Page 1

www.greyline.com

USER'S GUIDE

Installation & Operation

Instructions

Area-Velocity Flow Meter

Model AVFM 5.0

Manual Series A.2.2

Page 2

Note: This page has been left blank intentionally.

Page 3

AVFM 5.0 Area-Velocity Flow Meter

INDEX

CONNECTIONS ................................................................................................ 4

FUNCTION TEST .............................................................................................. 4

KEYPAD SYSTEM ............................................................................................ 6

CALIBRATION MENU ..................................................................................... 7

ICONS ................................................................................................................. 8

MESSAGE ICON ............................................................................................... 9

STATUS ............................................................................................................. 9

PASSWORD ..................................................................................................... 10

UNITS/MODE .................................................................................................. 11

CALIBRATION................................................................................................ 12

RELAY PARAMETERS .................................................................................. 16

SPECIAL FUNCTIONS ................................................................................... 17

INSTALLATION - SENSOR LOCATION ...................................................... 19

ENCLOSURE INSTALLATION ..................................................................... 23

FIELD TROUBLESHOOTING ........................................................................ 25

APPLICATIONS HOTLINE ............................................................................ 27

PRODUCT RETURN PROCEDURE ............................................................... 28

AREA-VELOCITY FLOW DATA SHEET ..................................................... 29

APPENDIX A – OPTIONS ............................................................................... 31

DATA LOGGING (OPTIONAL) ......................................................................... 39

SPECIFICATIONS ........................................................................................... 41

IMPORTANT NOTE: This instrument is manufactured and calibrated to meet product specifications.

Please read this manual carefully before installation and operation. Any unauthorized repairs or

modifications may result in a suspension of the warranty.

Available in Adobe Acrobat pdf format

Page 3

Page 4

!

AVFM 5.0 Area-Velocity Flow Meter

CONNECTIONS

POWER INPUT: 100 to 240 VAC 50/60Hz. No adjustments are necessary for voltages within this

range. Connect L (Live) N (Neutral) and AC Ground.

Optional DC: 9-32 VDC. Connect to + and - terminals.

Optional Thermostat and Heater modules are available rated for 115 VAC or 230 VAC.

IMPORTANT NOTE: To comply with CSA/UL electrical safety standards, AC power input and relay

connection wires must have conduit entry to the instrument enclosure. Installation requires a switch,

overcurrent fuse or circuit breaker in the building (in close proximity to the equipment) that is marked as

the disconnect switch.

Risk of electric shock. Loosen cover screw to access connections. Only qualified personnel

should access connections.

Note: Use of instrumentation over 40°C ambient requires special field wiring.

Note: User replaceable fuse is 2 Amp 250V (T2AL250V).

FUNCTION TEST:

Connect the sensor to the sensor terminals as shown on next page, then

apply power. Allow 30 seconds for the AVFM 5.0 to initialize.

A. Place QZ02L sensor (flat to the bottom) in a bucket of water

about 6” deep and select

UNITS/MODE

B. Select

menu) to see a level reading.

Velocity

Level

mode (from

mode and stir the water to see a

velocity reading.

Page 4

Page 5

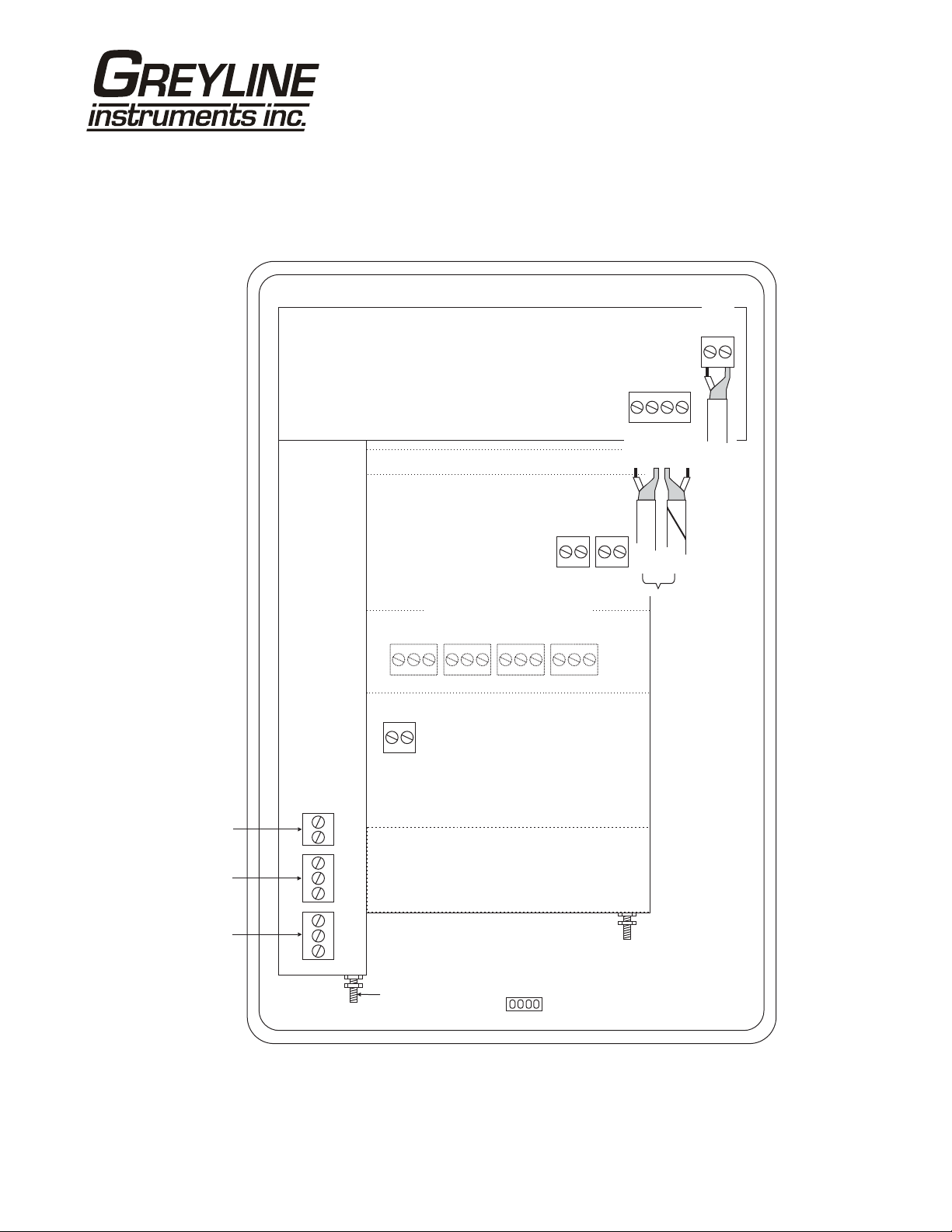

CONNECTIONS

DATA LOGGER OPTION

AVFM 5.0 Area-Velocity Flow Meter

SENSOR

CORE

GND

GND

GND

GRN

TMTR

BLK

WHT

4-20mA

4-20mA

VELOCITY

LEVEL

––

++

RCVR

4-20mA

FLOW

RLY2

RLY1

–

+

NO

C

NC

NO

C

NC

EXTRA RELAYS OPTION

NC

RLY3

NC

C

NO

C

NO

RLY4

AC

LN

HEATER OPTION

AC

GND

USB HARNESS

CONNECTOR

NC

C

RLY5

NC

NO

RLY6

SENSOR

C

NO

GND

Page 5

Page 6

AVFM 5.0 Area-Velocity Flow Meter

KEYPAD SYSTEM

The AVFM 5.0 uses a menu system. Arrows show the four directions to leave a menu box. Pressing a

corresponding keypad arrow will move to the next item in the direction shown. Move the cursor

(underline) under numerals and increase or decrease numerals with the and keys.

To store calibration values permanently (even through power interruptions), press .

Page 6

Page 7

CALIBRATION MENU

AVFM 5.0 Area-Velocity Flow Meter

Mode Flow}

Linear in

Volume USG

Time min

Temperature C

--Units/Mode--------

--Calibration-------

³

4mA Flo 0.000ft /s

20mA Flo 10.000ft /s³

}

20mA Vel 10.000 ft/s

4mA Vel 0.000 ft/s

20mA Level 12.000ft

4mA Level 0.000ft

Min Level 0.000in

Lvl Offset 0.000in

Min Vel 0.000ft/s

Damping 10%

Max Height 0.75ft

-- -----Channel Setup-

}Type Round

/minOn 1000 USG

/minOff 0.000 USG

Function Flow

Relay 1}

--Relay Parameters--

Calibration

Channel Setup

Relay Parameters

Data Logging

Special Functions

Simulation

Units / Mode}

--Menu Selections----

Password 0000

--Password----------

USG/m

Configuration

Mode Flow

Set Date May 27/2013

Set Time 11:27:40

Interval 10sec

Log Logging

Log Site ID 0}

--Data Logging-------

--Special Functions-

Language English}

Analog Out 4-20mA

Backlight High

6Relays

24Logger 1. T

Level 0.00in

Velocity 10ft/s

Reset Totalizer NO

Negative Totals NO

Flo Direction Off

Cal Constant 1.000

Restore Defaults NO

New Password 0000

Flow 1982.88USG/m

4-20mA Level 20.00

4-20mA Velocity20.00

4-20mA Flow 20.00

--Simulation--------

}Test Actual

Relays 1 2 3 4 5 6

Doppler 1.15

Analog Out 3

Sonar 1.11

Utility 1.25.02

--Configuration-----

}

dLog Use 0%

Data Log Logging

Sensor Good

Temperature 24C

--Message-----------

0.000ft/sAverage

Date Feb. 12/20} 10

--24 hr log--Velocity

50138 USGTotal

Date Feb. 12/20} 10

--24 hr log------Flow

0.000ftAverage

Date Feb. 12/20} 10

--24 hr log-----Level

0.000

Tot 20130.8 USG

Relays 1 2 3 4 5 6

9:15:00Min Time

11:08:00Max Time

0.000ft/sMaximum

0.000ft/sMinimum

9:15:00Min Time

11:08:00Max Time

52.20 USG/mMaximum

0.000 USG/mMinimum

34.82 USG/mAverage

0.000ftMaximum

0.000ftMinimum

9:15:00Min Time

11:08:00Max Time

Velocity 0.00ft/s

Flow 0.000 ft/s

Tot 0.000USG

Signal Cutoff 5%

Signal Strength 0%

EC 100%

--Status------------

}Level 0.00 ft

Relays 1 2 3 4 5 6

OPTIONAL FEATURES

Page 7

Page 8

ICONS

AVFM 5.0 Area-Velocity Flow Meter

1. 2.

1.

1.

1.

2.

2. 3.

2.

3.

4.

Message waiting. Press .Ç

Data logging .off

Data logging .on

USB file download.

File download completed.

Download Error.

Echo OK.

1.

2.

3.

No Echo.

Echo OK (PZxx series level sensor option).

No Echo (PZxx series level sensor option).

Page 8

Page 9

AVFM 5.0 Area-Velocity Flow Meter

USG/m

0.000

Tot 20130.8 USG

Relays 1 2 3 4 5 6

--Message----------Data Log Logging

Sensor Good

Temperature 24C

--Status------------

Velocity 0.00ft/s

}

Level 0.00 ft

Tot 0.000USG

Signal Cutoff 5%

Signal Strength 0%

EC 0%

Relays123456

dLog Use 0%

MAIN DISP LAY

The main display shows the units selected from the

Units/Mode menu,

Flow or Velocity rate being measured, TOTALIZER and RELAY states. The

AVFM 5.0 will start-up with this display.

