimum and press to simulate minimum Flow, Range or

Level and to output 4mA (0V) to the analog channel.

To simulate an intermediate Flow, Range or Level set Test to Actual

and then enter a value for the Flow, Range or Level. The analog

output and control relays will respond to the simulated value.

Page 19

Page 20

SENSOR MOUNTING METHODS

OCF 5.0 Open Channel Flow Monitor

Page 20

Page 21

OCF 5.0 Open Channel Flow Monitor

SENSOR MOUNTING/LOCATION

- Open Channel Flow Applications

Each sensor is equipped with a 3/4 inch isolation coupling which MUST be used in your installation. A

threaded nipple or length of conduit may be used to position the sensor at the desired height. The sensor

should be hand-tightened by turning the sensor stem only. DO NOT use a wrench and do not over

tighten.

IMPORTANT: Follow the flume manufacturer’s directions for sensor location. The sensor should be

centered above the flume approach section and mounted 8"/203 mm (minimum) above the maximum

liquid level (depending on sensor model).

The sensor should be protected from physical damage and the sensor cable should be routed in a

separate metal conduit.

Because the sensor is equipped with a temperature sensor, it should be shielded from direct sunlight.

Use the PVC “isolation coupling” supplied with the sensor and hand-tighten the sensor/coupling

assembly onto your mounting stand. Do not clamp directly to the sensor or to the isolation coupling.

Page 21

Page 22

OCF 5.0 Open Channel Flow Monitor

TYPICAL SENSOR POSITIONING

FOR FLUMES AND WEIRS

Always refer to the flume or weir manufacturer’s instructions for correct measurement point upstream

from the flume or weir. Location of the sensor is critical for accurate flow measurement.

If manufacturer’s instructions are not available, the following guidelines are generally accepted.

1. PARSHALL FLUME:

Position the sensor at 2/3 Approach as

illustrated above. Sensor height must be

8" (203 mm) or more above the highest

water level.

