Page 1

Control Flow From Outside a Pipe

Flow Switch with SensorNon-Contacting

Doppler Flow

Switch

Model DFS 5.1

Controls Flow with:

No pressure drop

No sensor fouling

No maintenance

Installs in Minutes

No moving parts

Ideal for "difficult" liquids

No contact, No maintenance

Easy Calibration

Clamp-on Flow Sensor

Installs without cutting the pipe

Mount the DFS 5.1 ultrasonic sensor on the outside of metal or

plastic pipes. The sensor continuously injects high frequency

sound through the pipe wall and into the moving fluid where

acoustic pulses are reflected back to the sensor from particles or

bubbles in the fluid.

Flow rates of most liquids can be accurately controlled including

acids, caustics, lubrication fluids, chemicals, abrasives, waste

water and sludge. There are no moving parts and no sensor

maintenance is required.

The compact, water tight electronics enclosure includes adjustable

controls with separate ON and OFF relay set-points and time delay.

A LED bargraph for flow rate and set points plus relay status are

included.

Installation can be made while the flow system is in full operation.

No contact is made with the moving fluid and no holes are drilled in

the pipe. There is no fouling or scale build-up on the sensor.

Page 2

Non-Contacting Flow Control

Pump protection … High or Low flow control

Overfill alarm … Bargraph flow rate indication

Each DFS 5.1 Flow

Switch Includes:

!

Adjustable ON and

OFF relay setpoints

!

Adjustable time delay

!

Flow rate bargraph

!

Relay LED

Install in these

Applications:

] Sewage

] Viscous liquids

] Acids

] Slurries

] Solvents

] Treated wastewater

No pipe cutting, No pressure drop,

No sensor fouling, No maintenance!

It takes just a few minutes to install and calibrate a DFS 5.1 Flow Switch. The

DFS 5.1 controls flow of most liquids in closed pipes. The ultrasonic sensor

mounts on the outside of any pipe from 1/2" to 180" (12.5 mm to 4.5 m) I.D.

Easy to Calibrate

The DFS 5.1 control relay can

be set to turn ON and

OFF at any flow rate

between 0.25 and 10

ft/sec (0.075 to 3

m/sec). Insert two

links for separate

ON/OFF set points or

just one link for a Hi or

Lo flow alarm. Set relay

actuation time delay

from 0 to 80 seconds.

Ideal for Pump Protection

Avoid expensive pump repairs and downtime. The DFS 5.1 strap-on Sensor can

be installed in minutes without shutting down flow or cutting pipe. Use the

adjustable relay time delay to eliminate relay "chatter" and reduce pump wear.

] Sludge

] Pulp stock

] Food products

] Oils

Reliable and Repeatable

Repeatability is ±0.1% of full scale (0.1 ft/sec or 0.003 m/sec). There are no

moving parts and no maintenance is required.

The clamp-on ultrasonic sensor cannot be damaged or fouled by contact with the

liquid it measures. Sealed in a stainless steel housing, the DFS 5.1 sensor

withstands moisture or accidental submersion in water up to 10 psi (69 Kpa).

] Paint

] Chemicals

] Aerated Water

] Cooling Water

Designed for "difficult" liquids

The DFS 5.1 Doppler Flow Switch is recommended for flow

control of liquids containing gas bubbles or solids: chemicals,

slurries, sewage, sludge, viscous liquids, wastewater, caustics

and abrasives. The ultrasonic sensor injects high frequency

sound through the pipe wall into the flowing liquid. Acoustic

pulses are continuously reflected back to the sensor and the

DFS 5.1 measures a frequency shift to calculate flow velocity.

Self-tunes to Extended Sensor Cable

Up to 500 ft (150 m) extra sensor coaxial cable can be added. Extended cable

and junction box can be ordered from Greyline. The cable can be cut or extended

as required during installation. The flow switch automatically tunes to the cable

length. No circuit adjustment or calibration is required

SENSOR

BUBBLES OR SOLIDS

REFLECT SOUND

SOUND WAVES

REFLECTED

BACK TO SENSOR

SOUND WAVE

TRANSMITTED

FROM SENSOR

Page 3

DFS 5.1 Specifications

General

Standard Features

Options

Greyline DFS 5.1 Doppler Flow Switch

Shipping Weight: 8 lbs (3.6kg)

Enclosure: watertight, dust tight NEMA4X (IP 67) polycarbonate with a clear shatter-proof face

