Page 1

Area-Velocity Flow Meter

Measure Flow in Open Channels and Partially-Filled Pipes

No Flume or Weir Required

Area-Velocity

Flow Meter

Model AVFM 6.1

Display, Transmit and Totalize

Flow in Open Channels and

Partially-Filled Pipes

No Flume or Weir Required

Three 4-20mA Outputs

Two Control Relays

Measures Reverse Flow

Modbus® RTU Optional

Area-Velocity Flow Meter

Submersible Ultrasonic Sensor

Measures Velocity and Level to Monitor Flow

with a single Ultrasonic Sensor

Measure flow through open channels, partially full pipes and

surcharged pipes without a flume or weir. Ideal for wastewater

stormwater, effluent, industrial wastewater, and irrigation water.

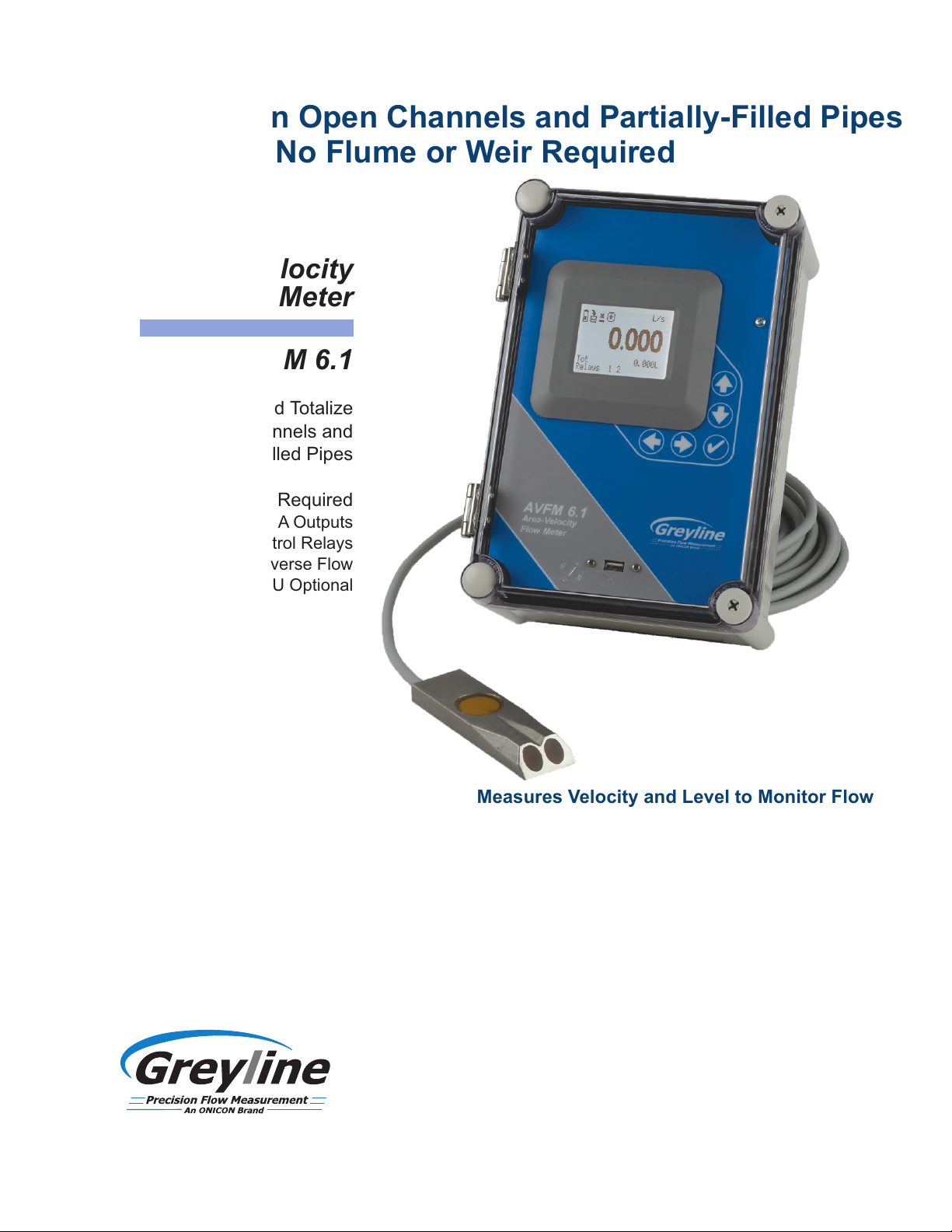

The AVFM 6.1 uses a submerged ultrasonic sensor to continuously

measure both Velocity and Level in the channel. The sensor

resists fouling, corrosion and abrasion. The flow meter can be

configured with the standard submerged velocity-level sensor, or

with submerged velocity plus a separate non-contacting ultrasonic

level sensor, for highly aerated fluids or those with high

concentration of suspended solids.