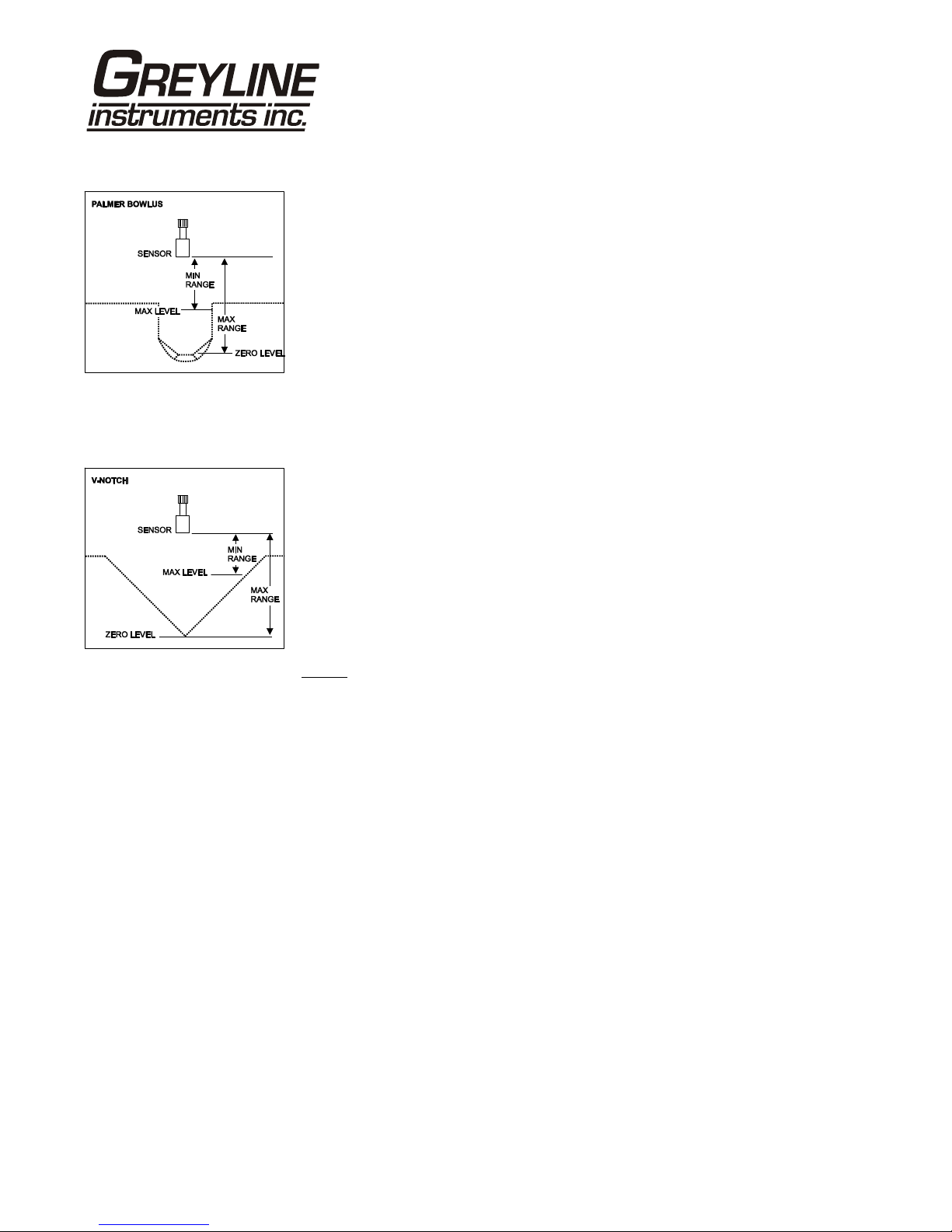

2. PALMER BOWLUS FLUMES:

Position the sensor at ½ the flume

Diameter upstream from the throat of

the flume. Sensor height must be 8" (203

mm) or more above the highest water

level.

3. V-NOTCH WEIRS

Position the sensor at 3 x maximum Head

upstream from the weir plate. Sensor height must

be 8" (20.3 cm) or more above the highest water

level.

STILLING WELLS

Stilling wells are recommended to reduce the effects of turbulence as water flows through the flume or weir. The

OCF 5.0 sensor is centered over the stilling well. Sensor height must be 8" (203 mm) or more above the highest

water level. The well must be kept clean of sediment and deposits on the side walls.

Page 22

Page 23

OCF 5.0 Open Channel Flow Monitor

ZERO POSITIONING OF SENSOR

- Open Channel Flow Applications

Locate the sensor at the position upstream from the throat of the flume or weir plate as recommended by

the manufacturer. A technique for accurate sensor height adjustment is shown:

Page 23

Page 24

OCF 5.0 Open Channel Flow Monitor

ENCLOSURE INSTALLATION

Locate the enclosure within 20 ft (6 m) of the sensor (500 ft -150 m optional). The enclosure can be wall

mounted with the four mounting screws (included) or panel mounted with Option PM Panel Mount kit

from Greyline Instruments.

Avoid mounting the enclosure in direct sunlight to protect the electronics from damage due to

overheating and condensate. In high humidity atmospheres, or where temperatures fall below freezing,

Option TH Enclosure Heater and Thermostat is recommended. Seal conduit entries to prevent moisture

from entering enclosure.

NEMA4X (IP66) WITH CLEAR COVER

1. Open hinged enclosure cover.

2. Insert #12 screws (supplied) through the four enclosure mounting holes

to secure the enclosure to the wall or mounting stand.

Additional conduit holes can be cut in the bottom of the enclosure when

required. Use a hole saw or Greenlee-type hole cutter to cut the required

holes.

DO NOT make conduit/wiring entries into the top of the enclosure.

