Page 1

USER'S GUIDE

Installation & Operation

Instructions

Portable Transit Time Flow Meter

Model PTFM 1.0

www.greyline.com

Manual Series A.1.6

Page 2

Note: This page has been left blank intentionally.

Page 2

Page 3

PTFM 1.0 Portable Transit Time Flow Meter

INDEX

BATTERY.................................................................................................................4

CONNECTIONS.......................................................................................................4

QUICK BENCH TEST..............................................................................................5

SENSOR INSTALLATION......................................................................................6

KEYPAD SYSTEM ..................................................................................................7

CALIBRATION MENU ...........................................................................................8

ICONS .......................................................................................................................9

MESSAGE.................................................................................................................10

STATUS ....................................................................................................................10

PASSWORD..............................................................................................................11

UNITS/MODE...........................................................................................................12

SET UP......................................................................................................................13

CALIBRATION ........................................................................................................15

DATA LOGGING.....................................................................................................16

SPECIAL FUNCTIONS............................................................................................17

SENSOR MOUNTING .............................................................................................19

FIELD TROUBLESHOOTING................................................................................24

COMMON QUESTIONS AND ANSWERS............................................................26

APPLICATIONS HOTLINE.....................................................................................28

PRODUCT RETURN PROCEDURE.......................................................................28

FLOW METER DATA SHEET................................................................................29

APPENDIX A - CONVERSION TABLE.................................................................33

PIPE CHARTS ..........................................................................................................34

APPENDIX B – Liquid Speed of Sound...................................................................38

IMPORTANT NOTE: This instrument is manufactured and calibrated to meet product specifications.

Please read this manual carefully before installation and operation. Any unauthorized repairs or

modifications may result in a suspension of the warranty.

If this product is not used as specified by the manufacturer, protection may be impaired.

Available in Adobe Acrobat pdf format.

Page 3

Page 4

PTFM 1.0 Portable Transit Time Flow Meter

BATTERY

- A built-in rechargable NiMH battery supplies power for 18 hours continuous operation when fully

charged.

- Display brightness is adjustable to conserve power.

- State of charge is shown for normal use, sleep mode and charging.

- When switched OFF with the AC power module connected the flashing battery indicates charging,

solid battery shows fully charged.

- The PTFM 1.0 will switch off automatically when the battery is fully discharged.

- Full charge requires approximately 6 hours charging.

- Sleep mode extends battery life for long term data logging. Maximum log time is 18 days at 5 minute

sample rate.

CONNECTIONS

SENSORS

Use type SE16B supplied with 12 ft (4 m) coaxial cables and BNC connectors. Set of optional PTC50

50 ft (15 m) extension sensor cables available.

4-20mA

Active only when powered by AC charger, maximum load 500 ohm.

USB

Cable Part #USB-PD is supplied for connecting the PTFM 1.0 to a PC or laptop.

POWER

An AC powered 15 volt DC power module is supplied for battery charging and continuous use.

Page 4

Page 5

PTFM 1.0 Portable Transit Time Flow Meter

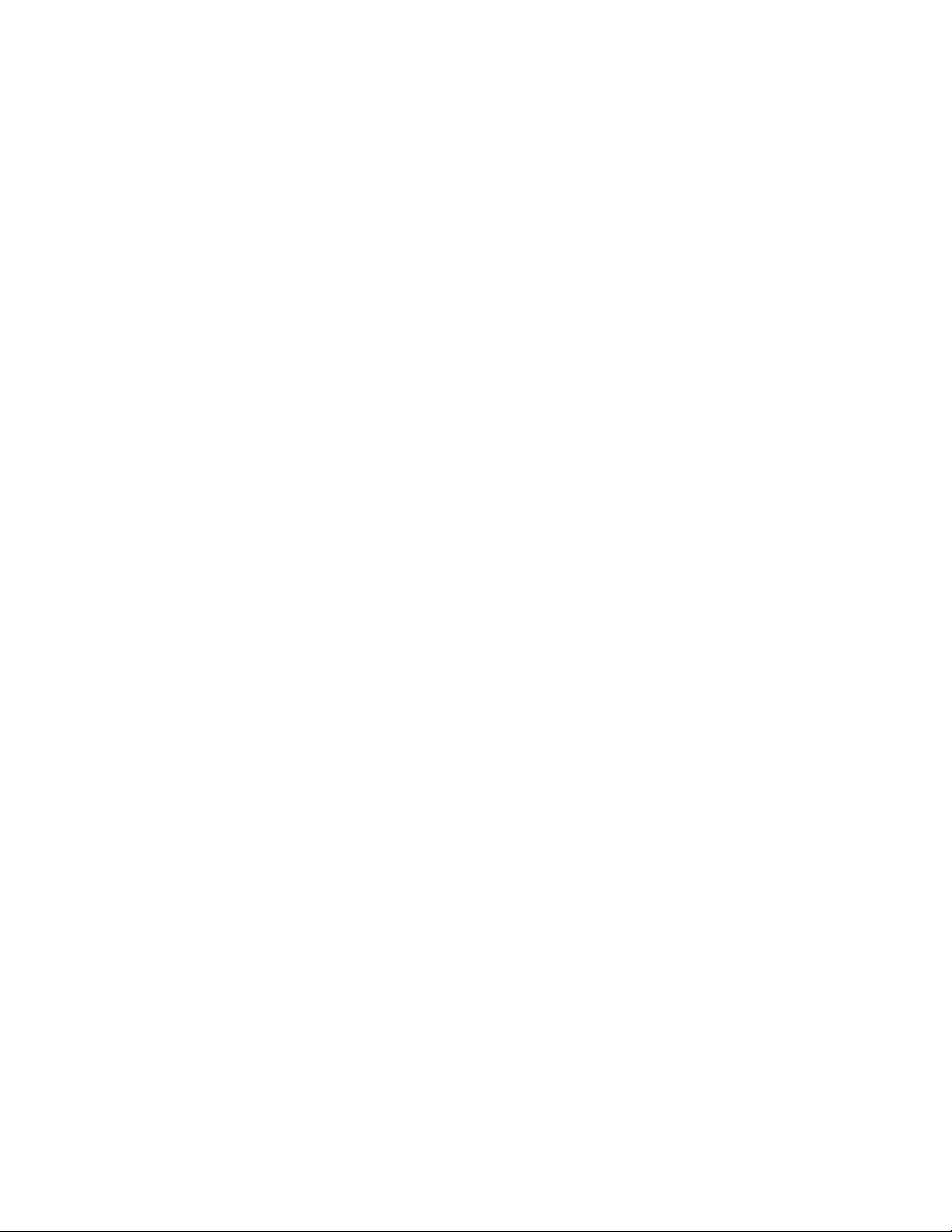

COMPOUND

~0.8”

20 mm

QUICK BENCH TEST

In the PTFM Setup menu set parameters to perform a bench test:

- Set Fluid = Water

- Set Temperature = 20°C

- Set Pipe OD = 0.15 inch

- Set Pipe Wall = 0.06 inch

- Set Pipe material = ABS

- Set Lining = None

- Set Crossings = 4

- Press to view Signal Strength at bottom of menu.

- Press twice to exit Setup and return to main display.

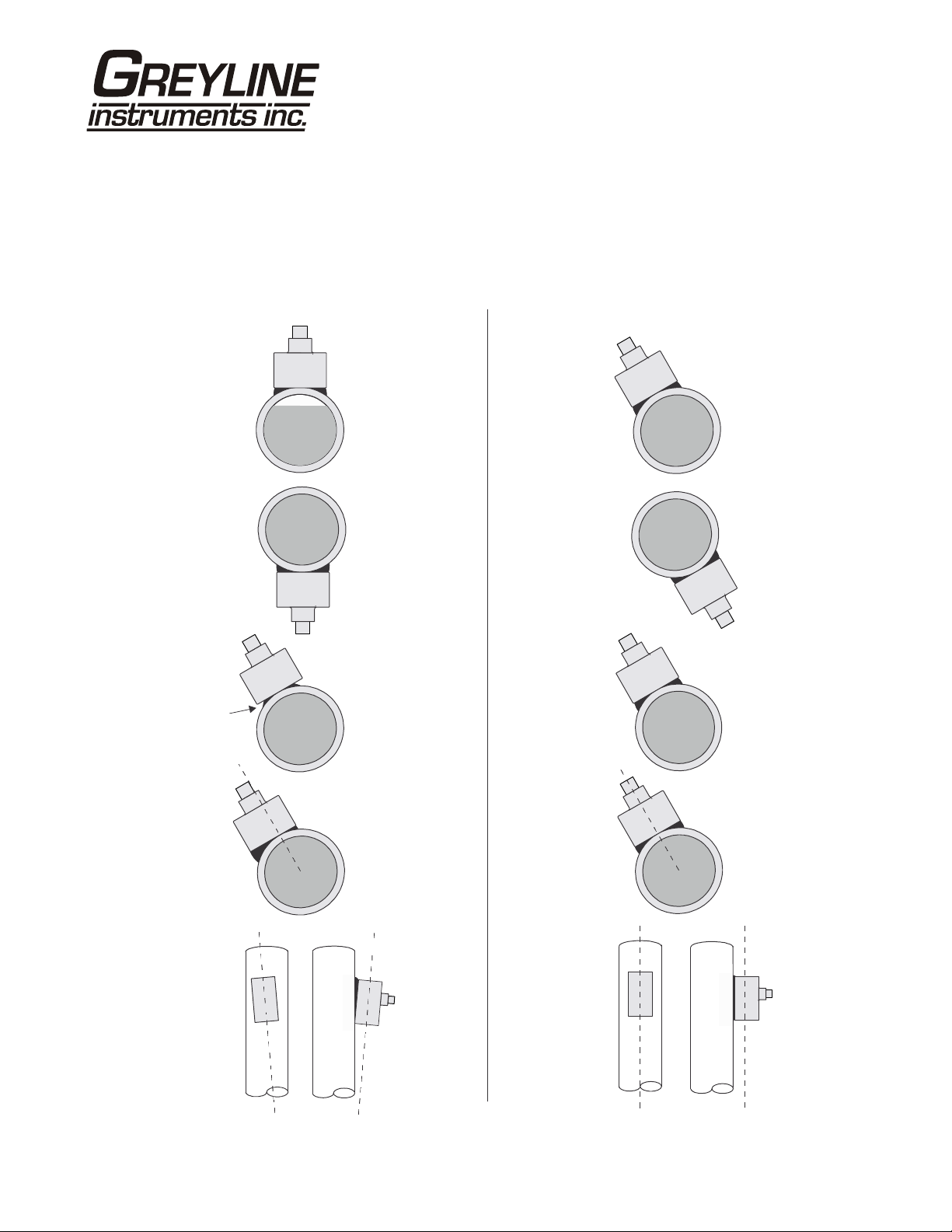

From main display press to view Status menu. Apply coupling compound to the face of sensors and

press together as indicated in the illustration below.

The Status menu should indicate a high Signal Strength (75-100%).

COUPLING

Page 5

Page 6

SENSOR INSTALLATION

PTFM 1.0 Portable Transit Time Flow Meter

Page 6

Page 7

PTFM 1.0 Portable Transit Time Flow Meter

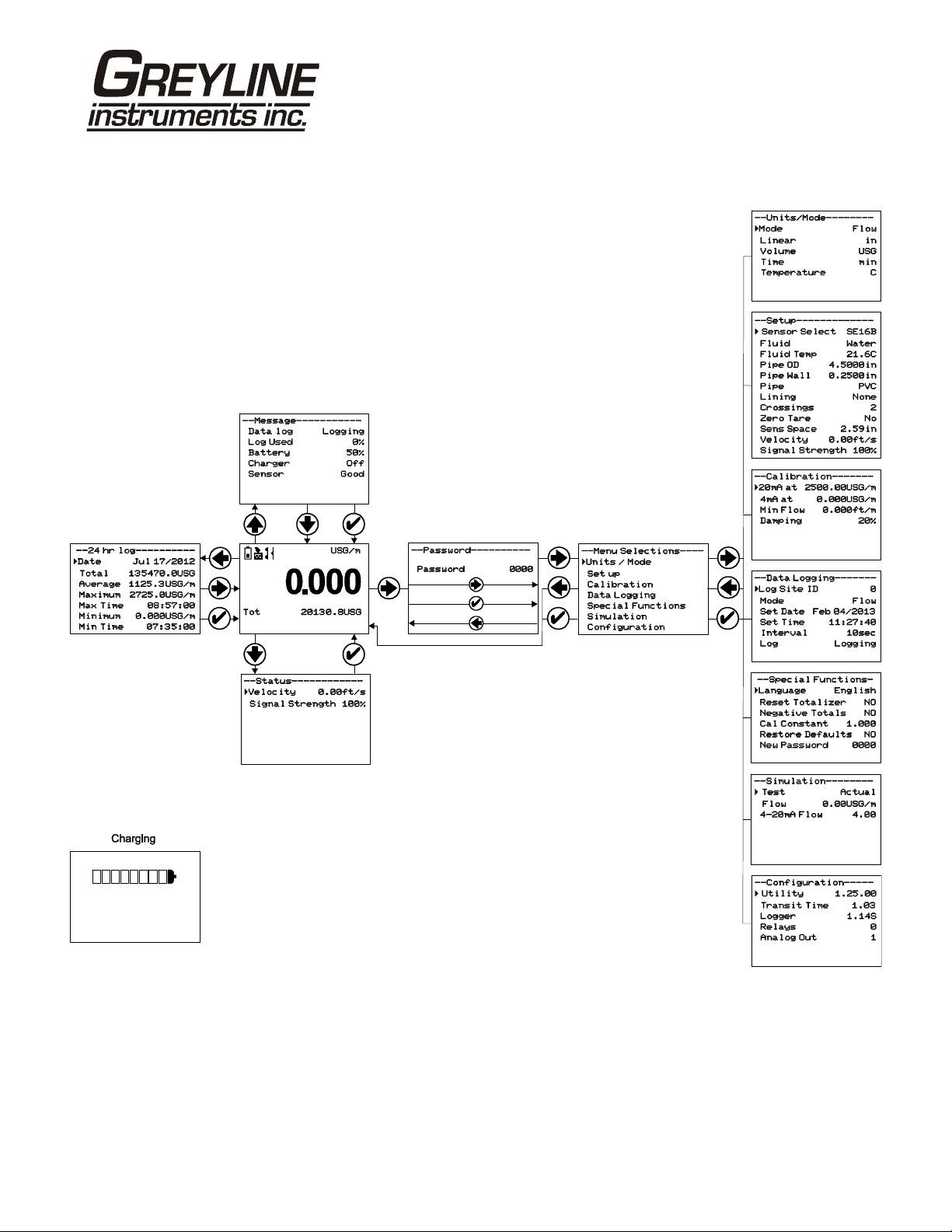

KEYPAD SYSTEM

The following diagram shows the PTFM 1.0 menu system. Arrows show the four directions to leave a

menu box. Pressing a corresponding keypad arrow will move to the next item in the direction shown.