MESSAGE ICON

Press from the main display to view temperature measurement, status of the

data logger and error/warning messages provided by the instrument. The

Message Icon will appear on the main display if error messages are being

generated by the instrument. Press to return to the main display.

STATUS

Press from the MAIN display to view instrument status.

Velocity Will be displayed in ft/sec or m/sec.

Level Is displayed in the selected units.

Displays the current totalizer reading.

Tot

Signal Cutoff Adjust the setting in percent to suppress flow readings

at zero flow when fluid swirling or pipe vibration may

cause the instrument to continue reading. Example:

Signal Cutoff at 5% will force the display

and outputs to zero when signal strength drops below

5%.

Signal Strength Displays percentage of signal being received by the

ultrasonic sensor.

EC Displays level measurement Echo Confidence

Relays 1 2 3 4 5 6 Energized relays will display with reversed font eg:

Page 9

Page 10

AVFM 5.0 Area-Velocity Flow Meter

--24 hr log------Flow

Date Feb. 12/2010

}

Total 50138 USG

Average 34.82 USG/m

Maximum 52.20 USG/m

Max Time 11:08:00

Minimum 0.000 USG/m

Min Time 9:15:00

--Password----------

Password 0000

24 HR LOG (Data Logging option only)

Press from the MAIN display to view a formatted flow report from instruments

with a built-in data logger. Press to pan through

Flow summaries. Press to scroll down one day or repeatedly to scroll to a

Level, Velocity and

specific date. Up to 365 days can be stored. Newest date will overwrite the oldest.

Press to return to the main display.

PASSWORD

Password (a number from 0000 to 9999) prevents unauthorized access

The

to the

Calibration menu.

From the Main display press to get to

password is 0000 and if it has not been changed press to proceed to the

Selections

screen.

Password. Factory default

If a password is required, press to place the cursor under the first digit and or

to set the number, then to the second digit, etc. Press or to proceed to

the

Menu Selections screen.

A new password can be stored by going to

Password.

Special Functions/New

Menu

Page 10

Page 11

AVFM 5.0 Area-Velocity Flow Meter

--Units/Mode-------Mode Flow

}

Linear in

Volume USG

Time min

Temperature C

--Units/Mode--------

Mode Flow

Linear} in

--Units/Mode--------

Mode

Linear

}Volume USG

ft3

bbl

IMG

USMG

--Units/Mode--------

Mode Flow

Linear in

Volume USG

Time} sec

day

min

--Units/Mode--------

Mode Flow

Linear in

Volume USG

Time min

Temperature} C

ft

mm

m3

IG

hr

UNITS/MODE

From

Velocity or Level. Flow mode displays the flow rate in engineering

Mode press the and then the or to select Flow,

units (e.g. gpm, litres/sec, etc.) Press the to store your selection then the to

the next menu item.

From

Linear press the key and then the or to select your units of

measurement. Press the to store your selection.

m

Press the key to move the

save your selections.

symbol to each subsequent menu item and the to

Note: the volume selection "bbl" denotes U.S. barrels.

Temperature press then to select C or F.

Press or to return to the Menu Selections screen.

L

F

Page 11

Page 12

AVFM 5.0 Area-Velocity Flow Meter

--Calibration-------

20mA Flo 10.000ft /s³

}

4mA Flo 0.000ft /s³

20mA Vel 10.000 ft/s

4mA Vel 0.000 ft/s

20mA Level 12.000ft

4mA Level 0.000ft

Min Level 0.000in

Lvl Offset 0.000in

Min Vel 0.000ft/s

Damping 10%

CALIBRATION

Press to

Calibration and to enter. Use or to position before

each menu item and to enter. When settings are completed press to store and

return to the Calibration menu.

20mA Flo

[5V Flo]

Press and enter the flow rate value for 20mA.

Note

: Analogue output can be selected as 4-20mA or 0-5V in Special Functions.

4mA Flo

[0V Flo]

20mA Vel

[5V Vel]

4mA Vel

[0V Vel]

20mA Level

[5V Level]

Press and enter the flow rate value for 4mA.

Press and enter the velocity value for 20mA.

Press and enter the velocity value for 4mA.

Optional for QZ02L-A type sensor. Press and enter the level

value for 20mA.

4mA Level

[0V Level]

Optional for QZ02L-A type sensor. Press and enter the level

value for 4mA.

MaxRg

Only for PZ12LP/QZ02L-B type sensor. Press and enter the

zero water level (distance from the PZ12-LP sensor to the zero

water level).

MinRg

Only for PZ12LP/QZ02L-B type sensor. Press and enter the

max level (distance from the PZ12-LP sensor to the max water

level).

Min Level

Optional for QZ02L-A type sensor. Press and enter a

minimum level cutoff. Level reading less than

Min Level

will be forced to zero.

Page 12

Page 13

AVFM 5.0 Area-Velocity Flow Meter

Lvl Offset

Optional for QZ02L-A type sensor. Press and enter an

offset to level measurement. Set to 0.00 when sensor mounted

on floor of channel. When sensor is mounted above the floor

of the channel enter the distance between channel floor and

bottom of sensor. Maximum offset is ± 36” (914 mm).

Note: 4mA is not affected by

is the bottom of the channel or pipe.

LEVEL

SENSOR

TOP VIEW

SENSOR

SIDE VIEW

USE THE MB-QZ

STAINLESS STEEL

MOUNTING BRACKET

(SUPPLIED)

Min Vel

Press and enter a minimum velocity cutoff. Forward and

reverse velocities less than

Min Vel will be forced to zero.

Damping

Increase damping to stabilize readings under turbulent flow

readings or to reject spurious level readings. Decrease for

faster response to changes in flow.

Press from the

Calibration display to return to Menu Selections.

Lvl Offset settings. 4mA

SENSOR ELEVATED

ABOVE FLOOR OF

PIPE OR CHANNEL

SENSOR

U-SHAPE STAINLESS STEEL

18 GA. RECOMMENDED

HEIGHT AS REQUIRED

END VIEW

Page 13

Page 14

AVFM 5.0 Area-Velocity Flow Meter

--Channel Setup-----Type Round

}

Max Height 0.75ft

CHANNEL SETUP

Round Select Round for open pipes. Set Max Height to the

inner diameter of the pipe.

Rectangle Select Rectangle for rectangular channels. Enter the

channel width.

Trapezoid Select Trapezoid for trapezoidal shaped channels.

Specify the

in the following illustration.

TRAPEZOIDAL

Egg Select Egg for Egg shaped channels. Enter the Max

Height

of the channel.

Width and Slope of the channel as shown

SLOPE = x

y

CHANNEL

WIDTH

y

x

HEIGHT

= 3R

Page 14

R

2R

3R

R/2

Page 15

AVFM 5.0 Area-Velocity Flow Meter

--Custom Channel----Type Custom

}

Reset Data No

Max Height 0.75 ft

Division 0.05 ft

Increment # 0

Width 0.000 ft

Level 0.000 ft

CUSTOM CHANNELS

Reset Data Old data MUST be removed before entering data for a new

channel. Press then press to

old data.

Max Height Enter the maximum height of the channel.

Division Divide the maximum height into equal increments (maximum

of 40) and enter this division value (example 1”, 1 cm etc.)

Increment # Enter the increment number if you want to edit a previous

entry or to skip entering widths for some levels (Note: The

custom channel will interpolate widths between entry points).

Width Enter the measured width of the channel at the level shown

(Note: To enter 0 width you must press and then to store

a 0 width data point).

Level Displays the level of the channel for each increment and width

entry.

MAX

HEIGHT

Note

:

Custom channel data in equal width increments with variable height

measurements must be converted to the format shown above using the “Channel

Data Translator” PC software.

WIDTH

Yes and press to clear

INCREMENT #DIVISION

10

9

8

7

6

5

4

3

2

1

0

LEVEL

Page 15

Page 16

AVFM 5.0 Area-Velocity Flow Meter

--Relay Parameters-Relay 1

}

Function Flow

On 1000 USG

Off 0.000 USG

RELAY PARAMETERS

Relay Press and or to select a relay (2 relays are standard, 4

additional are optional).

Function Press or to select Off, Pulse, Flow,

Velocity or Level.

Flow

On Position the cursor under the numerals and press or to set

digits to the relay

Off set digits to the Off set point.

Pulse Press and set digits to the flow volume per relay pulse. Use

this feature for remote samplers, chlorinators or totalizers.

Minimum time between pulses is 2.25 seconds and pulse

duration is 350 milliseconds.

Return to

Velocity

On

Position the cursor under the numerals and press or to set

digits to the relay

Off set digits to the Off set point.

Level

On

Position the cursor under the numerals and press or to set

digits to the relay

Off set digits to the Off set point.

LOE mode Specify the state of the relay for loss of echo condition:

Off, On or Hold.

Press to return to

On set point.

Relay and enter settings for each relay.

On set point.

On set point.

Menu Selections

Page 16

Page 17

AVFM 5.0 Area-Velocity Flow Meter

--Special FunctionsLanguage English

}

Analog Out 4-20mA

Backlight High

Reset Totalizer NO

Negative Totals NO

Flo Direction Off

Cal Constant 1.000

Restore Defaults NO

New Password 0000

--Special Functions-

Language English

}Backlight High

Medium

Low

Key Hi/Lo

Key High

Key Med

Key Low

Off

DATA LOGGING (OPTIONAL)

Refer to Options section of this manual.

SPECIAL FUNCTIONS

Language Select English, French or Spanish

Analog Out Select 4-20mA or 0-5V mode for the analog output.

Backlight Select High, Medium or Low for continuous

backlight.

Select

minute) after a keypress and then

key is pressed again.

Select

after a keypress and then backlight off until a key is

pressed again.

Reset Totalizer Press and select Yes to erase and restart the

totalizer at zero.

Negative Totals Select Yes to have reverse flow readings deducted

from the totalizer. Select

only and ignore reverse flow.

Flo Direction Select On to enable flow direction measurement.

Select

Select

measurement.

Cal Constant Scales the velocity reading. Set to 1.000 for QZ02L

sensor.

Restore Defaults Select Yes and press to erase all user settings and

return the instrument to factory default settings.

New Password Select any number from 0000 to 9999 and press

. Default setting of 0000 will allow direct access to

the calibration menus. Setting of any password greater

than 0000 will require the password to be entered to

access the calibration menus.

Press to return to

Menu Selections.

Key Hi/Lo for high backlight (for 1

Lo backlight until a

Key High, Med or Low for backlight

No to totalize forward flow

Off to disable flow direction measurement.

Invert to invert the sense of the flow

Page 17

Page 18

AVFM 5.0 Area-Velocity Flow Meter

--Simulation-------Test Actual

}

Level 0.00in

Velocity 10ft/s

Flow 1982.88USG/m

4-20mA Level 20.00

4-20mA Velocity20.00

4-20mA Flow 20.00

Relays 1 2

SIMULATION

Exercises the 4-20mA (0-5V) outputs, digital display and control relays.

Test Select Maximum and press to simulate maximum Flow, Level and

Velocity and to output 20mA (5V) to the analog channels.

Select

Minimum and press to simulate minimum Flow, Level and

Velocity and to output 4mA (0V) to the analog channels.

To simulate an intermediate Flow, Level and Velocity set

Actual and then enter a value for the Level and Velocity.

The Flow calculation, analog outputs and control relays will respond to

the simulated values.