Note: This non-metallic enclosure does not automatically provide

grounding between conduit connections. Grounding must be provided as part of the installation. Ground

in accordance with the requirements of the National Electrical Code. System grounding is provided by

connecting grounding wires from all conduit entries to the steel mounting plate or another point which

provides continuity.

CLEANING

Cleaning is not required as a part of normal maintenance.

Page 24

Page 25

ERROR/WARNING MESSAGES

OCF 5.0 Open Channel Flow Monitor

ECHO LOSS

- or -

ECHO TOO CLOSE

SENSOR OPEN

SENSOR SHORTED

No valid echoes received within the LOE TIME setting. The OCF 5.0 will hold the

display and outputs at the last reading until a new echo is received.

Your choice of Units exceeds 9,999,999. Use USMG/d, IMG/d or m3/d so that

Units will be 9,999,999 or less

Indicates that the target is less than Min Range distance from the sensor (too close

to the sensor).

Instrument has detected sensor connection/cable Open.

Instrument has detected sensor connection/cable Shorted.

Page 25

Page 26

OCF 5.0 Open Channel Flow Monitor

FIELD TROUBLESHOOTING

SYMPTOMS CHECK

Display - full scale A

- zero B

- erratic - random C

- drifting up D

- drifting down E

ECHO LOSS prompt - flashing F

Calibration Non-Linear H

SYMPTOMS FAULTS SOLUTIONS

Unit “See’s” Wrong Target Due To:

A - sensor cover not removed - remove protective cover after installation

A,C,D,F - sensor not aimed correctly

A,D,F - dust/dirt buildup on sensor - clean carefully (do not scratch sensor face)

A,D,F - condensation on sensor - lower Sensor

- insulate sensor mounting location

- increase Min Range (CALIBRATION menu) by

1-3” / 2.5-7.5 cm

- wipe sensor face and body with Rain-X

A,D - sensor mounting stand pipe

- too long / - too narrow

- dirty / - gasket intruding

C,E - very turbulent flow in open channel - increase Damping (CALIBRATION menu)

C,E - very turbulent level in tank - increase Damping (CALIBRATION menu)

Unit Picks-Up Interference Due To:

- lower Sensor below stand pipe intrusion

- install stilling well on flume or weir

- change tank fill method

A,C - noise from high pressure fill - install submerged fill pipe

A,D - sensor coupling over tightened - hand tighten only (like a light bulb)

A,D - sensor coupling not used - use coupling supplied

C - other ultrasonic unit in close proximity - synchronize

Electrical interference:

C - sensor cable connections reversed

C - through sensor cable - use properly grounded metal conduit

Page 26

Page 27

OCF 5.0 Open Channel Flow Monitor

C - sensor cable extended and junction not

- Use metal Junction Box

insulated

C - through enclosure - use metal enclosure

C - through 4-20mA output cable - use shielded twisted pair (shielded to AC ground)

- use grounded metal conduit

C - wiring or installation close to variable

speed drive or inverter

- follow V.S.D. manufacturer’s instructions for Drive

grounding, wiring and shielding

Unit Receives No Return Echo Due To:

C,F,E - foam on liquid surface - use stilling well (open channel flow)

B - target beyond Max Range - recalibrate

F - sensor damaged - remove sensor from mounting and aim at a flat,

stable target to test

F - sensor misalignment - check with a level

Wiring Problems Due To Sensor Cable:

A,C,F, - open circuit - check connections/continuity (8850 to 12700 ohms

max./-30°C to +70°C )

B,F - short circuit - check connections/continuity (8850 ohms min.)

F - too long (max 500 ft., 150 m)

C - bundled/run in conduit with power cable

C - sensor ground shorted to conduit/enclosure - insulate

A - extended with wrong type of wire - use RG62A/U coaxial only

C - close to high voltage/large motors

C - AC chassis/ground missing on instrument

power connections

Non-Linearity Due To:

H - vapour - dissipate fumes, Calibration in-situ

H - zero not set accurately - see “Zero Positioning of Sensor”

H - wrong flume, or K&n selected (FLOW

- select correct flume

mode)

- temperature measurement inaccuracy - install sensor sunscreen

- mount sensor closer to flow

Page 27

Page 28

OCF 5.0 Open Channel Flow Monitor

PZxx Series Sensors

Troubleshooting

Resistance measured (between the shield and center wire) across the coaxial cable ends by mulitmeter

indicates ambient temperature.