Move the cursor (highlighted) under numerals and increase or decrease numerals with the and

keys.

To store calibration values permanently, press the .

Page 7

Page 8

CALIBRATION MENU

PTFM 1.0 Portable Transit Time Flow Meter

Page 8

Page 9

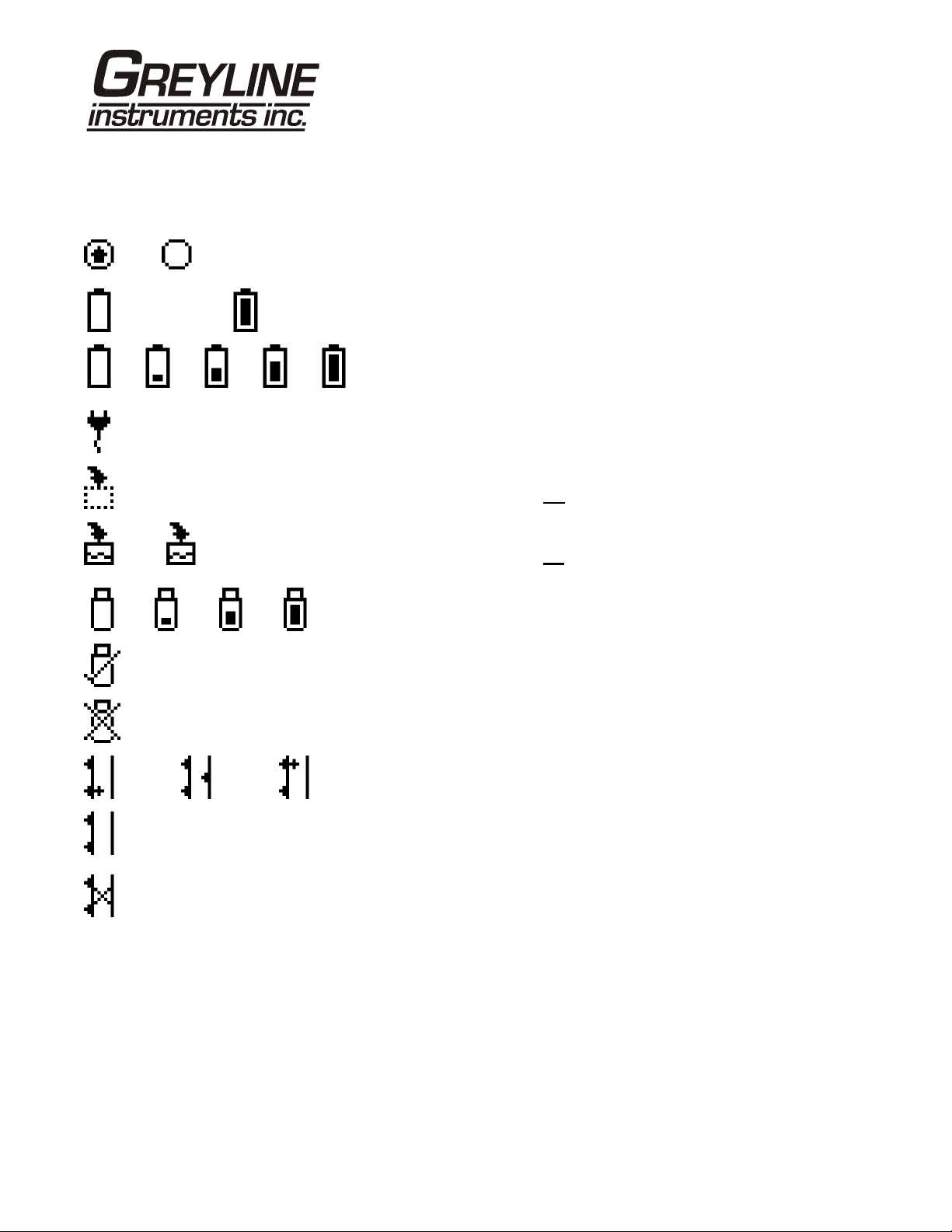

ICONS

PTFM 1.0 Portable Transit Time Flow Meter

1. 2.

Battery 0%. Battery 100%.

1. 2. 3. 4. 5.

1. 2.

1. 2. 3. 4.

Message waiting. Press .

Battery charging.

Charger connected.

Data logging off.

Data logging on.

USB file download.

File download completed.

1. 2. 3.

Download Error.

PTFM Echo OK.

PTFM – No Echo, Empty Pipe.

PTFM – No Sensors Attached /Wrong Settings.

Page 9

Page 10

PTFM 1.0 Portable Transit Time Flow Meter

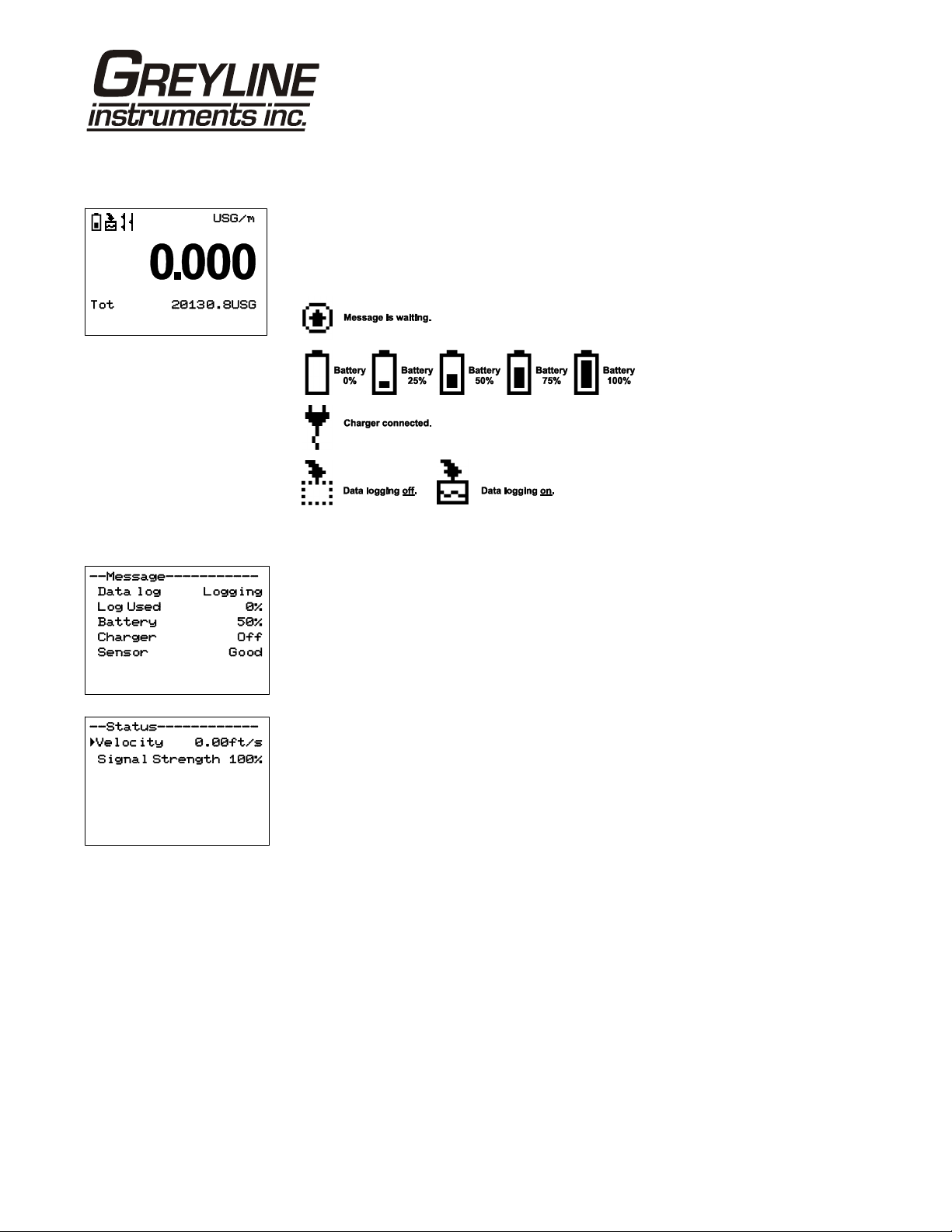

MAIN DISPLAY

The main display shows the units selected from the Units/Mode menu, Flow or

Velocity rate being measured and TOTALIZER. The PTFM 1.0 will start-up with

this display.

MESSAGE

Press from the MAIN display to view error/warning messages provided by the

instrument. The Message icon will appear on the MAIN display if error messages

are being generated by the instrument. Press to return to the main display.

STATUS

Press from the MAIN display to view instrument status.

Velocity Displayed in ft/sec or m/sec.

Signal Strength Displays percentage of signal being received by the ultrasonic

sensor.

Page 10

Page 11

PTFM 1.0 Portable Transit Time Flow Meter

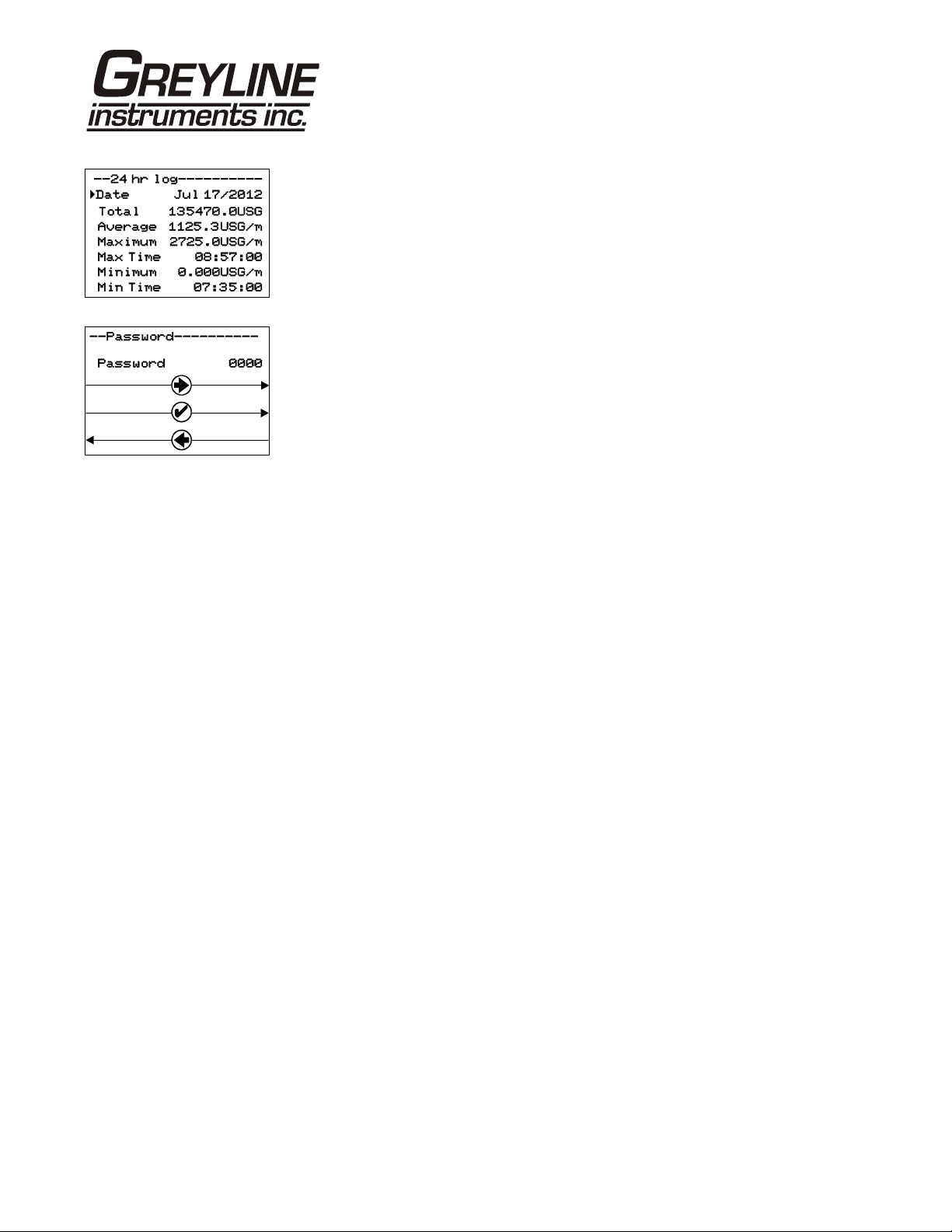

24 HR LOG

Press from the MAIN display to view a formatted flow report from instruments

with a built-in data logger. Press to scroll down one day or repeatedly to scroll

to a specific date. Up to 365 days can be stored. Newest date will overwrite the

oldest. Press to return to the main display.

PASSWORD

The password (a number from 0000 to 9999) prevents unauthorized access to the

Calibration menu.

From the Main display press the key to get to Password. Factory default

password is 0000 and if it has not been changed press the to proceed to the

Menu Selections screen.

If a password is required, press to place the cursor under the first digit and or

to set the number, then to the second digit, etc. Press or to proceed to

the Menu Selections screen.

A new password can be stored by going to Special Functions/New Password.