Test to

Page 18

Page 19

AVFM 5.0 Area-Velocity Flow Meter

INSTALLATION - SENSOR LOCATION

1. Choose a sensor mounting location where silt or deposits are least likely to accumulate.

2. For best results flow should be evenly distributed across the channel and relatively free of turbulence.

(The AVFM 5.0 is very effective at averaging level and velocity readings in turbulent conditions, but

best accuracy and response time is achieved with evenly distributed flow.)

3. Avoid vertical drops, obstructions or elbows immediately up and downstream from the sensor. Locate

the QZ02L sensor at least 10 times maximum Head (level) and 10 times the channel width from these

flow disturbances.

4. The QZ02L submerged level-velocity sensor requires a minimum water level of 1 in. (25.4 mm).

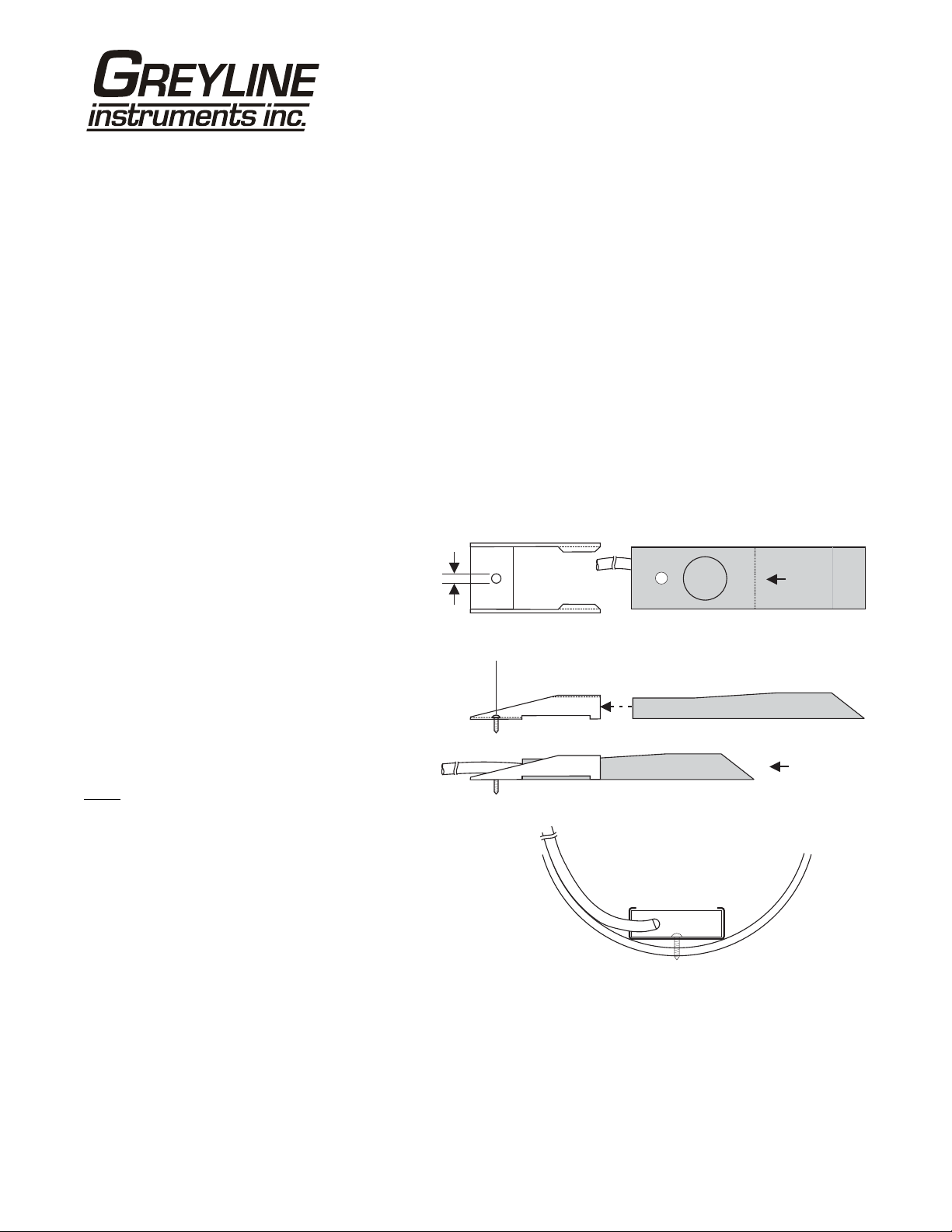

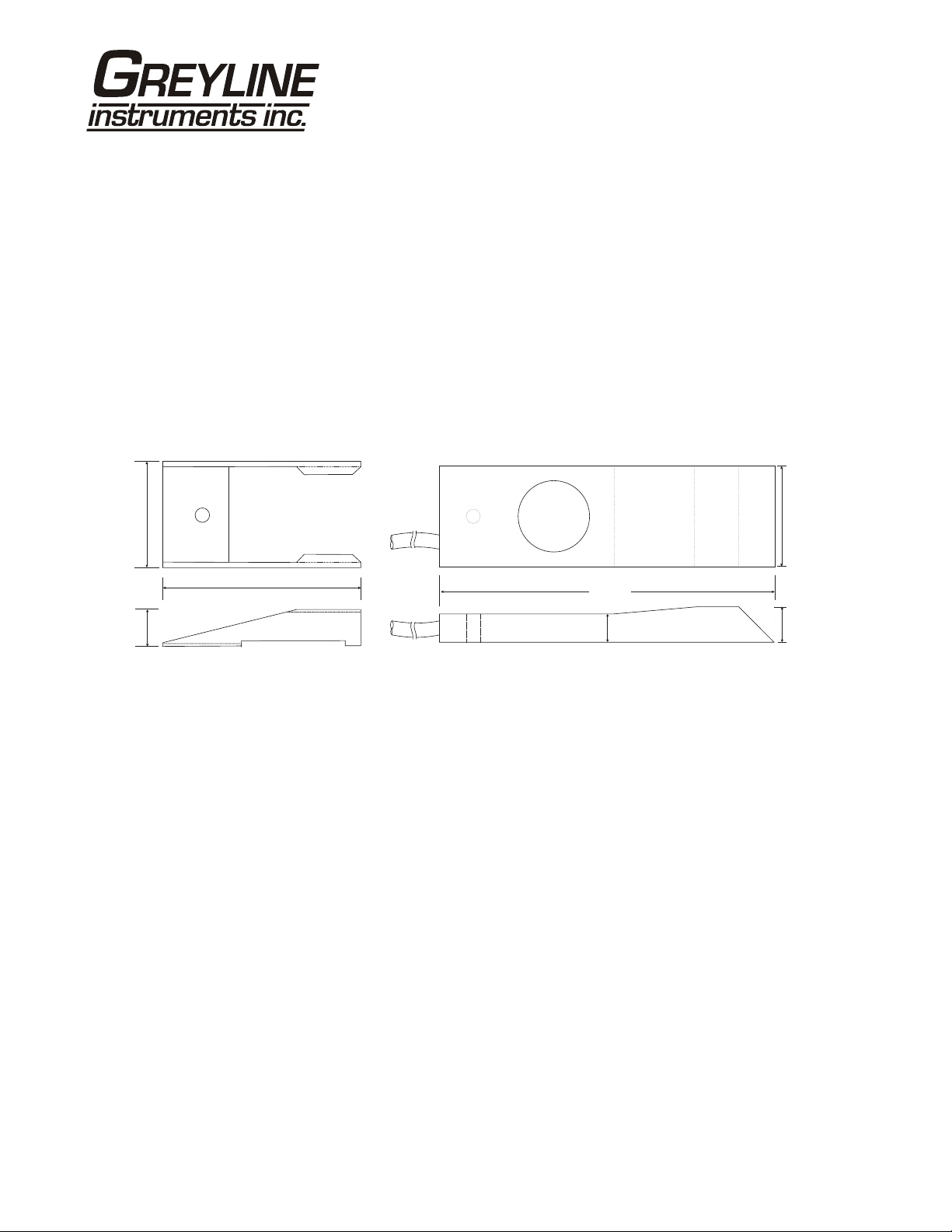

QZ02L VELOCITY-LEVEL SENSOR MOUNTING

Mount the QZ02L sensor with the

stainless steel bracket and hardware

0.2"

(5 mm)

supplied. Ensure that the sensor is

parallel to the water surface (check with

a level). Mount with the tapered end of

the sensor pointing upstream and the

sensor cable pointing downstream.

Clip or tie wrap the sensor cable securely

to the pipe or channel wall.

Note: The mounting bracket is designed

to release the sensor if weeds or rags are

caught by the sensor.

MB-QZ

MOUNTING

BRACKET

FASTEN MOUNTING

BRACKET WITH A

SET SCREW

FASTEN SENSOR

CABLE TO PIPE OR

CHANNEL WITH

METAL CLIPS OR

TIE WRAPS

TOP VIEW

SIDE VIEW

VELOCITY/LEVEL SENSOR

LEVEL

SENSOR

INSERT SENSOR INTO

MOUNTING BRACKET

END VIEW

SENSOR

QZ02L

FLOW

FLOW

Page 19

Page 20

AVFM 5.0 Area-Velocity Flow Meter

GOOD

END VIEW

SENSOR

SENSOR

BAD

END VIEW

SENSOR

SENSOR

FLOW

SENSOR

SENSOR

END VIEW

SENSOR

SENSOR

END VIEW

FLOW

Page 20

Page 21

AVFM 5.0 Area-Velocity Flow Meter

OPTIONAL PIPE BAND MOUNTING WITH QZ02L SENSOR

Install the stainless steel pipe band with the sensor mounting

bracket at the invert (bottom) of the pipe. Ensure that the

sensor bracket is parallel to the water surface (check with a

level). Mount so the tapered end of the sensor will point

upstream and the sensor cable will point downstream. (Turn

the ¼” adjustment nut clockwise to expand the bracket and secure to the pipe wall by friction fit.)

Insert the sensor into the mounting bracket and tie-wrap the sensor cable securely to the pipe band using

the holes provided.

BAND

ADJUSTMENT JACK

VSJ PIPE MOUNTING BAND

DETAIL

BAND ADJUSTMENT

SENSOR MOUNTING

BRACKET

JACK

OPTIONAL QZ02L-DP VELOCITY SENSOR MOUNTING

Mount the velocity sensor at or near the bottom of the channel or pipe in a position where it will be

continuously submerged. The QZ02L-DP velocity sensor does not have to be parallel to the water

surface. Position where silt or solids will not build-up on the sensor.