Resistance vs. Temperature

Page 28

Page 29

FUSE REPLACEMENT

1. Turn OFF power.

2. Loosen cover screw and open.

3. Remove power module.

4. Locate fuse on Power Board.

5. Replace fuse with 2 AMP/ 250V, 5 x 20mm fuse.

6. Reinstall power module into chassis.

OCF 5.0 Open Channel Flow Monitor

Page 29

Page 30

OCF 5.0 Open Channel Flow Monitor

APPLICATIONS HOTLINE

For applications assistance, advice or information on any Greyline Instrument contact your Sales Representative,

write to Greyline or phone the Applications Hotline below:

United States: Tel: 315-788-9500 Fax: 315-764-0419

Canada: Tel: 613-938-8956 Fax: 613-938-4857

Toll Free: 888-473-9546

Email: info@greyline.com

Web Site: www.greyline.com

Greyline Instruments Inc.

Canada USA:

16456 Sixsmith Drive 11451 Belcher Road South

Long Sault, Ont. K0C 1P0 Largo, FL 33773

PRODUCT RETURN PROCEDURE

Instruments may be returned to Greyline for service or warranty repair.

1 Obtain an RMA Number from Greyline -

Before shipping a product to the factory please contact Greyline by telephone, fax or email to obtain an

RMA number (Returned Merchandise Authorization). This ensures fast service and correct billing or

credit.

When you contact Greyline please have the following information available:

1. Model number / Software Version

2. Serial number

3. Date of Purchase

4. Reason for return (description of fault or modification required)

5. Your name, company name, address and phone number

2 Clean the Sensor/Product -

Important: unclean products will not be serviced and will be returned to the sender at their expense.

1. Rinse sensor and cable to remove debris.

2. If the sensor has been exposed to sewage, immerse both sensor and cable in a solution of 1 part

household bleach (Javex, Clorox etc.) to 20 parts water for 5 minutes. Important: do not immerse

open end of sensor cable.

3. Dry with paper towels and pack sensor and cable in a sealed plastic bag.

4. Wipe the outside of the enclosure to remove dirt or deposits.

5. Return to Greyline for service.

Page 30

Page 31

OCF 5.0 Open Channel Flow Monitor

LIMITED WARRANTY

_____________________________________

Greyline Instruments warrants, to the original purchaser, its

products to be free from defects in material and workmanship for a

period of one year from date of invoice. Greyline will replace or

repair, free of charge, any Greyline product if it has been proven to

be defective within the warranty period. This warranty does not

cover any expenses incurred in the removal and re-installation of

the product.

If a product manufactured by Greyline should prove defective

within the first year, return it freight prepaid to Greyline

Instruments along with a copy of your invoice.

This warranty does not cover damages due to improper installation

or handling, acts of nature, or unauthorized service. Modifications

to or tampering with any part shall void this warranty. This

warranty does not cover any equipment used in connection with the

product or consequential damages due to a defect in the product.

All implied warranties are limited to the duration of this warranty.

This is the complete warranty by Greyline and no other warranty is

valid against Greyline. Some states do not allow limitations on how

long an implied warranty lasts or limitation of incidental or

consequential damages, so the above limitations or exclusions may

not apply to you.

This warranty gives you specific legal rights, and you may also

have other rights which vary from state to state.

Greyline Instruments Inc.