Page 11

Page 12

PTFM 1.0 Portable Transit Time Flow Meter

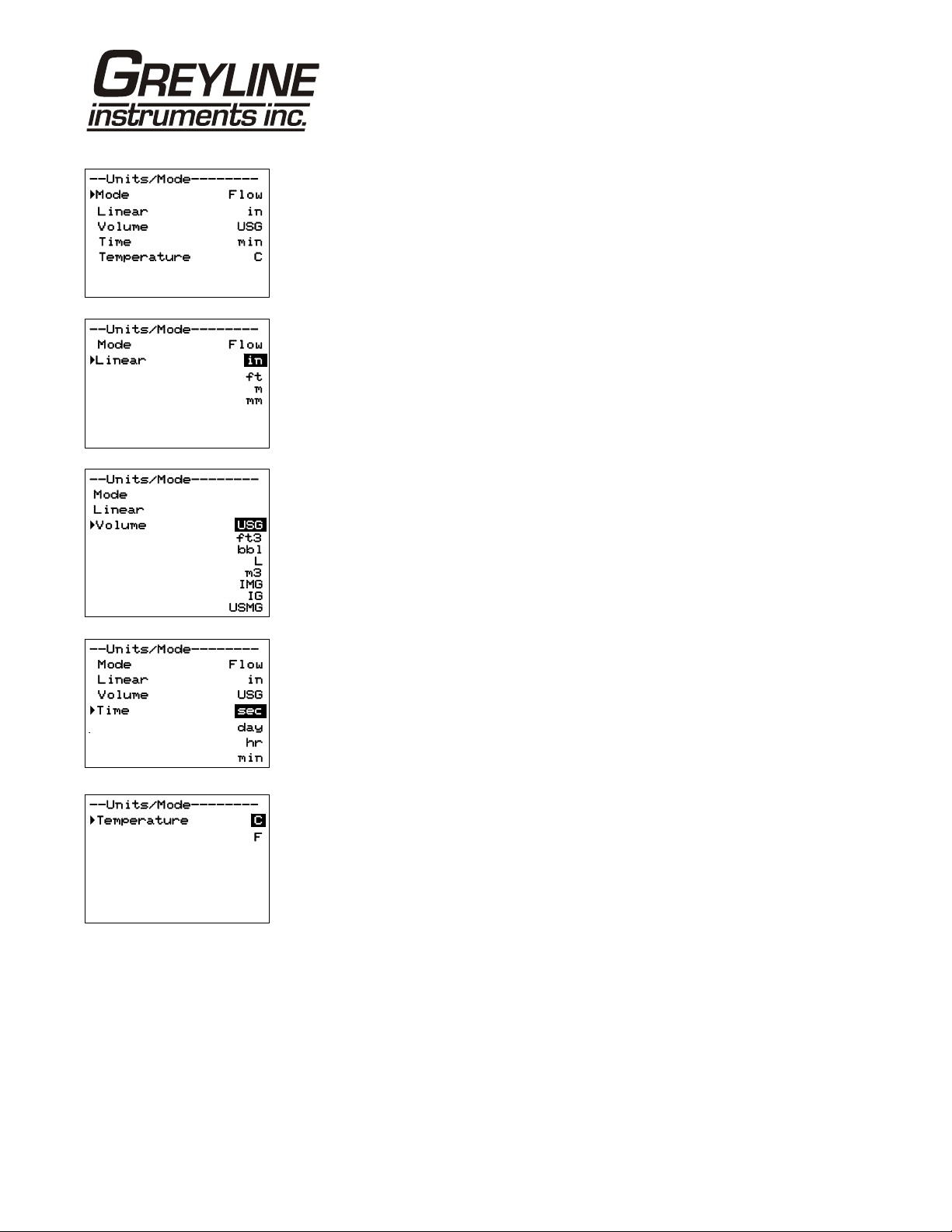

UNITS/MODE

From Mode press the and then the or to select Flow or Velocity.

Flow mode displays the flow rate in engineering units (e.g. gpm, litres/sec, etc.)

Press the to store your selection then the to the next menu item and to

enter.

From Linear press the key and then the or to select your units of

measurement. Press the to store your selection.

Press the key to move the symbol to each subsequent menu item and the to

save your selections.

Note: the volume selection "bbl" denotes U.S. oil barrel.

From Temperature press and then or to select C or F (Centigrade or

Fahrenheit).

Press or to return to the Menu Selections screen.

Page 12

Page 13

SET UP

PTFM 1.0 Portable Transit Time Flow Meter

Set Up

Sensor Select

Fluid Vel

V/C(@25C)

Fluid

Fluid Temp

Pipe OD

Pipe Wall

Go directly to Set up.

Choose SE16B.

When Fluid = Other – Enter the fluid velocity at 25C

from table or other reference in units of m/s

When Fluid = Other – Enter fluid velocity adjustment

factor over change in temperature in units of m/s per °C.

Select fluid type.

Other will require additional information:

Enter average fluid temperature.

Place the cursor under the digits and thenorto

change the numbers and decimal point. Pipe OD should

be entered as the exact outside diameter of the pipe where

the sensor is mounted. Refer to the Pipe Charts Appendix

in this manual for outside diameter of common pipe types

and sizes.

Enter wall thickness.

Refer to the Pipe Charts Appendix in this manual for

thickness of common pipe materials and sizes.

Pipe Vel

Pipe

Lining

Lining Thick

Lining Vel

When pipe = Other – Enter pipe material speed of sound

(consult factory).

Select pipe material.

Select Lining material.

None represents no liner.

Other will require additional information.

When Lining - Other is selected, enter lining

thickness.

When Lining - Other is selected, enter speed of sound

of lining material.

Page 13

Page 14

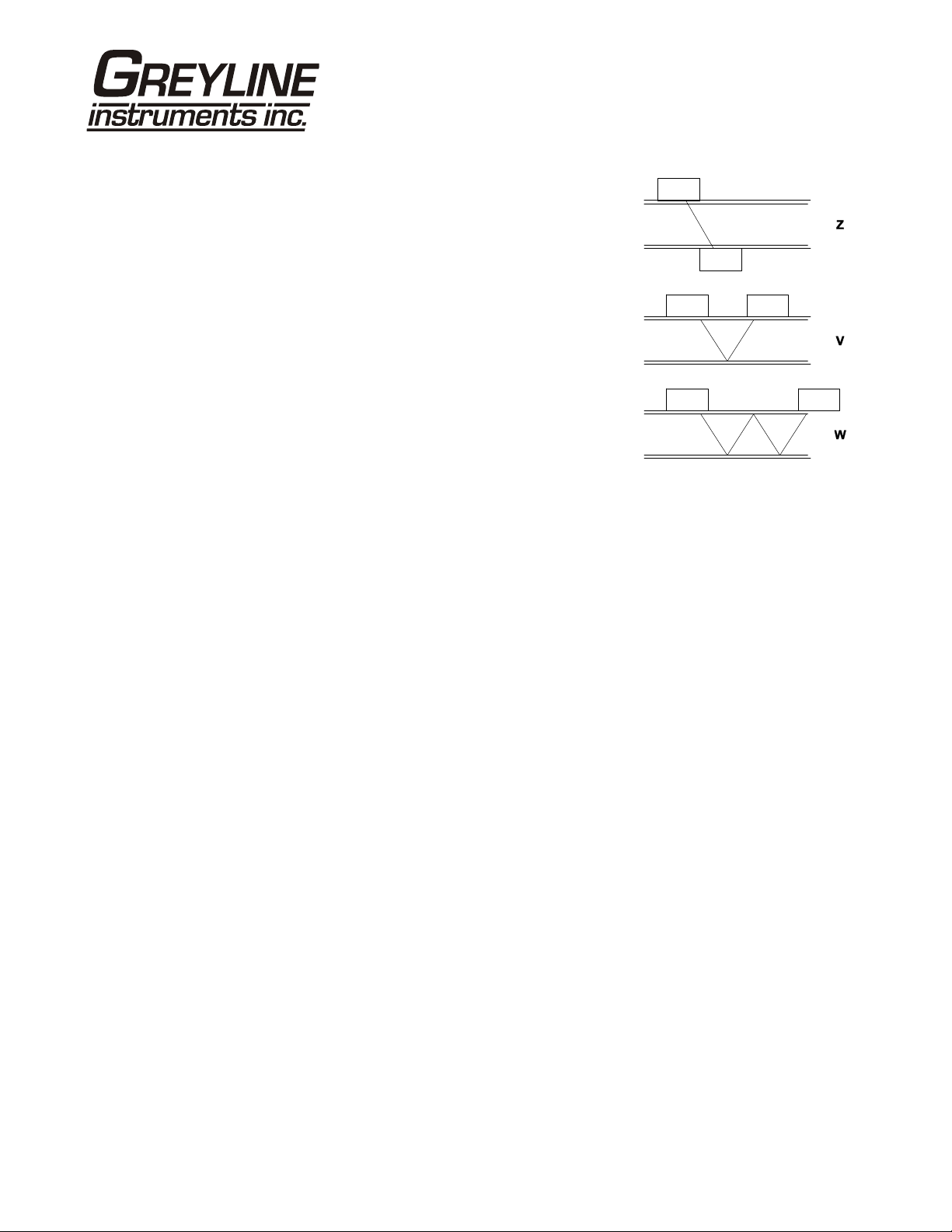

Crossings

PTFM 1.0 Portable Transit Time Flow Meter

1 = Z mounting

2 = V mounting

4 = W mounting

Zero Tare

To suppress readings or fluctuations at zero flow. Set

Calibration/Damping to 5% and under no flow conditions

and full pipe select Yes to force readings to zero.

Sens Space

Velocity

Signal Strength

Displays the calculated sensor spacing.

Displays the measured velocity.

Displays magnitude of signal being received by the

ultrasonic sensor.

Press from the Units/Mode display to return to Menu Selections.

NOTE:

Sensor separation distance is automatically calculated by

the instrument and will be displayed in the Setup menu.

Page 14

Page 15

PTFM 1.0 Portable Transit Time Flow Meter

CALIBRATION

Press the to Calibration and to enter. Use or to position before

each menu item and to enter. When settings are completed press to store and

return to the Calibration menu.

*20mA at Press then or to change the numbers and decimal point.

Use this menu to set the corresponding flow rate that will be

represented by 20mA analog output. If maximum flow is

unknown, enter an estimated flow rate and observe actual flow to

determine the correct maximum value. Any velocity or flow rate

up to +40 ft/sec (12.2 m/sec) may be selected.

*4mA at Press or to set the flow rate corresponding to 4mA analog

output. This setting may be left at zero flow (or velocity or can

be raised to any value less than the 20mA setting, or lowered to

any velocity or corresponding flow rate down to -40 ft/sec (-12.2

m/sec).

Min Flow Flow rates below this setting will be displayed as zero flow.

Damping Increase damping to stabilize readings under turbulent flow

conditions. Decrease for fast response to small changes in flow.

Damping is shown in percentage (maximum is 99%). Factory

default is 5%.

Press from the Units/Mode display to return to Menu Selections.

*Note 4-20mA circuitry is only powered by the AC power module.

To conserve power this output is not active in battery power mode.

Page 15

Page 16

PTFM 1.0 Portable Transit Time Flow Meter

DATA LOGGING

Setup

Select Data Logging from Menu Selections.

Log Site ID Enter a number from 00 to 99. The site ID will become part of

the downloaded file name to help distinguish downloads from

different instruments. Press to store the setting.

Mode Select Velocity (e.g. ft/sec or m/sec). Flow (e.g. USGPM or

l/sec). Press to store the setting.

Set Date Press or to scroll and select Month, Day and Year. Press

to store the setting.

Set Time Press or to select the current time in Hours, Minutes and

Seconds. Press to store the setting.

Interval Press or to select the logging interval.

Press to store the setting.

Log Select Start then to start logger. Select Stop then to stop

logger. Select Delete then to clear all previous logging

sessions.

RETRIEVE LOG FILE

Install Greyline Logger on your PC or laptop. Refer to the Help menu in the

program for detailed instructions.

- Connect the PTFM 1.0 to the PC using the supplied USB cable.

- Install the USB driver program from the install CD.

- Start the Greyline Logger Software.

- Select "xxxx scan for USB instruments xxxx" in the drop down window at the

top of the main window. PTFM 1.0 will be indicated.

- Click the download icon to start transferring data.

- Downloaded data appears in a pop-up window.

Page 16

Page 17

PTFM 1.0 Portable Transit Time Flow Meter

SPECIAL FUNCTIONS

Language Select English, French or Spanish

Reset Totalizer Press and select Yes to erase and restart the

totalizer at zero.

Negative Totals Select Yes to have reverse flow readings deducted

from the totalizer. Select NO to totalize forward

flow only and ignore reverse flow.

Cal Constant Factory set during calibration. (Refer to the calibration

certificate supplied with your instrument.)

Restore Defaults Select Yes and press to erase all user settings and return

the instrument to factory default settings.

New Password Select any number from 0000 to 9999 and press .

Default setting of 0000 will allow direct access to the

calibration menus. Setting of any password greater

than 0000 will require the password to be entered to

access the calibration menus.

Press to return to Menu Selections.

Page 17

Page 18

PTFM 1.0 Portable Transit Time Flow Meter

SIMULATION

Exercises the 4-20mA.

Test Select Maximum and press to simulate maximum Flow or Velocity and

to output 20mA to the analog channel.

Select Minimum and press to simulate minimum Flow or Velocity and

to output 4mA to the analog channel.

To simulate measurements between minimum and maximum set Test to

Actual and then enter for the flow measurement. The analog output will

respond to the simulated value.

SLEEP MODE

Logging in sleep mode requires a minimum sample time of 30 seconds. Selecting

sleep mode for 10 second sampling rate results in instrument always being

‘awake’.

BACKLIGHT

Three levels of backlight are selectable to conserve power.

CHARGING

A flashing battery indicates charging.

A solid battery indicates fully charged.

Page 18

Page 19

PTFM 1.0 Portable Transit Time Flow Meter

SENSOR MOUNTING LOCATION

The position of the sensor is one of the most important considerations for accurate Transit Time flow

measurement. The same location guidelines apply to Transit Time as most other types of flow meters.

Before permanently mounting a Transit Time sensor onsite testing is recommended to determine

optimum mounting position. Use the sensor coupling compound (supplied with each Greyline flow

meter, or petroleum gel, acoustic compound or electrocardiograph gel). Take several readings around the

axis of the pipe and then at several points upstream and downstream from the selected position,

checking for consistent readings. Avoid high or low reading areas. Mount the sensors where consistent

(average) readings were obtained or continue testing on another pipe section.

VERTICAL OR HORIZONTAL PIPE - Vertical pipe

runs generally provide evenly distributed flow. On

1 TO 5 O'CLOCKPOSITION

ON HORIZONTAL PIPES

Horizontal pipes and liquids with high concentrations

of gas or solids, the sensors should be mounted on the

side (1 to 5 o’clock positions) to avoid concentrations

of gas at the top of the pipe, or solids at the bottom.