Page 21

Page 22

AVFM 5.0 Area-Velocity Flow Meter

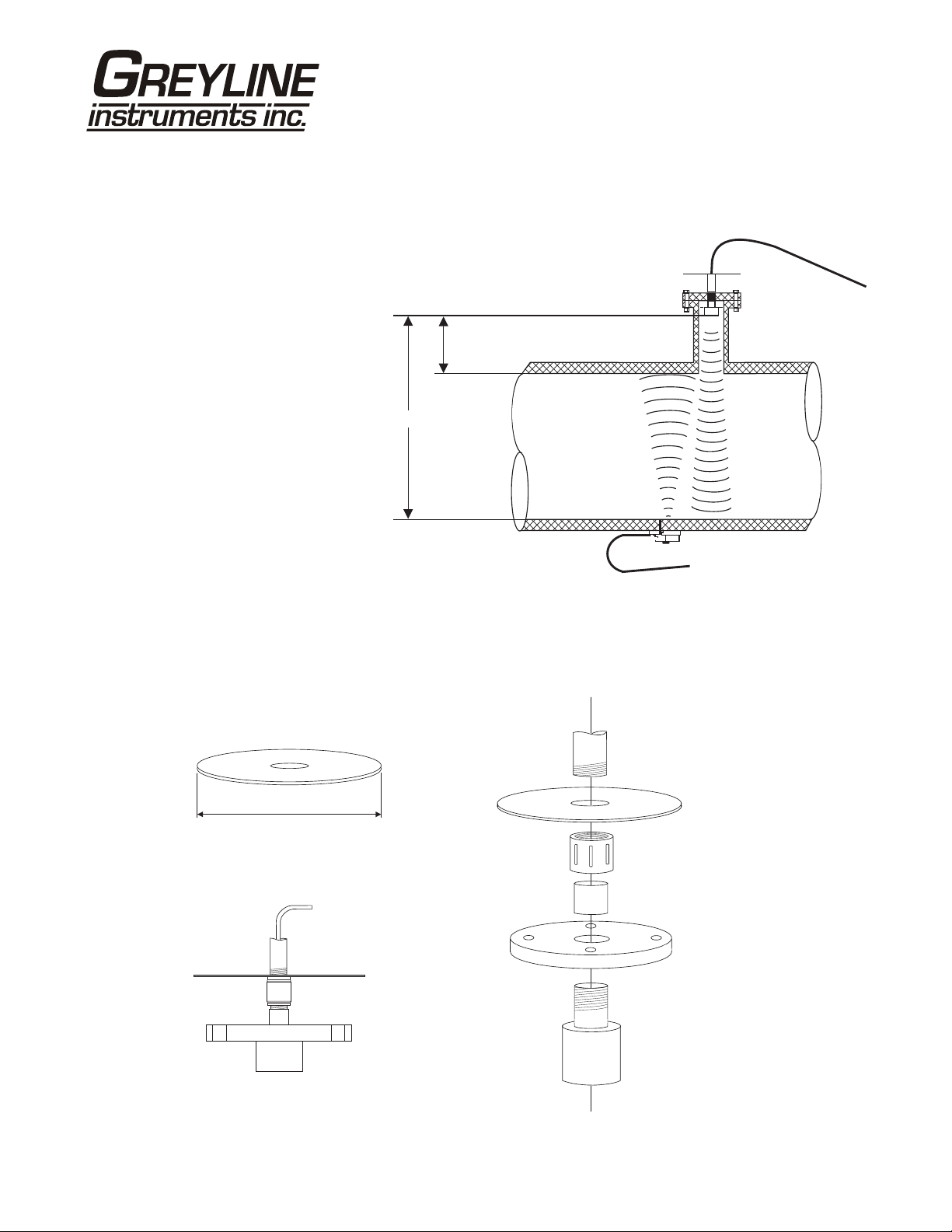

OPTIONAL PZ12-LP LEVEL SENSOR MOUNTING

Mount the PZ12-LP non-contacting ultrasonic level sensor in an unobstructed position at least 8” (203.2

mm) above the high water level. Install the stainless steel mounting bracket in a horizontal position

(check with a level) and then insert the PZ12-LP sensor.

PZ12-LP SENSOR

MB12 - MOUNTING BRACKET

QZ02L-DP VELOCITY SENSOR

PZ12-LP MANHOLE MOUNTING

PZ12-LP

WATER

PZ12-LP PIPE MOUNTING

PZ12-LP

WATER

Page 22

Page 23

AVFM 5.0 Area-Velocity Flow Meter

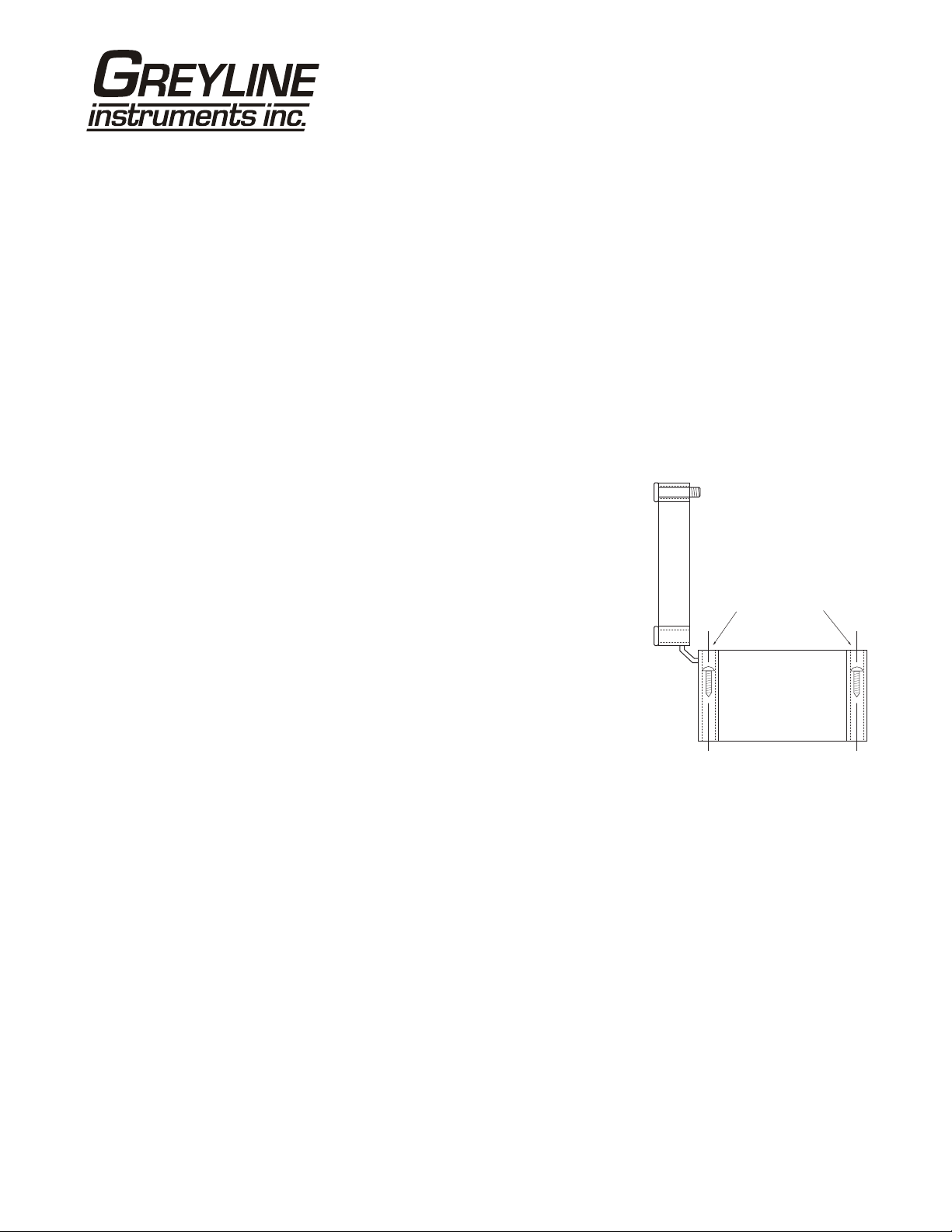

ENCLOSURE INSTALLATION

Locate the enclosure within 20 ft (6 m) of the sensor (up to 500 ft -150 m optional). The enclosure can

be wall mounted with the four mounting screws (included) or panel mounted with Option PM Panel

Mount kit from Greyline Instruments.

Avoid mounting the enclosure in direct sunlight to protect the electronics from damage due to

overheating and condensate. In high humidity atmospheres, or where temperatures fall below freezing,

Option TH Enclosure Heater and Thermostat is recommended. Seal conduit entries to prevent moisture

from entering enclosure.

NEMA4X (IP66) WITH CLEAR COVER

1. Open hinged enclosure cover.

2. Insert #8 screws (supplied) through the four enclosure mounting holes

to secure the enclosure to the wall or mounting stand.

Additional conduit holes can be cut in the bottom of the enclosure with a

hole saw or Greenlee-type hole cutter.

DO NOT make conduit/wiring entries into the top of the enclosure.

Note: This non-metallic enclosure does not automatically provide

grounding between conduit connections. Grounding must be provided as

part of the installation. Ground in accordance with the requirements of the

National Electrical Code. System grounding is provided by connecting

grounding wires from all conduit entries to the steel mounting plate or

another point which provides continuity.

CLEANING

Cleaning is not required as a part of normal maintenance.

COVER

ENCLOSURE

MOUNTING

HOLES

ENCLOSURE

END VIEW

Page 23

Page 24

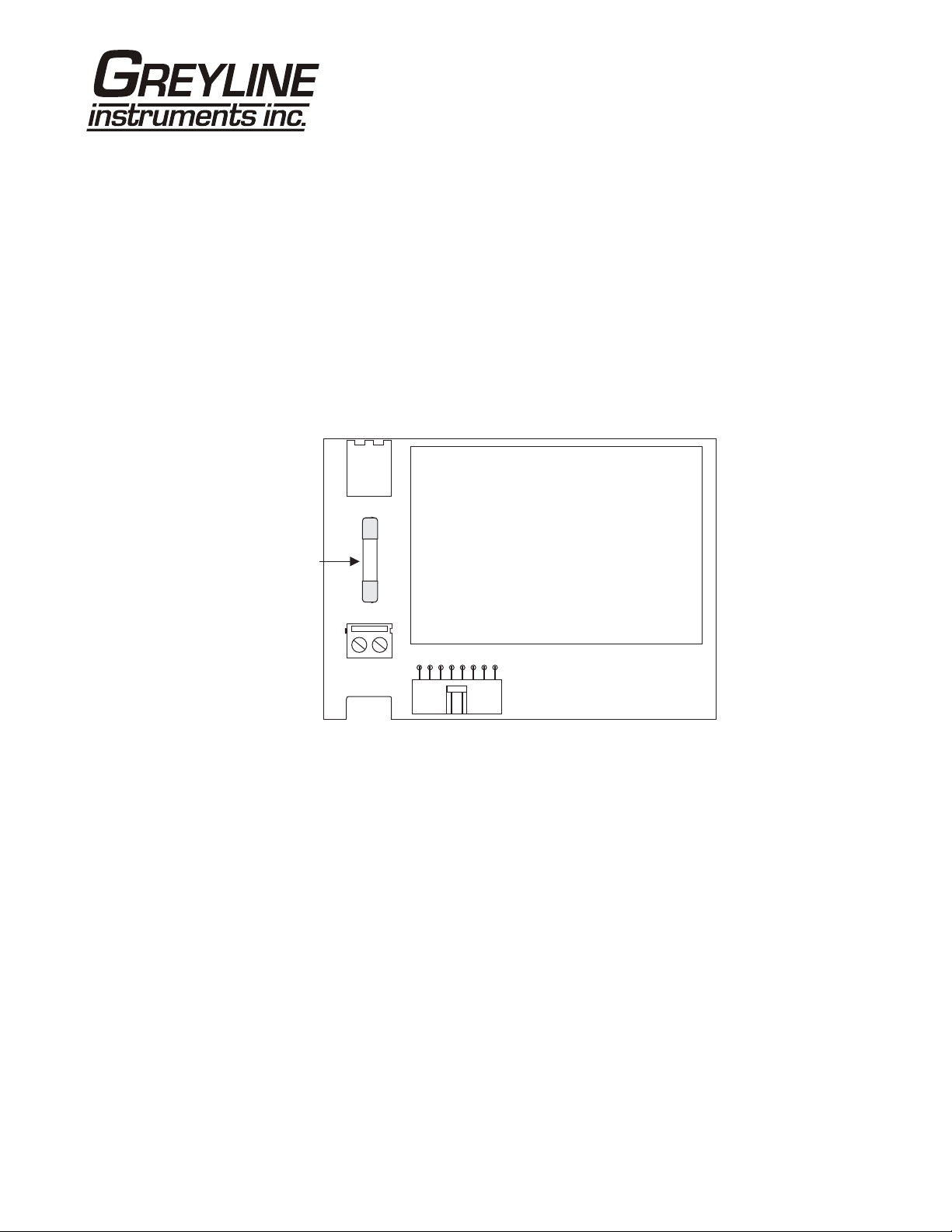

FUSE REPLACEMENT

1. Turn OFF power.

2. Loosen cover screw and open.

3. Remove power module.

4. Locate fuse on Power Board.

5. Replace fuse with 2 AMP/ 250V, 5 x 20mm fuse.

6. Reinstall power module into chassis.

AVFM 5.0 Area-Velocity Flow Meter

Fuse

POWER MODULE

Page 24

Page 25

AVFM 5.0 Area-Velocity Flow Meter

FIELD TROUBLESHOOTING

The AVFM 5.0 uses an ultrasonic level sensor to determine channel AREA and an ultrasonic Doppler

sensor to measure flow VELOCITY.