Page 31

Page 32

OCF 5.0 Open Channel Flow Monitor

APPENDIX A - OPTIONS

EXTRA SENSOR CABLE - OPTION XC

Each Greyline level instrument includes 25 ft. (7.6 m) RG62AU coaxial cable. Additional RG62AU

coaxial cable and Cable Junction Box (Option JB2X) may be installed to extend cable up to 500 ft

(152m) as required during installation. No adjustment is required when the sensor cable is extended or

shortened. Use only RG62AU (or RG62U) coaxial cable which is available from Greyline Instruments

or your local distributor. Nominal impedance of RG62AU cable is 93 ohms.

Extended sensor cable maybe installed in metal or plastic conduit. Recommended installation with a

junction box is illustrated below:

JUNCTION BOX - OPTION JB2X

NEMA4X (IP66) polycarbonate Junction Box with terminal strips is available from Greyline

Instruments. Includes compression fittings for watertight coaxial cable entries.

Page 32

Page 33

OCF 5.0 Open Channel Flow Monitor

EXTENDED SENSOR CABLE INSTALLATION IN MANHOLE

Page 33

Page 34

OCF 5.0 Open Channel Flow Monitor

SENSOR INTRINSIC SAFETY

(OPTION ISB)

When connected through Intrinsic Safety Barriers, Greyline PZ** Series sensors are certified for

installation in a hazardous location rated:

Class I, Groups C,D

Class II, Groups E,F,G

Class III

The Intrinsic Safety Barrier may be ordered with the Greyline instrument and is supplied mounted in the

Greyline instrument enclosure. Replacement barrier fuses (Part No. ISB- 011239) may be purchased

separately. The instrument enclosure containing the ISB Intrinsic Safety Barrier must be installed in a

non-hazardous location.

Page 34

Page 35

OCF 5.0 Open Channel Flow Monitor

Page 35

Page 36

OCF 5.0 Open Channel Flow Monitor

ENCLOSURE HEATER AND THERMOSTAT - Option TH

Instruments can be factory-equipped with an Enclosure Heater and Thermostat or the module can be

customer-installed. The Thermostat is factory set to turn ON at 40°F (4.5°C) and OFF at 60°F (15.5°C).

Power consumption is 15 Watts.

ENCLOSURE SUNSCREEN - Option SCR

Do not mount instrument electronics in direct sunlight. Overheating will reduce the life of electronic

components and condensate may form during the heat/cool cycles and cause electrical shorts.

Page 36

Page 37

OCF 5.0 Open Channel Flow Monitor

POWER INPUT OPTION

9-32VDC

OCF 5.0 Level & Flow Monitors may be ordered factory-configured for 9-32VDC power input.

QUICK BENCH TEST:

Connect Sensor as shown below, then Power. When properly connected figures will show on the large

LCD display. Test operation of the OCF 5.0 by holding the sensor steadily and aiming at a flat, stable

target 12 to 28" (305 to 711 mm) away from the end of the sensor. Allow a few seconds for the OCF 5.0

to lock onto the target before displaying its distance. The OCF 5.0 will now display Range in ft or cm

(factory calibration).

CONNECTIONS:

POWER INPUT: Connect 9-32VDC/0.5 Amps to the + and - terminals. The Power Input GND must be

connected to the nearest Ground pole. A 1 amp fuse in line is recommended.

Page 37

Page 38

OCF 5.0 Open Channel Flow Monitor

CONVERSION GUIDE

FROM TO MULTIPLY BY

US GALLONS CUBIC FEET 0.1337

US GALLONS IMPERIAL GALS 0.8327

US GALLONS LITRES 3.785

US GALLONS CUBIC METERS 0.003785

LITRES/SEC GPM 15.85

LITRES CUBIC METERS 0.001

BARRELS US GALLONS 42

BARRELS IMPERIAL GALS 34.9726

BARRELS LITRES 158.9886

INCHES MM 25.4

DEGREES F DEGREES C (°F-32) x 0.556

POUNDS KILOGRAMS 0.453

PSI BAR 0.0676

FOOT² METER² 0.0929

VOLUME CALCULATION FOR ROUND TANKS: 3.142 x R² x H

R = TANK RADIUS (½ TANK DIAMETER)

H = TANK HEIGHT

Page 38

Page 39

SPECIFICATIONS

Accuracy: ±0.25% of Range or 2

mm, whichever is

greater Repeatability

and Linearity: 0.1% F.S.