VERTICALPIPE USUALLY

HAS EVENLYDISTRIBUTED FLOW

VELOCITY INCREASING DEVICES: Generally the sensors must be mounted away from flow

disturbances such as valves, pumps, orifice plates, venturis or pipe inlets and discharges which tend to

increase flow velocity. Velocity increasing devices often cause cavitation, or rapid release of gas

bubbles, and readings both up and downstream may be intermittent or inaccurate. As a guideline, mount

the sensor at least 20 diameters upstream or 30 diameters downstream from velocity increasing devices.

Required distance from a velocity increasing device will vary in applications depending on the flow

velocity and the characteristics of the liquid itself.

TURBULENCE INCREASING DEVICES: Elbows,

flanged connections and tees tend to introduce

desirable conditions of an evenly distributed flow

profile. Sensor mounting 6 pipe diameters upstream

and 10 diameters downstream from these disturbances

is generally optimum.

The sensors are designed to mount longitudinally on a straight section of pipe. Do not attempt to mount

it on bends, elbows or fittings.

Page 19

Page 20

PTFM 1.0 Portable Transit Time Flow Meter

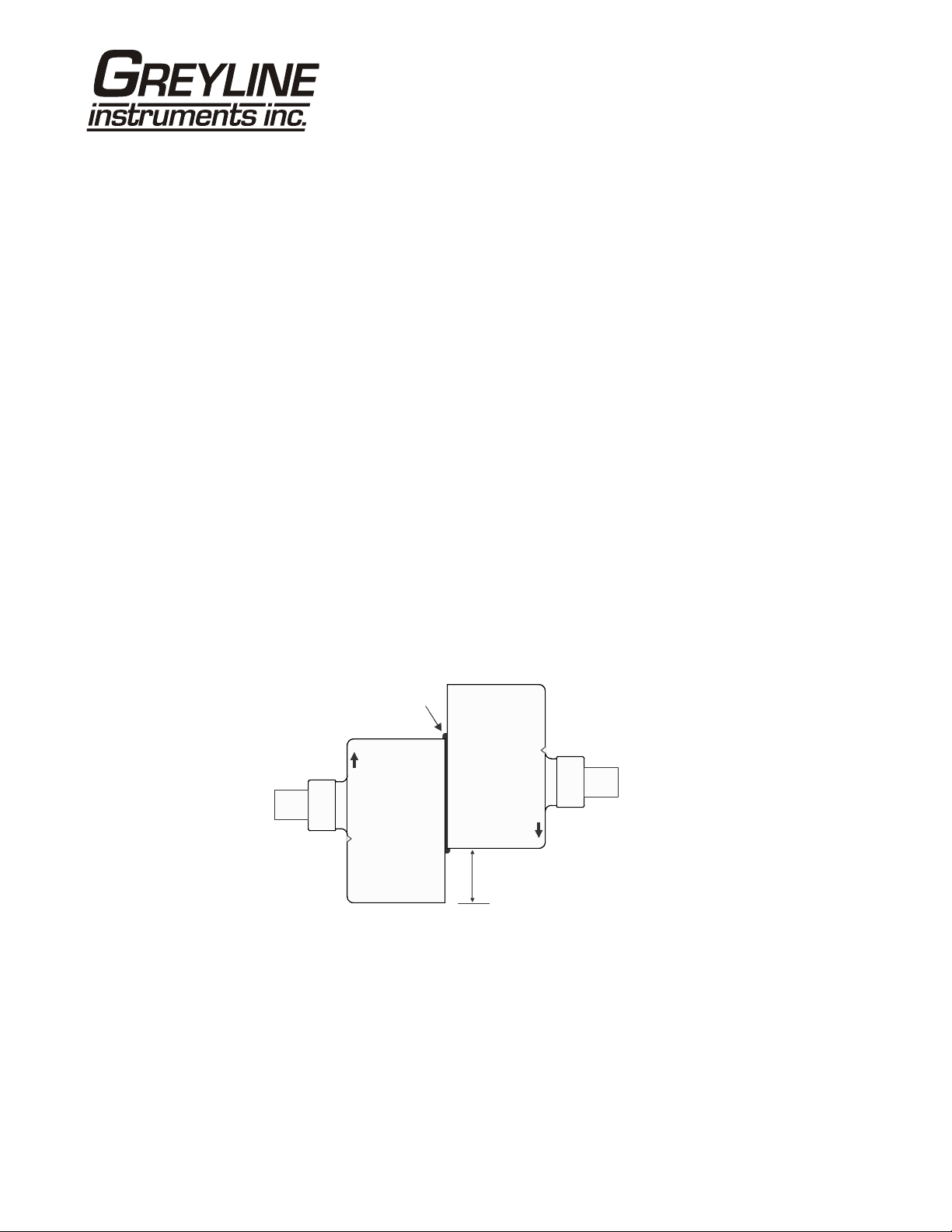

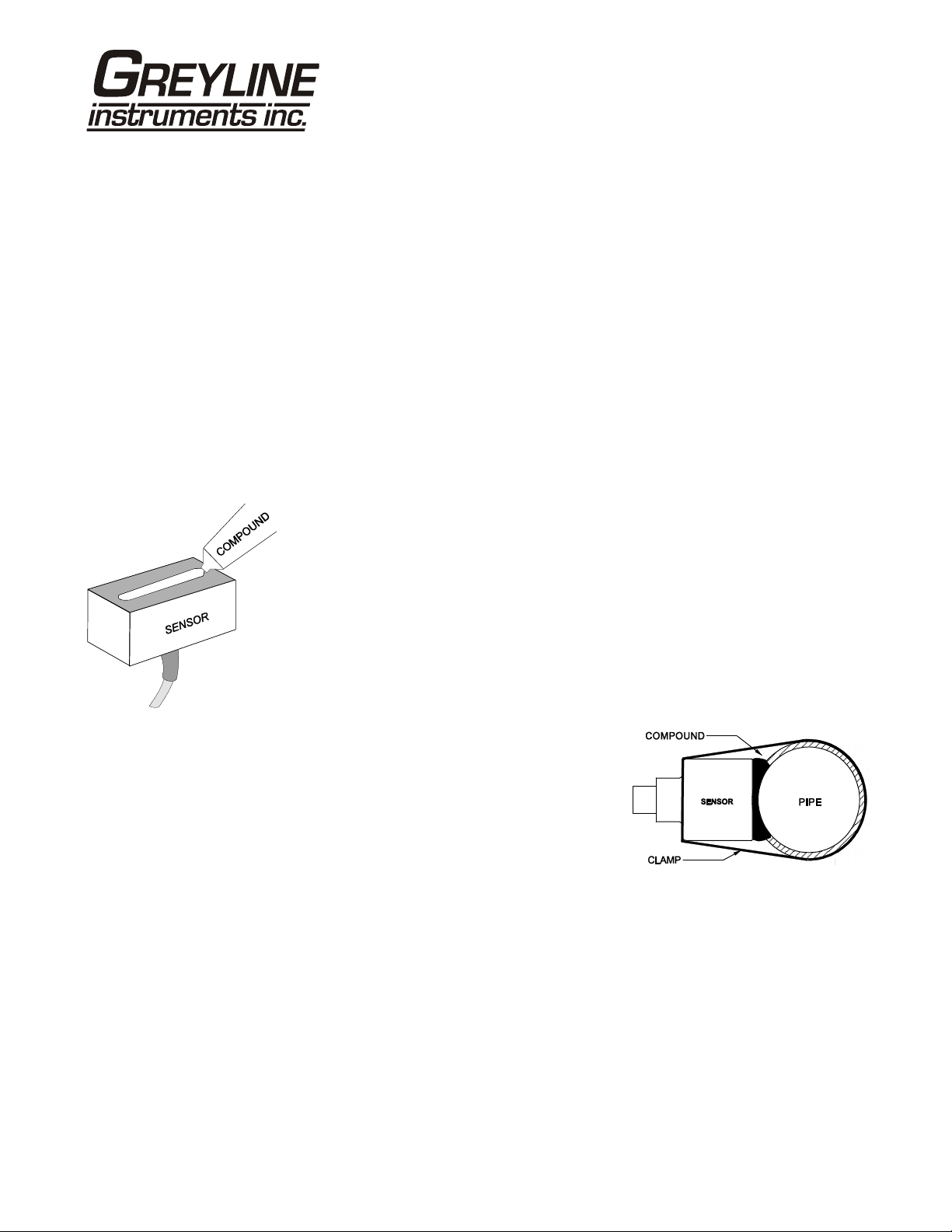

SENSOR MOUNTING

Prepare an area 2" wide by 4" long (50mm x 100mm) for sensor bonding by removing loose paint, scale

and rust. The objective of site preparation is to eliminate any discontinuity between the sensor and the

pipe wall, which would prevent acoustical coupling.

A TMK1 Sensor Mounting Kit is supplied with each Greyline flow meter. It includes recommended

coupling compound in a plastic applicator and a stainless steel mounting bracket with adjustable pipe

straps. Use the Alignment Bar (included) to align sensor brackets for V and W mode mounting.

Page 20

Page 21

PTFM 1.0 Portable Transit Time Flow Meter

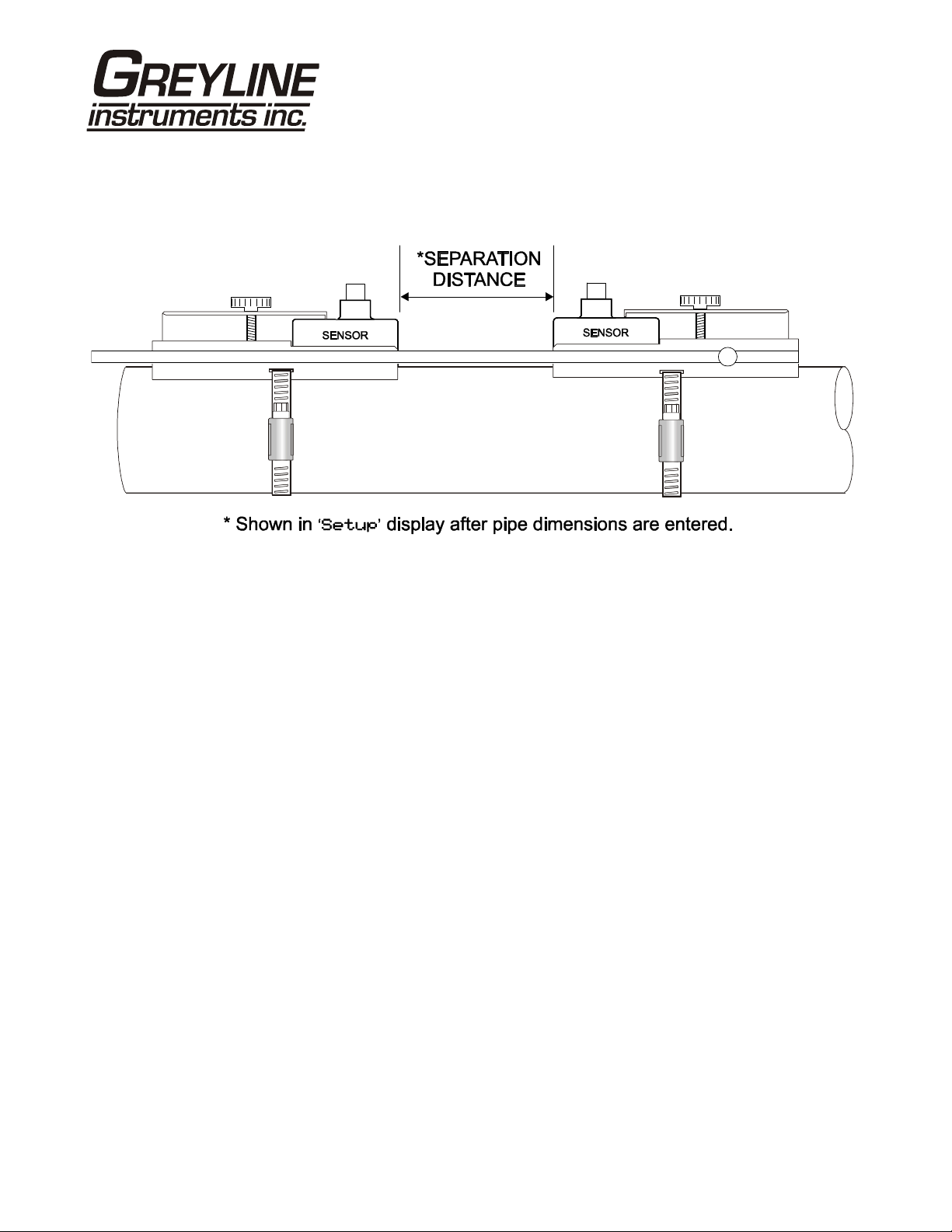

SEPARATION DISTANCE

Measure separation distance with a ruler or tape measure. Separation distance is automatically calculated

by the PTFM 1.0 based on parameters entered in the Set-up menu. Sens Space is displayed on the

Setup menu.

Page 21

Page 22

PTFM 1.0 Portable Transit Time Flow Meter

SENSOR COUPLING

For permanent or temporary bonding, the following are recommended:

a) Dow Corning silicon compound #4 (supplied)

Additional supply: order Greyline Option CC

b) Water-based sonic compound: Order Greyline Option CC30

c) Electrocardiograph gel

d) Petroleum gel (Vaseline)

The above are arranged in their order of preferred application.

d is only good for temporary bonding at room temperature.

DO NOT USE: Silicon RTV caulking compound (silicon rubber).

Use the pipe clamp and rail (supplied) as illustrated on previous page or use

a loop of electrical tape for temporary mounting. Apply silicon coupling

compound #4 to the colored face of the sensor. A bead, similar to toothpaste

on a toothbrush, is ideal. Do not overtighten (crush the sensor).

The sensor must be fixed securely to the pipe with coupling material

between the sensor face and the pipe. Sensor installation with

excessive coupling compound can result in gaps or voids in the

coupling and cause errors or loss of signal. Insufficient coupling

compound will create similar conditions.

Over time temporary coupling compounds (e.g. Petroleum Gel) may gradually sag away from the sensor

resulting in reduced signal strength and finally complete loss of signal. Warm temperatures, moisture

and vibration will accelerate this process. Dow Corning Silicone Compound #4 as supplied with the

PTFM 1.0 (and available from Greyline Instruments) is recommended for semi-permanent installations.