The QZ02L sensor combines both sensors in one housing.

An optional configuration uses the PZ12-LP “down-looking” level sensor and a QZ02L-DP velocity

sensor.

To troubleshoot the AVFM 5.0, verify correct operation of LEVEL and VELOCITY measurements

separately.

Note: Selecting “Defaults” in the SPECIAL FUNCTION menu will return the instrument to

“as-shipped” factory settings.

LEVEL (QZ02L SENSOR)

SYMPTOMS FAULTS SOLUTIONS

EC bar graph at zero - very turbulent flow - Increase LOE time (SPECIAL

FUNCTION

- very aerated flow - relocate sensor or use PZ12-LP

- sensor not level - level sensor with “Bullseye” level

- sediment/dirt/grease build-up on

sensor

- Level display reads 1.0 inches

VELOCITY (QZ02L SENSOR)

SYMPTOMS

- No velocity reading - Grease/sediment on sensor

FAULTS SOLUTIONS

- Level at or less than 1.0 inches

- Improper hook-up

- clean sensor with liquid soap

- Clean sensor with detergent

- Check sensor connections

)

Page 25

Page 26

AVFM 5.0 Area-Velocity Flow Meter

SENSOR CABLE RESISTANCE TEST

Unplug the green sensor terminal from the Doppler board and connect the sensor wires as shown. With a

multimeter, perform resistance checks for each set of wires. One single loose terminal may cause false

readings.

Test across shield and core of each wire: TMTR (black/white) and RCVR (black). Resistance should be

approximately 82.5K ohms for any cable length. High readings indicate an open circuit and low readings

indicate a short or partial short in the sensor cable.

Page 26

Page 27

AVFM 5.0 Area-Velocity Flow Meter

APPLICATIONS HOTLINE

For applications assistance, advice or information on any Greyline Instrument contact your Sales

Representative, write to Greyline or phone the Applications Hotline below:

United States: Tel: 315-788-9500 Fax: 315-764-0419

Canada: Tel: 613-938-8956 Fax: 613-938-4857

Toll Free: 888-473-9546

Email: info@greyline.com

Web Site: www.greyline.com

Greyline Instruments Inc.

Canada USA:

16456 Sixsmith Drive 105 Water Street

Long Sault, Ont. K0C 1P0 Massena, NY 13662

Page 27

Page 28

AVFM 5.0 Area-Velocity Flow Meter

PRODUCT RETURN PROCEDURE

Instruments may be returned to Greyline for service or warranty repair.

1 Obtain an RMA Number from Greyline -

Before shipping a product to the factory please contact Greyline by telephone, fax or email to obtain an

RMA number (Returned Merchandise Authorization). This ensures fast service and correct billing or

credit.

When you contact Greyline please have the following information available:

1. Model number / Software Version

2. Serial number

3. Date of Purchase

4. Reason for return (description of fault or modification required)

5. Your name, company name, address and phone number

2 Clean the Sensor/Product -

Important: unclean products will not be serviced and will be returned to the sender at their expense.

1. Rinse sensor and cable to remove debris.

2. If the sensor has been exposed to sewage, immerse both sensor and cable in a solution of 1 part

household bleach (Javex, Clorox etc.) to 20 parts water for 5 minutes. Important: do not immerse open

end of sensor cable.

3. Dry with paper towels and pack sensor and cable in a sealed plastic bag.

4. Wipe the outside of the enclosure to remove dirt or deposits.

5. Return to Greyline for service.

3 Ship to Greyline -

After obtaining an RMA number please ship the product to the appropriate address below:

Canadian and International USA

Customers: Customers:

Greyline Instruments Inc. Greyline Instruments Inc.

16456 Sixsmith Drive 204 150th Avenue

Long Sault, Ont. K0C 1P0 Madeira Beach, FL 33708

RMA# RMA#

Page 28

Page 29

AVFM 5.0 Area-Velocity Flow Meter

AREA-VELOCITY FLOW DATA SHEET

Greyline Instruments Inc.

16456 Sixsmith Dr., Long Sault, Ont. K0C 1P0

Tel: 613-938-8956 / Fax: 613-938-4857

105 Water Street, Massena NY 13662

Tel: 315-788-9500 / Fax: 315-764-0419

Contact: ________________________________ Title/Dept.: _________________________

Company: ___________________________________ Project: _________________________

Address: ____________________________________________________________________

Tel: _____________________________________ Fax: _________________________

Please complete and return this form to Greyline. It is

important. We use this information to check our database

for performance of Greyline flow meters in similar

applications, and to provide advice and recommendations

to you. Thanks for your cooperation.

SENSOR

Model/Type: _____________________________ Cable Length: _________________________

Elec. Class: _____________________________ Type of Pump: _________________________

Distance from nearest Pump, Controlling Valve, Orifice or open Discharge: ___________________

INSTRUMENT

Calibrated Range

Operating Temp.: ___________________________ Alarm: _________________________

Enclosure Class: __________________________ Pulse/Unit: _________________________

SERVICE CONDITIONS

Pipe Mat'l: _______________________________ % Solids: _________________________

Oper. Flow: _________________________________ Vibration: _________________________

Max. Flow: ____________________________ Max. Pressure: _________________________

Min. Flow: _____________________________ Max. Temp: _________________________

:

:

Model/Type: _________________________ Power Input: _________________________

: ___________________________ Indication: _________________________

Elec. Class: _____________________________ Output: _________________________

:

Pipe ID: _______________________________

Fluid: __________________________ Material Build-up: _________________________

q Vertical q Horizontal

/ Sketch Pipe Run:

Notes

By: _______________________________________________ Date: ___________________

Page 29

Page 30

LIMITED WARRANTY

_____________________________________

Greyline Instruments warrants, to the original purchaser, its

products to be free from defects in material and workmanship for a

period of one year from date of invoice. Greyline will replace or

repair, free of charge, any Greyline product if it has been proven to

be defective within the warranty period. This warranty does not

cover any expenses incurred in the removal and re-installation of

the product.

AVFM 5.0 Area-Velocity Flow Meter

If a product manufactured by Greyline should prove defective

within the first year, return it freight prepaid to Greyline

Instruments along with a copy of your invoice.

This warranty does not cover damages due to improper installation

or handling, acts of nature, or unauthorized service. Modifications

to or tampering with any part shall void this warranty. This

warranty does not cover any equipment used in connection with the

product or consequential damages due to a defect in the product.

All implied warranties are limited to the duration of this warranty.

This is the complete warranty by Greyline and no other warranty is

valid against Greyline. Some states do not allow limitations on how

long an implied warranty lasts or limitation of incidental or

consequential damages, so the above limitations or exclusions may

not apply to you.

This warranty gives you specific legal rights, and you may also

have other rights which vary from state to state.

Greyline Instruments Inc.

Page 30

Page 31

AVFM 5.0 Area-Velocity Flow Meter

APPENDIX A – OPTIONS

EXTRA SENSOR CABLE

(OPTION VXC)

Each Greyline AVFM 5.0 flow meter includes 25 ft. (7.6 m), 50 ft. (15 m) or 100 ft. (30 m) tri-coaxial

sensor cable. This cable is shielded from electrical interference and is watertight with a polyurethane

jacket. Additional cable and Cable Junction Box (Option JB2X or JB4X) may be ordered with the Flow

Meter, or the cable may be spliced and extended up to 500 ft (152 m) total length as required during

installation. No adjustment is required when the sensor cable is extended or shortened. Use only

Greyline tri-coaxial VXC shielded cable, or run three RG174U coaxial cables in a metal conduit.

Extended sensor cable can be installed in conduit for mechanical protection. Recommended installation

with a junction box is illustrated below:

AVFM

TO GREYLINE SENSOR

SHIELDED COAXIAL PAIR

BLK

BLK/GRN

BLK/WHT

GND

BLK

BLK/GRN

BLK/WHT

EXTENDED SENSOR CABLE

TO ELECTRONICS ENCLOSURE

- MAX. TOTAL CABLE LENGTH

500 ft (152m) SHIELDED

COAXIAL PAIR

- CONDUIT RECOMMENDED FOR

MECHANICAL PROTECTION

Downward AVFM

TO ULTRASONIC

LEVEL SENSOR

RG62AU COAXIAL

TO VELOCITY SENSOR

SHIELDED COAXIAL PAIR

GND

CORE

SHIELD

BLK/GRN

BLK/WHT

GND

CORE

SHIELD

BLK/GRN

BLK/WHT

GND

GND

EXTENDED SENSOR CABLE TO

ELECTRONICS ENCLOSURE

- MAX. TOTAL CABLE LENGTH

500 ft (152m) RG62AU coaxial

- CONDUIT RECOMMENDED FOR

MECHANICAL PROTECTION

EXTENDED SENSOR CABLE

TO ELECTRONICS ENCLOSURE

- MAX.TOTALCABLE LENGTH

500 ft (152m) SHIELDED

COAXIAL PAIR

- CONDUIT RECOMMENDED FOR

MECHANICAL PROTECTION

Page 31

Page 32

AVFM 5.0 Area-Velocity Flow Meter

COAXIAL CABLE PREPARATION

VXC Doppler sensor cable can be cut and spliced up to a maximum length of 500 ft (152 m). Cable ends

must be prepared as illustrated below.

GOOD

BLACK

(CONDUCTIVE)

SLEEVE

HASBEEN

REMOVED

BAD

BLACK

(CONDUCTIVE)

SLEEVE

HAS NOT BEEN

REMOVED

Page 32

Page 33

AVFM 5.0 Area-Velocity Flow Meter

JUNCTION BOX - OPTION JB2X & JB4X

NEMA4X (IP66) polycarbonate Junction Box with terminal strips is available from Greyline

Instruments. Includes compression fittings for watertight coaxial cable entries.