Power Input: 100-240VAC 50-60Hz (±10%), 2 Watts

Control Relay: 5 ampere DPDT

Set Points: ON/OFF adjustment from 0.25 to 10 ft/sec (0.075 to 3 m/sec)

Sensor: single-head ultrasonic with 20 ft (6m) shielded cable

Pipe Size: Any pipe ID from ½" to 180" (12.5 mm to 4.5 m)

Sensor Operating Temperature: -40° to 300°F (-40° to 150°C)

Electronics Operating Temperature: -10° to 140°F (-23° to 60°C)

Accuracy: ±2%, requires solids or bubbles minimum size of 100 microns, minimum

concentration 75 ppm. Repeatability: ±0.1%

Set-point: field-adjustable with separate ON/OFF set-points or select Hi flow alarm

or Lo flow alarm mode

Indication: flow rate LED bargraph, relay status LED

Time Delay: adjustable 0 to 80 seconds

Electrical Surge Protection: AC power input and sensor

Sensor mounting bracket, clamp and coupling compound included

Sensor Cable: up to 500 ft (150 m) shielded coaxial pair with cable Junction Box

Sensor mounting clamp: stainless steel, adjustable

Power input: 12-24 VDC (±10%), 3W Max

Applications

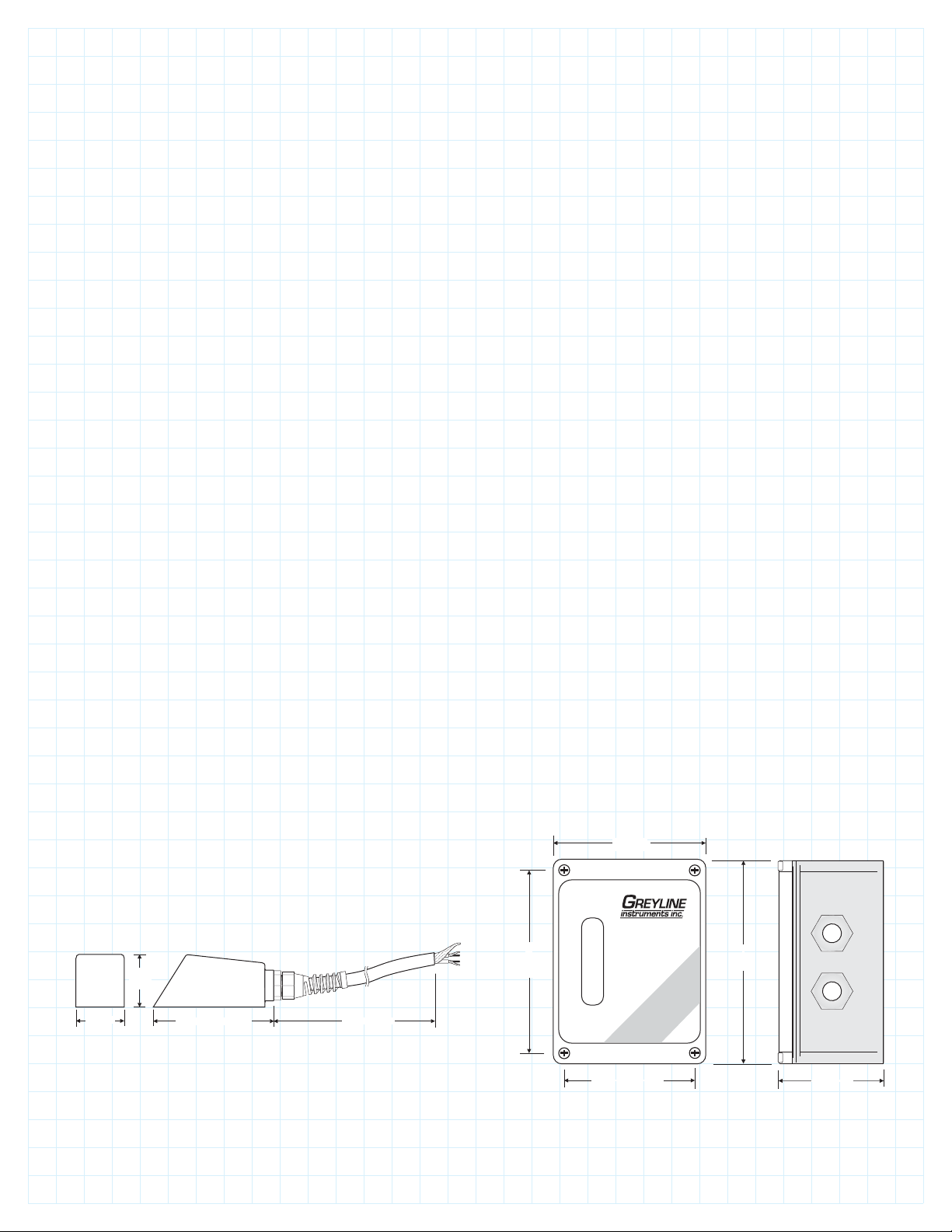

Dimensions

1.5”