View flow rate and total flow on the large backlit LCD display and

connect to external devices with three 4-20mA outputs and two

control relays. Flow rate, volume, run hours, and diagnostic

information available through the optional Modbus® RTU serial

communications.

Page 2

Ultrasonic Flow Monitor for

Partially Filled Pipes & Open Channels

Easy to Use

The AVFM 6.1 Area-Velocity Flow Meter

measures both Level and Velocity to

calculate flow in an open channel or pipe.

Configuration is simple: enter the pipe

diameter or channel dimensions and the

AVFM 6.1 automatically computes and

Submerged Sensor

Measures Level And Velocity

stainless steel mounting bracket (included) and a single screw into the bottom of the pipe or channel. No special

compounds, tools or hardware are required. The sensor is completely sealed with no orifices or ports.

Recommended Pipe or Channel Conditions

Careful selection of sensor mounting location results in best performance and maintenance-free operation. Avoid locations

where sediment builds up.

Best possible accuracy will result when the water is not highly turbulent and where velocity is evenly distributed across the

channel. The channel should not have drops or direction changes immediately upstream of the sensor mounting location.

Pipe or channel slope should not exceed 3%. See installation manual for specific installation recommendations.

The AVFM 6.1 can measure forward flow velocity up to 20 ft/sec (6 m/sec) and reverse flow up to 5 ft/sec (1.5 m/sec). The

electronics and software sample and average flow rates continuously to provide stable readings. The submerged

velocity/level sensor will measure flow in partially full and surcharged pipes with pressure up to 10 psi. No special set-up

or adjustment is required. Minimum recommended pipe diameter is 6” (150 mm).

displays flow volume.