Page 33

Page 34

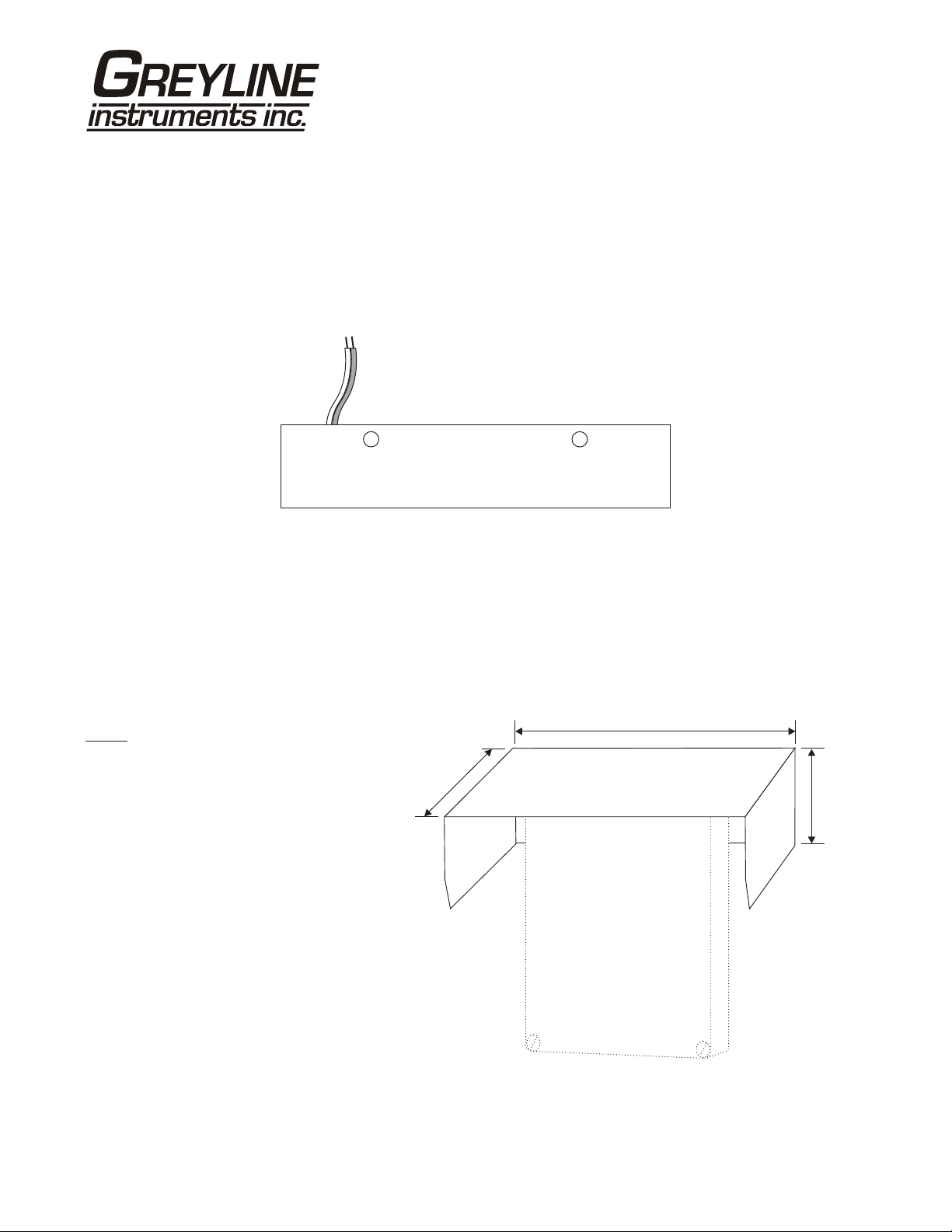

SS PIPE MOUNTING BAND – OPTION VSJ

Use optionalVSJ stainless steel Pipe Mounting Bands

for easy Sensor installation inround pipes.

Each Pipe Band includes:

!

Band Adjustment Jack allowing ±0.5” (13 mm) adjustment from

DETAIL

BAND ADJUSTMENT

JACK

BAND

ADJUSTMENT JACK

VSJ PIPEMOUNTINGBAND

SENSOR MOUNTING

BRACKET

the nominal band size

!

Stainless steel bracket for Sensor mounting

!

Pre-drilled for tie wraps (included) to secure Sensor cable

AVFM 5.0 Area-Velocity Flow Meter

CODE BAND SIZE

VSJ6 6”/150 mm IDpipes

VSJ8 8”/200 mm IDpipes

VSJ10 10”/250 mm IDpipes

VSJ12 12”/300 mm IDpipes

VSJ14 14”/350 mm IDpipes

VSJ15 15”/375 mm IDpipes

VSJ16 16”/400 mm IDpipes

VSJ18 18”/450 mm IDpipes

VSJ20 20”/500 mm IDpipes

VSJ24 24”

VSJ30 30”/750 mm IDpipes

/600 mm IDpipes

END

BRACKET

VSJHALF-PIPE

MOUNTING BAND

ADJUSTMENT

FLOW

SENSOR MOUNTING

BRACKET

JACK

Mounting Instructions:

Install the stainless steel pipe band with the

sensor mountingbracket at the invert (bottom)

of the pipe. Ensure that the sensor bracket is

parallel to the water surface (check with a

level). Mount so the tapered end of the sensor

will point upstream and the sensor cablewill

point downstream. Turn the ¼” adjusti

clockwise to expand the bracket and secure to

the pipe wall by friction fit.

Insert the sensor into the mountingbracket and

tie wrap the sensor cable securely to the

stainless steel pipe band.

ng nut

VSJ32-40 32-40” / 800-1000 mm IDpipes

VSJ42-54 42-54” / 1100-1375 mm IDpipes

VSJ56-72 56-72” / 1400-1800 mm IDpipes

FASTEN SENSOR

CABLE TOPIPE OR

CHANNEL WITH

TIE WRAPS

END VIEW

SENSOR

Page 34

Page 35

AVFM 5.0 Area-Velocity Flow Meter

SENSOR INTRINSIC SAFETY

When connected through Intrinsic Safety Barriers, the Greyline Sensor Model QZ02L and PZ series are

CSA certified for installation in a hazardous location rated:

Class I, Groups C,D

Class II, Groups E,F,G

Class III

Intrinsic Safety Barriers may be ordered with the Greyline instrument and are supplied mounted in the

Greyline instrument enclosure. Replacement barrier fuses (Part No. ISB- 011239) may be purchased

separately. The instrument enclosure containing the Intrinsic Safety Barriers must be installed in a nonhazardous location.

Page 35

Page 36

GN3SPEC-ISB-02

The intrinsic safety barrier

assemblies installed in the

AVFM 5.0 limit the voltage

and current supplied to the

transducers to the values

listed under ‘Barrier

Specifications’. To safely

install Greyline transducer(s)

certified for use in hazardous

locations you must refer to

the installation

drawings/specifications of

the certified transducer(s).

AVFM 5.0 Area-Velocity Flow Meter

2

2

1

s)

2

1

1

s)

s)

BARRIER SPECIFICATIONS

STAHL BARRIER

System Parameters

AVFM 5.0

Installed in

Non-Hazardous Location

STAHL 9001/02-093-390-101

3

TRANSDUCER

GND

TRANSDUCER

CONNECTIONS

Entity Parameters

(rated 9.6V, 27 ohm

(rated 9.6V, 27 ohm

STAHL 9001/02-093-390-101

4

4

3

(rated 9.6V, 27 ohm

STAHL 9001/02-093-390-101

4

3

9001/02-093-390-101

9.6V, 27 ohms

m

U

250V

Page 36

V

0C

9.3V

I

SC

390mA

P

0

906.8mW

C

a

4.1µF

L

a

0.16mH

Page 37

AVFM 5.0 Area-Velocity Flow Meter

ENCLOSURE HEATER AND THERMOSTAT - Option TH

Instruments can be factory-equipped with an Enclosure Heater and Thermostat or the module can be

customer-installed. The Thermostat is factory set to turn ON at 40°F (4.5°C) and OFF at 60°F (15.5°C).

Power consumption is 15 Watts.

TO AC POWER SUPPLY

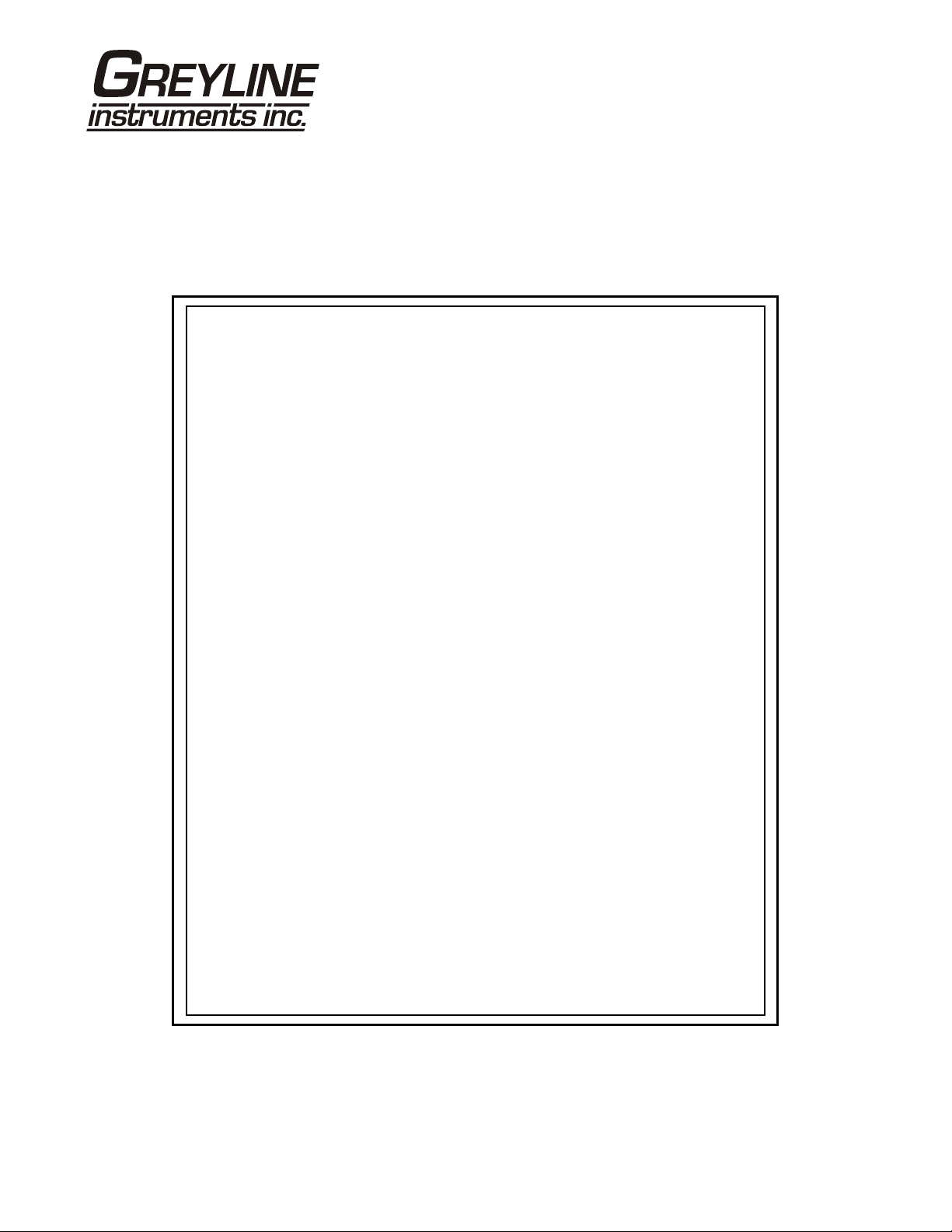

ENCLOSURE SUNSCREEN - Option SCR

Do not mount instrument electronics in direct sunlight. Overheating will reduce the life of electronic

components and condensate may form during the heat/cool cycles and cause electrical shorts.