Displays: White, backlit matrix -

displays flow rate,

totalizer, relay states,

operating mode and

calibration menu

Calibration: built-in 5-key calibrator

with English, French or

Spanish language

Power Input: 100-240VAC, 50/60Hz,

30 Watts or

Optional 9-32VDC, rated

9W (typical 4.1W with

standard features)

Output: Isolated 4-20mA (1000 ohm load max.)

Control Relays: Qty 2, rated 5 amp 240VAC SPDT, programmable flow alarm and/or

proportional pulse

Enclosure: watertight, dust tight NEMA4X (IP 66) polycarbonate with a clear

shatter-proof face

Environmental Conditions: Relative humidity up to 80% -23 to 60°C ambient temperature,

maximum 5000 m altitude, pollution degree 4, Installation Category II.

Sensitivity: adjustable. Damping: adjustable

Electrical Surge Protection: Sensor, 4-20mA output and AC power input

Approximate Shipping Weight: 10lbs (4.5 kg)

OCF 5.0 Open Channel Flow Monitor

Standard Sensor PZ15

Maximum Range: 15 ft (4.57 m)

Minimum Range (Deadband): 8" (203.2 mm)

Operating Frequency: 92 KHz

Beam Angle: 8°

Operating Temperature: -40° to 150° (-40° to 65°C)

Temperature Compensation: Automatic, continuous

Max. Operating Pressure: 20 psi (1.35 bar)

Sensor Face: PVC

Sensor Body: PVC

Cable Length: 25 ft. (7.6 m) continuous

Max. Cable Length: 500 ft. (152 m) RG62AU

Hazardous Rating: CSA rated Intrinsically Safe

Mounting: ¾" NPT

RG62AU coaxial. Optional 50

ft. (15 m) continuous

coaxial (splice)

Class I, Groups C,D, Class II,

Groups E,F,G with Optional

Intrinsic Safety Barrier.

Page 39

Page 40

Optional Sensor PZ32T

Maximum Range: 32 ft. (10 m)

Deadband (blanking): Programmable, minimum 12” (305

Beam Angle: 8° at 3 DB

Temperature Compensation: Automatic, continuous

Operating Frequency: 42 KHz

Exposed Materials: PVC and Teflon

Operating Temperature: - 40° to 150°F (-40° to 65°C)

Operating Pressure: 20 psi (1.35 Bar) maximum

Mounting: ¾” NPT (PVC isolation coupling

Sensor Cable: RG62AU coaxial, 25 ft. (7.6 m)

Hazardous Rating: with optional Intrinsic Safety Barrier:

OCF 5.0 Open Channel Flow Monitor

mm)

supplied)

standard

CSA, Class I,II,III, Div. I,II, Groups

C,D,E,F,G

Note: Max Range reduced to 25 ft

(7.6 m) with ISB option.

Optional Sensor PZ32TE

Maximum Range: 32 ft. (10 m)

Deadband (blanking): Programmable, minimum 12” (305

Beam Angle: 8° at 3 DB

Temperature Compensation: Automatic, continuous

Operating Frequency: 42 KHz

Exposed Materials: Teflon

Operating Temperature: -40° to 170°F (-40° to 76°C)

Operating Pressure: 20 psi (1.35 Bar) maximum

Mounting: ¾” NPT (Teflon isolation coupling

Sensor Cable: RG62AU coaxial, 25 ft. (7.6 m)

Hazardous Rating: with optional Intrinsic Safety Barrier:

mm)

supplied)

standard

CSA, Class I,II,III, Div. I,II, Groups

C,D,E,F,G,

Note: Max Range reduced to 25 ft

(7.6 m) with ISB option.

Page 40

Page 41

Loading...

Loading...