Page 22

Page 23

PTFM 1.0 Portable Transit Time Flow Meter

BAD

GOOD

SENSOR MOUNTING/COUPLING RECOMMENDATIONS

Page 23

Page 24

FIELD TROUBLESHOOTING

PTFM 1.0 Portable Transit Time Flow Meter

Possible Causes:

METER READING WHEN THERE IS NO FLOW?

Erratic measurement (set damping to 0% to check) due

to electrical noise or poor signal quality.

Variable Speed Drive interference

Sensor cable connections incorrect or loose

METER READING LOWER THAN EXPECTED?

Corrective Action:

Set Calibration / Damping to 5% with zero flow

use Setup / Tare function.

Try adjusting sensor spacing (+/- 10%) and

contact Greyline for further assistance.

Adjust Calibration / Min Flow setting.

Follow Drive manufacturers wiring and

Grounding instructions

Relocate Flowmeter, Sensors and wiring away

from VSD

Disconnect and reconnect sensor cables

ensuring that cable plugs are properly inserted

into terminals and tightened.

Calibration Error

Lower flow rate than expected

Erratic measurement (set damping to 0% to check) due

to electrical noise or poor signal quality.

NO ECHO INDICATION (Icon: No Echo)?

Sensor Connections

Sensors not mounted to Pipe or mounted improperly

Empty pipe or partially filled

Review calibration menu. Pipe dimensions and

fluid selection/fluid velocity.

Investigate pump/valves. Compare velocity

with alternate instrument.

Try adjusting sensor spacing (+/- 10%) and

contact Greyline for further assistance.

Check sensor connections at PTFM

Apply coupling compound and mount sensors

to pipe with proper sensor spacing.

Pipe must be fluid filled and acoustically

transparent in order to obtain echoes.

Page 24

Page 25

PTFM 1.0 Portable Transit Time Flow Meter

Possible Causes:

Coupling compound washed out, or sensor loose on

pipe.

METER READING HIGHER THAN EXPECTED?

Calibration Error

Higher flow rate than expected

Erratic measurement (set damping to 0% to check) due

to electrical noise or poor signal quality.

Pipe not Full

Corrective Action:

Remount sensor

Use Dow Corning Silicone #4

Review calibration menu. Pipe dimensions and

fluid selection/fluid velocity.

Investigate pump/valves. Compare velocity

with alternate instrument.

Try adjusting sensor spacing (+/- 10%) and

contact Greyline for further assistance.

Verify pipe is full by mounting sensors at top

of pipe and check echo icon. No echo if pipe is

not full.

High viscosity fluid

BATTERY CONDITIONING

Laminar flow profile due to high viscosity fluid

requires an adjustment to Cal Const.

To restore or condition your PTFM 1.0 battery

for best performance fully discharge the unit

(leave it on with backlight lit until it switches

off) and then charge for 6 hours, disconnect

charger momentarily, reconnect and charge

again for 6 hours.

Page 25

Page 26

PTFM 1.0 Portable Transit Time Flow Meter

COMMON QUESTIONS AND ANSWERS

The pipe vibrates. Will it affect the flow meter?

Common vibration frequencies are far lower than the sonic frequencies used by the Greyline flow meter,

and will not normally affect accuracy or performance. However, applications where very weak Transit

Time signal is present (when sensitivity is adjusted to maximum and signal strength is low), accuracy

may be affected by pipe vibration, or the flow meter may show readings under no-flow conditions.

Attempt to relocate the sensor on a pipe section where vibration is reduced, or arrange pipe mounting

brackets to reduce vibration at the sensor mounting location.

The flow meter must be installed in a high noise environment. Will this affect operation?

Greyline flow meters are designed to discriminate between environmental noise and the Transit Time

signal. High noise environments may affect the flow meter’s performance where low signal strength

and/or low flow velocities are being measured. Relocate the sensor in a quieter environment if possible.

Will pipe corrosion affect accuracy of the flow meter?

Yes. Rust, loose paint etc. must be removed from the outside of the pipe to provide a clean mounting

position when installing a Transit Time sensor. Severe corrosion/oxidation on the inside of the pipe may

prevent the Transit Time signal from penetrating into the flow. If the pipe cannot be cleaned, a spool

piece (PVC recommended) should be installed for sensor mounting.

What effect do pipe liners have on the flow meter?

The air gap between loose insertion liners and the pipe wall prevent the Transit Time signal from

entering the flow. Better results can be expected with bonded liners such as cement, epoxy or tar,

however an on site test is recommended to determine if the application is suitable for a Transit Time

flow meter.

Why is Transit Time recommended for clean liquids?

The Transit Time sensor transmits sound across the flow stream in order to measure sound velocity and

therefore requires a fluid medium that is relatively transparent to the acoustic signal. The Transit Time

system will not function when there is high volume of solids or aeration. As a guideline, Greyline

Transit Time flow meters are recommended for clean liquids with solids or bubbles content less than

2%. Most applications such as water, chemicals and oils will meet this minimum requirement.

Can the sensor be submerged in water?

Yes, for short periods of time or by accident, but it is not recommended for continuous operation. The

sensor is constructed to withstand submersion to 10 psi (0.7 Bar) without damage. Plastic seal jackets on

the sensor cables can be filled with coupling compound to provide additional moisture protection for the

BNC connectors.

Page 26

Page 27

PTFM 1.0 Portable Transit Time Flow Meter

What is the purpose of the Signal Strength Display?

The primary function of the signal strength display is to assist as a feedback when mounting sensors.

Signal Strength can also be a useful diagnostics tool when troubleshooting problems with an installation.

A low signal strength (< 10%) will cause the PTFM to be more susceptible to environmental noise and

may indicate a problem with the installation or other qualitative issues.

Does the PTFM 1.0 require periodic recalibration?

PTFM 1.0 calibration does not normally drift over time. Greyline offers a calibration service to verify

instrument accuracy.

ISO 9000 or similar quality management systems may require periodic and verifiable recalibration of

flow meters. PTFM 1.0 Flow Meters may be returned to Greyline for factory calibration and issue of a

new NIST traceable certificate. Refer to the ‘Product Return Procedure’ section of this manual for return

instructions.

Can the internal batteries be replaced?

The built-in rechargeable NiMH battery pack is not user-serviceable. The meter should be returned to

Greyline for battery service.

Page 27

Page 28

PTFM 1.0 Portable Transit Time Flow Meter

APPLICATIONS HOTLINE

For applications assistance, advice or information on any Greyline Instrument contact your Sales Representative,

write to Greyline or phone the Applications Hotline below:

United States: Tel: 315-788-9500 Fax: 315-764-0419

Canada: Tel: 613-938-8956 Fax: 613-938-4857

Toll Free: 888-473-9546

Email: info@greyline.com

Web Site: www.greyline.com

Greyline Instruments Inc.

Canada USA:

16456 Sixsmith Drive 11451 Belcher Road South

Long Sault, Ont. K0C 1P0 Largo, FL 33773

PRODUCT RETURN PROCEDURE

Instruments may be returned to Greyline for service or warranty repair.

1 Obtain an RMA Number from Greyline -

Before shipping a product to the factory please contact Greyline by telephone, fax or email to obtain an

RMA number (Returned Merchandise Authorization). This ensures fast service and correct billing or

credit.

When you contact Greyline please have the following information available:

1. Model number / Software Version

2. Serial number

3. Date of Purchase

4. Reason for return (description of fault or modification required)

5. Your name, company name, address and phone number

2 Clean the Sensor/Product -

Important: unclean products will not be serviced and will be returned to the sender at their expense.

1. Rinse sensor and cable to remove debris.

2. If the sensor has been exposed to sewage, immerse both sensor and cable in a solution of 1 part

household bleach (Javex, Clorox etc.) to 20 parts water for 5 minutes. Important: do not immerse

open end of sensor cable.

3. Dry with paper towels and pack sensor and cable in a sealed plastic bag.

4. Wipe the outside of the enclosure to remove dirt or deposits.

5. Return to Greyline for service.

Page 28

Page 29

PTFM 1.0 Portable Transit Time Flow Meter

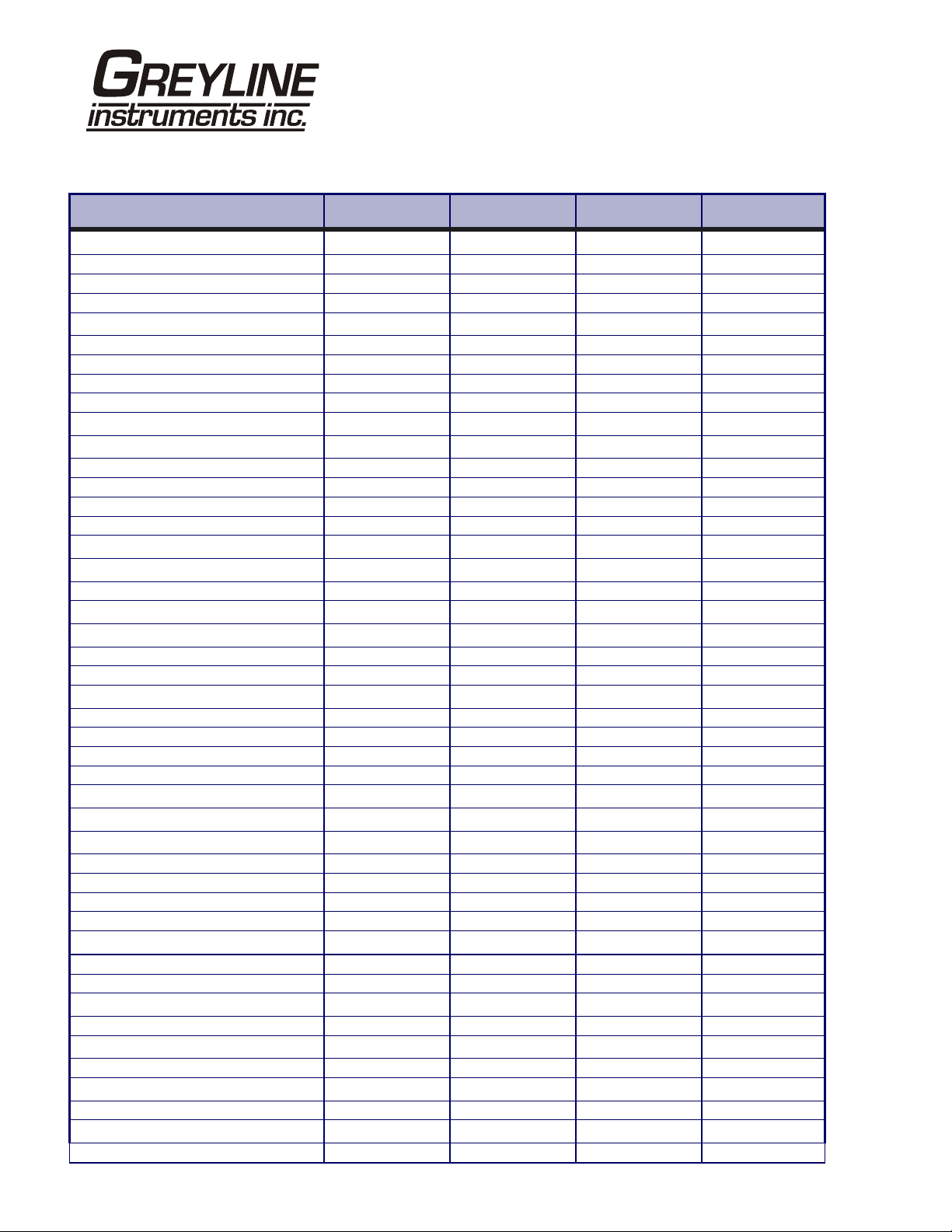

Contact

Title/Dept

Company

Address

Address

Tel

Fax

Email

Mobile

Pipe Run

[ ] Vertical

[ ] Horizontal

Pipe Full

[ ] Yes

[ ] No

Fluid Type

% of Solids

Nominal Pipe Size and Schedule

P

ipe

Outside Diameter

Wall Thickness

Pipe Material

Liner Material

Liner Thickness

Normal Flow

Maximum Flow

Minimum Flow

Maximum Temp

erature

Maximum Pressure

Vibration

[ ] Yes

[ ] No

Hazardous Rating

Notes / Additional Comments /

Pipe Run

Diagram

:

FLOW METER DATA SHEET

[ ] 16456 Sixsmith Drive, Long Sault, ON K0C 1P0

Tel: 613-938-8956 / Fax: 613-938-4857

[ ] 11451 Belcher Road South, Largo, FL 33773

Tel: 315-788-9500 / Fax: 315-764-0419

Contact Information

Service Conditions

Please complete and return this form to Greyline. It is important. We

use this information to check our database for performance of Greyline

flow meters in similar applications, and to provide advice and

recommendations to you. Thank you for your cooperation.

Page 29

Page 30

PTFM 1.0 Portable Transit Time Flow Meter

LIMITEDWARRANTY

_____________________________________

Greyline Instruments warrants, to the original purchaser, its

products to be free from defects in material and workmanship for a

period of one year from date of invoice. Greyline will replace or

repair, free of charge, any Greyline product if it has been proven to

be defective within the warranty period. This warranty does not

cover any expenses incurred in the removal and re-installation of

the product.

If a product manufactured by Greyline should prove defective

within the first year, return it freight prepaid to Greyline

Instruments along with a copy of your invoice.

This warranty does not cover damages due to improper installation

or handling, acts of nature, or unauthorized service. Modifications

to or tampering with any part shall void this warranty. This

warranty does not cover any equipment used in connection with the

product or consequential damages due to a defect in the product.

All implied warranties are limited to the duration of this warranty.

This is the complete warranty by Greyline and no other warranty is

valid against Greyline. Some states do not allow limitations on how

long an implied warranty lasts or limitation of incidental or

consequential damages, so the above limitations or exclusions may

not apply to you.

This warranty gives you specific legal rights, and you may also

have other rights which vary from state to state.

Greyline Instruments Inc.

Page 30

Page 31

SPECIFICATIONS

Flow Rate Range: ± 0.07 to 39 ft/sec (± 0.02 to 12

Electronics Operating

Electronics Enclosure: Portable, ABS enclosure

Language Selection: English, French, Spanish

PTFM 1.0 Portable Transit Time Flow Meter

m/sec) in most applications

Pipe Size: Ultrasonic Sensor mounts on any

pipe from 2" to 48" ID (50 mm to

1200 mm)

Display: White, backlit matrix - displays

flow rate, totalizer, operating mode

and calibration menu

Power Input: Built-in NiMH battery for up to 18

hours continuous operation

External charger with 100240VAC 50/60Hz input

Outputs: 4-20mA (500 ohm) when AC

powered

USB for Data Log transfer by

direct PC connection

Data Logger: Programmable 300,000 data point

capacity, time and date stamped

or formatted flow reports including

total, average, minimum, maximum and times of occurrence

PC Software: 'Greyline Logger' for Windows 98 or higher. Retrieves, displays and

saves data log files

Temperature: -5° to 140°F (-20° to 60°C)

Carry Case: Rated IP67 with protective molded foam insert

Accuracy: ±1% of reading or 0.1 ft/sec (0.03 m/sec), whichever is greater.