11" / 280 mm

Note:

Exposure to direct sunlight can cause

overheating and moisture condensation

which will reduce the operating lifeof

electronics.

Protect Instruments from direct sunlight

with this iridite finished aluminumsun

screen (Greyline Option SCR).

eal conduit entries with caulking

S

compound to further reduce moisture

condensation.

11"

280 mm

5"

127 mm

Page 37

Page 38

AVFM 5.0 Area-Velocity Flow Meter

POWER INPUT OPTION

9-32VDC

AVFM 5.0 Flow Meters may be ordered factory-configured for 9-32VDC power input.

CONNECTIONS:

POWER INPUT: Connect 9-32VDC to the + and - terminals. The Power Input GND terminal must be

connected to the nearest Ground pole. A 1-amp fuse in line is recommended.

4-20mA

FLOW

RLY2

RLY1

NO

C

NC

NO

C

NC

SENSOR

CORE

GND

GND

GND

TMTR

4-20mA

LEVEL

NO

RCVR

GRN

BLK

WHT

DATA LOGGER OPTION

4-20mA

VELOCITY

––

++

EXTRA RELAYS OPTION

NC

C

NC

NO

C

NC

NO

C

NC

NO

C

RLY3

DC

+–

–

+

DC

GND

RLY5

RLY4

USB HARNESS

CONNECTOR

RLY6

SENSOR

GND

Page 38

Page 39

AVFM 5.0 Area-Velocity Flow Meter

--Data Logging------Log Site ID 00

}

Mode Flow

Set Date Feb 18/2008

Set Time 11:27:40

Interval 10sec

Log Stop

Velocity

Mar 19/2009

12:28:41

99

60min

30min

15min

10min

5min

2min

1min

30sec

Start

Delete

DATA LOGGING (Optional)

Setup

Select

Data Logging from Menu Selections.

Log Site ID Enter a number from 00 to 99. The site ID will become

part of the downloaded file name to help distinguish

downloads from different instruments.

Press to store the setting.

Mode Select Velocity, LVT, Level or Flow.

Press to store the setting.

Set Date Press or to scroll and select Month, Day and Year.

Press to store the setting.

Set Time Press or to select the current time in Hours, Minutes and

Seconds.

Press to store the setting.

Interval Press or to select the logging interval.

Press to store the setting.

Log Stop, Start or Delete the log file.

Press or to

Press or to

Note:

You MUST delete old log and start a new log AFTER having set

changes to

Log Site ID, Mode and/or Interval for those

changes to be applied to the log file.

View 24-hr formatted Reports on the AVFM 5.0 display. Press from the MAIN

display to view a formatted flow report from instruments with a built-in data

logger. Press to pan through

summaries. Press to scroll down one day or repeatedly to scroll to a specific

date. Up to 365 days can be stored. Newest date will overwrite the oldest. Press

to return to the main display.

Page 39

Delete and to delete the log file.

Start and to start the logger.

Level, Velocity and Flow

Page 40

AVFM 5.0 Area-Velocity Flow Meter

RETRIEVE LOG FILE

Plug a USB Flash Memory Drive (not supplied by Greyline) into the USB output

cable from the instrument. The instrument display will show the USB file

download icon until the log file is transferred to the memory card and then display

file download completed icon. The USB flash drive may be removed.

Download file names will appear in this format:

AVFM__00A.LOG

MODEL TAG DOWNLOAD

Tag is set according to the

Logging menu.

Download letter will be A for the first download from an instrument. B for the

second, then C etc. At the letter Z a - character will appear indicating that the

maximum number of downloads for that instrument are on the USB flash drive.

Older files can be erased or moved from the flash memory drive or a new memory

drive can be used.

OPENING LOG FILES

Install Greyline Logger on your PC or laptop. Refer to the Help menu in the

program for detailed instructions.

Select File/Open/Instrument Log (.log) to open the log file from your USB flash

drive.

Log Site ID entered in the instrument Data

Page 40

Page 41

AVFM 5.0 Area-Velocity Flow Meter

SPECIFICATIONS

Electronics Enclosure: NEMA4X (IP 66), watertight and dust tight, polycarbonate with clear,

shatterproof hinged Lexan cover

Accuracy: Level: ± 0.25% of Range Velocity: ± 2% of Reading Repeatability: 0.1%

F.S., Linearity: 0.1%F.S.

Display: White, backlit matrix – displays flow rate, totalizer, relay states,

operating mode and calibration menu

Programming: Built-in 5-key calibrator with English, French or Spanish language

selection

Power Input: 100-240VAC, 50/60 Hz, (30 W max.)

Optional: 9-32VDC (9 W max.)

Output: 2 Isolated 4-20mA, 1000 ohm load maximum or 2 Isolated 0-5V

Control Relay: Qty 2, rated 5 ampere SPDT

Temperature Compensation: Automatic, temperature probe built in to level Sensor

Electrical Surge Protection: Sensor, 4-20mA, AC power input

Environmental Conditions: Relative humidity up to 80% -23 to 60°C ambient temperature,

maximum 5000 m altitude, pollution degree 4, Installation Category II.

Optional Enclosure Heater recommended for condensation protection

below 32°F (-1°C)

7.4 / 188 mm"

6.46 / 164 mm"

AVFM 5.0

Area-Velocity

Flow Meter

CONDUIT ENTRY

10.94"/278 mm

5.12/130mm"

10/254 mm"

SIDE VIEW

LOCATION

Page 41

Page 42

AVFM 5.0 Area-Velocity Flow Meter

Velocity/Level Sensor QZ02L

Minimum Velocity: 0.1 ft/sec (0.03 m/sec)

Maximum Velocity: 20 ft/sec (6.2 m/sec) [reverse flow to -5 ft/sec (-1.5 m/sec)]

Minimum Head: 1 in. (25.4 mm)

Maximum Head: 16 ft. (4.88 m)

Operating Temperature: 5 to 150°F (-15 TO 65°C)

Exposed Materials: PVC, epoxy resin, polyurethane, ultem

Sensor Cable: 25 ft. (7.6 m) submersible polyurethane jacket, shielded, 3 coaxial

Hazardous Rating: CSA rated Intrinsically Safe Class I, Groups C,D, Class II, Groups E,F,G

with optional Intrinsic Safety Barrier

MB-QZ - MOUNTING BRACKET QZ02L VELOCITY/LEVEL SENSOR

1.50

1.62"

LEVEL

41.2mm

SENSOR

"

38.1 mm

25 ft (7.6 m)

Sensor Cable

3.00"

0.56"

76.2mm

14.2mm

SIDE VIEW

5.00”

127 mm

0.50"

0.63"

12.7 mm

16 mm

Page 42

Page 43

AVFM 5.0 Area-Velocity Flow Meter

Optional (Velocity only) Sensor QZ02L-DP

Minimum Velocity: 0.1 ft/sec (0.03 m/sec)

Maximum Velocity: 20 ft/sec (6.2 m/sec) [reverse flow to -5 ft/sec (-1.5 m/sec)]

Operating Temperature: 5 to 150°F (-15 to 65°C)

Exposed Materials: PVC, epoxy resin, polyurethane, ultem

Sensor Cable: 25 ft (7.6 m) submersible polyurethane jacket, shielded, 3-coaxial

Hazardous Rating: CSA rated Intrinsically Safe Class I, Groups C,D, Class II, Groups

E,F,G, with optional Intrinsic Safety Barrier

MB-QZ - MOUNTING BRACKET

1.62"

41.2 mm

3.00"

76.2 mm

0.56"

14.2 mm

25 ft (7.6 m)

Sensor Cable

QZ02L-DP VELOCITY SENSOR

5.00”

SIDE VIEW

127 mm

0.50"

12.7 mm

1.50

38.1 mm

0.63"

16 mm

"

Optional Sensor PZ12-LP

Maximum Range: 12 ft (3.66 m)

Minimum Range: 8" (203.2 mm)

Beam Angle: 8°

Operating Temperature: -40 to 150°F (-40 to 65°C)

Exposed Materials: Sensor - PVC, Mounting Bracket - 316 Stainless

Hazardous Rating: CSA rated Intrinsically S afe Class I, Groups

C,D,Class II, Groups E,F,G with optional Intrinsic Safety Barrier

MB12 - MOUNTING BRACKET PZ12-LP ULTRASONIC SENSOR

25 ft (7.6 m)

Coaxial Cable

3.12"

79.2 mm

0.218 DIA

(5.5 mm)

3.00"

76.2 mm

FACE

VIEW

0.25 DIA

(6.35 mm)

4.00"

101.6 mm

3.00"

76.2 mm

SIDE

0.68"

17.3 mm

VIEW

0.62"

15.75mm

Page 43

Page 44

Dual Non-Contacting Sensor Configuration

AVFM 5.0 Area-Velocity Flow Meter

PZ Non-Contacting

Ultrasonic

Level Sensor

FLOW

SE4 Clamp-on

Velocity Sensor

Page 44

Page 45

CONNECTIONS

Dual Sensor Configuration

AVFM 5.0 Area-Velocity Flow Meter

CORE

GND

SENSOR

4-20mA

FLOW

RLY2

RLY1

–

+

NO

C

NC

NO

C

NC

DATA LOGGER OPTION

EXTRA RELAYS OPTION

NC

RLY3

NC

C

NO

C

NO

RLY4

AC

LN

HEATER OPTION

AC

GND

USB HARNESS

CONNECTOR

NC

RLY5

C

NO

VELOCITY

SENSOR

4-20mA

4-20mA

LEVEL

––

++

NC

C

NO

RLY6

GND

GND

RCVR

BLK

PZxx

GND

Level

TMTR

BLK

WHT

SE-4

DOPPLER SENSOR

Page 45

Page 46

AVFM 5.0 Area-Velocity Flow Meter

--Calibration-------

20mA Flo 10.000ft /s³

}

4mA Flo 0.000ft /s³

20mA Vel 10.000 ft/s

4mA Vel 0.000 ft/s

20mA Level 12.000ft

4mA Level 0.000ft

Min Level 0.000in

Lvl Offset 0.000in

Min Vel 0.000ft/s

Damping 10%

CALIBRATION

Non Contacting Level Sensor Configuration

Press to

Calibration and to enter. Use or to position before

each menu item and to enter. When settings are completed press to store and

return to the Calibration menu.

20mA Flo

[5V Flo]

Note

: Analogue output can be selected as 4-20mA or 0-5V in Special Functions.

Press and enter the flow rate value for 20mA.

4mA Flo

[0V Flo]

20mA Vel

[5V Vel]

4mA Vel

[0V Vel]

20mA Level

[5V Level]

Press and enter the flow rate value for 4mA.

Press and enter the velocity value for 20mA.

Press and enter the velocity value for 4mA.

Optional for QZ02L-A type sensor. Press and enter the level

value for 20mA.

4mA Level

[0V Level]

Optional for QZ02L-A type sensor. Press and enter the level

value for 4mA.