END

38 mm

VIEW

1.375”

35 mm

SIDE VIEW

3.375” / 85 mm

+

Recommended for liquids containing suspended solids or bubbles minimum size of 100

microns, minimum concentration 75 ppm

+

Sensor mounts on Vertical or Horizontal pipes.

+

Sensor Mounting Location:

6-10 pipe diameters from elbows, tees (turbulence increasing devices)

>30 pipe diameters from pumps, controlling valves and pipe discharge

+

Pipe Materials: steel, stainless steel, cast iron, PVC, fiberglass, any contiguous pipe

material that conducts sound, including lined pipes with liner bonded to pipe wall. Avoid

pipes with loose insertion liners and pipe materials which contain air pockets (concrete,

wood etc.)

3.54 in

90 mm

20 ft / 6 m

Mounting

4.2 in

107 mm

DFS 5.1

FLOW SWITCH

4.72 in

120 mm

SE4 ULTRASONIC

DOPPLER SENSOR

Mounting

2.24 in / 57 mm

FACE VIEW

2.42 in

61.5 mm

SIDE VIEW

ENCLOSURE

Page 4

Easy-to-install, Automatic Flow Control

Recommended for Pump Protection and Flow Alarms

Greyline DFS 5.1 Doppler Flow Switch

The DFS 5.1 flow sensor installs without cutting the pipe. It takes just a few minutes to

mount on the outside of any pipe. The switch/electronics enclosure can be mounted

20 ft (6 m) away from the sensor (optional up to 500 ft / 152 m) to simplify wiring to

pumps, alarms, valves or other equipment.

Switch adjustments and electrical connections are fast and easy. The DFS 5.1 relay

time delay is adjustable from 0 to 80 seconds to prevent nuisance alarms and relay

"chatter" in turbulent flow. Includes switch selectable "normal" and "failsafe" operating

modes.

Choose the DFS 5.1 Flow Switch for:

] No contact with the measured liquid

] No obstruction to flow - No pressure drop

] Sensor mounts easily on the outside of the pipe

] Can be installed while pipe line is in use

] Insensitive to pressure, specific gravity and conductivity

DFS 5.1 Doppler

Sensor with

Pipe Clamp

] Does not require pipe metering sections

] Does not require consideration of material compatibility with the liquid

How to Order

Applications Support

No Risk Appraisal

The Greyline

Guarantee

Repeatable, Reliable Flow Control

Use the DFS 5.1 for pump protection, valve control and flow/no-flow alarms. It is ideal

for "difficult" liquids like wastewater, slurries, abrasives and chemicals, or any liquid

which contains gas bubbles or solids. The standard Sensor mounts on any pipe 1/2"

(12.5 mm) diameter or larger.

Contact a Greyline sales representative in your area or phone one of our sales

engineers. Describe your requirements and receive our prompt quotation.

Take advantage of Greyline's applications experience. Phone toll free 1-888-473-9546

for advice and information on applications, installation or service for Greyline

instruments.

The Greyline DFS 5.1 Doppler Flow Switch must meet your requirements. Discuss

your application with a Greyline representative to arrange a 30-day trial.

Quality of Materials and Workmanship - Each instrument manufactured by Greyline is

warranted against defects in materials and workmanship for a period of one year from

date of purchase. Refer to our limited warranty included with each product.

Canada: 16456 Sixsmith Dr., Long Sault, Ont. K0C 1P0

Tel: 613-938-8956 / 888-473-9546 Fax: 613-938-4857

USA: 105 Water Street, Massena NY 13662

Tel: 315-788-9500 / 888-473-9546 Fax: 315-764-0419

Internet: www.greyline.com E-mail: info@greyline.com

RELIABLE MEASUREMENT AND CONTROL

Loading...

Loading...