The ultrasonic sensor mounts inside the

pipe or on the bottom of a channel with a

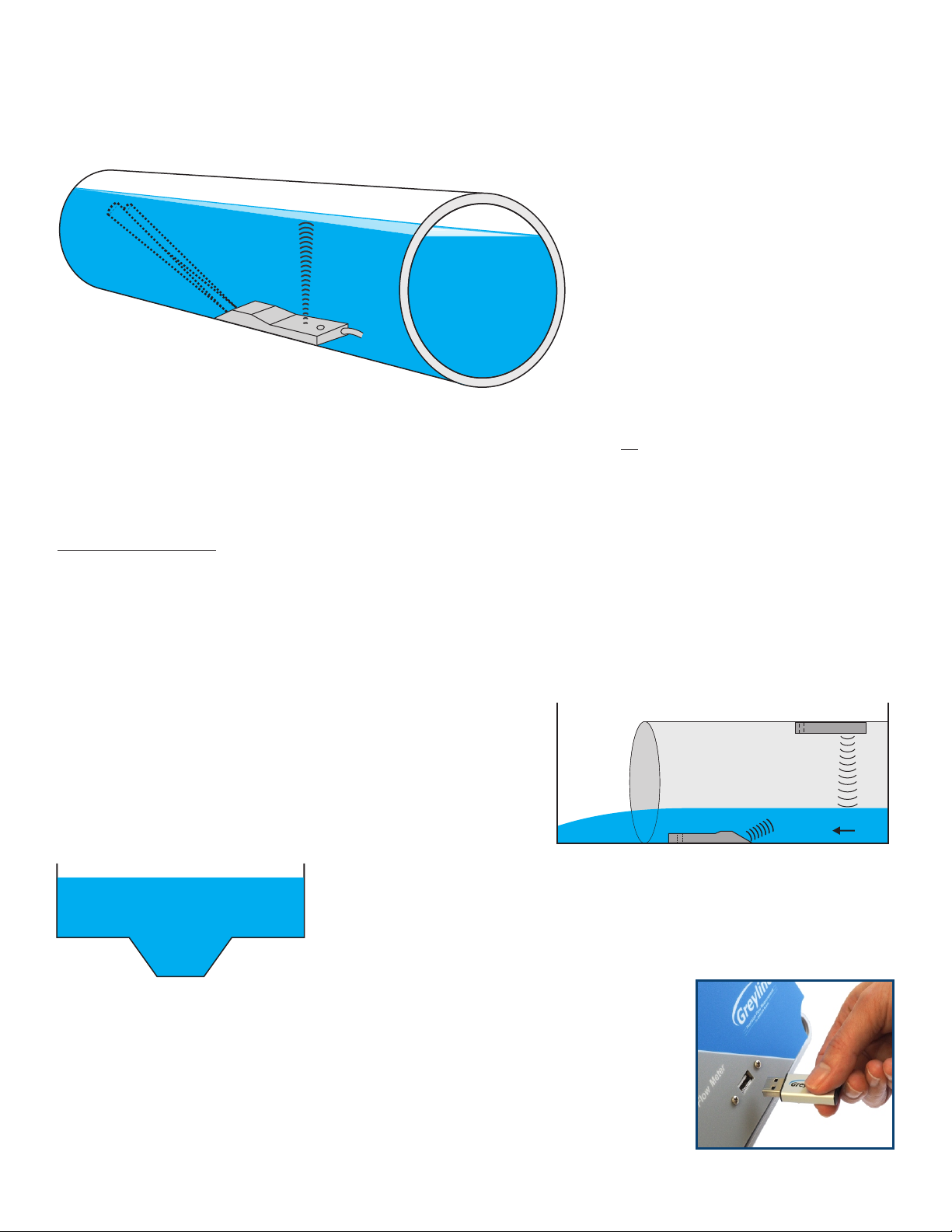

Alternate Sensor Configurations

Alternate sensor models are available for special applications: a

separate non-contacting ultrasonic level sensor with a submerged

velocity sensor. Sensor cable can be extended up to 500 ft (150 m).

Use this configuration for pipes or channels with high concentration of

air or suspended solids.

Custom Channel Shapes

Configure the AVFM 6.1 for

installation in irregular or compound channel shapes by entering the channel

width at multiple level points through a simple menu. Channels of virtually any

shape can be monitored with your choice of measurement units.

Standard 26 Million Point Data Logger

The AVFM 6.1 will store time and date-stamped

flow values at 10 second to 60 minute intervals.

Daily flow reports are automatically created where total, minimum, maximum and average

flow rates are displayed on the LCD display. Transfer log files and daily flow reports to any

USB flash drive just by connecting to the logger's USB output. Windows software is

included to display log files in graph and table formats, change measurement units and

generate flow reports. Or, download data as .csv file format for import directly to Microsoft

Excel.

VELOCITY

LOW PROFILE

NON-CONTACTING

ULTRASONIC

SENSOR

LEVEL

FLOW

Page 3

AVFM 6.1 Specifications

General Specifications

Channel Types:

Electronics Enclosure:

Accuracy:

Display:

Programming:

Power Input:

Outputs:

Control Relays:

Data Logging:

Operating Temp. (electronics):

Approximate Shipping Weight:

Approvals:

QZ02L Sensor

Velocity Measurement Range:

Level Measurement Range:

Operating Temperature:

Exposed Materials:

Sensor Cable:

Sensor Mounting:

Temperature Compensation:

Greyline AVFM 6.1 Area-Velocity Flow Monitor

Round pipe, rectangular, trapezoid, egg or custom shapes

Watertight and dust tight NEMA4X (IP 66) polycarbonate with clear, shatterproof cover

Level: ±0.25% of reading or ±0.08”, whichever is greater. Repeatability & Linearity 0.1%.

Velocity: ±2% of reading or ±0.04 ft/sec, whichever is greater. Requires solids or bubbles minimum size of

100 microns, minimum concentration 75ppm. Repeatability & Linearity 0.5%

White, back-lit matrix - displays flow rate, totalizer, relay states, operating mode and calibration menu

Built-in 5-key calibrator with English, French or Spanish language selection

100-240VAC 50-60Hz, 10VA maximum. Optional: 9-32VDC, 10 WATTS maximum

3 Isolated 4-20mA, 1000 ohm, (Flow, Level and Velocity) or 0-5VDC by menu selection

2 Relays, form 'C' dry contacts rated 5 amp SPDT; programmable for flow proportional pulse

(sampler/totalizer), flow and/or level alarm

Programmable 26 million point data capacity, time and date stamped plus formatted flow reports including

Total, Average, Minimum, Maximum and times of occurrence. Includes USB output to Flash Drives and

Windows software

-5° to 140°F (-20° to 60°C)