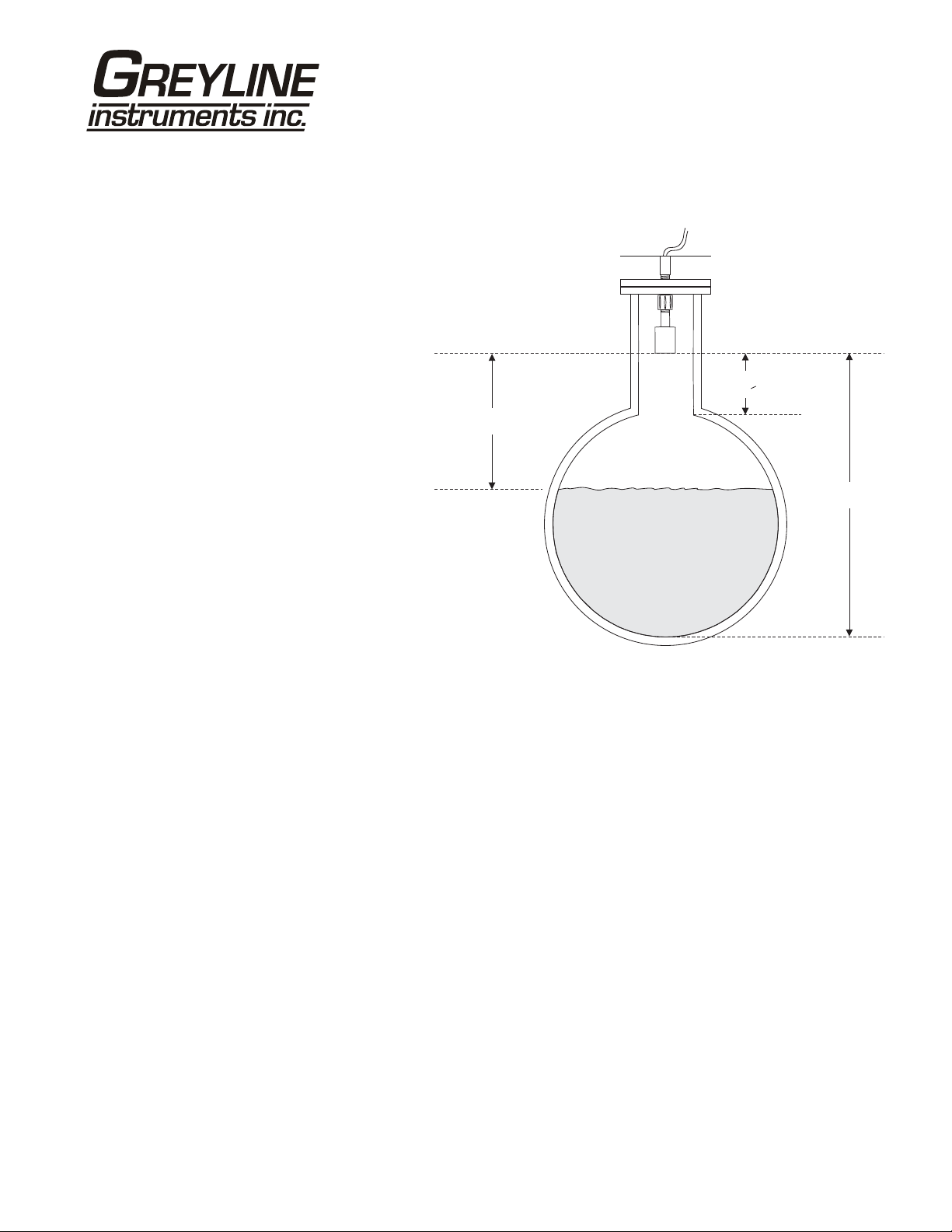

MaxRg

Only for PZxx type sensor. Press and enter the zero water

level (distance from the PZxx sensor to the zero water level).

Page 46

Page 47

AVFM 5.0 Area-Velocity Flow Meter

MinRg

Only for PZxx type sensor. Press and enter the max level

(distance from the PZxx sensor to the max water level).

SUNSCREEN

SENSOR

MinRg > dead band

Range

MaxRg

Min Vel

Press and enter a minimum velocity cutoff. Forward and

reverse velocities less than

Damping

Increase damping to stabilize readings under turbulent flow

readings or to reject spurious level readings. Decrease for

faster response to changes in flow.

Press from the

Calibration display to return to Menu Selections.

Min Vel will be forced to zero.

Page 47

Page 48

AVFM 5.0 Area-Velocity Flow Meter

PZxx FLANGE SENSOR MOUNTING METHODS IN ROUND PIPES

Notes:

1. Use the ¾” NPT “Isolation

Sunscreen

Coupling” supplied and hand

tighten only. Do not clamp sensor

body or stem.

Min Range

PZ15 8" (203.2mm)³

PZ 34 16" (406.4mm)³

2. Do not mount sensor or cover

flange in direct sunlight.

Max Range

3. Extend sensor cable up to 500 ft

(150 m) with RG62AU coaxial

only and junction box.

4. Standpipe diameter as large as

possible, typical standpipe: 6” /

150 mm diameter, 12” – 16” (300

– 500 mm) height.

Use a Sensor Sunscreen (option PZS) when sensor is installed indirect sunlight.

Level Sensor

SUNSCREEN

254 mm

COAXIAL CABLE

CONDUIT

SUNSCREEN

ISOLATION COUPLING

SPACER

FLANGE

ULTRASONIC

LEVEL SENSOR

Page 48

3/4" CONDUIT

SUNSCREEN

ISOLATION COUPLING

SPACER

FLANGE

NON-CONTACTING

ULTRASONIC

LEVEL SENSOR

Page 49

AVFM 5.0 Area-Velocity Flow Meter

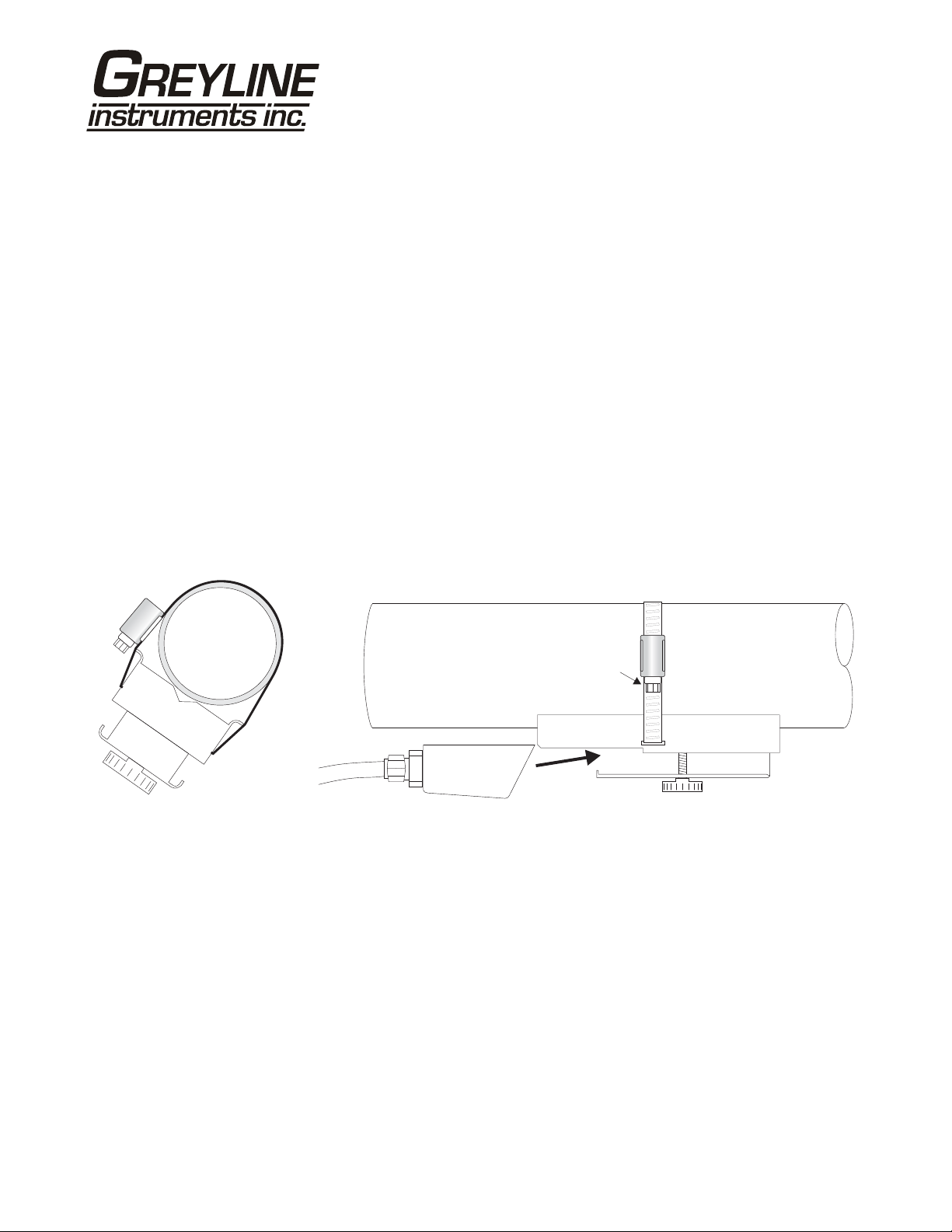

DOPPLER VELOCITY SENSOR COUPLING

Dual Sensor Configuration

For permanent or temporary bonding, the following are recommended:

a) Dow Corning silicon compound #4 (supplied)

Additional supply: order Greyline Option CC

b) High Temperature compound (supplied with Sensor Option SE3H)

Additional supply: order Greyline Option AP-1W

c) Water-based sonic compound: Order Greyline Option CC30

d) Electrocardiograph gel

e) Petroleum gel (Vaseline)

The above are arranged in their order of preferred application.

d & e are only good for temporary bonding at room temperature.

DO NOT USE: Silicon RTV caulking compound (silicon rubber).

COMPOUND

Use the PC4 pipe clamp (supplied) as illustrated above or

use a loop of electrical tape for temporary mounting. Apply

silicon coupling compound #4 to the coloured face of the

sensor. A bead, similar to toothpaste on a toothbrush, is

SENSOR

ideal. Do not overtighten (crush the sensor).

The sensor must be fixed securely to the pipe with coupling material

COMPOUND

between the sensor face and the pipe. Sensor installation with

excessive coupling compound can result in gaps or voids in the

coupling and cause errors or loss of signal. Insufficient coupling

SENSOR

PIP E

compound will create similar conditions.

TAPE OR

CLAMP

Over time temporary coupling compounds (e.g. Petroleum Gel) may gradually sag away from the sensor

resulting in reduced signal strength and finally complete loss of signal. Warm temperatures, moisture

and vibration will accelerate this process. Dow Corning Silicone Compound #4 as supplied with the

AVFM 5.0 (and available from Greyline Instruments) is recommended for semi-permanent installations.

Page 49

Page 50

AVFM 5.0 Area-Velocity Flow Meter

SENSOR MOUNTING

Dual Sensor Configuration

Prepare an area 2" wide by 4" long (50mm x 100mm) for sensor bonding by removing loose paint, scale

and rust. The objective of site preparation is to eliminate any discontinuity between the sensor and the

pipe wall, which would prevent acoustical coupling.

A PC4 Sensor Mounting Kit is supplied with each Greyline flow meter. It includes recommended

coupling compound in a plastic applicator and a stainless steel mounting bracket with adjustable pipe

straps.

Additional stainless steel bands (by customer) may be combined

END VIEW

to mount on pipes up to 180" / 4.5 m OD.

PIPE

SENSOR

ADJUSTABLE

STAINLESS

STEEL STRAP

PIPE

Page 50

Loading...

Loading...