Repeatability: ±0.25%, Linearity: ±0.5%

Calibration: Built-in 5-key programming with user-friendly calibration menu.

Password protected.

Sensitivity: Adjustable signal cut-off, signal strength and damping

Approvals: Charger is CE and UL approved. The PTFM 1.0 is not certified for use

in hazardous rated locations.

Page 31

Page 32

SE16B Transit Time Sensor

Pipe Diameter: 2” to 48” (50 mm to 1200 mm)

Operating Temperature: -40° to 300°F (-40° to 150°C)

Operating Frequency: 1.28 MHz

Sensor Cable: PTC12 12 ft (4 m) with BNC connectors and seal jackets

Submersion Rating: Withstands accidental submersion pressure up to 10 psi (0.7 Bar)

PTFM 1.0 Portable Transit Time Flow Meter

Optional PTC50 50 ft (15 m) with BNC connectors and seal jackets

Page 32

Page 33

PTFM 1.0 Portable Transit Time Flow Meter

APPENDIX A - CONVERSION TABLE

CONVERSION GUIDE

FROM TO MULTIPLY BY

US GALLONS CUBIC FEET 0.1337

US GALLONS IMPERIAL GALS 0.8327

US GALLONS LITRES 3.785

US GALLONS CUBIC METERS 0.003785

LITRES/SEC GPM 15.85

LITRES CUBIC METERS 0.001

BARRELS US GALLONS 42

BARRELS IMPERIAL GALS 34.9726

BARRELS LITRES 158.9886

INCHES MM 25.4

DEGREES F DEGREES C (°F-32) x 0.556

POUNDS KILOGRAMS 0.453

PSI BAR 0.0676

FOOT² METER² 0.0929

Note: BARRELS are U.S. oil barrels.

Page 33

Page 34

PIPE CHARTS

PTFM 1.0 Portable Transit Time Flow Meter

Ductile Iron Pipe - Standard Classes

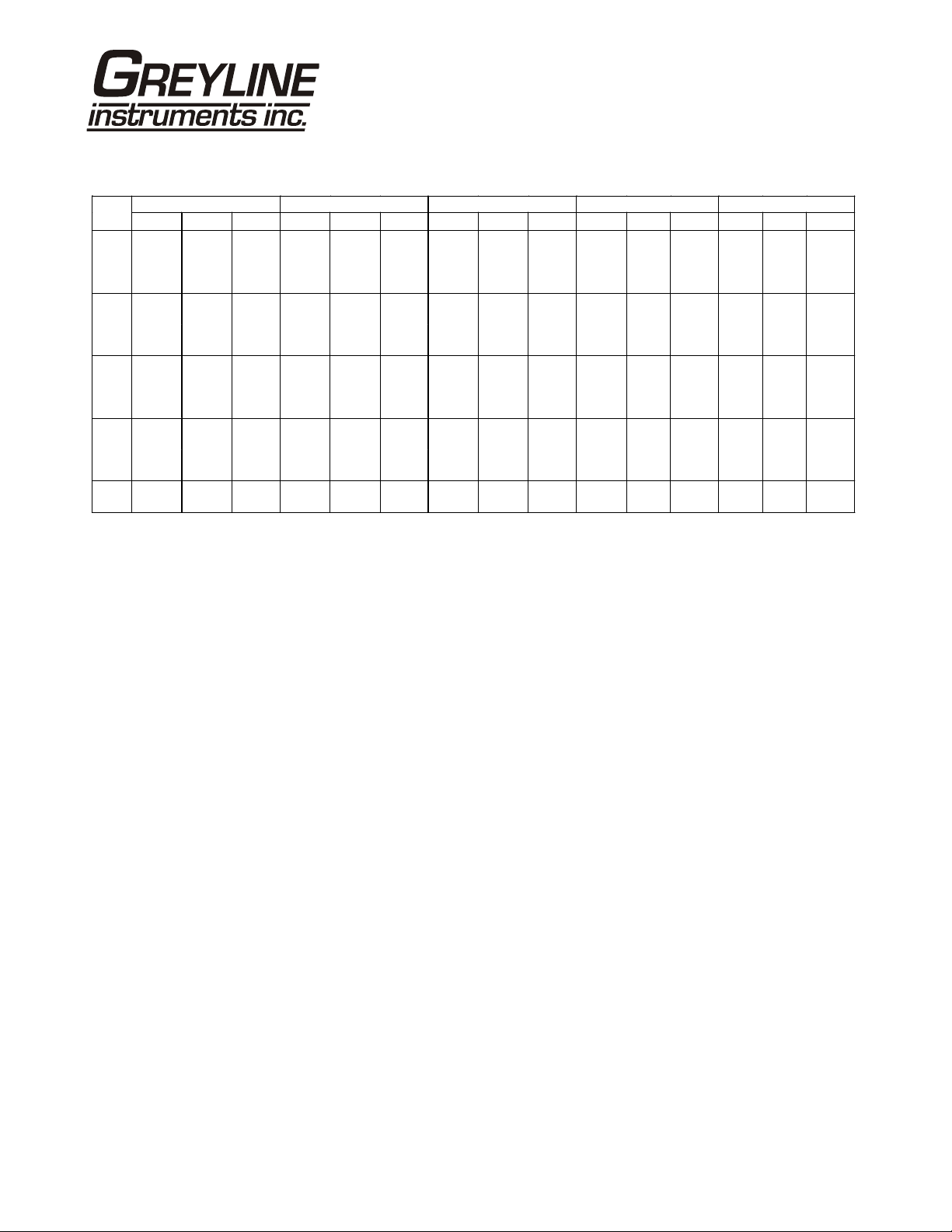

Size OUTSIDE Class Class Class Class Class Class Class CEMENT LINING

INCH D IA. 50 51 52 53 5 4 5 5 56 **STD **DOUBLE

INCH WALL I.D. WALL I.D. WALL I.D. WALL I.D. WALL I.D. WALL I.D. WA LL I.D. THICKNESS THICKNESS

3 3.96 0.25 3.46 0.28 3.40 0.31 3 .34 0.34 3 .28 0.37 3 .22 0.41 3.14

4 4.80 0.26 4.28 0.29 4.22 0.32 4 .16 0.35 4 .10 0.38 4 .04 0.44 3.93

6 6.90 0.25 6.40 0 .28 6.34 0.31 6.28 0.34 6 .22 0.37 6 .16 0.40 6 .10 0.43 6.04 .125 .250

8 9.05 0.27 8.51 0 .30 8.45 0.33 8.39 0.36 8 .33 0.39 8 .27 0.42 8 .21 0.45 8.15

10 11.10 0.39 10.32 0.32 10.46 0.35 10.40 0.38 10.34 0.41 10.28 0.44 10.22 0.47 10.16

12 13.20 0.31 12.58 0.34 12.52 0.37 12.46 0.40 12.40 0.43 12.34 0.46 12.28 0.49 12.22

14 15.30 0.33 14.64 0.36 14.58 0.39 14.52 0.42 14.46 0.45 14.40 0.48 14.34 0.51 14.28

16 17.40 0.34 16.72 0.37 16.66 0.40 16.60 0.43 16.54 0.46 16.48 0.49 16.42 0.52 16.36

18 19.50 0.35 18.80 0.38 18.74 0.41 18.68 0.44 18.62 0.47 18.56 0.50 18.50 0.53 18.44 .1875 .375

20 21.60 0.36 20.88 0.39 20.82 0.42 20.76 0.45 20.70 0.48 20.64 0.51 20.58 0.54 20.52

24 25.80 0.38 25.04 0.41 24.98 0.44 24.92 0.47 24.86 0.50 24.80 0.53 24.74 0.56 24.68

30 32.00 0.39 31.22 0.43 31.14 0.47 31.06 0.51 30.98 0.55 30.90 0.59 30.82 0.63 30.74

36 38.30 0.43 37.44 0.48 37.34 0.62 37.06 0.58 37.14 0.63 37.04 0.68 36.94 0.73 36.84

42 44.50 0.47 43.56 0.53 43.44 0.59 43.32 0.65 43.20 0.71 43.08 0.77 42.96 0.83 42.84 .250 .500

48 50.80 0.51 49.78 0.58 49.64 0.65 49.50 0.72 49.36 0.79 49.22 0.86 49.08 0.93 48.94

54 57.10 0.57 55.96 0.65 55.80 0.73 55.64 0.81 55.48 0.89 55.32 0.97 55.16 1.05 55.00

**REDUCE I.D. BY DIMENSION SHOWN

Page 34

Page 35

PTFM 1.0 Portable Transit Time Flow Meter

Stainless Steel, Hastelloy "C" & Titanium Pipe

Pipe Pipe Scheule 5 S (a) Schedule 10 S (a) Schedule 40 S Schedule 80 S

Size O.D. I.D. WALL I.D. WALL I.D. WALL I.D. WALL

½ .840 .710 .065 .674 .083 .622 .109 .546 .147

¾ 1.050 .920 .065 .884 .083 .824 .113 .742 .154

1 1.315 1.185 .065 1.097 .109 1.049 .133 .957 .179

1¼ 1.660 1.530 .065 1.442 .109 1.380 .140 1.278 .191

1½ 1.900 1.770 .065 1.682 .109 1.610 .145 1.500 .200

2 2.375 2.245 .065 2.157 .109 2.067 .154 1.939 .218

2½ 2.875 2.709 .083 2.635 .120 2.469 .203 2.323 .276

3 3.500 3.334 .083 3.260 .120 3.068 .216 2.900 .300

3½ 4.000 3.834 .083 3.760 .120 3.548 .226 3.364 .318

4 4.500 4.334 .083 4.260 .120 4.026 .237 3.826 .337

5 5.563 5.345 .109 5.295 .134 5.047 .258 4.813 .375

6 6.625 6.407 .109 6.357 .134 6.065 .280 5.761 .432

8 8.625 8.407 .109 8.329 .148 7.981 .322 7.625 .500

10 10.750 10.482 .134 10.420 .165 10.020 .365 9.750 .500

12 12.750 12.438 .156 12.390 .180 12.000 .375 11.750 .500

14 14.000 13.688 .156 13.624 .188

16 16.000 15.670 .165 15.624 .188

18 18.000 17.670 .165 17.624 .188

20 20.000 19.634 .188 19.564 .218

22 22.000 21.624 .188 21.564 .218

24 24.000 23.563 .218 23.500 .250

Pipe Pipe Schedule 60 Schedule 80 Schedule 100 Schedule 120 Schedule 140 Schedule 160

Size O.D. I.D. WALL I.D. WALL I.D. WALL I.D. WALL I.D. WALL I.D. WALL

½ .840 .546 .147 .466 .187

¾ 1.050 .742 .154 .614 .218

1 1.315 .957 .179 .815 .250

1¼ 1.660 1.278 .191 1.160 .250

1½ 1.900 1.500 .200 1.338 .281

2 2.375 1.939 .218 1.689 .343

2½ 2.875 2.323 .276 2.125 .375

3 3.500 2.900 .300 2.624 .438

3½ 4.000 3.364 .318

4 4.500 3.826 .337 3.624 .438 3.438 .531

5 5.563 4.813 .375 4.563 .500 4.313 .625

6 6.625 5.761 .432 5.501 .562 5.189 .718

8 8.625 7.813 .406 7.625 .500 7.439 .593 7.189 .718 7.001 .812 6.813 .906

10 10.750 9.750 .500 9.564 .593 9.314 .718 9.064 .843 8.750 1.000 8.500 1.125

12 12.750 11.626 .562 11.376 .687 11.064 .843 10.750 1.000 10.500 1.125 10.126 1.312

14 14.000 12.814 .593 12.500 .750 12.126 .937 11.814 1.093 11.500 1.250 11.188 1.406

16 16.000 14.688 .656 14.314 .843 13.938 1.031 13.564 1.218 13.124 1.438 12.814 1.593

18 18.000 16.500 .750 16.126 .937 15.688 1.156 15.250 1.375 14.876 1.562 14.438 1.781

20 20.000 18.376 .812 17.938 1.031 17.438 1.281 17.000 1.500 16.500 1.750 16.064 1.968

22 22.000 20.250 .875 19.750 1.125 19.250 1.375 18.750 1.625 18.250 1.875 17.750 2.125

24 24.000 22.064 .968 21.564 1.218 20.938 1.531 20.376 1.812 19.876 2.062 19.314 2.343

Page 35

Page 36

PTFM 1.0 Portable Transit Time Flow Meter

Cast Iron Pipe - ASA Standard

Pipe Pipe Class 50 Class 100 Class 150 Class 200 Class 250 Class 300 Class 350

Size O.D. WALL I.D. WALL I.D. WALL I.D. WALL I.D. WALL I.D. WALL I.D. WALL I.D.

3 3.96 0.32 3.32 0.32 3.32 0.32 3.32 0.32 3.32 0.32 3.32 0.32 3.32 0.32 3.32

4 4.80 0.35 4.10 0.35 4.10 0.35 4.10 0.35 4.10 0.35 4.10 0.35 4.10 0.35 4.10

6 6.90 0.38 6.14 0.38 6.14 0.38 6.14 0.38 6.14 0.38 6.14 0.38 6.14 0.38 6.14

8 9.05 0.41 8.23 0.41 8.23 0.41 8.23 0.41 8.23 0.41 8.23 0.41 8.23 0.41 8.23

10 11.10 0.44 10.22 0.44 10.22 0.44 10.22 0.44 10.22 0.44 10.22 0.48 10.14 0.52 10.06

12 13.20 0.48 12.24 0.48 12.24 0.48 12.24 0.48 12.24 0.52 12.16 0.52 12.16 0.56 12.08

14 15.30 0.48 14.34 0.51 14.28 0.51 14.28 0.55 14.20 0.59 14.12 0.59 14.12 0.64 14.02

16 17.40 0.54 16.32 0.54 16.32 0.54 16.32 0.58 16.24 0.63 16.14 0.68 16.04 0.68 16.04

18 19.50 0.54 18.42 0.58 18.34 0.58 18.34 0.63 18.24 0.68 18.14 0.73 18.04 0.79 17.92

20 21.60 0.57 20.46 0.62 20.36 0.62 20.36 0.67 20.26 0.72 20.16 0.78 20.04 0.84 19.92

24 25.80 0.63 24.54 0.68 24.44 0.73 24.34 0.79 24.22 0.79 24.22 0.85 24.10 0.92 23.96

Cast Iron Pipe - AWWA Standard

Class A Class B Class C Class D

Pipe

Size O.D. WALL I.D. O.D. WALL I.D. O.D. WALL I.D. O.D. WALL I.D.