10 Lbs. (4.5 Kg)

CE, CSA/UL/EN 61010-1

0.1 to 20 ft/sec (0.03 to 6.2 m/sec) and reverse flow to -5 ft/sec (-1.5 m/sec) in fluids containing bubbles or

solids with a minimum size of 100 microns and a minimum concentration of 75 ppm to act as acoustic

reflectors

Minimum Head: 1 in (25.4 mm). Maximum Head: 15 ft. (4.57 m)

5 to 175°F (-15 to 80°C)

316 stainless steel, epoxy resin, polyurethane

25 Ft. (7.6 m) submersible polyurethane jacket, shielded, 3-coaxial

Includes MB-QZ stainless steel mounting bracket

Automatic, continuous

Options

Industrial Automation Protocols:

Sensor Cable:

Sensor Cable Junction Box:

Enclosure Heater:

Intrinsic Safety Barriers:

Sensors:

Sensor Mounting Bands:

Dimensions

SIDE VIEW

25 ft / 7.6 m

cable length

Modbus® RTU via RS-485

50 ft. (15 m) or 100 ft. (30 m) submersible, continuous from Sensor - or splice up to total of 500 ft (150 m)

length

Watertight NEMA4 polycarbonate with connection terminal strip

Thermostatically controlled to -40° F/C - recommended for temperatures below 32°F (0°C)

For Sensor mounting in Class I,II,III, Div. I,II, Groups C,D,E,F,G hazardous locations

Separate non-contacting ultrasonic level sensor and submerged velocity sensor

Stainless steel sensor mounting bands for pipes 6” to 72” (150 to 1800 mm) diameter

7.4 / 188 mm"

0.50"

12.7 mm

4. "92

1 mm25

0.63"

16 mm

1.50"

38.1 mm

6.46 / 164 mm"

AVFM 6.1

Area-Velocity

Flow Meter

278

/

94"

.

10

mm"

254

/

10

5.12 / 130 mm"

Q VELOCITY/LEVEL SENSORZ02L

CONDUIT ENTRY

LOCATION

SIDE VIEW

ENCLOSURE

Page 4

New Open Channel or Partially-Filled Pipe Flow Meter

Measures Velocity and Level to calculate Flow

AVFM 6.1 Area-Velocity Flow Meter

w Measure flow in pipes and open channels of

any shape

w Ideal where flumes or weirs are difficult to

install

w Works with water level from 1" (25.4 mm) to

15 ft (4.5 m)

w Auto-detects field installation of options serial

Recommended for:

] Wastewater

] Industrial Effluent

] Stormwater

] Combined Sewers

] Natural Streams

] Irrigation Water

The AVFM 6.1 Area-Velocity Flow Meter includes a submerged ultrasonic

sensor that is installed at the bottom of an open pipe or channel. Exposed

materials are stainless steel so the sensor resists fouling and corrosion. It

has no moving parts and no orifices, ports or electrodes.

The AVFM 6.1 displays and totalizes flow. It includes three 4-20mA outputs

(Flow, Level and Velocity), plus two control relays for level alarms or flow

proportionate pulse output for samplers and chlorinators. It is easy to

calibrate with the built-in keypad and menu system. A built-in 26 million

point data logger with USB output is standard. Intrinsic Safety Barriers for

sensor and cable installation in hazardous rated channels is also optional.

communications and control relays.

How to Order

Applications Support

No Risk Appraisal

The Greyline Guarantee

USA: 11451 Belcher Road South, Largo, FL 33773

Tel: 315-788-9500 / 888-473-9546 Fax: 315-764-0419

Canada: 16456 Sixsmith Dr., Long Sault, Ont. K0C 1P0

Tel: 613-938-8956 / 888-473-9546 Fax: 613-938-4857

Internet: www.greyline.com E-mail: info@greyline.com

180701Printed in Canada

Contact a Greyline sales representative in your area or phone one of our sales

engineers. Describe your requirements and receive our prompt quotation.

Take advantage of Greyline's applications experience. Phone 1-888-473-9546 for

advice and information on applications, installation or service for Greyline instruments.

The Greyline AVFM 6.1 Area-Velocity Flow Meter must meet your requirements.

Discuss your application with a Greyline representative to arrange a 30-day trial.

Quality of Materials and Workmanship - Each instrument manufactured by Greyline is

warranted against defects in materials and workmanship for a period of one year from

date of purchase. Refer to our limited warranty included with each product.

RELIABLE MEASUREMENT AND CONTROL

Loading...

Loading...