3 3.80 0.39 3.02 3.96 0.42 3.12 3.96 0.45 3.06 3.96 0.48 3.00

4 4.80 0.42 3.96 5.00 0.45 4.10 5.00 0.48 4.04 5.00 0.52 3.96

6 6.90 0.44 6.02 7.10 0.48 6.14 7.10 0.51 6.08 7.10 0.55 6.00

8 9.05 0.46 8.13 9.05 0.51 8.03 9.30 0.56 8.18 9.30 0.60 8.10

10 11.10 0.50 10.10 11.10 0.57 9.96 11.40 0.62 10.16 11.40 0.68 10.04

12 13.20 0.54 12.12 13.20 0.62 11.96 13.50 0.68 12.14 13.50 0.75 12.00

14 15.30 0.57 14.16 15.30 0.66 13.98 15.65 0.74 14.17 15.65 0.82 14.01

16 17.40 0.60 16.20 17.40 0.70 16.00 17.80 0.80 16.20 17.80 0.89 16.02

18 19.50 0.64 18.22 19.50 0.75 18.00 19.92 0.87 18.18 19.92 0.96 18.00

20 21.60 0.67 20.26 21.60 0.80 20.00 22.06 0.92 20.22 22.06 1.03 20.00

24 25.80 0.76 24.28 25.80 0.89 24.02 26.32 1.04 24.22 26.32 1.16 24.00

30 31.74 0.88 29.98 32.00 1.03 29.94 32.40 1.20 30.00 32.74 1.37 30.00

36 37.96 0.99 35.98 38.30 1.15 36.00 38.70 1.36 39.98 39.16 1.58 36.00

42 44.20 1.10 42.00 44.50 1.28 41.94 45.10 1.54 42.02 45.58 1.78 42.02

48 50.50 1.26 47.98 50.80 1.42 47.96 51.40 1.71 47.98 51.98 1.96 48.06

54 56.66 1.35 53.96 57.10 1.55 54.00 57.80 1.90 54.00 58.40 2.23 53.94

60 62.80 1.39 60.02 63.40 1.67 60.06 64.20 2.00 60.20 64.82 2.38 60.06

72 75.34 1.62 72.10 76.00 1.95 72.10 76.88 2.39 72.10

84 87.54 1.72 84.10 88.54 2.22 84.10

100 Ft. 43 PSIG 200 Ft. 86 PSIG 300 Ft. 130 PSIG 400 Ft. 173 PSIG

Class E Class F Class G Class H

Pipe

Size O.D. WALL I.D. O.D. WALL I.D. O.D. WALL I.D. O.D. WALL I.D.

6 7.22 0.58 6.06 7.22 0.61 6.00 7.38 0.65 6.08 7.38 0.69 6.00

8 9.42 0.66 8.10 9.42 0.71 8.00 9.60 0.75 8.10 9.60 0.80 8.00

10 11.60 0.74 10.12 11.60 0.80 10.00 11.84 0.86 10.12 11.84 0.92 10.00

12 13.78 0.82 12.14 13.78 0.89 12.00 14.08 0.97 12.14 14.08 1.04 12.00

14 15.98 0.90 14.18 15.98 0.99 14.00 16.32 1.07 14.18 16.32 1.16 14.00

16 18.16 0.98 16.20 18.16 1.08 16.00 18.54 1.18 16.18 18.54 1.27 16.00

18 20.34 1.07 18.20 20.34 1.17 18.00 20.78 1.28 18.22 20.78 1.39 18.00

20 22.54 1.15 20.24 22.54 1.27 20.00 23.02 1.39 20.24 23.02 1.51 20.00

24 26.90 1.31 24.28 26.90 1.45 24.00 27.76 1.75 24.26 27.76 1.88 24.00

30 33.10 1.55 30.00 33.46 1.73 30.00

36 39.60 1.80 36.00 40.04 2.02 36.00

500 Ft. 217 PSIG 600 Ft. 260 PSIG 700 Ft.304 PSIG 800 Ft. 347 PSIG

Page 36

Page 37

PTFM 1.0 Portable Transit Time Flow Meter

½"

0.625

0.527

0.049

0.625

0.545

0.040

0.625

0.569

0.028

0.840

0.625

0.108

Copper Tubing

Pipe K L M Copper & Brass Pipe Aluminum

Size O.D. I.D. WALL O.D. I.D. WALL O.D. I.D. WALL O.D. I.D. WALL O.D. I.D. WALL

⅝" 0.750 0.652 0.049 0.750 0.666 0.042 0.750 0.690 0.030

¾" 0.875 0.745 0.065 0.875 0.785 0.045 0.875 0.811 0.032 1.050 0.822 0.114

1" 1.125 0.995 0.065 1.125 1.025 0.050 1.125 1.055 0.035 1.315 1.062 0.127

1 ¼" 1.375 1.245 0.065 1.375 1.265 0.055 1.375 1.291 0.042 1.660 1.368 0.146

1 ½" 1.625 1.481 0.072 1.625 1.505 0.060 1.625 1.527 0.049 1.900 1.600 0.150

2" 2.125 1.959 0.083 2.125 1.985 0.070 2.125 2.009 0.058 2.375 2.062 0.157

2 ½ 2.625 2.435 0.095 2.625 2.465 0.080 2.625 2.495 0.065 2.875 2.500 0.188 2.500 2.400 0.050

3" 3.125 2.907 0.109 3.125 2.945 0.090 3.125 2.981 0.072 3.500 3.062 0.219 3.000 2.900 0.050

3 ½" 3.625 3.385 0.120 3.625 3.425 0.100 3.625 3.459 0.083 4.000 3.500 0.250

4" 4.125 3.857 0.134 4.125 3.905 0.110 4.125 3.935 0.095 4.500 3.935 0.095 4.000 4.000 0.250

4 ½" 5.000 4.500 0.250

5" 5.125 4.805 0.160 5.125 4.875 0.125 5.125 4.907 0.109 5.563 5.063 0.250 5.000 4.874 0.063

6" 6.125 5.741 0.192 6.125 5.845 0.140 6.125 5.881 0.122 6.625 6.125 0.250 6.000 5.874 0.063

7" 7.625 7.062 0.282 7.000 6.844 0.078

8" 8.125 7.583 0.271 8.125 7.725 0.200 8.125 7.785 0.170 8.625 8.000 0.313 8.000 7.812 0.094

10" 10.125 9.449 0.338 10.125 9.625 0.250 10.125 9.701 0.212 10.000 9.812 0.094

12" 12.125 11.315 0.405 12.125 11.565 0.280 12.125 11.617 0.254

Page 37

Page 38

Fluid Sound Speed Table

APPENDIX B – Liquid Speed of Sound

Substance Form Index Specific Gravity Sound Speed

m/sec.

Acetic anhydride (22) (CH3CO)2O 1.082 (20ºC) 1180 2.5

Acetic acid, anhydride (22) (CH3CO)2O 1.082 (20ºC) 1180 2.5

Acetic acid, nitrile C2H3N 0.783 1290 4.1

Acetic acid, ethyl ester (33) C4H8O2 0.901 1085 4.4

Acetic acid, methyl ester C3H6O2 0.934 1211

Acetone C3H6O 0.791 1174 4.5

Acetonitrile C2H3N 0.783 1290 4.1

Acetonylacetone C6H10O2 0.729 1399 3.6

Acetylene dichloride C2H2Cl2 1.26 1015 3.8

Acetylene tetrabromide (47) C2H2Br4 2.966 1027

Acetylene tetrachloride (47) C2H2Cl4 1.595 1147

Alcohol C2H6O 0.789 1207 4.0

Alkazene-13 C15H24 0.86 1317 3.9

Alkazene-25 C10H12Cl2 1.20 1307 3.4

2-Amino-ethanol C2H7NO 1.018 1724 3.4

2-Aminotolidine (46) C7H9N 0.999 (20ºC) 1618

4-Aminotolidine (46) C7H9N 0.966 (45ºC) 1480

Ammonia (35) NH3 0.771 1729 6.68

Amorphous Polyolefin 0.98 962.6

t-Amyl alcohol C5H12O 0.81 1204

Aminobenzene (41) C6H5NO2 1.022 1639 4.0

Aniline (41) C6H5NO2 1.022 1639 4.0

Argon (45) Ar 1.400 (-188ºC) 853

Azine C6H5N 0.982 1415 4.1

Benzene (29,40,41) C6H6 0.879 1306 4.65

Benzol(29,40,41) C6H6 0.879 1306 4.65

Bromine (21) Br2 2.928 889 3.0

Bromo-benzene (46) C6H5Br 1.522 1170

1-Bromo-butane (46) C4H9Br 1.276 (20ºC) 1019

Bromo-ethane (46) C2H5Br 1.460 (20ºC) 900

Bromoform (46,47) CHBr3 2.89 (20ºC) 918 3.1

n-Butane (2) C4H10 0.601 (0ºC) 1085 5.8

2-Butanol C4H10O 0.81 1240 3.3

sec-Butylalcohol C4H10O 0.81 1240 3.3

n-Butyl bromide (46) C4H9Br 1.276 (20ºC) 1019

n-Butyl chloride (22,46) C4H9Cl 0.887 1140 4.57

tert Butyl chloride C4H9Cl 0.84 984 4.2

Butyl oleate C22H42O2 1404 3.0

2,3 Butylene glycol C4H10O2 1.019 1484 1.51

Cadmium (7) Cd 2237.7

Carbinol (40,41) CH4O 0.791 (20ºC) 1076 2.92

Carbitol C6H14O3 0.988 1458

Carbon dioxide (26) CO2 1.101 (-37ºC) 839 7.71

Carbon disulphide CS2 1.261 (22ºC) 1149

Carbon tetrachloride(33,35,47) CCl4 1.595 (20ºC) 926 2.48

v/°C - m/s/°C Δ

Page 39

Fluid Sound Speed Table

Substance Form Index Specific Gravity Sound Speed

v/°C - m/s/°C Δ

m/sec.

Carbon tetrafluoride (14) CF4 1.75 (-150ºC) 875.2 6.61

Cetane (23) C16H34 0.773 (20ºC) 1338 3.71

Chloro-benezene C6H5Cl 1.106 1273 3.6

1-Chloro-butane (22,46) C4H9Cl 0.887 1140 4.57

Chloro-diFluoromethane (3) (Freon 22) CHClF2 1.491 (-69ºC) 893.9 4.79

Chloroform (47) CHCl3 1.489 979 3.4

1-Chloro-propane (47) C3H7Cl 0.892 1058

Chlorotrifluoromethane (5) CClF3 724 5.26

Cinnamaldehyde C9H8O 1.112 1554 3.2

Cinnamic aldehyde C9H8O 1.112 1554 3.2

Colamine C2H7NO 1.018 1724 3.4

o-Cresol (46) C7H8O 1.047 (20ºC) 1541

m-Cresol (46) C7H8O 1.034 (20ºC) 1500

Cyanomethane C2H3N 0.783 1290 4.1

Cyclohexane (15) C6H12 0.779 (20ºC) 1248 5.41

Cyclohexanol C6H12O 0.962 1454 3.6

Cyclohexanone C6H10O 0.948 1423 4.0

Decane (46) C10H22 0.730 1252

1-Decene (27) C10H20 0.746 1235 4.0

n-Decylene (27) C10 H20 0.746 1235 4.0

Diacetyl C4H6O2 0.99 1236 4.6

Diamylamine C10H23N 1256 3.9

1,2 Dibromo-ethane (47) C2H4Br2 2.18 995

trans-1,2-Dibromoethene(47) C2H2Br2 2.231 935

Dibutyl phthalate C8H22O4 1408

Dichloro-t-butyl alcohol C4H8Cl2O 1304 3.8

2,3 Dichlorodioxane C2H6Cl2O2 1391 3.7

Dichlorodifluoromethane (3) (Freon 12) CCl2F2 1.516 (-40ºC) 774.1 4.24

1,2 Dichloro ethane (47) C2H4Cl2 1.253 1193

cis 1,2-Dichloro-Ethene(3,47) C2H2Cl2 1.284 1061

trans 1,2-Dichloro-ethene(3,47) C2H2Cl2 1.257 1010

Dichloro-fluoromethane (3) (Freon 21) CHCl2F 1.426 (0ºC) 891 3.97

1-2-Dichlorohexafluoro cyclobutane (47) C4Cl2F6 1.654 669

1-3-Dichloro-isobutane C4H8Cl2 1.14 1220 3.4

Dichloro methane (3) CH2Cl2 1.327 1070 3.94

1,1-Dichloro-1,2,2,2 tetra fluoroethane CClF2-CClF2 1.455 665.3 3.73

Diethyl ether C4H10O 0.713 985 4.87

Diethylene glycol, monoethyl ether C6H14O3 0.988 1458

Diethylenimide oxide C4H9NO 1.00 1442 3.8

1,2-bis(DiFluoramino) butane (43) C4H8(NF2)2 1.216 1000

1,2bis(DiFluoramino)- 2-methylpropane

(43)

1,2bis(DiFluoramino) propane (43) C3H6(NF2)2 1.265 960

2,2bis(DiFluoramino) propane (43) C3H6(NF2)2 1.254 890

2,2-Dihydroxydiethyl ether C4H10O3 1.116 1586 2.4

C4H9(NF2)2 1.213 900

Page 39

Page 40

Fluid Sound Speed Table

Substance Form Index Specific Gravity Sound Speed

v/°C - m/s/°C Δ

m/sec.

Dihydroxyethane C2H6O2 1.113 1658 2.1

1,3-Dimethyl-benzene (46) C8H10 0.868 (15ºC) 1343

1,2-1.0Dimethyl-benzene(29,46) C8H10 0.897 (20ºC) 1331.5 4.1

1,4-Dimethyl-benzene (46) C8H10 1334

2,2-Dimethyl-butane (29,33) C6H14 0.649 (20ºC) 1079

Dimethyl ketone C3H6O 0.791 1174 4.5

Dimethyl pentane (47) C7H16 0.674 1063

Dimethyl phthalate C8H10O4 1.2 1463

Diiodo-methane CH2I2 3.235 980

Dioxane C4H8O2 1.033 1376

Dodecane (23) C12H26 0.749 1279 3.85

1,2-Ethanediol C2H6O2 1.113 1658 2.1

Ethanenitrile C2H3N 0.783 1290

Ethanoic anhydride (22) (CH3CO)2O 1.082 1180

Ethanol C2H6O 0.789 1207 4.0

Ethanol amide C2H7NO 1.018 1724 3.4

Ethoxyethane C4H10O 0.713 985 4.87

Ethyl acetate (33) C4H8O2 0.901 1085 4.4

Ethyl alcohol C2H6O 0.789 1207 4.0

Ethyl benzene (46) C8H10 0.867(20ºC) 1338

Ethyl bromide (46) C2H5Br 1.461 (20ºC) 900

Ethyliodide (46) C2H5I 1.950 (20ºC) 876

Ether C4H10O 0.713 985 4.87

Ethyl ether C4H10O 0.713 985 4.87

Ethylene bromide (47) C2H4Br2 2.18 995

Ethylene chloride (47) C2H4Cl2 1.253 1193

Ethylene glycol C2H6O2 1.113 1658 2.1

50% Glycol/ 50% H2O 1578

d-Fenochone C10H16O 0.947 1320

d-2-Fenechanone C10H16O 0.947 1320

Fluorine F 0.545 (-143ºC) 403 11.31

Fluoro-benzene (46) C6H5F 1.024 (20ºC) 1189

Formaldehyde, methyl ester C2H4O2 0.974 1127 4.02

Formamide CH3NO 1.134 (20ºC) 1622 2.2

Formic acid, amide CH3NO 1.134 (20ºC) 1622

Freon R12 774

Furfural C5H4O2 1.157 1444

Furfuryl alcohol C5H6O2 1.135 1450 3.4

Fural C5H4O2 1.157 1444 3.7

2-Furaldehyde C5H4O2 1.157 1444 3.7

2-Furancarboxaldehyde C5H4O2 1.157 1444 3.7

2-Furyl-Methanol C5H6O2 1.135 1450 3.4

Gallium Ga 6.095 2870 (@30ºC)

Glycerin C3H8O3 1.26 1904 2.2

Page 40

Page 41

Fluid Sound Speed Table

Substance Form Index Specific Gravity Sound Speed

v/°C - m/s/°C Δ

m/sec.

Glycerol C3H8O3 1.26 1904 2.2

Glycol C2H6O2 1.113 1658 2.1

Helium (45) He4 0.125(-268.8ºC) 183

Heptane (22,23) C7H16 0.684 (20ºC) 1131 4.25

n-Heptane (29,33) C7H16 0.684 (20ºC) 1180 4.0

Hexachloro-Cyclopentadiene(47) C5Cl6 1.7180 1150

Hexadecane (23) C16H34 0.773 (20ºC) 1338 3.71

Hexalin C6H12O 0.962 1454 3.6

Hexane (16,22,23) C6H14 0.659 1112 2.71

n-Hexane (29,33) C6H14 0.649 (20ºC) 1079 4.53

2,5-Hexanedione C6H10O2 0.729 1399 3.6

n-Hexanol C6H14O 0.819 1300 3.8

Hexahydrobenzene (15) C6H12 0.779 1248 5.41

Hexahydrophenol C6H12O 0.962 1454 3.6

Hexamethylene (15) C6H12 0.779 1248 5.41

Hydrogen (45) H2 0.071 (-256ºC) 1187

2-Hydroxy-toluene (46) C7H8O 1.047 (20ºC) 1541

3-Hydroxy-tolune (46) C7H8O 1.034 (20ºC) 1500

Iodo-benzene (46) C6H5I 1.823 1114

Iodo-ethane (46) C2H5I 1.950 (20ºC) 876

Iodo-methane CH3I 2.28 (20ºC) 978

Isobutyl acetate (22) C6H12O 1180 4.85

Isobutanol C4H10O 0.81(20ºC) 1212

Iso-Butane 1219.8

Isopentane (36) C5H12 0.62 (20ºC) 980 4.8

Isopropanol (46) C3H8O 0.785 (20ºC) 1170

Isopropyl alcohol (46) C3H8O 0.785 (20ºC) 1170

Kerosene 0.81 1324 3.6

Ketohexamethylene C6H10O 0.948 1423 4.0

Lithium fluoride (42) LiF 2485 1.29

Mercury (45) Hg 13.594 1449

Mesityloxide C6H16O 0.85 1310

Methane (25,28,38,39) CH4 0.162 405(-89.15ºC) 17.5

Methanol (40,41) CH4O 0.791 (20ºC) 1076 2.92

Methyl acetate C3H6O2 0.934 1211

o-Methylaniline (46) C7H9N 0.999 (20ºC) 1618

4-Methylaniline (46) C7H9N 0.966 (45ºC) 1480

Methyl alcohol (40,44) CH4O 0.791 (20ºC) 1076 2.92

Methyl benzene (16,52) C7H8 0.867 1328 4.27

2-Methyl-butane (36) C5H12 0.62 (20ºC) 980

Methyl carbinol C2H6O 0.789 1207 4.0

Methyl-chloroform (47) C2H3Cl3 1.33 985

Methyl-cyanide C2H3N 0.783 1290

3-Methyl cyclohexanol C7H14O 0.92 1400

Page 41

Page 42

Fluid Sound Speed Table

Substance Form Index Specific Gravity Sound Speed

v/°C - m/s/°C Δ

m/sec.

Methylene chloride (3) CH2Cl2 1.327 1070 3.94

Methylene iodide CH2I2 3.235 980

Methyl formate (22) C2H4O2 0.974 (20ºC) 1127 4.02

Methyl iodide CH3I 2.28 (20ºC) 978

2-Methylphenol (46) C7H8O 1.047 (20ºC) 1541

3-Methylphenol (46) C7H8O 1.034 (20ºC) 1500

Milk, homogenized 1548

Morpholine C4H9NO 1.00 1442 3.8

Naphtha 0.76 1225

Natural Gas (37) 0.316 (-103ºC) 753

Neon (45) Ne 1.207 (-246ºC) 595

Nitrobenzene (46) C6H5NO2 1.204 (20ºC) 1415

Nitrogen (45) N2 0.808 (-199ºC) 962

Nitromethane (43) CH3NO2 1.135 1300 4.0

Nonane (23) C9H2O 0.718 (20ºC) 1207 4.04

1-Nonene (27) C9H18 0.736 (20ºC) 1207 4.0

Octane (23) C8H18 0.703 1172 4.14

n-Octane (29) C8H18 0.704 (20ºC) 1212.5 3.50

1-Octene (27) C8H16 0.723 (20ºC) 1175.5 4.10

Oil of Camphor Sassafrassy 1390 3.8

Oil, Car (SAE 20a.30) 1.74 870

Oil, Castor C11H10O10 0.969 1477 3.6

Oil, Diesel 0.80 1250

Oil, Fuel AA gravity 0.99 1485 3.7

Oil (Lubricating X200) 1530 5019.9

Oil (Olive) 0.912 1431 2.75

Oil (Peanut) 0.936 1458

Oil (Sperm) 0.88 1440

Oil, 6 1509

2,2-Oxydiethanol C4H10O3 1.116 1586 2.4

Oxygen (45) O2 1.155 (-186ºC) 952

Pentachloro-ethane (47) C2HCl5 1.687 1082

Pentalin (47) C2HCl5 1.687 1082

Pentane (36) C5H12 0.626 (20ºC) 1020

n-Pentane (47) C5H12 0.557 1006

Perchlorocyclopentadiene(47) C5Cl6 1.718 1150

Perchloro-ethylene (47) C2Cl4 1.632 1036

Perfluoro-1-Hepten (47) C7F14 1.67 583

Perfluoro-n-Hexane (47) C6F14 1.672 508

Phene (29,40,41) C6H6 0.879 1306 4.65

ß-Phenyl acrolein C9H8O 1.112 1554 3.2

Phenylamine (41) C6H5NO2 1.022 1639 4.0

Phenyl bromide (46) C6H5Br 1.522 1170

Page 42

Page 43

Fluid Sound Speed Table

Substance Form Index Specific Gravity Sound Speed

v/°C - m/s/°C Δ

m/sec.

Phenyl chloride C6H5Cl 1.106 1273 3.6

Phenyl iodide (46) C6H5I 1.823 1114

Phenyl methane (16,52) C7H8 0.867 (20ºC) 1328 4.27

3-Phenyl propenal C9H8O 1.112 1554 3.2

Phthalardione C8H4O3 1125

Phthalic acid, anhydride C8H4O3 1125

Phthalic anhydride C8H4O3 1125

Pimelic ketone C6H10O 0.948 1423 4.0

Plexiglas, Lucite, Acrylic 2651

Polyterpene Resin 0.77 1099.8

Potassium bromide (42) Kbr 1169 0.71

Potassium fluoride (42) KF 1792 1.03

Potassium iodide (42) KI 985 0.64

Potassium nitrate (48) KNO3 1.859 (352ºC) 1740.1 1.1

Propane (2,13)(-45 to -130ºC) C3H8 0.585 (-45ºC) 1003 5.7

1,2,3-Propanetriol C3H8O3 1.26 1904 2.2

1-Propanol (46) C3H8O 0.78 (20ºC) 1222

2-Propanol (46) C3H8O 0.785 (20ºC) 1170

2-Propanone C3H6O 0.791 1174 4.5

Propene (17,18,35) C3H6 0.563 (-13ºC) 963 6.32

n-Propyl acetate (22) C5H10O2 1280 (2ºC) 4.63

n-Propyl alcohol C3H8O 0.78 (20ºC) 1222

Propylchloride (47) C3H7Cl 0.892 1058

Propylene (17,18,35) C3H6 0.563 (-13ºC) 963 6.32

Pyridine C6H5N 0.982 1415 4.1

Refrigerant 11 (3,4) CCl3F 1.49 828.3 3.56

Refrigerant 12 (3) CCl2F2 1.516 (-40ºC) 774.1 4.24

Refrigerant 14 (14) CF4 1.75 (-150ºC) 875.24 6.61

Refrigerant 21 (3) CHCl2F 1.426 (0ºC) 891 3.97

Refrigerant 22 (3) CHClF2 1.491 (-69ºC) 893.9 4.79

Refrigerant 113 (3) CCl2F-CClF2 1.563 783.7 3.44

Refrigerant 114 (3) CClF2-CClF2 1.455 665.3 3.73

Refrigerant 115 (3) C2ClF5 656.4 4.42

Refrigerant C318 (3) C4F8 1.62 (-20ºC) 574 3.88

Selenium (8) Se 1072 0.68

Silicone (30 cp) 0.993 990

Sodium fluoride (42) NaF 0.877 2082 1.32

Sodium nitrate (48) NaNO3 1.884 (336ºC) 1763.3 0.74

Sodium nitrite (48) NaNO2 1.805 (292ºC) 1876.8

Solvesso 3 0.877 1370 3.7

Spirit of wine C2H6O 0.789 1207 4.0

Sulphur (7,8,10) S 1177 -1.13

Sulphuric acid (1) H2SO4 1.841 1257.6 1.43

Tellurium (7) Te 991 0.73

Page 43

Page 44

Fluid Sound Speed Table

Substance Form Index Specific Gravity Sound Speed

v/°C - m/s/°C Δ

m/sec.

1,1,2,2-Tetrabromo-ethane(47) C2H2Br4 2.966120 1027

1,1,2,2-Tetrachloro-ethane(67) C2H2Cl4 1.595 1147

Tetrachloroethane (46) C2H2Cl4 1.553 (20ºC) 1170

Tetrachloro-ethene (47) C2Cl4 1.632 1036

Tetrachloro-methane (33,47) CCl4 1.595 (20ºC) 926

Tetradecane (46) C14H3O 0.763 (20ºC) 1331

Tetraethylene glycol C8H18O5 1.123 1586/5203.4 3.0

Tetrafluoro-methane (14) (Freon 14) CF4 1.75 (-150ºC) 875.24 6.61

Tetrahydro-1,4-isoxazine C4H9NO 1442 3.8

Toluene (16,52) C7H8 0.867 (20ºC) 1328 4.27

o-Toluidine (46) C7H9N 0.999 (20ºC) 1618

p-Toluidine (46) C7H9N 0.966 (45ºC) 1480

Toluol C7H8 0.866 1308 4.2

Tribromo-methane(46,47) CHBr3 2.89 (20ºC) 918

1,1,1-Trichloro-ethane(47) C2H3Cl3 1.33 985

Trichloro-ethene (47) C2HCl3 1.464 1028

Trichloro-fluoromethane(3) (Freon 11) CCl3F 1.49 828.3 3.56

Trichloro-methane (47) CHCl3 1.489 979 3.4

1,1,2-Trichloro-1,2,2-Trifluoro-Ethane CCl2F-CClF2 1.563 783.7

Triethyl-amine (33) C6H15N 0.726 1123 4.47

Triethylene glycol C6H14O4 1.123 1608 3.8

1,1,1-Trifluoro-2-Chloro-2-Bromo-Ethane C2HClBrF3 1.869 693

1,2,2-Trifluorotrichloro-ethane (Freon 113) CCl2F-CClF2 1.563 783.7 3.44

d-1,3,3-Trimethylnor-camphor C10H16O 0.947 1320

Trinitrotoluene (43) C7H5(NO2)3 1.64 1610

Turpentine 0.88 1255

Unisis 800 0.87 1346

Water, distilled (49,50) H2O 0.996 1498 -2.4

Water, heavy D²O 1400

Water, sea 1.025 1531 -2.4

WoodAlcohol (40,41) CH4O 0.791 (20ºC) 1076 2.92

Xenon (45) Xe 630

m-Xylene (46) C8H10 0.868 (15ºC) 1343

o-Xylene (29,46) C8H10 0.897 (20ºC) 1331.5 4.1

p-Xylene (46) C8H10 1334

Xylene hexafluoride C8H4F6 1.37 879

Zinc (7) Zn 3298

Page 44

Page 45

Loading...

Loading...